Abstract

Background

The 2010 Deepwater Horizon (DWH) oil spill involved thousands of workers and volunteers to mitigate the oil release and clean-up after the spill. Health concerns for these participants led to the initiation of a prospective epidemiological study (GuLF STUDY) to investigate potential adverse health outcomes associated with the oil spill response and clean-up (OSRC). Characterizing the chemical exposures of the OSRC workers was an essential component of the study. Workers on the four oil rig vessels mitigating the spill and located within a 1852 m (1 nautical mile) radius of the damaged wellhead [the Discoverer Enterprise (Enterprise), the Development Driller II (DDII), the Development Driller III (DDIII), and the HelixQ4000] had some of the greatest potential for chemical exposures.

Objectives

The aim of this paper is to characterize potential personal chemical exposures via the inhalation route for workers on those four rig vessels. Specifically, we presented our methodology and descriptive statistics of exposure estimates for total hydrocarbons (THCs), benzene, toluene, ethylbenzene, xylene, and n-hexane (BTEX-H) for various job groups to develop exposure groups for the GuLF STUDY cohort.

Methods

Using descriptive information associated with the measurements taken on various jobs on these rig vessels and with job titles from study participant responses to the study questionnaire, job groups [unique job/rig/time period (TP) combinations] were developed to describe groups of workers with the same or closely related job titles. A total of 500 job groups were considered for estimation using the available 8139 personal measurements. We used a univariate Bayesian model to analyze the THC measurements and a bivariate Bayesian regression framework to jointly model the measurements of THC and each of the BTEX-H chemicals separately, both models taking into account the many measurements that were below the analytic limit of detection.

Results

Highest THC exposures occurred in TP1a and TP1b, which was before the well was mechanically capped. The posterior medians of the arithmetic mean (AM) ranged from 0.11 ppm (‘Inside/Other’, TP1b, DDII; and ‘Driller’, TP3, DDII) to 14.67 ppm (‘Methanol Operations’, TP1b, Enterprise). There were statistical differences between the THC AMs by broad job groups, rigs, and time periods. The AMs for BTEX-H were generally about two to three orders of magnitude lower than the THC AMs, with benzene and ethylbenzene measurements being highly censored.

Conclusions

Our results add new insights to the limited literature on exposures associated with oil spill responses and support the current epidemiologic investigation of potential adverse health effects of the oil spill.

Keywords: Bayesian methods, benzene, BTEX, censored data, Deepwater Horizon, ethylbenzene, n-hexane, oil spill inhalation exposure, toluene, total hydrocarbons (THCs), xylene

Introduction

The Deepwater Horizon (DWH) drilling rig explosion on 20 April 2010 released nearly 780 000 cubic meters (m3) (4.9 million barrels) of crude oil into the Gulf of Mexico in the ensuing 3 months. More than 55 000 workers were rostered as having been involved, or at least trained, in the oil spill response and clean-up (OSRC) (NIOSH, 2011). During the OSRC, many of these workers reported various acute health symptoms including headaches, nausea, lower and upper respiratory irritation, heat stress, mental and physical fatigue, and eye and skin irritation (NIOSH, 2010a,b; King and Gibbins, 2011). Health concerns for these participants led to the initiation of the GuLF Long-term Follow-up Study (GuLF STUDY), a prospective epidemiological study led by the National Institute of Environmental Health Sciences (NIEHS), to investigate possible short- and long-term adverse health effects experienced by the workers and volunteers who participated in the OSRC (Kwok et al., 2017).

Characterization of exposures is a critical component of any occupational epidemiological study because it allows the investigation of exposure–disease relationships. Health studies from previous oil spills reported adverse health effects that include genotoxic damage, endocrine alterations to dermal and respiratory irritation, and depressive symptoms (Aguilera et al., 2010; Laffon et al., 2016), but many of these studies lacked quantitative estimates of chemical exposures. Even in studies that presented air monitoring results, few measurements were available (Campbell et al., 1993; Morita et al., 1999, Laffon et al., 2006; Pérez-Cadahía et al., 2006, 2007; Meo et al., 2009), and they were not used in the investigation of quantitative exposure–response relationships.

The GuLF STUDY was designed, in part, to overcome some limitations of earlier studies by developing quantitative estimates of exposure to oil-related components as experienced by the OSRC workers. This paper focuses on a subset of the measurements, i.e. personal air measurements collected on the four oil rig vessels that had primary responsibility for containing and mitigating the oil spill. The vessels were located within a 1852 m (one nautical mile) radius of the wellhead, where a substantial portion of the underwater oil being released rose to the water surface. The vessels were the Discoverer Enterprise (Enterprise), the Development Driller II (DDII), the Development Driller III (DDIII), and the HelixQ4000. Data from these measurements are being reported because workers on these rig vessels encountered some of the highest exposures of the OSRC workers. Additionally, these workers were the only subpopulation of the study participants where job titles were routinely available, which allowed for a better representation of full-shift exposures that consider the combination of tasks worked and their duration.

Although crude oil contains a number of volatile compounds, six among these were selected for exposure assessment: total hydrocarbon (THC) measured as total petroleum hydrocarbons, benzene, toluene, ethylbenzene, xylene, and n-hexane (referred to as BTEX-H). These six were chosen because they previously have been associated with neurological impairment and hematologic (benzene and toluene) and carcinogenic (benzene) effects in health studies in non-oil spill contexts (ATSDR, 1999a,b, 2004; ACGIH, 2018; USEPA, 2019). THC and the BTEX chemicals also had the largest number of measurements collected over the OSRC effort.

This study aims to characterize occupational inhalation exposures of workers on these four rig vessels during the disaster response. Here, we describe our strategy for classifying job groups using the available air measurements collected for these six oil-related compounds (i.e. THC and BTEX-H). We developed exposure descriptive statistics for the six chemicals using Bayesian methods and present those results. We compared the results for statistical differences. The estimates became the basis for the exposure assessment in the GuLF STUDY cohort. In addition, these exposure profiles may be useful to the occupational hygiene community, particularly those working in the oil and gas exploration industry and disaster preparedness and response.

An overview of the entire exposure assessment for the study is presented by Stewart et al. (2020a). The strategy for developing exposure groups for the GuLF STUDY is described in Stenzel et al. (2020a). Estimates of inhalation exposures to these six substances for workers performing other spill-related activities (Huynh et al., 2020a,b; Groth et al., 2020a; Ramachandran et al., 2020) and exposures to other substances [i.e. dispersants (Arnold et al., 2020; Stenzel et al., 2020c), particulate matter 2.5 (PM2.5) (Pratt et al., 2020), and oil mist (Stewart et al., 2020b)] are presented elsewhere. Dermal exposures have also been described (Ng Gorman et al., n.d. 2019; Stewart et al., 2020b).

Background

On 20 April 2010 the DWH oil rig explosion and subsequent sinking of the rig damaged the underwater equipment, including severing of the riser pipe that connected the DWH and the wellhead, allowing oil to be released. Within hours of the explosion, response vessels reached the DWH to search and rescue workers, fight the ensuing fire, and close the blowout preventer (BOP) on the top of the well. The BOP, however, malfunctioned and could not be closed. Within a week, the Enterprise and the DDIII arrived, with the Q4000 and DDII arriving a few weeks later. The Enterprise was situated directly above the wellhead and was responsible for capturing at least a portion of the oil release. After the BOP failure, the next attempt to stop the spill involved putting a temporary containment dome over the BOP, but it was removed when it became plugged by methane hydrate crystals. The Responsible Party (RP) for the spill, as designated by the federal government, then inserted a 4-inch diameter tube into the end of the riser to divert the oil flow through the tube so that some of the oil and entrained gas could be collected by the Enterprise. The oil and gas were separated, and the oil was transferred to barges while the gas was flared. The Q4000, a multipurpose oil field construction and intervention vessel, pumped various materials through a manifold connected to the BOP to close the well at the Gulf floor, called a ‘top kill’ procedure, which also failed. The vessel also collected and flared oil and entrained gas through a manifold connected to the BOP. The RP finally installed a new BOP over the damaged well, which stopped the oil release, on 15 July 2010. The DDII and DDIII each drilled a relief well to ‘bottom kill’ the damaged well (i.e. plug the well deep under the Gulf floor) (The U.S. Commission on the BP Deepwater Horizon Oil Spill and Offshore Drilling, 2011; USCG, 2011).

Methods

Data collection

Contractors to the RP monitored rig personnel to assess exposures to jobs identified as having the highest potential for exposure. A total of 1554 personal exposure samples were collected on rig vessel workers and analyzed for 5–11 analytes, resulting in 13 241 personal measurements for the various chemicals. The measurements were collected using organic vapor badges (3M 3500 or 3520, or Assay Technology 521). All badges were analyzed using a gas chromatograph with a high flame ionization detector (Stenzel et al., 2020b) for THC (measured as total petroleum hydrocarbons) and BTEX-H. The total petroleum hydrocarbon analytical method reports the THC concentration as n-hexane and primarily measured hydrocarbons with boiling points that range from 36 to 216°C. Chemicals ranged from C5, n-pentane (vapor pressure of 514 torr at 25°C) to C12, n-dodecane (vapor pressure of 0.135 torr at 25°C). The types of hydrocarbon molecules included in the THC analysis can be branched, straight-chain, and/or cyclic in structure, saturated or unsaturated, and aromatic or non-aromatic. Oxygen-containing chemicals with boiling points in the above pressure range, such as alcohols, ketones, esters, aldehydes, and ethers, can also contribute to the THC concentration, but usually at a lower sensitivity than that observed for THC. Of the 1554 badges, 1017 were also analyzed for n-hexane, heptane, cyclohexane, trimethylbenzenes, and tetrahydrofuran. We excluded tetrahydrofuran from our analysis here because virtually all measurements (>99%) were censored. We also excluded cyclohexane, heptane, and trimethylbenzenes measurements because these analytes were not included in the GuLF STUDY protocol due to their lower toxicity as compared with the analytes included. The duration of the samples varied from less than 1 h to more than 24 h. We excluded samples (n = 60 samples, 457 measurements) with duration <4 h and >18 h to better reflect full work-shift exposures (8 to >12 h day−1). Finally, 58 samples (387 measurements) were excluded because either the RP indicated that the sample was not handled properly (e.g. the badge was not properly capped) or the sample description was either missing or too limited to assign the sample to a job. After exclusions the final count was 1436 samples (8139 measurements).

A substantial percentage of these rig measurements (~82%) were at or below the limits of detection (LOD) reported by the analytical laboratories, which calibrated their LODs to reflect compliance with the occupational exposure limits used by the RP (Stenzel et al. 2020b). Stenzel et al. (2020b) recalculated the measurements to reflect the analytic methods’ true LODs, which resulted in THC’s censoring being reduced from 52.2 to 23.7%, benzene’s from 97.9 to 92.4%, toluene’s from 85.3 to 37.1%, ethylbenzene’s from 90.9 to 53.0%, xylene’s from 85.0 to 40.8%, and n-hexane’s from 80.8 to 49.1%.

Classification of job groups

Job groups is the term we use in this manuscript to generally describe groups of workers with the same or closely related job titles. The job groups were developed from the measurements’ descriptive information and had to satisfy three criteria. The first was the assignment of measurements to the level of detail of the job titles provided by the GuLF STUDY participants in a telephone interview. The second criterion was to differentiate exposure levels across jobs. To achieve this goal, we used three exposure determinants to classify the measurement data: job title, rig vessel, and time period (see below, this section). Thus, a job group is a unique job title/rig/time period combination that places greater weight on specificity of the jobs than precision of the measurements. The third criterion required that each group have at least five measurements and <80% censoring (Huynh et al., 2016). About 500 unique job groups (130 job/rig groups × 4 time periods) were developed across the four vessels. Some jobs were present on multiple vessels, whereas others were unique to a particular vessel.

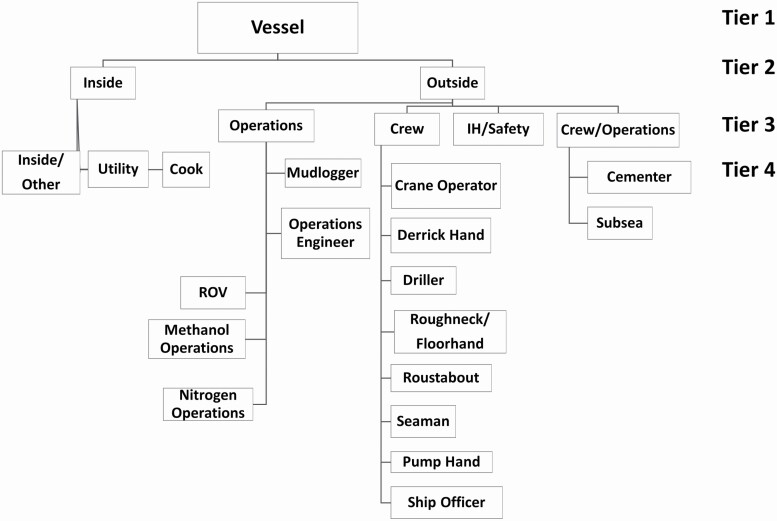

Using the measurement records and the interview responses of the study participants for the job titles, a hierarchy of job groups was established for each vessel. Fig. 1 shows a hierarchy of selected jobs on the Enterprise as an example. Broad groups were developed for workers with less specific job information (in particular, for study participants who did not provide a job title), with more specific jobs identified within the broad groups. After the broadest group on each vessel (i.e. ‘All groups’, tier 1), the next highest tier 2 refers to the working location on the vessels where the job spent most of the work shift, i.e. ‘Inside’ (living quarters and offices) or ‘Outside’. Under the ‘Outside’ tier was tier 3: ‘Crew’, which describes those jobs generally responsible for the everyday function of the vessel; ‘Operations’, which refers to those jobs generally working on the oil spill response; and ‘IH/Safety’, which denotes workers whose tasks involved monitoring other workers’ exposures and/or ensuring the safety of all people on the vessels. Tier 4 comprises individual jobs under crew, operations, and inside (see Supplementary Materials (SM), available at Annals of Work Exposures and Health online for a description of the individual jobs).

Figure 1.

Hierarchy of selected job groups on the Enterprise. Tiers 1–4 represent the levels of job classification from broad to most specific. See Supplementary Materials, available at Annals of Work Exposures and Health online for a description of individual job groups.

Exposure estimates were developed for five time periods to reflect key events that were expected to have had a substantial impact on the rig workers’ exposures:

Time Period 1a (TP1a) (22 April–14 May 2010). Oil flowed from the well into the Gulf of Mexico. Attempts to stop the flow by activating the BOP were unsuccessful. On 2 May, the DDIII initiated drilling of the first relief well. The Enterprise began capturing some of the leaking oil. Limited testing of subsea injection of dispersants 1524 m (5000 feet) below the water surface and vessel spraying of dispersants on the water surface were done to enhance decomposition, dispersion, and evaporation of the oil.

Time Period 1b (TP1b) (15 May–15 July 2010). Oil continued to flow from the well. Dispersants were routinely injected below the water surface (subsea injection) starting 15 May and continued to be sprayed on the water surface. Both the Enterprise and the Q4000 began flaring captured gas (Enterprise) and oil and gas (Q4000) in large quantities. The DDII began drilling the second relief well on 16 May. The well was mechanically capped on 15 July by replacing the damaged BOP. From then on, little oil was released from the wellhead.

Time Period 2 (TP2) (16 July–10 August 2010). On 4 August, the RP accomplished the ‘static kill’ of the well (i.e. pumped ‘heavy mud’ into the top 1524 m of the damaged well casing, followed, a day later, by pumping cement, which relieved pressure on the well). By 10 August, after several days of testing, the effort was deemed a success. Drilling of the two relief wells continued, and the vessels continued performing activities associated with the response effort.

Time Period 3 (TP3) (11 August–30 September 2010). Drilling continued on the two relief wells. The DDIII intersected the damaged well at ~5487 m (18 000 feet) below the Gulf water surface on 15 September. On 16 September, the RP began pumping cement into the base of the well, and the well was declared successfully sealed on 19 September. Final activities included removal or repositioning of underwater equipment, decontamination of the vessels and related equipment, and refurbishing of the vessels in preparation for their next assignment. The Q4000 left the area around 10 September.

Time Period 4 (TP4) (1 October 2010–31 December 2010). Removal or repositioning of underwater equipment, decontamination of the vessels and related equipment, and refurbishing of the vessels in preparation for their next assignment likely continued on the remaining three rig vessels until they were decommissioned from the response effort. The rig vessels then left the area. No personal samples were collected on rig vessels during this time period. The same job groups were used for all six chemicals.

Statistical analysis using Bayesian approach

For estimating THC exposures, we used a univariate Bayesian framework that accounted for censored data. We modeled the natural log (ln) of THC using a normal distribution with a mean (µ) and variance (σ) that were estimated from the data (accounting for censored data). Bayesian methods require the use of statistical priors [such as μ or ln(GM) (geometric mean) and σ or ln(GSD) (geometric standard deviation)] to inform the model. We specified the following uniform (Unif) priors for µ(ln(GM)) and σ(ln(GSD)): µ ~ Unif(ln 0.025, ln 50) and σ ~ Unif(ln 1.1, ln 12). The minimum for µ was set at ln(0.025), a ~28% reduction of the lowest LOD among the THC measurements (0.035 ppm). The maximum µ was based on the RP’s policy of taking various actions to reduce workers’ exposures when continuous levels of volatile organic compounds, as measured by direct-reading instruments on the rig vessels, exceeded 100 ppm (equivalent to 80 ppm THC) for 15 min. Therefore, the upper GM prior was conservatively specified as 50 ppm THC as a full-shift exposure. Because a geometric standard deviation (GSD) cannot be lower than 1, 1.01 was defined as the minimum GSD. The maximum GSD, 12, was set based on actual experience and existing literature that most stable work setting GSDs are in the range of 2–4 (Kromhout et al., 1993; Symanski et al., 2006).

Finally, we ran 5000 iterations of the model to obtain a distribution of the GM and GSD and used them to derive the arithmetic mean (AM) and 95th percentile for each job group.

To estimate BTEX-H levels, we used a bivariate Bayesian regression framework to jointly model THC and each of the BTEX-H chemicals individually (Groth et al., 2017, 2018). This approach allowed us to use THC, which had the lowest amount of censoring, to predict exposures for each of the BTEX-H chemicals using a simple linear regression relationship of the ln-transformed values while accounting for censoring in both the response (each of the BTEX-H chemicals) and the predictor (THC). The priors in this model, which helped inform the estimation of the regression parameters and censored values, were based on the relation between THC and the respective chemical (Groth et al., 2020b). Once the prior information had been incorporated, we ran the bivariate linear modeling framework on each job group, for each BTEX-H chemical separately regardless of censoring. Because 33% of the samples on the rig vessels analyzed for THC and the BTEX chemicals were not analyzed for n-hexane in TP1a and part of TP1b, we also estimated the missing n-hexane measurements in TP1a–b using the bivariate linear regression relationship between THC and n-hexane from TP1b. After running the final model 25 000 times for each job group, we obtained a distribution of 25 000 iterations of the GM and the GSD and converted these to the AM, and 95th percentile for the BTEX-H chemicals. From the 25 000 iterations of these statistics, we derived the posterior medians and the 95% credible intervals (95% CIs) for each statistic. All statistical procedures were conducted using R and RJAGS (R Core Team, 2015; Plummer, 2003). More detail on the statistical methods is found in the Supplemental Materials, available at Annals of Work Exposures and Health online of Stewart et al. (2020a).

Statistically significant differences between the THC AMs for the broad job groups were determined by non-overlapping 95% CI.

Results

Between 207 and 449 (total N = 1436) samples were collected on workers on each of the rig vessels, analyzed for THC and the BTEX chemicals (Table 1) and met the study inclusion criteria. The level of censoring across the chemicals varied from 11 to 96.2%, depending on the vessel and chemical. n-Hexane was collected on the same 1436 badges, but it was not included in the analyses until 26 May 2010, resulting in a total across the 4 rigs of 959 measurements that met the inclusion criteria. The missing 477 n-hexane measurements were derived from the relationship between THC and n-hexane in TP1b and were incorporated into the summary statistics.

Table 1.

Number of measurements and percent censoring by rig vessel and analyte. The total number of measurements for THC, BTEX-H is 8139.

| Drilling rig vessel | N | THC | Benzene | Toluene | Ethylbenzene | Xylene | n-Hexanea | |

|---|---|---|---|---|---|---|---|---|

| % ≤ LOD | N | % ≤ LOD | ||||||

| DDII | 343 | 34.1 | 96.2 | 58.3 | 61.5 | 50.7 | 200 | 75.0 |

| DDIII | 449 | 29.8 | 94.9 | 24.5 | 36.7 | 34.1 | 287 | 45.3 |

| Enterprise | 437 | 11.0 | 87.0 | 35.5 | 58.1 | 40.7 | 275 | 21.5 |

| Q4000 | 207 | 19.8 | 92.3 | 32.9 | 63.3 | 39.1 | 197 | 67.0 |

| Total | 1436 | 23.7 | 92.4 | 37.1 | 53.0 | 40.8 | 959 | 49.1 |

THC, total petroleum hydrocarbons.

a n-Hexane samples before imputation of n-hexane samples for TP1a.

Tables 2–6 display the median posterior estimates of the AMs, GMs, GSDs, 95th percentiles, and their 95% CIs for THC, toluene, ethylbenzene, xylene, and n-hexane for broad job groups on the four rig vessels. There were few groups for benzene that met the criteria, so they are not presented. The median posterior estimates for all job groups, rigs, and time periods that met the sample size and censoring criteria can be found in the SM, available at Annals of Work Exposures and Health online (including benzene). THC estimates are reported in parts per million (ppm) and BTEX-H in parts per billion (ppb). It should be noted that estimates for THC and BTEX-H in the tables and in the SM, available at Annals of Work Exposures and Health online are all posterior medians (including for jobs that have all measurements above the LOD).

Table 2.

The number of samples, the percentage of censoring, and the posterior medians of the AM (in ppm) and GSD (95% CI) for THC for broad job groups on the four rig vessels across four time periods (22 April 2010–30 September 2010).

| Job groups | N TP1a | % cens TP1a | AM_TP1a | GSD_TP1a | N TP1b | % cens TP1b | AM_TP1b | GSD_TP1b | N TP2 | % cens TP2 | AM_TP2 | GSD_TP2 | N TP3 | % cens TP3 | AM_TP3 | GSD_TP3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DDII | ||||||||||||||||

| All groups | 199 | 26 | 1.08 (0.80, 1.56) |

4.7 (4.0, 5.8) |

58 | 47 | 0.34 (0.22, 0.71) |

4.1 (3.0, 6.8) |

70 | 51 | 0.54 (0.28, 1.22) |

6.9 (4.5, 11.2) |

||||

| IH-safety | 9 | 44 | 0.72 (0.19, 4.01) |

7.7 (3.6, 11.7) |

||||||||||||

| Inside | 21 | 29 | 0.71 (0.37, 2.22) |

4.0 (2.6, 8.8) |

||||||||||||

| Outside crew | 96 | 24 | 1.24 (0.80, 2.28) |

5.2 (4, 7.2) |

40 | 45 | 0.29 (0.18, 0.62) |

3.7 (2.6, 6.5) |

42 | 52 | 0.27 (0.15, 0.73) |

4.7 (3.0, 9.7) |

||||

| Outside operations | 48 | 27 | 1.27 (0.71, 3.05) |

5.0 (3.6, 8.3) |

8 | 50 | 0.64 (0.17, 3.73) |

6.8 (3.0, 11.7) |

17 | 47 | 1.31 (0.44, 4.53) |

9.1 (5.2, 11.8) |

||||

| DDIII | ||||||||||||||||

| All groups | 88 | 33 | 5.21 (2.75, 11.02) |

7.5 (5.3, 11.0) |

218 | 18 | 0.95 (0.77, 1.21) |

3.4 (3.0, 4) |

49 | 41 | 0.34 (0.22, 0.65) |

3.6 (2.7, 5.8) |

75 | 55 | 0.28 (0.19, 0.48) |

3.9 (2.8, 6.2) |

| IH-safety | 19 | 11 | 0.85 (0.56, 1.67) |

2.6 (2, 4.2) |

9 | 11 | 0.74 (0.35, 3.52) |

3.3 (2.1, 8.7) |

20 | 55 | 0.38 (0.17, 1.44) |

5.1 (2.7, 10.8) |

||||

| Inside | 19 | 16 | 0.96 (0.51, 3.12) |

3.6 (2.5, 7.5) |

9 | 33 | 0.36 (0.17, 1.73) |

3.3 (1.8, 9.6) |

15 | 60 | 0.18 (0.09, 0.65) |

3.4 (1.9, 9.5) |

||||

| Outside crew | 52 | 38 | 3.70 (1.78, 9.34) |

7.7 (5.0, 11.5) |

138 | 17 | 0.91 (0.70, 1.26) |

3.4 (2.9, 4.2) |

22 | 55 | 0.16 (0.09, 0.45) |

3.1 (2.0, 8.4) |

24 | 42 | 0.30 (0.17, 0.84) |

3.6 (2.4, 8.2) |

| Outside operations | 32 | 28 | 6.59 (2.67, 19.72) |

7.5 (4.6, 11.5) |

31 | 26 | 1.12 (0.62, 2.94) |

4.2 (2.9, 7.5) |

7 | 43 | 0.42 (0.13, 2.70) |

5.4 (2.4, 11.4) |

6 | 50 | 0.50 (0.12, 3.45) |

6.9 (2.8, 11.7) |

| Enterprise | ||||||||||||||||

| All groups | 22 | 5 | 3.20 (1.69, 9.79) |

4.0 (2.8, 7.3) |

353 | 7 | 5.61 (4.27, 7.62) |

5.7 (5.0, 6.6) |

31 | 3 | 0.45 (0.36, 0.59) |

1.8 (1.6, 2.2) |

24 | 75 | 0.12 (0.07, 0.39) |

4.0 (2.2, 9.8) |

| IH-safety | 11 | 18 | 5.09 (1.36, 23.45) |

8.2 (4.4, 11.8) |

||||||||||||

| Inside | 7 | 0 | 0.95 (0.56, 2.82) |

2.1 (1.5, 5.2) |

||||||||||||

| Outside crew | 16 | 0 | 2.36 (1.37, 5.74) |

2.9 (2.1, 5.1) |

189 | 10 | 6.09 (4.17, 9.63) |

6.2 (5.2, 7.8) |

28 | 0 | 0.46 (0.38, 0.60) |

1.7 (1.5, 2.1) |

16 | 69 | 0.15 (0.07, 0.56) |

4.3 (2.2, 10.7) |

| Outside operations | 6 | 17 | 4.05 (0.80, 26.57) |

7.7 (3.8, 11.7) |

132 | 5 | 5.51 (3.79, 8.93) |

5.2 (4.3, 6.6) |

||||||||

| Q4000 | ||||||||||||||||

| All groups | 120 | 28 | 2.66 (1.54, 5.25) |

7.3 (5.6, 10.3) |

34 | 15 | 0.50 (0.36, 0.79) |

2.5 (2.0, 3.4) |

23 | 4 | 1.07 (0.60, 2.74) |

3.5 (2.6, 6.0) |

||||

| Outside crew | 69 | 32 | 2.15 (1.08, 4.93) |

7.5 (5.3, 11.3) |

32 | 12 | 0.51 (0.37, 0.77) |

2.4 (2.0, 3.3) |

20 | 5 | 1.14 (0.59, 3.14) |

3.8 (2.7, 7.3) |

||||

| Outside operations | 38 | 29 | 3.49 (1.47, 9.94) |

8.3 (5.1, 11.7) |

N, number of samples; % cens, percentage of censoring. Time Period 1a (22 April–14 May 2010) had limited measurements. The absence of a row for a particular broad job group indicates no measurements were collected or that it may have few measurements (N < 5) or level of censoring >80%.

Table 6.

The number of samples, the percentage of censoring, and the posterior medians of the AM (in ppb) and GSD (95% CI) for hexane for broad job groups on the four rig vessels across four time periods (22 April 2010–30 September 2010).

| Job groups | N TP1a | % cens TP1a | AM_TP1a | GSD_TP1a | N TP1b | % cens TP1b | AM_TP1b | GSD_TP1b | N TP2 | % cens TP2 | AM_TP2 | GSD_TP2 | N TP3 | % cens TP3 | AM_TP3 | GSD_TP3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DDII | ||||||||||||||||

| All groups | 199 | 35 | 52.6 (34.42, 89.07) |

7.1 (5.6, 9.3) |

||||||||||||

| IH-safety | 9 | 56 | 19.67 (3.84, 110.49) |

9.4 (5.1, 11.9) |

||||||||||||

| Inside | 21 | 52 | 36.27 (12.41, 123.10) |

9.3 (5.3, 11.9) |

||||||||||||

| Outside crew | 112 | 33 | 65.71 (36.82, 131.42) |

7.7 (5.7, 10.9) |

||||||||||||

| Outside operations | 48 | 29 | 40.84 (19.86, 108.29) |

6.7 (4.4, 11.0) |

||||||||||||

| DDIII | ||||||||||||||||

| All groups | 88 | 33 | 327.00 (169.20, 617.86) |

10.1 (7.2, 11.19) |

218 | 31 | 41.64 (28.92, 65.18) |

6.2 (5.1, 7.9) |

49 | 55 | 12.77 (6.19, 33.44) |

6.9 (4.2, 11.4) |

75 | 69 | 3.23 (2.09, 6.25) |

4.4 (3.0, 7.9) |

| IH-safety | 19 | 11 | 32.99 (15.23, 114.80) |

4.6 (3.0, 9.5) |

9 | 44 | 17.31 (4.61, 92.37) |

6.9 (3.5, 11.6) |

20 | 70 | 5.92 (1.97, 21.47) |

7.9 (4.2, 11.7) |

||||

| Inside | 19 | 53 | 32.29 (10.10, 110.37) |

9.9 (6.1, 11.9) |

9 | 56 | 9.61 (2.06, 52.66) |

8.1 (4.0, 11.8) |

15 | 67 | 2.78 (1.39, 7.04) |

2.9 (1.9, 7.3) |

||||

| Outside crew | 52 | 38 | 200.71 (91.88, 443.48) |

10.0 (6.7, 11.9) |

157 | 33 | 42.14 (27.46, 72.93) |

6.4 (5.0, 8.6) |

29 | 59 | 9.45 (4.03, 29.17) |

6.8 (3.8, 11.5) |

24 | 67 | 2.65 (1.09, 8.47) |

5.6 (3.0, 11.2) |

| Outside operations | 32 | 28 | 391.33 (154.03, 1040.12) |

9.7 (6.2, 11.9) |

31 | 35 | 49.11 (19.64, 140.19) |

8.5 (5.2, 11.8) |

7 | 57 | 6.09 (1.09, 39.07) |

7.5 (3.5, 11.7) |

6 | 67 | 2.76 (0.39, 20.81) |

6.9 (3.3, 11.6) |

| Enterprise | ||||||||||||||||

| All groups | 22 | 9 | 216.79 (88.92, 783.36) |

6.0 (3.8, 10.8) |

353 | 13 | 472.01 (323.98, 696.25) |

10 (8.5. 11.7) |

31 | 26 | 6.10 (4.16, 10.91) |

2.7 (2.2, 4.0) |

||||

| IH-safety | 11 | 18 | 216.00 (53.57, 958.38) |

10 (6.2, 11.9) |

||||||||||||

| Inside | 7 | 0 | 61.10 (18.88, 366.17) |

4.9 (2.7, 10.9) |

||||||||||||

| Outside crew | 16 | 0 | 136.81 (64.85, 482.72) |

4.1 (2.7, 8.1) |

194 | 14 | 461.21 (279.69, 758.49) |

9.8 (7.8, 11.8) |

28 | 21 | 6.35 (4.28, 10.91) |

2.7 (2.1, 3.9) |

||||

| Outside operations | 6 | 33 | 140.67 (21.94, 1003.79) |

9.4 (5.3, 11.9) |

132 | 11 | 441.75 (252.90, 763.95) |

10.2 (8.0, 11.9) |

||||||||

| Q4000 | ||||||||||||||||

| All groups | 120 | 56 | 68.21 (40.90, 113.27) |

11.4 (9.6, 12.0) |

34 | 74 | 2.71 (1.54, 5.87) |

3.6 (2.3, 8.1) |

||||||||

| Outside crew | 69 | 62 | 39.30 (19.96, 77.81) |

11.2 (8.8, 12.0) |

32 | 72 | 2.82 (1.61, 6.10) |

3.5 (2.3, 7.8) |

||||||||

| Outside operations | 38 | 45 | 87.80 (36.72, 211.88) |

10.5 (7.4, 11.9) |

See footnote, Table 2 for definitions.

Table 4.

The number of samples, the percentage of censoring, and the posterior medians of the AM (in ppb) and GSD (95% CI) for ethylbenzene for broad job groups on the four rig vessels across four time periods (22 April 2010–30 September 2010).

| Job groups | N TP1a | % cens TP1a | AM_TP1a | GSD_TP1a | N TP1b | % cens TP1b | AM_TP1b | GSD_TP1b | N TP2 | % cens TP2 | AM_TP2 | GSD_TP2 | N TP3 | % cens TP3 | AM_TP3 | GSD_TP3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DDII | ||||||||||||||||

| All groups | 199 | 77 | 5.82 (3.90, 9.83) |

6.6 (4.8, 9.8) |

58 | 57 | 7.07 (3.96, 16.74) |

5.6 (3.7, 9.9) |

70 | 33 | 7.49 (5.47, 11.61) |

3.2 (2.6, 4.4) |

||||

| IH-safety | ||||||||||||||||

| Outside crew | 96 | 73 | 8.02 (4.42, 16.55) |

7.7 (5.1, 11.4) |

40 | 53 | 8.38 (4.21, 23.04) |

5.8 (3.7, 10.6) |

42 | 29 | 8.5 (5.59, 15.60) |

3.4 (2.6, 5.1) |

||||

| Outside operations | 48 | 75 | 4.98 (2.45, 12.92) |

6.2 (3.8, 11.1) |

8 | 63 | 3.53 (0.72, 20.69) |

7.1 (3.1, 11.7) |

17 | 53 | 6.94 (2.54, 27.92) |

6.6 (3.3, 11.6) |

||||

| DDIII | ||||||||||||||||

| All groups | 88 | 53 | 36.82 (22.35, 76.70) |

5.5 (3.8, 9.2) |

218 | 28 | 12.89 (10.31, 16.86) |

3.7 (3.2, 4.4) |

49 | 31 | 10.97 (6.53, 24.42) |

4.5 (32., 7.4) |

75 | 45 | 6.05 (4.32, 9.75) |

3.5 (2.8, 5.0) |

| IH-safety | 19 | 11 | 8.32 (5.57, 15.32) |

2.4 (1.8, 3.8) |

9 | 11 | 14.91 (5.38, 77.04) |

4.6 (2.7, 10.5) |

20 | 40 | 6.15 (3.32, 17.98) |

3.6 (2.3, 8.2) |

||||

| Inside | 19 | 5 | 11.40 (8.12, 18.16) |

2.1 (1.8, 2.9) |

9 | 11 | 24.04 (9.65, 105.03) |

4.0 (2.5, 9.2) |

15 | 47 | 6.99 (3.22, 25.96) |

4.2 (2.5, 9.8) |

||||

| Outside crew | 52 | 54 | 32.54 (18.41, 83.04) |

5.3 (3.4, 10) |

138 | 35 | 12.76 (9.31, 19.08) |

4.3 (3.5, 5.5) |

22 | 45 | 6.3 (2.72, 21.98) |

5.5 (3.1, 11.0) |

24 | 42 | 8.51 (4.09, 25.65) |

5.0 (3.2, 9.6) |

| Outside operations | 32 | 56 | 44.68 (19.16, 128.37) |

7.4 (4.2, 11.6) |

31 | 32 | 12.18 (6.65, 32.81) |

4.4 (2.9, 8.1) |

7 | 29 | 7.29 (2.03, 43.84) |

5.5 (2.7, 11.3) |

6 | 67 | 3.43 (0.67, 22.15) |

5.9 (2.8, 11.5) |

| Enterprise | ||||||||||||||||

| All groups | 22 | 68 | 14.19 (4.91, 48.44) |

8.5 (4.7, 11.8) |

353 | 53 | 22.02 (15.48, 32.98) |

8.0 (6.6, 9.9) |

||||||||

| IH-safety | 11 | 64 | 10.64 (2.45, 53.26) |

9.3 (5.1, 11.9) |

||||||||||||

| Outside crew | 16 | 75 | 7.84 (2.42, 31.16) |

6.5 (3.7, 11.4) |

189 | 53 | 26.96 (16.30, 44.87) |

9.6 (7.2, 11.8) |

||||||||

| Outside operations | 6 | 50 | 14.31 (2.30, 106.07) |

8.3 (3.9, 11.8) |

132 | 48 | 17.83 (11.28, 32.03) |

6.4 (5.1, 8.6) |

||||||||

| Q4000 | ||||||||||||||||

| All groups | 120 | 66 | 10.73 (6.04, 20.38) |

8.8 (5.9, 11.7) |

34 | 71 | 2.42 (1.38, 5.49) |

3.8 (2.5, 7.9) |

23 | 78 | 1.88 (0.83, 5.24) |

4.3 (2.5, 10.2) |

||||

| Outside crew | 69 | 70 | 11.62 (5.69, 24.93) |

9.4 (6.1, 11.9) |

32 | 69 | 2.52 (1.44, 5.58) |

3.6 (2.4, 7.6) |

20 | 80 | 1.83 (0.72, 5.66) |

4.7 (2.6, 10.6) |

||||

| Outside operations | 38 | 66 | 4.64 (2.23, 13.00) |

5.9 (3.3, 11.2) |

See footnote, Table 2 for definitions.

Table 5.

The number of samples, the percentage of censoring, and the posterior medians of the AM (in ppb) and GSD (95% CI) for xylene for broad job groups on the four rig vessels across four time periods (22 April 2010–30 September 2010).

| Job groups | N TP1a | % cens TP1a | AM_TP1a | GSD_TP1a | N TP1b | % cens TP1b | AM_TP1b | GSD_TP1b | N TP2 | % cens TP2 | AM_TP2 | GSD_TP2 | N TP3 | % cens TP3 | AM_TP3 | GSD_TP3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DDII | ||||||||||||||||

| All groups | 199 | 63 | 24.63 (16.40, 41.78) |

6.8 (5.1, 9.5) |

58 | 43 | 22.15 (12.11, 54.21) |

5.8 (3.9, 9.9) |

70 | 34 | 21.93 (14.47, 39.59) |

4.1 (3.2, 6.1) |

||||

| IH-safety | 9 | 67 | 21.91 (4.24, 123.77) |

8.8 (4.4, 11.8) |

||||||||||||

| Inside | 21 | 67 | 14.37 (7.04, 44.76) |

4.1 (2.4, 9.6) |

||||||||||||

| Outside crew | 96 | 58 | 30.38 (17.03, 63.8) |

7.3 (5.1, 11.0) |

40 | 43 | 27.18 (13.02, 76.22) |

6.4 (4.1, 11.0) |

42 | 29 | 25.72 (15.36, 56.09) |

4.2 (3.1, 6.9) |

||||

| Outside operations | 48 | 65 | 19.41 (9.29, 49.41) |

7.3 (4.4, 11.5) |

8 | 50 | 10.12 (2.11, 58.88) |

7.3 (3.1, 11.7) |

17 | 53 | 21.72 (7.15, 85.99) |

8.1 (4.2, 11.8) |

||||

| DDIII | ||||||||||||||||

| All groups | 88 | 55 | 88.30 (52.21, 190.06) |

6.0 (4.2, 9.7) |

218 | 24 | 44.97 (34.96, 60.62) |

4.2 (3.6, 5.0) |

49 | 35 | 20.22 (12.27, 42.78) |

4.2 (3.1, 6.8) |

75 | 40 | 17.70 (12.18, 29.78) |

3.9 (3.0, 5.5) |

| IH-safety | 19 | 5 | 35.92 (23.78, 65.44) |

2.4 (1.9, 3.7) |

9 | 11 | 29.97 (12.85, 140.10) |

3.6 (2.2, 9.2) |

20 | 40 | 22.41 (10.38, 79.66) |

4.7 (2.8, 10.5) |

||||

| Inside | 19 | 16 | 22.62 (14.49, 46.10) |

2.6 (2.0, 4.3) |

9 | 11 | 28.80 (14.09, 94.22) |

3.0 (2.1, 6.5) |

15 | 40 | 11.91 (6.37, 34.82) |

3.2 (2.2, 7.1) |

||||

| Outside crew | 52 | 65 | 61.32 (30.84, 154.18 |

6.8 (4.2, 11.3) |

138 | 28 | 45.70 (32.25, 70.70) |

4.7 (3.8, 6.0) |

22 | 55 | 9.48 (4.33, 31.12) |

5.0 (2.9, 10.6) |

24 | 38 | 23.98 (11.23, 73.96) |

5.3 (3.4, 10.0) |

| Outside operations | 32 | 41 | 120.38 (56.01, 360.37) |

5.8 (3.6, 10.7) |

31 | 26 | 50.02 (26.55, 140.17) |

4.6 (3.1, 8.6) |

7 | 43 | 14.67 (3.35, 90.85) |

6.4 (2.8, 11.6) |

6 | 33 | 23.40 (5.07, 158.77) |

6.6 (3.1, 11.6) |

| Enterprise | ||||||||||||||||

| All groups | 22 | 68 | 53.00 (17.54, 171.36) |

9.6 (5.9, 11.9) |

353 | 38 | 134.56 (94.19, 202.11) |

8.4 (7.1, 10.2) |

31 | 16 | 11.56 (8.29, 17.92) |

2.4 (2.0, 3.3) |

||||

| IH-safety | 11 | 45 | 68.02 (16.75, 314.52) |

9.4 (5.3, 11.9) |

||||||||||||

| Inside | 7 | 57 | 10.02 (4.10, 29.21) |

2.6 (1.8, 6.1) |

||||||||||||

| Outside crew | 16 | 75 | 24.4 (7.22, 99.20) |

7.2 (4.2, 11.5) |

189 | 42 | 158.53 (96.86, 252.73) |

10.4 (8.1, 11.9) |

28 | 14 | 11.75 (8.39, 18.39) |

2.4 (2.0, 3.3) |

||||

| OutsideoOperations | 6 | 50 | 58.91 (9.06, 439.84) |

9.1 (4.8, 11.9) |

132 | 28 | 113.36 (70.44, 204.28) |

6.7 (5.3, 8.8) |

||||||||

| Q4000 | ||||||||||||||||

| All groups | 120 | 50 | 58.02 (32.88, 113.35) |

8.1 (5.8, 11.4) |

34 | 15 | 16.66 (12.90, 23.16) |

2.1 (1.8, 2.7) |

23 | 57 | 12.71 (5.77, 40.51) |

5.3 (3.1, 10.7) |

||||

| Outside crew | 69 | 55 | 57.35 (27.96, 121.16) |

9.2 (6.1, 11.8) |

32 | 13 | 17.04 (13.16, 23.76) |

2.1 (1.8, 2.7) |

20 | 60 | 11.71 (4.91, 40.22) |

5.7 (3.2, 11.1) |

||||

| Outside operations | 38 | 50 | 36.59 (16.39, 105.18) |

7.0 (4.3, 11.4) |

See footnote, Table 2 for definitions.

THC estimates

The highest exposure levels in any time period for the broad job groups presented in Table 2 were observed on the DDIII in TP1a and on the Enterprise in TP1b. Both of these time periods were before the well was mechanically capped at the end of TP1b (Table 2). The posterior medians of the AM across the time periods across both the broad and specific job groups presented in the SM, available at Annals of Work Exposures and Health online ranged from 0.11 ppm (‘Inside/Other’, TP1b and ‘Driller’, TP3) to 5.26 ppm (‘Remotely Operated Vehicles (ROV) tech’, TP3) on the DDII; 0.12 ppm (‘Welder’, TP3) to 7.40 ppm (‘ROV tech’, TP1a) on the DDIII; 0.12 ppm (‘All groups’, TP3) to 14.67 ppm (‘Methanol Operations’, TP1b) on the Enterprise; and 0.28 ppm (‘Roustabout’, TP2) to 3.49 ppm (‘Operations’, TP1b) on the Q4000 (SM, available at Annals of Work Exposures and Health online, Table 1). There were many outside jobs, and the exposure estimates varied substantially, whereas the inside jobs generally had fewer jobs and less variability (SM, available at Annals of Work Exposures and Health online). The posterior medians of the GSD for THC across all time periods and vessels ranged from 1.4 (‘Well tester’, Enterprise, TP1b) to 9.8 (‘Methanol Operations’, Enterprise, TP1b), and 28% of the GSDs were greater than 6.

Statistical differences among the broad job groups by time period were found among the THC AMs on the various rig vessels. The AM in TP1a was statistically greater than that in TP1b for workers on the DDIII (‘All groups’, 5.21, 95% CI 2.75, 11.02 ppm, TP1a versus 0.95, 95% CI 0.77, 1.21 ppm, TP1b; and ‘Outside crew’, 3.70, 95% CI 1.78, 9.34 ppm, TP1a versus 0.91, 95% CI 0.70, 1.26 ppm, TP1b). The AMs in TP1b were statistically greater than the AMs in TP2 for workers on the DDII (‘All groups’, 1.08, 95% CI 0.80, 1.56 ppm, TP1b versus 0.34, 95% CI 0.22, 0.71 ppm, TP2; and ‘Outside crew’, 1.24, 95% CI 0.80, 2.28 ppm, TP1b versus 0.29, 95% CI 0.18, 0.62 ppm, TP2); the DDIII (‘All groups’, 0.95, 95% CI 0.77, 1.21 ppm, TP1b versus 0.34, 95% CI 0.22, 0.65 ppm, TP2; and ‘Outside crew’, 0.91, 95% CI 0.70, 1.26 ppm, TP1b versus 0.16, 95% CI 0.09, 0.45 ppm, TP2); the Enterprise (‘All groups’, 5.61, 95% CI 4.27, 7.62 ppm, TP1b versus 0.45, 95% CI 0.36, 0.59 ppm, TP2; and ‘Outside crew’, 6.09, 95% CI 4.17, 9.63 ppm, TP1b versus 0.46, 95% CI 0.38, 0.60 ppm, TP2); and the Q4000 (‘All groups’, 2.66, 95% CI 1.54, 5.25 ppm, TP1b versus 0.50, 95% CI 0.36, 0.79 ppm, TP2). TP1b’s AMs were also statistically greater than those in TP3 for ‘All groups’ and ‘Outside crew’ on the DDIII (0.95, 95% CI 0.77, 1.21 ppm and 0.91, 95% CI 0.70, 1.26 ppm versus 0.28, 95% CI 0.19, 0.48 ppm and 0.30, 95% CI 0.17, 0.84 ppm, respectively). The Enterprise ‘Inside crew’ AM in TP1b was significantly lower than that of the ‘Outside crew’ (0.95, 95% CI 0.56, 2.82 ppm versus 6.09, 95% CI 4.17, 9.63 ppm) and ‘Outside operations’ (5.51, 95% CI 3.79, 8.93 ppm).

There were also statistical differences among the rigs. For ‘All groups’ in TP1b, the Enterprise AM was greater than the AMs for the DDII and DDIII (5.61, 95% CI 4.27, 7.62 ppm versus 1.08, 95% CI 0.80, 1.56 ppm and 0.95, 95% CI 0.77, 1.21 ppm, respectively), and the Q4000 AM was greater than that for the DDIII (2.66, 95% CI 1.54, 5.25 ppm versus 0.95, 95% CI 0.77, 1.21 ppm). Both the ‘Operations’ and ‘Outside crew’ AMs on the Enterprise also were greater than the corresponding AMs on the DDII and DDIII (5.41, 95% CI 3.68, 8.45 ppm and 6.09, 95% CI 4.17, 9.63 ppm versus 1.13, 95% CI 0.65, 2.60 ppm and 1.24, 95% CI 0.80, 2.28 ppm on the DDII and 1.12, 95% CI 0.62, 2.94 ppm and 0.91, 95% CI 0.70, 1.26 ppm on the DDIII, respectively). We found few statistical differences among the broad groups or among the specific job titles on an individual rig within a time period.

BTEX and n-hexane estimates

Tables 3–6 (and SM, available at Annals of Work Exposures and Health online, Tables 2–6) show the posterior medians of the AMs, GMs, GSDs, and 95th iles and their 95% CI for toluene, ethylbenzene, xylene, and n-hexane. Benzene estimates are shown in Table 6 of the SM, available at Annals of Work Exposures and Health online. BTEX-H estimates were generally about two to three orders of magnitude lower than the THC estimates. The posterior medians of the AMs for toluene ranged from 1.06 ppb (‘Outside crew’, Enterprise, TP3) to 107.4 ppb (‘IH-safety’, DDIII, TP1b) across all jobs, rigs, and time periods. Similarly, ethylbenzene AM posterior medians ranged from 0.79 ppb (‘Well tester’, Enterprise, TP1b) to 44.68 ppb (‘Outside operations’, DDIII, TP1a). The posterior medians of the AMs for xylene ranged from 1.89 ppb (‘Driller’, DDII, TP2) to 186.53 ppb (‘Methanol Operations’, Enterprise, TP1b). Hexane AM posterior medians were between 0.51 ppb (‘Outside operations’, DDII, TP3) and 482.15 ppb (‘Outside crew’, Enterprise, TP1b). The posterior medians of the AMs for benzene ranged from 0.19 ppb (‘Outside crew’, DDII, TP2) to 40.86 ppb (‘Ship officer’, Enterprise, TP1b). Posterior medians for the GSD varied substantially for all chemicals (percent of GSD estimates >6 were 33% for toluene, 41% for ethylbenzene, 47% for xylene, 75% for n-hexane, and 87% for benzene). The overall patterns of statistical differences among the broad job groups observed for THC on the various rigs and in the various time periods generally were seen for the BTEX-H estimates where sufficient measurements existed.

Table 3.

The number of samples, the percentage of censoring, and the posterior medians of the AM (in ppb) and GSD (95% CI) for toluene for broad job groups on the four rig vessels across four time periods (22 April 2010–30 September 2010).

| Job groups | N TP1a | % cens TP1a | AM_TP1a | GSD_TP1a | N TP1b | % cens TP1b | AM_TP1b | GSD_TP1b | N TP2 | % cens TP2 | AM_TP2 | GSD_TP2 | N TP3 | % cens TP3 | AM_TP3 | GSD_TP3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DDII | ||||||||||||||||

| All groups | 199 | 77 | 6.61 (4.17, 11.30 |

8.2 (5.7, 11.5) |

58 | 33 | 16.98 (10.46, 34.74) |

4.5 (3.4, 7.0) |

70 | 29 | 16.54 (10.84, 30.54) |

4.3 (3.3, 6.2) |

||||

| Outside crew | 96 | 78 | 6.51 (3.46, 13.16) |

8.7 (5.6, 11.7) |

40 | 28 | 18.53 (10.72, 43.49) |

4.4 (3.2, 7.4) |

42 | 36 | 15.08 (8.11, 38.63) |

5.1 (3.5, 8.9) |

||||

| Outside operations | 48 | 71 | 7.01 (3.23, 17.89) |

7.7 (4.5, 11.6) |

8 | 25 | 21.22 (6.23, 117.39) |

5.7 (2.9, 11.4) |

17 | 24 | 19.67 (8.19, 77.67) |

5.2 (3.1, 10.7) |

||||

| DDIII | ||||||||||||||||

| All groups | 88 | 33 | 30.90 (23.57, 43.77) |

3.0 (2.5, 3.9) |

218 | 21 | 34.99 (27.59, 46.55) |

4.0 (3.5, 4.7) |

49 | 20 | 18.33 (11.08, 37.64) |

4.4 (3.3, 6.5) |

75 | 23 | 40.14 (25.09, 76.13) |

4.9 (3.8, 7.0) |

| IH-safety | 19 | 5 | 107.4 (62.12, 247.70) |

3.2 (2.4, 5.3) |

9 | 0 | 76.12 (31.27, 335.11) |

3.8 (2.5, 8.8) |

20 | 25 | 106.10 (38.55, 374.50) |

7.5 (4.3, 11.6) |

||||

| Inside | 19 | 16 | 12.08 (7.22, 26.91) |

2.9 (2.2, 5.0) |

9 | 33 | 7.16 (3.05, 31.28) |

3.5 (2.1, 9.4) |

15 | 33 | 23.26 (8.74, 94.59) |

5.8 (3.4, 11.1) |

||||

| Outside crew | 52 | 37 | 28.83 (20.14, 48.31) |

3.2 (2.5, 4.7) |

138 | 26 | 24.96 (19.18, 34.52)8 |

3.6 (3.1, 4.4) |

22 | 27 | 5.42 (3.38, 10.92) |

2.9 (2.2, 4.7) |

24 | 17 | 24.85 (13.04, 69.51) |

4.2 (2.9, 7.6) |

| Outside operations | 32 | 28 | 39.43 (24.64, 80.42) |

3.4 (2.5, 5.4) |

31 | 16 | 38.29 (21.88, 89.58) |

3.9 (2.9, 6.5) |

7 | 0 | 26.44 (8.51, 151.35) |

4.6 (2.7, 10.6) |

6 | 17 | 49.69 (11.62, 319.47) |

6.6 (3.4, 11.6) |

| Enterprise | ||||||||||||||||

| All groups | 22 | 55 | 25.55 (9.46, 88.35) |

7.3 (4.3, 11.6) |

353 | 29 | 34.23 (26.67, 45.96) |

5.3 (4.6, 6.2) |

31 | 52 | 6.01 (3.26, 14.63) |

4.4 (3.1, 7.8) |

||||

| IH-safety | 11 | 45 | 18.73 (5.00, 90.95) |

8.1 (4.2, 11.8) |

||||||||||||

| Inside | 7 | 57 | 2.98 (1.13, 9.66) |

2.7 (1.8, 6.7) |

||||||||||||

| Outside crew | 16 | 56 | 16.99 (6.38, 64.99) |

5.7 (3.4, 10.8) |

189 | 33 | 23.39 (16.74, 35.16) |

5.2 (4.3, 6.4) |

28 | 50 | 5.96 (3.20, 14.70) |

|||||

| Outside operations | 6 | 50 | 19.57 (3.15, 143.16) |

8.4 (4.0, 11.8) |

132 | 18 | 50.22 (35.58, 77.25) |

4.6 (3.8, 5.7) |

||||||||

| Q4000 | ||||||||||||||||

| All groups | 120 | 39 | 31.88 (19.00, 62.96) |

7.0 (5.2, 10.1) |

34 | 21 | 18.05 (9.40, 47.52) |

4.9 (3.5, 8.4) |

23 | 26 | 7.09 (3.98, 17.59) |

3.6 (2.6, 6.5) |

||||

| Outside crew | 69 | 42 | 44.36 (21.71, 95.07) |

9.1 (6.2, 11.8) |

32 | 19 | 18.21 (9.51, 48.14) |

4.9 (3.4, 8.3) |

20 | 30 | 7.89 (3.97, 23.61) |

4.1 (2.8, 8.1) |

||||

| Outside operations | 38 | 37 | 15.43 (8.79, 37.62) |

4.3 (3.0, 7.7) |

See footnote, Table 2 for definitions.

Discussion

Our study characterizes exposures to select crude oil components for a set of broad job groups, as well as a list of specific jobs reported by the GuLF STUDY participants on the four rig vessels during the DWH OSRC. Exposure levels across jobs, rigs, and time periods may have been influenced by a number of factors including the vessel’s arrival time to the well site, the function of the vessel, the job tasks, the location of the job on the rig, the physical and chemical properties of the chemicals, weathering effects that changed the composition of the oil, and possibly the presence of other chemicals being used in normal and abnormal operations occurring on the rigs.

Time period was an important determinant of exposures. The Enterprise and the DDIII were the first two rig vessels to arrive at the wellhead, whereas the DDII and Q4000 arrived near the end of TP1a. The only rig measurements that met the N ≥ 5 study criteria in TP1a were collected on the DDIII and the Enterprise. The DDIII exposures to THC were not statistically different from those on the Enterprise in TP1a, which may simply reflect the background concentrations of the volatile chemicals prior to the application of dispersants. The AM for ‘All groups’ and ‘Outside crew’ on the DDIII in TP1a were statistically greater than the same groups in TP1b; those on the Enterprise were not. This difference may indicate that the application of dispersants (injection and surface spraying) in TP1b was successful in reducing exposures where there was less oil (the DDIII), but where the oil was greater (the Enterprise), dispersant application was less successful. It may also reflect on the Enterprise the intensive activity, especially dealing with oil-contaminated equipment, related to mitigating the spill, whereas on the DDIII and DDII, drilling the wells required contact with less oil-contaminated equipment. The DDIII started drilling the first relief well on 2 May 2010 and the DDII the second relief well on 16 May 2010. Although generally there was not much oil or gas vapor associated with the drilling process, crew members on the DDII and DDIII were exposed to chemicals from the drilling process and the background vapors associated with being near the wellhead, likely resulting in these two rigs having similar exposures. Finally, the Enterprise also was processing hydrocarbons flowing up from the well, separating the oil from the entrained gas and water, and recovering the oil at a rate of approximately 1270 m3 day−1 (8000 barrels day−1) peaking at 2384 m3 day−1 (15 000 barrels day−1) for a few days (McNutt et al., 2011), which may have contributed to the higher exposures in TP1b. ‘All groups’ and ‘Outside crew’ generally had higher statistically significant THC means on the rigs in TP1b than in TP2 (and for the Enterprise and DDIII, than in TP3) despite efforts during TP1b to reduce exposures. An estimate of the oil flow rate out of the well was 7950 m3 day−1 (~50 000 barrels day−1) (McNutt et al., 2011). Exposures fell in TP2 after the release was stopped on 15 July when the well was mechanically capped, likely because little fresh oil was rising to the surface and the existing surface oil had weathered to the degree that the concentration of volatiles was substantially reduced. In TP3, weathering continued to reduce the concentration of the volatile components, but statistical differences from TP2 generally were not observed, possibly because jobs may have been involved in decontaminating the vessels of oil (which may have increased exposures). Most BTEX-H exposures generally were very low compared with THC but reflected many of the same patterns among the broad job groups as observed for THC. Time period most likely serves as a proxy for the changing potential for exposure due to the spraying/injection of dispersants, the capping of the wellhead, the differing tasks being performed and the weathering of oil (Stenzel et al., 2020b).

Rig vessel also was found to be a significant determinant. The mean THC exposures on the Enterprise (‘All groups’, ‘Operations’, and ‘Outside crew’) in TP1b were statistically greater than the corresponding means on the DDII and DDIII, likely for reasons mentioned above. The Q4000 ‘All groups’ was also higher than the corresponding group on the DDIII. The former vessel, located close to the wellhead, assisted with the top kill operation and later was retrofitted to burn 1590 m3 day−1 (10 000 barrels day−1) of the oil/gas mixture.

The only significant difference found across the broad job groups on a vessel in a time period was the ‘Inside’ jobs, which had a lower AM than the ‘Outside crew’ and ‘Outside operations’ on the Enterprise in TP1b. By policy, inside areas were required to have carbon filters on the air intakes and the inside areas be maintained under positive pressure, and therefore we expected lower exposures compared with those of people working outside. Although seen for the Enterprise, this was not seen on the DDII or DDIII. The inside jobs mainly included cooks and utility operators, housekeepers, laundry workers, and administrators; some of whom may have gotten exposure from cleaning chemicals or oil from handling contaminated clothing. This difference may reflect the greater number of measurements on the DDII and DDIII on the former jobs than on the (presumably lower exposed) administrators. It is difficult to evaluate exposure sources for the ‘Outside crew’ and ‘Outside operations’ since there were a number of different jobs, some of which likely worked in other indoor locations (e.g. the engine room), and all spent time inside for meals and breaks. Nor were there many differences in specific job titles, possibly due to small numbers. In any case, because of the differences among the job groups, rigs, time periods, and chemicals, we chose specificity over precision of the estimates.

The characteristics of the six oil-related components in our study varied in concentration in the crude oil, solubility in water, and volatility in the air (Stenzel et al., 2020b). These differences likely contributed to the varying levels of censoring. Thus, although estimates were developed for the same job groups across all six chemicals, the exposure trends for these chemicals differed by job group, vessel, and time period. Similar statistical patterns, nevertheless, were generally observed across the means of the BTEX-H chemicals among the broad job groups for the rigs and the time periods as among the THC means.

Few studies reporting chemical exposures from this oil spill are available thus far. NIOSH collected a total of nine samples on the rig vessels, four jobs on the DDII on 21 June 2010 and five jobs on the Enterprise on 23 June 2010 (NIOSH, 2010a,b). For THC measurements, all the samples were non-censored, with the DDII samples ranging from 0.14 to 0.31 ppm and the Enterprise samples ranging from 0.02 to 0.12 ppm. For toluene, eight of the measurements were censored (LOD of 0.001–0.002 ppm). The ninth, collected on the air monitor technician on the Enterprise, was reported to be 0.0026 ppm, which falls between the LOD and the limit of quantification (LOQ). All nine benzene and ethylbenzene measurements were censored (LOD of 0.001–0.002 ppm). For xylene, six of the nine samples were censored (LOD of 0.001–0.003 ppm). Three of the samples were between the LOD and LOQ. The three non-censored concentration levels were 0.0031, 0.026, and 0.003 ppm. We compared the THC data to ours. The RP collected two THC samples on 21 June 2010 on the DDII with reported concentrations of 0.19 (censored) and 0.56 ppm THC. Similarly, the RP collected seven THC samples on 23 June 2010 on the Enterprise with reported concentrations ranging from 0.12 to 0.51 ppm.

Avens et al. (2011) analyzed the BTEX data that the RP made available to the public. These are a subset of our measurements, but the data had not been recalibrated to the analytic methods’ LODs (Stenzel et al., 2020b); thus their levels of censoring were much higher than our data. Additionally, the database available to Avens et al. only contained a subset of the data fields supplied to us. Finally, they pooled measurements from workers on all rig vessels and other offshore vessels, the latter having generally lower concentrations than those workers on the rig vessels (Huynh et al., 2020a), so a direct comparison with our estimates is misleading. Avens et al. (2011) also found that there was not an appreciable decrease in BTEX concentrations after the well was mechanically capped, which led them to conclude that BTEX exposures were primarily due to engine exhaust rather than the oil spill. They used the Kaplan–Meier method to account for censored samples which, in Huynh et al. (2014, 2016), was shown to have a higher degree of relative bias and root mean squared error than the Bayesian method we used at the levels of censoring encountered in this dataset. Moreover, their data also did not reflect the lower analytic LODs. Our study, in contrast, detected several statistically significant differences in AMs using ‘All groups’ among the rigs and time periods. Our results suggest a more complex scenario of the sources and the variables that affected BTEX exposures than suggested by Avens et al. The statistical differences we observed between TP1a, TP1b, TP2, and TP3 exposures suggest that THC and the BTEX exposures are consistent with oil-related remediation activities (e.g. stopping the oil release, processing of the hydrocarbons and flaring of the oil and gas), job tasks, and the background levels of the crude oil.

The GSD estimates for THC exposures were highly variable compared with most typically stable occupational situations. This is likely a reflection of the dynamic, non-routine, and time-dependent nature of the spill response work. Other contributing factors may include the small number of samples and high level of censoring in some jobs. Kromhout et al. (1993) reported that a median value of total GSD (GSDT) for 165 job/factory groups was 2.47 for all chemicals measured (2.65 for chemical gases and vapors, and 3.46 for outdoors). Symanski et al. (2006) reported similar GSD ranges in their review of 571 job groups from 39 studies, with the median GSDT approximating between 3.43 and 3.85 (GSDT was computed based on the reported within and between wR0.95 and bR0.95 values, respectively). These are ratios of the 97.5th to the 2.5th percentile of the corresponding log normal distributions of the individual workers’ exposure and the individual worker’s mean exposures level (Rappaport, 1991). Although these studies were not specifically on oil spill responses, our selected GSDs were three times greater than the typical range of GSDs found by those two groups of authors.

To further justify our GSD prior upper limit of 12, we did additional analyses based on data from Symanski et al. (2006) in which we estimated the GSDT for their less homogenous groups category (i.e., workers were classified across jobs/across locations and were less homogenous category defined by the authors). When the within wR0.95 and between bR0.95 values were 215.9 and 1538, which corresponded to a within GSD of 3.9 and between GSD 6.5 respectively, the GSDT at the 95th percentile of the cumulative ratio distribution was 10.2 (see Supplemental Materials, available at Annals of Work Exposures and Health online for calculation of GSDT based on those two papers).

Furthermore, as some of the job groups used in our analyses had relatively high GSDs, with the upper bound nearing 12, which indicates that the GSD prior may have restricted the model GSD estimates, we did a sensitivity analysis using a prior sample size approach (Quick et al., 2017) that does not restrict the upper bound. While the median posterior estimates of the AM for both approaches were comparable, the upper GSD estimates from Quick’s approach were indeed higher than 12 (see Supplemental File, available at Annals of Work Exposures and Health online for the results of the sensitivity analysis). We therefore suggest that the readers treat estimates with GSDs greater than 6 or with 95% CI’s upper bounds approaching 12 with caution as those GSDs or upper 95% CI estimates may correspond to exposure groups that had small sample sizes, high censoring, and/or that were poorly formed. As such, if a job group actually was associated with a GSD greater than 12, the AM reported here would be artificially low.

A number of statistical assumptions were made. First, we used a set of informative priors in these Bayesian analyses. If the priors were not correct or do not describe the jobs well, the estimates could be influenced by the priors. However, we took precautions to limit the influence of the priors by using methods described by Quick et al. (2017). Similarly, we assumed that the overarching prior relationships calculated from BTEX-H measurements across all jobs and vessels was representative of the individual jobs comprising the broader groups. Secondly, n-hexane values were estimated in TP1a and part of TP1b using the THC:hexane relationship found in TP1b. Although conditions were somewhat different in TP1a than TP1b (no application of dispersants, different tasks), we used that relationship in TP1b as it had the most similar conditions (fresh oil was surfacing in both time periods) of all the time periods in the study. Lastly, in order to use the methods in Groth et al. (2017), we assumed a linear relationship between THC and each BTEX-H chemical. We also relied on linear regression assumptions of linearity (including for measurements below LOD): normality of error terms, equal variances, and independence of observations. Furthermore, after performing a Shapiro–Wilk test that indicated lognormality for the majority of the job groups, we assumed that all the measurements of each chemical were lognormally distributed (not shown). Other relationships were not investigated.

As with most retrospective exposure studies, we recognize a potential for misclassification of measurements that could lead to biased estimates for some of these jobs. Sources of misclassification include limited data before TP1b, some small sample sizes, the presence of some highly censored job groups, the limited descriptive information available in the monitoring database for some measurements, and the often limited number of measurements over periods of performing of differing tasks. We tried to minimize this misclassification by using state-of-the-art exposure assessment strategies and gathering a wealth of information from a variety of sources including site visits, public records, and interviews with workers on the rig vessels. Lastly, bias could also have occurred in the sampling strategy since the measurements were collected by contractors of the RP to sample the jobs with the highest potential for exposures. The large number of samples over a period of about 6 months on the same jobs listed in vessel records of jobs suggests that little bias was likely to have resulted in the selection of sampled workers, although lower exposed workers were sampled less frequently and therefore those results may have more uncertainty. However, overall, the exposure levels are likely to be within the correct order of magnitude as indicated by the limited sampling by NIOSH (2010a,b).

A strength of this study is the large number of measurements collected on the rig vessels over a relatively short period of time, which allowed us to compute quantitative exposure estimates for the GuLF STUDY. Thus, the estimates are thought to be representative of the exposures of the workers with the assigned jobs. In addition, we used a Bayesian technique for estimating THC, a method that was found to produce relatively unbiased and precise estimates (overall relative bias ≤15% and root mean square error <65%, respectively) under the conditions of our data (small sample sizes, high censoring, and high variability). For the BTEX-H chemicals, the bias and imprecision is likely to be less, for two reasons: (i) the priors based on the THC chemical relationship generally provided more information than the priors used for THC alone; and (ii) the inclusion in the model of THC information with low censoring likely allowed us to more accurately estimate censored measurements and the means of the BTEX-H chemicals (assuming the linear relationship between THC and the chemical of interest was statistically significant). A third strength is that the models for all the chemicals provided CIs to indicate the degree of statistical uncertainty in the estimates (Huynh et al., 2016). Fourth, this study also used a variety of sources of background data to identify important determinants of exposures such as job, vessel, and time period to develop unique job groups, and the descriptive statistics often indicated statistical differences in exposure levels among the jobs groups by time period and rig. Lastly, we have developed a number of statistics useful for the GuLF STUDY and potentially for future studies, which allows exploration of different toxicological mechanisms.

There are currently no occupational exposure limits for THC. Perhaps the closest equivalent to THC is petroleum distillates, which has a NIOSH Recommended Exposure Limit of 86 ppm (NIOSH, 2007). The highest 95th percentile for THC was 74.55 ppm ‘Methanol Operations’, TP1b on the Enterprise. This value may be reflecting a contribution by methanol, which was used by this job to reduce the hydrate crystal buildup in the underwater oil collection equipment. As methanol was a possible fire hazard, the ‘Burner fire control’ job watched the water for bubbles possibly containing methanol to warn of the possible hazard. The contribution of methanol to THCs for both jobs (the primary jobs likely affected by methanol), however, is expected to be low because the former has a low sensitivity on the gas chromatograph and its collection efficiency on the charcoal pad in the sampling dosimeter is lower than the volatile hydrocarbon components of oil measured. Our BTEX-H estimates were substantially below the current exposure limits. The respective ACGIH Threshold Limit Values (TLVs®) for benzene, toluene, ethylbenzene, xylene, and n-hexane are 500, 20 000, 20 000, 100 000, and 50 000 ppb, respectively (ACGIH, 2018). The 95th ile values in our study were 280.59 ppb for benzene (‘Ship officer’, Enterprise, TP1b), 1356.8 ppb for toluene (‘Ship officer’, Q4000, TP2), 178.51 ppb for ethylbenzene (‘Pump hand’, Enterprise, TP1b), 955.32 ppb for xylene (‘Methanol Operations’, Enterprise, TP1b), and 3629 ppb for hexane (‘Methanol Operations’, Enterprise, TP1b). These values described in this report are likely to reflect actual inhalation concentrations as we found little indication of mandatory respiratory protection.

The estimates developed here were used as the bases for exposure groups in job–exposure matrices that allowed us to assign exposure estimates to the study participants in the GuLF STUDY through their responses to the study questionnaire (Stewart et al., 2020a). More detail on the use of the job group estimates described here to develop exposure group estimates in the epidemiologic study are found in Stenzel et al. (2020a). This exposure study, along with the epidemiological investigation, enables us to obtain new insights into exposure–disease relationships, which might warrant the reassessment of the current exposure limits as new health-related information becomes available from this study. It should be also noted that exposures to the mixture of the crude oil components occurred simultaneously; hence additive and synergistic toxicological effects among these six chemicals and also chemicals from the crude oil that we did not measure may have occurred. Epidemiological analyses should take into account this possibility in order to minimize bias.

Conclusions

Our study developed inhalation estimates of occupational exposures to THC and BTEX-H on the four rig vessels responding to the DWH oil spill response. Estimates were developed separately by chemical for measured job/rig/time period combinations to minimize error in the exposure estimates that can occur when combining dissimilar groups. We implemented Bayesian methods to account for the often highly censored data. THC and BTEX-H exposure means varied by job, rig vessel, and time period, with some being statistically different. Generally, as expected, the highest exposures were observed in TP1a and TP1b when the oil was continuously leaking and rising to the surface. Once the well was mechanically capped, exposures generally decreased. The individual BTEX-H exposures were substantially lower than those for THC. Exposures were generally low compared with OSHA standards. Our exposure study, along with the epidemiologic investigation, will add new insights to the limited literature on the exposures that occurred during the OSRC and the potential health effects associated with the work.

Supplementary Material

Acknowledgements

We thank RP for providing the measurements and Wendy McDonald and Caitlin Rousch of McDowell Safety and Health Services, Inc. for their tremendous efforts in organizing the data.

Funding

Intramural Research Program of the National Institutes of Health (NIH), National Institute of Environmental Health Sciences (NIEHS) (ZIA ES102945). Dr Sudipto Banerjee was also supported by the following NIH and National Science Foundation (NSF) grants during this work: NIH/NIEHS 1R01ES027027-01; NIH/NIEHS R01ES030210-01; NSF DMS-1513654; and NSF IIS-1562303. Dr Tran Huynh was also supported by the Center for Disease Control and Prevention/National Institute of Occupational Safety and Health K01OH011191 award during the revision of this manuscript.

Conflict of Interest

The authors declare no conflict of interest relating to the material presented in this article. Its contents, including any opinions and/or conclusions expressed, are solely those of the authors.

References

- Agency for Toxic Substances and Disease Registry (ATSDR) . (1999a) Toxicological profile for n-hexane.Atlanta, GA: U.S. Department of Health and Human Services, Public Health Service. Available at https://www.atsdr.cdc.gov/substances/toxsubstance.asp?toxid=68. Accessed 3 April 2019. [Google Scholar]

- Agency for Toxic Substances and Disease Registry (ATSDR) . (1999b) Toxicological profile for total petroleum hydrocarbons.Atlanta, GA: U.S. Department of Health and Human Services, Public Health Service. Available at https://www.atsdr.cdc.gov/ToxProfiles/TP.asp?id=424&tid=75. Accessed 9 September 2019. [Google Scholar]

- Agency for Toxic Substances and Disease Registry (ATSDR) . (2004) Interaction profile for benzene, toluene, ethylbenzene, and xylenes (BTEX).Atlanta, GA: U.S. Department of Health and Human Services, Public Health Service. Available at https://www.atsdr.cdc.gov/interactionprofiles/ip-btex/ip05.pdf. Accessed 9 September 2019. [Google Scholar]

- Aguilera F, Méndez J, Pásaro Eet al. (2010) Review on the effects of exposure to spilled oils on human health. J Appl Toxicol; 30: 291–301. [DOI] [PubMed] [Google Scholar]

- American Conference & Governmental Industrial Hygiene (ACGIH) . (2018) TLVs® and BEIs® based on the documentation of the threshold limit values for chemical substances and physical agents & biological exposure indices. Cincinnati, OH: ACGIH. [Google Scholar]

- Arnold S, Stewart PA, Pratt GCet al. (2021) Estimation of aerosol concentrations of oil dispersants COREXIT™ EC9527A and EC9500A during the Deepwater Horizon oil spill response and clean-up operations. Ann Work Expo Health; 65: i188–i201. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Avens HJ, Unice KM, Sahmel Jet al. (2011) Analysis and modeling of airborne BTEX concentrations from the Deepwater Horizon oil spill. Environ Sci Technol; 45: 7372–9. [DOI] [PubMed] [Google Scholar]

- Campbell D, Cox D, Crum Jet al. (1993) Initial effects of the grounding of the tanker Braer on health in Shetland. Br Med J; 307: 1251–5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Environmental Protection Agency . (2019) Integrated Risk Information System (IRIS). Available at https://www.epa.gov/iris. Accessed 31 May 2019.

- Gorman Ng M, Cherrie JW, Sleeuwenhoek Aet al. (2021) GuLF DREAM: a model to estimate dermal exposure among oil spill response and clean-up workers. Ann Work Expo Health; 65: i218–i233. [DOI] [PMC free article] [PubMed]

- Groth CP, Banerjee S, Ramachandran Get al. (2021) Methods for the analysis of 26 million VOC area measurements during the Deepwater Horizon oil spill clean-up. Ann Work Expo Health; 65: i140–i155. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Groth CP, Huynh TB, Banerjee Set al. (2021) Linear relationships between total hydrocarbons and benzene, toluene, ethylbenzene, xylene, and n-hexane during the Deepwater Horizon response and clean-up. Ann Work Expo Health; 65: i71–i88. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Groth C, Banerjee S, Ramachandran Get al. (2017) Bivariate left-censored Bayesian model for predicting exposure: preliminary analysis of worker exposure during the Deepwater Horizon oil spill. Ann Work Expo Health; 61: 76–86. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Groth CP, Banerjee S, Ramachandran Get al. (2018) Multivariate left-censored Bayesian modeling for predicting exposure using multiple chemical predictors. Environmetrics; 29: 1–16. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huynh TB, Groth CP, Ramachandran Get al. (2021a) Estimates of inhalation exposures to oil-related components on the supporting vessels during the Deepwater Horizon oil spill. Ann Work Expo Health; 65: i111–i123. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huynh TB, Groth CP, Ramachandran Get al. (2021b) Estimates of inhalation exposures among land workers during the Deepwater Horizon oil spill clean-up operations. Ann Work Expo Health; 65: i124–i139. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huynh T, Ramachandran G, Banerjee Set al. (2014) Comparison of methods for analyzing left-censored occupational exposure data. Ann Occup Hyg; 58: 1126–42. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huynh T, Quick H, Ramachandran Get al. (2016) A comparison of the β-substitution method and a Bayesian approach for handling left-censored data. Ann Occup Hyg; 60: 56–73. [DOI] [PMC free article] [PubMed] [Google Scholar]

- King BS, Gibbins JD. (2011) Health hazard evaluation of Deepwater Horizon response workers. Health Hazard Evaluation Report HETA 2010-0115 & 2010-0192-3138 (2011). Available at http://www.cdc.gov/niosh/h.he/reports/pdfs/2010-0115-0129-3138.pdf. Accessed 19 September 2018.

- Kromhout H, Symanski E, Rappaport SM. (1993) A comprehensive evaluation of within- and between-worker components of occupational exposure to chemical agents. Ann Occup Hyg; 37: 253–70. [DOI] [PubMed] [Google Scholar]

- Kwok RK, Engel LS, Miller AKet al. (2017) The GuLF STUDY: a prospective study of persons involved in the Deepwater Horizon oil spill response and clean-up. Environ Health Perspect; 125: 570–8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Laffon B, Fraga-Iriso R, Pérez-Cadahía Bet al. (2006) Genotoxicity associated to exposure to Prestige oil during autopsies and cleaning of oil-contaminated birds. Food Chem Toxicol; 44: 1714–23. [DOI] [PubMed] [Google Scholar]

- Laffon B, Pásaro E, Valdiglesias V. (2016) Effects of exposure to oil spills on human health: updated review. J Toxicol Environ Health Part B; 19: 3–4, 105–28. [DOI] [PubMed] [Google Scholar]

- McNutt M, Camilli R, Guthrie Get al. (2011) Assessment of flow rate estimates for the Deepwater Horizon/Macondo well oil spill. Flow Rate Technical Group report to the National Incident Command. Interagency Solutions Group, 10 March, 2011. Available at http://large.stanford.edu/courses/2011/ph240/mina1/docs/FRTG-final-report3_10_11-final-pdf.pdf [Google Scholar]

- Meo SA, Al-Drees AM, Rasheed Set al. (2009) Health complaints among subjects involved in oil cleanup operations during oil spillage from a Greek tanker “Tasman Spirit”. Int J Occup Med Environ Health; 22: 143–8. [DOI] [PubMed] [Google Scholar]

- Morita A, Kusaka Y, Deguchi Yet al. (1999) Acute health problems among the people engaged in the cleanup of the Nakhodka oil spill. Environ Res; 81: 185–94. [DOI] [PubMed] [Google Scholar]

- National Commission on the BP Deepwater Horizon oil spill and offshore drilling . (2011) Deepwater Horizon: the gulf oil disaster and the future of offshore drilling—report to the president (BP Oil Spill Commission Report). Available at http://www.gpo.gov/fdsys/pkg/GPO-OILCOMMISSION/content-detail.html. Accessed 16 June 2015.

- National Institute of Occupational Safety and Health . (2007) NIOSH guide to chemicals. DHHS (NIOSH) Publication No. 2005-149. Available at https://www.cdc.gov/niosh/npg/default.html. Accessed 16 June 2015.

- National Institute for Occupational Safety and Health . (2010a) Health hazard evaluation: Deepwater Horizon response. Available at https://www.cdc.gov/niosh/topics/oilspillresponse/gulfspillhhe.html. Accessed 14 August 2019.

- National Institute for Occupational Safety and Health . (2010b) Reducing occupational exposures while working with dispersants during the Deepwater Horizon response. Available at http://www.cdc.gov/niosh/topics/oilspillresponse/dispersants.html. Accessed 3 January 2013.

- National Institute for Occupational Safety and Health . (2011) NIOSH Deepwater Horizon roster summary report. Available at https://www.cdc.gov/niosh/updates/upd-12-19-11.html. Accessed 16 June 2018.

- Pérez-Cadahía B, Laffon B, Pásaro Eet al. (2006) Genetic damage induced by accidental environmental pollutants. Sci World J; 6: 1221–37. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pérez-Cadahía B, Lafuente A, Cabaleiro Tet al. (2007) Initial study on the effects of Prestige oil on human health. Environ Int; 33: 176–85. [DOI] [PubMed] [Google Scholar]

- Plummer M. (2003) JAGS: a program for analysis of bayesian graphical models using Gibbs sampling. In: Proceedings of the 3rd International Workshop on Distributed Statistical Computing (DSC 2003), March 20–22. Vienna, Austria. ISSN 1609-395X.

- Pratt GC, Stenzel MR, Kwok RKet al. (2021) Modeled air pollution from in situ burning and flaring of oil and gas released following the Deepwater Horizon disaster. Ann Work Expo Health; 65: i172–i187. [DOI] [PMC free article] [PubMed] [Google Scholar]