Abstract

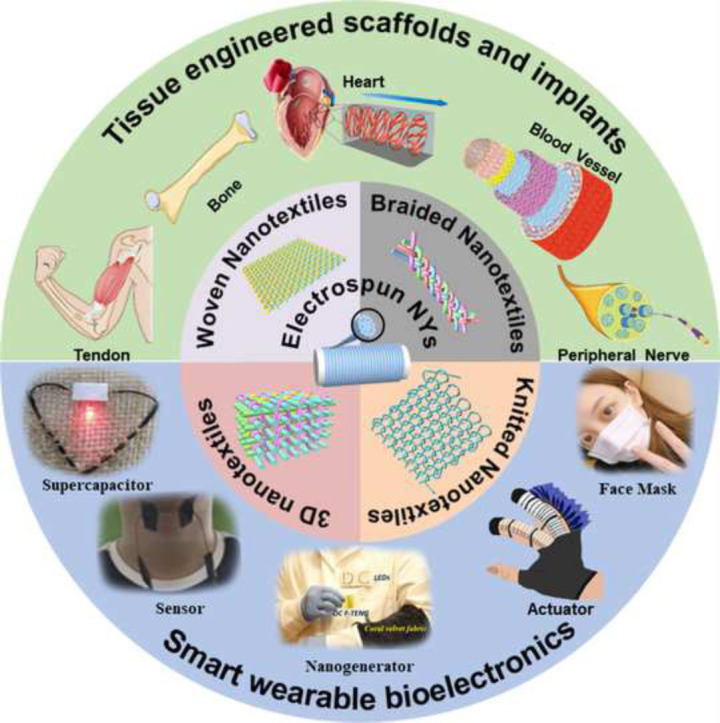

The pandemic of the coronavirus disease 2019 (COVID-19) has made biotextiles, including face masks and protective clothing, quite familiar in our daily lives. Biotextiles are one broad category of textile products that are beyond our imagination. Currently, biotextiles have been routinely utilized in various biomedical fields, like daily protection, wound healing, tissue regeneration, drug delivery, and sensing, to improve the health and medical conditions of individuals. However, these biotextiles are commonly manufactured with fibers with diameters on the micrometer scale (> 10 μm). Recently, nanofibrous materials have aroused extensive attention in the fields of fiber science and textile engineering because the fibers with nanoscale diameters exhibited obviously superior performances, such as size and surface/interface effects as well as optical, electrical, mechanical, and biological properties, compared to microfibers. A combination of innovative electrospinning techniques and traditional textile-forming strategies opens a new window for the generation of nanofibrous biotextiles to renew and update traditional microfibrous biotextiles. In the last two decades, the conventional electrospinning device has been widely modified to generate nanofiber yarns (NYs) with the fiber diameters less than 1000 nm. The electrospun NYs can be further employed as the primary processing unit for manufacturing a new generation of nano-textiles using various textile-forming strategies. In this review, starting from the basic information of conventional electrospinning techniques, we summarize the innovative electrospinning strategies for NY fabrication and critically discuss their advantages and limitations. This review further covers the progress in the construction of electrospun NY-based nanotextiles and their recent applications in biomedical fields, mainly including surgical sutures, various scaffolds and implants for tissue engineering, smart wearable bioelectronics, and their current and potential applications in the COVID-19 pandemic. At the end, this review highlights and identifies the future needs and opportunities of electrospun NYs and NY-based nanotextiles for clinical use.

Keywords: Electrospinning, Textile-forming technique, Nanoyarns, Tissue scaffolds, Wearable bioelectronics

Abbreviations: bFGF, basic fibroblast growth factor; CNT, carbon nanotube; COVID-19, coronavirus disease 2019; ECM, extracellular matrix; FDA, food and drug administration; GF, gauge factor; GO, graphene oxide; HAp, hydroxyapatite; HAVIC, human aortic valve interstitial cell; NGC, nerve guidance conduit; NHMR, neutral hollow metal rod; NMD, neutral metal disc; NY, nanofiber yarn; MeGel, methacrylated gelatin; MSC, mesenchymal stem cell; MSC-SC, MSC derived Schwann cell-like cell; MWCNT, multiwalled carbon nanotube; MY, microfiber yarn; PA6, polyamide 6; PA66, polyamide 66; PAN, polyacrylonitrile; PANi, polyaniline; PCL, polycaprolactone; PEO, polyethylene oxide; PGA, polyglycolide; PHBV, poly(3-hydroxybutyrate-co-3-hydroxyvalerate); PLCL, poly(L-lactide-co-ε-caprolactone); PLGA, poly(lactic-co-glycolic acid); PLLA, poly(L-lactic acid); PMIA, poly(m-phenylene isophthalamide); PPDO, polydioxanone; PPy, polypyrrole; PSA, poly(sulfone amide); PU, polyurethane; PVA, poly(vinyl alcohol); PVAc, poly(vinyl acetate); PVDF, poly(vinylidene difluoride); PVDF-HFP, poly(vinylidene floride-co-hexafluoropropylene); PVDF-TrFE, poly(vinylidene fluoride trifluoroethylene); PVP, poly(vinyl pyrrolidone); SARS-CoV-2, severe acute respiratory syndrome coronavirus 2; SC, Schwann cell; SF, silk fibroin; SWCNT, single-walled carbon nanotube; TGF-β1, transforming growth factor-β1; VEGF, vascular endothelial growth factor

Graphical abstract

1. Introduction

Biotextiles are one broad type of medical devices/materials with given textile structures and patterns and are used in specific biological environments, depending on their biocompatibility and biostability with cells and biological fluids. Biotextiles commonly include engineered textile scaffolds and implants [1], textile-based drug delivery carriers [2], hygiene textiles [3], and wearable bioelectronic devices [4]. For instance, the medical face masks are one typical biotextile, which are widely utilized to stop the transmission of severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) during the COVID-19 pandemic. According to a case study, wearing a face mask could reduce 80% and 47% of the infection risk for healthcare workers and non-healthcare workers, respectively [5]. Another study reported that 17–45% and 24–65% of projected deaths could be prevented by appropriately wearing face masks in New York and Washington, respectively [6]. Actually, the use of biotextiles dates back to the ancient times, and they were first utilized to close or cover open wounds on human skin [7]. Nowadays, the widespread combination of biotechnology and textile engineering has brought various innovative biotextiles, which are becoming more important than anyone realizes [8,9].

The generation of biotextiles usually includes two main procedures [10,11]. Firstly, fiber-constructed yarns are produced from various natural or synthetic polymers using many different spinning methods. Melt spinning, dry spinning, and wet spinning are the three most notable spinning routes in fiber science and textile engineering [12]. The as-obtained yarns are then processed into diverse textile patterns with predetermined shapes, porosities, and mechanical properties using textile weaving, knitting, and braiding techniques, as well as other 3D textile-forming methods. Fibrous yarns are assuredly the primary processing unit for the fabrication of biotextiles, and the performances of the yarns are responsible for the performances of the final fabricated biotextiles. Currently, the commercially used yarns for the fabrication of biotextiles are constructed with microfibers with the diameters on the micrometer scale (typically larger than 10 μm). For implantable material applications, the fiber diameters are obviously larger than those of protein fibrils (diameters of several to several hundred nanometers) that exist in the native extracellular matrix (ECM) [13,14]. The unmatching fiber morphologies and sizes of as-fabricated biotextiles inevitably result in unsatisfactory cell interactions and therapeutic effects [15,16]. For wearable bioelectronic applications, the large fiber diameters of conventional microfibers negatively affect the device miniaturization, the weight, and the performance [17]. Therefore, reducing the fiber diameter of yarns for textile use is greatly required to improve the structures and properties of conventional microfibrous biotextiles [[18], [19], [20]].

Another key element for the fabrication of biotextiles, especially for implantable textiles, is the biomaterial selection. Previous studies demonstrated that the selected materials can notably influence the biological properties of biotextiles [21,22]. The commercialized textile products for implantable material applications are mainly fabricated from some non-degradable and bio-inert polymers, including cellulose, polyamide, polypropylene, polyester, poly(etheretherketone), poly(tetrafluoroethylene), carbon, etc. [23]. For instance, the commercial implantable textile products, such as ULTRAPRO, AQUACEL, INTERGARD, and TIGR Matrix, that are utilized to treat hernias, skin wounds, vascular injuries and disease, and pelvic organ prolapses, respectively, are either nonabsorbable or partially absorbable [12,24]. The clinical data suggests that these commercial implantable biotextiles have played an extremely important role in saving patients' lives and/or improving their quality of life, but there are still some drawbacks that need to be addressed, especially for implantable textiles [24]. For example, a strong foreign body response may take place after the non-degradable textile products are implanted, and the subsequent fibrosis completely engulfs the implanted textiles, leading to the defuctionalization of textile implants [25]. In addition, the long-term use of these non-degradable textile implants can release some debris from wear, which may be harmful for the surrounding cells and tissues, possibly causing cellular malformation, apoptosis, and even carcinogenesis [26,27]. Therefore, polymers with improved biocompatibility and controllable biodegradability are doubtlessly more appropriate for the fabrication of biotextile implants, which are expected to be gradually absorbed, accompanied by the generation and healing of diseased or damaged tissues and organs.

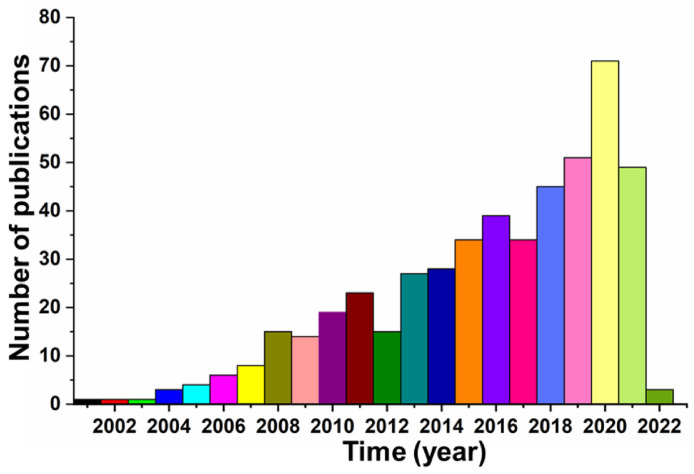

In the last two decades, electrospinning has been recognized as a feasible and versatile spinning method for generating fibers with diameters in the range of several to several hundred nanometers, which are at least ten times smaller than the fibers fabricated from traditional melt, dry, and wet spinning strategies [28]. The significantly decreased fiber diameter notably increased the specific surface area, and the ECM nanofibril-mimicking characteristics make electrospun nanofibers ideal materials for biomedical applications [29,30]. Importantly, a variety of biodegradable polymers with excellent biocompatibility and that originate from both natural and synthesized sources have been successfully processed into electrospun nanofibers, including silk fibroin (SF), collagen, gelatin, polydioxanone (PPDO), polycaprolactone (PCL), polyglycolide (PGA), poly(L-lactic acid) (PLLA), poly(lactic-co-glycolic acid) (PLGA), poly(L-lactide-co-ε-caprolactone) (PLCL), etc. [31,32]. In addition, various drugs and bioactive ingredients can be easily encapsulated into the nanofibers through the electrospinning technique, which can impart nanofibers with predetermined biological behaviors [33,34]. Moreover, a wide variety of post-treatment processes are perfectly suitable for the modification of electrospun nanofibers to further improve the properties and functions of as-prepared nanofibers [35,36]. The direct transformation of electrospun nanofibers into textile yarn-like structures, also named as nanofiber yarns (NYs), provides an innovative routine for renewing and updating the existing microfiber yarns (MYs) made from the traditional melt, dry, and wet spinning techniques [37]. Today, more and more studies are reporting modified electrospinning strategies for the fabrication of advanced NYs. 491 papers have been found using the terms “Electrospinning and Yarn” in the world-recognized database “Web of Science Core Collection”. The number of annual publications from 2000 to 2022 is shown in Fig. 1 . In the early 2000s, a few research groups started to modify the conventional electrospinning device to generate electrospun yarns. Since 2010, the number of publications related to electrospinning and yarns has been increasing rapidly every year. Moreover, some existing studies have already reported the innovative design and development of nanoarchitectured textiles using electrospun NYs for various biomedical applications in the most recent years.

Fig. 1.

Number of annual publications on Electrospun Yarns. The literary search is based on the terms “Electrospinning and Yarn” in the “Web of Science Core Collection” database from 2000 to 2022.

Although a lot of previous review papers introduced electrospinning strategies and their applications in biomedical engineering [[38], [39], [40], [41]], no review papers that systematically introduce the advances of electrospun nanofiber yarn-based textiles for biomedical applications were found. First, this review briefly introduces the basic principles of typical electrospinning techniques, including apparatuses and process parameters. Subsequently, this review highlights the recent progress in electrospun NY fabrication and summarizes the advantages and disadvantages of different strategies. Then, how the material composition and spinning process influence the morphologies, structures, and properties of electrospun NYs is discussed. This review also gives a comprehensive overview of the generation of nanotextiles that use electrospun NYs. Afterwards, this review presents some significant examples that highlight the advanced applications of electrospun NYs in biomedical fields. At the end of this review, we explore and identify the challenges, opportunities, and future needs of electrospun NYs and NY-based biotextiles for clinical use. Fig. 2 shows the whole schematic of the present review.

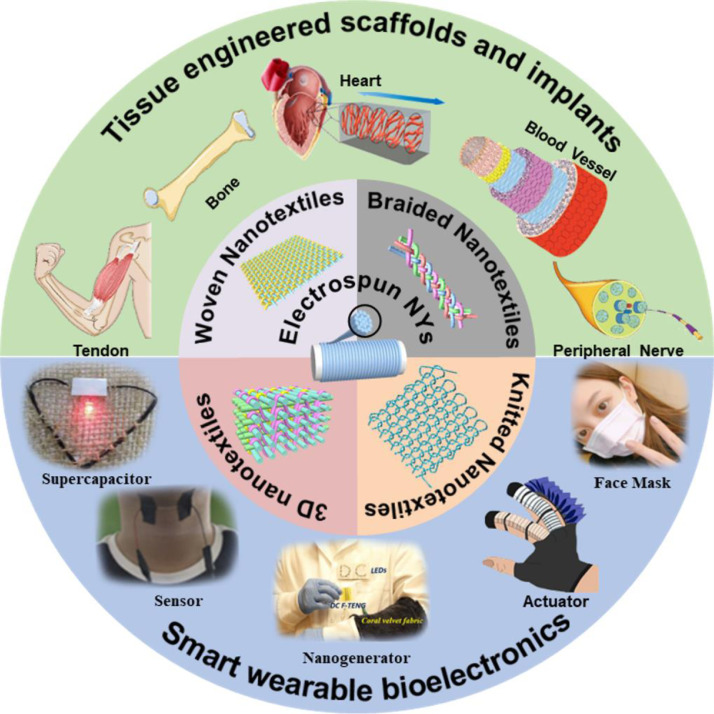

Fig. 2.

Fabrication of electrospun NY-based biotextiles and their applications in various biomedical fields. Some figure elements were rearranged and reprinted with permissions from Refs. [42], [43], [44], [45], [46], [47].

2. Principle and process of conventional electrospinning

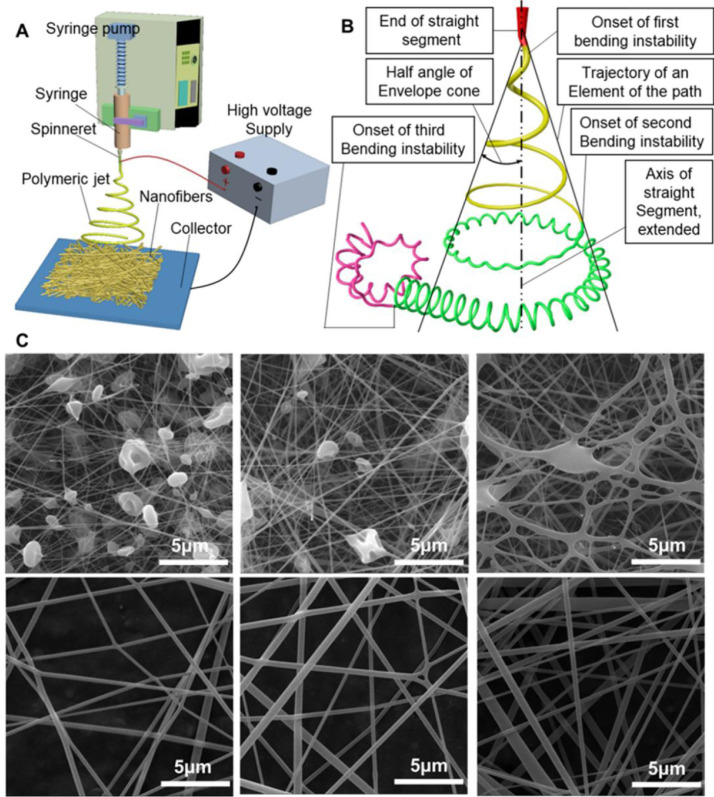

Electrospinning is a versatile, low cost strategy and is a simple process for producing polymeric nanofibers [48]. A conventional electrospinning device for lab research use is relatively simple, as shown in Fig. 3 A, mainly including one spinneret (usually in the form of a needle with a blunt tip), one syringe equipped with a syringe pump, one high voltage supply, and one conductive collector (usually in the form of an aluminum plate). Unlike the traditional melt spinning, dry spinning, or wet spinning, electrospinning employs a high-voltage electrostatic field to drive the whole spinning process. When an external electric field is applied to the spinneret, the electrostatic charges accumulate at the tip of a liquid droplet. Consequently, the electrostatic repulsion among the surface charges works against the surface tension and deforms and reshapes the droplet into a stretched cone (named a Taylor cone), and a jet is subsequently ejected from the Taylor cone when a threshold voltage is reached. This jet initially streams forward along a straight line and then experiences a complex whipping path due to bending instabilities, as shown in Fig. 3B [49]. The solvent volatilizes and the polymeric jet is elongated into a thinner diameter during the stretching and motion, and, finally, the nanofibers are generated and deposited on a preset collector. In general, a complicated electrohydrodynamic process occurs during electrospinning, which involves four distinct stages: liquid droplet charging and Taylor cone formation, jet initiation and straight segment formation, jet instability and whipping, and jet solidification and nanofiber deposition [50].

Fig. 3.

(A) Schematic of a basic electrospinning system. (B) Schematic of a pathway of an electrospun polymeric jet. (C) SEM images of electrospun nanofibers with different morphologies. The electrospun nanofibers were fabricated from different solution concentrations by dissolving cellulose acetate in a mixed solvent of acetone and N, N-Dimethylacetamide (2/1, v/v): 8% (w/w), 9% (w/w), 10% (w/w), 11% (w/w), 12% (w/w), 13% (w/w). (B) Redrawn based on Ref. [49]. (C) Reprinted with permission from Ref. [56].

Three typical instabilities occur with an electrically charged polymeric jet that affect the formation of nanofibers during the electrospinning process [[51], [52], [53]]. The Rayleigh instability is an axisymmetric varicose instability that tends to break the polymeric jet into small droplets. There is another axisymmetric instability, which happens under a much stronger electric field than the Rayleigh instability. The third type of instability is non-axisymmetric blending and whipping instability, which originates from the electrostatic repulsion among surface charges of polymeric jets as a result of a strong existing electrostatic field. To generate thinner nanofibers, it is significantly necessary to notably improve the whipping instability, which is responsible for bending and stretching of the jet during the jet movement [54,55]. Usually, the electrospinning strategy collects the nanofibers as meshes with dense packing densities and low thickness (usually < 1 mm). Three broad categories of factors affect the electrospinning process and the morphology and structure of collected polymeric nanofibers. Polymer solution variables are the first factor, which include molecular weight, concentration, viscosity, and solvent selection. The processing variables are another factor, referring to the applied voltage, solution feeding rate, spinning distance, spinneret, and collector selection. The third factor is environmental variables, including humidity, temperature, and atmospheric gas. An example of the influences of the polymer solution on the morphology of electrospun cellulose acetate nanofibers is shown in Fig. 3C [56]. Several recent reviews on how the process variables, environmental variables, and polymer solution variables influence the morphology and structure of electrospun nanofibers have been provided by Mailley et al. [57], Ibrahim and Klingner [58] and Haider et al. [59].

3. Electrospinning-based yarns

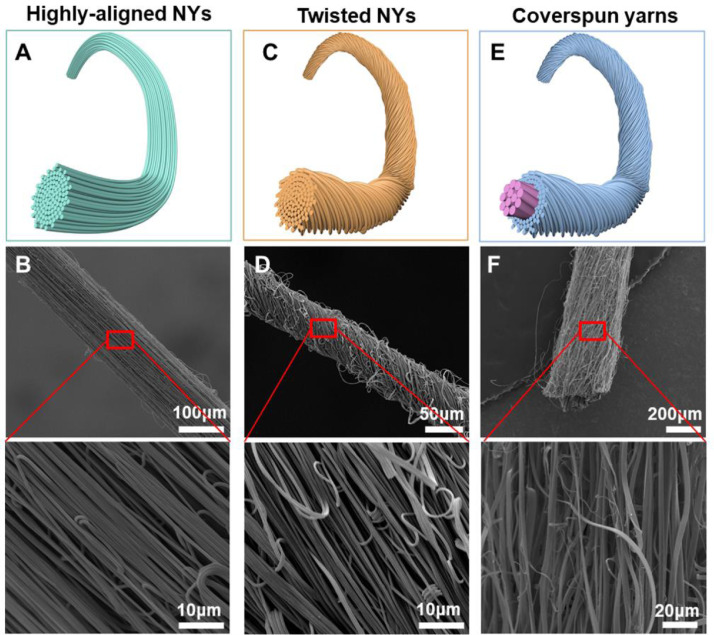

The idea of transforming electrospun nanofibers into yarn-like structures, i.e., NYs, was first reported by Anton Formhals in 1934 [60]. However, the electrospinning technique did not regain attention in the nanoscience community until the 1990s. In 2003, Ko et al. re-proposed the concept of employing modified electrospinning technology to generate NYs, but there were no detailed descriptions about their equipment [61]. Since then, modifying the conventional electrospinning devices to manufacture high quality NYs has become a long-term goal for fiber scientists and textile researchers. Over time, a series of traditional textile strategies have been introduced to modify the electrospinning technique for the production of NYs. At present, electrospinning-based yarns are mainly categorized into three different types, i.e., aligned NYs, twisted NYs, and coverspun yarns. Their schematics and morphologies are shown in Fig. 4 . The aligned NYs are constructed with numerous nanofibers that are uniaxially aligned along the yarn longitudinal direction, as shown in Fig. 4A and B [62]. The twisted NYs are also made of numerous nanofibers, but the nanofibers exhibit some twists as shown in Fig. 4C and D. The coverspun yarns are fabricated by coating numerous nanofibers on microfibers to generate a nanofiber-coated microfiber core-sheath structure, as shown in Fig. 4E and F. In addition, all the electrospinning-based yarns can also be categorized into discontinuous and continuous types in terms of the NY generating mechanisms and the continuity and length of the obtained yarn. For the discontinuous type, a limited yarn length (several millimeters to tens of centimeters) is generated at one time. As for the continuous type, at least several meters of yarns are manufactured at one time without the yarn breaking.

Fig. 4.

Different types of electrospun NYs. Schematic and SEM images of electrospun NYs with highly aligned fibrous structures (A, B) and with high twisting (C, D) and electrospun nanofiber-coated microfiber coverspun yarns with core-sheath structures (E, F). The blue dashed line indicates the inner microfibers of the coverspun yarns. (B) Reprinted with permission from Ref. [62].

3.1. Electrospun NY fabrication in a discontinuous manner

It is well-known that all the spinning methods include one necessary jet stretching process to refine and solidify fibers. The traditional melt spinning, dry spinning, and wet spinning utilize easily controlled compressed air, mechanical interaction, or a combination of both to realize the stretching of fibers Therefore, the stretching force is limited, and only microfibers with diameters larger than 10 μm can be generated [[63], [64], [65]]. In comparison, the dramatic stretching force caused by the complex three-dimensional whipping and bending instability during electrospinning is employed to stretch and solidify polymeric jets, and fibers with diameters of several to several hundred nanometers are formed [55]. However, the whipping and bending instability that are necessary for the nanofiber generation are also difficult to control, which creates significant hurdles for the continuous and controllable preparation of electrospun NYs. The reasonable control of the jet trajectory to arrange nanofibers into uniaxially aligned structures is one primary key process for the fabrication of high-quality electrospun NYs.

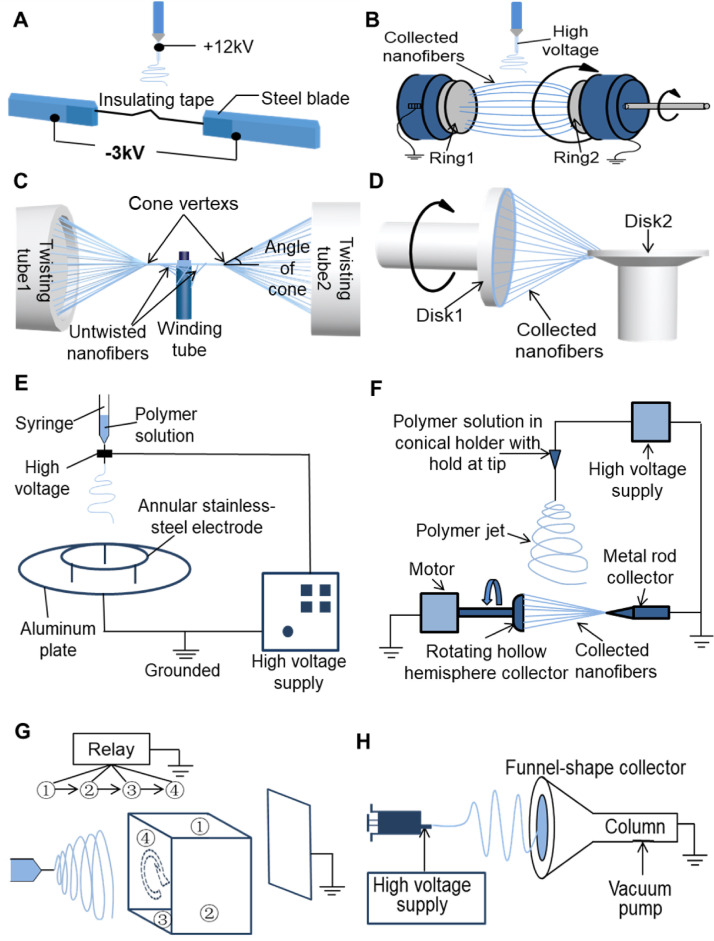

Currently, two oppositely-placed electrodes with a constant gap, constructed with two steel blades (Fig. 5 A) [66], two metal rings (Fig. 5B) [67,68], two tubes (Fig. 5C) [69], or two vertically-arranged metal disks (Fig. 5D) [70], were widely explored to balance the electrical field and achieve the alignment of electrospun nanofibers. The as-obtained nanofibers are further twisted into short electrospun NYs with a limited length in the range of several to tens of millimeters. The electrospun NYs generated by these methods commonly possess super-aligned fiber structures and controlled twisting degrees. Importantly, the fabrication devices are simple and versatile. Moreover, one conventional textile yarn supply device has been introduced to the vertically-arranged metal disk electrospinning system in Fig. 5D, which could generate nanofiber-coated microfiber coverspun yarns with controllable twists [71].

Fig. 5.

Schematic of some representative electrospinning devices for the fabrication of electrospun NYs in a discontinuous manner. (A) NY collector constructed with two steel blades. (B) NY collector constructed with two metal rings. (C) NY generator made from two twisting tubes and one winding tube. (D) Yarn generator made from two vertically arranged metal disks. (E) NY generator made by putting an annular stainless-steel electrode on an aluminum plate. (F) NY generator containing one hollow metal hemisphere and one metal rod with a sharp end. (G) Device with an auxiliary polyhedron electrode to facilitate NY formation. (H) Funnel NY-generating device. (A-H) were redrawn based on Refs. [[66], [67], [68],70,[72], [73], [74], [75], [76]].

In order to improve the yarn length, some relatively complicated devices have been designed and developed. For example, an annular stainless-steel collector on an aluminum plate was used to obtain polyacrylonitrile (PAN) nanofiber bundles in an annular shape (Fig. 5E), which were subsequently cut, pre-drafted, and twisted into short electrospun NYs with a length of 15 cm [72]. However, the short NYs obtained by this method presented an uneven and hairy appearance and a low breaking strength of roughly 5 cN/tex. In several other studies, a modified collector containing one hollow metal hemisphere and one metal rod with a sharp end (Fig. 5F) was designed to collect electrospun NYs with aligned structures and adjustable twists [73,74]. However, only 10 cm long NYs could be produced by this method. One study set an auxiliary polyhedron electrode between the spinning needle and collector, in Fig. 5G, and a rotating electric field was formed through a rapid change of the electric field of each plane in the polyhedron, which could directly twist the polyethylene oxide (PEO) nanofibers into NYs with diameters of 5 μm [75]. However, the spinning process was very unstable. Worse still, the diameters of as-obtained NYs were tiny (about 5 μm), resulting in poor mechanical properties. In another study, a funnel-shaped collecting device was developed for bundling and forming yarns, presented in Fig. 5H [76]. Specifically, the funnel-shaped collecting device could produce a high-speed airflow to bundle and twist nanofibers, but only false twisting processes were demonstrated to be produced by using this device. Moreover, the chaotically oriented fiber morphology was observed in the as-prepared NYs. In addition, some existing studies employed a high-speed rotating cylinder to collect aligned nanofiber mats and, subsequently, twist the nanofiber mats into short NYs [77,78]. As mentioned above, various modified electrospinning methods have been designed and implemented to manufacture discontinuous electrospun NYs, but it is not very realistic to further apply them into large-scale textile formation due to the limited yarn lengths. Therefore, the current trend is to develop devices that can fabricate electrospun NYs in a continuous manner.

3.2. Electrospun NY fabrication in a continuous manner

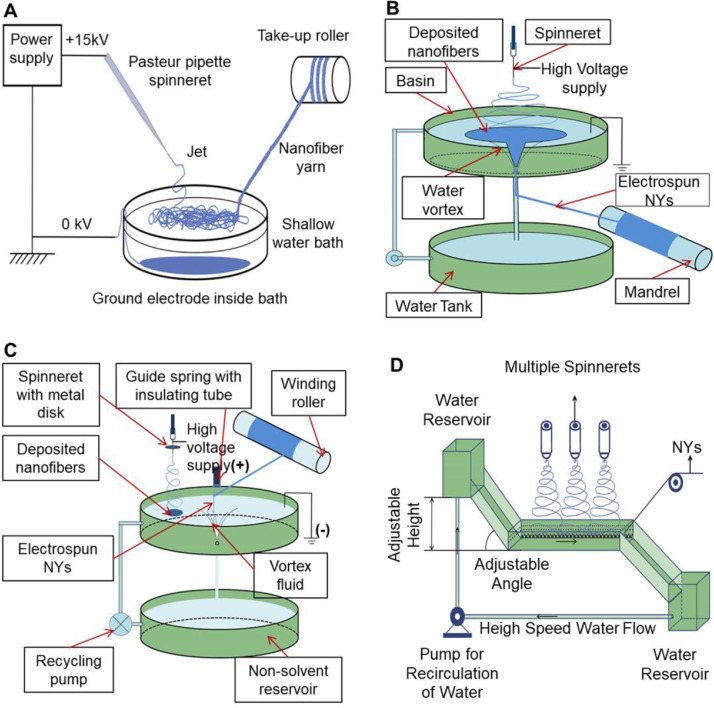

Several studies employed the mechanisms of wet spinning to modify the conventional electrospinning devices for the fabrication of NYs in a continuous manner. A similar electro-wet spinning method is presented to generate continuous NYs, as shown in Fig. 6 A [79,80]. A new collecting apparatus, consisting of a water coagulation bath, a nanofiber guiding bar, and a NY take-up cylinder, was utilized to take place of the metal plate collector used in conventional electrospinning. Polymeric nanofibers were directly deposited into a coagulation bath, and the assembled nanofibers were further stretched into yarn-like structures and pulled from the water to air with the aid of the guiding bar and take-up cylinder. Several synthetic polymers, including PCL, poly (vinylidene difluoride) (PVDF), poly(vinyl acetate) (PVAc), and PAN, have been electrospun into continuous NYs, demonstrating the feasibility of electro-wet spinning. By modifying the electro-wet spinning setup, a dynamic liquid support system was introduced to continuously collect the electrospun NYs, as shown in Fig. 6B [81]. The electrospun nanofibers were first deposited on the surface of the water in the upper basin. A small hole was created in the center of the upper basin to generate a water vortex when the water flowed out into the bottom water storage tank. The water vortex can draw the deposited nanofiber assembly into a NY. Poly(vinylidene floride-co-hexafluoropropylene) (PVDF-HFP) has been electrospun into NYs with highly aligned fibrous structures by using this dynamic electro-wet spinning method. To increase the controllability and stability of the NY fabrication process, Yousefzadeh et al. further modified the dynamic electro-wet spinning device [82]. As shown in Fig. 6C, an auxiliary disk electrode was applied onto the spinneret to concentrate the electrical field and limit the deposition area of nanofibers on the water's surface. A water vortex was created to assist in the NY formation. The NYs were guided through a spring tube and collected on a winding roller located above the basin hole. Importantly, this modified setup was demonstrated the ability to impart the NYs with a twist. Both untwisted and twisted PAN NYs were fabricated, and the twisted NYs presented obviously enhanced breaking strength compared to the untwisted NYs (13.9 ± 3.7 MPa vs 3.0 ± 0.3 MPa). Moreover, Fig. 6D shows an innovative nanofiber formation system constructed with multiple spinnerets [83], which significantly increased the production rate of PAN NYs and effectively improved the controllability and stability of the dynamic electro-wet spinning technique. Some existing studies also utilized the electro-wet spinning technique to fabricate electrospun PAN NYs [84,85]. Although some great efforts have been devoted to these electro-wet spinning methods, there are also some major limitations and drawbacks, including uncontrolled twisting parameters, high yarn breakage rate, and limited polymer source (only suitable for polymers insoluble in water).

Fig. 6.

Schematic of some reprehensive electro-wet spinning devices for the fabrication of electrospun NYs in a continuous manner. (A) Electro-wet spinning device for the generation of untwisted NYs. (B) Electro-wet spinning device for the generation of twisted NYs. (C) Electro-wet spinning device with an auxiliary disk electrode for the generation of twisted NYs with high controllability. (D) Electro-wet spinning device with multiple spinnerets for the large-scale production of untwisted NYs. (A-H) were redrawn based on Refs. [79], [80], [81], [82], [83].

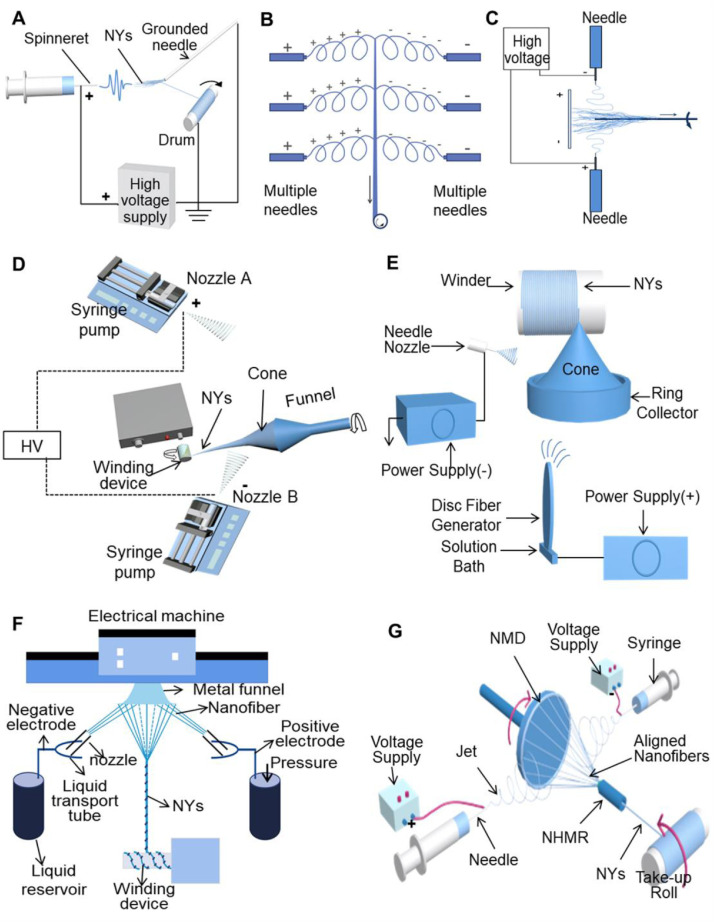

The mechanisms of traditional dry spinning were also employed to modify the conventional electrospinning device for the fabrication of continuous NYs. A self-bundling electrospinning method was reported to continuously generate NYs, as shown in Fig. 7 A [86,87]. A grounded needle tip was employed to induce the self-bundling behavior of nanofibers ejected from a high voltage charged needle tip, and the self-bundled NYs were further pulled back and wound onto a rotating drum. The conductivity of the spinning solution is the fatal factor for the self-bundling electrospinning. Organic salts should be added into the polymer solution to improve the conductivity. After adding benzyl triethylammonium chloride (BTEAC), four different types of synthetic polymers, including PAN, poly(L-lactic acid) (PLLA), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), and poly(m-phenylene isophthalamide) (PMIA), were electrospun into NYs, demonstrating the feasibility and versatility of this NY-forming technique. Although this self-bundling electrospinning technique presented simple and energy-saving features, the nanofibers’ self-bundling behavior was difficult to be precisely controlled during the NY-forming process, resulting in low quality NYs and a high yarn breakage rate. One study further designed a conjugated electrospinning apparatus to manufacture continuous poly(vinyl alcohol) (PVA) and poly(vinyl pyrrolidone) (PVP) NYs [88]. Positive and negative voltages were applied to two oppositely placed needles. The nanofibers were ejected from the two needles that carried opposite charges, which were attracted to each other and further bundled into a NYs. To increase the NY production rate of conjugated electrospinning, a multiple conjugate electrospinning system made of three sets of oppositely-placed needles was designed, as shown in Fig. 7B [89]. Continuous tricalcium phosphate encapsulated PLLA NYs were prepared by using this multiple conjugate electrospinning setup. The conjugated electrospinning device was also modified by placing a neutral collector (metal plate or cylinder) in the middle of two oppositely-placed needles, as shown in Fig. 7C [90,91]. By using a similar methods as used by Su et al., different polymers, including PAN, PLA [92], PLLA [93,94], and poly(acrylonitrile-co-methyl acrylate) [95], have been fabricated into electrospun NYs. One conventional textile yarn supply device was further introduced to the modified conjugate electrospinning system [96]. Two different nanofiber coverspun yarns, including nylon nanofiber-coated nylon microfiber yarns and PLA nanofiber-coated copper wire yarns, were manufactured. Some studies employed similar methods to develop some complicated yarn structures, such as hollow polyurethane (PU) NYs [97], hollow carbon nanotube (CNT)/polyamide 6 (PA6) NYs [98], PAN/CNT/Cotton coverspun yarns [99], poly(L-lactic acid) (PLLA)/ PA6 coverspun yarns [100] and multilayer PA6/PU/PA6 coverspun yarns [101].

Fig. 7.

Schematic of some representative conjugate electrospinning devices for the fabrication of electrospun NYs in a continuous manner. (A) Self-bundling electrospinning NY-forming device. (B) Multiple conjugate electrospinning NY-generating system. (C) Conjugated electrospinning NY-generating device modified by placing a neutral collector in the middle of two oppositely placed needles. (D) Conjugated electrospinning NY-generating setup modified with a funnel. (E) Hybrid needle-needleless electrospinning NY-fabricating system. (F) Modified multiple conjugate electrospinning NY-forming apparatus. (G) Conjugated electrospinning NY-generating device made by introducing an innovative collector constructed with NMD and NHMR. (A-G) were redrawn based on Refs. [62,86,89–91,102–105,109].

Fig. 7D shows a modified conjugate electrospinning device [102]. An intermediate funnel collector was employed to collect the oppositely charged nanofibers spun from two oppositely placed needles. A hollow nanofiber “cone” was formed on the edge of funnel, and PVDF-HFP NYs were produced by twisting and pulling away from the as-formed nanofiber cone. The highest number of twists of the NYs reached 7400 twists per meter. The same research group developed a hybrid needle-needleless electrospinning system, as shown in Fig. 7E, which extremely improved the productivity of PVDF-HFP NYs (∼240 m/h) [103]. The yarn and nanofiber diameters were in the ranges of 52 μm to 206 μm and 541 nm to 1.6 μm, respectively. Another research group developed double and multiple conjugate electrospinning devices to increase the production efficiency of nanofibers, thus resulting in the obvious improvement of yarn production efficiency (Fig. 7F) [104,105]. By using a similar device, as shown in Fig. 7D, various polymers containing PAN, poly(vinylidene fluoride trifluoroethylene) (PVDF-TrFE), PCL, and poly(sulfone amide) (PSA) have been fabricated into electrospun NYs [[106], [107], [108]].

It should be noticed that our previous study introduced an innovative collector into the conjugated electrospinning device (Fig. 7G). This method significantly improved the alignment and evenness of electrospun NYs. Importantly, continuous NYs with lengths in the range of tens to hundreds of meters could be produced. One collector was constructed with a neutral metal disc (NMD) placed oppositely from neutral hollow metal rod (NHMR), which were both in the middle of two oppositely placed needles. This homemade collector was demonstrated to effectively adjust the distribution of the external electric field and generate highly aligned nanofibers, and the obtained nanofibers were deposited in the gap between the edge of the NMD and the sharp end of NHMR. The collected nanofibers with super-aligned structures were then bundled and twisted into continuous NYs. Due to the highly aligned fibrous structure and excellent yarn evenness, the mechanical properties of the as-generated NYs were obviously enhanced. The PAN NYs showed high breaking stresses that ranged from 7.6 to 9.1 cN/tex, which were similar to the strength of textile-used cotton MYs [62,109,110]. In addition, one yarn supply and one tension device were further applied into this NY-forming system and could continuously provide conventional MYs. Several different types of nanofiber coverspun yarns, including PLGA nanofiber-coated PLA microfiber yarns, methacrylated gelatin (MeGel) nanofiber-coated PLA microfiber yarns, and MeGel/PLGA nanofiber-coated PLA microfiber yarns, were fabricated, which provided an effective finishing method for improving the properties of commonly-used textile MYs [111,112]. In general, various modified conjugate electrospinning methods are widely employed for the continuous generation of NYs, originated from a simple device, have widespread polymer spinnability, and have excellent handleability.

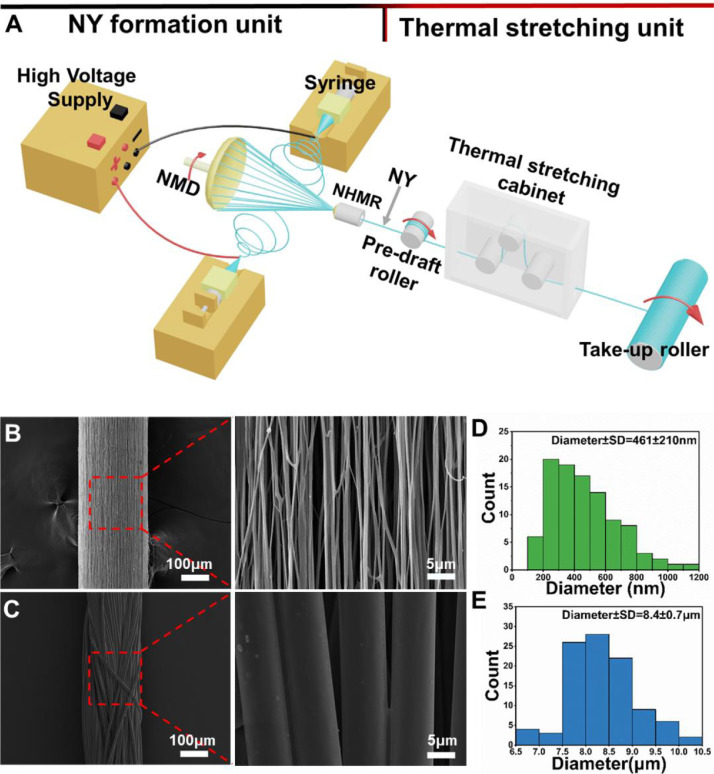

It is well-known that ideal electrospun NYs should not only present high nanofiber alignment and excellent yarn evenness but also possess appropriate mechanical properties that satisfy the fabrication requirements of various textile forming strategies. We summarized the index and reference of diameters and mechanical properties of electrospun NYs using different polymers and processing methods in Table 1 . It can be seen that both the twisting and hot stretching processes are effective ways to increase the mechanical properties of electrospun NYs. The twisting process utilizes physical force to improve the friction and adhesion among the nanofibers of electrospun NYs. In comparison, the hot stretching process could notably increase the fiber alignment and crystallinity of electrospun NYs, leading to improved mechanical performances. For example, one study investigated the effects of the hot stretching process on the mechanical properties of PAN NYs fabricated from self-bundling electrospinning [113]. They found that the mechanical properties of stretched NYs presented a remarkable improvement compared to unstretched NYs. For instance, the breaking strengths were 45 ± 2.5 MPa for unstretched NYs, 146 ± 9.6 MPa for 100% stretched NYs, and 372 ± 14.2 MPa for 300% stretched NYs. The tensile moduli were 0.8 ± 0.11 MPa for unstretched NYs, 5.2 ± 0.56 MPa for 100% stretched NYs, and 11.8 ± 0.46 MPa for 300% stretched NYs. Most Recently, another study introduced an integrated electrospinning device constructed with one nanoyarn-forming unit and one hot drawing unit to fabricate high performance PLLA NYs, as shown in Fig. 8 [132]. The hot drawing process was demonstrated to effectively increase the alignment and crystallinity of PLLA NYs, resulting in admirable mechanical properties that even surpassed the commercial PLLA MYs. The breaking load, breaking stress, and Young's modulus of 3-fold stretched PLLA NYs were 3.6 ± 0.1 N, 51.6 ± 0.8 MPa, and 1302.8±5.4 MPa, respectively. In comparison, the breaking load, breaking stress, and Young's modulus of commercial PLLA MYs were 2.7±0.1 N, 34.3±0.5 MPa, and 457.0±0.7 MPa, respectively [121]. A combination of twisting and hot stretching is obviously beneficial for synergistically improving the structural and mechanical properties of electrospun NYs.

Table 1.

Summarization of diameters and mechanical properties of some representative electrospun NYs using different polymers and processing methods.

| Materials | Yarn diameter | Fiber diameter | Young's modulus | Ultimate strength | Twisting | Hot stretching | Ref |

|---|---|---|---|---|---|---|---|

| PAN | /; / | ∼1300 nm; / |

0.8 GPa; >5.2-11.8 GPa |

45 MPa; 146-372 MPa |

×; × |

×; √ |

[113] |

| PAN | 1.16 tex; / |

411.8 nm; / |

1.66 GPa; 7.51 GPa |

58.08 MPa; 171.84 MPa |

√; √ |

×; √ |

[114] |

| PAN | 11.4-15.3 tex | 750-1000 nm | 0.55-0.64 N/tex | 0.45-0.54 N/tex | √ | × | [72] |

| PAN | 2.1 tex | 474 nm | 1440 MPa | 54.75 MPa | √ | × | [90] |

| PAN | 340.7 μm; / | /; / | 1.9 GPa; 4.5 GPa |

61.3 MPa; 116. 6 MPa |

√; √ |

×; √ |

[91] |

| PAN | 10-12 μm | / | 9.18 GPa | 100–180 MPa | √ | × | [69] |

| PAN | 39.9-71.3 tex | 220 ∼ 260 nm | / | 0.013-0.026 N/tex | √ | × | [115] |

| PAN | 1.51-1.78 tex | / | 1.68-1.88 N/tex | 0.076-0.091 N/tex | √ | × | [109] |

| PAN | 70-216 μm | 400-700 nm | / | 50.71 MPa | √ | × | [105] |

| PAN | 41.8-58.6 tex | / | / | 0.03-0.05 N/tex | √ | √ | [116] |

| PAN | 40-150 μm | 480-650 nm | 1.4-3.2 N/tex | 0.06-0.13 N/tex | √ | × | [110] |

| PAN | / | 1200-1650 nm | / | 3.80-4.25 MPa | √ | × | [106] |

| PCL | / | 330-440 nm | 12.44-68.14 MPa | 4.12-41.54 MPa | √ | × | [117] |

| PCL | / | 810-1320 nm | / | 1.56-2.03 MPa | √ | × | [106] |

| PLLA | 164 μm; / |

6000 nm; 2300-3200 nm |

0.037 N/tex; 0.012-0.34 N/tex |

0.0015 N/tex; 0.0039-0.01 N/tex |

√; √ |

×; √ |

[118] |

| PLLA | 209-435 μm | 461-763 nm | 0.2-0.6 N/tex | 0.04-0.08 N/tex | √ | √ | [119] |

| PLLA | 358-470 μm | 481-789 nm | 0.2-0.3 N/tex | 0.02-0.04 N/tex | √ | × | [94] |

| PLLA | 69.1 μm | 558.0 nm | 116.2 MPa | 23 MPa | × | × | [120] |

| PLLA | 241-494 μm | 449 -515 nm | 152.7-1191.5 MPa | 10.9-58.4 MPa | √ | √ | [121] |

| PLGA | / | 800 nm | 138.20 MPa | 59.48 MPa | √ | × | [117] |

| PLGA/PCL | / | 560 nm | 64.45 MPa | 5.40 MPa | √ | × | [117] |

| PLGA/PEO | 93 μm | 48 nm | / | 487.5 MPa | √ | × | [122] |

| PVDF-TrFE | 175-306 µm | 200-600 nm | 30.5 MPa | √ | × | [123] | |

| PVDF-TrFE | / | 790-970nm | / | 2.81-10.16 MPa | √ | × | [106] |

| PVDF-HFP | 30-450μm | 480-1500 nm | / | 60.4 MPa | √ | × | [102] |

| PVDF-HFP | 30-150 μm | 592 nm | / | 93.6 MPa | √ | × | [124] |

| PVDF-HFP | 46.2 μm | 631 nm | 334.0 MPa | 127.7 MPa | √ | √ | [125] |

| PVDF-HFP | 500 μm | / | / | 88.7 MPa | √ | × | [126] |

| PA66 | 84.7-175.3 μm | 90-220 nm | / | 86.75-118.56 MPa | √ | × | [127] |

| PA66 | 133-222 μm | 252-256 nm | 213-363 MPa | 64-88.4 MPa | √ | × | [128] |

| PA66 | 499-613 μm | 210-240 nm | 113-486 MPa | 13.7-23.9 MPa | × | × | [129] |

| PSA | 150-200 μm | 435-785 nm | / | 0.25-1.91 N/tex | √ | × | [130] |

| PPDO | 216 μm | 483 nm | 768 MPa | 190 MPa | √ | × | [131] |

Fig. 8.

(A) An innovative electrospinning system integrating one NY-forming unit and one thermal stretching unit. (B) SEM images of electrospun PLLA NYs. (C) SEM images of commercial PLLA MYs. (D) Fiber diameter distribution of the electrospun PLLA NYs in B. (E) Fiber diameter distribution of the commercial PLLA MYs in C. (A-E) Reprinted with permission from Ref. [132].

4. Electrospun NY-constructed biotextiles

In the textile industry, fiber-constructed yarns are the most widely used building blocks for the generation of various textiles. Microfibrous yarns have been extensively used in various textile processing technologies for thousands of years [1,9]. The application of electrospun NYs in the traditional textile processing techniques offers the potential to manufacture nanotextiles that exhibit superior characteristics and optical, electrical, mechanical, and biological properties due to size effects and surface/interface effects. The electrospun NY-constructed nanotextiles possess predetermined textile structures and patterns in one or multiple dimensions and open a new window to renew and update the existing microfibrous textiles. During traditional textile engineering, different textile-forming techniques, primarily including weaving, knitting, braiding, and other 3D textile-fabricating methods, can be easily adapted to fabricate nanotextiles and create different textile patterns, which notably affect the shape, structure, porosity, stability, and mechanical performances of as-generated biotextiles. Table 2 summarizes the features of each textile-forming strategy.

Table 2.

Summarization of various textile-forming methods.

| Textile Method | Schematic | Merits | Demerits |

|---|---|---|---|

| Weaving |  |

Controllable size, structure and porosity; Strong and anisotropic mechanical properties; Excellent durability |

Relatively inextensible in the warp and weft directions but opposite in the other bias directions |

| Braiding |  |

Excellent hierarchical organization; High strength and stiffness along the braiding direction; Excellent durability |

Lower porosity than woven and knitted patterns |

| Knitting |  |

Controllable size, structure and porosity; Easily stretchable in all the directions |

Lower Young's modulus than the other types of textiles |

| 3D textile-forming strategy |  |

3D structure; Controllable size and porosity; Enhanced mechanical properties along the thickness direction compared to other 2D textile patterns |

Complex fabrication system |

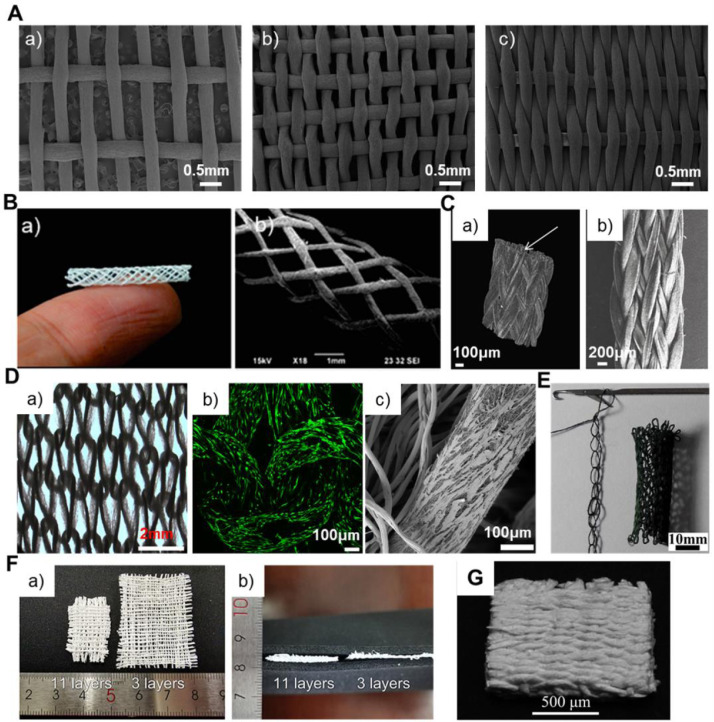

Weaving is a well-established textile creation method. In this process, one set of weft yarns are frequently interwoven into one set of warp yarns to generate different weaving patterns, commonly including plain, twill, and satin structures. Khil et al. first reported the use of electrospun NYs for a textile weaving strategy [79]. PCL NYs were fabricated using an electro wet-spinning device and further processed into a woven fabric with a plain pattern. Wu et al. developed a series of woven nanotextiles with different yarn weaving densities using high strength PLLA electrospun NYs, as shown in Fig. 9 A, and demonstrated the possibility of controlling the structure, pore size, and mechanical properties by using different NY weaving densities [121]. Importantly, they also found that the PLLA NY weaving density could dramatically affect the cell adhesion, growth, and proliferation. The PLLA NY-based woven nanotextiles are potential candidates for biomedical applications due to their controllable structures and properties.

Fig. 9.

(A) PLLA electrospun NY-constructed woven nanotextiles with different NY weaving densities. (B) PLLA electrospun NY-constructed braiding nanotextiles with a tube-like structure. (C) Solid braiding nanotextiles made from 24 strands of PPDO electrospun NYs. (D) Weft knitting nanotextiles constructed with a plied yarn. The plied yarn was composed with one PAN electrospun NY and one PLA MY. (E) PANI-coated PAN electrospun NY-constructed weft knitting nanotextiles with a tube-like structure. (F) 3D multilayered nanotextiles made from PLLA electrospun NYs. (G) 3D multilayered nanotextiles made from SF/PLLA electrospun NYs. (A) Reprinted with permission from Ref. [121]. (B) Reprinted with permission from Ref. [133]. (C) Reprinted with permission from Ref. [134]. (D) Reprinted with permission from Ref. [135]. (E) Reprinted with permission from Ref. [136]. (F) Reprinted with permission from Ref. [120]. (G) Reprinted with permission from Ref. [137].

Braiding is one of the most ancient textile strategies, originally developed by humans for generating ropes. In the braiding process, three or more yarns are interlaced into a diagonally overlapping structure to create different braided patterns. Joseph et al. braided PLLA electrospun NYs into a hollow structure for potential use as stents or vascular grafts, as shown in Fig. 9B [133]. Abhari et al. used PPDO electrospun NYs to fabricate a series of braided nanotextiles with different braiding densities [134]. A braided pattern fabricated with 24 strands of PPDO electrospun NYs is shown in Fig. 9C. Importantly, they demonstrated the feasibility of adjusting the structure, porosity, and mechanical properties of PPDO NY-based braiding patterns. Wu et al. also constructed a number of PLLA NY-based braiding nanotextiles and found that the NY-based braids significantly promoted the cell adhesion and proliferation compared to the braiding pattern fabricated using commercial PLLA MYs [121]. The braided nanotextiles made from electrospun NYs also showed extensive potential applications in biomedical textile products.

Knitting is another ancient textile method for creating clothes. Even now, people still have intensive interest in generating knitted clothes, hats, and gloves manually. During the knitting process, the yarns are set as a series of meandering loops and are interconnected into various patterns, which are commonly divided into two major categories, i.e., weft knitting and warp knitting. In general, the weft knitting patterns exhibit higher flexibility and stretchability than the warp knitting patterns. In one study, Wu et al. first generated a plied yarn constructed with one PAN electrospun NY and one commercial PLA MY and then knitted the plied yarn into a weft knitting pattern, as shown in Fig. 9D [135]. They further investigated the cellular behaviors of cells seeded on this weft knitting pattern and found that the cells preferred to adhere and proliferate on the PAN NYs compared to the PLA MYs. Moreover, the cells were found to elongate and align along the fiber orientation in the yarn loop, indicating the feasibility of controlling the cell growth by adjusting the knitting pattern. In another study, Wu et al. employed PANI-coated PAN NYs to successfully generate a tube-like weft knitting structure, as shown in Fig. 9E, demonstrating the potential of this knitted nanotextile for use in smart wearable textile applications [136]. Currently, no electrospun NYs have been reported to generate the warp knitting pattern because the flexibility, abrasive resistance, and tensile strength of the fabricated electrospun NYs are far behind the fabrication requirements of warp knitting techniques.

With the rapid development of textile techniques, some complex 3D textile-forming strategies have been explored and implemented. A 3D textile pattern can be achieved by using automated and programmable machines, which could extremely expand the applications of textile products in the biomedical fields. It is known that all the tissues and organs in the human body present 3D architectures and structures. The development of 3D electrospun NY-based textiles could maintain the unique features originating from electrospun nanofibers and, meanwhile, closely resembling the hierarchical and anisotropic characteristics of native tissues and organs. One study reported the fabrication of 3D textile patterns using PLLA electrospun NYs [120]. They utilized a noobing technique to process three orthogonal sets of NYs into a relatively complex 3D textile structure with multiple layers, as shown in Fig. 9F, and found that cells could easily penetrate all the layers of the textile scaffold and form a 3D cell-textile construction. Another study also developed a 3D multilayered textile pattern using electrospun SF/PLLA NYs, as shown in Fig. 9G [137]. Although electrospun NYs have been widely reported for generating different textile patterns, tremendous effort should still be made for the fabrication of more complex 3D textile patterns.

5. Tissue repair and regeneration applications

Tissue engineering is currently recognized as a promising treatment option for replacing the existing autografts, allografts, and xenografts in regenerative medicine. Biomaterial scaffolds, cells, and bioactive ingredients are three key elements in tissue engineering. Among them, biomaterial scaffolds are designed to resemble the components, structures, and various properties of native ECM, which promote the cell adhesion, growth, migration, proliferation, and differentiation. They also allow neo-tissue formation and regeneration with defined structures and functions [101]. Both electrospinning and textile forming strategies have attracted intense interest for fabricating fibrous biomaterial scaffolds and implants for diverse tissue engineering applications. Electrospun nanofibers possess structural similarities to the fibrils in native ECM. They also present a high surface area for increasing cell-material adhesion and interaction as well as adjustable chemical, physical, and biological properties for regulating cellular activities, remodeling ECM deposition, and facilitating tissue regeneration [39,138]. Unfortunately, most electrospun nanofibers are collected in the form of compact meshes, which exhibit unsatisfactory scaffold thickness and negatively affect the cellular infiltration and nutrition diffusion [135,139]. In comparison, textile-based scaffolds and grafts are designed and developed using textile technologies, which are more appropriate for resembling the hierarchical and anisotropic structures and strain-stiffening properties of native tissues. Therefore, constructing electrospun NYs and further processing them into diverse nanofibrous textile structures and patterns can combine and integrate the desirable characteristics from both electrospinning and textile fabrication techniques. These structures have been demonstrated to be great candidates for applications in surgical sutures and the repair and regeneration of various tissues, including peripheral nerves, tendons, bones, and cardiovascular tissues.

5.1. Surgical sutures

Surgical sutures are widely used and indispensable medical materials for closing wounded tissues and supporting their healing process after surgeries in clinics [140]. Among various commercial sutures, the absorbable synthesized sutures, including PLLA, PGA, PLGA, PLCL, and PPDO, have aroused more attention than the unabsorbable sutures, such as silk, nylon, and polypropylene, due to their higher biocompatibility, controllable degradation rates and mechanical properties, and minimal postoperative treatments. However, there are still some obvious limitations existing in these commercial absorbable sutures, which should be fully addressed. One key issue is mismatched fiber morphology and size. These sutures were all made of microfibers with diameters over 10 μm. Recently, to address this issue, several studies have been performed in innovative directions for employing electrospun NYs with great ECM fibril-mimicking characteristics as surgical sutures. From the perspective of suture composition, several absorbent synthesized polymers, such as PLGA [141], PLLA [142], PPDO [143], and PCL [144], were preliminarily investigated to electrospin them into NYs for surgical suture applications. It was found that the single electrospun NYs exhibited relatively low mechanical properties, which could not satisfy the requirements of practical applications [141]. One study utilized a multiple twisting technique to make 35 strands of NYs ply into one thread, which remarkably increased the mechanical properties of the NY-constructed thread [143]. They employed this nanofibrous thread as a suture for tendon repair. The results showed that the electrospun nanofibrous suture exhibited negligible immunogenicity, and significantly higher neovascularization was found in the nanofibrous suture than in the commercial microfibrous suture control. Several other studies reported the fabrication of electrospun nanofiber-coverspun yarns to enhance the mechanical properties of as-generated sutures [142,144,145].

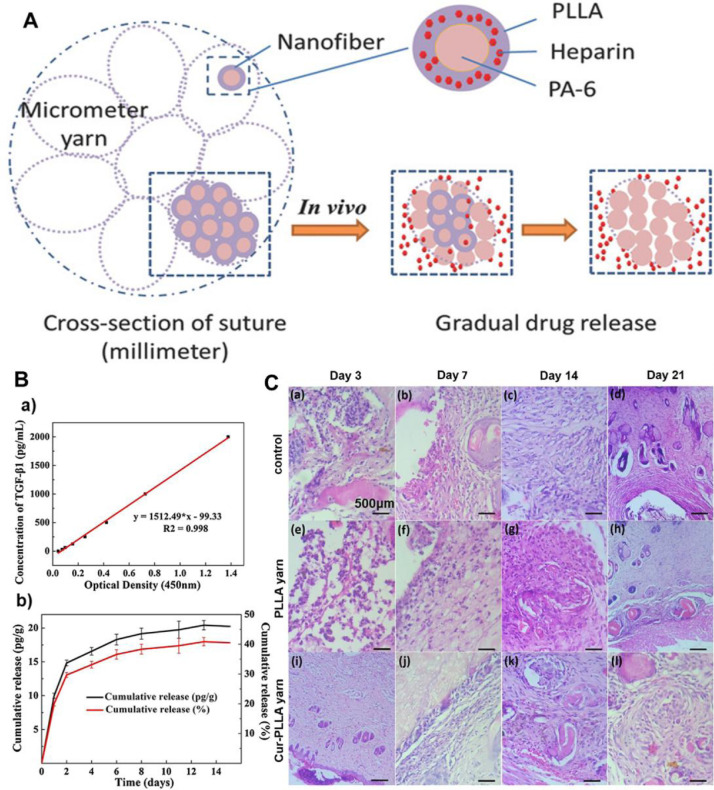

Another vital issue for the commercial sutures is a lack of necessary biological activity and function. The ideal suture should not only provide tissue securement but also promote wound healing. Although some effort was placed on exploring surface coating techniques to impart commercial sutures with drug-releasing functions, some key problems still remain. The application of electrospun NYs as surgical sutures can address these problems well. For example, a variety of bioactive materials, such as curcumin [142,144,145], vascular endothelial growth factor (VEGF) [142], aceclofenac [145], insulin [145], antimicrobial additives containing cefazolin [148], and silver nanoparticles [149], and biofunctional materials, i.e, carbon quantum dots [150], were incorporated into the nanofibers in NYs to exert predetermined biological functions during electrospinning. A schematic explanation about the release of heparin from electrospun NYs is shown in Fig. 10 A [142]. The growth factors and drugs exhibited sustained release behaviors when incorporated within electrospun NYs. For instance, Fig. 10B shows the release behavior of transforming growth factor-β1 (TGF-β1) from electrospun TGF-β1/PLGA nanofiber-coated PLGA microfibers coverspun yarns [146]. Moreover, another study demonstrated curcumin-loaded PLLA electrospun NYs as skin sutures [147], which exhibited a sustained release behavior with enhanced antibacterial and antiplatelet properties and improved cell migration and interaction in vitro as well as reduced inflammation and increased healing promotion performance in vivo, as shown in Fig. 10C.

Fig. 10.

Design and development of some representative drug-loaded electrospinning-based yarns for surgical suture application. (A) Schematic of the mechanisms of heparin release from electrospun heparin/PLLA nanofiber-coated PA6 microfibers coverspun yarns. (B) The cumulative release test of TGF-β1 from electrospun TGF-β1/PLGA nanofiber-coated PLGA microfibers coverspun yarns. (C) H&E staining of skin tissues sutured by using electrospun PLLA NYs and curcumin-loaded electrospun PLLA NYs for 21 days. (A) Reprinted with permission from Ref. [142]. (B) Reprinted with permission from Ref. [146]. (C) Reprinted with permission from Ref [147].

5.2. Peripheral nerves

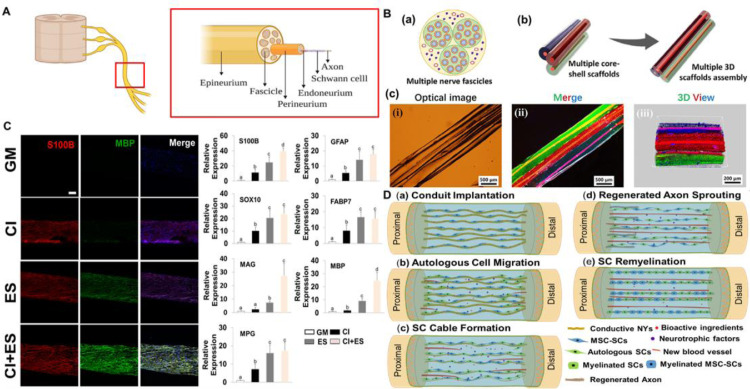

Native peripheral nerves exhibit a hierarchical cable-like structure, as shown in Fig. 11 A [153,154]. Motor or sensory axons are wrapped in a myelin sheath formed by Schwann cells (SCs) and surrounded by a layer of connective tissue (i.e., endoneurium). Multiple endoneurium-wrapped axons are bundled together with a layer of connective tissue (i.e., perineurium) to generate a series of fascicles, which are then grouped together with a layer of connective tissue (i.e., epineurium) into a nerve trunk. The peripheral nerve has a certain regeneration capacity. If a nerve injury gap (for humans) is less than 5 mm, an end-to-end coaptation is required to suture the two broken ends of the nerve trunk in a tension-free manner. For a larger defect gap, a nerve graft should be adopted to bridge the gap to assist in the nerve regeneration. A tube-like nerve graft, called a nerve guidance conduit (NGC), which can prevent the ingrowth of scar tissues and provide a relatively closed and concentrated environment for regeneration, is recognized as an effective structure for repairing the damaged nerves. Currently, most nerve grafts approved by the US Food and Drug Administration (FDA) are tube-like structures, such as Neurotube®, NeuroflexTM, and Neuragen® [155]. Unfortunately, the repair outcomes of these NGCs are unsatisfactory for large nerve defects, and they are not suggested to be utilized for nerve gaps over 30 mm in clinics [156,157]. The unsatisfactory efficacy is most probably due to the lack of ideal topographical and biological cues within the lumen of the NGCs.

Fig. 11.

Design and development of electrospun NYs and their potential applications as intraluminal fillings for peripheral nerve cell culture and tissue repair. (A) Schematic of peripheral nerve tissue. (B) Construction of three-column scaffolds made of conductive PCL/SF/CNT NYs and two layers of MeGel and alginate hydrogels. (a) The cross-sectional illustration of multiple nerve fascicles; (b) Schematic of the generation of three-column scaffolds. (c) Photograph (i), fluorescence image (ii), and 3D review image (iii) of as-prepared three-column scaffolds. The NYs were stained with a red color and the hydrogel shells were stained with red, green, and blue colors. (C)Phenotypic characterization of MSCs seeded on electrospun PPDO/CNT NYs and cultured under growth medium (GM), chemical induction (CI), electrical stimulation (ES), or a combination of CI and ES by using immunofluorescent staining and RT-PCR techniques. Bars that do not share letters are significantly different from each other, p < 0.05. (D) Illustration of the regenerative process using a multiple technique-integrated synergistic strategy containing conductive NYs, bioactive ingredients, and MSC-SCs to reconnect a large nerve gap. (A) Reprinted with permission from Ref. [151]. (B) Reprinted with permission from Ref. [152]. (C) Reprinted with permission from Ref. [131].

A variety of intraluminal filling materials, such as fibers, sponges, and hydrogels, are designed to improve the intraluminal microenvironment of NGCs, but a satisfactory regeneration treatment effect has still not been achieved. Most recently, the possibility of employing electrospun NYs as NGC fillers has been extensively explored. Compared to other filling materials, the electrospun NYs can better resemble the fascicle structures of native peripheral nerves, and the internal nanofibers of electrospun NYs can better replicate the size scale and longitudinal alignment of axons in fascicles [112]. Moreover, a bundle of electrospun NYs seems more like a natural nerve trunk. One study found that SCs cultured on the PLLA electrospun NYs presented a better spread morphology and proliferation rate than those cultured on electrospun PLLA nanofiber mats [158]. Biological cues have been combined with topographical guidance to improve the biological properties of electrospun NYs. Some bioactive polymers, including laminin [159] and MeGel [112], were utilized to construct electrospun NYs, which were found to significantly increase the biological activities of SCs. For example, MeGel was incorporated with PLGA to develop MeGel/PLGA nanofiber-coated PLLA microfiber yarns, which were demonstrated to notably promote cellular adhesion, migration, and proliferation as well as phenotypic maintenance [112]. In particular, a test was conducted to simulate in vivo cell migration after nerve injury, and it was found that the SCs migrated about 20 mm along the longitudinal axis of MeGel/PLGA/PLLA coverspun yarns after 14 days of culture.

Electrochemical cues have also been applied to integrate with the topographical cues provided by the electrospun NYs. For example, one study coated electrospun PCL NYs with polypyrrole (PPy) to form conductive NYs by in situ chemical polymerization, and it was demonstrated that the improved conductivity positively affected the growth and proliferation of SCs [160]. Another study fabricated conductive PCL/SF/CNTs NYs and further coated them with two layers of MeGel and alginate hydrogels to form three-column scaffolds, as shown in Fig. 11B [152]. The inner aligned NYs were demonstrated to guide the alignment and extension of neurites, and, meanwhile, the outer hydrogel shell was demonstrated to provide an epineurium-mimicking environment that protected the organization of nerve cells. In another study, CNTs were incorporated into PPDO nanofibers to generate conductive electrospun NYs, and it was demonstrated that increasing the CNT content could effectively promote the phenotypic maintenance of SCs [131]. This study also found that electrical stimulation notably increased the differentiation capacity of mesenchymal stem cells (MSCs) into SC-like cells on the CNT/PPDO electrospun NYs, as shown in Fig. 11C. Importantly, the synergistic effects of chemical induction and electrical stimulation remarkably promoted the maturation of SC-like cells and the secretion of multiple nerve growth factors. Moreover, Gopalakrishnan-Prema et al. fabricated several different types of NGCs by applying electrospun NYs with textile braiding techniques [161]. Electrospun PLLA NYs were braided with PPy-coated PLLA NYs, copper wires, or platinum wires to generate conductive NGCs. The braided platinum wires and electrospun PLLA NY NGCs exhibited improved bio-tolerability, enhanced neurite outgrowth, increased length of dorsal root ganglion compared to the braided NGCs made of other materials.

Unfortunately, all the existing studies have stayed at the in vitro level up until now. A tremendous effort should be made to speed up in vivo investigation and further clinical trials. Fig. 11D shows predicted regenerative mechanisms using multiple strategies to reconnect large nerve gaps. Conductive NYs loaded with cells, such as MSC-derived SC-like cells (MSC-SCs), and/or bioactive ingredients, such as various drugs, cytokines, and nucleic acids, can be employed as intraluminal filling materials and can exert synergistic effects. Conductive NYs can provide physical and electrochemical cues to guide the migration of autologous cells and directed regrowth of axons. They can also be utilized as carriers for loading bioactive ingredients and cells. Under the synergistic functions of multiple cues, ideal regenerative outcomes and functional recovery are expected.

5.3. Tendon

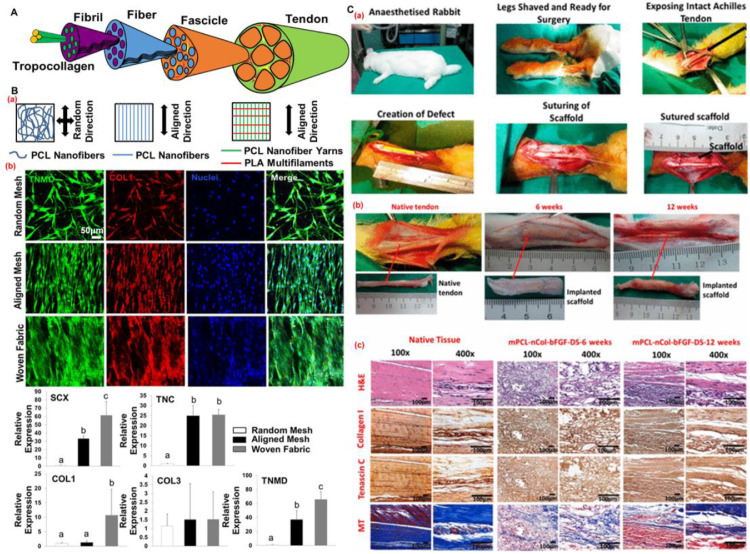

Tendon tissue is a dense connective tissue that presents a hierarchical fibrous organization along its longitudinal axis, as shown in Fig. 12 A. This consists mainly of tropocollagen molecules (∼1.5 nm in diameter), fibrils (50–500 nm in diameter), fibers (10–50 μm in diameters), and fascicles (50–400 μm in diameter) [162,163]. It has become clear that the replication of the hierarchical fibrous architecture of native tendon tissues is of significant importance for the design of scaffolds and grafts in tendon tissue engineering. More than 100 scientific papers have been published that report the exploration of electrospinning techniques to fabricate nanofibrous mats for tendon regeneration. Electrospun nanofibrous mats have been demonstrated to remarkably promote cellular adhesion, growth, proliferation, and migration as well as tenogenic differentiation. However, electrospun nanofibrous mats generally present low mechanical properties that cannot fulfill the rigorous mechanical requirements of native tendon tissues. Therefore, it is critical to develop some innovative strategies for improving the structures and mechanical properties of electrospun mats while maintaining their nanofiber characteristics. Several studies modified the typical electrospinning methods to fabricate mats made of aligned electrospun NYs and randomly distributed nanofibers, which exhibited relatively higher porosities and larger pore sizes than the typical random and aligned electrospun nanofiber mats, resulting in a higher cell proliferation rate [164,165]. Unfortunately, the mechanical properties of these mats were still low, and were even lower than typical electrospun mats.

Fig. 12.

Electrospun NYs and their biotextiles for promoting tenogenic differentiation and tendon regeneration. (A) Schematic of tendon tissue. (B) Comparative analysis of randomly electrospun PCL nanofiber mats, aligned nanofiber mats, and woven textile scaffolds made of electrospun PCL NYs and commercial PLA MYs. (a) Illustration of three different scaffolds; (b) Phenotypic characterization of MSCs seeded on the three different scaffolds by using immunofluorescent staining and RT-PCR techniques. Bars that do not share letters are significantly different from each other, p < 0.05. (C) In vivo analysis of tenocyte-loaded, braided mPCL-nCOL-bFGF textile scaffolds after in vitro dynamic stimulation for Achille's tendon reconstruction. (a) Photographs of the whole surgical procedure; (b) Photographs of harvested scaffold-tissue samples after 6 and 12 weeks of implantation; (c) Images of H&E staining, immunohistochemical staining, and Masson's trichrome (MT) staining of harvested scaffold-tissue samples after 6 and 12 weeks of implantation. (B) Reprinted with permission from Ref. [139]. (C) Reprinted with permission from Ref. [168].

Employing various textile forming techniques to process electrospun NYs into predetermined textile patterns provides a more appropriate strategy for addressing the drawbacks of electrospun nanofiber mats. Electrospun NYs are interwoven into woven nanotextiles to explore their potential in engineered tendon scaffold applications. The existing studies demonstrated that the woven nanotextiles exhibited controllable pore sizes, porosities, and mechanical and biological properties by adjusting the yarn weaving densities [139,166]. The woven nanotextiles were found to significantly enhance the tenogenic differentiation of stem cells, compared to the typical random and aligned electrospun nanofiber mats, by significantly increasing the gene expression levels of tenocyte-related markers, as shown in Fig. 12B. Biological cues have also been integrated with the topographical guidance provided by electrospun NYs to promote the cellular activities of tendon-associated cells. For example, thymosin beta-4 (Tβ4) was encapsulated into electrospun NYs, and they exhibited a sustained drug release profile for nearly one month and presented an additive effect on the promotion of the tenogenesis of stem cells [111]. Mechanical stimulation was also applied to accelerate the tenogenic differentiation of stem cells seeded on the electrospun NYs [167]. In addition, the mechanical stimulation has been integrated with the topographical cues of electrospun NY-based woven nanotextiles and a cellular coculture of human tenocytes and human umbilical vein endothelial cells to remarkably enhance the tenogenesis of stem cells [139].

The textile patterns fabricated by different textile-forming techniques dramatically affect the structures and mechanical properties of textile scaffolds, even if the same yarns are utilized. A multiple twist method has been utilized to ply 16 strands of single electrospun NYs into a thread with high mechanical performance that was more suitable for tendon regeneration applications than electrospun nanofiber mats [169]. A braiding technique was employed to generate braided nanotextiles from electrospun NYs, which exhibited notably enhanced tensile and suture-retention strengths and significantly promoted the tenogenic differentiation of stem cells compared to the aligned electrospun nanofiber mats [170]. In another study, basic fibroblast growth factor (bFGF) was loaded into electrospun PCL-micro/collagen-nano hybrid yarns (mPCL-nCOL-bFGF), and they were further fabricated into braided textile patterns for Achilles’ tendon reconstruction [168]. It was found that the tenocyte-seeded mPCL-nCol-bFGF scaffolds significantly enhanced the regeneration of tendon tissues in a rabbit Achilles tendon defect model after in vitro dynamic stimulation, as shown in Fig. 12C. A textile knitting technique was also utilized for generating NY-based tendon scaffolds. For instance, electrospun nanofiber coverspun yarns, employing microfibers as the core and electrospun nanofibers as the sheath, were first fabricated and then processed into knitted textile patterns [171]. An in vivo study using a rabbit patellar tendon defect model showed that the knitted textile scaffolds dramatically promoted the remodeling and regeneration process for neo-tissues.

5.4. Bone

Electrospun NYs and their nanotextiles also represent potential scaffolds for bone tissue engineering applications, originating from their ECM nanofibril-mimicking structures and controlled porosities. One study fabricated electrospun PLCL NYs, chopped them into short forms, and then encapsulated the short NYs into type I collagen hydrogels [172]. The NY-enhanced hydrogels significantly promoted the osteogenic differentiation of stem cells compared to hydrogels only. Importantly, the NY-enhanced hydrogel system was easily injected through a 16-gauge needle, which highlighted its potential as an injectable bone scaffold. In another study, electrospun SF/PLLA NYs were processed into textile patterns with 3D structures, which exhibited great mechanical performance, with a breaking strength of 180.4 MPa and a Young's modulus of 417.6 MPa [173]. A rabbit femoral condyle model experiment demonstrated that the 3D electrospun NY-based textile scaffolds significantly promoted the regeneration of new bone tissues.

Unlike other soft tissues, such as tendons and nerves, the ECM of bone tissue is composed of both organic (mainly type I collagen) and mineralized inorganic components. Along with type I collagen fibrils, the native bone ECM contains abundant hydroxyapatite (Ca10(PO4)6(OH)2, HAp) (an inorganic material, >70% of dry tissue weight), which remarkably influences the structure and properties of the bone ECM [174]. Therefore, various inorganic components were integrated into electrospun NY-based scaffolds to better resemble the complex organic-inorganic features and functions of natural bone ECM. For example, HAp particles were deposited on electrospun SF/PLCL NY-constructed scaffolds through a post-modification process, and they exhibited improved cellular adhesion, proliferation, and infiltration [175]. In another study, a post-soaking method was employed to deposit HA nanoparticles onto a 3D electrospun SF/PLLA NY-based textile scaffold, which was demonstrated to significantly improve cellular attachment and proliferation and to notably increase the osteogenic differentiation of stem cells [176]. It should be noticed that one study reported the development of electrospun PLLA NY-reinforced HAp/gelatin composite scaffolds and demonstrated that the scaffolds could notably promote the bone formation in a rabbit mandibular bone defect model [177] The regenerated bone tissues possessed a compressive strength that was almost similar to the native rabbit mandible. Moreover, a similar electrospun NY-enhanced scaffold was demonstrated to increase the formation of a mature lamellar bone in a rat femoral segmental defect model [178].

5.5. Cardiovascular system

Electrospun NYs and NY-constructed nanotextiles have also be explored for potential use in the repair and regeneration of the cardiovascular system, including vascular, cardiac, and heart valve leaflet tissues. The blood vessel is a long, tube-like structure that is mainly constructed of three complicated layers, i.e., intima, media, and adventitia [179]. Endothelial cells, smooth muscle cells, and fibroblasts are three main cell phenotypes in vascular tissues. Electrospun NYs have been demonstrated to improve the adhesion, elongation, proliferation [180,181], and angiogenic activity [182] of endothelial cells. The electrospun NYs could also support the differentiation of stem cells into smooth muscle cell-like phenotypes [135]. Several commercial FDA-approved textile vascular grafts, such as Gelsoft and Gelweave, have been utilized to replace diseased aortic vessels and have played key roles in saving patients’ lives [183,184]. In comparison to large aortic vessels, the repair of small blood vessels, with diameters less than 6 mm (for humans), remains a huge clinical challenge due to their tiny structures and complications after surgery. Most recently, one study developed an electrospun NY with a hollow structure for use as a vascular scaffold [185]. The wall thickness and outer diameter of the hollow NY scaffold were 156 ± 26.5 μm and 1.1 ± 0.15 mm, respectively. The hollow NY scaffold effectively supported the attachment and proliferation of endothelial cells in vitro, which is potentially valuable for the repair of small blood vessels.

The textile techniques also offer unique advantages for better mimicking the directional cellular alignment and anisotropic mechanical properties of cardiac tissues in the heart. In one study, conductive electrospun NYs were first fabricated and then interwoven into a woven pattern [42]. After that, one or multiple layers of woven fabric were integrated into a hydrogel system to engineer the anisotropy of 3D cardiac tissues. Researchers also seeded cardiomyocytes onto the woven nanotextiles and incorporated endothelial cells within the hydrogel to successfully achieve the endothelialization of engineered myocardium. In another study, a combined use of a woven nanotextile and a hydrogel was conducted to construct a nanotextile-enhanced hydrogel scaffold to engineer the anisotropic structure and properties of valvular tissues [186]. The composite scaffold exhibited mechanical properties similar to native valvular tissues and was found to support the growth and phenotypic maintenance of human aortic valve interstitial cells (HAVICs). Importantly, the composite scaffold could effectively inhibit the calcification of diseased HAVICs, which allows it to be potentially feasible as a living replacement for diseased valves.

6. Wearable textile devices and bioelectronics

Conductive fibrous yarns and textiles, which can be seamlessly integrated into everyday textile products, offer higher flexibility, stretchability, and breathability than solid and non-fibrous materials [4,187]. Among various fibrous assemblies, highly flexible and lightweight electrospun NYs exhibit high surface areas and enhanced conductivity, making them more appropriate candidates as the next generation of smart wearable devices and bioelectronics for monitoring, diagnosing, and managing medical conditions. The design and construction of conductive NYs with high flexibility and electrical performances are essential for nanofibrous textile bioelectronics. The material selection, referring to the matrix material and conductive materials, plays a key role in determining the physical properties of the fabricated devices. Three main categories of conductive materials, including conductive polymers, carbon nanomaterials, and metal nanomaterials, have been extensively investigated and utilized to fabricate conductive electrospun NYs. Table 3 summarizes the electrical performance and stretchability of some representative conductive or piezoelectric electrospun NYs. It was found that, compared to conductive polymers, the introduction of carbon nanomaterials, including multiwalled CNTs (MWCNTs), single-walled CNTs (SWCNTs), graphene, and MXene flakes, can significantly increase the conductivity of electrospun NYs. In addition, compared to the directed addition technique, the surface coating method is more beneficial for generating electrospun NYs with high conductivity. For instance, electrospun nylon NYs coated with MXene exhibited a high electrical conductivity (up to 1.2 × 105 S/m) [188]. Moreover, some piezoelectric polymers, including PVDF and PVDF-TrFE, were utilized to impart electrospun NYs with piezoelectric properties. For example, one study developed electrospun PVDF-TrFE NYs that exhibited a piezoelectric potential and a piezoelectric voltage constant of 500 mV and 0.412 mVm/N, respectively [189]. It should be also noticed that choosing a yarn matrix material with a high elasticity, such as PU, can impart the final fabricated conductive NYs with a high stretchability, which is especially meaningful for the parts of textiles undergoing frequent, large deformations during various daily movements. Tremendous effort should be made to further improve the conductivity or piezoelectricity of electrospun NYs while providing them with high stretchability, comfortability, structural stability, and reproducibility in the future. This section reviews the state-of-the-art applications of conductive or piezoelectric electrospun NYs in diverse wearable textile bioelectronics, including harvesters and storage systems, actuators, and sensors, as well as advanced face masks.

Table 3.

Summarization of electrical performances and stretchabilities of some representative conductive or piezoelectric electrospun NYs.

| Materials | Conductivity or Piezoelectric voltage constant | Stretchability | Ref |

|---|---|---|---|

| PANi/PVP | 4.1 × 10−2 S/m | / | [190] |

| PANi/PAN | 1.3 kΩ/m | ∼20% | [191] |

| PANi/PCL | 600 kΩ/m | / | [192] |

| Fe3O4/PANi/PAN | 0.091-0.629 S/m | / | [193] |

| PA6; MWCNT/PA6 |

1 × 10−13 S/m; 2.4 × 10−6 S/m |

/; / |

[98] |

| PA6; SWCNT/PA6 |

1 × 10−13 S/m; 3 × 10−5 S/m |

<61% | [194] |

| MWCNT-coated PA66 | 20 S/m | ∼125% | [195] |

| MWCNT-coated PAN | 0.28 S/m | >10% | [196] |

| Graphene/PAN | / | 119% | [197] |

| PAN-based carbon; Graphene/PAN-based carbon |

7700 S/m; 16500 S/m |

/; / |

[198] |

| Graphene/PAN-based carbon | 6644 S/m | 0.5% | [199] |

| PAN-based Carbon; PMMA-based Carbon; Copper nanoparticles/Carbon |

20634 S/m; 27181 S/m; 47213 S/m |

/; /; / |

[200] |

| MWCNT/SWCNT coated PU | 1300 S/m | 1200% | [201] |

| MXene flakes coated nylon; MXene flakes coated PU |

1.2 × 105 S/m; 7800 S/m |

43%; 263% |

[188] |

| Silver nanowire/PU | 40 kΩ/m | 500% | [202] |

| PPDO; CNT/PPDO |

1.73 × 10−8 S/m; 3.52 × 10−4 S/m |

64%; 53% |

[131] |

| PVDF | 0.4323 mVm/N | / | [203] |

| PVDF-TrFE | 0.412 mVm/N | / | [189] |

| PVDF-TrFE | / | 65% | [204] |

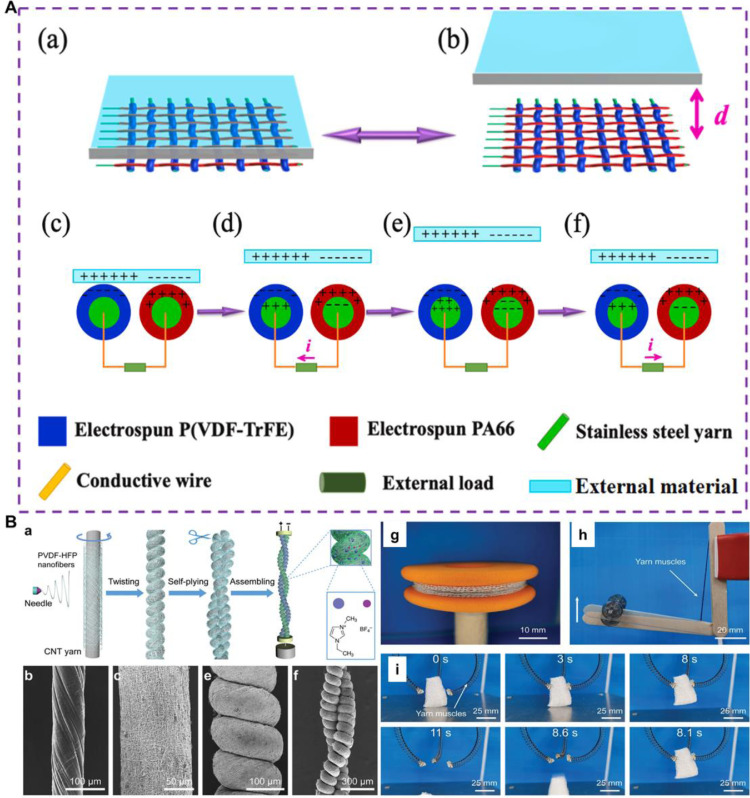

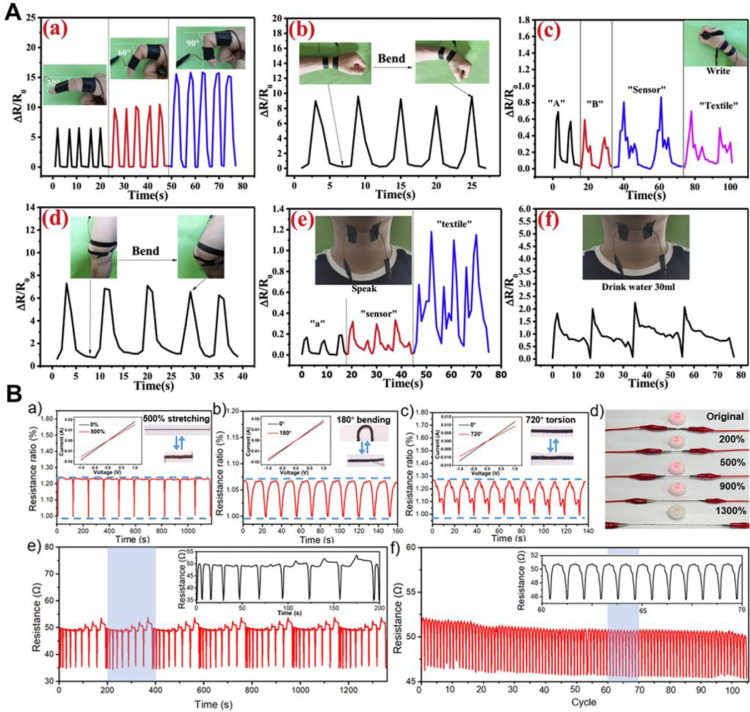

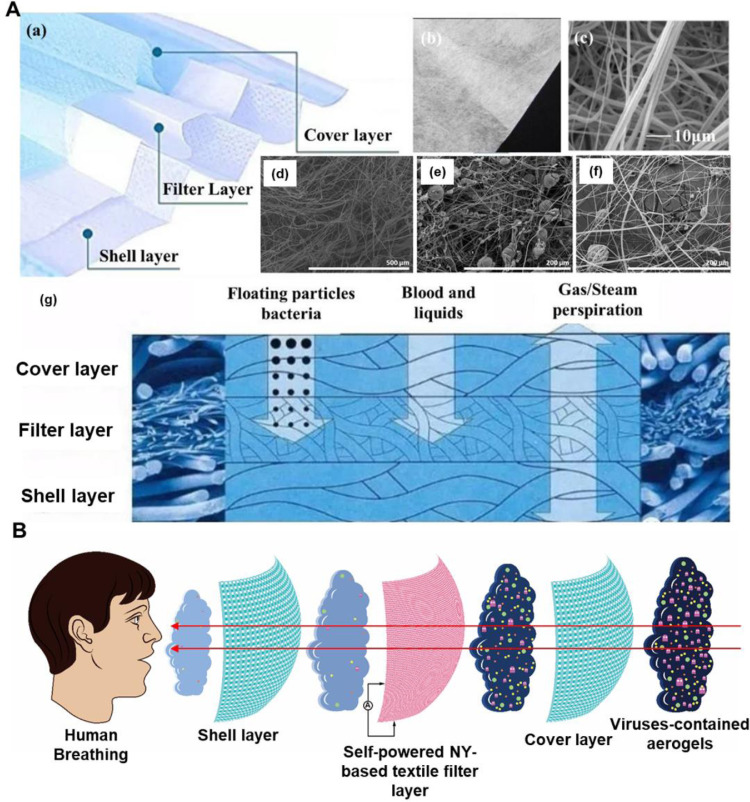

6.1. Harvesters and storage systems