Abstract

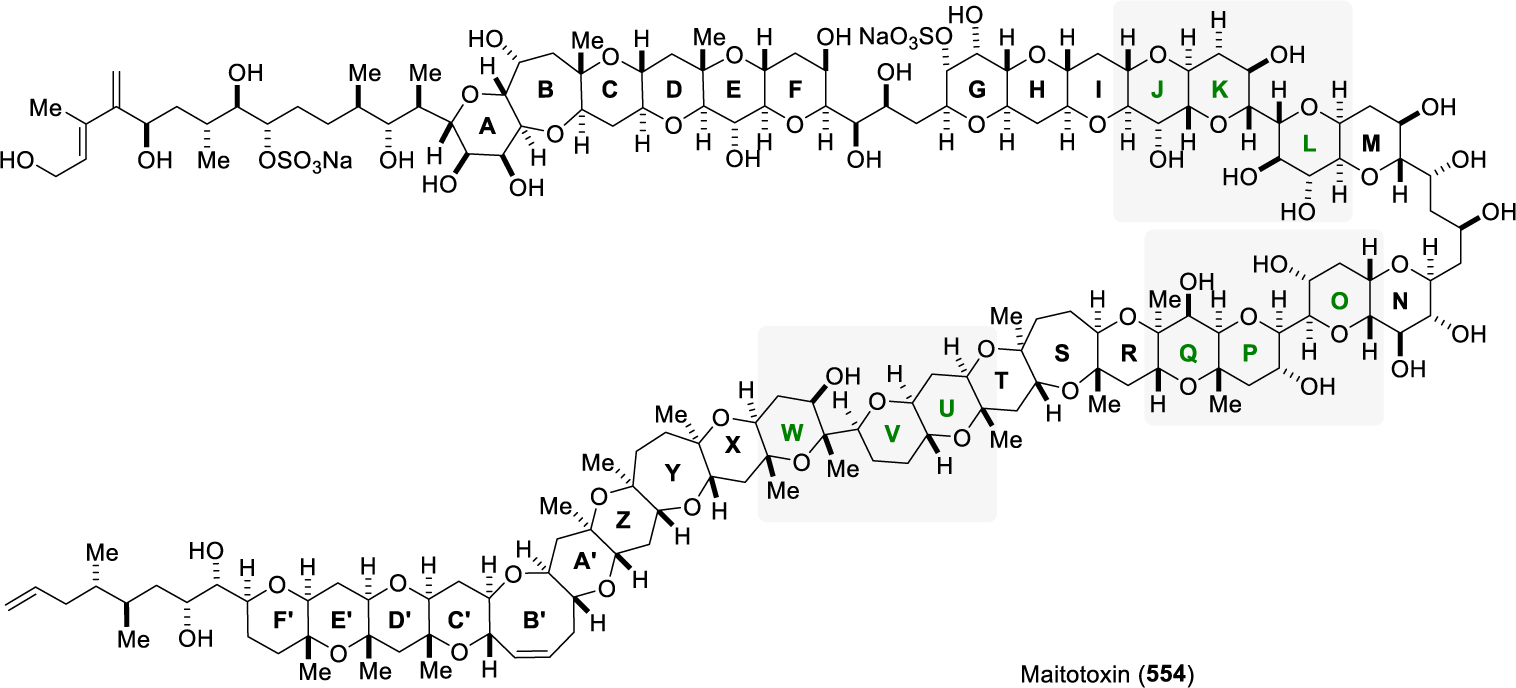

This review describes the development of strategies for carbonyl-olefin metathesis reactions relying on stepwise, stoichiometric, or catalytic approaches. A comprehensive overview of currently available methods is provided starting with Paternò-Büchi cycloadditions between carbonyls and alkenes followed by fragmentation of the resulting oxetanes, metal alkylidene-mediated strategies, [3+2]-cycloaddition approaches with strained hydrazines as organocatalysts, Lewis acid-mediated and Lewis acid-catalyzed strategies relying on the formation of intermediate oxetanes, and protocols based on initial carbon-carbon bond formation between carbonyls and alkenes and subsequent Grob-fragmentations. The review concludes with an overview of applications of these currently available methods for carbonyl-olefin metathesis in complex molecule synthesis. Over the past eight years, the field of carbonyl-olefin metathesis has grown significantly and expanded from stoichiometric reaction protocols to efficient catalytic strategies for ring-closing, ring-opening, and cross carbonyl-olefin metathesis. The aim of this review is to capture the status quo of the field and is expected to contribute to further advancements in carbonyl-olefin metathesis in the coming years.

Graphical Abstract

1. INTRODUCTION

The formation of carbon-carbon bonds is of fundamental importance in the field of synthetic chemistry and invaluable for the synthesis of many important biologically active molecules, including current pharmaceuticals and complex natural products. The development of new, sustainable, efficient, and selective catalytic procedures for carbon-carbon bond formation, therefore, represents a key research goal in synthetic chemistry. The metathesis reaction between two alkenes is among the most powerful catalytic carbon-carbon bond forming reactions available and has led to profound synthetic developments in the petroleum, materials, agricultural, and pharmaceutical industries.1–13 The word metathesis, derived from the Greek words for “change” and “position,” directly describes a chemical reaction which redistributes two subunits of two substrates. Olefin-olefin metathesis reactions are classified by a mechanistic profile that relies on olefins 1 and 2 and proceeds through an initial [2+2]-cycloaddition with a metal alkylidene 3 to form a cyclic 4-membered intermediate (Figure 1A). A subsequent [2+2]-cycloreversion forms two new alkene products 4 and 5 that each contain parts of the reactive partners 1 and 2. Since its discovery, olefin-olefin metathesis has spurred important advances in the field of chemistry with broad implications for the synthesis of bioactive compounds and pharmaceuticals. In comparison, the corresponding carbonyl-olefin metathesis reaction between alkenes 1 and carbonyls 6 similarly enables carbon-carbon bond formation to result in new alkenes 4 (Figure 1B); however, this transformation remained, until recently, significantly less developed. Also referred to as a carbonyl-olefin exchange reaction14–20 or oxametathesis21–23 this review provides a comprehensive overview of currently available strategies for this transformation with a particular focus on viable substrate classes and accessible products. Specifically, this review has been organized to discuss the current status of each independent strategy to achieve carbonyl-olefin metathesis.

Figure 1.

Olefin-Olefin Metathesis (A) versus Carbonyl-Olefin Metathesis (B).

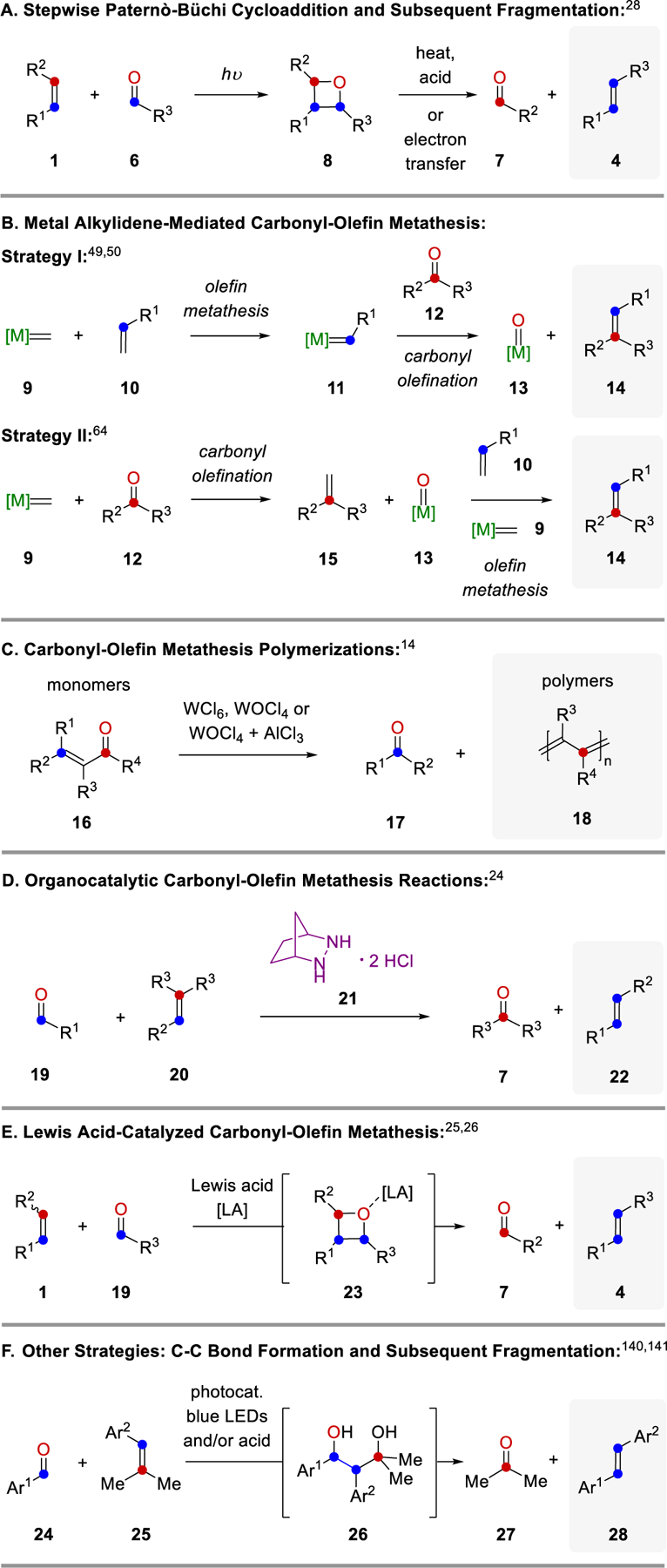

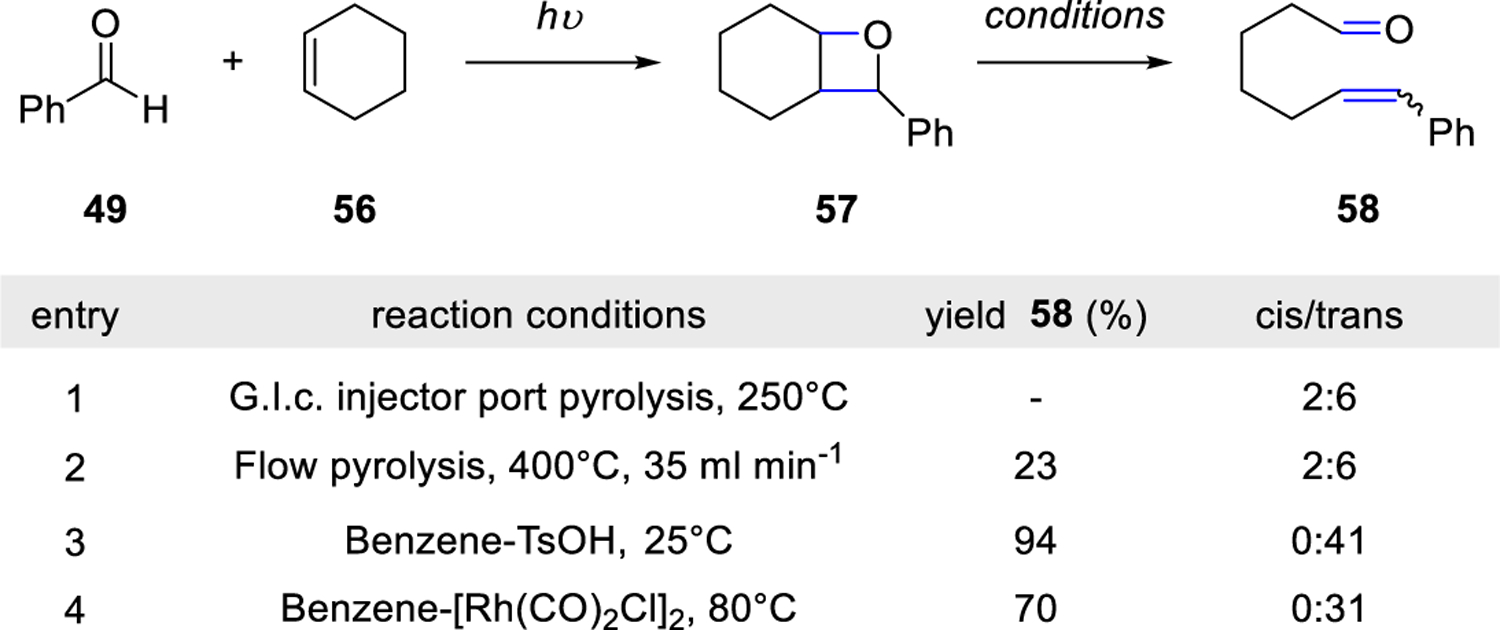

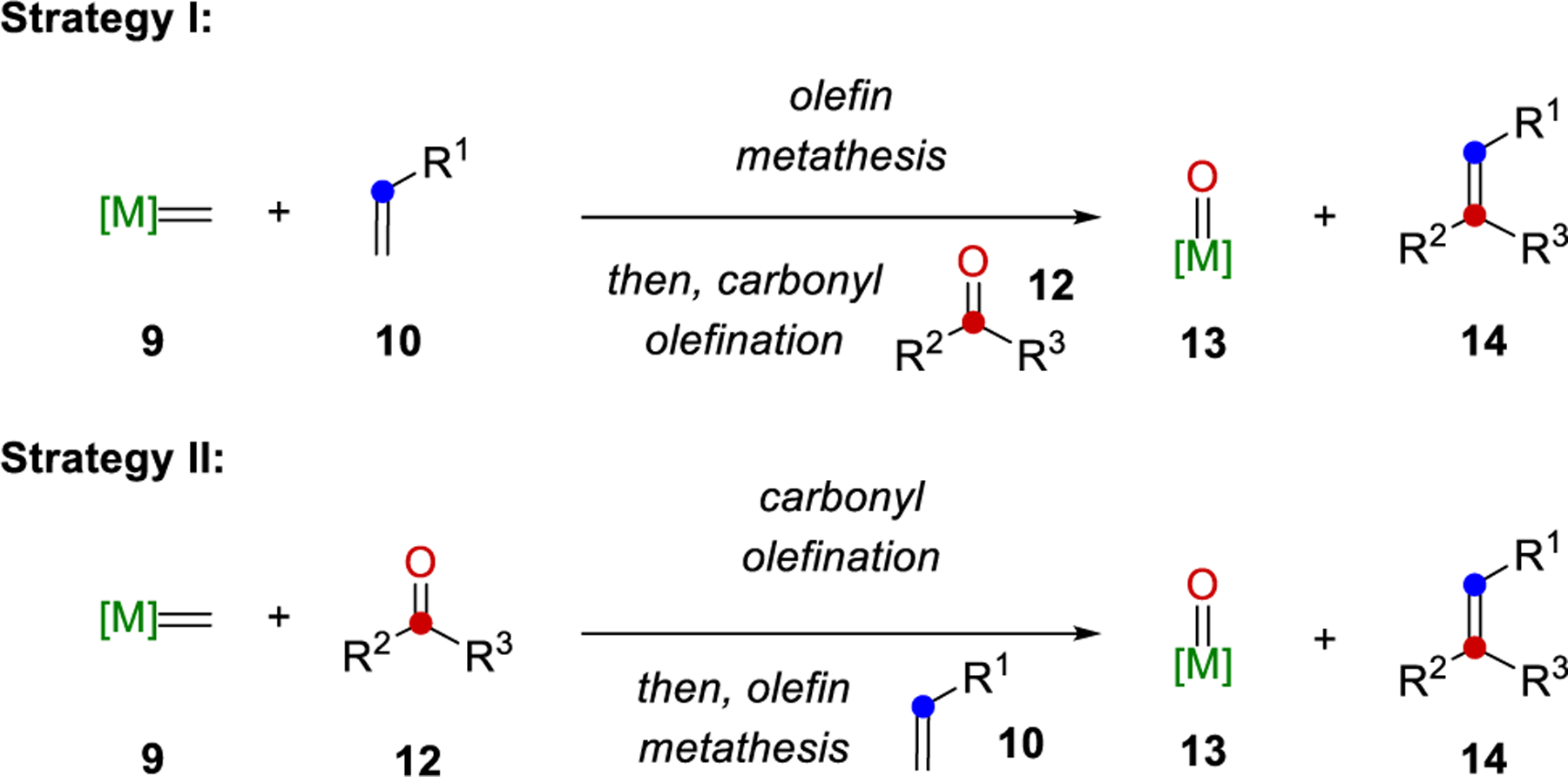

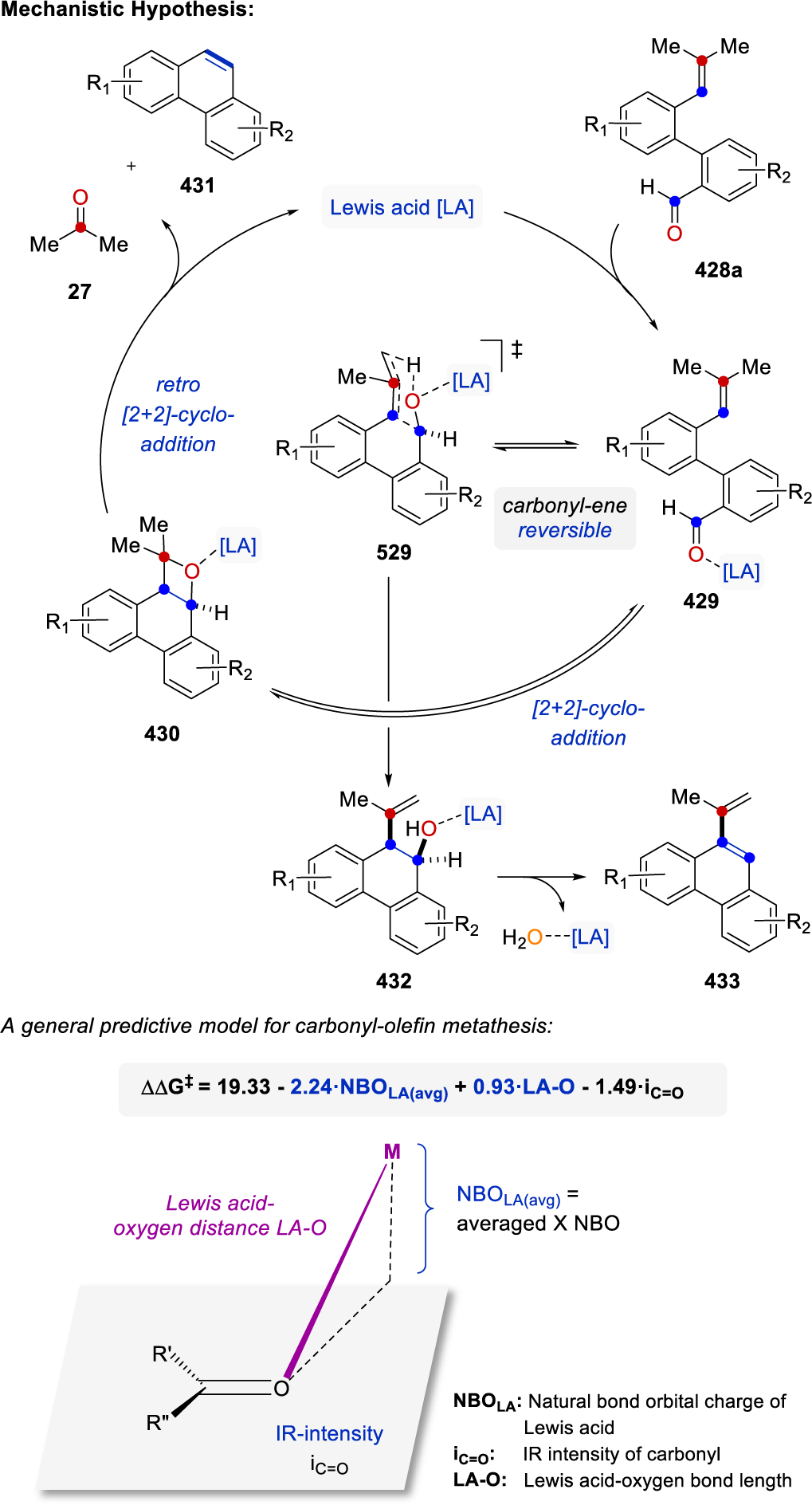

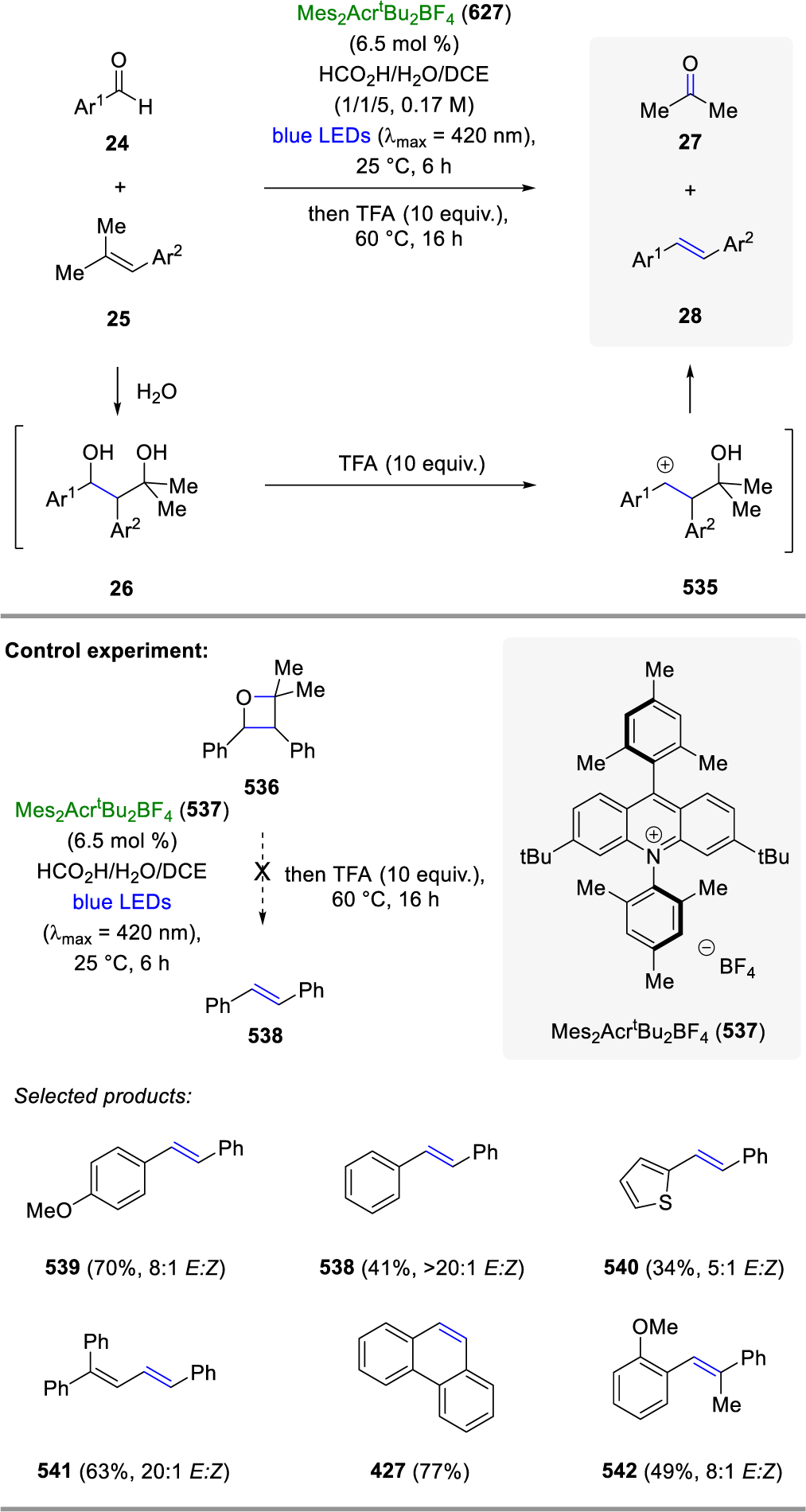

The earliest reported protocols for carbonyl-olefin metathesis rely on a stepwise [2+2]-cycloaddition between alkenes 1 and carbonyls 6 following a Paternò-Büchi reaction protocol under UV-light irradiation to form oxetanes 8 (Figure 2A).28 Fragmentation of 8 under elevated temperatures, acidic conditions, or electron transfer-induction results in alkenes 4 as the desired carbonyl-olefin metathesis products and carbonyls 7 as byproducts. An alternative approach for carbonyl-olefin metathesis is based on metal alkylidenes 9 following one of two strategies (Figure 2B): (1) Upon reaction of alkene 10 with a metal alkylidene 9, complex 11 is formed reminiscent of the initiation step in olefin-olefin metathesis. Subsequent carbonyl olefination with carbonyl 12 results in the desired alkene 14 and metal oxo-species 13. Unfortunately, attempts for the reduction of 13 and its subsequent reintroduction to enable a catalytic process, remain unsuccessful, which renders this strategy stoichiometric in nature.49,50 (2) Alternatively, the steps of carbonyl olefination and olefin metathesis can be reversed to first enable the reaction of carbonyl 12 with metal alkylidene 9 to form a new intermediate alkene 15 together with metal-oxo species 13.64 Olefin metathesis between alkenes 15 and 10 enabled by additional metal alkylidene 9 results in the desired carbonyl-olefin metathesis products 14. Similarly to strategy I, the formation of metal oxo-species 13 renders strategy II stoichiometric in metal alkylidene reagent required. A third and distinct approach for carbonyl-olefin metathesis relies on α,β-unsaturated ketones 16 to provide polyconjugated polymers 18 upon reaction with tungsten-based reagents (Figure 2C).14 The first catalytic strategy for carbonyl-olefin metathesis was based on a [3+2]-cycloaddition reaction paradigm between carbonyls 19 and unsaturated carbocycles 20 with hydrazine 21 as organocatalyst (Figure 2D). Carbonyl-olefin metathesis reactions following this design principle have been reviewed in 2019.24 An alternative catalytic approach for carbonyl-olefin metathesis takes advantage of Lewis acids to activate carbonyls 19 for a [2+2]-cycloaddition with alkenes 1 to result in the formation of intermediate oxetane 23, which upon activation with the Lewis acid undergo retro-[2+2]-cycloaddition to result in alkene 4 and carbonyl 7 as metathesis products (Figure 2E). These Lewis acid-based approaches have been reviewed in 201725 and 2018.26 Importantly, all of these approaches are based on cycloaddition reactions that proceed either directly between carbonyl and alkene substrates, or between one of these starting materials and a suitable catalyst or reagent. A final strategy to achieve formal carbonyl-olefin metathesis reactions is instead centered on the initial formation of a carbon-carbon single bond between carbonyls 24 and alkenes 25 to access diols 26 as reactive intermediates, which can undergo a subsequent Grob fragmentation to form olefins 28 and acetone 27 as products.140,143

Figure 2.

Overview of Currently Available Strategies for Carbonyl-Olefin Metathesis.

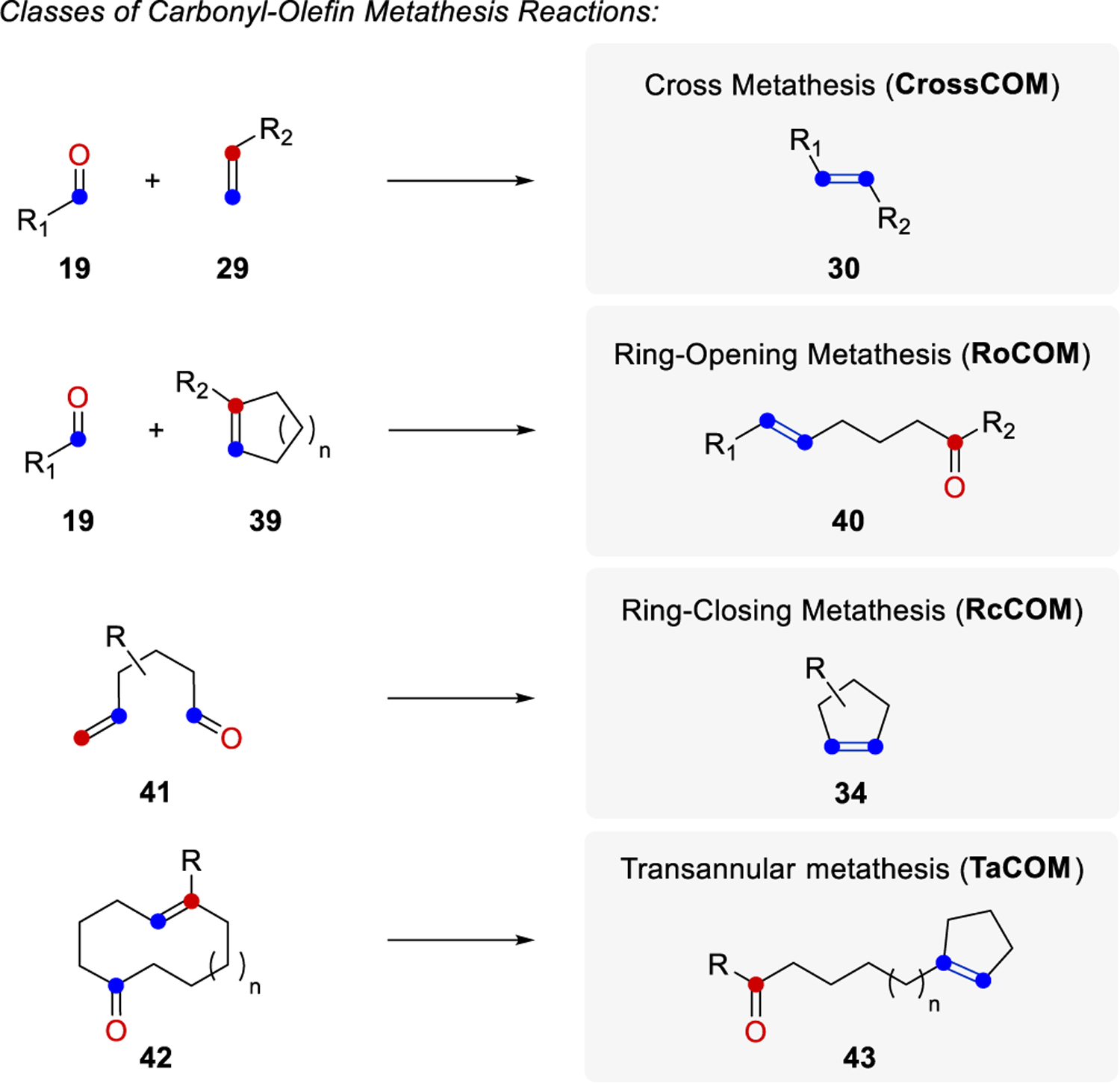

Although less advanced compared to olefin-olefin metathesis, developments in the field of carbonyl-olefin metathesis have grown significantly over the past decade. Importantly, categories of carbonyl-olefin metathesis reactions have been developed that are complementary to those of olefin-olefin metathesis and provide access to similar alkene products (Figure 3). Specifically, olefin-olefin metathesis reactions are classified into three main categories including cross metathesis, ring-opening metathesis, and ring-closing metathesis (Figure 3A). Cross metathesis (CM) reactions between two alkenes 28 and 29 can form more functionalized alkenes 30 upon conversion with a suitable catalyst. Since olefin-olefin metathesis reaction are reversible, the controlled formation of product 30 can be challenging due to its ability to also function as a substrate in subsequent catalytic cycles. Ring-opening metathesis (ROM) reactions between linear alkenes 28 and cyclic alkenes 31 yield acyclic dienes 32 as products, taking advantage of the release of ring-strain as the driving force. The third category represents intramolecular, ring-closing metathesis (RCM) reactions of alkenes 33 to generate unsaturated products 34. Additionally, two different strategies for polymerizations have been developed based on olefin-olefin cross and ring-opening metathesis. Particularly, ring-opening metathesis polymerizations (ROMP) are chain-growth, addition polymerization reactions of cyclic alkenes 35 driven by the release of ring strain while acyclic diene metathesis polymerizations (ADMET) are stepwise-growth, condensation polymerization reactions of terminal dienes 37 that result in polyenes 38 due to the favorable extrusion of ethylene gas as a metathesis byproduct.

Figure 3.

Classes of Olefin-Olefin Metathesis and Carbonyl-Olefin Metathesis Reactions Developed.

The area of carbonyl-olefin metathesis has seen significant advances in recent years, and complementary strategies for cross, ring-opening, and ring-closing carbonyl-olefin metathesis have now been developed (Figure 3B). In comparison to olefin-olefin metathesis, carbonyl-olefin metathesis reactions are often irreversible, which is advantageous with regard to reaction design and achieving high yield and conversation. However, the substrate scope for carbonyl-olefin metathesis currently remains more limited compared to olefin-olefin metathesis. Most examples of cross carbonyl-olefin metathesis reactions (crossCOM) require aryl aldehydes 19 as substrates, which together with alkenes 29 form exclusively (E)-alkenes 30. Similarly, ring-opening carbonyl-olefin metathesis (RoCOM) reactions are dependent on aryl aldehyde substrates 19 and cyclic alkenes 39 to form unsaturated ketones 40. Ring-closing carbonyl-olefin metathesis reactions of unsaturated ketones 41 give access to 5-, 6-, and 7-membered ring systems 34. In addition to these three categories for carbonyl-olefin metathesis, one strategy for polymerization has been reported based on cross metathesis of enones 16 resulting in polyenes 18 similar to ADMET in olefin-olefin metathesis. Finally, transannular carbonyl-olefin metathesis reactions of cyclic, unsaturated ketones 42 were developed following a ring-closing metathesis approach to result in ring-contraction products 43.27

2. CARBONYL-OLEFIN METATHESIS VIA PATERNÒ-BÜCHI CYCLOADDITIONS AND SUBSEQUENT FRAGMENTATIONS

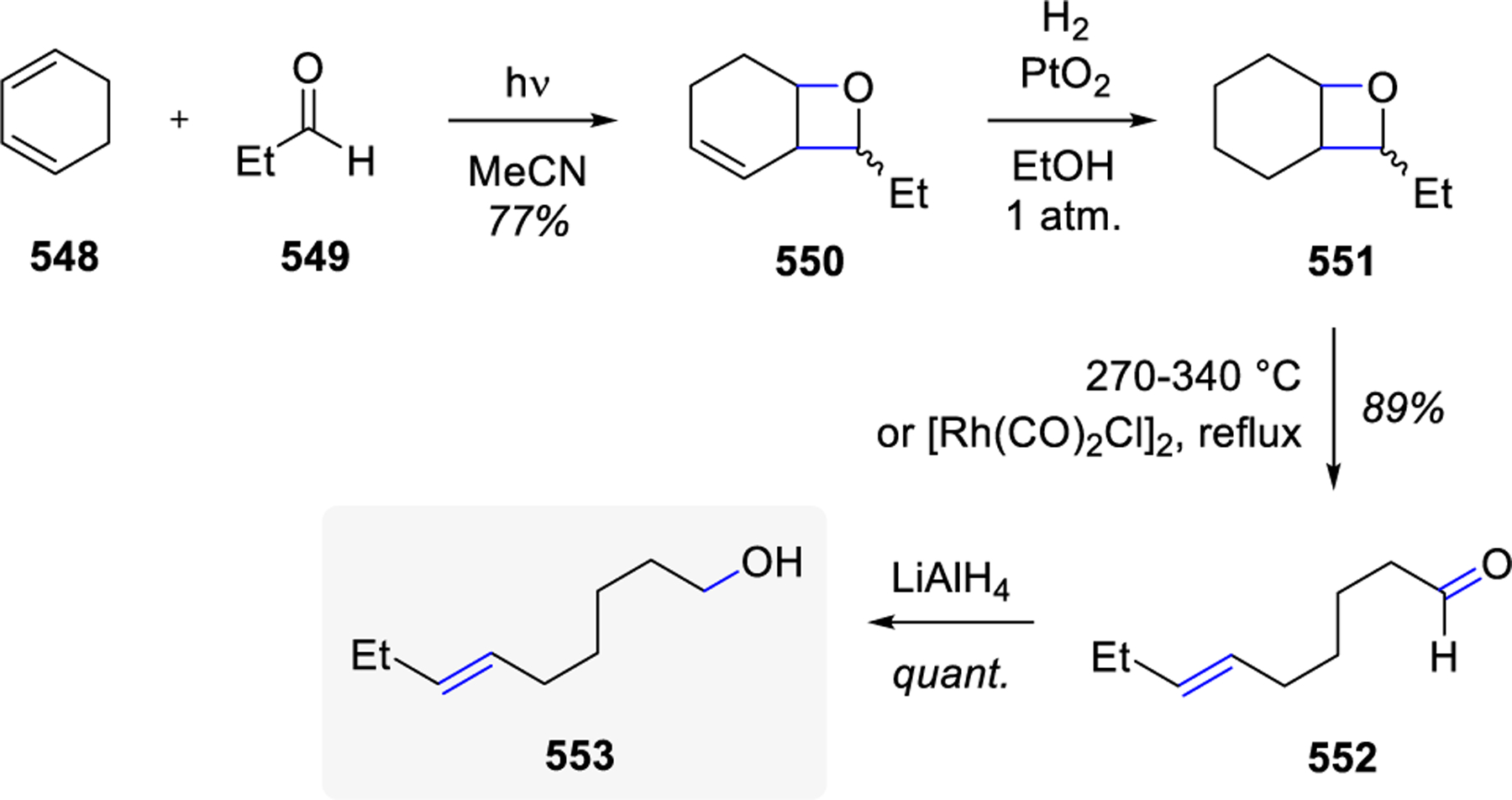

The earliest approaches to realize carbonyl-olefin metathesis take advantage of a two-step process between olefins 1 and carbonyls 6 upon photochemical irradiation following Paternò-Büchi reaction protocols (Scheme 1). Oxetane 8 is formed via a [2+2] photochemical cycloaddition, and subsequent fragmentation can be induced by an acid- or heat-mediated cycloreversion to provide the net carbonyl-olefin metathesis products alkene 4 and aldehyde 7. Although this strategy represents the first approach to facilitate carbonyl-olefin metathesis reactions, its applications remain limited mostly due to a restricted substrate scope and functional group tolerance resulting from the harsh reaction conditions often requiring pyrolysis. This section outlines the developments, advancements, and insights gained regarding carbonyl-olefin metathesis reactions via Paternò-Büchi reactions in combination with fragmentation from the early, simple examples to more recent applications that allow for access to complex polycyclic compounds.

Scheme 1.

Paternò-Büchi Reaction

In 1963, Scharf and Korte28 investigated the photo-induced cyclodimerization of norbornene 44. Following initial unsuccessful attempts to dimerize norbornene in the presence of UV light, aryl ketones were added as photosensitizers. The presence of benzophenone led to a new isolated product that was not the dimer of norbornene, but rather oxetane 45, formed from the Paternò-Büchi reaction between norbornene and benzophenone (Scheme 2). The structure was confirmed by subjecting oxetane 45 to acidic conditions, which provided the fragmentation product 46 that was subsequently oxidized upon cleavage of the alkene fragment to the corresponding dicarboxylic acid. This overall transformation is a net ring-opening carbonyl-olefin metathesis reaction resulting in the formation of 46, albeit serving the purpose of structural elucidation of oxetane 45.

Scheme 2.

Photo-Induced Oxetane Formation of Norbornene and Benzophenone by Scharf and Korte

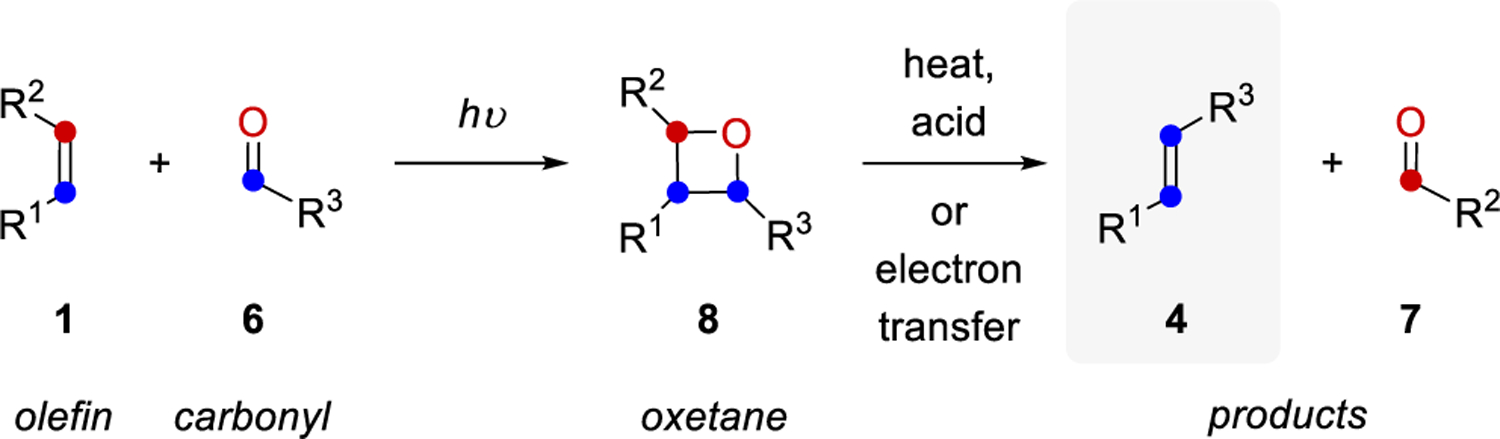

Structural elucidation of oxetane 47 was performed previously by Kohler and Richtmeyer in 1930 (Scheme 3). The reaction of 47 with acetyl chloride in methanol at elevated temperatures resulted in the formation of alkene 48 and benzaldehyde 49, which was confirmed upon conversion into the corresponding phenyl hydrazone.29 Similarly, acid-mediated fragmentations of oxetanes formed upon UV irradiation of 2-methyl-2-butene with benzaldehyde, acetophenone, and n-butyraldehyde were used by Büchi and coworkers for the purpose of structure elucidations and mechanistic investigations of the initial [2+2]-cycloaddition between carbonyls and alkenes.30

Scheme 3.

Structural Elucidation of Oxetanes via Acid-Mediated Fragmentations by Kohler and Richtmeyer

Oxetane fragmentation to carbonyl-olefin metathesis products has also been reported with catalytic amounts of Rh(I) complexes functioning as Lewis acids (Scheme 4).31 Specifically, Grigg and co-workers investigated the rearrangements of epoxides and oxetanes in the presence of [Rh(CO)2Cl]2 and discovered that oxetane 45 fragments to provide 46, quantitatively, incorporating a newly formed aldehyde and tri-substituted olefin. Likewise, oxetane 50 results in furan 51 and benzaldehyde 49 upon treatment under identical reaction conditions, albeit shorter reaction times (Scheme 4). Notably, the authors reported faster transformations when relying on CF3CO2H but a cleaner reaction profile with [Rh(CO)2Cl]2. The direction of the observed oxetane cleavage is predicted by the assumption that the coordination of the rhodium to the ether oxygen atom allows for fragmentation to form the most stable carbonium ion.

Scheme 4.

Rh(I)-Catalyzed Rearrangements of Vinyl Oxetanes by Grigg

In 1973, Jones and co-workers first recognized the synthetic potential of this photolysis-pyrolysis sequence enabling carbonyl-olefin metathesis.32 Their studies were focused on the specifics of oxetane decompositions while the reactive oxetanes were first formed via Paternò-Büchi cycloaddition reactions, which were then heated to 280–300 °C in diphenylmethane to induce fragmentation to the metathesis products (Scheme 5). The authors pointed out that while these transformations may also be performed under mild acid conditions, the pyrolysis route provides a clean product mixture with minimal side reactivity or decomposition. The pyrolysis results are consistent with the regioselective fragmentation of the weakest C-O bond in the rate-determining step, which the authors suggest could proceed via a concerted or stepwise reaction mechanism.

Scheme 5.

Photolysis-Pyrolysis Sequence for Carbonyl–Olefin Metathesis by Jones

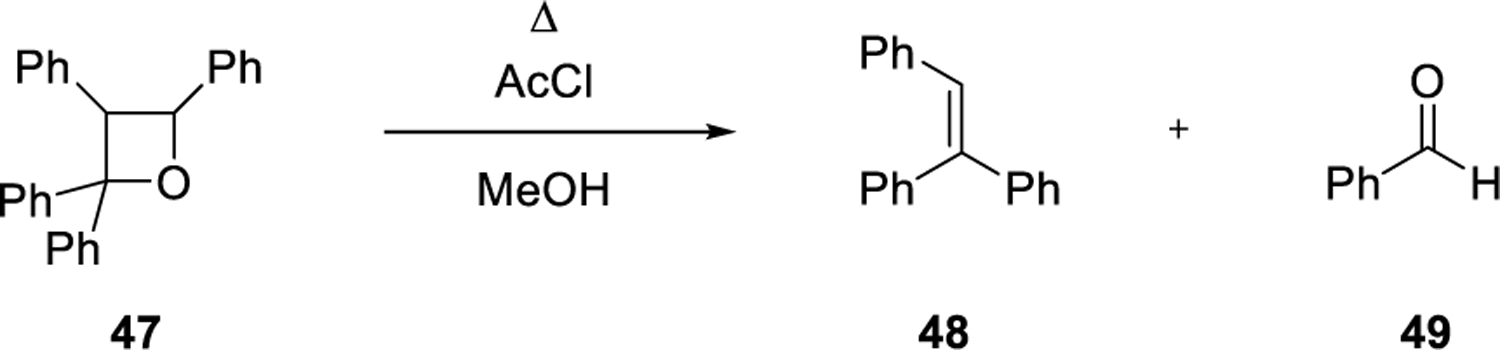

In the following years, Jones and co-workers published the application of the photolysis-pyrolysis sequence for carbonyl-olefin metathesis toward the formation of long-chain enals.33 The photolysis of benzaldehyde 49 and cyclohexene 56 allowed for isolation of oxetane 57 which under various thermolysis conditions provided good yields of cis- and trans-7-phenylhept-6-enal 58, representing an overall ring-opening carbonyl-olefin metathesis reaction (Scheme 6). In the presence of catalytic acid or a Rh(I) complex that has been previously reported17 for the fragmentation of oxetanes to metathesis products, trans-enal 58 was exclusively formed in 94% and 70% yields, respectively, with benzene as the solvent.

Scheme 6.

Formation of Long-Chain Enals via Carbonyl-Olefin Metathesis by Jones

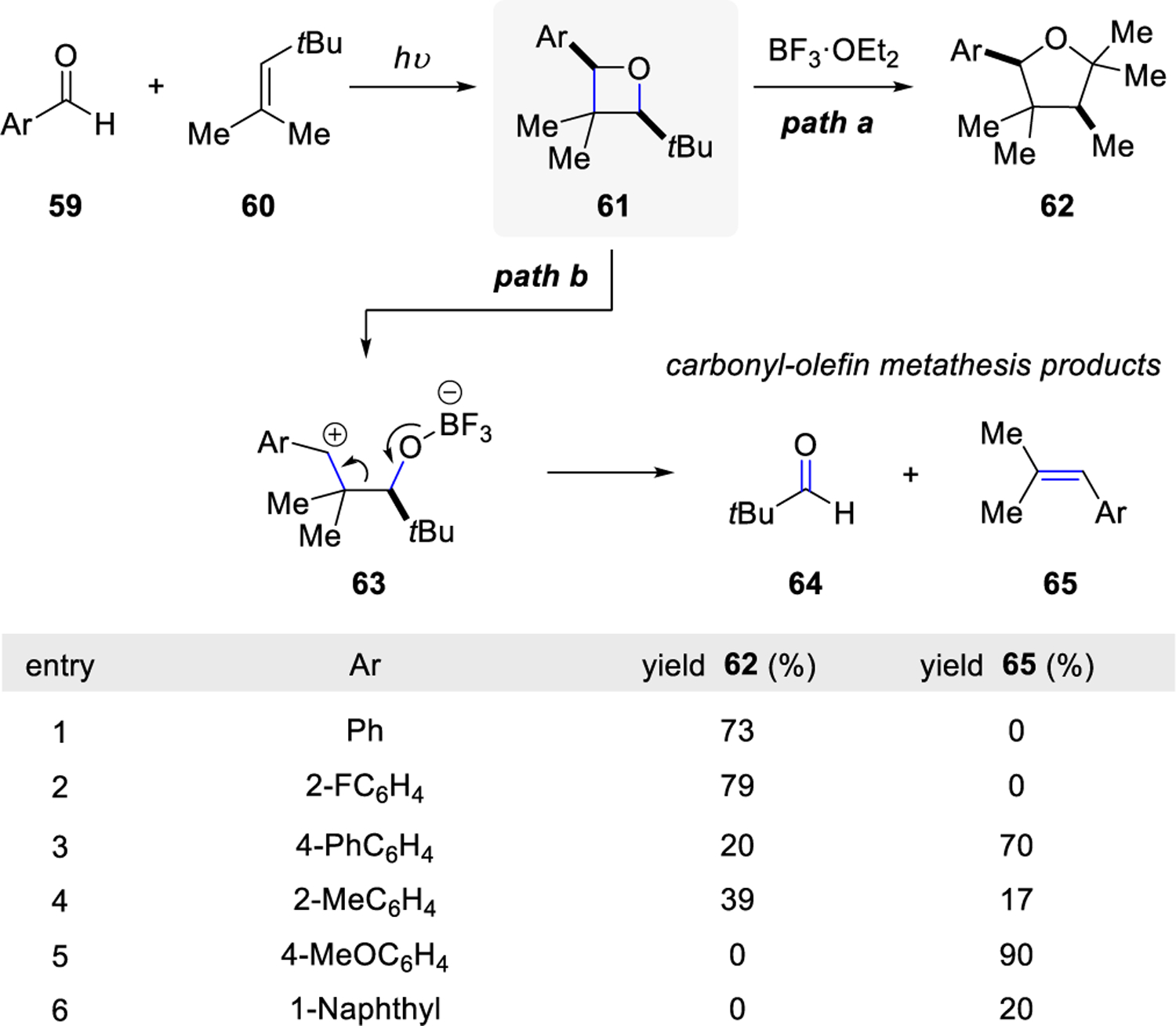

The Lewis acid-promoted fragmentation of oxetanes was reported by Carless and Trivedi in 197934 during their attempts towards the ring-expansion of oxetanes. Oxetane 61, formed from aryl aldehyde 59, provided ring expansion product 62 or the olefin product 65 in the presence of BF3·OEt2, resulting in a two-step metathesis reaction (Scheme 7). The ratio between ring expansion product 62 and the carbonyl-olefin metathesis product 65 was controlled by the electronic nature of the substituents on the aryl group of the aldehyde. Benzaldehyde and aryl aldehydes with electron-withdrawing groups were shown to promote pathway a for ring expansion, whereas electron-donating groups, such as methoxy groups, promoted exclusively pathway b, resulting in carbonyl-olefin metathesis products 64 and 65. The authors suggested that the isolation of ring expansion product 62 supports the formation of intermediate carbocations upon treatment of oxetanes with protic and Lewis acids.

Scheme 7.

Lewis Acid Fragmentation of Oxetanes by Carless

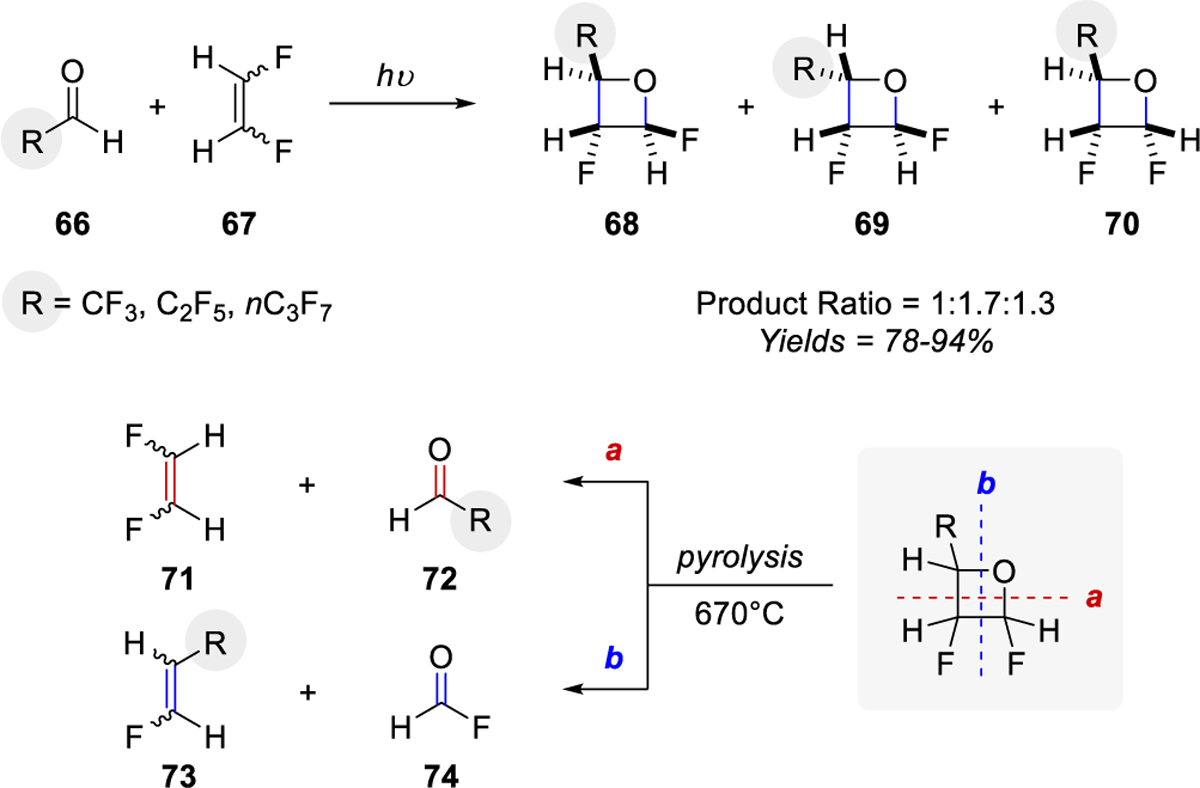

Barlow and co-workers reported the flow pyrolysis of fluorinated oxetanes at 670 °C.35 Following the synthesis of a variety of fluorinated oxetanes 68, 69, and 70 in good yields via a Paternò-Büchi reaction of fluorinated aldehydes 66 and alkene 67, pyrolysis was performed to provide carbonyl-olefin cross-metathesis products via fragmentation pathways a and b (Scheme 8). Interestingly, the flow pyrolysis fragmentation was not selective for the formation of cis or trans olefins but varied with changes in diastereoselectivity and substitution of the oxetane intermediate.

Scheme 8.

Flow Pyrolysis of Fluorinated Oxetanes by Barlow, Coles, and Haszeldine

A qualitative study, which was reported in 198036, aimed to determine the conditions required to favor various fragmentation pathways of oxetanes 75, taking into consideration that previous results obtained based on thermolysis protocols may have been altered by the presence of trace amounts of acid (Scheme 9). In order to determine if the fragmentation was entirely due to thermolysis and not trace acid for acid-catalyzed decomposition, N,N,N’,N’-tetramethylenediamine (TMEDA) was used as the solvent based on previous reports of its beneficial use with extremely acid-sensitive compounds. Nishida and coworkers’ observations are consistent with an earlier report by Jones32 that fragmentation of 75 was indeed sensitive to the reaction conditions. Specifically, base treatment of solvent or the reaction vessel resulted in an increase of fragmentation pathway b leading to alkene 79 and benzophenone (80). Subsequent efforts of Nishida and coworkers centered on mechanistic investigations of oxetane fragmentation to differentiate between a biradical pathway and a possible concerted reaction path. The results obtained suggest that if a concerted fragmentation was feasible, it was not significantly favored over the diradical process.

Scheme 9.

Thermal Fragmentation 2-Aryl Substituted Oxetanes by Nishida

The formation of keto oxetanes 83 was reported in 198137 by Maruyama. Fragmentation of these oxetanes via pyrolysis in TMEDA (to avoid residual acid) provided two different products, olefin 81 and dihydrofuran 87 (Scheme 10). The starting materials, olefin 81 and diketone 82 were regenerated in an overall carbonyl-olefin metathesis reaction following a Paternò-Büchi reaction while the opposite fragmentation provided 87 as the rearranged product in trace amounts. This study also aimed to gain additional support for a radical-based oxetane fragmentation pathway by correlating the bond strengths in the oxetane ring to the structure of the possible intermediate biradicals and the observed results were consistent with the s-character of an intermediate carbon-centered radical.

Scheme 10.

Pyrolysis of Keto Oxetanes by Maruyama

In 1989, Shima and co-workers38 employed the use of photosensitizers for photoinduced ring cleavage in order to develop the regioselective and efficient cleavage of oxetanes. Previous studies of the fragmentation of oxetanes into carbonyl-olefin pairs had not focused on the factors that control regio- and stereochemical reaction outcomes. The ring cleavage was attempted with such electron acceptors as 1-cyanonaphthalene 91, 1,4-dicyanonaphthalene 92, and 9,10-dicyanoanthracene 93 (Scheme 11). Quantum yields for the fragmentation of aryl substituted oxetanes varied depending on the oxetane substitution and aryl groups of the photosensitizer. Notably, the quantum yield was increased with more electron-donating substituents on the oxetane. Yields of the carbonyl-olefin metathesis products, 89 and 90, were improved for oxetanes containing aryl groups with electron-donating substituents such as p-Me or p-OMe (entries 4 and 6, Scheme 11).

Scheme 11.

Photosensitized Ring-Cleavage in the Presence of Electron Acceptors by Shima

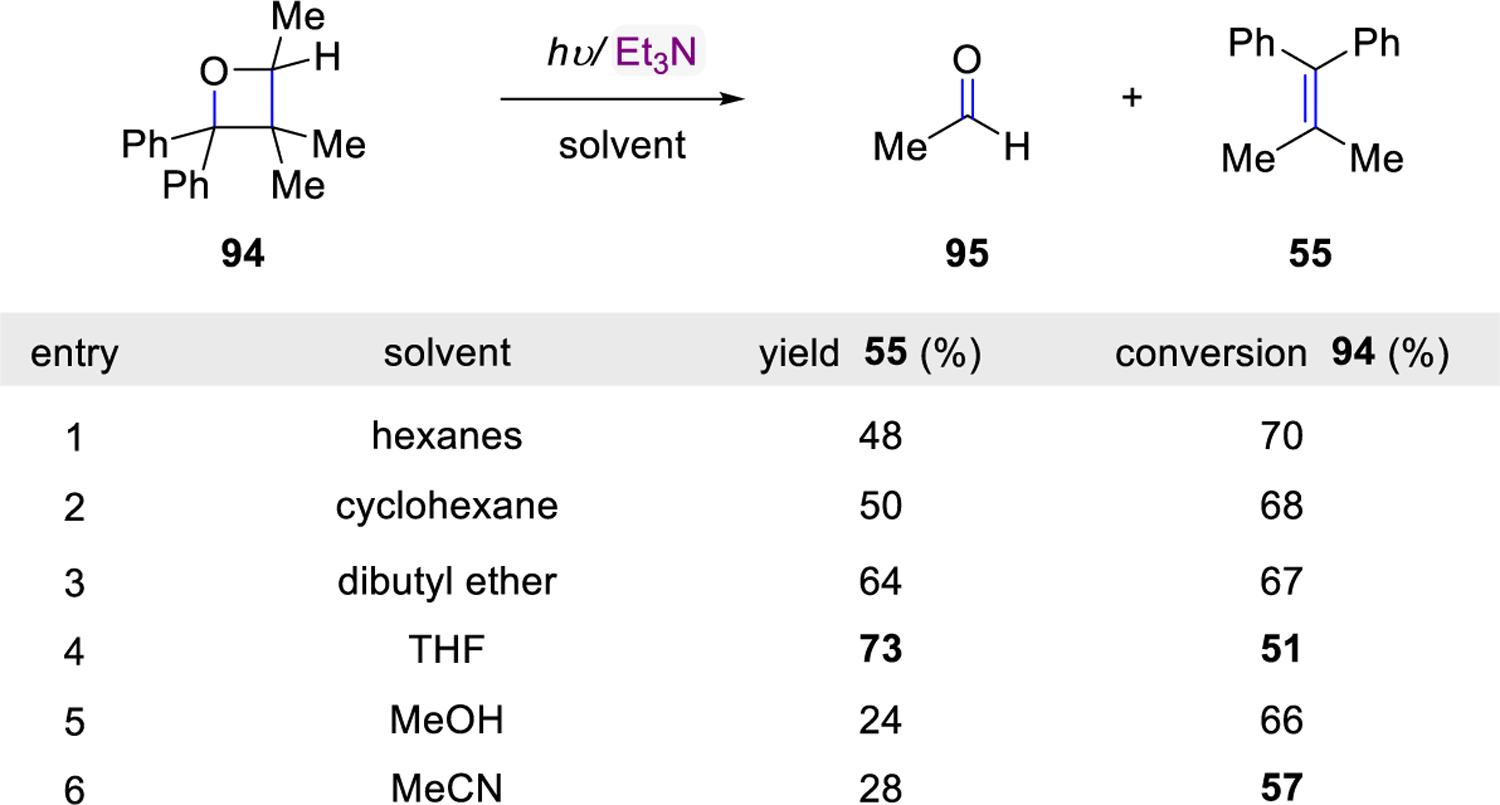

Shima and co-workers followed up on their initial report of regioselective oxetane fragmentation via photochemical electron transfer to aromatic nitriles as electron acceptors with an investigation into related oxetane fragmentations with an electron donor.39 Importantly, the presence of trimethylamine functioning as electron donor resulted in the exclusive formation of 1,1-diarylethene product 55 (Scheme 12) while in contrast, the fragmentation in the presence of electron acceptors38 had provided substituted benzophenones 89 and olefins 90 (Scheme 11). The reaction occurred most efficiently in nonpolar solvents, such as hexanes, but proceeded inefficiently in polar solvents suggesting the formation of an exciplex, as a coordinated complex, between the oxetane and triethylamine in the initiation process.

Scheme 12.

Photosensitized Ring-Cleavage in the Presence of an Electron Donor by Shima

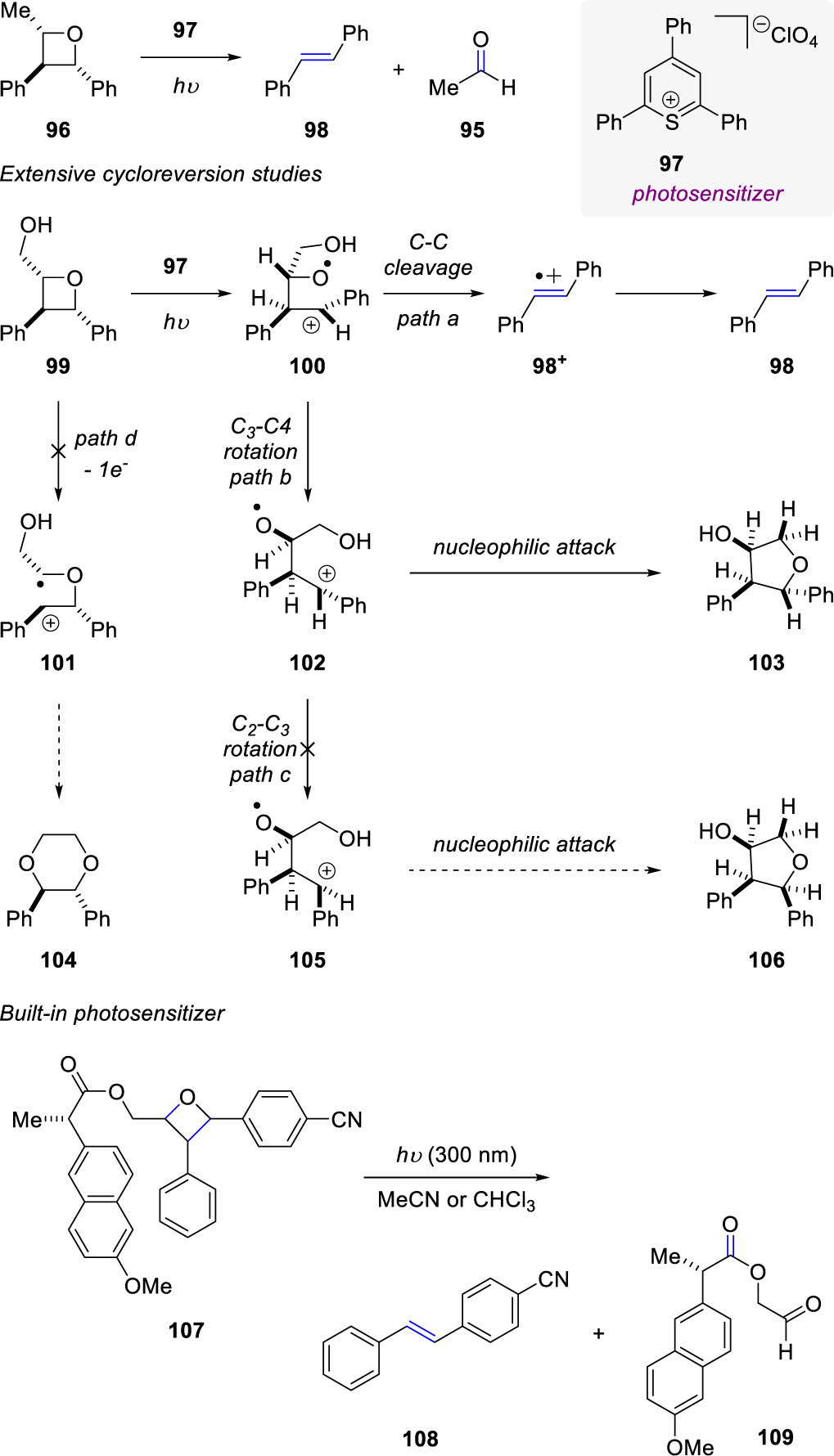

In 2002, Miranda and co-workers utilized photoinduced electron transfer (PET) of triaryl(thia)pyrylium salts (97) to promote cycloreversion of oxetane 96 yielding trans-stilbene 98 and acetaldehyde 95 (Scheme 13).40 They quickly followed up on their initial report with extensive cycloreversion studies employing oxetane 99.41 The predominant electron transfer reaction occurred from the triplet excited state of photosensitizer 97, followed by C-O bond cleavage to form 100. Following path a, an additional C-C bond cleavage formed trans-stilbene radical cation 98+ and ultimately yielded trans-stilbene 98. Miranda and co-workers also observed the formation of 103, which is hypothesized to arise through path b, where rotation of the C3-C4 bond created intermediate 102, followed by intramolecular nucleophilic attack of the pendant alcohol. Potential products 104 and 106 were not observed over the course of their investigations, ruling out paths c and d as active mechanistic pathways. Miranda and co-workers42 aimed to expand their previous work, and in 2005 achieved the cycloreversion of oxetane radical anions generated by PET. The formation of 109 resulted from a Paternò-Büchi reaction of trans-cinnamyl alcohol and p-cyanobenzaldehyde followed by esterification. Fragmentation to olefin 108 and carbonyl 109 was possible due to the “built-in” photosensitizer, 1-methoxynaphthalene, that was introduced via esterification of the oxetane intermediate prior to fragmentation. Interestingly, the choice of solvent, acetonitrile or chloroform, provided distinct results. Acetonitrile as the solvent allowed for more efficient intramolecular fluorescence quenching, whereas stereodifferentiation was increased in chloroform indicating that one diastereomer was more conducive to fragmentation.

Scheme 13.

Photochemical Cycloreversion of Methoxynaphthalene-Oxetane Dyads by Miranda

In 2006, Miranda, Griesbeck, and co-workers43 reported the cleavage of bicyclic oxetane 110 obtained upon photocycloaddition of benzaldehyde and 2,3-dihydrofuran by means of reductive electron-transfer. They described this “metathesis” of oxetanes as an “attractive tool for the synthesis of new carbonyl-ene pairs” (Scheme 14). The cycloreversion of oxetane 110 was photoinduced by the electronically excited reductants in acetonitrile, which led to the formation of the carbonyl-olefin product 111 as a trans/cis mixture of isomers. Mechanistic studies determined that quenching rate constants were dependent on the substitution of the phenyl group and further investigation revealed that the reaction was exergonic in the case of substrates with electron-withdrawing groups. Product analysis established a “photo-photo metathesis” wherein both cycloaddition and cycloreversion were induced by photochemical processes.

Scheme 14.

Carbonyl-Olefin Metathesis of Bicyclic Oxetanes by Miranda and Griesbeck

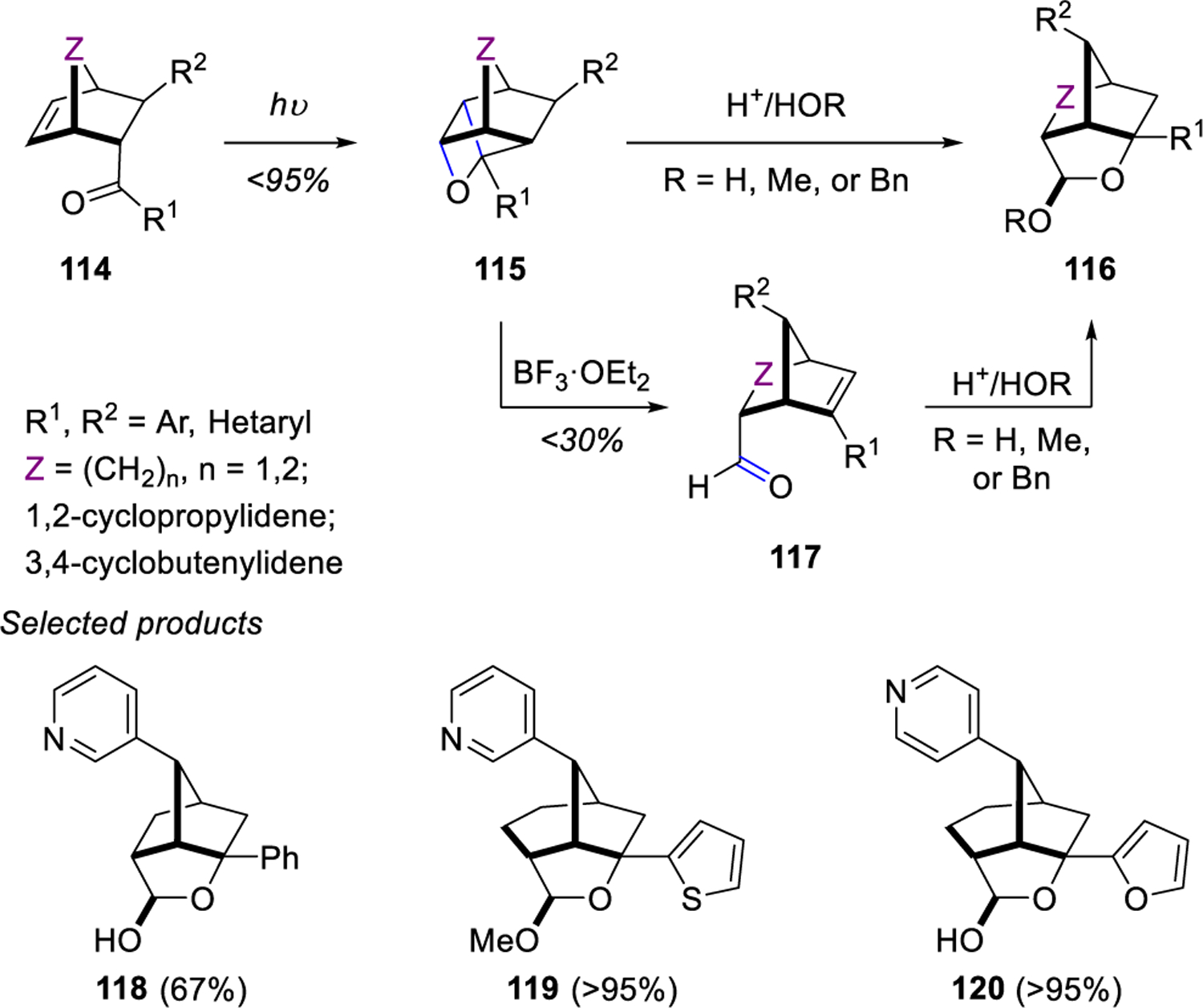

In 2009, Kutateladze and Valiulin22 recognized the synthetic potential of acid-catalyzed oxetane fragmentations and decided to build on earlier work by Jones and coworkers.33 Specifically, they developed a two-step sequence for carbonyl-olefin metathesis in which strained α-aryl and α-heteroaryl oxetanes 115 were formed and subsequently subjected to mild acid-catalyzed conditions to afford polycyclic aldehydes 117 or hemiacetals 116 (Scheme 15). This reaction design relied on the oxetane moiety itself being part of the strained intermediate formed to ultimately allow for access to a variety of diverse polycyclic systems from readily available starting materials.

Scheme 15.

Photoprotolytic Oxametathesis in Polycyclic Systems by Kutateladze

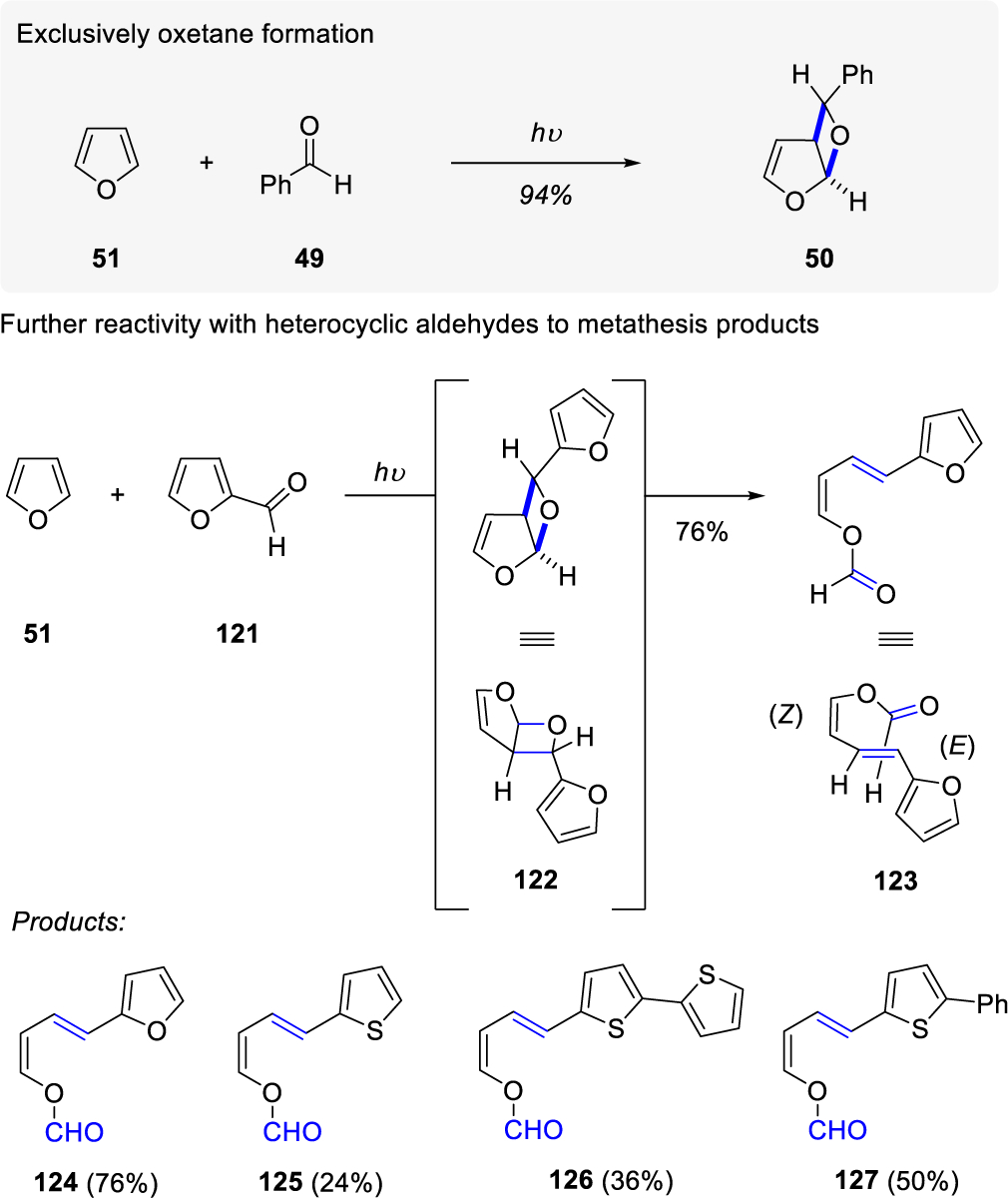

In 2010, D’Auria and co-workers44 reported the metathesis reaction of furans and 2-substituted heterocyclic aldehydes via a proposed intermediate oxetane 122 (Scheme 16). The irradiation of 51 and 121 provided Z,E-olefin 123 as the exclusive product and the Z,E-olefin stereochemistry was observed for all other metathesis products observed (124–127). The selectivity of Z-olefin is set from 51 and the E-olefin arises from the fragmentation of the exo-oxetane intermediates (i.e. exo-122). Interestingly, tri-substituted heterocyclic aldehydes and non-arylated aldehydes provided exclusively oxetane products. The authors propose that the metathesis result of di-substituted heterocyclic aldehydes is due to possible participation of the π-aromatic orbitals in the oxetane C-O bond cleavage.

Scheme 16.

Oxetane Formation vs. Metathesis by D'Auria

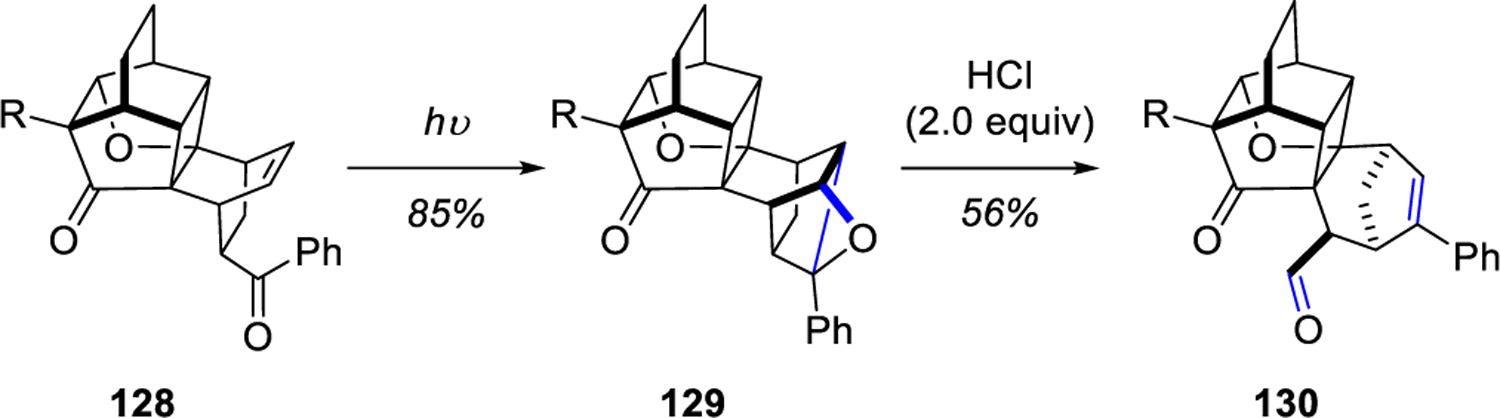

In 2011, Kutateladze and co-workers23 reported a photoprotolytic carbonyl-olefin metathesis reaction that expedites the growth of molecular complexity over a few experimentally simple steps (Scheme 17). 128 was subjected to Paternò-Büchi reaction conditions to form oxetane 129 in 85% yield and the subsequent acid-catalyzed cycloreversion produces the alternative carbonyl-olefin pair metathesis product 130. Interestingly, when oxetane intermediate 129 was subjected to acidic conditions, a byproduct also formed in the presence of excess acid (greater than 2.0 equivalents), in which the metathesis product underwent a second electrophilic addition of H+ to the styrene moiety of 130 to generate a benzylic cation that was intercepted by an internal nucleophile, the enol.

Scheme 17.

Photoprotolytic Oxametathesis Leading to Molecular Complexity by Kutateladze

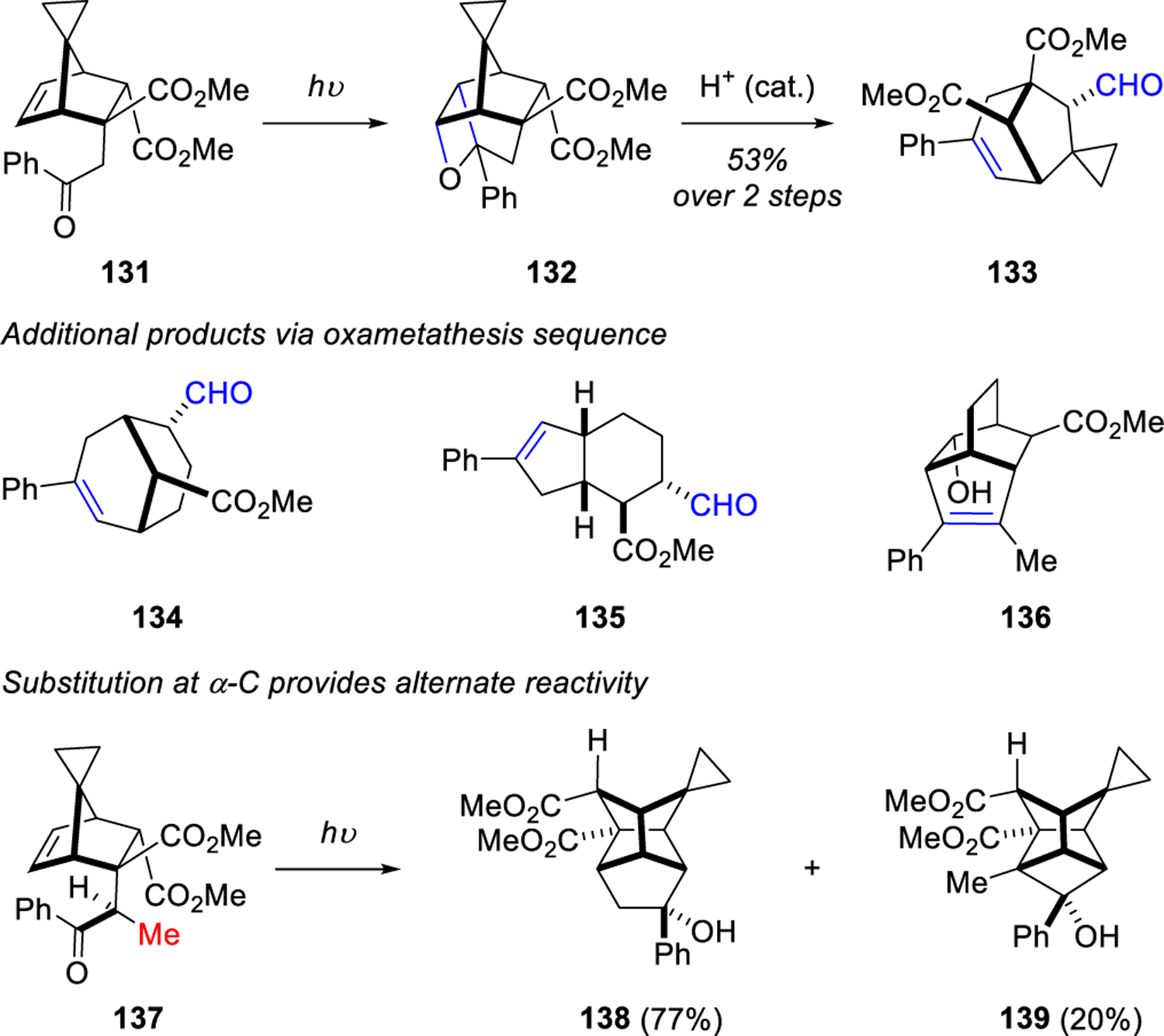

A similar method for the construction of polycyclic systems was subsequently reported by Kutateladze in 2013.24 This work expanded the two-step sequence with the photoinduced intramolecular formation of oxetanes and subsequent acid-catalyzed fragmentation to form carbonyl-olefin products (134-136, Scheme 18). Scheme 18 displays the formation of γ-oxetane 132 from acetophenone adduct 131 which subsequently transformed into the metathesis product 133 under acidic conditions. The incorporation of an α-methyl substituent in 137 provided a different reaction pathway that did not result in the carbonyl-olefin product, but rather a mixture of polycyclic compounds 138 and 139 with the stellane core as a result of a radical cyclization in which two C-C bonds were formed.

Scheme 18.

High-Yielding Photoprotolytic Oxametathesis in Polycyclic Systems by Kutateladze

The ability to form and fragment oxetanes has been crucial in the pioneering and understanding of carbonyl-olefin metathesis reactions. Since the discovery of the Paternò-Büchi chemistry, UV light has been utilized to synthesize a variety of oxetanes and their fragmentation patterns have provided valuable insight. Mechanistic elucidations have revealed that from oxetanes, carbonyl-olefin metathesis can be promoted with acid, heat, or UV light to result in the desired alkene products. Limitations of this approach for carbonyl-olefin metathesis are dictated by current shortcomings in Paternò-Büchi reactions to form the required oxetanes, which include the requirement for high energy UV-light and a narrow scope of the carbonyl and alkene substrates. Concomitant to the development of oxetane formation and fragmentation sequences for carbonyl-olefin metathesis, metal-based approaches relying on metal alkylidenes were developed to access distinct alkene products.

3. METAL ALKYLIDENE-MEDIATED CARBONYL-OLEFIN METATHESIS.

Metal alkylidene complexes have been extremely successful in the formation of C-C bonds from the redistribution of two olefin fragments through the scission and regeneration of C-C double bonds, enabling olefin-olefin metathesis. These alkylidene catalysts have made profound impacts in the synthesis of molecules related to the petroleum, materials, agricultural, and pharmaceutical industries.9 The capacity to perform these reactions catalytically is possible due to the ability for turnover of the metal alkylidene active catalyst with one of the olefin fragments following metathesis. The carbonyl-olefin metathesis reaction, however, when utilizing the same metal alkylidene complexes is unable to effect turnover of the metal alkylidene due to the resulting unreactive metal-oxo byproduct (13) formed following the initial metathesis reaction, thereby making these reactions stoichiometric (Scheme 19). For this reaction, these processes are not technically carbonyl-olefin metathesis reactions, because no new carbonyl is formed. Despite this inability to perform the carbonyl-olefin metathesis reaction catalytically with metal alkylidene complexes, the contributions to the field are nevertheless significant. Importantly, carbonyl additives have played an important role in ring-opening metathesis polymerization reactions with W- and Mo-alkylidene catalysts in order to terminate propagation, as the resulting metal-oxo species is unreactive.45 Similarly, Grubbs and coworkers reported the trapping of titanium carbene species with ketones and aldehydes as a method to terminate the living polymerization of norbornene.46 Furthermore, the vast majority of carbonyl-olefin metathesis reactions applied in complex molecule synthesis has thus far relied on metal-mediated approaches, which highlights the synthetic potential and importance that these transformations hold. Although stoichiometric in metal reagent, metal alkylidene-mediated approaches for carbonyl-olefin metathesis have seen important advances since an initial report by Grubbs in 1990. The developments in this area are highlighted in this part of the review with a particular focus on substrate scope and metal reagents used.

Scheme 19.

Strategies for Metathesis with Metal Alkylidenes

Two strategies have been developed for carbonyl-olefin metathesis with metal alkylidene complexes. Strategy I relies on an initial olefin metathesis reaction between the metal alkylidene 9 and alkene 10 through a metallacyclobutane intermediate47,48 (Scheme 19, Strategy I). Carbonyl olefination then occurs with the newly formed metal alkylidene and the carbonyl 12 to provide the desired olefin 14, thereby completing the net carbonyl-olefin metathesis reaction. Strategy II employs the reverse reactivity in which carbonyl olefination occurs initially between metal alkylidene 9 and carbonyl 12 to form a metal-oxo byproduct and alkene intermediate, which then undergoes olefin metathesis with metal alkylidene resulting from 9 and alkene 10 to provide the net carbonyl-olefin metathesis product 14.

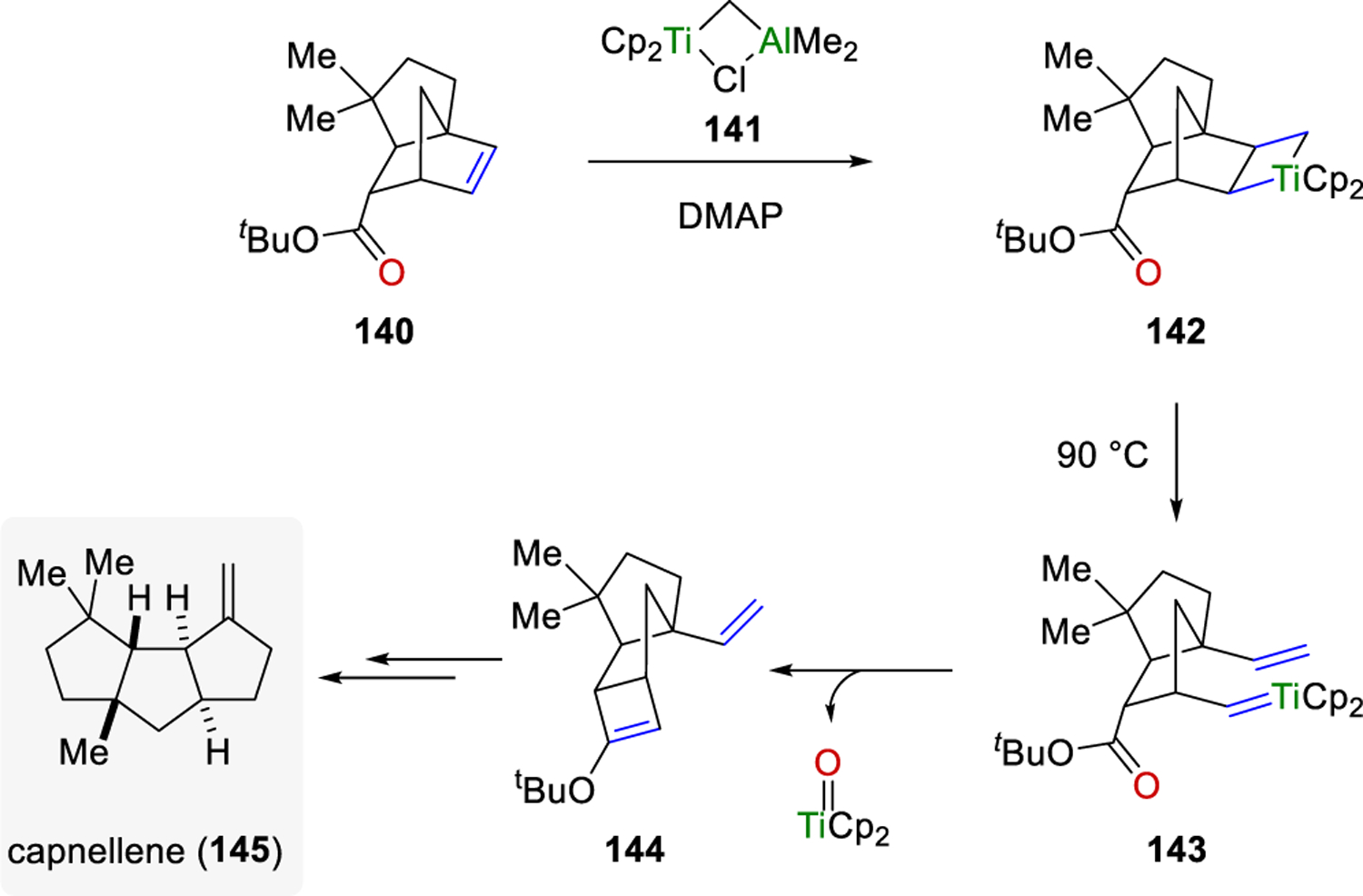

Stille and Grubbs were able to apply strategy I to the synthesis of capnellene (Scheme 20).49,50 Bicyclic intermediate 140 was converted to metallacyclobutane 142 with titanaethylene 141; subsequent heating initiated ring opening to 143 for an initial olefin metathesis reaction. Carbonyl olefination occurred with intramolecular trapping of the alkylidene with the proximal ester species for the net carbonyl-olefin metathesis product 144, which served as a key intermediate towards the total synthesis of (±)-Δ(9,12)-capnellene (145).

Scheme 20.

Application of Strategy I by Grubbs

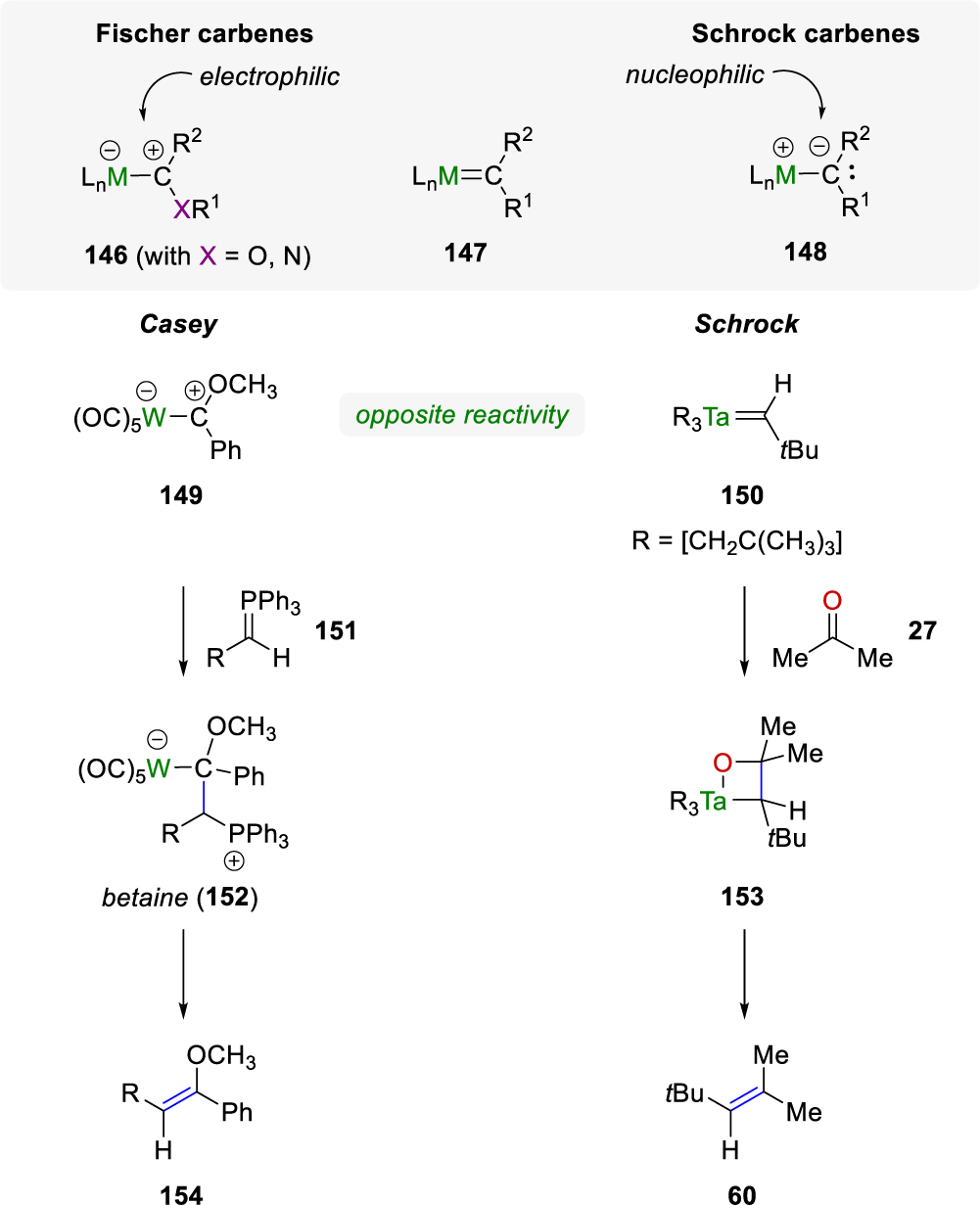

The use of either Fischer51 (146) or Schrock52 (148) metal-carbenes in “Wittig-like” reactions is well-known in the literature. Specifically, in 1972, phenylmethoxycarbenepentacarbonyltungsten(0) 149 was reacted with a carbon nucleophile 151 to form a betaine intermediate in which subsequent fragmentation provided the olefin product 154 (Scheme 21).53 Conversely, Ta[CH2C(CH3)3]3[CHC(CH3)3] (150)54 used by Schrock55 reacted with acetone in a nucleophilic manner to provide the oxametallocycle intermediate 153, which fragmented to the desired olefin product 60. This reactivity was similar to the use of the Tebbe56,57 and Petasis58 reagents whereby a metal-carbenoid reacted with a carbonyl to form a four-membered titanium oxide ring intermediate that fragmented to provide the methylenated product.

Scheme 21.

Fischer and Schrock Metal-Carbenes

The inherent reactivity of titanium carbene species with ketones and aldehydes46,59 has been applied to ring-opening metathesis polymerization reactions (ROMP) for polymer cleavage to enable access to endcapped polymers and metathesis-inactive metal-oxo species 158 (Scheme 22). These living ROMP reactions were therefore quenched deliberately while installing a known moiety in place of the metal. Ethers have been commonly used for Ru-mediated polymerizations while carbonyls, such as benzaldehyde, have been employed for Mo- and W-mediated polymerizations.45

Scheme 22.

Carbonyl-Olefin Metathesis Used for Endcapping Reactions of Polymers by Grubbs

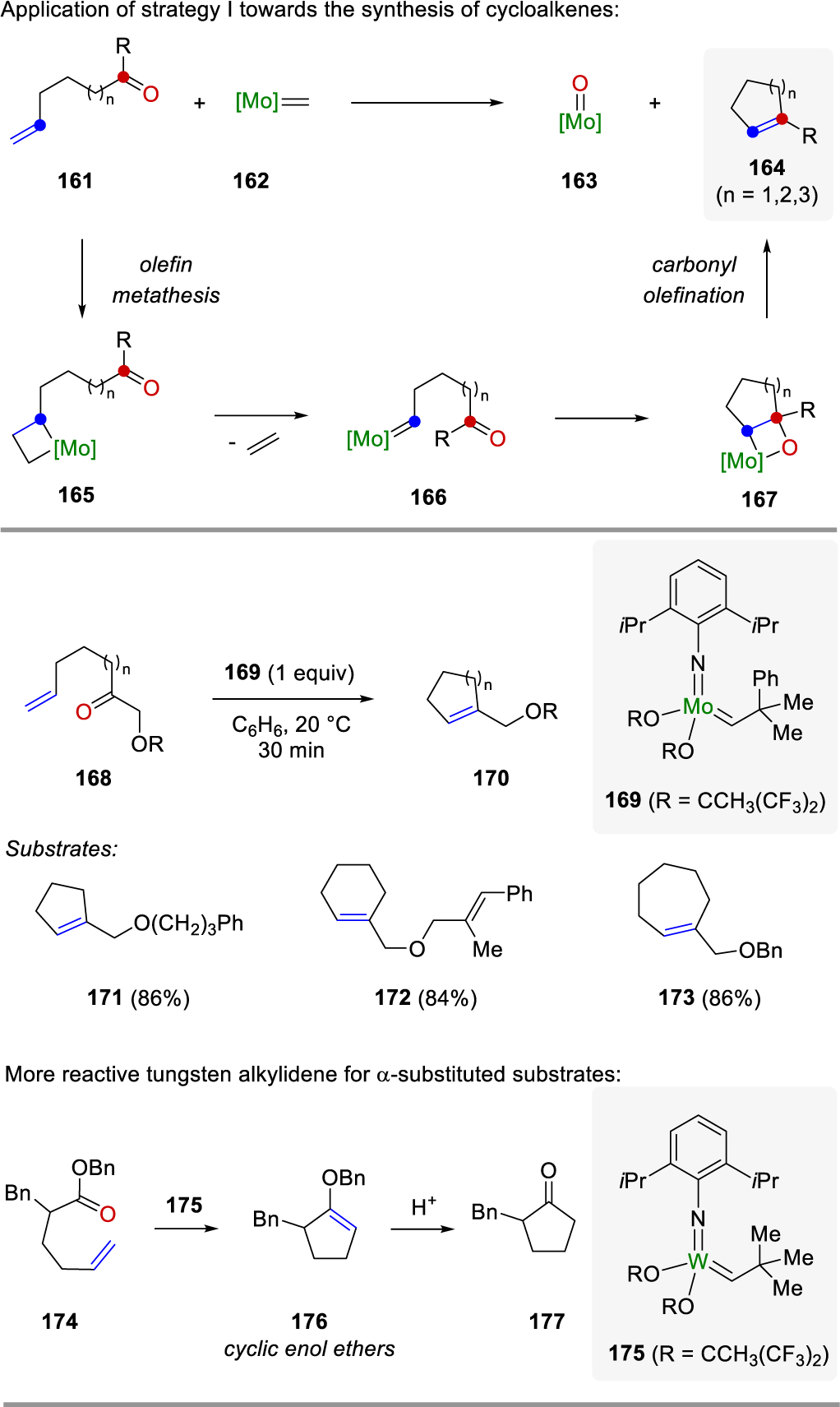

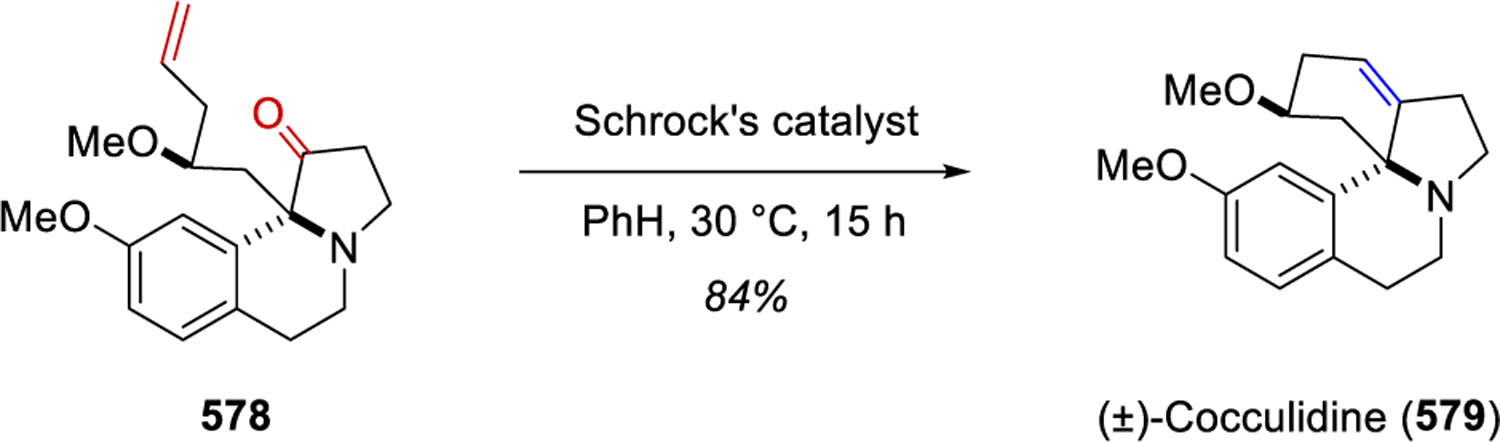

In 1993, Fu and Grubbs60 reported a new method for alkylidene-mediated carbonyl olefination based on the initial discovery by Grubbs during studies toward the synthesis of capnellane49,50 (Scheme 23). Following strategy I, the molybdenum alkylidene complex 162 initially undergoes a [2+2]-cycloaddition with 161 to form a metallacyclobutane intermediate 165, followed by fragmentation to afford a new alkylidene 166. This can then undergo a subsequent intramolecular carbonyl olefination to produce the desired cycloalkene 164. The preference for an initial olefin metathesis reaction over the carbonyl olefination allowed for the ring-closing metathesis to occur instead of the formation of an acyclic diene. Stoichiometric amounts of the metal alkylidene 169 were required to provide a substrate scope with access to 5-, 6-, and 7-membered cycloalkenes (171, 172, and 173, respectively) in high yield. Initial attempts towards ring-closing metathesis employed a specific class of substrates (174) containing esters and α-substitution with the more reactive tungsten alkylidene 175 previously reported by Schrock.61–63 The tungsten alkylidene complex formed cyclic enol ethers 176 that then reacted further to form cyclic ketones 177.

Scheme 23.

Olefin Metathesis and Carbonyl Olefination by Grubbs

A few years later, Nicolaou and co-workers reported a new method that utilized strategy II for the generation of cyclic enol ethers from olefins and esters using excess amounts of the Tebbe and Petasis reagents (Scheme 24).64 The proposed mechanism begins with the initial formation of an acyclic enol ether 180 and oxo-titanium complex 179 through a carbonyl olefination reaction of 178 with the Tebbe reagent. Then, a second equivalent of the Tebbe reagent reacts to form the titanacyclobutane 181. Subsequent fragmentation to afford the titanium alkylidene 182 then allows for an intramolecular cyclization to form a second titanacyclobutane 183, which fragments to the desired cyclic enol ether metathesis product 184 via olefin metathesis. This method is able to generate both 6- and 7-membered cyclic enol ethers (191–193) and is tolerant of a number of functional groups within the substrates (188–190).

Scheme 24.

Application of Strategy II for the Conversion of Olefinic Esters to Cyclic Enol Ethers by Nicolaou

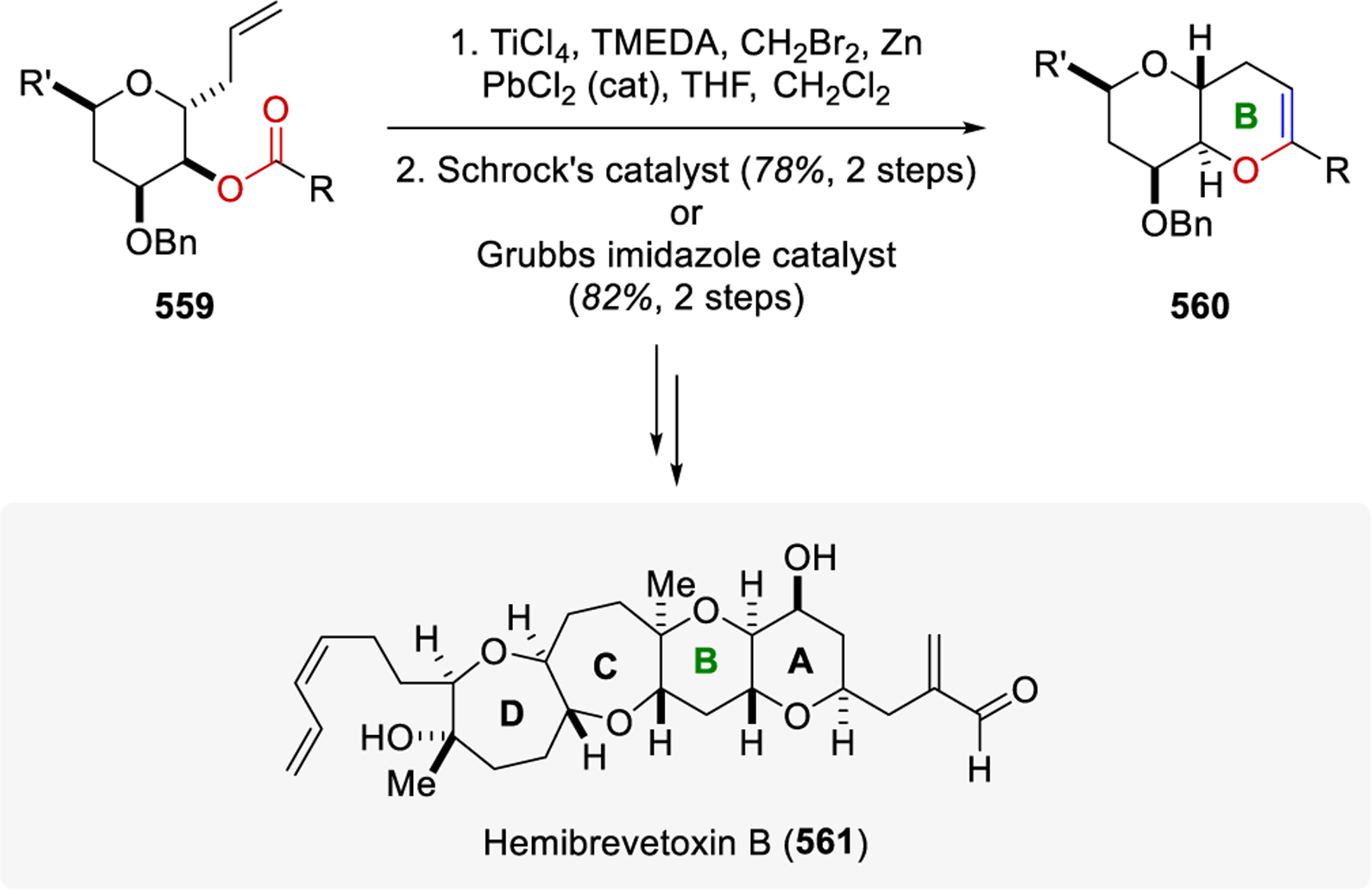

The use of strategy II with metal alkylidenes for the formation of cycloalkenes and cyclic enol ethers was further exploited by Allwein and Rainier in 1998 with an application to the synthesis of a family of compounds associated with neurotoxicity, “red tide” catastrophes, and potent antimicrobial activity.65 They developed a three-step protocol for the synthesis of fused ether ring systems 198 that included an enol ether epoxidation of 194 to provide 195, C-C bond formation to form 196, and finally a ring-closing metathesis of 196 to 197 (Scheme 25). The ring-closing metathesis was performed through pre-functionalization of the carbonyl in olefinic-ester substrate 199 with Takai’s conditions,66 providing primarily the olefinated ester 200 and only trace amounts of ring-closing metathesis product 202. A stoichiometric amount of Schrock’s molybdenum alkylidene catalyst 201 was then employed to perform the ring-closing metathesis in 76% yield.

Scheme 25.

Iterative Pathway Towards Fused Ether Ring Systems by Allwein and Rainier

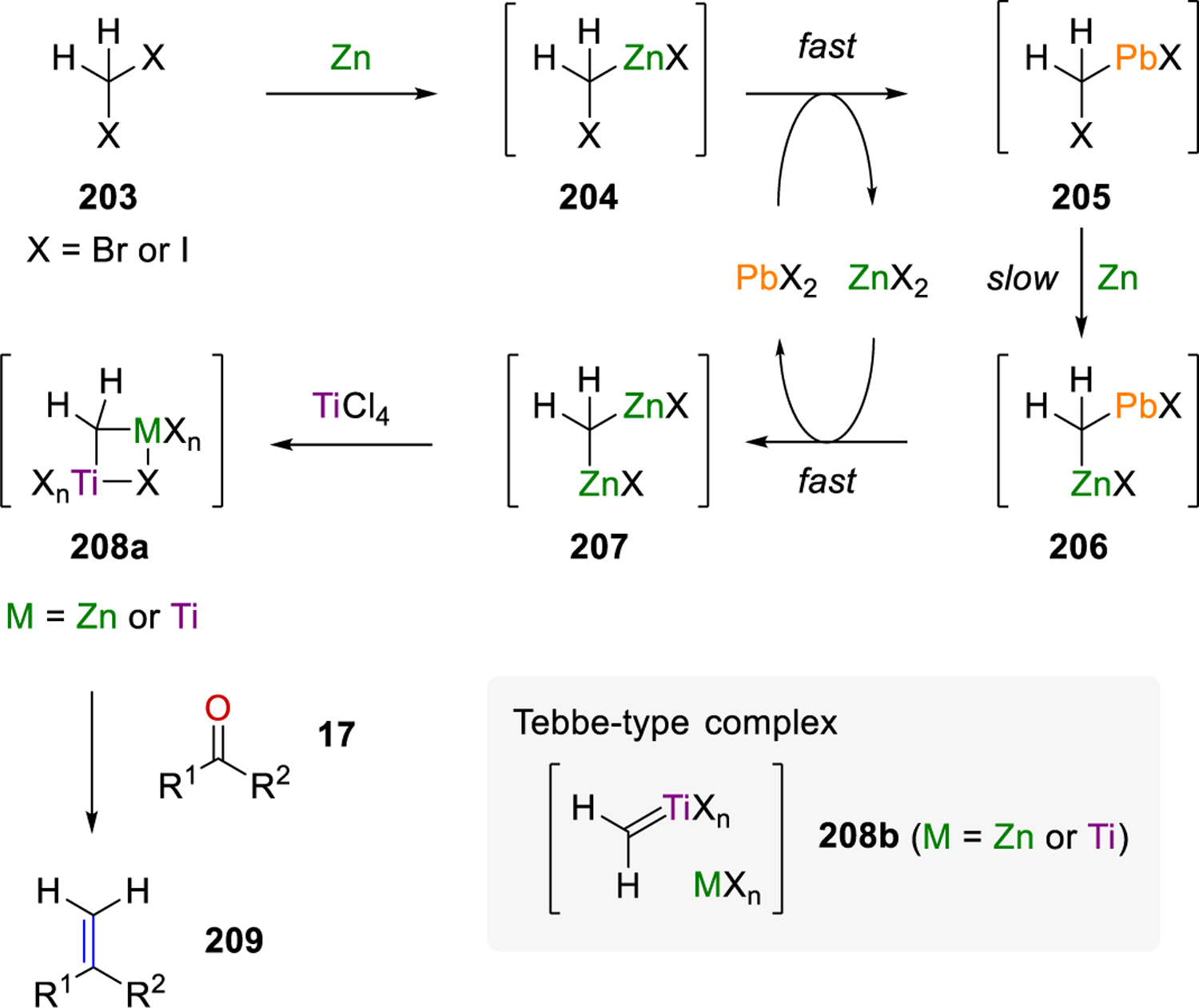

In the following years Takai-Utimoto reaction conditions were developed to realize similar cyclization strategies. Specifically, Takai-Utimoto conditions for a Wittig-type olefination were reported in 1994 that utilized an alkyl halide, PbX2, TiCl4, and Zn.66 The reaction begins with the formation of a zinc-carbenoid species 204, followed by transmetalation with PbX2 as an accelerant (Scheme 26). Reduction and a second transmetalation lead to geminal dizinc 207. The formation of titanium-containing geminal dimetallic compound 208a occurs prior to olefination of carbonyl compound 17. The Takai and Utimoto group assumed the Tebbe-type complex 208b as another possible key intermediate for the methylenation of carbonyl compounds. These conditions employed strategy II where initial carbonyl olefination is followed by olefin metathesis.

Scheme 26.

Mechanism of the Takai-Utimoto Conditions

Bennasar and co-workers67 employed strategy II for the synthesis of 1,4-dihydroquinolines using the Petasis reagent.58 Methylenation of N-protected olefinic amides following a ruthenium-catalyzed ring-closing metathesis of the resulting enamides allowed for the formation of 1,4-dihydroquinolines 213a-c in up to 75% yield (Scheme 27). Acetanilide 214 was obtained in only 20% yield after treatment with dimethyl titanocene, presumably as a consequence of its competitive interaction with the amide and carbamate carbonyl groups. Enamides 210a and 210b underwent olefin metathesis reaction with the second-generation Grubbs catalyst 212, also in 75% yield, showing that the steric hindrance of the protecting group does not affect the reactivity of the catalyst. The Bennasar group also transformed the hydroquinolines obtained into quinolines. One year later, the Bennasar group expanded this protocol to the syntheses of indoles 215, 1,2-dihydroisoquinolines 217a, and dihydrobenzoazepines 217b.68 In general, the synthesis of dihydrobenzoazepines resulted in lower yields and mixture of products due to alkene isomerization reactions during the ring-closing metathesis step. An exception was 217a and 217b, where the addition of benzoquinone to the reaction mixture reduced the isomerization process and increased the yield to 50%.

Scheme 27.

Synthetic Route to Benzo-Fused N-heterocycles by Bennasar

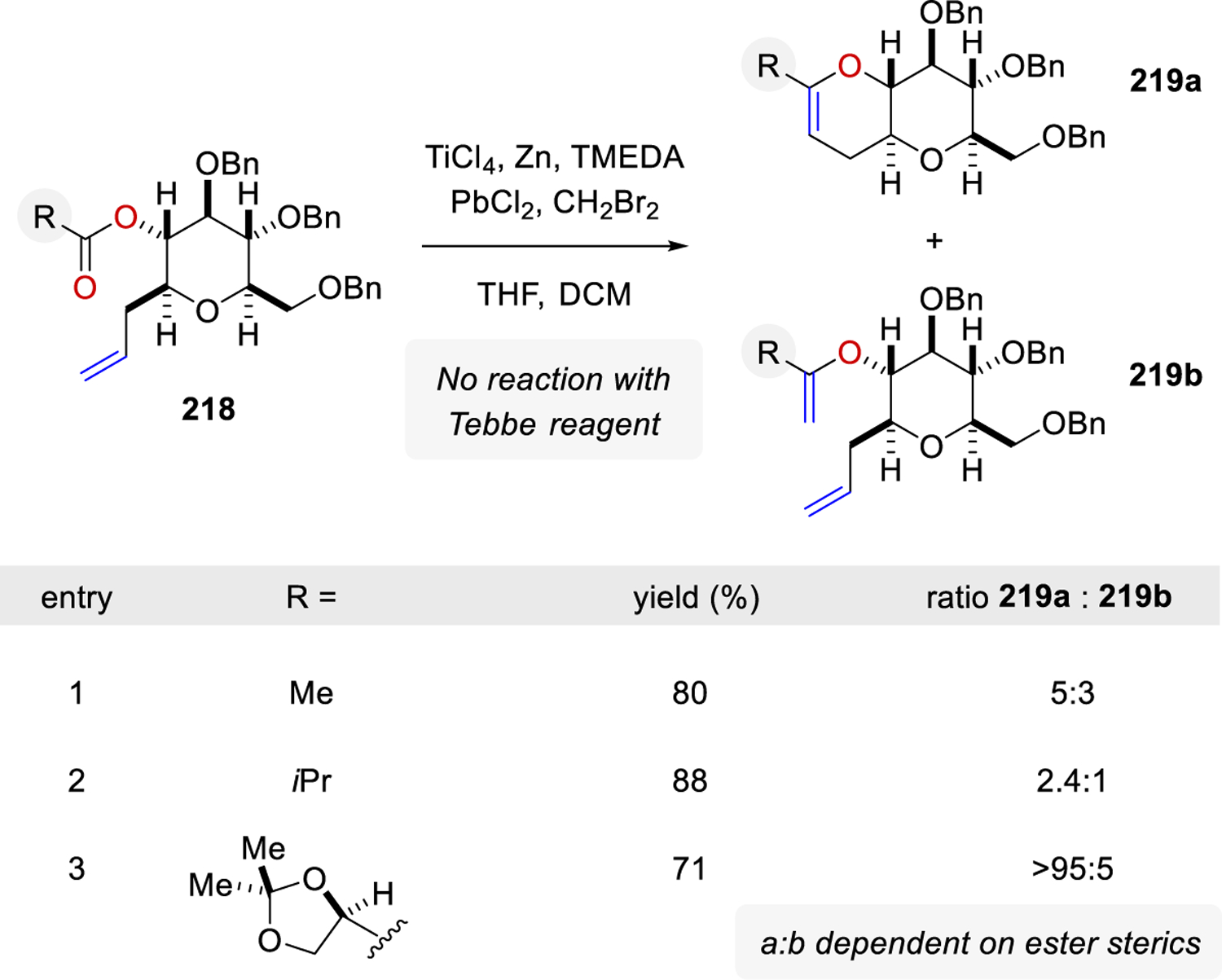

Majumder and Rainier were able to further optimize the metathesis reaction69 using the Takai-Utimoto titanium alkylidene66 to achieve the preferential formation of the cyclic enol ether product 219a over the acyclic enol ether product 219b (Scheme 28). Initial investigations using the Takai-Utimoto alkylidene demonstrated the mild nature of the protocol and additionally determined that unlike Nicolaou’s report,64 in which cyclic enol ethers resulted from acyclic enol ether intermediates and a subsequent enol ether ring-closing metathesis, the acyclic enol ethers were not precursors to cyclic enol ethers. Therefore, a Strategy I reaction mechanism was proposed wherein an olefin metathesis reaction occurred followed by a carbonyl olefination reaction forming the cyclic enol ether metathesis product. It was determined that these metathesis reactions utilizing the Takai-Utimoto reagent protocol were dependent on the steric environment of both the ester and olefin moieties.

Scheme 28.

Modified Takai-Utimoto Reduced Titanium Reagent for the Olefinic Ester Cyclization by Rainier

Iyer and Rainier later discovered that the specific type of in situ generated titanium alkylidene reagent was crucial to the ratio of acyclic to cyclic enol ether metathesis products (221 and 222, Scheme 29).70 The titanium methylidene reagent derived from dibromomethane as the alkylidene source favored the formation of the acyclic enol ether product, while the corresponding ethylidene reagent resulting from dibromoethane produced the cyclic enol ether as the sole metathesis product. Further exploration into the substrate scope with this updated protocol determined that the ratio of products greatly favored or provided solely the cyclic enol ether metathesis product 224 in up to 82% yield.

Scheme 29.

Reactivity of Reduced Titanium Alkylidenes for Cyclic Enol Ether Formation by Rainier and Iyer

In 2009, the application of reduced titanium ethylidene reagents was reported for the rapid entry into polycyclic ether skeletons common in the brevetoxin class of compounds.71 This two-directional approach allowed for the formation of tricyclic ether rings via the ring-closing metathesis reaction of substrates containing two olefin ester moieties. The optimized reaction conditions provide 6- and 7-membered cyclic enol ethers and could perform the double metathesis reaction in up to 65% yield (230-233, Scheme 30). The use of this carbonyl-olefin metathesis strategy for the synthesis of cyclic enol ethers allowed for the formation of a heptacyclic compound from C-glycoside precursor in just six steps.

Scheme 30.

Polycyclic Ether Skeletons Synthesis by Rainier

Following their success with the carbonyl-olefin metathesis reaction to form cyclic enol ethers, the Rainier group reported a similar application to the synthesis of macrocycles.72 Macrocyclic motifs, as shown in Scheme 31, are present in a number of biologically active small molecules73 and general synthetic protocols for their formation are desirable. Rainier was able to apply the previously reported conditions70 relying on the use of dibromoethane to access macrocyclic ethers in excellent yields. Specifically, 6- and 7-membered cyclic enol ethers 236-238 were formed within the structure of macrocyclic compounds in up to 87% yield.

Scheme 31.

Olefinic Lactone Cyclization by Rainier

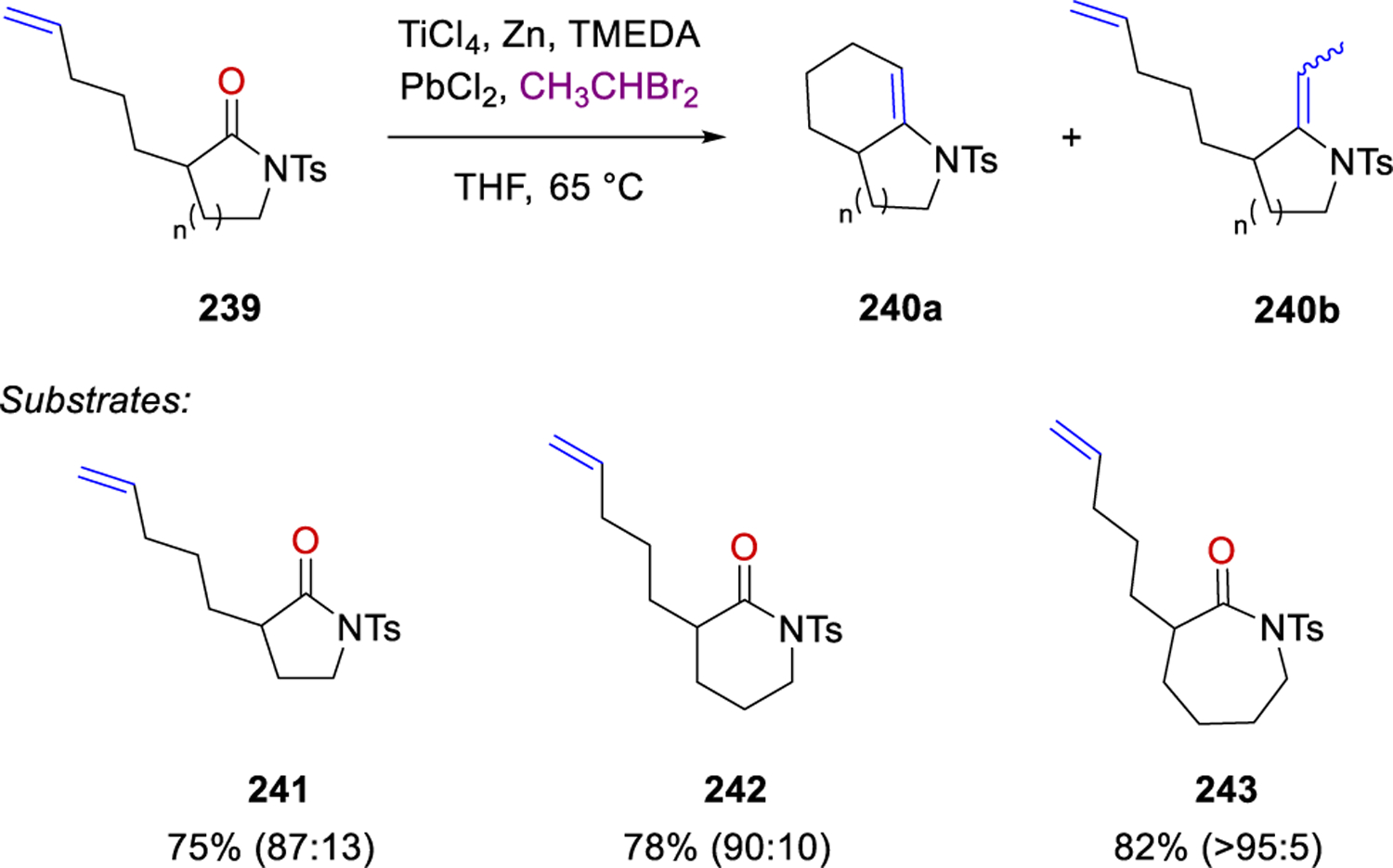

Lastly, Zhou and Rainier were able to further exploit this reduced, in situ generated titanium ethylidene reagent for the formation of cyclic enamides74 from olefinic-amide and olefinic-lactam substrates in good yield and high selectivity towards the cyclic enamide (Scheme 32). 5-, 6- and 7-membered lactams (241–243) provided 75–82% yield of the carbonyl-olefin metathesis products with greater selectivity for the cyclic product with increased ring size of the lactam.

Scheme 32.

Synthesis of Cyclic Enamides by Rainier

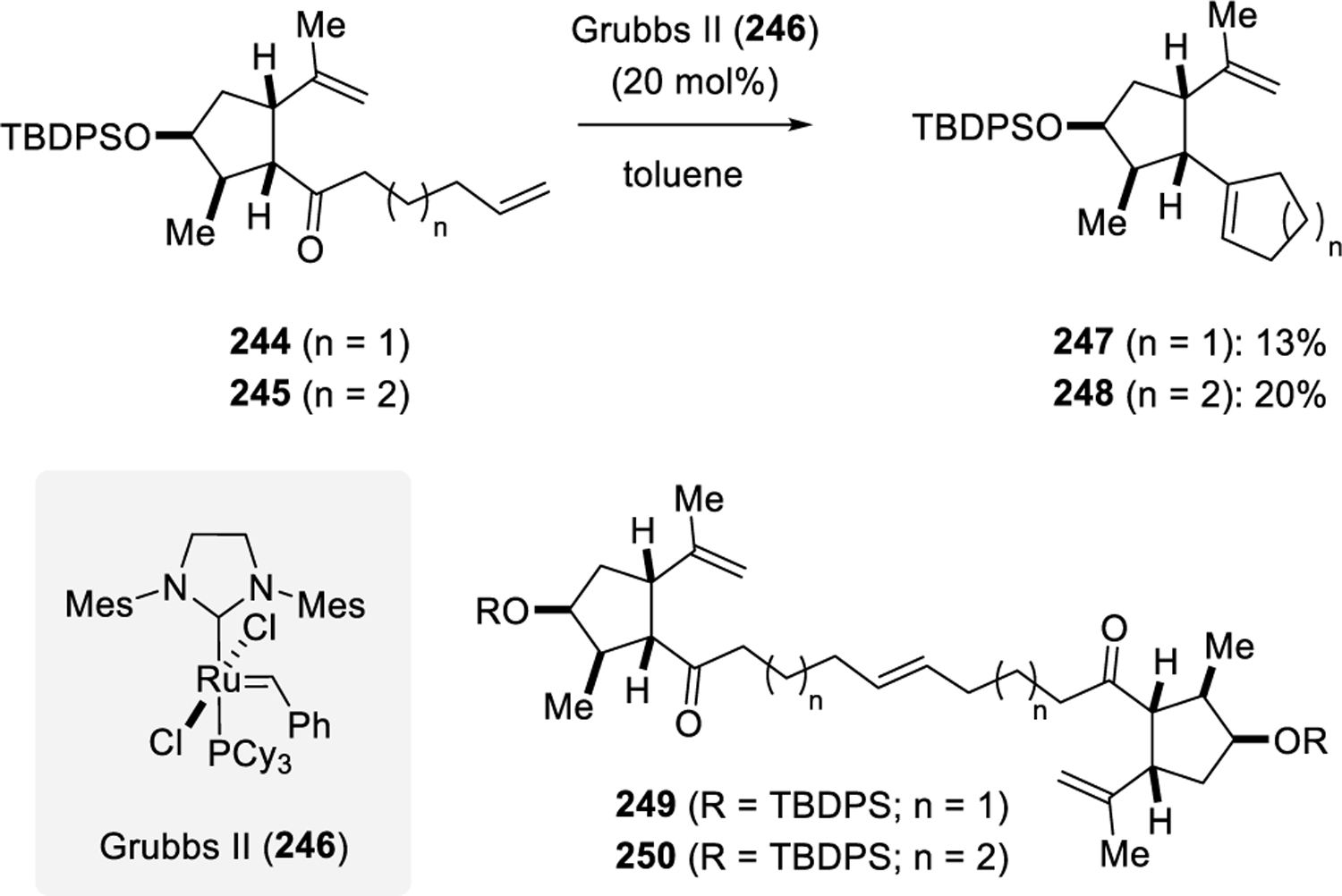

In 2016, Chakraborty and Roy reported a study aimed at the synthesis of cyclopentanes and medium-sized rings relying on a Grubbs II (246) catalyzed ring-closing olefin-olefin metathesis sequence and Grubbs II-mediated carbonyl-olefin metathesis.75 Specifically, terminal alkenes 244 and 245 are converted with 20 mol% Grubbs II (246) to result in the formation of cyclopentene 247 and cyclohexene 248 in 13% and 20% yield, respectively, as the carbonyl-olefin metathesis products. Additionally, the formation of the olefin-olefin metathesis product (not shown) is observed in both reactions in up to 40% yield. The authors state that ring-closing carbonyl-olefin metathesis is known to require stoichiometric amounts of Grubbs II (246) to proceed, however, carbonyl-olefin metathesis has never been observed with ruthenium alkylidenes and reported examples rely exclusively on stoichiometric amounts of molybdenum alkylidenes as reagents. Based on the 1H-NMR and 13C-NMR spectra obtained by Roy and Chakraborty, we postulate that the products obtained are in fact the dimers 249 and 250 resulting upon cross olefin-olefin metathesis. Spectra included in the original report do not extend to the carbonyl region, which consequently do not allow for differentiation between the carbonyl-olefin metathesis products lacking the carbonyl functionality or the dimeric products formed. It thus appears that compounds 247 and 248 were misassigned and ruthenium-alkylidenes such as 246 do not promote carbonyl-olefin metathesis.

The use of metal alkylidenes, specifically Ti-, Ru-, W-, and Mo-alkylidenes, has been a seminal reaction paradigm for carbonyl-olefin metathesis. Two strategies to utilize these alkylidenes for carbonyl-olefin metathesis have been developed, relying on either an initial olefin metathesis, followed by a carbonyl-olefination (Strategy I) or the reversed approach, employing an initial carbonyl-olefination, followed by olefin metathesis (Strategy II) to access the desired olefin. Both of these strategies have been applied to synthesize a myriad of highly functionalized products including cyclic enol ethers, benzo-fused N-heterocycles, and cyclic enamides. Notably, many of these products remain inaccessible with recently developed catalytic protocols for carbonyl-olefin metathesis, which shows the synthetic value of these stoichiometric approaches. Additionally, metal alkylidene-mediated carbonyl-olefin metathesis reactions remain the only strategies currently used in reports of natural product synthesis with the exception of one early example relying on a Paternò-Büchi approach.

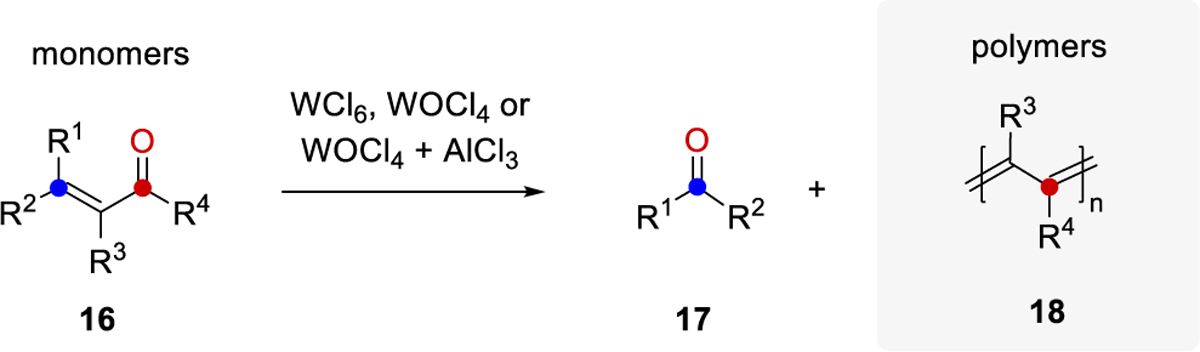

4. CARBONYL-OLEFIN METATHESIS POLYMERIZATIONS

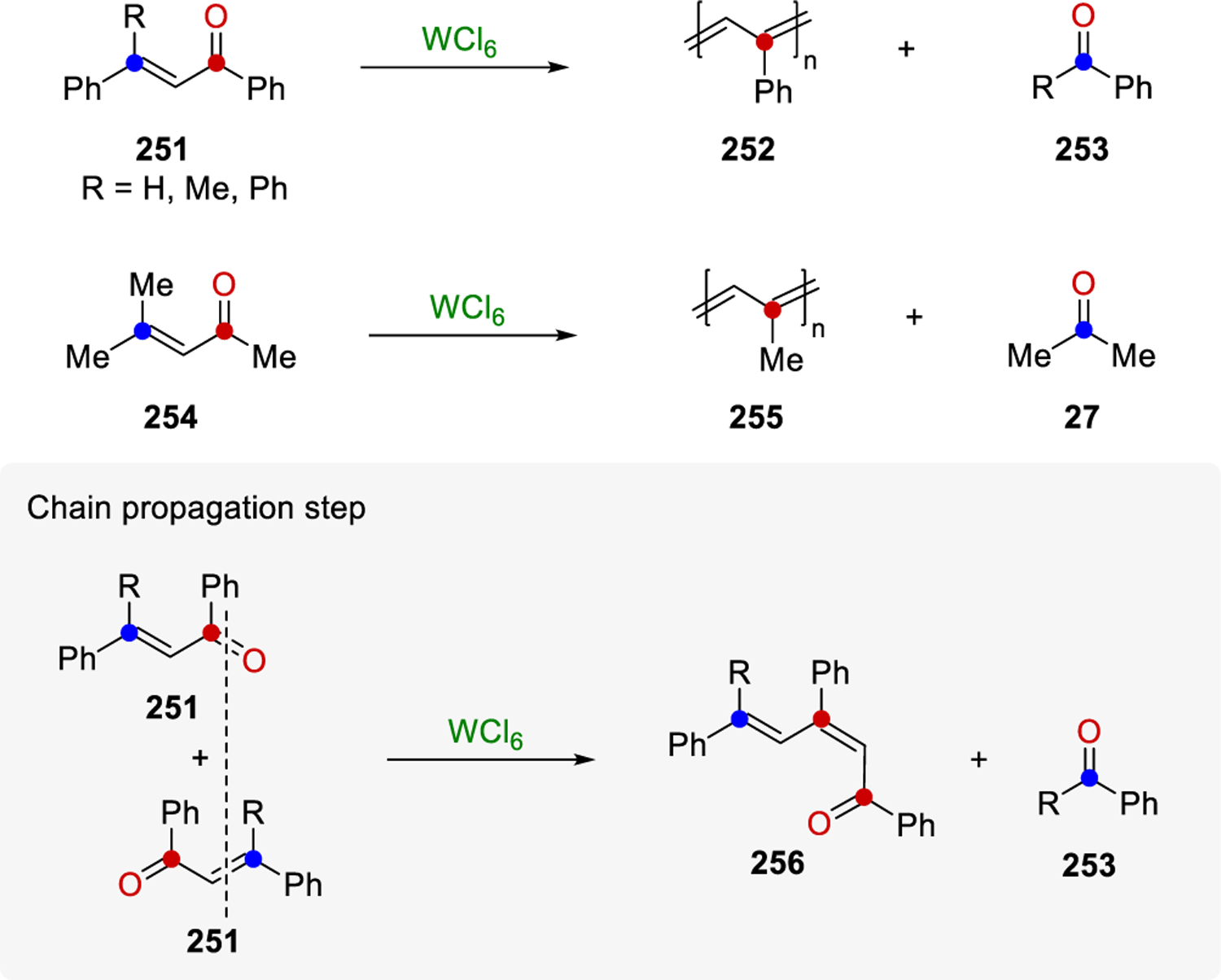

Amongst the earliest reported carbonyl-olefin metathesis reactions were the polymerizations of enones 16 with tungsten-based reagents, resulting in the formation of conjugate polymers 18 (Scheme 34). These types of carbonyl-olefin metathesis reactions were initially referred to as “carbonyl-olefin exchange reactions,” and were reported as early as 1983.14 Although the polymers accessible by this approach are important in various areas of materials science, the transformation remained limited in its scope with only three reported monomers undergoing carbonyl-olefin metathesis. Nevertheless, the reaction holds great synthetic potential and raises interesting mechanistic questions.

Scheme 34.

Carbonyl-Olefin Exchange Reactions Enabling Polymerizations

In particular, a consecutive mechanism relying on olefin metathesis, carbonyl-olefin metathesis and final carbonyl metathesis steps was proposed that postulated efficient reactivity of metal-oxo intermediates in subsequent alkene additions. Interestingly, this reactivity has proven elusive in attempts to render metal alkylidene-mediated carbonyl-olefin metathesis reactions catalytic. An additional interesting aspect of carbonyl-olefin metathesis polymerizations is the reliance on tungsten-based reagents to promote the desired transformation, which could exhibit Lewis acid characteristics or form tungsten alkylidenes in situ. This chapter summarizes the developments in the area of carbonyl-olefin metathesis polymerizations and focuses on reaction scope, catalyst investigation, optimization of reaction conditions, and mechanistic insights obtained.

Conjugated polymers are an important part of polymer science, with applications in the fields of bioengineering, materials and biosensors. This class of materials has unique and valuable properties—such as desirable electrical characteristics, conductivity, photoconductivity, paramagnetism, and catalytic activity—that have been extensively investigated.76 The general methods to prepare conjugated polymers include polymerizations, polycondensation, and polymer analogous conversion.77 In 1983, Schopov discovered the carbonyl-olefin exchange reaction (COER) as an additional tool for accessing conjugated polymers.14 Specifically, upon treatment of α,β-unsaturated ketone 251 with WCl6, polyphenylacetylene 252 and benzaldehyde (253, R = H, Scheme 35) were formed. Additionally, polymethylacetylene 255 was also accessible from mesityl oxide 254 and WCl6.14,78 Subsequent investigations revealed that substituting the R-group in 251 for a methyl or phenyl group similarly enabled the formation of 252, and the nature of byproduct 253 affected the yield of the polymer; specifically, benzaldehyde and acetophenone were found to interact with WCl6, while benzophenone did not react or affect the reactivity, leading to higher yields of 252.15 Chain propagation, the first step of COER, is described as double bond cleavage to form a new carbonyl compound 256 and a new C–C double bond in 256, similar to the redistribution of atoms observed in olefin metathesis reactions.16 Newly formed dimer 256 contains a carbonyl and olefin end-groups that are able to undergo COER with a second α,β-unsaturated ketone and continue the process to obtain the conjugated polymer. This polymerization is thus considered a stepwise process and a polycondensation reaction.

Scheme 35.

Carbonyl-Olefin Exchange Reaction as Synthetic Route to Polyconjugated Polymers by Schopov

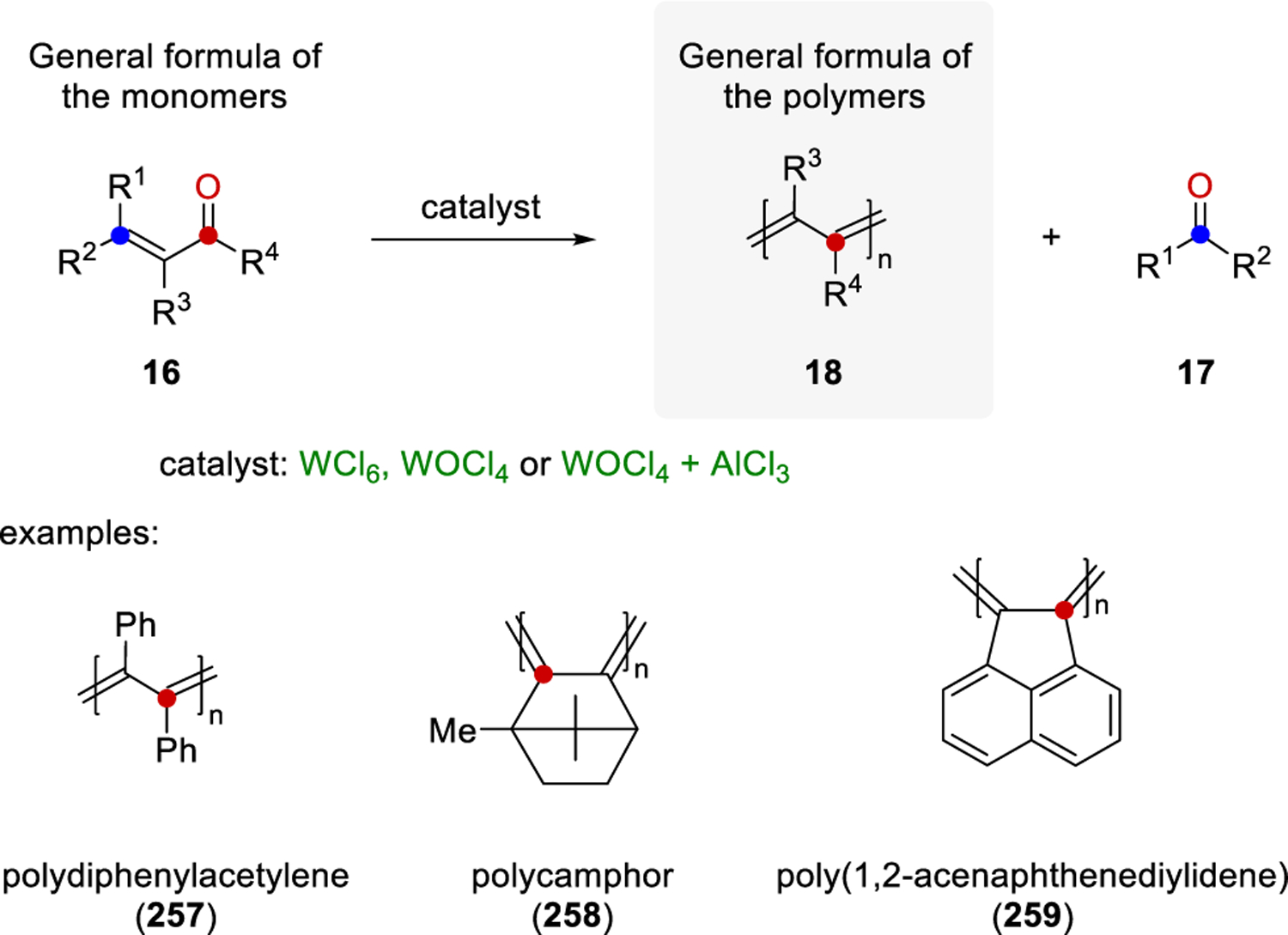

The groups of Schopov and Jossifov carried out several investigations on COER to determine the optimized reaction conditions and important experimental results were obtained: a) the general formula of the monomers is a substituted propenone 1614,15,78 (Scheme 36); more substituted monomers lead to higher yields,18 b) the reaction can be carried out without solvent, or in benzene or chlorobenzene as the optimal solvents,14,15 c) higher yield and molecular weight were observed when increasing the amount of WCl6 (up to equimolar ratios), time, and temperature (120 °C), 15,19 d) during the reaction tungsten changes its degree of oxidation,78 and e) the polymer is obtained as a doped complex with WCl6 while polymer 18 can be obtained after a treatment with concentrated sodium hydroxide solution.18 Additionally, it was found that WOCl4 or WOCl4 with AlCl3 as additives led to higher yields of 18 and, in some cases, quantitative transformation of the monomer.20 Several polyconjugated polymers were obtained under the optimized reaction conditions such as polydiphenylacetylene (257),18 polycamphor (258),79 and poly(1,2-acenaphthenediylidene) (259).14

Scheme 36.

General Formulas and Examples of Conjugated Polymers Obtained with Carbonyl-Olefin Exchange Reaction

Importantly, several compounds including benzophenone 80, tetraphenylethylene 262, traces of molecular oxygen 264, and dibenzyl 265 were identified as byproducts of this polymerization21 (Scheme 37). The presence of these compounds supported the hypothesis that several double bond forming reactions were taking place during the polymerization process. Considering the olefin moiety the “head” and the carbonyl group the “tail,” three types of propagation steps can occur: COER (considered a head to tail propagation), olefin metathesis (OM, considered a head to head propagation), and reductive coupling (RC, considered a tail to tail propagation). Compound 265 was not observed as part of the byproducts reported and the origin of 266 is probably due to an inner double bond metathesis with a carbonyl group.

Scheme 37.

Types of Propagation Steps Proposed by Jossifov

The proposed mechanism for the tungsten-catalyzed polymerization by Schopov21 and Jossifov21,80,81 involves all three types of propagation steps, specifically OM, COM (or COER), and RC82 transformations taking place simultaneously (Scheme 38). The OM involves the formation of metallacyclobutane intermediates from olefins and metal alkylidene complexes via [2+2] cycloadditions and subsequent fragmentations. The COM reaction consists of the redistribution of the metal carbene generated from OM and a carbonyl group to form a new olefin and an oxo-metal complex. Then, the oxo-metal species could either react with a second olefin or with a carbonyl through a [2+2] cycloaddition to start the next cycle of CM. This cycle entailed the formation of a dioxometallacyclobutane and subsequent cleavage to the metal carbene and molecular oxygen. The metal carbene could then react with a second carbonyl group to form an olefin and regenerate the oxo-metal complex to continue the cycle. The hypothesis is based on the existence of similar catalytic systems,83 the established [2+2]-metathesis reactions mechanism relying on transition metal carbene complexes,84 the byproducts observed, and the tungsten oxo-alkylidene complexes reported by Bryan and Mayer.85

Scheme 38.

Possible Mechanism for the Synthesis of Polyconjugated Polymers by Schopov and Jossifov

Notably, Bryan and Mayer reported a series of oxo-alkylidene complexes generated via oxidative addition of ketones to form two divalent ligands with tungsten (Scheme 39). WCl2(PMePh2)4 reacts with two equivalents of ketone forming a metallaoxirane complex 267 via substitution of two phosphine ligands. Some of these complexes decomposed to the oxo-alkylidene complex 268 at room temperature in a few days. However, small changes in the ketones affected the reactivity: tetrasubstitutedethylene compounds, ketones, and other unidentified byproducts were formed together with oxo-tungsten complex (W(O)Cl2L3). Therefore, this proved not to be a general method for preparing oxo-alkylidene complexes. Based on the past evidence and existing literature, Jossifov investigated the polymer formation via reductive coupling of diketone 267 with WCl6·AlCl3,86 which was previously used as a two-component catalyst for COER.20 Polydiphenylacetylene with carbonyl end-groups was obtained, although molecular oxygen was not detected, which means that the polymerization proceeded as a normal RC. This result supports part of the “carbene mechanism” (Scheme 38).

Scheme 39.

Synthesis of Tungsten Metallaoxirane and Tungsten Oxo-Alkylidene Complexes by Mayer

In particular, a consecutive mechanism relying on olefin metathesis, carbonyl-olefin metathesis and final carbonyl metathesis steps was proposed that postulated efficient reactivity of metal-oxo intermediates in subsequent alkene additions. Interestingly, this reactivity has proven elusive in attempts to render metal alkylidene-mediated carbonyl-olefin metathesis reactions catalytic. An additional interesting aspect of carbonyl-olefin metathesis polymerizations is the reliance on tungsten-based reagents to promote the desired transformation, which could exhibit Lewis acid characteristics or form tungsten alkylidenes in situ.

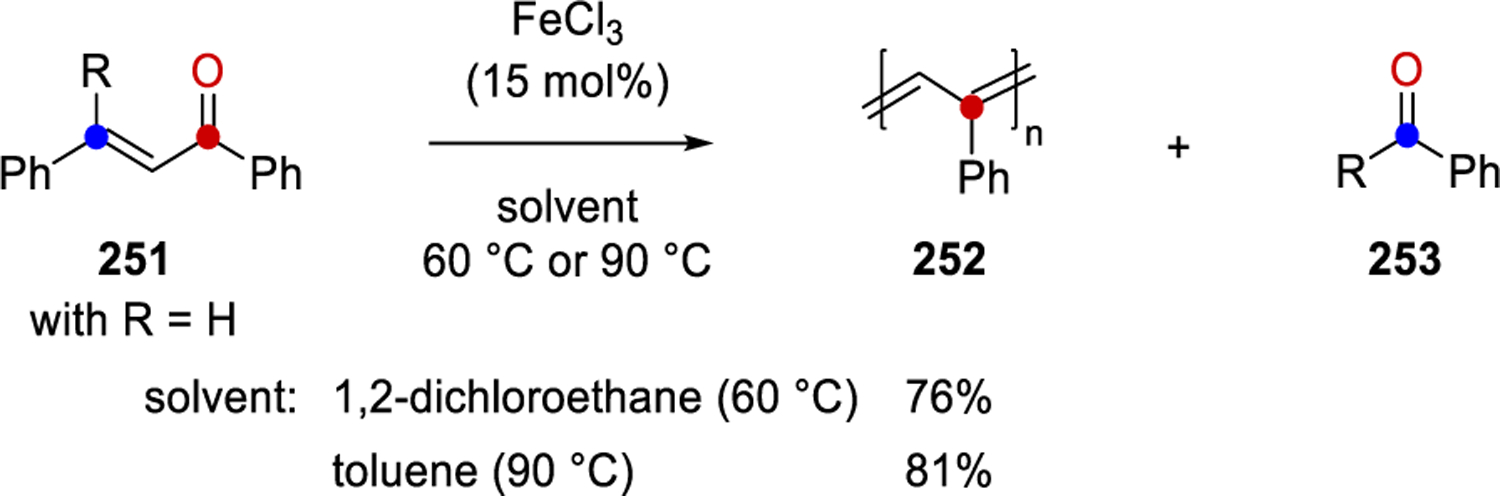

In 2018, Dimova and coworkers reported an FeCl3-catalyzed carbonyl-olefin metathesis polymerization reaction of chalcone 251 to form polyphenylacetylene 252.87 Specifically, when chalcone 251 is converted with 15 mol% FeCl3 at 60 °C in 1,2-dichloroethane, the authors observe the formation of polyphenylacetylene 252 in 76% yield as a predominantly trimeric product. In comparison, when the reaction is conducted in toluene at 90 °C under otherwise identical reaction conditions, 252 is obtained in increased yields of 81% while fractions of molecular masses up to 5000 g·mol-1 are registered.

In summary, these examples highlight the potential of carbonyl-olefin metathesis as a tool for the polymerization of enones. Initial mechanistic studies suggest that all three types of propagation occur simultaneously in these transformations to form the desired polymer products. Despite the fact that the polymers synthesized by these transformations are limited in scope and size, the reactions hold tremendous synthetic potential. While new advances have been reported recently for other categories of carbonyl-olefin metathesis, the most recent developments in tungsten-mediated carbonyl-olefin metathesis polymerizations date back to the 1990s. Only a single, more recent report describes the use of Lewis acids for carbonyl-olefin metathesis polymerization reactions.

5. ORGANOCATALYTIC CARBONYL–OLEFIN METATHESIS REACTIONS

The first catalytic strategy for carbonyl-olefin metathesis was reported by Lambert and coworkers in 2012.88 In contrast to the classic [2+2]-cycloaddition and retro-[2+2]-cycloaddition paradigm usually operative in double bond metathesis reactions, their reaction design principle takes advantage of a [3+2]-cycloaddition and retro-[3+2]-cycloaddition using 1,3-dipoles (Scheme 41). The reliance on this alternative class of pericyclic reactions circumvents some of the challenges presented by [2+2] manifolds; however, 1,3-dipolar cycloadditions present their own set of unique issues. Principle amongst these challenges is the typically high stability of the intermediate, five-membered ring cycloadducts. In contrast to the four-membered ring intermediates of both olefin metathesis and carbonyl-olefin metathesis reactions involving oxetanes, the Lambert design requires some means to destabilize the intermediate cycloadducts, whether it is through the use of strained substrates or, ideally, catalyst design.

Scheme 41.

Reaction Design Principle for the First Catalytic Carbonyl-Olefin Metathesis Reaction.

The specifics of the Lambert blueprint call for the use of hydrazine catalysts, which engage the carbonyl component by condensation to form azomethine imines (or more accurately, their conjugate acid hydrazonium ions). The metathesis then proceeds by reversible 1,3-dipolar cycloadditions with the olefin. The key principle in this design is that, by virtue of the locally symmetric nature of the pyrazolidine intermediate, cycloreversion can occur via two different exit channels: one to reform the starting materials and the other to generate new olefin and hydrazonium intermediates. In precisely the same way as olefin metathesis reactions, the equilibrium point of this inherently reversible process is dictated by elements of ring strain, conjugation, or mass action. It should be stressed that a particular advantage of this platform is that the engagement of the carbonyl and olefin occurs through mechanistic processes—condensation and cycloaddition, respectively—that are compatible with a broad range of functionality. This design thus holds promise for substantial generality, even if much of that promise is as yet unrealized. Nevertheless, this reaction paradigm has been shown to be applicable to catalytic ring-opening and ring-closing carbonyl-olefin metathesis reactions with several distinct substrate architectures.

5.1. Ring-Opening Carbonyl-Olefin Metathesis

In the first implementation of the hydrazine-catalyzed design, Griffith, Vanos, and Lambert88 demonstrated the ring-opening carbonyl-olefin metathesis (ROCOM) of cyclopropenes in 2012 (Scheme 42). The optimal catalyst for this transformation was the symmetric bicyclic hydrazine 21 as its bis-hydrochloride salt. With catalytic 21, aryl or aliphatic aldehydes 19 underwent ROCOM with cyclopropenes 20 to furnish β,γ-unsaturated aldehydes 22. Notably, the carbonyl-olefin metathesis products were formed with complete (E)-selectivity.

Scheme 42.

Catalytic Ring-Opening Carbonyl-Olefin Metathesis via 1,3-Dipolar Cycloadditions.

These reactions were found to proceed in up to 95% yield for a variety of electronically differentiated aryl aldehydes including furan and thiophene derivatives. Aliphatic aldehydes proceed in yields of 35% with the use a slow addition protocol (Scheme 43). It was presumed that the lower efficiency of the aliphatic substrates was due at least in part to side reactions resulting from deprotonation/tautomerization of the intermediate hydrazonium intermediates. The proposed mechanistic hypothesis involves initial condensation between aldehydes 19 and the symmetric hydrazine catalyst to form the corresponding hydrazonium ion 269. Interestingly, of the two possible geometric isomers of this hydrazonium ion (E-269 and Z-269), the authors propose (and calculations support) that cycloaddition with cyclopropane 20 is favored for E-269 via an exo-transition state due to minimized steric interactions, despite the fact that Z-269 is the thermodynamically favored isomer. The resulting pyrazolidine cycloadduct 270 undergoes proton transfer to form 271, which then proceeds through strain-relieving cycloreversion to result in hydrazonium ion 272. Hydrolysis of 272 reveals the carbonyl-olefin metathesis product, enal 22, with concomitant regeneration of the hydrazine catalyst 21.

Scheme 43.

Hydrazine-Catalyzed Ring-Opening Carbonyl–Olefin Metathesis by Lambert.

The Lambert and Houk groups89 followed up this initial report with a detailed mechanistic investigation of this hydrazine-catalyzed carbonyl-olefin metathesis reaction platform.88 Computational analysis fully supported the mechanistic rationale described above and underscored the role of ring strain of the cyclopropane substrates (20). Specifically, the substantial cyclopropane ring strain accelerated the initial [3+2] cycloaddition and led to intermediate fused cyclopropane cycloadducts that also benefited from high ring strain to accelerate the [3+2]-cycloreversion step (Scheme 44). Of particular importance was the finding that other strained olefins such as cyclobutenes and cyclopentenes were likely to have significantly higher activation barriers for the key cycloreversion step using hydrazine catalyst 21. This understanding argued strongly for the design of alternative hydrazine structures that could induce more facile cycloreversions with less reliance on substrate ring strain.

Scheme 44.

Distortion-Accelerated and Strain-Release-Promoted [3+2] and retro-[3+2] in Organocatalytic Carbonyl-Olefin Metathesis by Lambert and Houk.

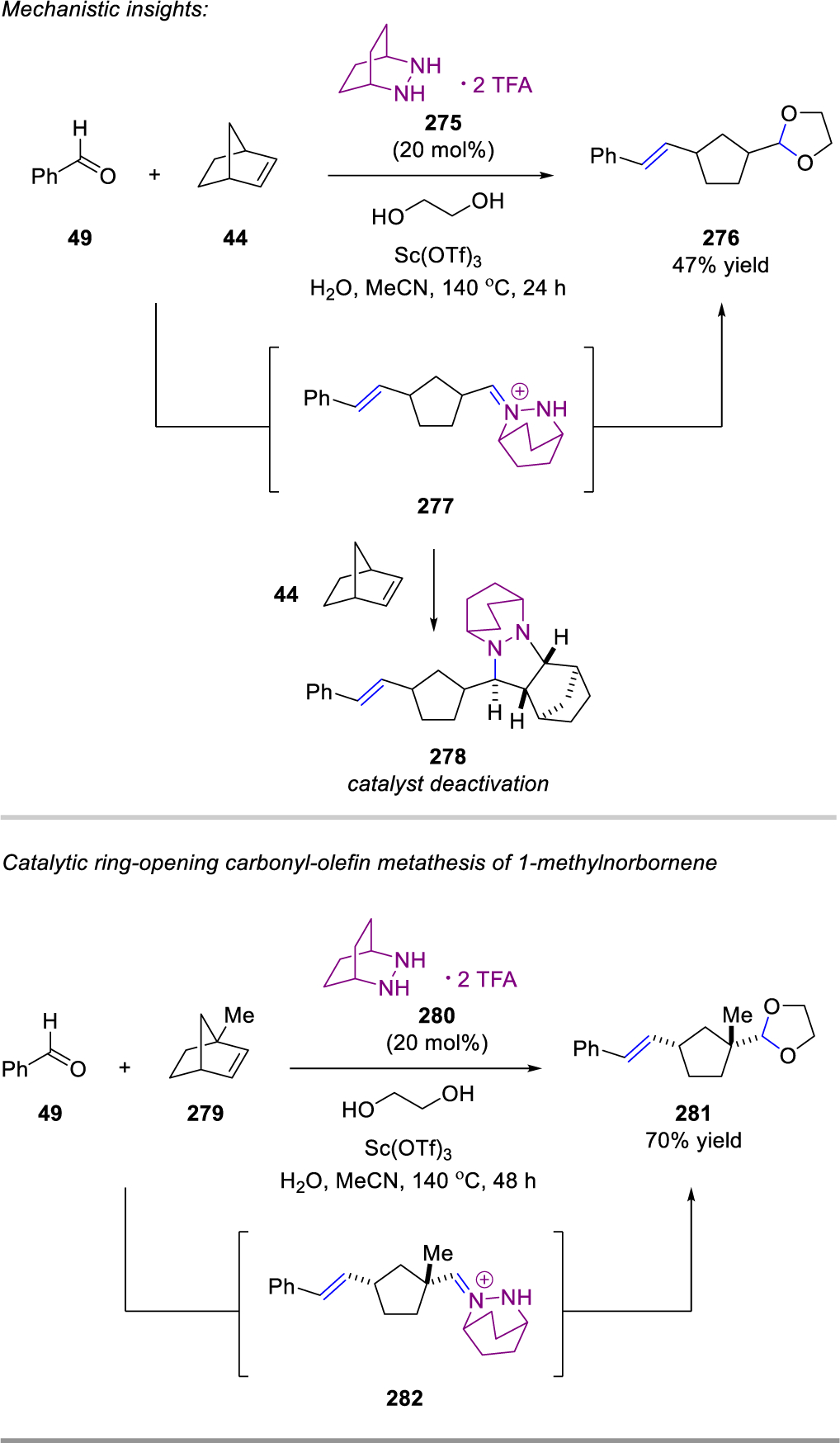

In 2020, Lambert and coworkers expanded the concept of hydrazine-catalyzed ring-opening carbonyl-olefin metathesis reactions of aldehydes to include norbornenes (Scheme 45), using a combined approach of catalyst design and computational analysis.90 The major challenge confronting a shift to a significantly less-strained substrate like norbornene is that the [3+2]-cycloreversion becomes both endergonic and the rate-determining step of the catalytic cycle. In order to identify a hydrazine that would enable a viable catalytic process with such substrates, a virtual screen of catalysts was conducted. Each step of the catalytic cycle was calculated in order to avoid misleading winners (i.e. structures that minimized cycloreversion but at the expense of an energetically inaccessible other step), and indeed a number of important potential pitfalls were identified. From this expansive study, a second-generation [2.2.2]-bicyclic hydrazine catalyst was identified that promised reasonably accessible cycloaddition and cycloreversion energies with norbornene.

Scheme 45.

Hydrazine-Catalyzed Ring-Opening Carbonyl-Olefin Metathesis of Norbornenes by Lambert.

Both of the cycloaddition and cycloreversion steps between benzaldehyde (49) and norbornene (44) with the [2.2.2]-bicyclic hydrazine 275 (Scheme 45) could be investigated separately because of the isolable nature of the intermediate cycloadducts. These studies confirmed the computational predictions and suggested a catalytic process should be attainable. Initial results proved encouraging as the use of 20 mol% 275 resulted in the formation of acetal 276 as the ring-opening metathesis product in 47% yield. However, the formation of cycloadduct 278, resulting from cycloaddition of hydrazonium intermediate 277 with a second equivalent of norbornene 44, was also observed. As 278 was resistant to cycloreversion under the reaction conditions, its formation resulted in full catalyst deactivation. Based on these results, it was postulated that hydrolysis of 277 is a key step in the turn-over of the hydrazine catalyst 275. In an attempt to overcome this limitation, methylnorbornene 279 was utilized to destabilize hydrazonium 282 by the introduction of steric strain and hopefully facilitating hydrolysis compared to undesired cycloaddition of a second equivalent of norbornene 279. In fact, the reaction between 49 and 279 provided 74% yield of 281, demonstrating the feasibility of ring-opening carbonyl-olefin metathesis of norbornenes. The authors conclude that competitive cycloaddition of hydrazonium 282 is still observed even with methylnorbornene 279, and thus future efforts should focus on the development of catalysts that promote a more facile hydrolysis step.

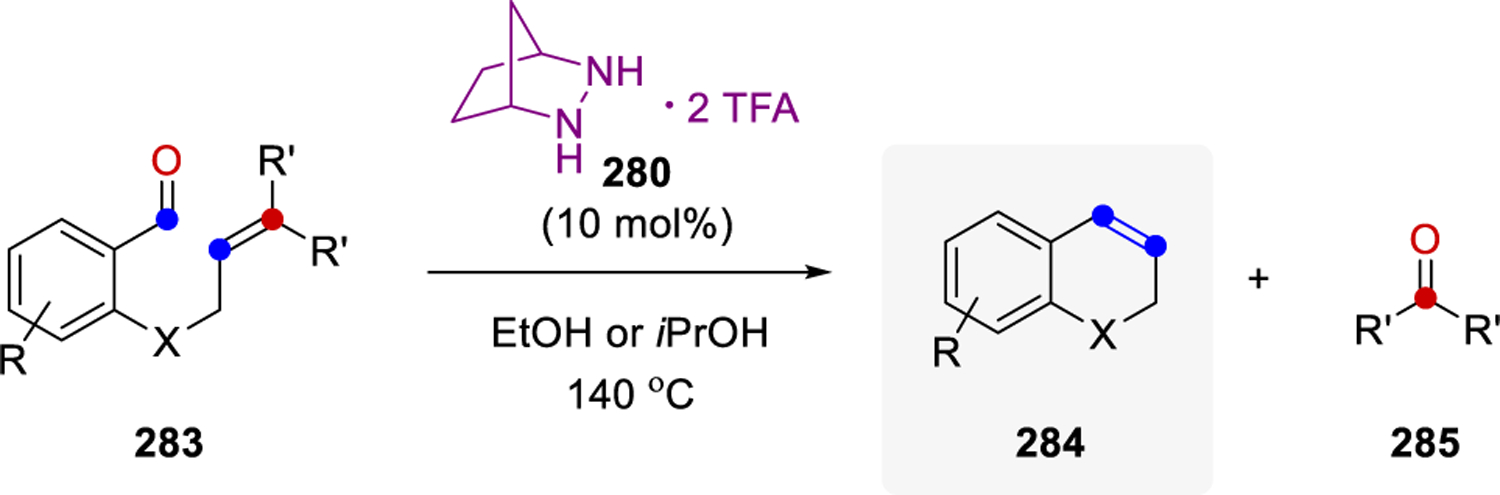

5.2. Ring-Closing Carbonyl-Olefin Metathesis

In 2019, Lambert and coworkers extended hydrazine-catalyzed carbonyl-olefin metathesis to the arena of ring-closing metathesis reactions (Scheme 46). Similar to the reaction design for ring-opening metathesis, these transformations rely on the initial condensation between the carbonyl moiety in 283 and the hydrazine catalyst 280 to form a hydrazonium intermediate. This reactive intermediate can then undergo a cycloaddition with the pendant alkene to form the pyrazolidine cycloadduct, which upon retro-[3+2]-cycloaddition and hydrolysis, gives rise to the desired metathesis product 284 and a carbonyl byproduct 285.

Scheme 46.

Catalytic Ring-Closing Carbonyl-Olefin Metathesis via 1,3-Dipolar Cycloadditions.

Hydrazine-catalyzed carbonyl-olefin metathesis ring-closing reactions were first established by Lambert and coworkers for salicylaldehyde allylic ethers 286 resulting in the formation of 2H-chromenes 287 (Scheme 47).91 The method utilizes the [2.2.1]-bicyclic hydrazine 280 as the catalyst and showcases a new approach to afford electronically and functionally differentiated 2H-chromenes (287a-287f) in up to 90% yield. Interestingly, the corresponding ketone substrates also prove reactive under the optimal reaction conditions; however, the low yields observed with these substrates point to complications in the condensation and/or cycloaddition steps due to steric strain. Lambert and co-workers were also able to provide additional mechanistic support for the hypothesis of sequential [3+2]- and retro-[3+2]-cycloadditions88–90 with the crystallization of cycloadduct 289. The configuration of 289 was confirmed by X-ray crystallographic analysis. The syn-pentane interaction between the gem-diethyl group was speculated to exert steric pressure on pyrazolidine cycloadduct, potentially accelerating the rate of cycloreversion and suppressing deallylative side reaction. Subsequent exposure of 289 to the optimized reaction conditions resulted in the formation of the desired carbonyl-olefin metathesis product 278a in 73% yield. As opposed to ring-opening metathesis (vide supra), the instability of the ketone hydrazonium byproduct allowed rapid hydrolysis, enabling catalyst turnover and minimizing deactivation.

Scheme 47.

Synthesis of 2H-Chromenes via Hydrazine-Catalyzed Carbonyl–Olefin Metathesis by Lambert

In 2020 Lambert and coworkers further expanded the application of hydrazine-catalyzed carbonyl-olefin ring-closing metathesis reactions to the synthesis of 1,2-dihydroquinolines.92 While the electron donating nitrogen was found to retard the rate of cycloaddition in N-allyl-2-aminobenzaldehyde compared to the salicylaldehyde counterpart, it facilitated a more rapid rate-determining cycloreversion. Such rate enhancement permitted the replacement of the diethylallyl group for a less hindered (and commercially available) prenyl group, while still inhibiting any deallylation side reaction. N-prenylated aminobenzaldehydes 290 underwent the desired transformation to result in a variety of 1,2-dihydroquinolines 291 bearing distinct substitution in up to 93% yield (Scheme 48). Notably, the corresponding N-Boc protected substrates underwent facile in situ deprotection to give rise to quinolones in 61% yield.

Scheme 48.

Synthesis of 1,2-Dihydroquinolines via Hydrazine-Catalyzed Carbonyl–Olefin Metathesis by Lambert

The use of strained hydrazines as catalysts has served as a powerful reaction design to develop catalytic carbonyl-olefin metathesis reactions. The unique [3+2]-cycloaddition strategy relying on the formation of cyclic hydrazonium intermediates enables ring-opening and ring-closing carbonyl-olefin metathesis reactions that allow for the facile synthesis of acyclic unsaturated aldehydes, chromenes, and dihydroquinolines as highly-desired heterocyclic scaffolds. Mechanistic investigations prompted strategic catalyst design to expand the scope of hydrazine-catalyzed carbonyl-olefin metathesis reaction. While the products obtained following ring-closing carbonyl-olefin metathesis protocols are similarly accessible in Lewis acid-catalyzed approaches, the unsaturated aldehydes resulting upon ring-opening carbonyl-olefin metathesis reactions are not, which renders this a particularly powerful and complementary transformation.

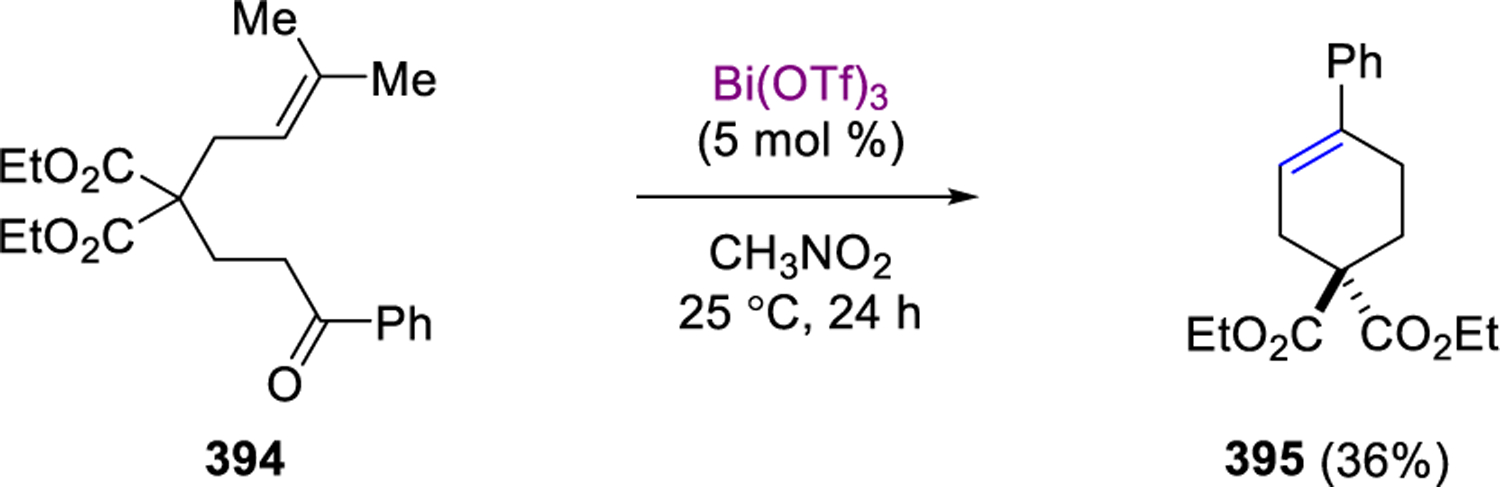

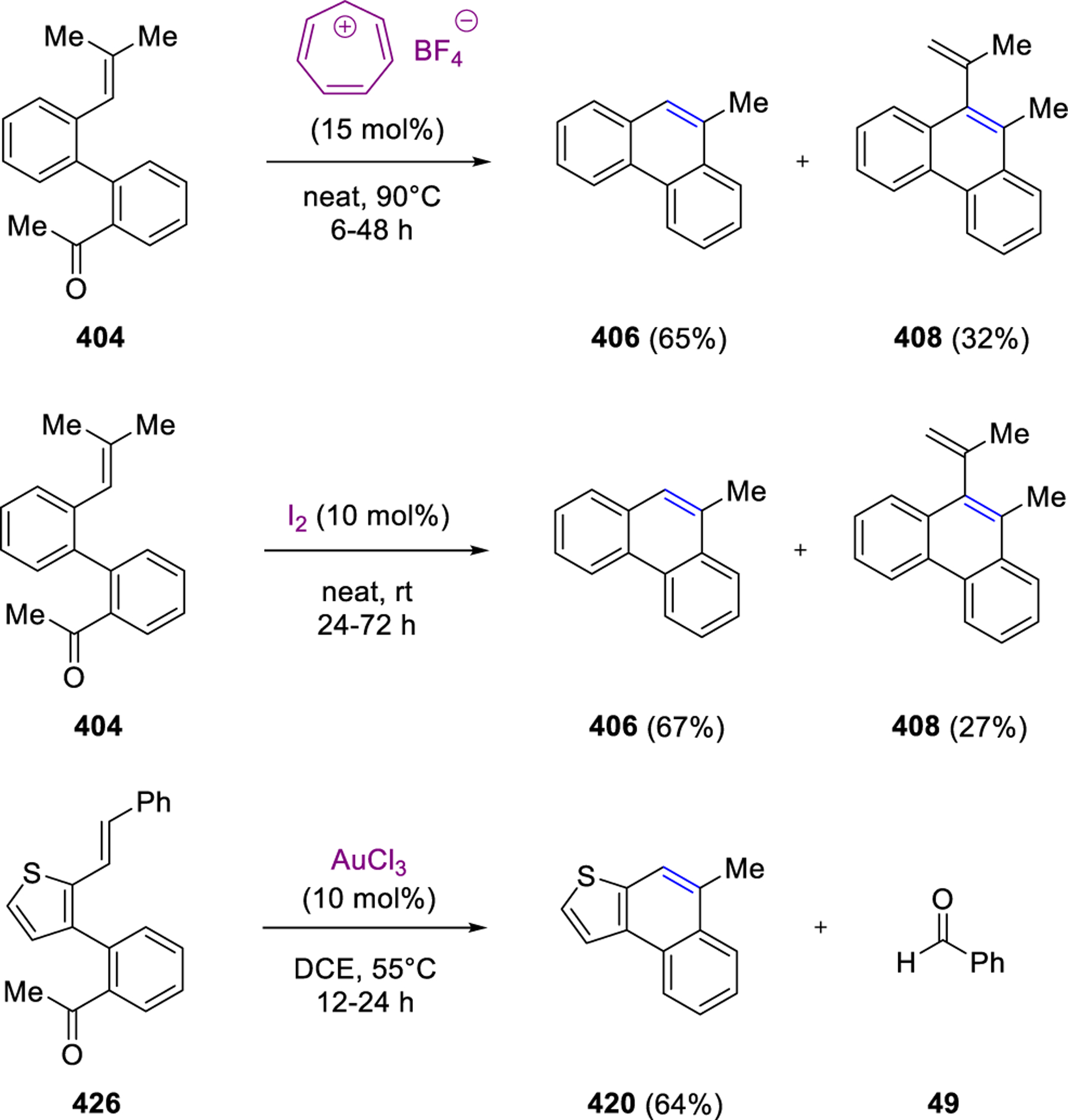

6. LEWIS ACID-CATALYZED CARBONYL-OLEFIN METATHESIS REACTIONS

In the early 1970s, the first reports appeared of carbonyl-olefin metathesis reactions between carbonyls and alkenes relying on equimolar amounts of Lewis acids. These transformations also proceed via initial [2+2]-cycloadditions between the alkene 1 and carbonyl 6 moieties to form intermediate oxetanes 8 (Figure 2A). However in comparison to previous stepwise protocols relying on Paternò-Büchi reactions and thus photochemical irradiation, Lewis acid-mediated approaches undergo in situ oxetane formation and fragmentation to provide the desired carbonyl-olefin metathesis products 4 and carbonyl byproducts 7 (Figure 2A). These transformations allow for broader applications and additional substrate complexity while proceeding under overall milder reaction conditions compared to originally reported carbonyl-olefin metathesis conditions based on oxetane pyrolysis.26,27 The Lewis acid takes on a dual role in these reactions to first activate the carbonyl substrate for a [2+2]-cycloaddition and subsequently the oxetane intermediate formed for a [2+2]-cycloreversion. Importantly, this reaction design principle relies on coordinative interactions between catalyst and substrate to forego the formation of metal-oxygen bonds and thus the formation of the corresponding oxidized metal-oxo species compared to metal alkylidene-mediated carbonyl-olefin metathesis approaches. Consequently, this design principle holds great potential as a catalytic strategy for carbonyl-olefin metathesis and has led to important advances in catalytic ring-closing, ring-opening, transannular and cross metathesis of alkenes and carbonyls (Scheme 49). This chapter provides an overview of carbonyl-olefin metathesis reactions initially mediated by Lewis acids, followed by a detailed discussion of currently available Lewis acid-catalyzed variants for each class of carbonyl-olefin metathesis reactions.

Scheme 49.

Lewis Acid-Catalyzed Carbonyl-Olefin Metathesis

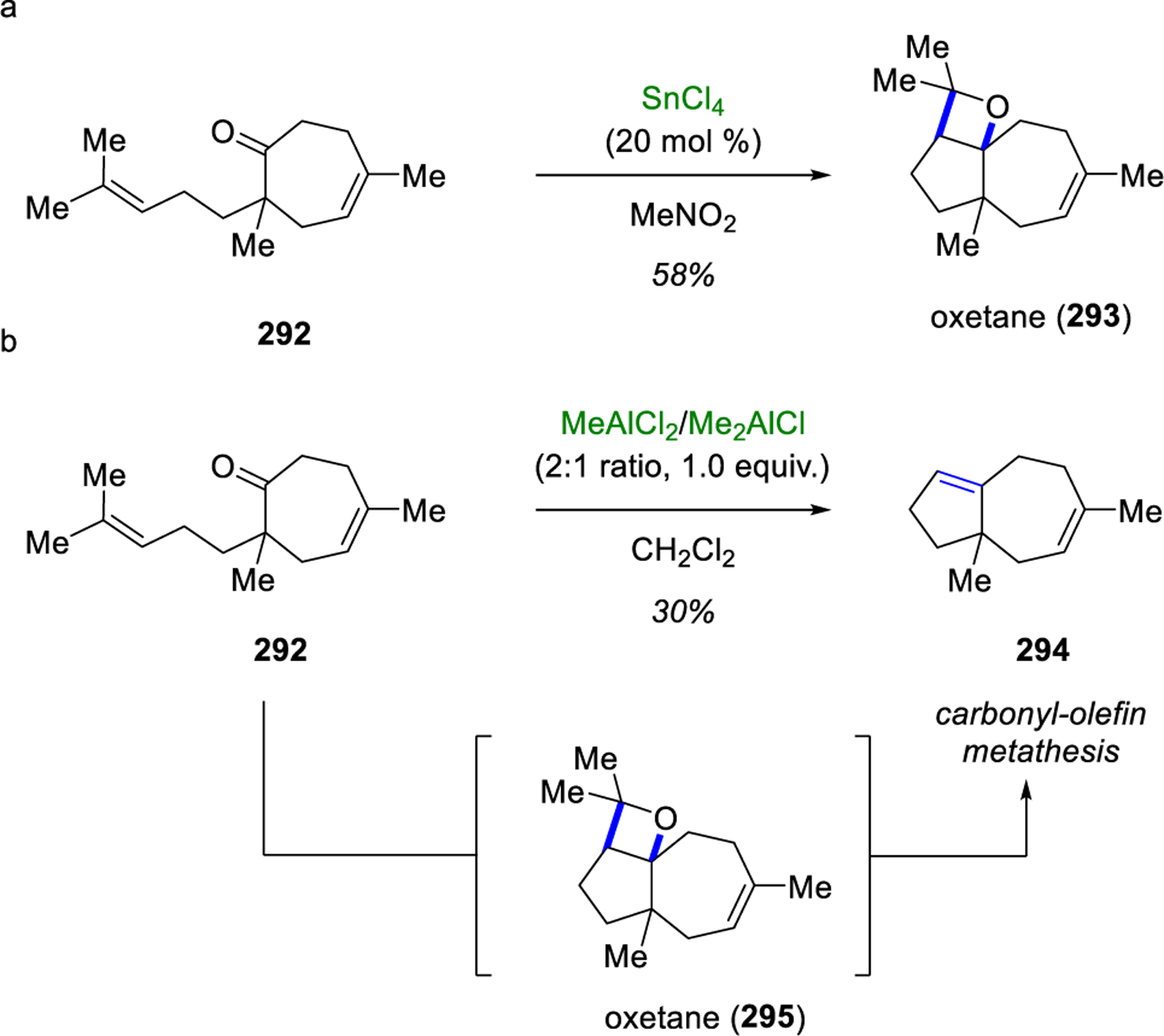

6.1. Lewis acid-Mediated Carbonyl-Olefin Metathesis

In their studies towards carbon sesquiterpenes, Demole, Enggist and Borer were the first to realize the potential of a one-pot procedure for oxetanes formation relying on Lewis acids. Specifically, cis-oxetane 293 was formed and isolated in 58% yield upon subjection of ketone 292 to 20 mol% SnCl4 via an intramolecular [2+2]-cycloaddition (Scheme 50a).93 Following this report, in 1984 Snider employed the use of the same substrate 292 in his studies of intramolecular ene reactions.94 The treatment of cycloheptanone 292 with stoichiometric amounts of a mixture of MeAlCl2/Me2AlCl in a 2:1 ratio provided the formation of metathesis product 294 in 30% yield (Scheme 50b). Snider proposed that the metathesis reaction proceeds through a stepwise cycloaddition to form oxetane 295 in situ followed by a retro-cycloaddition to provide the metathesis product 294 upon the loss of acetone. Interestingly, the reaction does not occur in the presence of Me1.5AlCl1.5, but a complex mixture is recovered when 292 is treated with stoichiometric amounts of MeAlCl2 indicating the significance of the strength of the Lewis acid in facilitating the carbonyl-olefin metathesis reaction.

Scheme 50.

Lewis acid-mediated metathesis reactions by Demole and Snider.

In 1994, the cross carbonyl-olefin metathesis reaction of benzaldehyde 49 and isobutylene 296 or methyl-2-butene 298 was reported by Bickelhaupt, van Schaik, and Vijn95 to provide yields of 15% and 30%, respectively, of metathesis products 297 and 299 (Scheme 51). A heterogeneous Lewis acid catalyst, EPZ-10,96 consisting of clay-supported ZnCl2 (12% ZnCl2 content) was used to promote metathesis in this reaction. Interestingly, higher temperatures and reactions times increased conversions but with accompanying byproduct formation. A stepwise mechanism is proposed (Scheme 51) that begins with Lewis acid activation of carbonyl 49, followed by nucleophilic addition of olefin 298 to form carbocation 300. An intramolecular addition results in the formation of oxetane 301 which, upon subsequent Lewis acid-assisted fragmentation, yields the carbonyl-olefin metathesis product 299. The reaction is reported to be limited to carbonyl compounds that lack α-hydrogen substituents due to resulting competing aldol condensation reactions with the acetone byproduct of the carbonyl-olefin metathesis reaction.

Scheme 51.

Solid Promoted Lewis Acid-Promoted Carbonyl-Olefin Metathesis by Bickelhaupt and Coworkers

A more complex example of carbonyl-olefin metathesis was reported by Khripach and coworkers in 2006 during their studies towards the synthesis of steroid frameworks.97 Specifically, carbonyl-olefin metathesis product 306 was produced in 60% yield following attempts by Khripach to protect the carbonyl moiety in seco-steroid 304 as a dithioketal upon treatment with excess BF3·OEt2 (Scheme 52). Interestingly, the corresponding Z-olefin isomer 307 failed to undergo the carbonyl-olefin metathesis reaction under identical reaction conditions. The suggested mechanistic hypothesis for this transformation includes an intramolecular, Lewis acid-assisted [2+2]-cycloaddition and cycloreversion of the resulting intermediate oxetane 305.

Scheme 52.

Lewis Acid-Promoted Transannular Carbonyl-Olefin Metathesis by Khripach and Coworkers

In their work towards marine natural product pestalone, Schmalz and coworkers attempted to deprotonate the ether subunits in ortho-prenylated benzophenone and instead detected the formation of an indene-derived metathesis product in 20% yield.98 Subsequent optimization efforts provided 87% yield for the resulting carbonyl-olefin metathesis products with the optimal conditions requiring 1.5 equivalents of BF3·OEt2 in DCM at −40 °C after one hour (Scheme 53). Further application of this protocol was investigated for a series of acetophenone derivatives. Specifically, substrates bearing prenyl (310), geranyl (312) and homoprenyl substituents (313) in the ortho position provided 38–87% yield of the desired carbonyl-olefin metathesis products containing 5- and 6-membered cycloalkenes (311 and 314, Scheme 53). The authors propose a stepwise mechanism for this transformation that relies on initial exo-trig cyclization of 315 following Lewis acid activation of the carbonyl moiety (Scheme 53). Tertiary carbocation 316 is then formed and isomerizes to the more stable benzylic carbocation 317 via an intermediate oxetane. Lastly, fragmentation of carbocation 318 results in the formation of indene 311 as the desired carbonyl-olefin metathesis product with acetone as the byproduct.

Scheme 53.

BF3·OEt2 Induced Metathesis Cyclization of Pestalone Derivatives by Schmalz and Coworkers

6.2. Catalytic Carbonyl-Olefin Ring-Closing Metathesis of Aryl Ketones

Despite the fact that acid-mediated carbonyl-olefin metathesis reactions have been reported in the literature over the last 40 years, acid-catalyzed carbonyl-olefin metathesis reactions have only recently been realized. Lewis acids have now been employed allowing for a catalytic pathway as they activate the carbonyl moiety making it more electrophilic for the nucleophilic attack of the olefin moiety. The coordinating nature of Lewis acids allows for catalyst turnover to occur whereas loss of H+ of Brønsted acids or metal-oxo species in metal alkylidene promoted metathesis reactions, did not allow for this turnover. This section outlines the application of Lewis acids26,27,99–102 towards catalytic carbonyl-olefin ring-closing metathesis reactions relying on aryl ketone substrates.

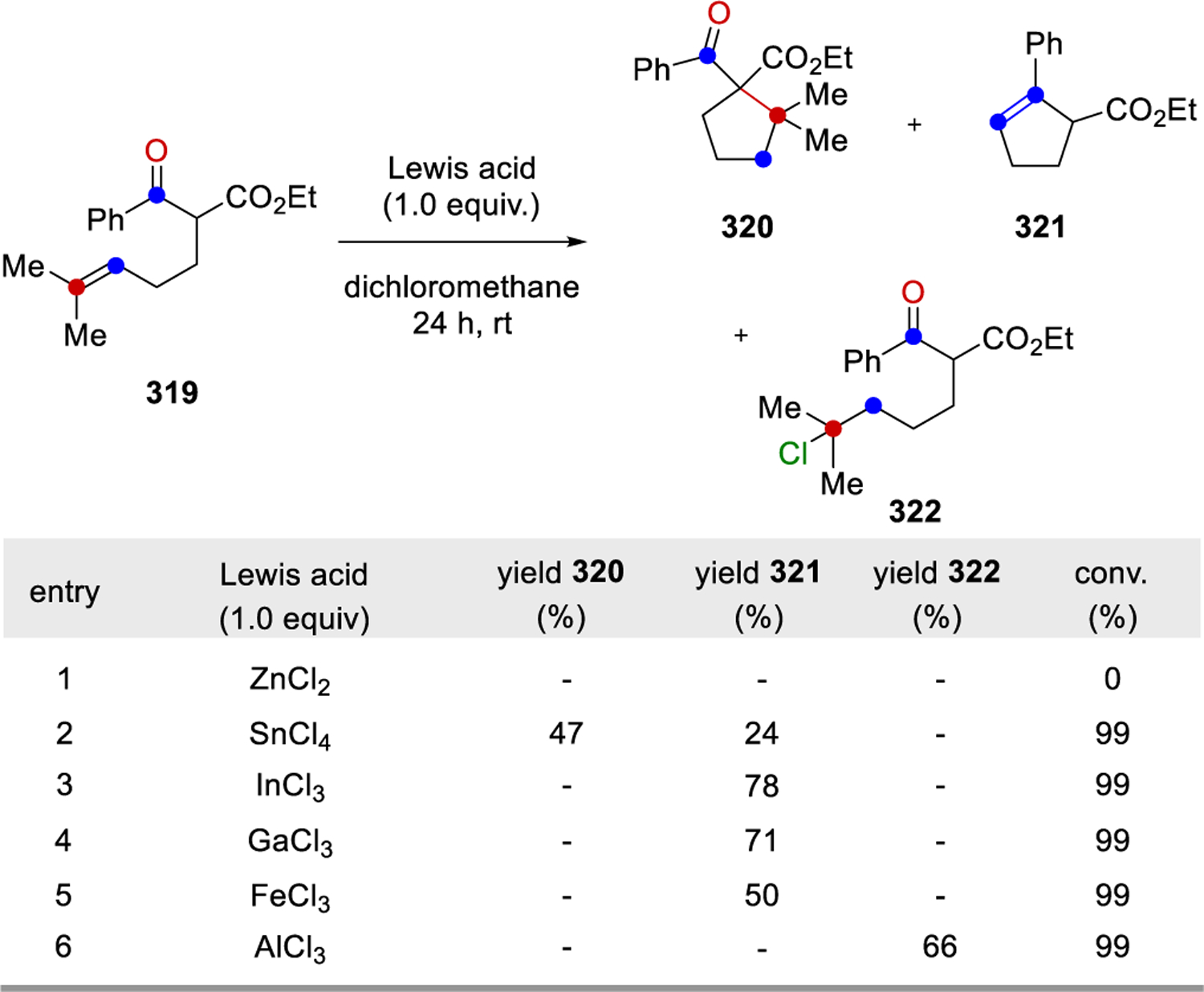

6.2.1. Formation of 5-Membered Rings

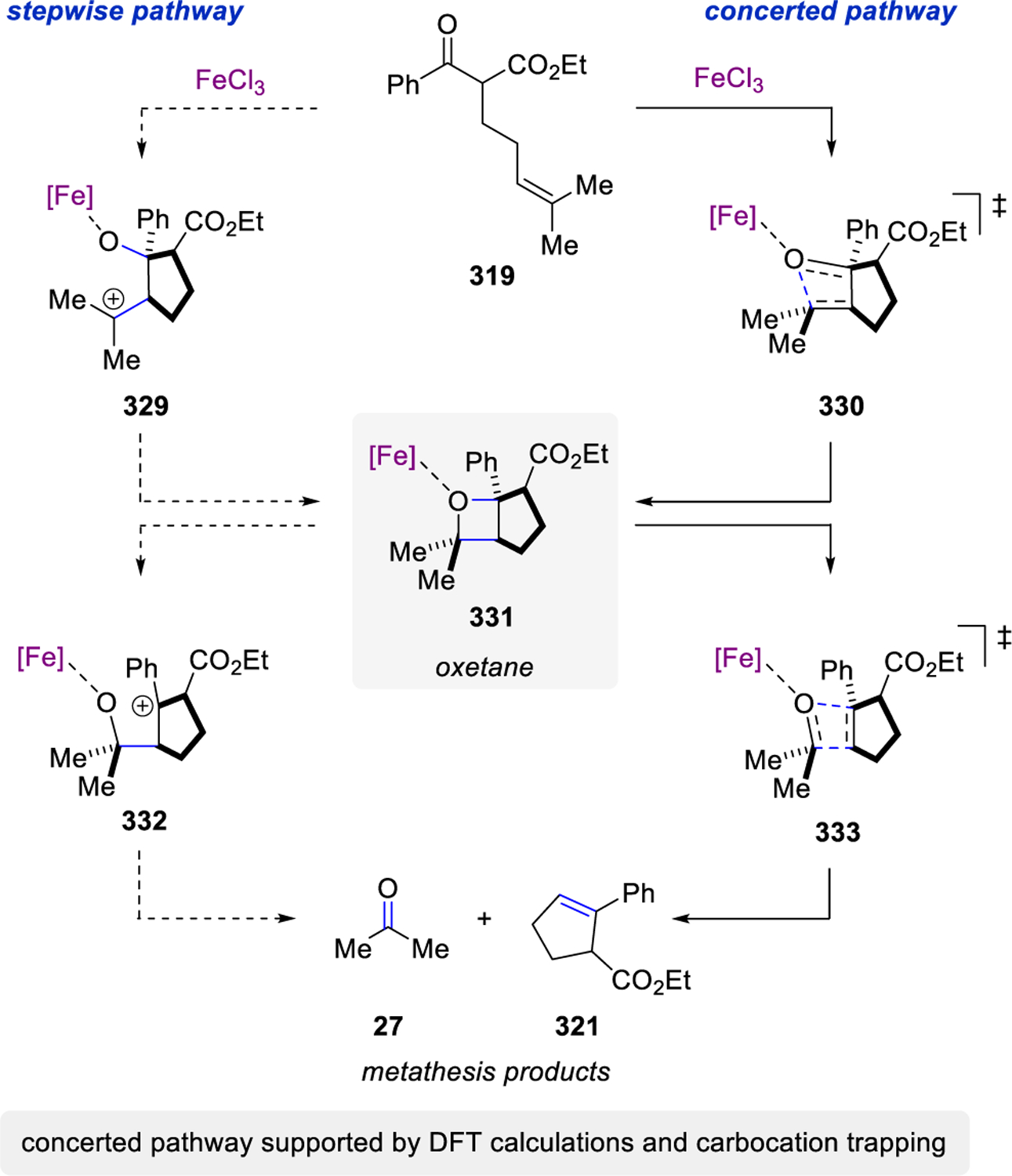

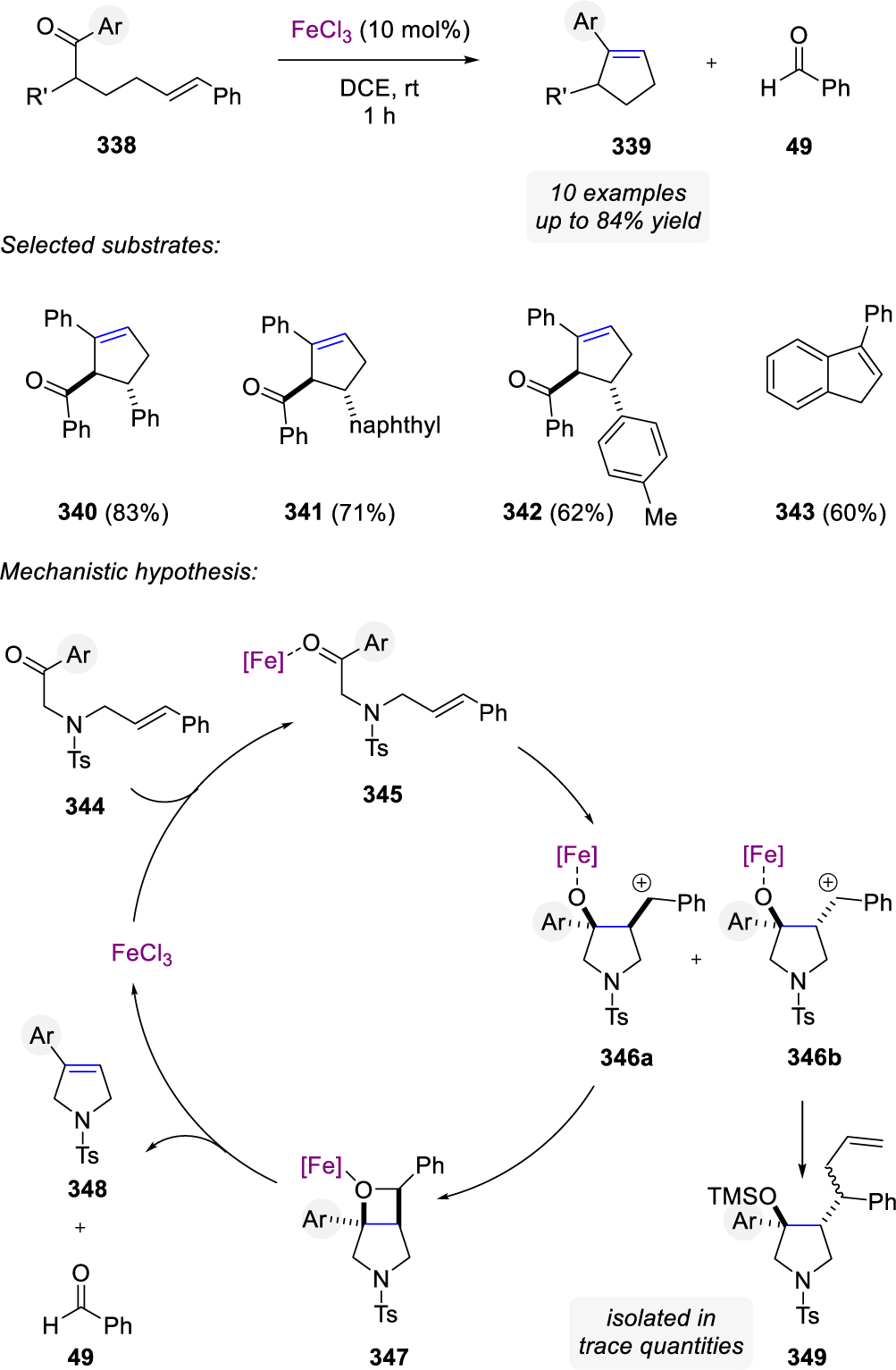

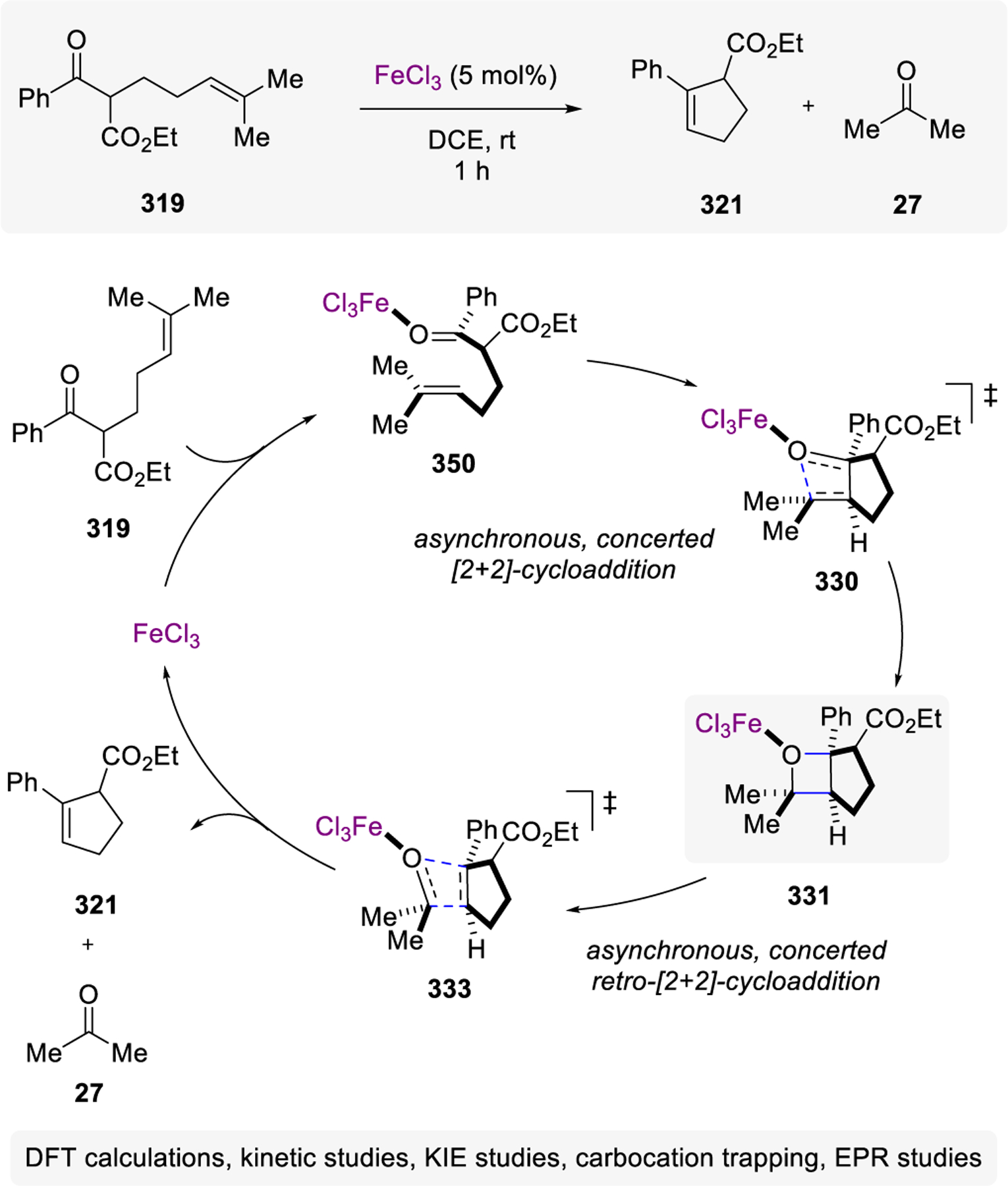

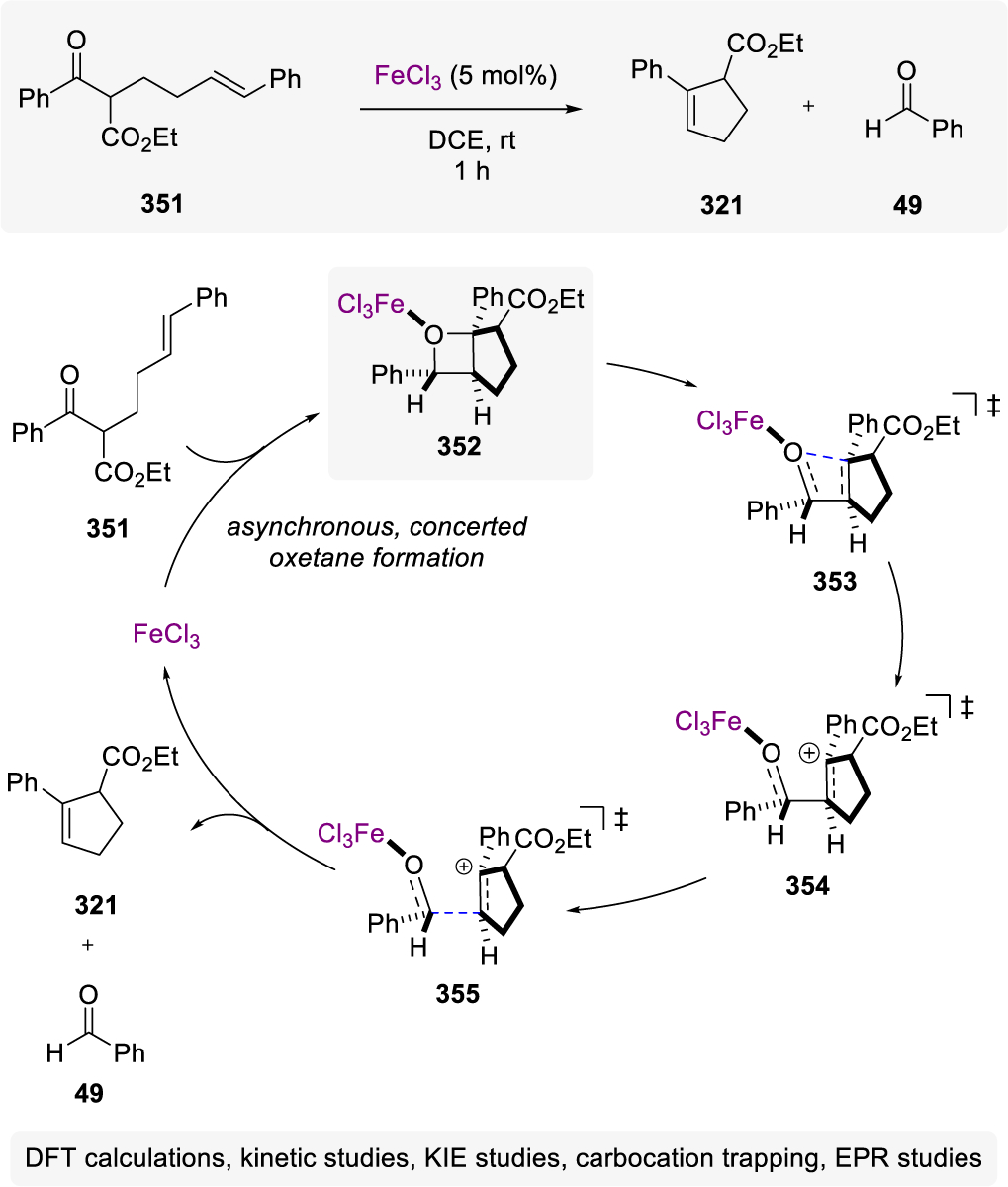

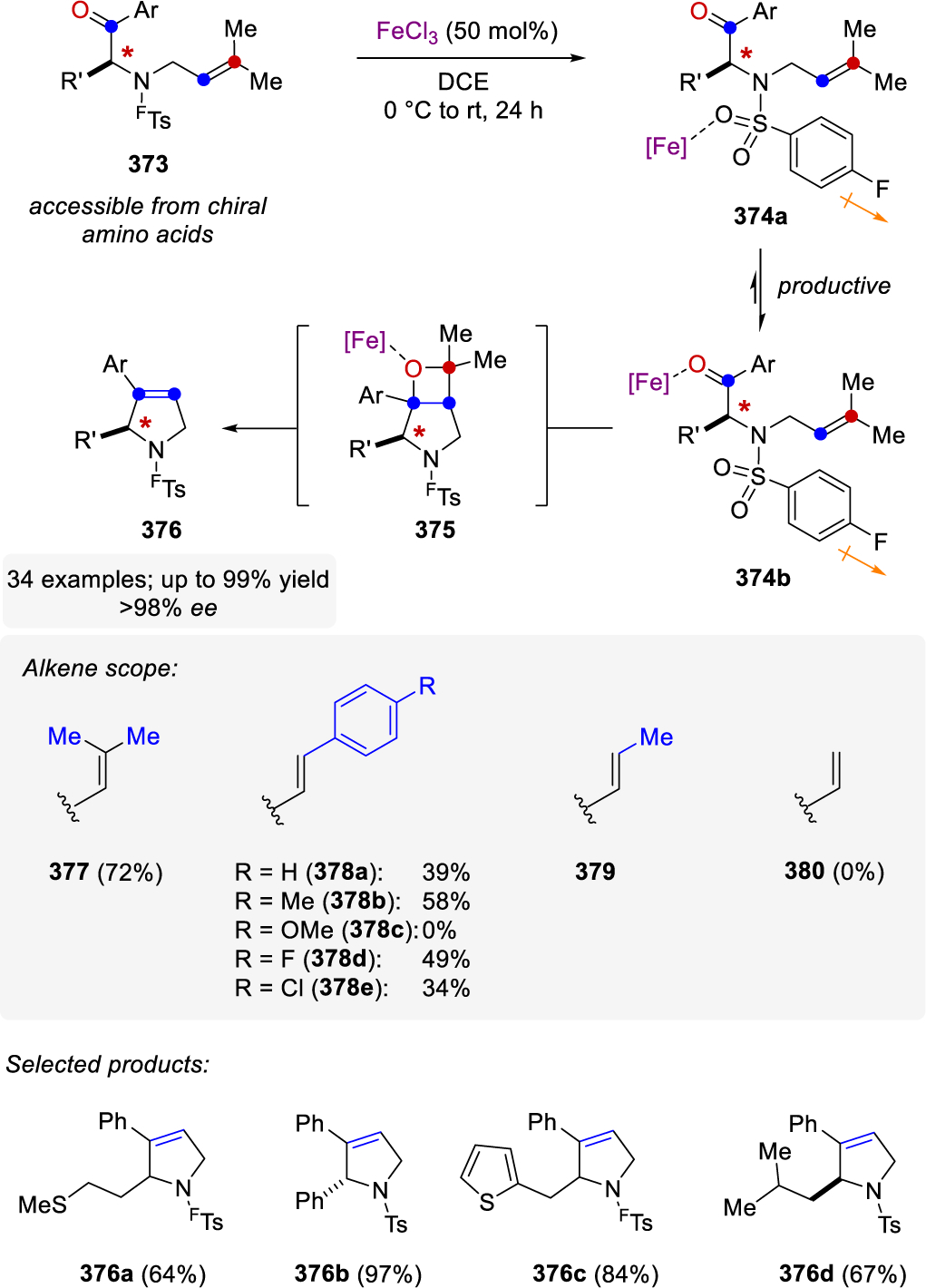

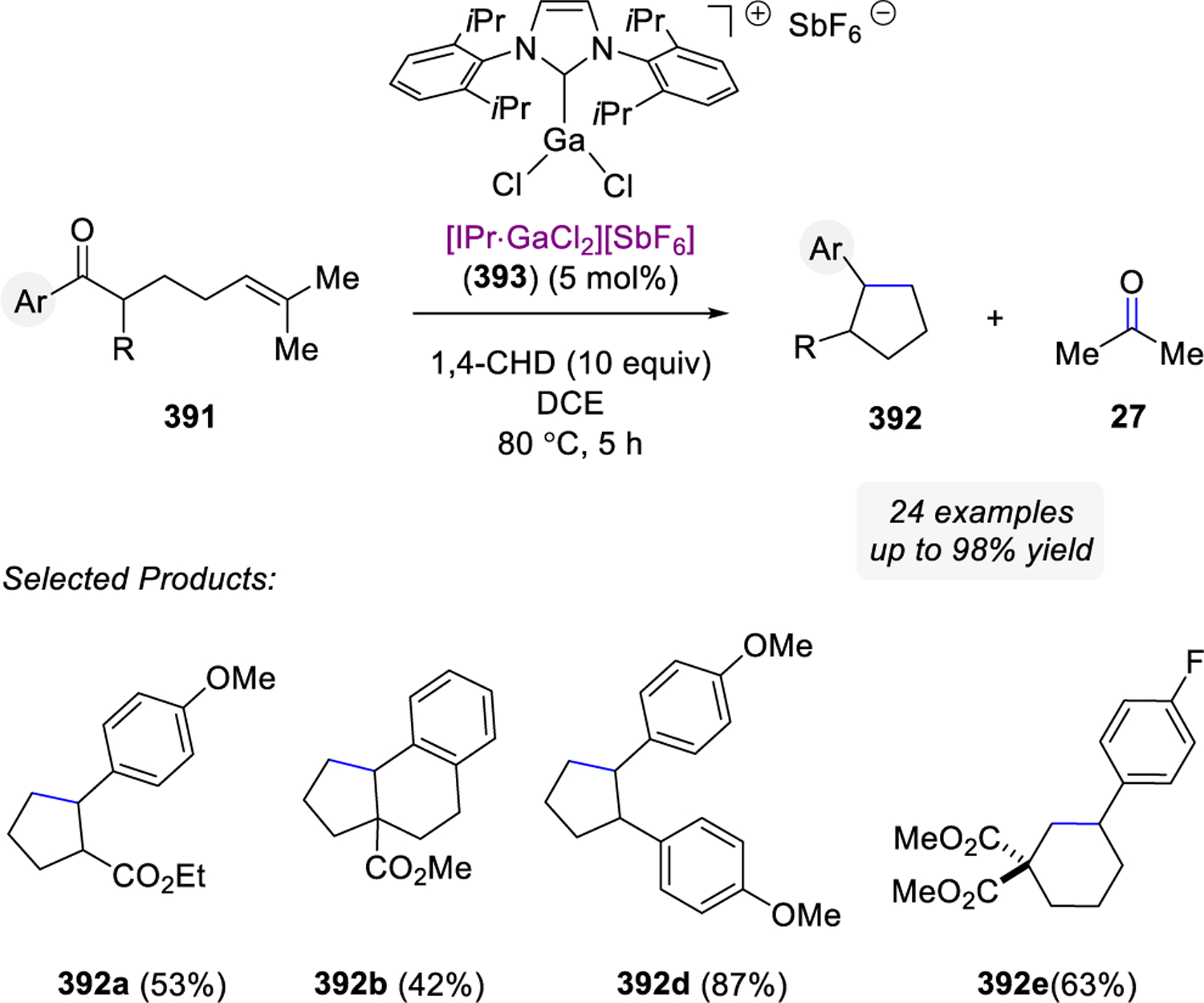

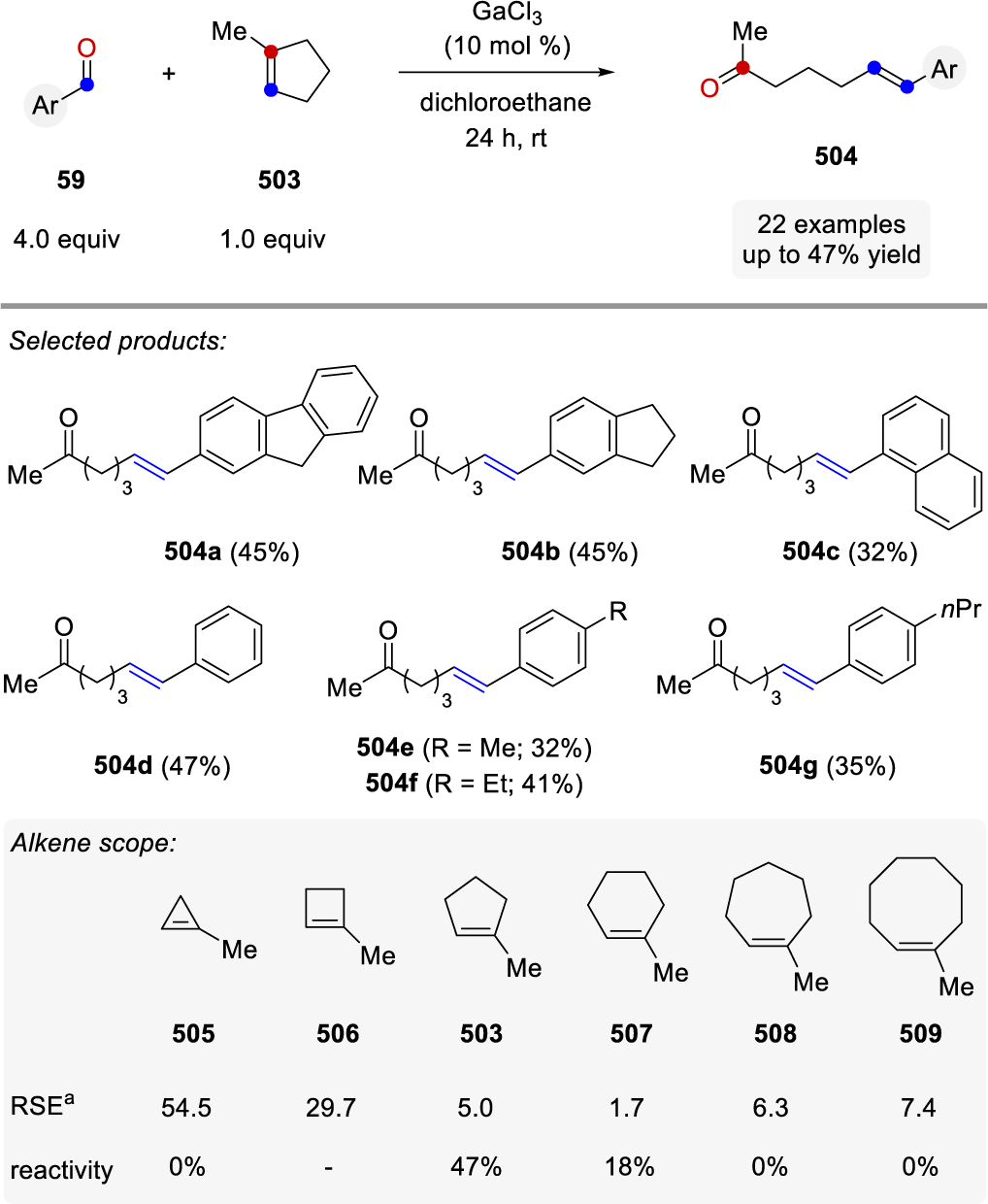

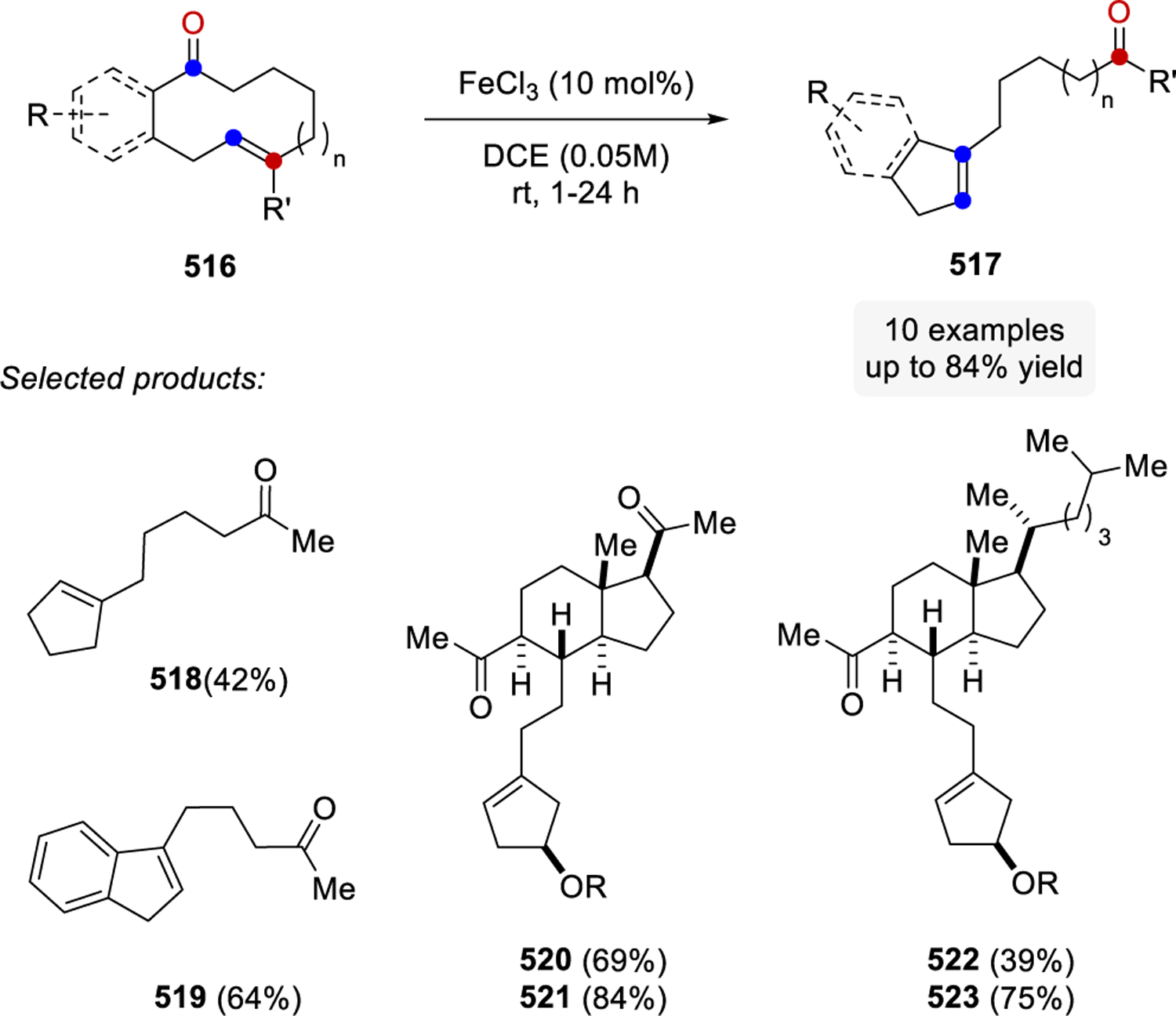

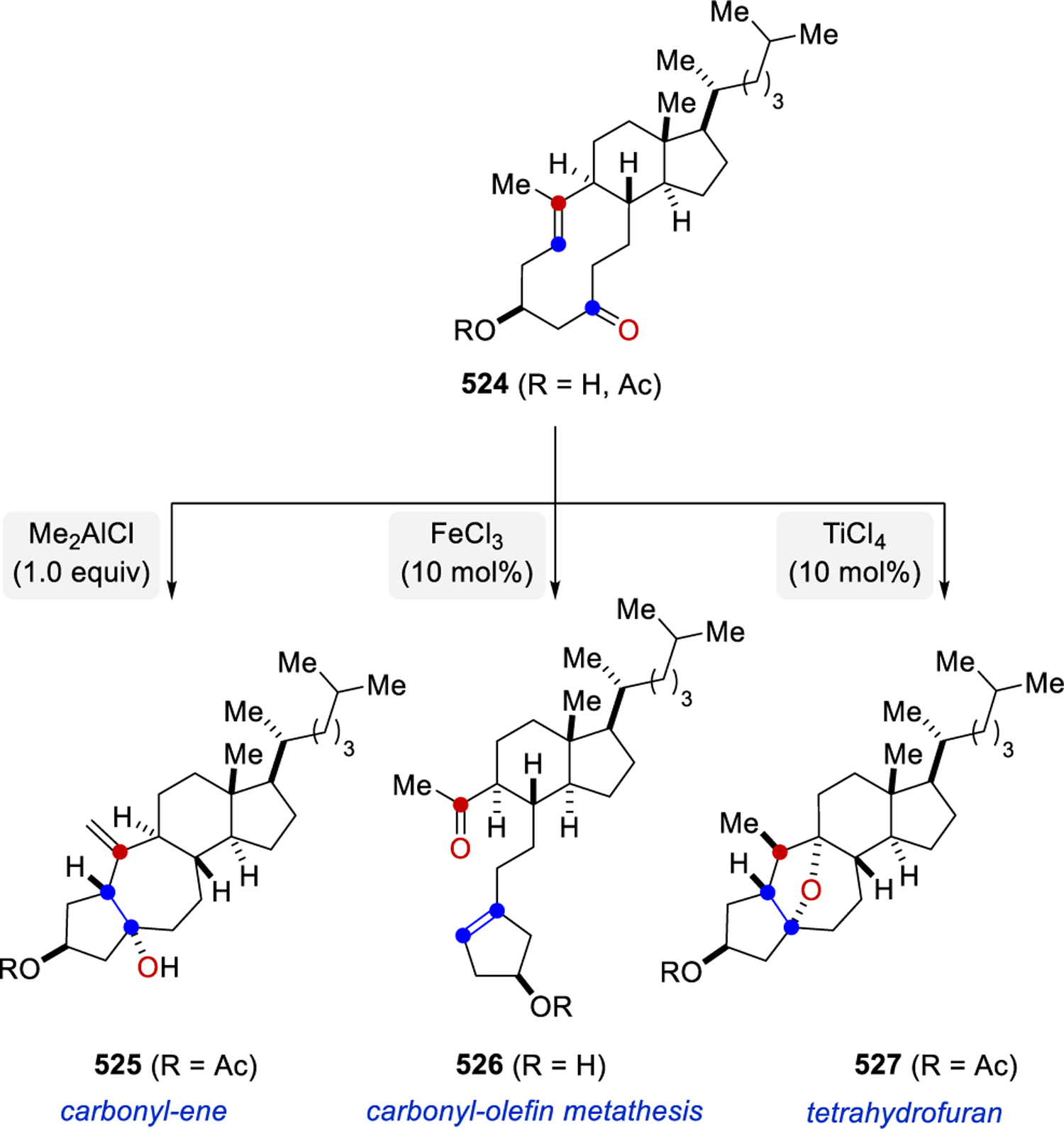

In 2016, Schindler and co-workers reported a carbonyl-olefin ring-closing metathesis reaction relying on FeCl3 as Lewis acid catalyst, which proved uniquely effective for the synthesis of 5-membered rings.99–102,103,104 Initial studies relied on the investigation of β-ketoester 319 with a variety of distinct Lewis acid in stoichiometric reactions (Scheme 54). While weak Lewis acids, such as ZnCl2, resulted in no reactivity, strong Lewis acids including AlCl3 formed the hydrochlorination product 322 exclusively in 66%. Importantly, several Lewis acids, such as SnCl4, InCl3, GaCl3, and FeCl3 proved capable in promoting the desired carbonyl-olefin metathesis reaction while FeCl3 proved superior and resulted in quantitative formation of cyclopentene 321.

Scheme 54.

Initial Studies of Carbonyl-Olefin Ring-Closing Metathesis by Schindler and Coworkers Show Several Lewis Acids Capable of Promoting the Desired Transformation

Reaction conditions relying on catalytic quantities of FeCl3 (5 mol%) in dichloroethane at room temperature were ultimately identified as optimal (Scheme 55). While prenylated alkenes (325) proved superior and formed the desired carbonyl-olefin ring-closing metathesis products quantitatively, styrene derivatives (326a, 327) and their electron-rich (326b) and electron-poor analogs (326c-d) formed the metathesis products in 49 to 70% yield. Importantly, (Z)-styrene (328) was identified as a viable substrate in FeCl3-catalyzed carbonyl-olefin ring-closing metathesis reactions albeit resulting in lower yields than the corresponding (E)-analog 326a. The initial report by the Schindler laboratory included 38 examples of 5-membered rings systems formed in up to 97% yield, while a limited number of successful 6-membered ring formations were shown to proceed in up to 71% yield. Notably, several functional groups, including esters, amides, ethers, lactones, halogens, and sulfones were tolerated well under the optimal reaction conditions resulting in a variety of structurally distinct cyclic products.

Scheme 55.

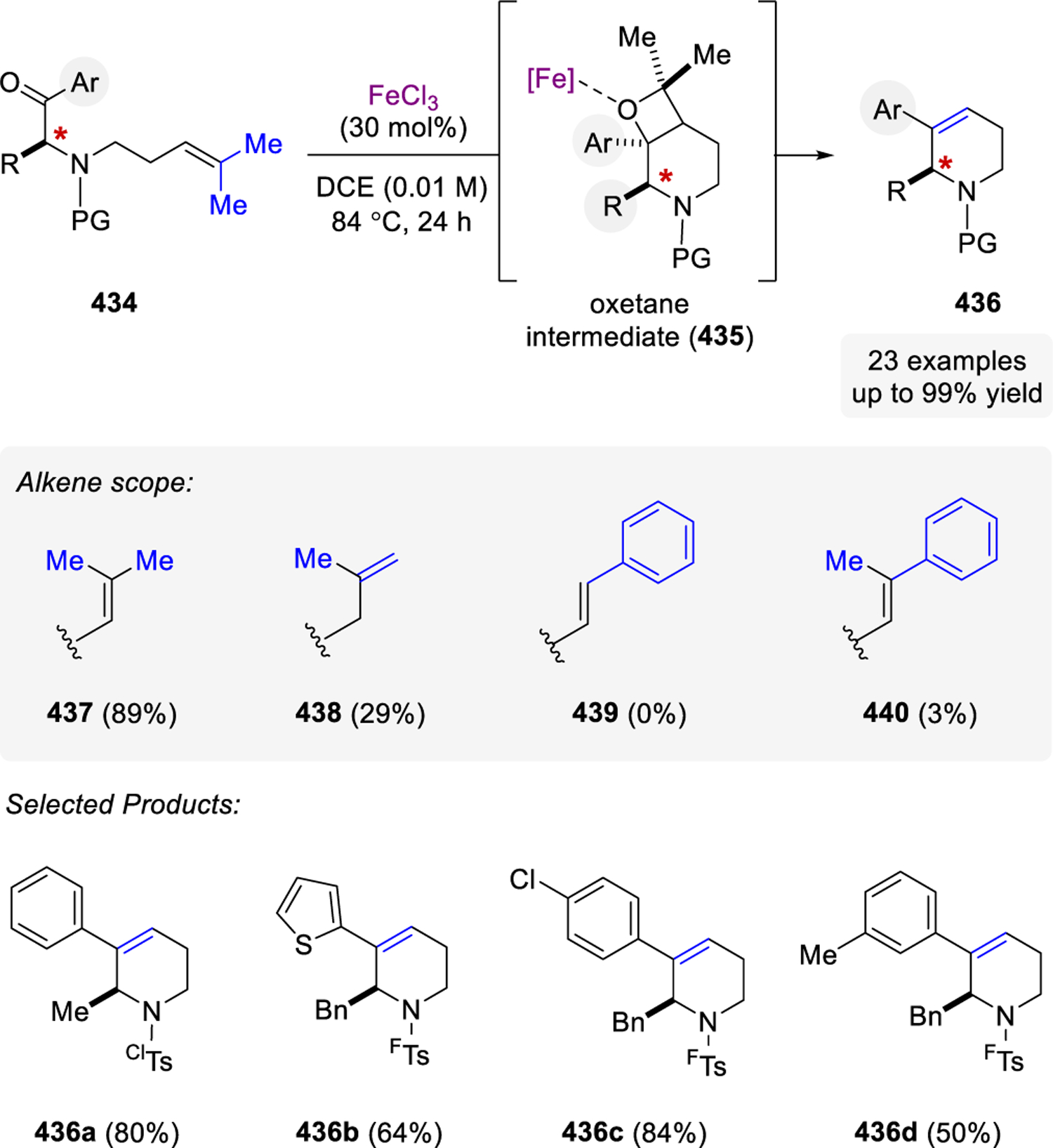

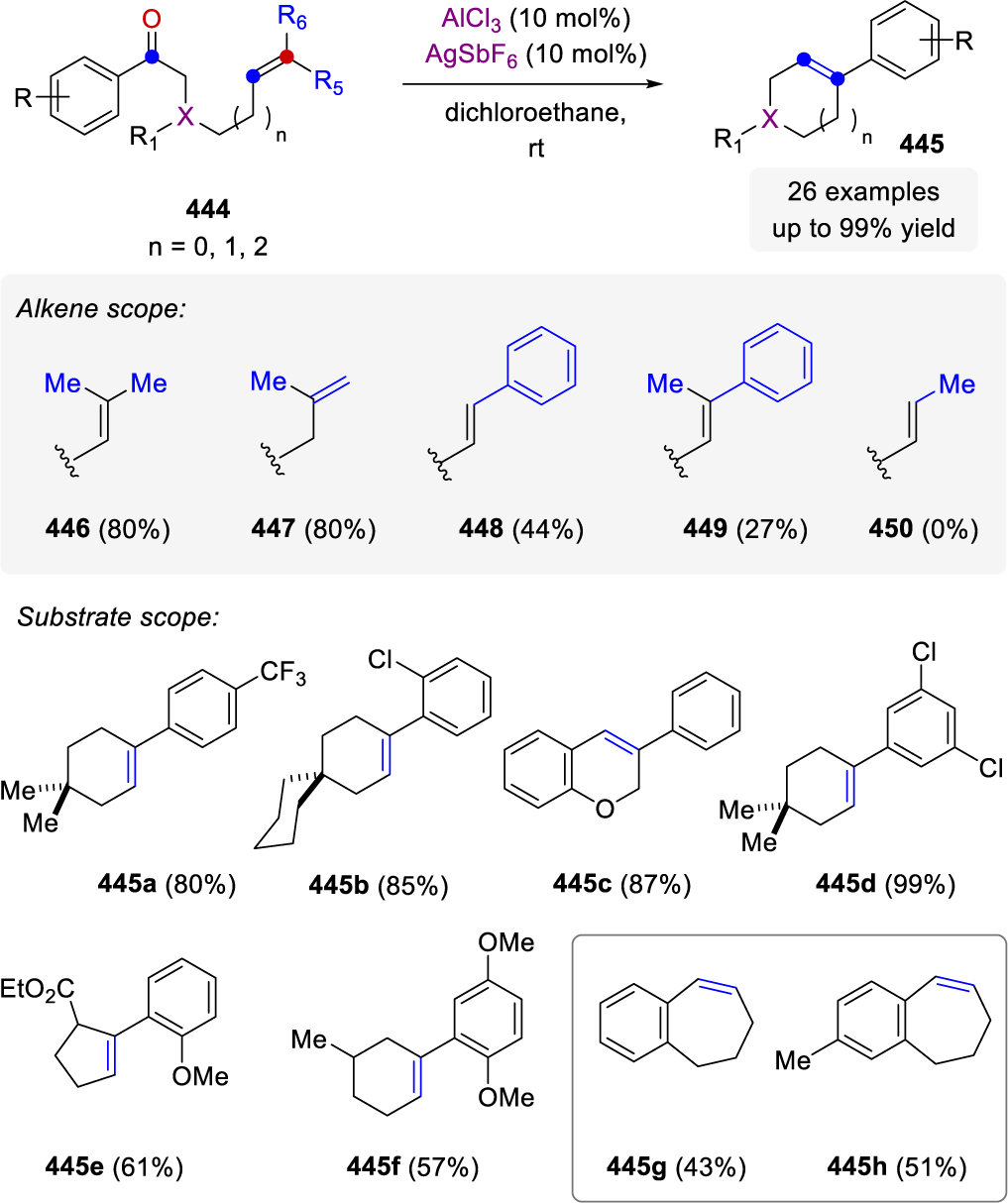

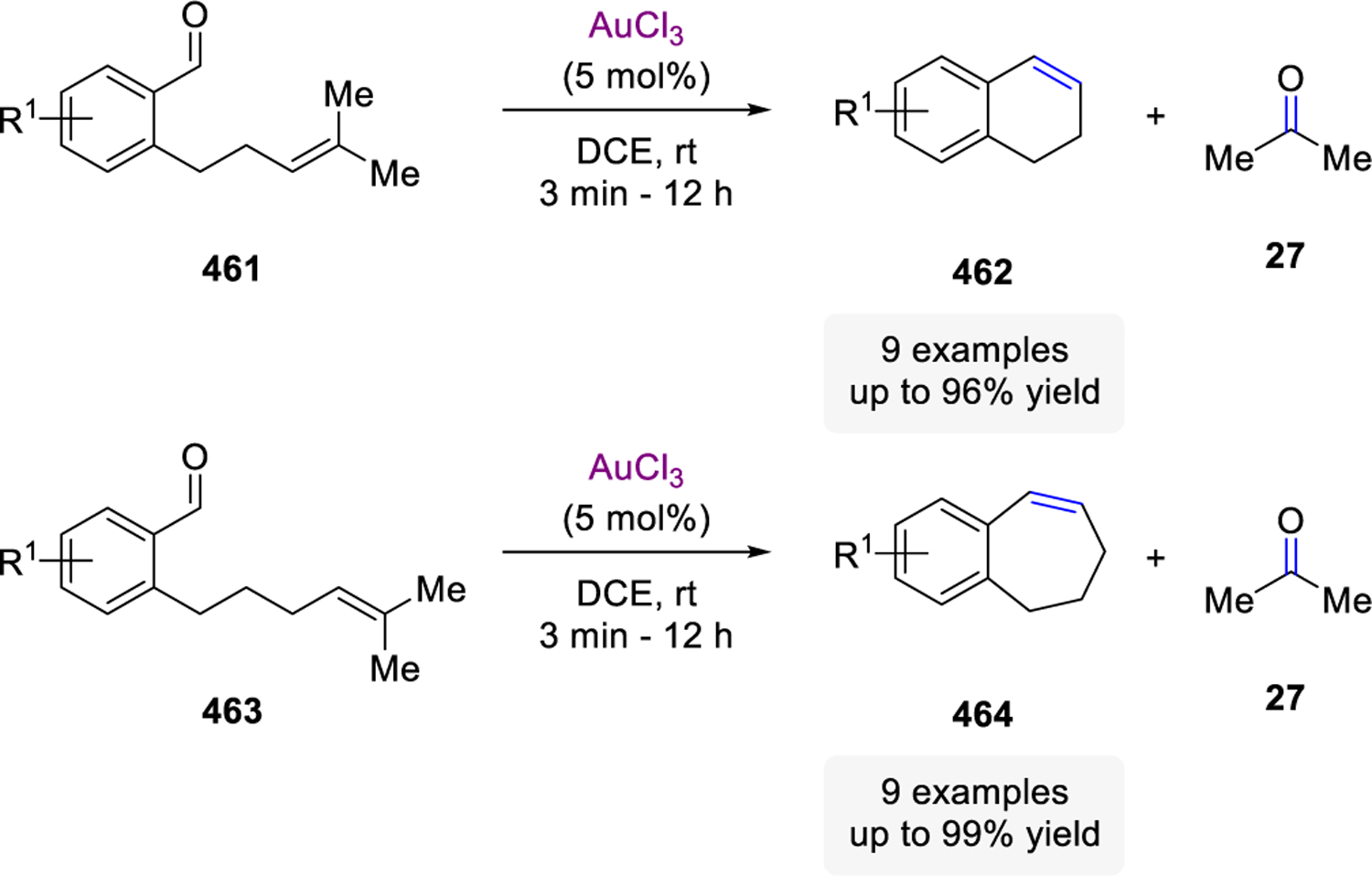

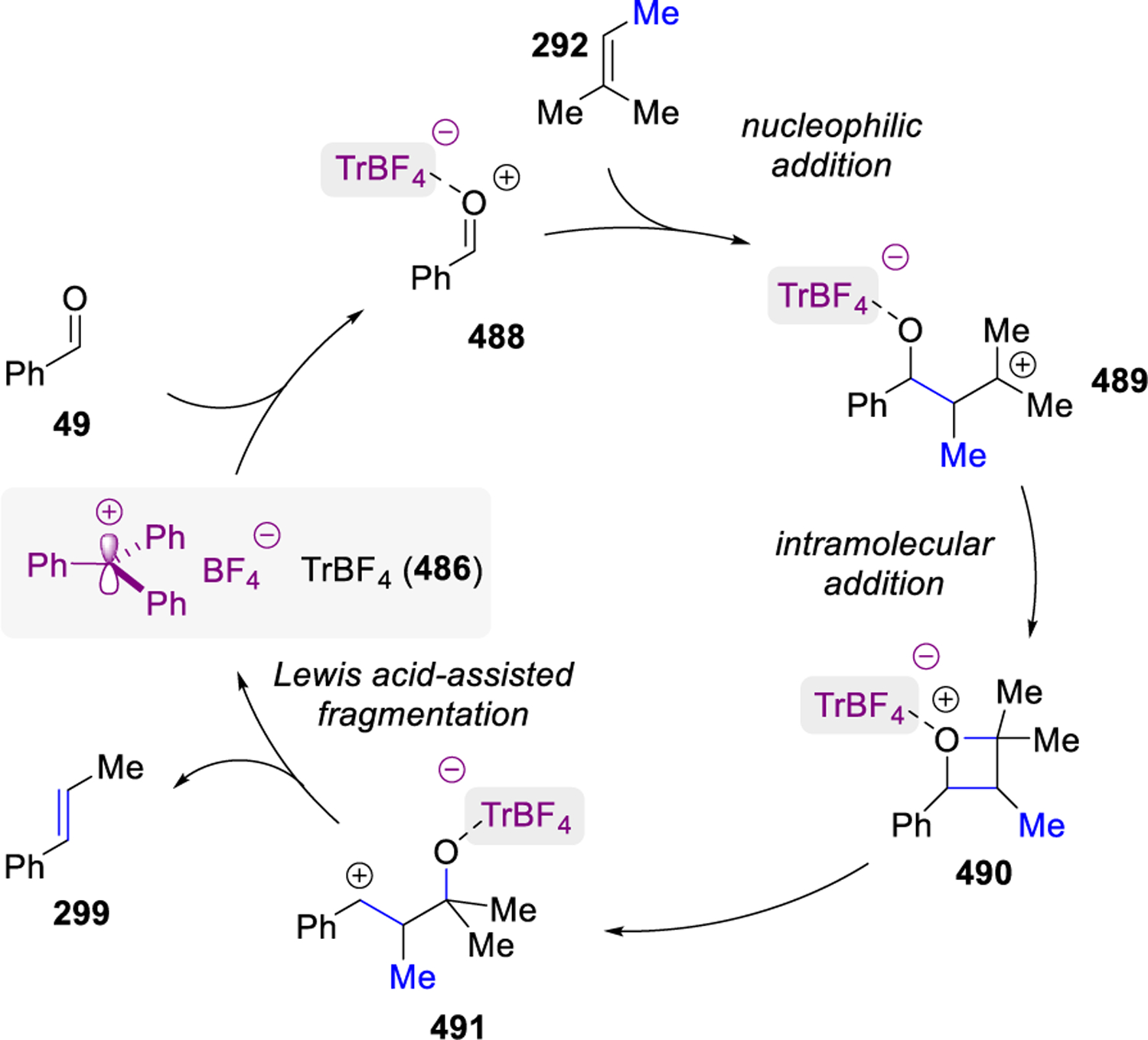

Scope of the FeCl3-Catalyzed Carbonyl-Olefin Ring-Closing Metathesis Reaction