Abstract

The European Commission has asked the EFSA to evaluate the risk for animal health related to the presence of hydroxymethylfurfural (HMF) in honey bee feed. HMF is a degradation product of particular sugars and can be present in bee feed. HMF is of low acute toxicity in bees but causes increased mortality upon chronic exposure. A benchmark dose lower limit 10% (BMDL10) of 1.16 μg HMF per bee per day has been calculated from mortalities observed in a 20‐day study and established as a Reference Point covering also mortality in larvae, drones and queens for which no or insufficient toxicity data were available. Winter bees have a much longer lifespan than summer bees and HMF shows clear time reinforced toxicity (TRT) characteristics. Therefore, additional Reference Point intervals of 0.21–3.1, 0.091–1.1 and 0.019–0.35 µg HMF/bee per day were calculated based on extrapolation to exposure durations of 50, 90 and 180 days, respectively. A total of 219 analytical data of HMF concentrations in bee feed from EU Member States and 88 from Industry were available. Exposure estimates of worker bees and larvae ranged between 0.1 and 0.48, and between 0.1 and 0.51 μg HMF/per day, respectively. They were well below the BMDL10 of 1.16 μg HMF/bee per day, and thus, no concern was identified. However, when accounting for TRT, the probability that exposures were below established reference point intervals was assessed to be extremely unlikely to almost certain depending on exposure duration. A concern for bee health was identified when bees are exposed to HMF contaminated bee feed for several months.

Keywords: Hydroxymethylfurfural, bee feed, honey bees, risk assessment

Summary

Following a request from the European Commission, the European Food Safety Authority (EFSA) Panel on Contaminants in the Food Chain (CONTAM Panel) evaluated the risks for animal health related to the presence of hydroxymethylfurfural (HMF) in feed for honey bees. Relevant general EFSA guidance and specific guidance for honey bees were applied for the risk assessment conducted in this opinion. The draft Opinion underwent a public consultation from 3 December 2021 to 10 February 2022. The comments received and how they were taken into account when finalising the scientific Opinion are available in Annex A to this scientific Opinion.

5‐Hydroxymethylfurfural (HMF) is a degradation product of hexoses and is present in honey and various bee feeds. Commercially available bee feeds contain either sucrose or mixtures of glucose and fructose and may contain varying levels of HMF depending on the conditions of production and use. The most important parameters for HMF formation in bee feeds are the type of sugar used, pH, temperature, water activity and concentration of divalent cations of the media. HMF is determined by spectrometric and chromatographic methods.

While the toxicokinetics of HMF are well investigated in mammals, no information on the toxicokinetics of HMF in honey bees could be identified. Several experimental studies have been carried out in which the effect of oral uptake of HMF in bees on mortality/survival was investigated and the concentrations of HMF causing mortality in experimental studies varied between 150 and 750 mg/kg bee feed. It was observed that HMF induced mortality in bees strongly aggravates with exposure time. However, field studies with bees ingesting HMF containing bee feed suggest that feeding with concentrations between 40 and 150 mg HMF/kg bee feed is not detrimental to bee colonies.

The mode of action by which HMF induces bee mortality has not been elucidated but it has been shown that HMF causes histopathological effects in the midgut of bees which were paralleled by increased mortality.

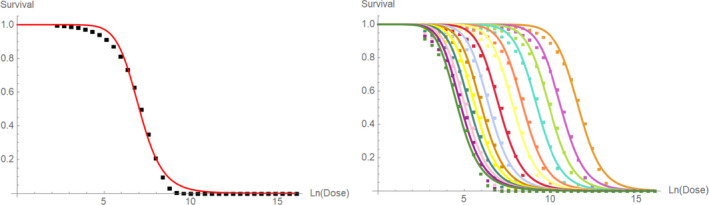

Based on the absence of acute toxicity even at high doses, HMF is considered to be of low acute toxicity. Increased mortality (decreased survival) rate has been identified as the critical chronic effect of HMF in bees. Three experimental studies have been identified as suitable for assessing the chronic concentration/dose response in worker bees. A benchmark response (BMR) of 10% was identified as appropriate for the critical endpoint. Benchmark doses lower limit 10% (BMDL10) of 32.7 μg/bee per day, 1.16 μg/bee per day and of 18.0 μg/bee per day were calculated from each of the three studies. A reference point (RP) of 1.16 μg HMF/bee per day was derived based on the lowest BMDL10 seen in the three suitable studies. This was considered as the primary BMDL10 for risk characterisation, even though it was substantially lower than the BMDL10 obtained from the other two studies suitable for risk assessment. The RP of 1.16 μg HMF/bee per day also covers HMF‐induced mortality in larvae, drones and queens for which no or only insufficient data are available.

Since analyses indicated that HMF has clear time reinforced toxicity (TRT) characteristics, additional RPs were established. Based on extrapolation factors calculated from results associated with the TRT assessment adjusted RP intervals, reflecting uncertainty across the two studies used for the TRT assessment, of 0.21–3.1, 0.091–1.1, 0.019–0.35 µg/bee per day were derived for exposure durations of 50, 90 and 180 days, respectively.

A total of 219 analytical samples of bee feed from three different European Member States and 88 analytical results with bee feed from a European company were available. Data on consumption of bee feed were not available. Therefore, the default consumption value of 8.8 mg sugar/bee for thermoregulation of worker bees from the respective EFSA opinion on risk assessment for pesticides in bees was used for the exposure assessment. For larvae, a consumption value of 9.3 mg sugar per day reported in the public literature was used for exposure assessments. To calculate the feed intakes for the exposure assessment, a 72% dry matter content was used.

Exposure scenarios for worker bees have been calculated with the HMF levels reported in the data sets from Member States (data set A) and Industry (data set B) assuming exclusive consumption of bee feed and using consumption values as described above. For worker bees, using average HMF concentrations, the highest exposure estimates at lower bound/upper bound (LB/UB) were 0.47/0.48 μg/bee per day for the subset of complementary feed (n = 95) from European Member States (data set A). When combining the data on complementary feed, complete feed and sugar syrup (n = 216), an exposure of 0.32/0.33 μg HMF/bee per day was obtained. Using the data from Industry (data set B), exposures, depending on storage time of bee feed, varied between 0.29 and 0.34 μg/bee per day. For larvae, exposure estimates at LB/UB were 0.50/0.51 μg/larva per day for complementary feed. With the complete data set from European Member States, an exposure of 0.34 μg/larva per day was derived. Using Industry data, exposures, depending on storage time of bee feed, ranged between 0.31 and 0.44 μg HMF/larva per day.

Considering a brand loyalty exposure scenario using the P95 concentrations from data set A driven by a few exceptionally high occurrence values which are about an order of magnitude higher than those usually observed in bee feed and which are likely the result of inappropriate production/storage conditions of the feed, P95 exposures of worker bees/larvae of up to 4.40 and 4.65 μg HMF per day could result.

The range of mean exposure scenarios for worker bees across data sets A and B in was 0.1–0.48 μg/bee per day, are all below the RP of 1.16 μg HMF/bee per day. Based on the uncertainty analysis, it is regarded almost impossible (probability < 1%) that the reference point for 20 days of exposure is exceeded. Considering the mortality rates that would trigger a concern for bee health as laid down in the protection goals defined for honey bees (i.e. a 10% reduction in colony size), the CONTAM Panel did not identify a concern for the health of worker bees due to exposure to HMF via bee feed. For larvae, where exposure scenarios ranged from 0.1 to 0.51 μg/larva per day, also no health concern was identified, even more so since larvae are not directly exposed to bee feed but only via the feeding nurses, and thus, actual exposures of larvae to HMF are likely to be much lower. No data on toxicity or exposure for queen and drones are available, but it can be confidently assumed that the assessment for worker bees is sufficiently conservative to also cover these bee casts.

Accounting for TRT, the range of exposure scenarios for adult bees (i.e. 0.1–0.48 μg/bee per day) is not fully below the reference point intervals established for prolonged exposures. Based on the uncertainty analysis, it is regarded extremely unlikely to unlikely (probability in the range of 2–16%) that the adjusted RP for 50 days of exposure is exceeded. It is regarded unlikely, to about as likely as not (probability of about 20–50%) that the adjusted reference point for 90‐day exposure is exceeded. It is considered about as likely as not, to almost certain (probability about 60–100%) that the adjusted reference point for 180 days of exposure is exceeded. Therefore, the CONTAM Panel identified a potential concern for the health of bees when exposed to HMF in bee feed for several months.

A brand loyalty exposure scenario using the P95 concentrations from data set A driven by a few exceptionally high HMF levels in bee feed which are likely the result of inappropriate production/storage conditions of the feed would lead to exposures greatly exceeding the primary and the TRT reference points.

A concentration of 95 mg HMF/kg bee feed would lead to a calculated daily exposure of 1.16 μg HMF per day and thus not of concern for worker bees. For larvae, the corresponding figure is 91 HMF/kg bee feed. In the absence of data, the concentration that is safe for worker bees also applies for drones and queens. Considering adjusted reference point intervals derived on the basis of the TRT assessment concentrations of 131, 49 and 15 mg HMF/kg bee feed were calculated for daily exposures of 1.59, 0.59 and 0.18 μg HMF, respectively, at feeding days 50, 90 and 180 (the daily exposures correspond to the arithmetic averages of adjusted reference point intervals for the three time points).

The CONTAM Panel identified a need to establish sensitive indicators for HMF‐induced adverse effects in bees and to collect and provide open access consumption data of bee feed. They also identified the need for studies on toxicokinetics of HMF in honey bees, preferably using radiolabelled HMF. The CONTAM Panel recommended further investigations on the effect of pH on the toxicity of HMF and HMF containing bee feed and on the identification of the potential presence of other toxic constituents in bee feed. A concentration of HMF in bee feed should be established considering brand loyalty feeding practices.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

1.1.1. Background

Sugar feeding can be used as a supplement in several beekeeping activities such as providing food for bee colonies during shortages of honey or nectar in winter. Hydroxymethylfurfural (HMF) is a compound formed by the degradation of simple sugars, especially fructose. HMF occurs in food and feed containing carbohydrates e.g. in feed sugars used to feed honey bees during winter.

In the Rapid Alert System for Food and Feed (RASFF) there are several notifications reporting high levels of HMF in feed for honey bees. Various studies suggest that high levels of HMF feed sugars used to feed honey bees could be implicated in bee mortality. Therefore, it might be necessary to regulate the presence of HMF in feed for honey bees in the frame of Directive 2002/32/EC1 1 to protect bee health.

Hence, it is appropriate to provide a scientific opinion on the risks posed to animal health related to the presence of HMF in feed for honey bees.

1.1.2. Terms of Reference

In accordance with Art. 29 (1) of Regulation (EC) No 178/2002, the European Commission asks the European Food Safety Authority to provide an opinion on the risks for animal health related to the presence of HMF in feed for honey bees.

1.1.3. Interpretation of the Terms of Reference

In the present assessment, risks for animal health related to the presence of HMF in both commercial and home‐made bee feed were assessed in managed honey bees (Apis mellifera sp.). As honey bee colonies can receive supplementary feed throughout the year, all individual bees (larvae and adults comprising workers, queens and drones) that potentially can be exposed were considered, and associated exposure and risk characterization scenarios were developed. The risks related to the presence of HMF in bee feed were assessed both on an individual level (i.e., considering different types of bees) and on a colony level (where relevant for populations). The effects of HMF in conjunction with other possible stressors for bee health (e.g. exposure to pesticides, parasitic infection) were not covered in the present assessment.

When considering the exposure of bees to HMF, it is important to include temporal considerations (i.e. time when the colony rear brood, from spring to autumn, versus the wintering period which is energetically costly when bees consume carbohydrates to thermoregulate and maintain a viable nest temperature).

1.1.4. Additional information

1.1.4.1. Life cycle and biology of honey bees

The honey bee (Apis mellifera sp.) lives in a colony of thousands of individuals depending on the season and their health. A colony includes one queen (fertile female), thousands of workers (unfertile females) and hundreds of drones (fertile males). Honey bee larvae hatch from eggs within three to four days. They are then fed by worker bees (nurses) and reach pupal stage (which do not feed) in around10 (queen) 11 (worker) and 14 (drone) days after hatching. Mature queens emerge after 16, worker bees after 21 and drones after 24 days. Honey bees feed on pollen and nectar, processed by worker bees in bee bread 2 and honey, respectively. They also feed on royal or worker jellies, 3 which are produced by worker bees. Once reaching maturity, the queen remains inside the colony for all her life, except for the days she mates and during swarming (biological reproduction). The drones leave the colony mainly to reproduce. Worker bees leave the hive only occasionally, however, once becoming forager bees, they leave the hive each day to collect food. A honey bee colony is perennial, because the honey bee queen lives multiple years until she is substituted by a new queen. Queens have an average lifespan of 1–2 years although a maximum lifespan of 8 years has been reported (see Remolina and Hughes, 2008). The data underpinning a recent EFSA review on background mortality rates (EFSA et al. (2020) suggest that the lifespan of a worker during the active season (spring to autumn) is between 15 and 45 days, while a slower metabolism during winter allows bees to live 100 days in areas with short winters and more than 200 days in areas with longer winters. EFSA (2020) suggests that the lifespan of drones ranges between 18 and 30 days in spring, 10 and 15 days in summer and 32 and 42 days in autumn. Drones are not produced during winter and therefore, they are not present in the hive during this period of the year.

1.1.4.2. Chemistry and formation of HMF from carbohydrates

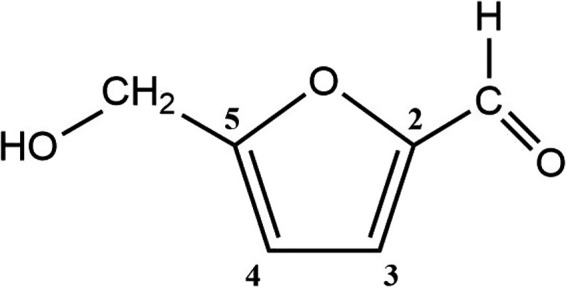

The chemical structure of HMF (5‐hydroxymethyl‐2‐furaldehyde, also named 5‐hydroxymethyl‐2‐furfural, 5‐hydroxymethylfurfural, hydroxymethylfurfural, or 5‐hydroxymethylfurane‐2‐carbaldehyde) is depicted in Figure 1.

Figure 1.

Chemical structure of HMF

HMF has the CAS number 67‐47‐0, the molecular formula C6H6O3, and the molar mass 126.11 g· mol−1. It is a colourless solid with a melting point of 32–35°C and a density of 1.21 g·cm−3.

HMF is a degradation product of hexoses and is present in numerous food items containing carbohydrates, e.g. milk, fruit juices, dried fruits, bread, and honey. There are two chemical mechanisms through which HMF can be formed from hexoses: (1) through acid‐catalyzed cyclisation with subsequent loss of water, and (2) through formation of a Schiff base with an amino acid, followed by tautomerisation to an 1,2‐enaminol with subsequent hydrolysis to a 3‐deoxyosone and cyclisation. Disaccharides and higher sugars containing hexoses can be hydrolysed to monosaccharides and therefore also lead to the formation of HMF.

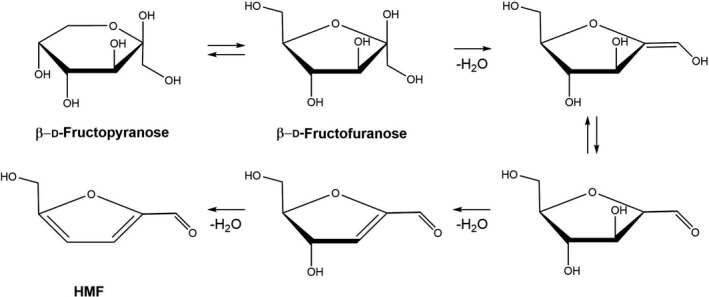

The acid‐catalyzed formation of HMF from mono‐ and disaccharides has first been shown by Düll (1895). It is believed to start from fructose as depicted in Figure 2. Glucose and other hexoses can also feed into this pathway leading to HMF, because they can isomerize to fructose.

Figure 2.

Proposed mechanism of dehydration of fructose to HMF (simplified scheme taken from Yang et al., 2019)

- Carbohydrates are depicted using the Haworth projection.

With respect to mechanism (2), Maillard (1912) first reported that HMF was a product of the reaction of glucose with the amino acid lysin (Maillard, 1912). For a depiction of the detailed mechanism, see Capuano and Fogliano (2011).

Honey is particularly rich in carbohydrates: depending on the source of the nectar, it contains 31–44% fructose, 23–41% glucose, 0.2–7.6% sucrose, 3–16% other disaccharides, and 0.1–4% higher sugars (Ball, 2007). The very low content of amino acids in honey of about 0.1% of the dry matter (Ball, 2007), the acidic pH values of 3.4–6.1 and recent studies by Yang et al. (2019) suggest that HMF is formed in honey primarily through the acid‐catalyzed successive dehydration of fructose according to the scheme depicted in Figure 2. The concentration of HMF in fresh honey is very low to undetectable (Bogdanov et al., 1999) but increases markedly during processing such as heating or long‐term storage (see Section 1.1.4.3). HMF is therefore used as a marker for fresh and unprocessed honey.

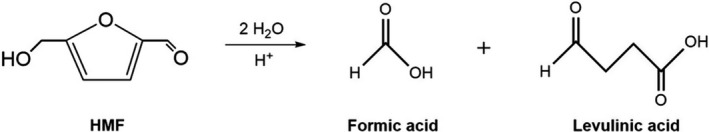

HMF is a stable compound under normal conditions and has been reported to decompose to formic acid and levulinic acid (see Figure 3) only at high temperature and very low pH. Therefore, decomposition of HMF is considered unlikely to take place to a significant extent in honey or bee feeds (Bailey, 1966).

Figure 3.

Decomposition of HMF

HMF can chemically react with amino and thiol groups of proteins due to its aldehyde group and is prone to biotransformation. The aspects of chemical reactivity and metabolism of HMF are considered in Section 3.1.1.

1.1.4.3. Concentration of HMF in honey and various bee feeds

Honey is the natural feed for honey bees when no nectar from flowering plants is available. When stored under natural conditions within the hive, concentrations of HMF in honey are very low (Bogdanov et al., 1999; Krainer et al., 2016). For example, HMF contents of fresh honey from Italy, Turkey, and India were 1.23–5.95, 0–11.5, and 0.15–1.70 mg/kg, respectively (reviewed by Shapla et al., 2018). Heating or improper storage can lead to considerably higher HMF levels. For example, when different honey samples were heated to 100°C for 1 min, the HMF concentration increased from 3.9 to 10.1 mg/kg (Tosi et al., 2001). Karabournioti and Zervalaki (2001) found that the increased levels of HMF in honeys of several botanical origins kept at various temperatures for 24 h were correlated with the temperatures Shapla et al. (2018) reviewed HMF concentrations of honey samples from 29 countries after storage for up to three years at temperatures up to 30°C; there was a clear trend for increasing HMF levels with longer storage times and higher storage temperatures, the highest value being 1,132 mg/kg in a Malaysian honey kept at 30°C for more than 2 years. The importance of time and temperature for the level of HMF was confirmed in a controlled study with coriander honey (Kamboj et al., 2019), but the authors emphasize that other factors such as pH, water content, sugar profile, presence of organic acids and floral source of the honey may also have an effect. The multifactorial reasons for HMF formation may explain the highly variable HMF levels reported in the review by Shapla et al. (2018).

In order to facilitate winter feeding of bee colonies from which honey has been removed, bee feed is given. For example, a concentrated solution of the disaccharide sucrose is a suitable bee feed, because sucrose does not lead to digestive problems and is less likely to crystallise than honey. Moreover, HMF is not formed from unhydrolyzed sucrose (Simpson et al., 1968). To further reduce the problem of crystallization at low temperatures, the presence of fructose is beneficial for bee feeds, such as in high fructose corn syrup (HFCS) and inverted sugar syrup. HFCS is produced from corn starch, which consists of amylose and amylopectin that are polysaccharides containing only glucose moieties. After acid‐catalyzed or enzymatic degradation part of the glucose is transformed to fructose. A complex fractionation and combination process can be used to obtain mixtures with various amounts of fructose, e.g. HFCS‐42 (42% of fructose) and HFCS‐90 (90% of fructose).

Inverted sugar syrup is a mixture containing glucose and fructose. It is obtained from sucrose through acid‐ or enzyme‐catalyzed hydrolysis. Additional fructose can be added to further hinder crystallization. Sometimes inverted sugar syrup is acidified with organic acids (i.e. citric, oxalic, acetic or lactic acid) which are supposed to improve its suitability as bee feed for the winter (Ceksteryte and Racys, 2006).

All commercially available bee feeds contain either sucrose or mixtures of glucose and fructose at different proportions. Some other sugars, such as mannose, galactose and lactose have been found to be harmful to honey bees (Barker and Lehner, 1974; Brodschneider and Crailsheim, 2010) and are therefore not used as supplemental feeding. The physicochemical properties of suitable feeds are mostly determined by the water content. Basically, there are four types of commercial bee feeds: Syrup, fondant, candy, and dry sugar. The water content of syrup may vary from 50% down to a few percent, and its consistency accordingly from a solution to a liquid gel or paste. Sugar syrup is commonly used from spring to autumn. When temperatures fall below 10°C, syrups may freeze and must be replaced by bee fondant or candy or granular sugar, all three of which can be consumed by honey bees throughout the winter. During the freezing of syrup HMF is concentrated in the liquid portion, which is the only one accessible to the bees (Wilmart et al., 2011). Thus, syrup crystallization may lead to higher HMF exposure.

Fondants and candies are prepared from an aqueous sucrose solution by gently evaporating most of the water and letting the sugar solidify with stirring to avoid crystallization; the temperature of cooking determines the consistency of the final product. Fondant is softer than candy, it is squeezable and pliable like dough because it contains more residual water. Sometimes, fondants are referred to as ‘soft candy’. With respect to dry sugar, pure granular sucrose (‘white sugar’) from sugar beets or sugar cane appears to provide the least risk to bees for digestive problems, whereas raw, brown, and waste sugars may contain other carbohydrates or contaminants and are not suitable (Somerville, 2014).

In conclusion, commercial bee feeds may contain varying levels of HMF, depending on the conditions during their production and use. Several parameters are known to influence the rate of HMF formation during preparation of bee feeds, the most important being the type of sugar and the pH, the temperature, the water activity, and the concentration of divalent cations of the media (Capuano and Fogliano, 2011).

1.1.4.4. Analytical methods for detection and quantification of HMF

The International Honey Commission (IHC, Bogdanov, 2009) recommends three analytical methods for the determination of HMF. These comprise two spectrophotometric methods, named after Winkler (1955) and White (1979), and one chromatographic method, using HPLC.

In the Winkler method, the HMF is reacted with p‐toluidine and barbituric acid to form a dye the absorbance of which is measured at 550 nm. Reaction only with p‐toluidine but not barbituric acid serves as reference. The major drawback of the Winkler method is the use of p‐toluidine, which is a carcinogenic compound.

The White method measures the absorbance of HMF at 284 nm directly, using as reference another aliquot to which sodium bisulfite has been added in order to convert HMF to a derivative which no longer exhibits absorbance at 284 nm. Refinements of this method account for UV‐absorbing matrix constituents (Kozianowski, 2016).

The HPLC method is based on the report by Jeuring and Kuppers (1980). Briefly, the diluted and filtered honey sample is analysed on a reverse phase HPLC column using isocratic elution and UV detection at 285 nm. Quantitative determination is carried out using external standardization.

The three methods were tested by the IHC with three honey samples covering the HMF concentration range of 4 to 40 mg/kg (Bogdanov, 2009). All three methods yielded comparable results for the samples with 40 and 20 mg/kg, and only small differences between the methods were observed at the lowest HMF levels. The reproducibility of the HPLC method and the White method were better than that of the Winkler method. Likewise, Zappalà et al. (2005) reported that the HPLC and the White methods give similar results for the HMF content of various unifloral honeys, whereas the Winkler method gave higher values. Truzzi et al. (2012) compared the HPLC and the White method for the determination of HMF in unifloral honey and honeydew samples with a HMF content of less than 4 mg/kg. For honey samples with an HMF content in the range of 1–4 mg/kg, both methods were suitable but the HPLC method was superior to the White method with respect to precision.

In general, the HPLC method appears to be more suitable for the determination of HMF than the spectrophotometric methods, in particular for samples containing matrix constituents which may interfere with the photometric measurement of HMF but are separated from HMF in the HPLC method (Kozianowski, 2016).

Various modifications of the HPLC method have been reported, including sample preparations using liquid‐liquid extractions (Chen et al., 2019). In addition, methods using high‐performance thin layer chromatography, gas chromatography, and micellar electrokinetic capillary chromatography have been developed for analysing HMF in honey (cited in Chen et al., 2019), but these methods are not commonly used. For a complete list of all methods for the determination of HMF in food see Morales (2009).

1.1.4.5. Legislation

HMF is currently not regulated under Directive 2002/32/EC 4 on undesirable substances in animal feed and also not listed in the Annex to Commission Regulation 68/2013 5 on the requirements for feed hygiene.

Article 15 of Regulation 178/2002 6 stipulates that feed shall not be placed on the market or fed to any food‐producing animal if it is unsafe e.g. if it has adverse effects on human or animal health.

2. Data and methodologies

The draft Opinion underwent a public consultation from 3 December 2021 to 10 February 2022. The comments received and how they were taken into account when finalising the scientific Opinion are available in Annex A to this scientific Opinion.

2.1. Collection and appraisal of data from public literature

In preparation of the present mandate, a call for a procurement for a literature search and review was launched with the aim to identify, collect and evaluate literature related to the effects on HMF in bee feed. A final project report was delivered in July 2020, and was published on 7 August 2020 (NFI‐DTU, 2020). Briefly, in the outsourced work four search strings related to (1) chemical identification, characterisation and formation, (2) occurrence in bee feed and honey, (3) toxicokinetics and (4) toxicity were designed to identify and collect potentially relevant studies in several databases. Results from the search was then evaluated regarding the potential relevance for the present opinion applying inclusion/exclusion criteria for the studies (for details see NFI‐DTU, 2020). No time limit was applied for this search. The total number of publications identified per research field and those identified as potentially relevant by the contractor were as follows (total number/potentially relevant): Chemical identification, characterisation and formation (3,862/55), occurrence in bee feed and honey (37/14), toxicokinetics (221/15), toxicity (500/8). The report contains summary tables (as annexes) containing all abstracts that were screened together with an evaluation of their relevance and listing the key points of the individual publications. The abstracts proposed as potentially relevant in the report were then screened by the WG members, and by applying expert judgement, the associated studies were considered as part of the assessment if relevant. In addition to the systematic search for retrieval of relevant literature, a ‘forward snowballing’ approach was applied by all WG members (see Jalali and Wohlin, 2012) to obtain further any relevant information.

2.2. Methodology – Occurrence data submitted to EFSA

Following the European Commission mandate to EFSA, a call for annual collection of chemical contaminant occurrence data in food and feed, including HMF, was issued by the former EFSA Dietary and Chemical Monitoring Unit (now Evidence Management Unit) in December 2010 with a closing date of 1 October of each year. European national authorities and similar bodies, research institutions, academia, food business operators and other stakeholders were invited to submit analytical data on HMF in feed. The data submission to EFSA followed the requirements of the EFSA Guidance on Standard Sample Description (SSD) for Food and Feed (EFSA, 2010). Occurrence data were managed following the EFSA standard operational procedures (SOPs) on ‘Data collection and validation’ and on ‘Data analysis of food consumption and occurrence data’.

The raw data on occurrence from EU MS are available at the EFSA Knowledge Junction community on Zenodo. 7

2.3. Feed consumption in honey bees

Honey bees consume nectar and honey to cover their carbohydrate requirements, during their development as larvae and later for their daily activities as adults. Food consumptions in honey bees have been extensively reviewed by EFSA through a systematic and narrative reviews (EFSA, in preparation).

As adults, bees consume nectar/honey during their entire life to achieve their various tasks in the hive and, thereafter, outside the hive, as forager bees. The activities that are the most expensive in terms of energetic costs are those related to foraging and thermoregulation for the brood (during the development of the colony from spring to autumn) and the nest (in winter). Indeed, bees consume nectar/honey to maintain the temperature (via thermoregulation) of the brood at about 34°C and the nest/bee nucleus at 5–8°C in the periphery and 15–20°C in the centre. Those activities require 32–128 mg sugar per day (foraging), 34–50 mg sugar per day (brood thermoregulation) and 8.8 mg sugar/bee per day (nest thermoregulation) (Rortais et al., 2005; EFSA PPR Panel, 2012). The estimate of an uptake of 8.8 mg sugar/bee per day is an average value obtained from a scenario that assumes the consumption of 20 kg of honey by 20,000 bees located in temperate EU regions during a 3‐month winter period (Rortais et al., 2005) and is therefore used for the exposure assessment in the present opinion. Notably, this consumption estimate does not take into account any natural variations (periods of low consumption alternated with periods of high consumption in relation to external temperature variations) that might occur during this long period across the various climatic regions found in EU. As bee feed is mainly given during the cold season, a default consumption value of 8.8 mg sugar/bee per day (nest thermoregulation) has been chosen as most appropriate for the exposure assessment. On a gram basis, which is used throughout this opinion, the caloric equivalents of the carbohydrates sucrose, glucose and fructose are virtually identical (about 4.0 kcal or 16 kJ per gram).

Standard feed consumption levels (i.e. doses and concentrations) in laboratory settings were established by Tosi et al. (2021), thus allowing to set up a toxicological reference point. They performed a ring‐test involving seven different laboratories in Europe and USA that investigated the feed consumption of worker bees in laboratory conditions and found that that the mean consumption of sucrose (consumed as a 50% aqueous solution) was 13 (day 1–10), 14 (day 21–30) and 12 (day 31–40) mg sucrose/bee per day, respectively. An average value of 13.5 mg/sugar per bee per day has been identified as most appropriate default consumption value for establishing exposures in toxicity tests to be able to derive doses from the concentrations given.

2.4. Methodology for exposure assessment

The exposure of workers to HMF for the different scenarios was estimated by using the concentration data provided by the data provider from MS (Data set A) and industry (Data set B). The CONTAM Panel considered that only chronic dietary exposure had to be assessed. In the absence of measured consumption data for worker bees default values have been used (see Section 3.3).

2.5. Methodology for risk characterisation

The risk characterisation was carried out by comparing the exposure estimates from the different scenarios with the reference point for bee toxicity. All the principles in the EFSA guidance on risk assessment for bees and pollinators (EFSA, 2013a,b) were followed.

3. Assessment

3.1. Hazard identification and characterisation

3.1.1. Toxicokinetics

No information is available on the toxicokinetics, i.e. the absorption, distribution, metabolism and excretion of HMF, in honey bees or other insects. However, a few toxicokinetic studies of HMF in rodents and humans have been conducted (reviewed in Abraham et al., 2011; Farag et al., 2020). For example, Godfrey et al. (1999) reported that the urine of rats and mice collected for 48 h after oral administration of 14C‐labelled HMF at doses ranging from 5 to 500 mg/kg body weight (bw) contained 60–80% of the administered dose, while 10–25% were excreted with the faeces. The studies on the tissue distribution as well as on the excretion suggest that HMF is rapidly and completely absorbed, metabolised and excreted after oral ingestion by rodents.

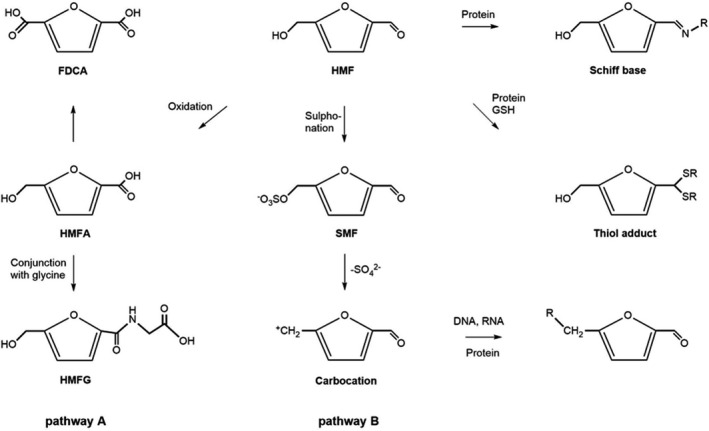

The major metabolic pathways of HMF in mammals are depicted in Figure 4.

Figure 4.

Major metabolic pathways and reactivity of HMF and its metabolites. R represents biomolecules capable of covalent binding through their amino or thiol groups

Pathway A involves oxidation of the aldehyde group to yield 5‐hydroxymethyl‐2‐furoic acid (HMFA), followed by conjugation of HMFA with the amino acid glycine to give 5‐hydroxymethyl‐2‐furoyl glycine (HMFG), or further oxidation to 2,5‐furane dicarboxylic acid (FDCA, Figure 4). HMFA, HMFG, FDCA and traces of other metabolites were also detected in human urine after consumption of HMF‐containing fruit juices (Pryor et al., 2006; Abraham et al., 2011 and literature cited therein).

Another metabolic pathway of HMF (pathway B in Figure 4) comprises the conversion of HMF to 5‐sulfoxymethylfurfural (SMF) via sulfonation of the hydroxymethyl group. SMF represents an allylic sulfuric acid ester which readily splits into a sulfate ion and an electrophilic carbocation capable of covalent binding to nucleophilic sites of proteins and nucleic acids and thereby eliciting cytotoxic and mutagenic effects. The formation of SMF has been demonstrated in mice and humans.

Finally, the aldehyde group of HMF has been shown to react directly, i.e. without metabolism, with free amino groups and/or thiol groups of proteins, thereby forming Schiff bases or thiol adducts, respectively (Figure 4). This may contribute to the covalent binding of radioactivity observed in the kidney, bladder and liver of rodents after oral ingestion of 14C‐labelled HMF (Godfrey et al., 1999).

Although no studies on the metabolism of HMF in honey bees or in other insects have been conducted, it is of interest to note that the genome of honey bees has a smaller number of genes for the metabolism of xenobiotics relative to other insect genomes (Berenbaum and Calla, 2021, and literature cited therein).

In addition to the lack of information on the metabolism of HMF in honey bees, it is unknown if HMF can interact with their gut microbiota. Effects of HMF on the human gut microbiome have been reported (Aljahdali and Carbonero, 2019). Because the gut microbiota is important for the health of honey bees, exposure to HMF might change their composition with a negative health impact. The issues of HMF toxicokinetics in honey bees and effects on their gut microbiome require investigation.

3.1.2. Toxicity

The available laboratory toxicity and field studies with HMF are presented in the following Sections 3.1.2.1 and 3.1.2.2.

3.1.2.1. Experimental studies in honey bees

Bailey (1966) gave groups of 30 caged honey bees (Apis mellifera) taken from the same colony various sugar products dissolved in 60% sucrose syrup and measured the time until half the bees in a cage had died. The sugar products comprised sucrose hydrolysed with acids under various conditions, or with the enzyme, invertase. Honeys of different age and the degradation products HMF, levulinic acid and formic acid were also tested. Whereas sucrose hydrolysed with invertase was found to be nontoxic, bees fed carbohydrates hydrolysed with mineral or organic acids developed severe dysentery and died within a few days. Likewise, bees receiving unrefined sugar, heated honey, HMF, levulinic acid or formic acid died early. At the tested concentration of ca. 80 mM (corresponding to 1% HMF), the three degradation products were equally toxic to bees. HMF became harmless when diluted to 10 mM. Testing a mixture of HMF, levulinic acid and formic acid did not suggest that these compounds have a combined effect. Bees fed 8‐year‐old honey became more dysenteric compared with those fed fresh honey or syrup. The CONTAM Panel concluded that this study could not be considered for the present assessment as a concentration/dose response curve could not be established from this paper.

In two independent experiments carried out in 1973 and 1974, Jachimowicz and El Sherbiny (1975) fed groups of 500 (100 animals per test group in five replicates) newly emerged (0–3 days old) Carniolan worker bees (Apis mellifera carnica) for 20 days with ‘synthetic’ solutions made of glucose, fructose and sucrose (7:7:1 by weight) and 50% water to which HMF was added at concentrations of 0, 30, 150 and 750 mg/kg. The pH of the feeding solutions was adjusted to 3.9 by adding citric acid. In a separate experiment, it was shown that the addition of citric acid did not have an effect of the toxicity of the solution. A commercial invert sugar solution with identical sugar composition and 30 mg HMF/kg was also tested. Mortality rates reported here are the mean values from the two independent experiments which differed only marginally. A concentration of 30 mg HMF/kg did not lead to a significantly increased mean mortality rate (15%) as compared to the control (12.5%) after 20 days. In contrast, mean 20‐day mortality rates were clearly increased with concentrations of 150 mg/kg (58.7%) and 750 mg/kg (98.8%). The commercial solution exhibited the same mortality rate as the synthetic solution with the same HMF level.

Leblanc et al. (2009) fed triplicate groups of 100 caged freshly emerged worker bees (Apis mellifera ligustica) with either commercially available HFCS‐55 containing 57 mg/kg HMF or with HFCS‐55 spiked with pure HMF to produce final concentrations of 100, 150, 200 and 250 mg/kg HMF. The caged trials were recorded in multiples of four. Syrup consumption during the first 3 days was found to range between 50 and 70 mg per bee. Drinking water was supplied ad libitum. However, when the water supply expired without being replenished, more syrup was consumed, and the mortality increased dramatically. A mortality of 50% was reached in the 150 mg/kg group after 19 days. A comparison of 26‐day mortality showed that mortality did not differ significantly between the 57, 100, 150 and 200 mg HMF/kg groups while it was significantly higher in the 250 mg/kg group (more than 90% mortality at mean). The CONTAM Panel noted that in this study, no negative control (i.e. HMF‐free bee feed) was tested. Feed consumption was only measured on days 1–3 and days 5–26 and figures for consumption have not been reported. Bees have consumed more syrup because of lack of water occurring in some cages (where water supply expired without being replenished) leading to high consumption of HMF containing syrup and dramatically increased mortality in these cages. Actual figures (mean and standard deviation) for survival rates at day 26 were not reported. The percentage survival rates (numerical figures were not reported but only presented in a column chart) were clearly below 25% at all concentrations. Taking all these uncertainties with regard to the results and their presentation into account, the CONTAM Panel decided not to consider these results further in this assessment.

Smodiš Škerl and Gregorc (2014) fed caged worker bees (approximately 50 animals per cage, in five replicates), kept at 28°C and a relative humidity of 60%) with commercial sugar candies for 27 days purchased in Slovenia and a home‐made candy in order to investigate effects on bee longevity. Some of the candies contained high amounts of HMF. The candies were ‘MedoPip Standard’ (914.6 mg HMF/kg), ‘Medopip Plus’ (437.0 mg HMF/kg); ‘Apimel’ (58.3 mg HMF/kg), the ‘home‐made sugar candy’ (< 10.0 mg HMF/kg) and ‘Stimulans’ candy (< 10.0 mg HMF/kg). HMF concentrations were determined by HPLC. The longest worker survival (27 days) was found with the candies with lowest HMF levels namely ‘Apimel’, ‘home‐made sugar candy’ and ‘Stimulans candy’ while feeding with ‘Medopip Standard’ and ‘Medopip Plus’, the candies with the highest HMF, resulted in shorter life spans (24 and 20 days, respectively). Since the study only provides information on longevity but not on comparative survival of bees at the different doses at the same time points which would allow establishment of a concentration/dose response, the CONTAM Panel decided that it cannot be used for characterising the risk of HMF to bee health.

In order to assess the effect of HMF of mortality of larvae, Krainer et al. (2016) fed groups of artificially reared larvae with diets containing 50% royal jelly and 50% aqueous sugar solutions with varying fructose, glucose and yeast extract concentrations to fulfil the different demands of young and old larvae. HMF was added at nominal concentrations of 0, 5, 50, 750, 5,000, 7,500 and 10,000 mg/kg and the spiked diet fed for 6 days. For the control group, 12 replicates and for the test groups seven replicates with one plate containing 48 larvae each were tested. Larvae were kept at 34.5°C and 96% humidity. Mortality was assessed on day 7 and 22 of the observation period. On day 7, mortality of groups receiving 0, 5, 50, 750, 5,000, 7,500 and 10,000 mg/kg HMF was 9% (standard error (SE) ±1.19), 6.9% (±1.5), 10.1% (±1.77), 6.8% (±1.38), 52.4% (±2.72), 100% and 100%, respectively. The corresponding figures for the mortalities measured on day 22 were 28.1% (±0.019) at 0 mg/kg, 26.4% (±2.60) at 5 mg/kg, 30.2% (±0.027) at 50 mg/kg, 32.1% (±0.026) at 750 mg/kg and 87.5% (±0.018) at 5,000 mg/kg, respectively. The authors concluded that increased mortality was only reported in groups fed diets containing HMF concentrations higher than 750 mg/kg and that a concentration of 7,500 mg/kg caused a mortality of 100%. Experimental of LC50 values HMF for larvae of 4,280 mg/larva (day 7) and 2424 mg/kg (day 22) were determined. Using a total uptake of 170 µl feed, the calculated LD50s for larva were 778 µg HMF/larva (day 7) and (day 22) 441 µg HMF/larva.

In a second experiment, aimed at comparing HMF toxicity in larvae with adult animals, triplicate groups of 48 freshly hatched adult worker bees were feed sucrose solutions (50% w/v) containing either 0, 2,000, 4,000 and 8,000 mg HMF/kg. On day 7, mortalities in the different test groups were 0.7% (SE ± 0.470) each for the control group and the 2,000 mg/kg group, and 3% (± 0.985) and 5% (± 1.26) in the 4,000 and 8,000 mg/kg group, respectively. On day 22, the mortality of the control group was 6.7% (±1.44) and that of the 2,000 mg/kg group was 67% (±2.71). A 100% mortality was already reached at day 20 in the 4,000 mg/kg group and at day 15 in the 8,000 mg/kg group. For adult worker bees, an LC50 values of 82,778 mg HMF/kg (day 7) and 1,843 mg HMF/kg (day 22) were derived applying regression analyses. An LD50 was not calculated because feed consumption of worker bees was unknown. The authors concluded that on day 7 (after 6 days of treatment), larvae are much more sensitive towards HMF compared to adult worker bees; however, on day 22, adults show a lower LC50 (1,843 mg HMF/kg) as compared to larvae (2,424 mg HMF/kg), indicating a higher sensitivity of adult animals towards HMF.

Gregorc et al. (2020) fed groups of 70 caged newly emerged (0–24 h) Carniolan worker bees (Apis mellifera carnica) in five replicates for 50 days with commercial bee candy (Apifonda, Südzucker, Mannheim, Germany, 83% sucrose, 5.5% dextrose, 3.0 fructose, 2,5% maltose and 8.0% higher saccharides, approx. 90% dry matter) to which nominal concentrations of 0, 100, 500, 1,000 and 1,500 mg HMF/kg were added to assess HMF‐induced mortality rates. The bees were kept in incubators at 28°C and 65% relative humidity. Daily food consumption was recorded. For immunohistochemical analyses (in situ cell death detection kit (ISCDDK)), groups of 50 animals were given the same test concentrations as in the mortality study, and three animals were randomly sampled from each group at days 5, 10, 15 and 20 and their midguts removed. For the analysis of cell death, about 300 cells from each of the three bees were counted.

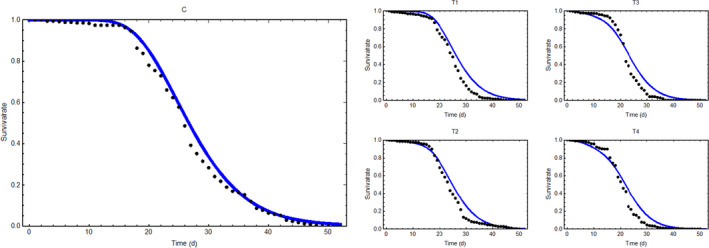

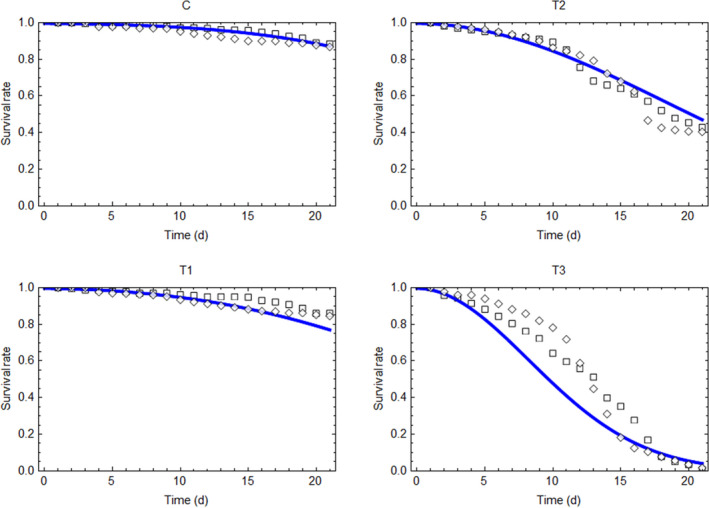

After 15–30 days of exposure, an increased mortality rate was observed that was clearly time and HMF concentration dependent. In Table 1, the % survival rates with standard deviations of the control and substance groups at the different time points in this experiment are presented in detail.

Table 1.

Effects of intake of HMF on survival rates in worker bees(a)

| Days | Apifonda | Apifonda + 100 mg/kg HMF | Apifonda + 500 mg/kg HMF | Apifonda + 1,000 mg/kg HMF | Apifonda + 1,500 mg/kg HMF | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| % survival | SD | % survival | SD | % survival | SD | % survival | SD | % survival | SD | |

| 5 | 99.7 | 0.3 | 99.2 | 0.5 | 99.6 | 0.5 | 99.4 | 0.6 | 99.5 | 0.4 |

| 10 | 98.8 | 0.2 | 97.5 | 0.7 | 98.3 | 0.4 | 97.5 | 0.2 | 97.8 | 1.2 |

| 15 | 97.6 | 0.4 | 95.5 | 0.9 | 96.9 | 1.0 | 96.1 | 1.1 | 91.9 | 2.3 |

| 20 | 91.7 | 6.2 | 88.6 | 6.0 | 87.7 | 7.4 | 87.7 | 6.2 | 75.0 | 11.6 |

| 25 | 70.9 | 6.6 | 65.7 | 8.3 | 57.6 | 9.9 | 49.6 | 18.1 | 37.8 | 13.6 |

| 30 | 42.4 | 10.7 | 33.0 | 11.1 | 27.7 | 10.4 | 18.0 | 6.0 | 11.9 | 4.3 |

| 35 | 21.9 | 4.5 | 10.5 | 0.9 | 9.0 | 1.0 | 4.4 | 1.1 | 3.4 | 2.3 |

| 40 | 11.9 | 3.8 | 2.6 | 0.7 | 5.4 | 0.8 | 0.9 | 1.2 | 0.9 | 0.4 |

| 45 | 4.5 | 1.8 | 1.1 | 0.5 | 3.2 | 0.5 | 0.0 | 0.0 | 0.0 | 0.0 |

| 50 | 0.8 | 0.7 | 0.0 | 0.0 | 1.0 | 0.8 | 0.0 | 0.0 | 0.0 | 0.0 |

HMF: Hydroxymethylfurfural; SD: standard deviation.

Data were kindly provided by Ales Gregorc.

During the first 2 weeks of treatment, sublethal effects on midgut cells were observed i.e. ISDDK‐positive midgut epithelial cells indicative of apoptosis. A hypertrophic enlargement of the digestive cells was seen with the first 5 days in HMF‐fed bees. After 10 days of HMF treatment, numerous affected cells were shed into the midgut lumen, as evidenced by observable apoptotic cell death in the apical region of midgut. Between day 10 and 15, increased cell death rates were observed in the 1,000 and 1,500 mg/kg treatment groups, resulting in the shedding of dead cells from the epithelium into the midgut lumen, followed by typical necrotic deletions. Notably some variations in pathological cell death were also observed in the 500 mg/kg group.

The authors concluded that the bees were sensitive to changes found in the midgut tissue already at sublethal HMF concentrations. HMF feeding and its potential detrimental effect can result in higher bee mortality which was monitored 14 days after caged bees were exposed to HMF. It was found that HMF has a dosage‐dependent cytotoxic effect on honey bee digestion; both sublethal and subclinical changes to the midgut occur at the cellular level before bees eventually die from high doses.

The CONTAM Panel noted that the concentration‐related increase seen in ISCDDK positive cells observed in particular at high doses after 5 days was not seen anymore at later time points, likely because of the progressing severity of cell lesions in the midgut which cannot be detected with such a rather sensitive method.

Frizzera et al. (2020) fed groups of 25 bees with sugar syrup (glucose 61%, fructose 39%) to which different concentrations of HMF were added (0, 50, 100, 200 and 400 mg/kg). At these concentrations, no effect of HMF on bee health was found, even in the presence of the mite Varroa destructor, a common stressor in honey bees. In another experiment, the survival of bees fed with sugar syrup (2:1) alone and with syrup containing 100,00 mg HMF/kg was compared, using 30 bees per group and three replicates. The high concentration of HMF was used because previous experiments had shown that 6,000–14,000 mg HMF/kg are formed in home‐made sugar syrups at a pH of 2 after 30–40 min of boiling, which is standard practice in when preparing bee syrups. A 100% mortality rate was reached after 14 days in the HMF group, while more than 85% of control bees were still alive. The CONTAM Panel noted that the survival rates of bees fed with various HMF concentrations in the first experiment were not different from control. In the second experiment only one very high dose was tested and no dose response curve can be derived. Therefore, this study could not be used for the risk characterisation.

A non‐peer‐reviewed study (Lüken and Ohe, 2016) aimed at investigating the effects on HMF on bee mortality. In a first trial carried out in summer, groups of bees (Apis mellifera carnica) received sugar solutions via a syringe containing nominal concentrations of 0, 40, 120, 240, 480, 960, 1,920 and 3,840 mg HMF/kg, respectively, for 30 days. The number of bees in the control group was 200, that in the test groups was 80. Bees were kept in a climate cabinet at 25°C ± 2°C and at a relative humidity of 60%. Average feed consumption (all groups) was 15.55 mg/bee per day. Cumulative mortality after 35 days was 46.25% in the control and 35.50% in the highest dose test group (numerical values for other groups not reported). In a second trial carried out in autumn, with identical test design except for an increased temperature of 33°C, average feed consumption in the different groups was 22.9 mg/bee per day. Cumulative mortalities after 30 days were 18.5, 13.75, 21.25, 18.75, 27.5, 45.0, 77.5 and 97.5%, respectively. The CONTAM Panel noted that this study was not peer reviewed and there were considerable discrepancies between the results of the two independent trials which could not be explained by the authors.

3.1.2.2. Field studies using honey bee colonies

Van der Zee and Pisa (2010, 2011) provided some evidence of bee mortality related to cases of high concentrations of HMF in a certain batch of a common bee feed used in the Netherlands. They collected data from 1,568 beekeepers after the 2009–2010 feeding season, in which an increase in mortality of bee colonies compared to previous years was observed. The Netherlands Centre for Bee Research (NCB) ran an investigation on the largely used inverted sugar syrup ‘Saint Ambrose Syrup’. The syrup batches, produced by De Bijenhoff, had high concentrations of HMF of up to 475 mg/kg and of glucose up to 32 mg/kg as compared to the low contents of sucrose (1–13 mg/kg). The producer of Saint Ambrose Syrup provided no information on HMF content and gave a concentration of 33 mg/kg for sucrose. The authors concluded that the high amounts of glucose were responsible for crystallisation of the feed which caused bees to starve, and HMF for the poisoning of honey bees. The combination of these factors increased the bee annual disease from an average of 23.1% in the previous years to 29.1% for the 2009–2010 winter season.

Kozianowski (2016) carried out a field study in 2012–2013 by adding pure HMF in concentrations between 20 and 150 mg/kg to a fructose/sucrose‐based commercial syrup. A total of 60 young colonies in six feeding groups were located in different but climatically comparable locations in the Jagst Valley (in northern Baden–Württemberg). The six groups were fed Apiinvert with 7, 20, 40, 80 or 150 mg HMF/kg syrup, or a 60% aqueous solution of pure sucrose (control) over a period of 14 days in late August/early September. The level of HMF in all feeds except the control increased during the feeding period on average by 20 mg/kg feed, probably due to the warm weather. When the feed stored in the combs was analysed after the winter, the HMF levels in the spiked Apiinvert feeds had dropped to 16–36 mg/kg. One colony exposed to 80 mg/mg did not survive due to loss of the queen. Another colony receiving 20 mg HMF/kg was recorded with high levels of faeces and a high number of deaths. The authors consider those two cases as typical individual events which cannot be attributed to HMF exposure and emphasise that no other adverse effects were found in the colonies even with the highest dose of HMF. From this study, it was demonstrated that HMF concentrations up to 150 mg/kg in a fructose/sucrose‐based feed syrup (Apiinvert) is well tolerated by bee colonies under practical conditions.

Semkiw and Skubida (2016) conducted a study on five different syrups as bee feeds in the winter of 2012–2013 and 2013–2014 with respect to feed consumption, colony strength and development dynamics, honey yield from spring flow and bee mortalities. The feeds analysed where three commercial starch syrups (Apifood ‐ from Poland, Apikel 20‐ from Germany, Apifortune ‐ from France), one commercial inverted sucrose syrup (Apiinvert ‐ from Germany) and a home‐made syrup (sucrose to water ratio 5:3). HMF levels in the feeds were not analysed in the study, but stated by the manufacturers as < 40 mg/kg for Apifood and < 20 mg/kg for Apikel 20. The authors assumed that the HMF content did not change with time due to the controlled temperature (15°C) during feed storage (2 months) and to the cold climate of the region. No crystallisation of the starch or inverted sucrose syrups occurred during the experiment and no significant differences in the condition of bee colonies were noted before or after overwintering, and during spring development. The authors conclude that HMF levels in bee feed not exceeding 40 mg/kg are safe for bee colonies.

3.1.3. Mode of toxic action of HMF in bees

A frequent cause of death of honey bees is called ‘dysentery’, which for bees means defecation inside the hive due to an excess amount of faecal matter in the gut. Bees retain 30–40% of their body weight in their intestine, and if the time between cleansing flights is too long, they will void inside the hive. This situation can arise for healthy bees in very cold and long winters, especially if their feed contains high amounts of indigestible solids, in particular ashes, the amount of which varies between different types of honey. Thus, dysentery is not necessarily a disease but a condition. However, lesions of the bee gut by toxins may also lead to dysentery.

Bailey (1966) observed that HMF caused gut ulceration in worker bees resulting in dysentery. He excluded a crucial role of the HMF breakdown products levulinic acid and formic acid because the amounts of these compounds formed in sugar solutions are too small to explain the mortality. Bailey also doubts that HMF itself is responsible for adverse effects of bee feed, noting that there might be other yet unknown compounds accounting for the toxicity.

Gregorc et al. (2020) stated that the mechanism by which HMF negatively affects bee health or leads to increased mortality is unknown. In their study, next to mortality, they have also investigated the effect of HMF on the midgut as it can be assumed that this is the tissue mainly exposed to HMF. Hypertrophic enlargement of digestive cells was observed as an early effect, followed by apoptotic cell death in the apical region of the midgut villi. With progressing time, the rate of cell death increased, resulting in shedding of dead cells from the epithelium into the lumen of the midgut. In bees exposed to high doses of HMF, apoptosis was followed by necrosis and increased mortality was paralleled by histopathological lesions in the midgut.

3.1.4. Identification of critical effects

3.1.4.1. Acute effects

The CONTAM Panel did not identify studies on acute effects of HMF in bees. However, based on the chronic studies presented in Section 3.1.2.1 even at very high doses HMF did not cause acute toxicity (i.e. mortality) within the first days of exposure (and actually in most cases only after exposure of 15 days or more). Therefore, HMF is considered of low acute toxicity for honey bees.

3.1.4.2. Chronic effects

In Section 3.1.2.2, field studies on the adverse effects of HMF on bee populations are described. In the study from Van der Zee and Pisa (2010, 2011), the colony collapse seen in the Netherlands was attributed to a combination of starvation of bees because of crystallised bee feed and high HMF contents in bee feed. Semkiw and Skubida (2016) found that concentrations of up to 40 mg HMF/kg bee feed had no adverse effects on colonies, and Kozianowski (2016) concluded that feeding of bees with concentrations of up to 150 mg HMF/kg bee feed had no adverse effects on colonies. The CONTAM Panel noted that field studies are more likely to reflect the real situation as compared to laboratory studies with an artificial and standardised setting and with a relatively low number of animals. However, the specific contribution of HMF to potentially adverse effects on bee colonies, and colony collapse is difficult to quantify, e.g. because actual concentrations of HMF in bee feed and doses of HMF taken up by the bees are difficult to quantify. Field studies are also prone to bias because of a series of potential confounders also affecting bee vitality and longevity such as climatic factors, exposure to plant toxins, xenobiotics such as pesticides, diseases or predators. These additional confounders and stressors can be excluded in laboratory studies.

Therefore, the CONTAM Panel decided to use the results of laboratory studies for derivation of a reference point for the toxicity of HMF which are described in detail in Section 3.1.6.1. In all these studies, bee mortality/survival rate was used as an endpoint for assessing the toxicity of HMF and was therefore identified as the critical effect for the present assessment.

The CONTAM Panel considered the studies from Jachimowicz and El Sherbiny (1975), Krainer et al. (2016) and Gregorc et al. (2020) as most appropriate for deriving a reference point for the adverse effect (mortality) of HMF in bees. The data obtained from these studies enabled assessing concentration/dose–response relationships and were suitable for benchmark concentration (BMC) and benchmark dose (BMD) analyses. Therefore, they were considered further in the assessment (see Section 4.4).

The CONTAM Panel notes that none of these studies were fully compliant with existing OECD guidelines on chronic toxicity (OECD, 2016, 2017). However, the study design in the respective studies is considered appropriate and valid with regard to most study parameters (e.g. number of animals/replicates, application of feed, climatic conditions, overall reporting) even if positive controls have not been tested. Notably, mortality has been assessed for an even longer time period than the 10 days requested in OECD 245 i.e. 20 and 22 days in the Jachimowicz and El Sherbiny (1975) and Krainer et al. (2016) studies and even up to 50 days in the Gregorc et al. (2020) study. In all of the three studies, background mortality even at around 20 days of exposure was below the threshold of 15% (set for an exposure of 10 days in OECD 425). Background mortalities from Gregorc et al. (2020) from day 25 onwards exceeded this threshold and the results from these time points were therefore not considered.

Besides the three appropriate studies discussed above, it was noted that the autumn trial in the non‐peer‐reviewed study by Lüken and von der Ohe (2016) could also be used for BMD/BMC analysis. However, background mortalities were slightly above the applied cut‐off criterion of 15%, and no effect was seen in the summer trial, which was otherwise conducted under identical conditions except for temperature (see Section 3.1.2.1). The autumn trial in the Lüken and von der Ohe (2016) study was therefore only used as a reference, adding to the completeness, in the evaluation of the range of BMD/BMC values across available studies, described in the next section.

3.1.5. Concentration/dose response assessment

Table 2 below presents an overview of the study parameters and results from Jachimowicz and El Sherbiny (1975), Krainer et al. (2016) and Gregorc et al. (2020). Information on consumption of bee feed by worker bees has not been presented in any of these studies. Therefore, the HMF concentrations reported have been converted to daily doses per bee using mean values for sugar solution intakes in laboratory studies as described by Tosi et al. (2021). Considering that the length of the above‐mentioned laboratory studies, or the time points at which increased mortality was observed in all three studies was after around 20 days, this was done by using the average intake over the first 20 feeding days as reported by Tosi et al. (accepted) and dividing by half to account for pure sugar consumption. This resulted in an average daily sugar consumption of 13.5 mg/bee per day.

Table 2.

Overview of toxicity studies with worker bees and larvae considered for derivation of BMCs/BMDs for HMF

| References | Bees per group | Number of feeding days | sugar/water ratio of bee feed | Number of dead bees per group(a) | Concentration in mg HMF/kg feed | Dose in μg HMF/bee per day | Percentage of mortality/survival with SD/SE as reported in the studies | Derivation of dose | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Jachimowicz and El Sherbiny (1975)(b),(c) | 500 workers (5 replicates with 100 bees) | 20 | 50/50 |

Year 1973 |

Year 1974 |

Year 1973 |

Year 1974 |

Assuming an uptake of 27.0 mg bee feed/bee per day based on default uptake of 13.5 mg sugar/bee per day(a),(g) | ||

| 60 | 65 | 0 | 0 | 12.0 | 13.0 | |||||

| 70 | 80 | 30 | 0.81 | 14.0 | 16.0 | |||||

| 287 | 300 | 150* | 4.05* | 57.4* | 60.0* | |||||

| 496 | 492 | 750* | 20.25* | 99.2* | 98.4* | |||||

| Krainer et al. (2016)(d) | 144 workers (3 replicates with 48 bees) | 7/22 | 50/50 | 7 days | 22 days | 7 days | 22 days | Assuming an uptake of 27.0 mg bee feed/bee per day based on default uptake of 13.5 mg sugar/bee per day(a),(g) | ||

| 1 | 10 | 0 | 0 | 0.7 ± 0.47 | 6.7 ± 1.44 | |||||

| 1 | 97 | 2,000 | 54.00 | 0.7 ± 0.47 | 67.0 ± 2.71* | |||||

| 7 | 144 | 4,000 | 108.00 | 3.0 ± 0.985* | 100* | |||||

| 7 | 144 | 8,000 | 216.00 | 5.0 ± 1.26* | 100* | |||||

| 336/576 larvae (7 replicates with 48 bees, for test groups and for control 12 replicates with 48 bees) | 6 (observation at day 7 or 22) |

33/77 (Considering average sugar contents of Royal Jelly and home‐ made syrup |

30 | 94 | 0 | 0 | 9.0 ± 1.19 | 28.1 ± 0.019 | Assuming an uptake of 28.3 mg bee feed/larvae per day based on uptake of 28.3 μL bee feed/larvae per day(b),(f) | |

| 23 | 89 | 5 | 0.14 | 6.9 ± 1.5 | 26.4 ± 2.60 | |||||

| 34 | 102 | 50 | 1.41 | 10.1 ± 1.77 | 30.2 ± 0.027 | |||||

| 23 | 108 | 750 | 21.22 | 6.8 ± 1.38 | 32.1 ± 0.026 | |||||

| 176* | 294* | 5,000* | 141.50* | 52.4 ± 2.72* | 87.5 ± 0.018* | |||||

| 336* | 336* | 7,500* | 212.25* | 100* | ‐‐ | |||||

| 336* | 336* | 10,000* | 283.00* | 100* | ‐‐ | |||||

| Gregorc et al. (2020)(e) |

350 workers (5 replicates with 70 bees) |

5 | 90/10 | 1 | 0 | 0 | 99.7 ± 0.3 | Assuming an uptake of 15.0 mg bee feed/bee per day based on a default uptake of 13.5 mg sugar/bee per day(a),(g) | ||

| 3 | 100 | 1.50 | 99.2 ± 0.5 | |||||||

| 1 | 500 | 7.50 | 99.6 ± 0.5 | |||||||

| 2 | 1,000 | 15.00 | 99.4 ± 0.6 | |||||||

| 2 | 1,500 | 22.50 | 99.5 ± 0.4 | |||||||

|

350 workers (5 replicates with 70 bees) |

10 | 90/10 | 4 | 0 | 0 | 98.8 ± 0.2 | ||||

| 9 | 100 | 1.50 | 97.5 ± 0.7 | |||||||

| 6 | 500 | 7.50 | 98.3 ± 0.4 | |||||||

| 9 | 1,000 | 15.00 | 97.5 ± 0.2 | |||||||

| 8 | 1,500 | 22.50 | 97.8 ± 1.2 | |||||||

|

350 workers (5 replicates with 70 bees) |

15 | 90/10 | 8 | 0 | 0 | 97.6 ± 0.4 | ||||

| 16 | 100 | 1.50 | 95.5 ± 0.9 | |||||||

| 11 | 500 | 7.50 | 96.9 ± 1.0 | |||||||

| 14 | 1,000 | 15.00 | 96.1 ± 1.1 | |||||||

| 28 | 1,500 | 22.50 | 91.9 ± 2.3 | |||||||

|

350 workers (5 replicates with 70 bees) |

20 | 90/10 | 29 | 0 | 0 | 91.7 ± 0.4 | ||||

| 40 | 100 | 1.50 | 88.6 ± 6.0 | |||||||

| 43 | 500 | 7.50 | 87.7 ± 7.4 | |||||||

| 43 | 1,000 | 15.00 | 87.7 ± 6.2 | |||||||

| 87 | 1,500 | 22.50* | 75.0 ± 11.6* | |||||||

HMF: Hydroxymethylfurfural; SD: standard deviation.

*: Considered as significantly different from control by the study authors.

Percentage of mortality or survival have been converted to dead bees per group.

SE/SD of mortality rates were not reported.

Values are mortality rates.

Values are mortality rates.

Values are survival rates.

Value as reported in Krainer et al. (2016).

Average consumption value derived from Tosi et al. (2021).

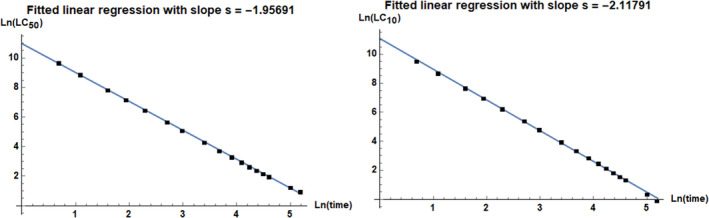

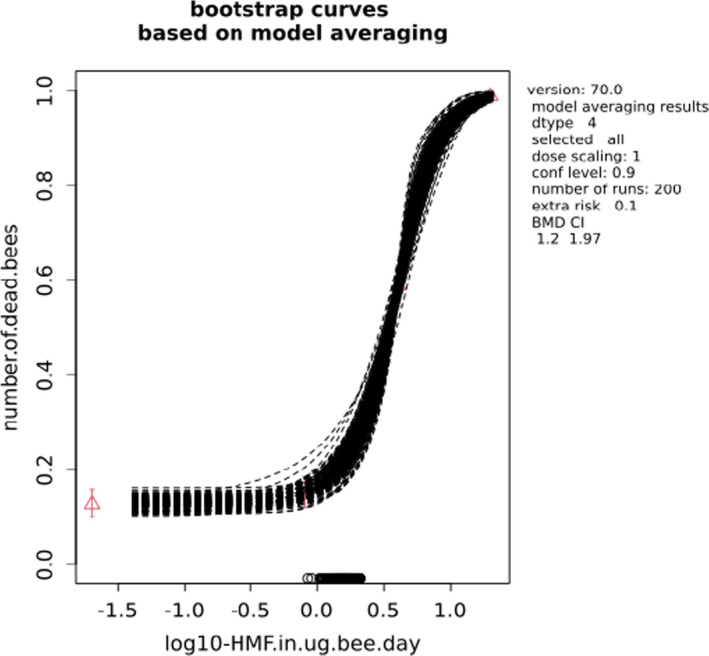

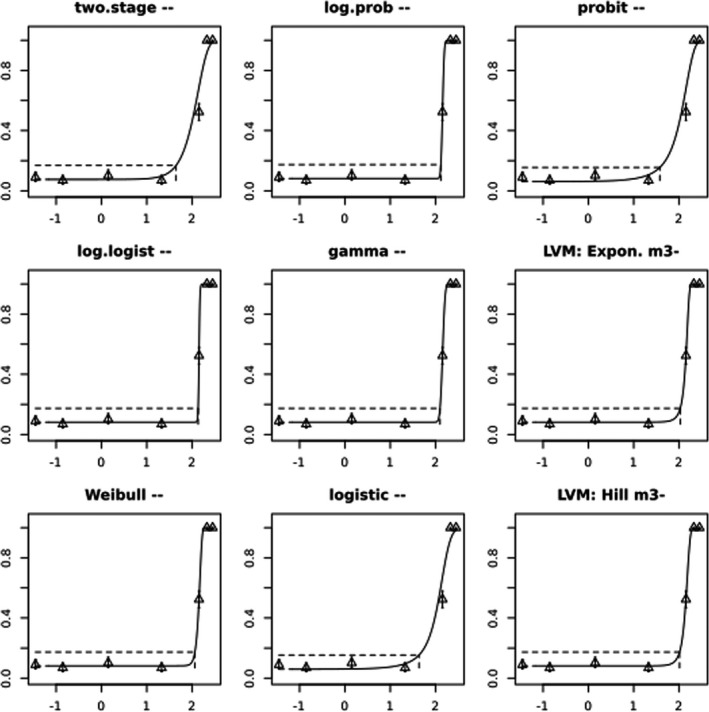

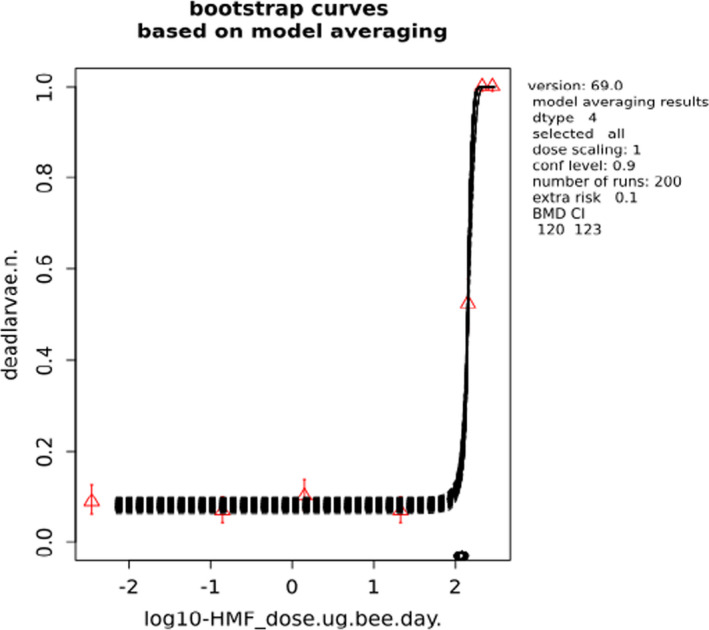

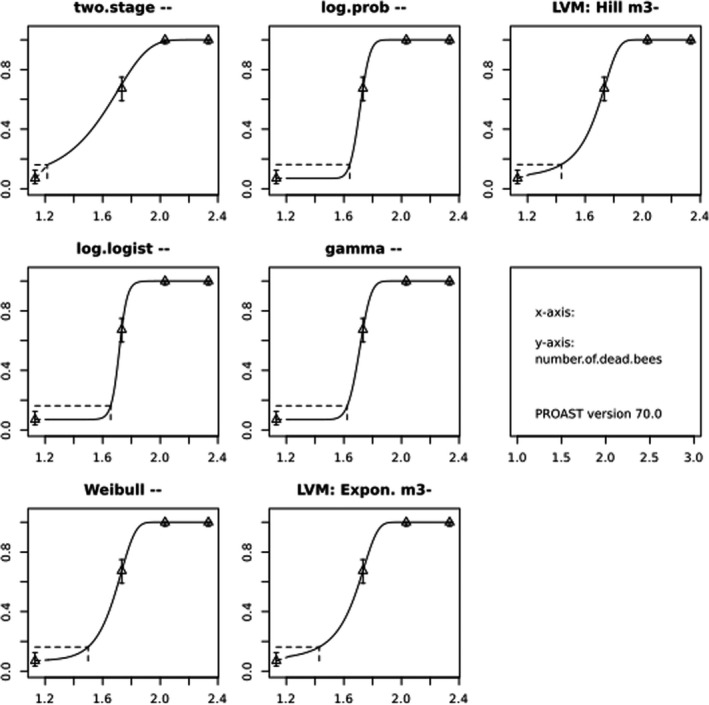

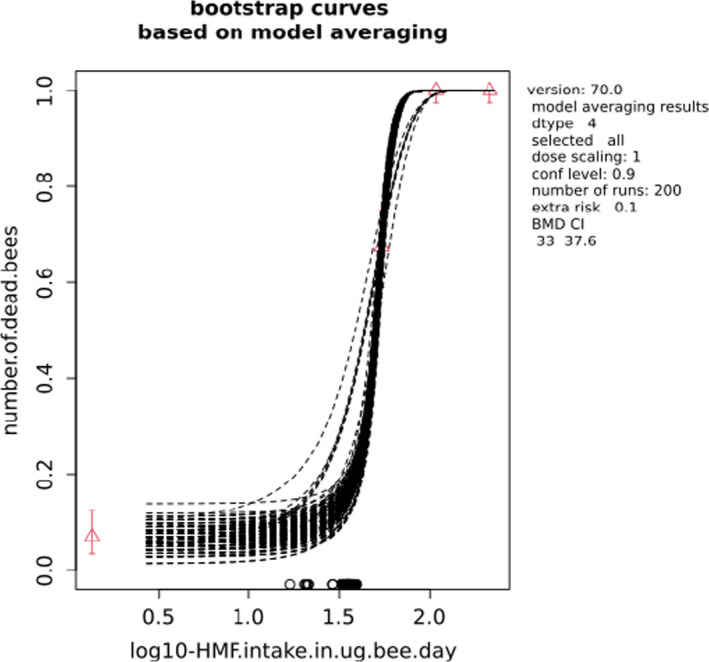

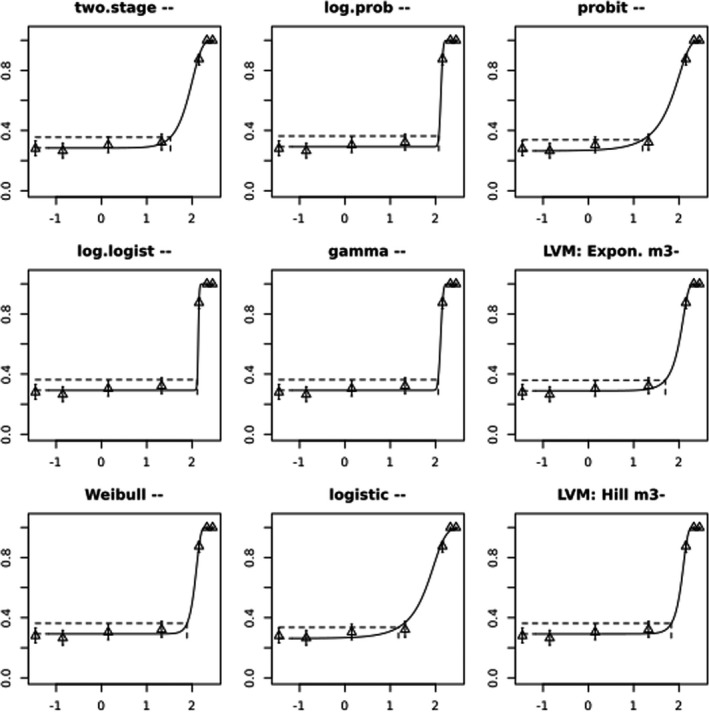

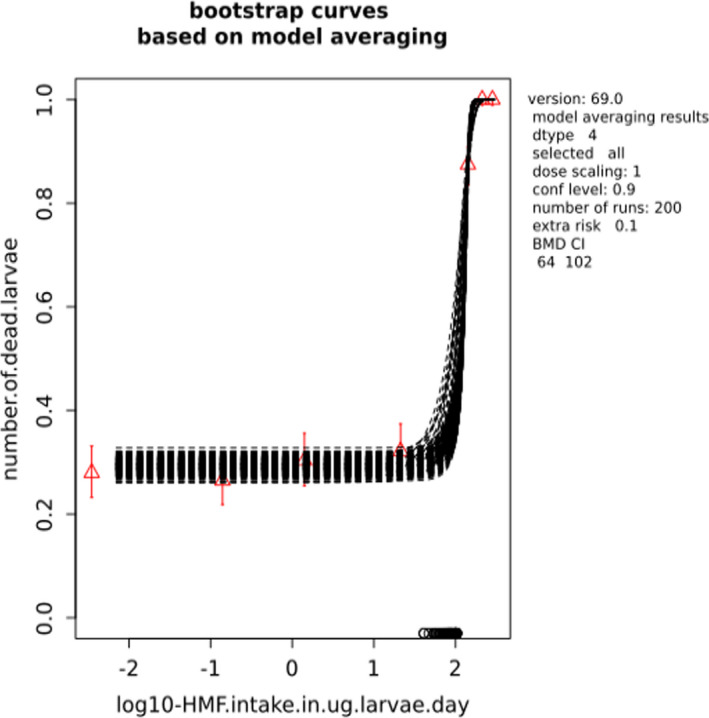

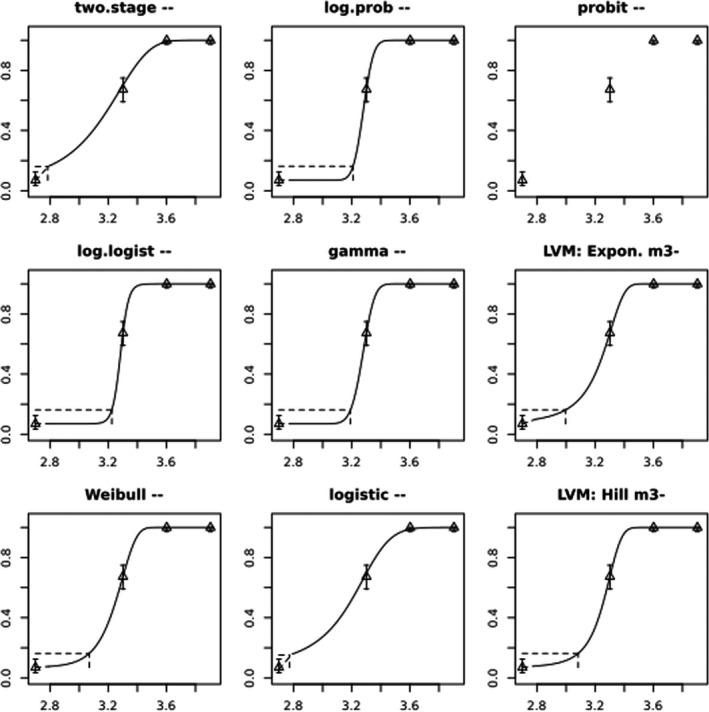

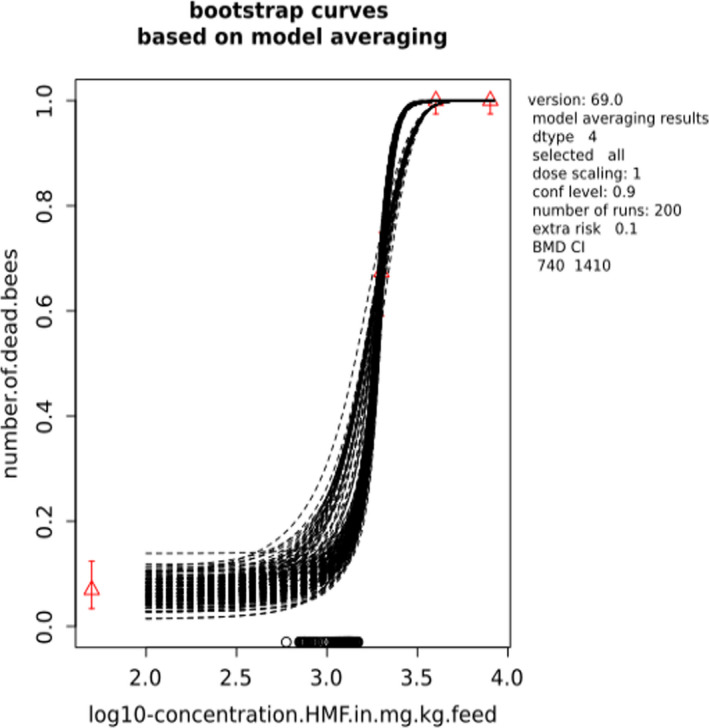

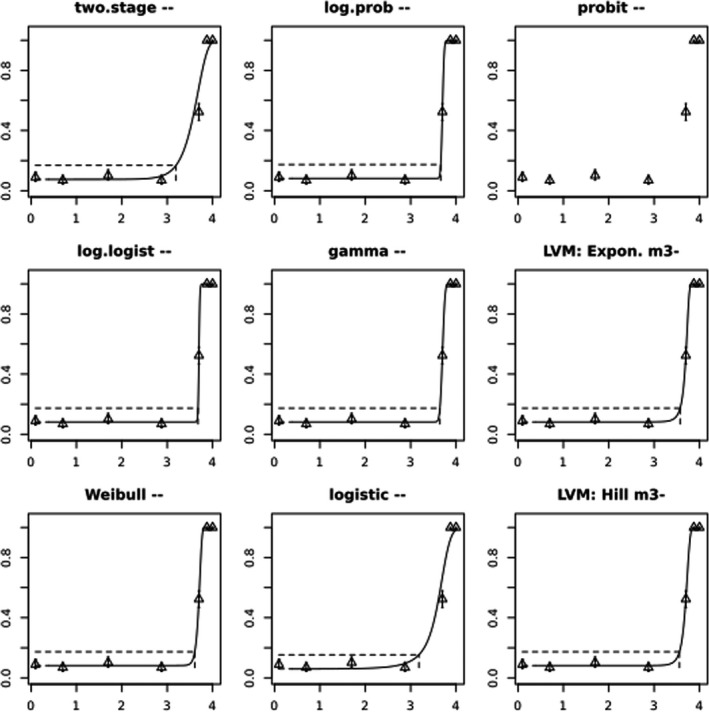

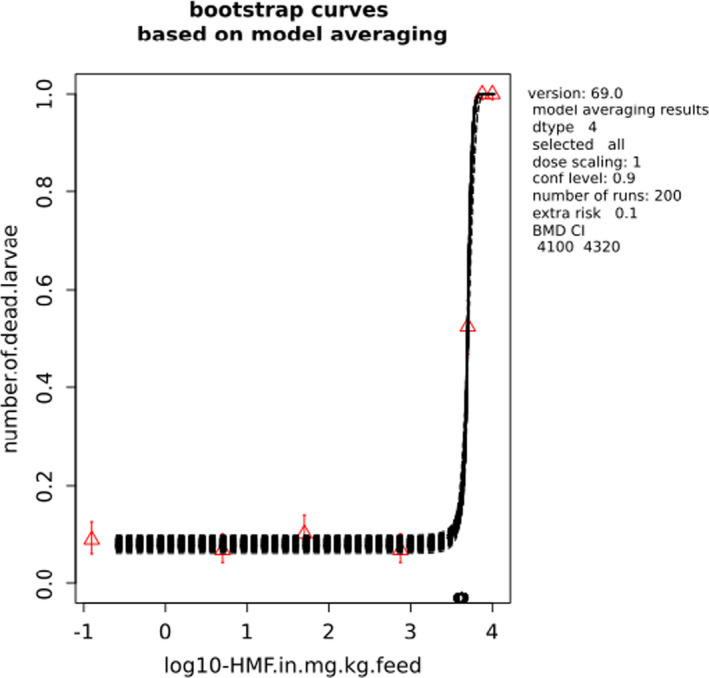

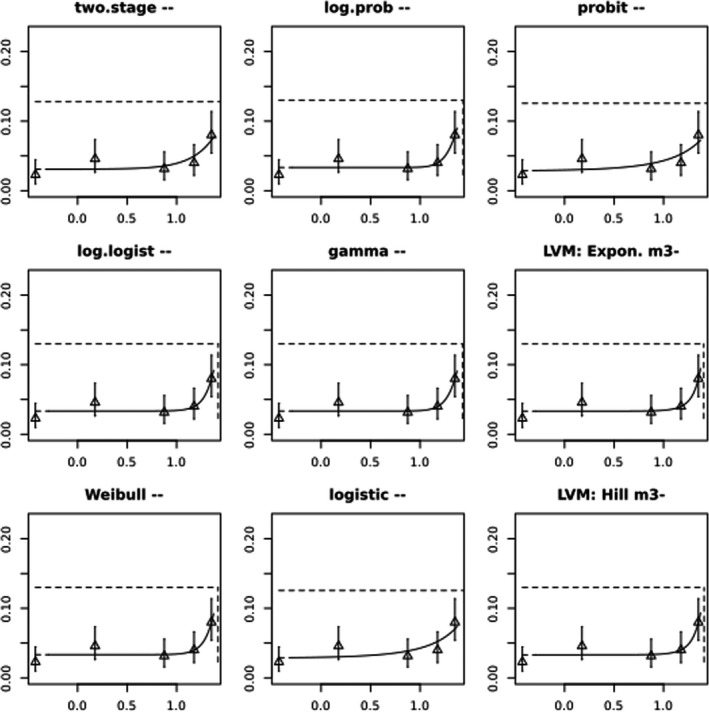

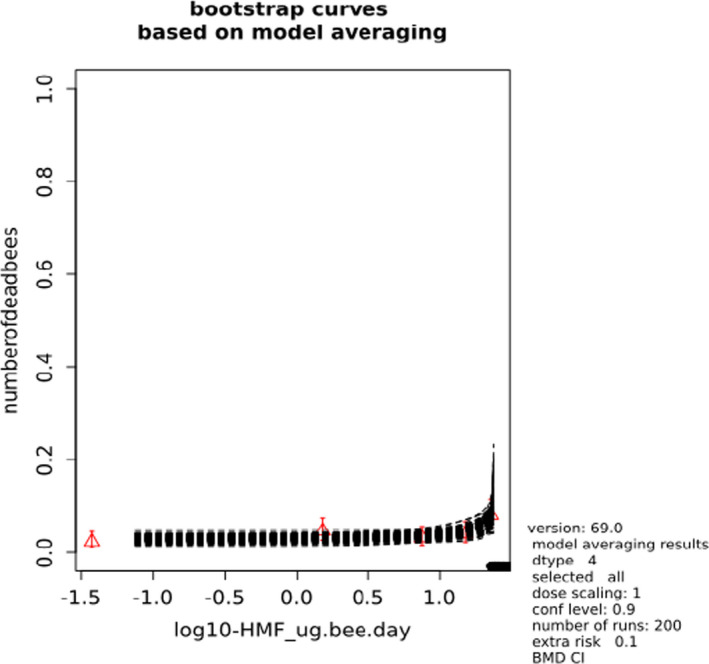

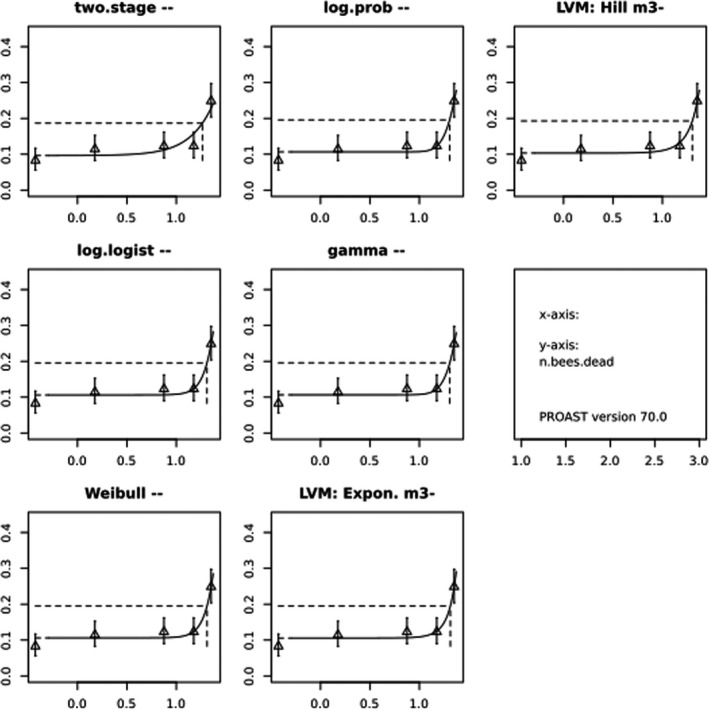

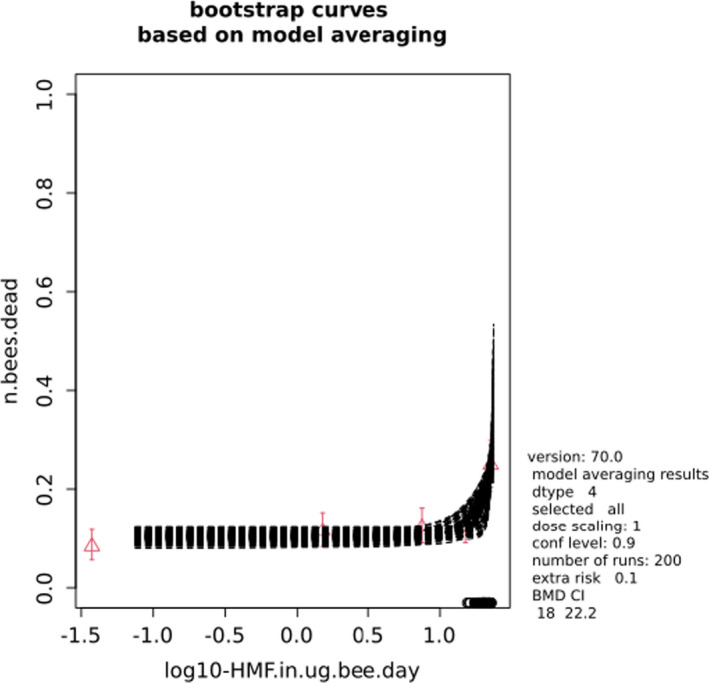

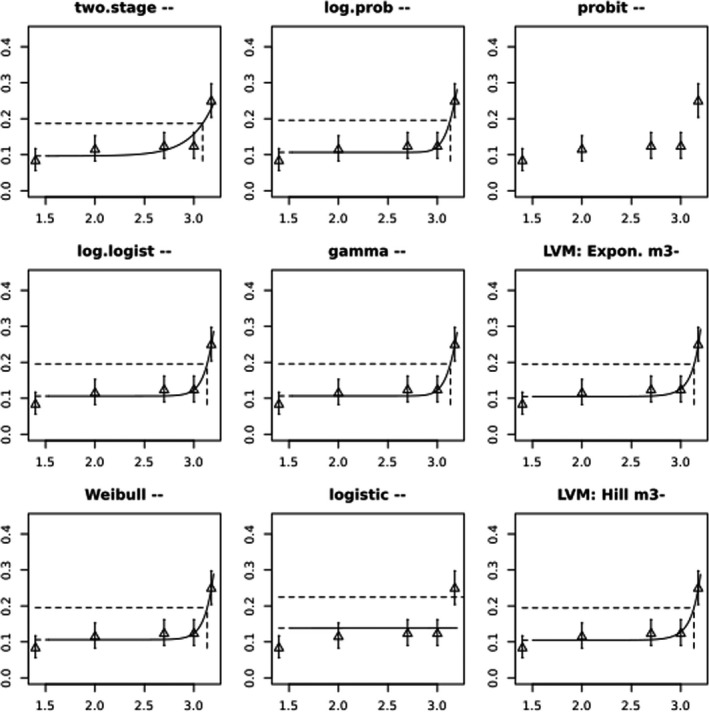

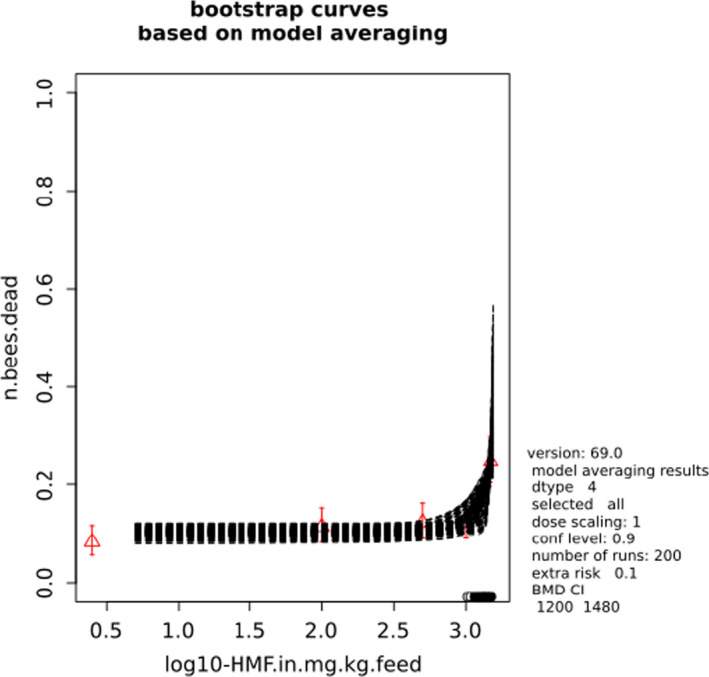

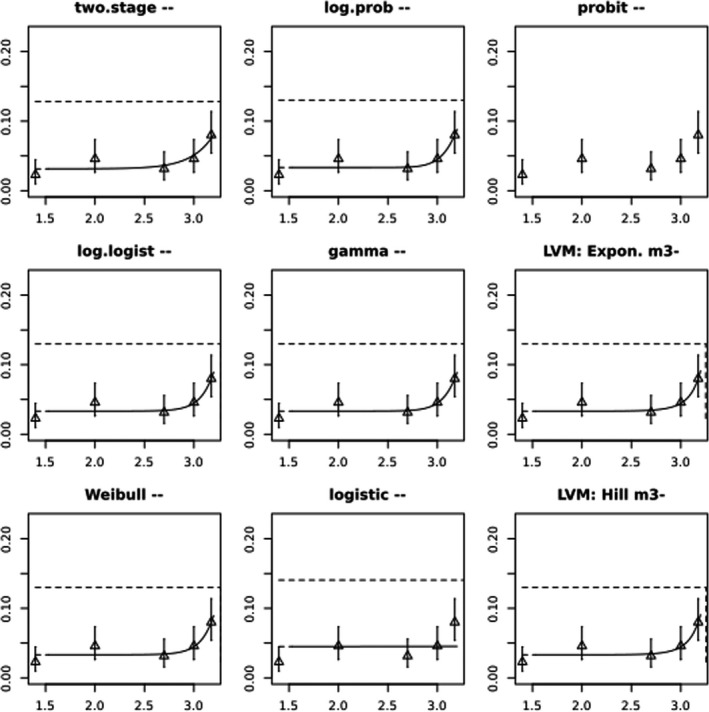

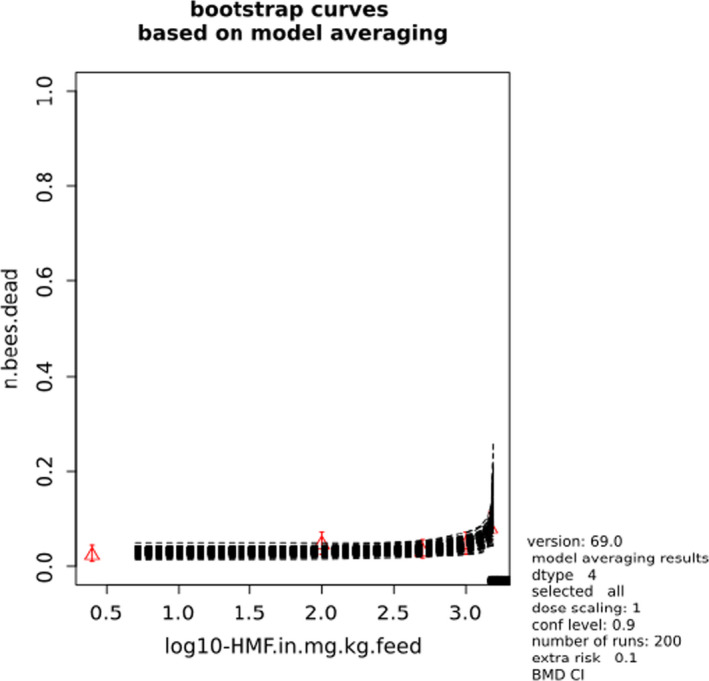

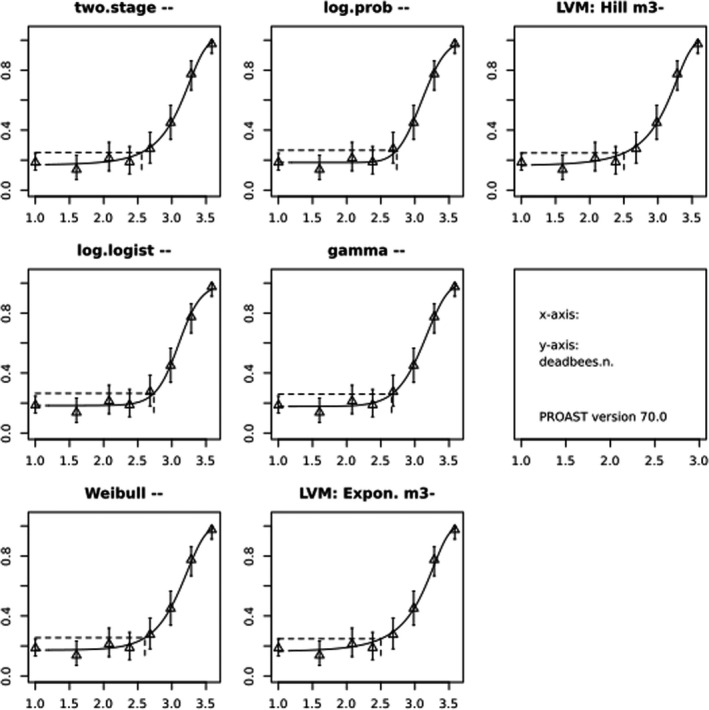

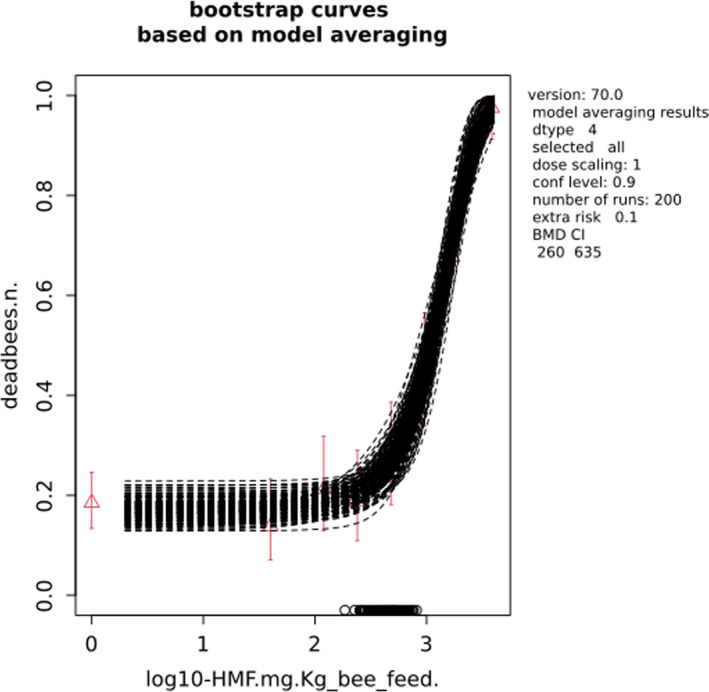

In Jachimowicz and El Sherbiny (1975), Krainer et al. (2016) and Gregorc et al. (2020), bee mortality or survival was given in percentages with standard deviations. However, it was regarded more appropriate to treat mortality as a quantal response in order to calculate a benchmark concentration/benchmark dose (BMC/BMD) in line with EFSA guidance (EFSA Scientific Committee, 2017). Therefore, results in the papers were first converted to mortality rates (the number of dead bees per test group), and analyses were then performed using the EFSA web tool for BMD analysis, which uses the R‐package PROAST, version 69.0, for the underlying calculations. Table 2 provides an overview on the study parameters and results of the toxicity studies.

For conversion of reported HMF study concentration to doses a daily sugar dose for larvae has been derived from information on the total daily intake and dry matter of syrups. In Krainer et al. (2016), an actual total intake of bee feed by larvae over 6 days of 170 µL (28.3 µL/larva per day) was reported. Due to lack of data regarding the mix solutions (50% ww of sugars water solutions and 50% ww of royal jelly), more detailed information were taken from Aupinel et al. (2005). As described by Aupinel et al. (2005) and mentioned in Krainer et al. (2016), three typologies of syrups were used as part of the 6‐day feeding protocol, based on larvae stage development: day 1–2 solution A (dry matter 29.55%), day 3 solution B (dry matter 33.05), day 4–6 solution C (dry matter 36.55). Using the dry matter average for these sugar solutions (33%), a daily sugar consumption of 9.3 mg/larvae per day was calculated, and used for conversion of concentrations to daily HMF doses per larva. In this process, an average density for sugar solutions equal to 1 was applied to enable consideration of feed uptake on a weight basis (mg bee feed/larva per day) since this was expressed on a volume basis by Krainer et al. (2016), as described above. This is as a pragmatic approach in the absence of reliable information, i.e. the complexity and limited information in Krainer et al. (2016), combining different sugar types and royal jelly mixture, makes calculation of density questionable. The sugar consumption used for larvae is thus indicative.

Following EFSA guidance on BMD derivation (EFSA Scientific Committee, 2017) for quantal endpoints a BMR of 10% was selected for derivation of BMCs/BMDs. The choice of a BMR of 10% for mortality in bees is based on the specific protection goals for honey bees, which considers a reduction in colony size of 10% as a trigger for concern, agreed by the EU agricultural ministers (Council of the EU, 2021).

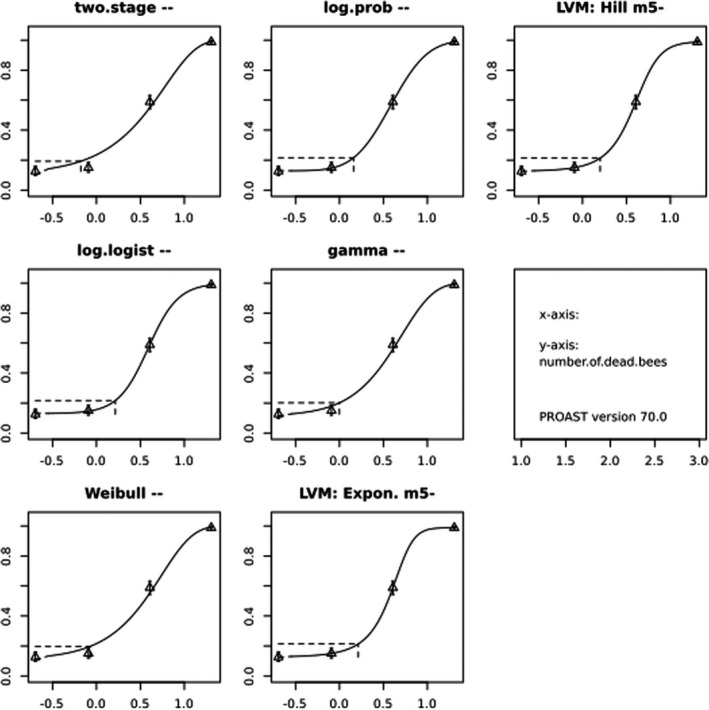

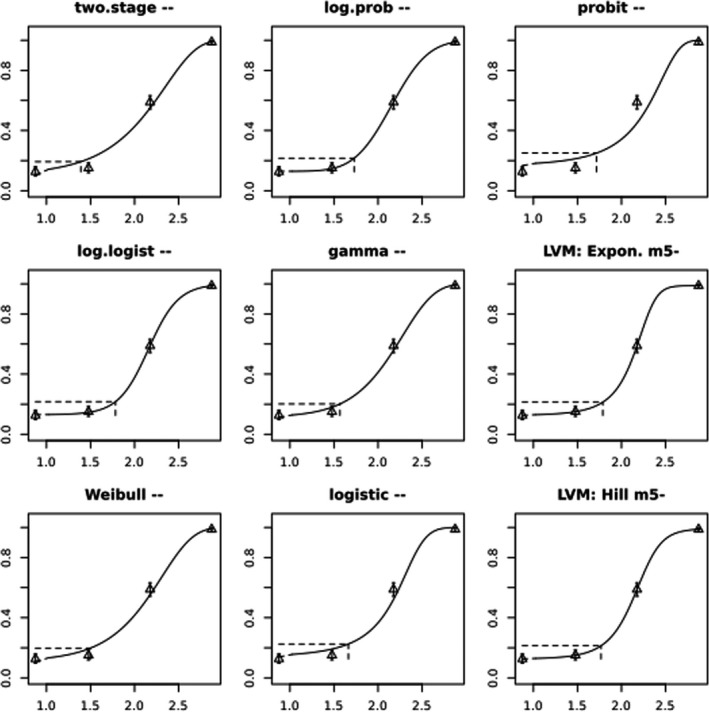

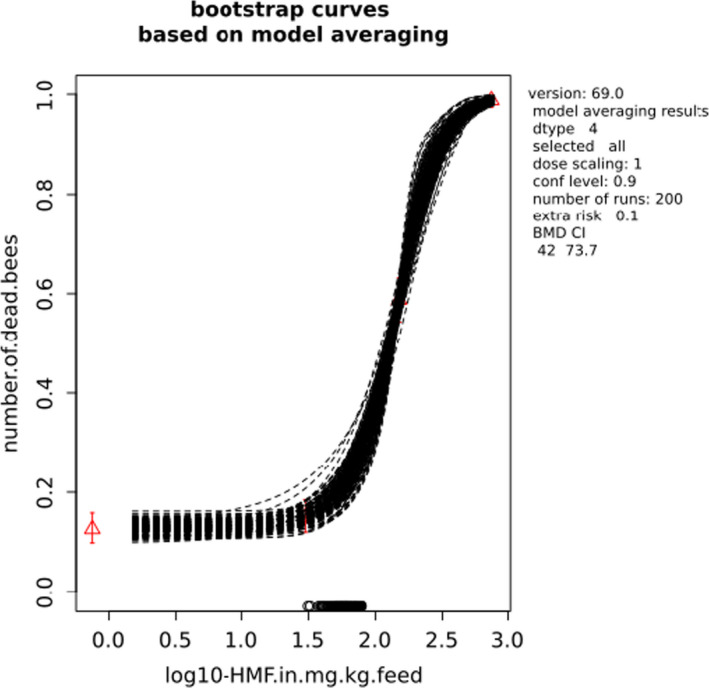

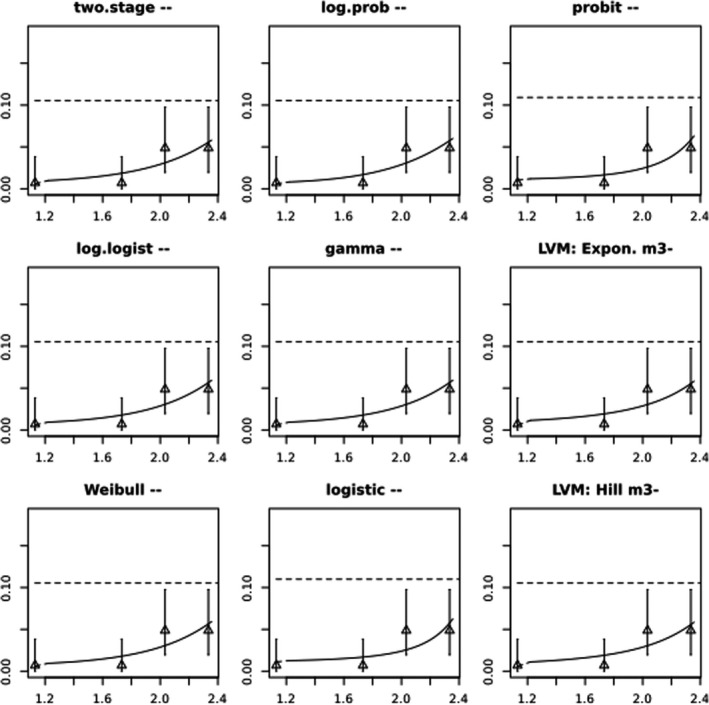

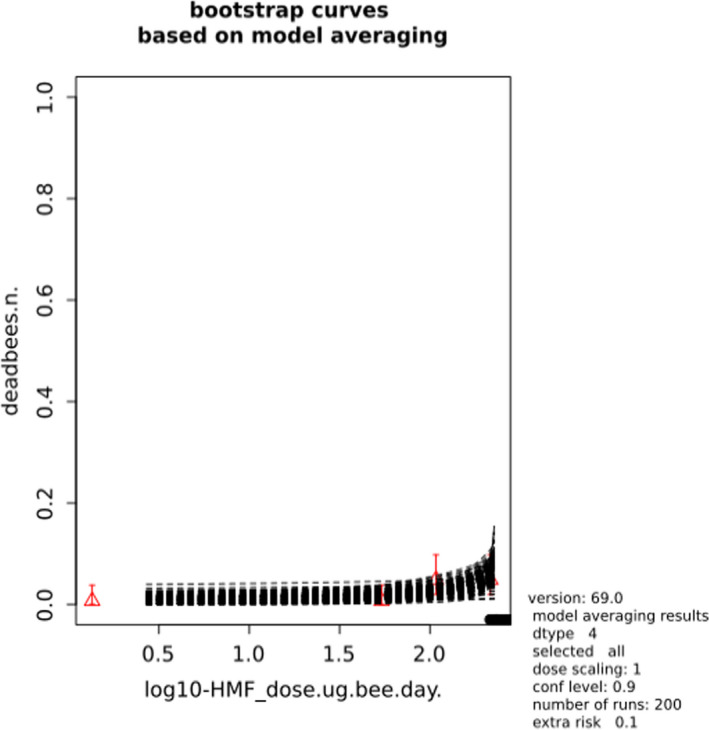

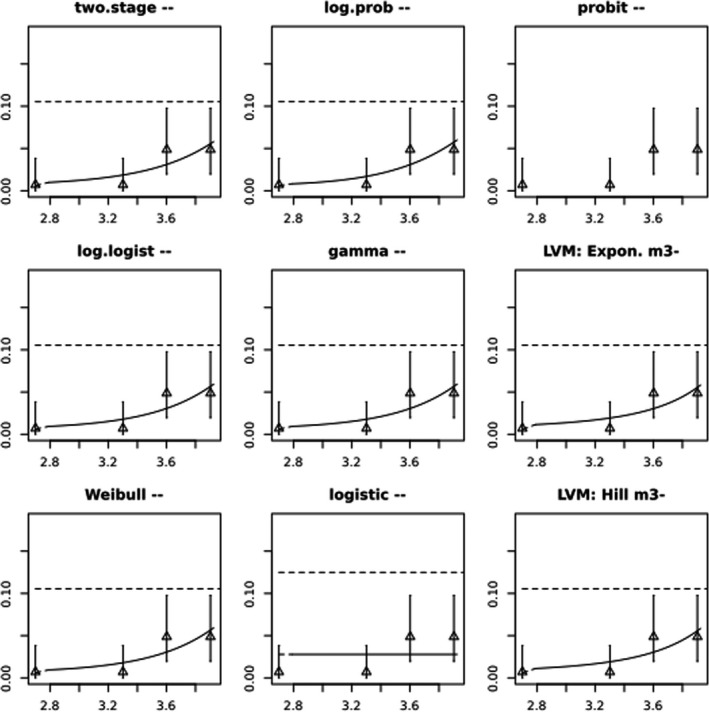

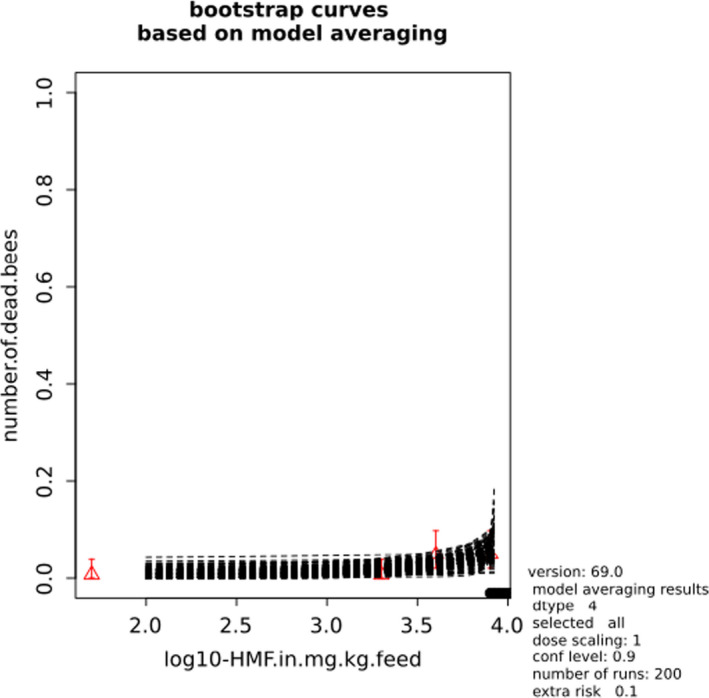

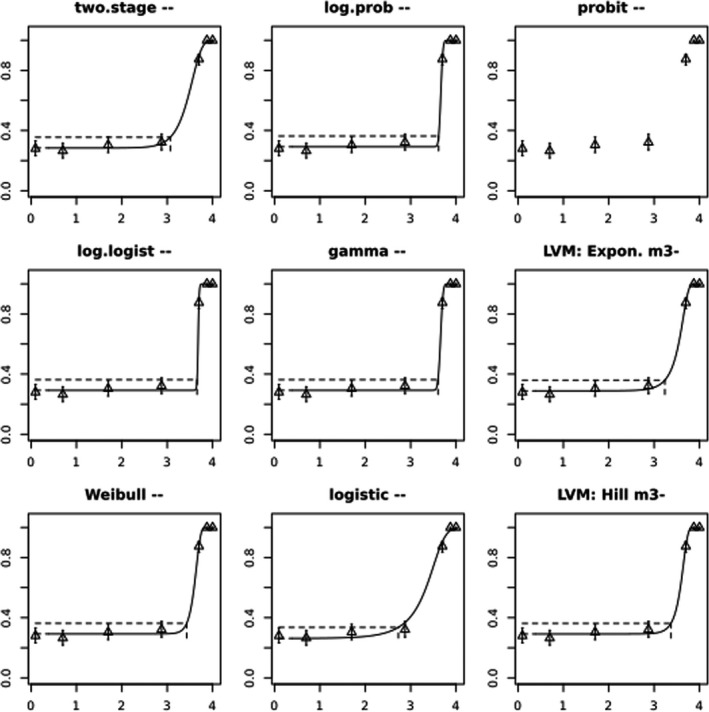

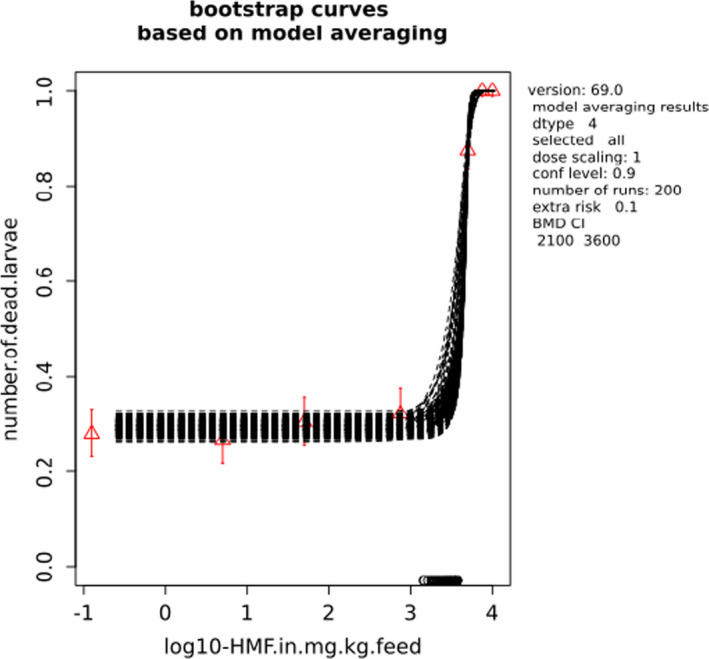

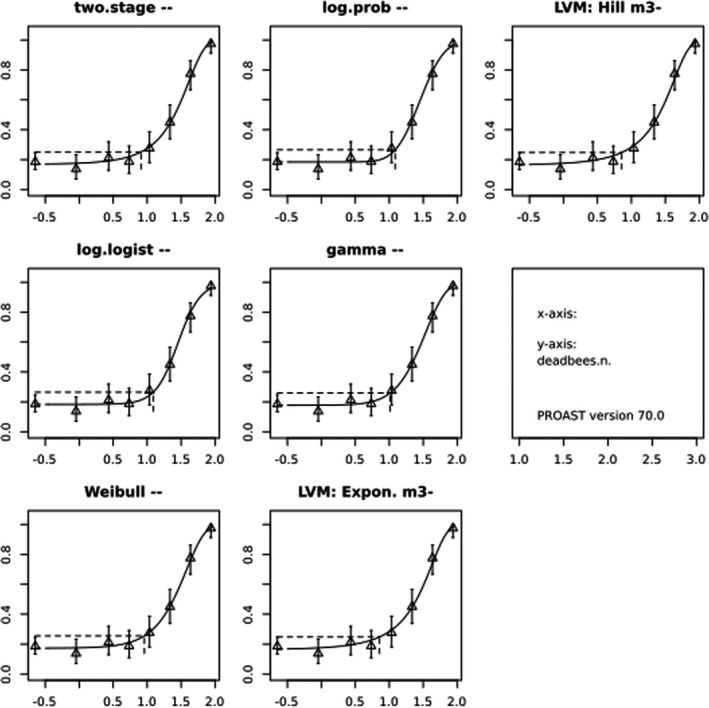

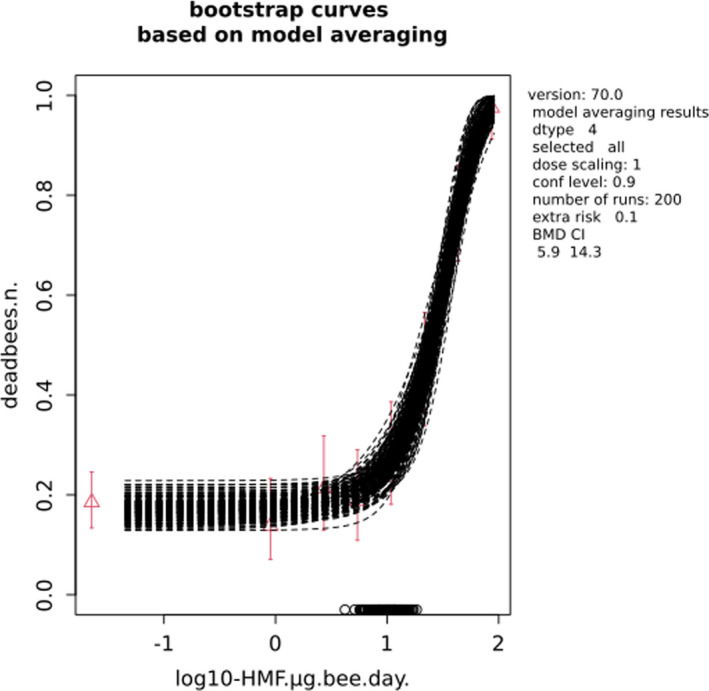

BMCs/BMDs based on data from Jachimowicz and El Sherbiny (1975), Krainer et al. (2016) and Gregorc et al. (2020) are reported in Table 3, and the underlying analyses are presented in further detail in Appendix A. Using data from Jachimowicz and El Sherbiny (1975), a BMDL of 1.16 µg/bee per day (BMCL = 42.1 mg HMF/kg) resulted for worker bees exposed for 20 days. Exposure durations between 5 and 20 days could be considered in the BMD analysis for workers using data from Gregorc et al. (2020). However, significant dose–response trends were only observed after 15 and 20 days of exposure (see Appendix A) resulting in a lowest BMDL of 18 µg/bee per day (BMCL = 1,200 mg HMF/kg) associated with the latter exposure duration (20 days). In Kranier et al. (2016), effects of HMF upon exposure durations of 7 and 22 days, in workers and larvae, respectively, were evaluated. Overall, the BMD analysis of this study suggests that larvae and workers do not clearly differ in their sensitive to HMF, and the lowest BMDL, resulting after 22 days of exposure for workers, was 32.7 µg/bee per day (BMCL = 745 mg HMF/kg). In summary, the lowest BMDL across studies is 1.16–32.7 based on worker bees and an exposure duration of 20/22 days. The details on BMC/BMD calculations are presented in Appendix A.

Table 3.

BMC and BMD calculations for bee mortality observed in relevant studies

| Study | Bees | Duration of the study (days) | BMR 10% | |

|---|---|---|---|---|

| BMCL/BMDL | BMCU/BMDU | |||

| Krainer et al. (2016) | Workers | 7 |

8,420 mg/kg 228.0 μg/bee per day |

227,000 mg/kg 1,170.0 μg/bee per day |

| 22 |

745 mg/kg 32.7 μg/bee per day |

1,410 mg/kg 37.6 μg/bee per day |

||

| Larvae | 7 |

4,090 mg/kg 115 μg/larva per day |

4,320 mg/kg 123 μg/larva per day |

|

| 22(b) |

2,130 mg/kg 64.3 μg/larva per day |

3,600 mg/kg 102 μg/larva per day |

||

| Jachimowicz and El Sherbiny (1975)(a) | Workers | 20 |

42.1 mg/kg 1.16 μg/bee per day |

73.7 mg/kg 1.97 μg/bee per day |

| Gregorc et al. (2020) | Workers | 15 |

1,550 mg/kg 23.3 μg/bee per day |

7,320 mg/kg 58.7 μg/bee per day |

| Workers | 20 |

1,200 mg/kg 18.0 μg/bee per day |

1,480 mg/kg 22.2 μg/bee per day |

|

| Lüken and von der Ohe (2016) | Workers | 30 |

262 mg/kg 5.91 μg/bee per day |

635 mg/kg 14.3 μg/bee per day |

BMR: Benchmark reference; BM(D/C)L: Benchmark (dose/concentration) lower bound; BM(D/C)U: Benchmark (dose/concentration) upper bound.

The BMCs/BMDs reported are the lowest BMCLs/BMDLs and highest BMCUs/BMDUs from simultaneous dose‐response modelling of two independent experiments with identical study design.

Note that exposure was for 6 days followed by a 16‐day observation period.

For comparative purposes, a BMD/BMC analysis was also conducted for the data from the autumn trial in Lüken and von der Ohe (2016). As shown in Table 3, the BMDL from this study is covered by the BMDL range across critical studies for worker bees (1.16–32.7 µg/bee per day), supporting the primary data. Details behind this additional BMD/BMC analysis can also be found in Appendix A.

3.1.6. Derivation of a reference point for bee health

3.1.6.1. Derivation of a reference point based on benchmark analyses

As described earlier, the lowest of BMDL10 of 1.16 μg/bee per day for worker bees is based on data from Jachimowicz and El Sherbiny (1975). The studies from Gregorc et al. (2020) and Krainer et al. (2016) are more recent suggesting that they, e.g. might have the advantage of being more in tune with todays’ environmental conditions. Also, the age of the bees at the start of the experiment is lower (< 24 h old) compared to Jachimowicz and El Sherbiny (1975) (0–3 days old). For preparation of the different concentrations in Jachimowicz and El Sherbiny (1975) weighted amounts of commercially produced (pure) HMF was added to test mixtures (sugars, citric acid, water), and no heating was involved limiting the likelihood of formation of (additional) HMF. From a general standpoint, it is considered that the three studies have been conducted following a similar protocol. They mainly differ with respect to feeding solutions, the range of tested concentrations and the number of bees used.

Jachimowicz and El Sherbiny (1975) provided a protein source and an inverted sugar solution with a pH of 3.9. It can be noted that Frizzera et al. (2020) found a significantly lower survival in bees fed with a sugar solution acidified to a pH of 2.80, either with lemon or hydrogen chloride, compared to bees fed the same sugar solution without an acidic element. Although Jachimowicz and El Sherbiny (1975) did not find an effect of acidity (diet with pH = 3.9), with respect to mortality rate, it cannot be excluded that acidity in combination with HMF could modulate the toxicity. Compared to Jachimowicz and El Sherbiny (1975) the feeding solutions in both Krainer et al. (2016) and Gregorc et al. (2020) are likely to be neutral. However, it can be noted that based on data from the Industry product, which the present exposure assessment is based on, has a pH of around 4, similar to that in Jachimowicz and El Sherbiny (1975). Thus, regardless of a potentially modulating effect on toxicity, a slightly acidic solution may nevertheless reflect a likely exposure scenario as the industry product on which the exposure assessment is based upon is widely marketed.

The dose range applied in the three critical studies is quite different. Compared to Jachimowicz and El Sherbiny (1975), it is a factor 2 and about a factor 10 larger in Gregorc et al. (2020) and Krainer et al. (2016), respectively, using the same/similar number of dose groups (Table 2). Also, the number of bees in Jachimowicz and El Sherbiny (1975) is higher compared to Gregorc et al. (2020) and Krainer et al. (2016) (i.e. 500 vs. 250 and 300, respectively), and two independent experiments were performed in the Jachimowicz and El Sherbiny (1975) study in subsequent years yielding very similar results (Table 3). As noted earlier, the lowest BMDL for workers varies considerably across the three studies (1.16–32.7 μg/bee per day), which to some extent appear related to the fact that Jachimowicz and El Sherbiny (1975) is better designed for evaluation of lower doses.

More detailed analyses indicate that results from Krainer et al. (2016) should be taken with caution due to extrapolation problems. For the 7‐day duration, this is in particular the case for workers, reflected by the wide BMD/BMC confidence interval/s in Table 3. The lowest BMDL from this study (32.7 µg/bee per day) is also estimated with extrapolation since the first experimental dose level is associated with a 67% response (Table 2). Since this BMDL is not constrained by any data in the relevant dose range, i.e. 0–54 µg/bee per day (Appendix A), it may not be reliable in spite of a narrow BMD confidence interval (Table 3). It can, however, be noted that the corresponding BMD/BMC for larvae, which is less problematic, is not smaller than 54 µg/bee per day (Table 3) still supporting the suggestion made in the previous section that larvae are not more sensitive to HMF compared to workers, considering that the BMDL for workers is between 0 and 54 µg/bee per day.

Based on this examination of the BMD results, it is regarded appropriate to mainly rely on the data from Jachimowicz and El Sherbiny (1975) and Gregorc et al. (2020), considering the lowest BMDL to be 1.16–18 µg/bee per day based on worker bees and 20‐day exposure. Even though the data from Gregorc et al. (2020) only show a significant effect at the highest dose (Table 2), it credibly suggests that the HMF dose‐response curve for workers could be displaced towards higher doses compared to results from Jachimowicz and El Sherbiny (1975). Also, although the data from Krainer et al. (2016) are not recommended for derivation of the actual reference point, the overall result from this study nonetheless supports that a reference point for workers also covers toxicity in larvae.

Overall, based on consideration of the differences between studies, including the quantitative analyses of the dose‐response data, the CONTAM panel did not find it reasonable to disregard the lower end of the BMDL interval across studies in favour of more recent investigations. Therefore, the main reference point for bee health is set to 1.16 µg/bee per day. As noted, the results for workers is regarded to cover larvae, and while it is assumed that the reference point also covers drones and queens the lack of data prevented quantitative analysis of this issue. As the exposure period (20 days) covers almost the entire average life span of a summer bee (15–38 days), and since the species tested was the species of concern, it was not regarded necessary to apply a standard uncertainty factor for inter‐sub species differences.

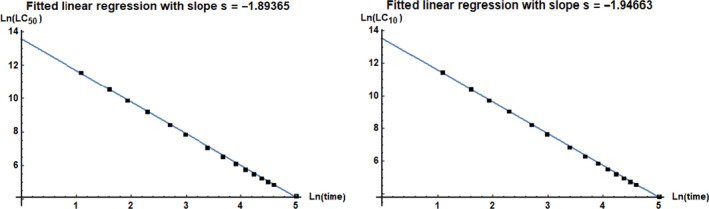

3.1.6.2. Assessment of time reinforced toxicity

While 20‐day exposure is within the range of the life span for a summer bee, although it does not cover the full life span of summer bees, winter bees can live for up to a few months but for them no toxicity data are available. Time reinforced toxicity (TRT) can be expected with bioaccumulative compounds, and can also occur when a lesion caused by a toxicant creates further harm even in the absence of the toxicant.