Abstract

In spite of the fact that petroleum-based plastics are convenient in terms of fulfilling the performance requirements of many applications, they contribute significantly to a number of ecological and environmental problems. Recently, the public awareness of the negative effects of petroleum-based plastics on the environment has increased. The present utilization of natural resources cannot be sustained forever. Furthermore, oil is often subjected to price fluctuations and will eventually be depleted. The increase in the level of carbon dioxide due to the combustion of fossil fuel is causing global warming. Concerns about preservation of natural resources and climate change are considered worldwide motivations for academic and industrial researchers to reduce the consumption and dependence on fossil fuel. Therefore, bio-based polymers are moving towards becoming the favorable option to be utilized in polymer manufacturing, food packaging, and medical applications. This paper represents an overview of the feasibility of both Poly Lactic Acid (PLA) and polyhydroxyalkanoates (PHAs) as alternative materials that can replace petroleum-based polymers in a wide range of industrial applications. Physical, thermal, rheological, and mechanical properties of both polymers as well as their permeability and migration properties have been reviewed. Moreover, PLA's recyclability, sustainability, and environmental assessment have been also discussed. Finally, applications in which both polymers can replace petroleum-based plastics have been explored and provided.

The dwindling nature, high price of petroleum, concerns about climate change, as well as the ever-growing population are all urging the plastics industries to adapt sustainable natural biopolymers solutions such as PLA and PHAs.

1. Introduction

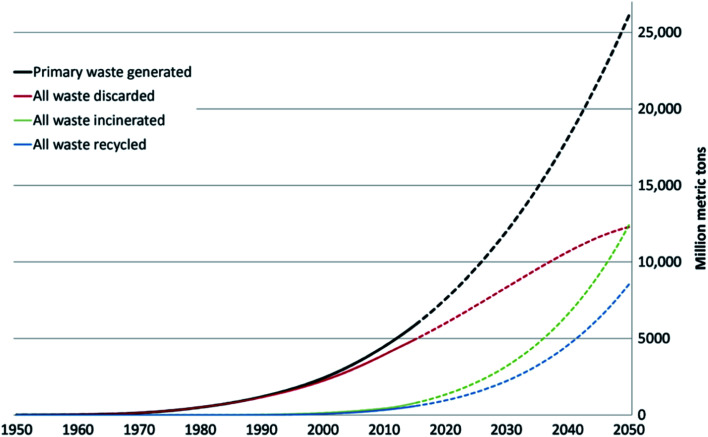

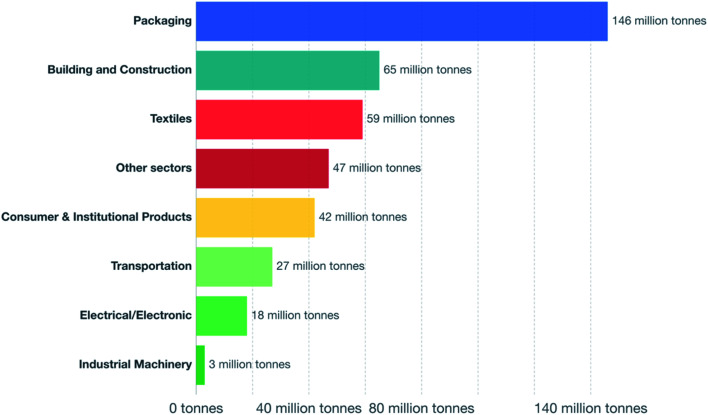

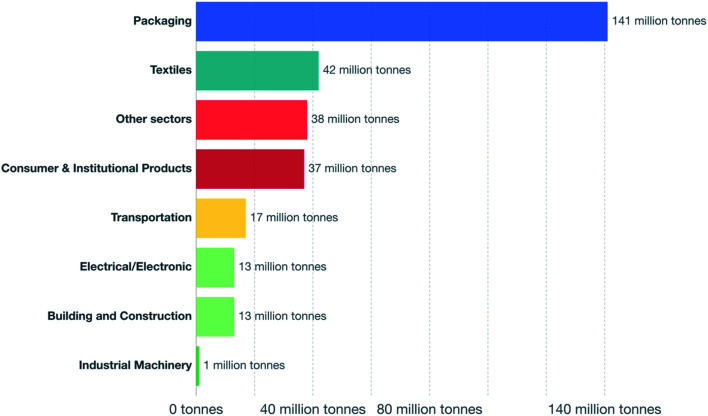

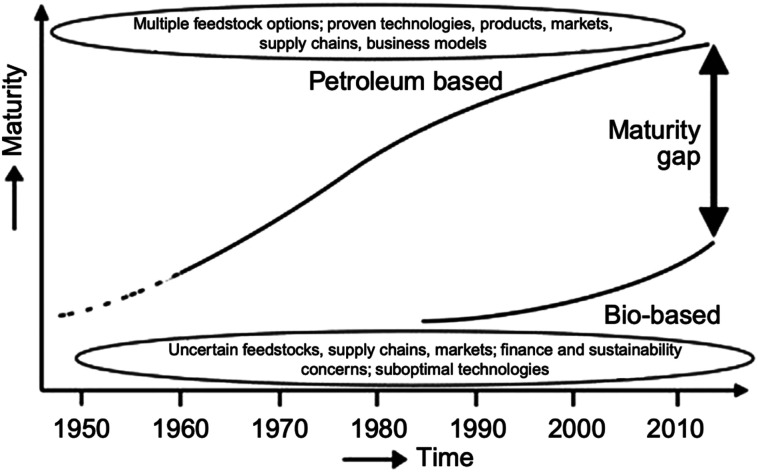

The worldwide production of polymers has been continuously rising from 2 million tons in 1950 to around 381 million tons in 2015. This is approximately equal to the mass of two thirds of the global population and need to be disposed of by the end of their life cycle.1,2 The rapid production growth of plastics is extraordinary, surpassing most other man-made materials with the exception of steel and cement.1 In 2010, the plastic waste generation was estimated to be around 274 million tons. Fig. 1 represents the cumulative plastic waste generation and disposal between 1950 and 2010. Between the period of 1950 and 2015, the cumulative waste generation of primary (plastics manufactured from virgin materials) and recycled plastics was around 6300 million tons. Roughly, 800 million tons (around 12%) of plastics have been incinerated. 600 million tons (around 9%) have been recycled, and only 10% of which have been recycled more than once. Approximately, around 60% of all plastics ever produced until 2010 were discarded and are accumulating in the natural environment and landfills.1 To date, plastics do not experience significant recycling rates and hence are discarded or incinerated together with other solid waste.3 Between 22% and 43% of polymers end up in landfills, therefore, wasting the carbo feedstock and eventually leading to ground water pollution by the leaching of toxic additives. Waste from polymers accumulates in the natural environment in which they can remain for up to two thousand years.4 The pollution resulting from polymers is especially harmful in the marine environments, where 100 million tons of polymers can cause an ecosystem service damage of roughly US $ 13 billion per year.5 As per Fig. 2 and 3, packaging was the dominant use of primary plastics, with around 42% of plastics entering the use phase and it was also the dominant source for plastic waste with around 141 million tons. Fossil fuels trigger environmental concerns. The scientific evidence that carbon dioxide is one of the main reasons behind global warming and climate change is overwhelming. The CO2 continuous measurements at Mauna Loa since 1958 have conclusively shown increasing CO2 levels in more recent times. During this period, the data shows an increase at a rate of 1.5 ppm per year for the ambient concentration of CO2. A trend which if to continue the same, will mean doubling the CO2 levels by 2150.6 In the past 800 years, the average concentration of carbon dioxide in the atmosphere was estimated to be around 280 ppm. In 2019, the average concentration of CO2 increased to over 400 ppm. The critical limit of global warming has been adjusted by the United Nations from 2.0 °C to 1.5 °C; to prevent dramatic and irreversible changes in weather. These limits are expected to be surpassed in 20–40 years if no serious mitigations are taken.7 The dwindling nature, high price of petroleum, concerns about climate change, as well as the continued population growth are some of the factors that are urging the plastics industries to adapt sustainable natural solutions. Today, the worldwide population exceeds 7 billion people and is expected to reach to around 9 billion by 2050. Therefore, energy needs are also expected to increase. It is expected that there will be an increase in the electricity generation from 20 × 1015 W h in 2010 to around 31.2 × 1015 W h in 2030. As shown in Table 1, in 2010 the world energy supply has been dominated by fossil fuel. However, combustion of fossil fuel is a main cause of air pollution.8 Consumption of fossil fuels increases hunger for energy and will eventually lead to higher greenhouse and CO2 emissions. A sudden collapse of the biosphere might be triggered due to the progressive global warming and continuous reckless depletion of natural resources.9–13 Recent government policies that are focused on conservation of energy, as well as CO2 and footprint reduction are also driving the research about polymers towards the use of renewable and sustainable biopolymers. For example, Canada has announced that it is going to ban single use plastics by the end of 2021 in order to reach to zero plastic wastes by 2030.14 Furthermore, concerns about preservation of natural resources and climate change are considered worldwide motivations for academic and industrial researchers to reduce the consumption and dependence on fossil fuel.15 It is widely recognized that in order to meet the continuously increasing needs of materials of a constantly growing world population while at the same time maintaining functioning ecosystems, societies are required to switch to plant-based resources which are renewable on a short time scale and whose consumption and conversion are green.16 The main aim is to use biopolymers that contain the highest possible number of renewable resources to have a green future.17,18 Therefore, bioplastics are moving towards becoming the favorable option to be utilized in polymer manufacturing and various applications.13,19–23

Fig. 1. Cumulative plastic waste generation and disposal-solid lines show historical data from 1950–2010; dashed lined show projections of historical trends to 2050.1.

Fig. 2. Primary plastic production by industrial sector, 2015.1.

Fig. 3. Plastic waste generation by industrial sector, 2015.1.

Total global energy consumption for 20108.

| Types of energy | Energy consumption, % |

|---|---|

| Oil | 35.3 |

| Coal | 27 |

| Natural gas | 20.5 |

| Nuclear | 5.0 |

| Hydroelectric | 5.8 |

| Biomass | 6.3 |

| Other renewable | 1.1 |

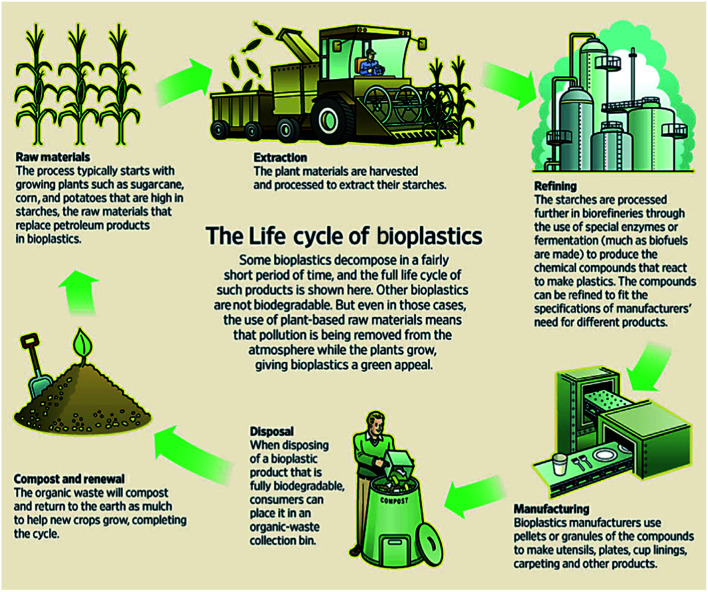

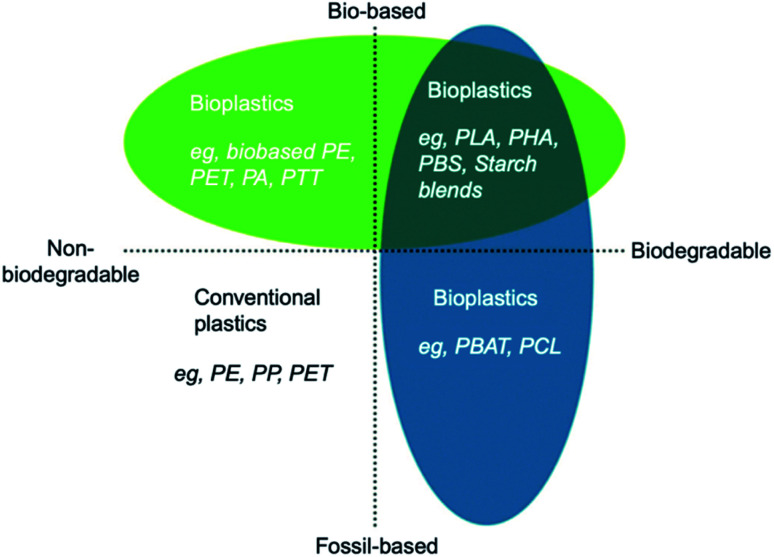

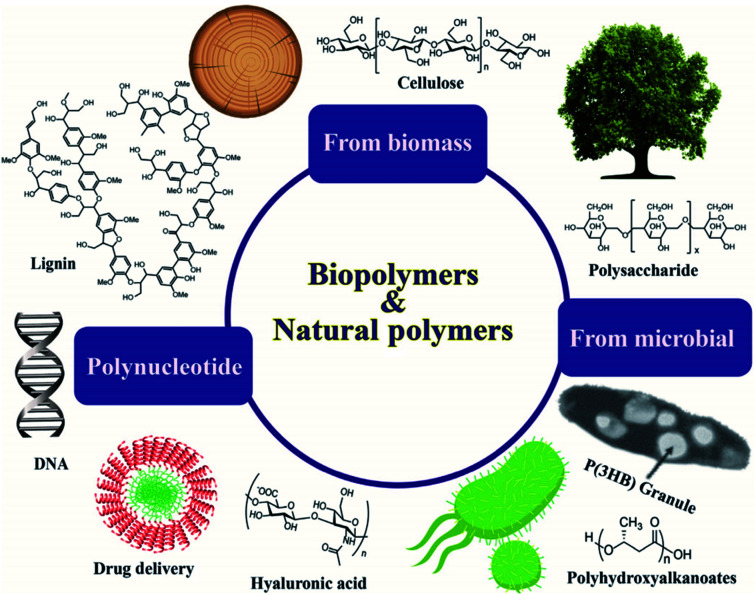

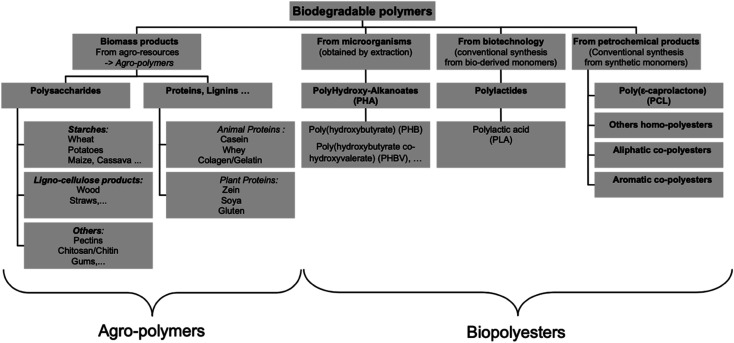

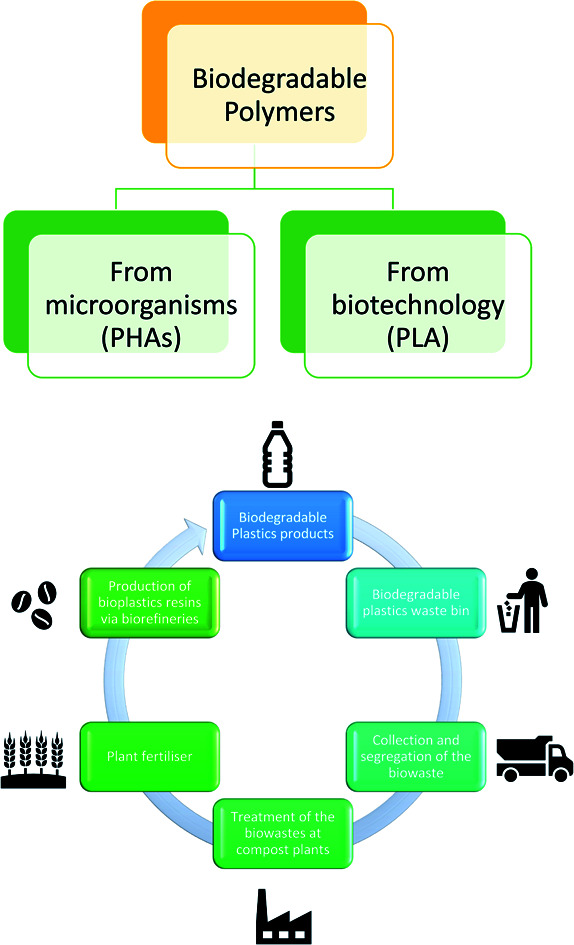

Bioplastics are one type of plastic which can be generated from natural resources such as starches and vegetable oils. Bioplastics are basically classified as bio based and/or biodegradable. Not all bio-based plastics are biodegradable and similarly not all biodegradable plastics are bio based. Bioplastics are referred to as bio based when the focus of the material is on the origin of the carbon building block and not by where it ends up at the end of its cycle life. Bio plastics are said to be biodegradable if they are broken down with the effect of the right environmental conditions and microbes which in turn use them as a food source. The bioplastics are considered compostable if within 180 days, a complete microbial assimilation of the fragmented food source takes place in a compost environment. The difference between the two branches of bioplastics is shown in Fig. 4.24 An illustration of the bioplastics' life cycle is presented in Fig. 5. The cycle initiates by growing plants that are rich in starches such as corn and sugarcane. The next step is the extraction of starches out of these plants by processing and harvesting the plants. The extracted starches are then refined and fermented by special enzymes to produce chemical compounds that produce plastics after they react. Plastics in the form of pellets are then used to manufacture products. After their full use, the manufactured products are then placed in an organic waste container and finally the last stage of the cycle begins.24Fig. 6 shows a classification of materials based on their biodegradability and bio-based content.25 As shown in Fig. 7, biopolymers can be classified according to their origin into three categories. Firstly, polymers that are made from renewable resource/biomass and agricultural resources. The second group contains polymers obtained from animal origin or microbial products and that are useful in pharmaceutical as well as medical applications. The last group includes chemically synthesized biodegradable polymers that have been altered from natural polymers or obtained from petrochemical resources.26

Fig. 4. Difference between bio based and biodegradable bioplastics.24.

Fig. 5. Life cycle of bioplastics.24.

Fig. 6. Materials' classification based on their biodegradability and bio-based content.25.

Fig. 7. Classifications of biopolymers based on their origins.26.

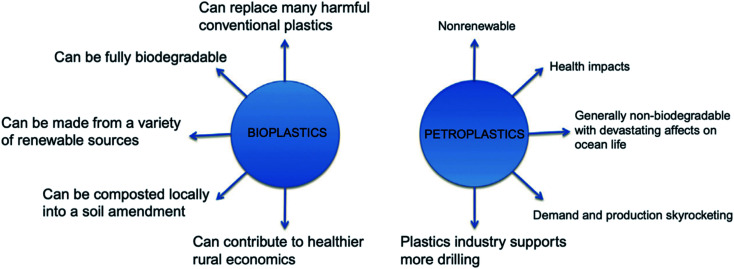

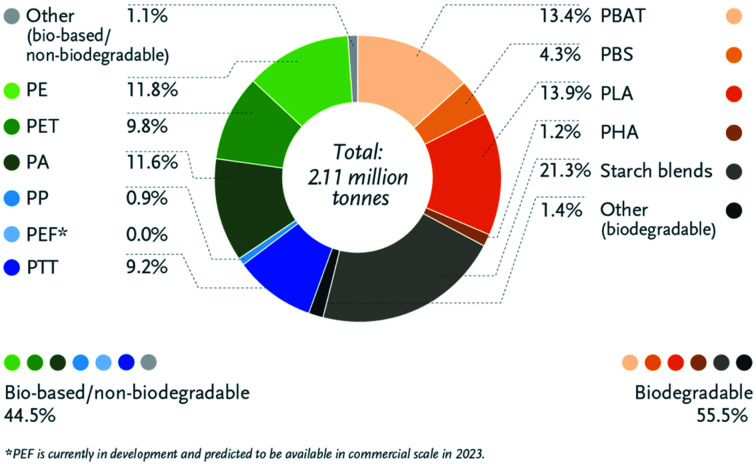

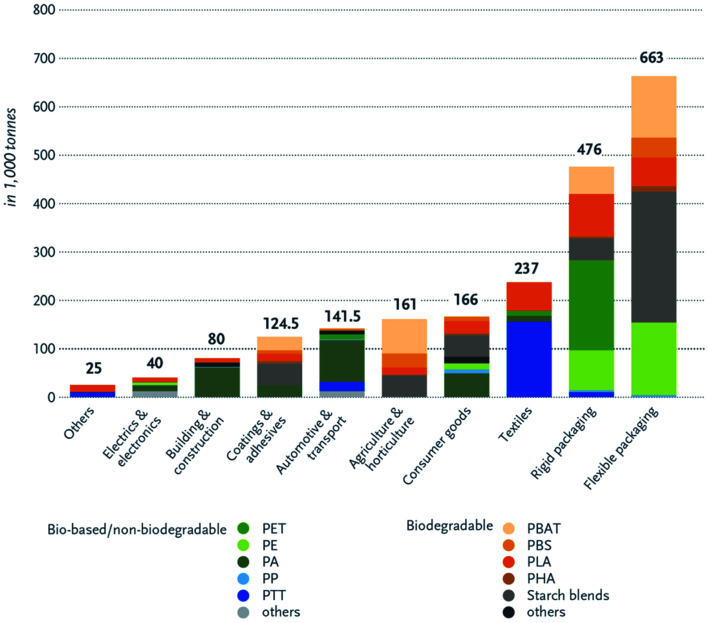

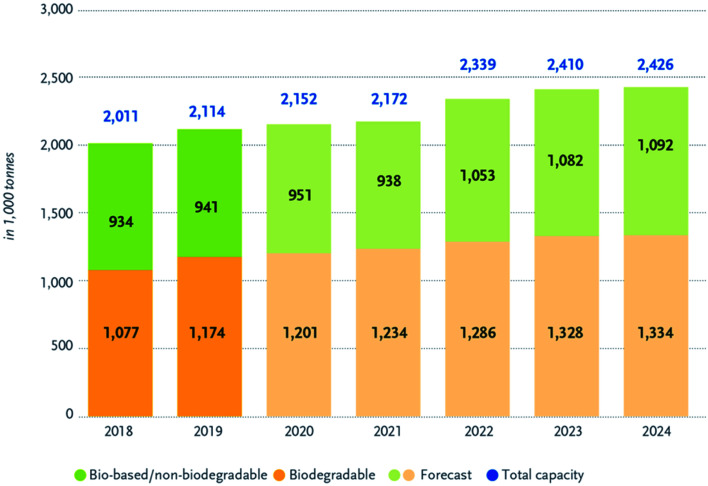

Bioplastics have many advantages over petroleum-based plastics. The incorporation of bioplastics in different applications is under growth and development. Fig. 8 presents the main differences between bioplastics and petroleum based plastics.24 Bioplastic fast market growth is more than 8–10% per year. The global demand for bioplastics is expected to increase due to the availability of raw material, their renewability, their technical properties and advanced functionalities, their recycling solution, as well as their wide processing window (as shown in Table 2). Fig. 9 and 10 introduce the global production capacities of bioplastics in 2019 by material type, and market segment respectively. Fig. 11 shows global production of bioplastics between 2018 to 2024. Innovative and new biopolymers such as PHAs and polypropylene (PP) show the highest relative growth rate. All the bio-degradable plastics including PLA and PHAs accounts for over 1 million tons of the worldwide production capacities of bioplastics. The production of biodegradable plastics is estimated to increase to 1.33 million in 2024, this will mainly be due to PHA's vital growth rate. Bioplastics continued to be used in number of applications including but not limited to, packaging, electronics, catering, and automotive. With around 1.14 million tons (more than 53%), packaging continues to be the largest field for bioplastic applications in 2019. Nonetheless, applications such as building construction and automotive have increased their bioplastics share in a significant way. Based on the market data compiled by European Bioplastics in association with the research institute Nova-Institute, the global production of bioplastics is expected to raise to around 2.43 million tons in 2024 compared to around 2.11 million tons in 2019.27

Fig. 8. Comparison between bioplastics and petro plastics.24.

Processibility window for some typical commercial biodegradable polymers28a.

| Polymer | Injection molding | Extrusion | Extrusion blow molding | Cast film extrusion | Blow molding | Fiber spinning | Thermoforming |

|---|---|---|---|---|---|---|---|

| PLA | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| PHB | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| PHB–PHV | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| PBS | ✓ | ✓ | |||||

| PCL | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| PBST | ✓ | ✓ | ✓ | ✓ | |||

| PBAT | ✓ | ✓ | ✓ | ||||

| PTMAT | ✓ | ✓ | ✓ | ✓ | |||

| PVA | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| PP, PE with additives | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Starch | ✓ | ✓ | ✓ | ✓ | |||

| Starch with PVA | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Cellulose | ✓ | ✓ | ✓ | ||||

| Starch with cellulose acetate | ✓ | ✓ | ✓ | ✓ | ✓ |

Abbreviations: PLA, poly(lactic acid); PHB, polyhydroxybutyrate; PHV, poly(hydroxyl valerate); PBS, poly(butylenes succinate); PCL, poly(ε-caprolactone); PBST, poly(butylene succinate terephthalate); PBAT, poly(butylene adipate terephthalate); PTMAT, poly(tetramethylene adipate terephthalate); PVA, poly(vinyl alcohol); PP, poly(propylene); PE, poly(ethylene); PVA, poly(vinyl alcohol).

Fig. 9. Global production capacities of bioplastics by material type, 2019.27.

Fig. 10. Global production capacities of bioplastics by market segment, 2019.27.

Fig. 11. Global production capacities of bioplastics.27.

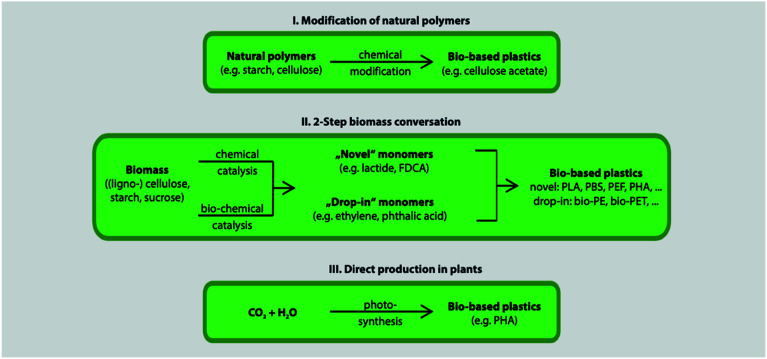

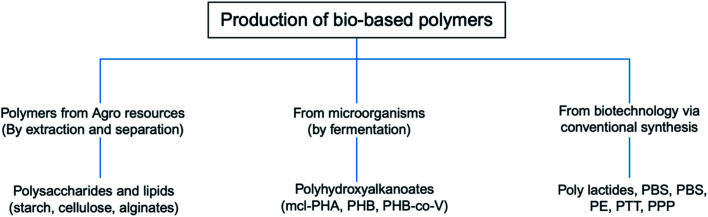

Fig. 12 shows the three main routes to obtain bio-based plastics. The first approach is by alteration of natural polymers whilst preserving the polymer backbone intact. This method is used for the production of cellulose-based and starch plastics and it is considered today as the most important method. Furthermore, this approach is used for bio-based polymers and fibers that are used in non-plastic and non-food applications. The second approach consists of two steps biomass conversion that are normally complex and divided into various sub steps. The first step consists of the production of bio-based monomers via means of biochemical and/or chemical transformation. This step is usually followed by polymerization of the monomers in the final step. This approach is gaining much attention as a result of the advancements in the bio-technological and chemical production of monomers. Bio-based monomers that have not been applied to the market in the past or have new structures are called novel monomers. They are intended to replace standard plastics due to their enhanced functionality and hence additional markets and applications. Novel bio-based plastics require the development of new recycling systems. On the other hand, drop-in monomers are bio-based versions of conventional monomers. The use of drop-in monomers in the manufacturing of conventional plastics is beneficial. This is because they cannot be distinguished by performance nor structure from their petrochemical counterparts. This allows them to enter existing processing and recycling systems easily. The third approach includes the production of polymeric material directly inside microorganisms or plants without additional modification. This approach is becoming more feasible now, thanks to the progress in genetic engineering and biotechnology that made it possible to move genes responsible for polymer's production such as PHAs from bacteria into crops. This approach has been subjected to several studies, yet, no significant amount of bio-based plastics has been produced accordingly.29 In general, the production of bio-based polymers from renewable resources can be done in different ways as shown in Fig. 13 and 14. Firstly, by the use of natural bio-based polymers with partial modification in order to meet the requirements. A clear example of that would be starch. Secondly, the production of bio-based polymers from microbial production such as PHA. Thirdly, producing bio-based monomers by fermentation and conventional chemistry followed by polymerization such as PLA. Finally, polymers that are prepared from petrochemical products (synthetic monomers, such as polycaprolactone (PCL)).30–32 An overview of the commercially produced biodegradable polymers are shown in Table 3.24

Fig. 12. The three main approaches to bio-based plastics.29.

Fig. 13. The three main ways for the production of bio-based polymers.30,31.

Fig. 14. Main biodegradable polymers classification.30.

A list of the main biodegradable polymers and their suppliers (past & present)24a.

| Polymer | Trade name | Company |

|---|---|---|

| Starch | Solanyl | Rodenburg, Netherlands |

| PLA | NatureWorks PLA | Cargill, USA |

| PLA | Galactic, Belgium | |

| l-PLA | Purac, Netherlands | |

| PLA-based resins: Bio-Flex and Biograde PLA | FKuR, Germany | |

| Lacty | Schimadzu, Japan | |

| PHA | Nodax | Procter and Gamble, USA (previously), Danimer Scientific (present) |

| Mirel | Metabolix, USA (discontinued) | |

| Biomer | Biomer, Germany | |

| ENMAT | TianAn Biologic Materials, China | |

| PCL | Tone | Dow Chemicals, USA |

| CAPA | Perstorp, UK | |

| Celgreen | Daicel, Japan | |

| PEA | BAK | Bayer, Germany |

| Aliphatic polyesters | PBS | BASF, Germany |

| PBS | Mitsubishi Gas Chemical, Japan | |

| PBS | Showa Highpolymer, Japan | |

| PBS | Ire Chemicals, Korea | |

| PBS | Anqing Hexing Chemical Co., China | |

| Aliphatic copolyesters | PBSA Bionolle | Showa Highpolymer, Japan |

| EnPol, PBSA | Ire Chemicals, Korea | |

| PBSA | Kingfa, China | |

| PBSA | IPC-CAS, China | |

| Aromatic copolyesters (PBAT) | Biomax | DuPont, USA |

| Eastar Bio | Eastman Chemicals, USA | |

| Ecoflex | BASF, Germany | |

| MATER-BI | Novamont, Italy |

Abbreviations: PLA, poly(lactic acid); PHA, polyhydroxyalcanoates; PCL, poly(ε-caprolactone); PEA, poly(esteramide); PBAT, poly(butylene adipate-co-terephthalate).

Biobased plastics are intended to reduce carbon emissions due to the fact that bio-based raw materials absorbed CO2 from the atmosphere. At the same time, biodegradable plastics are under research and development in order to reduce the pollution caused by petroleum-based plastics. This is because they degrade much faster than other conventional plastics. PLA is both: biobased and biodegradable under industrial composting conditions (at a high temperature, around 58 °C). Because of its good mechanical properties, processability, renewability, and non-toxicity, PLA is considered today as one of the most commercially promising bioplastics. When compared with most other biodegradable polymers, PLA has better durability, transparency, and mechanical strength. PLA's global production volume was estimated to be around 190 000 tons in 2019 and is expected to double every 3–4 years. PLA has been used in single use applications and disposable packaging products such as food packaging.7,33

PHAs are a significant polymer family that are 100% bio-based and bio-degradable. PHAs are microbiologically produced polyesters that have tunable physical and mechanical properties. This is accompanied by low environmental impact due to their biodegradability and non-toxicity nature. Therefore, they are promising candidates for a sustainable future manufacturing. Ranging from brittle thermoplastics to gummy elastomers, PHAs' properties can be altered by the selection of bacteria, fermentation conditions, and substrate. Due to their flexible properties, PHAs can eventually substitute PP, polyethylene (PE), and polystyrene (PS), which are the main polymers of today's global polymer market.34 Biodegradable polymers such as PHAs have the potential to lower the amount of pollution caused by the constantly growing demand of polymers. Compared to PLA, PHAs are both compostable and biodegradable in marine environments. On the other hand, PLA is compostable but may stay for up to a thousand years in the marine environment.4 PHAs' biocompatibility is another important aspect. Due to the facts the PHAs are non-toxic, and they occur naturally in human tissues and blood, they have been used in medical applications.35 A drop of fossil energy use by 95% and greenhouse gas emission by 200% can be achieved by substituting petroleum-based polymers with PHAs.4 Therefore, PHAs have the potential to contribute to a green industrial evolution.36,37

The objective of this work is to focus on both PLA and PHAs as alternative, affordable, sustainable, biodegradable materials that can replace petroleum-based polymers in a wide range of industrial applications. Therefore, physical, thermal, rheological, and mechanical properties of both polymers as well as their permeability and migration properties have been reviewed. Furthermore, PLA's recyclability, sustainability, and environmental assessment have been also reviewed. The combination of all of these aspects for both of PLA and PHAs polymers in literature is rare. The main aim of this review is to gain a better understanding of the role of these aspects for the purpose of widening the usage of both of these polymers in different applications and therefore contribute to lowering both, the amount of waste resulting from petroleum-based plastics and their pollution in the environment.

2. Poly(lactic acid)

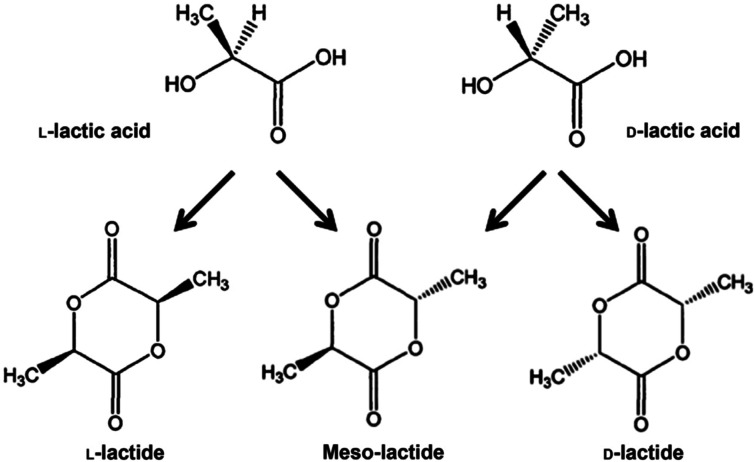

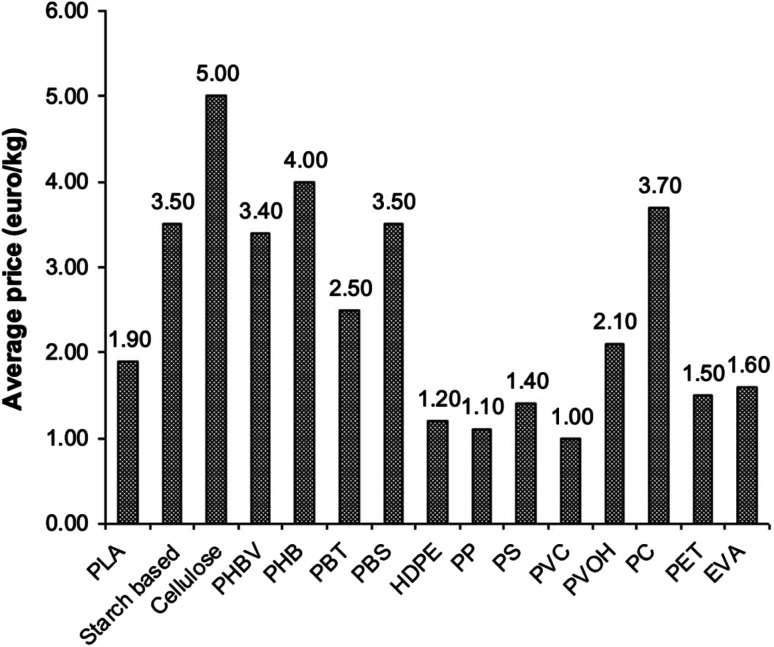

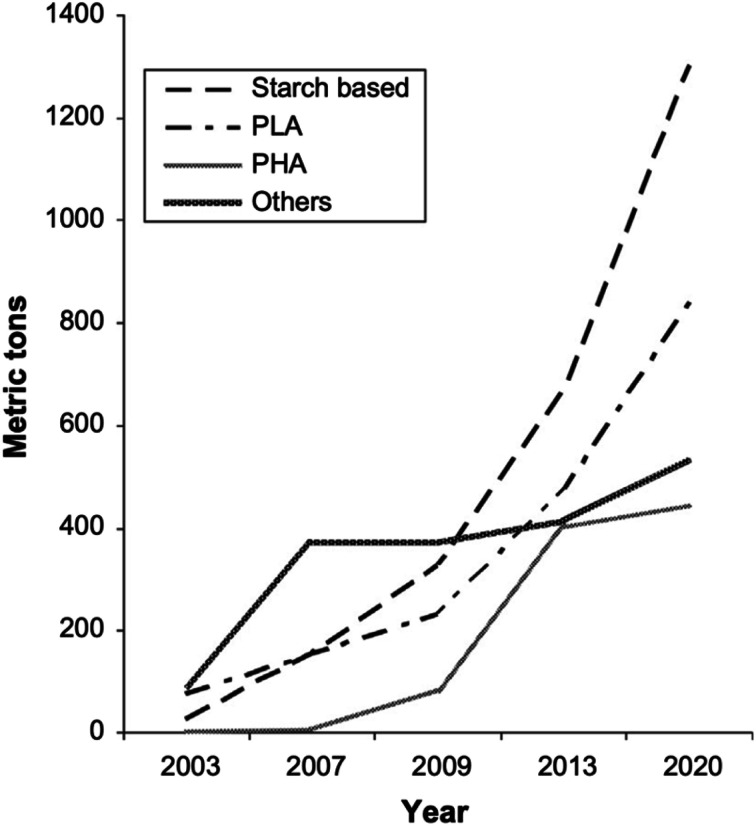

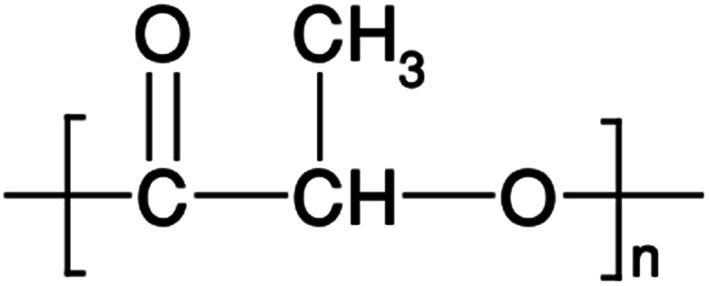

PLA's chemical structure is shown in Fig. 15. The raw material used in the synthesis of PLA is the high purity monomer, lactide. Lactide can be obtained in two synthesis steps: oligomerization of lactic acid (LA) followed by cyclisation. Lactic acid optical monomers consist of l-lactic acid and d-lactic acid. From both optical monomers, three possible stereo forms of lactide can be formed from the oligomer of lactic acid as shown in Fig. 16. These stereo forms are: ll-lactide (LLA), dd-lactide (DLA) and dl-lactide (meso-lactide (MLA)).38 LA is the basic building block for the production of PLA. LA is chemically known as 2-hydroxy-propionic acid with chiral stereoisomers l (−) and d (+). Naturally occurring LA is mainly found in the l form, while chemically synthesized LA can be a racemic d and l mixture. LA is a highly water-soluble and is a biologically stable substance. PLA is a rigid thermoplastic polymer that is classified under the family of aliphatic polyesters. PLA is mainly derived from renewable resources, particularly sugar and starch. The PLA family includes poly(l-lactide) (PLLA), poly(d-lactide) (PDLA), poly(dl-lactide) (PDLLA), poly(meso-lactide), and copolymers obtained from the monomers.39 Polymerization of l-lactide yields poly(l-lactide) while poly(d-lactide) is produced by polymerization of d-lactide. Based on the stereochemistry of the polymer backbone, PLA can be semicrystalline or amorphous. PLLA and PDLA are semi-crystalline, while PDLLA and poly(meso-lactide) are amorphous.30,39–42 Due to its relatively low price and availability, PLA is considered to be one of the highest potential bio polyesters for packaging and medical applications. Today, different companies produce a wide range of PLA products with various l/d ratios.43–47 The enantiomeric purity of lactic acid stereo-copolymers affects the physical properties of polylactide. PLA's wide availability and tunability made it a strong alternative to conventional plastics for packaging applications such as: cups, bottles and trays.44,46,47 Reports in literature confirm that PLA's biodegradation does not result in any eco-toxicological effect.48Fig. 17 gives an overview about the prices of both, conventional and biodegradable plastics in 2009. It is clear that PLA's price is the lowest of all biodegradable polymers. In addition, as the figure suggests, the nearest competitor to conventional polymers such as: PE, PP, PS, polyethylene terephthalate (PET), and Ethylene Vinyl Acetate (EVA) is PLA. At the same time, there is a great potential for PLA to replace polycarbonates (PC), this is because when compared to PC, the price of PLA is significantly lower. PLA can replace PC in various applications, specifically, in electronics'/electric's casings.49Fig. 18 shows that the future of PLA's production is promising, and it has the potential to overtake the sum of other biodegradable polymers such as Poly(Butylene Succinate) (PBS) and PCL.

Fig. 15. The chemical structure of PLA.30.

Fig. 16. The optical monomers of lactic acid along with the three stereo form of lactides.38.

Fig. 17. Average prices of various polymers in 2009.49.

Fig. 18. Renewable biodegradable polymer's global production in 2003 to the projection for 2020.49.

2.1. PLA's synthesis

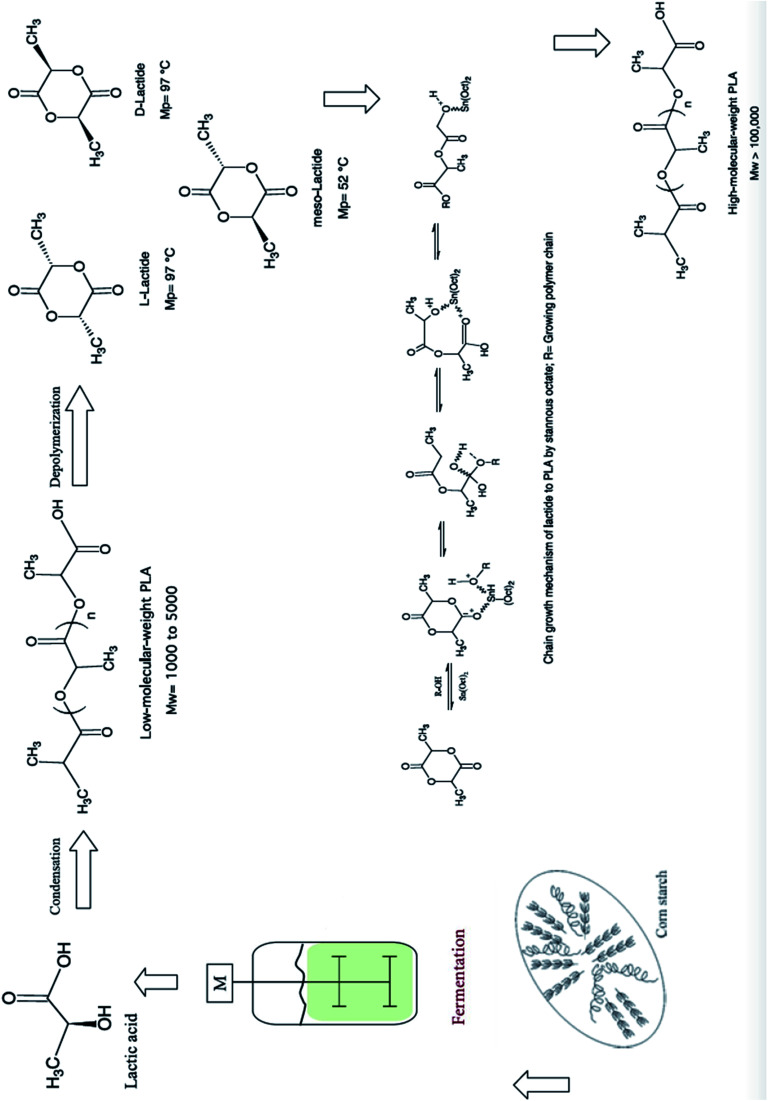

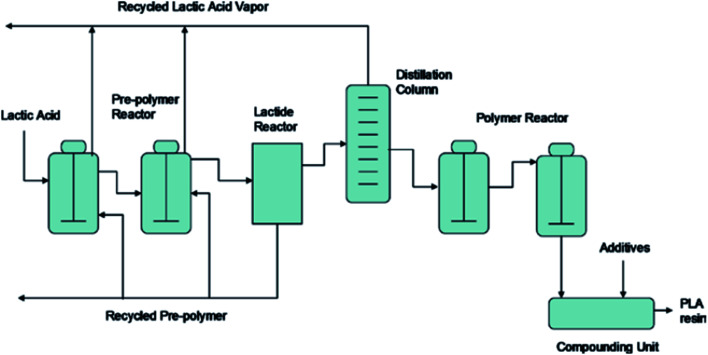

The synthesis for PLA begins with LA production, then lactide formation, and it finally ends with LA polymerization.50 The synthesis of PLA can be accomplished in three steps which are: firstly, the production of LA by microbial fermentation, secondly, the purification of LA followed by lactide preparation, and finally, polycondensation of LA or Ring Opening Polymerization (ROP) of lactides.51Fig. 19 shows PLA's production steps.28 Polycondensation is the cheapest route, and it includes both: solution and melt polycondensations. Yet, it is hard to produce a solvent-free PLA with high molecular weight using these routes.46 This can be attributed to the extended reaction times and the use of solvent in direct condensation which results in low to intermediate molecular weights. The production of high molecular weight PLA was found to be possible by polycondensation through the use of chain extension.52 Defined as bifunctional groups with low molecular weight compounds, chain extenders increase biopolymers' molecular weights in a rapid reaction.53 High molecular weight polymers can be achieved by azeotropic condensation polymerization without using chain extenders or adjuvants. However, high amount of catalyst impurities is expected as a result of the high levels required for acceptable reaction rates. Problems such as catalyst toxicity, un-desirable degradation, and un-controlled hydrolysis rates can be resulted from residual catalysts. The addition of phosphoric or pyrophosphoric acid can deactivate the catalyst. It is recommended to use two equivalents of acid to divalent tin catalyst. This can assist in enhancing polymers' heat and storage stability as well as the weathering resistance. The addition of strong acids such as sulfuric acid can be used to precipitate and filter the catalyst.54 However, the most common route to produce high molecular weight PLA is through ROP. The purified LLA, DLA, and MLA are converted into corresponding high molecular weight polyester via catalytic ROP.50 ROP process involves the ring opening lactide in the presence of catalyst. The process includes three main steps, which are: polycondensation, depolymerization and ROP.55,56 This route involves extra purification steps which are relatively expensive and complicated. Controlling both: the ratio and sequence of d- and l-LA units in the final polymer is feasible by controlling the residence time and temperatures along with the type of catalyst and its concentration.57 Transition metals such as lead, tin, zinc, yttrium, bismuth, and aluminium can be used as catalysts.58 PLA is chemically synthesized by heavy metal catalyst. Yet, for some applications such as biomedical and food applications, the trace residues of such heavy metal catalysts are undesirable. Therefore, replacing these heavy metal catalysts with safe and environmentally acceptable candidates is a high priority aim. Fig. 20 shows PLA's ROP process as reported by NatureWorks LLC.59

Fig. 19. PLA's production steps.28,55.

Fig. 20. ROP process for PLA as reported by NatureWorks LLC.59.

Due to its environmentally friendly nature as well as the fact that it can be carried out under mild conditions, enzymatic polymerization has been reported as one of the most feasible alternatives for synthesis of polymers.60 Synthesizing fine structure polymers from low-cost raw materials can be achieved with highly specific enzymatic reactions. On the other hand, chemical processes need elevated temperatures, extremely pure monomers, and anhydrous conditions to avoid side reactions.61 Therefore, enzymatic polymerization using LA-polymerizing enzyme can be the preferred PLA biosynthetic process to replace chemical synthesis methods. Yet, research is still going today to discover natural PLA producing microbes. Moreover, one of the most preferred methods is the one-step microbial production of PLA. This is because it is capable of controlling the composition of polymer via combining metabolic intermediates of LA monomers at different ratios in a single step process. One-step processes for the synthesis of PLA can be achieved utilizing PLA lactic acid bacteria strains.62

2.2. PLA's physical & thermal properties

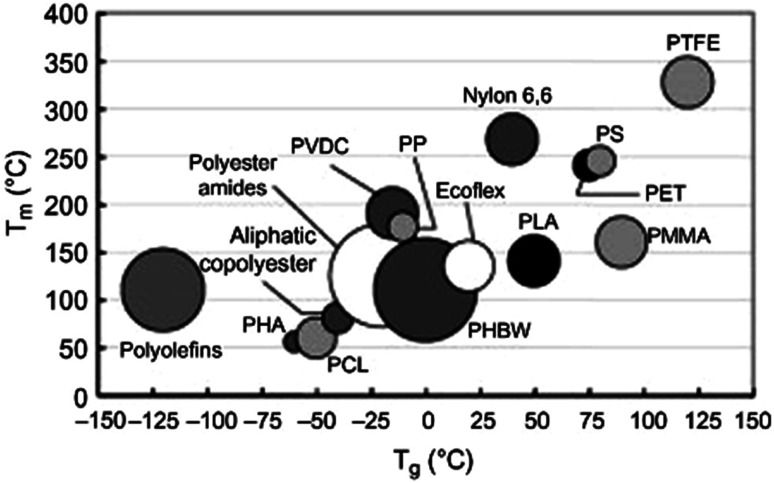

PLA's physical, mechanical, and rheological properties are all affected by its glass transition temperature (Tg).63 PLA can be manufactured into various useful items using thermal processes, such as extrusion and injection molding. As a result, PLA's rheological properties, especially its shear viscosity, have significant impact on the thermal processes. PLA's melt rheological properties have a significant impact on the polymer flow conditions during the processing stage. Generally, high molecular weight PLA has melt viscosities in the order of 500–1000 Pa at shear rates of 10–50 s−1. Such polymer grades are equivalent to molecular weight of 100 000 g mol−1 for injection molding to that of 300 000 g mol−1 for film cast extrusion applications.54 Low molecular weight PLA, that is roughly around 40 000 g mol−1 shows Newtonian-like behavior at shear rates for typical film extrusion, whereas a pseudoplastic, non-Newtonian fluid behavior has been reported for the melts of high molecular weight PLA. Compared to amorphous PLA, semi crystalline PLA tends to exhibit higher shear viscosity under similar processing conditions. Furthermore, when the shear rates increase, the viscosities of the melt decrease drastically, that is, the polymer melt shows a shear-thinning behavior. The glass transition temperature and the melting point (Tm) are the two physical parameters required to predict the behavior of semicrystalline PLA. On the other hand, the glass transition temperature is the vital physical parameter in predicting amorphous PLA's behavior.46,64,65 Crystalline PLLA has been reported to have a density of 1.290 g ml−1, while amorphous PLLA's density was reported to be 1.248 g ml−1. PLA of 100% crystallinity has been reported to have a melt enthalpy of 93 J g−1. Yet, higher values of up to 148 J g−1 have been also reported.66Table 4 shows the physical properties of PLA along with other biopolymers.

PLA's physical properties along with other biopolymers67a.

| Properties | PLA | PLLA | PDLLA | PGA | PDLLA/PGA (50/50) | PDLLA/PGA (75/25) | PCL | PHB |

|---|---|---|---|---|---|---|---|---|

| Density (g cm−3) | 1.21–1.25 | 1.24–1.30 | 1.25–1.27 | 1.50–1.71 | 1.30–1.40 | 1.3 | 1.11–1.146 | 1.18–1.262 |

| Tensile strength (MPa) | 21–60 | 15.5–150 | 27.6–50 | 60–99.7 | 41.4–55.2 | 41.4–55.2 | 20.7–42 | 40 |

| Young's modulus (GPa) | 0.35–3.5 | 2.7–4.14 | 1–3.45 | 6.0–7.0 | 1–4.34 | 1.38–4.13 | 0.21–0.44 | 3.5–4 |

| Elongation at break (%) | 2.5–6 | 3.0–10.0 | 2.0–10.0 | 1.5–20 | 2.0–10.0 | 2.5–10 | 300–1000 | 5.0–8.0 |

| Specific tensile strength (N m g−1) | 16.8–48.0 | 40.0–66.8 | 22.1–39.4 | 40.0–45.1 | 30.9–41.2 | 31.8–42.5 | 18.6–36.7 | 32.0–33.9 |

| Specific tensile modulus (kN m g−1) | 0.28–2.80 | 2.23–3.85 | 0.80–2.36 | 5.00–4.51 | 0.77–2.14 | 1.06–2.12 | 0.19–0.38 | 2.80–2.97 |

| Glass transition temperature (°C) | 45–60 | 55–65 | 50–60 | 35–45 | 40–50 | 50–55 | (−60)–(−65) | 15.0–5.0 |

| Melting temperature (°C) | 150–162 | 170–200 | Amorphous, no melt | 220–233 | Amorphous, no melt | Amorphous, no melt | 58–65 | 168–182 |

Abbreviations: PLA, poly(lactic acid); PLLA, poly(l-lactic acid); PDLLA, poly(d,l-lactic acid); PGA, poly(glycolide); PCL, poly(ε-caprolactone); PHB, polyhydroxybutyrate.

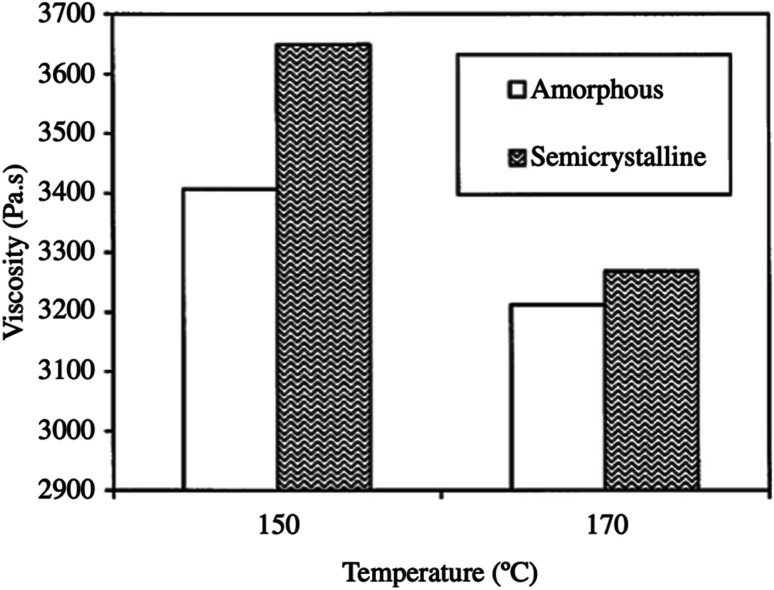

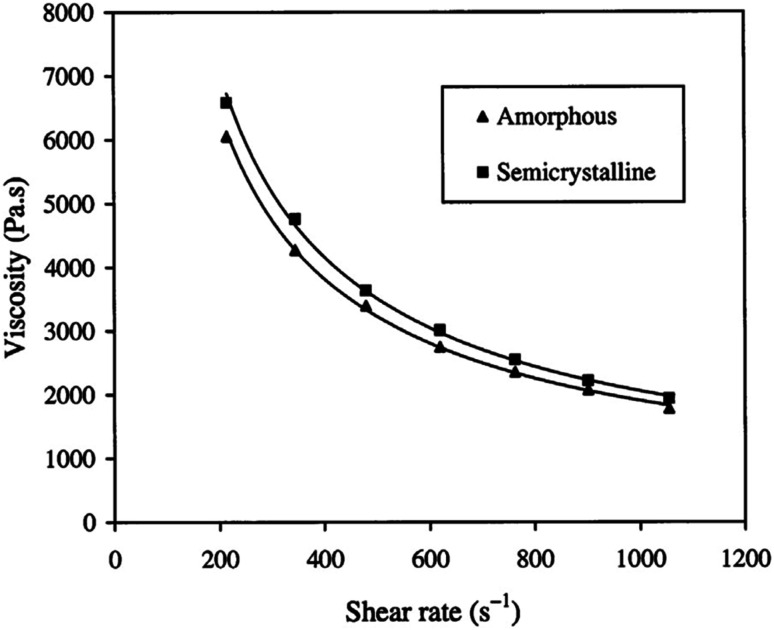

If the PLA contains higher than 93% of the l-lactic it is said to be semi-crystalline. On the other hand, PLA with lower optical purity-that is a PLA with 50–93% l-lactic is totally amorphous. Based on that, controlling the l/d ratio is crucial in deciding upon the crystallinity of polymer. The decrease of both: the extent and rate of PLLA crystallization is mainly due to macromolecular imperfections. Commercially, the majority of PLA is made from l- and d,l lactide copolymers; this is because PLA production often includes some meso-lactide impurities.30 In a study conducted by Fang and Hanna, the rheological properties of both semi crystalline and amorphous PLA resins have been obtained by attaching a tube rheometer to an extruder. The investigation was done at temperatures of 150 °C and 170 °C. Fig. 21 summarizes their results and shows that at higher temperatures, semi crystalline PLA exhibited a higher viscosity than amorphous PLA. This is attributed to the variation in the molecular structure. In the semi crystalline PLA, the molecules are arranged in an organized pattern. This has resulted in a relatively large flow resistance due to the stronger intermolecular forces. On the other hand, in amorphous PLA, the molecules are arranged in a random form which resulted in less flow resistance. Generally, semi crystalline structures offer stronger physical and mechanical properties than amorphous materials. A drop in the shear viscosities for both semi crystalline and amorphous PLA was observed when the temperature increased. Higher viscosity values were obtained at 150 °C when compared to those attained at 170 °C. This is due to the fact that at high temperatures, the connections between the molecular chains become weaker as a result of the higher vibrational amplitude of the PLA molecules, which transforms the melt to flow smoothly. In addition, the viscosity' of PLA melt is highly affected by the shear rate. As observed in Fig. 22, as the shear rate increases for both semi crystalline and amorphous PLA, values of the viscosity for both drop drastically. The relationship between the shear rate and the viscosity is nonlinear but shows a typical non-Newtonian pseudoplastic behavior. This can be explained by the strong shearing action during extrusion that resulted in breaking the molecular chains down.68

Fig. 21. Melt viscosity of semi crystalline and amorphous PLA at different temperatures.68.

Fig. 22. Shear rate impact on the melt viscosity for both semi crystalline and amorphous PLA.68.

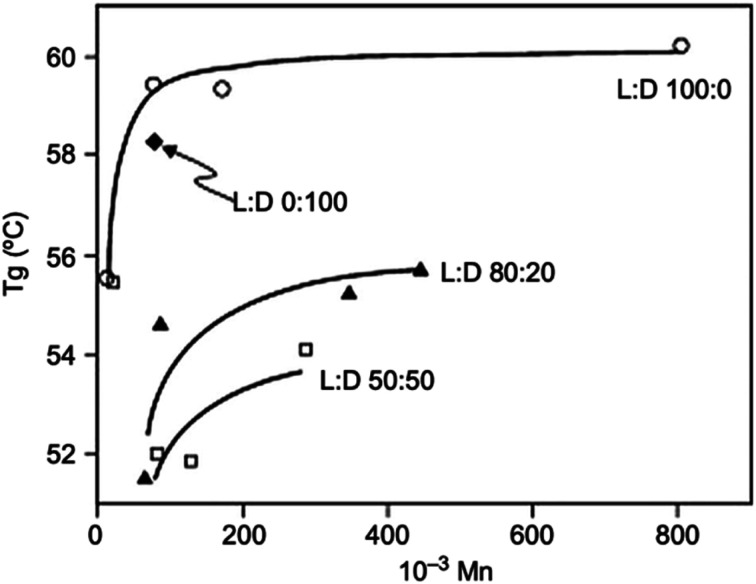

The thermal properties of PLA, its crystallinity degree as well as its crystallization depend on the polymer molecular weight, polymerization conditions, thermal history, and purity.50 Generally, Tg of polymers depends upon the number average molecular weight, microstructure, and stereocomplex configuration.69 Typically, Tg of PLA is in the range of 50 to 80 °C and its Tm is in the range of 130 to 180 °C. A pure PLA fully in l or d stereochemistry has a Tg of 60 °C, and a melting point of 180 °C.70Table 5 presents the glass transition and melting temperatures for PLA copolymers along with PET.71 PLA has relatively low melting temperature and high glass transition temperature when compared to other polymers. Fig. 23 shows a comparison of the melting temperature and glass transition temperature of PLA with other polymers.39 Achmad et al. have reported that both PLLA and PDLA are semicrystalline polymers with melting points of around 180 °C. At the same time, they have also reported that the copolymer PDLLA is an amorphous material with a glass transition temperature of only 50–57 °C.72 A comparison of glass transition temperature of PLA with various optical purity of the polymer with respect to their molecular weights is shown in Fig. 24. As shown, PLA's Tg is dependent on the optical purity and the molecular weight of the polymer. Tg for PLA increases with molecular weight. PLA with higher l-lactide content exhibits higher Tg values than the same polymer with the same content of d-lactide.73,74 As the l-content decreases, crystallinity, melting temperature, and glass transition temperature all decrease.73,75 In case of semi-crystalline PLA, the melting temperature is a function of the initial PLA structure as well as the various processing parameters. A presence of meso-lactide in the structure reduces the melting temperature. With increasing the molecular weight, the crystallinity decreases, however, the melting temperature increases until it approaches a maximum value.76 Furthermore, Table 6 shows how the molecular number (Mn), Tg, Tm, enthalpy, and crystallization temperature (Tc) of PLA can be different for various types of lactide isomers.77 It can be observed that irrespective of whether the isomer type is l or d, both Tg and Tm increase with an increase in Mn.

Glass transition and melting temperatures for PET and a range of PLA copolymers71b.

| Copolymer ratio | Glass transition temperature (°C) | Melting temperature (°C) |

|---|---|---|

| PET | 80 | 255 |

| 100/00 (l-/d,l) PLA | 63 | 178 |

| 95/05 (l-/d,l) PLA | 59 | 164 |

| 90/10 (l-/d,l) PLA | 56 | 150 |

| 85/15 (l-/d,l) PLA | 56 | 140 |

| 80/20 (l-/d,l) PLA | 56 | (125)a |

Melting point achieved by strain crystallization.

Abbreviations: PET, poly(ethylene terephthalate); PLA, poly(lactic acid).

Fig. 23. Melting and glass transition temperature of PLA and some other polymers.39.

Fig. 24. A comparison of glass transition temperature of PLAs with various l-lactide and d-lactide contents as a function of molecular weight.73.

The effect of isomers type on PLA's thermal properties77.

| Type of isomer | M n × 103 | M w/Mn | Glass transition temperature (°C) | Melting temperature (°C) | Melting enthalpy (J g−1) | Crystallization temperature (°C) | Crystallization enthalpy (J g−1) |

|---|---|---|---|---|---|---|---|

| l | 4.7 | 1.09 | 45.6 | 157.8 | 55.5 | 98.3 | 47.8 |

| dl | 4.3 | 1.90 | 44.7 | — | — | — | — |

| l | 7.0 | 1.09 | 67.9 | 159.9 | 58.8 | 108.3 | 48.3 |

| dl | 7.3 | 1.16 | 44.1 | — | — | — | — |

| d | 13.8 | 1.19 | 65.7 | 170.3 | 67.0 | 107.6 | 52.4 |

| l | 14.0 | 1.12 | 66.8 | 173.3 | 61.0 | 110.3 | 48.1 |

| d | 16.5 | 1.20 | 69.1 | 173.5 | 64.6 | 109.0 | 51.6 |

| l | 16.8 | 1.32 | 58.6 | 173.4 | 61.4 | 105.0 | 38.1 |

2.3. PLA's mechanical properties

Depending on various parameters such as: polymer structure, material formulation (blends, plasticizers, composites, etc.), orientation, crystallinity, and molecular weight, the mechanical properties of commercial PLA can be diverse, ranging from elastic soft to stiff, high-strength materials. Developed by NatureWorks LLC, a summary of PLA's mechanical properties along with some physical and thermal properties is shown in Table 7.78 Similar to PS, PLA is a brittle material with low elongation at break and impact strength. Nonetheless, it is comparable to PET when it comes to its tensile strength and modulus. A comparison between the mechanical properties of PLLA, PS and PET is shown in Table 8.79 Due to its poor toughness, the use of PLA in applications that requires plastic deformation at higher stress levels has been avoided. This has opened the door to develop various modification techniques to improve the mechanical properties of PLA, specifically its toughness. Such techniques involve, blending with other polymers, the use of plasticizers, the addition of reinforcing fillers and fibers as well as nucleating agents.80

A summary of PLA's mechanical properties along with some physical and thermal properties as reported from NatureWorks LLC78a.

| Properties/applications | Ingeo™ 2003D | Ingeo™ 3052D | Ingeo™ 3801X | ASTM method |

|---|---|---|---|---|

| Specific gravity | 1.24 | 1.24 | 1.25 | D792 |

| Melt flow rate, g per 10 min (210 °C, 2.16 kg) | 6 | 14 | 8 | D1238 |

| Relative viscosity | NP | 3.3 | 3.1 | — |

| Clarity | Transparent | Transparent | Opaque | — |

| Tensile strength at break, psi (MPa) | 7700 (53) | NP | NP | D882 |

| Tensile yield strength, psi (MPa) | 8700 (60) | 9000 (62) | 3750 (25.9) | D882 |

| Tensile modulus, kpsi (GPa) | 500 (3.5) | NP | 432 (2.98) | D882 |

| Flexural strength, psi (MPa) | NP | 15 700 (108) | 6400 (44) | D790 |

| Flexural modulus, psi (MPa) | NP | 515 000 (3600) | 413 000 (2850) | D790 |

| Tensile elongation (%) | 6.0 | 3.5 | 8.1 | D882 |

| Notched Izod impact, ft-lb per in (J m−1) | 0.3 (16) | 0.3 (16) | 2.7 (144) | D256 |

| Heat distortion temperature (°C) | 55 | 55 | 65 (at 66 psi) | E2092 |

| 140 (at 16.5 psi) | ||||

| Melt temperature (°C) | 210 | 200 | 188 | — |

| Crystallinity melt temperature (°C) | NP | 145–160 | 155–170 | D3418 |

| Glass transition temperature (°C) | NP | 55–60 | 45 | D3418 |

| Applications | Designed for fresh food packaging and food service ware applications such as: dairy containers, food service ware, transparent food containers, hinged ware, cold drink cups | Designed for injection molding applications that require clarity with heat deflection temperatures lower than 49 °C. Applications include: cutlery, cups, plates and saucers, as well as outdoor novelties | Designed for non-food contact injection molding applications that require opaque molded parts with heat deflection temperatures between 65 °C and 140 °C | — |

NP: not provided.

A comparison of the mechanical properties of PLLA, PS and PET79a.

| Polymer | Tensile strength (MPa) | Tensile modulus (GPa) | Percentage elongation | Notched Izod (J m−1) |

|---|---|---|---|---|

| PLLA | 59 | 3.8 | 4–7 | 26 |

| PS | 45 | 3.2 | 3 | 21 |

| PET | 57 | 2.8–4.1 | 300 | 59 |

Abbreviations: PLLA, poly(l-lactic acid); PS, poly(styrene); PET, poly(ethylene terephthalate).

2.4. PLA's permeability

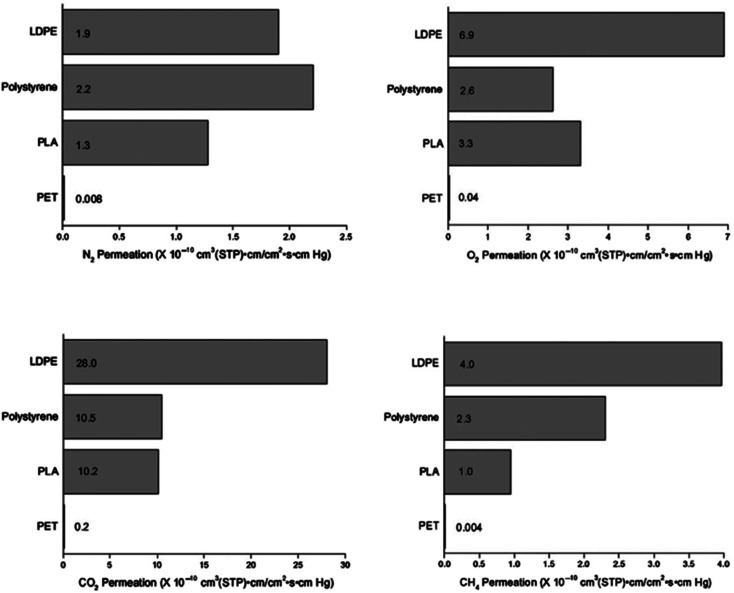

When considering PLA as a packaging material, PLA's gas permeation properties are of significant importance. Packaging requires materials that have low-permeability, in order to prevent the occurrence of oxidation and the loss of flavor and aroma which may reduce the shelf-life of food. Since PLA is a biodegradable polymer with the potential to replace conventional petroleum based plastics, it crucial for PLA to have as effective permeability properties as these existing polymers.33 A study on gas permeation of PLA for oxygen, methane, nitrogen, and carbon dioxide was conducted by Lehermeier et al.81 The study concluded that PET's permeability was lower than that for PLA, which means that PET has superior barrier properties to PLA with an l : d ratio of 96 : 4. This is because PET contains aromatic rings in the polymer chain backbone, which decreases free volume and chain mobility. Crystallization can substantially improve the barrier properties. The increase of crystallinity in biaxially orientated PLA film with an l : d ratio of 95 : 5 with 16% crystallinity resulted in a drop of the permeability to 4.5 times lower than PLA film samples that have l : d ratio of 96 : 4 and 98 : 2 with 1.5% and 3% crystallinity, respectively. This is because crystallinity enhances the compactness of the structure, which makes it difficult for gas molecules to diffuse through the film. Fig. 25 presents a comparison of the permeation properties of 100% linear PLA with an l : d ratio of 96 : 04 with other polymers that are mainly used for packaging. In general, compared to both PS and LDPE, PLA possesses better barrier properties. With respect to nitrogen, carbon dioxide, and methane, PLA exhibits good barrier properties. On the other hand, PLA demonstrates a slightly weaker barrier properties for oxygen. This finding is significant; because it shows that PLA can be utilized as a robust packaging material to replace different petroleum-based plastic films. PLA's biodegradability, its “green” production along with its good barrier properties have made PLA a strong future packaging material candidate.81 For packaging materials, permeability to water is also of great importance. The water vapor permeability of different biodegradable polymers was studied and compared by Shogren.82Table 9 shows the water transmission rates for these materials. In comparison to many biodegradable polymers, PLA exhibits good water resistance except when it is compared to PHBV. Annealing of PLA at 130 °C prompts the formation of a crystalline structure, which in turns enhances water resistivity. This is because the molecular cross-sectional area for diffusion decreases while the diffusion path length increases due to crystallization, imposing restraints on the mobility of the amorphous phase.82

Fig. 25. Properties of permeation for 100% linear PLA with an l : d ratio 96 : 04 compared to other plastics commonly used for packaging at 30 °C.81.

Transmission rates of water vapor for several biodegradable polymers82a.

| Film | Crystallinity (%) | Solubility parameter (J cm−3)1/2 | Water vapor transmission rate (g per m2 per day) | ||

|---|---|---|---|---|---|

| T = 6 °C | T = 25 °C | T = 49 °C | |||

| PLA-crystalline | 74 | 21.5 | 1.8 | 13 | 124 |

| PLA-amorphous | 69 | 21.5 | 3.1 | 21 | 204 |

| PHBV, HV = 6% | 62 | 21.4 | 3.5 | 26 | 245 |

| PHBV, HV = 12% | 66 | 22.7 | 27 | 82 | 333 |

| PHBV, HV = 18% | 0 | 22.7 | 54 | 172 | 1100 |

| PCL | 67 | 20.8 | 41 | 177 | 1170 |

| Bionolle | 0 | — | 59 | 330 | 2420 |

| BAK 1095 | 0 | — | 134 | 680 | 3070 |

| Cellulose acetate propionate | 41 | 24.2 | 590 | 1700 | 5200 |

| Cellulose acetate | 33 | 25.7 | 1020 | 2920 | 7900 |

Water solubility parameter is 47.9 (J cm−3)1/2. Abbreviations: PLA, poly(lactic acid); PHBV, poly(3-hydroxybutyrate-co-3-hydroxyvalerate); PCL, poly(ε-caprolactone); Bionolle, blown film containing an aliphatic polyester; BAK 1095, blown film containing poly(ester-amide).

2.5. PLA's degradation

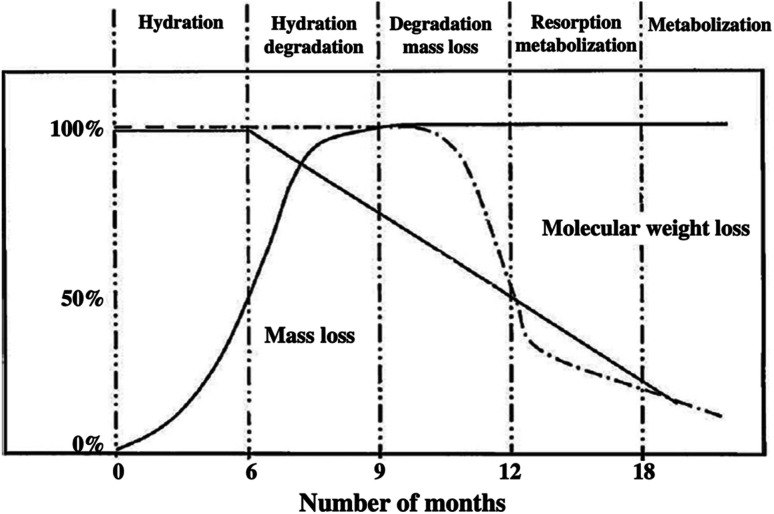

PLA is known for its environmental qualities and it is considered more environmentally friendly than other commonly used plastics for food packaging applications such as: PS, PE, and PP. In spite that numerous polyesters, such as PBS, PHA, and PCL are also categorized as biodegradable, yet, PLA has the advantage of producing mass production out of it because it is produced by lactic acid fermentation from sugar. Furthermore, although PBS and PCL are considered biodegradable, they are produced from petrochemical sources. At the same time, further improvement for PHA is required to enhance its production. Understanding PLA's biodegradation is of great importance for many plastic industries today in order to meet the current stringent environmental regulations. Furthermore, understanding the biodegradation behavior of PLA inside the living body is vital because PLA has been implemented in various medical applications such as sutures and implants. The erosion of PLA used in biomedical applications can be controlled by manipulating PLA's average molecular weight. PLA degradability in body fluids and tissues can be reduced by adding a d-lactide isomer. This is attributed to the fact that living body do not produce a suitable enzyme to act on d-lactic acid.83 The attack of polymers by external elements is the main cause behind polymer's degradation. This is due to the high stability of polymer chains which rarely undergo autocatalysis. PLA is produced from lactic acid that is obtained by the fermentation of sugars by bacteria (organic process). However, when lactic acid is converted to PLA, major changes in the chemical and biological degradation occur. PLA does not have the ability to be broken down directly and consumed by living organisms as efficiently as lactic acid itself. An important factor that affects PLA's biodegradability is its stereochemistry. Chemical bonding affects the degradation of polymers. Hydrolysis reactions are responsible for most degradation of the d-lactic acid. Exposing PLA to water for a long period is required to initiate the hydrolysis process. An approximation of the degradation times for neat polymers along with their derived copolymers are shown in Table 10. An important reason for the variation in degradation kinetics of a copolymer is that the additional monomer affects the crystallinity and reduces the steric effects.84 Increasing the glycolide portion has been found to increase the chain's cleavage rate. The degradation time was found to increase due to copolymerization of l-lactide with d,l-lactide. This is attributed to the oligomer d-lactic acid, that does not tend to degrade naturally by the body's enzymes. This approach can be used to extend the functionality of PLA implants in the human body. Therefore, controlling the composition of PLA's copolymers is critical for the release of drugs in the living body.85 Crystallization is another factor that affects polymer's degradation. The amorphous portion of PLA was found to be less resistant to degradation than the crystalline portion.86–89 Not only that, but it was also found that when compared to the fully amorphous regions of PLA, the amorphous regions that exist between the crystalline regions had good hydrolysis resistance.86 Molecular weight of a polymer has also a high impact on its biodegradability. High molecular weight polyesters are found to degrade at a slower rate.90,91 This is because high molecular weight molecules have greater entanglement, which means that they resist hydrolysis for chain cleavage.83 Other factors that influence the degradation of PLA are water uptake and acidity. Water uptake is related to hydrolytic degradation, where breakage of the polymer is achieved by the water molecules.92 The hydrolysis process induced by the water uptake is significant because it ensures the functionality of biopolymers in biological systems and their degradation by microorganisms. There are different factors that affect the extent of water uptake. Some of these factors are molecular weight, purity, morphology, shape of the specimen, and the processing history of the polymer. A crystal structure can decrease the capacity for water permeation. This can be accomplished by copolymerization or quenching of the polymer. Water uptake of PLA leads to the splitting of ester bonds; then, the oligomers can be assimilated by living cells. Acidity controls the rate of reaction of ester splitting through catalysis.93 Chu compared the degradation of poly(glycolic acid) and poly(lactide-co-glycolide) sutures. Results suggest that the breaking strength of an entire suture depends on the pH, particularly at high and low pH values.94Fig. 26 shows the in vivo degradation mechanisms for typical resorbable polymers such as PLA.95 At the start, the hydration process takes place over the first 6 months. During that time, the molecular weight remains the same, however, mass loss occurs. In order for the hydrolysis reaction with the ester bonds to be initiated, excess water is needed to penetrate the higher molecular weight structure. When enough water is accumulated in the polymer, water-soluble monomer oligomers are generated from the cleavage of the ester bonds. Lactic acid monomers are formed, which cause hydration degradation during a period of 6 to 9 months. Such monomers diffuse into the body fluids, causing substantial mass loss. Then, they are further transferred to the liver for metabolization. Throughout this stage, the lactic acid in the body's fluids goes through enzymatic degradation, however, this is only limited to the l-lactic acid because human's body does not produce the d-lactic acid enzyme. A longer period of time is required for the d-lactic acid to undergo hydrolytic degradation. Eventually, the d-lactic acid finally reduces to CO2 and water before being rejected from the body. As shown in Fig. 26, by the 9th month, a total mass loss of the entire bioresorbable polymer took place, this was accompanied by a gradual reduction of the molecular weight.95

Approximate degradation time of selected biodegradable polymers96.

| Polymer | Approximate degradation time (months) | Degradation products |

|---|---|---|

| Poly(glycolic acid) | 6 to 12 | Glycolic acid |

| Poly(l-lactic acid) | >24 | l-Lactic acid |

| Poly(d,l-lactic acid) | 12 to 16 | d,l-Lactic acid |

| Poly(d,l-lactic-co-glycolic acid) (85/15) | 5 to 6 | d,l-Lactic acid and glycolic acid |

| Poly(d,l-lactic-co-glycolic acid) (75/25) | 4 to 5 | d,l-Lactic acid and glycolic acid |

| Poly(d,l-lactic-co-glycolic acid) (65/35) | 3 to 4 | d,l-Lactic acid and glycolic acid |

| Poly(d,l-lactic-co-glycolic acid) (50/50) | 1 to 2 | d,l-Lactic acid and glycolic acid |

Fig. 26. The in vivo degradation mechanisms for typical resorbable polymers.95.

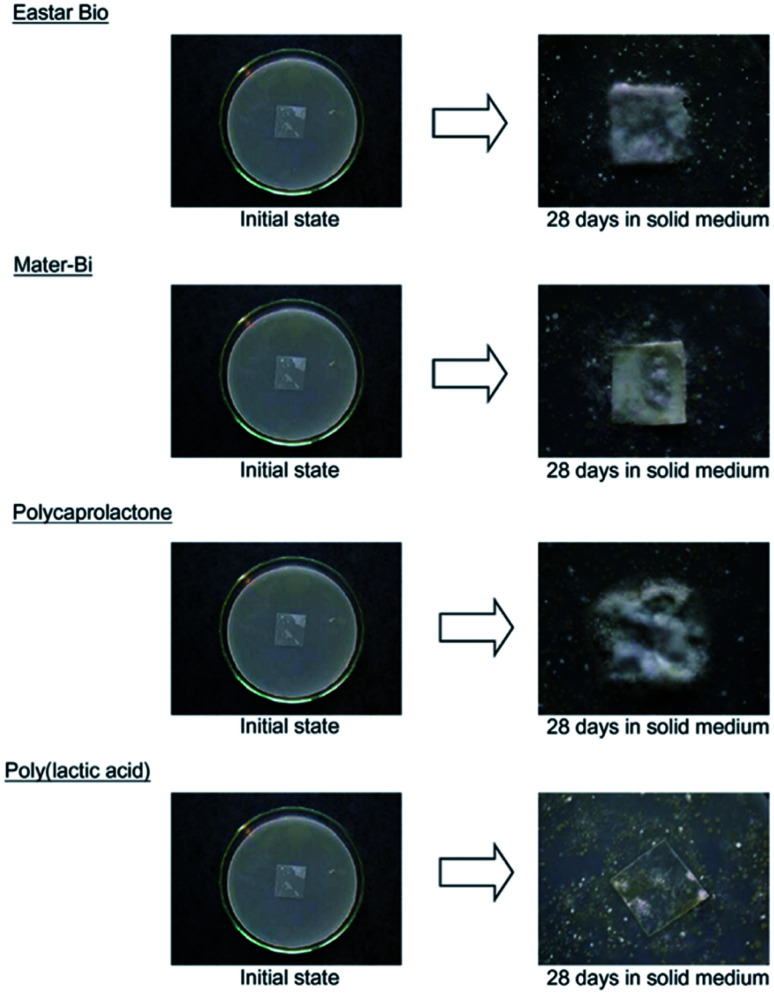

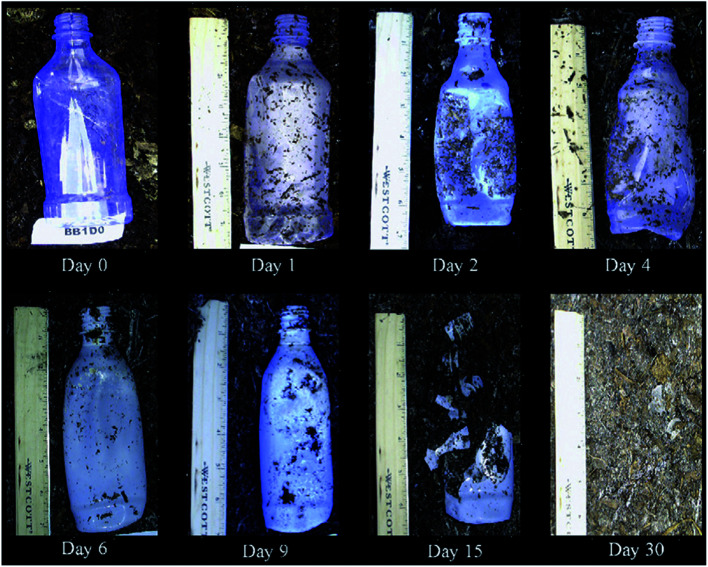

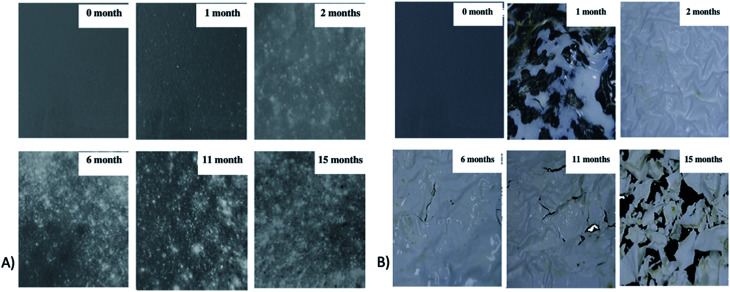

In a study conducted by Torres et al., various types of filamentous fungi were used to decide upon the types of microorganism strains that can affect PLA's degradation. Two analyses on dl-LA and its oligomers separately at a concentration of 10 g L−1 were conducted. In order to avoid biological contamination, which can produce faulty results, sterilization was undertaken. All microorganism strains were reported to actively consume lactic acid and oligomers. Out of the analyzed microorganism strains, two strains of Fusarium moniliforme and one strain of Penicillium roqueforti could totally utilize dl-LA and dl-LA oligomers as the sole carbon and energy source. On the other hand, other microorganism strains could only partially assimilate the dl-lactic acid and oligomer substances.97 Massardier-Nageotte et al. investigated the percentage of biodegradation for various polymers for different days. As per the results in Table 11, PLA had the slowest biodegradation rate among all biomaterials used in the study. Results showed that there was a lack of microorganism colonization on the surface of the PLA sample compared to the other biomaterials. Results of such observations are shown in Fig. 27. Different data suggests that PLA is durable and has the ability to resist degradation for a longer period of time compared to other biopolymers, while at the same time it has the ability to maintain its biodegradable characteristics. For some applications that require long-term use such as: woven fabrics and matting, the ability of PLA to maintain its functionality becomes of great importance.98 In one study, Kale et al. investigated the biodegradability of polylactide bottles in real and simulated composting conditions. They have used 500 ml bottles made out of PLA in their investigation. The bottles were used for packaging spring water and were manufactured by NatureWorks LLC. PLA bottles were made out of 96% l-lactide with a bluetone additive. The PLA bottles were exposed to composting burial and international standard of ASTM D5338 and ISO 14855-1 under controlled conditions. PLA bottles were completely decomposed by 30 days when they were buried in a compost pile made of cow manure, wood shavings, and waste feed. Due to the environmental heat and the microbiological action, the temperature in the compost pile reached to around 65 °C which is higher than the glass transition temperature of PLA (60.6 °C). As a result, PLA bottles were distorted in days 1 and 2. The structure of the PLA bottles remained tough until days 6–9, when a powdery texture appeared on the surface and fragmentation took place. By day 15, the PLA bottles lost their structures and large portions of the bottles had composted. By day 30, very negligible residuals from the bottle were observed. Fig. 28 shows the complete history of the degradation of the PLA bottle in the compost pile. The biodegradation of PLA sheets under various composting conditions was investigated by Rudeekit et al. After one moth of exposing the PLA sheets to wastewater treatment conditions, white spots on the surface were observed. It was also found that the areas impacted by the white spots had grown substantially larger over the testing period. Areas of white spots are shown in Fig. 29A. Moreover, it was found that PLA degraded more rapidly under composting plant conditions at high temperature (50–60 °C) and relative humidity higher than 60%. By day 8, the PLA sheets became brittle and started to break into small pieces. This is attributed to the fact that the degradation temperature at the land composting plant was higher than PLA's Tg. Therefore, when the temperature exceeds PLA's Tg, chain movement took place and that enabled the penetration of water to induce the hydrolysis reaction. PLA sheets degraded more slowly under landfill conditions than those left to degrade under composting plant conditions. This is due to the higher humidity and temperature in the composting plant conditions compared to the landfill conditions. PLA under composting plant conditions degraded completely in only 30 days. On the other hand, around 6 months was required for the PLA sheets under the landfill conditions to exhibit major fragmentation. Moreover, around 15 months was required for them to reflect some disappearance. Results of PLA sheet's degradation under the landfill conditions are demonstrated in Fig. 29B.99 A summary of some of PLA's composting studies along with their findings is shown in Table 12.100

Biodegradation percentage for different biomaterials under aerobic conditions98a.

| Time (days) | PLA | Mater-Bi® | Eastar bio® | PCL |

|---|---|---|---|---|

| 7 | 3.2 | 23.9 | 4.9 | 13.7 |

| 14 | 3.6 | 35.7 | 11.6 | 29.3 |

| 28 | 3.7 | 42.8 | 15.1 | 34.8 |

Abbreviations: PLA, poly(lactic acid); Mater-Bi®, starch/polycaprolactone blend; Eastar bio®, poly(butadiene adipate-co-terephthalate); PCL, poly(ε-caprolactone).

Fig. 27. Status of different biomaterials after 28 days in solid medium.98.

Fig. 28. PLA bottle biodegradation's chronology in the compost pile.101.

Fig. 29. PLA sheets' degradation under: (A) wastewater treatment condition, (B) landfills conditions.99.

Summary of some of PLA's composting studies100a.

| Polymer | Degradation method | Findings | References |

|---|---|---|---|

| PLLA; in the form of non-woven fabrics and blown film; from Neste Oy | Bench-scale composting; CO2 measurements | 99% mineralization of PLLA films and 73% and 48% mineralization of PLLA fabrics after 60 days | 88 |

| PLA; in the form of bottles; from Biota | Composting, ISO 14855, ASTM D6400 at 58 °C and 55% relative humidity | 64.2% mineralization after 63 days | 102 |

| PLA; in the form of films | Composting; leaf compost rows, molecular weight measurement at 55–60 °C and 50–70% humidity | Two weeks were required for the PLA films to disintegrate physically in the compost rows; degradation rates reported were 109 173 and 68 532 Mw per week | 103 |

| PLA, laboratory synthesized PLLA | Controlled composting test (prEN14046); carbon dioxide evolution measurement | 92% (±17%) biodegradation for PLLA in 202 days (56% (±5%) biodegradation in 150 days) | 48 |

| Commercial PLA; in the form of 1.5 mm extruded thickness sheets | Composting; yard waste compost; CO2 evolution measurement and molecular weight changes | Significant decrease in the molecular weight of PLA | 104 |

| Commercial PLA; from Mitsui Chemicals | Composting (ISO 14855-1, ISO 14855-2, enzymatic degradation at 58 °C); CO2 evolution measurement based on titration and gravimetric methods | 91% biodegradation of PLA powder after 31 days under ISO 14855-1 | 105 |

| 80% biodegradation of PLA powder after 50 days under ISO 14855-2 | |||

| Commercial PLA, in the form of bottles and delicatessen containers | Composting under real conditions (compost pile; temperature 65 °C ± 5 °C; moisture 63% ± 5%, pH 8.5 ± 0.5); visual inspection; molecular weight changes; glass transition and melting temperature; decomposition temperature | PLA delicatessen containers degraded in less than 30 days under composting conditions while PLA bottles showed very negligible residuals left from the bottle after 30 days | 106 |

| PLA | Composting at laboratory scale – simulated aerobic composting facility (as per se ASTM D5338) | More than 60% degradation prior to 100 days | 107 |

Abbreviations: PLLA, poly(l-lactic acid); PLA, poly(lactic acid).

2.6. PLA's recyclability, sustainability & environmental impact

Although PLA is considered as a biodegradable polymer, yet, it still has some common characteristics with petroleum-based polymers. PLA has the characteristics of thermoplastic to undergo the melt recycling method. Nonetheless, recycling PLA remains less promising; this is due to the absence of commercial volumes to cover PLA recycling plants' setup costs. Therefore, research today is directed towards establishing PLA's recycling technology in the near future. Postconsumer PLA can be either crystalline or amorphous. Semicrystalline and/or crystalline PLA can be gathered from oriented sheets, films or spun bond fibers. On the other hand, amorphous PLA can be collected from injection molded, blow molded or thermoformed parts in the form of flakes from postconsumer products. It is always a good practice to make sure that the collected PLA from postconsumer products is of high quality prior to undergoing degradation. This is because degraded postconsumer products cannot be recycled or mixed with neat PLA as they can detriment the quality of the neat polymer. Degraded PLA can be spotted via weaker structure, fragmentation, powdery, leakage or color fading. Crystalline as well as amorphous PLA shall be dried prior to extrusion at temperatures range of 65–85 °C and 43–55 °C, respectively. This is important so as to avoid having a reaction of PLA with water molecules which can lead to hydrolysis degradation. Moreover, another purpose of drying PLA is to avoid having a sticky low melt temperature PLA in the reclaimer of the pre-extrusion dryer. Furthermore, non-PLA materials shall never be mixed with recycled PLA resin. For example, during the recycling process of PLA bottles, it is crucial to remove the polyethylene film-printed labels attached to the bottle to avoid any undesired effects that may result from the incompatibility of the polymers components. Moreover, additives such as impact modifiers, reinforcing agents, and fillers may have an un-pleasant effect on the recycled PLA and therefore must be subjected to compatibility testing prior to the recycling process.108

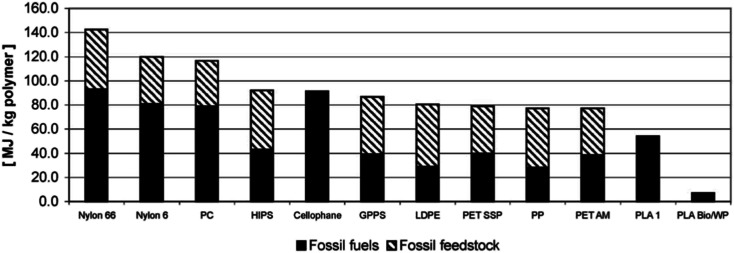

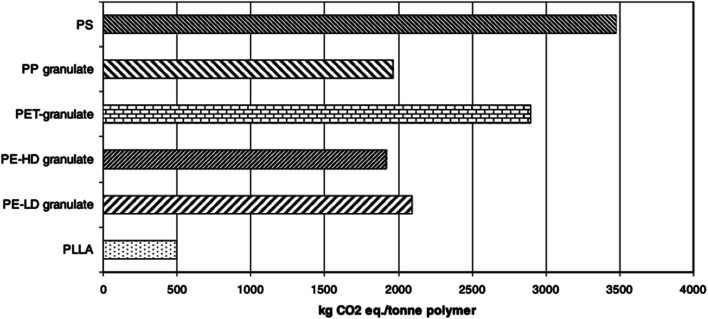

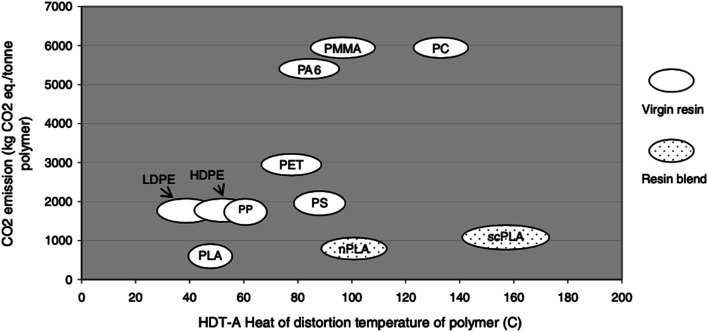

For the purpose of comparing the eco-profile of PLA and other materials, researchers have been relying on Life Cycle Assessment (LCA). Basically, LCA can be efficiently used to evaluate the Carbon Footprint (CF) of various materials and products. Information extracted from LCA can play an important role in minimizing the environmental impacts of products. Due to its agricultural origin, PLA is usually assumed to be an environment-friendly polymer. However, there are various elements that can influence the environmental impact of plastic products. Some of these elements may include the capability to recycle, reuse, requirement of cleaning postconsumer items, and transportation.109,110 Simon et al. investigated the LCA for aluminum cans (0.5 L and 0.33 L), PET bottles (0.5 L, 1.0 L, 1.5 L, and 2.0 L), beverage cartons (1.0 L), PLA bottle (1.5 L), and glass beverage bottles (0.33 L and 0.5 L). Results suggest that the lowest greenhouse emission was that for PLA bottle at a 66 kg carbon dioxide equivalent (CO2-eq.), followed by the 1.5 L PET bottle at 85 kg CO2-eq., and then the beverage carton at 88 kg CO2-eq. Nonetheless, when the materials were subjected to incineration and landfill, a tremendous increase of greenhouse emission was observed, however, greenhouse emission of PLA bottles remained the lowest with 498 CO2-eq. and 500 CO2-eq., in case of incineration and landfill respectively. Such conclusions suggest that recycling is the ultimate method to maintain a greener environment. Therefore, incineration and landfill should only be considered after products' end of life.111 Initially, NatureWorks LLC published the first LCA for PLA using corn as the feedstock. Using the first LCA, Vink et al. reported the gross energy consumption for the production of PLA. Results were unsatisfactory. Therefore, many industries saw that the production of PLA lacks justification in terms of its renewable properties and sustainability in spite of its feedstock origin being from corn. However, comparing PLA with other petroleum-based materials, PLA remains superior as it utilizes fewer fossil inputs, as illustrated in Fig. 30. Nonetheless, to improve the environment-friendly selling points of PLA, Vink et al. proposed substitution of fossil energy inputs with biomass/wind power.112 After many years of PLA production and study of renewable energy resources, Vink et al. reported that NatureWorks LLC was able to reach a 90% reduction in carbon emissions.113 That was also followed by more enhancement of the NatureWorks' PLA production process as reported by Vink et al.114 In another study conducted by Groot and Borén, an LCA for l-lactide, d-lactide, PLLA, and two PLLA/PDLA blends made from cane sugar, was carried out and then compared with that of fossil-based polymers. The global warming potential for PLLA along with other fossil-based polymers is shown in Fig. 31. It is clear that the global warming potential of PLLA is much lower than that of fossil-based polymers, and that is one of the reasons for which many companies today are switching to biomaterials. The global warming potential against the heat of distortion temperature for PLA and other polymers is shown in Fig. 32. Data for non-PLA polymers are all from the European Plastics Association and refer to virgin non-compounded materials. The data for PLA is for a virgin resin, while nPLA and scPLA are for a resin blend. The global warming potential of nPLA and scPLA are somewhat higher than that for neat PLLA, but still much more favorable than for fossil-based polymers on a weight by weight basis.115

Fig. 30. Fossil fuel energy consumption for PLA and some petroleum-based polymers. HIPS, high impact polystyrene; GPPS, general purpose polystyrene; PET SSP, polyethylene terephthalate, solid-state polymerization (bottle grade); PET AM, polyethylene terephthalate, amorphous (fibers and film grade); PLA1, PLA without adoption of biomass and wind power; PLA Bio/WP, PLA with adoption of biomass wind power.112.

Fig. 31. Global warming potential associated with the production of PLLA and other polymers.115.

Fig. 32. Global warming potential of polymer production as a function of the heat distortion temperature of the polymer.115.

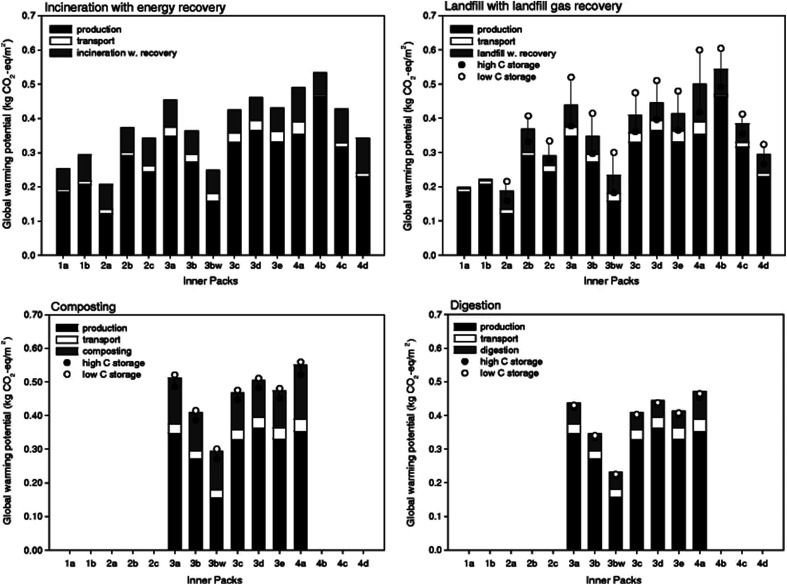

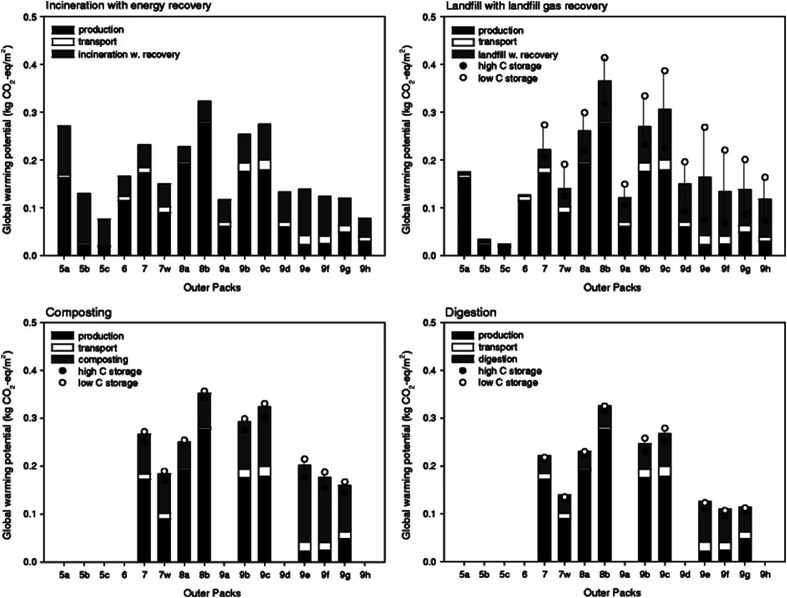

PLA is a tempting substitute for petroleum-based polymers for various applications including packaging, as well as the manufacturing of containers and cups. Petroleum-based polymers require many years to break down into harmless substances, however, PLA is fully degradable and aid in reducing the burden to the environment. In a study conducted by Vercalsteren et al., four types of cups that are commonly used in small indoor as well as large outdoor public events in Belgium were analyzed: the reusable polycarbonate cup (PC), the one-way polypropylene cup (PP), the one-way PE-coated cardboard cup, and the one-way polylactide cup (PLA). The functional unit was defined as the recipients needed to serve 100 L of beer or soft drink at a small-scale indoor event (2000–5000 visitors) and a large-scale outdoor event (more than 30 000 visitors). Factors including production of the cups, consumption stage (at the events), and the processing of cups wastes were taken into consideration. By comparing the environmental impacts of the four types of cups on both of the small indoor and large outdoor events, it was concluded that none of the cup systems has the highest or the lowest environmental score for all environmental impact categories considered in the study (carcinogens, ecotoxicity, fossil fuels, etc.). Therefore, it was not possible to draw a straightforward conclusion about the selection of the most favorable cup system (neither at small nor large events) with regard to the environment. Furthermore, the various events' size had also an impact on the eco-efficiency of the cups. For example, the lowest environmental impact in small public events was reported when the PC cup was utilized. This can be attributed to the reusable PC. Therefore, the PC cups were washed by hand which lowered the use of water and detergent throughout the cleaning process. However, at large public events, the environment impact for the PC cups was higher. This was due to the fact that there was more frequent cleaning for the PC cups which made them wear out faster, hence, they were regularly replaced. The highest eco-indicator points were for PLA cup, yet, for long-term applications, PLA still remains competitive due to its current technology development still being at the beginning stage. Furthermore, some of the environmental aspects associated with PLA such as acidification/eutrophication and dependence on fossil fuels could be further reduced under the appropriate measures. The successful implementation of such measures resulted in an almost 20% decrease in the eco-indicator points for the NatureWorks' second-generation Ingeo (PLA6) when compared to their first-generation type PLA cup (PLA5).116 In an investigation conducted by Hermann et al., the authors compared the use of different biomaterials (paper, polylactic acid, bio-based polyethylene, and a bio-based polyester) as well as conventional polymers (PP and PE) in the fabrication of 1 m2 that is mostly laminated and printed packaging film. The impact assessment for non-renewable energy use, total energy use, global warming potential, depletion of abiotic resources, photo-oxidant formation, acidification, eutrophication, water use, and land use were presented. The materials for the films and laminates were selected based on their collaboration with a multinational food producer and its film suppliers and converters. The two criteria for selection were that films and laminates must consist of at least in part of bio-based materials and that they must exhibit or are expected to have comparable barrier properties as the current materials used in the market. Different inner packs (1a–4d in Table 13) as well as outer packs (5a–9h in Table 13) alternatives were analyzed. Inner packs materials are chosen to have a good water and oxygen barriers because they are in a direct contact with the food. Outer packs are not in direct contact with the food, and they only serve as containers or bags for the inner packs. Fig. 33 shows the different global warming potential for the various inner packs. The global warming potential was calculated by adding all emissions of fossil greenhouse gas emissions and subtracting the biogenic carbon that is physically embedded in the product. Both fossil and biogenic emissions of greenhouse gases from the waste treatment stages were considered. Among all the biodegradable laminates for inner packs, the one double-layer PLA film (no. 3bw–3bw refers to PLA that was produced using wind energy instead of fossil energy) scored best for composting and digestion. Overall, the environmentally most attractive outer packs are bio-based PE (no. 5c), paper/PP laminate (no. 9a), paper/EVA (no. 9h), paper/bio-based polyester (no. 9g) and to a somewhat lesser extent also paper/petrochemical PE (no. 9d) (see Fig. 34). According to the study, inner and outer packs that contain PLA film produced without using wind energy, offer no significant environmental advantages. Nonetheless, when PLA's future technology is taken into consideration or if wind credits are assigned, PLA laminates become environmentally comparable with the reference material in the investigation.117

Laminates included in the study; biodegradability is indicated by an asterisk. Reference materials are 1a and 1b for inner packs and 5a and 6 for outer packs. For inner packs: PP laminates are 1, PP hybrids are 2, PLA laminates are 3, paper laminates are 4. For outer packs: PE films are 5, PP film is 6, PLA film is 7, cellulose films are 8 and paper laminates are 9 (ref. 117)b.

| Material type | Number | Material type | Number |

|---|---|---|---|

| OPP/PE/MOPP | 1a | PE | 5a |

| OPP/PE/MOPP | 1b | Bio-based PE | 5b |

| Paper/PE/MOPP | 2a | Bio-based PE | 5c |

| Cellulose/PE/MOPP | 2b | OPP | 6 |

| PLA/PE/MOPP | 2c | PLA | 7* |

| MPLA/PLA/PLA | 3a | Cellulose | 8a* |

| PLA/AlOx coated PLA | 3b* | Cellulose | 8b* |

| PLA/SiOx coated PLA | 3c* | Paper/OPP | 9a |

| PLA SiOx coated/SiOx coated PLA | 3d* | Paper/PLA | 9b* |

| MPLA/MPLA | 3e* | Paper/PLA | 9c* |

| Paper/SiOx coated PLA/PLA | 4a* | Paper/PE | 9d |

| Paper/aluminum/PLA | 4b | Paper/BBP | 9e* |

| Paper/MPET/peelablea PP | 4c | Paper/BBP | 9f* |

| Paper/MPET/peelable PE | 4d | Paper/BBP | 9g* |

| Paper/EVA | 9h |

The layer can be easily removed, manually, from the laminate.

Abbreviations PP, poly(propylene); OPP, oriented poly(propylene); MOPP, metallised oriented poly(propylene); PE, poly(ethylene); PLA, poly(lactic acid); AlOx, aluminum oxide; MPLA, metallised PLA; SiOx, silicone oxide; MPET, metallised poly(ethylene terephthalate); BBP, bio-based polyester, that is not further specified as per the producer's request; EVA, ethyl vinyl acetate.

Fig. 33. Inner packs' global warming potential for four waste treatment types.117.

Fig. 34. Outer packs' global warming potential for four waste treatment types.117.

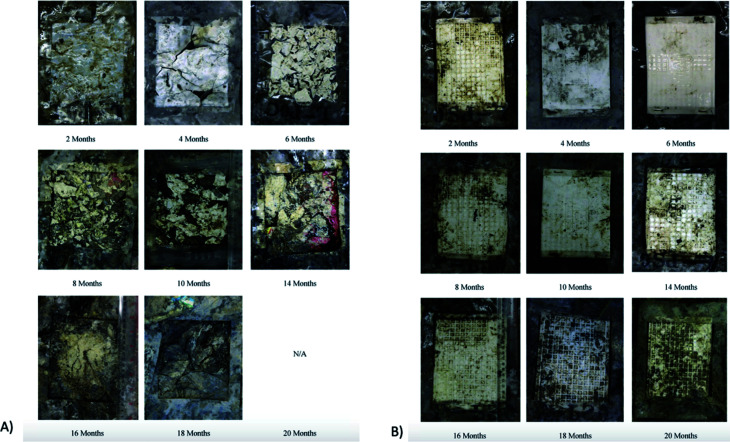

In their investigation, Leejarkpai et al. discussed the importance of considering the role of land-use change on the environmental impact of PLA. Land-use change is an element that need to be considered when lands are converted to crops. This can involve significant amount of processing including decomposition, nitrification/denitrification, and combustion. All such processes contribute in way or another to the global warming. The study showed that the highest CO2 emissions are related to that of PLA with land-use change consideration followed by PET, while the lowest emissions were reported for PS. However, under landfill conditions, the study reported that PLA showed a superior biodegradation property compared to PS. The structure of PLA sheets was subjected to biodegrading and it was broken down after 6 months burial in landfill conditions as shown in Fig. 35A. On the other hand, no significant difference in the structure of PS sheets was spotted even after 20 months as illustrated in Fig. 35B. Hence, the superior PLA's biodegradation characteristics plays an important role in reducing the plastic pollution due to nondegradable plastics.118

Fig. 35. The chronology under landfill conditions for up to 20 months for: (A) PLA sheets, (B) PS sheets.118.

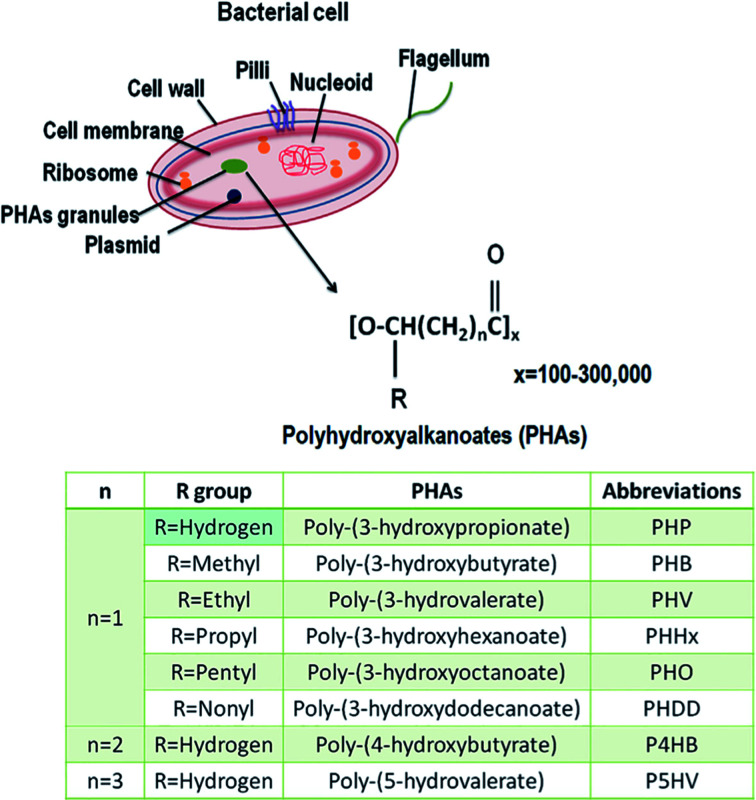

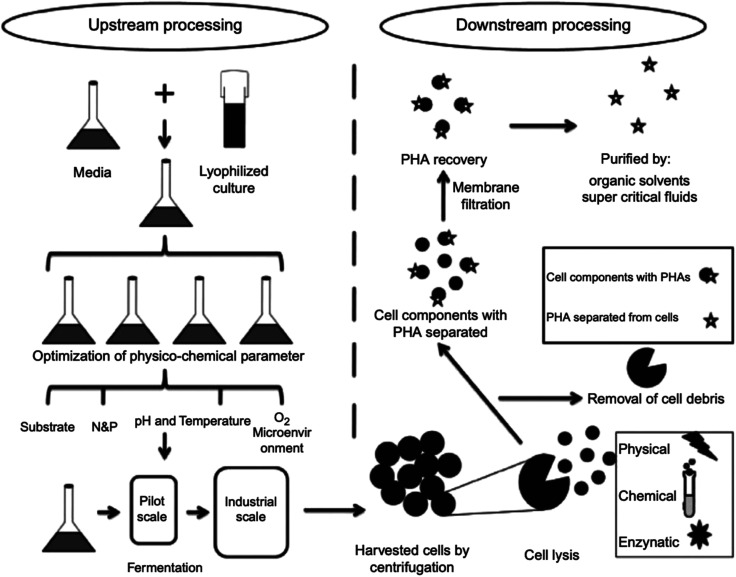

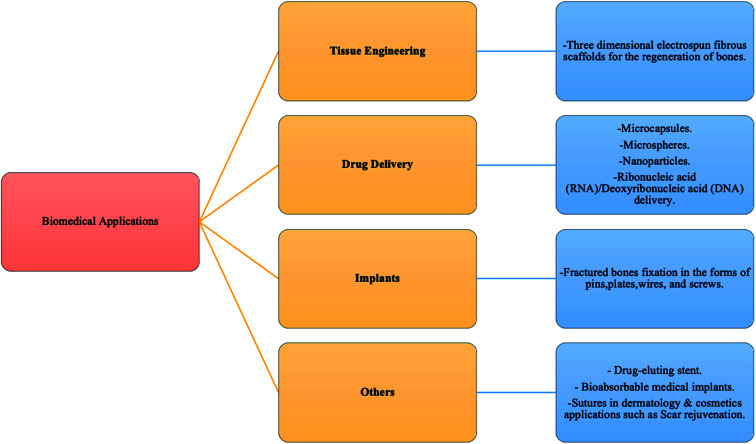

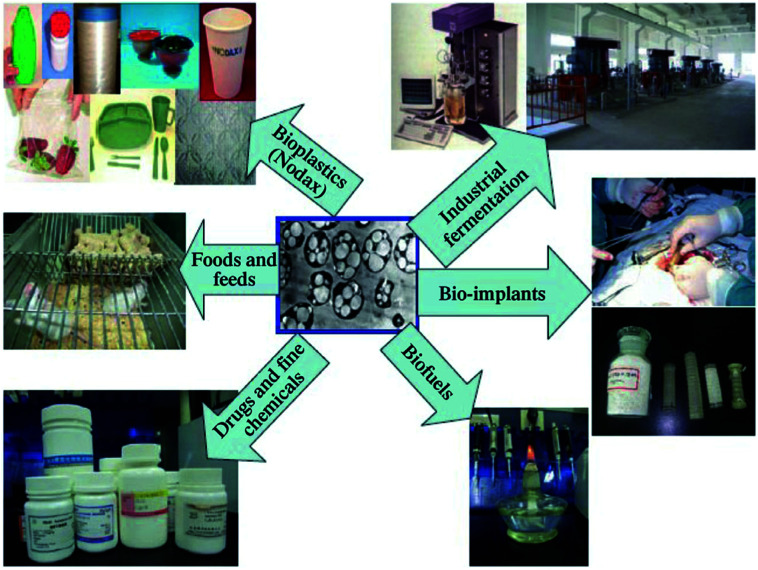

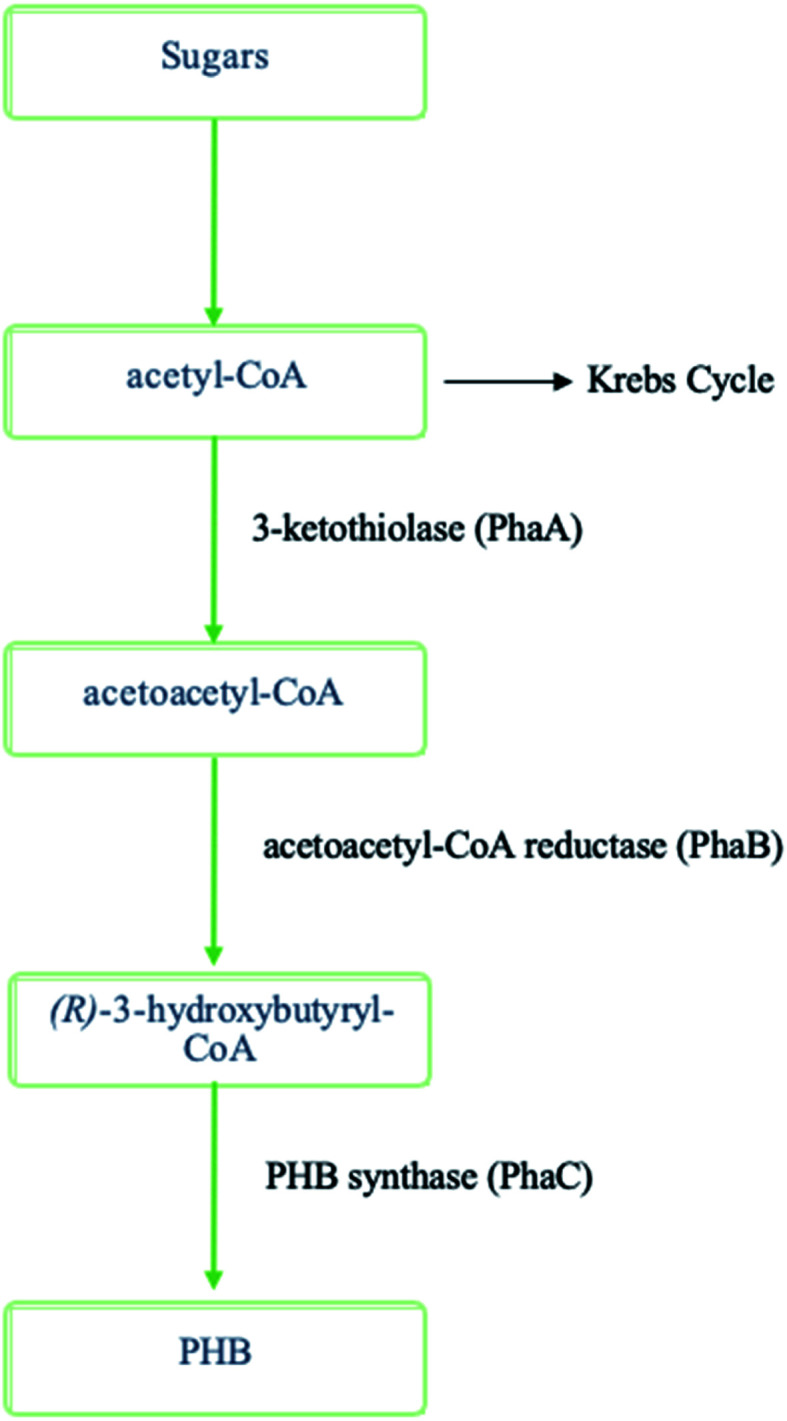

3. Polyhydroxyalkanoates (PHAs)