Abstract

Medical robots are invaluable players in non-pharmaceutical treatment of disabilities. Particularly, using prosthetic and rehabilitation devices with human-machine interfaces can greatly improve the quality of life for impaired patients. In recent years, flexible electronic interfaces and soft robotics have attracted tremendous attention in this field due to their high biocompatibility, functionality, conformability, and low-cost. Flexible human-machine interfaces on soft robotics would make a promising alternative to conventional rigid devices, which could potentially revolutionize the paradigm and future direction of medical robotics in terms of rehabilitation feedback and user experience. In this review, the fundamental components of the materials, structures, and mechanisms in flexible human-machine interfaces are summarized by recent and renown applications in five primary areas: physical and chemical sensing, physiological recording, information processing and communication, soft robotic actuation, and feedback stimulation. This review further concludes by discussing the outlook and current challenges of these technologies as a human-machine interface in medical robotics.

Keywords: flexible electronics, medical robotics, machine learning, human-machine interaction, prosthetics, rehabilitation

Flexible electronics and devices could potentially revolutionize the paradigm and future direction of medical robotics. Herein, the materials, structures, and mechanisms in flexible human-machine interfaces used in prosthetic and rehabilitation robots are summarized in five primary areas: sensing, recording, communication, actuation, and stimulation. The current challenges and outlook of these technologies in medical robotics are discussed.

1. Introduction

With a growing population and the subsequent rise of age-associated diseases, the development and integration of novel sensors and materials into medical robotics have the potential to prolong life expectancy and enrich the quality of life for the next generation.[1–5] The motivation for the advancement of medical robotics stems from the United Nations’ (UN) report that 46% of seniors (defined as 60 years and older) have some form of disability in comparison to 15% of the general public.[6] The higher ratio of disabled persons in the senior population is due to the greater frequency of age-associated diseases such as stroke, Parkinson’s, and Alzheimer’s disease that can lead to physical and cognitive impairment.[3,5,7] According to the Center for Disease Control (CDC), of disabled Americans, 13.7% of the population has a mobility impairment and 10.8% has a cognitive disability that can be alleviated with medical-assisted robotics and novel therapeutics.[3,8,9]

Despite the prevalence of cognitive and physical disabilities, the application of robotics for medical therapeutics only coincided with the paramount shift in medical ideology in the early 1980s on the neuroplasticity of the brain after injury.[10–13] In the late 20th century, researchers found that over long periods of time guided exercises had a significant improvement in restoring lost brain function and mobility.[14] These remedial motions were integrated into a wheelchair-adaptable therapeutic for stroke patients in 1989 with MANUS: the first medical robot designed specifically for rehabilitation.[3,12,15,16] Later in the 1990s, the KAIST KARES wheelchair further integrated torque sensors and vision-based servoing to allow for guided user navigation.[17,18] The field has continued to grow well into the 21rst century, with the keyword “rehabilitation robotics” in PubMed’s annual academic articles skyrocketing from 191 to 772 papers in 2010 and 2020 respectively.

The progression of feedback sensors, modern designs, and novel materials similarly generated broader user-acceptance of medical prosthetics.[19,20] Up until the sixteenth century, prosthetic appendages were mainly used as a form of aesthetic with minimal added functionality past holding and gripping tightly onto objects.[21] It was not until the early 1500s – when people could fabricate prosthetic limbs using complex moveable metal (iron) designs to replace or augment the fixed fabric, copper, and wooden schemes – that mechanical prosthetics were given broader mobility, stability, and functionally.[22] The innovation in prosthetic fabrication in the 21rst century has further advanced through the development of three dimensional (3D) printable soft materials and electronic skin sensors for flexible lightweight designs that enhance user-communication with their environment.

Despite the recent improvements to the material, design, and functionality of medical robotics, as well a $6.39 billion dollars market,[23] up to 40% of limb impairment patients still option out of using artificial replacements.[19] The common issues cited are the unnatural feel, poor functionality, and heavy weight of the device.[19] At its core, the inherent limitation of wearable robotics is that the electronics are not recognized as an extension of the human body, resulting in a high cognitive effort for the user to control. Additional shortcomings include their limited environmental feedback, power supply, and failure to autonomously respond appropriately to external (possibly dangerous) stimuli.[24] For many prostheses, the same sensory information can be acquired through the users’ stump.[19] Recent advancements in soft robotics and electronic skin (e-skin) may offer a way to bridge this communication gap, allowing the user to have broader functionality in their medical device for an enhanced user-experience.[25]

Initially proposed in science fiction movies, the first tangible application of e-skin for prosthetics occurred in 1974 with minor sensory feedback incorporated onto a robotic arm.[26] Now the base of many wearable devices, e-skin has been shown to outperformed human skin in capturing thermal, humidity, physiological, various chemical, and tactile sensations while maintaining a high spatiotemporal resolution under varying degrees of strain. Unfortunately, recording these multimodal chemical, temperature, and pressure signals can drain power and electrically interfere with the accuracy of sensor readings. It is therefore imperative to reduce the sensor density and improve the efficiency of data collection by maximizing the environmental information extracted through novel signal processing and machine learning (ML) techniques.[27] To make the replacement from current rigid electronics, e-skin requires a low mechanical modulus (high stretchability),[28–30] aesthetic appearance,[31] low-cost,[32] lightweight design,[29] large-scale fabrication techniques,[32] self-healing properties,[30] and be thermally stable.[29] With these functions, e-skin can provide the user with a more accurate understanding of their dynamic environment as well as update medical staff on the progress of their patient.

The combination of soft robotics with e-skin can additionally provide the user with a safe, light, and low complexity mode of actuation without the high cognitive strain associated with its rigid and heavy counterpart.[33–35] In particular, when e-skin tactile sensing communicates harmful external stimuli to the user, soft robotics can utilize its flexibility and high degree of freedom to efficiently move away and adapt to the scenario.[19,36] Together, e-skin and soft robotics can therefore alleviate problems such as limited functionality,[37] heavy weight,[19] and poor aesthetic design.[31] Unfortunately, the tradeoff to such mobility is structural degradation of the robot over long periods of duress. To replace the current metal designs, soft robotic materials therefore require the ability to withstand rapid exposure to extreme temperatures and toxic chemicals as well as continuous deformations and elongations.[38] Through dual sensory communication and flexible robotic actuation, e-skin and soft robotics devices can restore the user’s lost sensory awareness in the extremity, allowing the patient to see the limb as an extension of their body rather than a lifeless mechanical appendage.

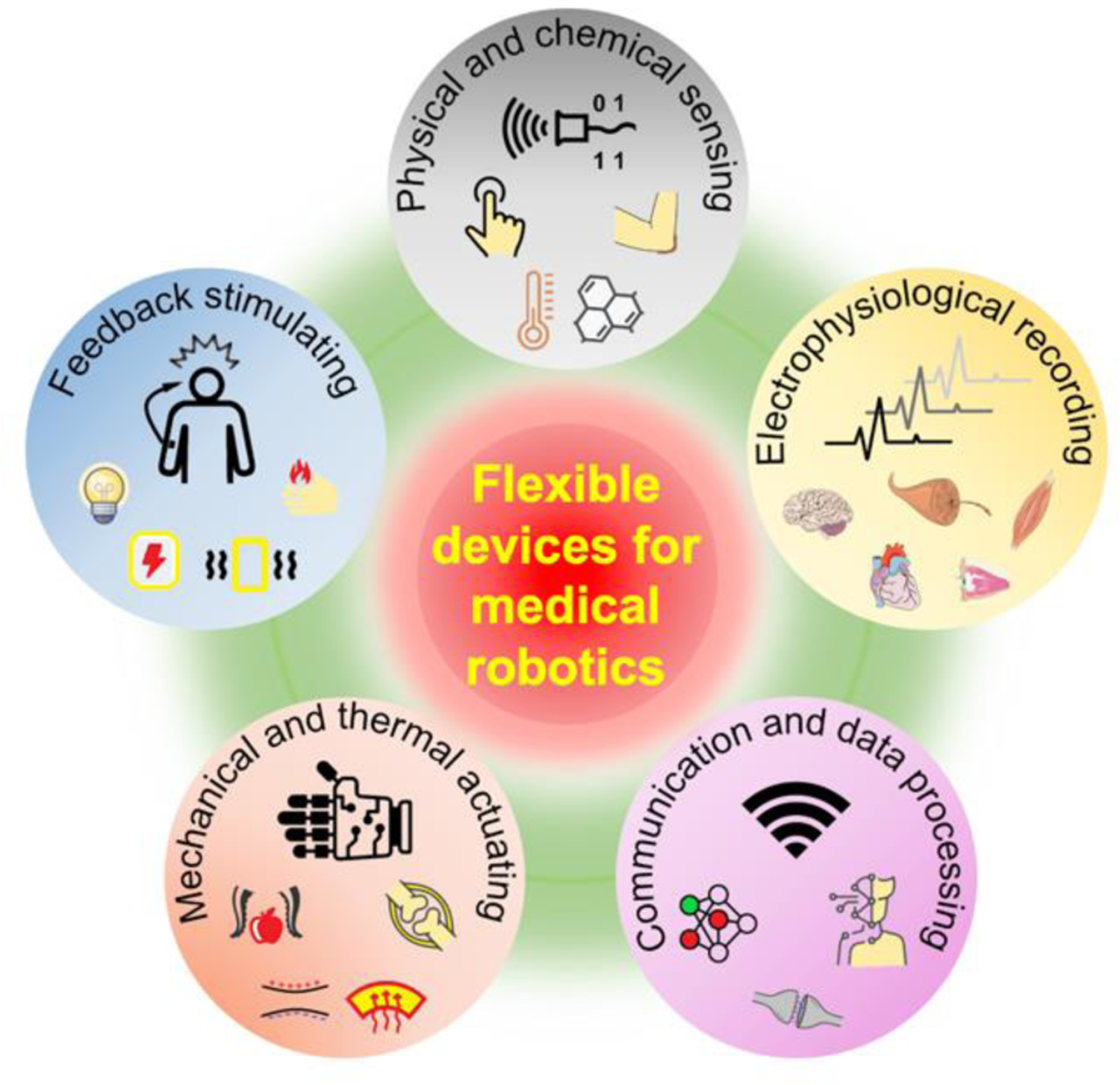

This review investigates the recent progressions made in flexible electronics and soft devices that tackle the current user-problems associated human-machine interaction (HMI) in medical robotics. The article breaks down HMI devices for medical robotic applications into five major categories: sensing, recording, communication, actuation, and stimulation (Figure 1). The first component, materials, provides a broad overview of the different compounds and structures that are currently being investigated for various medical robotic applications. The subsequent sensing section reviews mechanical, temperature, and chemical sensors that have been applied to e-skin. The paper provides specific attention to bioelectrical signal recording in the following section, analyzing the different techniques used to invasively and non-invasively detect electrophysiological information. After data collection methodologies have been discussed, the review will compare the various algorithms and techniques used to process and communicate information to the user. The review will then discuss soft robotics and actuators (thermal and mechanical) for human-like lightweight motion. Finally, the paper will end on robotic stimulation, in which various electrical and burgeoning optogenetic stimulations as well as noninvasive virtual reality (VR) and artificial reality (AR) applications are assessed. Each area of the review has been further supplemented with recent research studies, indicating the stage and future application of each methodology. In the final section, the challenges of flexible electronics and devices are summarized, noting their potential future directions within the scientific community.

Figure 1.

Representative applications of flexible electronics in HMIs for medical robotics.

2. Materials and Structures

The incorporated materials (Figure 2) and structural designs (Figure 3) in flexible devices directly impact their various properties. One of the most important properties for medical applications is biocompatibility, which includes the safety, comfort, and normal functionality of the device in vivo or on the skin. In the following subsection, various flexible materials and structural designs in HMI devices are introduced, alongside their desired properties, with specific attention given to their biocompatibility and functionality in various medical robotics.

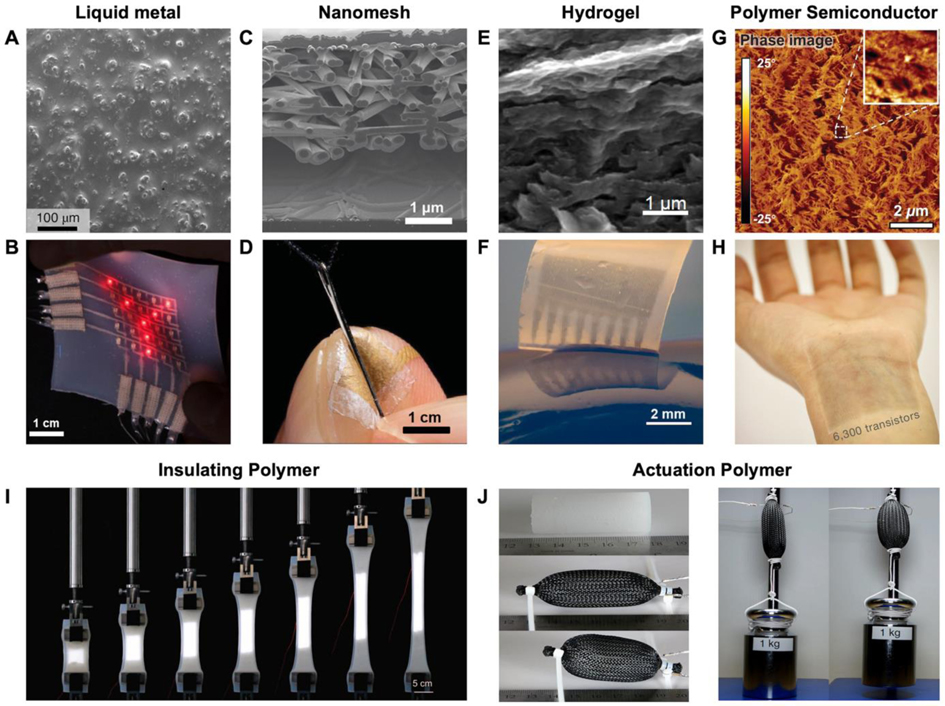

Figure 2.

Materials for soft electronic devices. A) Scanning electron microscopy (SEM) image of the surface on a biphasic gallium–indium (bGaIn) alloy film. B) Photograph of a multilayer LED display based on the bGaIn interconnects. A,B) Reproduced with permission.[40] Copyright 2021, Springer Nature. C) Cross-sectional SEM image of a gold nanomesh-based pressure sensor. D) The ultrathin pressure sensor attached conformally to the index finger. C,D) Reproduced with permission.[44] Copyright 2020, American Association for the Advancement of Science (AAAS). E) SEM image of interconnected poly(3,4-ethylenedioxythiophene) (PEDOT) polymer networks in the electrically conductive hydrogels (ECH). F) A micropatterned ECH elastic electrode array. E,F) Reproduced with permission.[58] Copyright 2019, Springer Nature. G) Atomic force microscope (AFM) phase image of a semi-conductive polymer under 100% strain. G) Reproduced with permission.[41] Copyright 2017, AAAS. H) A large-scale array of intrinsically stretchable transistors using the polymer as the semiconductor layer. H) Reproduced with permission.[42] Copyright 2018, Springer Nature. I) A hyper-elastic light-emitting capacitor encapsulated in insulating polymer (Ecoflex 00–30) under uniaxial stretching. I) Reproduced with permission.[66] Copyright 2016, American Association for the Advancement of Science. J) McKibben-type artificial muscles (soft polymer composite material inside braided mesh sleeving) and corresponding actuation. J) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license.[65] Copyright 2017, The Authors, published by Springer Nature.

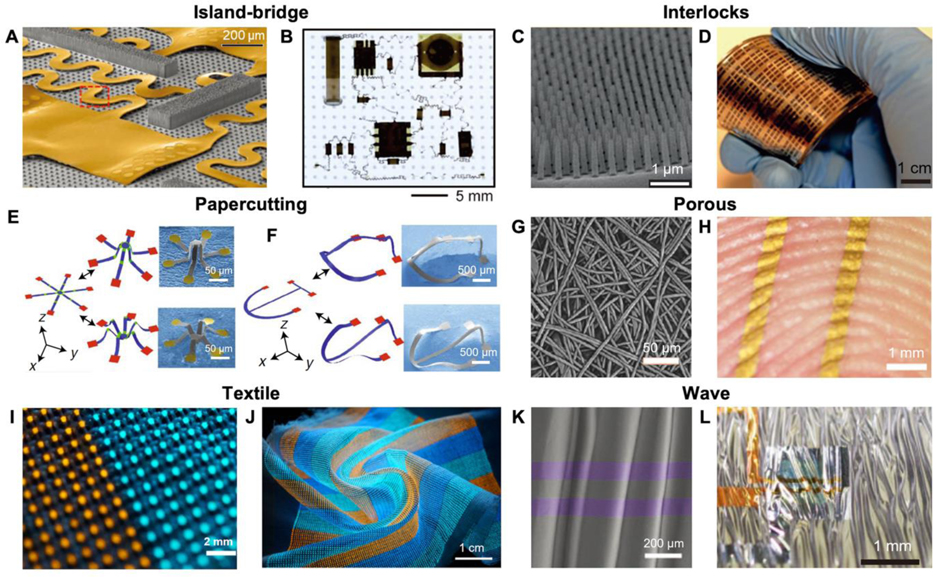

Figure 3.

Structures of soft electronic devices. A) Angled-view SEM of serpentine bridging interconnect networks. B) Optical image of the island-bridge device at equal-biaxial 50% strains. A,B) Reproduced with permission.[43] Copyright 2014, AAAS. C) SEM image of a dense array of reversible interlocking of Pt-coated polymer nanofibers. D) Photograph showing a nanofibers-based strain gauge with interlocking structure. C,D) Reproduced with permission.[61] Copyright 2012, Springer Nature. E) Papercutting inspired 3D microelectronic devices formed of SU8+Silicon in micrometers scale. F) 3D microelectronic devices in tens of micrometers scale using silicon. E,F) Reproduced with permission.[70] Copyright 2018, Springer Nature. G) SEM image of a nanomesh-based conductor with porous structure. H) A photo of a conductor attached conformally to a fingertip. G,H) Reproduced with permission.[73] Copyright 2017, AAAS. I) Photograph of a soft multicolor display in form of textile. J) The display under complex deformations, including bending and twisting. I,J) Reproduced with permission.[47] Copyright 2021, Springer Nature. K) SEM image of ultrathin transistors on an elastomer with waves formed by pre-stretching. L) Stretchable transistors on the elastomer with waves. K,L) Reproduced with permission.[48] Copyright 2013, Springer Nature.

2.1. Mechanical biocompatibility

From a mechanical perspective, biocompatible devices for medical applications must be flexible, elastic, and compliant enough to adapt to any target tissues’ complex morphology. Proper conformability can reduce damage to the device and body during tissue displacement and motion artifacts while also improving patient comfort and outcome.[39] HMI materials can be broadly classified into two categories: inherently elastic and intrinsically non-stretchable components. The former, such as liquid metals[40] (Figure 2A and 2B) and conductive or semiconductive polymers,[41,42] directly rely on their mechanical properties for flexibility without further modification (Figure 2G and 2H). The latter (rigid materials), on the other hand, gain elasticity through flexible structural designs. A common method for incorporating rigid components into flexible devices is to use thin strips of the material. Bending strains decrease linearly with thickness, making inherently inelastic materials flexible when fabricated into ultrathin films or wires (on the nanometers/micrometers scale). Typical examples are metallic films on flexible circuits,[43] or nanomesh electrodes (Figure 2C,D) in flexible sensors.[44] Another way to obtain flexibility is through structural designs, like serpentine (Figure 3A and 3B),[45] kirigami,[46] fabric (Figure 3I and 3J),[47] and waves (Figure 3K and 3L).[48] Such structures can not only endow a degree of flexibility and stretchability to rigid devices, but also further enhance the elasticity of inherently soft devices.[49] Upon gaining flexibility through materials and structures, HMI devices must be further processed into the appropriate biocompatible morphology suitable for different tissues (similar material to tissues).

2.2. Chemical biocompatibility

The chemical composition of flexible devices should be adaptable to various biochemical environments (biofluids like sweat and interstitial fluid) to ensure user safety and prevent device failure, especially in biological fluids containing various erosive ions and attacking immune cells.[50] For implantable devices, noble metals such as platinum (Pt) and gold (Au) play an important role in neural interface electrodes due to their chemical stability in physiological environments.[51] Another commonly used biocompatible material is hydrogels (see Figure 2E and 2F). As a material whose features resemble water-rich tissue in the human body, hydrogels can greatly reduce the inflammatory response of foreign objects, regulate cell or protein attachment, and prevent device failure in vivo,[52] which is important for implants.[53,54] Coating hydrogels on electronics[55] or mixing conductive materials such as carbon nanotubes (CNTs),[56] ionic liquids,[57] or conductive polymers[58] into the gel can help maintain biocompatibility while also preserving the electronic properties. For devices that are not chemically biocompatible, the last commonly used technique is to completely seal the device in biocompatible material, like polyimide (PI) or polydimethylsiloxane (PDMS).[59]

2.3. Functionality and performance

The functionality and performance of many medical robotics can be evaluated by the device’s sensitivity, electrode interface impedance, actuation capability, or stimulator charge injection capability, all of which are dependent on the electrical properties of the material and structural designs. As an example, conductive polymers and hydrogels have considerable charge storage and injection capabilities. Because of this, they are commonly used in electrostimulation electrodes,[58] electrophysiological recording electrodes, and nano-percolation networks that maintain statistical stability of impedance under deformation conditions.[44,60] In terms of structural design, such as mechanical sensor microstructure, to improve the functionality and sensitivity of the device (Figure 3C and 3D),[61] the combination of electroactive polymer (EAP) actuator and hydraulic structure can improve actuation capability[62,63] as the structural design of a pneumatic chamber will achieve the pre-defined actuating motion (Figure 2I and 2J).[64–66] In addition, self-healing can be achieved by leveraging the bonding properties of the relevant materials,[67] while biodegradability is mainly achieved by using inherently unstable materials.[68,69] Notably, 3D flexible electronics maintain conductivity while gaining an extra dimension and thus more sophisticated functions that 2D electronics do not offer (Figure 3E and 3F).[70–72]

2.4. Comfort and convenience

For wearable devices, biocompatibility also includes comfort and convenience, as the user needs to wear the device for long periods of time. Generally, porous structures have a high stretchability and breathability (See Figure 3G and 3H), which can facilitate conformal and comfortable attachment to the skin.[73] Moreover, textiles, the most common structure in our clothes, are also naturally porous due to the space between the fibers and yarns.[74] Due to their breathability, these aforementioned 2D porous materials facilitate the outflow and evaporation of sweat and are not only comfortable to wear but also do not cause much skin irritation.[75] In addition to breathability, lightweight is also an attractive feature of flexible devices. Unlike rigid devices based on bulky metal and silicon materials, flexible devices made of plastic and rubber are usually lighter. For example, using flexible lightweight materials, a prosthetic system weighing 300 grams was developed that mimics a commercially available prosthetic device that weighs more than 400 grams.[76] The benefit of lightweight devices is that they provide a more labor-saving feeling for better user comfort. Furthermore, the transparency based on polymers, or nanomesh materials, also contributes to greater aesthetic properties of flexible devices.[77,78]

2.5. Discussion

Collectively, research into materials and structures is fundamentally driving the growth of flexible electronics. It is important to note that most of the materials and structures discussed are versatile and can have multiple roles in prosthetics and rehabilitation robotics such as sensing and recording, computing and storage, as well as actuation and stimulation. The current challenges and potential future directions of materials and structures in flexible electronics include: 1) Although most studies mention durability and functionality, for many devices this is just a theoretical prediction or proof of concept. 2) Compared to rigid devices, the manufacturing precision and integration density of flexible devices are still in their infancy. This places a high requirement on the machinability of materials and structures to ensure flexibility. 3) The manufacturing cost of materials and structures is the key in determining the device’s price. Many materials and structures are already costly for proof of concept in the lab. For mass production, low-cost solutions need to be continuously explored.

3. Sensing

In the human body, the skin protects internal tissue from damage[79] while transmitting abundant external information to the brain through various high-density subcutaneous receptors.[80] In this way, the skin acts as a platform for the embodiment and extraction of internal and external sensations, such as physical (pressure and stretching),[81,82] chemical (perspiration),[83] and physiological (respiration and pulse)[84,85] information.

In medical robotics, e-skin presents itself as an optimal replacement for human skin to collect external and internal information from a patient. In the past decade, various flexible e-skin sensors that mimic the functions and features of human skin have already been integrated onto medical robotics to sense external information[86] for rehabilitation applications.[87] In rehabilitation, the absence of supervision may lead to incorrect patient posture, which reduces the efficiency of rehabilitation and can even aggravate a disability.[88] Collecting information from the patient during rehabilitation, specifically strain[89] and pressure,[90] can inform the therapist in real-time about the accuracy of the movement as well as the physiological status. At the current stage, e-skin can mimic or surpass human skin performance in mechanical and thermal sensing (as shown in Table 1) and functionalities in terms of various chemical,[91] physiological, and proximity sensing[92] to deliver accurate and diversified information to users. In such scenarios, e-skin sensing can achieve autonomous electronic rehabilitation by monitoring the patient in real-time, providing a promising solution for the development of personalized rehabilitation science.[93,94]

Table 1.

Comparison of key sensing performance of natural skin and artificial skin.

| Limit of detection | Sensitivity pressure | Spatial resolution | Response time | Sensitivity (temperature) | Mechanical property | Refs. |

|---|---|---|---|---|---|---|

| 1 mN[86] | 0.078–0.018 kPa[95] | 1 mm[96] | 15 ms[86] | 20 mk[97] | Stretchable ~30%[95] | Human skin |

| 0.08 Pa | >220 kPa−1 | 50 μm | 9 ms | NA | Flexible | Bai et al.[98] |

| NA | 0.01 kPa−1 | 0.1 mm | 15 ms | NA | Flexible | Yan et al.[99] |

| 1 ug ~ 1.25 Pa | 4.4 kPa−1 | 5 mm | NA | NA | Flexible | Wu et al.[100] |

| 0.3 Pa | >5000 kPa−1 | 1000 DPIa | <1 ms | NA | Flexible | Lee et al.[101] |

| <0.5 Pa | 192 kPa−1 | 0.8 cm | 10 ms | NA | Flexible | Zang et al.[102] |

| NA | NA | 5 mm | NA | 20 mk | Flexible | Yokota et al.[103] |

| 7.3±1.2 Pa | >1.25 MPa−1 | 2 mm | NA | 2410 ppm °C−1 | Stretchable ~800% | Hua et al.[104] |

| 10 Pa | ~1.78×10−3 kPa−1 | 318 CPIb | 32 ms | 3×10−4 °C −1 | Flexible | An et al.[105] |

| NA | 0.41% kPa−1 or 0.075% kPa−1 | 0.5 mm | NA | ~0.01 °C −1 | Stretchable ~20% | Kim et al.[106] |

| 100 Pa | 28.9 kPa−1 | 1 mm | 40 ms | <0.1 K | Flexible | Zhang et al.[107] |

DPI, dots per inch

CPI, capacitors per inch.

3.1. Pressure sensing

There are many e-skin pressure sensing mechanisms that have been widely and reliably adopted in medical robotics.[108–110] Several of these exemplary principles (such as piezoresistive, piezocapacitive, piezoelectric, piezoionic, and more) are discussed below alongside their applications in prosthetic sensing and rehabilitation health monitoring.

3.1.1. Pressure sensing mechanisms

Conventional static force-sensing mechanisms in e-skins mainly consist of resistive and capacitive sensing. Due to its simple mechanism and convenient data collection strategy, resistive pressure sensing has been extensively applied using various recording mechanisms.[111] Bulky piezoresistive e-skins, like sponge-based sensors, rely primarily on pressure-induced changes in the number of conductive pathways[112] or in the shape of the sensing material.[113] Meanwhile, another resistive sensor may analyze the changes in the contact resistance, like the quantum tunneling effect (Figure 4A).[114,115] This type is much more sensitive and thinner than the bulky option. An e-skin based on bilayer microdome arrays can use microstructures to maximize the changes in surface contact resistance based on the tunneling effect (Figure 4B).[115] Nevertheless, some drawbacks, like large hysteresis,[116] large confounding temperature sensitivity,[117] and varying pressure sensitivity[118] have limited the performance of resistive sensors. Compared with resistive sensors, capacitive sensors have excellent linearity with lower power consumption.[119] For piezocapacitive e-skins, capacitance changes are mainly based on the deformation of the dielectric layer. Normal pressure and tangential strain can be measured through a capacitive sensor as the dielectric layer can be deformed under tensile and external pressure (Figure 4C). As demonstrated in Figure 4D,[120] a capacitive pressure sensing array with cross-arranged electrodes was fabricated using CNTs as the electrode material and PDMS as the dielectric layer.

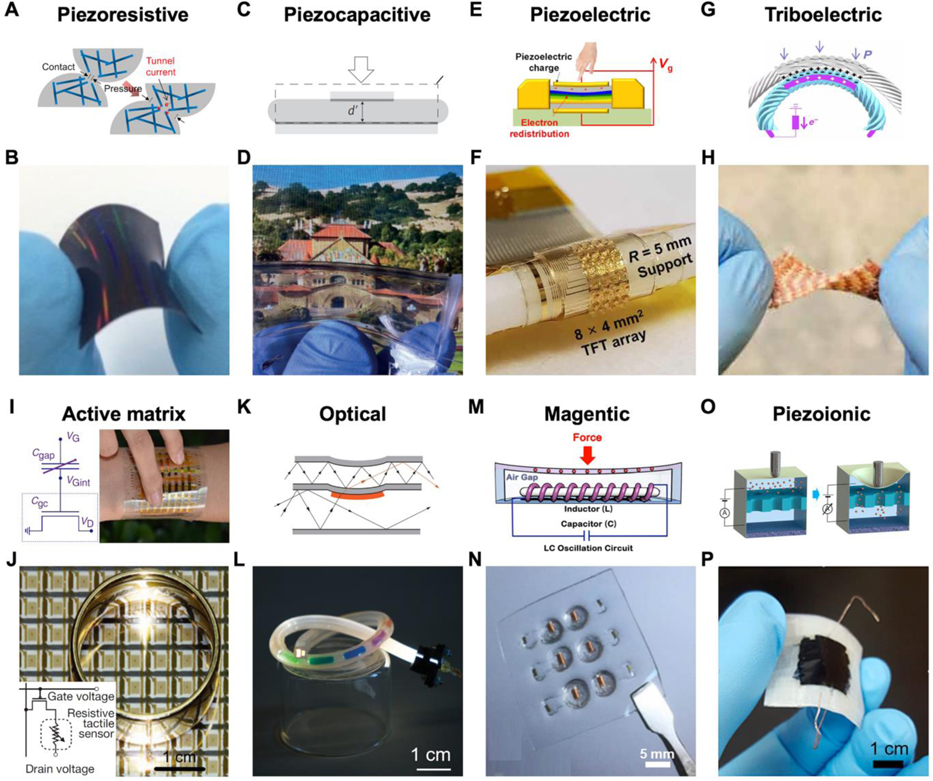

Figure 4.

Sensing mechanisms and examples of flexible pressure sensors. A) A piezoresistive mechanism. B) A giant tunneling effect-based piezoresistive pressure sensor. A,B) Reproduced with permission.[115] Copyright 2014, American Chemical Society. C) Piezocapacitive mechanism. D) Transparent piezocapacitive sensors. C,D) Reproduced with permission.[120] Copyright 2011, Springer Nature. E) A piezoelectric mechanism. F) Scalable tactile sensor arrays with piezoelectric materials in active matrixes. E,F) Adapted with permission.[124] Copyright 2020, AAAS. Reprinted/adapted from ref.[124]. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC). G) Triboelectric sensing mechanism. H) Triboelectric mechanism-based textile for pressure sensing. G,H) Adapted with permission.[127] Copyright 2020, American Association for the Advancement of Science (AAAS). Reprinted/adapted from ref.[127]. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC). I) Piezocapacitive active matrix. Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license.[102] Copyright 2015, The Authors, published by Springer Nature. J) Piezoresistive active matrix. Reproduced with permission.[48] Copyright 2013, Springer Nature. K) Optic pressure sensing mechanism. L) A stretchable multifunctional fiber-optic sensor. K,L) Reproduced with permission.[136] Copyright 2020, AAAS. M) A magnetic mechanism. N) A tactile sensor based on GMI material. M,N) Reproduced with permission.[100] Copyright 2018, AAAS. O) Piezoionic mechanism. P) A patchable pressure sensor mimicking ion-channel-engaged sensory organs. O,P) Reproduced with permission.[145] Copyright 2016, American Chemical Society.

Piezoelectric and triboelectric have their unique advantages in dynamic force measurements, i.e. high-frequency measurement, and self-power supply.[121–123] As an example of piezoelectric sensors, a dual-gated ZnO-based thin-film transistor (TFT) was fabricated (Figure 4E)[124] where external pressure causes noticeable voltage changes in the flat-band of the device (Figure 4F). In practice, this sensing mechanism is well-suited for HMI’s high-frequency environment, such as the detection of surface textures by robotic hands (high-frequency vibrations) and [125] wearable pulse monitors.[126] A representative example is shown in Figure 4G and 4H, where an all-textile triboelectric generator (TENG)-based machine washable sensor array was woven into different parts of a vest to enable measurement of pulse and respiratory waves.[127] Nonetheless, the major drawbacks of these two sensing mechanisms are the unreliable static sensing performances and drift in long-term measurements.[108]

Achieving a high integration density of sensing arrays is dependent on the fabrication process, materials, and the data acquisition method.[128] Meanwhile, the high integration density of the electronics easily leads to crosstalk and interference of the signals. An attractive approach to address this issue is to have transistors that maintain the sensing unit state integrated around the device to control and amplify the signal, namely the “active matrix”.[129] The previously mentioned resistive, capacitive, and piezoelectric cells are all capable of being integrated into active matrices. As shown in Figure 4I, capacitive integration uses primarily pressure-sensitive capacitors directly as gate capacitors, where the change in capacitance is translated into a variation in drain current in the field-effect transistor (FET)-based device.[102,130–132] On the other hand, piezoresistive sensors can be connected to the source or drain of the FET, where the drain current of the FET varies with the applied pressure (Figure 4J).[48,77,133–135]

Other pressure sensing mechanisms, like optical,[136–138] magnetic,[99,139] and piezoionic,[140–142] are emerging and accelerating the growth of the pressure-sensitive e-skin field. Optical pressure sensors rely on the differences in optical signal between the electromagnetic emitter and receiver, where an external force can deform the light guide (transmission medium) and alter the optical signal received (Figure 4K). By exploiting this principle, Figure 4L demonstrates a stretchable distributed fiber-optic sensor that can simultaneously monitor real-time deformations such as bending and pressing.[136] In addition to optical methods, magnetic sensors are also suitable for high-resolution pressure perception.[143] A pressure sensor was recently developed using soft materials that contain magnetic particles, where the external force applied changes the uniformly distributed magnetic particles and changes the internal magnetic field in the device.[99] As another example, Figure 4M and 4N illustrate a GMI-based pressure sensor with a high sensitivity to force stimuli.[100] Some innovative e-skins based on the piezoionic mechanism have been proposed.[140,144] The mechanical deformation of the e-skin can be indicated by a change in voltage or current due to the redistribution of ions with different mobility (Figure 4O). As demonstrated in Figure 4P, e-skins can utilize the piezoionic principle to measure the applied force by detecting the current between the nanopore membrane.[145]

3.1.2. Pressure sensing in prosthetics

Most existing commercial prostheses lack sensory capabilities and prevent amputees from actively and passively perceiving external information, which dramatically diminishing the user's ownership of the prosthesis. Flexible pressure-sensitive e-skins can be integrated on prostheses to provide sensory functions by transducing mechanical information to electrical signals. Passively detecting various external signals and actively sensing the state of the grip grant amputees the ability to perceive environmental stimuli and self-position their limbs, thus bringing revolutionary functionality to prosthetics.[146]

Physical integration of the e-skin with the prosthetic is the first and most basic step in establishing the human-machine interface. However, integrating e-skins may limit their sensing performance. One fundamental problem lies in the mechanical attachment of the e-skin to the complaint 3D shapes of artificial limbs, which leads to strain interference in sensor performance. Assorted tactics have been reported to mitigate bending-induced parameter variations from materials and structural design aspects.[48,77] From functional, durable, and aesthetic perspectives, conformal integration should be the first consideration, where most e-skins are attached directly and seamlessly to the prostheses’ surface using adhesives.[139,147] Others like the fabric e-skin can be conformally attached to the surface of the robotic arm using a computer-aided design and weaving technology. (Figure 5A).[148] In an alternative integration example, mold methods can transform the complex geometry of prostheses into relatively regular shapes that are smoother for e-skin installation.[112,149] Mentioning precision and quickness, fabricating flexible e-skins on robotic surfaces through optical scanning to model and 3D printing is another potential method for personalized integration.[150,151] Not as sophisticated as the above solutions, direct sprayed-on or coated integration are simple methods. As a model case, an e-skin named “Electrick” fabricated by simple coating technologies was reported. After spraying conductive materials and integrating electrodes onto the object, electric field tomography was performed to detect the shunting current between the user’s finger and sensors for touch sensing.[152] Researchers have also reported options for prostheses with flexible sensors embedded in the manufacturing process,[153,154] which solves the problem of surface mounting, but also presents a replacement challenge.

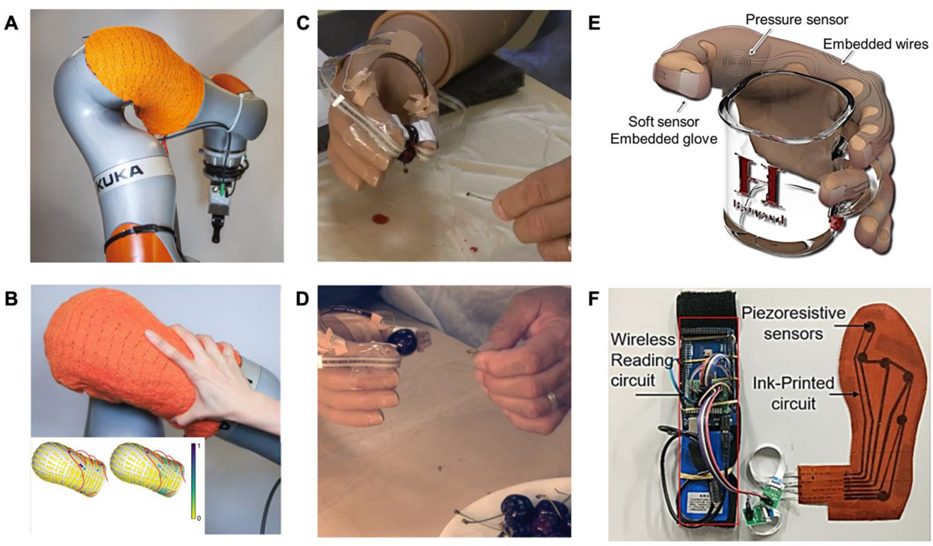

Figure 5.

Applications of flexible pressure sensors in medical robotics. A) Pressure-sensitive textiles integrated on a robotic arm. B) Demonstration of human touch on the arm and corresponding pressure mapping. A,B) Reproduced with permission.[148] Copyright 2021, Springer Nature. C) A cherries’ stem pulling experiment for illustrating the importance of tactile sensing ability in active prosthetic control. Without tactile feedback, the subject removed the stem but crushed the cherry attribute to unstable force control. D) Subjects wearing an artificial hand with tactile sensing ability removed the stem without damaging the cherry. C,D) Reproduced with permission.[157] Copyright 2014, AAAS. E) A flexible pressure sensor for detecting grasping force. Reproduced with permission.[162] Copyright 2014, IEEE. F) Smart insoles to monitor plantar pressure. Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license.[163] Copyright 2019, The Authors, published by MDPI.

Daily interactions between amputees and the environment in the form of touch and collisions require passive pressure sensing. For example, coverage of piezoresistive textiles on a robotic arm can provide a spatial map of pressure distributions (Figure 5B).[148] Compared with passive perception, active sensing refers to amputees detecting unstructured environments with prosthetics subjectively, such as identifying the stiffnesses and texture of objects, user-interaction with people, and grasping.[155] As an example, parallel ridges were fabricated on the surface of a poly(vinylidene difluoride) (PVDF)-based piezoelectric sensor to detect texture-induced vibrations.[156] Furthermore, adding e-skins on prosthetics creates a closed-loop sensory feedback control, which allows for a more accurate, facile, and compliant touch and grasp. In an example, sensory feedback control was demonstrated by pulling the stem from a cherry (without crushing it) using an artificial limb, which requires facile control through relayed feedback of the grasping force (Figure 5C and 5D).[157] Collectively, with the assistance of artificial skin, active and passive interactions make up the prosthetic pressure perception.

3.1.3. Pressure sensing in rehabilitation

Pressure monitoring is essential for rehabilitation, especially for extremities recovery and small pressure capture in health monitoring (heartbeats, pulse, etc.). Eg. fingertip and palm pressure feedback can inform the user about their gripping force for stroke patients to regain accurate grasping ability.[44,158–161] A liquid metal-based pressure-sensitive glove was used to train a subject to relearn a specific manual skill by providing real-time pressure monitoring (Figure 5E).[162] In another application, the medical importance of plantar pressure monitoring in patients with lower extremity disabilities are tremendous. Through analyzing the pressure concentration points on the foot, the gait phase can be identified for real-time correction of improper movements in rehabilitation.[163] Additionally, the imitation of human gait also facilitates the adaptability and compliance of bionic prosthesis to the human body.[164,165] In one example, a pressure-sensitive insole with an inkjet printing circuit and sensing units made of CNT embedded in PDMS was fabricated for detecting plantar pressure. These pressure data can be used to train ML algorithms to classify human gait phases (Figure 5F).[163] In rehabilitation, micro-vibrational physiological signals, such as a heartbeat[166,167] and pulse,[168,169] can provide information on the body's status and load, allowing for the immediate adjustment of the rehabilitation intensity and planning. Moreover, pressure monitoring of bedridden patients or prosthetic sockets can also effectively prevent skin ulceration due to prolonged pressure.[170,171]

3.2. Strain sensing

The mechanism for strain and pressure sensing overlap in many ways. However, there are still many differences in applications that are worthy of further consideration and discussion, especially for the detection of human and prosthetic postures.

3.2.1. Strain sensing mechanisms

The mechanisms of pressure sensors mentioned above, like resistive, capacitive, and optical, etc.,[172] can also be applied to flexible strain sensors. It is worth noting that some microscopic mechanisms in strain sensing, like misplace,[173,174] disconnection,[175] and crack propagation[168,176] are not available in pressure sensing. The most widely accepted capacitive structure for strain sensors is the “sandwich” structure. Inherent stretchable polymers are attractive materials for dielectric layers due to their stretchability and permittivity. Nanomaterials[177,178] and liquid metals[179] can be used as electrodes owing to their stable conductivity under tensile strain. Piezoelectric and triboelectric strain sensors are two other major types of stretchable strain sensors.[180–182] Piezoelectric materials, like BaTiO3,[183] zinc oxide (ZnO),[184] PVDF,[185,186] can be utilized to fabricate strain sensors by converting strain readings into voltage signals. Similar to the mechanism behind pressure sensing, flexible waveguides[136,153] and magnetic materials[187,188] have also been investigated for wearable strain sensing applications.

3.2.2. Strain sensing in prosthetics

Flexible strain gauges are commonly used in prosthetic control and proprioception. Prosthetics can be controlled by neural electrophysiological signals (will be further discussed in section 4) and mechanical signals such as gestures[189,190] or body movements.[191] By using simple and accurate signal gathered from non-invasive and visible sensors, gesture control strategy has become an intuitive and reliable control method for prosthetics.[146] Flexible strain sensors prove to be promising alternatives to monitor these mechanical signals owing to their stretchability, durability, and lightweight nature. As shown in Figure 6A, a biofuel powered strain sensor was integrated onto a human elbow to capture strain signals. By utilizing the strain signal, the subject successfully controlled the prosthetic to assist walking in real-world environments (Figure 6B).[192] Tiny stretching of the skin, such as muscle contractions and relaxation (i.e. mechanomyography) can also be detected by flexible strain gauges[193–195] or pressure-sensitive units[196] for prosthetic control.

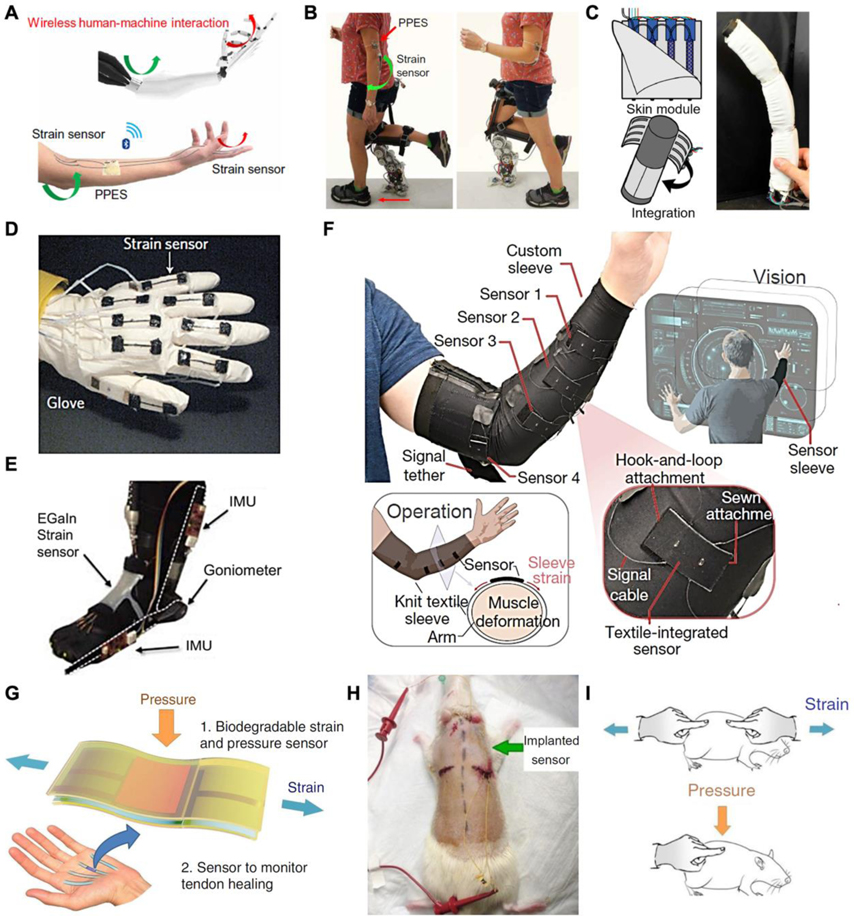

Figure 6.

Applications of flexible strain sensors in medical robotics. A) A perspiration-powered integrated e-skin (PPES) and strain sensor. B) The use of PPES and strain sensor for prosthesis control. A,B) Reproduced with permission.[192] Copyright 2020, AAAS. C) A robot skin with integrated strain sensors and actuators that can turn objects into soft robots. Reproduced with permission.[200] Copyright 2018, AAAS. D) A data glove using stretchable strain sensors. Reproduced with permission.[175] Copyright 2011, Springer Nature. E) A liquid metal-based strain sensor for detecting ankle angles. Reproduced with permission.[201] Copyright 2011, IEEE. F) Demonstration of a textile-based strain sensor-integrated sleeve to detect hand motion. Reproduced with permission.[194] Copyright 2020, Springer Nature. G) An implantable strain sensor can be attached to the tendon for real-time healing assessment. H) The strain sensor implanted subcutaneously on the back of a rat. I) External strain and pressure applied on the sensor. G-I) Reproduced with permission.[204] Copyright 2018, Springer Nature.

Besides pressure sensing, proprioception is another crucial perception for prosthetics, which allows the amputee to directly feel the posture of the device. In particular, flexible strain sensors can sense the stretching and relaxation of prosthetics like the human body's mechanoreceptors located on the muscles, skin, and tendons.[197] Commercial prosthetics are mostly driven by motors, where the angle encoder inside the device can accurately reflect the movements. Soft actuators lack this ability because of their continuous mode of motion, making the application of flexible strain sensors on soft actuators extremely attractive.[37,198,199] A noteworthy example to detect bending angles, an essential part of its self-perception, is flexible capacitive sensors alongside soft actuators. This hybrid robotic skin can turn inanimate objects into soft robots by estimating their current position. As shown in Figure 6C, to demonstrate the proprioceptive ability, the bend angle of a foam integrated with the robotic skin was calculated from the dimension of the device and the electrical signals.[200] Therefore, the combination of soft actuators and flexible sensors is a promising direction for future soft robotic systems.

3.2.3. Strain sensing in rehabilitation

For rehabilitation, the rotation of the joints, the contraction and relaxation of the muscles, and the natural breath cause strain on the human skin and are essential information to record. A healthy hand allows for dexterous manipulation. In terms of rehabilitation, the angle of the hand joints monitored by the sensors can be used as a basis for measuring movements, which provides rich data for hand rehabilitation. As shown in Figure 6D, a stable flexible strain gauge based on the “island and gap” structure of aligned CNT thin films was recently demonstrated.[175] Using this strain gauge for hand rehabilitation, a data glove can be fabricated to accurately detect the motion of each finger individually. In gait rehabilitation, ankle angles are essential physical information for orthotic devices to address pathological gaits. Figure 6E presents an EGaIn based-strain sensor that can be applied on top of the ankle to measure the joint’s angle to provide feedback on the foot’s motion during rehabilitation.[201] Unlike large strain measurements of joint angles, measuring the strain from small muscle deformations requires a high sensitivity. Figure 6F demonstrates an ultra-sensitive and resilient strain-mediated contact in anisotropically resistive structures based on a compliant strain gauge. To verify the effectiveness of this sensor, researchers fabricated a textile-based sensor that was integrated into the sleeve to detect small muscle deformations and classify hand and wrist movements.[194] On the skin, respiratory waves and pulses can also contribute to slight stretches, which can be captured by sensitive strainers for health monitoring during rehabilitation.[94,202,203]

In addition to monitoring external strain on the human skin, recently in vivo strain sensing has been investigated to monitor inner tissue, e.g. tendons and muscle recovery, by continuously providing real-time and long-term information for rehabilitation surveillance.[179,204] As shown in Figure 6G, an implantable capacitive multifunctional sensor was designed to measure pressure and strain signals under the skin. After being implanted on the back of a rat (Figure 6H), the in vivo sensor can accurately and stably detect strain and pressure signals applied on the implanted region (Figure 6I). This device was fabricated with biodegradable materials, which avoids the need for surgical extraction.[204] The design of these strainers provide a new paradigm for in vivo biomechanical measurements.

3.3. Thermal sensing

As temperature is another dimension of physical information beyond mechanical perception, mimicking thermoreceptors on the human skin is vital for the sensory function of prostheses. Currently, some temperature-sensitive e-skins can outperform the human skin in terms of sensitivity, accuracy, and detection range.[205,206]

3.3.1. Thermal sensing mechanisms

Resistive metallic temperature sensors[207] and thermistors[208] are the most commonly used sensors in flexible thermal electronics. The mechanism of resistive metallic temperature detectors relies on the linearity between resistance and temperature found in metals.[209] Thin metal films, like Au,[210] Pt[211] are widely employed in constructing flexible temperature detectors due to their good linearity and proven success in their microfabrication technologies. Unfortunately, the sensitivity of many metal materials can be a significant drawback for temperature sensing applications. Thermistors are another common class of resistive temperature sensor and can be categorized into nonlinear positive temperature coefficient (PTC) and negative temperature coefficient (NTC) sensors. In the PTC type, fluctuations in the temperature alter the specific volume of the material, which in turn affect its resistance and current measured. Conductive nanomaterial-filled polymers[212,213] are a promising candidate for flexible PTC temperature sensors, where the volume changes as the material progresses through the melting point of crystalline regions, thus affecting the resistance.[214] For measuring spatial temperature gradients, an organic active matrix with polymer PTC sensor pads was fabricated on a PI substrate, which exhibits a bending insensitivity and high spatial resolution (Figure 7A and 7B).[103] The negative temperature coefficient (NTC) thermistor has a clear advantage over other temperature sensors in that it exhibits a much simpler structure while presenting equivalently high temperature sensitivity.[215]

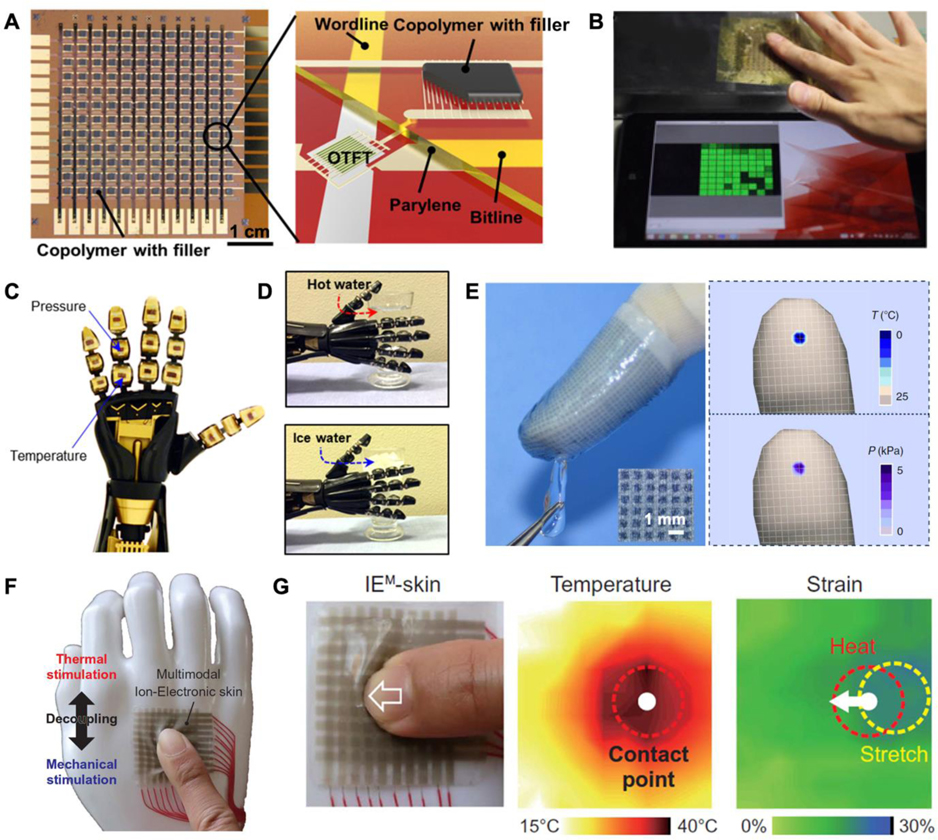

Figure 7.

Temperature sensors and applications in medical robotics. A) A PTC temperature sensing array. B) Temperature mapping after touching the sensing sheet. A,B) Reproduced with permission.[103] Copyright 2015, The Authors, published by National Academy of Sciences. C) A prosthetic hand integrated with pressure and temperature sensors on different regions. D) The robotic hand touching and identifying hot and cold cups. C,D) Adapted with permission.[222] Copyright 2017, AAAS. Reprinted/adapted from ref. [222]. The Authors, some rights reserved; exclusive licensee AAAS. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC). E) An e-finger assembled with flexible dual-parameter temperature–pressure sensors touching an ice cube and corresponding photograph temperature and pressure mappings. E) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license.[107] Copyright 2015, The Authors, published by Springer Nature. F) A multimodal ion-electronic skin attached to a dummy hand and its temperature/strain sensor responses under a weak unidirectional shear. G) Photo of finger press and corresponding schematic of temperature and strain variation. F,G) Reproduced with permission.[230] Copyright 2020, AAAS.

In addition to resistive temperature sensors, thermocouples and PN junction sensors are also two common thermosensing mechanisms. Thermocouples can generate a potential difference under different temperature between different materials based on the thermoelectric (Seebeck) phenomenon.[216] Whereas the forward voltage in PN junction temperature sensors can vary with temperature, converting the heat into electrical signals in the diodes and transistors. The advantage of this method is its small size, fast response time, and good linearity.[106,217] Moreover, some optical temperature sensors use infrared (IR) thermography[218] and colorimetric techniques with thermochromic liquid crystals that can be used to record the temperature more intuitively[219] and have already been applied to measure the temperature of the human body. Some remarkable designs based on biomaterials and structures have superior temperature response properties, offering another method for thermal perception.[97]

3.3.2. Thermal sensing applications

Thermal perception for prosthetics can complement pressure sensing for extracting more tactile information from the environment, which not only informs the amputee about the environment thermographically, but can also prevents the user from danger or potential device failure due to extreme heat or cool.[220,221] Figure 7C shows an intrinsically stretchable rubbery electronic, which can be used to fabricate thermistors.[222] Researchers demonstrated the sensor’s functions by using a robotic hand equipped with e-skin to grab and measure the temperature of different cups. (Figure 7D) One important lesson learned from studying the natural perception of human skin is that the identification of materials is inseparable from accurate temperature perception. As a heat source and sensor, the human hand can effectively perceive the heat dissipation ability for fluid flow rate sensing[223] and identifying the thermal characteristics of surface materials.[224] One such example used an artificial fingertip with e-skin to acquire information about the thermal properties and surface texture of different materials. Using machine learning, the combination of vibrational and thermal information was used to identify the group (e.g. wood, metal, plastic) and type (e.g. aluminum, copper, pine, etc.) of the material.[224] In medical rehabilitation, temperature sensing is commonly used to monitor the body, which can be a reference for health.[225,226]

In the field of medical rehabilitation, monitoring body temperature at different locations can reflect the body's state (both physiological and psychological) in real time. For example, the potential fatigue and psychological tension during the rehabilitation process can cause temperature variations due to sweat evaporation.[226] In addition, some disease-induced disabilities have distinct thermal characteristics (either high or low) at the extremities due to abnormal blood circulation and metabolism state. For example, the foot temperature of some diabetic patients can be about 5 degrees Celsius higher than that of healthy people. Long-term monitoring of body temperature by using flexible temperature sensors is convenient and can effectively prevent medical abnormalities such as foot ulcers.[227]

3.3.3. Multifunctional simultaneous sensing

Simultaneous detection of thermal and mechanical signals is challenging due to the coupling problem; however, it is possible. Five mainstream existing multisensory (mechanical and thermal) detection modes have been developed. The most conventional multisensory model is for temperature and pressure sensors to be placed on different parts of a prosthesis (Figure 7C and 7D).[222] Integrating the two sensors into one substrate would provide a higher spatial resolution.[104,105] Nonetheless, both types mentioned above cannot intrinsically measure two signals simultaneously at one point, resulting in a waste of valuable space at key locations (like fingertips). The development of novel dual-parameter sensors that transduce different stimuli into separate signals can minimize signal interference, allowing the detection of both temperature and pressure at a single point without decoupling analysis.[107,228,229] In Figure 7E, by taking advantage of independent thermoelectric and piezoresistive effects, a dual parameter device can simultaneously transduces temperature and pressure stimuli into separate electrical signals.[107] Another potential solution is to measure pressure and temperature in a single parameter, which is more efficient data collection. The first stretchable e-skin that decoupled temperature and strain in a single parameter is shown in Figure 7F.[230] The e-skin has a simple electrode-electrolyte-electrode structure, where two variables (temperature and strain) are derived from analyzing the ion relaxation dynamics: the charge relaxation time of the capacitance as a strain-insensitive feature to measure absolute temperature, and the normalized capacitance as a temperature-insensitive extrinsic feature to measure strain. In the demonstration, it can provide real-time thermal information, force directions, and strain graphics in various tactile motions (shear, pinch, spread, torsion; Figure 7G). Another promising multimodal detection method based on machine learning is the “cross-reactive” sensor matrix. Instead of responding to certain specific stimuli like conventional “lock and key” sensors, this sensor has the ability to respond to a wide range of stimuli. Utilizing machine learning methods to directly analyze the coupled multimodal data, these devices can achieve a certain degree of decoupling. This approach greatly reduces the complexity of the sensor mechanism and structure.[231] These dual-monitoring devices greatly enriches the external information that can be acquired by prosthetic haptics.

3.4. Chemical sensing

Although physical sensing still dominates the field, the past decade has seen an exponential growth in the exploration of molecular detection, which provides another dimension for human understanding of their own health condition and external environment.

3.4.1. Chemical sensing mechanisms

For chemical detection, the mainstream detection routes are electrochemical and optical detection. Electrochemical methods are attractive due to their high sensitivity, low response time, and long-term stability.[232] Electrochemistry has several main regimes for chemical detection: the amperometric approach (including voltammetry and chronoamperometry)[91] based on redox reactions, the potentiometric approach (based on the Nernst equation),[91,233] and electrochemical impedance spectroscopy (EIS) based on analyzing surface properties changes caused by affinity binding.[234] In addition to conventional electrochemical biosensing techniques, the transistor-based approach, including field-effect transistors (FET) and organic electrochemical transistors (OECT) also show great promise owing to their ability for in situ amplification of the detected signal.[235,236] For optical methods there are also two prevailing techniques. One is based on the colorimetric method, whose principle and structure are simple, but more difficult to reach high sensitivity. In recent years, with the popularity of smartphone cameras, the quantitative measurement of color is highly attractive for in-home monitoring of optical sensors.[237] The last method is the fluorescence approach, where the wavelength of the light emitted is larger than the wavelength received, which is more sensitive and suitable for trace substance measurement.[238]

3.4.2. Chemical sensing applications

Chemical sensors for prosthetic and robotic applications have been less investigated than mechanical and thermal sensors. From a bionic perspective, human skin does not have accurate chemical sensing capabilities, but rather uses mechanoreceptors to sense chemical contact and nociceptors to perceive chemical damage. However, there are enormous quantities and types of chemicals in the environment (e.g., gases, food, toxins, etc.), where rapid and accurate identification of these substances could provide the user with essential information about the environment. Thus, adding chemical sensing capability to prostheses can prevent users from being exposed to harmful chemicals, such as organophosphate pesticide residues in agricultural products, and subsequently reduce the potential risk of harm.[239] Moreover, some researchers have also proposed the employment of chemosensing in daily diets.[91] Furthermore, the chemical and biomolecular information collected by the e-skin from the human body could greatly benefit the design of next-generation HMI toward personalized robotic rehabilitation.

Although chemical sensing is not sufficiently developed for prosthesis, in the field of health monitoring, sweat chemical sensing (including electrochemical and optical modalities) is well-studied and highly relevant to rehabilitation exercises.[240] Sweat detection can respond in real-time to changes in the volume and rate of sweat loss,[241,242] as well as the concentration of various ions and metabolites in the body.[45,243–245] In this regard, sweat can potentially communicate to the user about health and rehabilitation progress, informing the user when to rehydrate and replenish electrolytes. Moreover, some diseases of the locomotor system provoke abnormal elevations of metabolites and biomarkers, such as L-dopa in Parkinson’s disease[246–248] uric acid in gout,[45] which are very important evaluation factors. In addition to monitoring patient fatigue, sweat sensing can also be used for psychological applications by monitoring the level of stress hormones such as cortisol and norepinephrine.[249,250] In this promising field, many in-situ, multi-channel devices are emerging.[251–253] Recently, a fully integrated wearable sensor array for multiplexed in-situ perspiration analysis was reported, where the sodium, potassium, lactate, and glucose content of sweat can be measured simultaneously by electrochemical methods. Conventional commercially available integrated-circuit components (more than ten chips) can be applied on a FPCB to serve as data processing and transmission.[83] Integrating in-situ sensing, on-site processing, and data transmission together, chemical sensing platforms can achieve the goal of continuous, real-time sensing of ions and metabolites, which is crucial to obtain more comprehensive knowledge about a wearer’s well-being.

3.5. Other Sensing Techniques

While the skin has receptors for sensing mechanical and thermal information, there are no specific receptors that sense humidity. Rather, the human brain is able to "perceive" wetness indirectly by analyzing mechanical and thermal information (normal pressure and tangential adhesion between the liquid and the skin as well as heat conduction of the liquid).[254,255] Such mechanisms, which may require intelligent cross-sensor algorithms, are not available in the current e-skin. Existing flexible humidity sensors are mainly fabricated by accommodating different transducing materials, such as graphene, CNT, and MoS2, on flexible substrates. The change in the resistive or dielectric properties of these materials as they absorb moisture is used to reflect the humidity in the air.[256–258] Due to new sensing mechanisms, e-skin can exhibit greater functionality beyond the human skin, such as proximity[259,260] and magnetic field sensing,[261,262] which can be seen as complements to the natural skin capabilities, allowing HMI devices to obtain richer information about the external environment.

Other mechanisms of flexible health monitoring in rehabilitation, like optoelectronic[263,264] and ultrasound[265,266] devices, can also be applied to heartbeat, pulse oximetry, blood pressure, and other on-body measurements. As an example, organic flexible LEDs and photodiodes are driving the application of photoplethysmogram (PPG) in the wearable sector. PPG uses optical differences between the vascular and other tissues or oxygenated and deoxygenated hemoglobin to measure heart rate,[263] blood oxygen,[267] and other in-depth cardiovascular information.[268]

3.6. Discussion

In this section, the mechanisms and applications behind pressure, strain, temperature, and chemical sensors are discussed for human-machine interfaces in medical robotics. In many cases, the sensing capabilities of each have surpassed human skin in terms of function and performance, which is crucial for the development of artificial limbs with the same or better sensory function as human limbs. This allows the users to better perceive the information around them. Providing real-time monitoring of human motions and physiological signatures provides rich data for the field of disability rehabilitation, which is conducive to the formulation of personalized rehabilitation strategies to achieve better rehabilitation results.

Despite the rapid expansion of all these flexible sensors in the last decade, there are still many challenges to be investigated. First, flexible sensors attached to prostheses and human skin generally require compliant flexible characteristics, which places a limit on the thickness of e-skins. Normally, ultra-thin e-skins have better mechanical compliance, but their mechanical strength decreases significantly with their thickness. How to endow flexible sensors ultra-low thickness and high strength through material selection and structural design will directly determine the performance and durability of these interfaces. Secondly, fabrication of large area e-skins is challenging. Most of the existing research on flexible sensors are miniaturized proof-of-concept. Large-area fabrication must still comply with conformal design from 2D to 3D, signal crosstalk handling, the self-healing requirement, as well as the low preparation costs (time and money). Thirdly, the principles of bionics have not been fully developed and applied to electronic skin, like moisture detection. Lastly, further sensing capabilities beyond human skin still need to be explored, especially in chemical detection, as reliable chemical sensing opens up another dimension for the human to perceive the external environment.

4. Electrophysiological recording

Electrophysiological signals carry a wealth of information about the human body. One prominent parameter carried through the nervous system is movement intention. Motor intention originates from the primary motor cortex of the brain and is transmitted from the central nervous system to the peripheral nervous system in the form of electrophysiological signals, which are translated into mechanical contractions of the muscles.[269] Such bioelectrical signals propagating through the nervous system can be detected both in vivo and on the skin’s surface (using electrodes). Subcutaneous invasive electrophysiological signals can be derived through brain interfaces,[270–272] using electrocorticography (ECoG)[273,274] on the cortical surface as well as local field potentials (LFP)[275,276] extracted from electrodes inserted into the cortex. Invasive recording techniques routinely use peripheral in vivo tissues with electroneurography (ENG)[277,278] and electromyography (EMG),[279,280] which can record peripheral nerve activity and muscle electrical signals respectively. Non-invasive electrophysiological recording is also widely accepted and can be extracted on the skin’s surface. Common wearable techniques include electroencephalography (EEG),[281,282] surface electromyography (sEMG),[283,284] and electrooculography (EOG),[285] which capture the electrical activity of the brain, muscles, and eye movements respectively. Utilizing these electrophysiological signals to capture and decode the movement intention can provide a natural way to control prosthetics. Thus, the vast number of studies on different interface locations and various probing devices to record electrophysiological signals have established the foundation of user-communication with prosthetics.[24,286,287] Another popular detection technique for electrophysiological signals captured via invasive and wearable devices is electrocardiogram (ECG),[288,289] which cannot be used for prosthetic control, but does provide auxiliary information for disability rehabilitation monitoring.

There are two broad categories for electrophysiology recording - implantable (also known as sensing neural interfaces) and non-invasive (also known as wearable electrodes) recording.[290–292]. Of the two, non-invasive sensors are more extensively researched and is generally preferred by many patients. Compared to commercially available rigid electrodes based on silicon wafers and rigid packaging, flexible electrodes are also more biocompatible (details described in section 2) and can adapt to the complex tissue geometries of the human body,[293–295] such as sulci in the cerebral cortex,[296,297] bundled peripheral nerves,[298] and stretching motions on the skin.[299] In this section, we will mainly review flexible implantable and epidermal electrophysiological recorders for medical robotics.

4.1. Invasive modalities

Implantable electrodes that are embedded under the skin or inserted into the target tissue, especially around deep or delicate tissues, are more accurate than non-invasive electrodes as they obtain substantially more biological signals. Various electrodes, with different materials, shapes, and characteristics, can be places on or in the human brain, peripheral nerves, and muscles to record ECoG,[300] LFP,[301] ENG[302] and EMG[303] respectively.

4.1.1. Sensing neural interfaces

Biocompatibility is the determining factor for the safety and stability of implants in long-term chronic operation (see section 2).[304] Apart from the biocompatibility, the requirements of implantable sensing neural interfaces for good performance lie primarily in the device impedance, and hence conductivity and capacitance. As impedance adds noise to the signal, lower impedance electrodes are expected to have a higher signal-to-noise ratio (SNR) overall. Moreover, low electrode impedance combined with the distributed capacitance between the electrodes and the recording amplifier will enhance the high-frequency response performance of the electrode.[305]

Materials underlying the biocompatibility and electrical properties of the implantable devices are constantly developing. Traditional commercial implantable neural interfaces (e.g., Utah electrodes[306] and Michigan electrodes[307]) typically contain noble metals[308] (high conductivity and chemical stability), and silicon-based materials[309] (ideally suited to existing microfabrication techniques) as electrodes. With further evolution of processing technology, these materials can be fabricated into ultra-thin and ultra-fine forms, thus enabling high-density integration, as well as endowing some flexibility.[310,311] Recent advancements in soft and nanomaterials have opened up more options for flexible recording electrodes, like conductive polymers (e.g., PEDOT)[302,312] and nanomaterial composites (metal-based, CNT, graphene)[313–317]. Apart from the conductive functional materials, the insulative packaging materials are also a critical part of sensing recorders. Many popular insulating soft materials have been used for packaging sensing electrodes,[318] such as PI,[319,320] PDMS,[321,322] hydrogel,[323,324] etc., as they have suitable mechanical, dielectric and biological properties.

Recently, there has been a focus on wireless transmission of data and energy for flexible implants, which can reduce messy wires and improve user mobility and social interaction.[325] Moreover, given the damage of the surgery to the human body, fully implantable non-removable devices should be operational for a long period of time (ideally lasting a full human lifetime) to avoid the surgery associated with frequent battery replacement. Recent advances in wireless charging and self-powered technologies have been established to limit the number of times a user must undergo replacement surgery.[326] Specifically, recent studies have demonstrated the feasibility of piezoelectric,[327] near field communication (NFC),[328] and ultrasonic technologies[329] in power supply and data transmission.

4.1.2. ECoG and LFP

As invasive brain monitoring electrodes, ECoG and LFPs play an important role in examining motor intention and elucidating the fundamental pathogenesis of various neurological disorders, such as epilepsy and Parkinson’s disease.[330,331] ECoG and LFPs can be delineated depending if they are inserted into the cerebral cortex. LFP recorders mostly use microelectrodes to penetrate directly into the cerebral cortex, which capture more accurate and deeper brain signals. In contrast, ECoG electrodes are generally placed on the surface of the cerebral cortex and can collect signals without penetrating the tissue, with a larger recording area with relatively less damage to the brain.[270] Harvesting these brain signals as an information source bring three distinct advantages to HMI. Firstly, the brain acts as the source of motor intention, which is essential to reduce the delay time between conscious action and robotic actuation.[332] Moreover, the high spatial and temporal resolution of ECoG and LFPs can provide finer and more accurate control signals for prostheses as the neuronal areas can be recorded independently at a higher density.[333,334] Beyond these, as the recorders directly interface with the brain, they circumvent the communication and control channels in peripheral nerves and muscles, which is of great significance for patients with damaged peripheral nervous systems or other severe spinal cord injuries.[335]

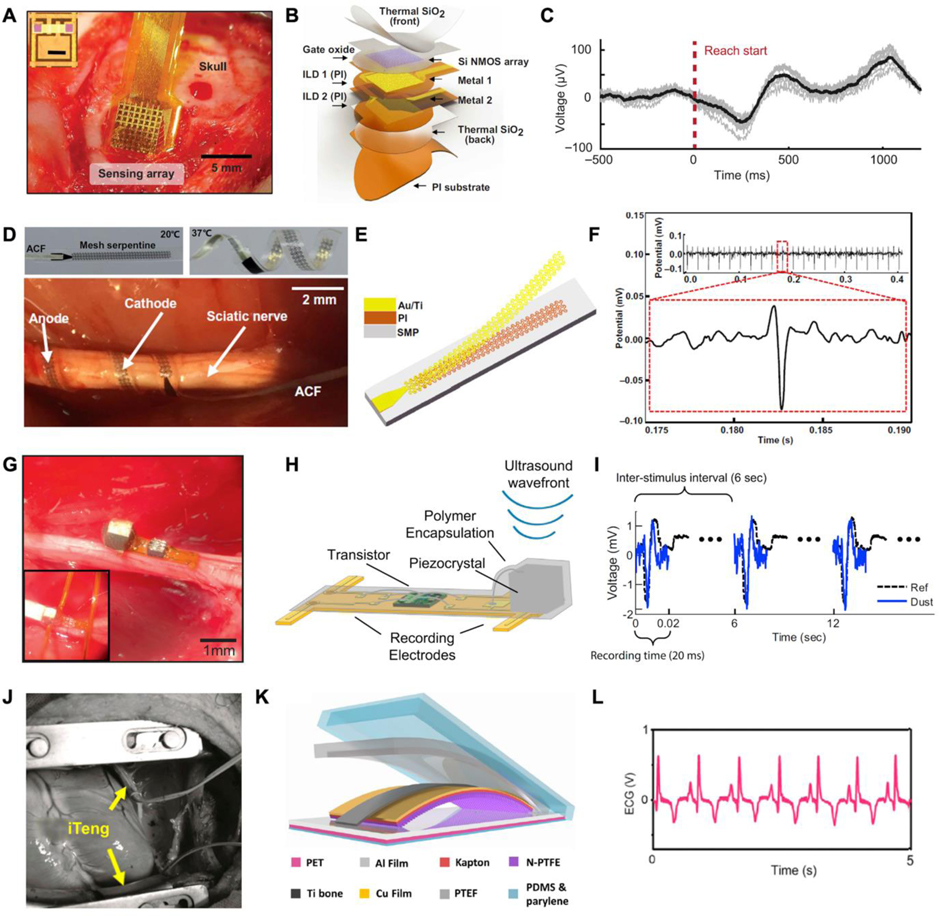

From the perspective of information richness, it is apparent that a one-channel recording neural interface is not the best choice, especially for brain-machine interfaces (BMIs). Thus, neural interfaces are rapidly evolving in two conceptually different,[304] but complementary,[336] directions (high integration[337] and flexibility[290]). Flexible electrode array is an attractive approach to combine high density and flexibility, increasing data collection. Conventional BMIs with probe-like morphology for LFP recordings are generally small and rigid.[338] As materials and manufacturing processes evolve, more micro-wires are becoming flexible alternatives to microneedle arrays, which are able to remain relatively stationary as the brain moves, improving signal stability while reducing tissue damage.[339–342] An exemplary case is a flexible filamentary bioinspired neuron-like electronic, which consists of a polymer-metal-polymer structures. The bending stiffness of this implant is comparable to that of a neuron’s axon, enabling biocompatible high-resolution LFP recording.[310] Referring to another brain (ECoG) recording, ultrathin film electrode arrays are a promising and widely adopted option for electrodes used on the surface of the cortex, owing to its high recording density in a non-penetrating fashion.[296,343–346] With this format, a multiplexed neural interface with capacitive electrodes incorporates high spatial resolution with long-term temporal mapping capabilities on a thin PI substrate (Figure 8A). In this device, the thermally grown silicon dioxide (t-SiO2) serves as a biofluid barrier as well as a dielectric medium, providing both encapsulation and capacitive functions (Figure 8B). To verify the feasibility of the device, the arrays were implanted over sensorimotor cortices in monkeys, which presents a stable long-term recording. (Figure 8C).[347] As another representative type of flexible structures, the mesh structure also distinguishes it for both inserted and superficial neural implants owing to its stretchability and adaptability.[301,348–350]

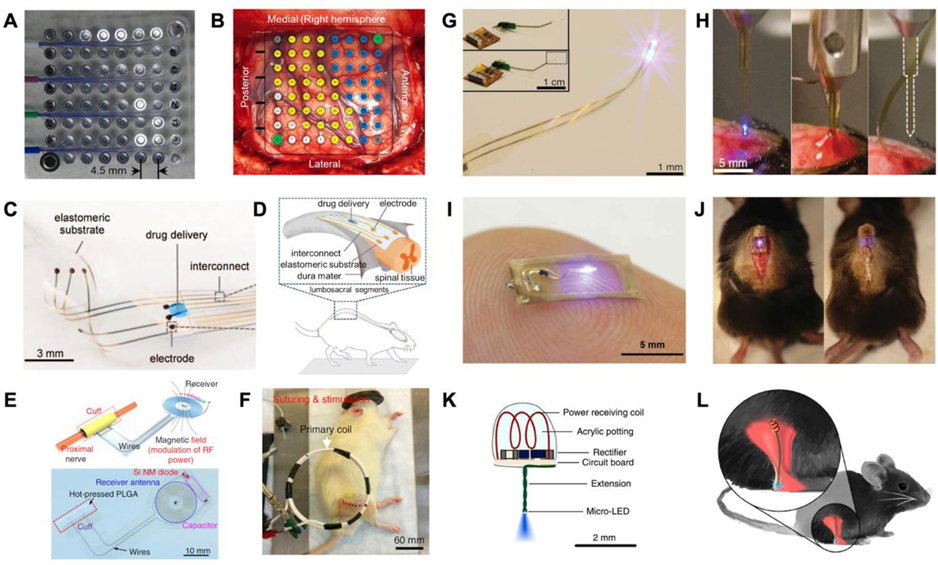

Figure 8.

Implantable electrophysiological recorders. A) A neural interface was implanted epidurally over rat’s cortex to record μECoG. B) Exploded view of the high-definition neural interface for μECoG mapping. C) Corresponding recorded μECoG signals. A-C) Reproduced with permission.[347] Copyright 2020, American Association for the Advancement of Science. D) Bipolar twining electrodes integrated on the sciatic nerve for ENG recording. E) Layout of the twining electrode. F) Recorded ENG signal evoked by the shaking of the anesthetized rabbit’s leg. D-F) Reproduced under the terms of the CC-BY Creative Commons Attribution 4.0 International license.[358] Copyright 2019, The Authors, published by AAAS. G) Optical image of an ultrasonic neural dust. H) Exploded view of the key components of the EMG recording system. I) EMG signals recorded by the neural dust. G-I) Reproduced with permission.[372] Copyright 2016, Elsevier. J) Photographs of a TENG-powered ECG recording system conformed around a pig heart. K) Exploded view of the ECG recording system. L) The filtered ECG recorded in vivo. J-L) Reproduced with permission.[382] Copyright 2016, American Chemical Society.

4.1.3. ENG

Electrical activity recorded from efferent axons in peripheral nerves provide another alternative for monitoring motor intention. In contrast to the neurons hidden in the cortex, peripheral neurons have a cable-like morphology. Various adapted peripheral electrodes have been proposed, such as implants around the nerve (cuff electrodes[351] and flat interface nerve electrodes (FINE)[352]), longitudinally through the nerves (wire[353] and longitudinal interfascicular electrodes (LIFE)[354]), and through the nerves via shafts (such as transverse interfascicular multichannel electrodes (TIME)[355]). To accommodate peripheral nerve movement and deformation, most of the above electrodes are moderately flexible. For these cable-like peripheral nerves, the flexible cuff electrodes (both spiral[356,357] and helical[358,359] shaped) are the most common ones that must be mentioned.[360] In this type, spiral means that the ability to circumscribe the nerve, which somewhat limits the variation in nerve diameter (nerve growth), unless the electrodes are stretchable spiral cuffs.[302,361] For helical electrodes, self-morphology is an attractive property.[362] As shown in Figure 8D, an electrode inspired by climbing twining plants for neural recording and stimulation was fabricated.[358] This device mainly consists of an array of serpentine electrodes (Au, 200 nm thick) and PI strips (2 μm thick) on matching substrates of shape memory polymer (SMP; ~100 μm thick; Figure 8E) that enabling devices wrapped on nerves under body temperature. In vivo Vagus nerve stimulation was carried out on a rabbit to demonstrate the validity of the device (Figure 8F). Nevertheless, ENG signals have a low signal-to-noise ratio and limited stability.[363]

4.1.4. EMG

The exploration of electromyography for prosthesis control is based on the assumption that the user’s intentions can be extracted from the activation of the remnant muscles.[364,365] In contrast to surface EMG, implantable EMG has many advantages, such as higher signal quality, less movement artifacts, and the ability to record small and deep muscle activity.[364] Generally, two methods, penetrating or surficial (those between the epimysium and the skin), undertake the EMG recording.[366] The penetrating electrodes are mostly rigid enough to maintain their structural integrity in the muscle.[367,368] In contrast, surface electrodes generally are more flexible,[364,369] whose morphology in the limited space between this epimysium and the skin is either 1D or 2D thin electrode layers[370,371] or very tiny electrodes (millimeter or even sub-millimeter level).[369,372] As a representative case of tiny wireless electrodes, millimeter neural interface (“neuron dust”) provides a promising and effective solution to record electrical activities of various neural tissue.[54,373,374] In one representative example, an ultrasonic backscattering concept-based neural dust demonstrated stable wireless ENG and EMG recording from the sciatic nerve and the gastrocnemius muscle respectively (Figure 8G). In the neural dust, a piezoelectric crystal receiving ultrasonic pulses acts as a wireless power supply and data transmitter, a single custom transistor serves as a data transducer, and a pair of recording electrodes can be integrated on a PI substrate of size 0.8×3×1 mm (Figure 8H and 8I).[372] The microscopic size of these “dust” also opens up the possibility of injectable implantation, which greatly reduces the difficulty and expense of implantation.

4.1.5. ECG

Studies toward ECG recording, an important physiological indicator for patient health, also facilitate the development of rehabilitation. In fact, the heartbeat is an autonomic response without intend control, thus, ECG signals cannot be applied to control prosthetics. In the disability rehabilitation, monitoring ECG signals still provides useful information for analyzing the relationship between rehabilitation intensity and body load. Also, ECG monitoring provides immediate alerts such as arrhythmia, bradycardia, tachycardia, heart failure, etc.[288] Unlike static neural implants mentioned above, in vivo ECG recording equipment on the surface of the heart is subjected to dynamic movement.[375–378] Consequently, leveraging this biomechanical beating to energize the implant is a unique feature of some ECG monitors compared to the other aforementioned electrophysiological recorders.[379] As implants, flexible self-powered ECG devices have been explored through piezoelectric,[380,381] triboelectric[382,383], and photovoltaic[384] methods. For example, Figure 8J demonstrates a TENG-powered ECG recording system conformed around a pig heart. Owing to the triboelectric material, which couples the contact electrification and electrostatic induction mechanism in the heartbeat (Figure 8K), and the structure, the device successfully performed real-time wireless cardiac monitoring (Figure 8L).[382] This self-powered approach holds the promise of true freedom of movement for rehabilitators. However, both invasive and wearable ECG measurements require electrodes to be placed directly on the surface of human tissues, which can cause discomfort to the user. In recent years, the rapid emergence of PPG is a potential alternative monitoring solution for ECG, as it can obtain superficial vascular information through infrared optical signals, while being placed comfortably around the finger, ear, or forehead in a non-contact way.[268]

4.2. Non-invasive methods

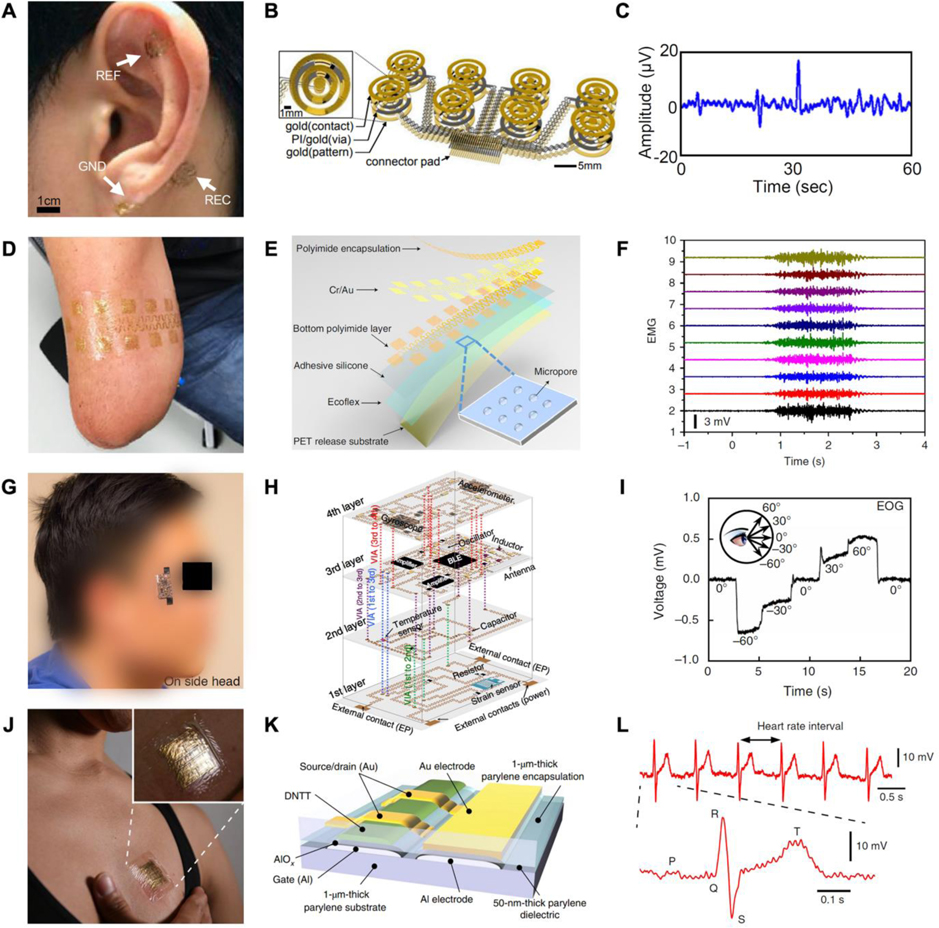

In recent years, the emergence of designs and technologies resembling ultra-thin epidermal electrodes,[299,385,386] multichannel large-area electrodes,[387,388] and flexible hybrid integrated systems in the field of flexible electronics[389,390] has brought unlimited possibilities for non-invasive physiological electrical recording in the field of medical robotics.

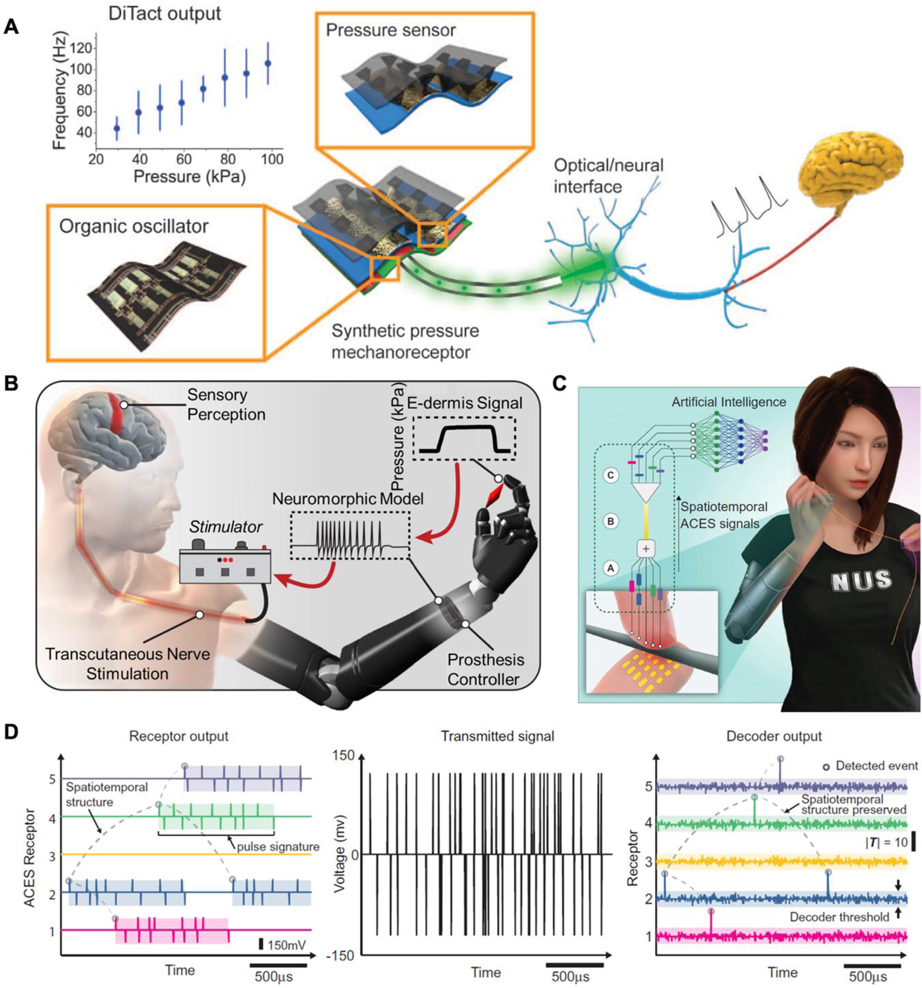

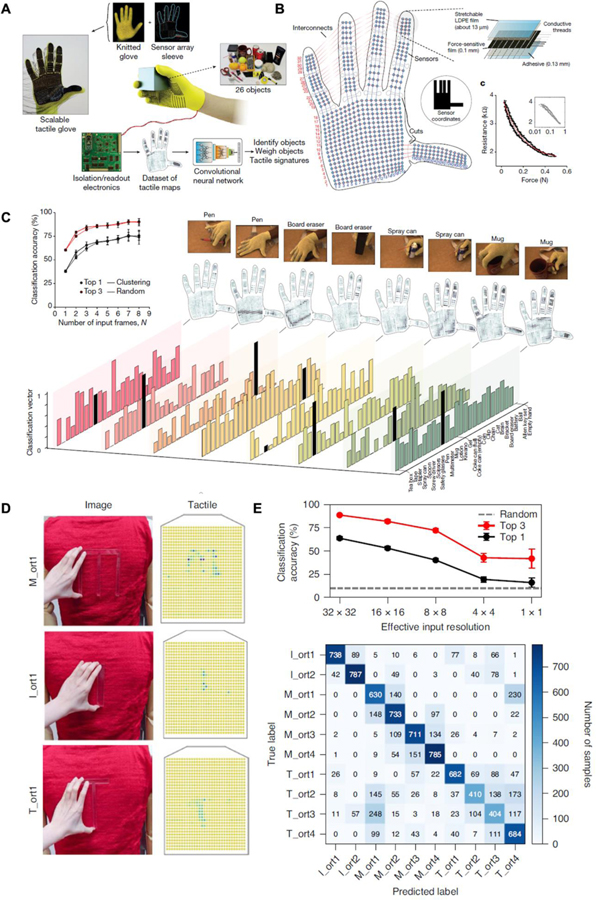

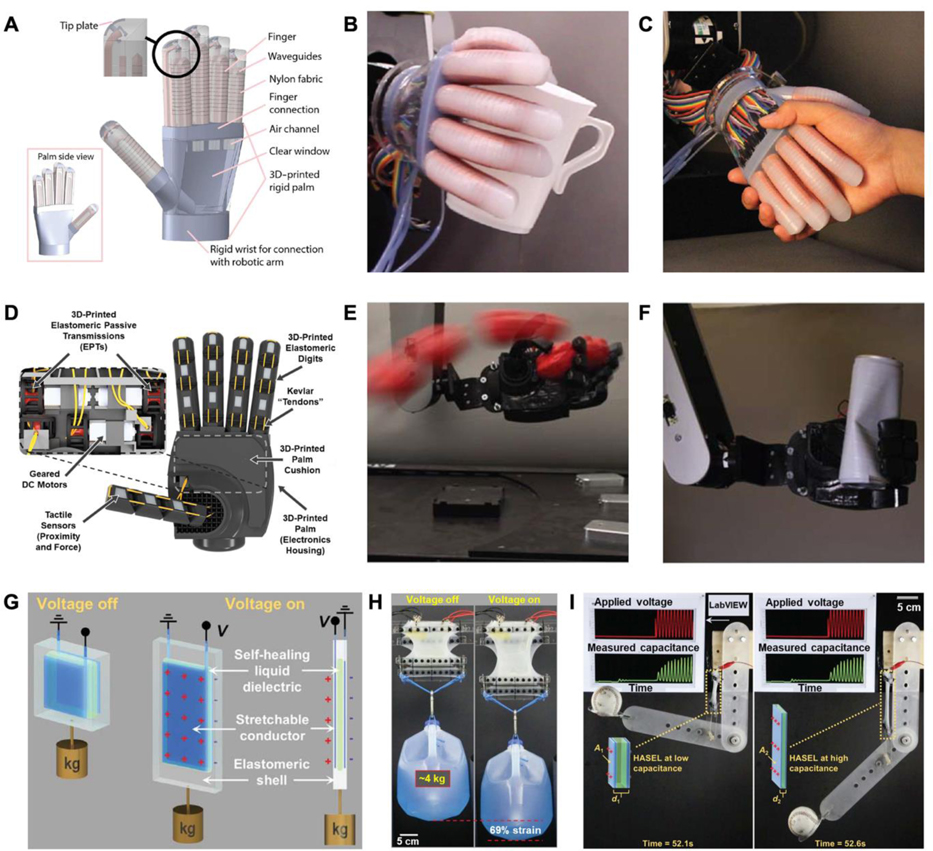

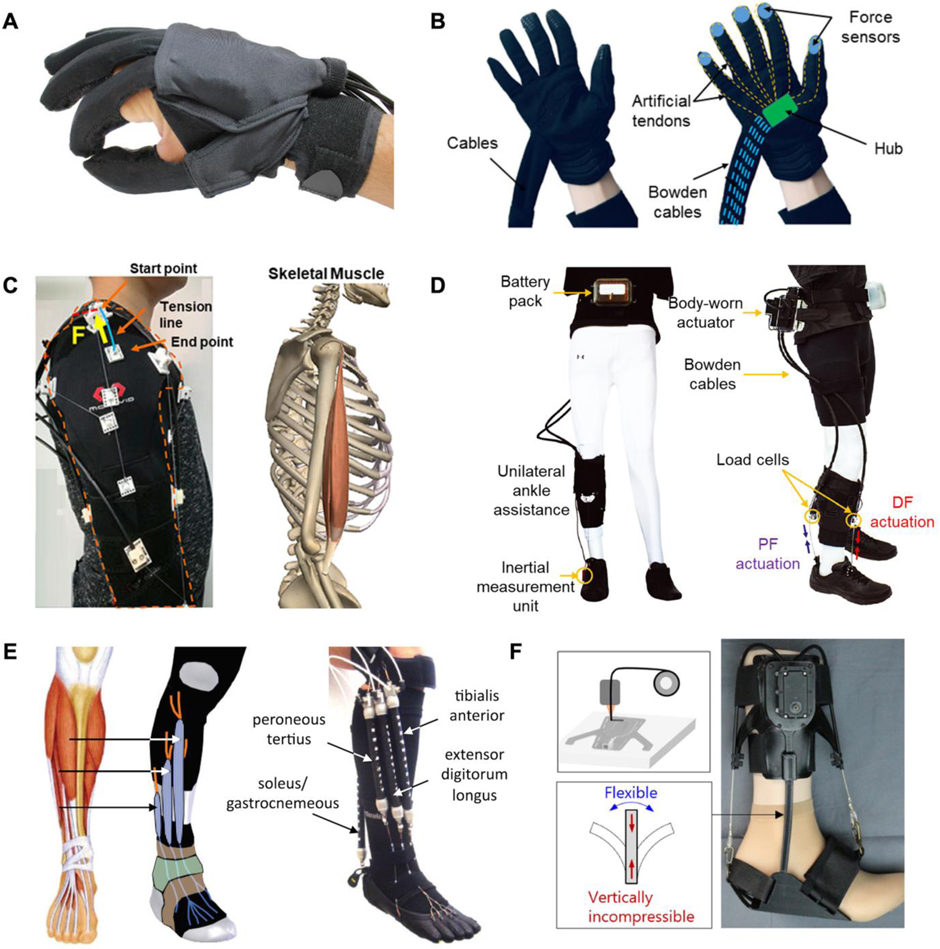

4.2.1. Skin surface electrophysiology