Highlights

-

•

γ-Aminobutyric acid (GABA) treatment retained a better quality of Chinese olives.

-

•

GABA reduced the chilling injury index and weight loss in cold-stored Chinese olives.

-

•

GABA retained higher TSS, total sugar, sucrose, TA, and tannin in Chinese olives.

-

•

The optimal concentration of GABA for harvested Chinese olives was 1 mM.

-

•

GABA showed a great potential application for postharvest Chinese olive fruit.

Keywords: Chinese olive fruit, Cold storage, Quality attributes, Chilling injury, γ-Aminobutyric acid (GABA)

Abstract

This study developed a useful technique to maintain quality and mitigate chilling injury of cold-stored Chinese olive fruit. Influence of dose (0, 0.5, 1.0, 1.5, 2.0 mM) of γ-aminobutyric acid (GABA) on the quality attributes and chilling damage of Chinese olive when stored at 2 °C for 100 d was investigated. Compared to control samples, GABA-treated fruit displayed lower chilling injury index, cell membrane permeability, and weight loss percentage, but higher hue angle h° value, higher levels of chlorophyll, total soluble sugar, sucrose, total soluble solids, titratable acid, and tannin, and 1.0 mM GABA is the optimal concentration to retain the quality attributes and reduce the chilling injury of Chinese olive fruit during cold storage.

Introduction

Chinese olive (Canarium album L.) is an evergreen fruit tree belonging to the family of Burseraceae and the genus of Canarium Linn. It is originated in southeastern China and introduced to other subtropical and tropical areas of Asian countries (He & Xia, 2007). Chinese olive is widely distributed in China, Vietnam, Thailand, Philippines, Indonesia, Malaysia, India, and Sri Lanka. China is considered the world’s largest producer and planter of Chinese olive fruit. Unlike olive (Olea europaea L.) that belongs to the family of Oleaceae and the genus of Olea and is regarded as a socioeconomically important oil crop and distributed in Mediterranean countries, Chinese olive is an edible fruit that has a relatively low content of oil but is rich in health-promoting substances such as bioactive compounds (flavonoids, phenolic compounds, tannin, phenylpropanoids, triterpenoids, carotenoids, chlorophyll, minerals, and vitamins) (He & Xia, 2007). However, Chinese olive fruit after harvest is prone to quality deterioration such as moisture loss, fruit shrinkage, color change in fruit surface from bright green to yellow, or even fruit diseases that can seriously affect its commercial value and edible quality and shorten its storage life (Jia et al., 2016). With the expanded cultivation area and the increased yield of Chinese olive in recent years, it is significant to explore preservation technologies for promoting the storability of postharvest Chinese olives.

Cold storage is an effective method to slow down the metabolic processes for lengthening the storage life of fresh produce (Luo, Li, Du, Mou, & Mao, 2015). However, Chinese olives are chilling-sensitive fruit prone to chilling injury, resulting in shrinkage, discoloration, or brown pits on the fruit surface, fruit browning, and quality deterioration. These problems severely affect fruit edible quality during cold storage (Kong et al., 2016, Kong et al., 2018). Thus, the development of suitable and convenient techniques to control chilling injury is critical for cold chain transportation of Chinese olives.

γ-Aminobutyric acid (GABA) is a natural signal metabolite in the plant, which can rapidly accumulate in regulating biotic and abiotic stress responses (Han et al., 2021, Li et al., 2018, Wang et al., 2018, Yang et al., 2013). GABA is a natural, safe, and biologically active compound. It has beneficial effects on human health and is used widely in foods (Oh et al., 2019, Sheng et al., 2017). Prior works indicated that exogenous GABA treatment could ameliorate chilling injury symptom in cold-stored fresh produce such as banana (Wang et al., 2014), blood orange (Habibi et al., 2019), peach (Shang, Cao, Yang, Cai, & Zheng, 2011), and zucchini (Palma et al., 2019). However, there is no report on the influences of exogenous GABA treatment on the quality attributes and chilling injury of Chinese olive during cold storage. Thus, the aims of current work were to assess the potential application of exogenous GABA for retaining quality attributes and improving cold tolerance of fresh Chinese olives during cold storage, and provide an alternative technique such as GABA postharvest treatment for alleviating chilling injury and enhancing storability of cold-stored Chinese olive fruit.

Materials and methods

Fruit and treatment

Fruit of ‘Tanxiang’ Chinese olive (Canarium album L. cv. Tanxiang) at commercial maturity, which the hue angle of fruit surface with green-yellow was 146.50 and the amount of pulp total soluble solids (TSS) was 13.00, were collected in the end of October from Fujian Minqing Chinese olive orchard, Fuzhou, China, and immediately shipped to our lab. Uniform Chinese olives with no damage were chosen randomly, 300 Chinese olives were used for evaluating the physiological and quality parameters at the harvest day, and another 15 000 Chinese olives were divided into five groups (3 000 fruit per group). For GABA treatment, the Chinese olives were separately immersed into 0.5, 1.0, 1.5, and 2.0 mM GABA for 10 min. For the control group, the Chinese olives were submerged with distilled water for 10 min. All treated Chinese olives were air-dried and packaged in polyethylene bags (one hundred fruit per bag), then stored in the controlled environmental chambers at 2 °C (90% relative humidity) for 100 d. During cold storage, at 20-day intervals, sampling three bags with 300 Chinese olives from each group were used for the following measurements.

Evaluation of chilling injury

Chilling injury (CI) was evaluated according to the visual fruit surface browning scale of the 100 individual Chinese olive fruit. Based on the extent of CI occurrence and the scale of browning on the fruit surface, CI included six levels: 1, no CI symptom; 2, slight CI symptom (browning area<1/4); 3, moderate CI symptom (1/4 ≤ browning area<1/2); 4, severe CI symptom (1/2 ≤ browning area<3/4); 5, very severe CI symptom (3/4 ≤ browning area<100 % browning); 6, complete CI symptom (100 % browning). The index of CI was calculated according to calculation formula Σ (CI level × the ratio of corresponding Chinese olive fruit in each CI level).

Measurement of cell membrane permeability

The methodologies of Wang et al., 2014, Lin et al., 2016 were used to estimate the cell membrane permeability. Two grams of pulp tissue discs (diameter 5 mm) from ten individual Chinese olives were obtained and washed with distilled water. The pulp tissue discs were then put in a test tube that contained 25 mL of distilled water, and hereafter were placed at 20 °C for 3 h. Model SG68 desktop conductivity meter (Mettler-Toledo, Zurich, Switzerland) was used to assay the initial cell membrane permeability (C1) of the solution. Then the tube was boiled for 30 min and the final cell membrane permeability (C2) was determined after the boiled solution was cooled down to 20 °C. The cell membrane permeability (%) was calculated as: (C1 / C2) × 100, and expressed as a percentage.

Assessments of pulp TSS content and fruit weight loss percentage

The methodologies of Lin et al., 2020, Liu et al., 2021 were used to determine the pulp TSS content with a manual refractometer.

The weight loss percentage of fresh Chinese olives during storage was assayed referring to the methodology of Lin et al. (2020). Weight loss percentage (%) was calculated as: (W0-W) ÷ W0 × 100, where W0 = initial fruit weight at storage day 0, kg; W = fruit weight at different storage days, kg. The result was expressed as a percentage.

Measurement of pericarp chlorophyll content and fruit surface hue angle(h)

Pericarp tissues (0.5 g) from ten individual Chinese olive fruit were used to measure the pericarp chlorophyll content based on the methodologies of Kong et al., 2018, Lin et al., 2020. The result was presented as g kg−1.

The methodologies of Zhang et al., 2019, Farcuh et al., 2020 were used to measure fruit surface hue angle. ADCI-60-C colorimeter (Beijing Chentaike Instrument Technology Co., Ltd., China) was applied to assay the chromaticity a* and b* values in the fruit equatorial surface of ten individual Chinese olives. The hue angle (h°) was calculated as: h°=180°+arctan(b*/a*).

Assay of sugar content

Fruit tissue (∼2.0 g) from ten Chinese olives were used to assay the amounts of total soluble sugar, reducing sugar, and sucrose based on the methodologies of Lin et al., 2020, Liu et al., 2021. The data was presented as g kg−1.

Measurement of titratable acid (TA) and tannin content

A bench-top pH meter (JENCO 6173pH, USA) was used to assay the TA content according to the methodologies of Lin et al., 2020, Liu et al., 2021, which was based on acid-base titration, and the data was presented as a percentage.

Fruit tissue (∼2.0 g) from ten Chinese olives were used to assay the tannin content according to the methodology of Kong et al. (2018). Tannins were extracted with 4% vanillin solution in methanol and concentrated HCl for 15 min, then determined spectrophotometrically at 500 nm (spectramax plus384, Molecular devices, USA), against methanol as a blank. The data was presented as g kg−1.

Statistical analysis

All parameters were assayed in triplicate. Data is presented as average and their standard error. SPSS software was applied to analyze the experimental data. A one-way ANOVA analysis was employed to observe the differences of mean separations. Statistically significant differences were determined between groups when p < 0.05.

Results

Changes in the CI index and cell membrane permeability

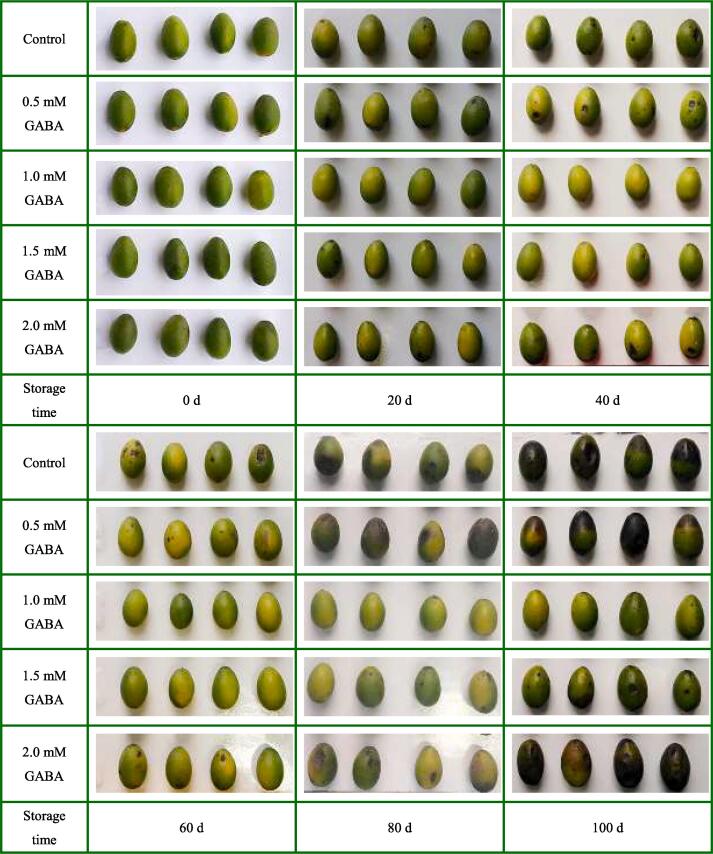

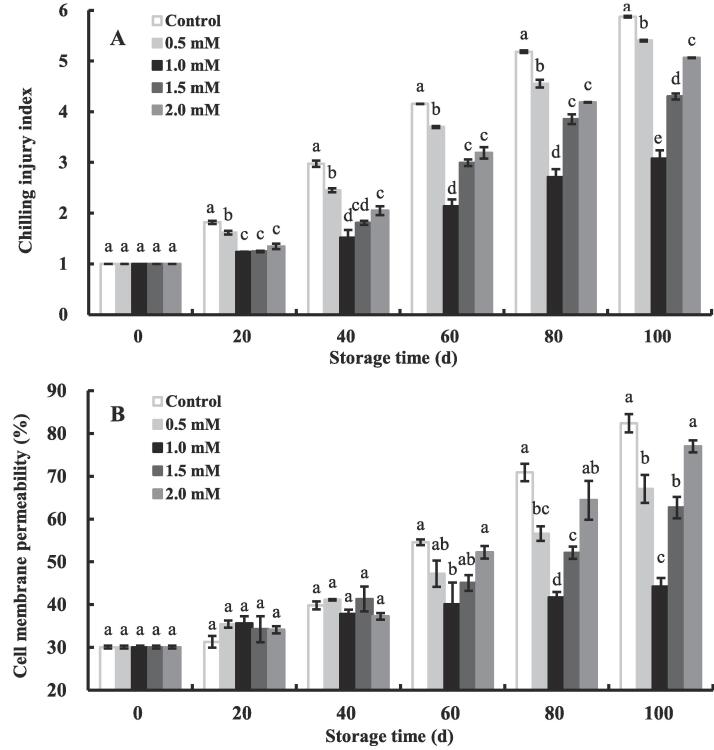

Chilling injury symptoms appeared after 20 d of storage in the cold environment (Fig. 1), and the CI index of Chinese olive fruit gradually increased during storage, and this process was inhibited by the GABA treatment (Fig. 1, Fig. 2A). In the first day of sampling (day 20), the control samples display slight CI symptoms, while the GABA treatment effectively delayed and suppressed the development of CI symptom (Fig. 1). The best effect was obtained at the concentration of 1.0 mM of GABA, which developed CI symptom after 40 d of storage. Additionally, during 20 ∼ 100 d, GABA-treated fruit displayed a notably (p < 0.01) lower CI index than control fruit (Fig. 2A).

Fig. 1.

The appearance of the control and different concentration GABA-treated Chinese olive fruit during cold storage.

Fig. 2.

Effects of exogenous GABA treatment (0.5, 1.0, 1.5 or 2.0 mM) on CI index (A) and cell membrane permeability (B) of Chinese olive fruit during storage at 2 °C for 100 d. Each data stands for an analyze of three replicates and their standard errors. Different letters represent significant differences (p < 0.05) between different groups on the same storage day.

The cell membrane permeability in Chinese olives increased during storage (Fig. 2B). After storage for 60 d, GABA-treated fruit exhibited lower levels of cell membrane permeability than control fruit. Similar to the results of the CI index, among different concentrations (0.5, 1.0, 1.5, or 2.0 mM) of GABA treatment, 1.0 mM of GABA exhibited the most effective inhibitory effects. When stored for 100 d, the cell membrane permeability in 1.0 mM GABA-treated group was 46.30% lower than control samples, while 0.5, 1.5, or 2.0 mM GABA-treated fruit displayed 18.61%, 23.91%, and 6.57% lower than control samples, separately. Notable differences were observed between GABA-treated samples and control fruit (p < 0.05) (Fig. 2B).

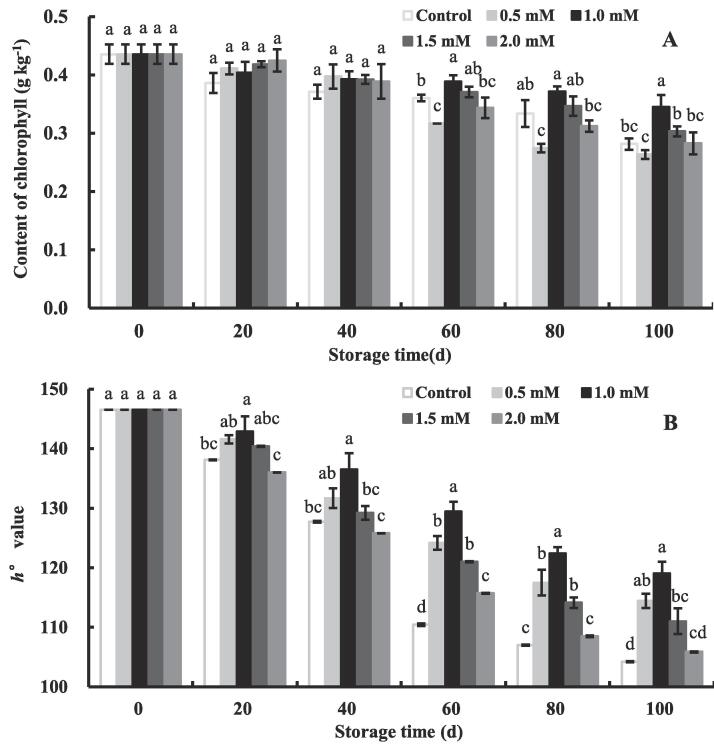

Changes in the chlorophyll content and fruit color

The chlorophyll content in all samples declined continuously along with the extension of storage time (Fig. 3A). During 100-days preservation, the control samples demonstrated a reduction in the chlorophyll content from 0.44 to 0.28 g kg−1. While the chlorophyll content in all GABA-treated samples was at higher levels than control samples from days 20 to 40. However, during 60 ∼ 100 d, different concentrations of GABA treatment exhibited different trends compared to control samples. There were higher levels of chlorophyll in 1.0 or 1.5 mM GABA-treated samples, but lower levels in 0.5 or 2.0 mM GABA treated-fruit. When stored for 100 d, the chlorophyll content with 0.28, 0.27, 0.34, 0.30 and 0.28 g kg−1 was assayed in control, 0.5, 1.0, 1.5, and 2.0 mM GABA-treated samples, respectively, suggesting that 1.0 mM GABA treatment could validly retain higher level of chlorophyll (p < 0.05) and retarded de-greening of Chinese olives (Fig. 3A).

Fig. 3.

Effects of exogenous GABA treatment (0.5, 1.0, 1.5 or 2.0 mM) on chlorophyll content and hug angle (h°) value of Chinese olive fruit during storage at 2 °C for 100 d. Each data stands for an analyze of three replicates and their standard errors. Different letters represent significant differences (p < 0.05) between different groups on the same storage day.

Color changes of Chinese olive fruit were measured by the values of hue angle (h°). As presented in Fig. 3B, h° value decreased in all samples during the whole storage, and its declination trends in GABA-treated samples were slower than control fruit, the treatment of GABA with 1.0 mM displayed the most effective effect on retaining the hue angle in postharvest Chinese olives (Fig. 3B). During storage, the hue angle (h° value) of fruit color in control samples showed a decreasing trend from 146.5° at day 0 to 104.22° at day 100, while it declined from 146.5° at day 0 to 119.06° at day 100 in 1.0 mM GABA-treated fruit, with a notably (p < 0.05) difference between control and 1.0 mM GABA-treated samples during 20 ∼ 100 d (Fig. 3B), indicating that the fruit color changed faster in control samples while retained at a relatively stable level in 1.0 mM GABA-treated fruit, which showed a similar trend as the chlorophyll content.

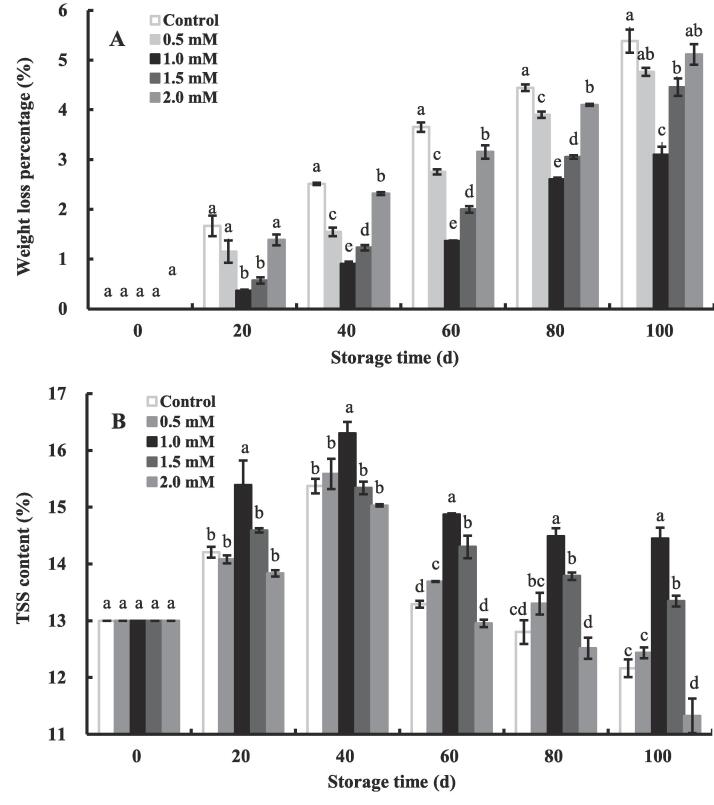

Changes in the fruit weight loss percentage and TSS content

The weight loss percentage in all samples increased observably during cold storage (Fig. 4A). Compared to control samples, GABA-treated samples displayed a lower weight loss percentage during 20 ∼ 100 d (Fig. 4A). For example, when stored for 60 d, the weight loss in 0.5, 1.0, 1.5, and 2.0 mM GABA-treated fruit was 24.7%, 62.6%, 45.3%, and 13.7% lower than control samples, respectively. Moreover, at the end of storage (at day 100), the loss of weight reached 5.38% in control fruit, while that was 4.76%, 3.1%, 4.46%, and 5.12% in 0.5, 1.0, 1.5, and 2.0 mM GABA treated-group, respectively (Fig. 4A). Notable differences were observed between GABA-treated samples and control fruit after 40 d of storage (p < 0.05), with the most effective effect from the 1.0 mM GABA treatment on reducing the weight loss in postharvest Chinese olives.

Fig. 4.

Effects of exogenous GABA treatment (0.5, 1.0, 1.5 or 2.0 mM) on weight loss percentage (A) and TSS content (B) of Chinese olive fruit during storage at 2 °C for 100 d. Each data stands for an analyze of three replicates and their standard errors. Different letters represent significant differences (p < 0.05) between different groups on the same storage day.

The TSS content of Chinese olives increased dramatically since the beginning of storage and peaked at day 40, then declined sharply during the middle and late storage period (Fig. 4B). The TSS content in 1.0 mM GABA treated-fruit was notably (p < 0.05) higher than 0.5, 1.5, and 2.0 mM GABA treated-fruit, and also clearly (p < 0.05) higher than control samples. Additionally, among different concentrations (0.5, 1.0, 1.5, or 2.0 mM) of GABA treatment, 1.0 mM of GABA was found to be the most effective in promoting the TSS content in the early storage period (0 ∼ 40 d) and inhibiting the TSS content decline during the middle and late storage period (40 ∼ 100 d) (Fig. 4B). However, 2.0 mM GABA treatment did not have any additional beneficial effect on the TSS content, and no notable discrepancy (p > 0.05) was found as compared to control fruit except day 100 (Fig. 4B).

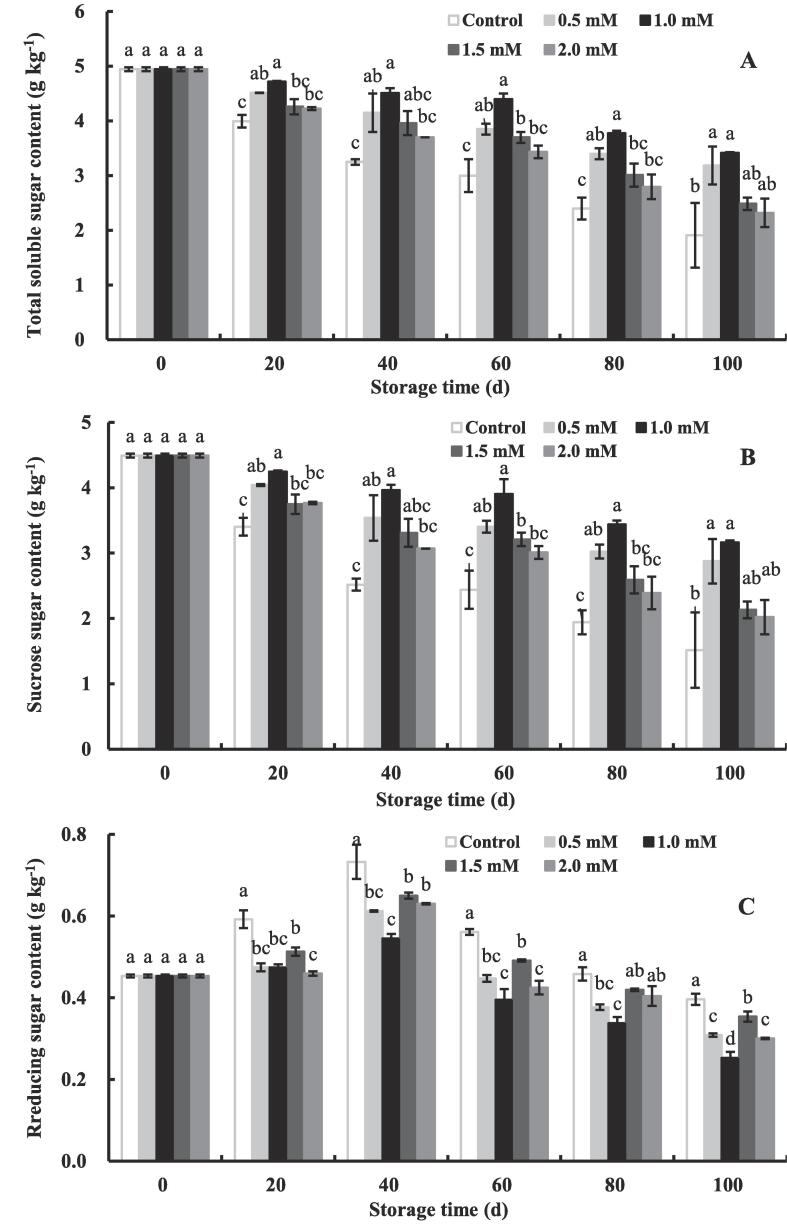

Change in the sugar content

As shown in Fig. 5A, the total soluble sugar content in control samples decreased continuously within the whole storage time, and its decreasing trends in GABA-treated samples were inhibited, 1.0 mM GABA treatment showed the most effective effect on the reduction of total soluble sugars in postharvest Chinese olives (Fig. 5A). After 100 d of storage, the total soluble sugar content in 1.0 mM GABA-treated fruit was 3.42 g kg−1, while 1.91 g kg−1 in the control fruit (Fig. 5A).

Fig. 5.

Effects of exogenous GABA treatment (0.5, 1.0, 1.5 or 2.0 mM) on the contents of total soluble sugar (A), sucrose (B) and reducing sugar (C) of Chinese olive fruit during storage at 2 °C for 100 d. Each data stands for an analyze of three replicates and their standard errors. Different letters represent significant differences (p < 0.05) between different groups on the same storage day.

The sucrose content reduced steadily in all samples throughout the whole storage process, and the decrease was obviously inhibited by the GABA treatment (Fig. 5B). When stored for 100 d, the sucrose content in 0.5, 1.0, 1.5, and 2.0 mM GABA-treated fruit was 1.9, 2.1, 1.4, and 1.3-fold higher than control fruit, separately, suggesting that 1.0 mM of GABA had the best effect on delaying the decrease of the sucrose content (Fig. 5B).

The contents of reducing sugar in all groups exhibited a notorious increase in the early storage period and displayed a peak value on day 40 (Fig. 5C). After that, the amounts of reducing sugar descended rapidly in the subsequent storage period, while GABA treated-Chinese olives exhibited lower levels, and 1.0 mM of GABA attained the lowest level compared to others from day 40 to day 100 (Fig. 5C).

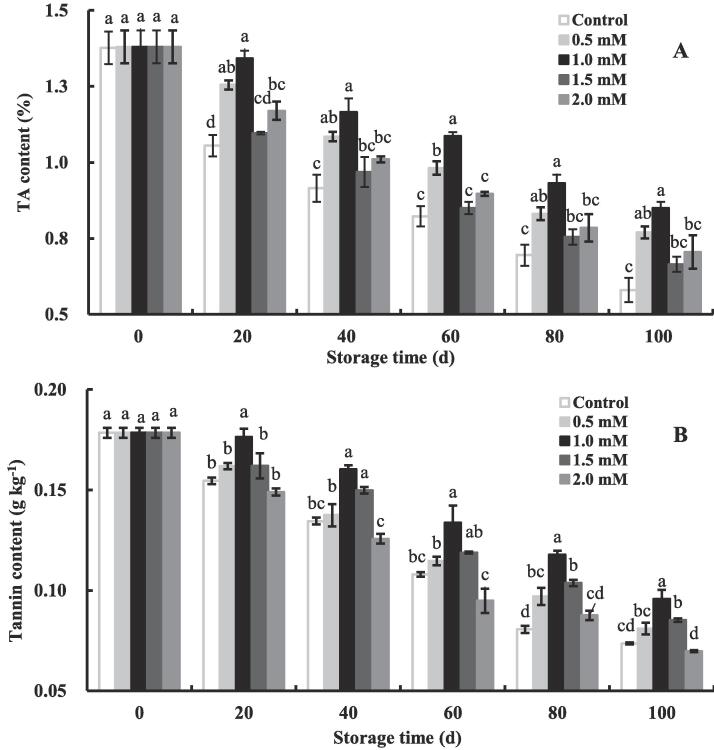

Changes in the contents of TA and tannin

As shown in Fig. 6A, the TA content in all samples reduced progressively with the prolonged storage day. The GABA treatment obviously inhibited this reduction. Compared to day 0, the TA content in 1.0 mM of GABA treated-fruit decreased by 38% at day 100, whereas its decline in control samples was 58%, a notably (p < 0.05) higher TA content was shown in the 1.0 mM GABA-treated group (Fig. 6A).

Fig. 6.

Effects of exogenous GABA treatment (0.5, 1.0, 1.5 or 2.0 mM) on TA (A) and tannin (B) contents of Chinese olive fruit during storage at 2 °C for 100 d. Each data stands for an analyze of three replicates and their standard errors. Different letters represent significant differences (p < 0.05) between different groups on the same storage day.

As illustrated in Fig. 6B, the tannin content in all samples experienced similar decreasing trends throughout the whole storage process. Additionally, compared to control samples, during 20 ∼ 60 d, 2.0 mM GABA-treated fruit displayed lower values of tannin, whereas 0.5, 1.0, or 1.5 mM treated-fruit exhibited higher levels of tannin, with a clear (p < 0.05) discrepancy between 1.0 mM treated-samples and control fruit.

The above data indicate that the most effective concentration of GABA for maintaining the TA and tannin content in postharvest Chinese olives was 1.0 mM.

Discussion

Chinese olive fruit is susceptible to chilling stress. During low-temperature transport and storage period, severe chilling injury can lead to fruit quality deterioration and cause economic loss. The use of GABA treatment evidently enhanced the storage fruit quality and reduced chilling injury of Chinese olive fruit in this study. The fruit quality and chilling tolerance of Chinese olive could be effectively maintained by the treatment of 1.0 mM of GABA, which was superior to the treatments of 0.5, 1.5, and 2.0 mM GABA. All concentrations alleviated the chilling injury and retained commodity shelf life in various degrees.

Previous reports demonstrated that the enhancement of chilling tolerance in fresh postharvest produce was due to the treatment with GABA (Palma et al., 2019). However, the optimal concentration is variable in different plants and an improper concentration may result in an opposite effect. Wang et al. (2014) indicated that 20 mM GABA treatment could help reduce CI symptom in banana peel. Shang et al. (2011) found that 5 mM GABA treatment could effectively reduce the internal browning of peach fruit, which was a typical CI symptom. In this work, 1 mM GABA was the most effective concentration for reducing CI symptom (Fig. 1) and maintaining the cell membranes integrity of Chinese olive when stored at 2 °C for 100 d, as indicated by the suppressed increase of the CI index and cell membranes permeability (Fig. 2). Furthermore, an enhanced chilling tolerance of Chinese olives treated by 1 mM of GABA was proved by the slower decline of the chlorophyll content and h° value than control fruit (Fig. 3). These data indicate that GABA acted as a repressor of CI in cold-stored Chinese olives during the storage period.

Postharvest quality attributes of fresh fruit are usually affected by weight loss and nutritional compositions like TSS, TA, and sugar (Jiang et al., 2018, Lin et al., 2020, Liu et al., 2021). Cao et al. (2016) found that 100 μM of melatonin could enhance chilling tolerance and keep higher TSS in peaches during cold storage. Our findings demonstrated that GABA treatment could lower the CI index (Fig. 2A), reduce weight loss (Fig. 4A) in cold-stored Chinese olives. Among different concentrations of GABA, 1.0 mM of GABA showed the most significant effect (Fig. 1, Fig. 2A, Fig. 4A). Besides, compared with control fruit, 1.0 mM of GABA always kept a clearly (p < 0.05) lower CI index (Fig. 2A) and a higher level of TSS in Chinese olives during storage at days 20 ∼ 100 (Fig. 4B). These results, thus, further implied that 1.0 mM of GABA suppressed the development of CI in cold-stored Chinese olives, which was because the treatment of 1.0 mM GABA reduced weight loss and induced the accumulation of TSS, and thus enhanced the cold tolerance of Chinese olive fruit.

Soluble sugars play an active role in protecting plant cells from damage via cold stress (Li et al., 2016, Wang et al., 2020). Zhao et al. (2019) reported that near-freezing temperature (NFT) could improve chilling tolerance of cold-stored nectarines, which was associated with NFT suppressing the sucrose degradation, maintaining a higher sucrose amount and a lower level of reducing sugar in nectarine fruit during cold storage. These previous studies demonstrate that soluble sugar metabolism plays a crucial role in inducing cold tolerance of fruit. In the present work, compared to non-treated fruit, a lower CI index (Fig. 2A), a lower reducing sugar amount (Fig. 5C), but higher contents of soluble sugars and sucrose (Fig. 5A, 5B) were observed in GABA-treated Chinese olives during cold storage, with the most significant effect from the treatment of 1.0 mM GABA (Fig. 1). These results further proved that GABA induced chilling tolerance of cold-stored Chinese olives, which was because GABA retained higher levels of soluble sugars and sucrose.

Titratable acidity (TA) was used as an indicator to evaluate the quality of fresh produces (Jiang et al., 2018, Lin et al., 2020). Our work indicated that TA content in all samples declined through the whole storage, the application of 0.5 mM and 1.0 mM GABA effectively suppressed the reduction of TA content as compared to control through the whole preservation, but the 1.5 mM and 2.0 mM GABA treatment showed no significant difference against control during storage except day 20 (Fig. 6A).

Tannin is the main source of astringent taste in fresh fruit (Ju et al., 2021, Yin et al., 2012, Zeng et al., 2021). Tannin, as an important constitutive trait of the quality in Chinese olives, was detected in our samples. Our works show that the application of 0.5 ∼ 1.5 mM GABA could suppress the decrease of tannin in postharvest Chinese olives with the most effective effect from the treatment of 1.0 mM GABA, which retained the highest tannin content in Chinese olives during storage at days 20 ∼ 100 (Fig. 6B).

The above data indicate that GABA could maintain the fruit quality and enhance the tolerance of CI in cold-stored Chinese olives, as indicated by reduced CI index and higher contents of TSS, soluble sugar, sucrose, TA, and tannin. However, the possible mechanism of exogenous GABA for enhancing the cold tolerance and quality attributes of fresh Chinese olive is still unclear. Thus, the mechanism of GABA-improved cold tolerance and fruit quality of postharvest Chinese olive fruit needs to be further explored.

Conclusion

The above results indicated that the exogenous application of different concentrations of GABA (0.5, 1.0, 1.5 and 2.0 mM) on postharvest Chinese olive fruit could alleviate chilling injury and maintain quality to some extent during cold storage, and 1.0 mM showed that most significant effects. The treatment of 1.0 mM GABA effectively delayed the increases of CI index and cell membrane permeability, reduced weight loss, suppressed the decreases of total chlorophyll, h° value, and TSS content, and kept higher contents of soluble sugar and tannin. In general, out findings indicate that the treatment with 1.0 mM of GABA is an effective method for mitigating CI and maintaining the fruit quality of Chinese olives during cold storage.

CRediT authorship contribution statement

Zhongqi Fan: Investigation, Data curation, Formal analysis, Writing – original draft. Bin Lin: Investigation, Data curation, Formal analysis. Hetong Lin: Supervision, Resources, Conceptualization, Project administration, Writing – review & editing. Mengshi Lin: Writing – review & editing. Jianye Chen: Supervision. Yifen Lin: Supervision, Writing – review & editing.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 31871860 and 31201441), and the Science and Technology Innovation Foundation at Fujian Agriculture and Forestry University of China (Grant Nos. CXZX2020115A, CXZX2018054 and CXZX2017284).

Contributor Information

Hetong Lin, Email: hetonglin@163.com.

Yifen Lin, Email: yifenlin@126.com.

References

- Cao S., Song C., Shao J., Bian K., Chen W., Yang Z. Exogenous melatonin treatment increases chilling tolerance and induces defense response in harvested peach fruit during cold storage. Journal of Agricultural and Food Chemistry. 2016;64:5215–5222. doi: 10.1021/acs.jafc.6b01118. [DOI] [PubMed] [Google Scholar]

- Farcuh, M., Copes, B., Le-Navenec, G., Marroquin, J., Cantu, D., Bradford, K. J., … Deynze, A., V. (2020). Sensory, physicochemical and volatile compound analysis of short and long shelf-life melon (Cucumis melo L.) genotypes at harvest and after postharvest storage. Food Chemistry: X, 8, 100107. 10.1016/j.fochx.2020.100107. [DOI] [PMC free article] [PubMed]

- Habibi F., Ramezanian A., Rahemi M., Eshghi S., Guillén F., Serrano M., Valero D. Postharvest treatments with γ-aminobutyric acid, methyl jasmonate or methyl salicylate enhance chilling tolerance of blood orange fruit at prolonged cold storage. Journal of the Science of Food and Agriculture. 2019;99:6408–6417. doi: 10.1002/jsfa.9920. [DOI] [PubMed] [Google Scholar]

- Han S., Liu H., Han Y., He Y., Nan Y., Qu W., Rao J. Effects of calcium treatment on malate metabolism and γ-aminobutyric acid (GABA) pathway in postharvest apple fruit. Food Chemistry. 2021;334:127479. doi: 10.1016/j.foodchem.2020.127479. [DOI] [PubMed] [Google Scholar]

- He Z., Xia W. Analysis of phenolic compounds in Chinese olive (Canarium album L.) fruit by RPHPLC-DAD-ESI-MS. Food Chemistry. 2007;105:1307–1311. doi: 10.1016/j.foodchem.2007.04.049. [DOI] [Google Scholar]

- Jia Y.L., Zheng J., Yu F., Cai Y.X., Zhan X.L., Wang H.F., Chen Q.X. Anti-tyrosinase kinetics and antibacterial process of caffeic acid N-nonyl ester in Chinese olive (Canarium album) postharvest. International Journal of Biological Macromolecules. 2016;91:486–495. doi: 10.1016/j.ijbiomac.2016.05.098. [DOI] [PubMed] [Google Scholar]

- Jiang X., Lin H., Shi J., Neethirajan S., Lin Y., Chen Y.…Lin Y. Effects of a novel chitosan formulation treatment on quality attributes and storage behavior of harvested litchi fruit. Food Chemistry. 2018;252:134–141. doi: 10.1016/j.foodchem.2018.01.095. [DOI] [PubMed] [Google Scholar]

- Ju Y.L., Yang L., Yue X.F., He R., Deng S.L., Yang X.…Fang Y.L. The condensed tannin chemistry and astringency properties of fifteen Vitis davidii Foex grapes and wines. Food Chemistry: X. 2021;11:100125. doi: 10.1016/j.fochx.2021.100125. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kong X., Ren S., Lin H., Li N., Lin Y., Zhuo S. Characteristics of cell wall metabolism of harvested Chinese olive fruits with different maturities in response to chilling injury during cold storage. Food Science. 2018;39(3):229–235. doi: 10.7506/spkx1002-6630-201803035. [DOI] [Google Scholar]

- Kong X., Zhou H., Lin H., Lin Y., Chen Y., Wang H. Effects of harvesting date on chilling injury of Chinese olive fruits during cold storage. Food Science. 2016;37(22):255–262. doi: 10.7506/spkx1002-6630-201622039. [DOI] [Google Scholar]

- Li D., Li L., Xiao G., Limwachiranon J., Xu Y., Lu H.…Luo Z. Effects of elevated CO2 on energy metabolism and γ-aminobutyric acid shunt pathway in postharvest strawberry fruit. Food Chemistry. 2018;265:281–289. doi: 10.1016/j.foodchem.2018.05.106. [DOI] [PubMed] [Google Scholar]

- Li D., Limwachiranon J., Li L., Du X., Luo Z. Involvement of energy metabolism to chilling tolerance induced by hydrogen sulfide in cold-stored banana fruit. Food Chemistry. 2016;208:272–278. doi: 10.1016/j.foodchem.2016.03.113. [DOI] [PubMed] [Google Scholar]

- Lin Y., Li N., Lin H., Lin M., Chen Y., Wang H.…Lin Y. Effects of chitosan treatment on the storability and quality properties of longan fruit during storage. Food Chemistry. 2020;306:125627. doi: 10.1016/j.foodchem.2019.125627. [DOI] [PubMed] [Google Scholar]

- Lin Y., Lin H., Lin Y., Zhang S., Chen Y., Jiang X. The roles of metabolism of membrane lipids and phenolics in hydrogen peroxide-induced pericarp browning of harvested longan fruit. Postharvest Biology and Technology. 2016;111:53–61. doi: 10.1016/j.postharvbio.2015.07.030. [DOI] [Google Scholar]

- Liu J., Lin Y., Lin H., Lin M., Fan Z. Impacts of exogenous ROS scavenger ascorbic acid on the storability and quality attributes of fresh longan fruit. Food Chemistry: X. 2021;12:100167. doi: 10.1016/j.fochx.2021.100167. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Luo Z., Li D., Du R., Mou W., Mao L. Hydrogen sulfide alleviates chilling injury of banana fruit by enhanced antioxidant capacity and proline content. Scientia Horticulturae. 2015;83:144–151. doi: 10.1016/j.scienta.2014.12.021. [DOI] [Google Scholar]

- Oh S.J., Kim H.S., Lim S.T., Reddy C.K. Enhanced accumulation of gamma-aminobutyric acid in rice bran using anaerobic incubation with various additives. Food Chemistry. 2019;271:187–192. doi: 10.1016/j.foodchem.2018.07.175. [DOI] [PubMed] [Google Scholar]

- Palma F., Carvajal F., Jiménez-Muñoz R., Pulido A., Jamilena M., Garrido D. Exogenous γ-aminobutyric acid treatment improves the cold tolerance of zucchini fruit during postharvest storage. Plant Physiology and Biochemistry. 2019;136:188–195. doi: 10.1016/j.plaphy.2019.01.023. [DOI] [PubMed] [Google Scholar]

- Shang H., Cao S., Yang Z., Cai Y., Zheng Y. Effect of exogenous γ-aminobutyric acid treatment on proline accumulation and chilling injury in peach fruit after long-term cold storage. Journal of Agricultural and Food Chemistry. 2011;59:1264–1268. doi: 10.1021/jf104424z. [DOI] [PubMed] [Google Scholar]

- Sheng L., Shen D., Luo Y., Sun X., Wang J., Luo T.…Cheng Y. Exogenous γ-aminobutyric acid treatment affects citrate and amino acid accumulation to improve fruit quality and storage performance of postharvest citrus fruit. Food Chemistry. 2017;216:138–145. doi: 10.1016/j.foodchem.2016.08.024. [DOI] [PubMed] [Google Scholar]

- Wang P., Liu K., Gu Z., Yang R. Enhanced γ-aminobutyric acid accumulation, alleviated componential deterioration and technofunctionality loss of germinated wheat by hypoxia stress. Food Chemistry. 2018;269:473–479. doi: 10.1016/j.foodchem.2018.07.050. [DOI] [PubMed] [Google Scholar]

- Wang X., Chen Y., Jiang S., Xu F., Wang H., Wei Y., Shao X. PpINH1, an invertase inhibitor, interacts with vacuolar invertase PpVIN2 in regulating the chilling tolerance of peach fruit. Horticulture Research. 2020;7:168. doi: 10.1038/s41438-020-00389-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang Y., Luo Z., Huang X., Yang K., Gao S., Du R. Effect of exogenous γ-aminobutyric acid (GABA) treatment on chilling injury and antioxidant capacity in banana peel. Scientia Horticulturae. 2014;168:132–137. doi: 10.1016/j.scienta.2014.01.022. [DOI] [Google Scholar]

- Yang R., Guo Q., Gu Z. GABA shunt and polyamine degradation pathway on γ-aminobutyric acid accumulation in germinating fava bean (Vicia faba L.) under hypoxia. Food Chemistry. 2013;136:152–159. doi: 10.1016/j.foodchem.2012.08.008. [DOI] [PubMed] [Google Scholar]

- Yin X.R., Shi Y.N., Min T., Luo Z.R., Yao Y.C., Xu Q.…Chen K.S. Expression of ethylene response genes during persimmon fruit astringency removal. Planta. 2012;235:895–906. doi: 10.1007/s00425-011-1553-2. [DOI] [PubMed] [Google Scholar]

- Zeng L., Shi L., Lin H., Lin Y., Lin Y., Wang H. Paper-containing 1-methylcyclopropene treatment suppresses fruit decay of fresh Anxi persimmons by enhancing disease resistance. Food Quality and Safety. 2021;5:1–8. doi: 10.1093/fqsafe/fyab007. [DOI] [Google Scholar]

- Zhang L., Wang L., Zeng X., Chen R., Yang S., Pan S. Comparative transcriptome analysis reveals fruit discoloration mechanisms in postharvest strawberries in response to high ambient temperature. Food Chemistry: X. 2019;2:100025. doi: 10.1016/j.fochx.2019.100025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhao H., Jiao W., Cui K., Fan X., Shu C., Zhang W.…Jiang W. Near-freezing temperature storage enhances chilling tolerance in nectarine fruit through its regulation of soluble sugars and energy metabolism. Food Chemistry. 2019;289:426–435. doi: 10.1016/j.foodchem.2019.03.088. [DOI] [PubMed] [Google Scholar]