Highlights

-

•

A recently released high-quality rice hybrid JLY1468 was compared with an old rice hybrid LYPJ.

-

•

Hardness of cooked rice was 37% lower in JLY1468 than in LYPJ.

-

•

The glucose production rate from starch digestion was 33% faster in JLY1468 than in LYPJ.

-

•

This study indicates potential health risks associated with soft-textured high-quality rice.

Keywords: Amylose content, Gel consistency, Grain quality, Hybrid rice, Paste property, Starch digestion, Temperature, Texture profile

Abstract

Field experiments were conducted to compare two hybrid rice cultivars—a recently released high-quality cultivar (Jingliangyou 1468, JLY1468) and a relatively older cultivar (Liangyoupeijiu, LYPJ). Results showed that hardness, springiness, cohesiveness, resilience, and chewiness of cooked milled rice were all lower in JLY1468 than in LYPJ, due to its lower amylose content and altered paste properties of milled rice flour. Active digestion duration of cooked milled rice was 26% shorter and the glucose production rate from starch digestion was 33% faster in JLY1468 compared with LYPJ. Texture and starch digestion properties of cooked milled rice as a factor of temperature during the grain-filling period were different between LYPJ and JLY1468 due to differing amylose contents and gel consistencies of milled rice flour in response to temperature. This study highlights that attention should be paid to potential health risks associated with the development of high-quality hybrid rice cultivars with soft texture.

Introduction

China is the world’s most populous country with over 1.4 billion people, or 18%, of the world’s population (Worldometer, 2021). Food security in China is not merely a matter of national interest but also has an obvious bearing on global food security (Bruins and Bu, 2006). Ensuring adequate supply of rice is a crucial factor in promoting food security in China, where more than 65% of the population depends on rice as a staple food (Hsiaoping, 2005). With continuous increases in rice yields since the 1980s, rice self-sufficiency has been achieved in China (Deng et al., 2019). The development of hybrid rice, which out-yields inbred rice by 10–20% (Peng et al., 1999, Cheng et al., 2004), has played an important role in this achievement (Yuan, 2014).

However, the higher yields of hybrid rice alone may not necessarily make hybrid rice technology acceptable outside of China, and poor grain quality has been a major constraint in the adoption of hybrid rice in certain countries (Virmani and Zaman, 1998). This constraint is also a challenge in the development of hybrid rice in China, where the demand for high-quality rice has increased as living standards have improved (Peng, 2016). To meet this challenge, many Chinese hybrid rice breeders have worked to improve grain quality.

Rice grain quality is a composite trait that includes milling, appearance, cooking, eating, and nutritional qualities (Huang et al., 2017). The eating quality is generally considered the most important for rice consumer satisfaction, and thus its improvement has been one of the most important objectives in rice breeding programs (Phing Lau et al., 2016, Sattari et al., 2015). In China, rice consumers generally prefer to eat soft-textured rice, and Chinese rice breeders have specifically focused on this trait preference when developing new rice cultivars (Yang et al., 2013, Zhou et al., 2015). Accordingly, the physicochemical properties relating to the texture of cooked rice such as amylose content, gel consistency, and paste properties, have attracted great interest by Chinese rice researchers in recent years (Tong et al., 2014, Zhang et al., 2020, Zhu et al., 2013).

Additionally, improving living standards is driving up the demand for healthy food in China (Huang and Hu, 2021). White or milled rice (the most common form consumed) is generally categorized as a food having a high glycemic index, and there is ample evidence that higher consumption of milled rice is associated with an increased risk of type 2 diabetes in Asian populations, including the Chinese (Villegas et al., 2007, Hu et al., 2012, Ma et al., 2014). At present, China has the highest number of diabetics (mainly type 2) in the world; 116 million Chinese people had diabetes in 2019, which accounts for 25% of the global diabetes population (Saeedi, et al., 2019). Moreover, it is estimated that China has a pre-diabetic population that may number around 500 million people (Xu et al., 2013). For these reasons, Huang and Hu (2021) appealed that Chinese rice breeders should begin considering low glycemic index as another key target for rice production.

In recent years, through dedicated breeding efforts, multiple hybrid rice cultivars with high grain quality have been developed in China, and these cultivars generally have low amylose content and consequently a softer texture of the cooked rice (Huang, 2021, Huang and Hu, 2021). However, soft-textured rice with a lower amylose content is generally less resistant to digestion and has a higher glycemic index (Fitzgerald et al., 2011), although there is no direct report of this being observed in any high-quality hybrid rice cultivar with low amylose content. This potential contradiction highlights the need to fully evaluate the texture and digestion properties and related physicochemical traits of the high-quality soft-textured hybrid rice cultivars with low amylose content. In this study, comparisons between two hybrid rice cultivars released 18 years apart—a recently released cultivar with high grain quality and a relatively older cultivar with high yield potential—are made focusing on traits such as texture profiles and starch digestion properties of cooked milled rice as well as amylose and protein content, gel consistency, and paste properties of milled rice flour.

Materials and methods

Site and soil

Field experiments were conducted at the research farm of the Hengyang Academy of Agricultural Sciences (26°53′ N, 112°28′ E, 71 m asl), Hunan Province, China in 2019 and 2020. The soil was mostly clay with a pH of 5.86, organic matter content of 31.0 g kg−1, available N content of 145 mg kg−1, available P content of 14.1 mg kg−1, and available K content of 187 mg kg−1.

Experimental details

Two rice cultivars, Liangyoupeijiu (LYPJ) and Jingliangyou 1468 (JLY1468), were used in this study. LYPJ is a high-yielding hybrid cultivar (Peiai 64S × 9311) released in 1999 and was the first super hybrid rice cultivar approved by the Ministry of Agriculture of China. This cultivar has been widely commercialized, being planted on wide agroclimatic regions in southern China and southeastern Asia (e.g., Vietnam and Philippines) from 12° to 35° N (Lü and Zou, 2003). JLY1468 is a high-quality hybrid cultivar (Jing 4155S × R1468) released in 2017 that is a recommended cultivar in the High-Quality Rice Project of Hunan Province. This cultivar is widely adapted to the Yangtze River basin and south China (China Rice Data Center, 2021) as well as other regions and countries with similar agroclimatic conditions.

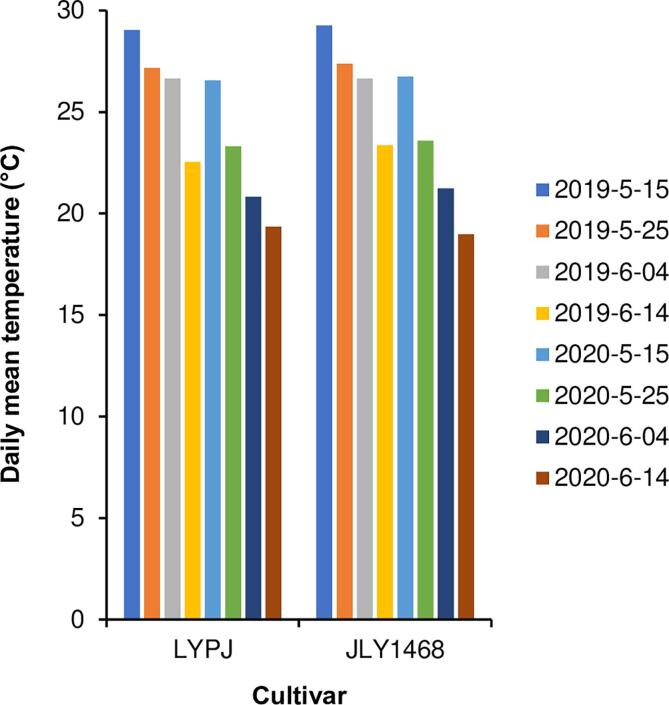

Four sowing dates—May 15th and 25th, and June 4th and 14th—were employed for each cultivar in each year in order to run the experiment under the different weather conditions that typify temperature during the grain-filling period, a major environmental factor affecting starch accumulation and grain quality in rice (Wang et al., 2021). The average daily mean temperature during the grain filling period ranged from 19.0 to 29.3 °C depending on the cultivar, year, and sowing date (Fig. 1).

Fig. 1.

Average daily mean temperature during the grain-filling period of the two hybrid rice cultivars, Liangyoupeijiu (LYPJ) and Jingliangyou 1468 (JLY1468), grown during four sowing dates across two years.

The two cultivars were arranged in a completely randomized block design with three replicates for each sowing date. The plot size was 30 m2. Pre-germinated seeds were sown in a seedbed, and 25-day-old seedlings were manually transplanted at a hill spacing of 20 cm × 20 cm with two seedlings per hill. N fertilizer was applied in three splits: 75 kg N ha−1 one day before transplanting, 45 kg N ha−1 seven days after transplanting, and 30 kg N ha−1 at panicle initiation. P fertilizer (75 kg P2O5 ha−1) was applied one day before transplanting. K fertilizer (150 kg K2O ha−1) was split equally at one day before transplanting and at panicle initiation. A floodwater depth of 5–10 cm was maintained from transplanting until seven days before maturity, when plots were drained. Insects, pathogens, and weeds were controlled by chemical application as required.

Sampling and measurements

About 500 g of rice grains were collected from each plot and dried in the sun. The sundried grains were stored at room temperature and humidity for three months and then processed into milled rice with a laboratory-scale milling machine (JGMJ8098, Shanghai Jiading Cereals and Oils Instrument Co., Ltd., Shanghai, China).

About 5 g of whole milled rice was ground into flour with a high-speed blender (YS-02, Yanshan Zhengde Machinery Equipment Co., Ltd., Beijing, China) to determine amylose and protein content, gel consistency, and paste properties (peak, trough, breakdown, final, setback, and consistency viscosities; time to peak viscosity; and paste temperature). The amylose and protein content and gel consistency were measured according to the methods reported by Huang et al. (2013). The paste properties were measured using a Rapid Visco Analyzer (RVA-Super 4; Newport Scientific Pty Ltd., Warriewood, Australia) following standard procedures (AACC, 1999).

Approximately 10 g of whole milled rice were soaked in 16 ml of distilled water in an aluminum cup for 30 min, and then the aluminum cup was covered with its lid and placed in an electric rice cooker (GDF-2003; Zhuhai Gree Group Co., Ltd., Zhuhai, China) containing about 700 ml of boiling water and allowed to steam for 40 min. Texture profiles (hardness, springiness, cohesiveness, resilience, and chewiness) of the cooked rice were determined using a texture analyzer (Rapid TA+; Shanghai Tengba Instrument Technology Co. Ltd., Shanghai, China). About 100 mg samples of the cooked rice were subjected to in vitro digestion to determine the amount of glucose produced per unit fresh weight at six digestion times (15, 60, 120, 180, 240, and 300 min) using a Glycemic Index Analyzer (NutriScan GI20; Next Instruments, Condell Park, NSW, Australia). The starch digestion process of the cooked rice (i.e., the change in the amount of glucose produced over time) was fitted to the exponential association model for calculating starch digestion parameters, including active digestion duration, total glucose production, and glucose production rate (Huang et al., 2021).

Statistical analysis

All measured parameters were compared between the two cultivars using analysis of variance at the p < 0.05 probability level. Pearson’s correlation analysis was employed to evaluate relationships of texture profiles and starch digestion properties of cooked milled rice as well as physicochemical properties of milled rice flour against average daily mean temperature during the grain-filling period for each cultivar separately at the p < 0.05 and p < 0.01 probability levels. The data analysis was performed using Statistix 8.0 (Analytical software, Tallahassee, FL, USA).

Results

Texture and digestion properties of cooked milled rice

All texture profiles of cooked milled rice were significantly different between the two rice cultivars (Table 1). Hardness, springiness, cohesiveness, resilience, and chewiness of cooked milled rice were lower in JLY1468 than in LYPJ by 37%, 4%, 15%, 17%, and 49%, respectively. There was significant difference in active digestion duration of cooked milled rice between the two cultivars (Table 2). The active digestion duration was 26% shorter in JLY1468 compared with LYPJ. Total glucose production from starch digestion of cooked milled rice was the same between the two cultivars. The difference in the glucose production rate from starch digestion of cooked milled rice was significant between the two cultivars, occurring 33% faster in JLY1468 than in LYPJ.

Table 1.

Texture profiles of cooked milled rice from the two hybrid rice cultivars, Liangyoupeijiu (LYPJ) and Jingliangyou 1468 (JLY1468), grown during four sowing dates across two years.

| Cultivar | Year-Sowing date | Hardness (g) | Springiness | Cohesiveness | Resilience | Chewiness (g) |

|---|---|---|---|---|---|---|

| LYPJ | 2019-5-15 | 1173 | 0.784 | 0.615 | 0.433 | 557 |

| 2019-5-25 | 1150 | 0.796 | 0.653 | 0.454 | 634 | |

| 2019-6-04 | 1057 | 0.790 | 0.614 | 0.445 | 561 | |

| 2019-6-14 | 946 | 0.764 | 0.617 | 0.451 | 499 | |

| 2020-5-15 | 1041 | 0.784 | 0.615 | 0.445 | 465 | |

| 2020-5-25 | 985 | 0.795 | 0.633 | 0.425 | 479 | |

| 2020-6-04 | 967 | 0.786 | 0.610 | 0.435 | 452 | |

| 2020-6-14 | 879 | 0.778 | 0.617 | 0.439 | 383 | |

| Mean | 1025 a | 0.785 a | 0.622 a | 0.441 a | 504 a | |

| SE | 20 | 0.002 | 0.003 | 0.002 | 15 | |

| JLY1468 | 2019-5-15 | 510 | 0.691 | 0.466 | 0.319 | 165 |

| 2019-5-25 | 574 | 0.723 | 0.514 | 0.361 | 215 | |

| 2019-6-04 | 669 | 0.746 | 0.545 | 0.371 | 275 | |

| 2019-6-14 | 716 | 0.761 | 0.533 | 0.364 | 293 | |

| 2020-5-15 | 554 | 0.736 | 0.507 | 0.344 | 199 | |

| 2020-5-25 | 640 | 0.770 | 0.534 | 0.374 | 252 | |

| 2020-6-04 | 739 | 0.783 | 0.565 | 0.401 | 331 | |

| 2020-6-14 | 780 | 0.791 | 0.587 | 0.396 | 339 | |

| Mean | 648b | 0.750b | 0.531b | 0.366b | 259b | |

| SE | 19 | 0.007 | 0.007 | 0.005 | 12 |

Means of cultivars sharing the same letter are not significantly different at the p < 0.05 probability level.

Table 2.

Starch digestion properties of cooked milled rice from the two hybrid rice cultivars, Liangyoupeijiu (LYPJ) and Jingliangyou 1468 (JLY1468), grown during four sowing dates across two years.

| Cultivar | Year-Sowing date | Active digestion duration (min) | Total glucose production (mg g−1) | Glucose production rate (mg g−1 min−1) |

|---|---|---|---|---|

| LYPJ | 2019-5-15 | 114 | 351 | 3.07 |

| 2019-5-25 | 115 | 347 | 3.04 | |

| 2019-6-04 | 104 | 325 | 3.13 | |

| 2019-6-14 | 124 | 329 | 2.74 | |

| 2020-5-15 | 135 | 374 | 2.94 | |

| 2020-5-25 | 153 | 385 | 2.69 | |

| 2020-6-04 | 140 | 357 | 2.56 | |

| 2020-6-14 | 132 | 333 | 2.63 | |

| Mean | 127 a | 350 a | 2.85 b | |

| SE | 6 | 6 | 0.10 | |

| JLY1468 | 2019-5-15 | 88 | 342 | 3.92 |

| 2019-5-25 | 90 | 358 | 4.14 | |

| 2019-6-04 | 93 | 355 | 3.90 | |

| 2019-6-14 | 92 | 350 | 3.81 | |

| 2020-5-15 | 91 | 348 | 3.83 | |

| 2020-5-25 | 107 | 344 | 3.35 | |

| 2020-6-04 | 97 | 345 | 3.56 | |

| 2020-6-14 | 96 | 356 | 3.75 | |

| Mean | 94 b | 350 a | 3.78 a | |

| SE | 3 | 4 | 0.11 |

Means of cultivars sharing the same letter are not significantly different at the p < 0.05 probability level.

Physicochemical properties of milled rice flour

Amylose content of milled rice flour significantly differed between the two cultivars, showing 27% lower in JLY1468 compared with LYPJ (Table 3). The difference in protein content of milled rice flour was not significant between the two cultivars. There was a significant difference in gel consistency of milled rice flour between the two cultivars, with JLY1468 being 8% lower than LYPJ. The differences were significant between the two cultivars for all paste properties of milled flour except for trough viscosity (Table 4). Peak and breakdown viscosities were 23% and 62% higher in JLY1468 than in LYPJ, respectively, whereas final, setback, and consistency viscosities were 8%, 219%, and 15% lower in JLY1468 than in LYPJ, respectively. The time to peak viscosity was 2% shorter in JLY1468 compared with LYPJ. JLY1468 had 3% lower paste temperature than LYPJ.

Table 3.

Amylose and protein content and gel consistency of milled rice flour prepared from grains of the two hybrid rice cultivars, Liangyoupeijiu (LYPJ) and Jingliangyou 1468 (JLY1468), grown during four sowing dates across two years.

| Cultivar | Year-Sowing date | Amylose content (mg g−1) | Protein content (mg g−1) | Gel consistency (mm) |

|---|---|---|---|---|

| LYPJ | 2019-5-15 | 239 | 91.4 | 84.0 |

| 2019-5-25 | 238 | 89.5 | 85.3 | |

| 2019-6-04 | 240 | 89.1 | 84.7 | |

| 2019-6-14 | 237 | 96.1 | 84.7 | |

| 2020-5-15 | 241 | 88.8 | 84.7 | |

| 2020-5-25 | 237 | 87.7 | 86.0 | |

| 2020-6-04 | 232 | 88.3 | 87.0 | |

| 2020-6-14 | 229 | 95.4 | 86.3 | |

| Mean | 237 a | 90.8 a | 85.3 a | |

| SE | 1 | 0.8 | 0.4 | |

| JLY1468 | 2019-5-15 | 162 | 85.5 | 77.7 |

| 2019-5-25 | 167 | 92.6 | 78.7 | |

| 2019-6-04 | 177 | 92.2 | 78.0 | |

| 2019-6-14 | 182 | 93.8 | 80.0 | |

| 2020-5-15 | 166 | 81.9 | 81.7 | |

| 2020-5-25 | 169 | 80.7 | 79.3 | |

| 2020-6-04 | 180 | 92.6 | 74.3 | |

| 2020-6-14 | 186 | 98.0 | 77.7 | |

| Mean | 174 b | 89.7 a | 78.4 b | |

| SE | 2 | 1.3 | 0.6 |

Means of cultivars sharing the same letter are not significantly different at the p < 0.05 probability level.

Table 4.

Paste properties of milled rice flour prepared from grains of the two hybrid rice cultivars, Liangyoupeijiu (LYPJ) and Jingliangyou 1468 (JLY1468), grown during four sowing dates across two years.

| Cultivar | Year-Sowing date | Viscosity (cP) |

Time to peak viscosity (min) | Paste temperature (°C) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Peak | Trough | Breakdown | Final | Setback | Consistency | ||||

| LYPJ | 2019-5-15 | 3343 | 1983 | 1360 | 3842 | 498 | 1858 | 5.62 | 81.0 |

| 2019-5-25 | 3376 | 2102 | 1274 | 3922 | 545 | 1819 | 5.67 | 80.8 | |

| 2019-6-04 | 3298 | 1966 | 1332 | 3728 | 430 | 1762 | 5.64 | 80.5 | |

| 2019-6-14 | 3148 | 1943 | 1204 | 3676 | 529 | 1733 | 5.76 | 79.4 | |

| 2020-5-15 | 2920 | 1791 | 1129 | 3123 | 203 | 1332 | 5.91 | 79.2 | |

| 2020-5-25 | 2439 | 1525 | 914 | 2754 | 315 | 1229 | 6.02 | 77.3 | |

| 2020-6-04 | 2321 | 1491 | 830 | 2657 | 335 | 1166 | 6.18 | 76.3 | |

| 2020-6-14 | 2021 | 1307 | 714 | 2457 | 436 | 1150 | 6.15 | 80.3 | |

| Mean | 2858b | 1764 a | 1095b | 3270 a | 411 a | 1506 a | 5.87 a | 79.4 a | |

| SE | 106 | 59 | 51 | 117 | 25 | 63 | 0.05 | 0.6 | |

| JLY1468 | 2019-5-15 | 4392 | 2084 | 2308 | 3385 | −1007 | 1301 | 5.49 | 77.6 |

| 2019-5-25 | 4167 | 1953 | 2214 | 3395 | −772 | 1442 | 5.51 | 77.4 | |

| 2019-6-04 | 4055 | 1824 | 2231 | 3433 | −622 | 1609 | 5.51 | 77.1 | |

| 2019-6-14 | 3884 | 1778 | 2106 | 3357 | −527 | 1579 | 5.53 | 77.4 | |

| 2020-5-15 | 3331 | 1595 | 1736 | 2639 | −692 | 1045 | 5.78 | 74.4 | |

| 2020-5-25 | 3017 | 1662 | 1355 | 2698 | −319 | 1036 | 6.05 | 72.8 | |

| 2020-6-04 | 2835 | 1597 | 1238 | 2709 | −127 | 1111 | 6.06 | 71.3 | |

| 2020-6-14 | 2408 | 1401 | 1006 | 2557 | 149 | 1156 | 6.09 | 86.5 | |

| Mean | 3511 a | 1737 a | 1774 a | 3022b | −490b | 1285b | 5.75b | 76.8b | |

| SE | 141 | 48 | 102 | 82 | 75 | 47 | 0.06 | 0.9 | |

Means of cultivars sharing the same letter are not significantly different at the p < 0.05 probability level.

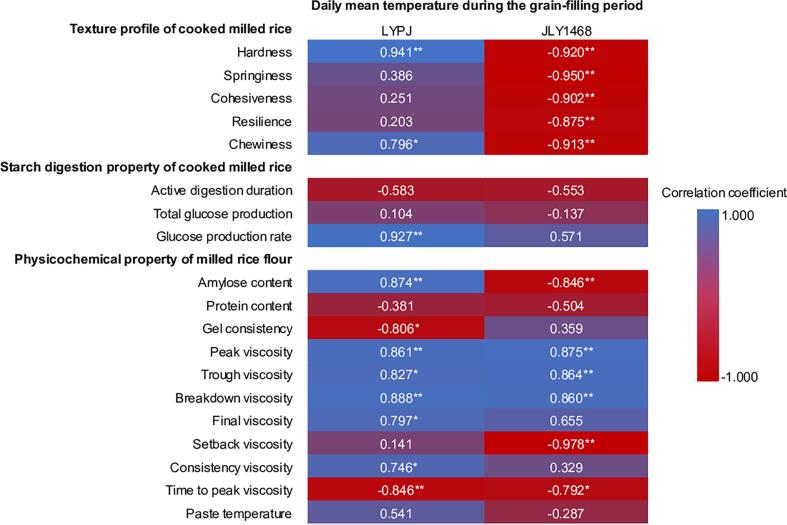

Relationships between rice quality traits and temperature during the grain-filling period

The relationships between texture profiles of cooked milled rice and average daily mean temperature during the grain-filling period were not consistent in the two cultivars (Fig. 2). For LYPJ, hardness and chewiness were significantly positively while springiness, cohesiveness, and resilience were not significantly related to average daily mean temperature during the grain-filling period. For JLY1468, all texture profiles were significantly negatively related to average daily mean temperature during the grain-filling period. The relationships between starch digestion properties of cooked milled rice and average daily mean temperature during the grain-filling period were also not consistent in the two cultivars. In particular, a significantly positive relationship between the glucose production rate from starch digestion and average daily mean temperature during the grain-filling period was observed for LYPJ but not for JLY1468.

Fig. 2.

Pearson’s correlation coefficients of texture profiles and starch digestion properties of cooked milled rice as well as physicochemical properties of milled rice flour against average daily mean temperature during the grain-filling period for the two hybrid rice cultivars, Liangyoupeijiu (LYPJ) and Jingliangyou 1468 (JLY1468). The data used in the analysis are from Table 1, Table 2, Table 3, Table 4 and Fig. 1 (n = 8). * and ** denote significant correlation coefficients at the p < 0.05 and p < 0.01 probability levels, respectively.

Some inconsistent relationships between physicochemical properties of milled rice flour and average daily mean temperature during the grain-filling period were also observed between the two cultivars (Fig. 2). Amylose content was significantly positively related to average daily mean temperature during the grain-filling period for LYPJ, while for JLY1468 this relationship was reversed. Gel consistency was significantly negatively while final and consistency viscosities were significantly positively related to average daily mean temperature during the grain-filling period for LYPJ; none of these relationships were significant for JLY1468. The relationship between setback viscosity and average daily mean temperature during the grain-filling period was not significant for LYPJ, whereas this relationship was significantly positive for JLY1468.

Additionally, there were some consistent and significant relationships between physicochemical properties of milled rice flour against and average daily mean temperature during the grain-filling period in the two cultivars (Fig. 2). Namely peak, trough, and breakdown viscosities were significantly positively related to average daily mean temperature during the grain-filling period in both LYPJ and JLY1468.

Discussion

In China, rice consumers generally preferer soft-textured rice with low amylose content (Huang and Hu, 2021), and satisfying these trait preferences of consumers has been a major pursuit for rice breeders in recent years (Yang et al., 2013, Zhou et al., 2015). These trait preferences are supported by the results of this study, which showed that the recently developed high-quality cultivar JLY1468 had lower hardness, springiness, cohesiveness, resilience, and chewiness of cooked milled rice and lower amylose content of milled rice flour than the relatively older cultivar LYPJ.

The gel consistency of milled rice flour is also an important physicochemical property determining the texture of cooked milled rice, and higher gel consistency is generally associated with softer texture (Binodh et al., 2006). However, in this study, the difference in gel consistency of milled rice flour did not explain the texture difference of cooked milled rice from the two cultivars, with lower gel consistency and softer texture being observed in JLY1468, compared with LYPJ. Despite this, the gel consistency in JLY1468 (78.4 mm) is still within the scope of gel consistency for soft rice (greater than60 mm) (Table 3; Binodh et al., 2006).

Paste properties are physicochemical traits that have become commonly used for evaluating rice eating quality in recent years (Zhang et al., 2017, Peng et al., 2021). Zhu et al. (2013) evaluated relationships between paste properties of milled rice flour and texture profiles of cooked milled rice. Their results showed that trough, final, and setback viscosities were significantly positively, breakdown viscosity was significantly negatively, and peak viscosity, the time to peak viscosity, and paste temperature were not significantly or consistently related to most texture profiles. These results were partly confirmed by the results of this study, which showed that final and setback viscosities were significantly lower but breakdown viscosity was significantly higher in JLY1468 having the softer texture, than in LYPJ. However, in this study, we also found significant differences in other paste properties of milled rice flour between these two cultivars with contrasting texture profiles, with JLY1468 showing higher peak viscosity, lower consistency viscosity, shorter time to peak consistency, and lower paste temperature than LYPJ. This finding suggests that more investigations on various rice cultivars are needed in order to establish more reliable relationships between paste properties of milled rice flour and texture profiles of cooked milled rice.

Importantly, and for the first time, this study evaluated the starch digestion properties of the recently developed high-quality rice. The results showed that active digestion duration of cooked milled rice was significantly shorter, while the glucose production rate from starch digestion was significantly faster in the more recently developed high-quality cultivar JLY1468 than in the relatively older cultivar LYPJ. In this regard, it has been reported that amylose is resistant to digestion in comparison to other starch molecules due to the strong interaction among the linear polymers of amylose (retrogradation) and between amylose and lipids that results in complex formation on the surface of starch granules (Svihus et al., 2005). Therefore, in this study, the faster glucose production rate from starch digestion in JLY1468 could be partially explained by its lower amylose content compared to LYPJ. These indicate that the starch digestion rate of cooked milled rice should have been increased in China in recent years as a result of the development of soft-textured rice with low amylose content that is preferred by consumers. Because rice starch with less resistance to digestion has a higher glycemic index (Fitzgerald et al., 2011), the increase in the starch digestion rate of cooked milled rice may lead to an increase in the risk of type 2 diabetes associated with rice consumption. This view is supported by a population-based study showing that the consumption of rice with a high glycemic index was negatively associated with glucose homeostasis in 3,918 Chinese adults aged 23–69 years (Cheng et al., 2017).

Prior to this study, the risk of type 2 diabetes associated with milled rice consumption has been documented in China (Villegas et al., 2007, Hu et al., 2012, Ma et al., 2014), but no attention has been given to how the potential contributions of these more recently developed low amylose, soft-textured rice lines—which have received unprecedented interest and support in rice research and production in China in recent years—on the risk of developing type 2 diabetes. We hope that the results of our study will serve to attract attention and help raise societal awareness of the health risks associated with this type of rice in China and other major rice-consuming countries. The results of this study also highlight the need to find feasible approaches to resolve the potential contraindication between rice eating quality and the risk of type 2 diabetes in rice consumers.

Additionally, this study observed that relationships of texture profiles of cooked milled rice with regards to temperature during the grain-filling period varied by cultivar; namely, cooked milled rice became harder with increasing temperature during the grain-filling period in LYPJ, whereas a reverse trend was observed in JLY1468. Reports showing that increasing temperature during the grain-filling period resulted in increased and decreased amylose content of milled rice flour in rice cultivars with high and low amylose content, respectively (Zhong et al., 2005, Zhang et al., 2019), which may explain the results of this study. However, the physiological mechanisms for the opposing effects of temperature during the grain-filling period on amylose content in rice cultivars with high and low amylose content are not well documented and require further investigation.

This study revealed that relationships between starch digestion properties of cooked milled rice and temperature during the grain-filling period were dependent on cultivar; namely, cooked milled rice became faster to digest with increasing temperature during the grain-filling period in LYPJ, but no significant trend was observed in JLY1468. Amylose content is an important factor influencing starch digestion in rice, and faster digestion rate is generally associated with lower amylose content (Fitzgerald et al., 2011). However, the change in amylose content of milled rice flour did not explain the difference in the starch digestion rate of cooked milled rice with regard to increasing temperature during the grain filling period in LYPJ in this study, where both amylose content of milled rice flour and starch digestion rate increased with increasing temperature. This could be attributed to the starch digestion of rice is being affected not only by its amylose content, but also other starch traits, such as starch gelatinization and retrogradation properties, the particle size of starch granules, the ratio of amylose to amylopectin, the crystallite structure of amylopectin, starch resistance against enzymatic hydrolysis, and interactions of starch with other components (Kaur et al., 2016). Park et al. (2017) observed that starch digestion rate was negatively correlated with gel consistency in rice. Therefore, in this study, the increased starch digestion rate of cooked milled rice correlated with increasing temperature during the grain-filling period in LYPJ could be attributed to decreased gel consistency of milled rice flour. The results of this study also highlight the need for further understanding of the effect of temperature during the grain-filling period on gel consistency in different cultivars.

Conclusions

The recently developed high-quality hybrid rice cultivar JLY1468 has a softer texture of cooked milled rice than the relatively older hybrid rice cultivar LYPJ, due to its lower amylose content and altered paste properties including, but not limited to, lower final and setback viscosities, and higher breakdown viscosity. A faster starch digestion rate (which generally means a higher glycemic index) is associated with JLY1468 compared with LYPJ, indicating a potential health risk associated with the development of soft-textured high-quality hybrid rice. In addition, this study finds that relationships between texture and starch digestion properties of cooked milled rice with temperature during the grain-filling period are different in LYPJ and JLY1468, due to varied amylose contents and gel consistencies in response to temperature.

CRediT authorship contribution statement

Min Huang: Conceptualization, Formal analysis, Writing – original draft, Funding acquisition. Liqin Hu: Investigation. Jialin Cao: Investigation. Ruichun Zhang: Investigation. Jiana Chen: Investigation. Fangbo Cao: Investigation. Longsheng Liu: Investigation. Shengliang Fang: Investigation. Ming Zhang: Investigation.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This study was supported by the National Key R&D Program of China (2016YFD0300509).

References

- AACC. (1999). AACC Approved Methods of Analysis (11th ed.). Cereal & Grains Association (Method 61-02.01).

- Binodh A.K., Kalaiyarasi R., Thiyagarajan K., Manonmani S. Phyiso-chemical and cooking quality characteristics of promising varieties and hybrids in rice (Oryza sativa L.) Indian Journal of Genetics. 2006;66:107–112. [Google Scholar]

- Bruins H.J., Bu F. Food security in China and contingency planning: The significance of grain reserves. Journal of Contingencies and Crisis Management. 2006;14(3):114–124. [Google Scholar]

- Cheng G., Xue H., Luo J., Jia H., Zhang L., Dai J., Buyken A.E. Relevance of the dietary glycemic index, glycemic load and genetic predisposition for the glucose homeostasis of Chinese adults without diabetes. Scientific Reports. 2017;7:400. doi: 10.1038/s41598-017-00453-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cheng S., Cao L., Yang S., Zhai H. Forty years’ development of hybrid rice: China’s experience. Rice Science. 2004;11:225–230. [Google Scholar]

- China Rice Data Center. (2021). The Database for Chinese Rice Varieties and Their Genealogy. Retrieved from https://www.ricedata.cn/variety/varis/616628.htm. Accessed December 30, 2021.

- Deng N., Grassini P., Yang H., Huang J., Cassman K.G., Peng S. Closing yield gaps for rice self-sufficiency in China. Nature Communications. 2019;10:1725. doi: 10.1038/s41467-019-09447-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fitzgerald M.A., Rahman S., Resurreccion A.P., Concepcion J., Daygon V.D., Dipti S.S.…Bird A.R. Identification of a major genetic determinant of glycaemic index in rice. Rice. 2011;4(2):66–74. [Google Scholar]

- Hsiaoping C. In: Rice is life: Scientific perspectives for the 21st century. Toriyama K., Heong K.L., Hardy B., editors. International Rice Research Institute; 2005. Rice consumption in China: Can China change rice consumption from quantity to quality; pp. 497–499. [Google Scholar]

- Hu E.A., Pan A., Malik V., Sun Q. White rice consumption and risk of type 2 diabetes: Meta-analysis and systematic review. British Medical Journal. 2012;344(mar15 3):e1454. doi: 10.1136/bmj.e1454. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huang M. The decreasing area of hybrid rice production in China: Causes and potential effects on Chinese rice self-sufficiency. Food Security. 2021 doi: 10.1007/s12571-021-01199-z. [DOI] [Google Scholar]

- Huang M., Cao J., Liu Y.u., Zhang M., Hu L., Xiao Z.…Cao F. Low-temperature stress during the flowering period alters the source–sink relationship and grain quality in field-grown late-season rice. Journal of Agronomy and Crop Science. 2021;207(5):833–839. [Google Scholar]

- Huang M., Hu L.-Q. Low glycemic index: The next target for rice production in China? Journal of Integrative Agriculture. 2021;20(6):1727–1729. [Google Scholar]

- Huang M., Jiang L., Zou Y., Zhang W. On-farm assessment of effect of low temperature at seedling stage on early-season rice quality. Field Crops Research. 2013;141:63–68. [Google Scholar]

- Huang M., Shan S., Chen J., Cao F., Jiang L., Zou Y. In: Advances in International Rice Research. Li J., editor. InTech; 2017. Comparison on grain quality between super hybrid and popular inbred rice cultivars under two nitrogen management practices; pp. 111–124. [Google Scholar]

- Kaur B., Ranawana V., Henry J. The glycemic index of rice and rice products: A review, and table of GI values. Critical Reviews in Food Science and Nutrition. 2016;56(2):215–236. doi: 10.1080/10408398.2012.717976. [DOI] [PubMed] [Google Scholar]

- Phing Lau W.C., Latif M.A., Rafii M.Y., Ismail M.R., Puteh A. Advances to improve the eating and cooking qualities of rice by marker-assisted breeding. Critical Reviews in Biotechnology. 2016;36(1):87–98. doi: 10.3109/07388551.2014.923987. [DOI] [PubMed] [Google Scholar]

- Lü C.G., Zou J.S. Comparative analysis on rice plant type of two super hybrids and Shanyou 63. Agricultural Sciences in China. 2003;2:513–520. [Google Scholar]

- Ma R.C.W., Lin X.u., Jia W. Causes of type 2 diabetes in China. The Lancet Diabetes & Endocrinology. 2014;2(12):980–991. doi: 10.1016/S2213-8587(14)70145-7. [DOI] [PubMed] [Google Scholar]

- Park J.E., Bae I.Y., Oh I.K., Lee H.G. Effects of amylose contents and degree of gelatinization of rice flour on in vitro starch digestibility, physical characteristics, and morphological properties. Food Engineering Progress. 2017;21(4):341–350. [Google Scholar]

- PENG S.-B. Dilemma and way-out of hybrid rice during the transition period in China. Acta Agronomica Sinica. 2016;42(3):313. doi: 10.3724/SP.J.1006.2016.00313. [DOI] [Google Scholar]

- Peng S., Cassman K.G., Virmani S.S., Sheehy J., Khush G.S. Yield potential trends of tropical rice since the release of IR8 and the challenge of increasing rice yield potential. Crop Science. 1999;39(6):1552–1559. [Google Scholar]

- Peng Y., Mao B., Zhang C., Shao Y., Wu T., Hu L.…Xiao Y. Correlations between parental lines and indica hybrid rice in terms of eating quality traits. Frontiers in Nutrition. 2021;7 doi: 10.3389/fnut.2020.583997. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saeedi, P., Petersohn, I., Salpea, P., Malanda, B., Karuranga, S., Unwin, N., Colagiuri, S., Guariguata, L., Motala, A. A., Ogurtsova, K., Shaw, J. E, Bright, D., & Williams, R. (2019). Global and regional diabetes prevalence estimates for 2019 and projections for 2030 and 2045: Results from the International Diabetes Federation Diabetes Atlas, 9th edition. Diabetes Research and Clinical Practice, 157, 107843. [DOI] [PubMed]

- Sattari A., Mahdinezhad N., Fakheri B., Noroozi M., Beheshtizadeh H. Improvement of the eating and cooking qualities of rice: A review. International Journal of Farming and Allied Sciences. 2015;4:153–160. [Google Scholar]

- Svihus B., Uhlen A.K., Harstad O.M. Effect of starch granule structure, associated components and processing on nutritive value of cereal starch: A review. Animal Feed Science and Technology. 2005;122(3-4):303–320. [Google Scholar]

- Tong C., Chen Y., Tang F., Xu F., Huang Y., Chen H., Bao J. Genetic diversity of amylose content and RVA pasting parameters in 20 rice accessions grown in Hainan, China. Food Chemistry. 2014;161:239–245. doi: 10.1016/j.foodchem.2014.04.011. [DOI] [PubMed] [Google Scholar]

- Villegas R., Liu S., Gao Y.-T., Yang G., Li H., Zheng W., Shu X.O. Prospective study of dietary carbohydrates, glycemic index, glycemic load, and incidence of type 2 diabetes mellitus in middle-aged Chinese women. Archives of Internal Medicine. 2007;167(21):2310. doi: 10.1001/archinte.167.21.2310. [DOI] [PubMed] [Google Scholar]

- Virmani S.S., Zaman F.U. In: Advances in hybrid rice technology. Virmani S.S., Siddiq E.A., Muralidharan K., editors. International Rice Research Institute; 1998. Improving grain quality of hybrid rice: Challenges, strategies, and achievements; pp. 177–186. [Google Scholar]

- Wang W., Cui W., Xu K., Gao H., Wei H., Zhang H. Effects of early- and late-sowing on starch accumulation and associated enzyme activities during grain filling stage in rice. Rice Science. 2021;28(2):191–199. [Google Scholar]

- Worldometer, 2021. Countries in the World by Population. https://www.worldometers.info/world-population/population-by-country.

- Xu Y., Wang L., He J., Bi Y., Li M., Wang T.…Ning G. Prevalence and control of diabetes in Chinese adults. Journal of the American Medical Association. 2013;310:948–959. doi: 10.1001/jama.2013.168118. [DOI] [PubMed] [Google Scholar]

- Yang J., Wang J., Fan F., Zhu J., Chen T., Wang C.…Xu J. Development of AS-PCR marker based on key mutation confirmed by resequencing of Wx-mp in milky princess and its application in japonica soft rice (Oryza sativa L.) breeding. Plant Breeding. 2013;132:595–603. [Google Scholar]

- Yuan L.-P. Development of hybrid rice to ensure food security. Rice Science. 2014;21(1):1–2. [Google Scholar]

- Zhang A., Gao Y., Li Y., Ruan B., Yang S., Liu C.…Qian Q. Genetic analysis for cooking and eating quality of super rice and fine mapping of a novel locus qGC10 for gel consistency. Frontiers in Plant Science. 2020;11:342. doi: 10.3389/fpls.2020.00342. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang H., Huang M., Chen G., Zou Y. Relationships between amylose content and pasting properties in Chinese rice. Crop Research. 2017;52:202–208. [Google Scholar]

- Zhang, H., Huang, M., Wei, Y., Chen, J., Shan, S., Cao, F., Chen, G., & Zou, Y. (2019). Amylose content and starch granule size in rice grains are affected by growing season. Phyton-International Journal of Experimental Botany, 88, 403–412.

- Zhong L.J., Cheng F.M., Wen X., Sun Z.X., Zhang G.P. The deterioration of eating and cooking quality caused by high temperature during grain filling in early-season indica rice cultivars. Journal of Agronomy and Crop Science. 2005;191:218–225. [Google Scholar]

- Zhou M., Deng G., Liang H., Zhou W., Dai G., Gao L.…Liang S. Breeding of high-quality soft-grain indica CMS line Longfeng A. Agricultural Science & Technology. 2015;16:1136–1139. [Google Scholar]

- Zhu B.o., Li B., Gao Q., Fan J., Gao P., Ma M., Feng X.i. Predicting texture of cooked blended rice with pasting properties. International Journal of Food Properties. 2013;16(3):485–499. [Google Scholar]