Graphical abstract

Keywords: 3D printing, Custom hardware, Diffuser membrane, Lab-scale reactor, Aeration, Bioreactor

Highlights

-

•

An FDM-3D printed multi-feature laboratory receptacle is reported on.

-

•

Water tightness and permeability in a single 3D printed body is detailed.

-

•

Slicing software and gcode post-processing settings are quantified.

-

•

Tests of the diffuser membrane in the object are evaluated.

-

•

Hardware specifications and costs are reported.

Abstract

Water research is one of many fields where fused filament fabrication 3D printing offers the freedom of customization and the inclusion of commercial components. We present our 330 mL 3D printed laboratory receptacle that has been customized to control pressurized air and liquid in one body. During our tests, water has been stored without loss, and batches were frozen whilst circulating and diffusing air through the liquid. The printing has been optimized with the slicer software and gcode editing, letting the fused filament 3D printer to build a diffuser membrane surrounded by air-tight walls. Detailed construction instructions are given, including piping and control board for operation. According to the functionality of the receptacle and the aeration system, the solutions have been found durable and low-cost. Disadvantages are the time invested in creating customized code, and certain limitations of the membrane itself.

Specifications table

| Hardware name | 3D printed receptacle with diffuser membrane for manipulating pressurized air and water |

|---|---|

| Subject area | Material sciences |

| Water chemistry | |

| Environmental sciences | |

| Hardware type | Aerated reactor |

| Laboratory measurements | |

| Customization | |

| Open source license | CC BY |

| Cost of hardware | EUR 50.23 (shipping costs excluded) |

| Source file repository | https://doi.org/10.17632/9b4d8g9jc4.1 |

1. Hardware in context

Water research is taking advantage on the falling costs of digital technology and new prototyping techniques such as 3D printing. Models, tools and spare parts, even water quality sensors can be produced fast, with larger freedom and / or at lower costs than before. The positive effects are the most pronounced in developing countries as well as in niche areas of research. A further advantage of 3D printing is that open-source hardware, software and commercially available components can co-exist in custom designs. Using this technology, water scientists have developed new prototypes and instrumentation. The new methods create new possibilities, save on costs and increase availability as compared to off-the-shelf options. Examples include monitoring gauges based on an open-source electronic platform for remote locations, as well as 3D printed rain gauges, or lab tools such as a micropump pipette, mobile water quality sensor and DIY laboratory kit for DNA analysis. Their advantages are:

-

1.

Increasing the density and frequency of field measurements [1];

- 2.

- 3.

Our paper focuses on a custom-made laboratory device for freezing water samples. The purpose of building the device was to 1) develop techniques for desktop fused filament fabrication (FFF) 3D printers that can produce air-tight wall and air permeable membranes in the same prints and 2) to create an environment for influencing the ion migration that is caused by the propagation of the freezing front during freezing by diffusing bubbles into the water through a membrane.

Additive manufacturing processes for membranes have been presented by several authors. Those membranes serve water treatment by nanofiltration and reverse osmosis [8], [9], [10]. The authors mention that there are over 50 different additive manufacturing (3D printing) methods for processing different materials, with FFF, a solid-based method becoming widely known since 2009 when the patent US5121329A on the parent technology expired. Our equipment, expertise and methods were simple as compared to desalination membranes. We relied on a desktop printer and diffused air instead of moving ions. Therefore our experiment is closer to aeration devices and aerated bioreactors and has little to do with filtration. For more detail on FFF 3D printing, refer to Goh et al. [11]. The membraned hardware was used in our laboratory experiment to produce simultaneous air diffusion and slow, directional freezing.

Ice crystals are known to form from pure water only, and there is a phenomenon known as brine rejection, where freezing always concentrates soluble salts, organic compounds and suspended materials in the liquid solute [6], [12]. Therefore, ice that crystallizes early has the lowest ion concentration and ice that freezes at the end has the highest. This can be used for two things. Freezing has been studied for the treatment of water, where brine rejection pushes pollutants into one spot [7], [13], [14]. In contrast, when freezing is used for conservation of quality, brine rejection is unfavorable, because permanent changes might occur to the solute and the solids. Freezing is nonetheless used in practice as a conservation method, indicating that it needed to be researched [15], [16], [17]. In summary, ways to change brine rejection by reinforcing or mitigating ion migration are both interesting.

Our paper presents a custom scientific hardware, where the key component was a 3D printed receptacle. The receptacle had a membrane bottom that diffused air into the liquid. Bubbles rose through the water and contacted a freezing front progressing from the sides of the receptacle inward. We theorized that bubble contact causes micro-scale melting and might change freezing and brine rejection. Furthermore, we describe how we programmed the 3D printer for airtight walls and an air-permeable membrane within one receptacle. Our experimental setup used a laser-cut control board with off-the-shelf components. The 3D models were drafted in FreeCAD 0.17 and printed using a Prusa i3 MK2S printer. The control panel was cut to shape with an Epilog Mini 24 laser machine.

2. Hardware description

We built customized laboratory equipment relying on 3D printing filament and sheet plastic. With the 3D printed receptacle, we obtained a container without any obstructions inside such as an air pipe or a diffuser disk. The advantage of avoiding off-the-shelf components was that removing ice blocks was easy and without the risks of 1) damaging diffuser components and 2) losing ice whilst waiting for these components to thaw out and let the ice block slide out from the receptacle. A further advantage of 3D printing was that a rectangular container could be built. Dicing of the ice samples was easy due to their rectangular shape. After a single pair of receptacles and corresponding lids had been built, air was circulated through a closed system. This avoided evaporation loss. The control board was cut from a plastic sheet, equipped and fixed on a tripod. The tripod is not described in the present paper. The description of the receptacle and control board components follows.

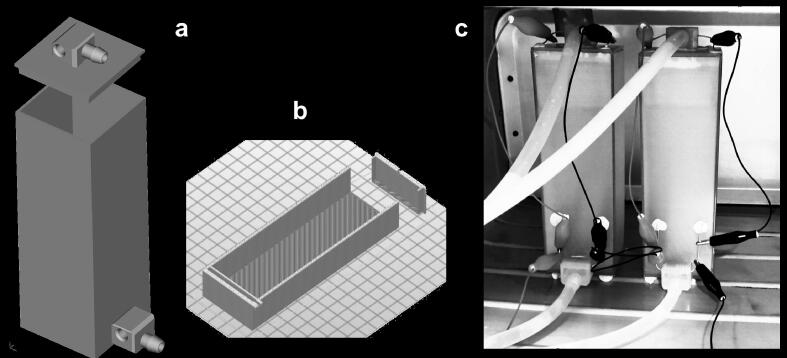

The receptacle consisted of eight parts fixed together into four separable components: a receptacle body, a lid for the receptacle, and two heated air connections (Fig. 1). The receptacle body consisted of a main body and an air inlet nozzle. The volume was 330 mL, with 250 mL volume for water and room for air above. Its internal dimensions were 48 mm × 48 mm × 144 mm [W × L × H], with a wall thickness of 1.6 mm. The air chamber under the diffuser membrane had a volume of 8 mL with dimensions of 46.8 mm × 46.8 mm × 3.6 mm. The lid component was equipped with an air outlet nozzle on its upper side. It was further equipped with a thin plastic sheet on its bottom to protect the nozzle from icing (held by a support piece). Heated air connections were installed on the nozzles. A 10 Ohm resistor slid into them prevented ice buildup and blockage due to condensation.

Fig. 1.

3D printed receptacle with membrane diffuser and heated air connections. Panel a: model of the receptacle; panel b: longitudinal section of the model with the air chamber and the membrane visible at its bottom; panel c. a pair of receptacles with tubing and resistors inside the freezing unit.

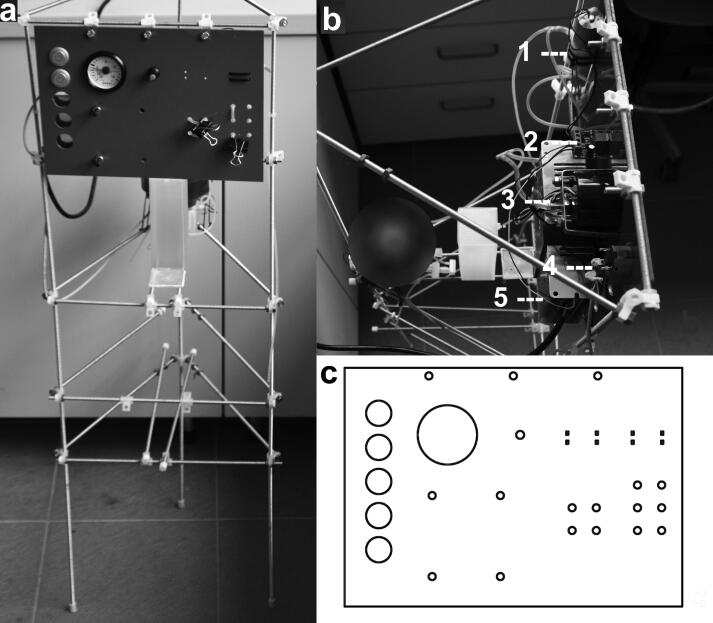

The plastic sheet control board had been drafted using FreeCAD 0.17 and after cutting it with a laser, electronics and piping were mounted on it. The 210 × 297 × 3 mm plastic sheet held a transformer (12 V output, 10A), a start button, a voltage controller, a diaphragm air pump and a manometer (Fig. 2). All the items were fitted into the board or fixed to its back. The transformer was fixed using metal bolts and 3D printed plastic hinges. The vacuum and pressure port of the pump were equipped with 2/4 mm silicon pipes and clips to select the air flow direction. The voltage controller allowed us to set the rate of air flow. Low voltage cables linked the voltage controller with the resistors.

Fig. 2.

Laser-cut polyethylene terephthalate glycol (PETG) control board and detailed view of control equipment. Panel a: front view of the control board fixed to a metal frame; panel b: installations on the back side of the board with diaphragm pump (1), voltage controller (2), manometer (3), power switch (4) and 12 V power supply (5). The receptacle is visible on panels a and b as well as stored on the frame during production.

3. Design files

Design file summary

Fig. 1: Illustration of receptacle models and receptacles in operation.

Fig. 2: Illustration of the control board, its components and its SVG model.

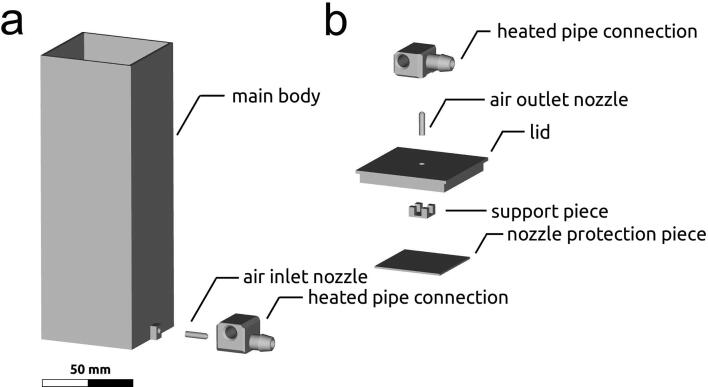

Fig. 3: Illustration of the assembly of the receptacle.

Fig. 3.

Assembly of the receptacle.

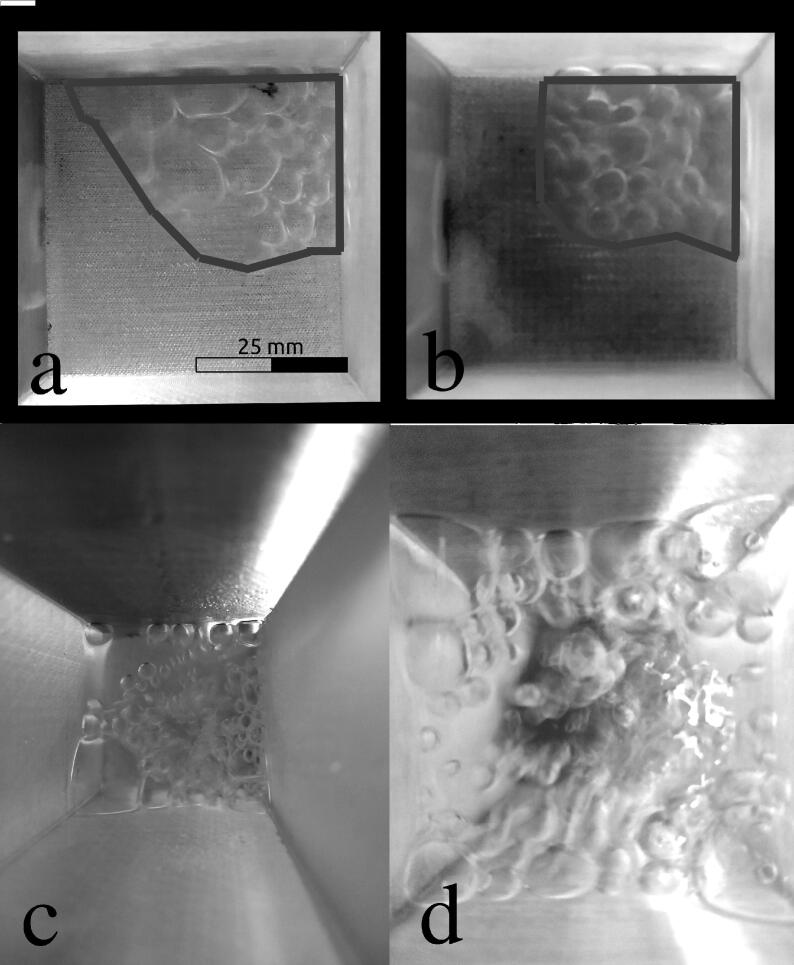

Fig. 4: Illustration of the aeration membrane in operation.

Fig. 4.

The active surface of the membrane at 0.2 bar in a) new receptacle and b) in a receptacle after about twenty freezing cycles; bottom panels show air distribution performance c) in 2 cm water and d) after 11.4 cm that was the operational water depth.

GCODE (post-processed): printing code with manually edited extrusion volumes.

STL (model): Model of the receptacle that needs manual editing of the gcode to create a diffuser membrane.

STL files: Ready-to-print component files of the receptacle and the control board.

SVG file: Ready-to-cut file of the control board for laser cutting of sheet material.

Bill of materials

Bill of materials

| Designator | Component | Number | Cost per unit – currency | Total cost – currency | Source of materials | Material type |

|---|---|---|---|---|---|---|

| Receptacle | 1.75 mm printer filament | 35 m | 22.99 € | 2.68 € | https://shop.prusa3d.com/en/filament/52-clear-petg-filament-1-kg.html# | PETG |

| Piping 4/6 mm | 5 m | 1.12 € | 5.59 € | https://szilikonwebaruhaz.hu/lista/4d0dd5473e260-Szilikon-cso | Silicone | |

| 4 resistors | 4 pcs | 5.42 € | 2.17 € | https://www.soselectronic.hu/products/vitrohm/590–0-5–10-r-po590-05t10r-1–19605 | ||

| Control board | 210 mm × 297 mm plastic sheet | 1 pcs | 4.39 € | 4.39 € | https://www.ebay.fr/itm/3mm-Petg-Polyester-Drap-White-Clear-A5-A4-A3-Grande-Point-de-Sale-Display-Etc/362824490116?hash=item547a065c84:m:mpkSLBiWJDUOdr_Fd3vQBWQ | PETG |

| 12 V LED Power Supply | 1 pcs | 14.56 € | 14.56 € | https://www.ebay.fr/itm/AC-100 V-240 V-To-DC-5 V-12 V-24 V-36 V-LED-Light-Drive-Power-Supply-Switch-Adapter/254256260282 | ||

| Voltage controller | 1 pcs | 1.32 € | 1.32 € | https://www.ebay.fr/itm/LM317-DC-Linear-Converter-Down-Voltage-Regulator-Board-Speed-Control-Module/401000177231?hash = item5d5d791e4f:g:NTEAAOSw0fhXiFq- | ||

| Mini Diaphragm Pump | 1 pcs | 3.87 € | 3.87 € | https://www.ebay.fr/itm/DC-3 V-5 V-6 V-Small-Mini-370-Motor-Air-Pump-Vacuum-Pump-Self-Priming-Breast-Pump/263420388861?hash = item3d551425fd:g:Lb4AAOSwTO9aTfBa | ||

| Power cable | 1.5 m | 3.00 € | 3.00 € | https://www.ebay.fr/itm/Cable-alimentation-secteur-220–240-V-Europe-European-Power-cable-1 m50-150 cm/153727035839?hash=item23cad869bf:g:HUkAAOSwJ9Vdz ~ 8L | ||

| Power button | 1 pcs | 2.35 € | 2.35 € | https://www.ebay.fr/itm/5pcs-10 mm-Self-Latch-Round-Push-Button-Switch-2-Pin-DS-211-LED-Lamp-Switch/223082903829?hash = item33f0c6f915:m:myPsIoOZTQsutFirkYwm-UQ | ||

| Low voltage wires | 5 m | 3.67 € | 1.84 € | https://www.soselectronic.hu/products/no-name/la-014-10bk-l1sw10-5079 | ||

| Plastic strip self-loc cable ties | 2 pcs | 3.95 € | 0.95 € | https://www.ebay.fr/itm/Cable-ties-Tie-wraps-black-Nylon-plastic-ties-cable-binding-ties-VARIOUS-SIZES/222204782713?hash=item33bc6fe879:m:mfuwZ3g__LrVXn654DH_ADA | 2.5 × 200 mm | |

| Mini crocodile clamps | 12 | 2.50 € | 2.50 € | https://www.soselectronic.hu/products/no-name/kk-05-rd-6636 | ||

| 1.75 mm printer filament | 16 m | 22.99 € | 1.98 € | https://shop.prusa3d.com/en/filament/52-clear-petg-filament-1-kg.html# | ||

| Bolts with nuts (M6 × 80) | 4 pcs | 0.10 € | 0.40 € | Local store |

5. Building instructions

Receptacle

All pieces of the receptacle were drafted in the parametric design software FreeCAD (0.17, 0.19), and exported into STL (STereoLithography) files. These files were then loaded into a slicer software (Prusa Slicer 2.1.0) that can create code from 3D models for the 3D printer. Slicer settings were adjusted to have prints that are water-tight and also air-tight at low pressures. Slicing parameters were customized based on our previous experiences with water proofing. The control settings were 1) plastic flow; 2) print speed and acceleration; 3) nozzle temperature and 4) layer height. To learn more about FFF printing parameterization and the meaning of the following parameters, refer to Goh et al. [11]. The gcode files in the article's online repository contain all the printing parameters. The parameters can be imported into a slicing software, and the following description includes all relevant changes we made.

The extrusion multiplier was increased to 115% and extra plastic flowed into each layer. As a consequence, layers and perimeters fused better, closing gaps and trapping water and air. Layer adhesion and precision was further increased by reducing the print speed and acceleration, increasing the nozzle temperature and setting an optimal layer height. Movements were set to 20 mm/s, and at small perimeters to 5 mm/s. This reduction corresponds to about 33% of the printer’s standard capabilities. Acceleration for print head movements was reduced to 300 mm/s2. This corresponds to about 25% of the printer’s standard capabilities. The nozzle temperature was increased to the highest recommendation for the selected filament (250 Celsius). Layer height was set at 0.2 mm (about 50% of the nozzle diameter). Slicing was executed and the gcode was saved.

Moving away from the idea of water and air tightness, we focused on the air diffuser membrane that is a part of the same print object. The air diffuser membrane was designed to comprise three horizontal layers (0.6 mm thick in total) supported from below (3D Honeycomb). Even if the membrane was thin by design, our slicer settings (described above) did not produce a good and distributed permeability. Therefore, a special software (Repetier-Host 2.1.6) and a table editor (LibreOffice Calc 6.0.7.3) were used that allowed printer code (gcode) visualization and editing. The Repetier software allowed us to identify the code commanding the extrusion of the layers. This code was copied into the table editor, where the extrusion was decreased from 115% to 95%. Inside the walls of the air entry nozzle, near the three layers of the membrane, extrusion had to be increased to 193% to keep air tightness after the modifications. The consequences of the marginal overlap of wall-building and membrane-building printer commands were eliminated though plastic flow into these structurally successive layers. Table 1 summarizes the adjustments and their effects.

Table 1.

Adjustments of printing parameter in the slicer software and the gcode file for airtight walls and air-permeable membrane in the same object.

| Part | Setting | Value | % of standard | Effect |

|---|---|---|---|---|

| Water- and airtight walls | too low | air and water escapes | ||

| Plastic flow | N.A. | 115% | Watertight FFF walls | |

| too high | too much plastic | |||

| too low | weak spots | |||

| Printing speeds | 20 (5) mm/s | ≈ 33% | Airtight FFF walls | |

| too high | printing too slow | |||

| too low | not air tight | |||

| Acceleration | 300 mm/s2 | 25% | Airtight FFF walls | |

| too high | unknown | |||

| too low | printing problems | |||

| Nozzle temperature | 250 °C | max. tolerable | Airtight FFF walls | |

| too high | plastic is damaged | |||

| too low | weak adhesion | |||

| Layer height | 0.2 mm | 50% of nozzle | Airtight FFF walls | |

| too high | weak adhesion | |||

| Air-permeable membrane | too low | large bubbles, less entry points | ||

| # of layers | 3 | NA | Balanced flow and layer number | |

| too high | tiny bubbles, less entry points | |||

| too low | large bubbles, less entry points, higher operation pressure | |||

| Plastic flow | NA | 95% | Balanced flow and layer number | |

| too high | tiny bubbles, less entry points, higher operation pressure | |||

A food-grade PETG (Polyethylene Terephthalate Glycol) was used for printing for its chemical neutrality. The Prusa i3 MK2S model was operated with a standard 0.4 mm hotend. The orientation of the prints is shown in Fig. 3. Fill density was 15%. Four extruded lines of plastic produced the walls, 16 layers formed the bottom, and 9 layers on the top. Supports were used only on the build plate and only if necessary.

The receptacle was assembled into two final components, leaving only the receptacle body and the lid separable. For this, air nozzles were installed into their slots with glue (cyanoacrylate). Then, 10 Ohm resistors were inserted into the heated joints. The nozzles were then surrounded by putty-like pressure-sensitive adhesive, and the heated joints were slid over the nozzle pipe on both the lid and the body. The legs of the resistors were bent and fixed to provide additional stability. The receptacle lid was then equipped with a thin plastic sheet of cyanoacrylate to protect the nozzle slot.

The air intake slot is at the bottom of the receptacle, and the release slot is at the center of the lid. The receptacle was joined to the air pump through 4/6 silicon pipes. This diameter was necessary to avoid the blockage of the pipes from the condensation freezing. A shrinking piece was employed to connect the receptacle to the pump with a snippet of 2/4 silicon pipe.

6. Operation instructions

The receptacle can be operated using any solute and gas that the PETG material can tolerate. Closed-circuit aeration can be done by joining the air outlet socket with the vacuum side of the diaphragm pump. To start operation, liquid is poured into the receptacle, up to a maximum recommended volume of 250 mL. The receptacle is then closed and placed into the desired environment, that in our case was a freezer operated at −8 °C. The power cable is then joined to the mains and the power is switched on. The voltage controller can be adjusted to ensure the desired air flow.

7. Validation and characterization

The air-tightness of the receptacle was tested by immersing it under water whilst in operation. The lid of the receptacle was sealed with a putty-like pressure sensitive adhesive. Some air was detected escaping at the inlet joint, however, this was deemed to be small enough to be acceptable to keep evaporation practically zero and the cooling efficiency of the refrigerator high.

The diffuser membrane was checked for its permeability (Fig. 4). Air entry points were present only on 1/3 of the membrane surface and near one corner. This might be related to the extrusion setting that has a delayed effect during printing. Some of the plastic dragged from the nozzle onto the membrane. The movement of the printer head produces extra material within < 2 mm measured from the walls. The correct amount was deposited on one third of the membrane which was then air-tight. This was detected during the first test prints, and refined later. Still, over-extruded walls surround the under-extruded membrane layer at any Z coordinate. The print nozzle paths run from wall to wall and several are diagonal. This makes air entry points group near one of the corners, at the end of the route where excess plastic was not deposited anymore. In spite of this limitation, bubbles dispersed and rose uniformly in the water column two centimeters above the bottom. Bubble size was estimated based on photographs of bubbles passing a scaling rod underwater. An overview of the membrane and aeration characteristics is given in Table 2:

Table 2.

Aeration characteristics.

| Characteristics | Value |

|---|---|

| Fluid space bottom area | 2190 m2 |

| Total diffuser area | 2190 m2 |

| Active diffuser area | 838 mm2 |

| Active diffuser area to fluid space area | 38% |

| Number of entry points | 50 |

| Entry point density, total area | 22,831 ·m−2 |

| Entry point density, active area | 59,665 ·m−2 |

| Calibrated air flow | 14.7 L·h−1 |

| Bubble diameters | 1–3 mm |

| Pressure difference | 0.2 bar |

Air flow through the diffuser membrane was measured by the following steps. First, a long pipe was connected to the lid of the receptacle, where air escapes. The pipe was filled with a known volume of water. Then, the receptacle was filled with water. The receptacle was then sealed using the putty-like pressure sensitive glue. Starting the pump pushed the water out from the top pipe. The time between starting the pump and emptying of the pipe was recorded. The pump rate was set the same for all experiments, assuring a diffuser air flow of 14.7 L/h.

The durability of the receptacle was assessed after nine months of operation, or twenty freezing cycles, by measuring bubble size as well as the number of air entry points. The bubble size did not increase, but the number of the entry points became limited to 29% of the surface of the diffuser (Fig. 4). This degradation could be caused by the freezing cycles or to the operation of the diffuser itself, however, as we did both in parallel, differentiation was impossible.

Discussion

The 3D printing code of the receptacles was edited manually to provide contrasting wall qualities in a single object. The method was labor intensive and took four trial printouts to make it work and about 16 h of labor and 40 h of printing. We confirmed a method that can be employed in any 3D printed object to ensure water and air tightness, as well as to create layers that are intentionally weak for air or water permeability, and within the same item. The receptacles were successfully employed for the experiment with the custom-built control panel cut with a laser from an industrial plastic sheet. Consumer electronics were installed on the board. KCl and KMnO4 solutions were successfully frozen, diced and the spatial concentration was evaluated statistically and visually. The measurements were repeated without air diffusion into the receptacles for comparative purposes. While checking the air tightness of the receptacle, some air escaped. Air tightness was incomplete around the entry point. However, the amount of air loss was negligible.

Future research with FFF printed membranes could start out from our values and aim for optimization and quantify effects of parameter adjustments. Note that a research like that must be directed on the membrane itself; our research aimed to build a membrane surrounded by water-tight walls. For future manipulation of water and air in any FFF prototype, we recommend an increase of the extrusion multiplier from 193% with 33% increments to stop leakage at the edge of membrane or other weak points. Our membrane mildly deteriorated during the experiment. The general durability of the 3D printed membrane was impossible to determine. We recommend experiments directed on 1) operating pressure; 2) bubble size; 3) active membrane surface; 4) air flow rate and 5) membrane durability. The membrane was used during about twenty freezing cycles or forty hours of operation, with a 20–25% shrinking of the active surface. Without the freezing cycles, the durability of the membrane might be higher.

FFF 3D printing technology allowed us to manipulate pressurized air and water at laboratory scales by a custom-designed receptacle and controllable air circulation system. According to the qualities of the receptacle and the aeration system, the solutions were adequate and low-cost, with limited durability of the membrane itself. Apart from the findings regarding manipulating air and water, we see minor value in the receptacle itself for further use in the same context. However, a two-fold upscaling would be possible with the same desktop printer and there are much larger 3D printers on the market. We see uses as a lab-scale reactor for microbiology culture, for activated sludge experiments, or constructed wetland column experiment aeration. Recent literature has shown 3D printed plastics are chemically compatible with not only water but a wide range of solvents too [18], [19], [20] – and this should be discussed in future works.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

Acknowledgements

I wish to recognize the assistance of Baptiste Denaeyer and Guillaume Torreilles at FabLab CESI Écully Lyon and thank them for their help with voltage control and cutting the control board.

Icons on the graphical abstract: icon made by smashicons featuring waterproofness; icon made by freepic featuring wind; icon made by surang featuring chemistry; icon made by Good Ware featuring snowflake from www.flaticon.com.

Funding

The writing of this publication was funded by the University of Sopron [grant number: EFOP-3.6.1] and made in frame of the ”EFOP-3.6.1-16-2016-00018 – Improving the role of research + development + innovation in higher education through institutional developments assisting intelligent specialization in Sopron and Szombathely”.

References

- 1.Wickert A.D. The Alog: inexpensive, open-source, automated data collection in the field. Bull. Ecol. Soc. Am. 2014;95(2):166–176. doi: 10.1890/0012-9623-95.2.68. [DOI] [Google Scholar]

- 2.P. Valent, M. Danáčová, R. Výleta, Calibration of a low-cost 3D printed rain gauge utilizing an open-source Arduino platform, in: Proceedings of the 17th International Multidisciplinary Scientific GeoConference (SGEM). ISBN: 978-619-7408-04-1.

- 3.Damase T.R., Stephens D., Spencer A., Allen P.B. Open source and DIY hardware for DNA nanotechnology labs. J. Biol. Methods. 2015;2(3):e24. doi: 10.14440/jbm.2015.7210.14440/jbm.2015.72.s30210.14440/jbm.2015.72.s30110.14440/jbm.2015.72.s300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Wijnen B., Anzalone G.C., Pearce J.M. Open-source mobile water quality testing platform. J. Water Sanit. Hyg. Dev. 2014;4(3):532–537. [Google Scholar]

- 5.Bravo-Martinez J. Open-source 3D-printed 1000 µL micropump. HardwareX. 2018;3:110–116. [Google Scholar]

- 6.Shafique U., Anwar J., uz-Zaman W., Rehman R., Salman M., Dar A., Jamil N. Forced migration of soluble and suspended materials by freezing front in aqueous systems. J. Hydro-Environ. Res. 2012;6(3):221–226. [Google Scholar]

- 7.Gay G., Lorain O., Azouni A., Aurelle Y. Wastewater treatment by radial freezing with stirring effects. Wat. Res. 2003;37:2520–2524. doi: 10.1016/S0043-1354(03)00020-4. [DOI] [PubMed] [Google Scholar]

- 8.Chowdhury M.R., Steffes J., Huey B.D., McCutcheon J.R. 3D printed polyamide membranes for desalination. Science. 2018;361(6403):682–686. doi: 10.1126/science.aar2122. [DOI] [PubMed] [Google Scholar]

- 9.Siddiqui A., Farhat N., SzS B., Linares L.V., Picioreanu C., Kruithof J.C., van Loosdrecht M.C.M., Kidwell J., Vrouwenvelder J.S. Development and characterization of 3D printed feed spacers for spiral wound membrane systems. Wat. Res. 2016;91:55–67. doi: 10.1016/j.watres.2015.12.052. [DOI] [PubMed] [Google Scholar]

- 10.Lee J.Y., Tan W.S., An J., Chua C.K., Tang C.Y., Fane A.G., Chong T.H. The potential to enhance membrane module design with 3D printing technology. J. Membr. Sci. 2016;499:480–490. [Google Scholar]

- 11.G.D. Goh, Y.L. Yap, H.K.J. Tan, S.L. Sing, G.L. Goh, W.Y. Yeong, Process-structure-properties in polymer additive manufacturing via material extrusion: a review. Crit. Rev. Solid State 45(2) 113–133. https://doi.org/10.1080/10408436.2018.1549977

- 12.Shafique U., Anwar J., Ali Munawar M., Zaman W.-u., Rehman R., Dar A., Salman M., Saleem M., Shahid N., Akram M., Naseer A., Jamil N. Chemistry of ice: migration of ions and gases by directional freezing of water. Arab. J. Chem. 2016;9:S47–S53. [Google Scholar]

- 13.Lorain O., Thiebaud P., Badorc E., Aurelle Y. Potential of freezing in wastewater treatment: soluble pollutant applications. Wat. Res. 2001;35(2):541–547. doi: 10.1016/s0043-1354(00)00287-6. [DOI] [PubMed] [Google Scholar]

- 14.Gao W. Freezing as a combined wastewater sludge pretreatment and conditioning method. Desalination. 2011;268(1-3):170–173. [Google Scholar]

- 15.Xue S., Wen Y., Hui X., Zhang L., Zhang Z., Wang J., Zhang Y. The migration and transformation of dissolved organic matter during the freezing processes of water. J. Environ. Sci.-China. 2015;27:168–178. doi: 10.1016/j.jes.2014.05.035. [DOI] [PubMed] [Google Scholar]

- 16.Gardolinski P.C.F.C., Hanrahan G., Achterberg E.P., Gledhill M., Tappin A.D., House W.A., Worsfold P.J. Comparison of sample storage protocols for the determination of nutrients in natural waters. Wat. Res. 2001;35(15):3670–3678. doi: 10.1016/s0043-1354(01)00088-4. [DOI] [PubMed] [Google Scholar]

- 17.Zhang J.-Z., Ortner P.B. Effect of thawing condition on the recovery of reactive silicic acid from frozen natural water samples. Wat. Res. 1998;32(8):2553–2555. [Google Scholar]

- 18.Cocovi-Solberg D.J., Rosende M., Michalec M., Miró M. 3D printing: the second dawn of lab-on-valve fluidic platforms for automatic (bio) chemical assays. Anal. Chem. 2018;91(1):1140–1149. doi: 10.1021/acs.analchem.8b04900. [DOI] [PubMed] [Google Scholar]

- 19.Heikkinen I.T.S., Kauppinen C., Liu Z., Asikainen S.M., Spoljaric S., Seppälä J.V., Savin H., Pearce J.M. Chemical compatibility of fused filament fabrication-based 3-D printed components with solutions commonly used in semiconductor wet processing. Addit. Manuf. 2018;23:99–107. [Google Scholar]

- 20.Dragone V., Sans V., Rosnes M.H., Kitson P.J., Cronin L. 3D-printed devices for continuous-flow organic chemistry. Beilstein J. Org. Chem. 2013;9(1):951–959. doi: 10.3762/bjoc.9.109. [DOI] [PMC free article] [PubMed] [Google Scholar]