Abstract

The use of dried grape pomace (DGP) as a bulking agent for partly substitution of sugar, milk powder and whey powder in compound chocolate (CC) was investigated. D-optimal mixture design was used to determine the effect of composition on the particle size, flow behaviour (Casson yield value and plastic viscosity), as well as total phenolic and resveratrol contents before and after in vitro digestion. The various models (linear, quadratic and cubic) which were identified as significant (P < 0.05) were used in this study. As a result, DGP was found suitable to be used in CC as a bulking agent to partially substitute sucrose, milk powder and whey powder to increase functional properties and decrease the cost of the CC. For CC with the most acceptable rheological properties and a satisfactory level of TPC and resveratrol, optimum usage levels of DGP were identified as 7.1% to 10.0%. Further studies will require to modify flow behaviours by optimizing the particle size of pomace.

Electronic supplementary material

The online version of this article (10.1007/s13197-021-05180-8) contains supplementary material, which is available to authorized users.

Keywords: Grape pomace, Compound chocolate, Functional food, Mixture design, Optimization

Introduction

There is a significant increase in the demand and interest for healthy products. For this purpose, re-formulation and the use of bioactive components are required. However, for the success of novel products, there should be no significant deviations in terms of quality features with conventional products. Furthermore, it is of great importance that costs and end-product prices are reasonable (Ortega-Heras et al. 2019). The components that can be used for this purpose include industrial fruit wastes. The use of these wastes and by-products in new foodstuffs for economic reasons, cost reduction, functional property development, and nutritional value is becoming widespread (Beres et al. 2019).

One of the important trends in the food industry is the use of natural materials with high dietary fibres content and high antioxidant activity in the formulation of functional food (Mildner-Szkudlarz et al. 2012). The health benefits of fruit waste are known, but the valorisation of waste products in the food industry is not sufficiently investigated. During the fruit and vegetable processing, about 10–35% of raw materials are separated as waste products. Due to the high moisture content of fruit wastes, pomace can be rapidly exposed to microbiological development. The improper storage conditions and delays in processing, can increase the risk of microbial deterioration (Majerska et al. 2019).

Grape is one of the most common agricultural products and 80% of this fruit is used in wine production (Mildner-Szkudlarz et al. 2012). Grape pomace, which can also be defined as press residue, mainly consists of crust, stalk, and seed which in wine industry, constitutes approximately 20% of the mass of grape. Discharge of grape wastes into the environment can lead to environmental problems such as increased soil acidity, phyto-toxicity, and methane gas production (Iora et al. 2015). Therefore, adding value to wine and grape juice wastes is important for environmental safety and waste management. Generally, industrial grape waste is used as the animal feed or compost without the need for any further processes (Beres et al. 2019).

Furthermore, dried grape pomace (DGP) has a high phenolic, protein and fibres content and can be used in the composition of foods to improve nutritional quality of products (Iora et al. 2015). Especially grape peel is an ideal source for dietary fibres and many phenolic compounds such as flavonols, flavanols, anthocyanins and proanthocyanidins (mono-, oligo- and polymeric proanthocyanidins) (Majerska et al. 2019). Proanthocyanidins have shown important properties such as anti-viral, anti-bacterial, anti-oxidant, and enzyme-inhibition activity (Cadiz-Gurrea et al. 2017). However, the level and composition of them depends on the grape type, the climate of the growing region, and the technique of wine production (Mildner-Szkudlarz et al. 2012). Besides, about 70% of grape polyphenols remain in the grape pomace after wine production, and this waste material can be used as natural colorant, antioxidant, and preservative agents (Beres et al. 2019).

Enrichment of foodstuffs with fibre is an acceptable approach by consumers therefore, many authors have studied about use of grape pomace for enrichment of different products such as pasta (San’Atana et al. 2014), yoghurt and salad dressing (Tseng and Zhao 2013), bakery products (Mildner-Szkudlarz et al. 2012), and meat products (Sanchez-Alonso et al. 2007). Nevertheless, the use of grape pomace in chocolate and derivative products has been investigated in a limited number of studies. Bonarius et al. (2014) investigated the possibility of using grape pomace to replace sucrose in chocolate products. In this study, the addition of lecithin decreased the Casson yield value in the control sample but did not change this parameter in the samples containing grape pomace. In our knowledge, research on the using grape pomace has been mostly restricted to conventional chocolate, not compound chocolate. Compound chocolate (CC) is a chocolate-derived product including vegetable fats, especially a combination of palm stearin and palm olein. Compound chocolate is produced as an alternative to conventional chocolate due to its lower cost. Therefore, according to growing demand by consumer for low-cost and low-calorie food enriched by bioactive components, identifying the bulking agents (from waste products) for CC is important.

The aim of this research was to replace sugar, milk powder, and whey powder in CC formulation with grape pomace to reduce the product cost and provide waste management. Furthermore, some quality properties and health related aspect such as total phenolic content, resveratrol content and in vitro digestion were evaluated.

Materials and methods

Materials and formulation

The red grape pomace of Cabernet Sauvignon from the wine process (2018 campaign) was supplied by a national winery, located in Izmir, Turkey. The material was dried to a moisture content of about 5% at 60 °C. Stems and seeds were removed manually from dried grape pomace. Dried grape pomace (DGP) (0.00–15.0 g/100 g), cocoa butter replacer (Trio30 and Unika44, AAK, Istanbul, Turkey) (31.44 g/100 g), sugar powder (SMS Kopuz, Istanbul, Turkey) (25.0–40.0 g/100 g), cocoa powder (Altinmarka, Istanbul, Turkey) (7.00 g/100 g), skimmed milk powder (MP) (Enka, Konya, Turkey) (3.00–10.50 g/100 g), whey powder (WP) (Enka, Konya, Turkey) (3.00–10.50 g/100 g), soy lecithin (Brenntag Chemistry, Istanbul, Turkey) (0.40 g/100 g), sodium chloride (Salina, Konya, Turkey) (0.03 g/100), polyglycerol polyricinoleate (PGPR) (Palsgaard, Zierikzee, Netherlands) (0.10 g/100 g) and ethyl vanillin (Ekin Chemistry, Istanbul, Turkey) (0.03 g/100 g) were used in this study.

The compound chocolate preparation

The CC samples were prepared by using a pilot-scale ball-mill (Alpy, Istanbul, Turkey) according to the method described by (Toker et al. 2017). Each sample group was produced in lots of 2 kg using the formulations presented in Table 1. Refinining-conching time and shaft speeds were 2 h and 60 rpm, respectively, at 45 °C. Molten CC was cooled to 35 °C for moulding. The moulding was performed in polycarbonate chocolate moulds (80 × 40x4 mm) which preheated to 35 °C. The moulded CC samples were cooled for 30 min in cooling chambers set at 10 °C. The cooled CC samples were removed from the moulds, coated with aluminium foils and were stored at temperatures between 13and 15 °C, therefore prevented from light and heat prior to analysis.

Table 1.

Study design and amounts of independent variables

| Sample | Run | Coded values | Real values (g/100 g) | ||||

|---|---|---|---|---|---|---|---|

| A | B | C | Sugar | MOP | DGP | ||

| GC1 | 1 | 0.656 | 0.098 | 0.246 | 40.000 | 6.0060 | 14.994 |

| GC2 | 2 | 0.631 | 0.344 | 0.025 | 38.501 | 21.000 | 1.4990 |

| GC3 | 3 | 0.517 | 0.344 | 0.139 | 31.547 | 21.000 | 8.4530 |

| GC4 | 4 | 0.570 | 0.265 | 0.165 | 34.758 | 16.187 | 10.055 |

| GC5 | 5 | 0.614 | 0.227 | 0.159 | 37.452 | 13.841 | 9.7070 |

| GC6 | 6 | 0.656 | 0.227 | 0.117 | 40.000 | 13.862 | 7.1380 |

| GC7 | 7 | 0.410 | 0.344 | 0.246 | 25.004 | 21.000 | 14.996 |

| GC8 | 8 | 0.526 | 0.228 | 0.246 | 32.114 | 13.886 | 15.000 |

| GC9 | 9 | 0.588 | 0.316 | 0.096 | 35.867 | 19.275 | 5.8580 |

| GC10 | 10 | 0.612 | 0.185 | 0.203 | 37.353 | 11.258 | 12.390 |

| GC11 | 11 | 0.631 | 0.344 | 0.025 | 38.501 | 21.000 | 1.4990 |

| GC12 | 12 | 0.485 | 0.302 | 0.213 | 29.611 | 18.400 | 12.989 |

| GC13 | 13 | 0.656 | 0.098 | 0.246 | 40.000 | 6.0060 | 14.994 |

| Control | 40.000 | 21.000 | 0.0000 | ||||

MOP, milk originated powders as total skimmed milk powder and whey powder in equal amounts; DGP, dried grape pomace

Characterization of dried grape pomace

Solid matter, ash, protein, fat contents of DGP were determined by using the method used by Acan et al. (2021). The sugar profile as glucose, fructose, xylose, and sucrose contents was analysed by using HPLC-RID (Agilent 1100, USA) and Hypersil APS-2 (5 µm, 100 × 3.0 mm) column according to the methodology described by (Di Mattia et al. 2014).

Determination of particle size

The particle size as D90 value of CC samples was measured with a precision of 0.001 mm using a micrometre (Mitutoyo, Japan).

Determination of flow behavior

Casson yield and plastic viscosity values were determined according to the method described by Toker et al. (2017) and by using stress and strain-controlled rheometer (Anton Paar, MCR 302, Graz, Austria) equipped with parallel plate configuration and Peltier heating/cooling system. Prior to rheological analyses, the samples were melted at 45 °C using a water bath. The data obtained in the 4th stage were fitted to the Casson model as described at Eq. 1 and the model parameters, yield stress (τ0) and plastic viscosity (ηpl) were calculated using the software.

| 1 |

where τ, τ0, ηpl, and γ represent shear stress (Pa), yield stress (Pa), plastic viscosity (Pa.s) and shear rate (1/s), respectively (Rao, 1999).

Total phenolic content

To determine the total phenolic content (TPC), extraction of DGP and compound chocolate samples were performed by making some changes in the method applied by (Di Mattia et al. 2014). A total of 5 g of ground sample and 25 mL of hexane were mixed with a shaker at room temperature for 1 h and then centrifuged at 9000 rpm for 5 min. The supernatant of samples was discarded and left for 4 h in an oven set at 40 °C to evaporate hexane residue. 2 g of sample was taken and 10 mL of acetone/water/acetic acid (70/29.8/0.2, v/v/v) solution was added. The mixture was homogenized in glass tubes sealed with parafilm in an ultrasonic water bath at 40 °C for 1 h. The mixture was filled into the flask and centrifuged at 9000 rpm for 5 min and the upper phase was passed through a 0.22 µm filter with the help of a syringe.

TPC of samples was determined using the method applied by (Singleton and Rossi 1965). 2.5 mL of 0.2 N Folin solution was added to 0.5 mL of sample extract and then 2 mL of 7.5% sodium carbonate solution was added to extract and left for 30 min at room temperature at the darkness. The absorbance of the samples was measured by spectrophotometer (UV-1800, Shimadzu, Kyoto, Japan) at 760 nm. The total amount of phenolic substances in samples was calculated in mg Gallic acid equivalent (GAE) (mg GAE/kg). Equation 2 obtained from the calibration curve was used to determine the TPC.

| 2 |

The resveratrol content of samples

To determine the resveratrol content, extraction of CC samples was performed according to the method developed by (Romero-Pérez et al. 2001) with some modifications. 20 mL of 70% EtOH was added to 4 g of the sample and vortexed for 1 min. The vortexed samples were covered with parafilm and kept in a shaking water bath at 40 °C for 2 h at 150 rpm. At the end of the time, 20 mL of hexane (100%) was added to the samples and vortexed for 1 min prior to leaving in the shaking water bath at room temperature for 1 h at 150 rpm. Falcon tubes were centrifuged at 9000 rpm for 5 min. Extracts were filled into vials by passing 0.45 µm filters and injected into HPLC (LC 20A, Shimadzu, Kyoto, Japan) equipped with a fluorescence detector (RF-20A). The amount of resveratrol was determined in gradient elution system (B 20% (0.00 min) → 50% (4.00 min) → 20% (4.01)) at 300 nm excitation, 386 nm emission wavelength and using GIST C18 (100 × 2.1 mm, 2 µm) column. Mobile phase A was acetonitrile/0.1% o-phosphoric acid solution (5/95 v / v) and mobile phase B was acetonitrile/0.1% o-phosphoric acid solution (80/20, v/v), column temperature was 50 °C, flow rate was 0.6 ml / min, and injection volume was 2 µL.

Simulated in vitro digestion

Bioaccessibility analysis was performed in terms of total phenolic and resveratrol content in CC samples by the in vitro digestion method described by (Lee et al. 2016) with some modifications. Synthetic digestion juices were prepared at the concentrations and pH specified in Supplementary File 1 and 2 includes in vitro digestion steps of compound chocolate samples.

Experimental design

D-optimal mixture design by a statistical package, Design-Expert (Stat-Ease Inc. version 7.0, Minneapolis) was used in order to determine the influence of three independent variables on the model system properties, consisting of 13 experiments. The D-optimal design is constructed to minimize the general variance of the predicted regression coefficient and maximize the determinant of the information matrix which is useful for restricted surfaces (Spanemberg et al. 2019). The effect of dried grape pomace (C) replacement by sugar (A) and milk originated powders (MOP) (B = MP + WP, in equal amounts) on the particle size and rheological properties, total phenolic content, and resveratrol content of the CC samples besides in vitro digestion were evaluated. Component proportions were expressed as fractions of the mixture with a sum (A + B + C) of 61 g. Considering results of preliminary sample preparations and grape pomace using advice of previous studies (Mildner-Szkudlarz et al. 2012; Ortega-Heras et al. 2019), the quantity of DGP, sugar and MOP were restricted between 0.0–15.0 g/100 g, 25.0–40.0 g /100 g and 6.0–21.0 g/100 g, respectively. Also, the study design and amount of ingredients were detailed in Table 1.

Data analysis

Design Expert (Stat-Ease Inc. version 7.0, Minneapolis) program was used for data analyses. Regression coefficients of linear, quadratic, cubic and interaction terms were determined and factors that were insignificant for the model were removed by backward elimination regression (P > 0.1).

Results and discussion

Characterization of DGP

The amounts of solid, fat, protein and ash were determined from the DGP samples and were shown in Supplementary File 3. Before the grinding process, the dry matter could reach to the desired dry matter content. In addition, glucose, sucrose, fructose, and xylose levels were measured to determine the sugar profile. In red wine production, fermentable sugars may not be present in pomace because they are converted to alcohol (Deaimici et al. 2016). However, the sugar level and composition in the pomace were found remarkable in this study. The total fat and protein ratios of the pulp samples are consistent with those found in previous studies (Deng et al. 2011; Iora et al. 2015). The TPC and resveratrol levels were examined as bioactive compounds (Supplementary File 3). In the drying of the grape pomace, the bioactive component should be taken into consideration and high temperature–time should not be applied. Therefore, chocolate in which relatively low heat treatment conditions are applied may be the right choice for optimal utilization of these bioactive compounds in the grape pomace composition. A study showed that the total amount of phenolic compounds of Cabarnet sauvignon pomace was 51,010 mg GAE/kg which was in agreement with our study while the ash content was higher than our result (Iora et al. 2015). However, the amount of ash in red grape pomace was reported as 8.12 g/100 g (Zhao et al. 2017). The difference in ash contents may be related to the mineral profile, soil composition, cultivation practices, origin and variety (Beres et al. 2019).

Particle of size of compound chocolate

The correct particle size is very important in production of chocolate products because it has a significant effect on the textural (Kieran Keogh et al. 2013), rheological (Jolly et al. 2003), color (Mexis et al. 2010), water activity (Konar 2013), and melting properties (Do et al. 2007). D90 values of the CC samples were determined between 25.6 and 150.4 µm with the highest value at the GC8 coded sample and the lowest particle size at the control sample (Table 2).

Table 2.

The results of particle size, Casson model and melting parameters and bioaccessibility of compound chocolate samples

| Samples | Particle size (µm) | Casson model parameters | % Bioaccessebility | |||

|---|---|---|---|---|---|---|

| τ0 (Pa) | ηpl (Pa s) | R2 | Total phenolic content | Resveratrol content | ||

| Control | 25.6 ± 2.2 | 2.21 ± 0.15 | 1.37 ± 0.02 | 0.9882 | 215.7 | – |

| GC1 | 145.3 ± 9.3 | 3.06 ± 0.12 | 1.76 ± 0.11 | 0.9898 | 25.9 | 79.9 |

| GC2 | 40.0 ± 3.6 | 2.29 ± 0.03 | 1.06 ± 0.01 | 0.9931 | 84.0 | 56.6 |

| GC3 | 49.0 ± 6.7 | 2.62 ± 0.10 | 1.36 ± 0.04 | 0.9917 | 34.9 | 97.0 |

| GC4 | 73.6 ± 6.5 | 2.63 ± 0.11 | 1.60 ± 0.30 | 0.9909 | 35.0 | 69.3 |

| GC5 | 77.2 ± 6.3 | 2.66 ± 0.04 | 1.79 ± 0.03 | 0.9916 | 35.8 | 55.5 |

| GC6 | 64.2 ± 4.1 | 2.31 ± 0.09 | 1.39 ± 0.02 | 0.9923 | 33.8 | 32.3 |

| GC7 | 119.3 ± 36.1 | 2.62 ± 0.21 | 1.98 ± 0.22 | 0.9926 | 29.0 | 17.1 |

| GC8 | 150.4 ± 9.7 | 1.19 ± 0.01 | 3.60 ± 0.09 | 0.9889 | 24.8 | 41.2 |

| GC9 | 43.3 ± 5.9 | 2.30 ± 0.05 | 1.19 ± 0.01 | 0.9933 | 36.1 | 98.8 |

| GC10 | 78.6 ± 6.6 | 3.09 ± 0.13 | 2.13 ± 0.07 | 0.9911 | 23.3 | 93.0 |

| GC11 | 41.4 ± 2.7 | 2.62 ± 0.18 | 1.56 ± 0.04 | 0.9894 | – | – |

| GC12 | 81.7 ± 5.0 | 2.18 ± 0.04 | 1.75 ± 0.00 | 0.9935 | 32.3 | 40.3 |

| GC13 | 147.5 ± 4.4 | 4.12 ± 0.11 | 1.92 ± 0.01 | 0.9905 | 25.8 | 82.3 |

τ0: Yield stress, ηpl: Plastic viscosity, R2: Determination coefficient

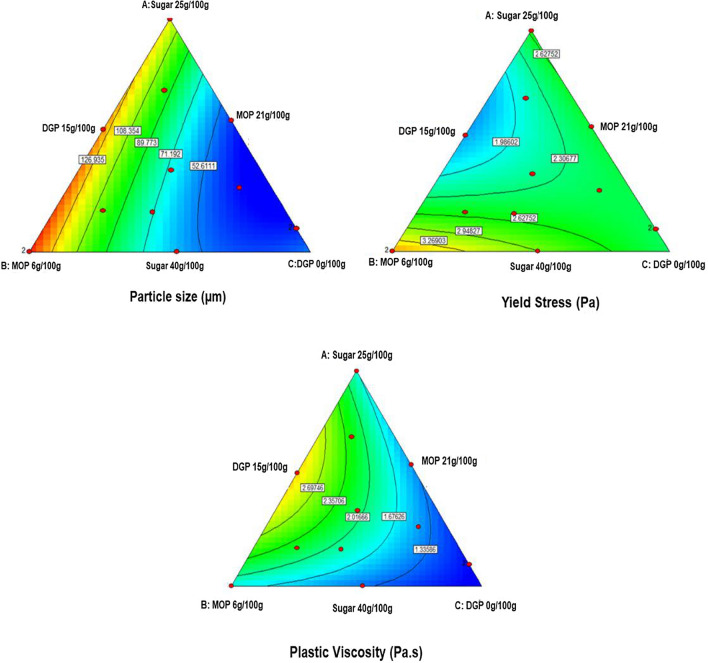

The effect of composition on particle size was successfully determined by using a quadratic model particle size: 120.65A + 145.52B + 52.95C − 186.81AC − 152.39BC, with a high R2 value as 0.9431. The model expressing the effect of DGP on the particle size of CC and lack of fit were found to be insignificant (P < 0.05). The interaction between two variables AC and BC on the particle size was identified as significant (P < 0.05). The interaction between sugar and milk originated powders (AB), was excluded from the model by backward elimination regression (BER) since the effect of the binary combination was insignificant (P > 0.1). As the amount of DGP increased in the formulation, particle size values increased as well. As seen in Fig. 1, particle size values were found to be much higher at the points where the DGP amount was maximum and the MOP amount was minimum. In a previous study, the result of particle size in the milk chocolate prepared with lyophilized grape powder was demonstrated that grape powder significantly acts as a bulking agent and increased particle size (Carvalho et al. 2018). Coarse particles form a sandy structure and affect the mouth feel, while small particles determine flow properties (Beckett 2008). Acan et al. (2021) demonstrated that the DGP particles with irregular shapes and a high level of particle size distribution have an important effect on the rheological properties of chocolate spread. However, during the processing of the grape pomace, the initial particle size of pomace can be further reduced by increasing the grinding speed, time or number of grinding steps.

Fig. 1.

Effect of grape pomace on compound chocolate samples on particle size, yield stress and plastic viscosity values

Flow behaviour

Shear stress values of the CC samples as a function of shear rate at 40 °C are shown in Supplementary File 4. Due to the shear stress of the DGP added CC samples against the applied shear rate, the curve was directed to the x axis. The apparent viscosity of CC samples decreased against increasing shear rate which indicated that the CC samples had shear thinning behaviour. The results were in agreement with the previous study which showed that molten chocolate had shear thinning behaviour (Toker 2016; Pirouzian et al. 2016, 2017). To determine yield stress and plastic viscosity, the Casson model which had high R2 values (0.988–0.994) was used according to the standard method of the International Confectionery Association. The yield stress and plastic viscosity values were varied between 1.19–4.12 Pa, and 1.06–3.60 Pa s, respectively.

The effect of grape pomace on yield value and Casson plastic viscosity of CC samples were explained using cubic models for yield stress: 2.62A + 4.22B + 2.37C − 8.31AB − 3.60BC + 24.14ABC and plastic viscosity: 1.84A + 1.81B + 1.18C + 7.02AB − 22.78ABC − 5.25AB(A–B), with R2 values 0.9372 and 0.9343, respectively (Table 3). The model expressing the effect of DGP on the yield stress and plastic viscosity of CC and lack of fit value was insignificant (P > 0.05). The effect of Sugar-MOP (AB) and MOP-DGP (BC) binary combinations and Sugar-MOP-DGP (ABC) triple combination of the yield stress value were significant in terms of the model (P < 0.05). The effect of Sugar-MOP (AB) binary combination and Sugar-MOP-DGP (ABC) triple combination on Casson plastic viscosity were found to be significant in the model (P < 0.05).

Table 3.

ANOVA for particle size, rheological and melting properties, TPC and resveratrol contents

| Particle size | Casson parameters | Total phenolic content | Resveratrol content | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield stress | Plastic viscosity | Before digestion | After digestion | Before digestion | After digestion | |||||||||

| DF | F | DF | F | DF | F | DF | F | DF | F | DF | F | DF | F | |

| Model | 4 | 33.17* | 5 | 17.91* | 5 | 19.92* | 2 | 430.43* | 2 | 10.27* | 3 | 9.81* | 4 | 66.20* |

| Linear Mixture | 2 | 57.15* | 2 | 12.21* | 2 | 21.96* | 2 | 430.43* | 2 | 10.27* | 2 | 12.28* | 2 | 74.92* |

| AB | 1 | BER | 1 | 59.03* | 1 | 52.97* | – | – | – | – | – | – | – | – |

| AC | 1 | 9.85* | – | – | – | – | – | – | – | – | 1 | 4.85 | 1 | 60.22* |

| BC | 1 | 10.89* | 1 | 11.87* | BER | BER | – | – | – | – | BER | BER | 1 | 40.11* |

| ABC | – | – | 1 | 15.09* | 1 | 19.22* | – | – | – | – | – | – | – | – |

| AB(A–B) | – | – | BER | BER | 1 | 3.76 | – | – | – | – | – | – | – | – |

| AC(A–C) | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| BC(B–C) | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Residual | 8 | 6 | 7 | 10 | 10 | 9 | 8 | |||||||

| Lack of Fit | 6 | 117.24* | 5 | 0.96 | 5 | 0.51 | 8 | 8 | 7 | 6 | ||||

| Pure Error | 2 | 1 | 2 | 2 | 2 | 2 | 2 | |||||||

| Cor Total | 12 | 11 | 12 | 12 | 12 | 12 | 12 | |||||||

| R2 | 0.9431 | 0.9372 | 0.9343 | 0.9885 | 0.6726 | 0.7657 | 0.9707 | |||||||

| Adjusted-R2 | 0.9147 | 0.8849 | 0.8874 | 0.9862 | 0.6071 | 0.6876 | 0.9560 | |||||||

| Predicted-R2 | 0.8986 | 0.0668 | 0.5606 | 0.9818 | 0.5363 | 0.6007 | 0.9059 | |||||||

| Adequate Precision | 14.008 | 18.101 | 16.135 | 50.363 | 8.58 | 8.52 | 25.625 | |||||||

A; sugar, B; Milk originated powders as total mass of skimmed milk and whey powders equally, C; Dried grape pomace, BER; Backward elimination regression, TPC; Total phenolic content

*P < 0.05

If the sugar is substituted by an alternative substance in the chocolate composition, the similar flow characteristics are important for product quality and the efficiency of the different process steps. However, as the amount of DGP used in the CC formulation increased, plastic viscosity value increased. Besides, the decreases in MOP and increases in DGP and sugar, increased the yield stress. The rheological properties of CC were influenced by the particle size of the waste material. Many factors, such as the amount and distribution of fat in the formulation, the number of solid particles, the size, and shape of the particles and the type of emulsifier used, may affect the flow behaviour of chocolate products (Glicerina et al. 2013). According to results of this study, the use of DGP in formulation up to a maximum of 10% showed no major differences in the Casson viscosity and yield stress values with conventional chocolate.

Grape pomace improved rheological properties in bakery products (Majerska et al. 2019). It was reported that replacement of wheat flour by grape seed flour at different ratios, improved the rheological properties of dough (Mironeasa et al. 2012). Also, one study demonstrated that the substitution of flour with white and red grape pulp at the ratio of 10% and 20% in the muffins prepared with whole wheat flour, caused changes in the quality parameters that could be associated with the rheological properties of the dough (Ortega-Heras et al. 2019). The fiber content and particle size properties of grape pomace can be correlated with the results of rheological properties. Also, the activity of the surfactants used in formulation and coating the particles with oil has an important effect on the flow behavior.

Acan et al. (2021) used 0.23–15.0 g/100 g grape pomace at the formulation of chocolate spread and modeled the rheological behavior of samples with the Ostwald-de Waele model. The authors reported the shear-thinning behavior of chocolate products affecting both processing and sensory properties. Also, they mentioned that irregular shapes and a high level of particle size distribution may affect the rheological properties of chocolate products.

Bonarius et al. (2014) stated that the Casson plastic viscosity value increased due to the use of grape pomace, which may be due to the irregular shape of the pomace particles or the high proportion of small particles resulting in a high particle surface/volume ratio. Furthermore, completely substituting sucrose with grape pomace is a difficult practice due to its effects on rheological properties. But partial substitution and use of surfactant may ensure acceptable flow properties.

Bioaccessibility of bioactive compounds

Total phenolic content (TPC)

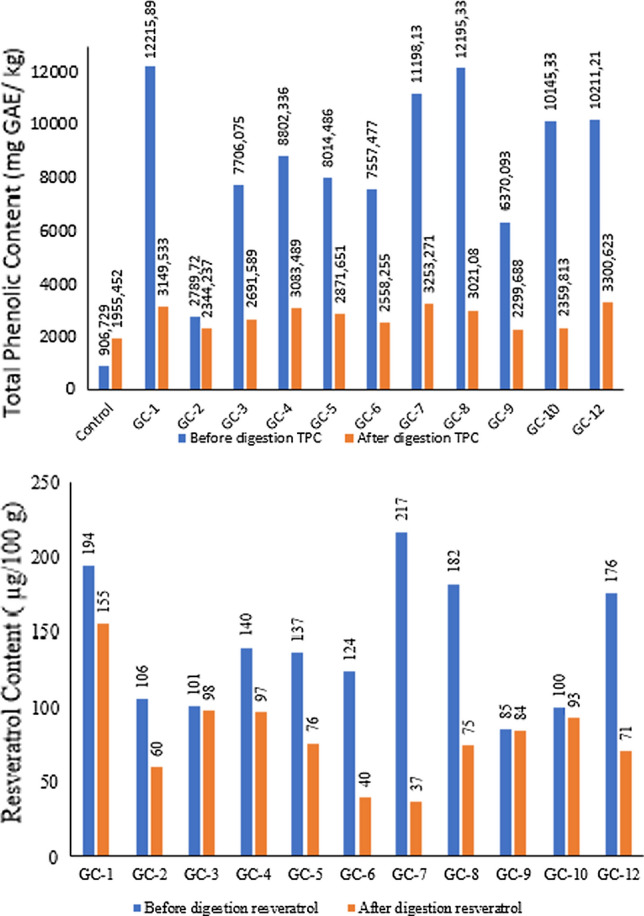

Pre-digestion TPC results of CC samples ranged between 2789.72 and 12,215.89 mg GAE/kg, post-digestion TPC results 2299.69–3300.62 mg GAE/kg and % bioaccessibility values ranged between 23.26 and 4.03%. The pre-digestion, post-digestion and % bioaccessibility values for the control sample were 906.73 mg GAE/kg, 1955.45 mg GAE/kg and 215.66%, respectively. TPC value was found to be highest as expected in GC1, GC7, GC8 and GC13 which containing the highest DGP (Table 3). Acan et al. (2021) reported that the TPC content of chocolate spread enriched with DGP ranged from 3415 to 13,754 mg GAE/kg and the digestibility of the products was ranged from 25 to 84%. The level of TPC before and after digestion in our study is slightly lower than the results of Acan et al. (2021) which may be related to the differences in the formulation.

Generally, fruit-based dietary fibers have a more nutritional value than cereal-derived dietary fibers because they contain certain amounts of bioactive compounds such as polyphenols and carotenoids (Mildner-Szkudlarz et al. 2012). In addition, Cabarnet sauvignon pomace has higher total phenolic, flavonoid, monomeric anthocyanin, and dietary fiber content and lower antioxidant activity than some other commonly processed red grape pomace such as Tanat and Merlot (Iora et al. 2015). Therefore, Cabarnet sauvignon pomace can be defined as an ideal source for increasing the TPC content of CC products. Grape pomace and wine wastes have been successfully used for enrichment the different foodstuffs with TPC components (Maner et al. 2017).

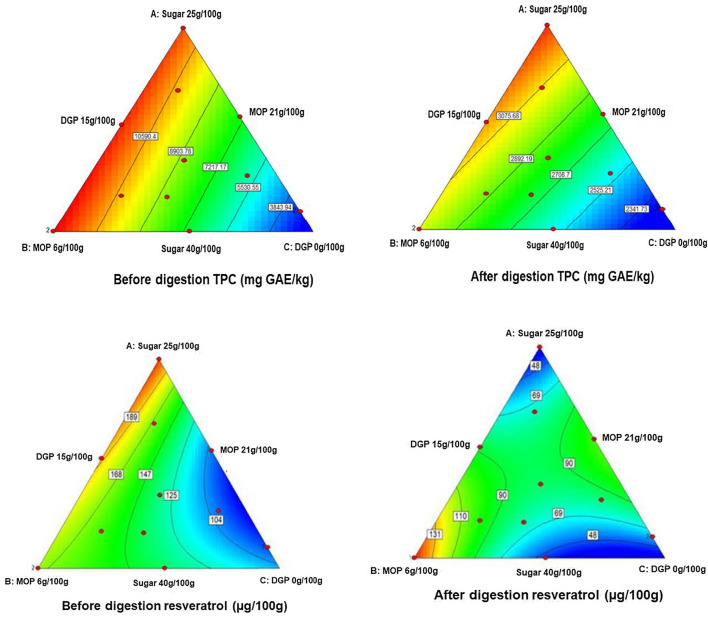

The phenolic content present in the control sample comes from cocoa beans. However, origin, post-harvest conditions, and chocolate processes have effects on the TPC and phenolic profile of the final product. As shown in Fig. 2, a high amount of phenolic substances in CC samples decreased as a result of in vitro digestion. One study showed the losses of grape pomace phytochemicals after in vitro gastrointestinal digestion (Correa et al. 2017). Alkaline pH, some compounds in the composition, oxidation, and degradation during heat treatment and mixing can cause losses in phenolic compounds (Mildner-Szkudlarz et al. 2012).

Fig. 2.

Total phenolic (mg GAE/kg) and resveratrol (µg/100 g) contents of compound chocolate samples

Health effects of phenolic compounds depend on their intake in free or bound form. For example, bound phenolics have chemopreventive activity against colon cancer and can act as local antioxidants in the gastrointestinal tract. However free and soluble phenolics are easily absorbed in the stomach and small intestine, dispersed throughout the system, and their benefits are related to their scavenging capacity (Chandrasekara and Shahidi, 2011). Generally, the undissolved form of phenolic compounds, make a covalent binding with cellulose, hemicellulose, lignin, and pectin in the cell wall. The absorption of bound phenolics differs from free compounds. This absorption is affected by the structure of the compound, conjugation with other phenolics, molecular size, solubility, and glycosylation. The partial release takes place in the gastrointestinal lumen due to the interaction with microorganisms in the gastrointestinal lumen, metabolization of compounds by enzymes and carrier molecules. Approximately 5–10% of dietary phenolic is absorbed in the small intestine (Beres et al., 2019).

Besides, grape pomace is an ideal source for fibers and has many health benefits (Majerska et al. 2019). Lignin as a dietary fiber is the main fraction of grape pomace (Mildner-Szkudlarz et al. 2012). Beres et al. (2019) suggested that the digestive system may act as an extraction system to increase accessibility and antioxidant capacity of bioactive compounds. Therefore, the use of dried grape pomace in the food matrix may be more advantageous compared to drinking grape pomace extracts in the bioaccessibility of compounds.

TPC contents of CC samples were explained by using linear models as TPC before digestion: 11,455.34A + 12,277.01B + 2157.32C, and TPC after digestion: 3259.17A + 3015.89B + 2158.24C which were identified as significant (P < 0.05). R2 values for TPC before and after digestion were 0.9885 and 0.6726, respectively (Table 3). Low R2 values after digestion implied that composition of CC had no influence on protection or destruction of phenolics in gastrointestinal system. Figure 3 showed the effect of composition on the TPC of CC samples. TPC values of CC samples showed rise with increasing concentrations of grape pomace.

Fig. 3.

Effect of composition on total phenolic and resveratrol contents of compound chocolate

Resveratrol content

Resveratrol pre-digestion and post-digestion bioaccessibility properties in the compound chocolate matrix were shown in Table 2 and Fig. 2. Pre-digestion resveratrol content of CC samples ranged between 85 and 217 µg/100 g, whereas post-digestion contents and % bioaccessibility values ranged between 37–155 µg/100 g and 17.1–98.8%, respectively. As expected, the amount of resveratrol before digestion reached maximum levels in GC1, GC7, GC8 and GC13 samples where DGP was used in higher amounts than other samples. As shown in Fig. 2, the amount of resveratrol decreased in in vitro digested CC samples.

Resveratrol contents of CC samples were explained by using linear models as resveratrol before digestion: 210.52A + 170.42B + 107.27C − 264.93AC, and resveratrol after digestion: 29.33A + 151.74B + 33.92C + 293.31AC − 185.71BC which were identified as significant (P < 0.05). As shown in Table 3, R2 values for pre-digestion and post-digestion resveratrol content are 0.7657 and 0.9707, respectively. High R2 value for post-digestion resveratrol content demonstrated that contrary to total phenolic contents, the ingredients of CC significantly affect resveratrol digestion in gastrointestinal system. Figure 3 showed the effect of composition on the resveratrol content of CC before and after digestion. Pre-digestion provided higher amounts of resveratrol at high DGP and low sugar concentrations. After digestion, high DGP and low MOP resulted in higher resveratrol content. Our results are in agreement with the results of Acan et al. (2021) which reported that the bioaccessibility values of chocolate spread enriched with DGP ranged between 47.6 and 95.7%.

As the concentration of DGP increased, the levels of TPC and resveratrol in the product increased. Maximum levels of TPC and resveratrol in the CC samples were observed at 12.989% and 14.996% DGP concentration, respectively. Also, an increase in the DGP content of products caused a significant increase in the particle size values with the maximum (150.4 µm) at 15% DGP compared with conventional chocolate (25 µm) which represents that DGP can act as the bulking agent in the chocolate formulation.

Conclusion

As a result of developments in the food industry, it has been determined that national and international companies have requested to find low-cost bulk materials that can be used in chocolate and chocolate-derived products. The availability of inexpensive bulk materials is especially important in products produced with low cost concerns, such as compound chocolate. According to their composition, fruit by-products and industrial wastes can be defined as low-cost raw materials that can be used to enrich food formulations. An important advantage is that some of them may be ready for use only after minimal processing. In this study, standard reference chocolate was made without using DGP. The compound chocolate with DGP was successfully produced and the effect of formulation on the different properties of the product was investigated. Usage of 7.130% to 10.055% DGP in the formulation as a bulking agent was found as the optimum concentrations of DGP to produce the optimum final compound chocolate with the most acceptable rheological properties and a good level of TPC and resveratrol in the final products. Also, partially replacement of sucrose, milk powder and whey powder with DGP can decrease the final cost of chocolate and provide waste management at the industrial scale. Besides, it caused decreases in the sugar content and an increase in the level of natural functional components such as TPC and resveratrol in the product which can use to develop functional compound chocolate. However, further studies are required to modify flow behaviours of compound chocolate by optimization of dry grape pomace in terms of particle size. Finally, the sensorial organoleptic evaluation of the final product formulated for successful commercialization and marketing survey "it is worth to be buy" as well should be investigated by further studies.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Abbreviations

- DGP

Dried grape pomace

- CC

Compound chocolate

- PGPR

Polyglycerol polyricinoleate

- MP

Skimmed milk powder

- WP

Whey powder

- TPC

Total phenolic contents

Authors' contributions

NK, IP, KP and OST were responsible for conceptualization and writing of KB, MK, MG and MY were responsible for methodology and formal analysis.

Funding

This work was funded by the Scientific and Technological Research Council of Turkey (TUBITAK), Project No. TOVAG-217O054.

Declarations

Conflicts of interest

The authors confirm that they have no conflicts of interest with respect to the work described in this manuscript.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Change history

1/14/2023

The article was revised due to 4 supplement files were missed in the original publication of the article and now it has been included.

References

- Acan BG, Kilicli M, Bursa K, Toker OS, Palabiyik I, Gulcu M, Yaman M, Gunes R, Konar N. Effect of grape pomace usage in chocolate spread formulation on textural, rheological and digestibility properties. LWT Food Sci Technol. 2021;138:110451. doi: 10.1016/j.lwt.2020.110451. [DOI] [Google Scholar]

- Beckett ST. The science of chocolate. 2. UK: Royal Society of Chemistry; 2008. [Google Scholar]

- Beres C, Freitas SP, de Oliveira Godoy RL, de Oliveira DCR, Deliza R, Iacomini M, Mellinger-Silva C, Cabral LMC. Antioxidant dietary fibre from grape pomace flour or extract: does it make any difference on the nutritional and functional value? J Funct Foods. 2019;56:276–285. doi: 10.1016/j.jff.2019.03.014. [DOI] [Google Scholar]

- Bonarius GA, Vieira JB, der Goot AJ, Bodnar I. Rheological behaviour of fibre-rich plant materials in fat-based food systems. Food Hydrocoll. 2014;40:254–261. doi: 10.1016/j.foodhyd.2014.03.016. [DOI] [Google Scholar]

- Cádiz-Gurrea MDLL, Borrás-Linares I, Lozano-Sánchez J, Joven J, Fernández-Arroyo S, Segura-Carretero A. Cocoa and grape seed byproducts as a source of antioxidant and anti-inflammatory proanthocyanidins. Int J Mol Sci. 2017;18(2):376. doi: 10.3390/ijms18020376. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Carvalho JCS, Romoff P, Lannes SCDS. Improvement of nutritional and physicochemical proprieties of milk chocolates enriched with kale (Brassica olereacea var. acephala) and grape (Vitis vinifera) Food Sci Technol. 2018;38(3):551–560. doi: 10.1590/fst.15018. [DOI] [Google Scholar]

- Chandrasekara A, Shahidi F. Bioactivities and antiradical properties of millet grains and hulls. J Agric Food Chem. 2011;59(17):9563–9571. doi: 10.1021/jf201849d. [DOI] [PubMed] [Google Scholar]

- Corrêa RC, Haminiuk CW, Barros L, Dias MI, Calhelha RC, Kato CG, Correra VG, Perlta RM, Ferreira IC. Stability and biological activity of Merlot (Vitis vinifera) grape pomace phytochemicals after simulated in vitro gastrointestinal digestion and colonic fermentation. J Funct Foods. 2017;36:410–417. doi: 10.1016/j.jff.2017.07.030. [DOI] [Google Scholar]

- Deaimici KM, de Oliveria LC, da Rosa GS, de Oliveira E. Drying kinetics of fermented grape pomace: determination of moisture effective diffusivity. Revista Brasileria De Engenharia Agricola e Ambiental. 2016;20(8):763–768. doi: 10.1590/1807-1929/agriambi.v20n8p763-768. [DOI] [Google Scholar]

- Deng Q, Penner MH, Zhao Y. Chemical composition of dietary fiber and polyphenols of five different varieties of wine grape pomace skins. Food Res Int. 2011;44(9):2712–2720. doi: 10.1016/j.foodres.2011.05.026. [DOI] [Google Scholar]

- Di Mattia C, Martuscelli M, Sacchetti G, Beheydt B, Mastrocola D, Pittia P. Effect of different conching processes on procyanidin content and antioxidant properties of chocolate. Food Res Int. 2014;63:367–372. doi: 10.1016/j.foodres.2014.04.009. [DOI] [Google Scholar]

- Do TA, Hargreaves JM, Wolf B, Hort J, Mitchell JR. Impact of particle size distribution on rheological and textural properties of chocolate models with reduced fat content. J Food Sci. 2007;72(9):E541–E552. doi: 10.1111/j.1750-3841.2007.00572.x. [DOI] [PubMed] [Google Scholar]

- Glicerina V, Balestra F, Dalla Rosa M, Romani S. Rheological, textural and calorimetric modifications of dark chocolate during process. J Food Eng. 2013;119(1):173–179. doi: 10.1016/j.jfoodeng.2013.05.012. [DOI] [Google Scholar]

- Iora SR, Maciel GM, Zielinski AA, da Silva MV, Pontes PVDA, Haminiuk CW, Granato D. Evaluation of the bioactive compounds and the antioxidant capacity of grape pomace. Int J Food Sci Technol. 2015;50(1):62–69. doi: 10.1111/ijfs.12583. [DOI] [Google Scholar]

- Jolly MS, Blackburn S, Beckett ST. Energy reduction during chocolate conching using a reciprocating multihole extruder. J Food Eng. 2003;59(2–3):137–142. doi: 10.1016/S0260-8774(02)00443-0. [DOI] [Google Scholar]

- Kieran Keogh M, Murray CA, O’Kennedy BT. Effects of selected properties of ultrafiltered spray-dried milk powders on some properties of chocolate. Int Dairy J. 2013;13(8):719–726. doi: 10.1016/S0958-6946(03)00124-9. [DOI] [Google Scholar]

- Konar N. Influence of conching temperature and some bulk sweeteners on physical and rheological properties of prebiotic milk chocolate including containing inulin. Eur Food Res Technol. 2013;236(1):135–143. doi: 10.1007/s00217-012-1873-x. [DOI] [Google Scholar]

- Lee S-J, Lee S-Y, Chung M-S, Hur SJ. Development of novel in vitro human digestion systems for screening the bioavailability and digestibility of foods. J Funct Foods. 2016;22:113–121. doi: 10.1016/j.jff.2016.01.005. [DOI] [Google Scholar]

- Majerska J, Michalska A, Figiel A. A review of new directions in managing fruit and vegetable processing byproducts. Trends Food Sci Technol. 2019;88:207–219. doi: 10.1016/j.tifs.2019.03.021. [DOI] [Google Scholar]

- Maner S, Sharma A, Banerjee K. Wheat flour replacement by wine grape pomace powder positively affetcs physical, functional and sensory. Proc Natl Acad Sci India Sect B Biol Sci. 2017;87(1):109–113. doi: 10.1007/s40011-015-0570-5. [DOI] [Google Scholar]

- Mexis SF, Badeka AV, Riganakos KA, Kontominas MG. Effect of active and modified atmosphere packaging on quality retention of dark chocolate with hazelnuts. Innov Food Sci Emerg Technol. 2010;11(1):177–186. doi: 10.1016/j.ifset.2009.09.001. [DOI] [Google Scholar]

- Mildner-Szkudlarz S, Bajerska J, Zawirska-Wojtasiak R, Gorecka D. White grape pomace as a source of dietary fibre and polyphenols and its effect on physical and nutraceutical characteristics of wheat biscuits. J Sci Food Agric. 2012;93(2):389–395. doi: 10.1002/jsfa.5774. [DOI] [PubMed] [Google Scholar]

- Mironeasa S, Codina GG, Mironeasa C. The effects of wheat flour substitution with grape seed flour on the rheological parameters of the dough assessed by Mixolab. J Texture Stud. 2012;43(1):40–48. doi: 10.1111/j.1745-4603.2011.00315.x. [DOI] [Google Scholar]

- Ortega-Heras M, Gomez I, de Pablos-Alcalde S, Gonzalez-Sanjose ML. Application of the just-about-right scales in the development of new healthy whole-wheat muffins by the addition of a product obtained from white and red grape pomace. Foods. 2019;8(9):419–433. doi: 10.3390/foods8090419. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rao M. Rheology of fluid and semisolid foods principles and applications. Maryland: An Aspen Publication; 1999. [Google Scholar]

- Rasouli Pirouzian H, Peighambardoust SH, Azadmard Damirchi S. Sucrose-free milk chocolate sweetened with different bulking agents: effects on physicochemical and sensory properties. Biol for Int J. 2016;8(2):340–349. [Google Scholar]

- Rasouli Pirouzian H, Peighambardoust SH, Azadmard Damirchi S. Rheological properties of sugar-free milk chocolate: comparative study and optimization. Czech J Food Sci. 2017;35(5):440–448. doi: 10.17221/231/2016-CJFS. [DOI] [Google Scholar]

- Romero-Pérez AI, Lamuela-Raventós RM, Andrés-Lacueva C, de la Torre-Boronat MC. Method for the quantitative extraction of resveratrol and piceid isomers in grape berry skins Effect of powdery mildew on the stilbene content. J Agric Food Chem. 2001;49(1):210–215. doi: 10.1021/jf000745o. [DOI] [PubMed] [Google Scholar]

- Sanchez-Alonso I, Solas MT, Borderias AJ. Physical study of minced fish muscle with white-grape by-product added as an ingredient. J Food Sci. 2007;72(2):94–101. doi: 10.1111/j.1750-3841.2007.00273.x. [DOI] [PubMed] [Google Scholar]

- Sant'Anna V, Christiano FDP, Marczak LDF, Tessaro IC, Thys RCS. The effect of the incorporation of grape marc powder in fettuccini pasta properties. LWT Food Sci Technol. 2014;58(2):497–501. doi: 10.1016/j.lwt.2014.04.008. [DOI] [Google Scholar]

- Singleton VL, Rossi J. Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Vitic. 1965;16:144–158. [Google Scholar]

- Spanemberg FE, Korzenowski AL, Sellitto MA. Effects of sugar composition on shelf life of hard candy: optimization study using D-optimal mixture design of experiments. J Food Process Eng. 2019;42(6):e13213. doi: 10.1111/jfpe.13213. [DOI] [Google Scholar]

- Toker O (2016) Çikolata kaplama formülasyonunda kullanılan bitkisel yağ tipi ve içeriğinin optimizasyonu. PhD Thesis, Tekirdag Namık Kemal University, Turkey (in Turkish).

- Toker OS, Zorlucan FT, Konar N, Dağlıoğlu O, Sagdic O, Sener D. Investigating the effect of production process of ball mill refiner on some physical quality parameters of compound chocolate: response surface methodology approach. Int J Food Sci Technol. 2017;52(3):788–799. doi: 10.1111/ijfs.13336. [DOI] [Google Scholar]

- Tseng A, Zhao Y. Wine grape pomace as antioxidant dietary fiber for enhancing nutritional value and improving stability of yoğurt and salad dressing. Food Chem. 2013;138(1):356–361. doi: 10.1016/j.foodchem.2012.09.148. [DOI] [PubMed] [Google Scholar]

- Zhao J, Jin Y, Du M, Liu W, Ren Y, Zhang C, Zhang J. The effect of dietary grape pomace supplementation on epididymal sperm quality and testicular antioxidant ability in ram lambs. Theriogenology. 2017;97:50–56. doi: 10.1016/j.theriogenology.2017.04.010. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.