Abstract

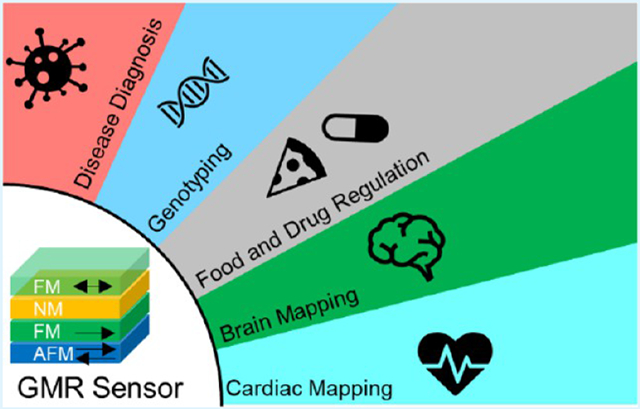

The giant magnetoresistance (GMR) effect has seen flourishing development from theory to application in the last three decades since its discovery in 1988. Nowadays, commercial devices based on the GMR effect, such as hard-disk drives, biosensors, magnetic field sensors, microelectromechanical systems (MEMS), etc., are available in the market, by virtue of the advances in state-of-the-art thin-film deposition and micro- and nanofabrication techniques. Different types of GMR biosensor arrays with superior sensitivity and robustness are available at a lower cost for a wide variety of biomedical applications. In this paper, we review the recent advances in GMR-based biomedical applications including disease diagnosis, genotyping, food and drug regulation, brain and cardiac mapping, etc. The GMR magnetic multilayer structure, spin valve, and magnetic granular structure, as well as fundamental theories of the GMR effect, are introduced at first. The emerging topic of flexible GMR for wearable biosensing is also included. Different GMR pattern designs, sensor surface functionalization, bioassay strategies, and on-chip accessories for improved GMR performances are reviewed. It is foreseen that combined with the state-of-the-art complementary metal-oxide-semiconductor (CMOS) electronics, GMR biosensors hold great promise in biomedicine, particularly for point-of-care (POC) disease diagnosis and wearable devices for real-time health monitoring.

Keywords: GMR, flexible sensor, disease diagnosis, genotyping, food safety, brain mapping, cardiac mapping

Graphical Abstract

1. INTRODUCTION

The GMR effect was discovered by Fert and Grünberg for the first time in 1988 from multilayer structures composed of alternating ferromagnetic (FM) and nonmagnetic (NM) conductive layers (Figure 1(A1))1,2 This effect is observed as a “giant” change in the electrical resistance depending on the relative alignments of the magnetizations of adjacent FM layers. The magnetizations of FM layers can be remotely controlled by an external magnetic field, and the resistance of a GMR system is a function of the field magnitude. In this sense, GMR sensors become the preferred option for measuring ultralow magnetic fields, especially in small spaces. Since then, GMR sensors have become extremely widespread throughout the main industries and strategic applications, such as MRAM (magnetoresistive random-access memory), hard disk drives, nonvolatile memory, etc.3-5 The practical significance of the GMR effect has been recognized worldwide and was conferred the Nobel Prize in Physics in 2007.

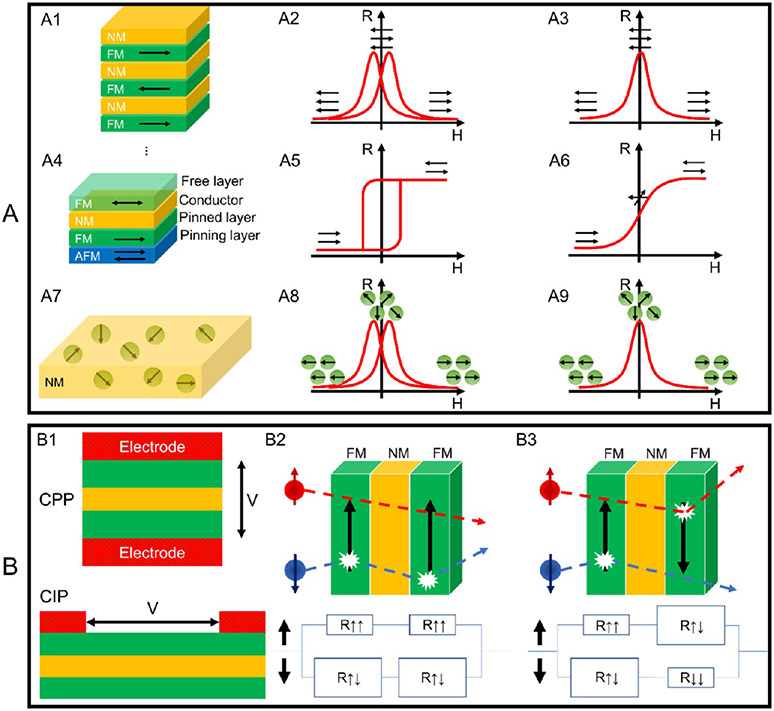

Figure 1.

(A) Schematic views of (A1) GMR multilayer structure, (A4) spin valve structure, and (A7) GMR granular solids, and the R─H curves of the GMR structures in (A2, A3) A1, (A5, A6) A4, and (A8, A9) A7. Schematic views of (B1) the CIP and CPP configurations and (B2, B3) the two-channel models.

GMR systems display superior sensitivities over anisotropic magnetoresistance (AMR) and Hall sensors. Benefiting from the advances in thin-film deposition platforms and micro- and nanofabrication techniques, GMR sensors can be patterned into different shapes and configurations to match different application purposes. In addition, the flexibility of designs allows single GMR, Wheatstone bridge GMR, and GMR array configurations based on needs. Combined with the standard complementary metal-oxide-semiconductor (CMOS) technologies, GMR sensors have been successfully integrated within chips, including in microelectronic circuits, providing compact sensing with better performance.6,7 In the field of biosensors, the enzyme-linked immunosorbent assay (ELISA) and electro-chemical immunoassay (ECIA) platforms are widely used immunoassay tools for disease diagnosis; however, they require not only sophisticated laboratory equipment with frequent equipment maintenance but also professional operation handled by technicians.8-10 These intrinsic characteristics make them unsuitable for point-of-care use.11,12 On the other hand, the optical labels in optical biosensors such as fluorescent dyes, quantum dots, and surface-enhanced Raman spectroscopy (SERS), although quite powerful, are vulnerable to photobleaching and unstable at room temperature, which has greatly restricted their applications for on-field tests. In recent years, significant progress has been made in the field of plasmonic biosensors, with many new plasmonic building blocks such as semiconductors, metals, magnetic materials, and meta-materials being reported to control the light properties in classical and quantum regimes. However, the main challenges in plasmonic biosensors are detection of small molecules at ultralow concentrations and production of compact devices for point-of-care (POC) analysis.13,14 The field-effect transistor (FET)-based biosensors, on the other hand, are versatile tools that directly convert the target molecules and receptor interactions into electrical signals. Although FET-based biosensors have shown high detection sensitivity and fast response, there are still great challenges in building FET-biosensors with miniaturization, low cost, simple operation, reproducibility, and reliability for nonspecialists.15,16 A lateral flow immunoassay (LFIA) is one of the most cost-effective sensors for the detection of multiple diseases including SARS-CoV-2, and the sensor response is read with the naked eye. It is by far the cheapest, fastest, and easiest option to fight the COVID-19 pandemic.17 However, applying the wrong sample size to the LIFA can lead to reliability problems in the test results. Additionally, sample pretreatment may be required for samples that may alter the capillary action (diffusion) of target molecules on the test strip.18,19 Gold nanoparticle-based colorimetry is another biosensing technique that significantly simplifies operating procedures and shortens detection time.20 The entire assay is performed with one solution mixture of the target and the probe without any washing steps, and the color change can be read directly with the naked eye. However, nanoparticle-based colorimetric assays have some disadvantages, such as low detection sensitivity and inability to perform multiplexed detection. Furthermore, it is still in the proof-of-concept stage and the background color of biological fluid samples such as human serum may interfere with the colored signal, affecting the accuracy of the results.21

As they use magnetic nanoparticles (MNPs) as labels, GMR biosensors have a robust labeling system. Furthermore, because biological tissues and fluids are nonmagnetic or diamagnetic, there is negligible background noise from the complex samples, and thus, a higher signal-to-noise ratio is greatly favored for magnetic biosensors such as GMR. Considering these intrinsic advantages of GMR biosensors, researchers are exploiting the potential of developing GMR biosensors into a user-friendly, cost-effective, and rapid testing tool for a growing list of biomedical applications in the field of magnetic field sensors, with an emphasis on biomedical applications such as magnetocardiography (MCG) and magnetoencephalography (MEG). Highly sensitive superconducting quantum interference devices (SQUIDs) are widely used for imaging the biomagnetic fields produced because of electric currents flowing in the active nerve cells in the brain and cardiac muscle. Because this kind of biomagnetic field is very weak, typically several picoteslas (1 pT = 1 × 10−12 T) for MCG and femtoteslas (1 fT = 1 × 10−15 T) for MEG.22 Very limited types of magnetic field sensors meet this requirement. SQUIDs, although highly sensitive, require cryogenic refrigeration to operate, which significantly increases their size, power consumption, and cost. GMR sensors, along with other femtotesla-level detection magnetic field sensors such as spin-exchange relaxation-free (SERF) atomic magnetometers (AMs) that do not require cryogenic operation, are at the forefront of research for MCG and MEG applications.23-27

In this paper, we focus on the recent advances of GMR sensors in biomedical applications. We first introduce different GMR systems including magnetic multilayer structure (Figure 1A1), spin valve trilayer structure (Figure 1A2), and magnetic granular structure (Figure 1A3). Among these, GMR spin valves are more widely used in biomedical areas because of the linear R─H (resistance-field) responses and simple trilayered thin-film structure. Unless otherwise noted, the GMR biosensors mentioned in this paper are GMR spin valves that consist of two FM layers separated by a thin NM spacer. The current in plane (CIP) and current perpendicular to plane (CPP) geometries, spin-dependent scattering, and two-channel resistor model are also explained in Section 2. Flexible GMR sensor is an emerging topic and holds great potential in the field of wearable sensors for in vivo health condition monitoring. Herein, we review some representative configurations of flexible GMR sensors. In Section 3, we review different GMR biosensor designs including biosensor patterns, GMR-based bioassay strategies, and accessories for improved GMR biosensing performances such as microfluidic channels, filters, and magnetic flux concentrator (MFC). Different research groups have independently reported point-of-care (POC) devices based on GMR biosensors, making it possible to carry out all-in-one, fully automatic, and GMR chip-based bioassays at the user end. In Section 4, we review the biomedical applications based on GMR biosensors such as for disease diagnosis, genotyping, food and drug regulation, brain and cardiac mapping, etc. The challenges and opportunities for GMR technology to become a superior healthcare solution are discussed in Section 5.

2. OVERVIEW OF DIFFERENT TYPES OF GMR SENSORS

2.1. GMR Effect in Magnetic Multilayer Systems.

The GMR can be described as the change in electrical resistance of magnetic multilayers in response to an external magnetic field. As shown in Figure 1A3, the FM layers are antiferromagnetically coupled in a zero field. Although the magnetizations of the FM layers are antiparallel, they can be aligned by an external magnetic field. The electrical resistance of a GMR FM/NM multilayer structure is relatively low when the magnetizations of FM layers are in parallel alignment (this resistance is denoted as RP), whereas the resistance is relatively high when magnetizations of FM layers are in antiparallel configurations, resistance denoted as RAP. The GMR ratio is characterized by (RAP – RP)/RP. This effect (i.e., the GMR ratio) is much larger than the anisotropic magnetoresistance (AMR) and therefore is called “giant” magnetoresistance. However, the presence of antiferromagnetic interlayer coupling is not a necessary condition for the GMR effect to occur. The GMR effect can also be achieved by arranging neighboring FM layers with different coercivities. As shown in Figure 1A2, the magnetizations of the soft and hard FM layers switch at different values of the applied magnetic field.

The second example of the GMR system is the spin valve trilayer configuration as shown in Figure 1A4, where the magnetization of one FM layer is pinned by an adjacent antiferromagnetic (AFM) layer, whereas the magnetization of the other FM layer is free to rotate with the external magnetic field. A typical R─H curve of the GMR spin-valve is schematically drawn in Figure 1A5. Although the GMR spin valves show a lower GMR ratio compared to the multilayer GMR systems, they are more popular for sub-picotesla to millitesla-range weak magnetic field detections. For the applications in GMR-based bioassays and magnetic field sensors, spin valves with a linear R─H curve are designed in the way that in zero fields, the magnetizations of FM layers are in a 90° configuration, as depicted in Figure 1A6. This 90° configuration in zero fields can be achieved by introducing magnetic shape anisotropy. Thus, for most spin valves in biomedical applications that require linear R─H responses, the sensors are designed with very high aspect ratios.

The magnetic granular system is another example that shows the GMR effect, denoted as g-GMR. In this g-GMR system, magnetic nanoparticles (MNPs) are either dispersed in conductive gel matrices or embedded in metallic matrices, as shown schematically in Figure 1A7. The R─H curves of g-GMR systems in Figure 1A8, A9 correspond to ferromagnetic and superparamagnetic nanoparticle conditions, respectively. This g-GMR system will be discussed in detail in Section 2.2.

So far, we have introduced three types of GMR structures. For the GMR multilayer structure and GMR granular solids, although they show very high MR ratios, they are not suitable for biomedical applications, because in most biomedical applications, a linear signal output (e.g., sensor voltage) as a function of the external magnetic field is preferred for quantitative bioassays and biomagnetic field recordings. To date, linear response curves are achieved in GMR spin-valve structures (Figure 1A6) by the perpendicular configuration of magnetizations through the manipulation of shape anisotropy or a bias field. It should be noted that there is a trade-off between the sensitivity (MR ratio) and linearity for GMR sensors. Although GMR spin valves show linear response curves and are able to detect weak magnetic fields in many reported works, they usually possess lower MR ratios compared to GMR multilayer structures, because only two FM layers are contributing to the GMR effect.

GMR sensors are generally built following two types of configurations: current in-plane (CIP) and current perpendicular to the plane (CPP), as represented in Figure 1B1. The CIP structure is preferred in industrial applications because it is easier to fabricate and more easily detectable than CPP because of a thicker film layer.28 In the CPP configuration, spin-dependent scattering is produced at the interfaces, consequently generating an interface resistance.29

It is observed that electron spin is conserved if the travel distance is below the mean free path,30 for this specific reason that the NM layer requires a thickness that does not exceed this limiting interval. Because of spin conservation, it is possible to meticulously describe the spin state separately; therefore, electric current flows in two separate channels: one for a spin down and the other for a spin up, as shown in Figure 1B2, B3. Taking the CPP configuration as an example, the resistivity can be self-averaged and modeled by resistors in series. The quantum mechanical tunneling effect of electrons in thin FM layers is primarily due to spin-dependent scattering from 4s to 3d orbitals. Strong scattering happened to spin aligned antiparallel to the direction of magnetization and weak scattering for parallel ones. The conductivity for each spin state is modeled with two resistors, one for each layer. Therefore, two pairs of resistors in parallel are obtained because the scattering of electrons is highly spin dependent in ferromagnetic materials. Spin up states are slightly scattered, and hence, low resistance; and spin down states are scattered in the ferromagnetic configuration, and hence, high resistance. Thus, the total resistance is approximately equal to the low resistance. The second configuration happens when a strong scattering for each spin occurs at least once in a layer.

2.2. GMR Effect in Granular Systems.

Although the GMR effect is prevalently reported in magnetic multilayer systems, any materials and microstructures that have interfaces between FM and NM materials are theoretically able to show the GMR effect.31,32 GMR structures such as granular MNPs embedded in an NM conductive matrix also show a spin-dependent scattering of electrons at the particle–matrix interfaces, as shown in Figure 1A7. In this section, we will discuss several granular GMR systems and their electron transport properties.

The first granular system reported showing the GMR effect was Co─Cu alloy thin film. It was reported by Berkowitz et al. and Xiao et al. independently in 1992.32,33 A microscopic photo of the granular Co─Cu thin film is shown in Figure 2A.32 Since then, other granular thin-film systems such as Co─Ag, Fe─Ag, and Fe─Cr have been demonstrated to show the GMR effect.34-36 To date, most of the granular material systems that exhibit the GMR effect are granular alloys containing two or more immiscible metal elements. The metals are typically deposited on the substrates via magnetron sputtering, molecular beam epitaxy (MBE), or other deposition methods. The magnetic elements then precipitate to form small granules due to low solubility.37

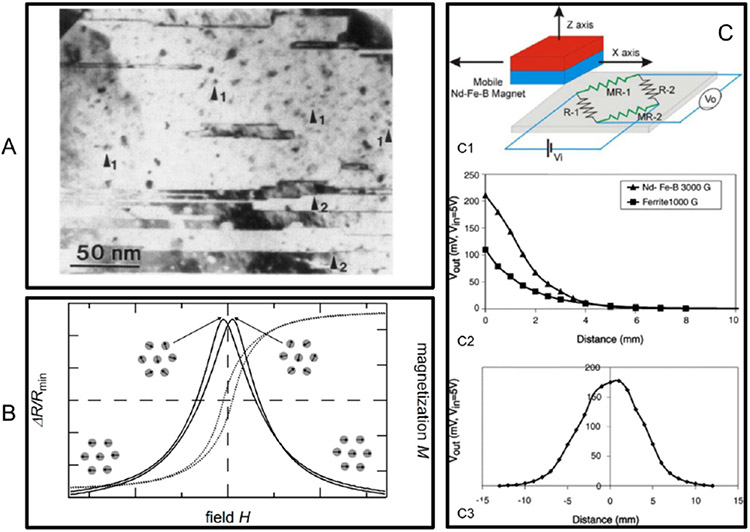

Figure 2.

Granular GMR films and sensors. (A) Micrograph of Co granules embedded in Cu matrix. (B) Schematic illustration of the GMR effect in granular thin films. (C) Granular GMR sensors. (C1) Sensor structure. (C2, C3) Response of the vertical and horizontal movement of the permanent magnet. (A) Reprinted with permission from ref 32. Copyright 1992 American Physical Society. (B) Reprinted from ref 29. Licensed under CC BY 4.0. (C) Reprinted with permission from ref 38. Copyright 2005 Elsevier B.V.

A schematic illustration of the origin of the GMR effect in granular systems is presented in Figure 2B. In the absence of an external magnetic field, the magnetization directions of the small magnetic granules are randomly distributed, and the resistance of the system is at its maximum.29 When a magnetic field is applied, the magnetization directions of these granules are aligned along the external field direction, which results in the reduction of resistance. Different theoretical models have been proposed to describe the GMR effect in granular alloys. Among them, the very first and most frequently used was reported by Zhang and Levy.39,40 They stated the GMR effect in granular films is similar to the CPP multilayer GMR systems, and therefore, their previous formalism for a CPP-GMR multilayer structure was used.41 By limiting the discussion to low temperature and assuming that the granules are single-domain MNPs, they found that the GMR ratio of granular thin films could be further increased by (1) reducing impurities in the matrix, (2) increasing the spin-dependent to spin-independent potentials ratios, (3) increasing interfaces’ spin-dependent scattering roughness, (4) decreasing the sizes of granules until these granules can be magnetically saturated by the applied field (for a fixed magnetic field and temperature condition, if the applied field cannot magnetically saturate the granules, then the GMR ratio decreases with the size of the granules), and (5) increasing the concentration of the magnetic granules. They also pointed out that the size distribution of the granules was a key factor that affect the GMR ratio of the granular system.

On the basis of the granular alloy films, several granular GMR sensors have been developed. For example, Arana et al. reported a linear position sensor based on Ag─Co alloy thin films.38 The schematic sensor structure is shown in Figure 2C1. They demonstrated that the granular GMR sensors can be used to measure the position of the permanent magnets, and the results are shown in Figure 2C2, C3.

2.3. Flexible GMR Sensors.

2.3.1. Printable GMR Sensors.

Recent years have witnessed increasing research interests in flexible sensors, in that these devices possess great potentials in the field of wearable appliances. One of the most cost-efficient ways to fabricate such flexible sensors is printing. Although printable electronics have been developed for many years, printable GMR sensors were first demonstrated in 2012 by Karnaushenko et al.42 To get a printable magneto-sensitive ink, they first deposited [Co/Cu]50 GMR multilayer films on a buffer-layer-coated silicon substrate via magnetron sputter deposition. Next, the as-deposited GMR multilayers are released from the substrate, dried, and ball milled into GMR flakes. These [Co/Cu]50 GMR flakes were then dispersed in a conductive polymer-based binder solution, and the resulting magnetic ink was printed on various substrates including flexible ones such as paper, as shown in Figure 3A. These printable sensors were proven to be able to achieve a maximum GMR ratio of 8% at room temperature.

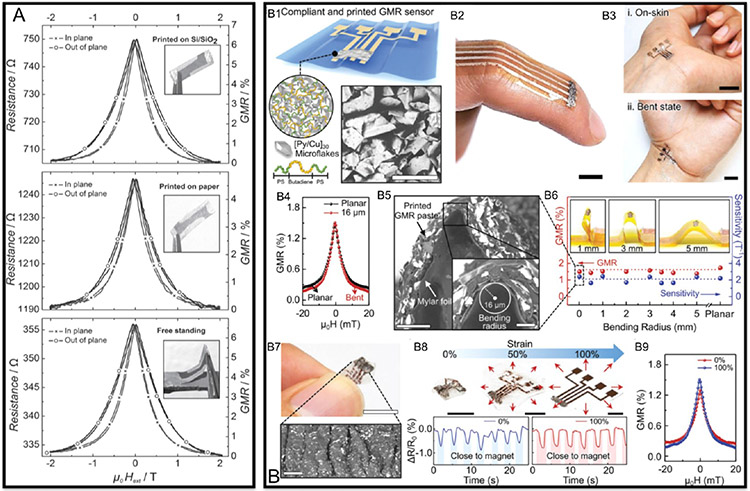

Figure 3.

GMR effect in polymer mixed GMR flakes. (A) GMR ratios for sensors painted on Si wafer (top), paper (middle), and the free-standing sensor (bottom). (B) Printable and stretchable GMR sensors. (B1) Schematic illustration of the printable GMR sensor. (B2, B3) Photographs of flexible GMR sensors on skin. (B4, B5) show the GMR ratio and morphology of the sensor under a bending radius of 16 μm. (B6) GMR ratios and sensitivities under different bending conditions. (B7) Image of the sensor surface after stretching. (B8, B9) Performance and GMR ratio of the sensor under stretching conditions. (A) Reprinted with permission from ref 42. Copyright 2012 Wiley–VCH. (B) Reprinted from ref 44. Licensed under CC BY 4.0.

The metallic multilayer flakes are the cause of the GMR effect, whereas the conductive polymeric solution prevents the flakes from oxidation and serves as a binder to make the flakes printable. Therefore, these are two key factors that impact the performance of such printable GMR sensors. In 2015, Karnaushenko et al. prepared another type of printable GMR sensors with the same kind of GMR flakes but different conductive polymer matrix, and they increased the maximum GMR ratio to 37%.43 Very recently, Ha et al. fabricated a stretchable GMR sensor with high performance by screen printing.44 They used poly(styrene–butadiene-styrene) (SBS) elastomer as the binder solution and mixed it with [Pu/Cu]30 GMR multilayer microflakes, then printed the GMR paste onto a thin polymeric foil to obtain a flexible sensor as shown in Figure 3B1-B3. This screen-printed GMR sensor exhibited a GMR ratio of 1.95% under an external field of 0.88 mT and shows no obvious decrease in GMR ratio under bending (see Figure 3B4-B6) and stretching conditions (see Figure 3B7-B9), which made it a good candidate for wearable electronics.

2.3.2. GMR Sensors on Ultrathin Flexible Substrates.

Besides printing, a more traditional way of fabricating flexible GMR sensors is directly depositing the GMR multilayers on flexible substrates. In 1992, Parkin et al. demonstrated that Co/Cu multilayers deposited on thin Kapton substrates still show the GMR effect, and the GMR ratio was comparable to the Co/Cu multilayers on rigid silicon substrates.45 Since then, various organic thin films have been found to be suitable as substrates for flexible GMR sensors, such as polyethylene naphthalate (PEN)46 and polyethylene terephthalate (PET),47 because of their good mechanical properties including light weight and high strength.48 However, using organic thin films as substrates also has severe limitations.49 For one thing, the GMR multilayers are metallic films that can only be stretched or bent to a very small extent. For the other, because of the large elastic property differences between the metallic films and the substrates, the large residual strain could cause low robustness of GMR sensors. To overcome these limitations, Li et al. deposited dual spin-valve GMR structures on polydimethylsiloxane (PDMS) substrates with uniaxial tensile prestrains.50 The functional layers formed periodic wrinkled ribbons patterns as shown in Figure 4A1. This shape enabled a nearly constant GMR ratio and field sensitivity over a tensile strain range of 0–25% (see Figure 4A2). The fatigue tests revealed that these sensors can maintain their high performance after hundreds of stretching and releasing cycles, as shown in Figure 4A3.

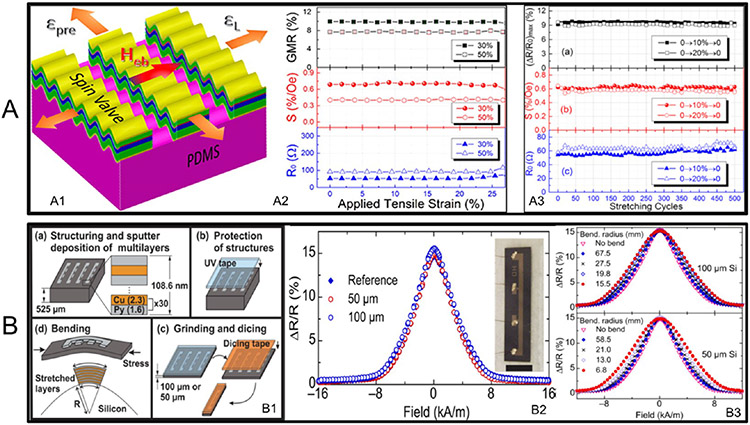

Figure 4.

GMR sensors on flexible substrates. (A) GMR sensors on prestressed PDMS substrates. (A1) Schematic illustration of the sensor. (A2) GMR ratio of the sensor under strain from 0 to 25%. (A3) GMR ratio during stretching–releasing cycles. (B) GMR sensors on ultrathin Si membrane. (B1) Schematic illustration of the fabrication process of the GMR sensor. (B2) GMR ratio of sensors on rigid Si wafer, 50 μm thick substrates, and 100 μm thick substrates. (B3) GMR ratio of the sensors under different bending conditions. (A) Reprinted with permission from ref 50. Copyright 2016 American Chemical Society. (B) Reprinted with permission from ref 54. Copyright 2015 AIP Publishing LLC.

Instead of polymer films, rigid substrates such as silicon wafers and glasses can also become flexible by decreasing their thickness to a micrometer range.51-53 For example, Pérez et al. reported the flexible GMR sensors on an ultrathin silicon substrate with thicknesses of 100 and 50 μm.54 As presented in Figure 4(B1), the fabrication process started with the deposition of GMR multilayers on silicon wafers, followed by a grinding process from the backsides of the wafers to reduce the thickness to 100 or 50 μm. The minimum acceptable bending radii were 15.5 mm and 6.8 mm for 100 and 50 μm silicon substrates, respectively. Within these ranges, a GMR ratio of around 15.3% was achieved regardless of membrane thickness and bending radius, as shown in Figure 4B2, B3.

3. GMR BIOSENSOR DESIGNS

3.1. Different GMR Biosensor Patterns.

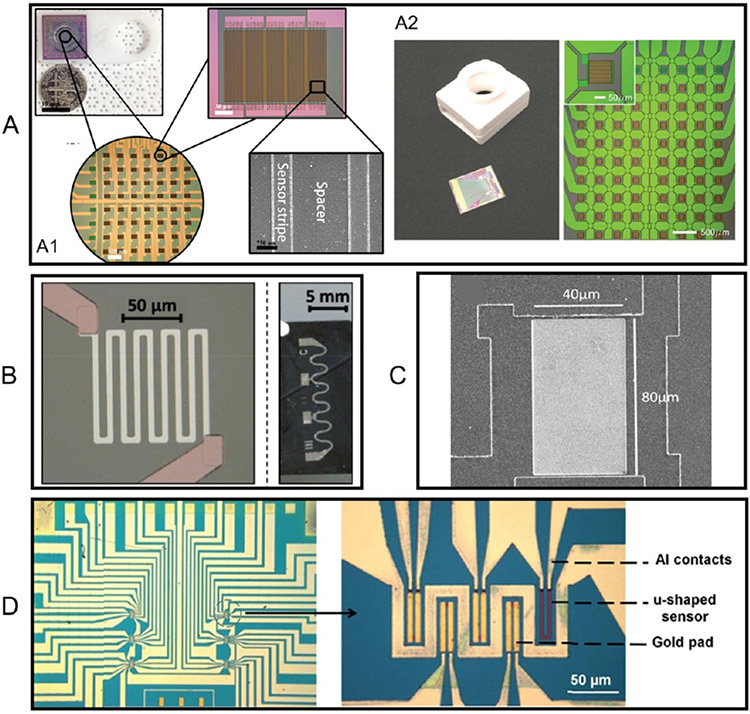

Benefiting from the current micro- and nanofabrication techniques, each GMR biosensor is typically in the size of tens to hundreds of micrometers. As shown in Figure 5, theoretically, GMR biosensors could be scaled to more than 1 million sensors/cm2.55,56 To date, different GMR biosensor patterns have been reported, for example, a stripe shape57,58 (Figure 5A), a spiral shape59,60 (not shown), a meander shape61 (Figure 5B), large-area62 (Figure 5C), and a “U” shape63 (Figure 5D). It is reported that for GMR-based bioassays, the MNP labels landing at the sensor edges cause larger signal differences compared to the same MNP labels landing on top of the sensor.20 This conclusion favors the design of GMR biosensors with higher aspect ratios, such as the stripe and spiral shapes. On the other hand, the large-area GMR biosensors realize the detection of MNP labels through a local-magnetic-reversal-nucleation mechanism.62,64

Figure 5.

Different GMR biosensor patterns. (A) GMR stripe shape biosensors. (A1, A2) Two types of GMR stripe biosensor designs reported independently by two research groups. (B) Spiral shape GMR biosensor pattern. (C) Large-area GMR biosensor pattern. (D) “U” shape GMR biosensor pattern. (A1) Reprinted from ref 57. Licensed under CC BY 4.0. (A2) Reprinted from ref 58. Licensed under CC BY 4.0. (B) Reprinted with permission from ref 61. Copyright 2015 Wiley–VCH. (C) Reprinted with permission from ref 62. Copyright 2017 AIP Publishing LLC. (D) Reprinted with permission from ref 63. Copyright 2016 The Royal Society of Chemistry.

In addition to the sensing mechanism-driven sensor pattern design, some practical issues should be considered when designing the GMR biosensors. Sensors with high aspect ratios (such as the stripe, spiral, and meander shapes in Figure 5A, B) have higher risks of open circuitry. Minor defects in the GMR thin films/substrates and even some photoresist residues (before the sensor pattern etching step) may cause breakage in these GMR sensors. This issue is mitigated when connecting dozens of GMR stripes in series and parallel. For example, in Figure 5A1, one GMR biosensor consists of 5 groups of GMR stripes connected in series and each group consists of 10 GMR stripes connected in parallel. GMR stripes connected in series can avoid the risks of open circuitry, whereas GMR stripes connected in parallel can increase the overall resistance as well as the signal-to-noise ratio (SNR).

Another major issue of stripe-shaped GMR biosensors is the small effective sensing area. Compared to the large area GMR biosensors, the effective sensing area of stripe-shaped GMR biosensors is small because of the spacers between sensor strips (see Figure 5A1). Some MNP labels may land on the spacers and do not contribute to the GMR signal. In addition, bioassay repeatability is a concern when measuring low abundancy target analytes because the captured MNP labels are randomly distributed on the sensor and spacer regions. In view of this, the large-area and “U”-shaped GMR biosensors are favored.

3.2. GMR Biosensor Surface Functionalization.

The sensitivity of the GMR biosensor is strongly dependent on the reactivity of capture probes that are immobilized on the sensor surface. Thus, the GMR sensor surface modification is a crucial step before transforming a GMR sensor into a functional biosensor. To date, different kinds of surface modification methods have been reported to modify the surface of rigid substrates including glass, silicon, polystyrene, etc.65-69 Herein, we introduce two frequently used GMR sensor surface modification methods, the 3-aminopropyltriethoxysilane (APTES)/glutaraldehyde (Glu) [APTES/Glu] and the 1-ethyl-3-(3-(dimethylamino)propyl) carbodiimide (EDC)/N-hydroxysuccinimide (NHS) [EDC/NHS]70 methods. The steps to carry out each surface modification method are summarized in Table 1.

Table 1.

GMR Sensor Surface Modification Methods

| method | APTES/Glu method | EDC/NHS method |

|---|---|---|

| pretreatment | GMR chips are subjected to oxygen plasma or washed with acetone followed by methanol and finally isopropanol then air-dried with nitrogen to remove organic residues adsorbed onto the surface | |

| modification steps | 1. add 0.5–10% APTES solution (in toluene/acetone) to the GMR sensor surface and incubate at room temperature for 5 min, then rinse with acetone, followed by deionized water, and dry with N2 | 1. add polyamine solution to the GMR sensor surface and incubate at room temperature for 5 min, then rinse with deionized water and dry with N2 |

| 2. add 5% Glu solution to the GMR sensor surface and incubate at room temperature for 5 h; rinse the GMR chip with deionized water and dry with N2 | 2. add polyacid solution to the GMR sensor surface and incubate at room temperature for 5 min, then rinse with deionized water and dry with N2 | |

| 3. GMR sensor is ready for immobilizing capture probes | 3. add EDC/NHS solution to GMR sensor surface and incubate at room temperature for 1 h; rinse the GMR chip with deionized water and dry with N2 | |

| 4. GMR sensor is ready for immobilizing capture probes | ||

It is worth mentioning that GMR sensors are usually coated with an ultrathin passivation layer (typically Al2O3, SiO2, and Si3N4 thin films) to avoid the corrosion caused by interfacing with biological samples. There is a trade-off on the thickness of this passivation layer. It should be thin enough to allow magnetic signals from MNP labels to be detectable by the GMR biosensors, and it should be thick enough to avoid the leakage of liquid through defects/pores in the passivation layer. Typically, this passivation layer is around tens of nanometers.

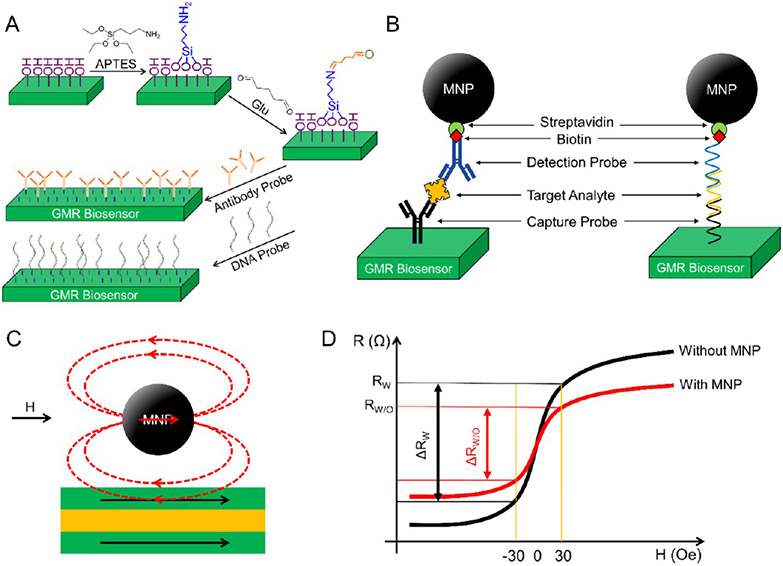

Before the surface modification steps, the substrate surfaces should be pretreated to remove organic residues and increase the surface hydrophilicity for better chemical treatment. For example, in some reported pretreatment steps, substrates are usually subjected to oxygen plasma (or ultraviolet ozone) and then treated with H2O2 solution.57,71,72 Substrate surfaces are more hydrophilic and are easier for further chemical treatment and grafting of proteins after the pretreatment. As shown in Figure 6A, in the APTES/Glu modification method, the GMR sensor surface is then treated with APTES, where the silanol groups will attach to the hydroxyl groups (─OH) from the substrate surface. Once on the surface, these silanes polymerize internally to form Si─O─Si (siloxane) linkages, exposing amine groups (─NH2) on the other end. Next, the Glu solution is added, where one of the two aldehyde groups (─CHO) is covalently bonded with the amine group from APTES. The other reactive aldehyde group can form a covalent bond with the amine groups from capture probes. Other GMR sensor surface modification methods using polyethylenimine (PEI),72 polyvinyl chloride (PVC),73 epoxysilane (3-glycidoxypropyl-trimethoxysilane),74 etc. have also been reported. After the surface modification with functional groups, GMR biosensors/chips can be stored under a dry environment before anchoring capture probes.

Figure 6.

(A) Schematic view of the APTES/Glu method for GMR sensor surface modification and functionalization of capture probes. (B) Schematic view of the sandwich assay. (C) Upon the application of an external magnetic field, the stray fields generated by MNPs can disturb the local magnetizations in the GMR biosensor’s free layer. (D) Schematic view of the R─H curves of the GMR sensor with and without the MNPs captured on the sensor surface. (A) Reprinted from ref 57. Licensed under CC BY 4.0.

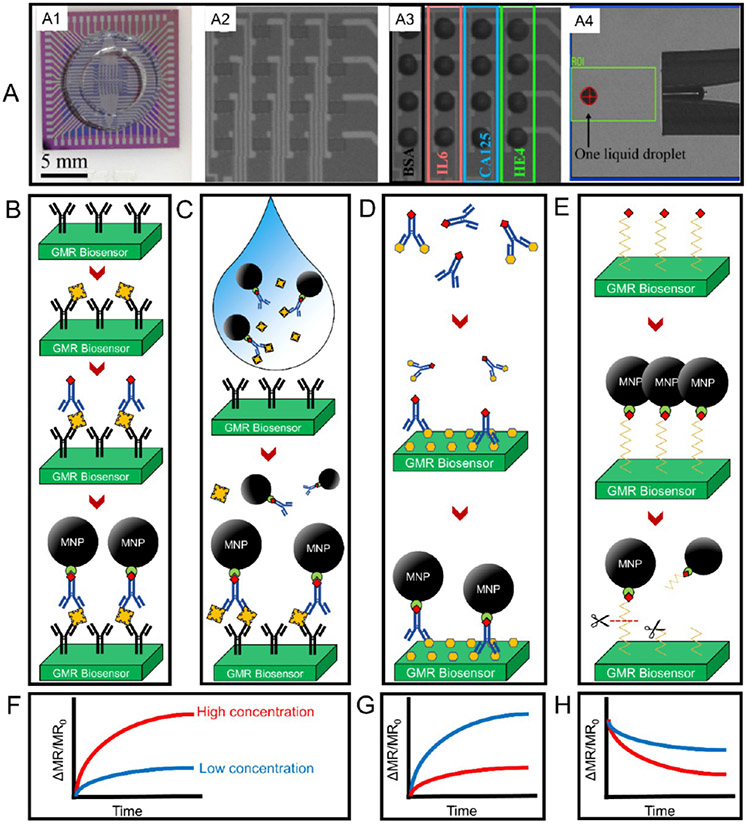

As is mentioned in Section 3.1, the modern micro- and nanofabrication techniques allow the integration of dozens to thousands of GMR biosensors in a fingernail-sized chip. Combined with the external CMOS electronics, each GMR biosensor works independently, which allows the multiplexed detection of a panel of target analytes in real time. For example, Figure 7A1 is a 2 cm × 2 cm GMR chip consisting of an 8 × 8 GMR biosensor array. Theoretically, these independently working biosensors allow the multiplexed detection of up to 64 analytes. With a nanoplotter facility (such as the SCIENION sciFLEXARRAYER product lines and the GeSiM microarray printers), a fixed volume of capture probe liquid droplet (see the photograph of one 400 pL droplet from Figure 7A4) can be precisely dispensed on each GMR biosensor with submicrometer and subnanoliter resolutions. Figure 7A2, A3 are the photographs of a 4 × 4 GMR biosensor array before and after dispensing capture probes (i.e., IL6, CA125, and HE4, BSA (bovine serum albumin) serves as negative control), respectively. The nanoliter volume droplets containing capture probes are incubated on the GMR biosensors overnight at 4 °C under a relative humidity of ~90% to allow immobilization. After anchoring the capture probes to GMR biosensors, the residues (unbound capture probes) are washed out and the biosensors are further blocked with BSA to avoid the nonspecific binding of ligands from biological samples.

Figure 7.

(A) GMR biosensor arrays designed for multiplexed bioassays. (A1) One example of a 2 cm × 2 cm GMR biosensor chip consists of 64 GMR biosensors working independently. (A2, A3) 4 × 4 GMR biosensor array before and after dispensing nanoliter volume capture probes and BSA. (A4) Photograph of one 400 pL liquid droplet dispensed by a nanoplotter facility. Steps of carrying out (B) a traditional sandwich bioassay, (C) a wash-free sandwich bioassay, and (D) a competitive bioassay on GMR biosensors. (E) Steps of carrying out enzyme detection on GMR biosensors. (F–H) Schematic drawings of GMR signals in the scenarios of high and low concentrations of target analytes for B–E, respectively. (A) Reprinted with permission from ref 77. Copyright 2018 Elsevier B.V.

It should be noted that the surface modification methods of GMR sensors described above are to increase the adsorption capacity of capture probes (such as capture antibodies, capture nucleic acids, etc.), to obtain a larger number (higher area density) of capture probes. After the functionalization step, it is crucial to apply a blocking layer (e.g., BSA) to cover the remaining binding sites on the sensors. The blocking layer can effectively reduce the nonspecific binding of reagents from the test sample, thus reducing the biosensor noise (note: this noise is caused by nonspecific binding, which is different from the inherent noise of the GMR sensor itself). In addition, the selection of suitable capture probes with the highest binding affinity and specificity for the target analyte is also of great significance for the overall implementation of GMR biosensors. The binding affinity and specificity information on capture probes for the target analyte can be either obtained from the manufacturer (if purchased from the manufacturer) or confirmed with the help of ELISA and Western blot. GMR biosensors can also be used for profiling the affinity and specificity of capture probes.55 Choosing the right type of capture probe with high binding affinity and specificity for the target analyte can further increase the detection limit of the GMR biosensor (in a biological manner) and reduce the time required for binding to reach equilibrium.75

3.3. Different GMR-Based Bioassay Strategies.

The GMR-based bioassay is similar to the standard immunoassay platforms such as ELISA (enzyme-linked immunosorbent assay). In Figure 6B, take the sandwich bioassay scheme as an example, where the capture probes (i.e., capture antibody, capture DNA/RNA, etc.) are first immobilized on the GMR biosensor surface, then the target analytes (i.e., protein biomarkers, peptides, ssDNA or RNA) of interest are introduced and specifically bind to the capture probes. Next, the MNP-labeled detection probes (i.e., detection antibody, detection DNA/RNA, etc.) are introduced and specifically bind to the target analytes and form a “sandwich” structure. The greater number of target analytes from the biological sample, the more MNPs are coupled on the GMR biosensor surface. As shown in Figure 6C, upon the application of an AC magnetic field, the stray fields generated by captured MNP labels can disturb the local magnetizations in the GMR biosensor’s free layer, resulting in a resistance change of the GMR biosensor (see Figure 6D). The change in resistance is usually monitored as the GMR biosensor signal (in the form of voltage or ΔMR, or ΔMR/MR0), which is then mapped into the domain of target analyte amount/concentration. The sandwich bioassay scheme itself is intrinsically highly sensitive and robust as the capture/detection probes bind to two sites from the target analyte. Thus, it has been widely used in the GMR-based bioassays for disease diagnosis, genotyping, toxin and pathogen detection, etc.71,76-80

However, the traditional GMR-based sandwich bioassay described above requires several wash steps to remove the unbound reagents, and thus, it is limited in lab-based bioassays handled by professionals, which as a result, limits its application for bioassays in nonclinical settings (i.e., school, home, clinic, in he field) by a layperson. Figure 7B shows the steps to carry out one sandwich assay on GMR biosensors. It requires the operator to wash out the unbound analytes after the incubation with a biological sample and then wash out the unbound detection probes before adding the MNP labels. In view of this disadvantage, a wash-free sandwich bioassay was reported in recent years to free the users’ hands.81,82 As shown in Figure 7C, the MNP labels, detection probes, and the biological sample containing target analytes are first incubated to allow the specific binding reach to equilibrium. This mixture is then added to the capture probe-functionalized GMR biosensors for a one-step assay. In this scenario, only the MNP label captured by the GMR biosensor surface through the capture probe–target analyte–detection probe structure causes the GMR signal change, whereas the unbound (or free) MNP labels are floating in the solution and their stray fields are too weak to be picked up by the GMR biosensors because magnetic fields decay with distance cubed. The GMR signal in the form of ΔMR/MR0 monotonically increases with the increase in target analyte concentrations as schematically shown in Figure 7F.

Other bioassay schemes such as the competitive bioassay, although less sensitive to experimental errors as it only requires one binding site on the target analyte, have also been reported for detecting small molecules that usually lack two binding sites/epitopes required for the sandwich assay.83-85 As shown in Figure 7D, the detection probes are at first incubated with a biological sample containing target analytes to allow the specific binding to saturate. The mixture is then added to GMR biosensors that are densely covered with target analytes, where the unoccupied detection probes can bind to GMR biosensors. After washing out the free reagents, MNP labels are added to bind to the immobilized detection probes through biotin–streptavidin interaction. For the GMR-based competitive bioassays, the GMR signal monotonically decreases with the increase in target analyte concentrations as schematically shown in Figure 7G.

As an honorable mention, the GMR biosensor has also been reported for the detection of enzyme/protease.86 As shown in Figure 7E, in an enzyme/protease assay, MNP labels are first bound to the GMR biosensor surface through a biotinylated peptide; with the addition of target enzyme/protease, peptides are cleaved, and MNP labels are released from the surface, causing a GMR signal drop (Figure 7H). With a higher concentration of target enzyme/protease, a higher GMR signal drop is expected. For example, Adem et al. reported the quantitative detection of the cysteine protease, papain. They immobilized MNPs to the surface of a GMR biosensor through the linkage of papain peptide.86 The GMR sensor array containing immobilized MNPs was then incubated with papain for 160 min, and the MNPs were released from the surface in a time-dependent manner. They detected a significant release of MNPs after 3.5 min of incubation using 4 nM of the cysteine protease, papain. They have also confirmed the detection of papain from urine samples.

On a separate note, all the GMR-based biosensors rely on the detection of MNP labels that are captured to or released from (i.e., in enzyme/protease assay shown in Figure 7E, H) the sensor surface. When an external magnetic field is applied, the stray field generated by these captured MNPs will interfere with the local magnetization in the free layer of the GMR biosensor, which will cause the sensor’s MR (and resistance) to change and achieve quantitative detection of the target analyte. There are several technical requirements for choosing MNP labels. First, MNPs should be superparamagnetic, and thus, they show zero magnetic moments in the absence of an external magnetic field. This superparamagnetic property of MNPs can effectively avoid the aggregation of nanoparticles, which may lead to a nonlinear increase in the magnetic signal with the concentration/amount of the target analyte. The requirement of superparamagnetism limits the magnetic core sizes of MNPs to tens of nanometers, as well as limiting the maximum magnetic moment per MNP. In pursuit of higher sensitivity for detecting an ultralow number of target analytes, MNP labels with larger magnetic moments are preferred. Thus, researchers can use multicore magnetic beads (usually several hundred nanometers to several micrometers) that are composed of smaller be superparamagnetic MNPs embedded in a matrix to maintain superparamagnetism and meanwhile high magnetic moment per MNP/bead. Second, MNPs should exhibit high colloidal stability (can be measured by the zeta potential). MNPs with low colloidal stability may precipitate during the bioassay process and cause false positive/negative results. The MNP surface chemical modifications and the pH of the solution can both affect the colloidal stability, and thus, special attention should be paid when designing MNPs. Third, MNPs should show uniform size distribution to improve the repeatability of results. For detecting samples with very low concentrations/number of target analytes, only very low amounts of MNPs are captured onto or released from the GMR biosensors. Thus, the variation in magnetic signal/moment generated by each MNP may cause repeatability issues. Although it is impossible to synthesize MNPs with identical sizes and shapes, higher size uniformity is preferred for GMR bioassays. More detailed discussions on how to choose and design MNPs for GMR-based bioassays are available in our previous work.87,88

3.4. GMR Point-of-Care Devices and Implementation Details.

3.4.1. GMR Point-of-Care (POC) Devices.

Point-of-care (POC) devices are intended for collecting clinical information on patients in resource-limited regions (mostly), clinics, and laboratories.89 The global POC diagnostics market is rapidly growing with acute and chronic diseases worldwide and overwhelming pandemics such as COVID-19.90-95 POC devices allow users with minimum training requirements to run tests at nonclinical settings; if combined with the Internet of Medical Things (IoMT), it could help patients receive proper healthcare at home and establish a comprehensive disease management database for government and healthcare organizations, benefiting the fast disease surveillance and control.94 The usefulness of the POC device is largely dependent on the cost (including cost per device and cost per bioassay), portability, accuracy, accessibility of assay reagents, and the average assay waiting time.

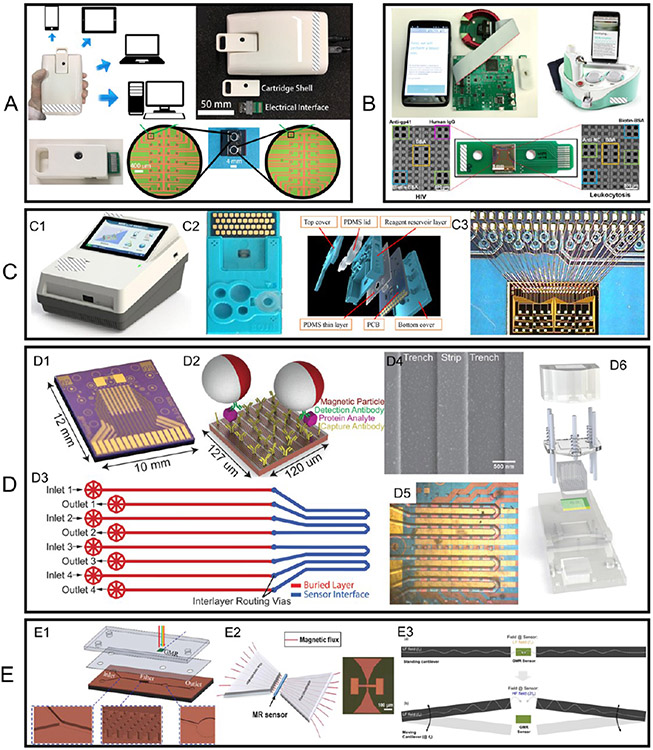

GMR biosensing platforms, after decades of development, have also been developed into POC devices by different research groups. As shown in Figure 8A, a University of Minnesota research group has developed a GMR POC device, Z-Lab.96 Z-Lab realizes real-time GMR signal collection and transmission wirelessly to a smartphone or through a USB connection to a desktop. This Z-Lab POC device consists of three parts: a plastic cartridge, an electrical interface connecting the electrodes from GMR biosensors to the PCB, and a hand-held device. The disposable, flash drive-sized cartridge contains one GMR chip that hosts 29 individual GMR biosensors. A Stanford University research group reported a GMR POC device called the Eigen Diagnosis Platform, as shown in Figure 8B.97 Sharing similar designs, the cartridge contains one GMR chip consisting of 80 individual sensors. Another group from the Chinese Academy of Sciences reported a GMR POC platform that added a microfluidic channel, as shown in Figure 8C, which allows for fully automatic assays.73 Instead of a cartridge with an electrical interface connecting the sensor electrodes, the GMR chip consisting of 40 individual sensors is wire-bonded to the PCB. The electrical parts of the GMR POC device are around $100 and each assay costs around $5 (including one GMR chip embedded in a disposable cartridge, MNP labels, and reagents) if mass produced.82

Figure 8.

(A–C) Photographs (and drawings) of three GMR POC devices reported by different groups. (D) (D3, D5) Microfluidic channels D3 and D5 (D1) aligned on the GMR sensor arrays with the sensor array compartmentalized into four complementary independent compartments. (D2) Sandwich assay. (D4) SEM image of MNP labels on GMR sensor stripes. (D6) Schematic view of cartridge integrating microfluidic chip and sensor array. (E1) Microfabricated micropillar arrays for on-chip filtering that is compatible with a microfluidic chip. (E2) (Left) Schematic view of MFC to amplify the magnetic field in the sensor region (left) and (right) a photograph of a pair of microfabricated MFCs. (E3) Schematic view of cantilever mechanical movement induced AC magnetic field in the GMR sensor region. (A) Reprinted with permission from ref 96. Copyright 2017 American Chemical Society. (B) Reprinted with permission from ref 97. Copyright 2021 Elsevier B.V. (C) Reprinted with permission from ref 73. Copyright 2018 Elsevier B.V. (D) Reprinted with permission from ref 100. Copyright 2015 The Royal Society of Chemistry. (E1) Reprinted with permission from ref 74. Copyright 2018 The Royal Society of Chemistry. (E2) Reprinted with permission from ref 101. Copyright 2020 Elsevier B.V. (E3) Reprinted from ref 102. Licensed under CC BY 4.0.

Although differing in the functional circuit implementations, all three of these devices constitute the same conceptual blocks for (1) signal generation, (2) signal decoupling, and (3) user accessibility. The signal generation methodology constitutes sinusoid generation for magnetic field and modulating control signal for the GMR array to facilitate implementation of the frequency-multiplexed scheme. These sinusoids are generated using high-resolution DAC devices. The core functionality of the signal decoupling stage is the removal of carrier tones from the GMR signal, which is usually ~30 dB larger than the higher harmonics of interest.82 This can be achieved either by the implementation of a Wheatstone bridge96 or through subtraction of a compensation signal.82,97 Post decoupling, the GMR signal is processed by filter implementations and the data are digitized using high-resolution ADC for frequency-domain processing. Finally, user accessibility is enabled through a customized mobile application guiding the user through individual process steps and providing the final bioassay results. The surface-functionalized GMR biosensors operate on the principle of localized proximity sensing where the binding of MNP labels to sensor surfaces causes a change to the sensor’s electrical resistance. This electrical resistance change is monitored in real-time in the form of magnetoresistance change (ΔMR/MR0, sometimes use ΔMR) in parts per million (ppm).

To clarify, we would like to bring to readers’ attention that although many groups reported GMR-based bioassays and biomagnetic field recordings (reviewed in Section 4), most of them are broadly defined as biosensors that may not have been integrated into POC devices yet. To prevent confusion, we use the broad term “biosensors” to refer to both POC devices and non-POC devices (such as benchtop systems) in the following context.

3.4.2. On-Chip Microfluidic Channels, Filters, and Magnetic Flux Concentrator (MFC).

Polymer-based microfluidic channels hold an important role in biological applications, especially for potential point-of-care measurements. By adding a microfluidic channel to a bioassay platform, it can effectively reduce the reagent cost (as a smaller volume of reagents is needed), enhance the bioassay speed, and meanwhile allow the integration of several processing steps into a single system. It can also make high-throughput biological screening possible by parallel processing multiple samples achieved with multiple fluidic paths and minimizing cross-contamination.98,99 For example, Bechstein et al. compartmentalized a GMR biosensor array using microfluidic channels to address individual sensor compartments with reagents.100 As shown in Figure 8D1, D3, D5), four microfluidic channels split the 64 GMR biosensors into four individual groups. The cartridge in Figure 8D6 integrates microfluidic channels and a GMR biosensor array chip and provides a pressure seal between each component. Thus, this compartmentalization approach allows the separation and cross-reactivity-free measurement of different kinds of analytes on a single GMR biosensor array chip. They used this design to observe pairwise cross-reactivities from multiplexed detection of cancer biomarkers epidermal growth factor receptor (EGFR), epithelial cell adhesion molecule (EpCAM), and transmembrane glycoprotein encoded by the Tacstd2 gene (Trop-2). For the control sample (channel 1), all three biomarkers (EGFR, EpCAM, and Trop-2) are mixed and multiplexed by GMR biosensors functionalized with these three corresponding capture antibodies, whereas for active samples (channels 2, 3, 4), only one kind of biomarker is added. Figure 8D) shows the sandwich assay strategy used for this experiment and the SEM image in Figure 8D4 confirms the captured MNPs on the GMR biosensor surface.

On top of the microfluidic channel, Tsai et al. fabricated an array of micropillars for filtering blood cells and passing only plasma to the guided-mode resonance biosensors area at the other terminal, as shown in Figure 8E1.74 Although this work is not designed for GMR biosensors, the idea of using micropillar arrays for on-chip filtering is worth learning. The filtering step is of great significance when dealing with raw biological samples such as whole blood, saliva, etc., where the large cells, viscous mucus, and debris may interfere with the biosensor signals. On the other hand, magnetic separation or ultra-centrifugation or a washing step is used to remove these signal interference factors in lab-based settings. This micropillar array as an on-chip filter makes it possible to carry all-in-one, fully automatic, and chip-based bioassays on site.

The detection of biomagnetic fields in the picotesla (pT) range is favored for many biomedical applications including brain and cardiac mapping (discussed in Sections 4.5 and 4.5). Magnetic flux concentrator (MFC) has been proposed as a possible method to improve the detection limit of many kinds of magnetic sensors including GMR, MTJ (magnetic tunnel junction), AMR, MEMS, etc.101,103-106 As shown in Figure 8E2, an MFC is usually made of high-permeability materials to improve the sensor sensitivity by concentrating the magnetic flux to the sensor area. It is reported that a good MFC can increase the magnetic flux by a factor of several hundred times.107 There are several factors affecting the flux concentration factor including the relative permeability of the material and the geometry of MFC structure such as the area ratio between the end and start sections of the concentrator. Guedes et al. reported that with the addition of a Co93Zr3Nb4 soft MFC, the detection limit of the GMR sensor in the thermal noise regime is improved from 1.3 to 0.064 nT/Hz1/2,103 In addition to MFC, MEMS piezoelectric cantilevers are also reported to assist the MFC in lowering the sensor noise floor as well as improving the detection limit.102,108,109 To be specific, as shown in Figure 8E3, a pair of MEMS piezoelectric cantilevers modulate the low-frequency magnetic signals into a high-frequency regime where the 1/f noise in the GMR sensor can be neglected. The results confirmed that this hybrid GMR-MEMS device shows an improved detection limit from 1 nT/Hz1/2 (low-frequency regime–1/f noise limited) to 1 pT/Hz1/2 (high-frequency regime–thermal noise limited).102

4. GMR BIOSENSOR-BASED BIOMEDICAL APPLICATIONS

4.1. GMR Biosensors for Disease Diagnosis.

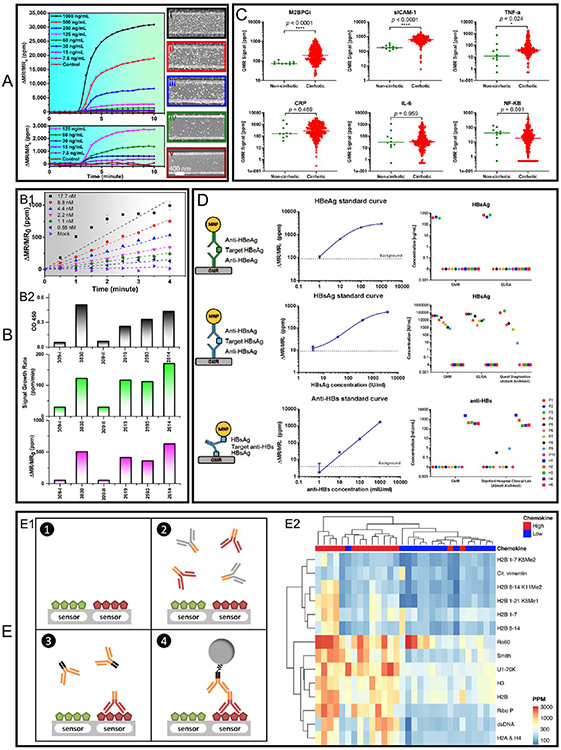

The past decade has seen a spike in applying GMR biosensors for the detection of a wide range of diseases and pathogens including SARS-CoV-2,110 influenza A virus (IAV),57,81,96 cirrhosis,71 hepatitis B virus (HBV),78,111,112 ovarian cancer,77 etc. In this section, we will cover some representative works in applying GMR biosensors for disease diagnosis with a focus on protein biomarkers detection. In 2017, Wu et al. reported a GMR POC device for the detection of IAV nucleoprotein (NP).96 They used the traditional sandwich assay strategy where the active GMR biosensors are surface-functionalized with IAV monoclonal capture antibodies (catalog #BE0159, clone H16-L10–4R5 (HB-65), Bio X Cell, West Lebanon, NH), and the control GMR biosensors are covered by BSA (negative control) or biotinylated BSA (positive control). Fifty microliter samples of recombinant influenza H1N1 NP (Sino Biological Inc. Beijing, China) of varying concentrations are tested. Followed by the addition of monoclonal detection antibody (catalog #MAB8257B, EMD Millipore Corporation, Temecula, CA,) and MNP labels (catalog #130-048-101, Miltenyi Biotec, Inc. Auburn, CA). The real-time GMR signal in the form of ΔMR/MR0 is recorded in a 10 min time window, as shown in Figure 9A. The GMR signal is averaged from 24 active biosensors and five negative control sensors. MNP labels are added at 3 min and, because of the high binding affinity of streptavidin (from MNP label) and biotin (from detection antibody), the binding saturates at 10 min. The GMR signal monotonically increases with the concentration of H1N1 NP. SEM images are taken on the biosensors after the assay to further confirm the binding of MNP labels on the GMR biosensor surfaces. As shown in Figure 9A(i-v), the density of captured MNP labels increases from control sensor (Figure 9A(v), to active sensors (Figure 9A(iv): 60 ng/mL, Figure 9A(iii): 250 ng/mL, Figure 9A(ii): 500 ng/mL, and Figure 9A(i): 1000 ng/mL). This confirms that the GMR signal is proportional to the concentration of target analytes (H1N1 NP in this scenario) as well as the MNP labels captured through the sandwich structure.

Figure 9.

(A, B1) Real-time GMR signal recorded from samples with varying concentrations of IV NP. A used a traditional sandwich assay scheme and B used a wash-free sandwich assay scheme. SEM images i–v of GMR biosensors after the bioassay show a varying number of immobilized MNP labeled on the sensor surface. The real-time GMR signal in A is the average of 24 active GMR sensors; error bars are not shown in this selected figure. The real-time GMR signal in B) is the average of 24 active GMR sensors; error bars are marked at 2 and 4 min and represent the standard deviation. (B2) Comparison of results from six nasal swab samples tested by ELISA (top) and GMR platform, where the GMR signal is represented by ΔMR/MR0 (bottom) and ΔMR/MR0/Δt (middle). Signal growth rate is the average of 24 GMR sensors, error bars are not shown. (C) Scatter plots of individual cirrhosis biomarkers from noncirrhotic and cirrhotic patients. Lines on the plots mark median biomarker signal levels. Respective p-values were calculated and shown. (D) HBeAg, HBsAg, and anti-HBs sandwich magnetic immunoassay structures (left column), the standard curves obtained from GMR biosensors (middle column), the analyte concentrations from serum samples calculated from GMR signals compared with other diagnostic methods (ELISA and/or Abbott Architect). The error bars in standard curves represent standard deviations of 80 identical sensor signals. (E) GMR multiplexed assay to identify interferon-associated autoantibodies in systemic lupus erythematosus (SLE). (E1) Another version of the sandwich assay involves antigen–primary antibody–secondary antibody–MNP label. (E2) An unsupervised hierarchically clustered heatmap shows the candidate autoantigens identified by SAM (significance analysis of microarrays). (A) Reprinted with permission from ref 96. Copyright 2017 American Chemical Society. (B) Reprinted from ref 81. Licensed under CC BY 4.0. (C) Reprinted with permission from ref 71. Copyright 2020 American Chemical Society. (D) Reprinted from ref 78. Licensed under CC BY 4.0. (E) Reprinted from ref 58. Licensed under CC BY 4.0.

In 2019, Su et al. reported the detection of IAV NP with a wash-free sandwich assay strategy.81 The preincubated MNP label-detection antibody-H1N1 NP complexes are added to GMR biosensors and GMR signals are recorded in real-time (Figure 9B1 plots the averaged GMR signal from 24 active sensors). Because the binding affinity between H1N1 NP and capture antibodies is weaker than streptavidin–biotin conjugations. It takes a longer time for the dynamic binding process to reach equilibrium (as well as a long time for the GMR signal to saturate). Thus, they only record the GMR signal for 4 min (before saturates) and use both GMR signal (ΔMR/MR0) and GMR signal growth rate (expressed as ΔMR/MR0/Δt) as indicators of H1N1 NP concentration. Because of the relative abundance of H1N1 NP from the biological sample and the capture antibodies from the GMR biosensor surface, the real-time binding curves show different slopes (growth rates) as seen in Figure 9B1. These two indicators are later used to calibrate the relative abundancies of IAV from swine nasal swab samples. The GMR signal and signal growth rate are compared with the ELISA results in Figure 9B2. All four positive and two negative results from GMR biosensors are consistent with those from ELISA, which proves the wash-free sandwich assay is a reliable method for the “yes or no” IAV level test in the raw samples taken from the field.

GMR-based sandwich assays have also been reported for the multiplexed detection of six cirrhosis biomarkers: mac-2-binding protein glycan isomer (M2BPGi), soluble intercellular adhesion molecule-1 (sICAM-1), c-reactive protein (CRP), nuclear factor kappa-light chain-enhancer of activated B cells (NF-κB), tumor necrosis factor-alpha (TNF-α), and interleukin-6 (IL-6). As shown in Figure 9C, the GMR signals (ΔMR/MR0) are scatter plotted for each biomarker from noncirrhotic and cirrhotic patients. Demonstrating the powerful abilities of GMR biosensor arrays in protein biomarker screening, allowing for faster, less expensive, and more accurate disease early stage detection. In addition, quantitative, multiplexed GMR bioassays are possible by plotting the standard GMR signal–analyte concentration curve and using it as a look-up table for calculating the analyte concentrations of unknown samples. For example, Gani et al. reported the multiplexed detection of HBV “e” antigen (HBeAg), HBV surface antigen (HBsAg), and the antibody against HBsAg (anti-HBs) from serum samples.78 They first obtained the assay standard curve for each analyte from 80 identical GMR sensors (Figure 9D middle column) then used these curves as look-up tables to calculate the analyte concentrations from 15 serum samples based on the GMR signal. As shown in the right column in Figure 9D, the quantitative results from GMR biosensors are compared with other diagnostic methods (ELISA and/or Abbott Architect). It shows that the GMR biosensor holds great promise as a more accessible alternative for HBV screening, diagnosis, and treatment monitoring.

Lee et al. reported the multiplexed detection of multiple autoantibodies associated with interferon (IFN) dysregulation in systemic lupus erythematosus (SLE).58 In this work, a different version of the sandwich bioassay strategy is used. As shown in Figure 9(E1), the GMR biosensors are functionalized with autoantigens to identify autoantibodies associated with dysregulation of the IFN pathway in SLE. Serum samples from SLE patients with high (n = 15) and low (n = 15) chemokine scores are tested on GMR biosensors. Once the autoantibodies specifically bind to the GMR biosensor surface, the residuals are washed out and antihuman IgG biotinylated antibodies are added as the bridge between autoantibodies and MNP labels added in the next step. An unsupervised hierarchically clustered heatmap is plotted and significance analysis of microarrays (SAM) is used to identify autoantigens with significantly different antibody reactivity between the groups, as shown in Figure 9E2. In this work, they discovered that 12 autoantibodies identified by SAM have not previously been associated with chemokine scores. They included histones (H2A and H4, H2B, and H3), methylated (K5Me1, K5Me2, and K11Me2), and unmodified peptides from the N-terminal tail of H2B, Ribo P, Sm, Ro60, and U1–70K. This work shows that GMR biosensor arrays can identify autoantibodies associated with relevant clinical manifestations of SLE, with potential for use as biomarkers in clinical practice.

4.2. GMR Biosensors for Genotyping.

GMR bioassay platforms combined with PCR (polymerase chain reaction) or LAMP (loop-mediated isothermal amplification) technologies have also been reported for the detection of viral nucleic acid (DNA or RNA) including human papillomavirus (HPV),113 hepatitis B virus (HBV),111,112 and cDNA (complementary DNA),114 and DNA mutations for cancer prognostics,79 etc. The first report of GMR multilayer (Si/(Ni80Fe20)1.6 nm/[Cu 1.9 nm/(Ni80Fe20) 1.6 nm]10/Ta 3 nm) biosensor for nucleic acid detection was by Schotter et al. in 2004.115 They used a spiral-shaped GMR multilayer biosensor that covers a circular area of 70 μm diameter. It achieved a dynamic detection range of 16 ng/mL to 10 μg/mL for DNA detection. Although the first report of applying GMR spin-valve biosensors for nucleic acid detection was in 2008 by Xu et al.113 They are able to detect as low as 10 pM HPV DNA (after PCR amplification) and achieved an accuracy of ~90% from 12 assays of different HPV genotypes (i.e., HPV16, 18, and 45).

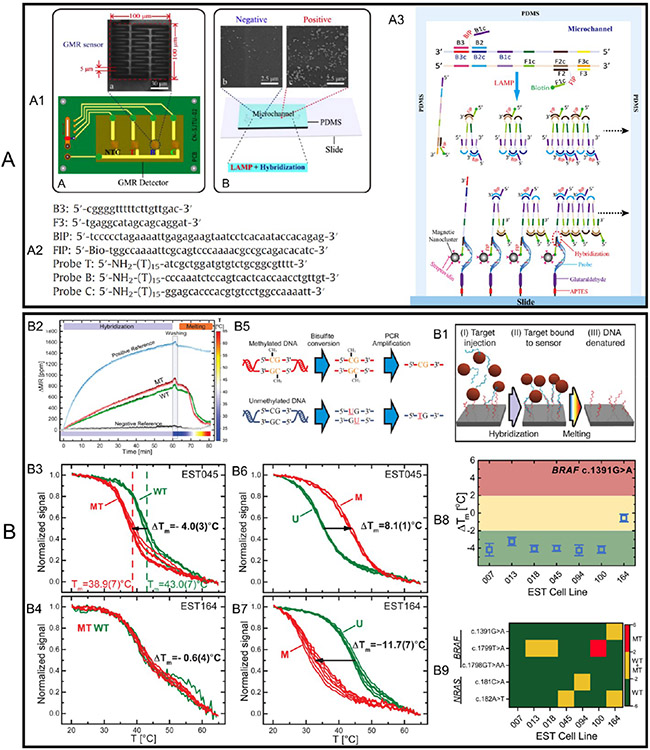

Following these pioneering works, another group reported the detection of HBV genotypes by integrating the GMR multilayer biosensors (NiFeCo 6 nm/[Cu 2.1 nm/(NiFeCo) 1.5 nm]10/Ta 100 nm.), LAMP technology, and a microfluidic chip.112 As shown in Figure 10A1, the microfluidic chip is used to shorten the assay time. The GMR multilayer biosensor is in a zigzag pattern with a line width of 5 μm and overall sensor area of 100 μm × 100 μm. Four GMR multilayer biosensors (3 active and 1 control) are welded on a PCB with a digital multimeter (not shown) for signal collection. A microfluidic channel with 300 μm (length) × 300 μm (width) × 100 μm (depth) is made from biocompatible PDMS. The primers B3, F3, BIP (B1c-B2), and biotinylated primer FIP (F1c-F2) are used to amplify the conserved domain of the HBV genome. Probe T hybridizes with all genotypes of HBV DNA and probes B and C uniquely hybridize with HBV genotype B and C, respectively. The sequences of primers and probes are shown in Figure 10A2. The LAMP amplification and DNA hybridization steps are schematically drawn in Figure 10A3. In short, primers were incubated with an HBV DNA template at 63 °C for 1 h. Meanwhile, the DNA probes from the GMR multilayer biosensor surface were hybridized with target HBV DNA fragments produced by LAMP. Finally, streptavidin-conjugated MNP labels were added and captured by the hybridized DNA pairs through the biotin at the terminal end of target HBV DNA, followed by a wash step to remove unbound reagents from the microfluidic channel. The GMR signal is collected and mapped to the HBV DNA concentration (before LAMP amplification). In this work, we achieved a detection limit of 10 copies/mL target HBV DNA through a 1 h LAMP amplification, 15 min MNP labeling, and 3 min wash step. We want to bring it to readers’ attention that some works report the limit of detection (LOD) by using the concentrations of nucleic acids before amplification, whereas other works report the LOD by using the concentrations after amplification.

Figure 10.

(A) GMR multilayer biosensors combined with LAMP and microfluidic channel for genotyping HBV DNA. (A1) Photographs of one GMR multilayer biosensor and four biosensors assembled on a PCB. (A2) Schematic view of the microfluidic channel made from PDMS and MNP labels bound on GMR multilayer biosensors. (A2) Sequences of primers and probes. (A3) LAMP amplification and DNA hybridization steps. (B) Simultaneous profiling of DNA mutation and methylation by melting analysis using GMR (SV) biosensors. (B1) Schematic protocol for the profiling DNA mutation and methylation using GMR biosensors. (B2) Real-time GMR signal (ΔMR) recorded in a complete cycle of hybridization, wash, and melting curve measurement. (B3, B4) Normalized melting curves from WT (wild type) and MT (mutant type) probes targeting BRAF c.1391 G > A mutation, where the EST045 (B3) and EST164 (B4) cell lines are wild type and heterozygous mutant, respectively. (B5) Schematic of the bisulphite conversion process. (B6, B7) are the curves from U (unmethylated) and M (methylated) probes (i.e., GMR biosensors functionalized with each type of probe). The melting curves are measured for (B6) the hypermethylated cell line EST045 and (B7) the unmethylated cell line EST164. (B8) Mutation profiling of melanoma cell lines. ΔTm measured for BRAF c.1391G > A mutation for the seven investigated EST cell lines. Error bars in B8 are one standard deviation (n = 4–6). (B9) Heat map of measured ΔTm with an applied threshold to genotype mutations: WT in green, heterozygous MT in yellow, homozygous MT in red. (A) Reprinted with permission from ref 112. Copyright 2013 Elsevier B.V. (B) Reprinted with permission from ref 79. Copyright 2017 American Chemical Society.

Rizzi et al. reported the GMR spin-valve biosensors for simultaneous profiling of DNA mutation and methylation by means of measuring the DNA melting point.79 DNA methylation is gaining increasing interest as complementary information to DNA mutations for cancer diagnostics and prognostics. The basic idea of this work is to first PCR amplify the genomic (mutation) or bisulphite-treated (methylation) DNA. The amplicons are then magnetically labeled with MNPs. After magnetic column separation and denaturation, the ssDNA-conjugated MNPs (i.e., MNP-ssDNA complexes) are introduced to the GMR biosensor array where multiple DNA probes are functionalized on each sensor. With the hybridization of MNP-ssDNA to probes, the GMR signal (in the form of ΔMR) is recorded in real time followed by a wash step, a melting curve measurement is carried out where the temperature is swept from 20 to 65 °C, as shown in Figure 10B1. For example, in Figure 10B2, in a DNA mutation analysis, two probes complementary to the wild type (WT) and mutant type (MT) are functionalized on different GMR biosensors. During the hybridization step, the GMR signal (ΔMR) increases with the binding of MNP labels. To obtain single-base specificity, at 60 min, we used stringent washing after hybridization. The hybrids are then challenged by increasing the temperature and continuously measuring DNA melting simultaneously for all probes (MT, WT, negative, and positive control probes) on the GMR biosensor array. A biotinylated DNA probe is used as a positive reference and a DNA probe with an unspecific sequence is used as a negative reference. Panels B3 and B4 in Figure 10 show the melting curves of WT BRAF amplicons hybridized to WT and MT probes for the c.1391G > A mutation. The GMR signal (ΔMR) is normalized by the initial signal at T = 20 °C and the melting temperature Tm is defined as the temperature at which the signal dropped 50%. ΔTm (= Tm(MT) − Tm(WT)) indicates a higher complementarity of the target to the WT probes than the MT probe, and hence that the target is WT. The EST045 cell lines (Figure 10B3) are wild type and a single base mismatch between the WT targe and MT probe causes great differences in the melting curves, whereas the EST164 cell lines (Figure 10B4) are heterozygous samples containing both MT and WT targets that can hybridize to both WT and MT probes. The resulting melting curves are overlapping.

Similarly, DNA methylation can also be detected by employing bisulphite treatment on the genomic DNA to convert a methylation event into a single base substitution, as shown in Figure 10B5. After the bisulphite conversion, the gene promoter region of interest is amplified by PCR. The amplicons are then hybridized to probes complementary to unmethylated (U) or methylated (M).Panels B6 and B7 in Figure 10 show melting curves to analyze the methylation status. For the hypermethylated cell line EST045 in Figure 10B6, the GMR biosensors functionalized with M probes show higher melting temperature and thus higher complementarity of the target ssDNA, proving the hypermethylated target DNA. On the other hand, for unmethylated cell line EST164 in Figure 10B7, the GMR biosensors functionalized with U probes show higher melting temperature, thus proving that target DNA strands are unmethylated. The multiplexed DNA profiling of melanoma cell lines is then carried out on a GMR biosensor array consisting of 64 individual sensors. Using the mutation and methylation detection techniques described above, they have simultaneously probed three mutation sites in BRAF, two mutation sites in NRAS, two methylation sites in the KIT promoter, and two methylation sites in the RARB promoter in triplicate. Figure 10B8 shows the ΔTm values measured for the BRAF c.1391 G > A mutation for all cell lines. Error bars are standard deviations (n = 4–6). ΔTm = −4 °C indicates a homozygous WT sequence, whereas a ΔTm value close to zero indicates a heterozygous mutation (i.e., EST 164). Furthermore, Figure 10B9 is the heatmap of ΔTm for all investigated mutations for each cell line. Classifying WT (ΔTm < −2 °C), heterozygous MT (−2 °C < ΔTm < 2 °C), and homozygous MT (ΔTm > 2 °C). They also applied it to detect the DNA methylation density. In its present format, the GMR biosensor platform can be used for the simultaneous triplicate investigation of about 20 mutation and methylation sites. Table 2 provides a summary of various disease/pathogen detection based on GMR biosensors.

Table 2.

Summary of GMR Biosensors for Detection of Biological Analytes

| disease/pathogen | target analyte | matrices | limit of detection (LOD) |

assay time | ref |

|---|---|---|---|---|---|

| ovarian cancer | cancer antigen 125 (CA125) | PBS buffer | 3.7 U/mL | 20 min | 77 |

| human epididymis protein 4 (HE4) | 7.4 pg/mL | ||||

| interleukin 6 (IL6) | 7.4 pg/mL | ||||

| cirrhosis | Mac-2 binding protein glycan isomer (M2BPGi) | serum | NA | 15 min | 71 |

| soluble intercellular adhesion molecule-1 (sICAM-1) | 96.9 pg/mL | ||||

| C-reactive protein (CRP) | 14.2 pg/mL | ||||

| nuclear factor kappa-light chain-enhancer of activated B cells (NF-κB) | NA | ||||

| tumor necrosis factor-alpha (TNF-α) | 12.6 pg/mL | ||||

| Interleukin 6 (IL6) | 4.9 pg/mL | ||||

| cardiovascular disease | pregnancy-associated plasma protein-A (PAPP-A) | PBS buffer, serum | 1 ng/mL | 40 min | 76 |

| proprotein convertase subtilisin/kexintype9 (PCSK9) | 433.4 pg/mL | ||||

| suppression of tumorigenicity 2 (ST2) | 40 pg/mL | ||||

| C-reactive protein (CRP) | blood | 1 ng/mL | 15 min | 85 | |

| tumor | alpha-fetoprotein (AFP) | serum | 0.52 ng/mL | 15 min | 73 |

| carcinoembryonic antigen (CEA) | 0.27 ng/mL | ||||

| cytokeratin 19 fragment (CYFRA21–1) | 0.25 ng/mL | ||||

| neuron specific enolase (NSE) | 0.5 ng/mL | ||||

| free β-subunit of human chorionic gonadotropin (free-β-hCG) | 0.3 ng/mL | ||||

| squamous cell carcinoma (SCC) | 0.3 ng/mL | ||||

| pepsinogen I (PG I) | 1 ng/mL | ||||

| pepsinogen II (PG II) | 0.5 ng/mL | ||||

| total prostate-specific antigen (tPSA) | 0.02 ng/mL | ||||

| free prostate-specific antigen (fPSA) | 0.07 ng/mL | ||||

| thyroglobulin (Tg) | 1 ng/mL | ||||

| carbohydrate antigen 19–9 (CA19–9) | 2 ng/mL | ||||

| hepatitis B virus (HBV) | HBV e antigen (HBeAg) | serum | 1 IU/mL | NA | 78 |

| HBV surface antigen (HBsAg) | 3 IU/mL | ||||

| antibody against HBsAg (Anti-HBs) | 1 mIU/mL | ||||

| HBV DNA | NA | 10 copies/mL | 1 h | 112 | |

| HBV DNA | NA | 200 IU/mL | 15 min | 111 | |

| human papillomavirus (HPV) | HPV DNA | NA | 10 pM | 10 min | 113 |

| influenza A virus (IAV) | IAV nucleoprotein (IAV NP) | PBS buffer | 15 ng/mL | 10 min | 96 |

| H3N2 virus | 125 TCID50/mL | ||||

| IAV nucleoprotein (IAV NP) | PBS buffer | 0.3 nM | 4 min | 81 | |

| H3N2 virus | nasal swab | 250 TCID50/mL | |||

| heart failure and other cardiac diseases | N-terminal pro-B type natriuretic peptide (NT-proBNP) | PBS buffer, human plasma | 0.01 ng/mL | <10 min | 116 |

| SARS-CoV-2 | anti-SARS-CoV-2 IgG | NA | 5 ng/mL | 10 min | 110 |

| anti-SARS-CoV-2 IgM | 10 ng/mL | ||||

| E. coli O157H:H7 | E. coli O157H:H7 bacteria particle | PBS buffer | 100 CFU/mL | NA | 80 |

| NA | NA | 117 | |||

| systemic lupus erythematosus (SLE) | histone H2A & H4 | serum | NA | 15 min | 58 |

| histone H2B 1–7 K5Me2 | |||||

| histone H2B 8–14 | |||||

| histone H2B 8–14 K11Me2 | |||||

| Histone H2B 1–21 K5Me1 | |||||

| histone H2B 1–7 | |||||

| histone H2B | |||||

| histone H3 | |||||

| plasmid double-stranded DNA (dsDNA) | |||||

| ribonucleoprotein 60 kDa (Ro60) | |||||

| ribosomal phosphoprotein P0 (Ribo P) | |||||

| citrullinated vimentin peptide (Cit. vimentin) | |||||

| small nuclear ribonuclearprotein 68 (U1–70K) | |||||

| Smith | |||||

| cancer | Jurkat leukemia cells | PBS buffer | NA | NA | 99 |

| HIV | HIV-1 glycoprotein 41 (gp41) | saliva | NA | 16 min | 97 |

| leukocytosis | neutrophil elastase (NE) | plasma | NA |

4.3. GMR Biosensors for Food and Drug Regulation.

Foodborne pathogens are a growing global public health concern that not only affects human health but also affects productivity and international trade.118-120 To prevent, control, and mitigate the impact of potential foodborne disease outbreaks. A growing number of biosensors, such as surface plasmon resonance (SPR), electrochemical, impedimetric, etc., have been reported for the rapid detection of foodborne pathogens.121-127 Among them, although GMR biosensors are still developing, they play an important role in the early and accurate detection of foodborne pathogens,80,117 allergens,128 and toxins.70

For example, most Escherichia coli (E. coli) are harmless and are part of a healthy intestinal tract. However, if it is transmitted to humans through consumption of contaminated or raw/undercooked food. It may cause illnesses including diarrhea, urinary tract infections, respiratory illness, and bloodstream infections. Many foodborne illness outbreaks related to E. coli have been reported in recent years.129,130 With faster detection time and high sensitivity, it will be a valuable tool for the real-time diagnosis of foodborne pathogens. Sun et al. reported that their GMR sandwich assay protocol can detect E. coli O157H:H7 as low as 100 CFU/mL.80 On the other hand, Kokkinis et al. reported an innovative method to detect E. coli bacteria particles dynamically, using GMR sensors as an MNP label speedometer.117 They labeled the E. coli bacteria by MNPs and passed the MNP-E. coli complexes through a microfluidic channel directed by an external magnetic field. A GMR sensor is placed at each end of the channel to detect the MNPs when pass through. For the control group, MNPs without conjugation of E. coli are passed through the channel. The velocity of MNPs in the microfluidic channel is calculated and used as an indicator of the presence of a pathogen in the sample fluid.