Abstract

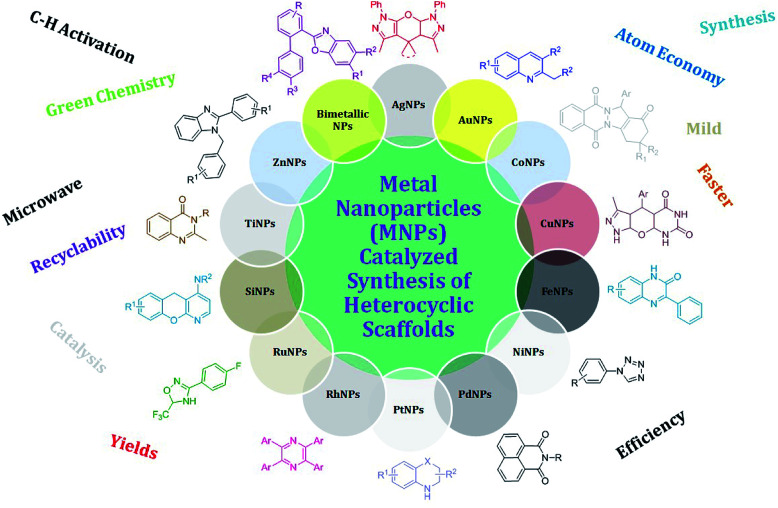

Heterocycles have been found to be of much importance as several nitrogen- and oxygen-containing heterocycle compounds exist amongst the various USFDA-approved drugs. Because of the advancement of nanotechnology, nanocatalysis has found abundant applications in the synthesis of heterocyclic compounds. Numerous nanoparticles (NPs) have been utilized for several organic transformations, which led us to make dedicated efforts for the complete coverage of applications of metal nanoparticles (MNPs) in the synthesis of heterocyclic scaffolds reported from 2010 to 2019. Our emphasize during the coverage of catalyzed reactions of the various MNPs such as Ag, Au, Co, Cu, Fe, Ni, Pd, Pt, Rh, Ru, Si, Ti, and Zn has not only been on nanoparticles catalyzed synthetic transformations for the synthesis of heterocyclic scaffolds, but also provide an inherent framework for the reader to select a suitable catalytic system of interest for the synthesis of desired heterocyclic scaffold.

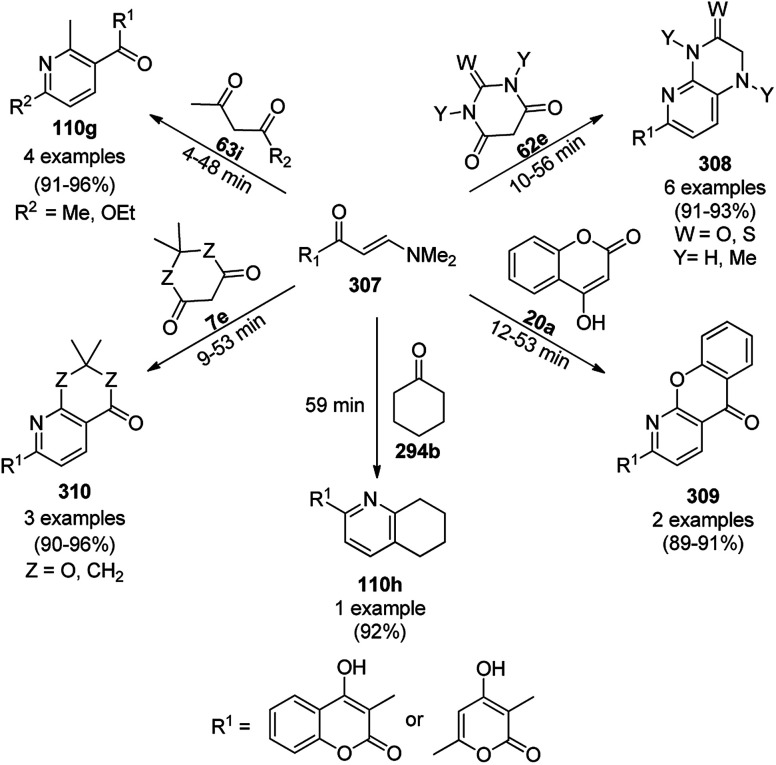

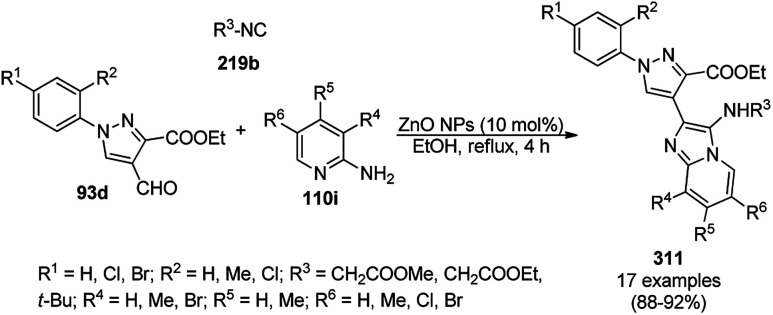

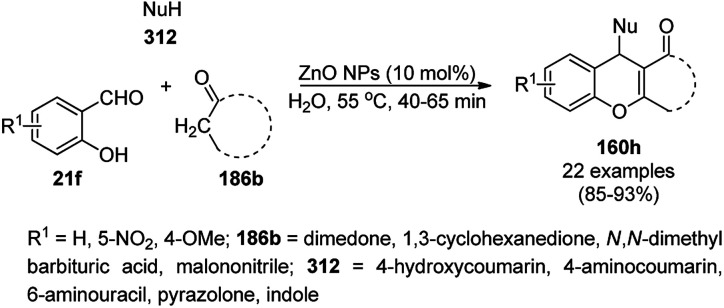

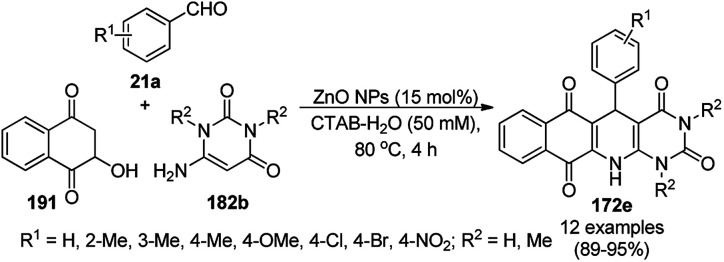

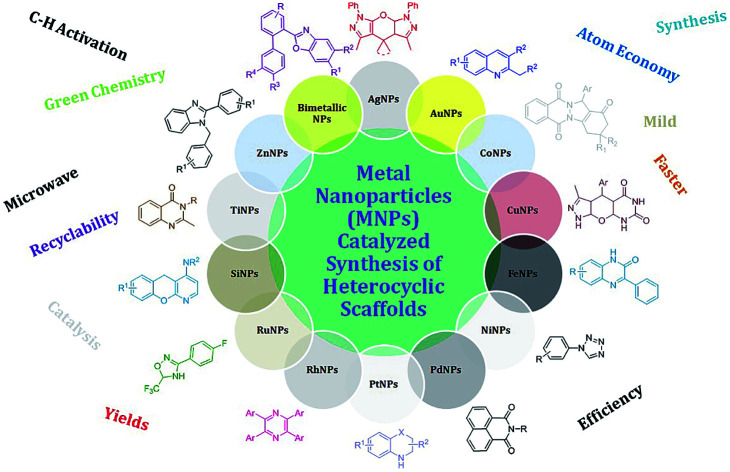

Metal nanoparticle (MNP)-catalyzed synthesis of nitrogen- and oxygen-containing heterocyclic scaffolds.

1. Introduction

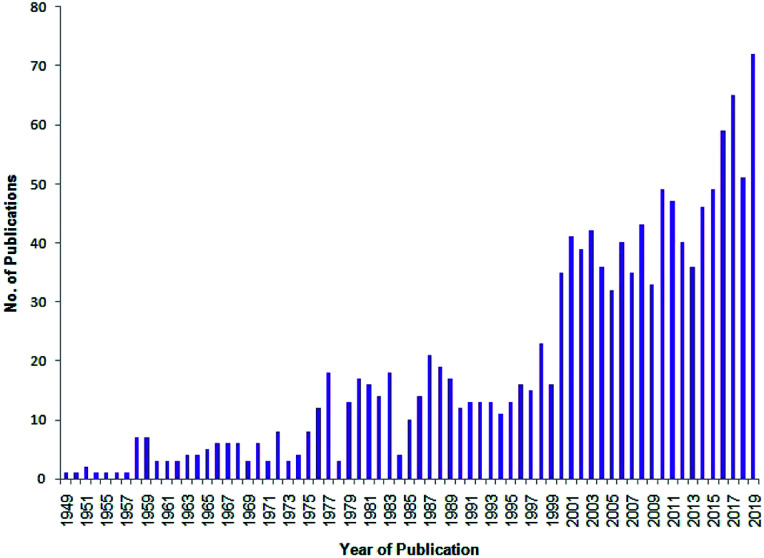

Heterocycles containing nitrogen1 and oxygen2 have been found to be of much importance among the United States Food and Drug Administration (USFDA) approved drugs. Specifically, 59% of the USFDA-approved drugs contain a nitrogen-containing heterocycle,1 and the USFDA has approved 311 drug candidates assembled with an oxygen-containing heterocycle.2 Numerous heterocyclic scaffolds have been synthesized with modern advancements with an endeavor towards drug discovery paradigm.3 A recent analysis on structures of USFDA-approved drugs administered in combination with other drugs as reported by Njardarson et al. revealed that the major importance of these heterocycles in combination drugs is in variety of therapeutic uses.4 The rich literature5–14 on the synthesis of these USFDA-approved drugs is also gaining momentum since for the clinical use of a drug, the drug molecule has be synthesized on a pilot scale using a suitable toolbox of organic chemistry.15 A plot of the number of publications versus year of publication performed using Sci-Finder16 for the search string ‘synthesis of heterocyclic scaffolds’ revealed the increasing popularity of heterocyclic scaffolds synthesized via several organic transformations (Fig. 1).

Fig. 1. Number of publications versus corresponding year of publication for the search string ‘synthesis of heterocyclic scaffolds’ accessed by Sci-Finder on Nov 28, 2019.

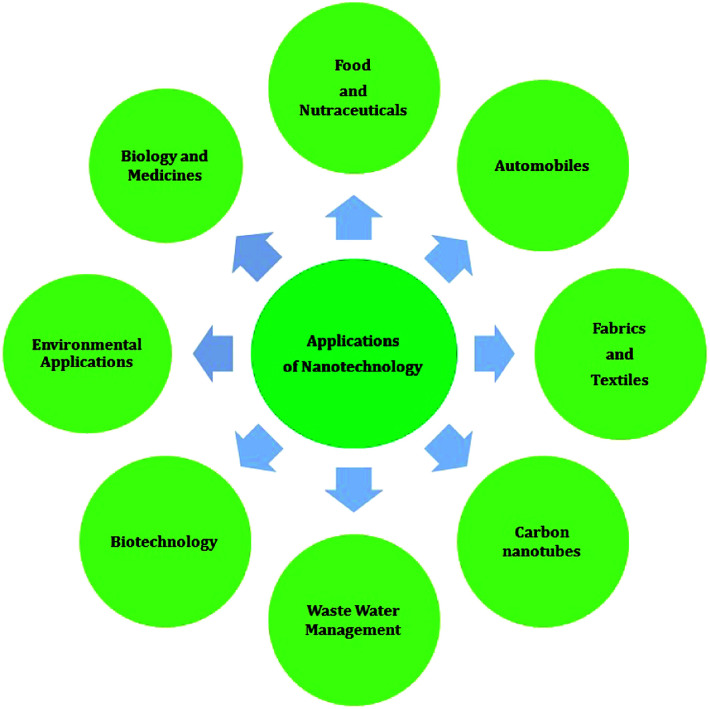

Nanomaterials are defined as materials with at least one of their dimensions in the nanometer range (1 nm to 100 nm). Recently, nanotechnology has advanced significantly, and thus has found substantial applications in therapeutics,17 food and nutraceuticals,18 wastewater management,19 biotechnology,20 biology and medicine,21 automobiles,22 fabrics and textiles,23 carbon nanotubes,24 and environmental applications25 (Fig. 2).

Fig. 2. Recent applications of nanotechnology.

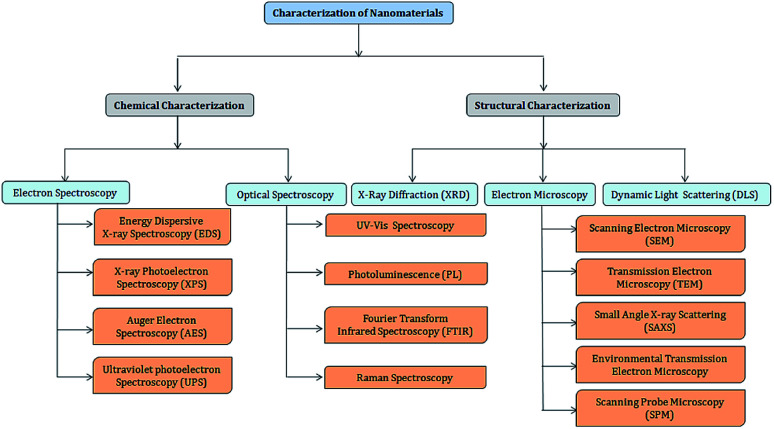

A wide variety of techniques is available for the characterization of nanomaterials due to the advancement of sophisticated and simple spectrophotometric and robotic instrumentation. The basic techniques required for the characterization of nanomaterials, namely chemical and structural characterization, are presented in Fig. 3. The size of nanoparticles can be characterized using transmission electron microscopy (TEM), X-ray diffraction (XRD), dynamic light scattering (DLS), high-resolution transmission electron microscopy (HR-TEM), scanning electron microscopy (SEM), atomic force microscopy (AFM), inductively coupled plasma-mass spectrometry (ICP-MS), UV-visible spectroscopy (UV-Vis), matrix-associated laser desorption ionization (MALDI), and nuclear magnetic resonance (NMR). The shape of NPs can be characterized using TEM, HR-TEM, and AFM, while XRD, X-ray photoelectron spectroscopy (XPS), inductively coupled plasma-mass spectrometry (ICP-MS), and NMR can be used to confirm their chemical composition. The surface properties of NPs can be determined using the BET (Brunauer, Emmett and Teller) technique and liquid NMR, and their magnetic behavior can be tested using vibrating sample magnetometry (VSM) and Mössbauer spectroscopy.26

Fig. 3. Basic techniques for the characterization of nano-materials. Chemical characterization includes optical spectroscopy such as optical absorption spectroscopy, which includes UV-Vis spectroscopy, photoluminescence (PL), Fourier transform infrared spectroscopy (FTIR), and Raman spectroscopy; and electron spectroscopy including energy dispersive X-ray spectroscopy (EDS), X-ray photoelectron spectroscopy (XPS), auger electron spectroscopy (AES), and ultraviolet photoelectron spectroscopy (UPS). Structural characterization involves X-ray diffraction (XRD); electron microscopic techniques such as scanning electron microscopy (SEM), transmission electron microscopy (TEM), small angle X-ray scattering (SAXS), environmental transmission electron microscopy (ETEM), and scanning probe microscopy (SPM); and dynamic light scattering (DLS) using a particle size analyzer.

2. Nanocatalysis

Catalysis (Greek: to dissolve) is the terminology coined by Swedish chemist Jöns Jacob Berzelius in 1836, which means a substance awakens dormant affinities by its mere presence.27 Catalysis can be categorised into homogenous catalysis and heterogeneous catalysis. Heterogeneous catalysis is more favoured over homogenous catalysis since the former is beneficial for the easier isolation, purification and recycling of costly catalysts for subsequent transformations. Most nanoparticles (NPs) are heterogeneous catalysts, boosting the goals of synthetic chemist to co-align green chemistry approaches.28

Nanocatalysts have a particle size in the nm scale, and thus have a large surface area, which enables the interaction of chemical reactants via cooperative activation to bring them in closer proximity with each other. Nanocatalysis has been recently employed for wide applications in nanotechnology, productions of fuels from biomass, wastewater treatment, bioelectrocatalysis, environmental applications,29 sustainable applications in green synthesis,30 and organic transformations.31 Grönbeck et al. recently summarized the mechanistic insight of nanocatalysis via computational methods, including density functional theory (DFT) and other computation tools.32

The synthesis of nanocatalysts (NCs) is generally achieved using metals and transition metals from their congener inorganic salts, which are treated with solid supports or linkers to generate reactive functional groups on their extreme periphery. The catalytic activity of NPs is generally achieved using doping agents via their incorporation into metals and metallic oxides, Lewis acids and bases33 and ionic liquids.34

3. Scope and applications of NPs in the synthesis of heterocycles

According to green chemistry, MNP-catalyzed organic transformations are the safest reactions, which do not affect the environment. Some of the important applications of MNPs and metal oxide NPs have been also demonstrated for different types of C–H activation, such as C(sp3)–H and C(sp2)–H functionalization,35,36 asymmetric C–C bond formation,37 biomedical applications,38 and various organic transformations.39 Shaaban et al. reviewed the applications of NPs with respect to heterocycles and fused heterocycles.40 Recently, Gómez et al. summarized the use of PdNPs for the synthesis of polyols via catalytic coupling and hydrogenation.41 Dandia et al. recently reported the synthesis of three-, five-, six- and seven-membered ring systems using nanocatalysts.42 Chaudret et al. recently covered the role of several MNPs in σ-H–H, σ-C–H, and σ-Si–H bond activation.43 Although there are numerous applications of NPs for a variety of organic transformations, in the present review we aimed to focus on the complete coverage of the applications of MNPs (metal nanoparticles) in the synthesis of heterocyclic scaffolds (Fig. 4) reported during the last ten years (2010 to the end of 2019). Thus, it is expected that this review article will give opportunistic insight to organic chemists to select suitable MNPs to achieve the synthetic transformation of choice in order to generate novel molecules, consequently enriching the synthetic armory of the toolbox of medicinal chemists to construct desired scaffolds.44

Fig. 4. Metal nanoparticle (MNP)-catalyzed synthesis of nitrogen- and oxygen-containing heterocyclic scaffolds.

3.1. AgNP-catalyzed synthesis of heterocycles

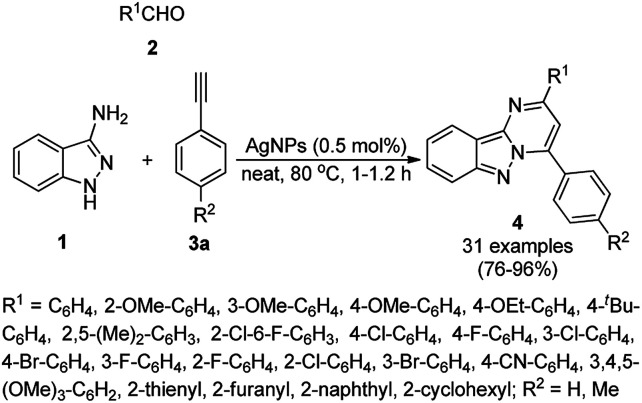

AgNPs have been recognized to be important in the synthesis of heterocyclic scaffolds.45,46 Balwea et al. synthesized pyrimido[1,2-b]indazole derivatives (4) using silver nanoparticles (AgNPs) obtained from the plant extract of Radix puerariae. The extract of Radix puerariae powder was treated with AgNO3 in basic medium and the synthesis of AgNPs was monitored using UV-Vis spectroscopy. The synthesized AgNPs were well characterized via TEM, EDX, XRD, dynamic light scattering (DLS) and zeta potential measurements. The synthesis of 4 was achieved using one pot A3 coupling involving the reaction of three components, i.e. 3-aminoindazoles (1), aryl/heteroaryl/alicyclic aldehyde (2), and substituted phenyl acetylene (3a), using AgNPs (0.5 mol%), solvent-free conditions at 80 °C for 1 h (Scheme 1).47 They also demonstrated the successful use of the AgNP-catalyzed A3 coupling on the gram scale in 90% yield. The catalysts were recovered after the reaction, washed with triple-distilled water, activated and used for up to three consecutive runs.

Scheme 1. Synthesis of pyrimido[1,2-b]indazole derivatives (4) using AgNPs under solvent-free conditions.

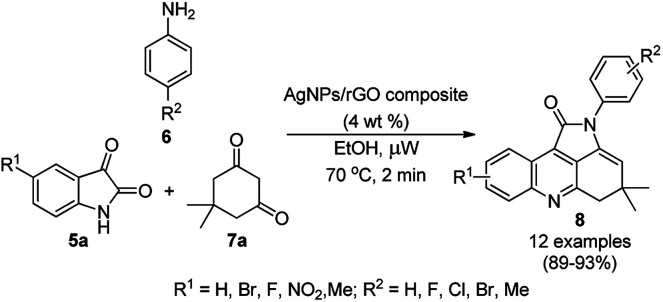

Graphene-supported MNPs have been recently gaining tremendous momentum in the development of C–C and C–X coupling reactions.48 In this endevour, Dandia et al. reported the synthesis of pyrrolo[2,3,4-kl]acridin-1-ones (8, Scheme 2) using AgNP-decorated reduced graphene oxide (AgNPs/rGO).49 A method free from high temperature, pressure and toxic chemicals was used for the synthesis of the nanoparticles via the simultaneous reduction of graphene oxide (GO) and preparation of AgNPs on GO. The structural characteristics of the nanoparticles were confirmed using TEM, XRD, SEM, XPS, EDX, UV-Vis spectroscopy, cyclic voltammetry, and Raman and FT-IR spectroscopy. The application of these AgNPs was demonstrated for the synthesis of 8 from a three-component reaction involving substituted isatins (5a), anilines (6) and dimedone (7a). The effects of various conditions such as catalyst and solvent were studied under microwave irradiation at 70 °C. Subsequently, employing the optimized conditions, the authors reported the rapid synthesis of 8 in 89–93% yield within 2 min. They reported that ethanol was the best solvent because of the relatively higher dispersion of the catalyst and reactants. Furthermore, the recovered catalyst was successfully used for seven consecutive catalytic cycles without significant loss in the yield of 8.

Scheme 2. AgNP-catalyzed synthesis of pyrrolo[2,3,4-kl]acridin-1-ones (8).

Further green applications of an AgNP-decorated GO (graphene oxide) composite as a catalyst “on water” were demonstrated by Dandia et al. for the synthesis of pyrano[2,3-c:6,5-c′]dipyrazol-2-ones (11) at rt in excellent yields (Scheme 3).50 The catalytic potential of AgNPs was proposed by the authors due to their role as a Lewis acid catalyst, which enabled Knoevenagel condensation–Michael addition and cyclization. The SEM and TEM images of the recovered catalysts revealed the integrity of the catalyst, and thus no significant loss of catalytic activity was observed for up to seven catalytic cycles.

Scheme 3. Chemoselective “on-water” synthesis of pyrano[2,3-c:6,5-c′]dipyrazol]-2-ones (11) catalyzed by AgNPs on GO composite.

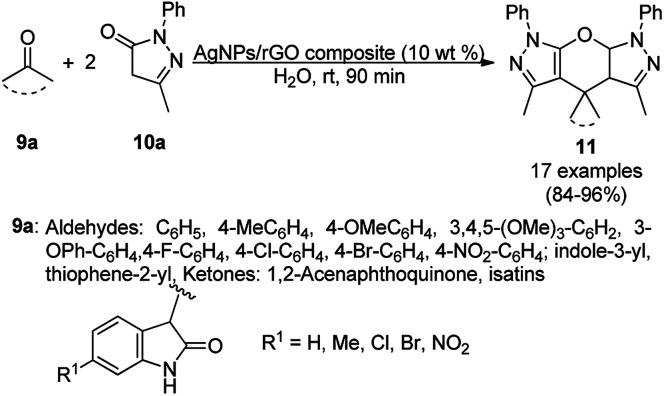

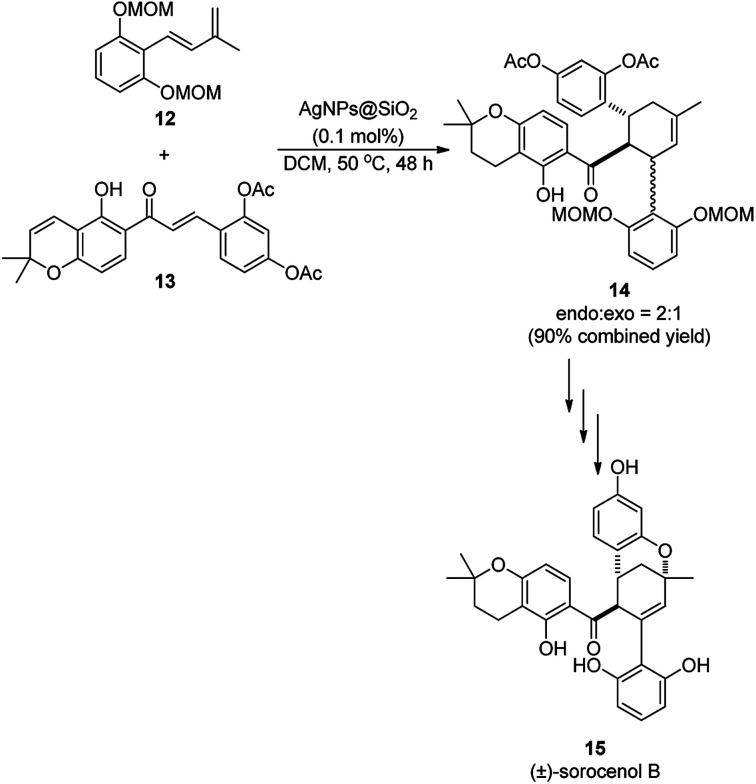

Porco et al. reported the use of AgNP-catalyzed Diels–Alder [4 + 2] cycloaddition (Scheme 4) for the successful synthesis of cycloadduct (14) from chalcone (13) and diene (12), which led to the formation of endo and exo diastereoisomers in a 2 : 1 ratio.51 Subsequently, 14 was used in the total synthesis of (±)-sorocenol B (15), an anti-cancer natural product, through several synthetic steps. The required AgNPs were synthesized following their previously reported protocol52via the reduction of silver tetrafluroborate (AgBF4) using tetrabutyl ammonium borohydride (Bu4NBH4) with silica gel in dichloromethane (DCM).

Scheme 4. AgNP-catalyzed synthesis of cycloadduct (14) for the total synthesis of natural product (15).

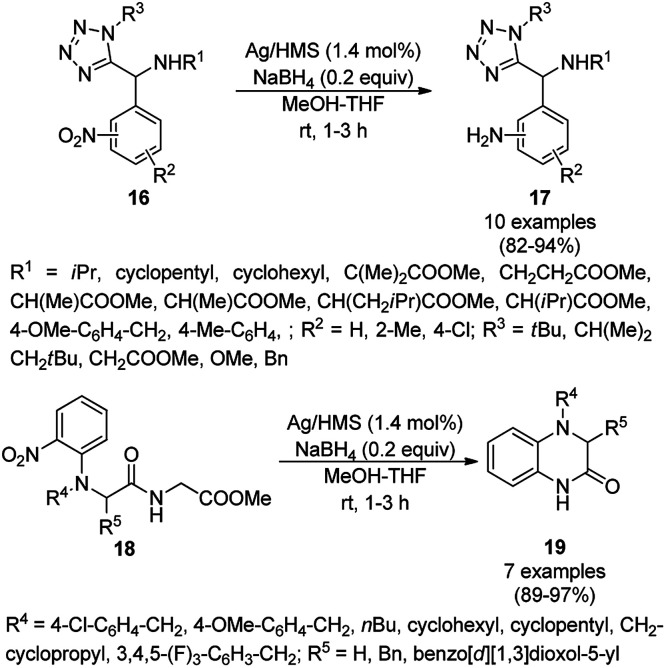

The AgNP-supported mesoporous silica (Ag/HMS)-catalyzed chemoselective reduction of tetrazoles containing nitroarenes (16) was reported by Lykakis et al. (Scheme 5) at a low catalytic loading with high functional group tolerance.53 When the same protocol was extended to the Ugi-Smiles product (18), it resulted in cyclisation with the synthesis of 19via in situ reduction–cyclization. The dihydroquinoxalnones (19) were claimed to inhibit soluble epoxide hydrolase, having anti-hypertensive and anti-inflammatory activity.

Scheme 5. AgNP-catalyzed chemoselective reduction of nitroarenes (16) and synthesis of 19.

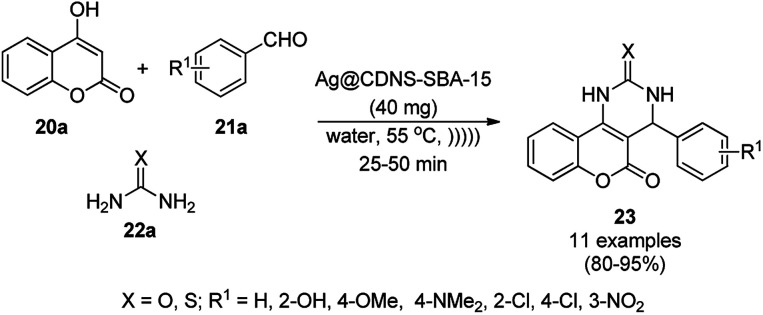

Heravi et al. recently reported the catalytic use of bio-assisted AgNPs supported on an SBA-15/cyclodextrin nanosponge adduct (Scheme 6) for the synthesis of benzopyranopyrimidines (23) from 4-hydroxycoumarins (20a), substituted benzaldehydes (21a), and urea or thiourea (22a) under ultrasonication.54 The cyclodextrin sponge played the key role by bringing the reagents in closer proximity of the AgNPs for the catalysis. The catalyst was reused and recycled for up to four times without losing its catalytic activity.

Scheme 6. Synthesis of benzopyranopyrimidines (23) reported by Heravi et al.

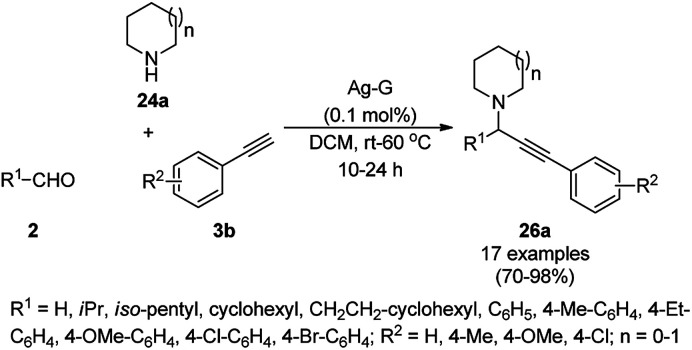

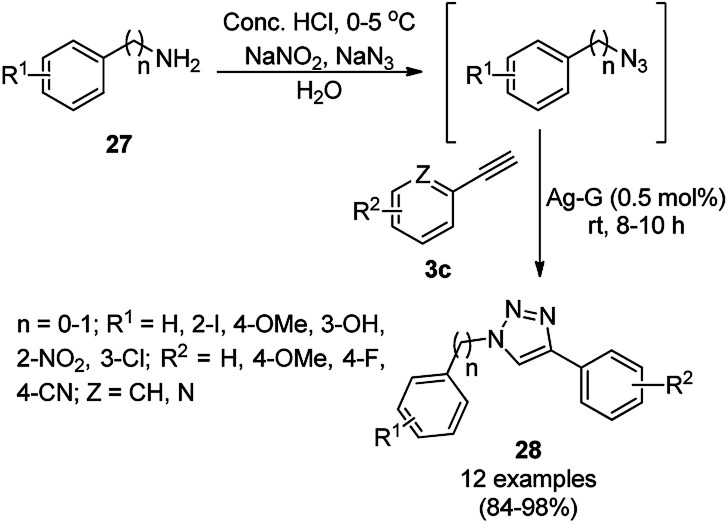

Jana et al. synthesized silver–graphene nanocomposites from graphene oxide (GO), silica-coated AgNPs previously synthesized from [3-(2-aminoethylamino)propyl]trimethoxysilane (AEAPS), (3-mercaptopropyl)-trimethoxysilane (MPS) and silver acetate. The silver-graphene nanocomposite-catalyzed A3 coupling of aldehydes (2), alicyclic amines (24a) and alkynes (3b) for the synthesis of propargyl amines (26a) was achieved successfully in dichloromethane (Scheme 7).55 A similar catalyst was also found to catalyze the synthesis of 1,2,3-triazoles via the click reaction of in situ generated azides from diazotization (Scheme 8) of anilines or arylalkyl amines (27), followed by cycloaddition with terminal alkynes (3c). The same catalyst was recycled for the synthesis of 26a and 28 for up to five consecutive runs without loss in its catalytic activity.

Scheme 7. Silver–graphene nanocomposite-catalyzed synthesis of propargyl amines (26a).

Scheme 8. Click reaction catalyzed by silver–graphene nanocomposites.

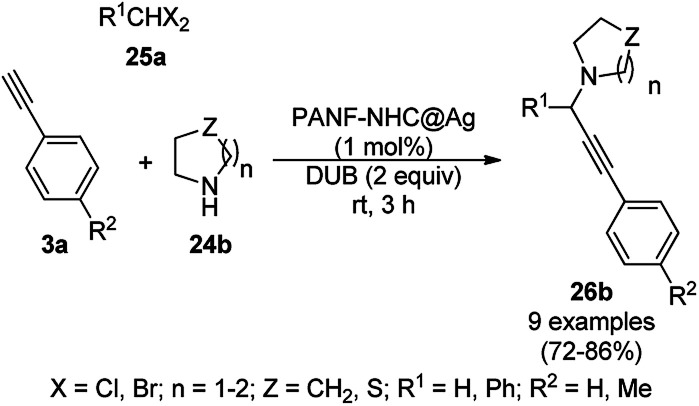

The N-heterocyclic carbine (NHC)-protected AgNPs supported on polyacrylonitrile fiber (PANF-NHC@Ag)-catalyzed three-component coupling of amines (24b), halomethanes (25a), and alkynes (3a) (AHA coupling, Scheme 9) was successfully carried out by Tian et al.56 The catalyst was prepared via the amination of PANF with ethylenediamine followed by its complexation with previously prepared [N-benzyl-N′-(methoxycarbonyl methyl)imidazolin-2-ylidene]silver chloride and reduction with sodium borohydride to obtain active NPs. These AgNPs were recycled for up to ten cycles without appreciable loss in their catalytic potential. The same AgNP-catalyzed reaction was also checked for its applicability in flow chemistry. Compared to reported protocols for AHA coupling, the PANF-NHC@Ag-catalyzed protocol was claimed to be superior since it is operational at rt in shorter times with high reusability under solvent-free conditions in comparison with AuNPs,57 CuCl,58,59 CuI,60 nano In2O3,61 FeCl3,62 CoBr2,63 AgOAc64 and Au/CeO2.65

Scheme 9. AHA coupling catalyzed by NHC-protected AgNPs.

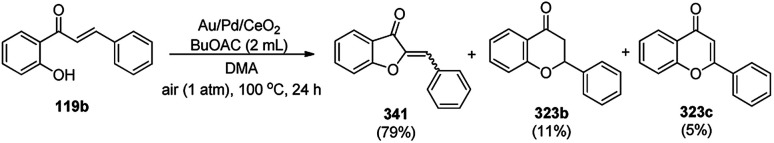

3.2. AuNP-catalyzed synthesis of heterocycles

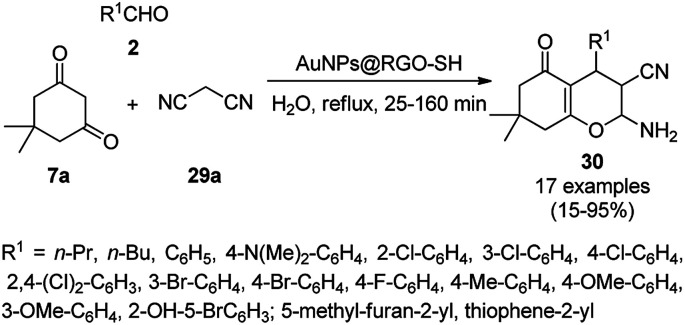

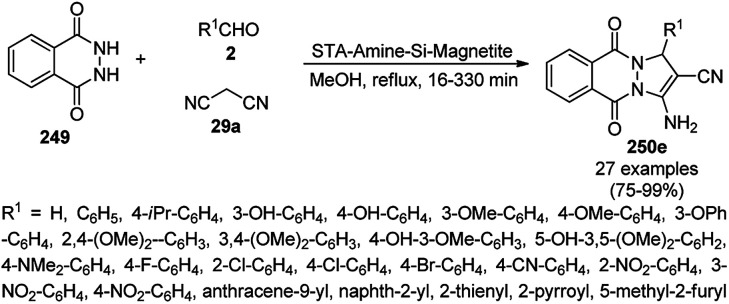

Tetrahydro-4H-chromenes show a broad spectrum of biological activity such as K+ channel activator,66 antimicrobial,67 insulin sensitizer,68 and anticancer activities.69 The green and effective synthesis of tetrahydro-4H-chromenes was reported by Naeimi et al. using gold NPs supported on thiol-functionalized reduced graphene oxide (AuNPs@RGO-SH) from substituted benzaldehyde (2), 7a and malononitrile (29a) in aqueous medium under reflux (Scheme 10).70 The self-developed catalysts were characterized using atomic force microscopy (AFM), field emission scanning electron microscopy (FE-SEM), FT-IR spectroscopy, thermal gravimetric analysis (TGA), and XRD. The catalytic potential of the catalysts was retained even after the sixth catalytic run, and it was found to yield 90% of 2-amino-4-(4-chlorophenyl)-7,7-dimethyl-5-oxo-3,4,5,6,7,8-hexahydro-2H-chromene-3-carbonitrile from the model substrates such as 4-chlorobenzaldehydes 7a and 29a after five catalytic reuses.

Scheme 10. Synthesis of tetrahydro-4H-chromenes (30) catalyzed by AuNPs@RGO-SH.70.

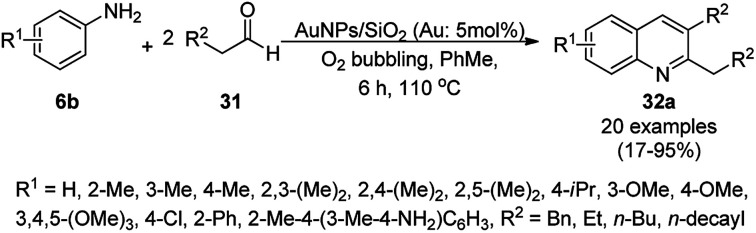

The synthesis of polysubstituted quinolines (32a) was reported by Che et al. via the cyclisation of substituted anilines (6b) with arylalkyl/alkyl aldehydes (31) using SiO2-supported AuNPs under an oxygenated environment (Scheme 11).71 The synthesized AuNPs/SiO2 were characterized via XRD, XPS, TEM, selected area electron diffraction (SAED) analysis, EDX, and ICP-MS. The same protocol using AuNPs/SiO2 (5 mol%) as the catalyst and toluene as the solvent at 110 °C for 6 h under bubbling O2 was further extrapolated for the synthesis of nitrogen-containing polyheterocyclic compounds from aryl or heteroaryl amine and 3-phenyl propanal, resulting in 17–95% yield. In the mechanistic pathway, the AuNPs/SiO2 played the key role as Lewis acid catalysts and the AuNPs together with O2 enabled the oxidative conversion of 1,2-dihydroquinoline to quinolines.

Scheme 11. Aerobic oxidative cyclocondensation of arylamines (6b) with arylalkyl aldehydes (31) in the presence of silica-supported AuNPs.

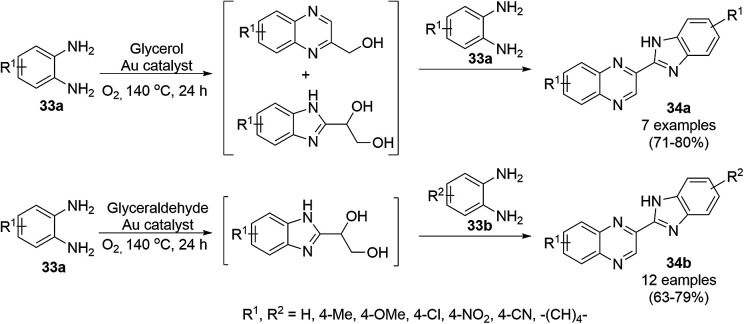

Climent et al. reported the one-pot synthesis of benzimidazoylquinoxalines (34a/b) from o-phenylene diamine (33a/b) and glycerol/glyceraldehyde using gold NPs immobilized on nanoparticulate CeO2 (Au/CeO2) in a catalytic amount in the presence of air (Scheme 12).72 AuCl4·3H2O was treated with NaOH, a colloidal solution of CeO2 and water until the complete removal of chloride, which was confirmed by the AgNO3 test. Further, it has been reduced by 1-phenylethanol at 160 °C for 2 h. Finally, the nanoparticulate size of the synthesized NPs was confirmed by high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM). These NPs were successfully recycled for the synthesis of 34a/bvia the oxidative coupling of glycerol with o-diaminobenzene with a slight loss in catalytic potential; however, the gold content in the recycled catalyst remained the same, which was confirmed by X-ray fluorescence.

Scheme 12. AuNP-catalyzed one-pot synthesis of benzimidazoylquinoxalines (34a/b) from o-phenylene diamine (33) and glycerol/glyceraldehyde.

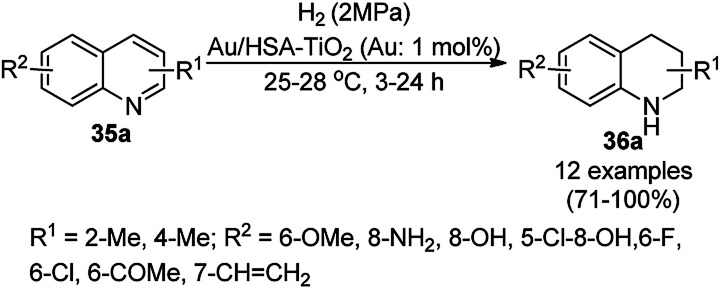

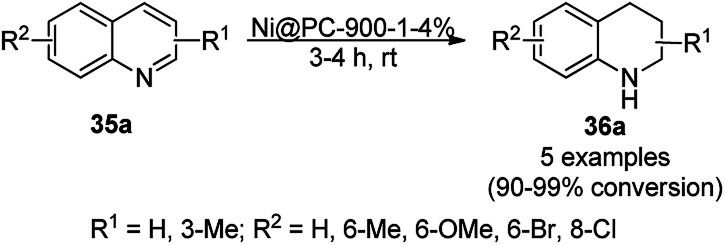

The chemoselective and regiospecific reduction of substituted quinolines (35a) was reported by Ren et al. using AuNPs supported on high surface area TiO2 (Au/HAS-TiO2) at 25–28 °C (Scheme 13).73 The prepared NPs were characterized via X-ray photoelectron spectroscopy (XPS), diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) and X-ray absorption near-edge structure (XANES). The same protocol was also found to be successful for the hydrogenation of nitrogen-containing heterocycles such as substituted quinolines, isoquinolines and other biologically significant heterocyclic compounds in excellent yields, as determined by GC. These self-developed reaction conditions were claimed by the authors to selectively reduce halogens, ketones, and olefins. The optimized protocol was reported to give a yield of 100% for the hydrogenation of 100 mmol of quinoline on a large scale.

Scheme 13. Chemoselective hydrogenation of quinolines (35a) catalyzed by Au NPs.

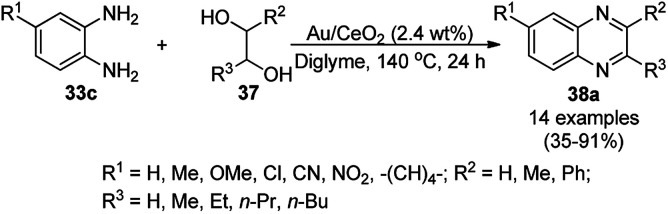

Iborra et al. reported the synthesis of quinoxalines (38a) from o-phenylene diamine (33c) and biomass-derived substituted glycols or vicinal diols (37) using AuNPs supported on CeO2 as the catalyst and diglyme as the solvent at 140 °C under base-free conditions (Scheme 14).74 The particle size of the synthesized NPs (3.5 nm) was revealed using high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM). The reusability of the catalyst was studied for up to four catalytic cycles; however, the catalytic activity was found to be reduced after the fourth cycle, as confirmed using % conversion to final compound.

Scheme 14. AuNP-catalyzed synthesis of quinoxalines (38a) from substituted o-phenylene diamine (33c) and glycols (37).

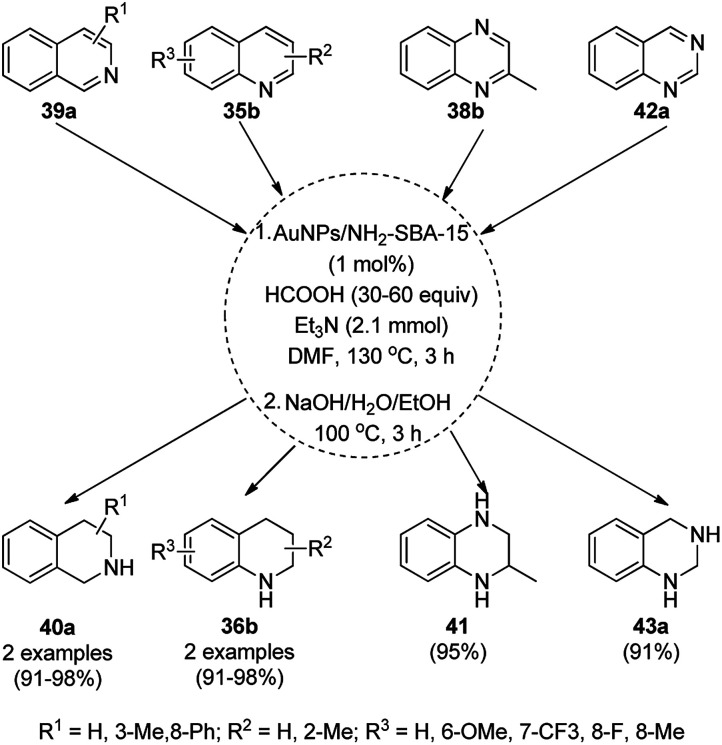

The hydrogenation of N-heterocyclic compounds such as isoquinolines (39a), quinolines (35b), quinoxalines (38b), and quinazoline (42a) was proven to be successful using AuNPs supported on 3-aminopropyl-functionalized silica (AuNPs/NH2-SBA-15) as the catalyst in anhydrous DMF in formic acid (Scheme 15).75 The scope of the reaction was also extended for the reduction of acridine, 1,10-phenanthroline, phenanthridine and benzo[h]quinoline. The authors also extended it for the reductive formylation of the above heterocycles using an excess amount of formic acid and deuteration of 2-methyl quinolines using deuterated formic acid and DMF-d7. The authors speculated and proved that the reaction proceeded via protonation using formic acid, which underwent 1,2-addition followed by disproportionation to yield the hydrogenated product.

Scheme 15. Hydrogenation of N-heterocyclic compounds (39a/35b/38b/42a) catalyzed by AuNPs supported on amino-functionalized silica.

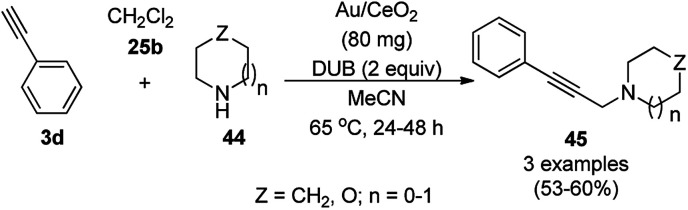

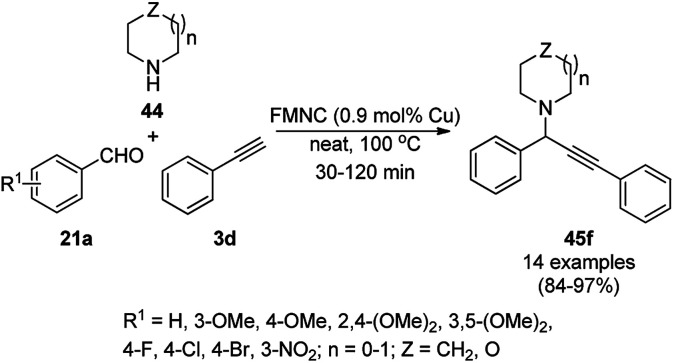

AuNP-supported ceria-catalyzed AHA coupling was reported for the synthesis of propargylamines (45) via the three-component coupling reaction of phenyl acetylene (3d), dichloromethane (25b), and alicyclic amines (44, Scheme 16).65 However, a limited number of examples was screened for AHA coupling, where the catalyst was recycled only three times with a poor-moderate yield of 30–53%. Herein, from a mechanistic point of view, DCM reacts with amine to form a Mannich base, which via the elimination of HCl, forms chloromethanamine. The latter reacts with phenylacetylene adsorbed on the surface of the catalyst to give propargylamines. As evident from the literature reports, the mechanism for AuNP-catalyzed AHA coupling is completely different from than that of AgNPs (Scheme 9),56 where DCM first reacts with amine to form an iminium ion, which then interacts with the metal-phenyl acetylide complex to form propargylamines.

Scheme 16. AHA coupling catalyzed by AuNPs for the synthesis of propargylamines (45).

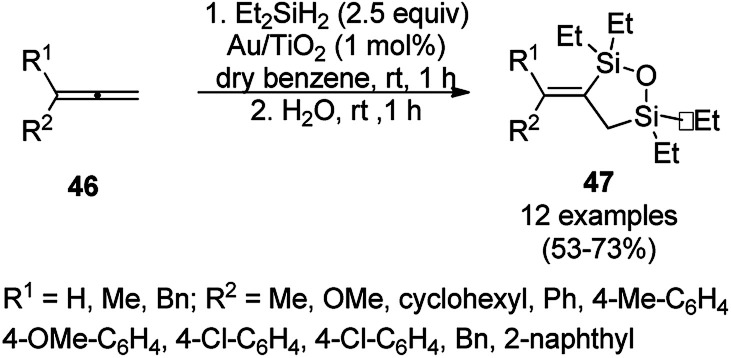

The AuNP-supported TiO2 (Au/TiO2)-catalyzed regioselective dehydrogenative 1,2-desilylation through the one-pot synthesis of novel 3-alkylidene 1,2,5-oxadisilolanes (47) from allenes (46) and diethyl dihydrosilane was reported (Scheme 17).76 Further, Stratakis et al. reported its use in C–C bond forming Hiyama-type reactions for the synthesis of aryl olefins. Further, they also reported the catalytic assistance of Au/TiO2 for the cis-1,2-dehydrogenative silylation of alkynes for the synthesis of 2,5-dihydro-1,2,5-oxadisiloles (49) (Scheme 18)77 from alkynes (48a) and dihydrosilanes in benzene at 25 °C followed by hydrolysis using water in a one-pot synthesis.

Scheme 17. Synthesis of 3-alkylidene-1,2,5-oxadisilolanes (47) reported by Stratakis et al.

Scheme 18. Au/TiO2-catalyzed synthesis of 2,5-dihydro-1,2,5-oxadisiloles (49) from alkynes (48a) and dihydrosilanes.

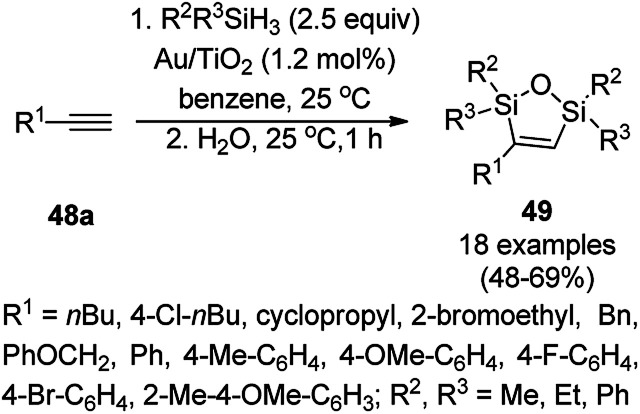

Heterogeneous AuNP-immobilized Al-SBA15-catalyzed post-Ugi cycloisomerization for the synthesis of spiroindolines (50) and six and seven membered heterocycles (51 and 52) was achieved successfully by Eycken et al. from Ugi products having external alkynes without using ligands (Scheme 19).78 The NPs were obtained by ball milling Al-SBA15, which was previously synthesized from aluminium isopropoxide and tetraethyl orthosilicate, with AuNPs, and finally characterized via XRD, XPS, TEM, BET and ICP-AES. The same protocol for cycloisomerization was also investigated for internal alkynes. The catalyst was recycled for up to twelve times without loss of their catalytic potential and leaching of Au into the reaction mixture.

Scheme 19. AuNP-catalyzed post-Ugi cycloisomerization of terminal alkynes (50).

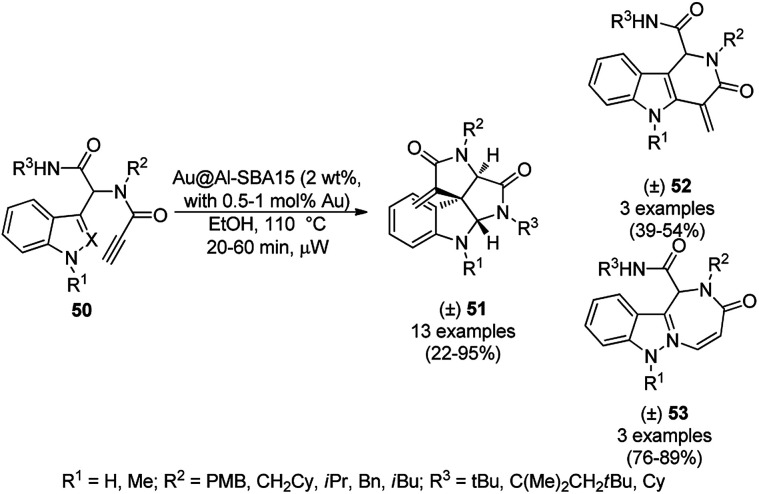

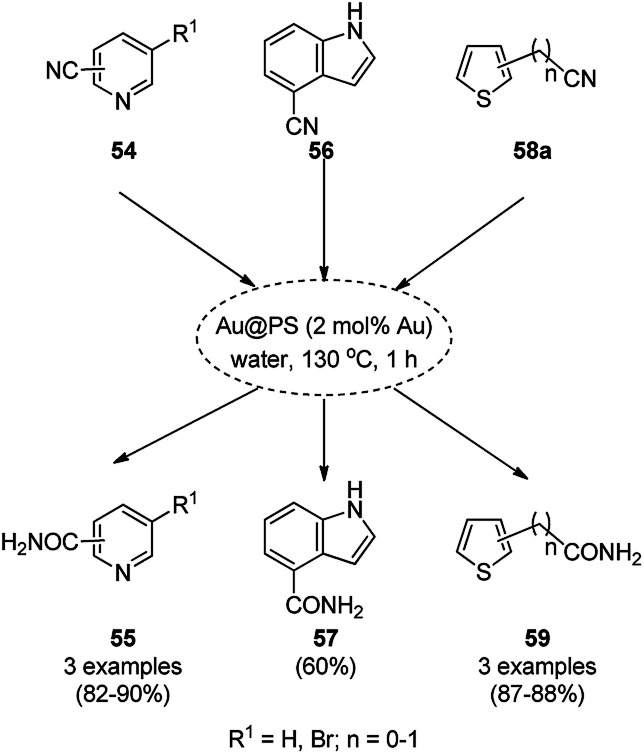

AuNPs supported on polystyrene (Au@PS) were reported for the catalysis of base- and ligand-free hydration of heterocyclic cyanides (54/56/58a) to amides (55/57/59) in moderate to good yields at 130 °C (Scheme 20).79 The AuNPs were synthesized via a reduction–deposition approach from HAuCl4·3H2O and polystyrene resin followed by ion exchange with borohydride (BH4−) to obtain purple-colored Au@PS NPs. The fully characterized catalyst was reused and recycled for up to 8 times. Together with heterocyclic cyanides, the hydration of cyanoarenes was also achieved successfully with the AuNPs.

Scheme 20. Catalytic hydration of cyanides (55/57/59) mediated under microwaves by Au@PS NPs.

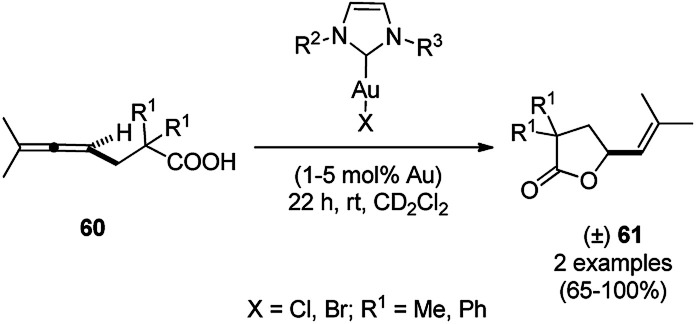

For the first time, dendrimer-encapsulated NHC ligated AuNPs supported on silica were reported for the lactonization of allene-carboxylic acids (60) by Somorjai et al. (Scheme 21).80 They screened the following reaction with more than ten of these catalysts to study the effect of AuNPs on the lactonization of 60. The catalyst was recycled for up to four runs without loss of its catalytic stability.

Scheme 21. AuNP-catalyzed lactonization of allene-carboxylic acids (60).

3.3. CuNP-catalyzed synthesis of heterocycles

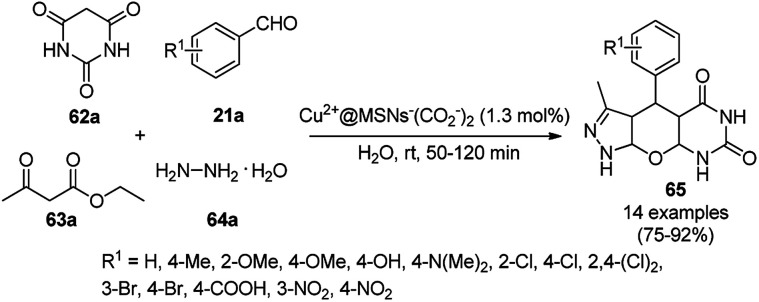

A variety of synthetic transformations for the construction of organic compounds utilizing CuNPs was reviewed and summarized by Santra et al.,81 Wang et al.82 and by Das.83 In comparison with other transition metals, as the least toxic, CuNPs have the advantage of green nanocatalysts. The one-pot multicomponent and green synthesis of pyrazolopyranopyrimidine-5,7-diones (65) from barbituric acid (62a), substituted aromatic aldehydes (21a), ethyl acetoacetate (63a) and hydrazine hydrate (64a) was reported using Cu-immobilized mesoporous silica nanoparticles [Cu2+@MSNs−(CO2−)2] with a low catalytic loading (1.3 mol%) in aqueous conditions at rt (Scheme 22).84 The synthesized catalyst was well characterized via XRD, SEM, TEM, energy dispersive X-ray (EDX), thermal analysis (TGA-DTA) and FT-IR studies. The catalyst was recycled several times without obvious loss in its catalytic activity.

Scheme 22. Cu2+@MSNs−(CO2)2-catalyzed synthesis of pyrazolopyranopyrimidine-5,7-diones (65).

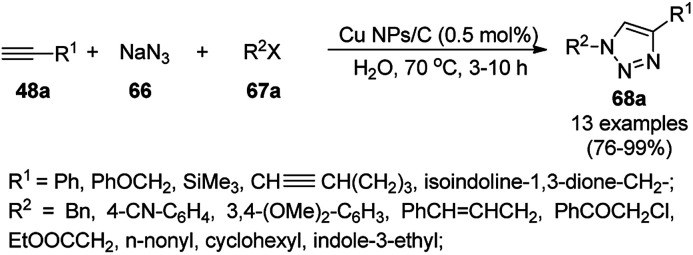

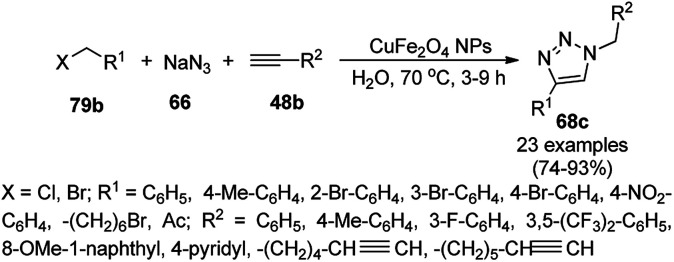

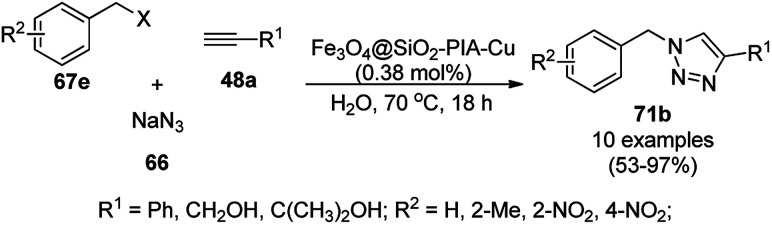

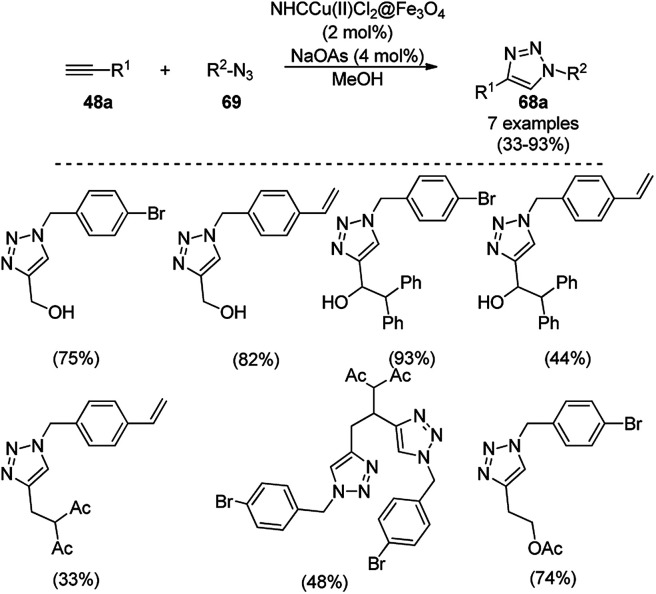

Alonso et al. reported the synthesis of 1,2,3-triazoles (68a) from alkyl halide (66), sodium azide (67a) and substituted alkynes/acetylenes (48a) via multi-component Huisgen 1,3-dipolar cycloaddition (Scheme 23) at 70 °C in water using copper nanoparticles (CuNPs) on activated charcoal (0.5 mol%).85 For this model reaction, a variety of catalysts supports was tested, but activated carbon was chosen as the efficient support because of the shorter reaction time to produce triazoles. The nanoparticles on activated charcoal were characterized via ICP-MS, TEM, EDX, XPS, and selected-area electron-diffraction pattern (SAED). The versatility of copper catalysts through click chemistry was successfully demonstrated using azide precursors such as diazonium salt, aniline and epoxide.

Scheme 23. Synthesis of substituted triazoles (68a) using CuNPs.

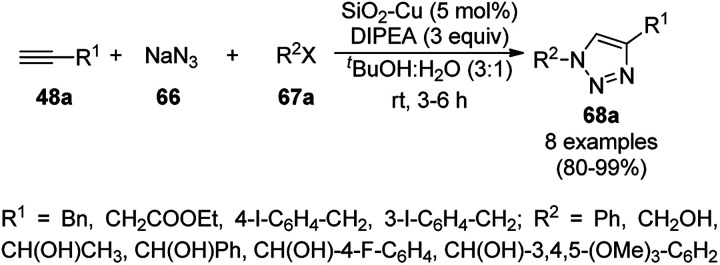

Following a similar approach, Coelho et al. reported the synthesis of 68avia the Huisgen 1,3-dipolar cycloaddition of 48a, 66, and 67a catalyzed by sol–gel-entrapped copper in a silica matrix using di-isopropyl ethyl amine (DIPEA) in tert-butanol : water (3 : 1) at rt for 3–6 h (Scheme 24).86 These NPs were synthesized via a one-pot method involving a sol–gel process by immobilization of up to 9.4 wt% copper using copper iodide within a silica matrix, and they were characterized using SEM, TEM, EDS, and EPR. The hot filtration test revealed that leaching of the CuNPs occurred during the reaction, which could not proceed without the assistance of the catalyst. The insoluble heterogeneous CuNPs were involved in the catalytic cycle of Huisgen 1,3-dipolar cycloaddition, as confirmed by the three-phase test.

Scheme 24. Synthesis of N-substituted triazoles (68a) catalyzed by CuNPs entrapped in a silica matrix.

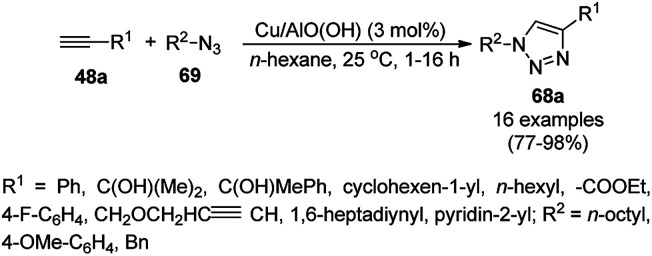

Park et al. reported the Huisgen [3 + 2] cycloaddition of terminal alkynes (48a) and substituted azides (69) without additives catalyzed by CuNPs in aluminum oxyhydroxide nanofibers using n-hexane as the solvent at rt (Scheme 25).87 The NCs were prepared from copper chloride (CuCl2·2H2O), Pluronic P123 as the stabilizer, and aluminum tri-sec-butoxide Al(sec-OBu)3, which were characterized via TEM, XPS, ICP, and nitrogen isotherms. The recycling of the nanocatalysts for the [3 + 2] cycloaddition was studied for up to five catalytic cycles with only 10% decay in catalytic potential, as studied using the model reaction of phenylacetylene and n-octyl azide in n-hexane for 12 h. ICP analysis confirmed that there was no significant leaching of Cu from the NPs in the reaction mixture during the reaction.

Scheme 25. Synthesis of 1,4-disubstituted triazoles (68a) from alkyne (48a) and azide (69) catalyzed by CuNPs.

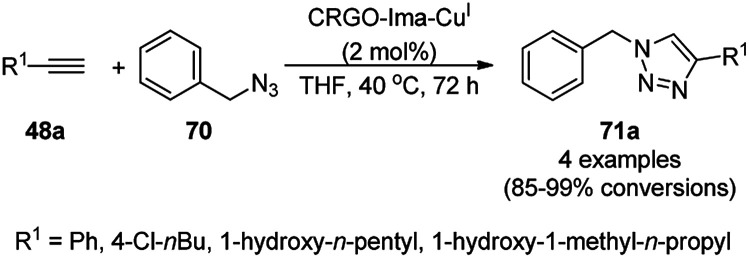

Cu(i) NPs supported on chemically reduced graphene oxide (CRGO-Ima-CuI) were synthesized via sequential chlorination, azidation, and click reaction using 1-propyl-3-methylimidazolium bromide followed by loading of copper using tetrakis(acetonitrile)copper(i) hexafluorophosphate (Scheme 26).88 CRGO-Ima-CuI was further successfully employed in the Huisgen [3 + 2] cycloaddition of 48a with benzyl azides (70) for the synthesis of triazoles (71a) in 98–99% conversion. The catalyst was recycled for up to ten reuses with a good catalytic performance.

Scheme 26. Synthesis of triazoles (70) catalyzed by CRGO-Ima-CuI NCs.

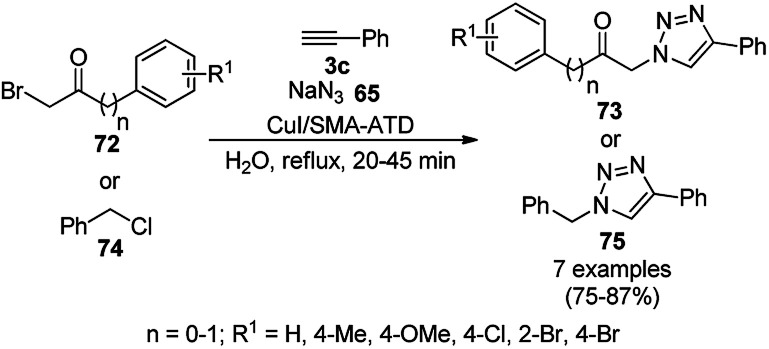

Heravi et al. reported the synthesis of triazoles (73/75) catalyzed by copper iodide (CuI) NPs immobilized on modified polystyrene-co-maleic anhydride (SMA, Scheme 27).89 SMA was modified by treatment with 4-amino-2-methyl-10H-thiene[2,3-][1,5]-benzodiazepine (ATD) hydrochloride, followed by the catalytic loading of copper using CuI. These CuNPs (CuI/SMI-ATD) were fully characterized via FT-IR, 1H NMR, SEM, TEM, EDAX and ICP-AES analysis. In the click reaction, from a mechanistic point of view, CuNPs take part via the formation of copper acetylide and preventing the conversion of Cu(i) into Cu(ii). The NPs were recycled for up to five times without loss in their catalytic activity. The stability of the complex formed with the NPs was studied at the M06/6-31G* level to reveal the immobilization of the CuNPs on the nitrogen site of the polymer-supported catalysts.

Scheme 27. Click reaction for the synthesis of triazoles (73/75) catalyzed by CuNPs.

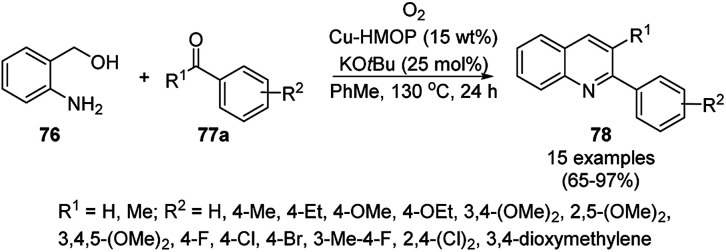

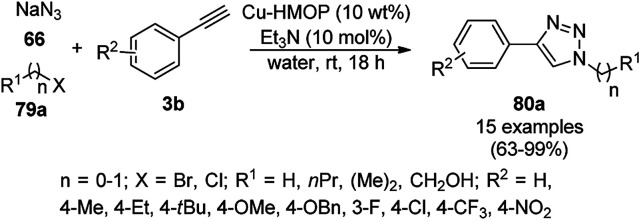

Copper-loaded hierarchical mesoporous organic polymer (HMOP) NC-catalyzed Frieldländer annulation for the synthesis of quinolines (78) was achieved from 2-amino benzyl alcohols (76) and aryl ketones (77a) under aerobic conditions (Scheme 28).90 Further, the same catalyst was used for the synthesis of 3-substituted 4-phenyl-1H-1,2,3-triazoles (80a) via the [3 + 2] cycloaddition of sodium azide (66) with substituted phenyl acetylene (3b), followed by nucleophilic substitution with alkyl halides (79a, Scheme 29). This protocol was also extended for the aerobic dehydrogenation of acyclic amines, 2,3-dihydroindoles and 1,2,3,4-tetrahydroquinolines. The catalyst was separated by centrifugation and recycled for five successive runs. The present protocol offers many advantages such as low catalytic loading, environmentally friendly nature, and use of a green solvent.

Scheme 28. Frieldländer synthesis of quinolines (78) catalyzed by Cu-HMOP.

Scheme 29. Click reaction for the synthesis of triazoles (80a) catalyzed by Cu-HMOP.

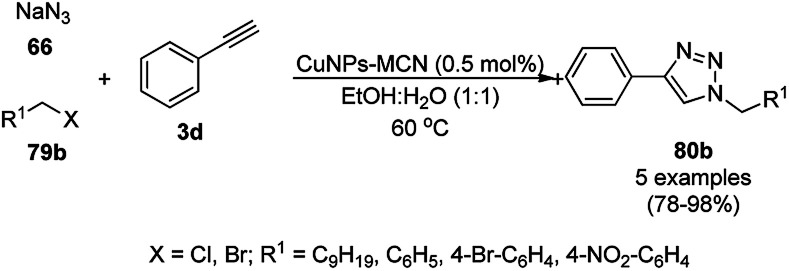

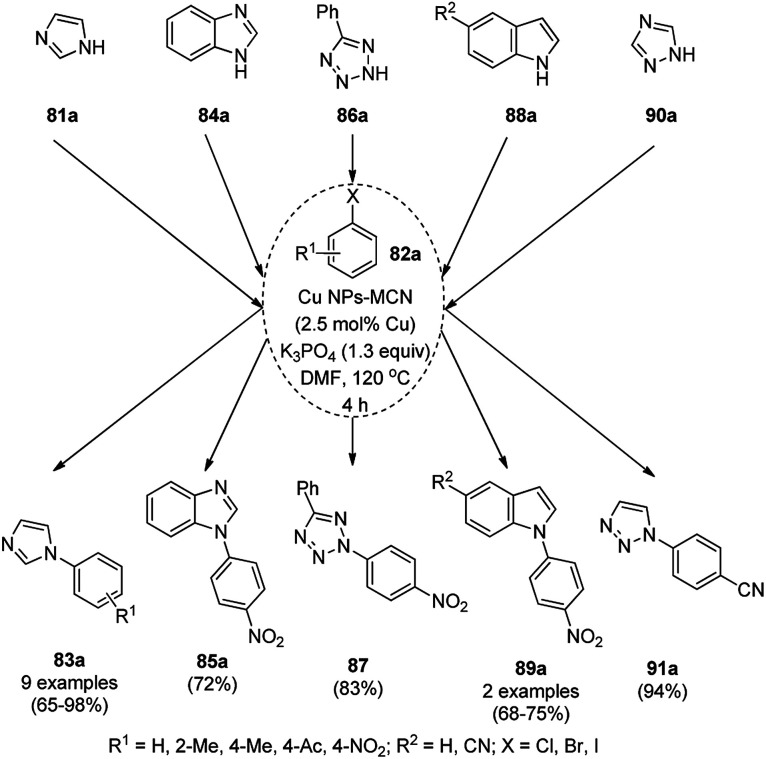

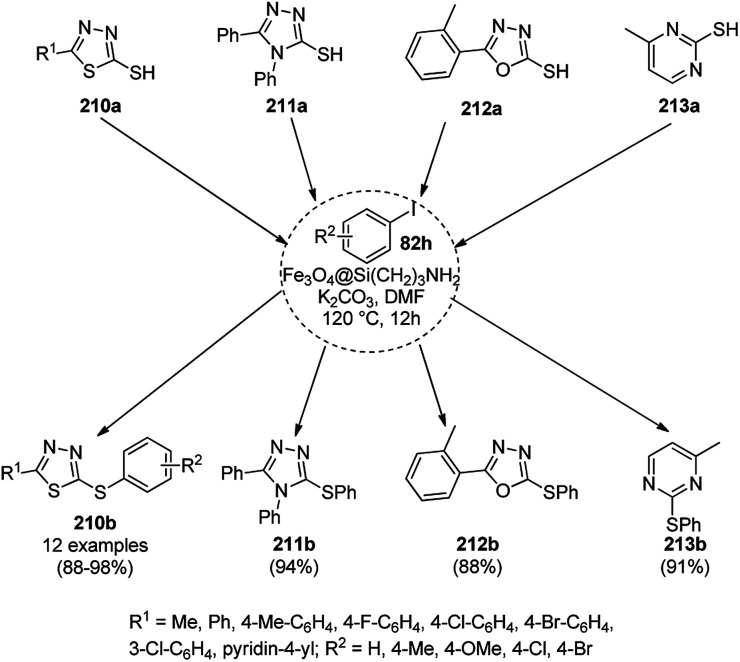

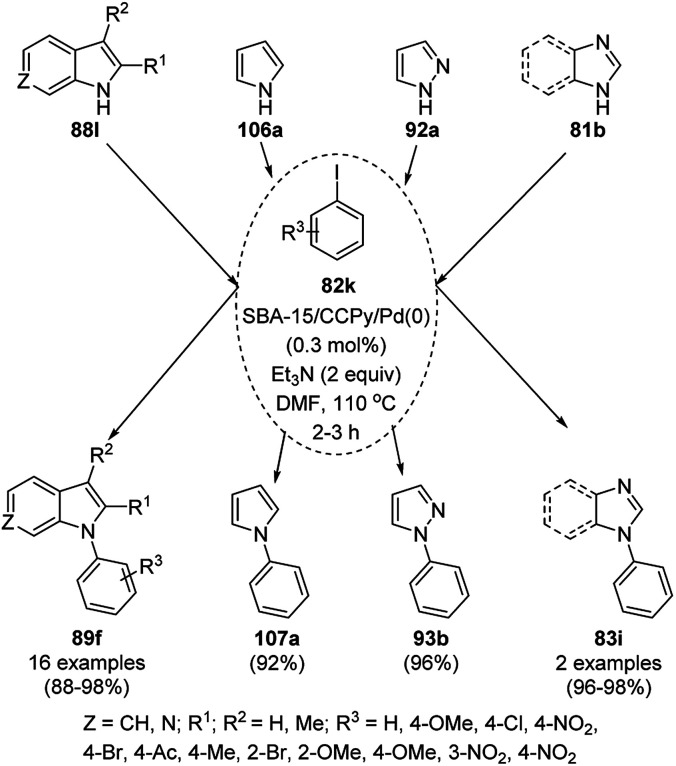

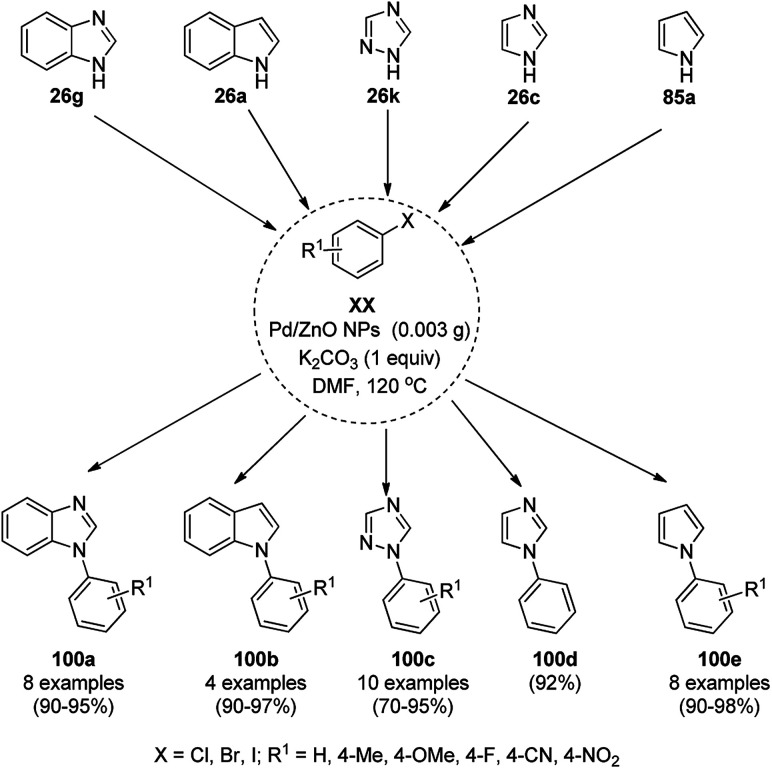

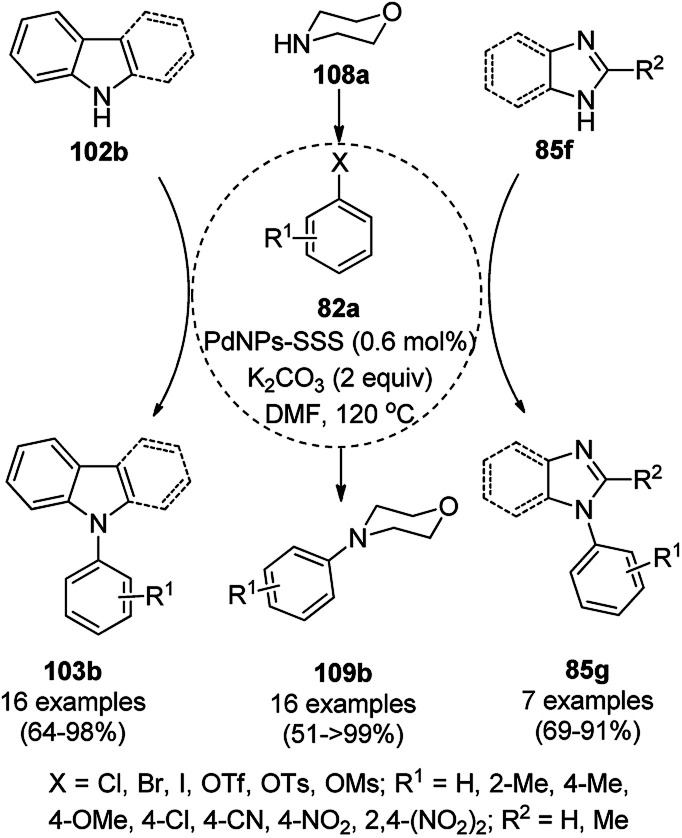

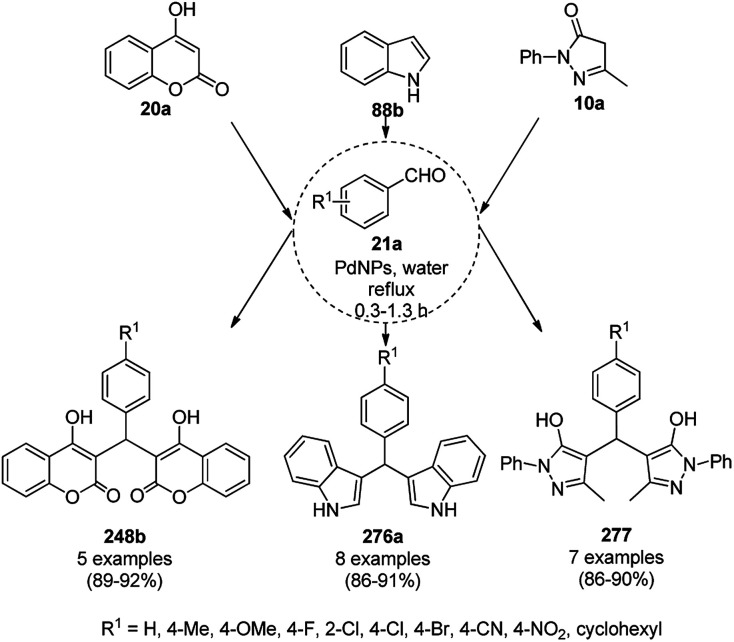

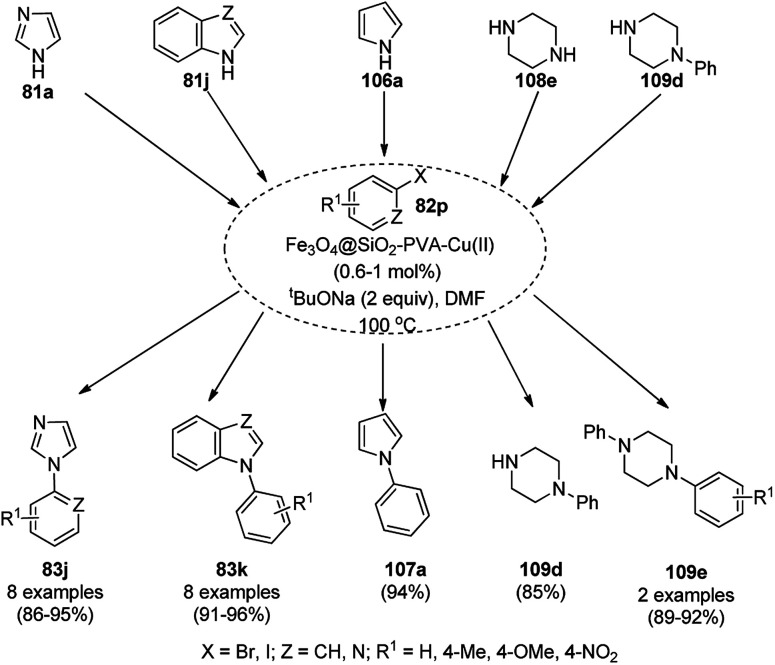

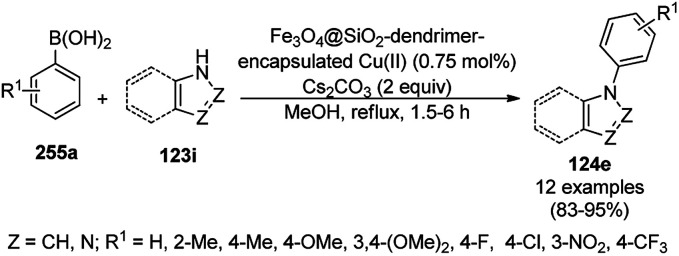

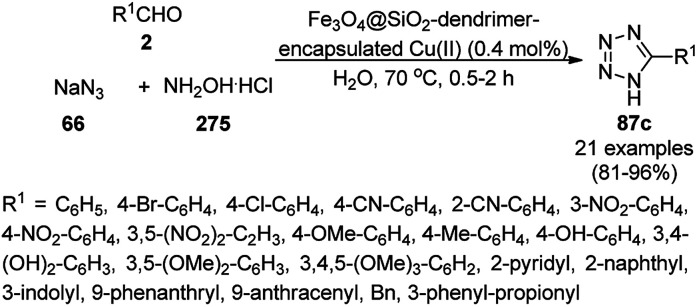

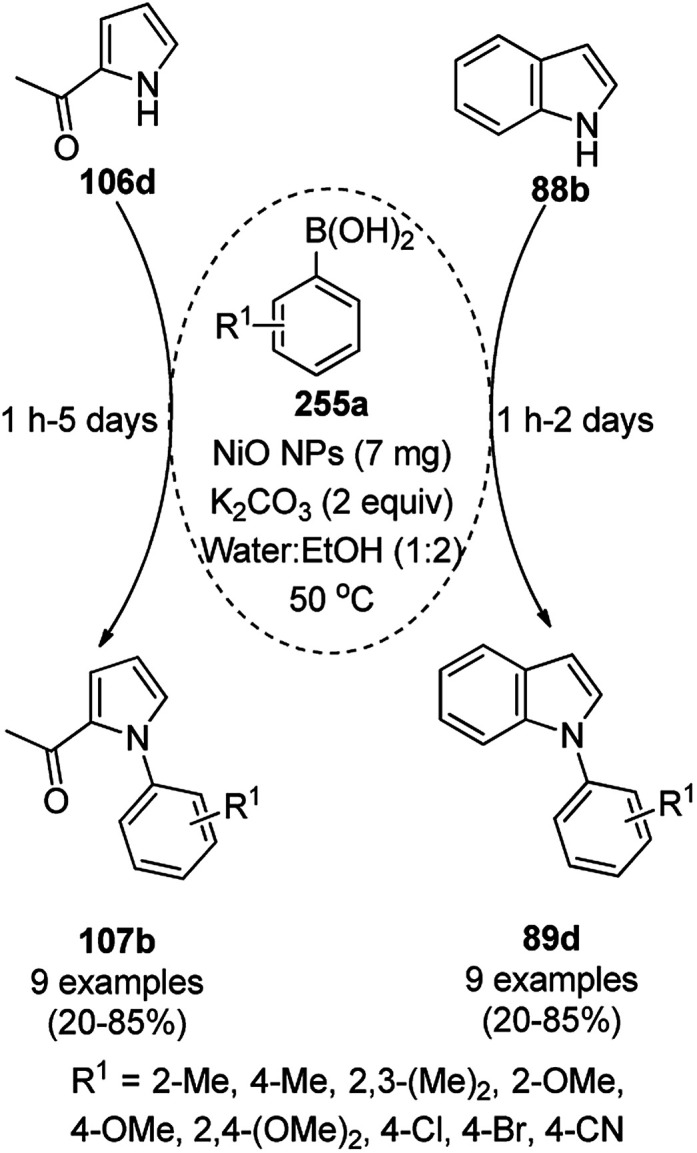

Dabiri et al. reported the catalytic use of CuNPs supported on mesoporous carbon nitride (CuNPs-MCN) for the synthesis of 1,2,3-triazoles (80b) via the Huisgen 1,3-dipolar cycloaddition of sodium azide (66), alkyl halide (79b) and alkyne (3b) in 78–98% yield (Scheme 30).91 They also used the same catalyst for the N-arylation of NH-heterocycles such as imidazole (81a), benzimidazole (84a), 3-phenyl-1,2,4,5-tetrazole (86a), and 5-substituted indole (88a), and 1,2,4-triazole (90a, Scheme 31) via their reaction with substituted halobenzenes (82a) in DMF at 120 °C. The NPs were prepared via the treatment of MCN with copper(iii) nitrate (Cu(NO3)2·3H2O) following the addition of a reducing agent such as ascorbic acid. The excellent yields (96–98%) of 80b (R1 = Ph) synthesized via the 1,3-dipolar cycloaddition of 66, 3d and benzyl bromide during eight reuses demonstrated the stability of the CuNPs, which was also confirmed by Dabiri et al. via TEM of the CuNPs obtained at the end of the eighth run. The present protocol was found to give high yields in a short time compared to other reported protocols.92–95

Scheme 30. CuNP-catalyzed 1,3-dipolar cycloaddition for the synthesis of triazoles (80b).

Scheme 31. N-Arylation of N–H heterocycles reported by Dabiri et al.

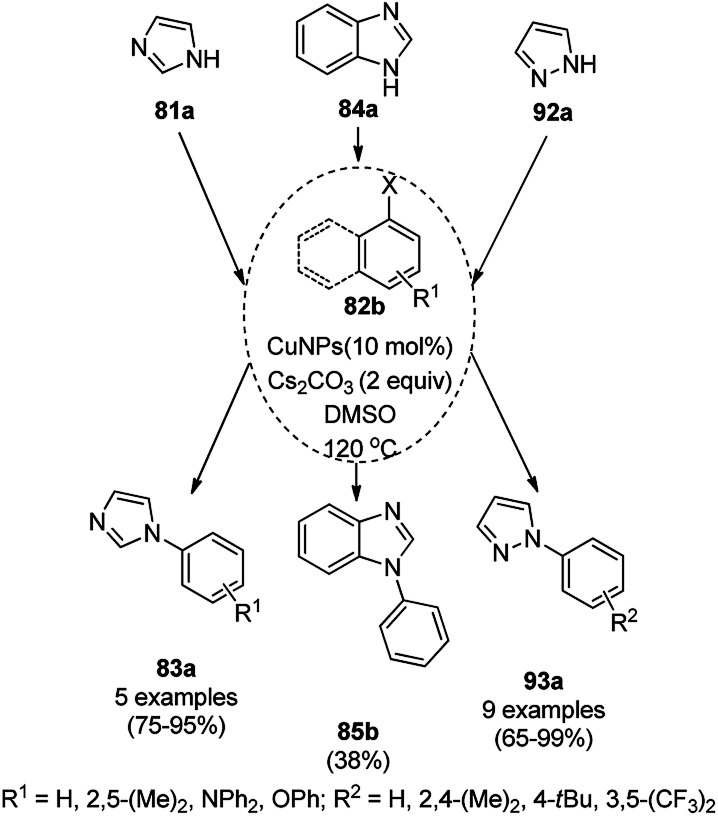

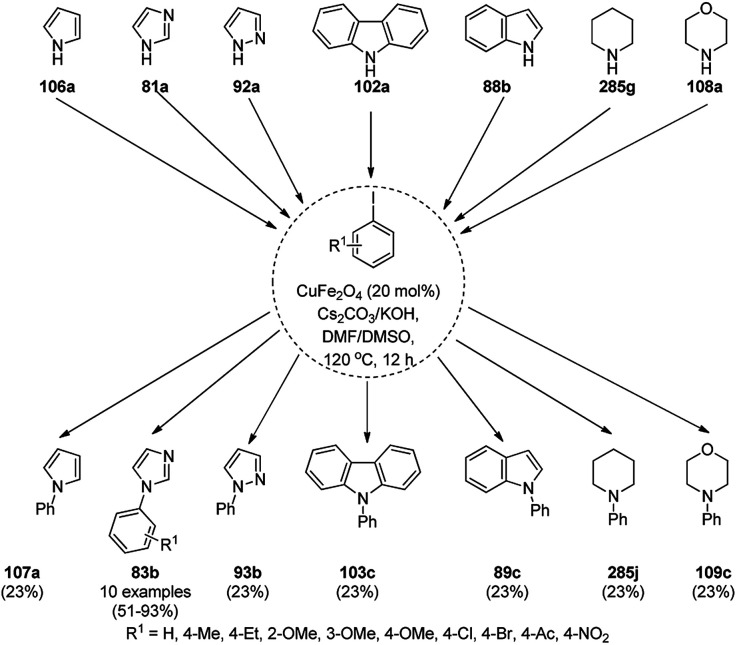

Yuan et al. reported the synthesis of N-arylated imidazoles/pyrazoles/benzimidazole (83a/85b/93a) from 5 or 6-5 membered N-containing heterocyclic compounds (81a/84a/92a) and aryl halides (82b) using copper nanoparticles in a catalytic amount (10 mol%) in DMSO at 120 °C using cesium carbonate as the base (Scheme 32).96 Nitrogen-rich copolymeric microsheets synthesized from melamine and cyanuric hydrochloride were treated with copper(ii) acetate and hydrazine hydrate to prepare the CuNPs. These NPs were further characterized via XPS, TEM, XRD and ICP-AES. The recyclability of the NCs was studied for up to five catalytic cycles; however, the catalyst gave a reduced yield of N-arylated imidazole of less than 50% after the fifth catalytic run.

Scheme 32. CuNP-catalyzed N-arylation of imidazoles (81a), benzimidazole (84a) and pyrazole (92a).

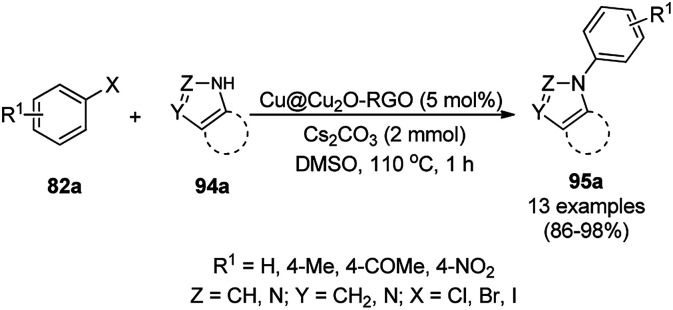

Similarly, Bazgir et al. reported the synthesis of N-arylated N-containing heterocycles (95a) using core–shell Cu@Cu2O NPs on reduced graphene oxide under aerobic conditions in a catalytic amount (5 mol%) using cesium carbonate as the base and DMSO as the solvent at 110 °C in 1 h (Scheme 33).97 The required CuNPs were synthesized via the reduction of reduced graphene oxide using l-ascorbic acid as the reducing agent followed by the catalytic loading of copper using copper sulfate (CuSO4) to obtain an actual catalytic loading of 26.2%, as confirmed by AAS. Further, the CuNPs were characterized via FT-IR and Raman spectroscopy, XRD, XPS, TEM, and EDX. Aryl iodides were found to yield more final product in comparison with aryl bromides and chlorides. Bazgir et al. claimed the efficient recyclability of the CuNPs, as evident from the 75% yield of the final product and 1.3% leaching of Cu at the end of the fifth catalytic run. The developed protocol was claimed to be simpler, less time-consuming and high yielding compared to reported works92,98–100 on the N-arylation of N–H heterocycles with aryl bromides catalyzed by heterogeneous copper catalysts.

Scheme 33. N-Arylation of imidazoles/triazoles/benzimidazoles (82a) catalyzed by CuNPs.

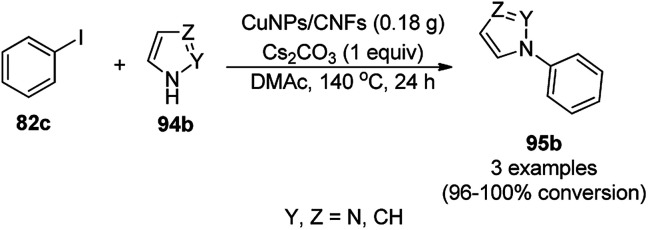

Li et al. reported the easier, quicker and ligand-free synthesis of N-arylated azoles (95b) such as imidazole, pyrazole and pyrrole (94b) via Ullmann-type coupling using CuNPs supported on carbon nanofibers (CuNPs/CNF) using Cs2CO3 as the base and dimethylacetamide (DMAc) as the solvent at 140 °C for 24 h (Scheme 34).101 A similar protocol was also explored in detail for the O-arylation of iodobenzene with substituted phenols in moderate to excellent conversions. CuNPs/CNF was prepared via the reduction of copper nitrate followed by its treatment with carbon nanofibers processed at high temperature calcination and characterized using FESEM, XPS, and XRD. The recyclability of the catalyst was studied for five cycles, yielding 64% conversion to phenoxybenzene from iodobenzene (82c) and phenol.

Scheme 34. N-Arylation of N-containing heterocycles (94b) catalyzed by CuNPs.

Nasrollahzadeh et al. reported the ligand-free N-arylation of azoles such as indoles (88b), imidazoles (81a), benzotriazole (96), benzimidazole (84a), pyrazole (92a), and 1,2,4-triazoles (90a) with haloarenes (82d) using CuO NPs as the catalyst, potassium carbonate as the base, and DMF as the solvent at rt to reflux conditions in moderate to excellent yields (Scheme 35).102 The green synthesis of CuO NPs was achieved via the treatment of the leaf extract of Tamarix gallica (family: Tamaricaceae), which contains several polyphenols as anti-oxidants, having reducing and anti-capping ability with an aqueous solution of CuCl2 at 70 °C. The structural integrity of the synthesized CuO NPs was confirmed via TEM, UV-Vis, FT-IR and powder XRD. The present protocol developed by Nasrollahzadeh et al.102 was tested for recycling of the catalyst with the reaction of iodobenzene and 90a, where the catalyst was recycled for up to five catalytic runs with only 4% of product loss in comparison with the first cycle.

Scheme 35. N-Arylation of azoles with haloarenes (81d) catalyzed by CuO NPs.

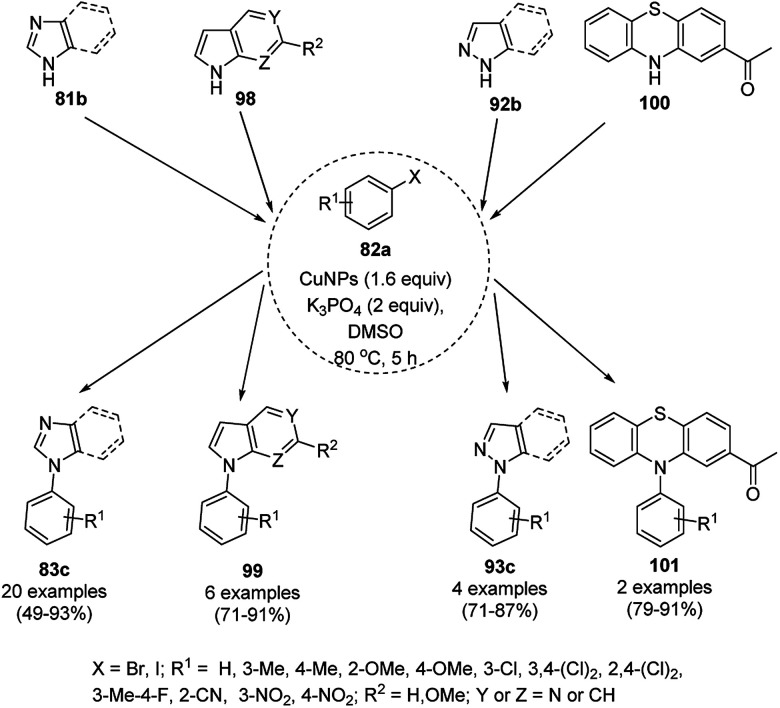

The N-arylation of heterocyclic compounds such as imidazoles/benzimidazoles (81b), indoles/azaindoles (98), pyrazoles/benzopyrazoles (92b) and phenothiazine (100) catalyzed by CuNPs as NCs with aryl bromides/iodides using potassium phosphate as the base and DMSO as the solvent at 80 °C in 49–93% yield was reported by Chattopadhyay et al. (Scheme 36).103 The reaction selectively proceeded with aryl iodides in a competitive manner with the chlorides/fluorides present in the aryl halides. The optimized protocol was shown to have a wide substrate scope for azoles and azines.

Scheme 36. N-Arylation of N-containing heterocycles reported by Chattopadhyay et al.

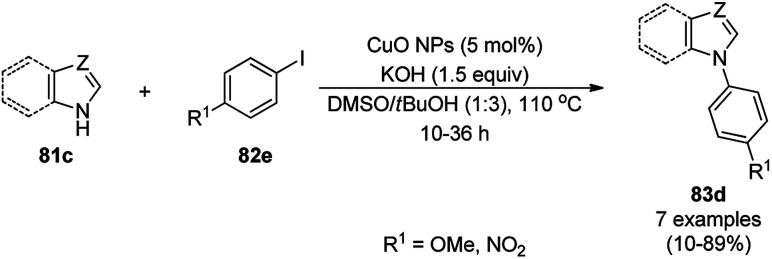

CuO NPs catalyzed the ligand-free C–N cross-coupling reactions of imidazoles, benzimidazoles, indoles (81c) with aryl iodides (82e) (Scheme 37) for the synthesis of N-arylated azoles (83d).104 The same protocol was also extended for the C–N, C–O and C–S cross-coupling reactions of amides, phenols and thiophenols with iodobenzenes. The reusability of the NCs was studied for the C–O cross-coupling reactions of phenol and iodobenzene for up to three cycles with yields of diphenyl ether of 95–97%.

Scheme 37. CuO NP-catalyzed C–N coupling of imidazoles, benzimidazoles, indoles (81c) with aryl iodides.

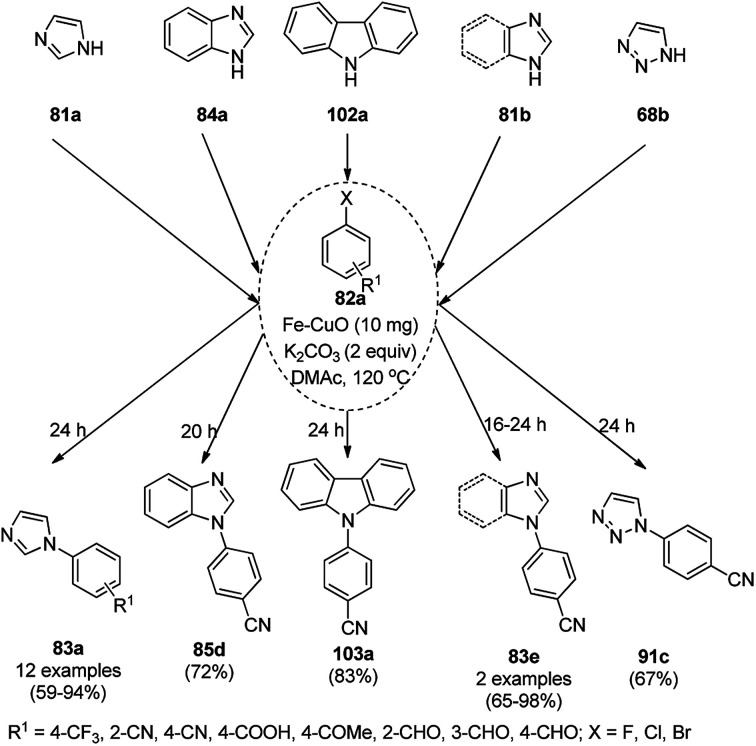

The lepidocrocite (γ-FeOOH)-supported CuO NP (Fe–CuO)-catalyzed N-arylation of imidazoles (81a), benzimidazoles (84a), carbazoles (102a), pyrrole or indole (81a) and 1,2,3-triazoles (68b) was successfully achieved (Scheme 38) in dimethyl acetamide by Dhanuskodi et al.105 The magnetically retrievable NPs were prepared via the adsorption of Cu2+ from CuSO4·5H2O on previously synthesized lepidocrocite106 in alkaline solution. The catalyst was separated under an external magnetic field and recycled up to six times without loss in its catalytic activity. The higher yields observed with Fe–CuO with a particle size of 7 nm compared to that of 33 nm revealed that the larger number of active sites available with a higher surface area catalyze the N-arylation significantly.

Scheme 38. N-Arylation of heterocycles catalyzed by CuNPs.

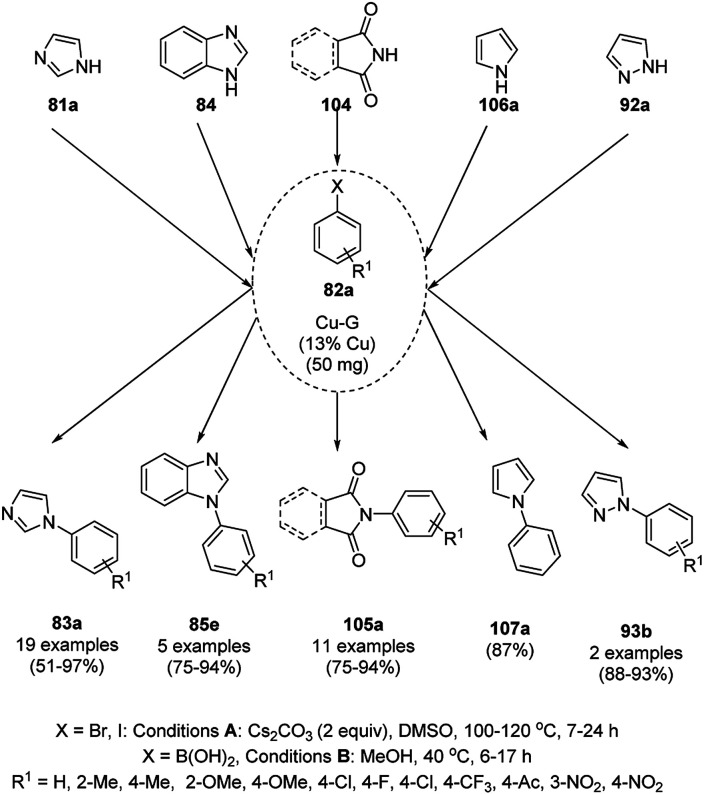

CuNP-graphene-based nanocomposites were reported for the N-arylation of N–H heterocycles such as imidazole (81a), benzimidazoles (84a), succinimide or phthalimide (104), pyrrole (106a) and pyrazole (92a) by Jana et al. (Scheme 39) using haloarenes and aryl boronic acids (82a).107 The same catalyst was also explored for O-arylation using aryl halides and phenols. The CuNP-graphene-based nanocomposites were synthesized via the treatment of GO with copper acetate and hydrazine and characterized via UV-Vis, AFM, TEM, Raman spectra, and XPS. The catalyst was recycled after filtration for up to seven runs of O-arylation with no change in catalytic performance. The present protocol was claimed to be high yielding compared to the reported protocols for the N-arylation of imidazole with iodobenzene such as copper-exchanged fluorapatite (CUFAP),108 Cu2O,109 and nano-Cuo,110 and that of imidazole with phenyl boronic acids using copper-exchanged fluorapatite (Cu-FAP)111 and poly aniline-supported CuI (PANI-Cu).112

Scheme 39. N-Arylation of heterocycles catalyzed by CuNPs.

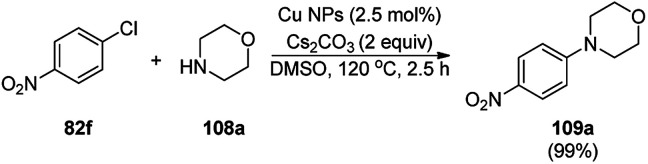

Cuboctahedral-shaped CuNPs were prepared via the reduction of Cu2+ from copper sulphate (CuSO4) with sodium hydroxide, hydrazine hydrate as the reducing agent (Scheme 40) and poly(acrylic acid) (PAA) as the capping agent.113 The prepared NPs were used for the C–N coupling of p-chloro nitrobenzene (82f) with morpholine (108a) to C–N coupled product (109a). The same NPs were also used to catalyze the Mannich reaction among acetophenone, benzaldehyde and aniline.

Scheme 40. CuNPs catalyzed C–N coupling of p-chloro nitrobenzene (82f) with morpholine (108a).

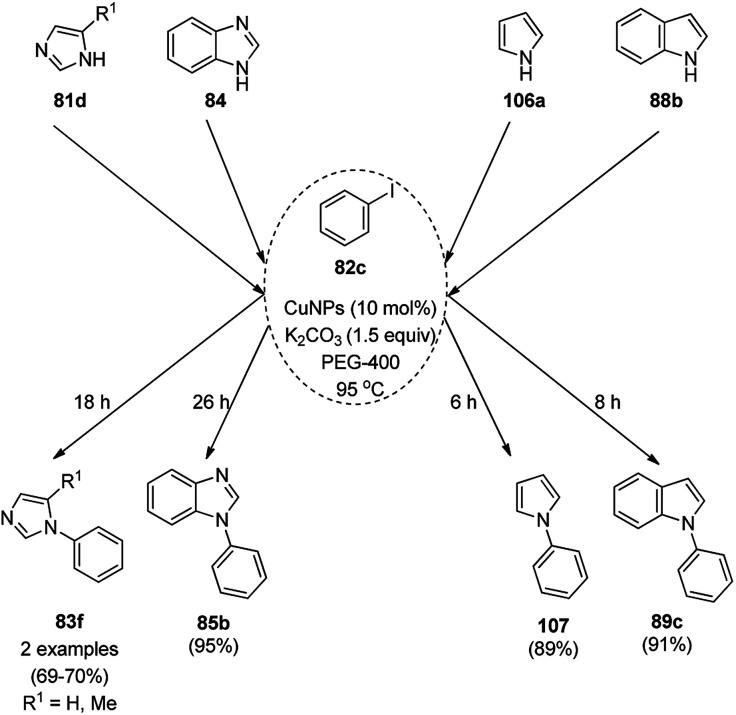

Kidwai et al. have reported C–N coupling of N–H heterocycles such as imidazoles (81d), benzimidazole (84a), pyrrole (106a) and indole (88b) with iodobenzene (82c, Scheme 41) in polyethylene glycol (PEG-400).114 CuNPs have been prepared by the treatment of micellar solution of CuSO4 and N2H2. It has been also found successful for the N-arylation of substituted anilines with haloarenes in moderate to excellent yields. Size screening of CuNPs for the synthesis of N-aryl aniline revealed that diminishing the particle of CUNPs increased the yields of N-arylated anilines.

Scheme 41. CuNP-catalyzed N-arylation of N–H heterocycles.

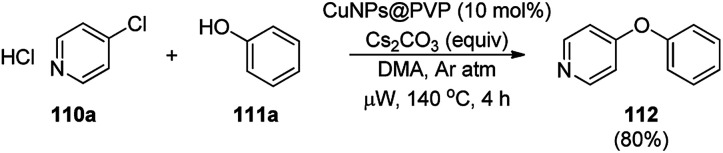

CuNPs protected by polyvinyl pyrrolidone (CuNPs@PVP) catalyzed Ullmann ether synthesis of 4-phenoxypyridine (112) from 4-chloropyridine hydrochloride (110a) and inactivated phenol (111a) was reported by Wheatley et al. (Scheme 42).115 The CuNPs were prepared from copper(ii) acetate and ploy(N-vinylpyrrolidone) and characterized via HRTEM, EDS, and PXRD. The higher yields achieved by microwave heating were attributed to the rapid energy consumption in one minute and uniform volumetric heating compared to conventional heating.

Scheme 42. CuNP-catalyzed Ullmann coupling for the synthesis 4-pyridyl phenyl ether (112).

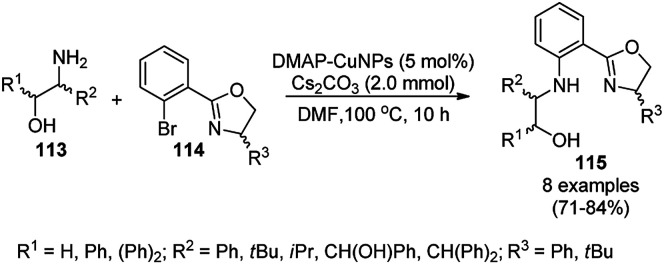

Yuan et al. reported the C–N bond formation using β-aminoalcohols (113) and aryl bromides (114) containing an oxazole ring catalyzed by 4-dimethylaminopyridine (DMAP)-stabilized copper nanoparticles (DMAP-CuNPs) in the presence of cesium carbonate as the base and DMF as the solvent at 100 °C for 10 h (Scheme 43).116 The NPs were synthesized via the controlled decomposition of DMAP-Cu(acac)2-carbohydrazide complex (acac: acetylacetonate) in water-free ethanol and characterized via TEM and XPS. The DMAP-CuNPs catalyzed the reaction in a homogenous medium in DMF and could be recovered by making them insoluble via the addition of diethyl ether or toluene. The CuNP-catalyzed Ullmann coupling was found to be significant with aryl bromides and iodides rather than chlorides and fluorides. The recyclability of the DMAP-CuNPs was studied in the reaction between imidazole and phenyl bromide to form N-phenyl imidazole, where they maintained their catalytic activity. This protocol was also extended for the N-arylation of imidazoles/pyrazoles/benzimidazoles/trifluroacetamides with aryl bromides having substituted oxazole in good to excellent yields.

Scheme 43. Ullmann coupling of β-aminoalcohols (113) with aryl bromides (114) catalyzed by DMAP-CuNPs.

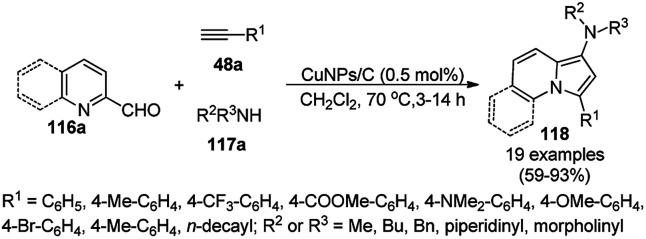

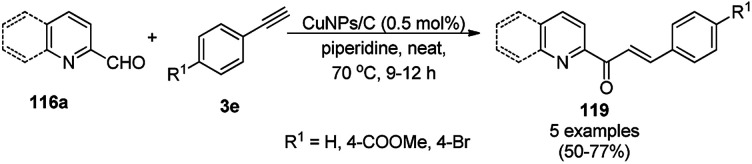

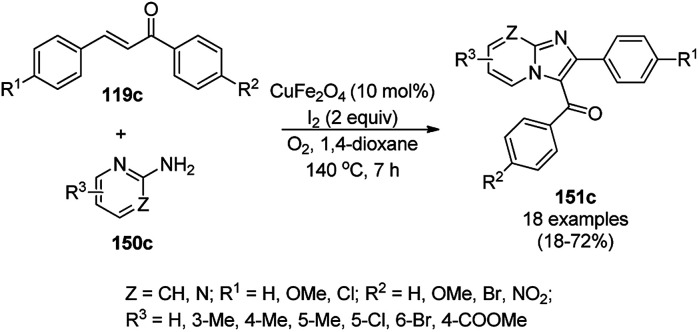

Alonso et al. reported the multicomponent synthesis of indolizines (118) from pyridine-2-carbaldehyde (116a), acetylenes (48a) and amine (117a) catalyzed by CuNPs supported on activated charcoal (0.5 mol%) using dichloromethane as the solvent at 70 °C (Scheme 44).117 The developed catalyst was also found to be successful for the synthesis of heterocyclic chalcone (119) from pyridine-2-carbaldehyde (116a) and phenyl acetylene derivatives (3e) in the presence of piperidine under neat conditions (Scheme 45). The CuNPs were prepared from copper(ii) chloride, lithium metal, and 4,4′-di-tert-butylbiphenyl in THF at rt following a reported procedure.85

Scheme 44. CuNP-supported activated charcoal-catalyzed synthesis of indolizines (118d).

Scheme 45. CuNP-supported activated charcoal-catalyzed synthesis of heterocyclic chalcones (119).

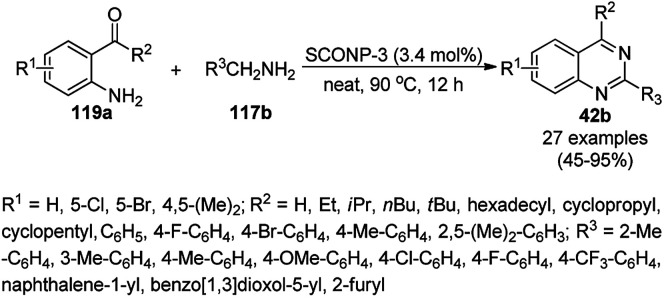

Wang et al. reported the synthesis of 2,4-disubstituted quinazolines (42b) from 2-aminobenzoketones (119a) and aryl or heteroaryl alkyl amine (117b) at 90 °C under solvent-free conditions using copper oxide nanoparticles supported on kaolin (SCONP-3) as a heterogeneous catalyst in moderate to excellent yields (Scheme 46).118 SCONP-3 was prepared from Cu(NO3)2·3H2O and kaolin followed by its treatment with aqueous Na2CO3 and calcination at 350 °C. The recycling of the catalyst was demonstrated by Wang et al. for up to four catalytic cycles with 67% yield from the model reaction of 2-aminobenzophenone with benzylamine. Mechanistically, CuO NPs bring the coupling reagents close to each other and facilitate the cyclization via the coordination with the formed iminic bond.

Scheme 46. Synthesis of 2,4-disubstituted quinazolines (42b) from 2-aminobenzoketones (119a) and aryl or heteroaryl alkyl amine (117b).

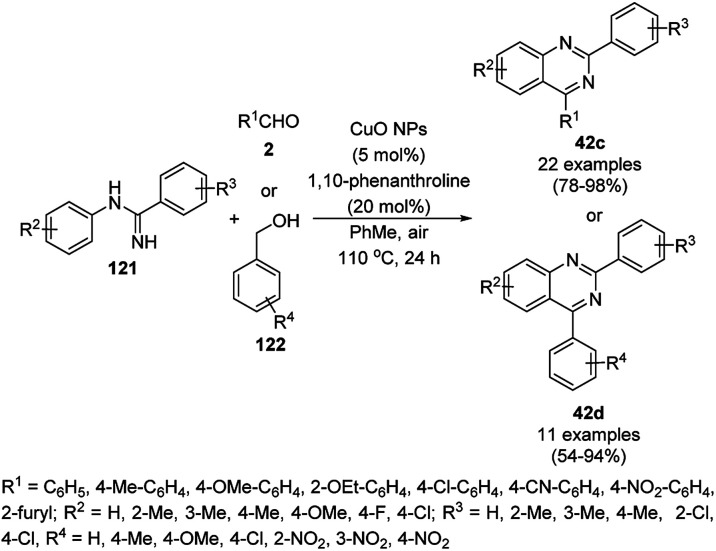

Zhang et al. also reported the synthesis of quinazolines (41c/d) catalyzed by CuO NPs via the oxidative coupling of substituted amidines (121) and substituted benzaldehydes (122) or benzyl alcohols (122) using 1,10-phenanthroline as the ligand and toluene as the solvent at 110 °C (Scheme 47).119 The developed protocol exhibited a wide scope with a variety of the substituents including electron-donating and withdrawing groups for the synthesis of quinazolines. The reaction with aryl aldehydes proceeded successfully for the synthesis of quinazolines, but did not occur with aliphatic aldehydes. The slight leaching of 2.7 ppm of Cu was observed using the model reaction between benzaldehyde and N-(4-chlorophenyl)benzimidamide, as confirmed by AAS. The XRD and TEM images of the NPs revealed that the catalyst maintained its integrity and morphology after three consecutive reuses, which allowed it to be employed for the next catalytic run without loss in catalytic activity.

Scheme 47. CuO NP-catalyzed synthesis of quinazolines (41c/d).

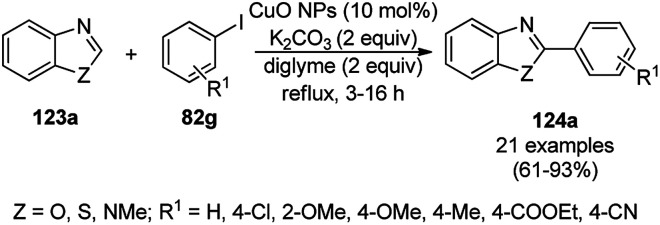

Zhang et al. reported the synthesis of 2-phenyl benzazoles (124a) via the direct arylation of N-containing heterocycles from benzazoles (123a) and aryl iodides (82g) catalyzed by ligand-free CuO nanospindles using diglyme as the solvent and K2CO3 as a mild inorganic base under reflux in an argon environment (Scheme 48).120 The prepared CuO NPs were characterized via XRD and FE-SEM. The recyclability of the catalyst was studied using benzoxazole and iodobenzene as a model reaction for up to three catalytic runs, where the catalyst retained its morphology, as evident from the XRD and EDS spectra of the recycled NPs.

Scheme 48. Synthesis of 2-phenylbenzazoles (124a) from benzazoles (123a) and aryl iodides (82g) catalyzed by CuO NPs.

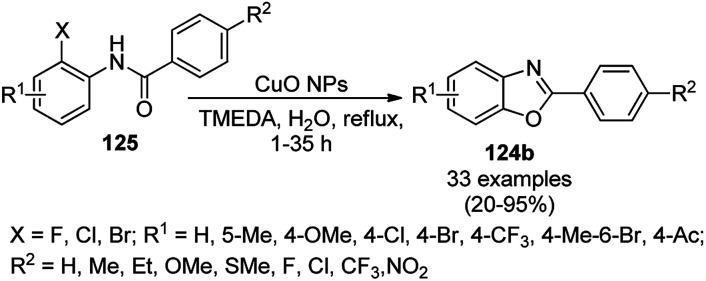

Patel et al. reported the green synthesis of 2-aryl benzoxazoles (124b) from o-halo benzanilides (125) using commercially available copper oxide (CuO) NPs in the presence of the organic base N,N,N′,N′-tetramethylethylenediamine (TMEDA) using water as the ultimate green solvent at 100 °C in 20–95% yield (Scheme 49).121 However, when 2-haloanilides (125) were treated with CuO NPs in the presence of an inorganic base such as caesium carbonate (CS2CO3), o-hydroxy phenylbenzamides were obtained as the major product. The recyclability of the catalyst was studied for up to five catalytic cycles without appreciable loss in its catalytic activity. However, a prolonged reaction time was required after the third and fifth catalytic cycles since agglomeration of the catalyst was observed.

Scheme 49. Synthesis of 2-arylbenzoxazoles (124b) from o-halobenzanilides (125) catalyzed by CuO NPs.

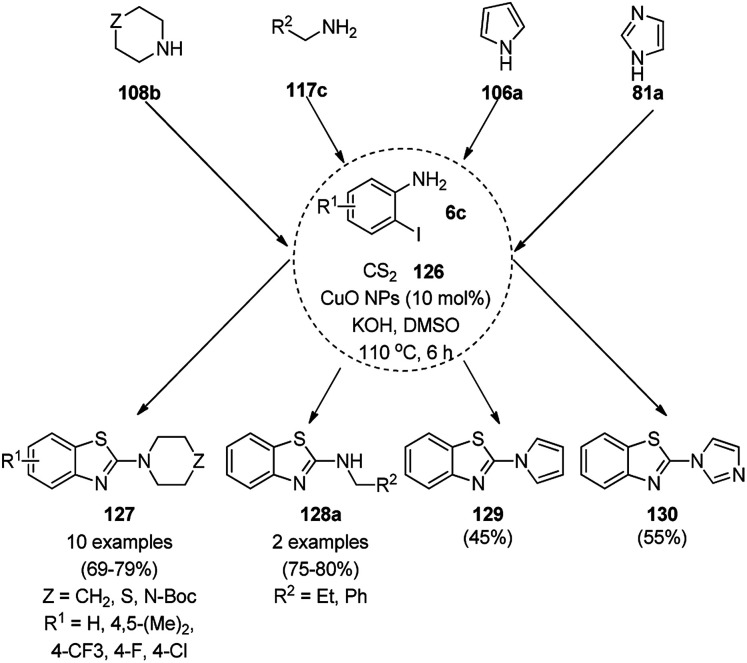

Nageswar et al. reported the synthesis of 2-aminobenzo[d]thiazoles (127/128a/129/130) under ligand-free conditions from substituted o-iodoaniline (6c), carbon disulfide (126) and alicyclic/heteroaromatic/benzyl/aliphatic amines (108/117c/106a/81a) using Cu(i) NPs as the NC (10 mol%) and KOH as the alkali in DMSO at 110 °C in 55–80% yield (Scheme 50).122 This coupling was found to be effective to construct the C–S bond from carbon disulfide and diverse amines. The tandem process of cyclization started from o-iodoaniline and potassium dithiocarbamate formed from the reaction of the base, carbon disulfide and amine followed by C–S bond formation and aromatization via the removal of H2S gas. The NPs at the end of three catalytic cycles were found to maintain their nanoparticulate behavior (TEM) and only 8% of product loss was observed at the end of the third catalytic run for the model three-component reaction of o-iodoaniline, carbon disulfide and amines.

Scheme 50. Cyclocondensation of 2-aminobenzothiazoles catalyzed by Cu(i) NPs.

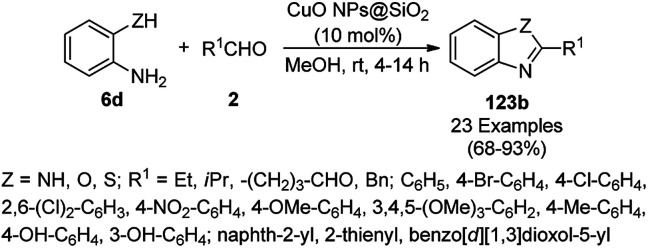

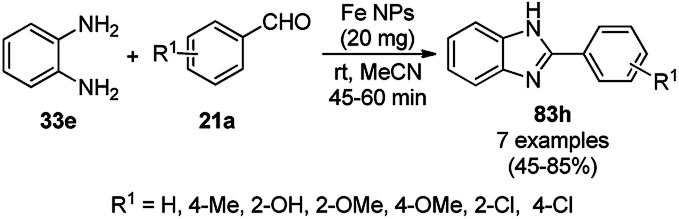

Mandal et al. reported the synthesis of 2-substituted benzazoles (123b) such as benzimidazoles/benzoxazoles/benzothiazoles from o-substituted anilines (6d), viz. 2-aminoanilines/2-aminophenols/2-aminothiophenols, and aryl/heteroaryl/aliphatic aldehydes (2) catalyzed by silica-supported CuO NPs using methanol as the solvent at rt in 68–93% yield (Scheme 51).123 In search of the best solid support, CuO NPs loaded on SiO2, montmarillonite, ZSM-5 and TiO2 were investigated, where the best results were observed with the CuO NPs loaded on silica. The recyclability of the catalyst was studied for up to five catalytic runs with significant yields of the 2-phenylbenzo[d]imidazoles between the reaction of o-phenylene diamine and benzaldehyde.

Scheme 51. Synthesis of 2-substituted benzazoles (123b) from o-substituted anilines (6d) and aldehydes (2) catalyzed by heterogeneous NCs.

CuO NPs catalyzed the ligand-free intramolecular cyclization of o-haloaryl derivatives (131) for the synthesis of benzimidazoles (84b) and benzothiazoles or benzoxazoles (123c) with a wide functional group tolerance (Scheme 52).124 The CuO NPs collected after centrifugation were recycled and reused for the synthesis of 2-phenyl benzoxazole for up to five runs without loss in their catalytic performance (97–100%) and texture (TEM and XRD). The supernatant collected during the cyclization of o-bromophenylbenzamide was subjected to AAS, which revealed zero leaching of Cu during the reaction.

Scheme 52. Intramolecular cyclization of o-haloarenes (131/132) catalyzed by CuO NPs for the synthesis of benzimidazoles (84b), benzothiazoles and benzoxazoles (123c).

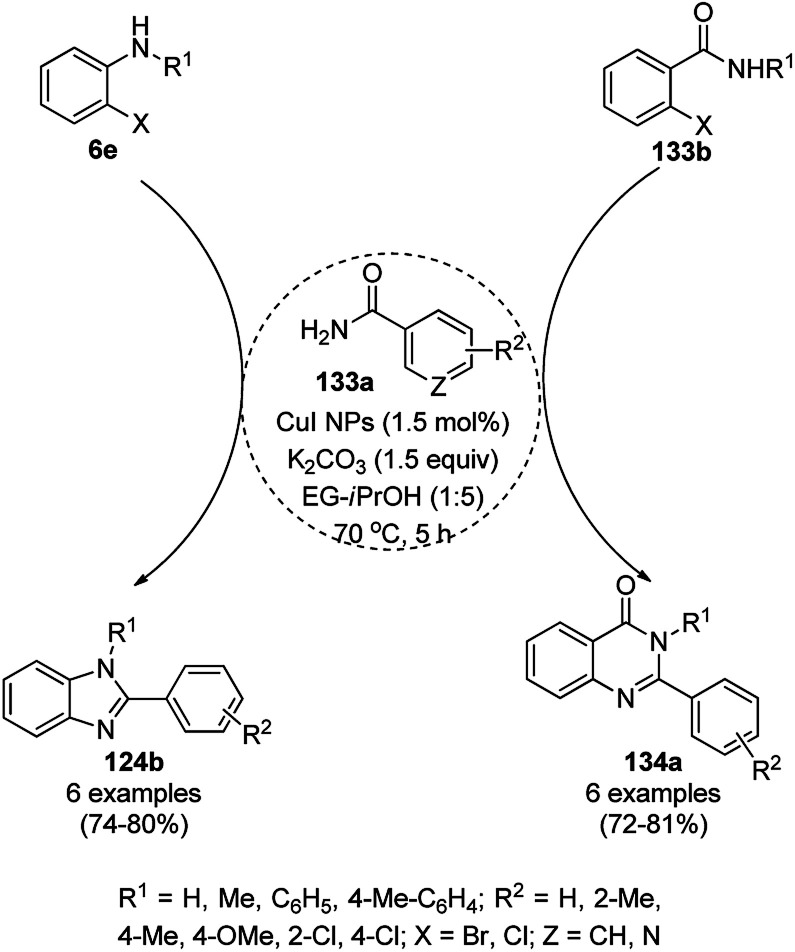

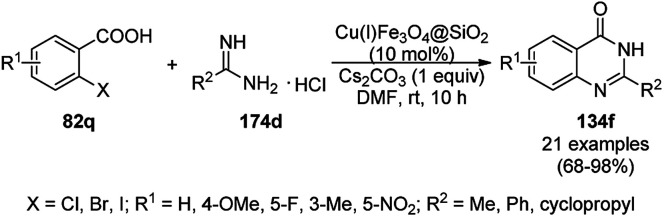

The copper iodide NP-catalyzed intermolecular amidation-cyclization for the one-pot synthesis of benzimidazoles (124b) and quinazolinones (134a) was reported via the cyclocondensation of o-halo anilines (6e) or o-halo benzamides (133b) with substituted benzamides (133a, Scheme 53).125 The CuI NPs were prepared using copper acetate (Cu(OAc)2·H2O), dimethyl glyoxime and potassium iodide. The same catalyst was also explored for the synthesis of carboxamides and cyclic amides via the N-arylation of benzamides and succinimides with haloarenes. The recyclability of the CuI NPs was demonstrated for up to five reuses with 75–85% yield of N-phenyl benzamides.

Scheme 53. CuI NP-catalyzed synthesis of benzimidazoles (124b) and quinazolinones (134a).

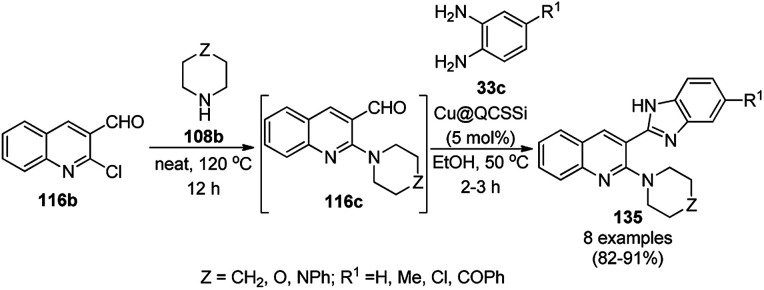

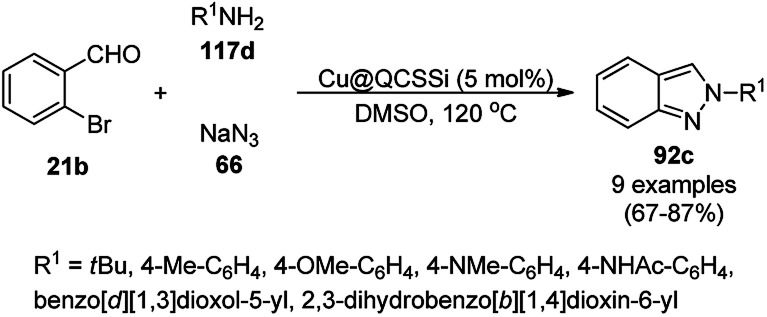

A copper(ii) complex supported on amino-functionalized silica (Cu@QCSSi) catalyzed the cyclocondensation of p-substituted o-phenylene diamine (33c) with in situ formed 2-amino-substituted quinoline-3-carbaldehyde (116b) for the successful one-pot synthesis of 3-(benzimidazol-2-yl)quinolines (135) in good to excellent (Scheme 54).126 The intermediate 116c was obtained via the nucleophilic substitution of 2-chloroquinoline-3-carbaldehyde (116b) with alicyclic amines (108b). Further, the same catalyst was also explored for the synthesis of 2-substituted indazoles (92c) from 2-bromobenzaldehyde (21b), amines (117d) and sodium azide (66) in DMSO at 120 °C (Scheme 55). The required catalyst was synthesized by grafting 2-oxo-1,2-dihydroquinoline-3-carbaldehyde (QC) on amino-functionalized silica followed by complexation using copper acetate. To assess the recyclability of the catalyst, it was recycled and reused for up to seven times, giving 84–90% yield of product for the reaction among 116b, morpholine, and o-phenylene diamine.

Scheme 54. Synthesis of 3-(benzimidazol-2-yl)quinolines (135) catalyzed by Cu@QCSSi.

Scheme 55. Synthesis of 2-substituted indazoles (92c) catalyzed by Cu@QCSSi.

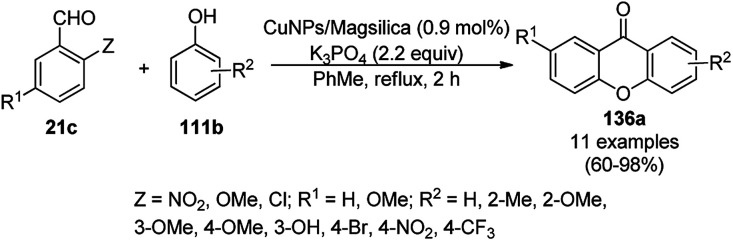

Gerbino et al. reported the ligand-free synthesis of xanthones (136a) from 2-substituted benzaldehydes (21c) and substituted phenols (111b) catalyzed by CuNPs supported on silica-coated maghemite (MagSilica) using potassium phosphate as the base and toluene as the solvent under reflux and argon in moderate to excellent yields (Scheme 56).127 The NCs could be recycled using an external magnet for up to four catalytic runs as the catalyst. Gerbino et al. reported about <50 ppb copper leaching, as confirmed by ICP-AES, making this method very economic.

Scheme 56. Synthesis of xanthones (136a) catalyzed by Cu-based magnetically recyclable NPs.

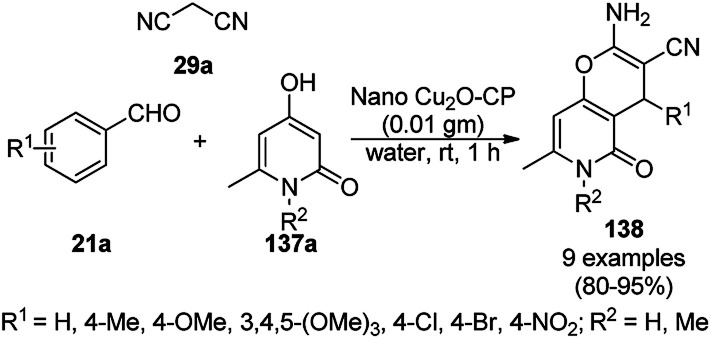

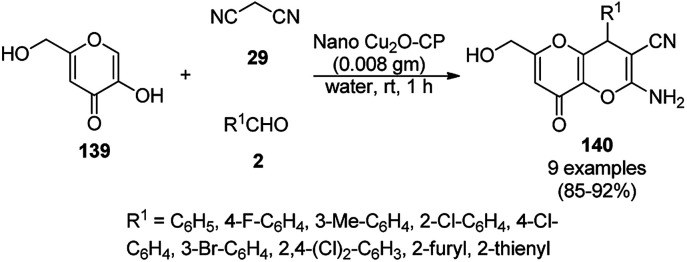

Baghbanian S. M. reported the green synthesis of pyrano[3,2-b]pyranones (138, Scheme 57) and pyrano[3,2-c]pyridones (140, Scheme 58) catalyzed by Cu2O NPs supported on nanozeolite clintoptilolite (nano Cu2O-CP) under mild aqueous conditions at rt in good to excellent yields.128 Specifically, 138 and 140 were obtained from the reaction of aldehyde (21a or 2) and malononitrile (29a) with 4-hydroxypyridine-2-ones (137a) and Kojic acid (139), respectively. The NPs were synthesized from nanozeolite, such as clintoptilolite, and copper chloride (CuCl2), and well characterized via XRD, BET, SEM, TEM, TEM-EDS, and XPS. The CuNPs yielded a better synthetic yield of the final product in comparison with NiNPs in water rather than other solvents such as ethanol, DMF, toluene, and DCM. In the absence of catalyst, only a trace amount of product was observed even after a prolonged reaction time. The reaction has the advantage that it can tolerate various electron-withdrawing and donating substituents under the optimized reaction conditions. The reusability of the catalyst was studied for up to eight catalytic cycles with high efficiency, which is attributed to the strong interaction of Cu2O NPs with the zeolite.

Scheme 57. Synthesis of pyrano[3,2-c]pyridines (138) catalyzed by nano Cu2O-CP.

Scheme 58. Synthesis of pyrano[3,2-b]pyranoes (140) catalyzed by nano Cu2O-CP.

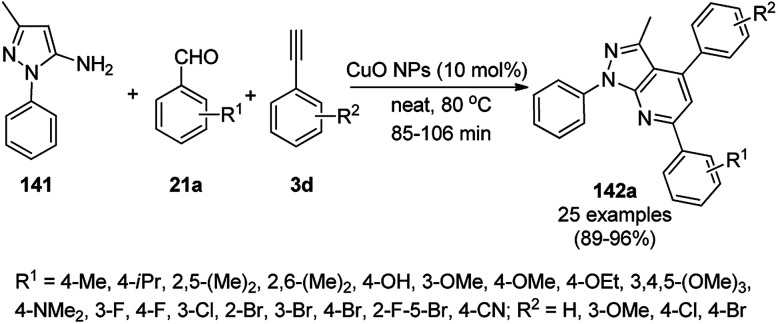

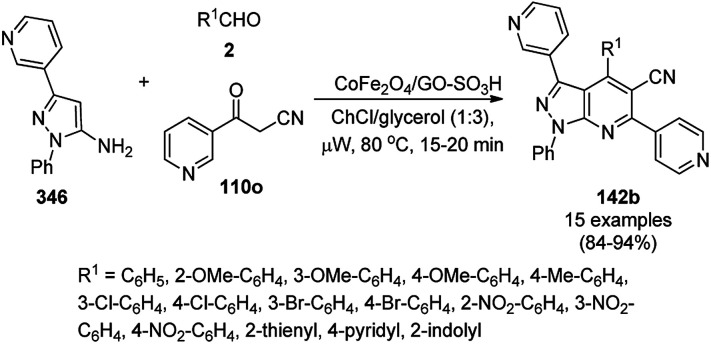

Jeong et al. reported the commercially available CuO NP-catalyzed synthesis of phenyl-1H-pyrazolo[3,4-b]pyridines (142a) via the three-component domino reaction of 3-methyl-1-phenyl-1H-pyrazol-5-amine (141), substituted aryl carbaldehydes (21a), and aryl alkynes (3b) under solvent-free conditions at 80 °C in 89–96% yield (Scheme 59).129 During the course of the domino reaction, the CuO NPs act as a Lewis acid catalyst to promote the Diels–Alder reaction. The recyclability of the catalysts revealed that the catalyst could be recycled for up to four catalytic cycles without loss in its catalytic potential.

Scheme 59. Synthesis of phenyl-1H-pyrazolo[3,4-b]pyridines (142a) catalyzed by CuO NPs.

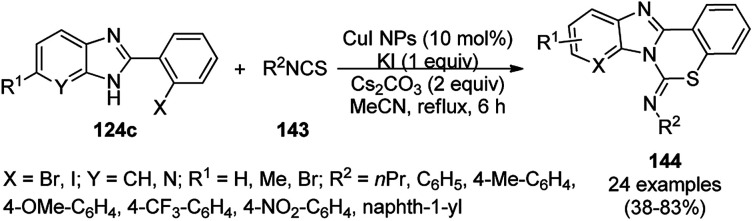

Wang et al. reported copper iodide nanocatalysts chelated to 1,10-phenanthroline for the synthesis of benzo[e]benzo[4,5]imidazo[1,2-c][1,3]thiazin-6-imines (144) from substituted 2-phenylbenzimidazoles (124c) and substituted isothiocyanates (143) using potassium iodide as the ligand, Cs2CO3 as the base and acetonitrile as the solvent under reflux (Scheme 60).130 The intramolecular SNAr reaction to form the C(sp2)–S bond proceeds on the surface of nano copper iodide catalyst chelated to 1,10-phenanthroline to promote the oxidative addition and reductive elimination. A recycling experiment was performed to assess the caliber of the catalyst for reuse, where after the second run it was observed that the catalyst gave a yield of 76% of the final product.

Scheme 60. Synthesis of benzo[e]benzo[4,5]imidazo[1,2-c][1,3]thiazin-6-imines (144) using CuI NPs as the catalyst.

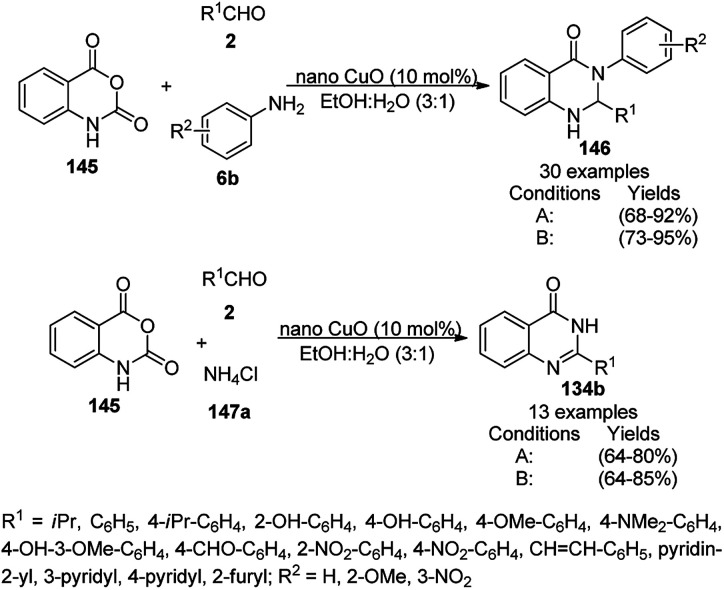

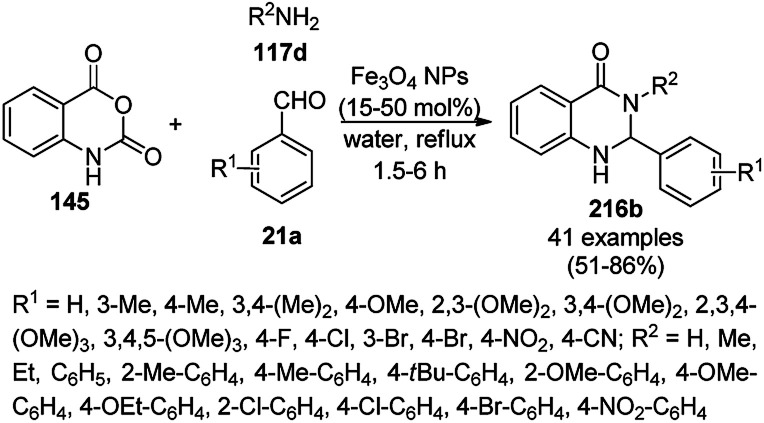

Zhang et al. reported the synthesis of 2,3-dihydroquinazolin-4(1H)-ones (146) and quinazolin-4(3H)-ones (134b) from isatoic anhydride (145), amine such as anilines (6b)/ammonium chloride (147a), and alkyl/aryl/heteroaryl aldehydes (2) catalyzed by nano CuO as a Lewis acid catalyst in aqueous ethanol (3 : 1) under reflux conditions (Scheme 61).131 They also synthesized all the compounds under ultrasonication and compared the yields of both reaction conditions. The developed protocol shows wide tolerance range for various functional groups. The recyclability of the catalysts was checked for up to four catalytic runs and the yields of the product was reported to range from 78–80% for the one-pot synthesis using 145, benzaldehyde and aniline.

Scheme 61. CuO NP-catalyzed synthesis of 2,3-dihydroquinazolin-4(1H)-ones (146) and quinazolin-4(3H)-ones (134b). Conditions A: reflux, 3 h; and conditions B: 60 °C, ultrasound, 10–30 min.

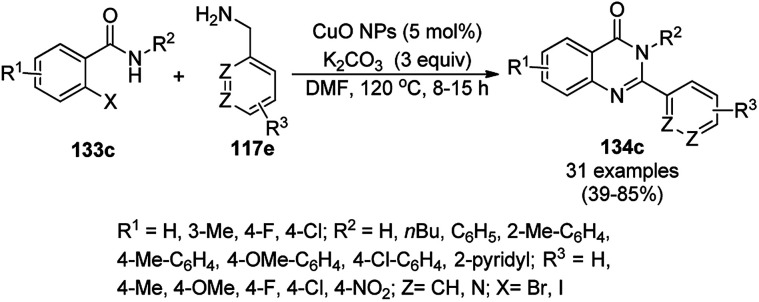

The CuO NP-catalyzed ligand-free and additive-free Ullmann coupling involving N-arylation followed by oxidative C–H amidation for the synthesis of 2,3-disubstituted quinazolinones was successfully achieved from 2-halobenzamides (133c) and arylalkyl amines (117e) in DMF (Scheme 62).132 The catalyst was separated by centrifugation and recycled successfully for up to three cycles for the synthesis of 134c in 39–85% yield. The decreased yield in the third cycle during reuses can be attributed to the agglomeration of the NPs during the course of the reaction (TEM).

Scheme 62. Synthesis of 2,3-disubstituted quinazolinones (134c) from 2-halobenzamides (133c) and arylalkyl amines (117e).

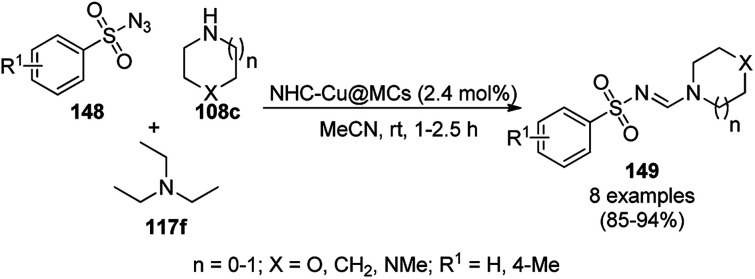

Shahrisa et al. reported the synthesis of N-sulfonylformamidines (149) using an N-heterocyclic complex-copper complex supported on magnetic cellulose (NHC–Cu@MCs) from the three-component reaction among arylsulfonyl azide (148), secondary alicyclic amines (108c) such as morpholine, N-methylpiperazine, piperidine and pyrrolidine, and triethylamine (117f) in acetonitrile at rt in 85–94% yield (Scheme 63).133 The NCs were synthesized via the treatment of ionic liquid-grafted magnetic cellulose with copper iodide, potassium tert-butoxide in THF, and further well characterized via TGA, VSM, SEM, XRD, EDX, and FT-IR. The scope of the reaction was explored with aliphatic amines, but was found to be unsuccessful for aromatic amines. The recyclability of the catalyst recovered using an external magnet was demonstrated for up to five catalytic runs with the loss of 20% of final product at the end of the fifth catalytic run. Specifically, 149 acts as a methylene donor and oxidant for the conversion of Cu(ii) into Cu(i), which co-ordinates with the nitrogen of 149 for the elimination of diethylamine and 1,3-dipolar addition to proceed.

Scheme 63. Three-component reaction for the synthesis of N-sulfonylformamidines (149) catalyzed by CuNPs.

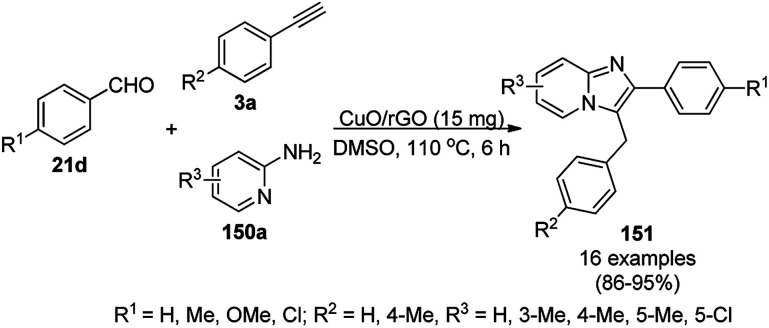

CuO NPs immobilized on reduced graphene oxide sheets (CuO/rGO) catalyzed the cyclocondensation of 2-benzaldehydes (21d), phenyl acetylenes (3a) and aminopyridines (150a), providing an efficient approach for the synthesis of imidazo[1,2-a]pyridines (151, Scheme 64) without any additives.134 The Cu(ii) catalyst promoted Cu(ii)-mediated aminomethylation of terminal alkynes 3a to give the intermediate propargylamines. The present 2D-nano composites were synthesized according to previously reported protocols135 and found to be stable, as evident from the hot filtration tests and reuse of the catalyst for up to five times.

Scheme 64. Synthesis of imidazo[1,2-a]pyridines (151) catalyzed by CuNPs.

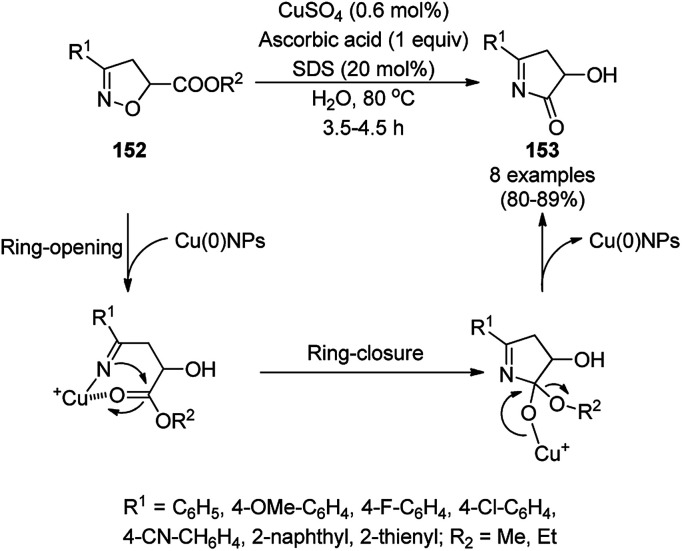

Cu(0)NP-catalyzed ring opening followed by the domino or sequential cyclization (Scheme 65) of Δ2-isoxazoline-5-esters (152) resulted in the synthesis of novel γ-hydroxy pyrrolinone (153) in 80–89% yield.136 Maiti et al. has achieved this transformation using in situ-fabricated CuNPs generated from CuSO4·5H2O as the metal precursor, SDS (sodium dodecyl sulfonate) as the surfactant, and ascorbic acid as the reducing agent under aqueous conditions. The in situ-generated cooperative assemblies were characterized via SEM, UV-Vis, DLS, TEM and PXRD. However, the same Cu(0)NP-catalyzed protocol at 60 °C yielded ring-opened β-hydroxy ketones from 152 in 79–89% yield and carboxamides from carbonyl azides in 79–95% yield. A lowed efficiency was observed with the recovered Cu(0)NPs.

Scheme 65. Cu(0)NP-catalyzed ring opening and domino cyclisation of Δ2-isoxazoline-5-esters (152).

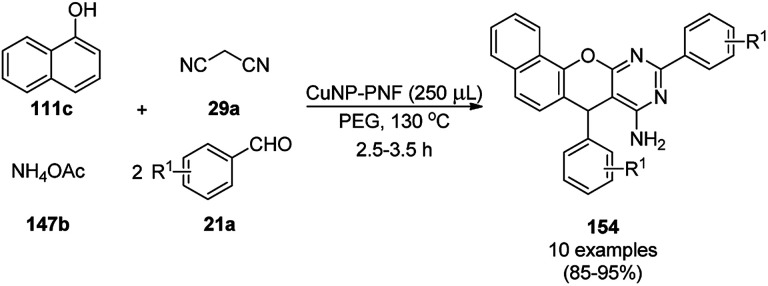

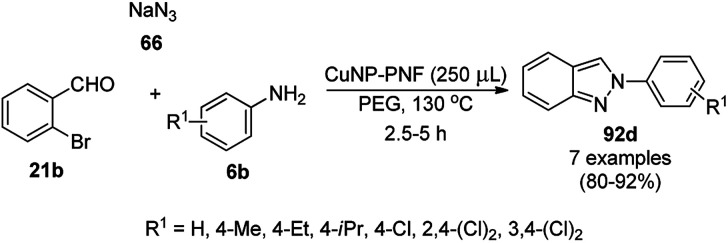

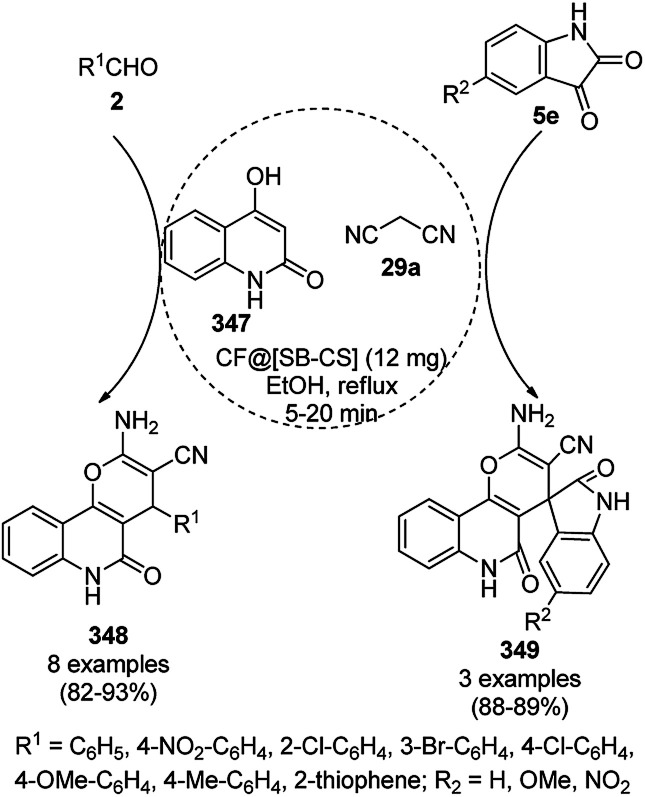

CuNPs decorated with peptide nanofibers (CuNP-PNF) catalyzed Knoevenagel condensation was reported for the synthesis of chromeno[2,3-d]pyrimidin-8-amines (154) from α-naphthol (111c), malononitrile (29a), ammonium acetate (147b) and benzaldehydes (21a) in polyethylene glycol (PEG, Scheme 66).137 The same protocol was also explored for the synthesis of 2H-indazoles (92d) from o-bromo benzaldehydes (21b), sodium azide (66) and substituted anilines (6b) in good to excellent yields (Scheme 67). PNF was synthesized via the self-assembly technique using histidine as a building block and CuCl as the metal precursor. CuNP-PNF played the key role in the synthesis of both heterocycles (154 and 92d) via co-ordination with the carbonyl oxygen of aldehydes (21a/b). The catalyst was recycled for up to four cycles for the Knoevenagel condensation of benzaldehyde, 111c, 29a and 147b.

Scheme 66. Synthesis of chromeno[2,3-d]pyrimidin-8-amines (154) catalyzed by CuNP-PNF.

Scheme 67. Synthesis of 2H-indazoles (92d) catalyzed by CuNP-PNF.

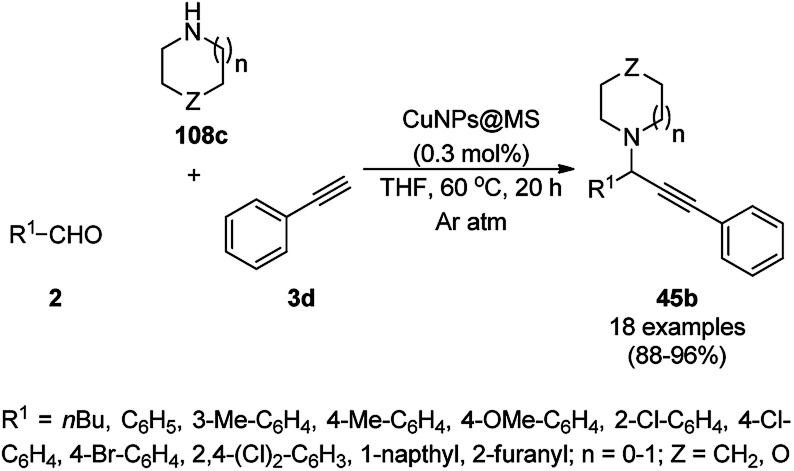

Supported CuNPs on biodegradable starch microparticles (CuNPs@MS) catalyzed the A3 coupling of aldehydes (2), amines (108c) and alkynes (3d) for the synthesis of propargylic amines (45b) was reported by Gholinejad et al. (Scheme 68).138 The NCs were prepared via the treatment of previously prepared starch microparticles139 with Cu(OAc)2·H2O and sodium borohydride. The CuNPs could catalyze A3 coupling via the activation of 3dvia the formation of copper acetylide. In the recycling experiment, at the end of the fifth run, a slight loss (10%) in the yield of the A3-coupled product of benzaldehyde, piperidine, and 3d was observed compared to that in the first catalytic run.

Scheme 68. Synthesis of propargylamines (45b) catalyzed by CuNPs@MS.

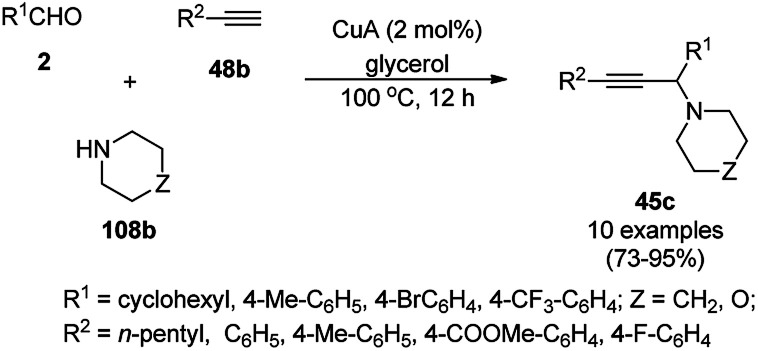

Favier et al. reported the catalytic use of Cu(0)NPs (CuA) in glycerol for the synthesis of propargylic heterocyclic amines (45c) via the A3 coupling of terminal alkynes (48b), carbaldehydes (2) and amines (108b) such as morpholines and piperidines (Scheme 69).140 They synthesized the CuNPs via the decomposition of di-μ-hydroxobis[(N,N,N′,N′-tetramethylethylenediamine)copper(ii)]chloride [Cu(2-N,N,N′,N′-TMEDA)(μ-OH)]2Cl2 in glycerol in the presence of polyvinylpyrrolidone (PVP) as a stabilizer to get red-purple colloidal solutions. The multi-purpose use of the catalyst was proven by the formation of C–N bonds from haloarenes and amines, cross-dehydrogenative coupling of tert-amines with terminal alkynes, A3-cycloisomerisation-tandem reactions and ketone-aldehyde-alkyne (KA2) reaction. The catalytic phase containing the zero valent CuNPs was recycled for more than five times, preserving its catalytic potential.

Scheme 69. A3 coupling catalyzed by zero valent CuA.

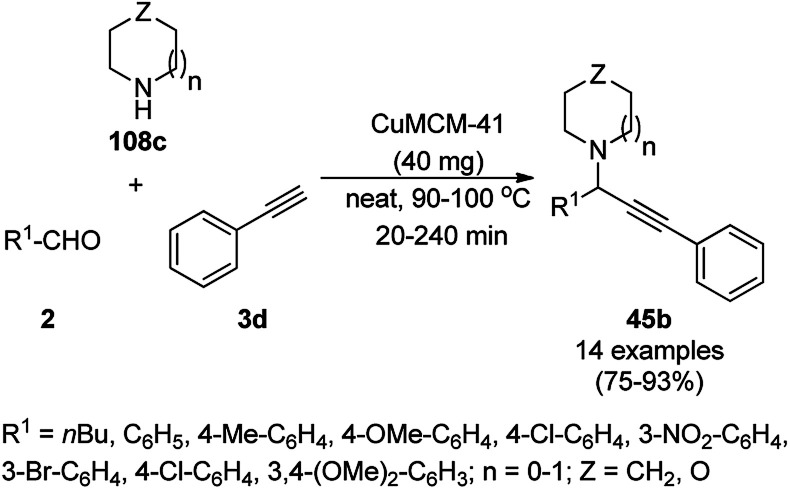

Copper-modified spherical MCM-41 (CuMCM-41) NP-catalyzed A3 coupling for the synthesis of propargylamines (45b) from aldehydes, amines and phenyl acetylene (3d) was achieved under solvent-free conditions (Scheme 70) in good to excellent yields.141 The NCs were synthesized by the treatment of an aqueous solution of cetyltrimethyl bromide (CTAB) with tetraethyl orthosilicate (TEOS), copper acetate monohydrate and ammonia. The catalyst was recycled up to three times with a slight loss in catalytic performance due to the blockage of its active sites. The present protocol exhibits some advantages such as higher yield, shorted reaction time, moderate temperature, operational without inert atmosphere and solvent compared to the literature reports.142–145

Scheme 70. A3 coupling catalyzed by CuMCM-41.

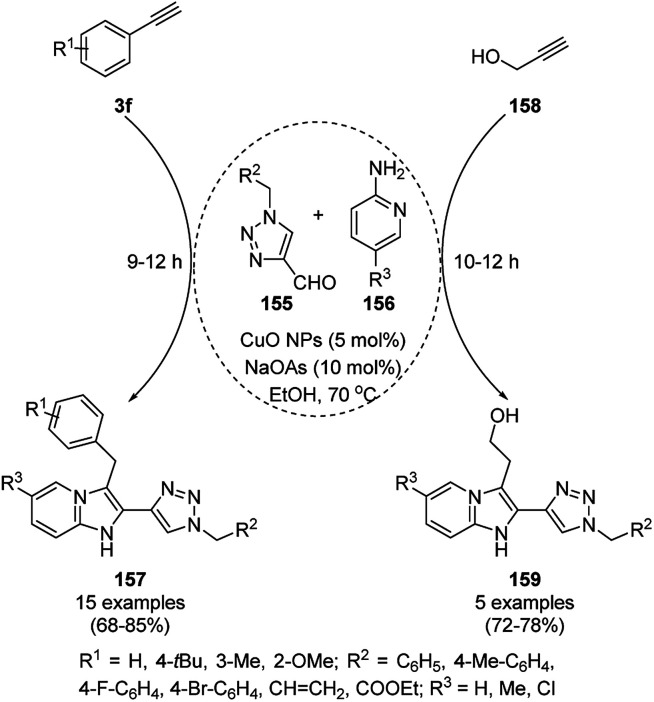

CuO NP-catalyzed A3 coupling-5-exo-dig cyclization for the successful synthesis of 2-triazolyl-imidazo[1,2-a]pyridines (157) from 1-alkyl-1,2,3-triazole-4-carbaldehyde (155), amidine (156) and phenyl acetylene (3f) was achieved by Khan et al. (Scheme 71) using sodium ascorbate as a reducing agent.146 The same CuO NP-catalyzed protocol was also explored for the synthesis of 2-(2-(1-alkyl-1,2,3-triazol-4-yl)-imidazo[1,2-a]pyridin-3-yl)ethanol (159) from propargylic alcohol (158). The NPs were reused for up to five times with moderate to good yields (68–82%).

Scheme 71. CuO NP-catalyzed synthesis of 2-triazolyl-imidazo[1,2-a]pyridines (157/159).

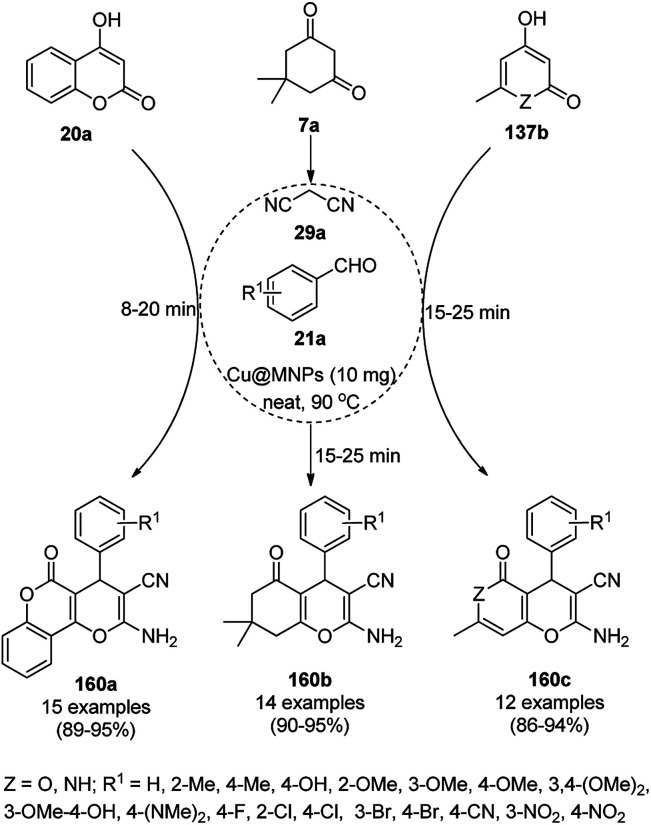

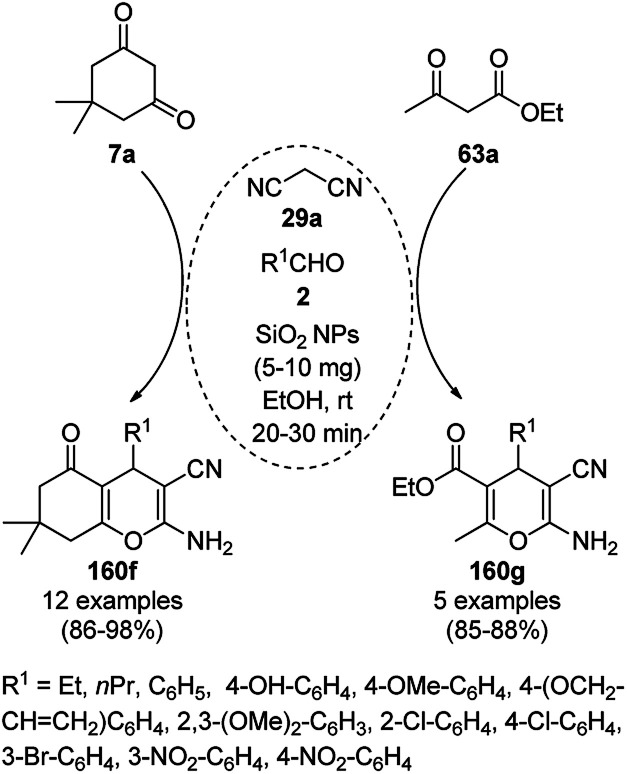

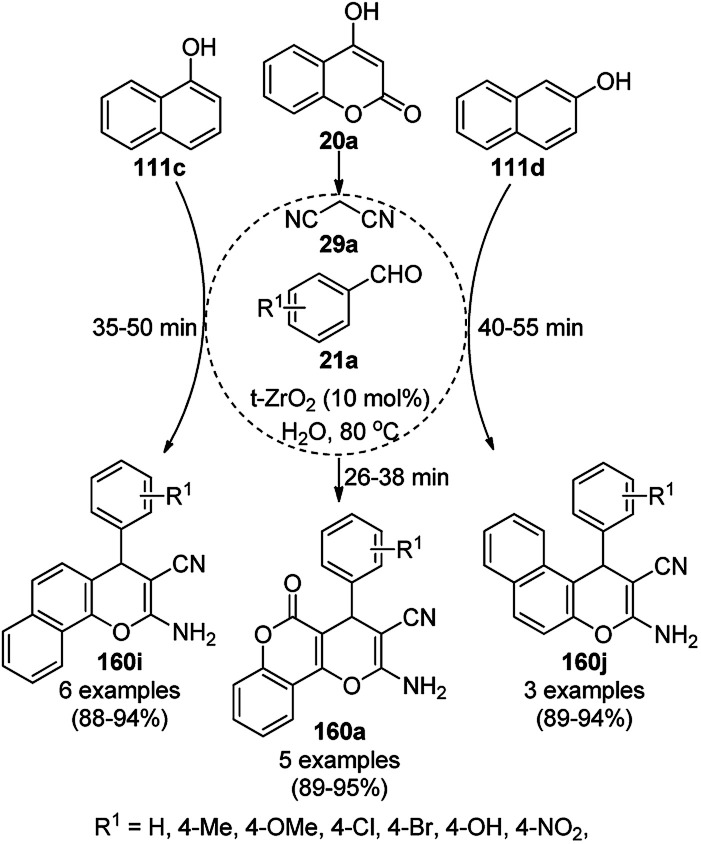

The copper complexed magnetic NP (Cu@MNP)-catalyzed synthesis of 2-amino-3-cyno-4H-pyrans (160a/b/c, Scheme 72) was reported by Jimenez et al. via the Knoevenagel–Michael-cyclization of malononitrile (29a) and substituted benzaldehydes (21a) under solvent-free conditions with 4-hydroxy coumarins (20a), dimedone (7a) and C–H-activated acids (137b), respectively.147 The catalyst was recycled for up to five runs with negligible loss in its catalytic activity for the model reaction among 20a, 29a and 4-chlorobenzaldehyde. After coating of Fe3O4 NPs with TEOS, 3-chloropropyltriethoxysilane (CPTES), MNPs bonded with propyl chloride were obtained, which were subsequently treated with diethylenetriamine, piperidine, and [Cu(salal)2] to obtain a salicylic-chelated ligand, and the final NPs were characterized via FTIR, TGA, VSM, EDX and XRD. The present protocol (Scheme 72) was claimed to be superior in terms of shorter reaction times, lower catalytic loading, and avoiding toxic organic solvents and tedious separation protocols compared with literature reports for the synthesis of 160a (R1 = 4-Cl) catalyzed by CuO NPs,148 dendrimer core of oxo-vanadium phthalocyanine MNPs (MNP@AVOPc),149 urea,150 potassium phthalimide-N-oxyl (POPINO),151 SiO2 NPs,152 t-ZrO2 NPs,153 and ZnO NPs.154

Scheme 72. Synthesis of 2-amino-4H-chromenes (160a/b/c) catalyzed by Cu@MNPs.

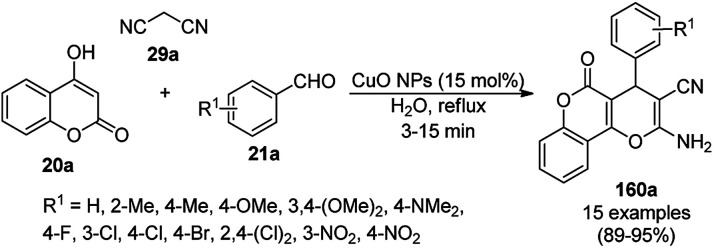

The CuO NP-catalyzed condensation of three components such as 4-hydroxycoumarin (20a), malononitrile (29a) and benzaldehydes (21a) was reported by Mehrabi et al. for the rapid synthesis of 3,4-dihydropyrano[c]chromenes (160a, Scheme 73).148 The NPs were synthesized via the sonochemical treatment of an alkaline solution of Cu(CH3COO)2·2H2O and polyvinyl alcohol (PVA). The products were purified via recrystallization, avoiding tedious chromatography.

Scheme 73. CuO NP-catalyzed synthesis of 3,4-dihydropyrano[c]chromenes (160a).

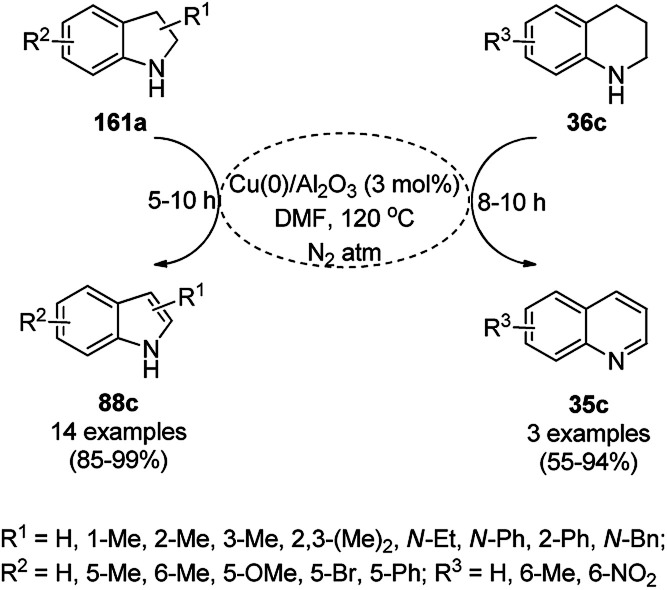

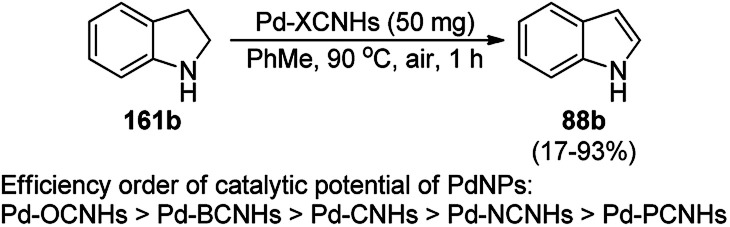

CuNPs from copper aluminium hydrotalcite (Cu/Al2O3) catalyzed the dehydrogenation of indolines (161a) and 1,2,3,4-tetrahydroquinolines (36c) in the report by Likhar et al. (Scheme 74).155 They have also reported the use of the same catalyst for the dehydrogenation of diverse amines and alcohols with significantly high turnover numbers (TON) and turnover frequency (TOF). The CuNPs were obtained via the co-precipitation of copper nitrate and aluminium nitrate followed by calcination at 473 K and chemical reduction in a Parr hydrogenator. The catalyst was reused with a regular catalytic performance during five consecutive runs.

Scheme 74. Dehydrogenation of indolines (161a) and 1,2,3,4-tetrahydroquinolines (36c).

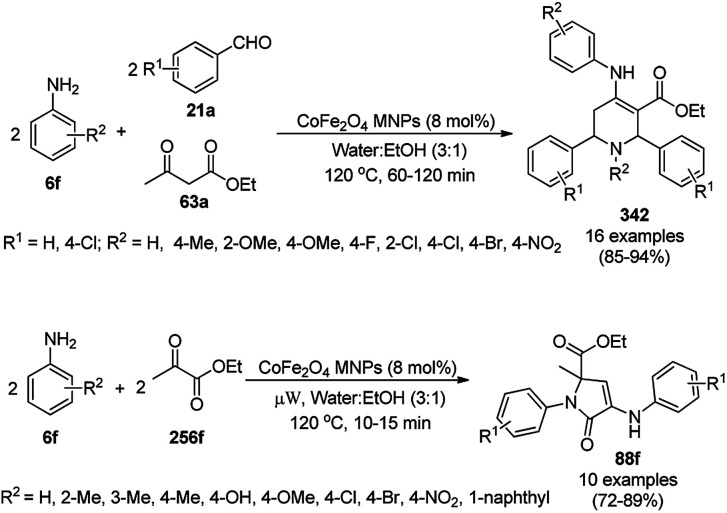

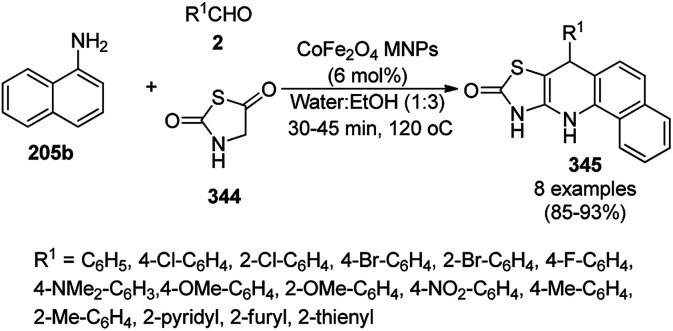

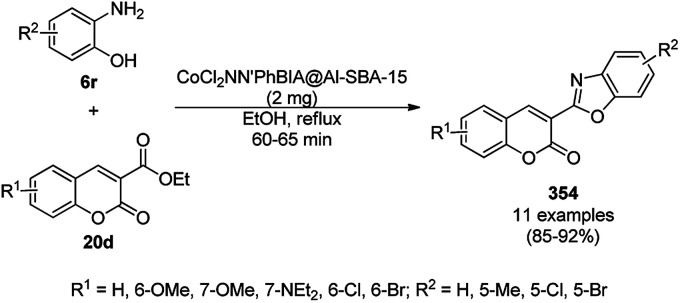

3.4. CoNP-catalyzed synthesis of heterocycles

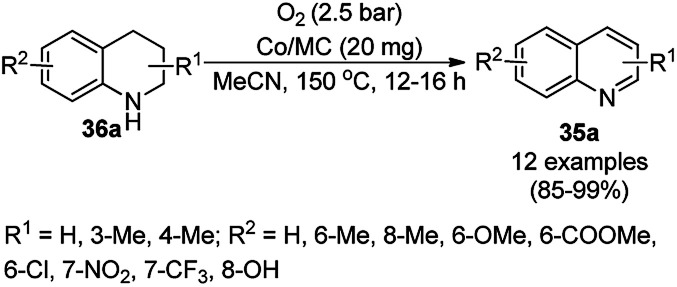

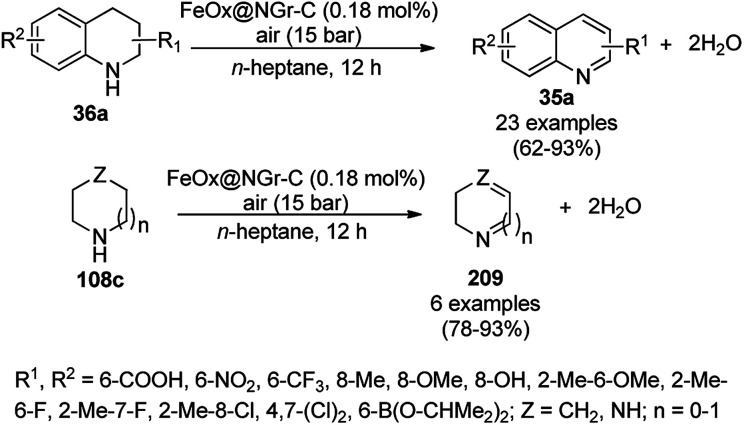

Zhang et al. recently reported the oxidative dehydrogenation of tetrahydroquinolines (36a) using nitrogen-doped carbon-supported cobalt nanoparticles (Co/MC) in acetonitrile at 150 °C under 2.5 bar O2 in 85–99% yield (Scheme 75).156 The catalyst was prepared from 2,4-dihydroxybenzoic acid, hexamethylenetetramine, melamine, Pluronic P123 and 1,6-hexanediamine, which were dispersed in ammonium hydroxide solution having Co(NO3)2·6H2O. The final catalyst was well characterized via TEM, XRD, XPS, ICP-AES, Raman spectroscopy, nitrogen physisorption measurements, and electron paramagnetic resonance (EPR). The oxidative dehydrogenation of tetrahydroquinolines with electron-donating groups was found to have higher activity than that with electron-withdrawing groups. The catalyst played a vital role via the formation of the radical oxyanion (˙O2−), which became instrumental species for the aromatic oxidation. The present sustainable and economical approach exhibits the advantages of high catalytic potential, operational without additives, and sufficiently stability and recyclability for up to five reuses in comparison with reported protocols.157–159

Scheme 75. Aerobic dehydrogenation of 1,2,3,4-tetrahydroquinolines (36a) catalyzed by nitrogen-doped carbon-supported CoNPs.

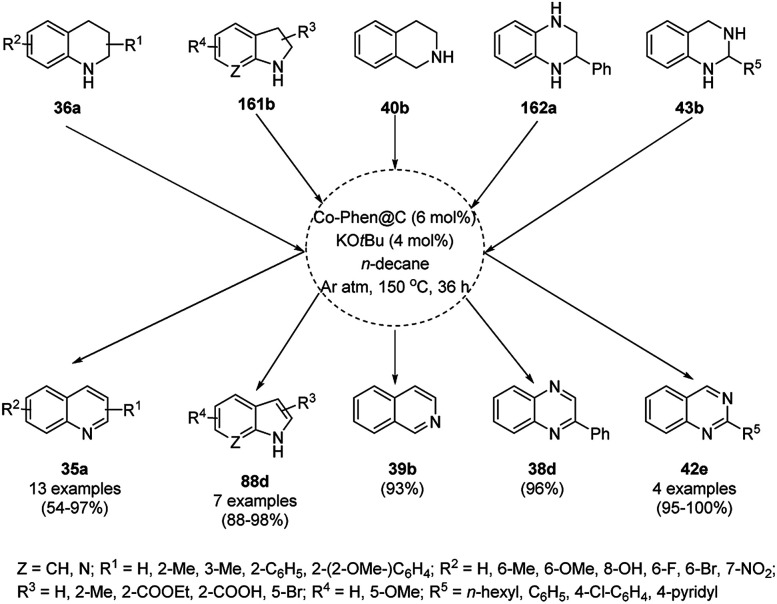

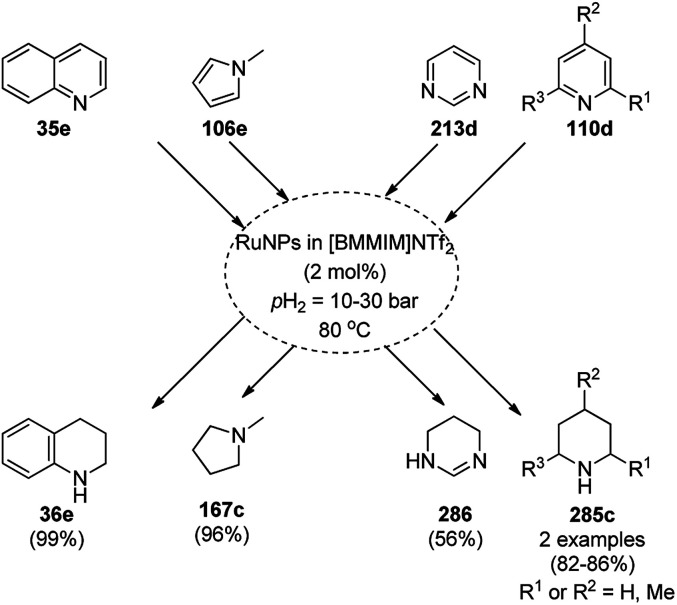

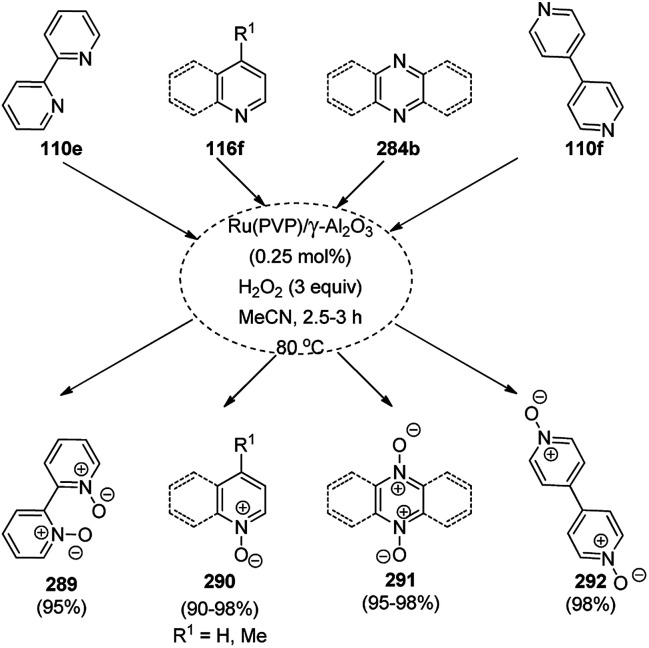

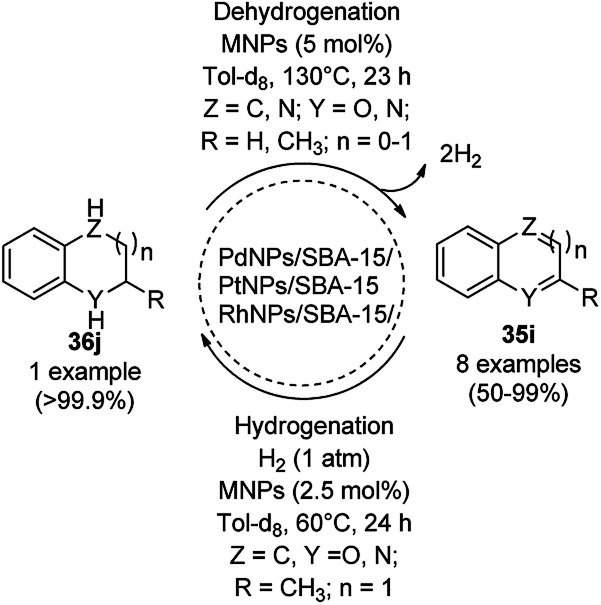

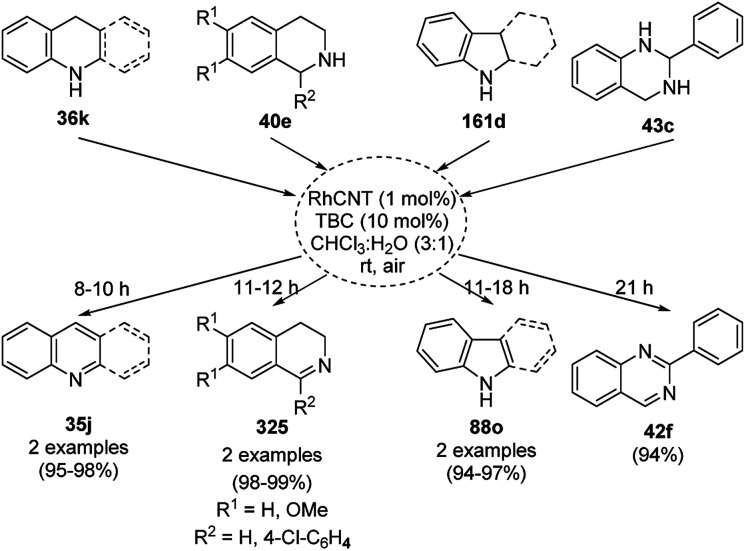

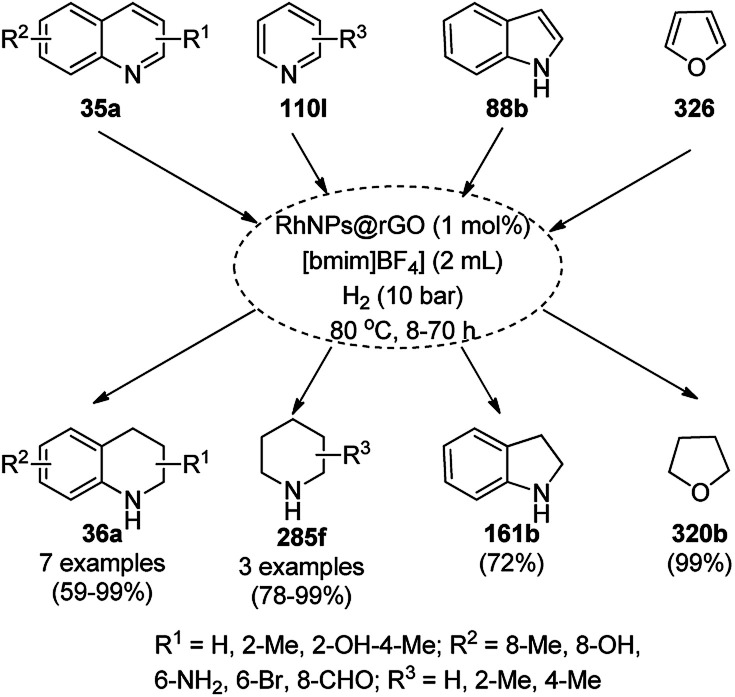

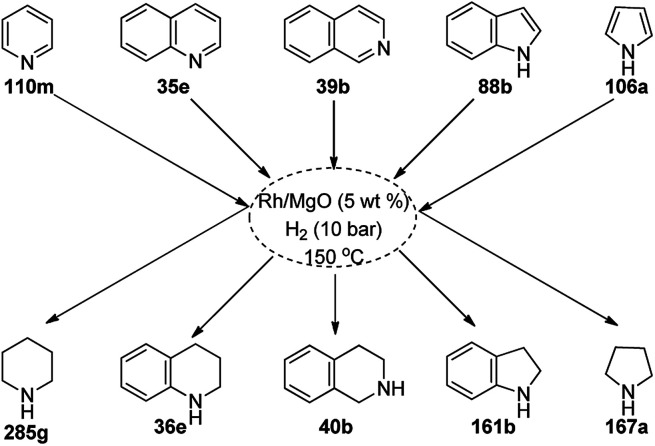

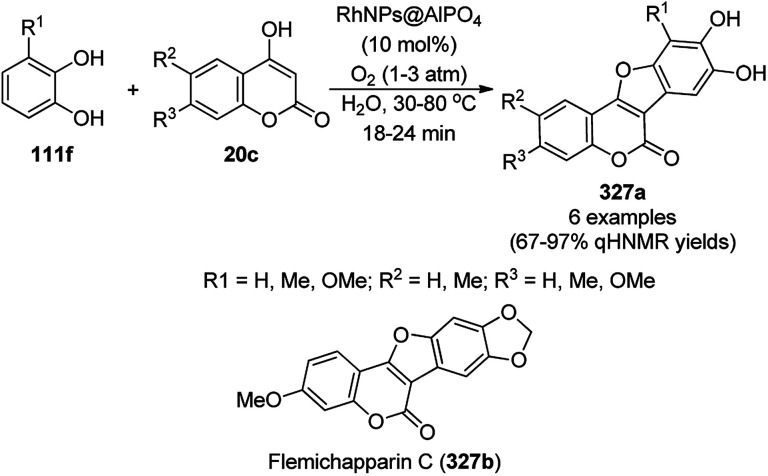

Balaraman et al. reported a Co-phenanthroline complex adsorbed on GO (Co-Phen@C) as a NC in the acceptorless dehydrogenation of saturated aza-heterocycles to N-heteroaromatics for the synthesis of quinoline (35a), indoles (88d), isoquinolines (39b), quinoxalines (38d), and quinazolines (42e) using potassium tert-butoxide as the base (Scheme 76).160 They synthesized the required catalyst via the sonochemical treatment of Co(ii) acetylacetonate and 1,10-phenanthroline to obtain a Co-phenanthroline complex followed by its adsorption on exfoliated GO. The robustness of the catalyst was studied in a recycling experiment, where it was recycled up to six cycles without any decay in the yield of N-heteroaromatics. The complete dehydrogenation of the partially dehydrogenated heterocycles to N-heteroaromatics revealed that the reaction proceeded through partial dehydrogenation followed by isomerization and complete dehydrogenation. Further, the use of the same catalyst was also explored for the hydrogenation of N-heteroaromatics (Scheme 77) in toluene at 120 °C.

Scheme 76. Dehydrogenation of aza-heterocycles catalyzed by Co-Phen@C.

Scheme 77. Hydrogenation of aza-heteroaromatic compounds catalyzed by Co-Phen@C.

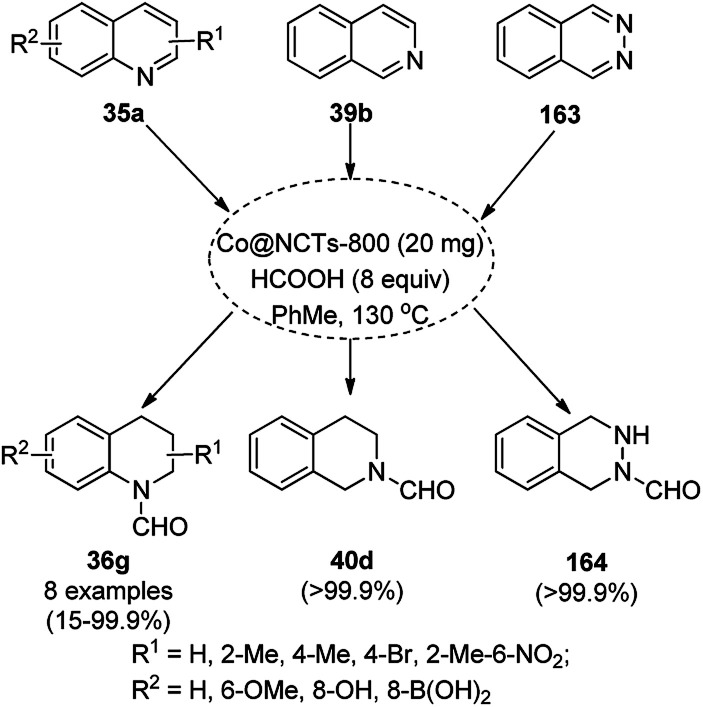

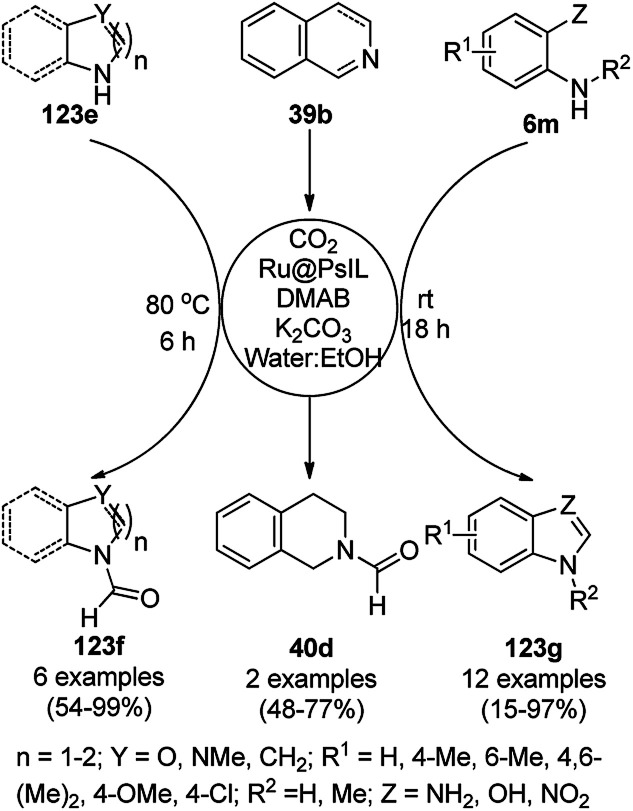

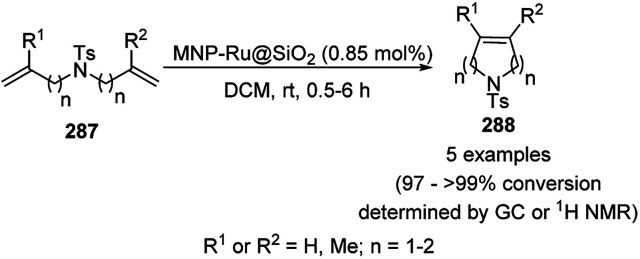

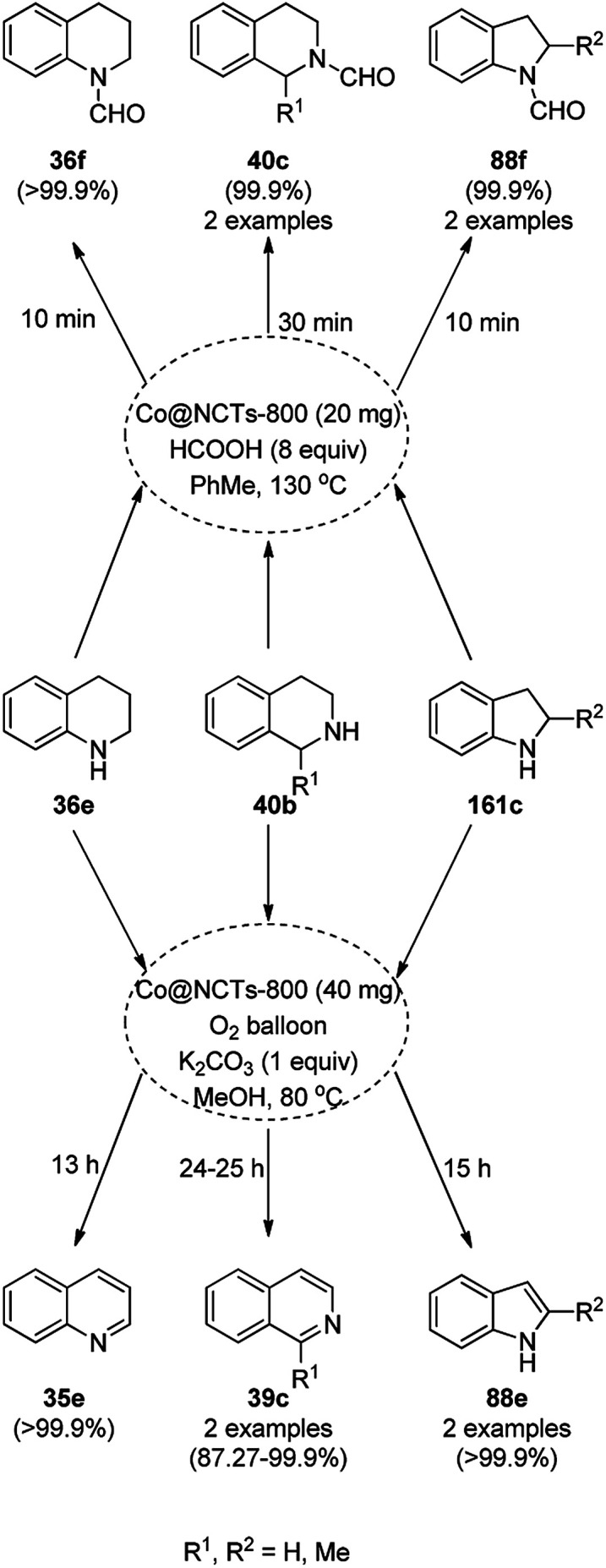

CoNPs encapsulated in nitrogen-doped CNTs Co@NCTs-800 catalyzed the oxidative dehydrogenation of partially saturated heterocycles such as 1,2,3,4-tetrahydro quinolines (36e), 1,2,3,4-tetrahydroisoquinoline (40b), and 2,3-dihydroindole (161c, Scheme 78) in excellent conversions into 35e/39b/88e, respectively, with methanol as the solvent and potassium carbonate as the base.161 The fine tuning of the reaction conditions in toluene using the same catalyst and higher equivalents of formic acid also enabled the formylation of 36e/40b/161c (Scheme 78) in excellent conversions into 36f/40c/88f, respectively. Under the latter conditions, the catalytic transfer hydrogenation of heteroaromatics such as quinolines (35a), isoquinoline (39c), and phthalazine (163) (Scheme 79) was achieved successfully. The required catalysts were synthesized from dicyanodiamide and cobalt(ii) acetylacetonate and their treatment at various temperatures under inert atmosphere. The recyclability of the catalyst was demonstrated for up to ten cycles without loss in its catalytic activity.

Scheme 78. Oxidative dehydrogenation of heterocycles (36e/40b/161c) and their formylation catalyzed by Co@NCTs-800. % Conversion is summarized in parentheses.

Scheme 79. Oxidative dehydrogenation of N-heteroaromatics. % Conversion is summarized in parentheses.

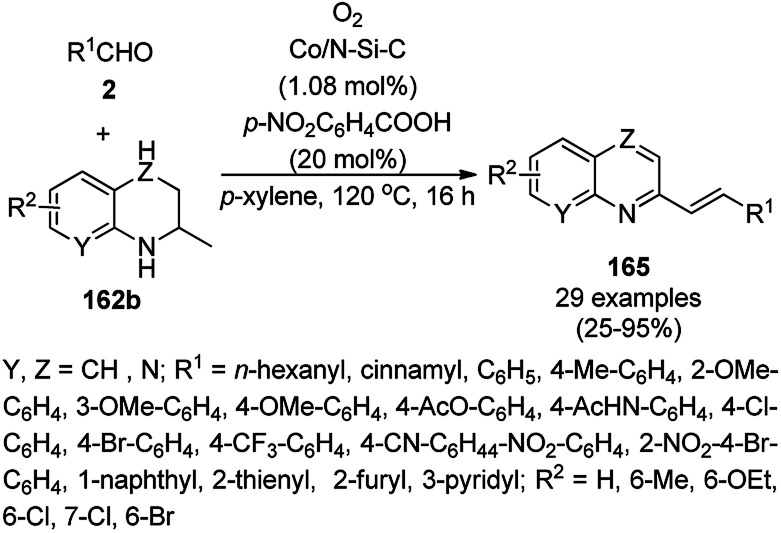

Cobalt nanocatalysts (CoNCs) supported on nitrogen-silica-doped carbon (Co/N–Si–C) catalyzed the dehydrogenative coupling of carbaldehydes (2) with cyclic amines (162b) for the synthesis of quinolines/quinoxalines (165) in the report by Zhang et al. using molecular oxygen as the oxidant and p-nitro benzoic acid as the additive (Scheme 80).162 The CoNCs were prepared from Co(OAc)2·4H2O and 1,10-phenanthroline followed by their treatment with TEOS and loading on the support. The recycled catalyst was reused six times for the model reaction between benzaldehyde and 2-methyl-1,2,3,4-tetrahydroquinoline, where the fresh and reused catalysts possessed almost similar particle sizes of 0.35 nm and 0.42, respectively (TEM). The controlled experiments eliminated the probability of the dehydrogenation of 2 to 2-methylquinolines following the coupling of amines to support the actual mechanism, which is partial dehydrogenation followed by coupling and complete dehydrogenation to finally give 165.

Scheme 80. Dehydrogenative coupling of amines with aldehydes catalyzed by CoNCs.

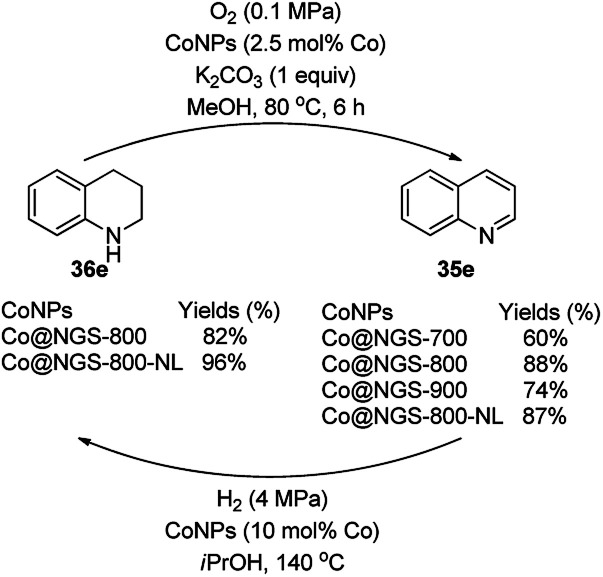

Li et al. reported the use of CoNPs supported on N-doped graphene cells (Co@NGS-800) as a bifunctional catalyst for the dehydrogenation of 1,2,3,4-tetrahydroquinoline (36e) and hydrogenation of quinoline (35e) in excellent conversion and high activity (Scheme 81).163 The same organic transformations were studied using various CoNPs encapsulated in N-doped graphene cells (Co@NGS-700, Co@NGS-800, and Co@NGS-900) obtained by pyrolysis at 700 °C, 800 °C and 900 °C, respectively. The Co@NGS-800 catalyst was recycled twelve and six times for the dehydrogenation of 36e, and hydrogenation of 35e, respectively, without loss in selectivity.

Scheme 81. Dehydrogenation and hydrogenation catalyzed by Co@NPGS.

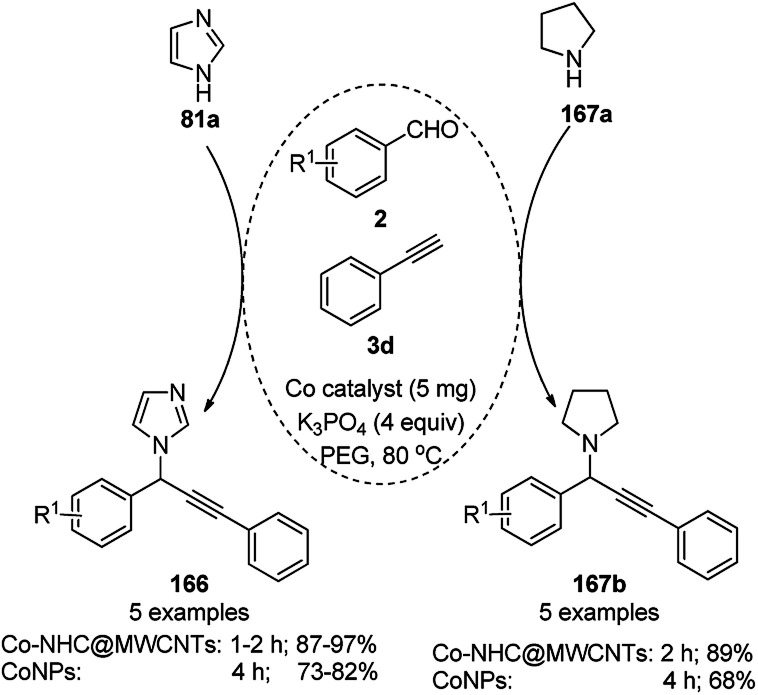

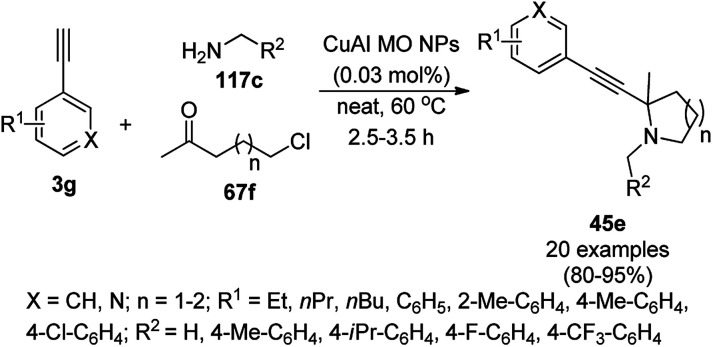

CoNPs and cobalt N-heterocyclic carbene grafted on multi-walled CNTs (Co–NHC@MWCNTs) catalyzed the synthesis of propargylamines (166/167b) from benzaldehydes (2), alkynes (3d) and amines (81a/167a) successfully (Scheme 82).164 Hajipour et al. synthesized the catalyst by grafting 1,4-diaminobenzene to obtain aniline@MWCNTs. Subsequently, it was treated with aniline, formaldehyde, and glyoxal to obtain an imidazolium salt followed by the loading of Co using CoCl2 to obtain the final NPs. The CoNPs were prepared via the neutralization of copper sulphate in aqueous NaOH to obtain a black powder. Greater yields of 166 and 167b were obtained in a shorter time with Co–NHC@MWCNTs than CoNPs. The present methodology was compared with other reported methods for the three-component reaction involving benzaldehyde, pyrrolidine, phenylacetylene catalyzed by nano Ag2O,165 Fe2O3,166 and CuNPs,167 and it was found that this method is the most suitable in terms of catalytic loading, reaction temperature and time and yield of 167b.

Scheme 82. Synthesis of propargylamines catalyzed by CoNPs.

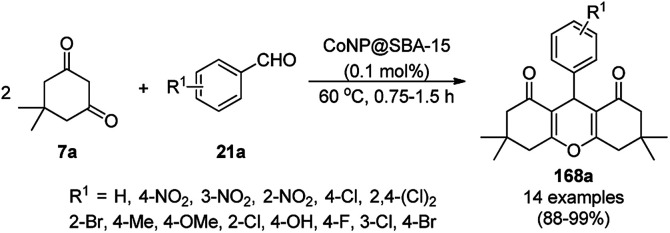

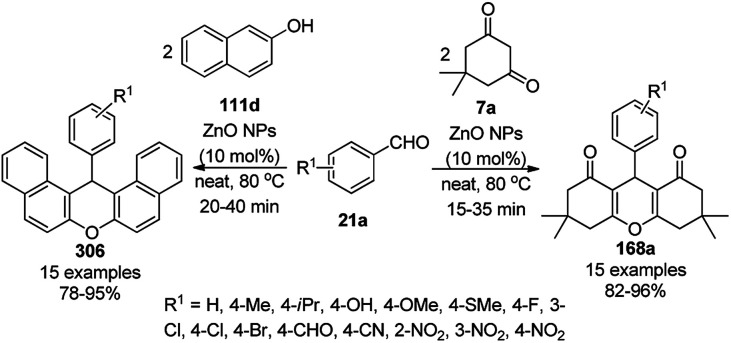

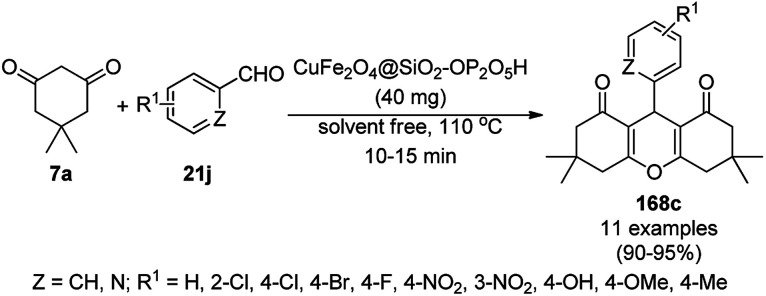

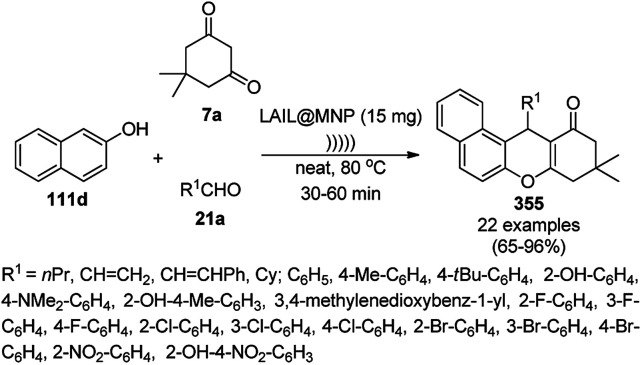

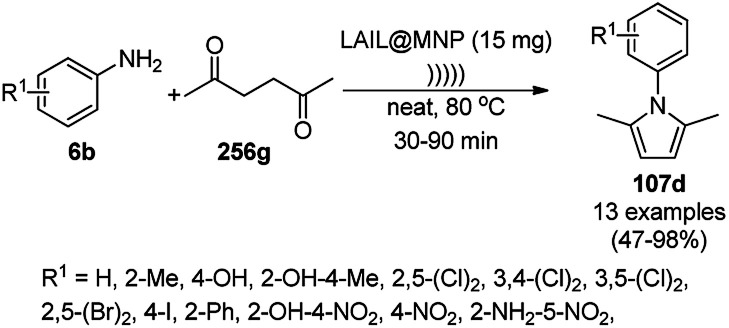

The synthesis of 1,8-dioxo-octahydroxanthenes was achieved using CoNPs supported on silica (CoNP@SBA-15)168 as a Lewis acid catalyst via the cyclocondensation of dimedone (7a) and benzaldehydes (21a) under aqueous conditions (Scheme 83).169 The stability of the CoNPs was established by their ten consecutive reuses for the reaction between 7 and benzaldehyde to obtain 168a in 88–99% yield. The said protocol was also compared with other reported protocols such as nano-TiO2,170 CuS quantum dots,171 and FeNPs.172

Scheme 83. Synthesis of 1,8-dioxo-octahydroxanthenes (168a).

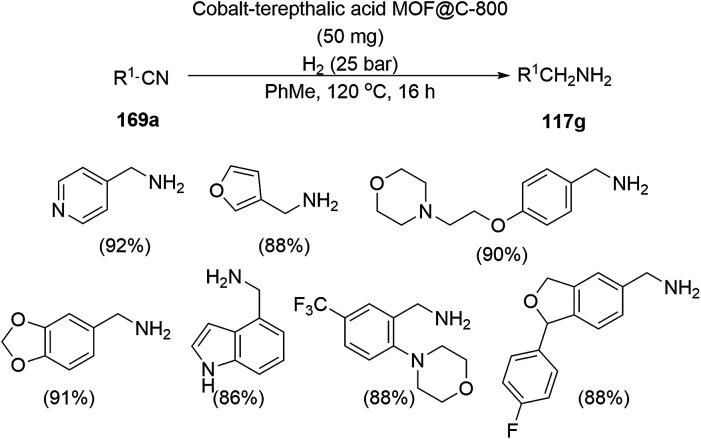

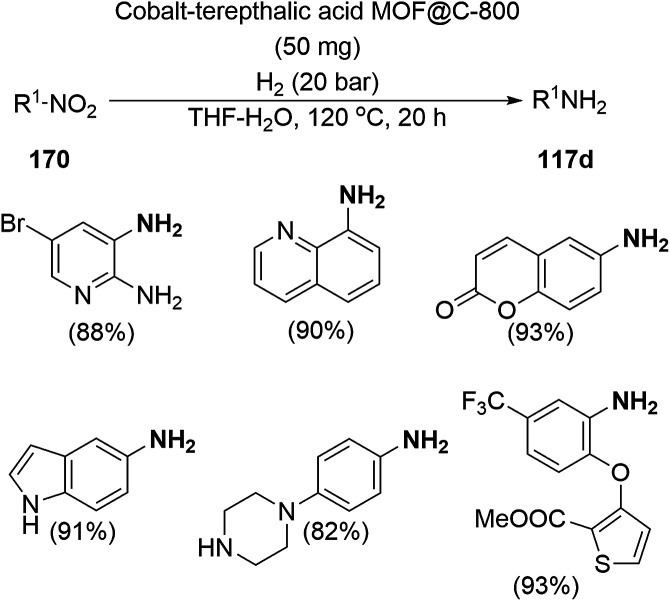

A CoNP-based NC (cobalt-terephthalic acid MOF@C-800) were reported for the hydrogenation of cyanide (169a) to primary amine (117g) in toluene at 120 °C (Scheme 84).173 This catalyst was synthesized via the treatment of cobalt(ii) nitrate hexahydrate with terephthalic acid via a solvothermal process. It was also used for the conversion of nitro-heteroaromatics (170) to heteroaryl amines (117d, Scheme 85). The stability of the catalyst was proven by its scaling on a multigram scale and reuse for up to five runs.

Scheme 84. Synthesis of methylamines (117g) from cyanides (169a) catalyzed by CoNPs.

Scheme 85. CoNP-catalyzed reduction of nitro-containing heterocycles (170) to aromatic amines (117d).

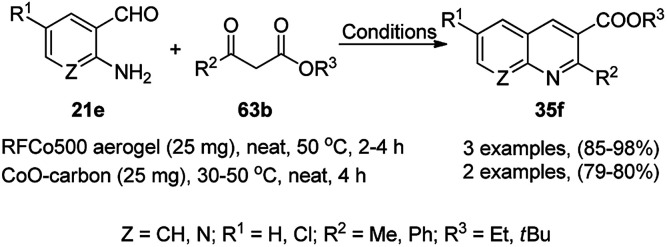

The cobalt(0)-doped carbon aerogel (RFCo500 aerogel)-catalyzed Friedländer annulation for the synthesis of quinolines (35f) from 2-amino-5-chlorobenzaldehyde (21e) and β-keto esters (63b) was achieved by Pérez-Mayoral (Scheme 86) under solvent-free conditions in good to excellent yields.174 The RFCo500 catalyst was synthesized from resorcinol, formaldehyde, organic aerogels and cobalt acetate. The catalyst was recycled for up to three runs with 20% loss in its catalytic activity compared to the first run. Another application of cobalt oxide NPs supported on different carbon supports was reported by Pérez-Mayoral et al. (Scheme 86) for the synthesis of quinolines (35f) using similar starting materials.175 CoO-carbon was synthesized via the treatment of cobalt nitrate or acetate with a carbon support.

Scheme 86. Friedländer annulation catalyzed by CoNPs catalyzed by RFCo500 aerogel and CoO-carbon.

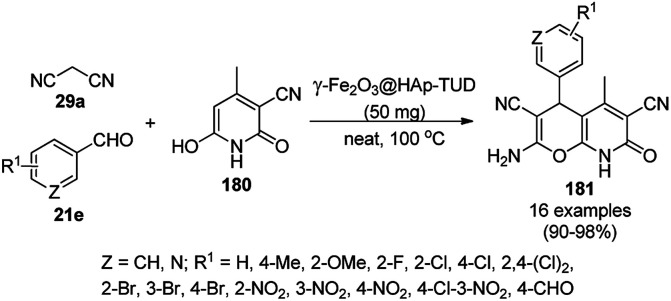

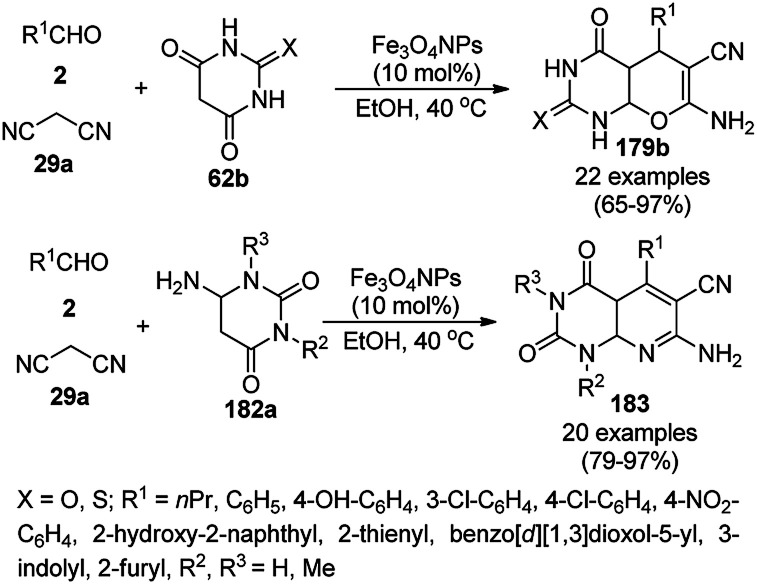

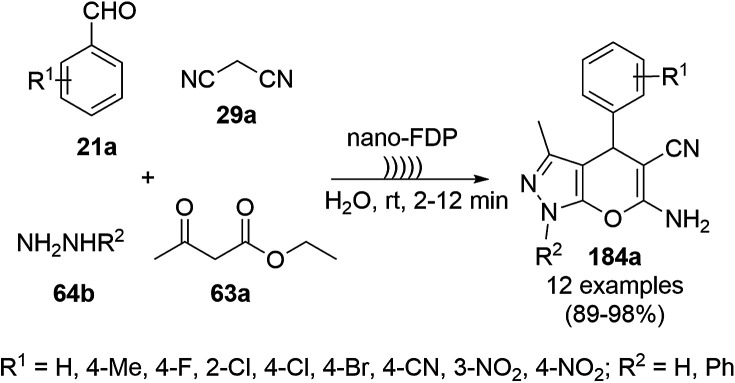

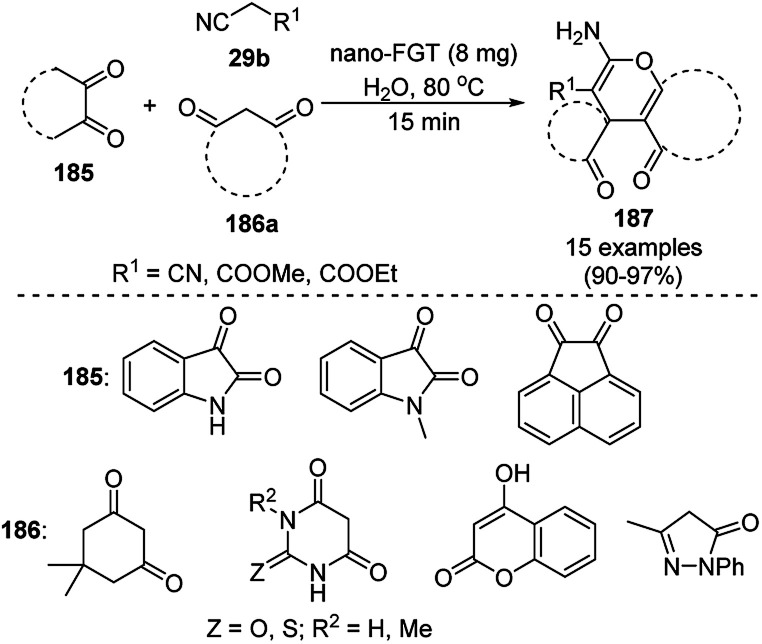

3.5. FeNP-catalyzed synthesis of heterocycles

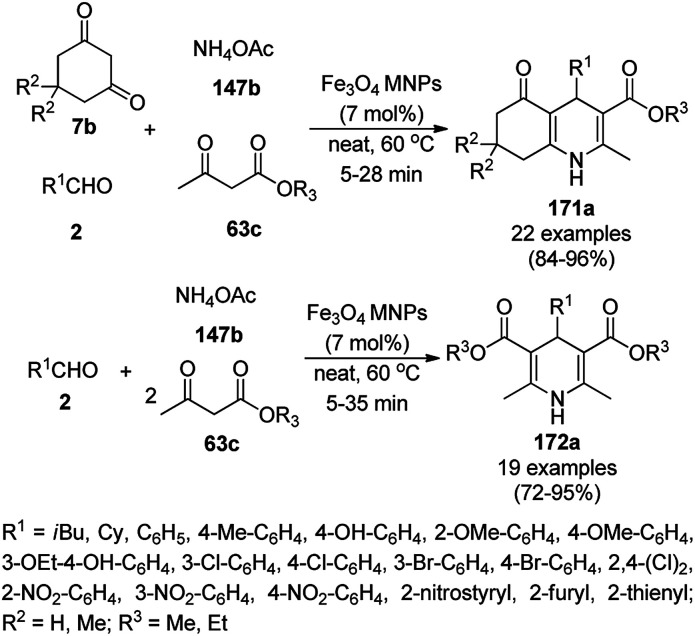

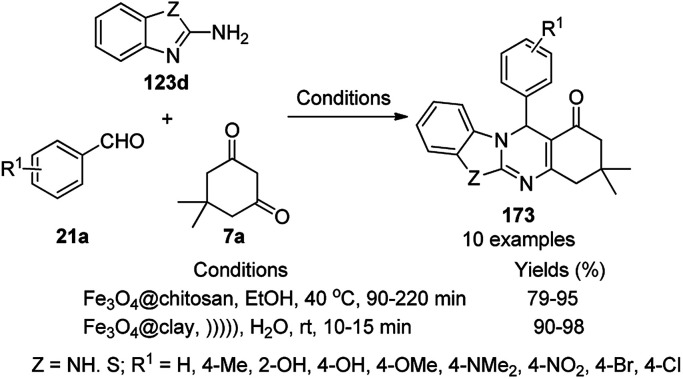

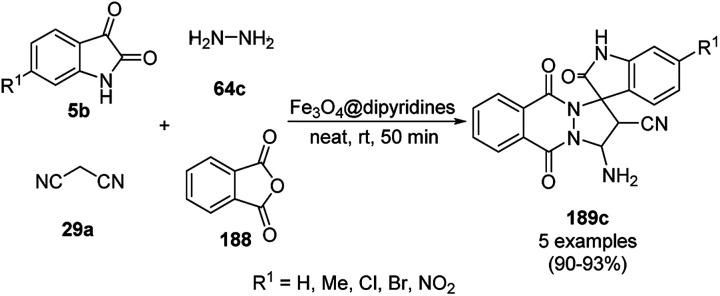

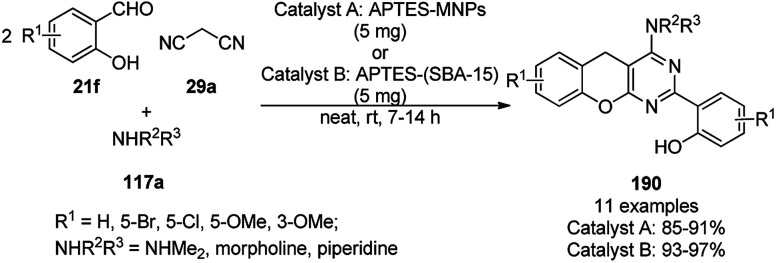

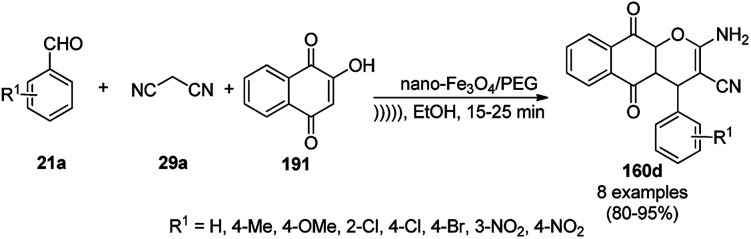

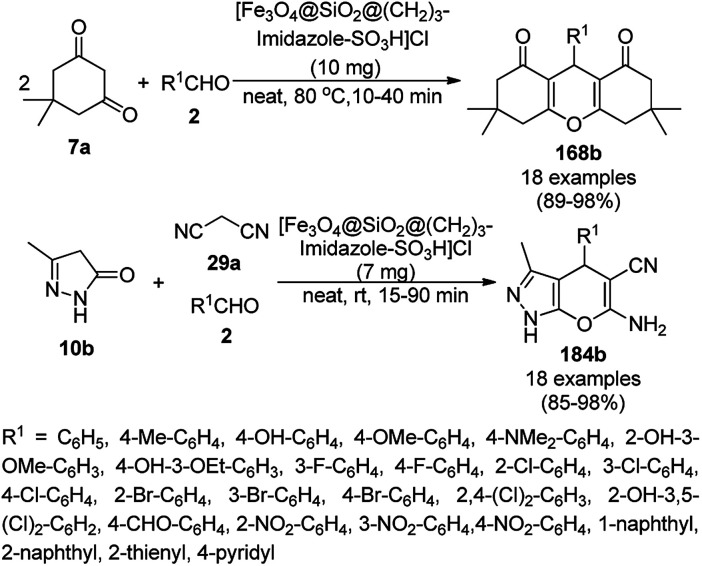

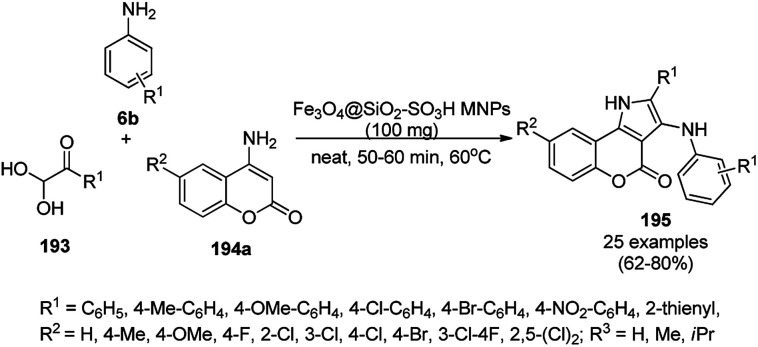

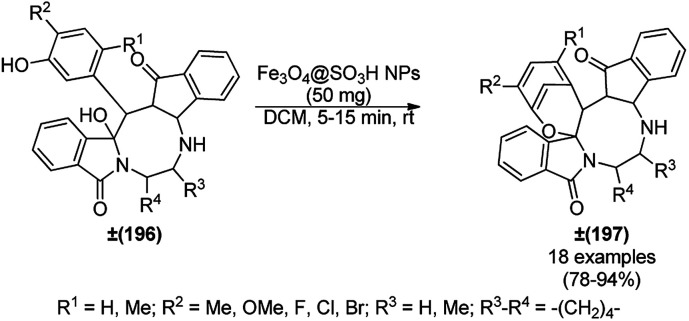

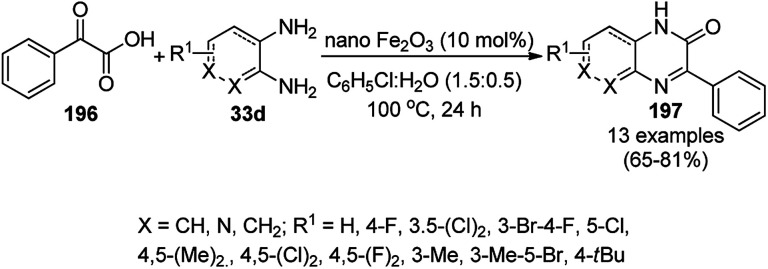

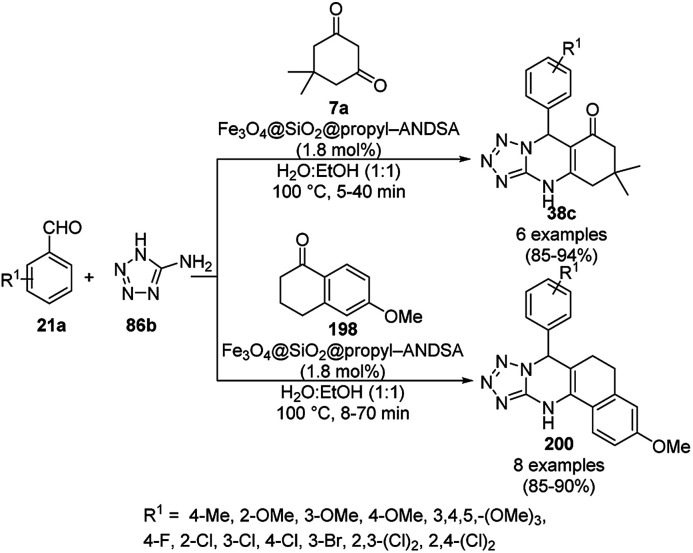

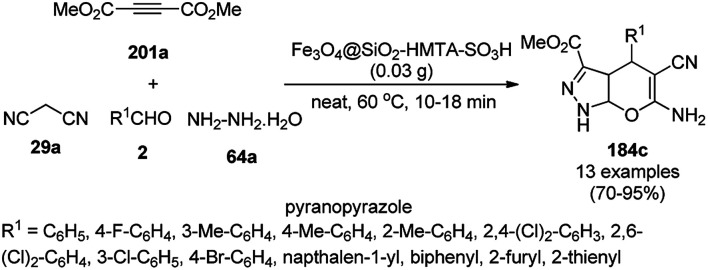

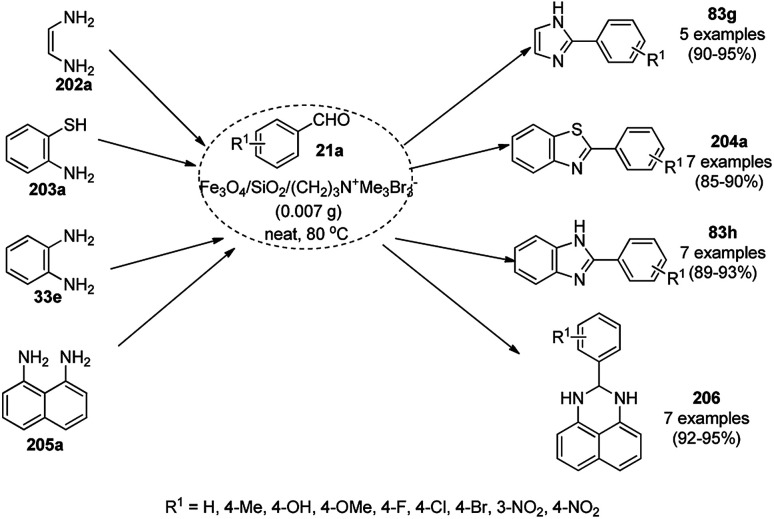

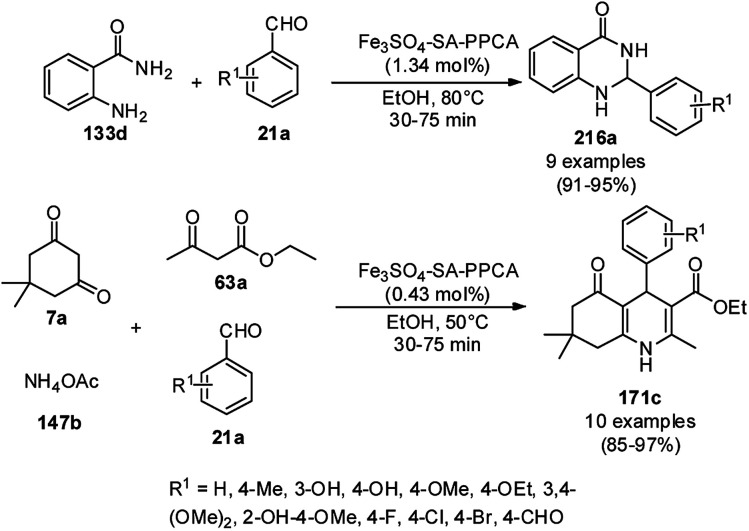

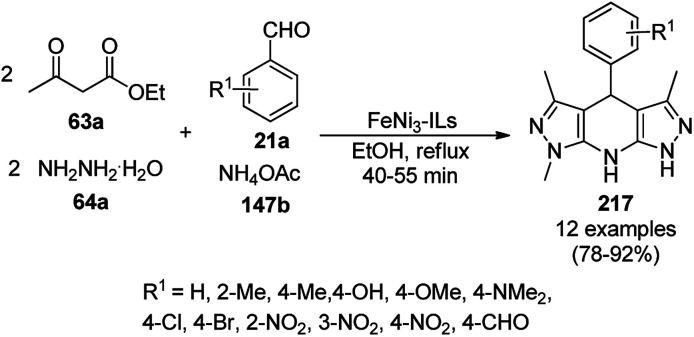

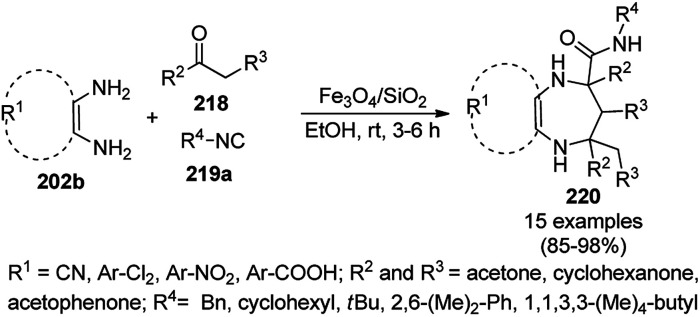

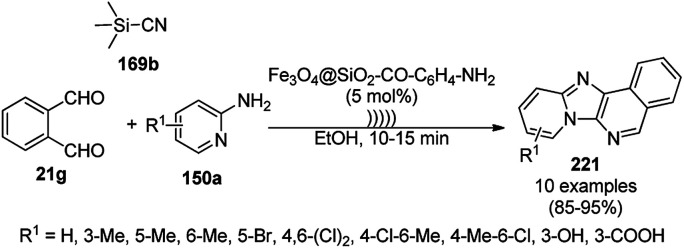

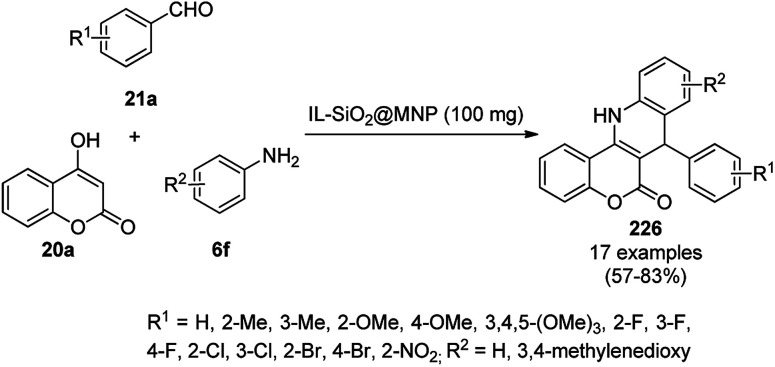

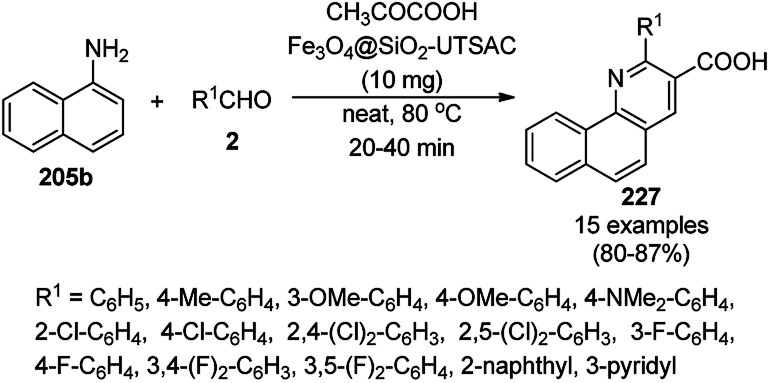

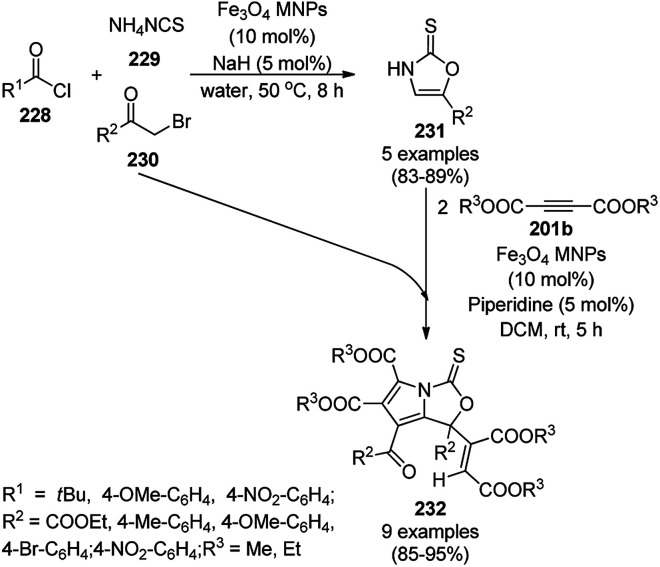

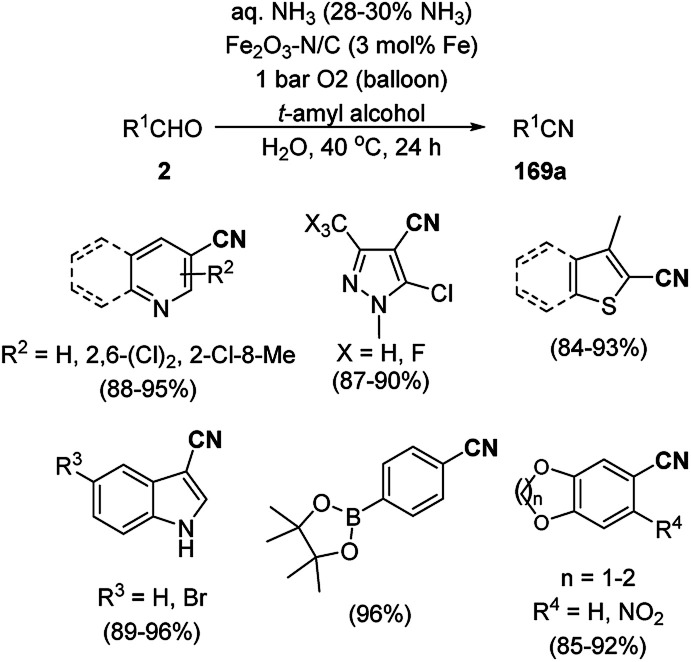

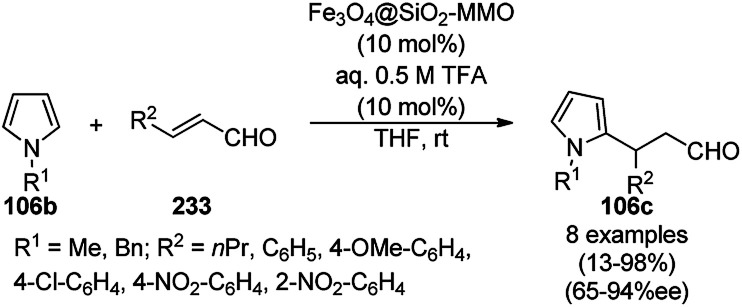

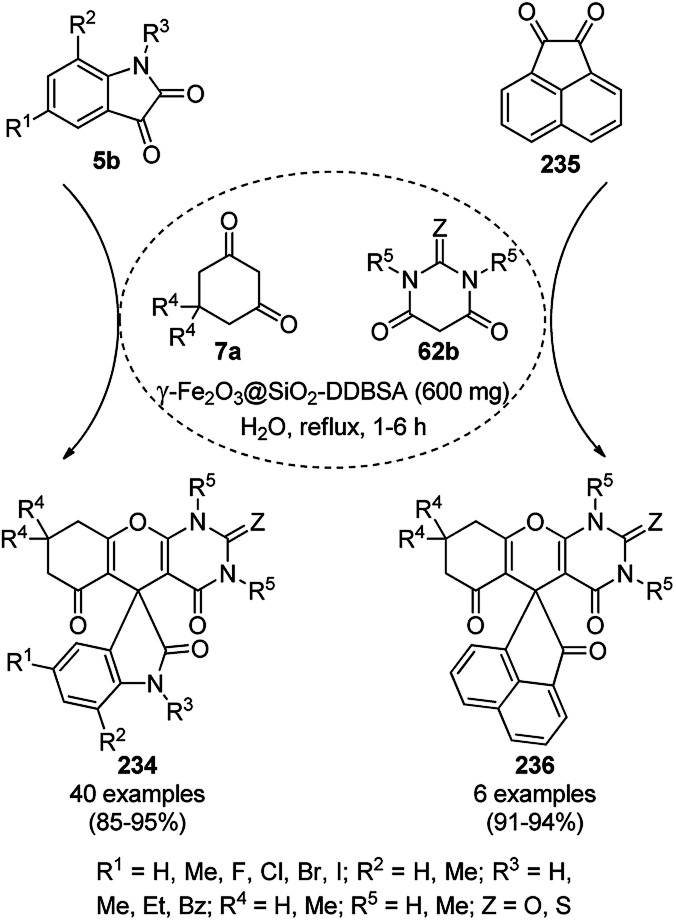

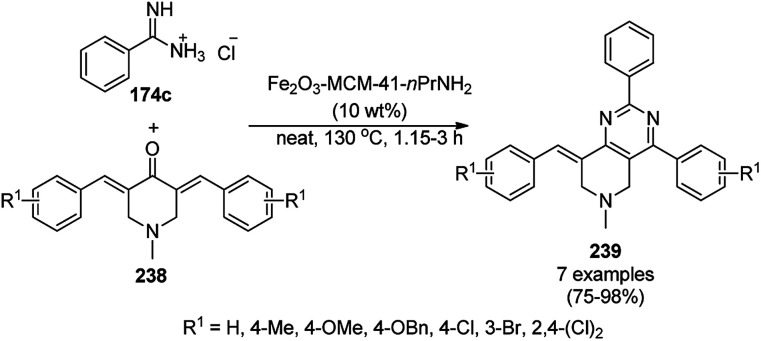

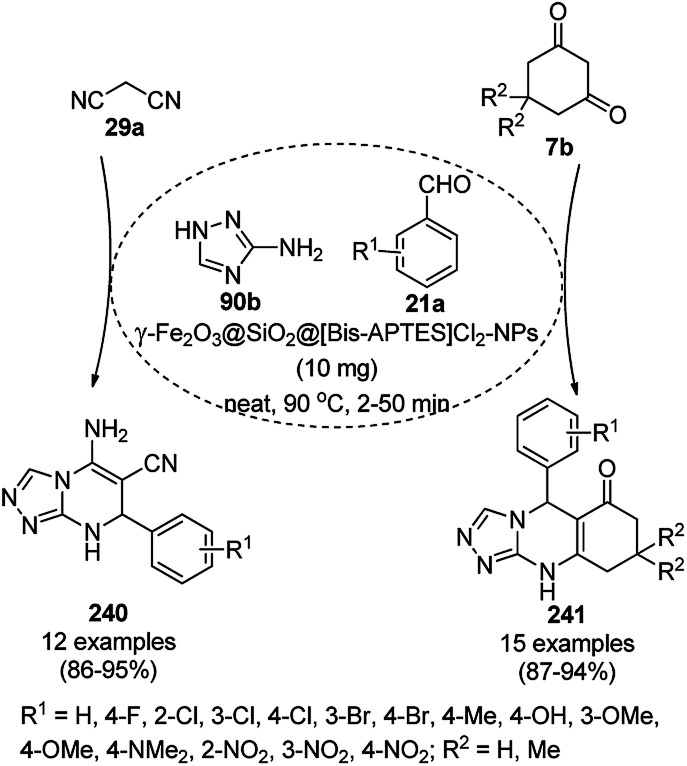

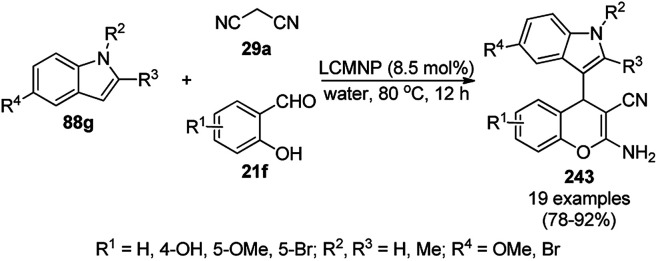

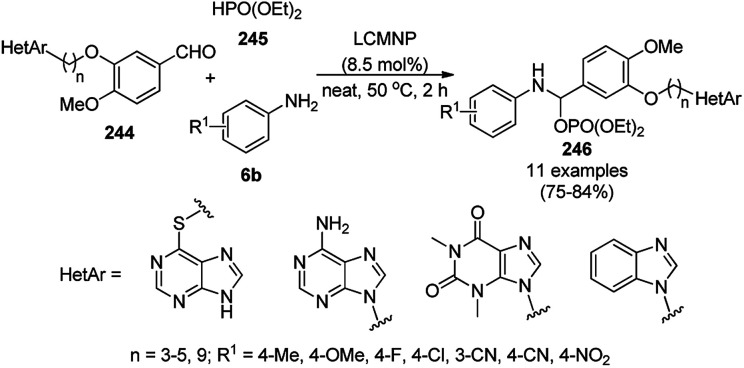

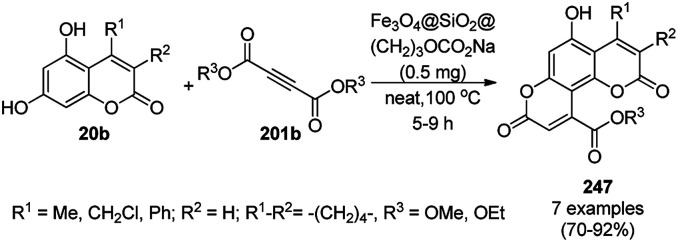

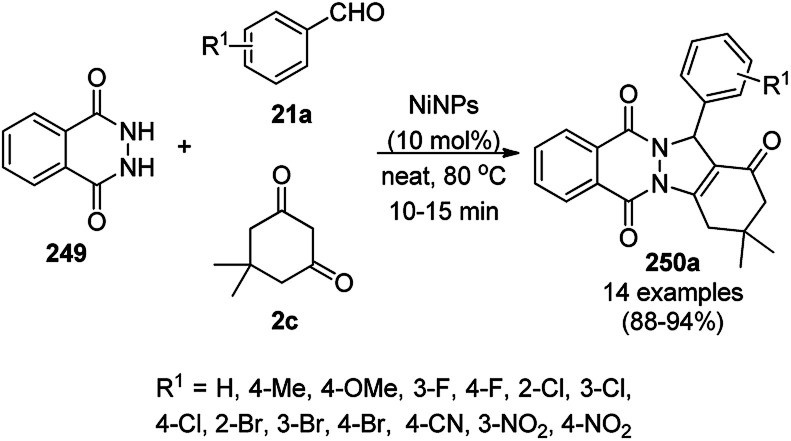

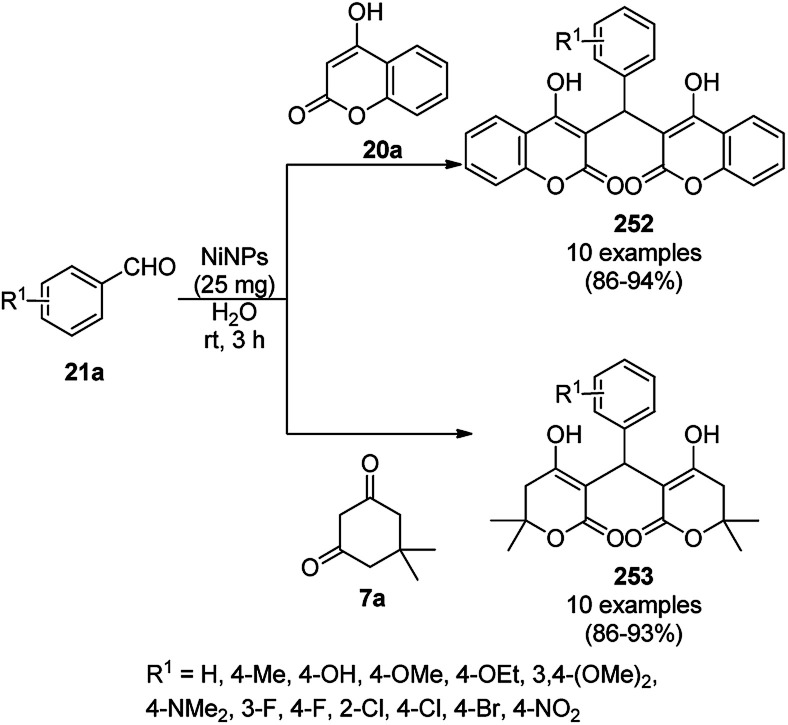

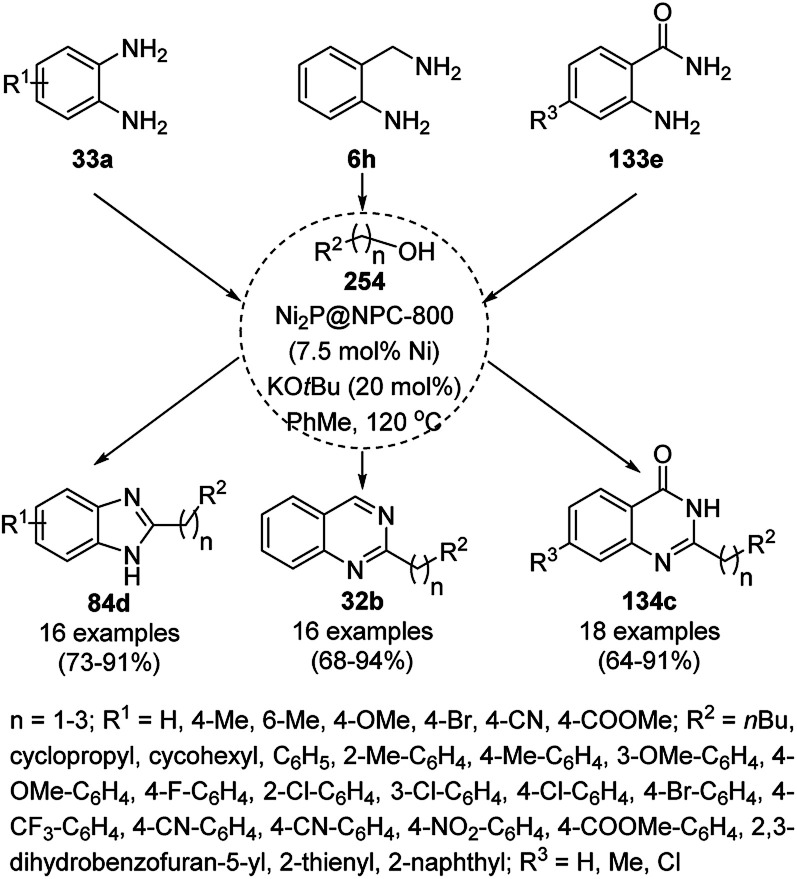

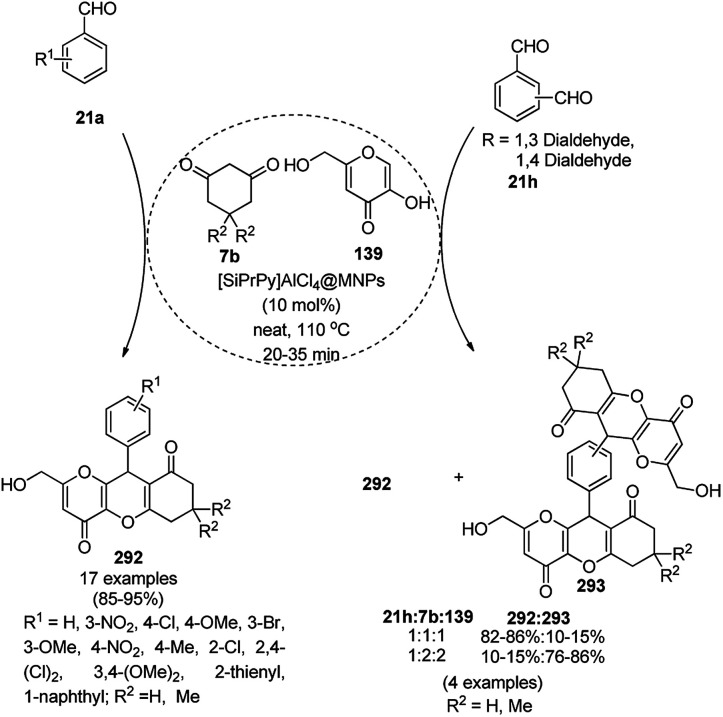

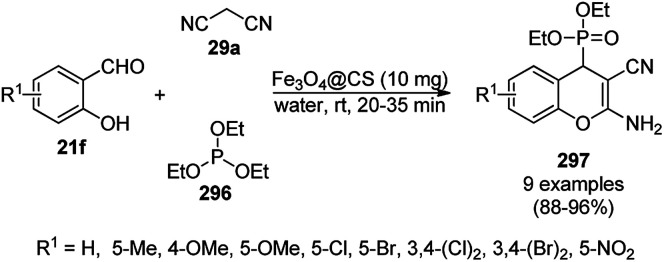

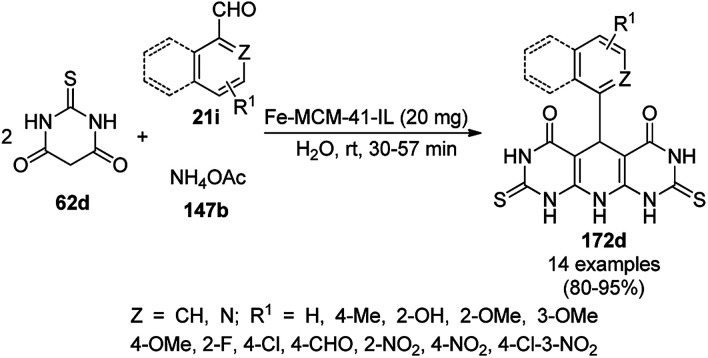

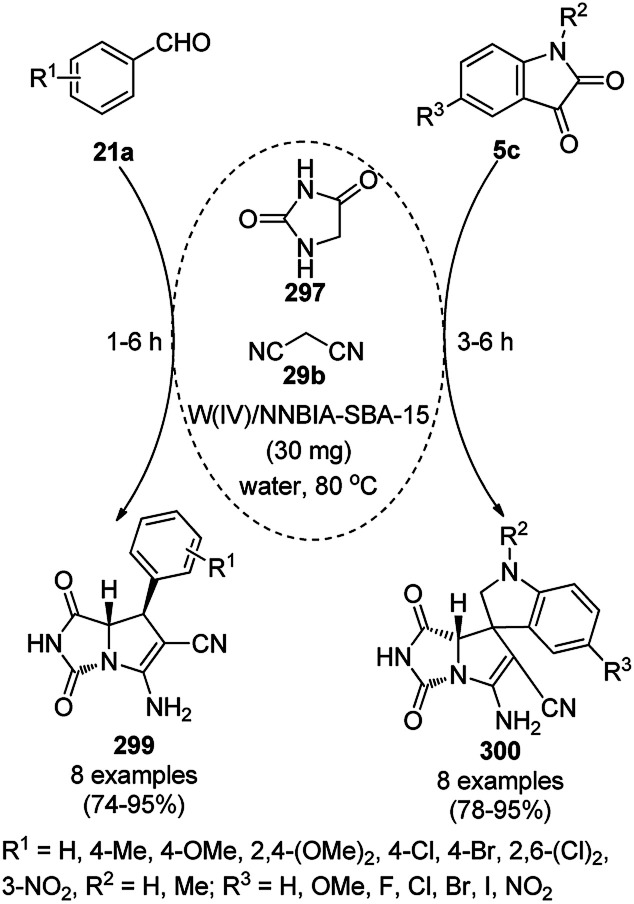

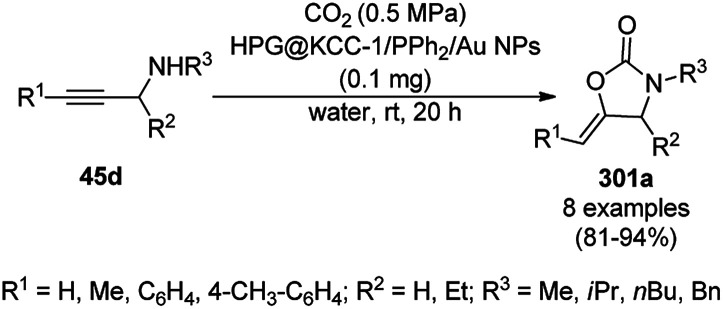

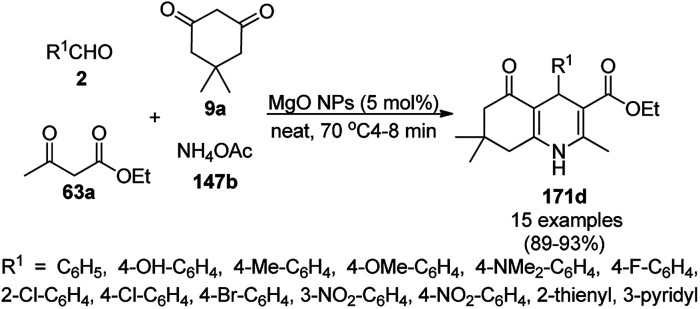

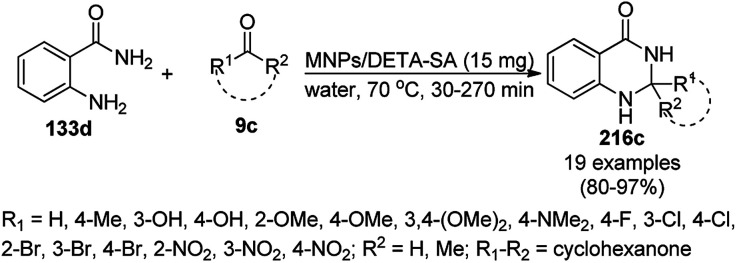

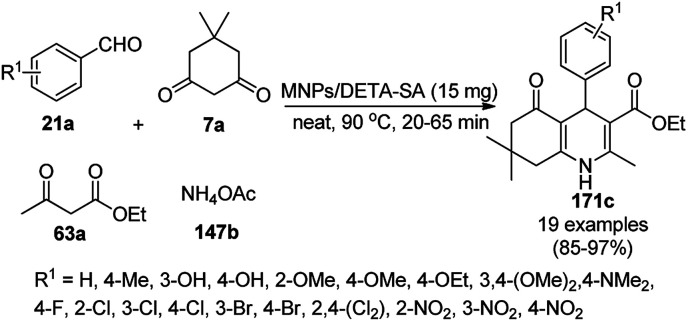

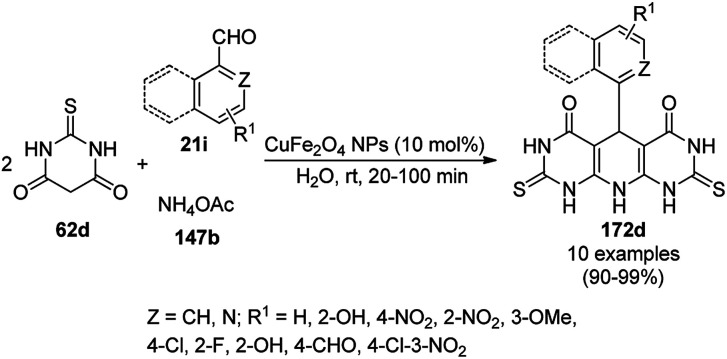

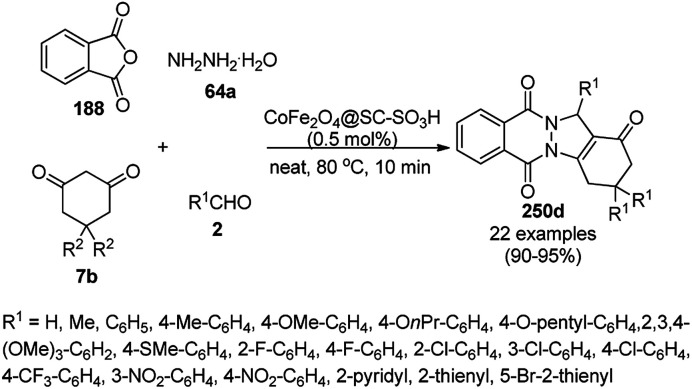

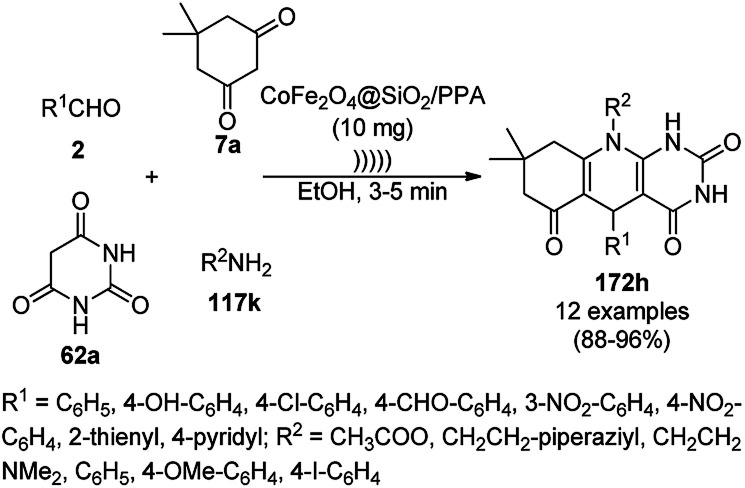

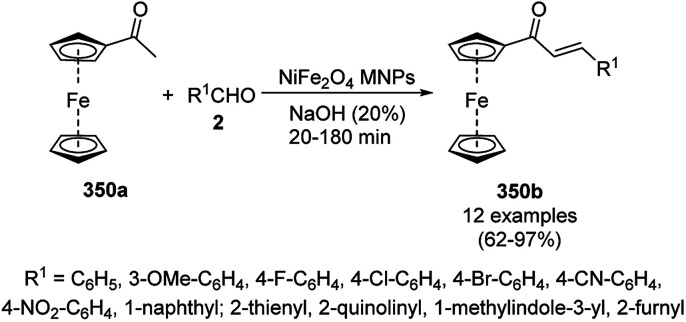

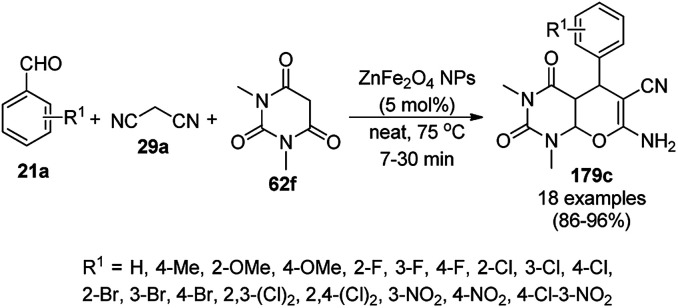

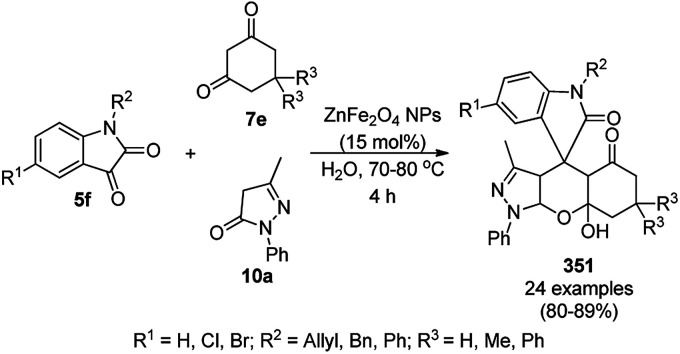

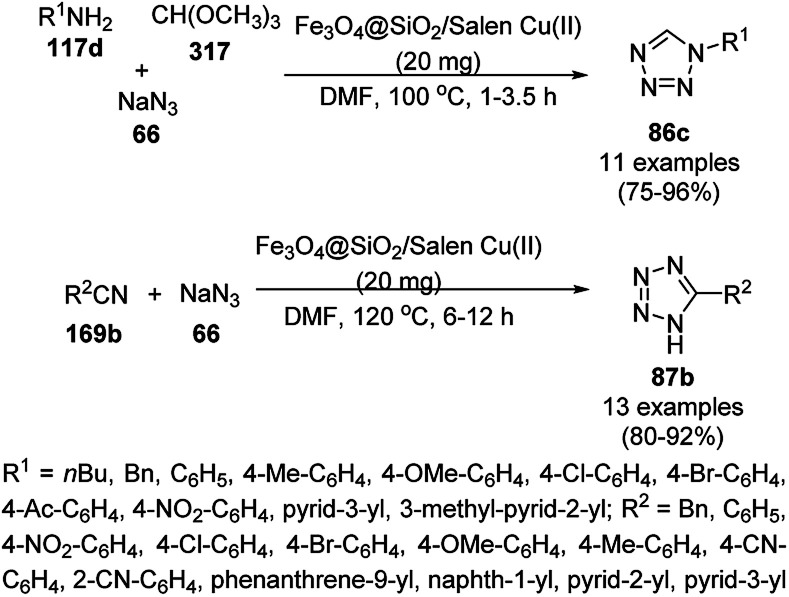

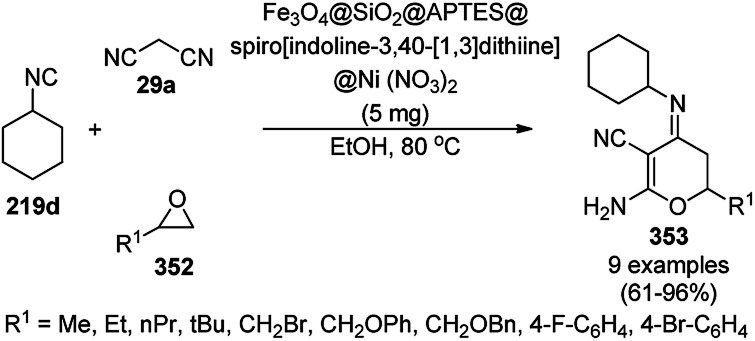

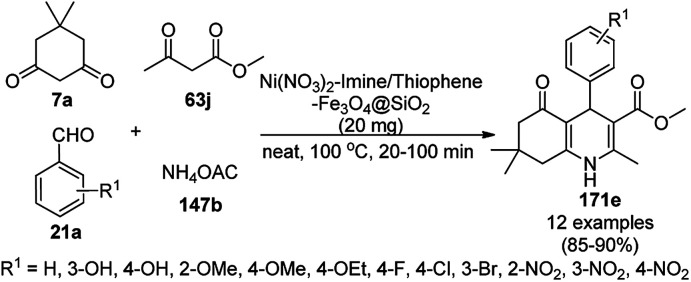

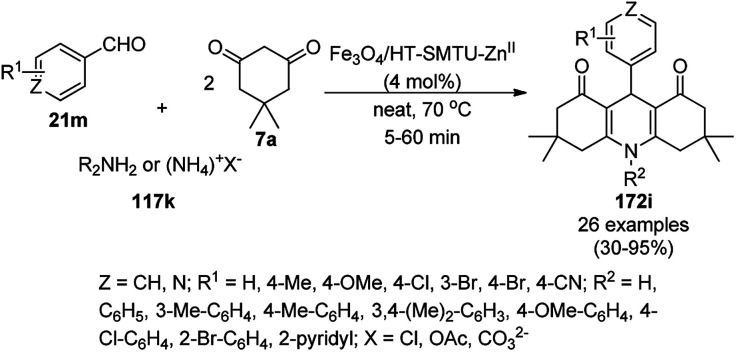

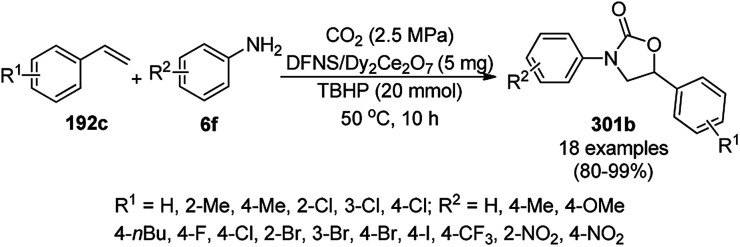

Magnetically retrievable FeNPs have been reported for the synthesis of various bioactive heterocycles176 and several organic transformations such as hydrogenation, dehydrogenation, Friedel–Crafts reactions, C–C bond formation and borylation.177 Fe3O4 MNP-catalyzed Knoevenagel–Michael-cyclization for the synthesis of polyhydroquinolines (171a) was successfully achieved by Nasr-Esfahani et al. using cyclic diones (7b), carbaldehydes (2), alkyl acetoacetate (63c) and ammonium acetate (147b, Scheme 87) under solvent-free conditions.178 The same protocol was also explored for the synthesis of 1,4-dihydropyrimidines (172a) from 2, 63c and 147b. The MNPs were prepared via the treatment of ferrous and ferric salts in the presence of ammonium hydroxide to obtain black-colored Fe3O4 MNPs. The catalyst was recycled up to five times without loss in its catalytic efficiency. Two years later, they also reported the applications of modified magnetic acidic NCs for the synthesis of bulky heterocyclic compounds.179 Recently, they also reported the synthesis of 1,4-dihydropyrano[2,3-c]pyrazoles using Fe3O4@SiO2 NPs grafted on nanobentonite and functionalized with organic and inorganic linkers and sulfonic acids in aqueous ethanol.180

Scheme 87. Fe3O4 MNP-catalyzed synthesis of polyhydroquinolines (171a) and 1,4-dihydropyrimidines (172).

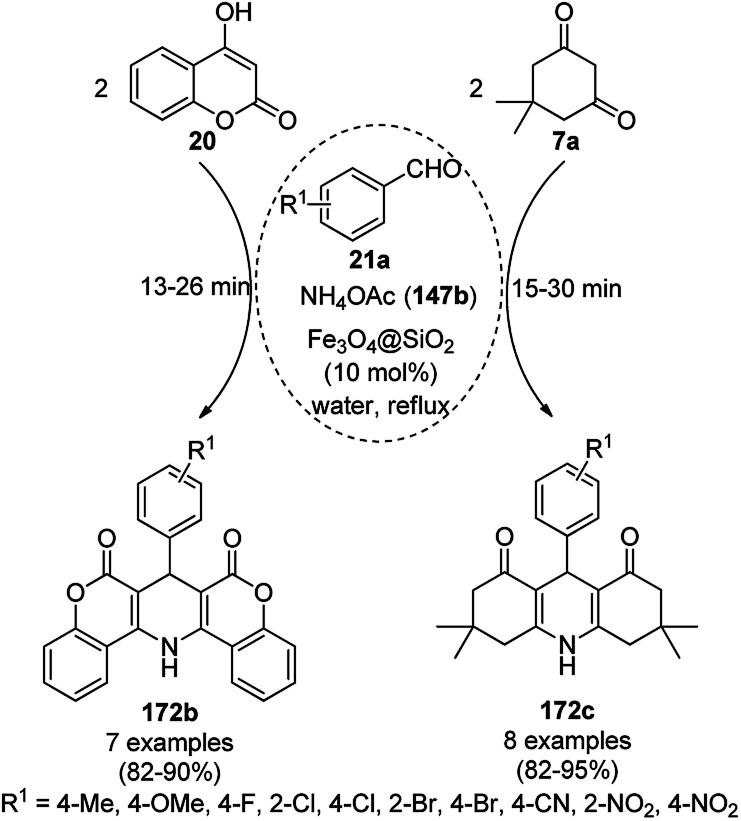

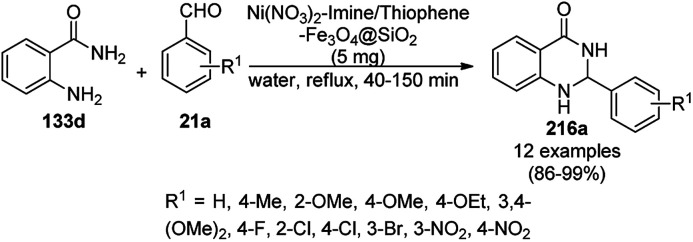

The Knoevenagel–Michael-cyclization via green “on water” chemistry for the one-pot synthesis of 1,4-dihydropyrimidines (172b/c) was successfully achieved using Fe3O4@SiO2 MNPs, which were synthesized by loading silica on Fe3O4 NPs (Scheme 88).181 The air- and moisture-stable catalysts were separated using an external magnet and reused up to five times with 85–92% yield.

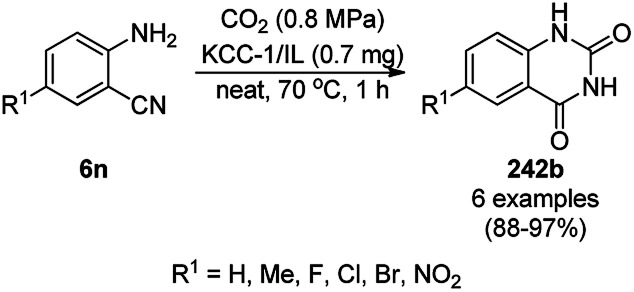

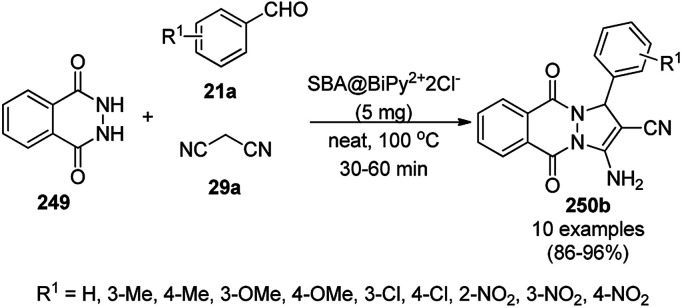

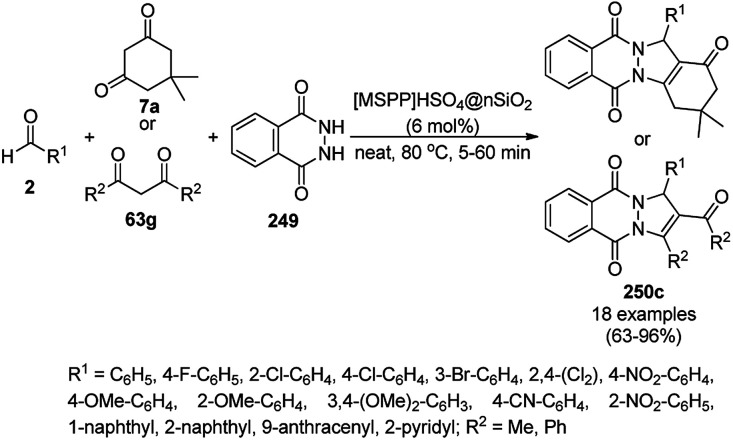

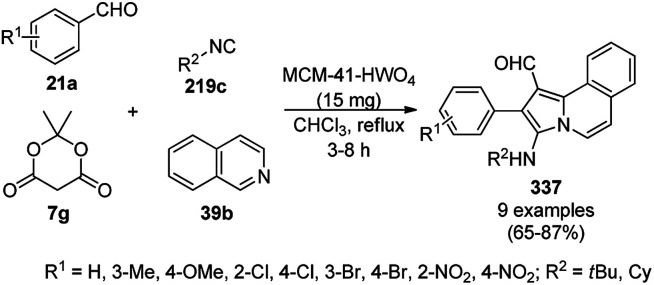

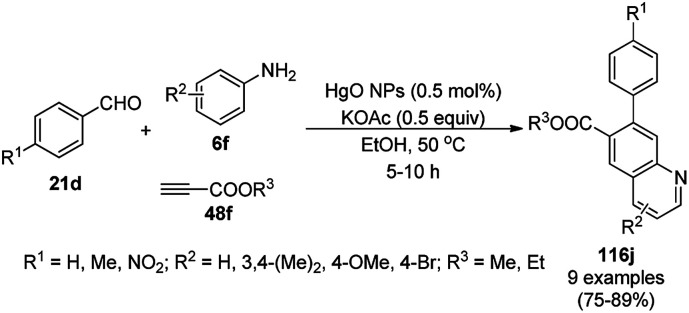

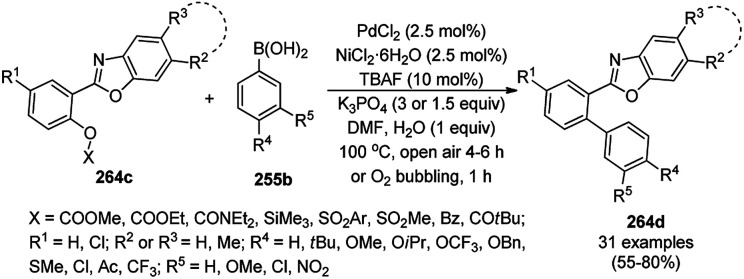

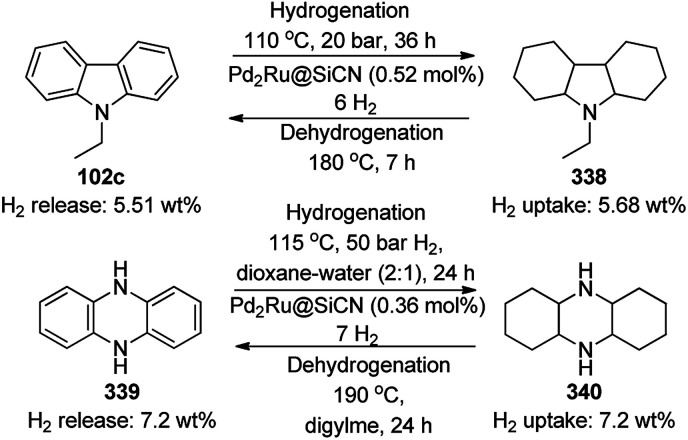

Scheme 88. “On water” chemistry for the synthesis of 1,4-dihydropyrimidines (172b/c).