Abstract

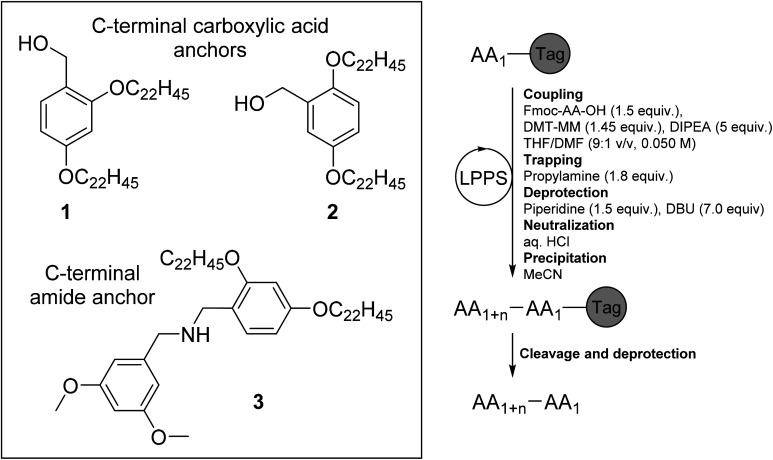

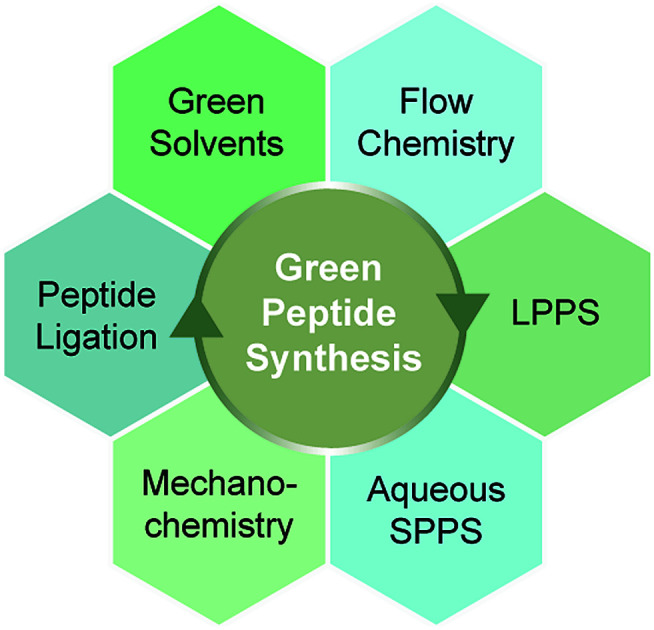

Solid-phase peptide synthesis (SPPS) is generally the method of choice for the chemical synthesis of peptides, allowing routine synthesis of virtually any type of peptide sequence, including complex or cyclic peptide products. Importantly, SPPS can be automated and is scalable, which has led to its widespread adoption in the pharmaceutical industry, and a variety of marketed peptide-based drugs are now manufactured using this approach. However, SPPS-based synthetic strategies suffer from a negative environmental footprint mainly due to extensive solvent use. Moreover, most of the solvents used in peptide chemistry are classified as problematic by environmental agencies around the world and will soon need to be replaced, which in recent years has spurred a movement in academia and industry to make peptide synthesis greener. These efforts have been centred around solvent substitution, recycling and reduction, as well as exploring alternative synthetic methods. In this review, we focus on methods pertaining to solvent substitution and reduction with large-scale industrial production in mind, and further outline emerging technologies for peptide synthesis. Specifically, the technical requirements for large-scale manufacturing of peptide therapeutics are addressed.

This review highlights the efforts made to date to promote greener peptide synthesis, from an industrial perspective.

1. Introduction

The first synthetic peptide therapeutic oxytocin was introduced in 1962, and as of 2017 over 60 peptide drugs have been approved in the US, Europe and Japan, more than 150 drugs are currently in active clinical development, and >260 have been tested in human clinical trials.1 An often vented concern about peptide therapeutics is their poor oral bioavailability, which seriously hampers oral administration. This drawback is usually circumvented by alternative routes of administration, such as subcutaneous injection or inhalation,2 but advances in peptide formulation such as using permeation enhancers for increased oral absorption will undoubtedly accelerate the growth of this important class of therapeutic molecules.3,4 Tellingly, the market for peptide therapeutics is currently valued at USD 23 billion, but is anticipated to increase to USD 57 billion by 2027.5 Peptide and protein active pharmaceutical ingredients (APIs) can be prepared by either chemical or biological routes, where chemical synthesis is the current standard for preparation of peptides (especially those bearing unnatural amino acids or particular functional groups), while biological routes such as recombinant expression and fermentation approaches, enzymatic or semisynthetic approaches are more advantageous for large peptides and proteins.6 Chemical synthesis of peptides can be achieved either in solution- or by solid-phase, both strategies having their advantages and disadvantages.7 For short peptides (≤10–15 amino acids), solution-phase synthesis is usually the strategy of choice.6 On the other hand, the landmark invention of solid-phase peptide synthesis (SPPS) by Merrifield, i.e. the anchoring of a peptide to an insoluble solid support composed of a polymer (e.g. polystyrene),8 has enabled the synthesis of longer peptides that were previously unobtainable via traditional solution-phase chemistry. Steady improvements in protecting groups, coupling reagents, and peptide synthesis conditions have enabled routine access to peptides of high purity, in a scalable manner.9–11 However, the SPPS synthetic cycle, comprised of a series of repetitive cycles of coupling, washing and deprotection steps with easy separation of reagents from the solid support by filtration, often employs super-stoichiometric amounts of reagents to push the reaction to completion, generally with poor atom economy (Fig. 1). Furthermore, owing to the major contribution of solvents to the mass balance of a typical SPPS process,12,13 more environmentally benign alternatives to the most frequently used solvents are needed, as well as technologies that promote reduced solvent use and recycling. Today, most of the reagents and solvents applied in peptide chemistry are classified as environmentally problematic substances by the ECHA (European Chemicals Agency) under the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation. Current and impending regulation by REACH has the classic SPPS solvents dimethylformamide (DMF) and dichloromethane (CH2Cl2) as well as N-methyl-2-pyrrolidone (NMP) and dimethylacetamide (DMAc) heading for restriction (ECHA Annex XVII) and/or authorization for use (ECHA Annex XIV),14 necessitating that alternative SPPS solvents are identified in the immediate future to avoid disruption of industrial production of therapeutic peptides.

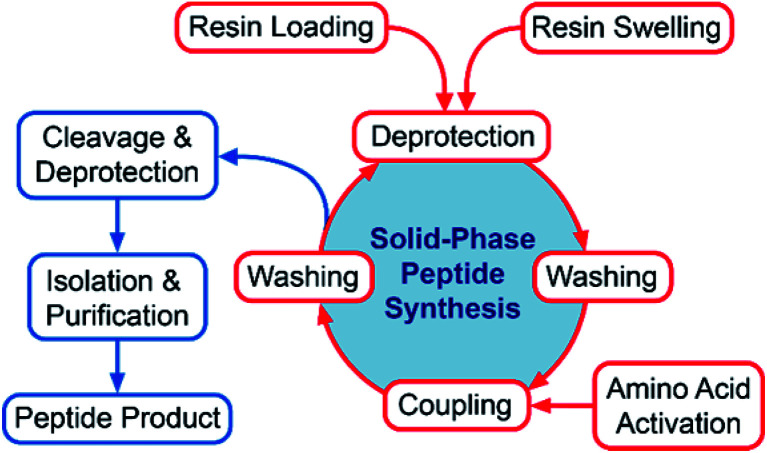

Fig. 1. Overview of the SPPS cycle and subsequent deprotection, work-up and purification steps. The present review focuses on technical aspects of the SPPS cycle (shown in red) while cleavage, deprotection, isolation and purification steps (shown in blue), are only briefly touched upon.

The greening of peptide synthesis has been reviewed from various perspectives in recent years. Albericio and co-workers have published two reviews primarily discussing the SPPS cycle, loading and cleavage and deprotection, water-based SPPS approaches as well as alternative synthetic approaches for peptide synthesis mostly of relevance to academic research.15,16 Isidro-Llobet et al. have given a high-level overview on the status of green peptide synthesis and purification discussing all aspects of peptide synthesis and new technological platforms for peptide synthesis and purification from an industrial viewpoint.17 Lax and Shah have reviewed the economic and environmental factors affecting the sustainability of peptide manufacturing from an industrial perspective, comparing solution and solid phase approaches with recombinant, semi-synthetic and ligation methods.18 To date no reviews have delved on the specific technical requirements for a green peptide synthesis protocol from an industrial large-scale manufacturing perspective. The aim of the present review is therefore to outline and discuss the technical requirements that the pharmaceutical industry has for SPPS and a green peptide synthesis protocol, and to put the progress made to date into an API manufacturing context. In relation to SPPS this review will focus on greener improvements pertaining to the SPPS cycle, including swelling, coupling, Fmoc-removal and washing steps (Fig. 1). A detailed analysis of peptide cleavage and deprotection, precipitation, intermediate processing (e.g. cyclisations, oxidation etc.), downstream purification, isolation, and the synthesis of raw materials for SPPS (e.g. amino acid building blocks and coupling reagents) is beyond the scope of the present review and is only briefly touched upon. In addition to SPPS, a selected number of emerging technologies for peptide synthesis (e.g. water-based SPPS, protein ligation and peptide synthesis in continuous flow) with potential use for future large-scale manufacturing of peptide APIs are highlighted and discussed.

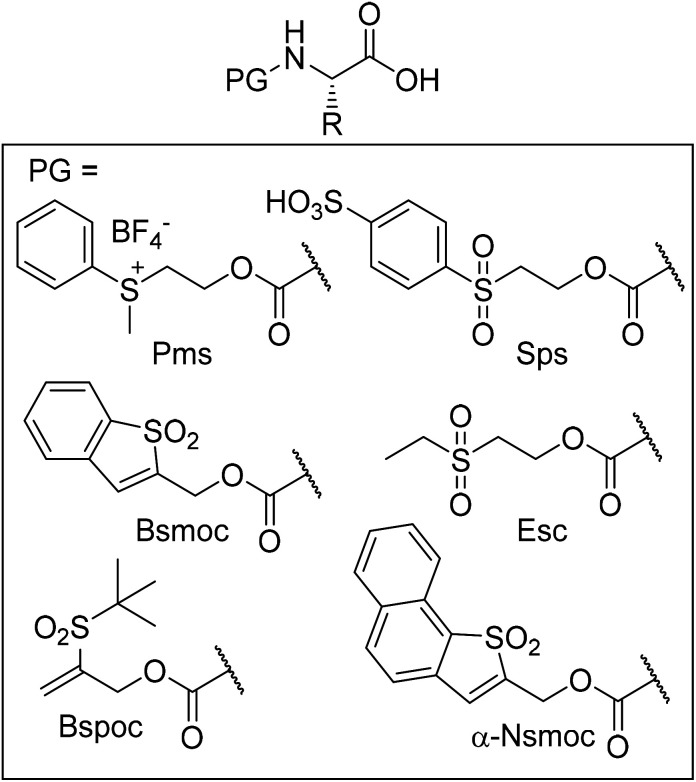

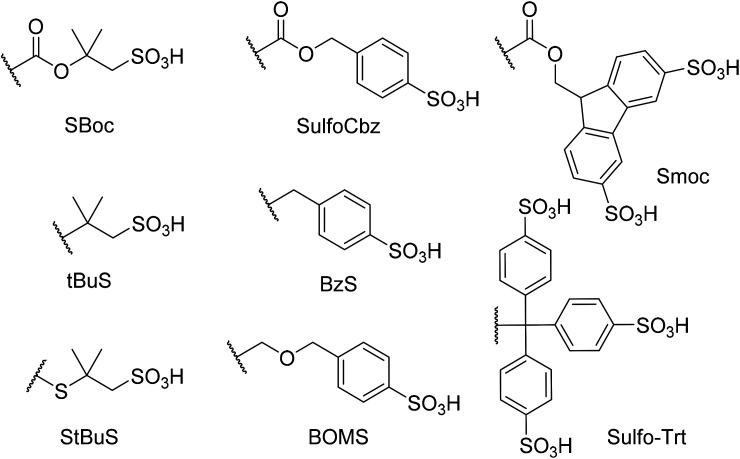

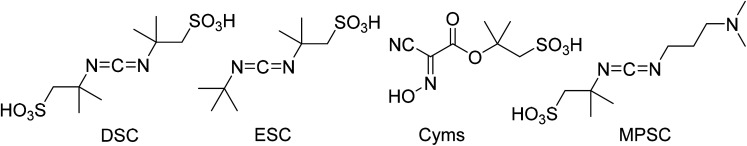

2. Peptide synthesis in an industrial setting

From the pharmaceutical industry perspective, the least disruptive short-term scenario for the continued manufacture of therapeutic peptides would be to adjust current SPPS protocols and transition to non-hazardous, green SPPS solvents. This would be greatly advantageous from a procurement point of view, as the necessary supply chain for a variety of raw materials (e.g. 9-fluorenylmethoxycarbonyl (Fmoc)-protected amino acids, activating reagents, resins or linkers) is fully established and cost-efficient building blocks can be easily procured from several independent suppliers in both non-GMP and GMP qualities.18,19 In the longer term, the development of a completely new platform for the synthesis of peptides, which would utilize raw materials with lower environmental impact, is attractive. For example, Fmoc-protected amino acids and coupling reagents are used in excess during SPPS processes (poor atom economy) and are additionally manufactured by classical organic synthesis means, often involving the use of processes with a large negative environmental footprint. Thus, transitioning from the current Fmoc-based chemistry to emerging peptide synthesis technologies appears desirable from an environmental perspective and should be pursued by both academia and industry. For example, this can be done in consortiums such as the American Chemical Society Green Chemistry Institute, where pharmaceutical companies are working together with academia to promote greener chemistries, including SPPS.20 Of crucial importance to this discussion, are considerations about the definition of a green solvent, especially in the context of organic synthesis. Several big pharmaceutical companies have published solvent selection guides which are very helpful when faced with the choice of process solvents.21,22 However, these guides are generally not aligned, and it can sometimes be difficult to deduce which criteria the classification of the solvents have been based upon. Indeed, the classification can be influenced by the area of expertise of the company and what would be considered as a good solvent for substitution for one company, could prove less pertinent for another. As there is no such thing as a perfectly green solvent, it is often a balance between benefits and drawbacks for a specific application. The IMI-CHEM21, a European consortium which promotes sustainable biological and chemical methodologies has also published a guide which is based on a survey of publicly available solvent selection guides.23 This consortium proposes a set of Safety, Health and Environment criteria aligned with the Global Harmonized System (GHS) and EU regulations. Finally, the volumes of solvents employed during manufacturing should also be kept in mind. For example, switching from a problematic solvent to a green solvent may have a larger negative environmental impact if the volumes are multiplied by several digits in the process, emphasizing the necessity for a holistic assessment of the process at hand. From a technical perspective, it may also not be possible to carry out the desired synthesis in a pilot plant beyond a certain volume (maximum capacity of reactors). At Novo Nordisk we have decided to focus on the ICH (International Council on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use) classification,24 and REACH status of solvents when conducting solvent substitution, taking both environmental and safety factors into account. Currently, we operate with three solvent categories: (a) REACH compliant, (b) REACH affected, (c) Incomplete data (currently REACH compliant but a significant amount of data is not available). The classification of solvents is clearly much more complex than reflected by these three categories, but we have judged that it is better to keep the classification simple and easy-to-use by our project teams. These teams can then proceed to make an in-depth analysis for individual projects taking all relevant aspects into consideration (e.g. recyclability, cost, supply chain, CO2-foot print etc.).

It should be noted that any new methodology for the manufacturing of peptides is unlikely to be applied to already marketed products. A seemingly simple change such as changing the solvent system will most likely affect the purity profile and critical quality attributes associated with the API. New impurities generated in the manufacturing process will have to be qualified in new toxicology studies etc. requiring extensive experimental and regulatory paper work.19 Typically, such changes are only made if there is a substantial financial incentive or if required by the authorities. Regulatory requirements can be dispensed for due to socio-economic considerations, to prevent a cost increase for the patient/society and to ensure that patients have uninterrupted access to medicines. The present review will hence discuss the greening of peptide synthesis from the perspective of new chemical entities and not for marketed drugs. In addition, a new SPPS solvent must fulfil several basic technical requirements to qualify as a reasonable substitute for DMF/NMP. Listed below, we have identified a set of criteria and considerations which would allow for the implementation of a process comparable to our current capability when using DMF or NMP.

2.1. SPPS large-scale synthesis equipment

SPPS on scale is normally performed in batch mode. Reactor volumes up to 1000 litres are common and reactors are often jacketed to allow heating/cooling. Large-scale SPPS reactors are fitted with a filter at the bottom and mixing is performed by mechanical agitation rather than bubbling of gas from the bottom of the reactor, shaking or similar means that are common for laboratory scale SPPS. The resin from which the peptide chain is growing during the SPPS cycle remains inside the reactor, and between coupling and deprotection steps the solvent is drained through the bottom filter and the resin is washed with solvents to remove excess reagents and by-products. Unlike in a laboratory setting, all operations for synthesis such as heating, filtering and addition of reagents and solvents as well as isolation and purification are time consuming and thus present engineering challenges. Solvents are typically stored in tank farms outside the facility and must be pumped in, filtering can be slow due to clogging or insufficient vacuum, reagents are dissolved in separate vessels and are pumped into the reactor with the resin etc. These are all engineering aspects that must be considered during process development to ensure a relatively smooth transfer to the pilot plant that take the plant's limitations into consideration. For the same reason the stability of reagents, building blocks and peptide resins in solution must be well understood to ensure that no significant decomposition occurs during extended holding times and to allow the preparation of solutions well in advance to increase efficiency.

2.2. SPPS solvent viscosity and melting point

The room temperature within a production plant will typically vary between 15–35 °C depending on the geographical location and the season. Moreover, for practical and safety reasons solvents are usually stored outside the production plant in tank farms in the terrain (or underground) exposed to the surrounding climate. Although measures are taken in modern facilities to insulate tank farms and ensure heating of piping for solvent transfer this is by no means the industry standard and solvents can, depending on the geographical location and season, experience temperatures well below room temperature. Consequently, to prevent technical challenges at low temperatures, it is preferable that solvents have melting points of ≤10 °C. From a recycling perspective it is preferable that solvents do not have very high boiling points. That said, cost-efficient recycling of for example DMF from SPPS processes is performed by some companies and used for cleaning of process equipment. The financial incentive for recycling will have to be evaluated case by case but ideally a boiling point below 100 °C should be aimed for. The viscosity of solvents should also be considered before implementing a new solvent system. Solvents with high viscosity can present challenges during solvent transfer and can complicate purging and cleaning of reactors and piping during and after production. This may necessitate elaborate and time-consuming cleaning procedures and large volumes of cleaning solvent, and in the worst case could lead to cross contamination. For pilot plant production in general we have found that a viscosity of ≤4 mPa s is acceptable, however, in the context of SPPS a viscosity nearer that of DMF (0.8 mPa s) may be required to ensure appropriate swelling of the resin and diffusion of reagents in commonly used solid supports.13

2.3. Scalability

To ensure that an SPPS process can be performed efficiently at a reasonable production scale in terms of kg-output of API and in a minimum of batches the following considerations regarding solubility of reagents, building blocks and by-products, reagent and solvent stability and resin swelling should be considered:

• Dissolution of building blocks, reagents and by-products: amino acid building blocks, reagents, by-products etc. should be soluble at a concentration of ≥0.25 M (ideally up to 0.40 M) to prevent excessive solvent volumes and clogging of filters. It can be tolerated that some building blocks are soluble at a lower concentration or that special conditions are applied for single couplings or deprotections but overall a concentration ≥0.25 M should be aimed for. Similarly, poor solubility of certain by-products may be compensated for by utilising alternative solvents for washing. For example, in standard SPPS the removal of diisopropylurea (DIU), a by-product from diisopropylcarbodimimide (DIC) mediated couplings, is complicated by the low solubility of DIU in many polar aprotic solvents. As a result, DIU can precipitate during couplings and lead to clogging of filters during draining and washing operations. To dissolve and remove precipitated DIU, 2-propanol (in which DIU has a high solubility) is commonly employed for washing steps.

• Reagent and solvent stability: during production, solutions of amino acids, coupling reagents and additives may be exposed to extended holding times at room temperature. Good stability for at least one week at room temperature is desirable for standard amino acid building blocks. Moreover, the solvent itself must also be stable throughout the peptide synthesis cycle, in particular with respect to possible side-reactions with the solid-supported peptide in order to prevent the formation of undesired acylated/alkylated peptide-related species that may be difficult to remove during purification (resulting in a yield reduction and/or increased solvent consumption during isolation and purification).

• Resin swelling: the resin swelling capability is essential for the process performance during synthesis, but it is important to avoid excessive swelling because it will limit the possible production scale. In general, we recommend swelling in the range of approximately 4–7 mL g−1 for the starting resin (resin with linker or preloaded with the first amino acid), which balances good swelling to facilitate the coupling and deprotection reactions during SPPS, while not swelling excessively. However, the acceptable maximum swelling should be evaluated case by case. If for example the yearly API demand is low and suitable equipment is available high swelling can be tolerated, in particular if it improves process robustness and product quality.

2.4. Process performance

We have found consideration of the following parameters critical to maximise output and optimise process time:

• Resins with the highest possible loading that does not impede process performance nor reduce product quality should be aimed for (ideally >1 mmol g−1). During development stages, the process will be optimized for the highest possible loading and it is not uncommon that high loadings cannot be achieved due to aggregation or other factors. We aim for a starting loading of minimum 0.30 mmol g−1 but ideally significantly higher.

• For a standard amino acid coupling cycle, the reaction time for completion of coupling at room temperature should not exceed 60–90 min and stay below 30–40 min for Fmoc-removal. In practise, this should make it possible to maintain a cycle time of ≤3 hours per amino acid residue, operations included.

• The loading of the first amino acid on polystyrene resin at room temperature should not exceed 120 min.

• During washings of the resin after coupling and deprotection, the solvent should remain efficient at solubilizing by-products and excess reagents in order to minimize the overall solvent volumes.

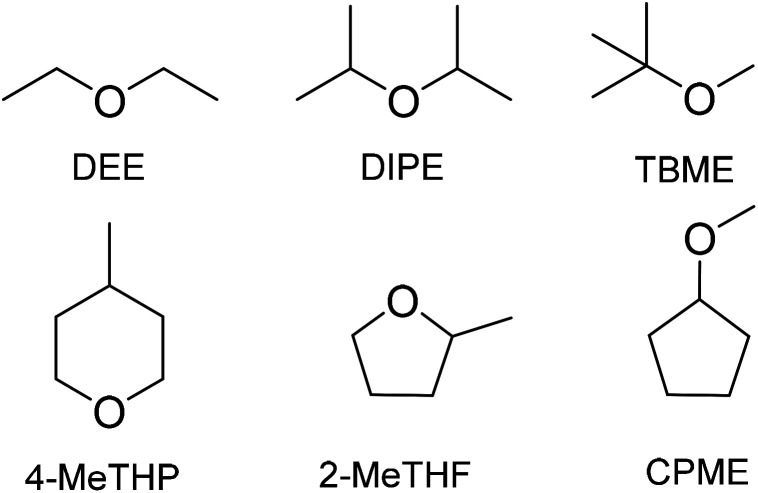

2.5. Cleavage, deprotection, purification and isolation

After completed elongation of the peptide chain, cleavage from the resin and removal of the side chain protecting groups to release the crude peptide, are most frequently carried out simultaneously. The reaction is typically performed using a cleavage cocktail comprised of trifluoroacetic acid (TFA), water and scavengers. Replacement of DMF, NMP or CH2Cl2, is unlikely to have a direct impact on this step since washing with a volatile solvent and thorough drying would remove any residual SPPS solvent that might influence the cleavage reaction or lead to generation of solvent-related impurities. Alternative final cleavage protocols such as using 0.1 N HCl in hexafluoro-2-propanol (HFIP) or trifluoroethanol (TFE) have been proposed to avoid using TFA,25 which in itself is hazardous and environmentally damaging, yet fluorinated solvents such as HFIP and TFE are REACH impacted. Soft cleavages allowing for release of fully protected peptide fragments (C-terminal acids) from the resin are usually conducted by treatment with dilute TFA or HFIP in CH2Cl2. CH2Cl2 is an ICH class 2 solvent and has been flagged with an SVHC profile in REACH and a substitution for an environmentally more benign solvent should be pursued. Post cleavage, several strategies for the isolation of peptide products are available. The exact strategy is usually evaluated on a case-by-case basis and is very dependent on the nature of the API. The various approaches all have pros and cons with respect to purity, yield and chemical waste generation. The most common strategy for work-up after cleavage involves removal of the resin by filtration, followed by precipitation of the cleaved peptide with an anti-solvent such as diisopropyl ether (DIPE) or t-butylmethyl ether (TBME). Ethers can be problematic due to their peroxide-forming propensity but can be handled if the appropriate safety precautions are taken. Precipitation of the peptide together with the resin is a viable alternative and may facilitate filtration and washing of the peptide product. An appropriate precipitation solvent should be able to dissolve all by-products (mainly scavenged side chain protecting groups). An extractive work-up process can also be utilised, in which the peptide product is solubilized in an aqueous buffer followed by washing with an appropriate organic solvent in order to remove by-products. Depending on the purity of the isolated crude peptide, several purification steps typically using reverse-phase HPLC and ion-exchange chromatography are usually applied for purification of the crude peptide. The purification process can consume significant quantities of solvent, usually acetonitrile (MeCN) and water. However, MeCN recycling is feasible and consequently can reduce the amount of waste drastically.26 After salt exchange to obtain the desired salt-form product isolation is typically performed by freeze-drying (lyophilisation). However, the use of spray-drying is becoming increasingly wide-spread because of high turnover resulting from a continuous process, and due to relatively small equipment size when compared to more traditional freeze-drying equipment. In the case of lyophilisation, the solution containing the API is often concentrated to increase throughput by for example rotary evaporation, thin-film evaporation or UF-DF (ultrafiltration–diafiltration).19

2.6. Cost, supply and intellectual property rights (IPR)

Ideally a new platform for peptide manufacturing should not increase the cost of the API compared to the current cost of manufacturing by SPPS. That said, scientist developing new methodology should not be discouraged by a higher cost of a new methodology as it is expected that a widely adapted technological breakthrough will result in a significant reduction in cost over time. Nevertheless, a “reality-check” of a new process or process solvent to assess if it is reasonable to expect that it can reach a cost similar to that for current SPPS should be performed. As a part of this exercise it is important to assess if there are any IPR related issues on the production or use of a new solvent system to ensure competitiveness between solvent manufacturers, a more robust supply chain and avoid obstacles in relation to licensing and royalties. In addition to the cost for a new solvent, the quality is essential to avoid potentially reactive impurities arising from the solvent manufacturing process or stemming from solvent decomposition. Moreover, a supply chain with multiple independent suppliers is necessary to ensure a reliable supply and to decrease the bulk price of the solvent. That said, it should be kept in mind that the greening of peptide synthesis in fact has the potential to reduce production cost. A change to new solvent systems may reduce the required solvent volumes, facilitate recycling of solvents, provide improved purity profiles and increased yields, avoid costly and time consuming problems pertaining to new environmental regulatory requirements etc.17,18 Benchmarking new processes using available green chemistry metrics such as atom economy, complete E-factor (cEF), and Process Mass Intensity (PMI) may provide useful input for reagent and solvent selection and reduction,27–29 and ultimately cost reduction. The cost of a peptide manufacturing process is the sum of the required: (i) FTEs (full-time employees), (ii) pilot plant time, and (iii) raw materials. The contribution from each of these categories varies between projects and is influenced by many factors such as scale and length of the peptide target and will inevitably affect the development programme. In 2018, CMC at Novo Nordisk assessed the cost of raw materials for the SPPS campaign of a 39-mer peptide as part of a clinical phase 2 programme (data not shown). From this analysis the cost distribution for raw materials revealed that solvents accounted for 27%, resin for 15%, coupling reagents for 23%, and amino acid building blocks and other reagents for the remaining 35% (three non-standard amino acid building blocks accounted for 16% of the 35%). During process optimisation towards phase 3 the cost contribution from solvents would likely increase even further when the equivalents of building blocks and reagents are adjusted. In conclusion, solvents represent one of the major raw material cost drivers in solid-phase peptide synthesis, and in addition to addressing environmental concerns and adhering to regulatory requirements there is a clear financial incentive to replace, reduce and recycle process solvents if possible.

3. SPPS in alternative solvent systems

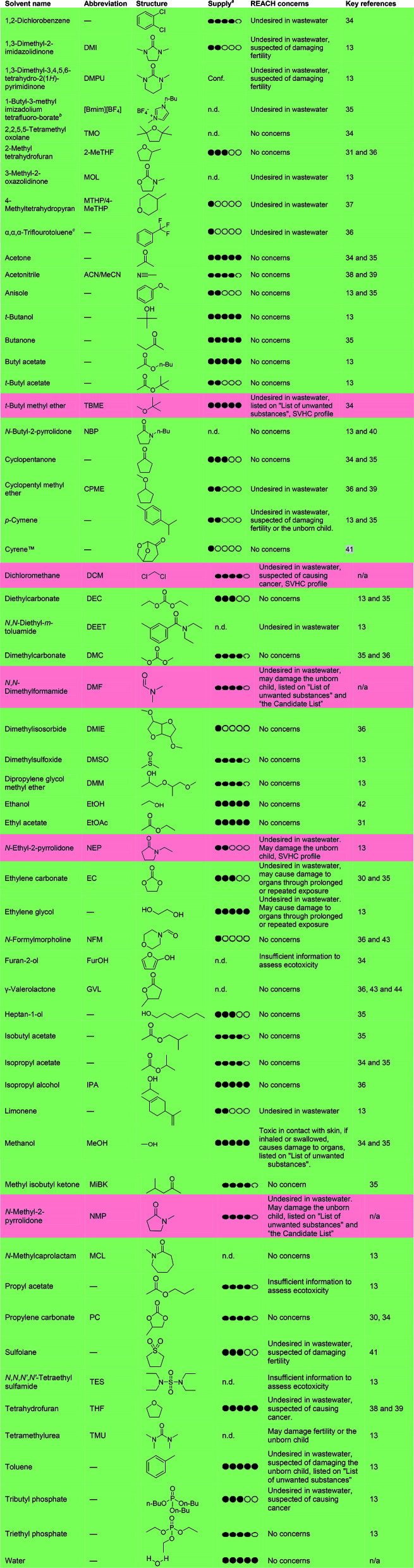

The concept of “greening” SPPS through replacement of problematic solvents has been gaining momentum in recent years and has been pioneered by a handful of research groups.30,31 The following subsections deal with the state-of-the-art in solvent replacement for resin swelling and the SPPS cycle as outlined in Fig. 1 (vide supra). A comprehensive overview of solvents previously described in the literature in relation to green peptide synthesis, and standard SPPS solvents (e.g. DMF, NMP and CH2Cl2), is outlined below along with key references and notes on supply based on the amounts manufactured and/or imported to the European Economic Area (EEA) annually as reported by ECHA (Table 1).14 The solvents have been assessed according to the Novo Nordisk internal EcoChem criteria, which takes into account both environmental and safety aspects of chemicals based on ECHA REACH data, and are divided into two categories; REACH compliant (green) and REACH affected (red). It should be noted that currently REACH compliant solvents may be suspected of having environmental or safety problems and could be under active investigation. This aspect should also be taken into consideration when selecting process solvents. Major REACH concerns for all solvents have been listed in Table 1.

Comprehensive list of solvents that have been used in relation to GSPPS, including key references. Solvent classification has been carried out by inspection of REACH authorisation, candidate list (SVHC, Substances of Very High Concern),14 PACT (the Public Activities Coordination Tool),32 endocrine disruptors and CMR (Carcinogenic, Mutagenic or toxic for Reproduction). Solvents are labelled as unaffected by REACH (green) or affected by REACH (red). It should be noted that many solvents that currently are not affected by REACH are under investigation due to environmental concerns and may become affected in the future. Major REACH concerns are summarised in a separate column. Supply is listed in five categories based on the amount of solvent manufactured and/or imported to the EEA annually as reported in ECHA33.

|

1 black circle indicates an annual supply in the EEA of <100 tonnes, 2 circles = 100–1000 tonnes, 3 circles = 1000–10 000 tonnes, 4 circles = 10 000–100 000 tonnes, and 5 black circles indicates >100 000 tonnes; n.d. = no data available; conf. = confidential; n/a = not applicable for standard solvents.

Imidazolium-based ionic liquids are associated with concerns regarding their ecotoxicity and thermal decomposition.45,46

Per- and polyfluoroalkyl substances are currently under investigation by ECHA REACH because these substances are considered to be persistent. The use of per- and polyfluoroalkyl substances will likely be restricted in the future.

3.1. Swelling, dissolution and stability

Good resin swelling is adamant to achieve efficient SPPS but at the same time should not be excessive to ensure high product output per production batch. At the on-set of SPPS, resin swelling is dominated by the properties of the resin itself but as the peptide chain grows it will gradually affect the swelling properties of the peptide resin. We have seen examples of peptide resins where the peptide induces a dramatic increase in swelling or conversely makes the resin shrink. Every peptide target will affect the swelling properties of the peptide-resin uniquely and this must be addressed during development to optimise all coupling and deprotection steps. Consequently, most of the scientific literature that investigates resin swelling look at the resin-linker system alone or with the first amino acid pre-loaded, which is a good starting point if it is kept in mind that this will change during the course of the synthesis. A compilation of swelling data was recently published by Albericio et al.,15 but in this section swelling data from many research teams are presented and discussed in full to give the reader the complete picture and possibility to make their own analysis of the data at hand.

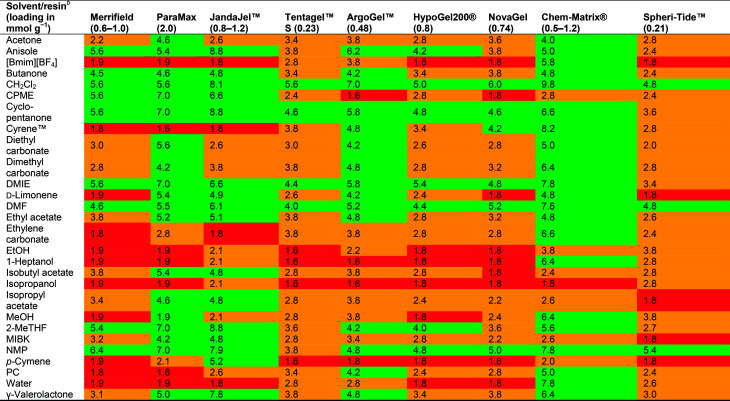

Lawrenson et al. studied the swelling properties of nine different starting resins in 25 solvents as outlined in Table 2.35 The solvents covered a wide range of polarities as well as hydrogen bond donor/acceptor properties, and were divided into three categories based on their resin swelling properties; good (swelling >4.0 mL g−1), moderate (swelling from 2 to 4 mL g−1), and poor (swelling <2 mL g−1). Significant differences between the different resins and solvents were observed. The most versatile resins were ChemMatrix® and ArgoGel™ (a crosslinked polyethylene glycol (PEG) resin and a PEG grafted onto polystyrene resin, respectively), which were able to swell >4 mL g−1 in a wide variety of solvents, and the least versatile resin was the polyamide SpheriTide™ which was only able to swell >4 mL g−1 in DMF, NMP and CH2Cl2. Swelling of the ChemMatrix® resin was sometimes excessive, which can be problematic from a production perspective as a higher swelling volume limits the batch size. The polystyrene-based resins showed different swelling properties with the Merrifield resin swelling well in some of the moderately polar solvents containing oxygen atoms, whereas the ParaMax resin swelled well in all of them. The JandaJel™ resin swelled particularly well in non-polar solvents such as limonene or p-cymene. Cyclopentanone and dimethyl isosorbide were found to be good solvents for almost all the resins, while moderate swelling was observed for the SpheriTide™ resin. Lawrenson et al. proposed that resin swelling is dependent on the composition of the resin rather than its functionalisation, although the structurally comparable Merrifield and ParaMax resins (ParaMax resin being a Merrifield resin functionalized exclusively on the para position of the aromatic ring) displayed differences in their swelling properties. Functionalising resins with different linkers and studying their swelling properties could shed more light on this topic.

Swelling properties of resins in different solvents in mL g−1 reported by Lawrenson et al.35a.

|

Green: good swelling (>4.0 mL g−1). Orange: moderate swelling (2.0 to 4.0 mL g−1). Red: poor swelling (<2.0 mL g−1).

The resin (100 mg) was weighed into a 2 mL syringe fitted with a polypropylene fritted disc (void volume = 0.12 mL). Solvent (2 mL) was added and the syringe was agitated for 1 hour at room temperature. The solvent was removed by compressing the syringe piston. The resin was then allowed to return to its maximum volume by slowly withdrawing the piston. The volume was recorded, and the degree of swelling calculated from the following formula: degree of swelling (mL g−1) = 10 × (measured volume − 0.12).

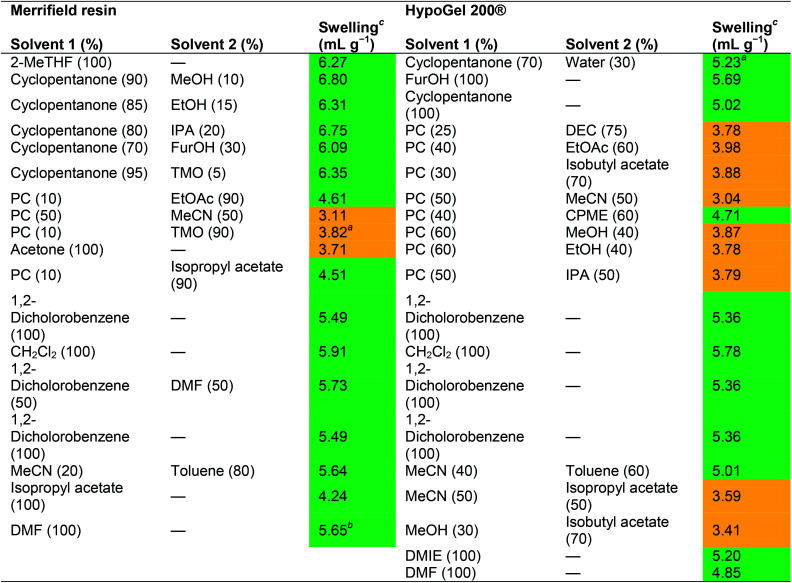

A computational model was applied to predict the swelling of resins in different solvents and solvent mixtures, suggesting that some solvent mixtures would achieve better swelling compared to neat solvents. Changing the physical properties by using solvent mixtures could increase the solubility of reagents or decrease melting point and/or viscosity of the solvent. Although a single solvent system might be preferred from a handling and recycling perspective, a major advantage of a mixed solvent system is the ability to adjust the solvent ratio. This flexibility could be beneficial throughout the SPPS cycle, when polarities of various functionalized peptide resins change, or to adapt to the physical properties of the vast number of reagents and resins. The influence of different ratios of solvent mixtures on swelling was further described by North and co-workers.34 Both in silico and laboratory experiments were carried out on Merrifield and HypoGel 200® resins (Table 3). Resin swelling was shown not to correlate linearly with solvent composition. Moreover, some solvent mixtures showed increased swelling volumes compared to the corresponding neat solvents. For example, propylene carbonate (PC) and ethyl acetate (EtOAc) swelled Merrifield resins at 1.8 and 3.8 mL g−1 respectively, while a 1 : 9 PC/EtOAc mixture swelled the same resin with a 20% increase compared to neat EtOAc. A 1 : 9 PC/EtOAc mixture and neat EtOAc were compared for the synthesis of the tripeptide H-Leu-Ala-Phe-OH on Merrifield resin. The 1 : 9 PC/EtOAc mixture gave a 5% increase in yield compared to neat EtOAc, but a higher purity was obtained in EtOAc (95.2% and 96.9% purity, respectively).

Swelling of Merrifield and HypoGel 200® resins in a variety of solvent combinations reported by North and co-workers34.

|

The solvents were not miscible in this ratio.

For mixtures of DMF and water, addition of >10% water reduced the swelling to the same level as observed for pure water (approximately 2 mL g−1).

The resin (100 mg) was weighed into a 2 mL syringe fitted with a polypropylene fritted disc (void volume = 0.12 mL). Solvent (2 mL) was added and the syringe agitated for 1 hour at room temperature. The solvent was removed by compressing the syringe piston. The resin was then allowed to return to its maximum volume by slowly withdrawing the piston. The volume was recorded, and the degree of swelling calculated from the following formula: degree of swelling (mL g−1) = 10 × (measured volume − 0.12).

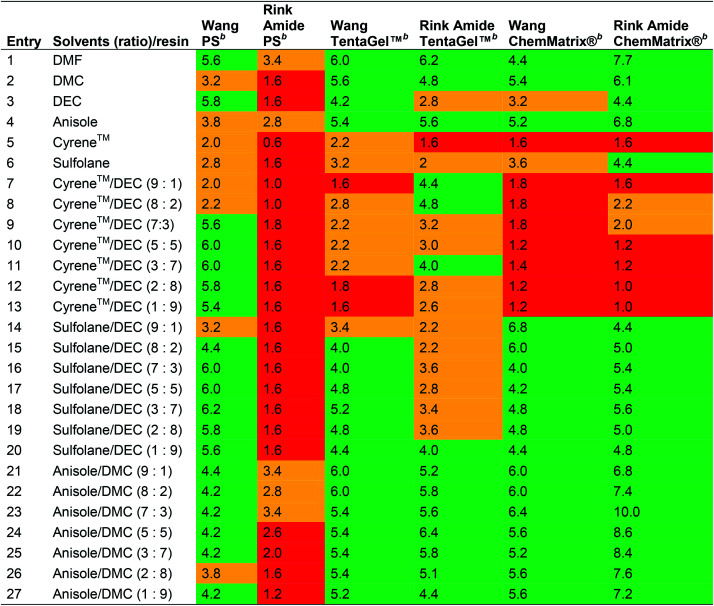

Ferrazzano et al. reported the combinations of Cyrene™ or sulfolane with DEC, and anisole with DMC in varying ratios as green alternatives for SPPS (Table 4),41 although sulfolane is undesired in waste water and suspected of reproductive toxicity, and anisole is suspected of causing genetic defects (see Table 1).14 The swelling properties of Merrifield, ChemMatrix® and Tentagel™ resins in combination with either Wang or Rink Amide linkers were evaluated.

Swelling volume in mL g−1 of PS, TentaGel™ and ChemMatrix® resins in neat and mixed solvents published by Ferrazzano et al.41a.

|

Green: good swelling (>4.0 mL g−1). Orange: moderate swelling (2.0 to 4.0 mL g−1). Red: poor swelling (<2.0 mL g−1).

The resin (100 mg) was weighed into a 3 mL syringe fitted with a polypropylene fritted disc (void volume = 0.2 mL). Solvent (2 mL) was added and the syringe agitated for 30 min at room temperature + 5 min equilibration. The solvent was removed under vacuum and the volume of the dry resin was recorded. The degree of swelling was calculated from the following formula: degree of swelling (mL g−1) = 10 × (measured volume − 0.2).

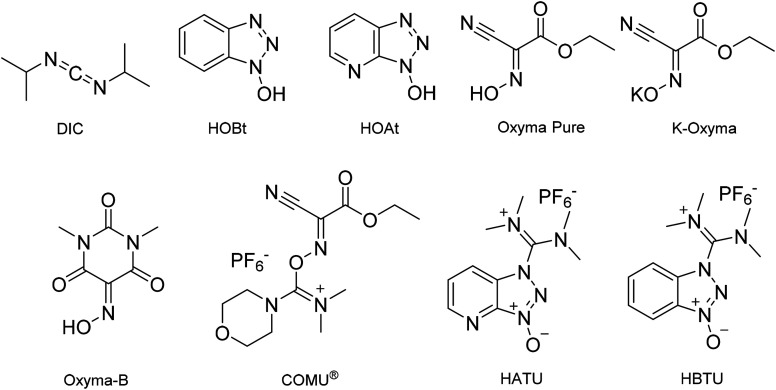

In line with the observations of Lawrenson et al. (vide supra), solvent mixtures generally gave improved swelling compared to neat solvents, and furthermore, the linker appeared to affect resin swelling. For the PS resin for example, more swelling was observed for the Wang over the Rink Amide linker, while for the ChemMatrix® resin the opposite was generally observed. When comparing Wang and Rink Amide linkers on TentaGel™ resin, most swelling was observed in 8 : 2 and 9 : 1 anisole/DMC (6.0 mL g−1, entries 21 and 22), and 5 : 5 anisole/DMC (6.4 mL g−1, entry 24) respectively. The best swelling for the Wang ChemMatrix® resin was obtained with 9 : 1 sulfolane/DEC (6.8 mL g−1, entry 14) while the Rink Amide ChemMatrix® resin had the highest swelling volume in 7 : 3 anisole/DMC (10.0 mL g−1, entry 23). Overall, Ferrazzano et al. found, as anticipated, that DMF display good swelling properties, but also that mixtures of anisole/DMC were able to match the swelling profile of DMF very well (entries 21 and 1, respectively). In addition to swelling, Ferrazzano et al. performed solubility experiments with the most promising solvent mixtures (Cyrene™/DEC (3 : 7), sulfolane/DEC (3 : 7) and anisole/DMC (7 : 3)). Dissolving Fmoc-Val-OH at a concentration of 0.2 M was only possible in sulfolane/DEC (3 : 7). Activated amino acids are typically more soluble, and so the solubility of Fmoc-Val-OH was reassessed with the activating reagents (1-cyano-2-ethoxy-2-oxoethylidenaminooxy)dimethylamino-morpholino-carbenium hexafluorophosphate (COMU®)/N,N-diisopropylethylamine (DIPEA), N,N′-diisopropylcarbodiimide (DIC)/ethyl (hydroxyimino)cyanoacetate (Oxyma Pure), DIC/hydroxybenzotriazole (HOBt), 1-[bis(dimethylamino)methylene]-1H-1,2,3-triazolo[4,5-b]pyridinium 3-oxid hexafluorophosphate (HATU), and 2-(1I-benzotriazol-1-yl)-1,1,3,3-tetramethyluronium hexafluorophosphate (HBTU). The best result was obtained with DIC/Oxyma Pure that was able to dissolve Fmoc-Val-OH in all solvent systems in 5 min. Next, DIC/Oxyma Pure in the three different solvent systems was evaluated for its ability to solubilise 18 representative Fmoc-protected amino acid building blocks. In all cases, the activated Fmoc-amino acid was fully soluble at a concentration of 0.2 M.41

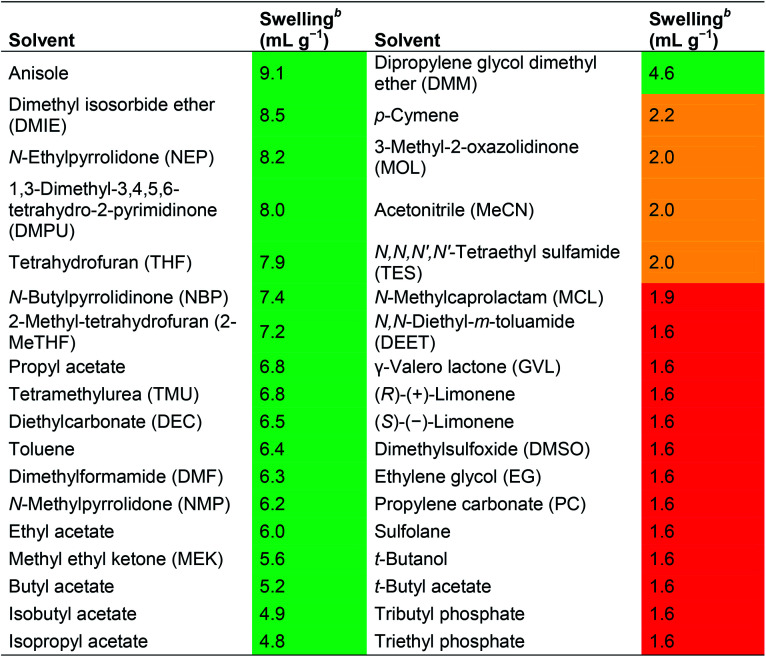

In another study, Lopez et al. studied the swelling and solubilisation properties of a wide range of solvents, including many environmentally problematic or poorly characterised ones (e.g. DMPU, tetramethyl urea and sulfolane), using an aminomethyl-polystyrene resin (Table 5). Initially, only solvents able to induce a resin swelling ±30% with respect to DMF were considered of interest (i.e. swelling in the range 4.4–8.2 mL g−1), however, later this was changed to solvents providing a swelling of ≥6 mL g−1.13

Swelling properties of aminomethyl polystyrene resin (loading 1.3 mmol g−1) in various solvents as reported by Lopez et al. The nature of the employed linker system was not disclosed13a.

|

Green: good swelling (>4.0 mL g−1). Orange: moderate swelling (2.0 to 4.0 mL g−1). Red: poor swelling (<2.0 mL g−1).

One gram of amino methyl resin was placed in a 10 mL graduated cylinder and the solvent was added to give a final volume of 10 mL. The suspension was gently stirred and allowed to settle for 3.0 h. The final swelling volume was measured in mL g−1.

Among the solvents studied, 14 solvents were found to swell the resin ≥6 mL g−1, and were studied further for their ability to dissolve two amino acids (Fmoc-Gln(Trt)-OH and Fmoc-Gly-OH), Oxyma, N,N′-diisopropylcarbodiimide (DIC) and N,N′-diisopropylurea (DIU) at a concentration of 0.2 M (Table 6). Out of the 14 solvents, five (anisole, propyl acetate, diethyl carbonate, toluene and ethyl acetate) were unable to dissolve the Fmoc-amino acids and/or DIU. With exception of propyl acetate and diethyl carbonate that were considered too poor, all solvents were evaluated for coupling and Fmoc-removal (vide infra). The partial solubility of DIU in THF, 2-MeTHF and DMF was accepted by the authors because these are expected to be removed by extensive washing after coupling. From a green SPPS perspective this is undesirable as the washing steps have the biggest negative impact in terms of solvent consumption. Moreover, out of 14 solvents studied in depth, seven are problematic from an environmental perspective (NEP, DMPU, THF, TMU, toluene, DMF and NMP, see Table 1), and should not be in scope for green SPPS.

Solubility of Fmoc-protected amino acids and reagents at 0.2 M concentration in different solvents reported by Lopez et al.13a.

| Solvent/reagent | Fmoc-Gln(Trt)-OH | Fmoc-Gly-OH | Oxyma | DIC | DIU |

|---|---|---|---|---|---|

| Anisoleb | I | I | S | S | I |

| DMIE | S | S | S | S | S |

| NEPc | S | S | S | S | S |

| DMPUc | S | S | S | S | S |

| THFb | S | S | S | S | PS |

| NBP | S | S | S | S | S |

| 2-MeTHF | S | S | S | S | PS |

| Propyl acetate | S | S | S | S | I |

| TMUc | S | S | S | S | S |

| DEC | I | I | S | S | I |

| Toluenec | I | I | I | S | I |

| DMFc | S | PS | S | S | PS |

| NMPc | S | S | S | S | S |

| EtOAc | S | I | S | S | I |

The indicated solvent (10 mL) was added to 2 mmol of each reagent. All mixtures were stirred at the same speed and temperature (22–23 °C) for 10 min. Subsequent visual inspection was reported as soluble (S), partially soluble (PS), or insoluble (I).

Poorly characterised solvent.

Environmentally problematic solvent.

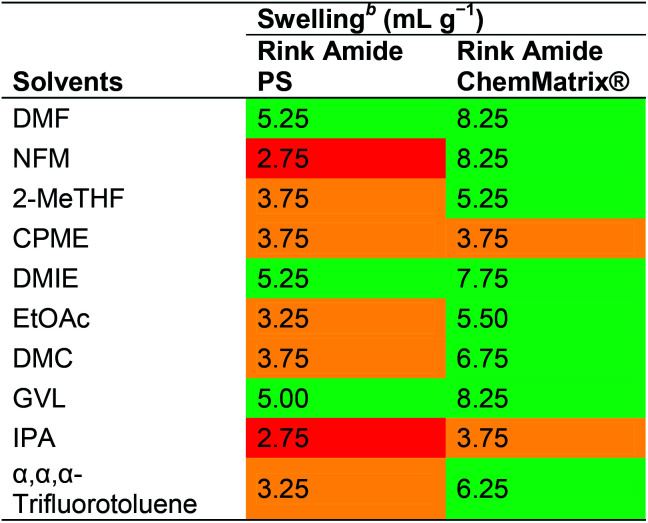

Albericio and co-workers reported a swelling study using PS and ChemMatrix® resins in nine green solvents selected based on the GSK solvents classification list.21,36 The resin swelling properties of NFM, 2-MeTHF, CPME, DMIE, EtOAc, DMC, GVL, IPA and α,α,α-trifluorotoluene were compared to DMF (Table 7). While the ChemMatrix® resin appeared to swell well in all solvents except CPME and IPA (3.75 mL g−1 in both cases), the PS resin only swelled above 4 mL g−1 in DMIE and GVL. In a more recent report focusing on NBP, Albericio and co-workers demonstrated that NBP is able to dissolve all Fmoc-protected amino acids and common coupling reagents at concentrations well above what is usually employed in SPPS, but that it is also overall slightly inferior to DMF in swelling of aminomethyl polystyrene and H-Rink Amide ChemMatrix resins.40

Swelling of Rink Amide PS and Rink Amide ChemMatrix® resins in various solvents reported by Albericio and co-workers36a.

|

Green: good swelling (>4.0 mL g−1), orange: moderate (2.0 to 4.0 mL g−1), and red: low (<2.0 mL g−1).

The resin (200 mg) was placed in a 5 mL syringe and enough solvent to swell the resin and allowed to stand for 5 min. The swelled resin was compressed with the piston until no more solvent could be removed. The piston was pulled slowly until the resin recuperated its maximum volume and the resin volume was recorded. The swelling was calculated according to the following formula: degree of swelling (mL g−1) = (volume of the swelled resin + 0.15 mL)/0.2 g.

In a production facility, amino acid building blocks and reagents may be exposed to prolonged holding times in solution. It is therefore important to investigate the stability of Fmoc-amino acids and reagents in solution in any new solvent introduced. For example, although unintentional partial Fmoc-removal may occur during storage (resulting in double incorporation of amino acids during coupling), few reports have looked into this important aspect of SPPS, and only for coupling reagents. Tofteng et al. examined the influence of microwave heating and water content in DMF on the stability and performance of a range of coupling reagents, and concluded that COMU® has poor hydrolytic stability in DMF at room temperature (<5 h), while HATU and especially DIC-Oxyma were more suitable for automated SPPS.47 Kumar et al. addressed the poor stability of COMU® in DMF by investigating COMU® in MeCN, GVL and NFM, and found it to be relatively stable in MeCN and GVL (89% and 84% of COMU® remaining after 48 h, respectively), whereas it completely degraded in DMF and NFM after 48 hours (0 and 3% of COMU® remaining, respectively).48

3.2. The peptide synthesis cycle

When investigating alternative solvents and reagents for SPPS, we suggest that reaction times at room temperature should ideally not exceed 90 min for couplings and 40 min for Fmoc-removal. This is typically the case for standard SPPS processes taking place in DMF or NMP, and within this timeframe full conversion should be achieved with minimal side-reactions. In addition, the process safety of coupling reagents should be considered carefully because these often contain high energy functional groups. Reagents derived from HOBt/HOAt should be used with care as these are known shock-sensitive and explosive substances.49–51 In a recent thermal stability study reported by Pfizer, 45 commonly employed peptide coupling reagents were evaluated.49 In general, coupling reagents based on the HOBt motif were found to be less safe.

3.2.1. Loading

To the best of our knowledge only two reports on green solvent substitution for the loading of the first amino acid on a resin have been disclosed. Al Musaimi et al. successfully applied 2-MeTHF as a CH2Cl2 substitute for the loading of the first amino acid on both Wang and 2-chlorotrityl resins, obtaining comparable loading (studying ten amino acids) and less racemisation of the first amino acid (studying five amino acids) when compared to CH2Cl2.52 Al Musaimi et al. have also described the use of GVL for the anchoring of 18 canonical amino acids onto a Wang resin, generally achieving good loading (>0.50 mmol g−1), and racemisation below 1.5%. Notable exceptions were the incorporation of His and Trp that required a special loading protocol at lower temperature to achieve 5.0 and 7.8% racemisation respectively at best.53 For peptide API production, prevention of racemisation is of utmost importance for quality and therefore the degree of racemisation observed for GVL (even 1% racemisation would be concerning) may limit its use in large-scale synthesis of peptide pharmaceuticals.

3.2.2. Coupling

Several studies dedicated to green SPPS have been published, investigating a wide variety of solvents. Lawrenson et al. studied ethylene carbonate (EC) and propylene carbonate (PC) as a replacement for DMF, initially in a solution-phase model, and later on solid support.30 PC showed the best results, with no epimerisation or side reactions, and its utlity as a solvent was demonstrated by the successful solution-phase synthesis of several tetramer peptides (Boc/Bn strategy) and the 9-mer peptide bradykinin A (Fmoc/tBu strategy) on an HMPB-ChemMatrix® solid support. In the bradykinin A synthesis, a comparable purity to the one obtained with DMF was achieved (77% and 79%, respectively). It should be noted that the synthesis was performed with reagents and amino acids at 0.1 M concentration, likely due to their poor solubility in the solvent. Low reagent concentrations are not recommended for large-scale synthesis, thus neat PC is unlikely to become a suitable alternative for DMF on scale.

Albericio and co-workers have published several papers on the use of various solvents for green SPPS. In one study, MeCN and THF were used as DMF substitutes, in combination with DIC and various additives (HOAt, HOBt, Oxyma Pure and Oxyma-B) on an H-Rink Amide AM ChemMatrix® resin, resulting in improved yields and suppression of racemisation compared to DMF. The methodology proved successful both in solution and on solid support for several peptide sequences with up to 10 amino acid residues, including difficult to couple amino acids such as 2-aminoisobutyric acid (Aib).38 The best yields were obtained with THF and Oxyma Pure as coupling reagent, but as the authors note, THF is not a green solvent and thus further work was required.14 In a follow-up study, the synthesis of the Aib-enkephalin pentapeptide was investigated on PS and PEG (ChemMatrix®) resins using 2-MeTHF or CPME in combination with DIC and an additive (HOBt, HOAt, Oxyma Pure, Oxyma-B or K-Oxyma) or with HBTU, HATU or COMU® (Fig. 2 and Table 8). The best results were obtained with DIC/Oxyma Pure in 2-MeTHF both on PS and PEG resins (PS: 97.0%, PEG: 81.9% yield) with a purity superior to the one obtained in DMF (PS: 42.8%, PEG: 53.0%). Even with K-Oxyma/DIC, which gave the best result in DMF (PS: 71.0%, PEG: 85.6% purity), the purity was still lower when compared to the synthesis in 2-MeTHF. With DIC/Oxyma Pure, CPME was superior to DMF on PEG resin (PS: 29.2%, PEG: 61.1% purity).

Fig. 2. Chemical structures of peptide coupling reagents and additives commonly employed in solid-phase peptide synthesis.

Purity of pentapeptide (H-Tyr-Aib-Aib-Phe-Leu-NH2) during solid-phase assembly on PS and ChemMatrix® resins, mediated by carbodiimide couplingsa.

| Resin | Coupling reagent | Solvent | Purityb (%) |

|---|---|---|---|

| PS | DIC/Oxyma Pure | 2-MeTHF | 97.0 |

| DIC/Oxyma Pure | DMF | 42.8 | |

| DIC/Oxyma Pure | CPME | 29.2 | |

| DIC/K-Oxyma | DMF | 71.0 | |

| ChemMatrix® | DIC/Oxyma Pure | 2-MeTHF | 81.9 |

| DIC/Oxyma Pure | DMF | 53.0 | |

| DIC/Oxyma Pure | CPME | 61.1 | |

| DIC/K-Oxyma | DMF | 85.6 |

1 h couplings were applied except for the Aib residues that were coupled twice (2 × 1 h).

Purity was determined by RP-HPLC analysis.

The uronium-based coupling reagents gave poor purities both in 2-MeTHF and CPME on both resins.39 In another study by Albericio and co-workers, the potential of IPA, EtOAc and 2-MeTHF for washing and deprotection, and 2-MeTHF for coupling was evaluated.31 Different protocols for the synthesis of the Aib-enkephalin pentapeptide and the Aib-ACP decapeptide on Rink Amide ChemMatrix® and Rink Amide PS resins were evaluated (Table 9).

Conditions reported by Albericio and co-workers for the synthesis of the Aib-enkephalin and Aib-ACP peptides on Rink Amide ChemMatrix® and Rink Amide PS resins31.

| Resin | Step | Method 1 (reference) | Method 2 | Method 3 | Method 4 | Method 5 |

|---|---|---|---|---|---|---|

| — | Washing | 1 × DMF | 1 × DMF | 1 × IPA | 1 × EtOAc | 1 × 2-MeTHF |

| 1 × CH2Cl2 | 1 × CH2Cl2 | 3 × EtOAc | ||||

| 1 × DMF | 1 × DMF | 1 × 2-MeTHF | ||||

| — | Deprotection | 20% piperidine in DMF (7 min) | 20% piperidine in DMF (7 min) | 20% piperidine in IPA (7 min) | 20% piperidine in EtOAc (7 min) | 20% piperidine in 2-MeTHF (7 min) |

| — | Washing | 1 × DMF | 1 × DMF | 1 × IPA | 1 × EtOAc | 1 × 2-MeTHF |

| 1 × CH2Cl2 | 1 × CH2Cl2 | 3 × EtOAc | ||||

| 1 × DMF | 1 × DMF | 1 × 2-MeTHF | ||||

| — | Coupling | Fmoc-AA-OH/DIC/Oxyma Pure (3 : 3 : 3 equiv.) 1 h | ||||

| DMF | 2-MeTHF | 2-MeTHF | 2-MeTHF | 2-MeTHF | ||

| Chem-Matrix resin | Purity (%), Aib-enkephalin | 53.0 | 81.9 | 30.8 | 91.9 | 95.0 |

| Purity (%), Aib-ACP | 37.8 | 70.0 | No data | 30.4 | 37.3, 42.8a, 87.1b | |

| PS resin | Purity (%), Aib-enkephalin | 71.8 | 97.0 | No data | 38.6, 54.6a | 41.6, 88.6a |

| Purity (%), Aib-ACP | No data | No data | No data | No data | 7.1a, 25.4b | |

Fmoc-removal performed at 40 °C.

Fmoc-removal and coupling performed at 40 °C.

The synthesis of Aib-enkephalin on Rink Amide ChemMatrix® resin resulted in a much higher purity when using 2-MeTHF for couplings (81.9% and 95.0%, methods 2 and 5) instead of DMF (53.0%, method 1), while employing IPA for washings and deprotection (method 3) gave the worst outcome (30.8%). Next, the different conditions were evaluated for the synthesis of the Aib-ACP decapeptide on Rink Amide ChemMatrix® resin. In this case, the best yield was obtained applying method 2 (70.0%), while methods 1 and 5 gave similar results (37.8% and 37.3% respectively) and method 4 gave a low purity (30.4%). The outcome using method 5 was improved significantly by heating the deprotection and coupling steps to 40 °C (87.1%), yet none of the other methods were evaluated at 40 °C, which would have been interesting for comparison purposes. The Aib-ACP peptide synthesis was not reported for methods 1–4 on the Rink Amide PS resin, and was overall inferior on this resin, while the best yield for the pentapeptide Aib-enkephalin on PS resin was obtained with method 2 (97.0%).

Albericio and co-workers have also reported a study using the green solvent GVL for SPPS and successfully applied it to coupling and deprotection under microwave irradiation with both PS and PEG-based resins.44 However, it was found that when using terminal glycine residues, GVL could undergo ring-opening acylation of the α-amino functionality. The extent of acylation for H-Gly-Phe-Leu-NH2 on solid support was evaluated by submitting the peptidyl bound resin in GVL to three stress conditions: room temperature for 12 hours, microwave irradiation at 90 °C for 10 min and room temperature for 12 hours in the presence of a 20% piperidine in GVL, yielding 15%, 25% and 70% acylation respectively. It should be noted that no acylation was detected during the synthesis of H-Leu-Phe-Gly-NH2 or the challenging Jung-Rademann and 65-74ACP (containing one Gly residue) decapeptides under similar conditions, indicating that side reaction is sequence dependent. It was subsequently found that GVL ring-opening could be mitigated by employing freshly prepared solutions of 4-Me-piperidine for Fmoc-removal,54 and the acylation could be eliminated by using dipeptides Fmoc-AA-Gly-OH for SPPS assembly of the peptide backbone to avoid N-terminal glycine in the peptide sequence.55 The need for using dipeptides appears rather cumbersome and may limit the use of GVL for SPPS on large scale.

As described earlier Lopez et al. studied a variety of solvents for their swelling properties and ability to dissolve Fmoc-amino acids and SPPS reagents. In the same paper, the most promising solvents were evaluated for peptide coupling and Fmoc-removal (Table 10).13 Coupling was performed in solution and the rate of amide bond formation between Fmoc-Leu-OH and H-Phe-OMe (1 equiv. each) in the presence of DIC and Oxyma Pure (1 equiv. each) was monitored over two hours. In less polar solvents such as anisole, toluene, 2-MeTHF, THF and ethyl acetate, the coupling reaction was fast, but precipitation of DIU and/or the dipeptide was also observed. In contrast, in the polar aprotic solvents DMF, DMPU, DMSO, NBP, NEP, NMP and TMU the reaction was slower, but no precipitation was detected. One should be careful with translating these results to SPPS though, as the choice of solvent will impact resin swelling and diffusion of reagents on solid support, and consequently reaction rates.

Solution-phase coupling efficiency in different solvents as reported by Lopez et al.13.

| Solvent/time (min) | Coupling reaction (% remaining S.M.)a | ||||

|---|---|---|---|---|---|

| 0 | 15 | 30 | 45 | 120 | |

| Anisole | 100.0 | 4.0 | 3.4 | 3.3 | N/Ab |

| DMF | 100.0 | 53.8 | 42.5 | 36.8 | 22.9 |

| DMI | 100.0 | 58.9 | 49.8 | 42.7 | 27.2 |

| DMPU | 100.0 | 76.5 | 66.4 | 56.4 | 42.2 |

| DMSO | 100.0 | 82.1 | 75.9 | 70.7 | 54.0 |

| EtOAc | 100.0 | 4.8 | 2.9 | 3.0 | N/Ab |

| 2-MeTHF | 100.0 | 13.4 | 9.8 | 7.9 | 4.4 |

| NBP | 100.0 | 58.7 | 50.7 | 45.9 | 30.6 |

| NEP | 100.0 | 65.1 | 56.7 | 50.7 | 33.5 |

| NMP | 100.0 | 67.1 | 58.7 | 51.7 | 34.9 |

| THF | 100.0 | 16.1 | 11.9 | 9.8 | 5.7 |

| TMU | 100.0 | 57.8 | 50.1 | 43.7 | 27.8 |

| Toluene | 100.0 | 5.6 | 4.7 | 4.3 | N/Ab |

Fmoc-Leu-OH (1 equiv.) and Oxyma Pure (1 equiv.) were dissolved and DIC (1 equiv.) was added. The mixture was stirred at room temperature for 10 min, and H-Phe-OMe (1 equiv.) was added. The reaction was monitored by RP-HPLC.

Not measured. Assumed to have reached full conversion.

Based on the results outlined in Table 10, five solvents (TMU, DMI, NBP, DMPU and DMSO) were selected for SPPS of a model octapeptide used in the manufacturing process of octreotide. It should be stressed that of the five selected solvents, three (TMU, DMI and DMPU) are problematic in relation to human and environmental toxicity and cannot be considered meaningful substitutes for DMF and NMP.14 SPPS was carried out on an automated peptide synthesiser and the crude purity of the peptide was compared head-to-head with SPPS in DMF. DMF provided the highest purity (86%) followed by NBP (80%), TMU (78%), DMI (78%), DMSO (52%) and DMPU (51%). However, because TMU and DMI show reproductive toxicity, these were deselected and NBP was the recommended solvent for SPPS. NBP gave a slightly lower crude yield compared to DMF (93% vs. 100% mass gain), but from an API production viewpoint it was more concerning that 1.5% epimerisation was observed in NBP (vs. 0% in DMF).13 The authors discussed that the lower yield and purity could be caused by the significantly higher viscosity of NBP compared to DMF (4 cP vs. 0.8 cP), giving poorer solvent and reagent diffusion in the resin and consequently inferior swelling, coupling, deprotection and washing. In order to generalise the use of NBP for peptide synthesis, it was suggested that increasing the temperature during synthesis may alleviate this problem, and a special protocol at 45 °C for problematic Fmoc-Arg(Pbf)-OH couplings was developed after it was found that δ-lactamisation of Arg was a particularly favoured side-reaction in NBP.56 Further work regarding amino acid racemisation and aspartimide formation showed that NBP performed on par with DMF in terms of racemisation but was superior to DMF at suppressing aspartimide formation at both 45 °C and room temperature.40 Still, further studies involving longer and more complex peptides, as well as a variety of linkers and resins would be beneficial to assess the use of NBP as a general substitute for DMF.

Another potential solution for greener SPPS is the use of mixtures instead of neat solvents. As it was demonstrated by North and co-workers, a mixture can offer better swelling properties than neat solvents as well as better solubility or chemical properties in general (vide supra). North and co-workers reported the synthesis of H-Leu-Ala-Phe-OH on Merrifield resin with DIC/Oxyma Pure in four different solvent mixtures and compared these to the synthesis performed in the neat solvents (Table 11).34 A small improvement in crude yield (approx. 5%) between neat EtOAc and the PC/EtOAc (1 : 9) mixture was observed (292 mg g−1 and 307 mg g−1, respectively). Both neat TMO and neat PC gave poor results (0 mg g−1 and 8 mg g−1 of resin respectively) while 132 mg g−1 were obtained in a TMO/PC (3 : 7) mixture and up to 200 mg g−1 was obtained for the TMO/PC (2 : 3) mixture, despite the immiscibility of the two solvents in this ratio. It should be noted that a rather low concentration was used for all syntheses (0.1 M) and that no studies on the solubility of reagents was reported. Moreover, without a head-to-head comparison with DMF it is difficult to judge the potential of these mixtures for application in SPPS.

Synthesis of H-Leu-Ala-Phe-OH in solvent mixtures and neat solvents reported by North and co-workers34a.

| Solvent | Yieldb (mg g−1) | Purity (RP-HPLC) |

|---|---|---|

| PC | 8 | 3.1% |

| EtOAc | 292 | 96.9% |

| TMO | 0 | — |

| EtOAc/PC (9 : 1) | 307 | 95.2% |

| TMO/PC (9 : 1) | 124 | 100% |

| TMO/PC (3 : 7) | 132 | 96.7% |

| TMO/PC (2 : 3)c | 200 | 94.2% |

Fmoc-removal was carried out with 20% piperidine in solvent (v/v) for 20 min. Couplings were performed for 1 h at room temperature. Fmoc-amino acid (3.0 equiv.), HBTU (3.0 equiv.), HOBt (3.0 equiv.) and DIPEA (6.0 equiv.) were dissolved at a 0.1 M concentration and stirred for 20 min before adding this mixture to the resin. For the synthesis in PC, after the final Fmoc-removal, the resin was also washed with EtOAc (5 mL).

Yields are given in mg g−1 of resin as the starting loading for the Merrifield resin was imprecise (0.4–0.8 mmol g−1).

Immiscible in this ratio.

Pawlas et al. have reported the synthesis of the melanocortin receptor agonist peptide in green solvent mixtures on a Ramage aminomethylstyrene (RMG-AMS) resin.37 The synthesis required SPPS assembly of the peptide backbone followed by the selective deprotection of a lysine and an aspartic acid followed by on-resin macro-lactamisation. For the SPPS assembly of the peptide backbone a 1 : 1 mixture of NBP and EtOAc was employed, followed by selective sidechain deprotection in a 1 : 1 mixture of MeCN and EtOAc, and final on-resin lactamisation in a 1 : 1 mixture of NBP and EtOAc. The desired peptide was obtained in 62% yield and 95% purity by RP-HPLC. By mixing the relatively expensive green solvent NBP with the cost-efficient solvent EtOAc, they managed to reduce production cost. Head-to-head comparison with the same synthesis in DMF was not disclosed, however, the yield is significantly better than the one reported by Bradley and co-workers (47%),57 using an alternative protecting group strategy for the Lys and Asp residues on a Rink Amide ChemMatrix® resin. In a follow-up report, Pawlas et al. reported an optimized protocol for the synthesis of the Aib-ACP decapeptide on RMG-AMS resin using a mixture of DMSO/EtOAc (1 : 9) as solvent for the coupling and deprotection steps.58 Couplings were carried out with 1.3 equiv. of Fmoc-amino acid and Oxyma Pure, and 3.25 equiv. DIC at 45–50 °C for 30 min (except for the Aib–Aib coupling that was coupled twice with 1 equiv. amino acid/Oxyma Pure/DIC). The peptide was obtained with a purity of 76% and a crude yield of 84% after cleavage and precipitation. Notably, Pawlas et al. discussed cost and supply chain and introduced the concept ReGreen in which EtOAc, DMSO and Oxyma Pure are recycled. To illustrate the benefits of recycling, a comparison of the solvent cost per AA coupling cycle was made for SPPS using either DMF, NBP/EtOAc (1 : 1), DMSO/EtOAc (1 : 9) or DMSO/EtOAc (1 : 9) with recycling steps. The cheapest AA coupling cycle was achieved using DMSO/EtOAc (1 : 9) with recycling (151 € per AA cycle) followed by DMF (297 € per AA cycle), and NBP/EtOAc (1 : 1) (406 € per AA cycle). By contrast, if DMSO/EtOAc (1 : 9) was utilised without recycling, the cost was estimated to 431 € per AA cycle.58 Furthermore, in a recent report Pawlas and co-workers also addressed the occurrence of hydrogen cyanide (HCN) formation during amide bond-forming reactions mediated by DIC and Oxyma.59,60 Binary solvent mixtures of NBP and EtOAc (1 : 1 and 1 : 4) gave significantly lower amounts of HCN and faster amide coupling than observed in DMF or neat NBP, and in addition the authors showed that HCN can be successfully scavenged during the coupling reaction by dimethyl trisulfide (DMTS) with no impact on amide bond formation.60

Recently, Ferrazzano et al. reported the synthesis of the Aib-enkephalin pentapeptide, Aib-ACP decapeptide, and the octreotide octapeptide in solvent mixtures that were found to display good swelling and solubilising properties (vide supra), including Cyrene™/DEC (3 : 7), sulfolane/DEC (3 : 7) and anisole/DMC (7 : 3) (Table 12).41 The synthesis of the Aib-enkephalin peptide in DMF gave very low to medium purity on Wang PS and Rink Amide ChemMatrix® resins respectively (Table 12, entries 1 and 2). In stark contrast, using the sulfolane/DEC (3 : 7) solvent system resulted in much higher purities (entries 3 and 4). Similarly, higher purity compared to DMF was obtained when using Cyrene™/DEC (3 : 7) on Wang PS resin (entry 5) and anisole/DMC (7 : 3) on Rink Amide ChemMatrix® resin (entry 6). Synthesis of the Aib-ACP peptide was only evaluated on Rink Amide ChemMatrix® resin, with DMF giving the best, albeit still low, purity (entries 7–9). Finally, the synthesis of the octreotide peptide was evaluated in DMF and in anisole/DMC (7 : 3) on a 2-chlorotrityl resin (entries 10 and 11). Again, DMF was found to be superior providing good purity (88%). However, by implementing a double coupling of Fmoc-Cys-OH or alternatively performing all couplings at 40 °C, a comparable purity could be obtained in the anisole/DMC (7 : 3) mixture.

SPPS evaluation of three solvent mixtures on Wang PS and Rink Amide ChemMatrix® resin as reported by Ferrazzano et al.41a.

| Entry | Peptide | Solvent | Resin | Purity (%) |

|---|---|---|---|---|

| 1 | Aib-enkephalin | DMF | Wang PS | 13.5 |

| 2 | Aib-enkephalin | DMF | Rink Amide ChemMatrix® | 53.0 |

| 3 | Aib-enkephalin | Sulfolane/DEC (3 : 7) | Wang PS | 72.8, 69.1b |

| 4 | Aib-enkephalin | Sulfolane/DEC (3 : 7) | Rink Amide ChemMatrix® | 62 |

| 5 | Aib-enkephalin | Cyrene™/DEC (3 : 7) | Wang PS | 37.3, 72.0b |

| 6 | Aib-enkephalin | Anisole/DMC (7 : 3) | Rink Amide ChemMatrix® | 72.1 |

| 7 | Aib-ACP | DMF | Rink Amide ChemMatrix® | 37.8 |

| 8 | Aib-ACP | Sulfolane/DEC (3 : 7) | Rink Amide ChemMatrix® | 10.0 |

| 9 | Aib-ACP | Anisole/DMC (7 : 3) | Rink Amide ChemMatrix® | 31.0 |

| 10 | Octreotide | DMF | H-Thr(tBu)-ol-2CT-PS | 88 |

| 11 | Octreotide | Anisole/DMC (7 : 3) | H-Thr(tBu)-ol-2CT-PS | 64.6, 82.3c, 84.9d |

Coupling was performed for 1 h at a 0.2 M concentration using 3 equiv. of Fmoc-protected amino acid, 3 equiv. of DIC and 3 equiv. of Oxyma Pure.

Double coupling 2 × 1 h of the Fmoc-Leu-OH amino acid.

Coupling of Fmoc-Cys-OH at 40 °C.

Coupling for all steps at 40 °C.

3.2.3. Fmoc-removal

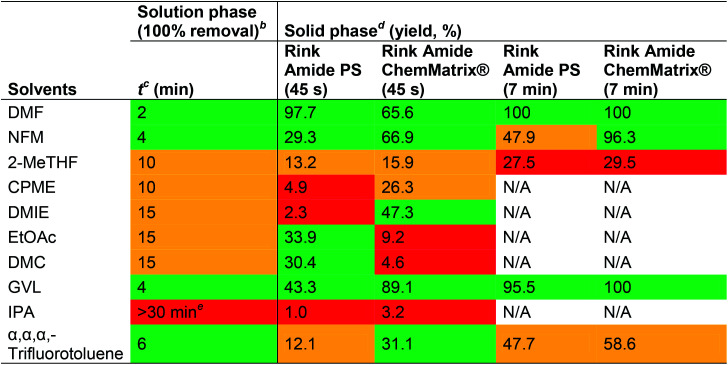

Fmoc-removal is almost exclusively carried out using piperidine in DMF or NMP, typically using a 20% piperidine solution. It has been shown that Fmoc-removal works better in polar DMF than in the less polar solvent CH2Cl2,61 and similar trends may well be observed when switching to a green solvent. In addition to DMF being a problematic solvent, piperidine is toxic on skin contact and inhalation, as well as a controlled substance due to its potential use in the making of illicit drugs.62,63 Thus, the greening of Fmoc-removal could potentially be achieved by substituting DMF and/or piperidine with a greener solvent/base or by reducing the amount of piperidine and DMF used for Fmoc-removal. These options have been addressed by several research groups as outlined below. Albericio and co-workers have reported a study comparing the performance of DMF, IPA, EtOAc and 2-MeTHF for Fmoc-removal in the synthesis of the Aib-enkephalin pentapeptide and the Aib-ACP decapeptide (all couplings were performed in 2-MeTHF, see Table 9, Section 2.2.2).31 For the synthesis of Aib-enkephalin on ChemMatrix® resin, EtOAc and 2-MeTHF gave the best purities (91.9% and 95.0%, respectively, compared to 81.9% in DMF), while for the more challenging peptide Aib-ACP, DMF was superior (70.0% in DMF vs. 30.4% and 37.3% in EtOAc and 2-MeTHF respectively). IPA proved to be inefficient under all conditions and was not studied further (method 3). For 2-MeTHF, heating the deprotection step to 40 °C improved the purity somewhat to 42.8% (method 5). If both the deprotection and coupling steps in 2-MeTHF were performed at 40 °C a significantly higher purity than that obtained in DMF was achieved (87.1% vs. 70.0%), but when the same syntheses were performed on PS resin, none of the solvents were able to compete with DMF. Method 5 (2-MeTHF at 40 °C) was found to be closest with a good purity (88.6%) but still inferior to DMF. The synthesis of the Aib-ACP peptide on PS resin was only reported in 2-MeTHF (method 5) and gave poor results even when both deprotection and coupling reactions were heated to 40 °C (25.4% purity). In a follow-up paper, Albericio and co-workers studied Fmoc-removal in nine green solvents (selection based on the GSK solvent list)21,36 Somewhat surprisingly, NFM was included in this study despite having a melting point of 21 °C, which should be poorly compatible with an experimental set-up at room temperature as described in the study. The Fmoc-removal was monitored on a heptapeptide in solution and on Rink Amide PS and ChemMatrix® resins (Table 13).

Fmoc-removal of a heptapeptide in solution and on solid support using 20% piperidine in different solvents as reported by Jad et al.36a.

|

Colour code for Fmoc-removal performance: green: good; orange: moderate; red: poor.

Fmoc-Phe-OH (0.1 mmol) was dissolved in the solvent to be studied and toluene was added as an internal standard. Piperidine was added, and the reaction was monitored by RP-HPLC.

Time required to achieve complete Fmoc-removal.

The resin was swelled in the solvent to be studied followed by addition of 20% piperidine in the same solvent for 45 s or 7 min. The resin was washed and coupled with Boc-Gly-OH, COMU® and DIPEA in DMF. Fmoc-removal of any remaining Fmoc-protected peptide was performed by treatment with 20% piperidine in DMF, followed by coupling with Boc-Leu-OH, COMU®, and DIPEA in DMF. The yield was calculated by the ratio of H-Gly-Ile-Asp-Tyr-Ile-Asn-Gly-NH2vs. H-Leu-Ile-Asp-Tyr-Ile-Asn-Gly-NH2.

16.6% of starting materials after stirring for 30 min.

First, the Fmoc-removal properties in various solvents were evaluated in solution using Fmoc-Phe-OH as a model system. NFM, GVL and α,α,α-trifluorotoluene gave the most promising results, affording complete Fmoc-removal in 4–6 min, although none of the evaluated solvents could match the deprotection kinetics observed in DMF (2 min). For the SPPS, the peptide Fmoc-Ile-Asp(OtBu)-Tyr(tBu)-Ile-Asn(Trt)-Gly (intermediate of the 65-74ACP peptide) on Rink Amide PS or Rink Amide ChemMatrix® resins was utilised as a model system. The efficacy of Fmoc-removal was evaluated in all solvents using a 45 s deprotection protocol. In general, Fmoc-deprotection was more efficient on the ChemMatrix® resin than on the PS resin (except for EtOAc and DMC). Notably, Fmoc-removal on the ChemMatrix® resin using GVL performed significantly better than in DMF (89.1% vs. 65.6%). Next, the solvents which performed well on both resins were evaluated using a 7 min deprotection protocol (NFM, 2-MeTHF, GVL and α,α,α-trifluorotoluene). GVL was found to cleave 95.5% of the Fmoc-group on the PS resin and 100% on the ChemMatrix® resin, almost on par with DMF (100% on both resins). NFM performed well with the ChemMatrix® resin (96.3%) but was inefficient on the PS resin (47.9%). α,α,α-Trifluorotoluene gave mediocre results on both resins (47.7% and 58.6%) and 2-MeTHF gave poor results on both resins (<30%). Heating of the Fmoc-removal was not evaluated in this study, although the authors had previously demonstrated that this could significantly improve the deprotection kinetics and the purity of the final product.31 Overall, GVL appeared most promising for Fmoc-removal although the solvent has potential drawbacks with ring-opening acylation of N-terminal glycine residues (vide supra).44 Lawrenson et al. used PC for SPPS on a ChemMatrix® resin with success and reported that Fmoc-removal with 20% piperidine in PC was comparable to using 20% piperidine in DMF (vide supra).30 A double 10 + 20 min deprotection protocol was used and afforded purities of 77% (PC) and 79% (DMF).

Zinieris et al. have studied the impact of the piperidine concentration during Fmoc-removal by comparing the rate of Fmoc-removal from Fmoc-Gln-, Fmoc-Val-, Fmoc-Pro- and Fmoc-Lys(Boc)- on a 2-chlorotrityl resin.61 Solutions of 5, 10 and 20% piperidine in DMF were compared by measuring the UV absorbance of the deprotection solution (Table 14).

Fmoc-removal using 5, 10 and 20% piperidine in DMF with half-lives and time needed for 99.99% deprotection for resin-bound Fmoc-Gln, Fmoc-Val, Fmoc-Pro, and Fmoc-Lys(Boc)61a.

| Resin-bound amino acid | 20% piperidine in DMF | 10% piperidine in DMF | 5% piperidine in DMF | |||

|---|---|---|---|---|---|---|

| t 1/2 (s) | Deprotection ≥ 99.99%b (min) | t 1/2 (s) | Deprotection ≥ 99.99%b (min) | t 1/2 (s) | Deprotection ≥ 99.99%b (min) | |

| Fmoc-Gln | 20.5 | 4.5 | 23.2 | 5.1 | 53.1 | 11.8 |

| Fmoc-Val | 41.5 | 9.2 | 44.6 | 9.9 | 47.1 | 10.4 |

| Fmoc-Pro | 25.4 | 5.6 | 27.0 | 5.9 | 32.0 | 7.1 |

| Fmoc-Lys(Boc) | 10.3 | 2.3 | 22.3 | 4.9 | 27.4 | 6.1 |

The deprotection solution was added to the resin and after 10 s was filtered and the UV-absorption of the filtrate was measured. The procedure was repeated until the UV absorption of the filtrate <0.05 AU. The percentage of the Fmoc-removal was expressed as a percentage of the absorption measured when the deprotection solution was added to the same amount of resin sample for 20 min. The time needed for 50% Fmoc-removal corresponds to the half-life of the deprotection step.

Time needed for 99.99% deprotection = −ln 0.0001 t1/2/0.693.

As expected, the required time to reach full deprotection increased with decreasing piperidine concentration. Interestingly, the difference for the sterically hindered Fmoc-Val was small and all deprotections were found to go to completion in <15 min. Zinieries et al. synthesised a sterically hindered 11-mer peptide (H-Ala10-Lys-OH) using deprotection mixtures containing 5, 10 or 20% piperidine in DMF,61 and showed that all three deprotection mixtures were suitable for Fmoc-removal with acceptable deprotection times (the last four alanine residues required longer deprotection times to reach completion). Next, the effect of piperidine concentration on SPPS was evaluated on 2-chlorotrityl resin comparing 5 and 20% piperidine in DMF for the synthesis of the ACP decapeptide and the pentamer Leu-enkephalin. As both peptides were obtained in comparable purities and yields, it appears that a reduction of the piperidine concentration from 20% to 5–10% is feasible for Fmoc-removal without compromising the crude purity. This could potentially have implications for large-scale manufacturing as fewer washes would be required to remove residual piperidine.

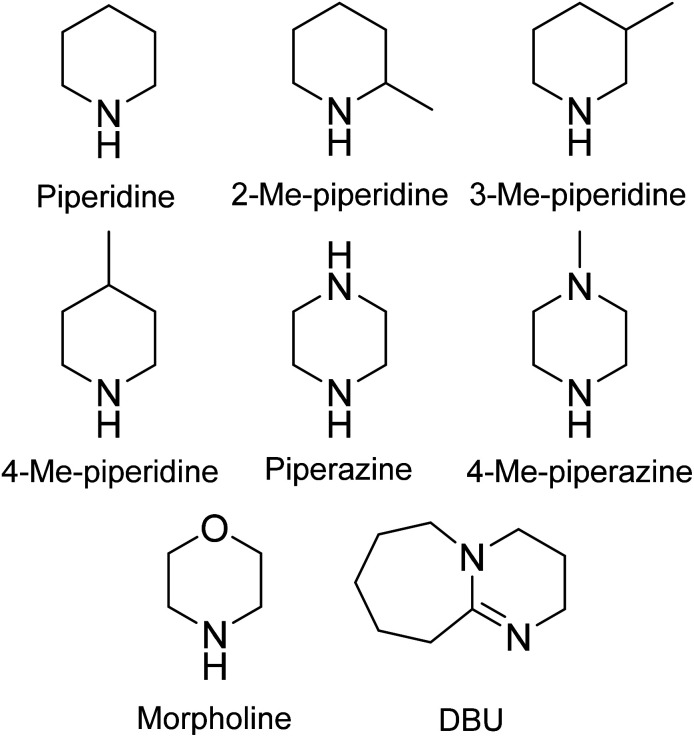

One approach for greening Fmoc-removal could be to identify an alternative base that works well in a green solvent and possibly at low concentrations. Several research groups have studied the substitution of piperidine with for example piperazine, 4-Me-piperidine and morpholine. Although most of these studies were conducted in DMF, they clearly demonstrated that piperidine substitution is feasible (vide infra).64–66 Lopez et al. studied the rate of Fmoc-removal on-resin using 4-Me-piperidine in various solvents (Table 15 and Fig. 3).13 A linear peptide derived from octreotide was treated with a 20% solution of 4-Me-piperidine in the desired solvent and aliquots of resin were removed for analysis after 5, 10 and 30 min. Unlike for the coupling reaction (vide supra), Fmoc-removal was observed to be slow in nonpolar solvents (e.g. anisole, EtOAc, 2-MeTHF, THF and toluene) and fast in polar aprotic solvent (e.g. DMF, DMSO, DMPU, NEP, DMI and NBP), giving full conversion in ≤5 min.

Fmoc-removal with 20% v/v of 4-Me-piperidine in a variety of solvents as reported by Lopez et al.13.

| Solvent/time | Fmoc-removala (% conversion)b | ||

|---|---|---|---|

| 5 min | 10 min | 30 min | |

| Anisole | 18.1 | 30.0 | 55.5 |

| DMF | 100.0 | 100.0 | 100.0 |

| DMI | 99.5 | 100.0 | 100.0 |

| DMPU | 100.0 | 100.0 | 100.0 |

| DMSO | 100.0 | 100.0 | 100.0 |

| EtOAc | 11.8 | 23.0 | 49.7 |

| 2-MeTHF | 11.4 | 21.0 | 58.6 |

| NBP | 100.0 | 100.0 | 100.0 |

| NEP | 100.0 | 100.0 | 100.0 |

| NMP | 100.0 | 100.0 | 100.0 |

| THF | 36.6 | 60.5 | 98.5 |

| TMU | 99.0 | 100.0 | 100.0 |

| Toluene | 16.5 | 25.3 | 50.4 |

Peptide resin aliquots were cleaved from the solid support with a 3% TFA solution in CH2Cl2 and the %-conversion to Fmoc-deprotected peptide was measured by RP-HPLC.

Relative area-% of deprotected peptide measured by RP-HPLC.

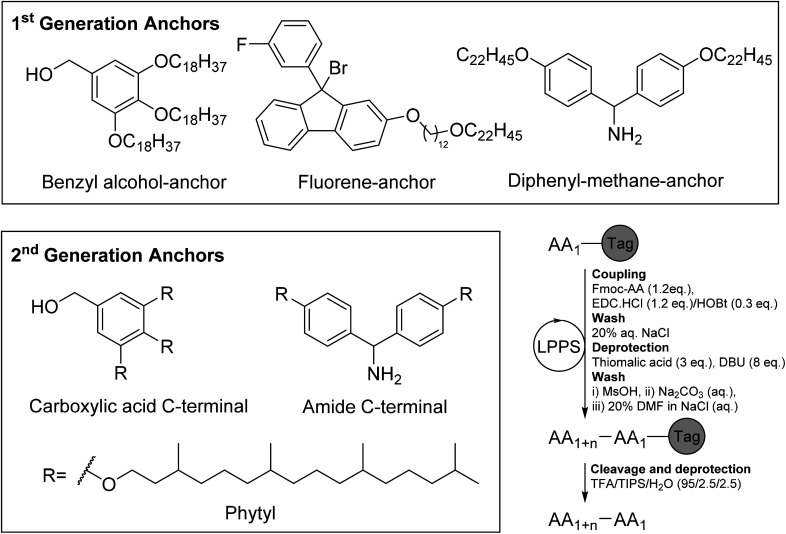

Fig. 3. Chemical structures of organic bases investigated for Fmoc-removal in SPPS.

Lebl and co-workers have studied 2-, 3-, 4-Me-piperidine and 4-Me-piperazine as potential replacements for piperidine.65 The kinetics of the Fmoc-removal of the Fmoc-Ile-chlorotrityl resin were monitored by measuring the UV absorbance of the resulting dibenzofulvene-base adduct. A comparison of 25% piperidine in DMF with 25% 2-, 3-, 4-Me-piperidine and 4-Me-piperazine was conducted and the half-time for Fmoc-removal was determined (Fig. 3 and Table 16). The study showed that both 3- and 4-Me-piperidine were comparable to piperidine. Furthermore, 4-Me-piperidine is in the same price range as piperidine and was further evaluated in the synthesis of four 10-mer peptides: (enkephalin)2, the luteinizing hormone-releasing hormone (LHRH), the ACP peptide (65–74) and the β-amyloid peptide (25–34). Both manual SPPS and a tilted plate centrifugation-based peptide synthesizer (96-wellplate, 24 copies of each sequences synthesised) were employed (Table 17).

Fmoc-removal with alternative bases to piperidine reported by Lebl and co-workers65.

| Base (25% in DMF) | t 1/2 a (min) |

|---|---|

| Piperidine | 2.0 |

| 2-Me-piperidine | 3.0 |

| 3-Me-piperidine | 1.9 |

| 4-Me-piperidine | 2.0 |

| 4-Me-piperazine | 7.8 |

Fmoc-Ile CTC-resin was placed in a glass cuvette and the deprotection mixture was added. The UV absorbance at 301 nm was determined every 2 min.

Comparison of piperidine and 4-Me-piperidine in the synthesis of four 10-mer peptides65.

| Peptide name/sequencea | Purity (RP-HPLC, %) | |

|---|---|---|

| Piperidine | 4-Me-piperidine | |

| (Enkephalin)2 (YGGFLYGGFL) | 92.3 | 92.5 |

| LHRH (EHWSYGWLPG) | 91.7 | 91.2 |

| ACP (65–74) (VQAAIDYING) | 83.6 | 84.0 |

| β-Amyloid (25–34) (GSNKGAIIGL) | 93.6 | 93.5 |

No detailed description of the synthesis was provided by the authors.