Abstract

Fabrication of functional scaffolds for tissue engineering and regenerative medicine applications requires material systems with precise control over cellular performance. 3D printing is a powerful technique to create highly complex and multicomponent structures with well-defined architecture and composition. In this review paper, we explore extrusion-based 3D printing methods (EBP, i.e., Near Field Electrospinning (NFES), Melt Electrowriting (MEW), Fused Deposition Modeling (FDM), and extrusion bioprinting) in terms of their ability to produce scaffolds with bio-instructive properties. These material systems provide spatio-temporal guidance for cells, allowing controlled tissue regeneration and maturation. Multiple physical and biochemical cues introduced to the EBP scaffolds are evaluated in their ability to direct cell alignment, proliferation, differentiation, specific ECM production, and tissue maturation. We indicate that the cues have different impacts depending on the material system, cell type used, or coexistence of multiple cues. Therefore, they must be carefully chosen based on the targeted application. We propose future directions in bio-instructive materials development, including such concepts as metamaterials, hybrid living materials, and 4D printing. The review gathers the knowledge essential for designing new materials with a controlled cellular response, fabrication of advanced engineered tissue, and developing a better understanding of cell biology, especially in response to the biomaterial.

Keywords: Tissue engineering, Additive manufacturing, Melt electrowriting, 3D scaffold, Cell differentiation, Biomaterials

Graphical abstract

Highlights

-

•

Extrusion-based printing allows for the fabrication of bio-instructive scaffolds.

-

•

Physical cues mostly direct cell alignment and spatial distribution.

-

•

Biochemical cues are used to drive cell differentiation in a system-specific way.

-

•

We extensively describe new possibilities in bio-instructive materials printing.

Abbreviations

- adECM

adipose-decellularized extracellular matrix

- ADMSCs

adipose tissue-derived mesenchymal stem cells

- aHSCs

primary fetal activated hepatic stellate cells

- algMC

alginate methylcellulose

- ALP

alkaline phosphatase

- BdECM

bone decellularized extracellular matrix

- BDNF

brain-derived neurotrophic factor

- BG

bioglass

- BMP-2

bone morphogenetic protein-2

- BMSCs

bone marrow stem cells

- CaP

calcium phosphate

- CaSH

calcium sulfate hemihydrate

- CChon

costal chondrocytes

- cdECM

cartilage-decellularized extracellular matrix

- ciPTECs

human conditionally immortalized proximal tubular epithelial cells

- CT

Citroflex

- CMs

neonatal rat cardiomyocytes

- CNF

nanocellulose

- COL1

collagen type I

- ColMA

methacrylate collagen

- CPCs

cardiac progenitor cells

- CS

composite scaffolds

- DAP

decellularized adipose tissue

- DCM

dichloromethane

- dECM

decellularized extracellular matrix

- Dex

dexamethasone

- EBP

extrusion-based 3D printing

- ECM

extracellular matrix

- EPL-

ε-poly-l-lysine

- FDM

Fused Deposition Modeling

- FEM

finite element method

- FGelMA

fish gelatin meth-acrylamide

- GAG

glycosaminoglycan

- g-C₃N4

graphitic carbon nitride nanoparticles

- GEL-

gelatin

- GelMA

gelatin methacrylate

- GO

graphene oxide

- HA

hyaluronic acid

- HaCaTs

human keratinocytes

- hAD-MSCs

human adipose tissue-derived mesenchymal stem cells

- HAp-

hydroxyapatite

- hBMSCs

human bone marrow stem cells

- hdECM

heart-decellularized extracellular matrix

- HDFs

dermal fibroblasts

- HDMECs

human dermal microvascular endothelial cells

- HFIP

1,1,1,3,3,3-hexafluoro-2-propanol

- hMF

human mammary fibroblasts

- hTMSCs

human inferior turbinate-tissue-derived mesenchymal stromal cells

- HUVECs

human umbilical vein endothelial cells

- hUVSMCs

human umbilical cord vein smooth muscle cells

- IGF-1

insulin-like growth factor-1

- iPSC-CM

human-induced pluripotent stem cell-derived cardiomyocytes

- KGN

kartogenin

- L6

rat myoblast cells

- L929

mouse fibroblast cells

- Lx2

human hepatic stellate cell line

- MC3T3-E1

murine calvarial pre-osteoblast cells

- MECM

meniscus extracellular matrix

- MEW

Melt Electrowriting

- mMSCs

mouse mesenchymal stem cells

- MPs

milk proteins

- MSCs

mesenchymal stem cells

- MA

mucic acid

- NFES

Near Field Electrospinning

- nHAp-

nano-hydroxyapatite

- NHDFs

neonatal human dermal fibroblasts

- NHLFb

primary human lung fibroblasts

- nnHAp-

nano-needle hydroxyapatite

- OCT2

transporters organic cation transporter 2

- PANI

polyaniline

- PCL-

polycaprolcatone

- PCSA

peptide-conjugated sodium alginate

- PcycloPrOx

poly(2-cyclopropyl-2-oxazoline)

- PDA

polydopamine

- PCEC

poly (ε-caprolactone)-poly (ethylene glycol)

- PEEK

polyetheretherketone

- PU

poly(ester)urethane

- PGA

poly(glutamic acid)

- pHAp-

plate hydroxyapatite

- PHBH

poly(3-hydroxybutyrate-co-3-hydroxyhexanoate)

- PHB

poly(3-hydroxybutyrate)

- pHCM

primary human cardiomyocytes

- pHMGCL-

poly(hydroxymethylglycolide-co-ε-caprolactone)

- PLA

poly(lactic acid)

- PLCL-

poly (l-lactic acid-ε-caprolactone)

- PLGA

poly(D, l-lactide-co-glycolide)

- PLL-

poly-l-lysine

- PLLA

poly(l-lactic acid)

- PMMA

poly(methyl methacrylate)

- PnPrOx

poly(2-n-propyl-2-oxazoline)

- Pred

prednisolone

- PRP

human platelet-rich plasma

- PVA

poly(vinyl alcohol)

- PVAc

poly(vinyl acetate)

- rBMSCs

rat bone marrow stromal cells

- RCSA

alginate precursor with conjugates of RGD

- rGO

reduced graphene oxide

- rMSCs

rabbit mesenchymal stem cells

- ROS

reactive oxygen species

- SES

solution electrospinning

- SF

silk fibroin

- SMP

silk microparticles

- SMSCs

synovium-derived mesenchymal stem cells

- SN

Syncroflex

- SNF

silk nanofibers

- SrHAp-

strontium substituted hydroxyapatite

- TdECM

tendon-derived decellularized extracellular matrix

- Tg

glass transition temperature

- Tm

melting temperature

- VEGF

vascular endothelial growth factors

- WF

whey protein

- YCSA

alginate precursor with conjugates of YIGDR

- YIGDR

tyrosine-isoleucine-glycine-serine-arginine

- β-TCP

β-tricalcium phosphate

1. Introduction

The main non-cellular component of a native tissue is an extracellular matrix (ECM). ECM is a 3-dimensional water-based network of proteins and proteoglycans, produced and remodeled constantly by the cells [1]. ECM contains structural, biochemical, and biomechanical signaling domains – the cues necessary for cell adhesion, migration, proliferation, and differentiation [2]. Every tissue has a specific hierarchical organization, with a certain combination of the signaling molecules [3], mechanical properties, and embedded cells [4].

As ECM provides a natural environment and support for the cells, tissue engineering approaches aiming to reconstruct native tissues commonly employ material scaffolds. The scaffold should constitute a suitable niche for cells to proliferate, differentiate, and ultimately form the new functional tissue [5,6]. Therefore, the ideal scaffold needs to meet a few key requirements. (I) Scaffold must be non-toxic, biocompatible, and bioactive [7], which means that the supporting cells should maintain their original morphology and function, migrate, and proliferate without eliciting inflammatory responses [8]. Upon implantation, good integration with surrounding tissues should be ensured [9]. (II) It should mimic the native structural arrangement of ECM fibers in a cell- and tissue-specific manner [10], which can be achieved with an appropriate scaffold architecture and surface topography [7]. These factors are responsible for the initial distribution of cells and influence cellular response and further tissue formation. (III) Another critical factor related to the architecture is open porosity. Interconnected pores allow selective permeability and transport of the oxygen, nutrients, waste products, and cell migration within the construct. Optimal pore size allows vascularization of newly formed tissue [11]. (IV) The scaffold should also have sufficient mechanical stability to support the growing cells and mimic mechanical properties of the specific native tissue, such as stiffness or strength [12]; e.g., it is known that softer substrates favor neuron spreading [13]. Additionally, the stability allows good surgical handling during implantation [14]. (V) Moreover, the degradation time needs to be adjusted to the specific application; for example, the degradation between 4 and 6 weeks is required for engineered skin tissue [[14], [15], [16]].

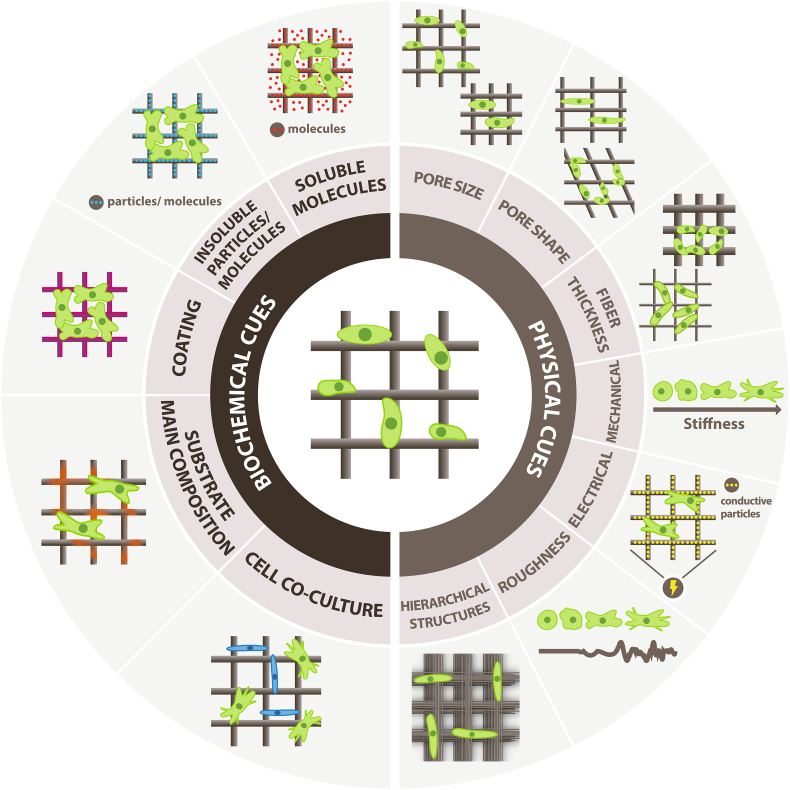

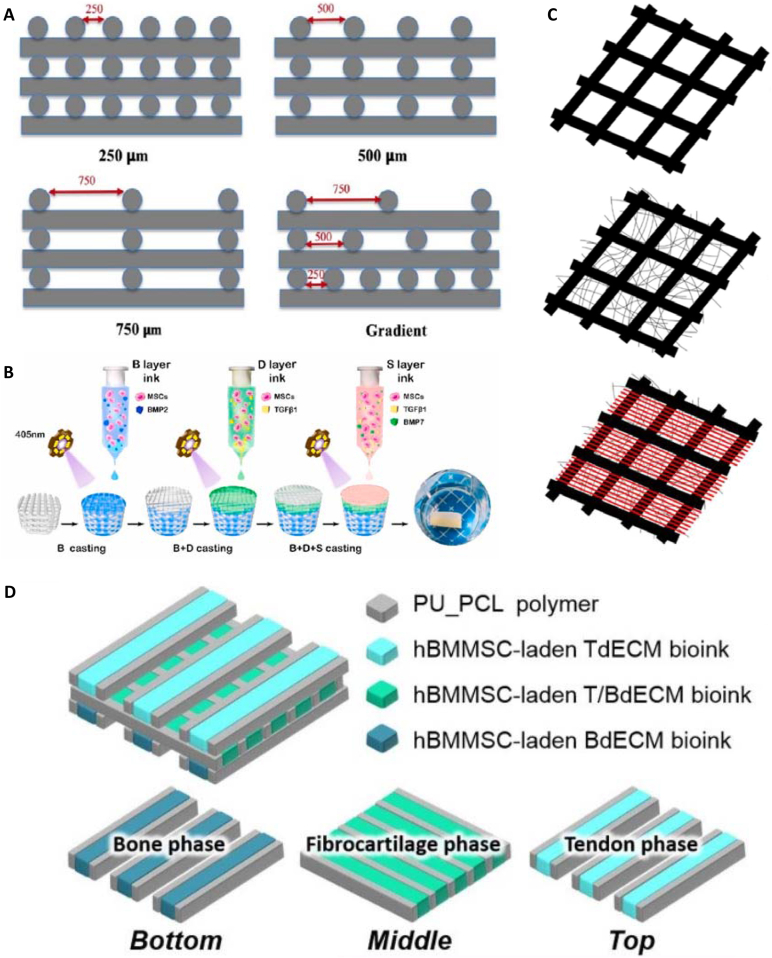

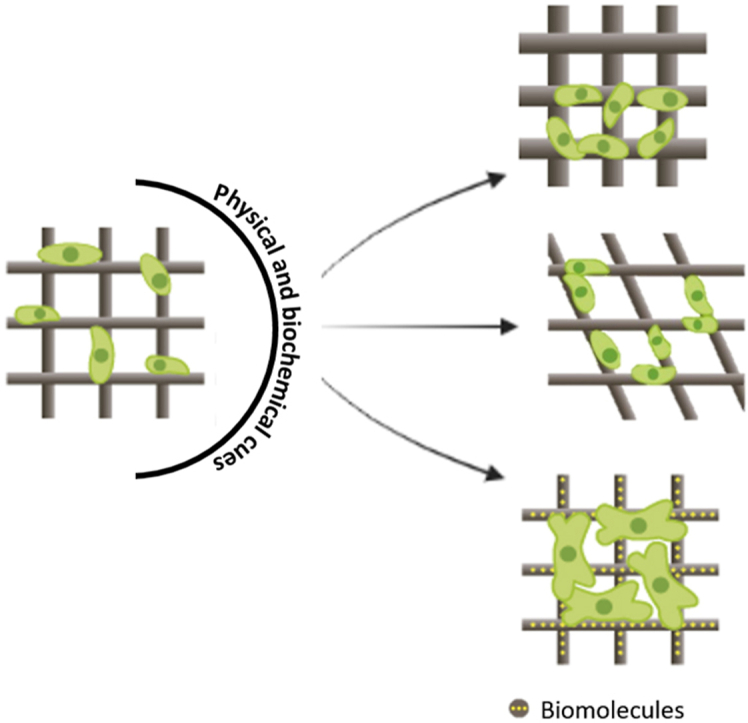

Meeting all of those requirements in one material system does not guarantee the successful formation of the complex and hierarchical structure recapitulating living tissues. Therefore, the concept of bio-instructive materials that can precisely control cell performance by providing specific physical and biochemical cues and direct tissue formation and its proper function gains much interest [9]. Bio-instructive materials provide spatio-temporal guidance for cells in a 3D environment [17] by introducing cell signaling [18] to closely imitate specific mechanical, biological, and compositional properties of native tissues. The cues can be presented inside the scaffold matrix or on the scaffold surface, and they can be divided into physical and biochemical ones (Fig. 1). Physical cues include mechanical, electrical, or topographical stimuli such as roughness or hierarchically ordered structures; biochemical signals include specific drugs, proteins, growth factors, or incorporated insoluble particles [19]. They direct cell behavior by regulating the adhesion, proliferation [20], migration patterns [21], differentiation of stem cells [22]. Both types of cues can be combined in one material system for better performance.

Fig. 1.

Schematic representation of biochemical and physical cues for cells provided by the printed scaffold.

This review describes the strategies for obtaining cell guiding and bio-instructive materials based on the EBP techniques. 3D printing provides unprecedented control over spatial distribution and patterning of different materials, allowing for the independent incorporation of different cues. For example, material stiffness, porosity, and composition can be tuned precisely and independently to match targeted tissues; also, gradients in the signaling can be relatively easily incorporated. Employing EBP for bio-instructive materials is a powerful growing approach, allowing to reach complexity relevant for building close mimics of native tissues. Here, we discuss different physical and biochemical cues, methods of their incorporation via printing, and applications of bio-instructive printed materials. Finally, future research perspectives are presented.

2. Extrusion printing for bio-instructive materials

2.1. Printing techniques

The principle of 3D printing is to precisely deposit the material (ink) to obtain a well-defined 3D structure. Components such as cell-laden solutions, biomaterials, and biological molecules can be deposited with high precision in three dimensions (x, y, and z) [5,23]. This enables building complex, hierarchical, and specific 3D scaffolds containing multiple cues that mimic defined features of the native microstructures of the tissues and organs [24].

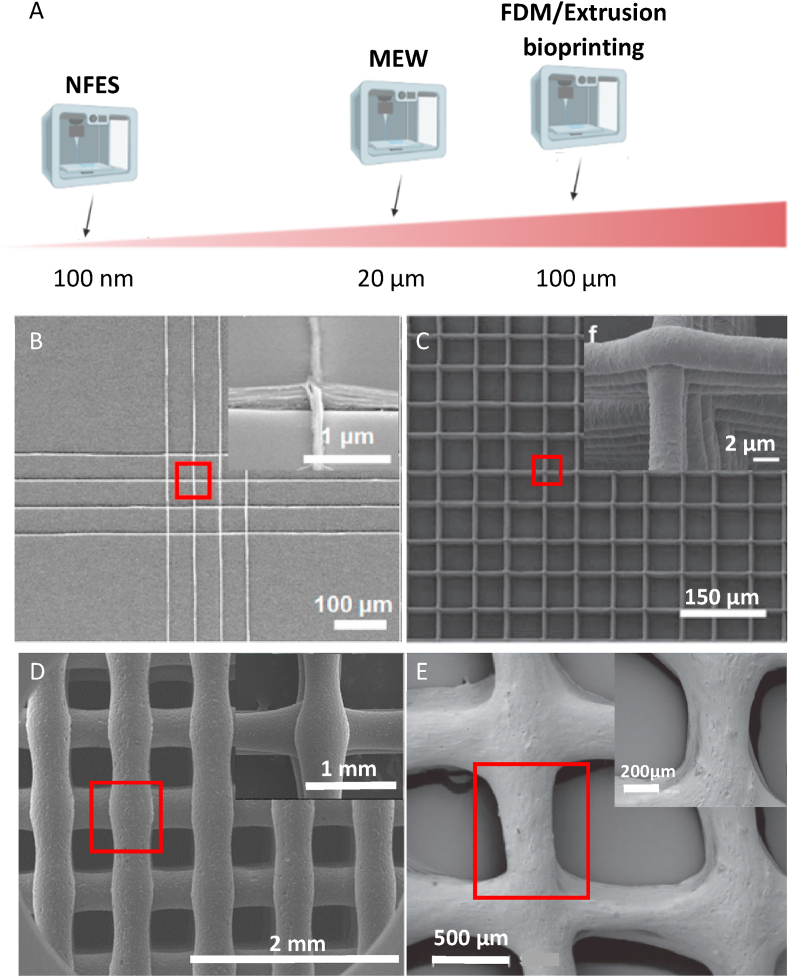

Various 3D printing techniques are used to fabricate scaffolds [25], with EBP approaches being the most broadly explored. EBP gained interest due to the relatively good resolution, a wide range of material choices, the possibility of high cell density printing, and affordability [26]. Moreover, it enables efficient printing of large, medically relevant scaffolds [27,28]. The most commonly used methods that can be classified as EBP are extrusion bioprinting, Fused Deposition Modeling (FDM), Melt Electrowriting (MEW), and Near Field Electrospinning (NFES) (Fig. 2) [29].

Fig. 2.

Resolution of EBP techniques. (A) Schematics showing typical strand sizes obtained with different EBP approaches. Typical scaffold printed with (B) NFES, (C) MEW, (D) FDM, and (E) extrusion bioprinting. (B) Reproduced with permission from Ref. [52], Copyright © 2019 American Chemical Society. (C) Adapted under the terms of the Creative Commons Attribution 3.0 license from Ref. [55], Copyright © 2020 IOP Publishing Ltd. (D) Adapted under the terms of the Creative Commons Attribution License from Ref. [56], Copyright © 2018 MDPI. (E) Adapted with permission from Ref. [57], Copyright © 2017 IOP Publishing Ltd.

This review associates extrusion bioprinting with hydrogel-based materials [30]. The material is placed in a reservoir and deposited on the printing stage with pressure or a mechanically-driven system [31]. For hydrogel printing, usually a crosslinking agent is required; a homogeneity of crosslinker distribution needs to be ensured [30]. The advantage of extrusion bioprinting is the possibility of adding the cells directly to the ink. Such a mixture composed of biomaterial and cells is called bioink [32]. The size of nozzles for printing bioinks is typically in the range of 150 μm – 600 μm to reduce high shear stresses and avoid clogging of the needle and cell death [33]. Hydrogels with different viscosities can be printed (between 30 and 6⋅10⁷ mPa⋅s [34]), and scaffolds in centimeter-scale are easily obtained [35].

While extrusion bioprinting is mainly used for printing hydrogel scaffolds with embedded cells, in the FDM process, the melted thermoplastic material is extruded onto the printing platform [36,37]. The material can be provided in the form of ready filament or pellets (depending of the printer), and is heated above melting temperature (Tm) to enable the flow through the nozzle [38]. To allow quick solidification, materials with a relatively high glass transition temperature (Tg) are required [39,40]. During the printing process, the temperature of the already deposited layer, in contact with the freshly printed layer, increases above the Tg, allowing good bonding between them. The low Tg carries a risk of disturbances in structure and non-uniform strength of the interlayer connections [41]. The FDM printers usually utilize nozzles with 0.1 mm – 1 mm diameter resulting in a maximum strand resolution of around 100 μm. Printing scaffolds in centimeter- [39] or even meter-scale for industrial applications is possible [42].

MEW offers higher resolution printing. This novel biofabrication method combines electrospinning and 3D printing principles, taking advantage of both techniques. With the assistance of the air pressure, the electrical field is used to draw fibers of a molten polymer through a metal nozzle onto a computer-controlled collector plate. By repetitive fiber-by-fiber stacking, highly complex and precise 3D constructs are obtained [43,44]. Typically, fibers printed with the MEW technique are in the range of a couple of micrometers (2 μm – 50 μm) [29,45]. After careful optimization, a fiber diameter below 1 μm can be obtained [46]. The scaffold's quality is dependent on the multiple printing parameters: applied voltage and pressure, collector speed, working distance, and process temperature. MEW allows printing volumetric scaffolds up to ca. 7 mm in height, with more than 300 accurately deposited layers [47].

NFES is the EBP approach with the highest resolution. It requires a higher voltage and shorter distance between nozzle and collector plate than MEW [48] and utilizes polymer melt or solution [49]. In traditional electrospinning, the fibers are randomly deposited on the collector due to the bending instabilities of the jet. In NFES, instabilities are overcome by reducing the spinning distance and applied voltage. It allows the control over electrospun fiber deposition on the moving platform, which results in the fabrication of 3D well-aligned nanofiber scaffolds [49]. NFES gives a sub-100nm resolution and fibers’ thickness below 20 nm using solution-based inks [50,51]; the lowest reported fiber diameter of the melted material was ca. 700 nm [49]. The NFES is a low-cost process with high controllability up to 80 printed layers (height of up to a couple of micrometers) [52]; different patterns can be obtained, such as triangles, diamonds, or hexagons [53]. The downside of producing ultrathin nanofibers is using organic solvents that are often toxic [54].

2.2. Materials

Depending on the processing principles of the specific EBP approach, different biomaterials are used. The hydrogels are associated in this review with extrusion bioprinting. The main advantages of hydrogel-based biomaterials include their biocompatibility, resemblance of hydrated tissue environment, biodegradation, and the possibility of cell encapsulation prior to printing [[58], [59], [60]]. Many natural and synthetic hydrogels, and their combinations, have been used to produce bio-instructive scaffolds [[61], [62], [63], [64]]. Most prominent examples of natural hydrogels are collagen [65], gelatin [66], alginate [67], chitosan [68] or decellularized extracellular matrix (dECM) [[69], [70], [71]]. Synthetic materials for extrusion printing include gelatin methacrylate (GelMA), polyacrylamide, or poly(ethylene glycol) [[71], [72], [73]]. Naturally derived inks are typically nontoxic, and often benefit from the presence of ECM proteins and adhesion domains for cells; however, they are weak by nature, and their properties can be tailored only to a certain extent [70,71]. The mechanical properties of synthetic hydrogels can usually be more flexibly adapted. Yet, those materials lack adhesion sites, thus showing lower cell adhesion and proliferation than natural ones [71]. To improve the properties of hydrogels in terms of biological performance and mechanical stability after printing, chemical modifications can be introduced, or multiple hydrogel types can be mixed [65,67,74,75].

FDM approach utilizes thermoplastic materials, which are often heated up to high temperatures (over physiological range), and melted before or during the deposition process. As a result, cell encapsulation is not possible; however, these materials typically offer better mechanical performance [76]. They are available in two different forms, i.e., either as filaments or pellets. The choice of the material form depends on the type of the printer. Filaments are used in the printers equipped with the filament spool holder and adjusted thermal nozzle, whereas pellets are utilized in the machines with the heated cartridge [76]. The most common materials available in the form of filament include acrylonitrile butadiene styrene, polycaprolactone (PCL), poly(lactic acid) (PLA), polyetheretherketone (PEEK), and polybutylene terephthalate [[77], [78], [79]]. Due to the production process, which requires at least one extra heating step that carries a risk of material's properties change or degradation, the number of inks available as filaments is limited. Moreover, printing with filaments does not allow easy employment of composites combining more than one type of material [80,81]. The use of pellets is more versatile. The typical materials available in pellet form are PCL, PLA, or poly(ester)urethane (PU) [82,83]. The material ink production process is simpler and less expensive. Using pellets facilitates printing of complex compositions, including multilateral inks and the addition of particles or molecules to improve the material printability or the properties of the final scaffolds [84].

Similar to FDM, the MEW approach utilizes thermoplastic polymers, typically with low Tm. The well-printable materials are characterized by the high molecular weight that ensures enough entanglements, relatively high viscosity, and low conductivity to achieve stable and continuous jet formation [44]. The golden standard material for MEW is PCL; however, other polymers were also proposed, including poly(l-lactic acid) (PLLA), poly (ε-caprolactone)-poly (ethylene glycol) (PCEC), poly(propylene), or poly(vinylidene fluoride) [85,86]. A more detailed description of MEW polymers and their requirements can be found in an excellent recent review [44].

Finally, the NFES approach is mostly based on using polymers that are soluble in volatile solvents [87]. With NFES, natural and synthetic polymers can be processed, e.g., alginate, gelatin, PCL, or PLLA [54,[88], [89], [90], [91]]. The use of organic solvents (e.g., acetic acid, poly (ethylene oxide), or 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP) [54,90,92]) restricts cell encapsulation and carries a risk of cytotoxicity. On the other hand, the printer set-ups are simpler as the heating elements are not needed. Moreover, uniform fibers thinner than in MEW printing can be obtained using high conductivity solvents [93,94].

The materials that can be processed using different EBP techniques (hydrogels, thermoplastics, and polymers soluble in volatile solvents) have their specific properties beneficial for successful tissue regeneration. Therefore, various studies employed a combination of those materials, and relevant printing approaches, to achieve synergistic effects. For example, a combination of hydrogel matrix with printed thermoplastic allows for encapsulation of cells in biocompatible hydrogel and the mechanical strengthening of the scaffold by the thermoplastic mesh [44,95].

3. Cues for cells

Using EBP approaches, various cues can be introduced to the scaffolds to direct cellular performance and tissue maturation. We systematically review them in the following chapters.

3.1. Physical cues for cells

Physical cues cover the whole spectrum of the substrate properties, excluding the addition of soluble factors or biochemical reagents [96]. The topography of the scaffold, such as pore size and shape, fiber thickness, fiber alignment, and degree of porosity, can direct cellular response. Scaffold architecture was shown to influence cell attachment, shape, proliferation, or migration patterns [22]; it is crucial for transporting nutrients and gas [97]. Mechanical properties, including substrate stability and stiffness, and electro-conductive properties, are other physical signals that influence cell performance [96]. Physical cues, especially those connected to the scaffold's design, can be relatively easily tuned with EBP methods.

3.1.1. Pore size

One of the most commonly studied cell cues is pore size, tunable with EBP in a technique-dependent range. The smallest pore size reported for NEFS was 10 μm [61]; however, as the size of mammalian cells is at the level of tens of micrometers, the smaller pores would not be effective for cell guidance [54]. With MEW, a pore size of 40 μm [55] and bigger (up to hundreds of microns) can be obtained [[98], [99], [100]]. Typically, the reproducibility limit is reported at the level of 200 μm. The pores smaller than that are challenging to obtain with high reproducibility and accuracy [101] due to residual charges that cause the jet's instabilities, thus affecting the accuracy of fiber deposition [102]. For the FDM and extrusion bioprinting, 100 μm or bigger pores are typically obtained [103,104]. The smaller distance between the strands often leads to strand merging [33]. This section describes the influence of pore size on cellular performance in the scaffolds produced via different methods, starting with the approach allowing the smallest pore sizes.

3.1.1.1. Near Field Electrospinning

Liang et al. [61] studied cell orientation on PCL micro-line arrays obtained via NEFS with interfiber distance ranging from 10 μm to 60 μm. The alignment of the NIH-3T3 cells was diminished with an increase in the fiber spacing [61]. Similar results were reported for NFES alginate fiber patterns, indicating higher alignment of HEK 293T cells while decreasing interfiber distance from 10 μm to 80 μm. For the spaces between fibers smaller than 40 μm, cell orientation was more strongly influenced by the nanofibers orientation, resulting in alignment of the majority of cells in the direction of the fibers in contrast to random cell alignment detected for higher interfiber distances [54]. For poly(γ-methyl l-glutamate) scaffolds, the NIH-3T3 cell coverage after four days increased from 66.42% to 88.38%, when the distance between fibers was increased from 250 μm to 750 μm, respectively, indicating slightly higher cell proliferation for scaffolds with bigger pores [88].

3.1.1.2. Melt Electrowriting

The smallest reported square pores obtained with MEW ranged from 40 μm to 100 μm. They were designed to investigate the M2-like polarization of human macrophages (differentiation toward the M2-type), which is identified by their elongation. M2 macrophages play a role in regulation and wound healing and release anti-inflammatory cytokines. M1 macrophages are usually pro-inflammatory and, if present for an extended time, can cause foreign body response. As this can lead to a failing of scaffold integration, M2 differentiation is preferred. The results have shown that all scaffolds, irrespective of the pore size, promoted the elongation of human macrophages; however, the smallest pores (40 μm square mesh) led to the highest percentage of elongated cells and polarization toward M2 type. Furthermore, in the 40 μm scaffolds, the length of the elongated cells was the highest. For the pore size increase from 40 μm to 100 μm, the number of elongated cells decreased from 50% to 20%, respectively. M2 marker CD163 was upregulated for scaffolds with pore sizes smaller than 60 μm. The authors concluded that scaffolds with the smallest pore size of 40 μm lead to polarization of macrophages toward the M2 type [55].

In another study, Brennan et al. [98] fabricated PCL melt electrowritten scaffolds with 100 μm, 200 μm, and 300 μm square pores, fiber diameter 4.01 μm ± 0,06 μm, to investigate the impact of pore size on human bone marrow stem cells (hBMSCs). Proliferation, morphology, adhesion, osteogenesis, and mechanosignaling were studied. The scaffolds with the smallest pore size showed the greatest seeding efficiency. However, higher proliferation was observed for the bigger pores. The cells were elongated and stretched along the fibers in the scaffolds with 200 μm and 300 μm pore sizes, while cells spread across the pores for the smaller pore size. Moreover, 100 μm scaffolds have shown enhanced deposition of minerals and collagen, indicating the best osteogenic properties of these scaffolds [98]. PCL scaffolds with an interfiber distance of 100 μm, 200 μm, and 400 μm were also fabricated to reinforce a Matrigel matrix. The results showed that smaller pores hindered the proliferation of fibroblasts compared to bigger pores (200 μm and 400 μm) [105]. In contrast, Xie et al. [99] have proved that higher human umbilical vein endothelial cells (HUVECs) proliferation rates were observed on the PCL scaffolds with smaller square pores (100 μm × 100 μm) in comparison to scaffolds with higher pore sizes (100 μm × 200 μm and 200 μm × 200 μm). The cells could fill the smallest pores after one week, while intermediate growth and some bridging were observed in the medium pore sizes. The scaffolds with the biggest pore size revealed the lowest cell growth rate and no filling of the pores. In addition, the study showed that the cells of different sizes displayed different morphologies. In a 200 μm square scaffold, smaller HUVECs (size below 100 μm) grew along the fibers and formed circles around the pores, whereas bigger bone marrow stem cells (BMSCs) (size over 200 μm) tended to bridge the pores [99]. Another study with PCL scaffolds further proved that the time needed for cells (osteoblasts) to bridge pores increases with the pore size. For 200 μm pore size, the cells bridged the pores after 14 days, while for 600 μm, the pores were not completely covered with cells even after 28 days. The authors have detected the linearity between pore size and the time needed for cells to bridge the pores [100].

Nguyen et al. [106] fabricated MEW PCL scaffolds with a pore size of 100 μm, 200 μm, and 300 μm to examine the effect of pore size and fiber sagging on the attachment and growth of fibroblasts (NIH-3T3). While the pore size of scaffolds increases, the MEW fibers start to hang and consequently sag. The 100 μm scaffold showed no sagging, while intermediate and most pronounced sagging were observed for the 200 μm and 300 μm pore scaffolds, respectively. One day after seeding, the 100 μm scaffold showed the highest fibroblast attachment to all scaffold layers. The 300 μm scaffolds had the lowest number of cell attachments. However, increased numbers of attached cells at the intersection of the printed fiber were detected. The fibroblast attachment was observed on sagged fibers only to the freely available top surface. Two weeks after seeding, the 100 μm and 200 μm pores were entirely filled with cells, while the 300 μm pores were filled up to 31.78% [106].

3.1.1.3. Fused Deposition Modeling

Compared to the NFES and MEW methods, FDM offers reproducible pores in higher sizes (100 μm or bigger). Greamre et al. [107] have fabricated PLA scaffolds with square pores varying in size (150 μm, 200 μm, 250 μm) for bone regeneration. After three- and seven-day cell culture, it was observed that hBMSCs were spread over the mesh and began to close the pores. However, the cells could not close any of the pores after seven days. The cells have shown homogenous distribution throughout the scaffold regardless of the pore size [107]. In a similar approach, PEEK scaffolds with square pores (300 μm, 450 μm, and 600 μm) were fabricated for bone substitution. The cell seeding efficiency of hBMSCs was the highest for the 300 μm scaffolds and decreased with increasing pore sizes. Even though scaffolds with 300 μm pore size have the largest surface area favoring cell adhesion, the cell viability on those scaffolds was lower than on the rest of the scaffolds. This may be due to the fact that the larger pores allow for more efficient transport of oxygen and nutrients, which are essential for cell growth. After seven days, the expression of osteogenesis genes was higher on the sample without any pores (control sample). However, after 14 days, the gene expression was higher for porous scaffolds, the most pronounced for 300 μm and 450 μm pore sizes. Moreover, in vivo studies have shown that 450 μm scaffolds had increased blood perfusion 12 weeks after implantation. At 4 and 12 weeks post-implantation, more enhanced bone formation was observed for 450 μm scaffolds than for the 300 μm and 600 μm scaffolds. The authors concluded that the scaffolds with 450 μm pores were most suitable for bone substitution due to good proliferation and osteogenic differentiation. Furthermore, these scaffolds were favorable for bone ingrowth and vascular perfusion [108].

In another study, PLA-epoxy scaffolds with dual porosity were fabricated using gas foaming and 3D printing. The scaffolds were produced with sub-macro (10 μm – 60 μm) and macro-sized (200 μm – 300 μm) pores. The results showed that the proliferation rate of NIH-3T3 cells on the neat PLA scaffolds (only macro-sized pores) was five times lower than on the scaffolds with dual porosity. Moreover, the cell attachment on neat scaffolds was very low compared to those with dual porosity. In conclusion, dual pore scaffolds have a higher surface area needed for cell attachment, affecting cell proliferation [109].

3.1.1.4. Extrusion bioprinting

Using extrusion bioprinting, Sadeghianmaryan et al. [68] have fabricated chitosan scaffolds with pore sizes ranging from 2 to 4 mm for cartilage tissue. The attachment of chondrocytes seeded on the scaffold increased with the decrease in the pore size because of the higher available surface area. Most of the cells after 24 h of culture had characteristic round morphology typical for these cells [68]. In another study, the gelatin-based square-mesh scaffolds with 200 μm, 302 μm, and 382 μm pores were fabricated to determine the relationship between pore size and gene expression of mesenchymal stem cells (MSCs). The data indicate that cells seeded post-printing on the scaffolds with smaller pores (200 μm) formed a quasi-2D layer around the scaffolds preventing infiltration of the scaffolds. In the case of the biggest pores (382 μm), the cells were attached to the strands and did not bridge the pores. The medium pores (302 μm) forced cells to aggregate between parallel strands. Furthermore, MSCs with HUVECs seeding on the 302 μm pore size scaffolds have enhanced angiogenic paracrine activity (secretion and expression of angiogenic factors) and cell spreading [110]. Gelatin scaffolds with a different square-shaped pore size (435 μm–∼800 μm) were also fabricated to examine their effect on the cellular behavior of seeded dermal fibroblasts (HDFs). HDFs in the 3D gelatin scaffolds with pore size bigger than 580 μm proliferate faster than in the scaffold with pore size 435 μm after 14 days of culture [66].

3.1.1.5. Summary

The pore size was mainly used to instigate cell attachment, alignment, and proliferation. The data show that the smaller pores allow for better seeding efficiency while bigger pores provide a higher proliferation rate due to more efficient transport of nutrients and oxygen. Moreover, the cells tend to spread across the small pore sizes (100 μm and less) while the elongated cells along the fibers can be observed for scaffolds with bigger pores. In the scaffolds composed of parallel fibers only, the cells showed clear alignment in the direction of fibers if the distance between parallel fibers was in the cell size range or smaller. If the distance between fibers was bigger, the random cell arrangement was more commonly observed. The most commonly used methods to produce scaffolds with different pore sizes are MEW and FDM. However, it should be noted that MEW allows creating scaffolds with a broader range of pore sizes than FDM due to the resolution limit of the latter one. A summary of the studies employing pore size as a cue is presented in Table 1.

Table 1.

Pore size and its influence on cell behavior.

| Printing method | Tissue | Cell cue | Main material(s) | Cell type(s) | Cell response | Ref. |

|---|---|---|---|---|---|---|

| NFES | Not specific | Micro-line arrays (10 μm–60 μm interfiber distance) | PCL | NIH-3T3 | Higher cell alignment with decreasing interfiber distance. | [61] |

| Increasing interfiber distance (10 μm–80 μm) | Alginate | HEK 293T | Higher cell alignment with decreasing interfiber distance. | [54] | ||

| Increasing interfiber distance (250 μm–750 μm) | PCL | NIH-3T3 | Higher cell proliferation for scaffolds with bigger pores. | [88] | ||

| MEW | Bone | Square pore size (100 μm, 200 μm, 300 μm) | PCL | hBMSCs | Higher cell seeding efficiency, enhanced mineral and collagen deposition for the smallest pores. | [98] |

| Skin | Pore size (100 μm × 100 μm, 100 μm × 200 μm and 200 μm × 200 μm) | PCL | HUVECs | Highest cell proliferation rate on the smallest pore size. | [99] | |

| Not specific | Square pore size (100 μm, 200 μm, 300 μm) | PCL | NIH-3T3 | Improved cell attachment to the smallest pore scaffolds. | [106] | |

| Square pore size (100 μm, 200 μm, 400 μm) | PCL/Matrigel | Fibroblasts | Enhanced proliferation rate for bigger pores (>100 μm). | [105] | ||

| Square pore size (40 μm–100 μm) | PCL | Human macrophages | The decreased number of elongated cells with increasing pore size. | [55] | ||

| Square pore size (200 μm–600 μm) | PCL | Osteoblasts | Increased time for pore bridging with increased pore size. | [100] | ||

| FDM | Bone | Square pore size (150 μm, 200 μm, 250 μm) | PLA | hBMSCs | Homogeneous cell distribution regardless of the pore size. | [107] |

| Square pore size (300 μm, 450 μm, 600 μm) | PEEK | hBMSCs | Higher bone formation in vivo for scaffolds with pore size 450 μm. | [108] | ||

| Not specific | Sub-macro (10 μm–60 μm) and macro-sized (200 μm–300 μm) pores | PLA | NIH-3T3 | Higher proliferation rate on scaffolds with dual porosity. | [109] | |

| Extrusion printing | Cartilage | Square pore size (2 mm–4 mm) | Chitosan | Chondrocytes | Higher cell attachment on smaller pore size scaffolds with round morphology. | [68] |

| Blood vessel | Square pore size (200 μm, 302 μm, and 382 μm) | Methacrylamide-modified gelatin | MSCs and HUVECs | Pore bridging for the smallest pore sizes. The angiogenic activity of HUVECS on bigger pores. | [110] | |

| Not specific | Square pore size (435 μm–∼800 μm) | Gelatin | HDFs | Higher proliferation rate on scaffolds with bigger pore sizes (>435 μm). | [66] |

3.1.2. Pore shape and fiber alignment

Scaffolds with various pore shapes (e.g. triangle, square, hexagon, sinusoidal, diamond) were printed [53,101]. The most commonly used pore shape is a square mesh [88,108]; however, the EBP allows for high flexibility in the designs, including well-organized and random alignment of the fibers. Importantly, in many studies, the design of the pore shape is interwoven with pore sizes.

3.1.2.1. Near Field Electrospinning

With the use of NFES, GelMA was reinforced with a 100 μm square pore size poly (ε-caprolactone)-poly (ethylene glycol) (PECL) scaffold to form a 3D fiber-reinforced hydrogel for cornea treatment. The reinforced GelMA scaffolds inhibit fibroblasts' differentiation of limbal stromal stem cells in serum-containing media, not observed in pure hydrogel scaffolds. Moreover, the results have shown that the cells in reinforced hydrogel scaffolds were elongated along PECL fibers [89]. In another study, Fattahi et al. [111] analyzed the effect of anisotropic properties of electrospun poly(methyl methacrylate) (PMMA) fibers reinforcing collagen gels, with embedded hMSCs, on cellular behavior (cell migration and proliferation). The cells tended to remodel and extend along the direction of the fibers inside the gel. In contrast, cells in the absence of PMMA fibers (embedded in pure hydrogel) have nearly uniform actin cytoskeleton's orientation in all directions [111].

Gill et al. [90] have fabricated gelatin scaffolds with different laydown angles (0°, 30°, 45°, and 90°). The laydown angle is the angle between fibers in consecutive printed layers. Human glioblastoma cells were seeded in the form of aggregates after printing. The results have shown higher initial cell attachment on all designs, except 0° laydown angle, due to the higher surface area formed by the stacked fibers. The cells migrated from the seeded aggregates, and their migration was guided by fiber topography (i.e. the cells were migrating along the fibers) [90].

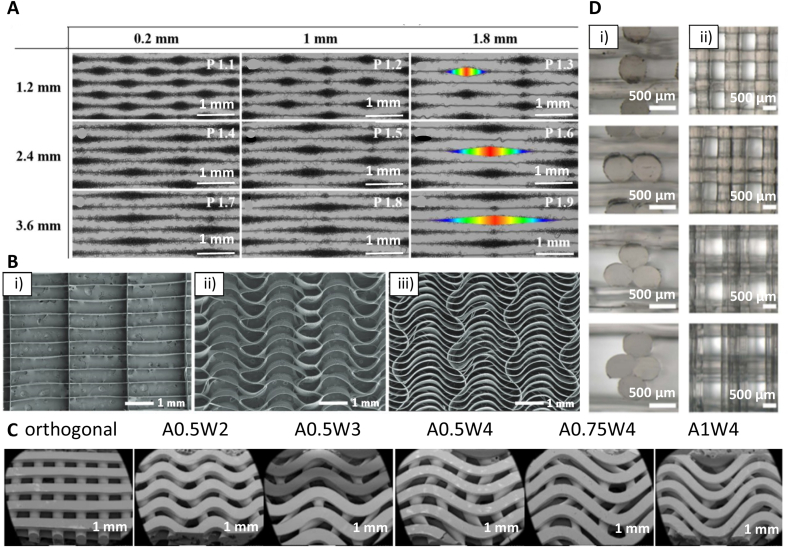

3.1.2.2. Melt Electrowriting

MEW was used by Gwiazda et al. [112] to fabricate PCL scaffolds for bone-ligament-bone regeneration constructs. The authors created scaffolds with aligned, crimped, and random patterns. hMSCs were seeded on the scaffolds post-printing, and the influence of the substrate design was analyzed. It was shown that the cells initially grow along the fibers and at day 1 of cell culture reveal clear directionality, following the arrangement of the fibers. One week after seeding, the topological guidance was still effective in the aligned and crimped scaffolds. However, the directed cell orientation was maintained only in the aligned scaffold after two to three weeks of in vitro expansion. The cell directionality disappeared in the crimped and random scaffolds after the cells reached confluence. It was also shown that the in vitro culturing led to softening of the scaffold/cell construct with crimped and aligned designs, resulting in a significantly reduced slope of the stress-strain curves of these scaffolds. Random designs were unaffected. However, the pore design did not influence cell metabolic activity, neither proliferation rate, nor differentiation toward osteoblast lineage [112]. In another study, hierarchically ordered 3D coil compacted PCL scaffolds have been fabricated with different densities of coils (Fig. 3A). The coil density could be altered by changing the collector plate speed; lower speed led to a higher density. After seven days of cell culture, the printed scaffold showed significantly increased cell proliferation than controls cultured on tissue culture plastic. The scaffolds with more dense coils have a higher surface area and displayed enhanced cell-cell interactions and cell-extracellular matrix interactions compared to less dense designs [113].

Fig. 3.

Examples of different pore shapes and fiber alignments in produced scaffolds. (A) SEM images of coil compacted PCL scaffolds with various interfiber distances and periodic diagonal lengths controlled by changing printing speed. (B) SEM images of PCL MEW scaffolds with 20 layers: i) rectangular pore shape (0.5 mm × 2 mm), and serpentine scaffold with 2 mm radial pore size with ii) 0.5 mm, and iii) 0.25 mm circumferential pore size. (C) SEM images of FDM scaffolds with linear and sinusoidal fiber alignment. A corresponds to interfiber distance, W corresponds to a wavelength of sinusoidal fibers. (D) PLA FDM scaffolds with different fiber cross-sections: circular as control, bilobed, trilobed, quadrilobed (from top to bottom), i) cross-section of printed scaffolds, ii) top view of printed scaffolds. (A) Adapted under the terms of the Creative Commons Attribution 4.0 International License from Ref. [113], Copyright © 2020 Springer Nature. (B) Adapted with permission from Ref. [117], Copyright © 2020 Wiley-VCH. (C) Adapted under the terms of the Creative Commons Attribution License from Ref. [119], Copyright © 2020 MDPI. (D) Adapted with permission from Ref. [123], Copyright © 2021 IOP Publishing Ltd.

Paxton et al. [114] have fabricated PCL tubular aligned (fibers in consecutive layers printed precisely on top of each other, 0.5 mm2 pore size) and non-aligned scaffolds (inconsistent fiber placement in consecutive layers, varying pore size: 0.02 mm2 – 0.33 mm2) with 20°, 50°, and 90° laydowns angles. Murine calvarial pre-osteoblast cells (MC3T3-E1) were seeded on top of the scaffolds. The scaffolds with the lower laydown angles (20° and 50°) showed more uncontrolled cell bridging (cells crossing the scaffolds in different directions) in comparison with the 90° scaffolds, where the cells first have grown on the fibers and then started to close pores. In the non-aligned scaffolds, cells bridge and fill areas with smaller pores and gradually expand to bigger pores. However, after 21 days, predictable and consistent growth and pore bridging have also been observed in the aligned scaffolds. In these scaffolds, the cells followed the direction of the PCL fibers more compared to the non-aligned scaffolds [114]. Tubular PCL scaffolds with different structures (square and rhombus with 200 μm pore size and random) were also fabricated for kidney tissue engineering. Human conditionally immortalized proximal tubular epithelial cells (ciPTECs), and HUVECs were seeded on separate scaffolds. Cell-specific behavior was observed. HUVECs could not bridge the pores, while the ciPTECs were able to form tight monolayers. The rhombus scaffolds enabled unidirectional cell orientation in the scaffold's fibers direction, which is not observed for square and random designs. Furthermore, rhombus scaffolds led to an increased collagen type IV deposition. The proximal tubule in the kidney is important for secretion and, consequently, functional transporters are essential. An increase in the gene expression of the transporters organic cation transporter 2 (OCT2) P-glycoprotein was observed in the rhombus scaffolds. The authors expect that the aligned cytoskeleton caused the increased transporter gene expression in those scaffolds [115].

Tourlomousis et al. [116] used machine learning metrology to investigate cell confinement in MEW scaffolds. The cell morphology of neonatal human dermal fibroblasts (NHDFs) was investigated in PCL scaffolds with varying designs. Scaffolds of 200 μm pore size and laydown angle of either 90o or 45° were prepared. Additionally, scaffolds with randomly oriented fibers were created with solution electrospinning (SES). Different electrospinning times (1 min and 3 min) were applied to produce SES scaffolds with varying fiber coverage of the glass substrate. The results showed that cells cultured on the 1 min SES scaffolds (non-uniform fiber coverage) showed a considerable variance in the cell area, which can be explained by the heterogeneity in the topography of these scaffolds. Furthermore, the NHDFs on these scaffolds developed lamellar shapes and were widespread. The cells on the 3 min SES scaffolds (uniform fiber coverage) had the smallest cell area. The MEW designs showed no statistical difference in the mean cell area. NDHFs seeded on the 90° MEW scaffolds were mainly attached along fibers and at crossing points of fibers while seeded on the 45° MEW scaffolds developed into triangular lamellar shapes [116].

In another study, MEW was utilized to create PCL scaffolds for heart valve tissue engineering. 20-layered serpentine scaffolds (radial pore size of 2 mm and circumferential pore size of 0.25 mm or 0.5 mm) and scaffolds with straight fibers (0.5 mm x 2 mm pore size) were created (Fig. 3B). Cell's pore bridging was observed one week after seeding of human umbilical cord vein smooth muscle cells (hUVSMCs) in the serpentine scaffolds but not in the straight fibers scaffolds. This can be explained by the higher surface area for the cell attachment in the design containing curvy fibers. However, after two weeks, pores in all scaffolds were entirely filled. In the next step, the MEW scaffolds were embedded in a fibrin gel loaded with hUVSMCs. Collagen I and III deposition was observed in the hybrid construct. A fibrin-only control was heavily contracted after one week of culture. In contrast, a hybrid construct maintained shape stability after two weeks of culture due to mechanical support provided by the MEW scaffold. The lack of shrinkage is essential for the sufficient closure of tissue-engineered heart valves [117]. Finally, Castilho et al. [118] fabricated a blend of poly(hydroxymethylglycolide-co-ε-caprolactone) (pHMGCL) with PCL (weight ratio 40:60) scaffolds for cardiac tissue engineering to better mimic the mechanical environment and structural organization of cardiac tissue. An enhanced alignment of cardiac progenitor cells (CPCs) was observed in rectangular pHMGCL/PCL scaffolds, whereas random cell arrangement was observed in square scaffolds [118].

3.1.2.3. Fused Deposition Modeling

Ji et al. [119] fabricated PCL scaffolds for bone tissue engineering with linear and sinusoidal fiber alignment (Fig. 3C) using the FDM technique. The results have shown that seeded hMSCs elongate along with the wavy designs and take the shape of curved strands, while on the linear pattern, the shape of the cells was more rounded. Moreover, scaffolds with the sinusoidal pattern have shown enhanced differentiation into bone cells than those with the linear design. According to the authors, higher osteogenesis for wavy scaffolds was the effect of the curvature, which caused the alignment and stretching of the cells. As a result, the cells developed mature focal adhesions, which promote osteogenesis [119]. PCL was also printed with 60 μm strand diameter into square shape grids. The printed stands had internal micro- (1 μm – 2.4 μm) and nano- (200 nm – 1000 nm) porosity. The authors have used for printing the bubbled viscous PCL/dichloromethane (DCM) solution, inducing additional porosity after printing due to DCM evaporation. The strands without internal porosity (nonporous) have been used as control. Mesenchymal stem cells (MSCs) were seeded post-printing. Quantification of collagen II production at day 28 of cell culture in the chondrogenic differentiation medium without TGF-β1 showed the chondrogenic differentiation enhancement by the porous topography as evidenced by increased chondrogenic markers (sGAG and collagen II production). In osteogenic induction medium with dexamethasone, MSCs on porous scaffolds exhibited improved osteogenic differentiation as indicated by the enhanced enzymatic activity of alkaline phosphatase (ALP) at day 14 and considerably higher production of osteocalcin at day 28 compared to the nonporous scaffolds. These results suggest an inherent effect of architecture and topography for directing stem cell differentiation [120]. In another study, PU scaffolds with a pore size of 500 μm and laydown angles of 90° and 60° have been printed to investigate the differentiation of BMSCs into chondrocytes. The characteristic ECM components for cartilage (GAGs, Col1) were observed for both designs. However, the 60° pattern has shown higher content of GAGs and collagen in comparison to the 90° pattern, indicating that the first one can favor chondrogenic differentiation. Moreover, the cell infiltration of the scaffold was higher on a 60° pattern. The upregulation of chondrogenic markers (Col2, Sox5, Sox6, Sox9) was observed for both types of scaffolds after 14 and 28 days of cell culture. The authors concluded that the 60° pattern scaffolds promote chondrogenic differentiation due to the lower surface area, allowing more cell-cell interactions and reducing the focal adhesion needed for chondrogenesis [121]. Theodoridis et al. [122] have studied the effects of pore geometry of 3D-printed PCL scaffolds on chondrogenic differentiation of adipose tissue-derived mesenchymal stem cells (ADMSCs). Scaffolds with a rectangular layered pattern with an average pore size of 200 μm, a triangular pattern with an average pore size of 210 μm, and a 3D honeycomb-like pattern with a hexagonal and small rectangular shapes with an average pore size of 425 μm have been fabricated. It was observed that a triangular pattern design was the most beneficial for chondrogenic differentiation as indicated by elevated expression levels of chondrogenic markers SOX9 and ACAN. However, after 26 days of culture, cells seeded on 3D honeycomb-like pattern scaffolds revealed higher proliferation, infiltration, and migration throughout the entire construct; those scaffolds were also characterized by seven-fold increased mechanical properties compared to the scaffolds before the cell culture [122].

Interestingly, Mainardi et al. [123] investigated cellular response to the fibers' shape. They used PLA scaffolds (diameter of 8 mm and a height of 4 mm) with four different geometries, three so-called multilobed designs: bilobed, trilobed, quadrilobed, and one circular design as control (Fig. 3D). A scaffold was placed in an oscillating platform to perform the dynamic cell seeding of the MG63 osteoblasts, fibroblasts, and chondrocytes. The medium with the cells was flowing through the scaffolds due to the effect of the bidirectional oscillation of the chamber. The results have shown that seeding efficiency for every type of cell was higher for multilobed scaffolds than circular ones, with 3.61-fold higher efficiency for trilobed scaffolds. The increased cell attachment on trilobed scaffolds was attributed to the asymmetrical shape of the fibers in the flow direction, causing fluid dynamics alteration. Consequently, the path followed by cells was changed compared to the circular scaffolds enhancing the cell seeding by providing more suited sites for cell adhesion. In addition, cells were more likely to spread parallel to the fiber axis in multilobed scaffolds while having a rounded shape for circular scaffolds due to the niches between two parallel fibers, which were not present for the circular scaffolds [123].

3.1.2.4. Extrusion bioprinting

Tijore et al. [62] 3D printed parallel strands from gelatin on gelatin hydrogel film crosslinked with the microbial transglutaminase, with the effecting spacing of ∼250 μm – 300 μm or 800 μm between two adjacent microchannels. hMSCs were seeded on the top of the strands and on a uniform gelatin film as a control. The cardiomyocyte markers β-MHC and cardiac troponin T were highly expressed within the cells seeded on the strands but not on the gelatin film. Moreover, cardiomyocyte beating potential was evaluated with neonatal rat cardiomyocytes (CMs), and remarkable consistent rhythmic beating was revealed for the cells seeded on the strands compared to controls. The authors assigned this effect to a more organized sarcomere structure developed in aligned CMs growing on the microchannels [62].

3.1.2.5. Summary

The results imply that the pore shape can significantly influence cell behavior. Especially MEW, which allows depositing fibers in the dimensions close to the single-cell size, emerged recently as a powerful approach to steer cellular response via the pore shape. Yet, obtaining volumetric scaffolds with this approach is still a challenge, and for more extensive constructs, the use of FDM or extrusion printing is more feasible. A summary of the studies employing pore shape as a cue is presented in Table 2.

Table 2.

Pore shape and its influence on cell behavior.

| Printing method | Tissue | Cell cue | Main material(s) | Cell type(s) | Cell response | Ref. |

|---|---|---|---|---|---|---|

| NFES | Cornea | Fiber guidance | PECL, GelMA | Limbal stromal stem cells | Restricted fibroblasts' differentiation on reinforced hydrogel scaffolds, cells elongated along the fibers. | [89] |

| Not specific | Fiber guidance | PMMA/collagen | hMSCs | Cells elongated along the fibers reinforcing hydrogel. | [111] | |

| Various laydown angles (0°, 30°, 45°, and 90°) | Gelatin | Human glioblastoma cells | Enhanced migration and proliferation on higher laydown angles. | [90] | ||

| MEW | Bone | Aligned, crimped, and random patterns | PCL | hMSCs | Maintained cell orientation on aligned scaffolds after 21 days of cell culture. | [112] |

| Fiber alignment (compacted coils) | PCL | hMSCs | Increased cell proliferation and cell-cell interactions on more dense coils. | [113] | ||

| Various laydown angles (20°, 50°, and 90°) | PCL | MC3T3-E1 | Enhanced directionality of cells along the PCL fibers for higher laydown angle. | [114] | ||

| Cardiac | Radial, circumferential and rectangular pore shape | PCL | hUVSMCs | Faster pore bridging for the radial pattern. | [117] | |

| Rectangular and square pore shape | pHMGCL/PCL | CPCs | Enhanced alignment of cells for rectangular scaffolds. | [118] | ||

| Kidney | Tubular scaffolds (square, rhombus, and random pore shape) | PCL | ciPTECs, HUVECs | Unidirectional cell alignment for rhombus pores with increased gene expressions. | [115] | |

| Not specific | Various laydown angles (45° and 90°) | PCL | NHDFs | Elongation along the fibers for higher laydown angle while the lamellar shape of cells on the smaller laydown angle. | [116] | |

| FDM | Bone | Linear and sinusoidal fiber alignment | PCL | hMSCs | Enhanced osteogenic differentiation on sinusoidal scaffolds. | [119] |

| Micro (1 μm–2.4 μm) and nano (200 nm–1000 nm) porosity of the deposited strands | PCL | MSCs | Improved osteogenic and chondrogenic differentiation in osteogenic and chondrogenic induction medium, respectively, for scaffolds composed of fibers with micro- and nanoporosity. | [120] | ||

| Cartilage | Various laydown angles (60° and 90°) | PU | BMSCs | Enhanced chondrogenesis on rhombus scaffolds. | [121] | |

| Rectangular, triangular, honeycomb pore shapes | PCL | ADMSCs | Enhanced chondrogenic differentiation on triangular scaffolds. | [122] | ||

| Not specific | Different geometry of fiber cross-section | PLA | MG63, fibroblasts, chondrocytes | Higher seeding density for multilobed scaffolds. | [123] | |

| Extrusion printing | Cardiac | Microchannels with different interfiber distances | Gelatin | hMSCs, CMs | Upregulated cardiomyocytes marker levels, cardiomyocytes rhythmic beating with CMs regardless of interfiber distance. | [62] |

3.1.3. Fiber thickness

Fiber thickness can be typically easily tuned by changing the printing parameters (e.g. pressure, voltage, nozzle, printing speed, depending on the specific technique) or printing approach. The smallest fiber diameter on the nano-level can be obtained using NFES, while MEW allows printing the fibers in the range of a few micrometers [48,49]. The thickest fibers can be obtained using FDM or extrusion bioprinting (in the range of hundreds of μm) [124].

An interesting study to analyze the influence of the fiber size on cell performance was proposed by Xie et al. [99]. The authors used MEW to print PCL scaffolds with varying fiber diameters (3 μm – 22 μm) and analyzed the behavior of two cell types with different sizes, namely BMSCs (typically cells with 200 μm in length) and HUVECs (less than 100 μm in length). The BMSCs adhered to thick fibers (printed at 500 mm/min), whereas they wrapped around thin fibers (printed at 2000 mm/min). In the scaffolds consisting of only thick fibers, BMSCs filled the pores by growing around them and systematically closing the space from the edges to the center. If a pore consisted of thick fiber in one direction and thin fibers in the other, the BMSCs exhibited oriented growth, bridging the pore from thin fiber to opposite thin fiber. The cells on scaffolds consisting of thin fibers only showed random growth, with cells bridging opposite or neighboring fibers. HUVECs were not affected by the fiber thickness and revealed only circular growth around the pores. This effect was assigned to the fact that HUVECs are smaller than BMSCs and do not have enough length to bridge the pores of the printed samples, and could only adhere and grow on single fibers [99].

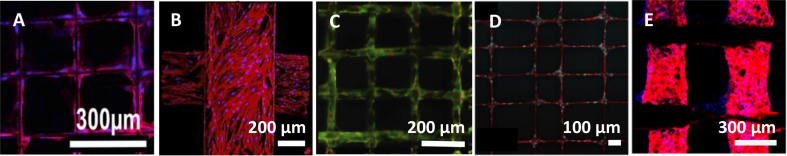

PCL square mesh (200 μm × 200 μm) scaffolds with a fiber diameter of around 20 μm and 530 μm were printed using MEW [112] and FDM [119], respectively. The hMSCs seeded on MEW scaffolds grew around the MEW fibers and started closing the pores after one week of cell culture (Fig. 4A). On the contrary, cells on FDM scaffolds have only grown along the fibers, and after one week of culturing, they coved the whole surface of fibers but did not fill in the pores (Fig. 4B) [112,119]. Also, the performance of MC3T3-E1 cells on fibers with different diameters can be observed when comparing scaffolds prepared with NFES [111], MEW [100], and FDM [125] (Fig. 4C–E). After two days of culture, the cells on the 2 μm diameter fibers obtained via NFES, were well attached and followed the fiber orientation. The cells did not grow between the fibers due to the pore sizes exceeding 100 μm. If the interfiber distance was lower than 100 μm, the cells grew between fibers [111]. For MEW PCL scaffolds with fiber diameters of around 50 μm low attachment of cells was noticed during the initial seeding time; however, after four days, the cells started proliferating on fibers and slowly closing pores for scaffolds with a pore size of 200 μm. The results indicate that pores' closing begins at the place with high curvature (corners of pores) and surface area [100]. The biggest fiber diameter (275 μm ± 28 μm) was measured for PCL scaffolds with a pore size of 746 μm ± 71 μm, fabricated using FDM. After one day, only a few cells were attached to the surface of fibers, but the number grew over time, and after seven days, the whole surface of fibers was covered with cells. The data suggest that the cells spread along the thick fibers rather than (or before) bridging the pores, possibly due to the high surface area provided by the fibers [125].

Fig. 4.

Cell cultured on the PCL scaffolds with different fiber diameters. hMSCs cells one week after seeding on: (A) MEW scaffold, (B) FDM scaffold. MC3T3-E1 cells seeded on: (C) MEW scaffold after four days, (D) NFES scaffold after two days, (E) FDM scaffold after one week. (A) Adapted with permission from Ref. [112], Copyright © 2020 Elsevier. (B) Adapted under the terms of the Creative Commons Attribution License from Ref. [119], Copyright © 2020 MDPI. (C) Adapted with permission from Ref. [100], Copyright © 2020 Elsevier. (D) Adapted with permission from Ref. [111], Copyright © 2017 Wiley-VCH. (E) Adapted with permission from Ref. [125], Copyright © 2014 American Chemical Society.

3.1.3.1. Summary

MEW approach is the most flexible in adjusting fiber thickness, as a broad range of fiber sizes can be obtained without changes in the hardware (the same nozzle can be used) solely via tuning printing parameters. In turn, extrusion printing of hydrogels is the most challenging in optimizing fiber diameter, as it typically requires taking into account multiple rheological characteristics (such as crosslinking kinetics, relaxation time, viscosity). There are also studies introducing gradient scaffolds with different fiber thicknesses in one design, where the nanometer fiber mats were employed as a catching layer which enhanced the seeding efficiency [126]. A summary of the studies employing fiber thickness as a cue is presented in Table 3.

Table 3.

Fiber thickness and its influence on cell behavior.

| Printing method | Tissue | Cell cue | Main material(s) | Cell type(s) | Cell response | Ref. |

|---|---|---|---|---|---|---|

| NFES | Not specific | Fiber thickness (∼ 2 μm) | PCL | MC3T3-E1 | The fibers entirely covered by cells on day two of cell culture. | [111] |

| MEW | Bone | Fiber thickness (20 μm) | PCL | hMSCs | Cell spreading on fibers and after two weeks of culture bridging the pores. | [112] |

| Not specific | Fiber thickness (3 μm–22 μm) | PCL | BMSCs, HUVECs | Adhesion of BMSCs to thick fibers and wrapping around thin fibers. Circular growth of HUVECs regardless of the fiber thickness. | [99] | |

| Fiber thickness (∼ 50 μm) | PCL | MC3T3-E1 | Completely closed pores after two weeks of cell culture. | [100] | ||

| FDM | Bone | Fiber thickness (20 μm) | PCL | hMSCs | Spreading of cells in the direction of fibers. | [119] |

| Fiber thickness (∼ 275 μm) | PCL | MC3T3-E1 | Completely covered scaffolds by cells after one-week culture. | [125] |

3.1.4. Mechanical cues

Cells can sense and respond to physical forces and the stiffness of the substrate through focal adhesions. By tuning the local mechanical properties of the scaffold, a particular cellular response can be evoked [127]. Scaffold stiffness can influence cell size, shape, alignment and guide stem cells' differentiation into particular lineages [128]. A static or dynamic force applied to the scaffold can influence cell morphology, spreading, proliferation, or differentiation [129].

3.1.4.1. Melt Electrowriting

MEW was used to produce PCL scaffolds with a hexagonal structure for human myocardial tissue engineering. The human-induced pluripotent stem cell-derived cardiomyocytes (iPSC-CM) were encapsulated in a collagen-based hydrogel and seeded on the printed scaffold. The pure PCL, 500 μm × 1000 μm rectangular scaffold, was used as a control. After seven days of culture, the cells covered both scaffold types and started to contract simultaneously across the whole scaffolds. However, the beating rate was higher for hexagonal scaffolds than rectangular ones. The authors assigned this effect to the fact that the hexagonal scaffolds had a higher elastic region (≈20–40 times) compared to the rectangular scaffolds. Moreover, hexagonal scaffolds have shown increased expression of maturation-related cardiac markers after 14 days of cell culture, which was not observed for rectangular scaffolds. The results indicate that the mechanical properties of the scaffolds influence cell contractions and cell maturation [43].

In another study, Castilho et al. [130] produced bi-layer scaffolds, composed of PCL mesh produced with MEW and GelMA casting, to mimic articular cartilage and examine the chondrogenesis under dynamic compression of scaffolds. The superficial tangential zone consisted of a densely distributed crossed fiber mat. A uniform box structure was employed in the middle and deep zones. The constructs were tested in cell culture without and with mechanical stimulation (a dynamic load ranging from 0 to ∼15%/20% amplitude strain, applied in a sinusoidal waveform with a frequency of 1 Hz). Production of glycosaminoglycan (GAG) and collagen II was observed. GAGs were deposited homogeneously in the whole scaffold, whereas collagen II was mostly found around cells. The results showed that the gradient constructs enhance cartilage formation when mechanically stimulated [130].

3.1.4.2. Fused Deposition Modeling

In another study, Chae et al. [83] produced PU/PCL hybrid scaffolds with encapsulated hBMSCs for tendon replacement. The square scaffolds were subjected to static tension by fixing the scaffolds in clamps and applying constant tension. The uniaxial alignment of cells (along the longitudinal axis) under static tension was observed while cells on the scaffolds without tension were randomly aligned. This effect was desirable since the cells in the native tendon are arranged along the collagen fibers [83].

3.1.4.3. Extrusion bioprinting

The stiffness of the hydrogel-based printed materials can be relatively easily tuned by changing e.g. crosslinking density, crosslinking chemistry, or bioink composition. The influence of scaffold stiffness on osteogenic differentiation and bone-like tissue formation was investigated using the bioprinting technique by Zhang et al. [67]. Two concentrations of alginate (0.8% w/v or 1.8% w/v) and gelatin (4.1% w/v) were mixed to fabricate soft and stiff scaffolds, respectively, with hMSCs encapsulated. The results demonstrated higher cell proliferation, enhanced ALP, and increased osteogenic differentiation in softer scaffolds than in stiffer ones. On day 42, significantly higher mineralization was observed in softer scaffolds. Immunohistochemistry staining revealed more osteocalcin protein expression in high mineral than low mineral regions [67]. The same authors in another study investigated the effect of alginate concentration on alginate/gelatin composite scaffold mechanical stiffness and the impact of the stiffness on MSCs' cell viability and morphology. With increasing content of alginate from 0.8% to 2.3%, the scaffold stiffness increased from 1.5 kPa to 14.2 kPa, respectively. After 14 days of cell culture, the cells formed a 3D interconnected network and exhibited a more spread morphology in the softer constructs. The reason was the lower diffusion rate of nutritions to the cells in stiffer constructs. The study proved that the alginate and gelatin composite scaffolds with lower stiffness (1.5 kPa) showed better cell spreading and migration [131]. In a similar study, the authors bioprinted scaffolds with stiffness variances using 2%, 5%, and 10% alginate solutions containing encapsulated mouse fibroblast cells (L929). The cell morphology, proliferation, and migration were investigated. On day 14 of cell culture, cell migration and proliferation throughout 2% and 5% alginate scaffolds were observed. However, in 5% alginate scaffolds cell aggregation was also detected. Cells formed spheroids in 10% alginate scaffolds due to the high network stiffness restricting cell mobility [132].

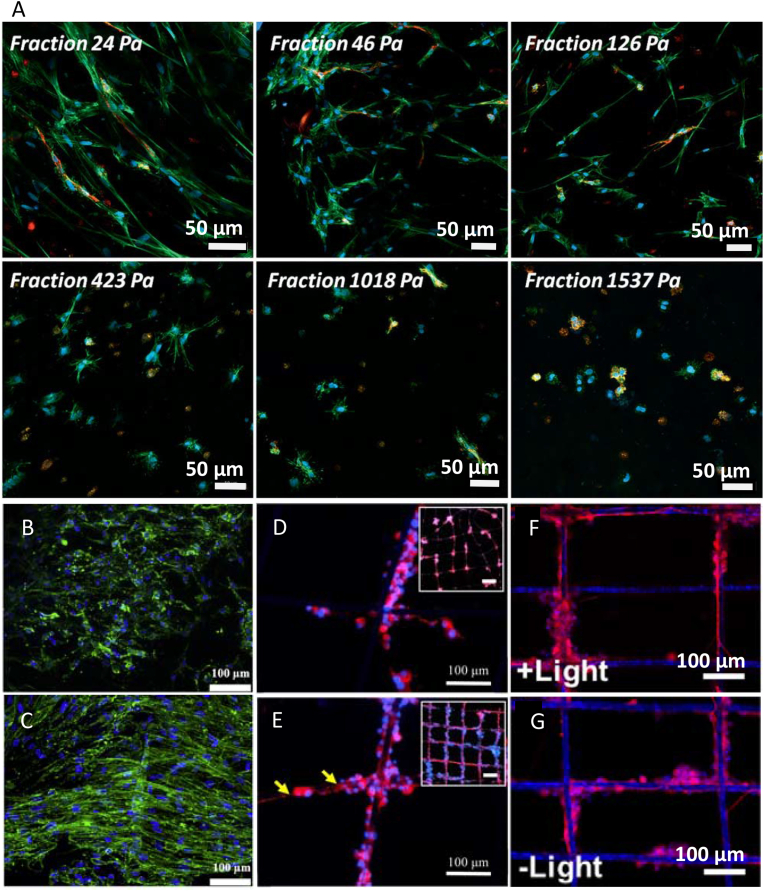

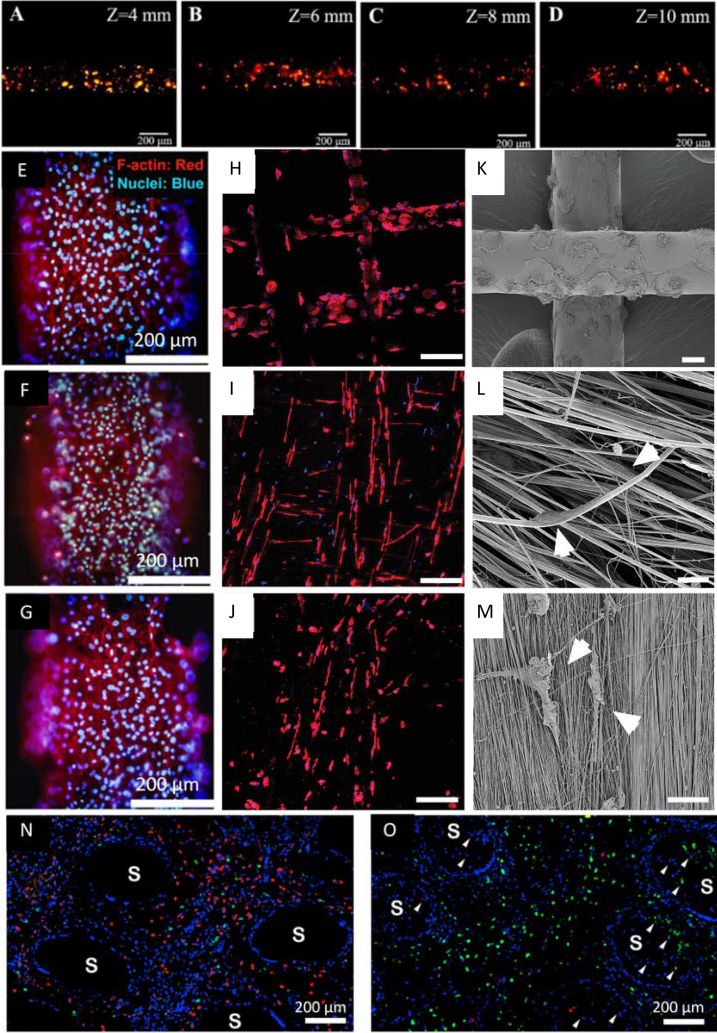

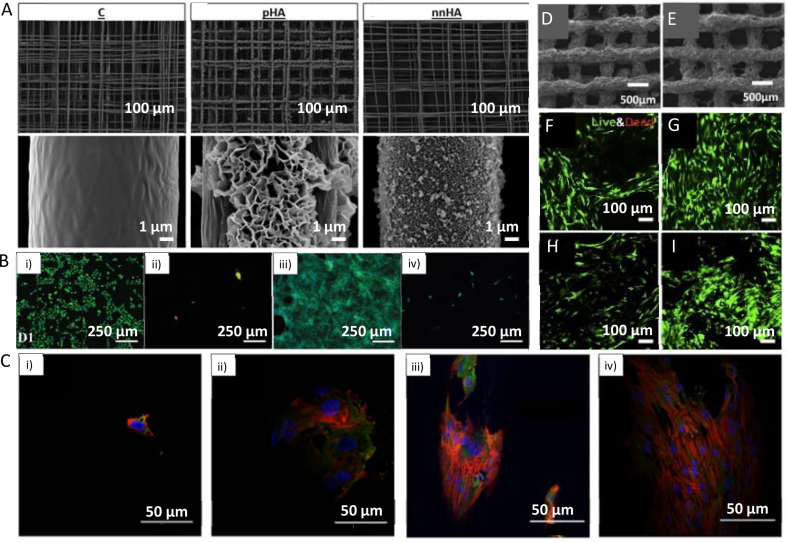

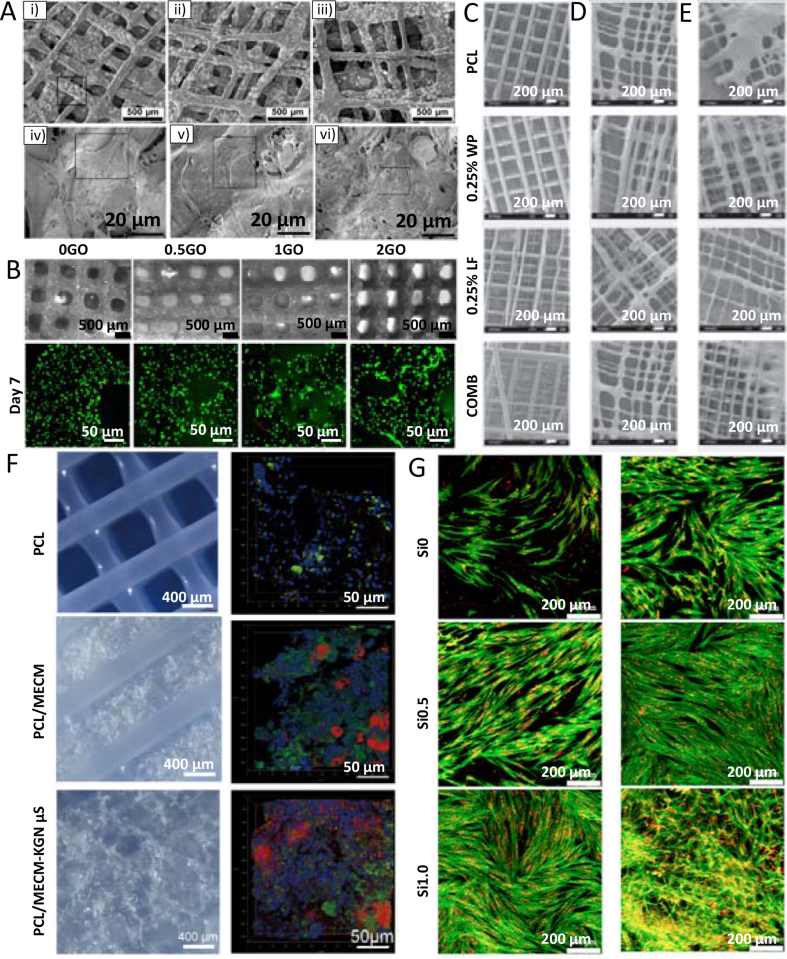

Lavrentieva et al. [133] fabricated scaffolds with stiffness gradient using photoactive hydrogel GelMA. Encapsulated human adipose tissue-derived mesenchymal stem cells (hAD-MSCs) and HUVECs were co-cultured for seven days. The gradient in stiffness in the printed material was obtained by mixing while printing two compounds, namely, GelMA with higher and GelMA with lower methacrylation degree. A microfluidic device was used for homogenous mixing of the compounds. Six gradient fractions were obtained in the final scaffolds, with a mechanical stiffness ranging from 23.7 Pa to 1537 Pa. After seven days of culture, actin staining confirmed decreased cellular spreading inside the material with increasing stiffness and no spreading for highest stiffness. The differences in the behavior of hAD-MSCs and HUVECs in the gradient fractions were noticed (Fig. 5A). HUVECs did not spread in fraction 125.6 Pa and higher. In contrast, some spreading of hAD-MSCs was observed even for the 423 Pa fraction [133].

Fig. 5.

Confocal microscopy of the cells before and after the application of mechanical or electrical cues. (A) hAD-MSCs and HUVECs (green - actin filaments, red - CD31, blue - nuclei) encapsulated in GelMA gradient fractions (with different stiffness indicated on the images) after one week of cell culture. hSCs-laden FGelMA hydrogel (green - actin filaments, blue - nuclei) cultured under (B) static and (C) dynamic conditions. PC12 cells (red - tubulin, blue - nuclei) cultured on PCL fibers with 80 μm thick gold coating (D) without and (E) with electrical stimulation treatment after five days. Yellow arrows indicate neurite length. PC12 cells (red - tubulin, blue - nuclei) cultured on PCL/GO/g-C3N4 scaffold (F) with and (G) without light stimulation after one week. (A) Reproduced under the terms of the Creative Commons Attribution 4.0 International License from Ref. [133], Copyright © 2020 Wiley-VCH. (B, C) Reproduced under the terms of the Creative Commons Attribution NonCommercial License 4.0 from Ref. [134], Copyright © 2020 Elsevier. (D, E) Reproduced with permission from Ref. [141], Copyright © 2020 Elsevier. (F, G) Reproduced with permission from Ref. [91], Copyright © 2020 Elsevier.

Das et al. [69] utilized the 3D bioprinting technique to fabricate an engineered heart tissue. As the bioink, the authors used porcine heart-derived ECM or collagen with homogenously distributed cardiomyocytes. Scaffolds were prepared and cultured in static and dynamic (kept on an orbital shaker) conditions for 14 days. Samples cultured in the dynamic conditions revealed a unidirectional, rod-shaped, and extended alignment of embedded cardiomyocytes with a defined sarcomeric pattern. Moreover, they have shown abundant expression of cardiac-specific proteins and genes encoding the proteins responsible for cell-cell and cell-matrix interaction, such as anti-cardiac troponin T and anti-α-sarcomeric actinin antibody. The formation of basement proteins (laminins and integrins) and matrix remodeling events were higher in dynamic than static conditions. No apparent aligned sarcomeres and rounded morphologic cardiomyocytes were observed later. These results suggested that fluid shear stress can provide dynamic stimuli which enhance cardiomyocytes’ maturation due to the cell-to-cell contact and cell-matrix interaction [69].

In another study, the auxetic scaffolds with primary human Schwann cell-laden Fish gelatin meth-acrylamide (FGelMA) were printed for application in neural tissue engineering. To obtain an auxetic scaffold with the grid design, they used pluronic F127 as sacrificial polymer and GelMA to provide a frame for clamping. The effect of mechanotransduction on neural differentiation was investigated by applying to the sample tensile forces with the help of a tensile bioreactor (20% tensile strain, 0.48 Hz frequency). The scaffolds that underwent stimulation revealed enhanced cellular proliferation and differentiation; cells showed spindled-like extended neurite growth compared to static cultures (Fig. 5B and C). Application of the tensile forces together with other cues, such as growth factors, further enhanced neural differentiation [134].

Shear stress applied while printing was also shown to influence cell orientation in printed construct and stimulate regeneration of muscle tissue. Distler et al. [135] printed oxidized alginate/gelatin hydrogel with encapsulated C2C12 muscle cells using different printing nozzles (d = 250 μm – 330 μm) and pressures (30 kPa – 60 kPa). The high shear forces evoked cell orientation along the printed direction. The authors investigated the differentiation of C2C12 cells, cultured with horse serum enhancement, into myotubes and recognized the myofilament and sarcomere formation. The results indicated that the aligned growth of C2C12 cells is a significant contributor in achieving ordered and synchronized contractile muscle tissues [135]. Similarly, another group evaluated the effect of shear stress on printed grid-shaped strands with C2C12 encapsulated cells in GelMA and methacrylate collagen (ColMA) hydrogels. The cells were cultured for five days in bioinks before printing to induce cell elongation as elongated cells are more sensitive to the shear stress than the round-shaped cells. The cells in the printed construct revealed an oriented structure, and after 28 days of culture, a significant increase in myotube formation in the printing direction was observed. Furthermore, myogenic gene expression such as MyoD1, myogenin, myosin heavy chain was higher than those in non-precultured myoblasts-laden GelMA bioink [72].

3.1.4.4. Summary

The changes in bioink stiffness influence cell morphology and differentiation. MSCs showed more spreading and migration on scaffolds with lower stiffness, an increase in scaffold stiffness decreased cell mobility in the scaffold. It was also demonstrated that MSCs cells differentiate into osteoblasts on more stiff scaffolds, while improved spreading of HUVECs was observed for softer scaffolds. The elastic properties of the scaffolds can also influence the behavior of cardiomyocytes which had higher contractions and maturation on more elastic scaffolds. The applied tension on scaffolds enhanced Schwann cells' proliferation and differentiation into the neural lineage. Moreover, the tension stimulation caused the alignment of cells in the direction of applied force. The shear stress during printing bioink with encapsulated C2C12 cells led to the oriented structure of cells, which supports muscle regeneration. These findings confirm the response of cells to the mechanical properties of the environment. Extrusion bioprinting, due to the possibility of bioink stiffness modification and shear stress applied to the cells during printing, is the method that uses mechanical cues to a great extent. A summary of the studies employing mechanical cues is presented in Table 4.

Table 4.

Mechanical cues and their influence on cell behavior.

| Printing method | Tissue | Cell cue | Main material(s) | Cell type(s) | Cell response | Ref. |

|---|---|---|---|---|---|---|

| MEW | Cardiac | Elastic properties of the scaffold | PCL | iPSC-CM | Enhanced level of cardiac markers and higher beating rate for softer scaffolds. | [43] |

| Cartilage | Dynamic load | PCL/GelMA | Chondrocytes | Enhanced cartilage formation after dynamic loading. | [130] | |

| FDM | Tendon | Constant tension | PU/PCL | hBMMSCs | Elongation of cells along the longitudinal axis of the applied tension. | [83] |

| Extrusion printing | Bone | Scaffold stiffness | Alginate/gelatin | hMSCs | Enhanced ALP activity and osteogenic differentiation on softer scaffolds. | [67] |

| Neural | Dynamic tensile load | FGelMA | Schwann cells | Enhanced cell proliferation and neural differentiation after mechanical stimulation. | [134] | |

| Cardiac | Fluid shear stress | Porcine heart-derived ECM | Cardiomyocytes | The upregulated expression of cardiac-specific proteins and unidirectional, extended cell alignment after mechanical stimulation. | [69] | |

| Muscle | Shear stress | Oxidized alginate/gelatin | C2C12 | Cell orientation along the printed direction for higher shear stresses in the nozzle. Increased myotubes differentiation. | [135] | |

| Shear stress | GelMA | C2C12 | Increased myotube formation in the printing direction with increased myogenic gene expression for pre-cultured bioinks. | [72] | ||

| Not specific | Scaffold stiffness | Alginate/gelatin | MSCs | Formation of the 3D interconnected cellular network and a more spread cell morphology in softer scaffolds. | [131] | |

| Scaffold stiffness | Alginate | L929 | Improved cell migration and proliferation throughout the scaffold in softer scaffolds. | [132] | ||

| Scaffold stiffness | GelMA | hAD-MSCs, HUVECs | Decreased cellular spreading and proliferation with increased scaffold stiffness. | [133] |

3.1.5. Electrical cues

Every cell has a membrane potential specific to the cell and tissue type. The addition of electrical cues can facilitate cell-cell interactions. The electrical cues were shown to influence cell migration and growth, and enhance cell adhesion [136], can be helpful during differentiation of stem cells into osteoblast lineage [137], and are particularly needed in nerve regeneration [138]. The electrical cues can be introduced via introducing the conductive particles into the scaffold matrix or grafting them on the surface of the scaffold [139].

3.1.5.1. Near Field Electrospinning

Vijayavenkataraman et al. [63] performed in vitro neural differentiation studies using PC12 cells seeded on PCL/rGO (reduced graphene oxide) conductive scaffolds fabricated using the NFES approach. PCL/rGO material was obtained by adding rGO powder with PCL pellets into a 70% w/v acetic acid. Scaffolds printed with the composite material had lower mechanical properties than the pure PCL scaffolds, which is beneficial for neural differentiation. In vitro results revealed that the PCL/rGO scaffolds had shown significantly higher cell attachment and proliferation than the pure PCL scaffolds. This effect was assigned to the increased surface area of the rGO nanostructure. Furthermore, the RT-PCR studies revealed the significantly higher expression of the three crucial genes associated with neural differentiation, namely, β3-tubulin, NF–H, and GAP43 in the scaffolds printed with PCL/rGO. Also, in these samples, immunocytochemistry results showed higher expression of NF200 and β3-tubulin, and higher neurite outgrowth when compared to pure PCL scaffolds. The enhanced protein expression could result from cell-cell interactions. As cells communicate with each other by means of electrical signals, the addition of conductive particles facilitates the contact between them [63].

3.1.5.2. Melt Electrowriting