Abstract

There has been an increase interest in natural plant fibers over the last decades with the intension to identify the ecologically acceptable alternatives to reduce the dependency on synthetic fibers. Naturally extracted okra fiber (Abelmoschus esculentus) was used in this study. Since okra is a stiff fiber, yarns with 100% Okra fiber was not possible to produce and tried to blend with polyester. The maximal ratio of okra was 20% with polyester to spin yarns in traditional ring spinning system. This study explores, for the first time, the possibility of manufacturing woven fabric with polyester-okra (80/20) yarns at weft direction with 100% cotton yarn at warp direction in order to prominent blend effect at weft direction. The properties of produced fabrics were compared with the same produced widely-used polyester-linen (PL) (80/20) counterpart. The both PO and PL woven fabrics were characterized in terms of fabric weight, thickness, abrasion, pilling, fuzzing, air permeability, tensile strength and tear strength. In addition, the morphological aspects of the fiber alignment in the woven fabric structure were observed using optical microscopic images. The performance of PO woven fabric was in acceptable ranges and can be considered as a sustainable blended woven fabric to meet the actual demand in the textile weaving industries.

Keywords: Okra fiber, PO blend, Woven fabric, Flax fiber

Graphical abstract

Okra fiber; PO blend; Woven fabric; Flax fiber.

1. Introduction

Non-biodegradable synthetic materials are being replaced with environmentally friendly alternatives over the past few decades. In this context, numerous research efforts have resulted in the development of blended woven fabrics using natural and synthetic materials [1]. Due to the several benefits of woven fabrics, researchers are interested in developing them for a variety of industrial applications including clothes, safety belts, netting, airbags, seat coverings, textile-reinforced concrete, fiber and textile-based bridging cables and so on [2, 3].

As an alternate source of biodegradable fiber, okra bast fiber (Abelmoschus esculentus) is plentiful in nature. Without proper utilization, a large volume of okra plant stem is thrown away in the field each year. It is one of the major vegetable crops in Indian subcontinents belonged to Malvaceae family. It has excellent strength and modulus, and good thermal properties and contains about 60–70% of cellulose [4]. The fiber is found on the outside of the plant's core, near the stem. The okra bast fiber is bright, shiny, and strong, similar to the bark fibers of jute, kenaf, flax, and hemp fibers, and it can be spun into a yarn. The okra fibers combine with the pectin found in the plant cell wall to form clusters [5]. Various retting or degumming processes can be used to separate the fiber from the pectin and the plant's center. When the retting process is initiated, the chemical bonds that hold the stem together are broken, resulting in the separation of the bast fibers from the woody core. This separation is caused by either microbial activity or a chemical reaction [6]. Few studies have been conducted using okra fiber. Previously okra fiber was used as a reinforcing filler to fabricate composites with different matrices including biodegradable corn starch, polylactic acid, polyvinyl alcohol and urea formaldehyde resin [2]. Nabaneeta et al. utilized the agro waste of okra fiber for handmade paper productions [7]. Sule et al. studied the properties of reinforced hybrid composite using okra/glass fiber [8]. Researchers studied the spinnability of staple okra to prepare spun yarn and concluded that, due to less elasticity, 100% okra fiber alone cannot be spun into yarn. So, blending with other fibre is the best alternative technology. Vanishree et al. prepared and studied the okra-cotton blended yarns in ring spinning system [9]. Researchers concluded that in case of blending of bast fibers, lack of blend homogeneity as well as cohesion among fibers inhibits the increase in bast fiber proportion in blended yarns [10, 11, 12]. According to the concept of blending, a fabric made from blended yarns usually offers superior qualities to a fabric made from a single fiber [13]. Blending of natural and synthetic fibers is an innovative concept of achieving comfort and functional properties at a time [14, 15]. The synthetic polyester fiber becomes more popular for textile fabrication due to low cost, high strength, durability, stretchability as well as easy care properties [16]. However, low moisture absorption, high static electricity, low breathability and non-biodegradability are demerits of polyester fiber. To improve such properties, blending of polyester with natural fiber is a popular way. Several researchers are carried out their research work using polyester and various types of natural fibers [17, 18, 19, 20].

Woven fabric patterns are created by interlacing two or more sets of fiber tows or yarns, one over and beneath successive orthogonal ones alternately. Woven fabrics have a higher yarn packing density than other textile structures such as knit and braid fabrics [21, 22]. The properties of woven fabrics depend on several parameters. Jahan et al. studied the mechanical properties of woven fabric using different fabric structures and concluded that tensile strength, abrasion resistance, stiffness & pilling resistance are high in plain weave compared to twill weave [23]. Several researchers have also conducted their research work with blended woven fabric. Based on the concept of natural and synthetic blended, Xiao et al. studied pilling properties of polyester/cotton blended woven fabric [24]. Kakvan et al. studied thermal comfort properties of cotton/nylon blended fabrics with high performance kermel fiber and observed the increase in fabric porosity, air permeability and thermal resistance with the increase of kermel fiber blend ratio [25]. Basit et al. observed the mechanical and thermal properties of blended woven fabric using tencel/cotton and others regenerated fibers and found that all blended fabric of tencel showed higher mechanical and comfort properties than 100% cotton fabric [26]. Afroz et al. investigated the mechanical property of cotton/tencel blended woven fabric and found higher strength and elongation of cotton/tencel blended fabric than 100% cotton fabric [27]. Besides this, linen fabric prepared from flax fiber becomes more popular because of high tensile properties, high stiffness, high moisture absorption, better cooling effect, good comfort, elegance appearance, and wicking abilities in recent decades [28, 29]. Polyester/flax blended fabric shown excellent UV protection performance, better comfort for good air and moisture permeability [30]. Needle punch nonwoven fabrics were made from 100 % okra fiber and a blend of jute fiber in four different ratios, namely, 80:20, 70:30, 60:40, and 50:50 [31]. Okra fiber can be the potential alternative of flax fiber due to its superior properties and availability.

Till date, no studies have been reported to blend naturally available okra fiber with synthetic ones for woven fabric. The current study investigated the blending of okra fiber with polyester fiber to produce polyester-okra (PO) blended yarn for woven fabric production. Herein, the naturally available flax fiber was also mixed with the polyester fiber to produce polyester-flax (PL) blended yarns for the preparation of PL blended woven fabric. Then, different fabric properties such as fabric weight, thread density, cover factor, thickness, abrasion, pilling, fuzzing, air permeability tensile strength and tear strength were measured and compared between PO and PL blended woven fabric. The structure of blended fabrics was also analyzed using optical microscopy images.

2. Experimental

2.1. Materials

Naturally available okra fiber was extracted from ladies finger farm, Dinajpur, Bangladesh. The other natural fiber flax (length 51 mm, fineness 2.3 Denier) was supplied from Nv JoS Vannest E SA, Harelbeke, Belgium. The synthetic fiber polyester (length 40 mm, fineness 1.2 Denier) used for blended yarn was purchased from Indorama Corp Pte Ltd., Jakarta, Indonesia. The 100% cotton yarn was provided by Sufia Cotton Mills Ltd., Mulaid, Sreepur, Gazipur, Bangladesh. The chemicals, NaOH, Na2CO3, and H2O2, used for scouring and bleaching were obtained from R.H. Corporation, Dhaka, Bangladesh.

2.2. Methodology

2.2.1. Preparation of blended yarn

At first Okra fiber was extracted using water retting process. After extractions, it was dried. The dried okra fiber was very much stiffer due to its higher diameter and presence of lignin. Removal of lignin okra fibers can be individualized and softened. That's why, extracted okra fiber requires further treatment to remove the excess amount of lignin. The treatment was carried out in an open bath system using 5 g/L NaOH, 3 g/L Na2CO3, 5 g/L H2O2, 1 g/L sequestering agent, 1 g/L wetting agent at 100 °C temperature for 60 min. The liquor ratio was 1:30 according to the weight of materials. Then, the treated okra fiber was cut into 38–40 mm by length consistent with 40 mm of polyester fiber. The prepared okra fiber and available polyester fiber were mixed together in different blend ratio to prepare blended fiber. The prepared blended fiber were used to produce polyester-okra (PO) blended yarn. Here, PO blended yarn of 30 Tex prepared for 90/10, 85/15 and 80/20 (Polyester/Okra) blend ratio. 75/25 PO yarn could not be produced because of lots of yarn breakages occurring due to intervening of okra fibers. The blending was carried out in the Blowroom line. For better comparison of the performance of okra corresponding 90/10, 85/15 and 80/20 polyester/Flax or linen (PL) yarn was also prepared. The preparation process was carried out using Trutzschler Blowroom line, TC 11 (Trutzschler) Carding machine, DX8 (Toyota) Breaker Drawframe, RSB D22 (Rieter) Finisher Drawframe, FL 100 (Toyota) Simplex and F 1520 (Jingwei) Ring Frame machineries at Multazim Spinning Mills Ltd., Mymensingh, Bangladesh. The spinning process was operated according to the process parameters in Table 1.

Table 1.

Process parameters of spinning.

| Parameters | Values |

|---|---|

| Card sliver linear density | 4.963kTex |

| Delivery speed of Carding | 168 m/min |

| Finisher drawn sliver linear density | 4.249kTex |

| Delivery speed of Finisher drawing | 600 m/min |

| Linear density of Roving | 615 Tex |

| Twist per meter of Roving | 24 |

| Flayer speed of Simplex | 700 rpm |

| Linear density of Yarn | 30 Tex |

| Twist per meter of yarn | 637 |

| Spindle speed of Ring Frame | 7000 rpm |

| Cradle load of Ring Frame | 12 Kgs |

| Ring diameter of Ring Frame | 38mm |

| Ring Traveler Size | No-2 |

| Spacer Size | 3.0mm |

2.2.2. Preparation of blended woven fabric

The prepared yarns were used to produce plain woven fabric using ZA209i (TSUDAKOMA) airjet loom at Sufia Cotton Mills Ltd. (Weaving Unit), Mulaid, Sreepur, Gazipur, Bangladesh. Weaving process was carried out in accordance with the process parameters in Table 2. 100% cotton yarn of 30 Tex was used as warp yarn in order to investigate the performance of okra at weft direction.

Table 2.

Process parameters of weaving.

| Parameters | Values |

|---|---|

| Warp yarn linear density | 30 Tex |

| Weft yarn linear density | 30 Tex |

| Warp yarn per inch | 76 |

| Weft yarn per inch | 68 |

| Fabric width | 63 inch |

| Loom speed | 450 rpm |

| Shedding system | Tappet |

2.3. Measurement and characterization

2.3.1. Characterization of fiber

The linier density of okra, flax and polyester fiber were measured using direct weighing procedure in accordance with ASTM D1577-07(2018) standard test method and expressed in Tex. The single fiber strength of okra, flax and polyester fiber were determined using Single Fiber Strength Tester TB400C-TESTEX under CRE (constant rate of extension) principle in accordance with ASTM D3822 standard test method for zero jaw separation, 100 mm/min test speed and 200 cN load cell and expressed in cN. The surface morphology of the fibers were investigated using scanning electron microscope (SEM) images. The image was originated from SEM, JEOL 6460LV, Tokyo, Japan. The accelerating voltage was 5.0 kV [32].

2.3.2. Characterization of yarn

Actual yarn count were measured using Wrap reel and electronic balance in accordance with ASTM D1059-17 standard test method for 120 yards test length and expressed in Tex. Mass variation, imperfection and hairiness were determined using USTER® Tester 6 in accordance with ASTM D1425/1425M-14 (2020) standard test method with 200 m test length and 200 m/min test speed. Mass variation was expressed in terms of unevenness (U%) and co-efficient of variation (CVm%). Imperfection index (IPI) value represent the total number of thick place (+50%), thin place (−50%) and neps (+200%) per 1000 m of yarn [33]. Yarn hairiness (H) corresponds to the total length of protruding fibers in centimeter, cm (only higher than 4mm) per cm length of yarn [33]. Yarn strength and elongation was tested by Titan Universal Testing Machine - James Heal under CRE (constant rate of extension) principle according to ASTM D 2256 standard for 250 mm of test length, 250 mm/min test speed and 100 N load cell. Strength and elongation were expressed in cN/Tex and percentage of initial length, respectively. All the experiments were performed under standard conditions (65 ± 2% RH and 20 ± 2 °C). The test was carried out by 10 reading for each type of yarns and the mean value was tabulated.

2.3.3. Characterization of fabric

2.3.3.1. Determination of thread density

The number of warp and weft threads per inch of woven fabric is known as thread density. The term EPI (ends per inch) and PPI (pick per inch) were used to measure the thread density. Thread density is crucial for GSM and cover factor. Pan et al. measured thread densities of woven fabric using the Fourier Transform method [34]. Maqsood et al. also calculated threads per square inch using the following formula (i) [35].

| (i) |

2.3.3.2. Determination of cover factor

The cover factor is a numerical statistic that indicates how much of a fabric surface area is covered by component yarns. For woven cloth, there are two cover factors, i) Warp cover factor and ii) Weft cover factor. Iftikhar et al. was calculated woven fabric cover factor by adding the ratio of threads per inch and the square root of the yarn count (cotton count/English count, Ne) of both warp and weft yarn using formula (ii) [36].

| (ii) |

2.3.3.3. Other characterizations

Fabric EPI (ends per inch) and PPI (pick per inch) was determined in accordance with ASTM D3775 standard and expressed in ends per cm and picks per cm. Fabric weight of the samples was examined using GSM cutter and electronic balance in accordance with ASTM D3776 standard test method for 100 cm2 of cut area. Fabric weight was expressed in grams per square meter (GSM). Thickness of fabric was tested using Analog Fabric Thickness Tester in accordance with ASTM D1777-96 standard for 1 inch2 area of pressure foot and test result was expressed in mm. Abrasion and pilling of fabric was determined using Martindale Test Materials – James Heal SM25 tester in accordance with ASTM D4970 standard for 2000 rubs and test result was expressed in terms of weight loss percentage and standard photography rating. Air permeability of fabric was obtained using TEXTEST air permeability tester in accordance with ASTM D737 standard for 20 cm2 of test area and 200 Pa air pressure. The test result of air permeability was expressed in terms of Cm3/Cm2/s. Fabric tensile strength was observed using Titan Universal Testing Machine- James Heal in accordance with ASTM D5035-11 standard for 100 mm jaw separation and 5000 N load cell at 50 mm/min test speed. The test result of tensile strength was expressed in Newton, N. Fabric tear strength was obtained using Elma Tear- James Heal in accordance with ASTM D1424 standard for 2000 N load cell at 300 mm/min test speed and test result was expressed in Newton, N. All the experiments were performed under standard conditions (65 ± 2% RH and 20 ± 2 °C). The test was carried out by 10 reading for each type of yarns and the mean value was tabulated. Optical images were obtained using CX31-P Olympus Polarizing Microscope [37].

3. Results and discussion

3.1. Properties of fibers

Extracted okra fiber, purchased flax and polyester fiber were subjected the performance in different conditions. The mean of the all test results for okra, flax and polyester fibers are illustrated in Table 3.

Table 3.

Fiber properties.

| Parameters | Okra fiber | Flax fiber | Polyester fiber |

|---|---|---|---|

| Linear density, Tex | 3.04 ± 0.89 | 0.30 ± 1.08 | 0.18 ± 0.78 |

| Tensile strength, cN | 94.75 ± 2.87 | 7.94 ± 2.18 | 7.41 ± 1.28 |

| Elongation, % | 1.3 ± 1.09 | 3.2 ± 0.82 | 18.78 ± 1.19 |

From Table 3, it was found that the linear density of okra fiber was 10.14 and 16.89 times higher than flax fiber and polyester fiber, respectively. Herein, the tensile strength of single okra, flax and polyester was found 31.17 cN/tex, 26.47 cN/tex and 41.17 cN/tex, respectively. The elongation of okra fiber found lower than flax and polyester. The microscopic view using scanning electron microscopy images of three different fibers were shown in Figure 1. The morphological aspects of flax fibers was more irregular shape and variable diameter with compared to the synthetic polyester fiber. This phenomena was also observable by the previous researchers [38].

Figure 1.

SEM images of a) Okra fiber, b) Flax fiber and c) Polyester fiber.

3.2. Properties of yarns

According to the standard methods of ring spinning system, the blended PO and PL yarns were prepared. The prepared blended yarns were subjected to evaluate the performances in different conditions. The mean of the all test results for 80/20 PO and 80/20 PL (maximal bend ratio) yarns are illustrated in Table 4.

Table 4.

Properties of PO and PL yarn.

| Parameters | 80/20 PO Yarn | 80/20 PL Yarn | |

|---|---|---|---|

| Actual yarn count, Tex | 29.59 ± 1.16 | 29.41 ± 0.86 | |

| Mass variation | Unevenness, U% | 31.84 ± 1.60 | 22.34 ± 1.80 |

| Co-efficient of variation, CVm% | 39.81 ± 1.50 | 27.93 ± 1.10 | |

| Imperfection index, IPI | Thick (+50%) | 4643 ± 1.10 | 3691 ± 2.18 |

| Thin (-50%) | 2600 ± 6.04 | 922 ± 4.80 | |

| Neps (+200%) | 6647 ± 5.44 | 7750 ± 3.55 | |

| Total/Km | 13890 ± 3.18 | 12363 ± 2.60 | |

| Hairiness, H | 7.60 ± 3.90 | 7.26 ± 2.01 | |

| Single yarn strength, cN/Tex | 32.35 ± 4.58 | 22.68 ± 3.78 | |

| Elongation, % | 10.82 ± 2.12 | 10.43 ± 1.88 | |

The mass variation and imperfection of PO and PL blended yarn was found so high. This occurred due to the lack of homogeneity, which was responsible for cohesiveness of materials as well as compactness. However, when two different fibers are blended, their cohesiveness reduces. Hence, yarn evenness reduces due to more number of thin and thick places [10]. Higher irregularity and imperfection were also found in case of cotton/ramie and areca/cotton blended yarn [11, 12].

3.3. Properties of fabrics

The prepared yarns were used to produce plain woven fabric. The prepared blended fabrics were subjected to evaluate the performances in different conditions. Herein, the ends per inch and picks per inch were calculated as dimensional properties. The thread density and cover factor was calculated using the equations (i) and (ii), respectively. Fabric tensile and tear strength tested in both warp and weft direction. The mean of the all test results for 80/20 PO and 80/20 PL (maximal bend ratio) blended fabrics were illustrated in Table 5.

Table 5.

Properties of PO and PL woven fabrics.

| Parameters | 80/20 PO Fabric | 80/20 PL Fabric | |

|---|---|---|---|

| Ends per cm | 30 ± 0.06 | 29 ± 0.02 | |

| Picks per cm | 27 ± 0.06 | 26 ± 0.02 | |

| Yarn crimp in fabric, % | Warp yarn | 5.8 ± 0.16 | 5.5 ± 0.08 |

| Weft yarn | 6.4 ± 0.16 | 6.1 ± 0.08 | |

| Fabric thread density, (threads/inch2) | 145 ± 0.08 | 143 ± 0.10 | |

| Fabric cover factor | 32.44 ± 0.18 | 31.95 ± 0.12 | |

| Fabric weight, (g/m2) | 206.4 ± 3.36 | 176.9 ± 2.16 | |

| Fabric thickness, (mm) | 0.51 ± 0.01 | 0.40 ± 0.02 | |

| Fabric abrasion | Weight loss, (%) | 11.3 ± 0.56 | 5.0 ± 0.76 |

| Shade change, (grade) | 4 ± 0.00 | 4 ± 0.00 | |

| Fabric pilling, (grade) | 2-3 ± 0.00 | 2 ± 0.00 | |

| Fabric fuzzing, (grade) | 3 ± 0.00 | 3 ± 0.00 | |

| Air permeability, (cm3/cm2/s) | 29.8 ± 1.63 | 40.5 ± 1.36 | |

| Tensile strength, (N) | Warp direction | 588.61 ± 4.78 | 565.34 ± 3.98 |

| Weft direction | 777.64 ± 5.67 | 630.11 ± 5.72 | |

| Tear strength, (N) | Warp direction | 52.2 ± 0.69 | 51.9 ± 0.74 |

| Weft direction | 63.9 ± 1.14 | 58.7 ± 1.08 | |

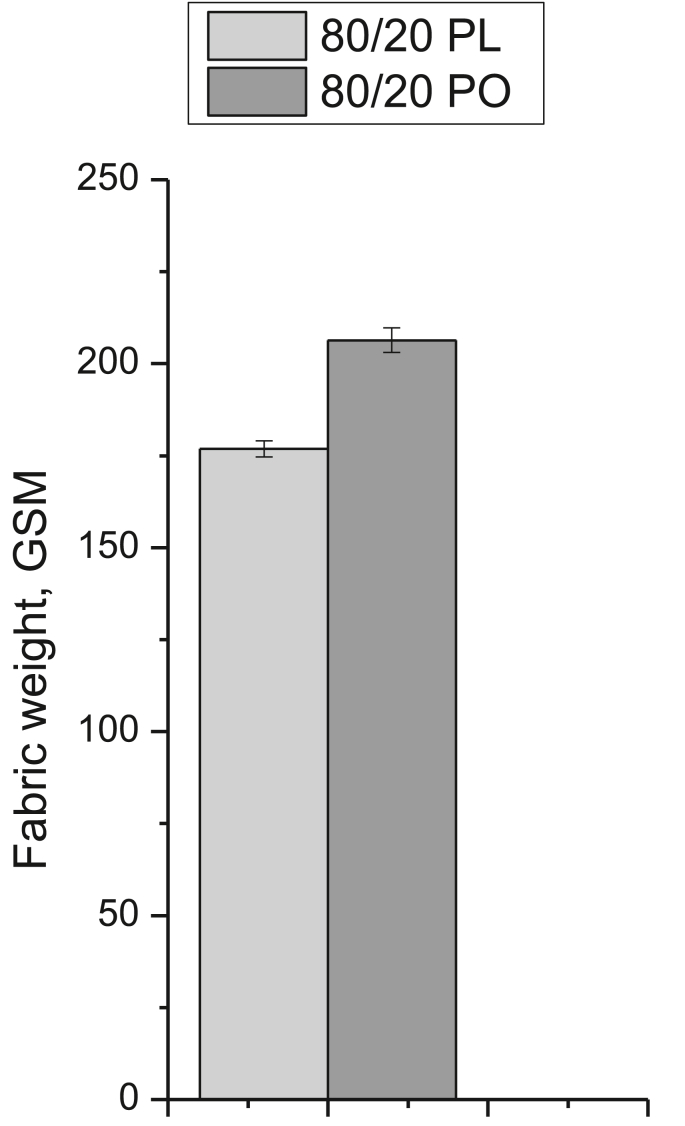

3.3.1. Analysis of fabric weight

The Fabric GSM is the weight in grams per square meter of fabric, and also a standard measurement for fabric weight. Fabric GSM is directly related to the fabric thickness, warp and weft yarn count, threads density and cover factor of woven fabric. In Table 5 and Figure 2, it was shown that fabric GSM of PO blended fabric is 14.29% higher than PL blended fabric. In case of 85/15 blended fabric GSM of PO and PL blended fabric was 197.3 gm/m2 and 174.7 gm/m2, respectively (Table 6). Herein, fabric GSM increased with the increases of blend ratio in case of both okra and flax. This happened due to the higher crimp level of PO blended fabric. In case of bulky yarn increases crimp size during weaving process and produce thick fabric. Therefore, the bulky yarn and higher thickness of PO blended fabric shown higher GSM. Simmilar phenomenon was also observed by Chidambaram et al. for the preparation of bamboo/cotton blended woven fabric, where fabric thickness as well as GSM was increased with the increases of blend ratio of cotton [39].

Figure 2.

Fabric weight (GSM) of PO and PL blended fabric.

Table 6.

Comparative properties of PO and PL blended woven fabric.

| Parameters | 85/15 PO Fabric | 85/15 PL Fabric | 80/20 PO Fabric | 80/20 PL Fabric | |

|---|---|---|---|---|---|

| Fabric weight, (gm/m2) | 197.3 | 174.7 | 206.4 | 176.9 | |

| Fabric thread density, (threads/inch2) | 145 | 143 | 145 | 143 | |

| Fabric cover factor | 32.44 | 31.95 | 32.44 | 31.95 | |

| Fabric thickness, (mm) | 0.47 | 0.38 | 0.51 | 0.40 | |

| Fabric abrasion | Weight loss, (%) | 10.1 | 8.2 | 11.3 | 5.0 |

| Shade change, (grade) | 4 | 4 | 4 | 4 | |

| Fabric pilling, (grade) | 2–3 | 2 | 2–3 | 2 | |

| Fabric fuzzing, (grade) | 3 | 3 | 3 | 3 | |

| Air permeability, (cm3/cm2/s) | 35.6 | 42.8 | 29.8 | 40.5 | |

| Tensile strength, (N) | Warp direction | 563.81 | 573.00 | 588.61 | 565.34 |

| Weft direction | 942.39 | 685.04 | 777.64 | 630.11 | |

| Tear strength, (N) | Warp direction | 57.9 | 54.8 | 52.2 | 51.9 |

| Weft direction | 63.9 | 67.8 | 63.9 | 58.7 | |

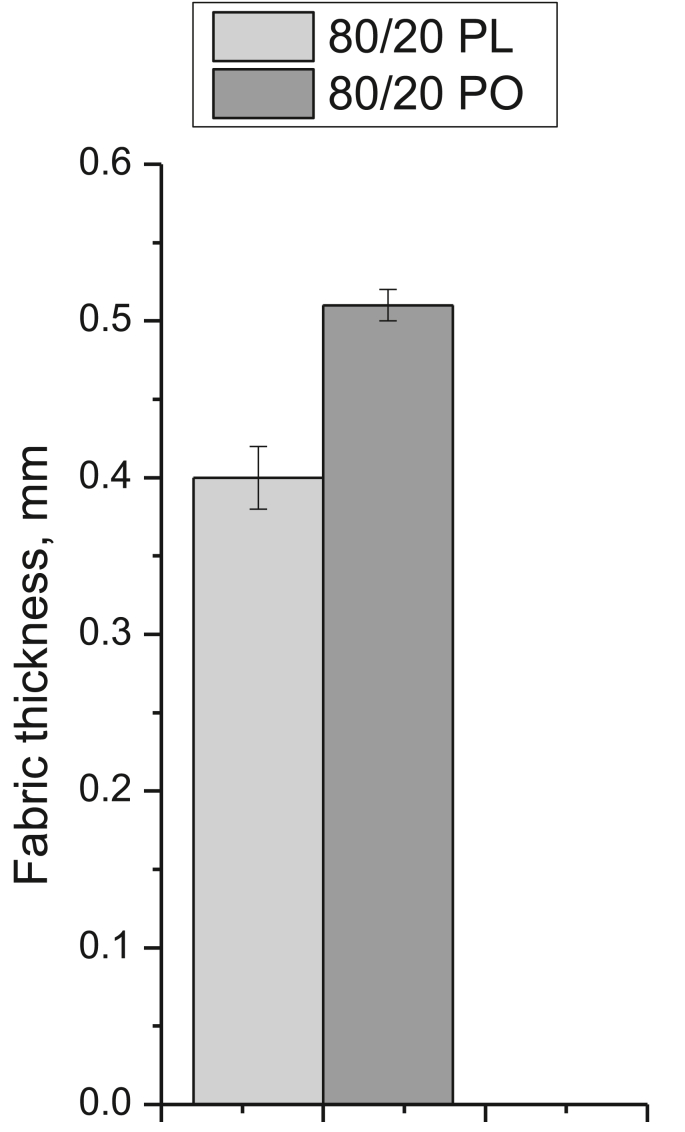

3.3.2. Analysis of fabric thickness

The distance between the two fabric surfaces under a particular applied pressure, which changes with the compressibility of fabric, is described as fabric thickness. It is also depends of yarn bulkiness, yarn evenness as well as fabric sufrace. From Table 5 and Figure 3, it was found that, thickness of PO blended fabric is higher than PL blended fabric. In case of 85/15 blended fabric thickness of PO and PL blended fabric was 0.47 mm and 0.38 mm, respectively (Table 6). Herein, fabric thickness increased with the increases of blend ratio for both okra and flax. This was occurred due to the bulky and noncompact structure of blended yarn. In case of nonhomogenious blending, stiffer and coarser bast fiber creates bulkiness due to the lack of compactness during spinning process [10]. Similar phenomenon was also observed by Chidambaram et al. for the preparation bamboo/cotton blended woven fabric, where fabric thickness was increased with the increases of blend ratio of cotton [39].

Figure 3.

Thickness of PO and PL blended woven fabric.

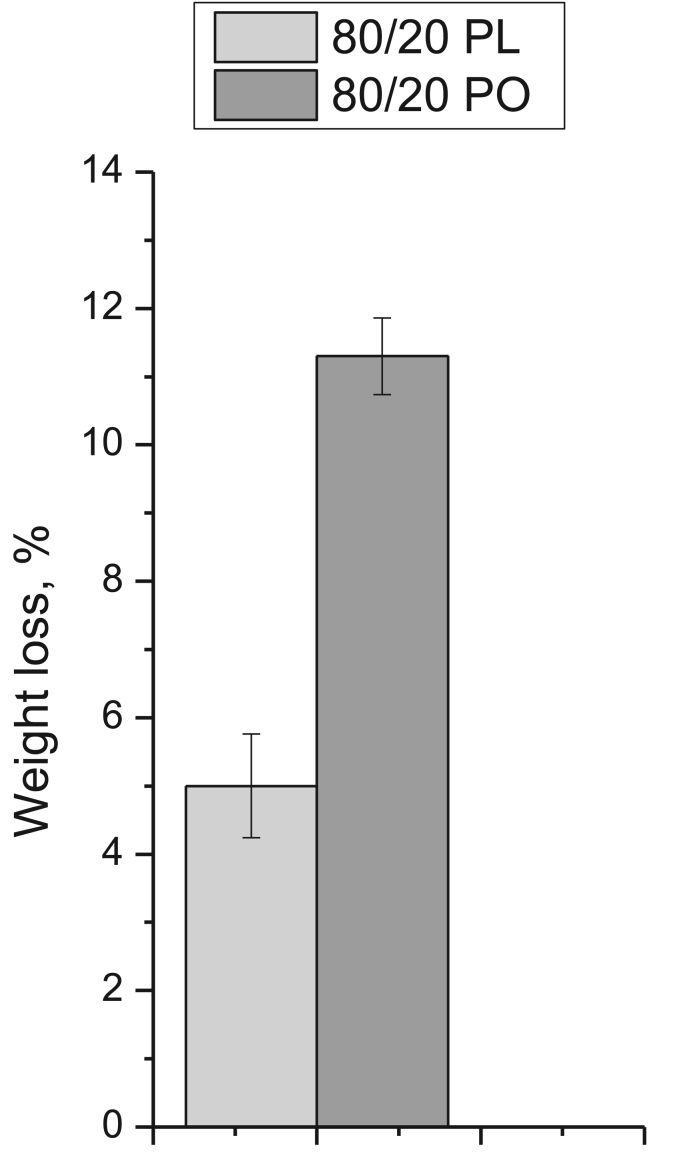

3.3.3. Analysis of fabric abrasion

Abrasion is the rubbing away of the fabric's component fibers and yarns and is one facet of wear.

It's a form of abrasion that's flat or simple. Threads breaking owing to the number of rotations are used to test it [23]. The major goal of this test was to prevent threads from breaking. From Table 5, it was shown that shade change grade of PO blend and PL blend is 4, which indicates slightly shade changed during abrasion. In addition, weight loss during abrasion of PO blended yarn was found high in Figure 4. It happened due to the losses of okra fiber from the fabric surface at the time of rubbing. The coarser ring yarn and stiffer fiber stay at the periphery of yarn [40]. That's why coarser and stiffer okra fiber was found at the periphery of yarn as well as fabric surface and lost during rubbing. Therefore, the prepared PO fabric was shown the acceptable range of abrasion properties [41].

Figure 4.

Weight loss of PO and PL blended woven fabric during abrasion.

3.3.4. Analysis of fabric pilling and fuzzing

Pilling is an ugly problem that occurs as a result of the production of little pills of entangled fiber sticking to the fabric surface during wear. Pills are created by pressing stray strands on the fabric surfaces. Fuzzing occur when the small fibers that make up the yarn break with each wash, wear, and the passage of time. Fabric pilling and fuzzing depends on fiber properties (length, strength, fineness, crimpiness), yarn properties (linear density, value and direction of twist, hairiness, friction coefficient, composition, spinning process) as well as fabric types and weave structure [23, 42]. In Table 5, it was shown that the fuzzing grade of PO and PL blended fabric is 3, which indicates that prepared PO and PL blended fabric has moderate surface fuzzing properties. In case of pilling property, it was observed that PO blended fabric shows better pilling resistance than corresponding PL blended fabric. This occurred due to the stiffness of okra fiber, which breaks/loss in case of rubbing rather than pill formation. Pilling tendency of fabric increases with the increases of polyester portion in case of polyester and natural fiber blend [43]. Therefore, the prepared PO fabric was shown the acceptable range of pilling and fuzzing properties [41].

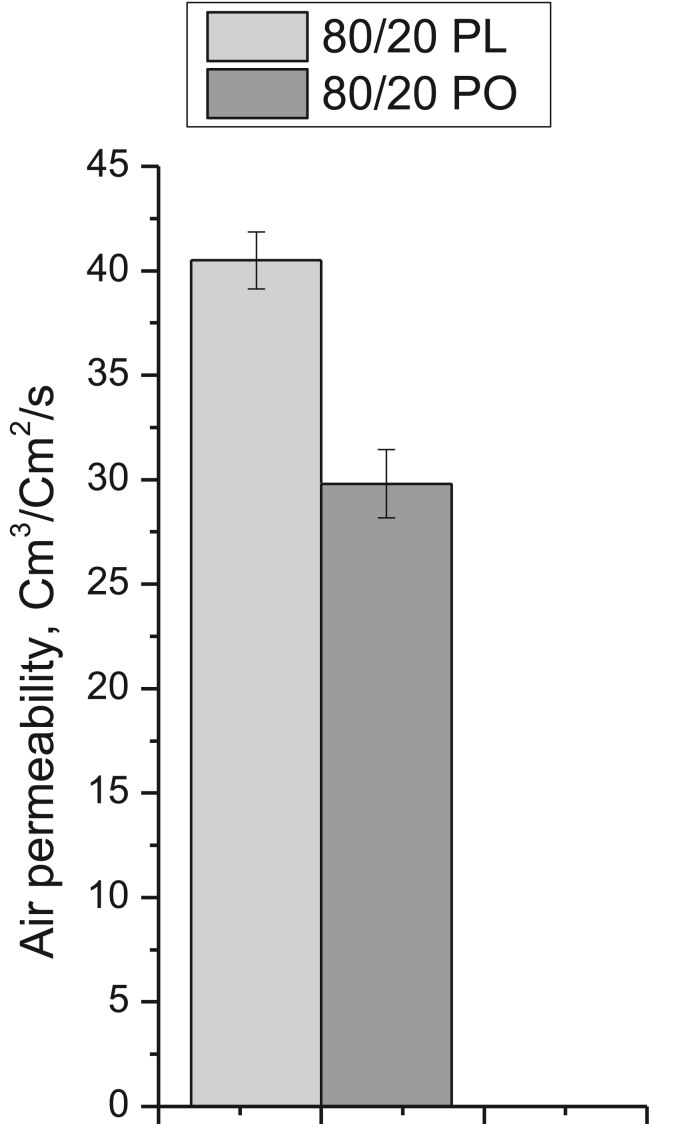

3.3.5. Analysis of fabric air permeability

The air passes through the pores from the surface of the fabric. The air permeability is the volume of air in cubic centimeter which is passed in one second through one square centimeter of the fabric at a pressure difference of one centimeter head of water [44]. It depends on the fiber fineness, shape and value of pores of the fabric and the yarn and fabric thickness [45, 46, 47]. Higher the pore value, higher the air permeability. In Table 5 and Figure 5, it was observed that air permeability of PO blended fabric is 26.42% lower than PL blended fabric. In case of 85/15 blended fabric air permeability of PO and PL blended fabric was 35.6 cm3/cm2/s and 42.8 cm3/cm2/s, respectively. Herein, air permeability was decreased with increases of blend ratio in case of both okra and flax fiber. This occurred due to the minimization of pore size with more projecting fibers of 80/20 blended yarn. Similar phenomenon also observed in case of bamboo/cotton blended plain woven fabric [39]. The acceptable range of air permeability mainly depends on the application of woven fabric. According to the report from R. Tugrul et al., the woven fabric air permeability will be more than 5 cm3/cm2/s [48]. Therefore, the PO blended woven fabric shown the air permeability of 29.8 cm3/cm2/s. Which was in the acceptable range of air permeability properties of woven fabric.

Figure 5.

Air permeability of PO and PL blended woven fabric.

3.3.6. Analysis of tensile strength

When a yarn or fabric is exposed to uniaxial tensile loading, its tensile strength is defined as the highest load which can withstand without breaking. The tensile strength of a woven fabric is one of the most essential features that distinguishes it from nonwoven and knitted materials in many applications [23, 49]. The tensile properties depend on specimen geometry, fiber type and arrangement, as well as the fabric structure [50]. Besides this, blend ratio also has an influence on tensile strength in case of blended fabric [51]. In Table 5 and Figure 6, it was expressed that tensile strength of PO blended fabric is 18.97% higher than PL blended fabric at weft direction. In case of 85/15 blended fabric tensile strength of PO and PL blended fabric was 942.39 N and 685.04 N at weft direction, respectively (Table 6). Herein, tensile strength was decreased with increases of blend ratio in case of both PO and PL blended fabric at weft direction. This occurred due to the inhomogeneous blending of bast fiber with synthetic fiber and inhomogeneity increases with the increase of bast portion of blended yarn [52]. Islam et al. also found lower tensile strength with decreases of polyester portion in case of polyester/cotton blended fabric [53].

Figure 6.

Tensile strength of PO and PL blended woven fabric (weft direction).

3.3.7. Analysis of tear strength

The sequential breakage of threads or groups of yarns along a line through a fabric is known as tear. Tearing strength of fabric depends on yarn strength, weave structure, yarn geometry, fabric geometry, relaxation of the fibers and their frictional characteristics [54]. From Table 5 and Figure 7, it is seen that tear strength of PO blended fabric is 8.14% higher than PL blended fabric at weft direction. In case of 85/15 blended fabric tensile strength of PO and PL blended fabric was 63.9 N and 67.8 N at weft direction, respectively (Table 6). Herein, tear strength decreased with the increase of blend ratio in case of both PO and PL blended fabric at weft direction. This happened due to the decreases of polyester portion in weft yarn as well as fabric. Islam et al. also found lower tear strength with decreases of polyester portion in case of polyester/cotton blended fabric [53]. Therefore, the prepared PO fabric was also shown the acceptable range of tear strength properties.

Figure 7.

Tear strength of PO and PL blended woven fabric (weft direction).

3.3.8. Optical microscopic view analysis

Differences between the structures of PO and PL blended fabrics were observed using optical microscopic images in Figure 8. The photographs were clearly indicated that the smaller fabric pore were present in 80/20 PO blended fabric comparing with 80/20 PL blended fabric. The overall observations and results revealed that the prepared PO blended fabric contain acceptable range of fabric pore and air permeability properties. In addition, color difference of the blended fabrics in Figure 8, was clearly indicated the presence of okra and flax fiber in polyester blended. Moreover, woven fabric was constructed using two sets of yarn named warp and weft. The interlacement of two sets of blended yarn were clearly shown in the microscopic images of Figure 8 (a, b).

Figure 8.

Optical microscopic images of a) 80/20 PO, b) 80/20 PL blended woven fabrics.

4. Conclusion

In this study, the extracted okra fiber was used to prepare PO blended yarn with polyester fiber in different blend ratio. Plain woven fabric was prepared from the PO blended yarn and compared with corresponding PL blended woven fabric. The loom performance was investigated and found not so satisfactory, that's why weaving process continued with low speed. The different woven fabric properties were investigated by fabric quality parameters such as fabric weight, thickness, abrasion, pilling, fuzzing, air permeability, tensile strength and tear strength. The PO blended fabric weight (GSM) was 206.4 g/m2, thickness was 0.51 mm, tensile strength was 588.61 N in warp direction and 577.64 N in weft direction, which was higher than PL blended fabric. On the other hand, the air permeability was 29.8 cm3/cm2/s and weight loss due to abrasion property was 11.3 % in PO blended yarn which was poor than PL blended yarn. The morphological aspects using optical microscopy were also provided the evident of yarn alignment on fabric structure as well as porous structure of fabric. The overall results suggested that PO blended fabric were acceptable range of woven fabric properties. Due to economical aspect and availability of okra fiber, the PO blended fabric are very promising and can be considered as the potential candidate to meet the actual demand of blended fabric in the textile weaving industries.

Declarations

Author contribution statement

Md. Rafiqul Islam: Conceived and designed the experiments; Performed the experiments; Wrote the paper.

Rony Mia: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Ahmed Jalal Uddin: Conceived and designed the experiments; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This work was supported by a research grant from the Bangladesh University of Textiles, Dhaka, Bangladesh.

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The authors would like to express thank and gratitude towards Multazim Spinning Mills Ltd.,Valuka, Mymensingh, Bangladesh and Sufia Cotton Mills Ltd., Mulaid, Sreepur, Gazipur, Bangladesh, for providing machineries and equipment on time during the course of this research work. The author also thanks for the academic support from the Bangladesh University of Textiles, Dhaka, Bangladesh.

References

- 1.Jiang H., Guo R., Mia R. Eco-friendly dyeing and finishing of organic cotton fabric using natural dye (gardenia yellow) reduced-stabilized nanosilver: full factorial design. Cellulose. 2022:1–17. 24/01/2022. [Google Scholar]

- 2.Khan G.M.A., Yilmaz N.D., Yilmaz K. Okra fibers: potential material for green biocomposites. Green Biocomp. 2017;1:261–284. Springer. [Google Scholar]

- 3.Ahmed T., et al. Evaluation of sizing parameters on cotton using the modified sizing agent. Clean. Eng. Technol. 2021;5:100320. [Google Scholar]

- 4.Franck R.R. Woodhead Publishing Limited and Crc Press; North America: 2005. Bast and Leaf Fiber Composite Materials (Bast and Other Plant Fibres) [Google Scholar]

- 5.Moniruzzaman M., Maniruzzaman M., Gafur M., Santulli C. Lady's finger fibres for possible use as a reinforcement in composite materials. J. Biobased Mater. Bioenergy. 2009;3(3):286–290. [Google Scholar]

- 6.Khan G., Saheruzzaman M., Razzaque S., Islam M.S., Alam M.S., Islam M.M. 2009. Grafting of Acrylonitrile Monomer onto Bleached Okra Bast Fibre and its Textile Properties. [Google Scholar]

- 7.Nabaneeta G., Minti G., Swapna C. Utilization of agro waste-okra and its potentiality. Asian J. Home Sci. 2017;12(1):250–256. [Google Scholar]

- 8.Sule U., Isa M., Ameh A., Ajayi O., Omorogbe O. Studies on the properties of short okra/glass fibers reinforcedepoxy hybrid composites. Int. J. Sci. Technol. 2014;2(7):260. [Google Scholar]

- 9.Vanishree S., Mhalae G., Naik S.D., Vastrad J. Properties of okra/cotton blended yarns. J. Pharmacogn. Phytochem. 2018;7(4):3091–3095. [Google Scholar]

- 10.Doke B.S. Cotton sunhemp blended yarns on microprocessor based ring frame. Textile Indust. Trade J. 2004;42:29–40. [Google Scholar]

- 11.Ahmed M., Chattopadhyay S., Chaphekar A., Gaikwad R., Dey S. Characteristics of degummed ramie fibre and its cotton blended yarns. Indian J. Fibre Text. Res. 2004;29:362–365. [Google Scholar]

- 12.Begum H.A., Saha S.K., Siddique A.B., Stegmaier T. Investigation on the spinability of fine areca fiber. J. Text. Inst. 2019;110(9):1241–1245. [Google Scholar]

- 13.Barsha U.H., Uddin M., Hasan M., Chowdhury S. Investigation on physical properties of jute cotton (jutton) blended fabric. Int. J. Text. Fash. Technol. 2018;8(2):1–8. [Google Scholar]

- 14.Chowdhury M., et al. Cleaner Engineering and Technology; 2022. A Feasibility Study to Analyze the Behavior of Heat Settings on the Cleaner Production of Knitted Fabrics; p. 100429. [Google Scholar]

- 15.Sk M.S., Mia R., Ahmed B., Rahman A., Palash M.M.R. Effect of neutralizers and silicone softeners on phenolic yellowing phenomenon of OBA treated cotton knitted fabric. Heliyon. 2021:e08320. doi: 10.1016/j.heliyon.2021.e08320. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Rahman M.M., et al. Synthesis and investigation of dyeing properties of 8-hydroxyquinoline-based azo dyes. J. Iran. Chem. Soc. 2021;18(4):817–826. [Google Scholar]

- 17.Chandrasekaran R., Periyasamy S., Shabaridharan K. Statistical analysis of the pilling behaviour of polyester/cotton and polyester/viscose blended woven fabrics. Fibres Text. East. Eur. 2018;26:66–70. [Google Scholar]

- 18.Kalaoğlu F., Önder E., Özipek B. Influence of varying structural parameters on abrasion characteristics of 50/50 wool/polyester blended fabrics. Textil. Res. J. 2003;73(11):980–984. [Google Scholar]

- 19.Rani K.V., Sarma B., Sarma A. Plasma sputtering process of copper on polyester/silk blended fabrics for preparation of multifunctional properties. Vacuum. 2017;146:206–215. [Google Scholar]

- 20.Kandi I., Das K.N., Mahish S.S. Thermo-physiological comfort properties of P/B blended suiting fabrics. Int. J. Innov. Res. Sci. Technol. 2013;2(12):7620–7629. [Google Scholar]

- 21.Kim J.-K., Sham M.-L. Impact and delamination failure of woven-fabric composites. Compos. Sci. Technol. 2000;60(5):745–761. [Google Scholar]

- 22.Mia R., Sk M.S., Oli Z.B.S., Ahmed T., Kabir S., Waqar M.A. Functionalizing cotton fabrics through herbally synthesized nanosilver. Clean. Eng. Technol. 2021;4:100227. [Google Scholar]

- 23.Jahan I. Effect of fabric structure on the mechanical properties of woven fabrics. Adv. Res. Test. Eng. 2017;2(2):1018. 2. [Google Scholar]

- 24.Xiao Q., Wang R., Zhang S., Li D., Sun H., Wang L. Prediction of pilling of polyester–cotton blended woven fabric using artificial neural network models. J. Eng. Fibers Fabr. 2020;15 1558925019900152. [Google Scholar]

- 25.Kakvan A., Shaikhzadeh Najar S., Psikuta A. Study on effect of blend ratio on thermal comfort properties of cotton/nylon-blended fabrics with high-performance Kermel fibre. J. Text. Inst. 2015;106(6):674–682. [Google Scholar]

- 26.Basit A., et al. Comparison of mechanical and thermal comfort properties of tencel blended with regenerated fibers and cotton woven fabrics. Autex Res. J. 2019;19(1):80–85. [Google Scholar]

- 27.Afroz F., Islam M.M. Study on mechanical property of woven fabrics made from 50/50 cotton-tencel blended siro yarn. Heliyon. 2021;7(10):e08243. doi: 10.1016/j.heliyon.2021.e08243. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Bilen U. The effect of linen and linen blends on the comfort properties of bedding fabrics. J. Nat. Fibers. 2021;18(3):430–441. [Google Scholar]

- 29.Dalbaşi E.S., Özçelik Kayseri G. A research on the comfort properties of linen fabrics subjected to various finishing treatments. J. Nat. Fibers. 2021;18(6):909–922. [Google Scholar]

- 30.Yan Y.X., Feng Y.N., Wang X.Y., Jin J., Tao J.W. Research on air permeability, moisture permeability and UV protection of polyester linen blended knitted fabric. Adv. Mater. Res. 2013;821:411–414. Trans Tech Publ. [Google Scholar]

- 31.Gogoi N., Gogoi M., Choudhury S. Utilization of agro waste-okra and its potentiality. Asian J. Home Sci. 2017;12(1):250–256. [Google Scholar]

- 32.Haque M.A., et al. Sustainable dyeing and functionalization of wool fabrics with black rice extract. Res. Environ. Sustain. 2022:100045. [Google Scholar]

- 33.Islam M.R., Ahmed S., Siddik M.A., Ashique S.M. Analysis of cotton yarn properties spun on aerodynamic compact and open-end rotor spinning. J. Text. Sci. Technol. 2021;7(1):22–40. [Google Scholar]

- 34.Pan R., Gao W., Li Z., Gou J., Zhang J., Zhu D. Measuring thread densities of woven fabric using the fourier transform. Fibres Text. East. Eur. 2015;23:35–40. [Google Scholar]

- 35.Maqsood M., et al. Modelling the effect of weave structure and fabric thread density on mechanical and comfort properties of woven fabrics. Autex Res. J. 2016;16(3):160–164. [Google Scholar]

- 36.Ali G., Iqbal M.Z., Iftikhar F.J. Advances in Supercapacitor and Supercapattery. Elsevier; 2021. MXene; pp. 255–269. [Google Scholar]

- 37.Mia R., et al. Natural dye extracted from Triadica sebifera in aqueous medium for sustainable dyeing and functionalizing of viscose fabric. Clean. Eng. Technol. 2022:100471. [Google Scholar]

- 38.Arenas J.P., Asdrubali F. In: Handbook of Ecomaterials. Martinez L.M.T., Kharissova O.V., Kharisov B.I., editors. 2018. Eco-materials with noise reduction properties; pp. 3031–3056. [Google Scholar]

- 39.Chidambaram P., Govindan R. Influence of blend ratio on thermal properties of bamboo/cotton blended woven fabrics. Sci. Eng. Health Stud. 2012;6:49–55. [Google Scholar]

- 40.Klein W. In: The Rieter Manual of Spinning. Eberli H., editor. Vol. 1. Rieter machine works ltd.; 2014. Raw material as a influencing spinning; p. 18. ch. 1. [Google Scholar]

- 41.Omeroglu S., Ulku S. An investigation about tensile strength, pilling and abrasion properties of woven fabrics made from conventional and compact ring-spun yarns. Fibres Text. East. Eur. 2007;15(1):39–42. [Google Scholar]

- 42.Izabela J. Assessment of a fabric surface after the pilling process based on image analysis. Fibres Text. East. Eur. 2009;17(2):73. [Google Scholar]

- 43.Sivakumar R., Pillay K. Study of pilling in polyester/cotton blended fabrics. Indian J. Textil. Res. 1981;6:22–27. [Google Scholar]

- 44.Bhattacharya S., Ajmeri J. Investigation of air permeability of cotton & modal knitted fabrics. Int. J. Eng. Res. Dev. 2013;6(12):1–6. [Google Scholar]

- 45.Atwal M.S. Factors affecting the air resistance of nonwoven needle-punched fabrics. Textil. Res. J. 1987;57(10):574–579. [Google Scholar]

- 46.Slater K. Comfort properties of textiles. Textil. Prog. 1977;9(4):1–70. [Google Scholar]

- 47.Olsauskiene A., Milasıus R. Proc. 2nd International Textile Clothing & Design Conference. 2004. Integrated fabric firmness factor as a criterion of air permeability designing. [Google Scholar]

- 48.Ogulata R.T. Air permeability of woven fabrics. J. Textile Appar. Technol. Manag. 2006;5(2):1–10. [Google Scholar]

- 49.Mia R., Sultana S., Bhuiyan M.S.K., Islam M.M. Improving ballistic performance of Kevlar fabrics by resin treatment. J. Textil. Inst. 2021:1–24. [Google Scholar]

- 50.Realff M., Seo M., Boyce M., Schwartz P., Backer S. Mechanical properties of fabrics woven from yarns produced by different spinning technologies: yarn failure as a function of gauge length. Textil. Res. J. 1991;61(9):517–530. [Google Scholar]

- 51.Basit A., Latif W., Baig S.A., Rehman A., Hashim M., Rehman M.Z.U. The mechanical and comfort properties of viscose with cotton and regenerated fibers blended woven fabrics. J. Mater. Sci. 2018;24(2):230–235. [Google Scholar]

- 52.Dhanalaxmi R., Vastrad J.V., Manish P. Mesta/organic cotton blended yarns for diversified end uses. Asian J. Home Sci. 2012;7(2):396–398. [Google Scholar]

- 53.Islam S., Ahmed M.S., Arifuzzaman A., Islam A.S., Akter S. Relationship in between strength and polyester content percentage of cotton polyester blended woven fabrics. Int. J. Cloth. Sci. 2019;6(1):1–6. [Google Scholar]

- 54.Eryuruk S.H., Kalaoğlu F. The effect of weave construction on tear strength of woven fabrics. Autex Res. J. 2015;15(3):207–214. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.