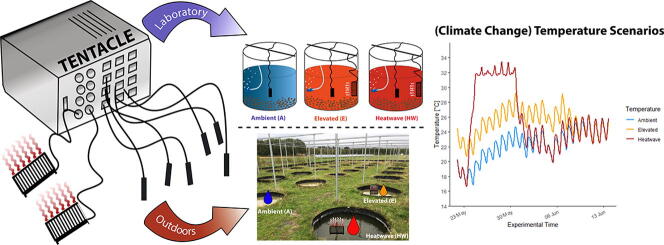

Graphical abstract

Keywords: Climate change temperature scenarios, Temperature manipulation, Heatwave, Aquatic micro-/mesocosm, Arduino controller, Transportable device

Abstract

Future global climate change with higher mean temperatures and increased intensity and frequency of heatwaves as extreme weather events will affect aquatic ecosystems with, yet, unpredictable severity and consequences. Although models suggest increased risk of species extinction up to the year 2050 for series of different climate change scenarios, environmental complexity may result in unconsidered effects of future temperature alterations on ecosystems. Apart from these environmental changes, additional anthropogenic stressors, e.g. chemical release, may cause unprecedented interaction effects on ecosystems. Ongoing efforts to better understand such temperature-chemical interaction effects comprise almost exclusively experimental designs using constant temperature regimes instead of environmentally realistic daily temperature variations. In this paper we describe an Arduino-based temperature and heatwave control device (TENTACLE) that is transportable, inexpensive, multifunctional, and easily reproducible. TENTACLE offers water temperature monitoring and manipulation of up to 3 different climate change-related scenarios: i) natural (ambient) sinusoidal fluctuations (laboratory applications), ii) elevated fluctuations, and iii) heatwaves as extreme events. The use of replaceable heating elements and low-cost materials suitable for field studies creates a high flexibility for researchers who may conduct in- or out-door, small- or large-scale, fresh- or salt-water experiments at different geographical locations.

Specifications table

| Hardware name | Transportable temperature and heatwave control device (TENTACLE) |

| Subject area |

|

| Hardware type | Temperature manipulations with sensors and logging system for laboratory- and field-applications |

| Closest commercial analog | No commercial analog is available |

| Open source license | Creative Commons Attribution-ShareAlike 4.0 Int. (CC BY-NC-SA 4.0) |

| Cost of hardware | 5200 Euro (2 operating boxes) |

| Source file repository | https://doi.org/10.17632/xh4h6kn382.2 |

Hardware in context

Temperature alterations in consequence of future global climate change (GCC) will affect aquatic ecosystems, entailing lentic freshwater bodies like shallow lakes, ponds or ditches. Latest climate assessments and calculated predictions of these prospective climate conditions [1] report higher mean temperatures and increased intensity and frequency of extreme weather events, such as heatwaves and warm spells [2], [3], [4]. The study of such direct GCC-related temperature effects on the physiology and phenology of aquatic organisms, species distribution patterns and biodiversity has been and continues to be of interest in different disciplines of environmental sciences. Indeed, modelling approaches evaluating different climate-warming scenarios indicate increased risk of species extinction for all magnitudes of temperature changes until mid of this century ergo likely future loss of biodiversity and associated changes in ecosystem processes and functioning [5], [6]. In the field of ecotoxicology, temperature-induced effects have received an increasing research interest through possible interactions with other anthropogenic stressors like chemicals. Temperature is expected to influence the fate of chemical compounds among others through modified degradation or distribution rates, and to cause biological and ecological effects, such as increased metabolism and changes in species composition.

At present, the joint effects of nonchemical GCC-related stressors and chemicals continue to be understudied with only few multiple stressor experiments being performed at population or community level in larger test systems (i.e. micro- and mesocosms) [7], [8], [9]. Given the ongoing effort of such climate-chemical multiple stressor experiments, these studies have almost exclusively applied an increased mean temperature within a constant temperature regime, instead of using environmentally realistic daily temperature variations [10], [11], [12]. The few available studies show the importance of including natural temperature fluctuations into the experimental design as they show more severe effects on species under chemical stress compared to using constant elevated mean temperatures [13], [14], [15]. Applying constant temperature regimes in climate-chemical multiple stressor experiments may thus not be representative for variable exposure conditions in natural habitats. Simulating different and environmentally realistic GCC-related changes of water temperature in indoor and outdoor aquatic micro- and mesocosms by a transportable device with the capability for long-term recordings and manipulations of temperature changes is thus highly desirable in this experimental field.

Water temperature changes are usually either controlled by common glass aquarium heaters with integrated temperature sensors or larger metal heating installations with external sensors, depending on the dimensions of the micro- or mesocosm. The basic functioning of those heating elements is simple with a set target temperature up to which the heater is automatically switched on. As soon as the target temperature is reached, the heater will turn off and will only heat towards target temperature again when a set threshold value is passed. Such a conventional heating element increases the temperature in the experimental test system over time to a target temperature which is pre-set by the manufacturer and non-adjustable, resulting in a constant temperature regime. A decrease in water temperature can only be obtained through a manual reset of the target temperature or by removing the power supply. Generating daily temperature variability would thus either be possible to a limited extent through major manual effort or for instance the integration and constant surveillance of automatic timers.

Experimental designs which consider environmental variability in their test systems (i.e. micro- or mesocosms) need novel features which comprise the manipulation and long-period measurements of multiple environmental conditions (i.e. temperature, salinity, pH and light) with real-time offsets from field measurements or self-developed environmental scenarios to study their effects on single species or communities [16]. Similar experimental designs apply automated monitoring through a sensor-carrying robot plus remote-controlled user interface for the environmental variables under investigation (i.e. temperature, pH, light intensity, light spectra, nutrients, flow and feeding) [17]. Other designs offered inexpensive materials and open-source hardware (Arduino) to control heating elements and CO2 injection systems [18]. They allow real-time monitoring and constant manipulation of water temperature by fully-automated systems, comprising temperature (micro-) controller in combination with installed heating elements and (digital) temperature sensors [19], [20], [21], or heat exchange pipes fed by hot water tanks combined with a differential thermocouple [22], respectively. Additional improvements in aquatic experimental research, particularly considering spatial and temporal aspects, are for instance provided by mesocosm infrastructures [23] equipped with autonomous and high frequency measuring systems. However, these settings own limitations in possibilities for experimental manipulation (e.g. temperature) so that researchers will need to add their own instruments and equipment to the available infrastructure.

Hardware description

While the latest experimental designs in aquatic test systems provide significant improvements for their individual research questions, the majority of global climate change experiments with a focus on future temperature scenarios apply mainly one type of future heating scenario with either constant target temperature regimes (e.g. [24]), a constant target temperature regime vs. reference temperature regime (e.g. [25]), or included periodically heating (e.g. [7]). Nowadays, easy accessible and cheap electronic components, improvements in the water resistance of building materials, and open-source electronic programming platforms, such as Controllino by Arduino, allow for device control of additional features in water temperature manipulations (e.g. different future temperature scenarios). This offers new opportunities for researchers in conducting environmentally realistic global climate change experiments.

The complete design of the TENTACLE device consists of two water resistant boxes (Rittal) that are equipped with identical hardware (box 1 and box 2). Device duplication allows for simultaneous control up to 32 aquatic test systems. Both boxes have identical dimensions and open with a lockable door (Rittal) on top allowing direct access to the hardware equipped with the following core components and electricity safety features: i) one Microcontroller (Controllino MEGA), ii) one DIN rail power supply (Mean Well), and iii) one surge protection (Phoenix), 4 circuit breakers (Schneider), 17 fuses (Phoenix, Wago Topjob, Schurter), and 16 solid state relays with visual indicators (Sensata/Crydom).

The core component of the device is the 12 V, 4.5 A power supplied microcontroller which can be connected to a computer via an USB 1.0/2.0 Type B-port to upload or edit the Arduino source code for device functionality. Because of such a quick and easy established connection to the microcontroller and all related device operations, short-term code modifications or adjustments are also possible outdoors when the device is already installed within the experimental setup. We integrated a combination of different electrical safety features to prevent harm in case of accidental water spillage or water entry because of precipitation during outdoor experiments. In the event of electrical short-circuits or an overload of the device, the power supply will immediately be cut off to exclude any potential threat towards the researcher.

The front, side and top part of each box is designed with: i) 16 sockets (Rean products) for digital temperature sensors (ControlByWeb, DS18B20), ii) 16 electrical sockets (Hirschmann) to connect electrical cables (Helucables) with heating elements (Eheim, Aqua Medic, Schego), iii) one RJ45 connector (Amphenol Socapex) for a common Screened Shielded Twisted Pair (SSTP) patch cord (Cat6 network cables), iv) one main electrical switch (Eaton Industries) to control the general power supply via CEE plug (Mennekes), v) one on/off selector switch (Eaton Industries) to control only the power supply of all heating elements, and vi) one green light signal (Eaton Industries).

We use these digital temperature sensors because they are ideal for continuous indoor and outdoor applications. The cable is waterproof and weather resistant with a stainless steel encapsulated 1-Wire temperature sensor that measures over a wide temperature range (−20 °C to + 85 °C) with high accuracy (±0.5C) for changing temperatures (−10C to +85 °C) when fully submerged in water. We additionally used shrink tubing as protective coverage of the connections between the stainless steel part and the cable. The standard cable comes with 10 m length required for the installation in larger aquatic test systems with larger distances between the device and the test systems. The wires for data, ground and electricity can be easily connected to a miniature connector (Rean products).

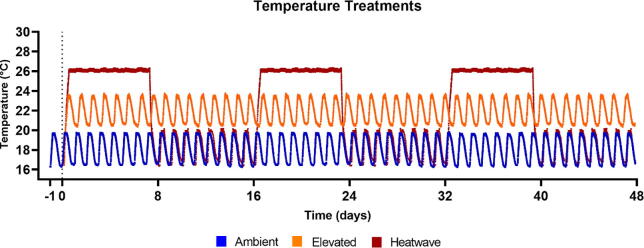

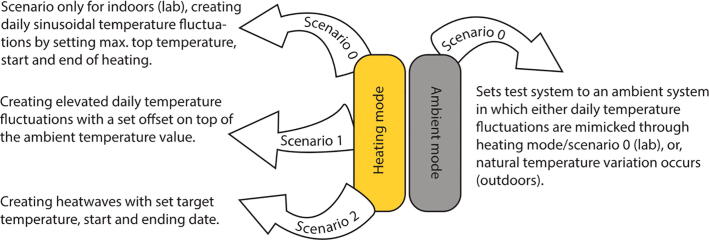

For the simplified connection of heating elements, we modified the black 3 G 1 electricity cable (Helukabel) by adding a grey cable mount at the end (Hirschmann) that fits to the corresponding plugs of the device. Cable length was chosen (10–15 m) based on estimated distance between the box and the test systems in later planned field experiments. The last electricity plug of Box 1 (no.16) is set to constant electricity supply to provide power for a computer. This becomes of great important for field experiments where power plugs might not be as available as in indoor laboratory studies. The other end of the electricity cable has a waterproofed 250 V, 16 A Schuko-connector (PCE) which fits on all conventional heating elements. We achieved very satisfactory results with the device in small scale indoor experiments with one 150 W heating element (Eheim) and two 300 W and 600 W (Aqua Medic, Schego) heating elements in large scale outdoor experiments (see Validation and characterization). For the larger test systems in the field, the electricity cable connects to a field power socket (Hongyi) to supply electricity for two heating elements. In this setup, we additionally place the waterproofed Schuko-connectors in water resistant green plastic eggs (Heitronic) to protect them from weather disturbances and to additionally prevent any accidents, e.g. during sampling campaigns in the field. Considering the different temperature scenarios (Fig. 1), temperature signal processing is required to mimic elevated temperature fluctuations (scenario 1) by calculating the mean temperature of all ambient test systems at a set time interval. Temperature fluctuations in ambient test systems are either naturally occurring outdoors or simulated indoors (scenario 0 of Fig. 1). In the latter case, sinusoidal fluctuations represent daily temperature fluctuations. The calculated offset to this mean value will determine whether a heating element in scenario 1 is switched on or off. Temperature data reads from scenario 0, therefore, determine the outcome of scenario 1, while the heatwave settings (scenario 2) are completely independent from any of the other temperature scenarios, in this case resulting in minor daily fluctuations (see scenario 2 in Fig. 7 as an example). Thus, the following two programming options for temperature are possible: i) programmed temperature pattern and ii) programmed elevation of temperature compared to a reference.

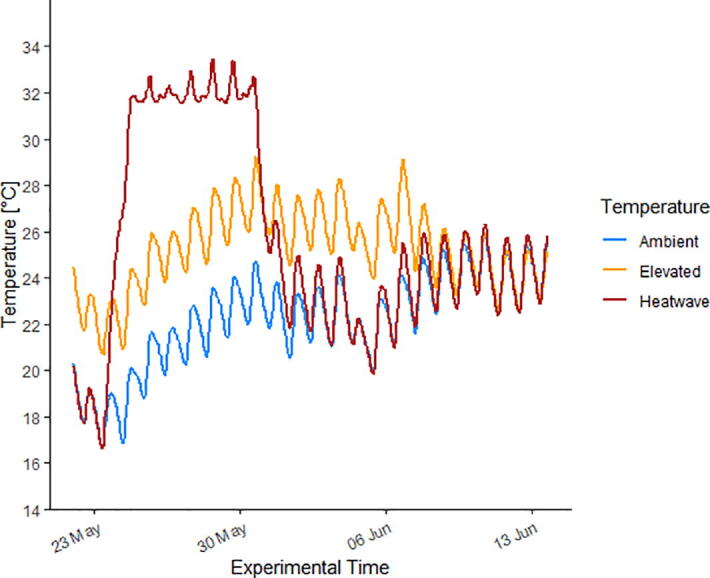

Fig. 1.

All three different temperature scenarios (ambient, elevated and heatwaves) over time with an exemplary average ambient temperature (blue) of 18 °C (scenario 0 indoors), elevated temperature (orange) of 22 °C (scenario 1) and 8 days heatwave (red) with 26 °C (scenario 2) as top target temperature. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

Fig. 7.

Overview of all probe and scenario settings on the Probes states & settings interface and their application in an experiment. The ambient mode (right side) does not include scenario 1 and 2 as for the heating mode (left side).

The dual connection from a computer with a common SSTP patch cord allows for real-time computer communication with the device and is needed to set and monitor the desired heating scenarios in the assigned test system via an installed computer graphical user interface (GUI). Most computer models provide by default only one available RJ45 connector so that for instance an USB 3.0 to ethernet network adapter will be required for the connection of the second box.

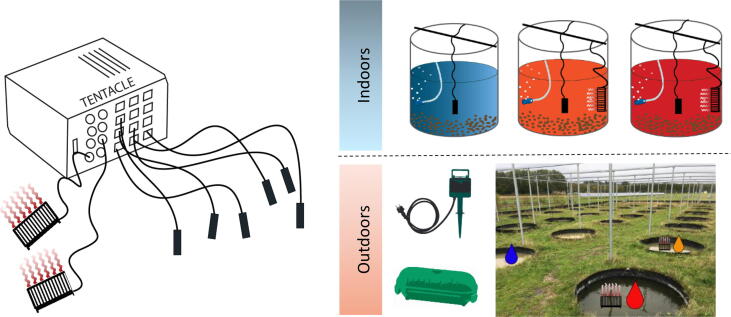

Each box is either directly power supplied via a 400 V, 16 A CEE cable, suitable for indoor experiments, with a 4P, 400 V, 16 A plug, or indirectly via two H07RN-F electric extension cables (Kalle Red), applicable in outdoor experiments, connected to a 4P, 400 V, 32 A power distributer (IP44) with two 400 V, 16 A CEE sockets. For the additional protection against electrical hazards during field experiments, all power current connecting parts were either additionally boxed in waterproofed cases or, if possible, placed indoors. Finally, the power distributer connects to the main power supply to guarantee full functionality of all device parts. We also installed an additional selector switch which is only controlling the electricity flow to the heating elements but not of the microcontroller. This setting is, for instance, favourable when only water temperature monitoring is needed while keeping the initial setting of heating scenarios running. For further safety aspects and to visually indicate if current voltage is present in the device, we also installed a green LED that is only turned on with activated T2 safety main switch. Fig. 2 presents a schematic drawing of all the features and the usage of the device with different test systems.

Fig. 2.

Features and applications of the device in different test systems (indoors and outdoors), including a TENTACLE box with integrated Arduino microcontroller and electrical components, connected heating elements, and temperature sensors.

We developed a transportable, automated device to monitor and manipulate water temperatures in up to 3 possible highly environmentally realistic scenarios (i.e. current natural ambient fluctuations in indoor applications, future elevated fluctuations, and heatwaves as extreme events) with replaceable heating elements in indoor- and outdoor test systems of different sizes. We use an Arduino microcontroller in our transportable temperature and heatwave control device (TENTACLE) as core operating unit to switch heating elements on and off via the main configurations of the computer GUI. We designed an easy, self-explanatory and MS Windows compatible GUI for TENTACLE which comprises various settings in the main configuration window for temperature manipulations, information about last in-situ temperature measurements, probes states and selected scenario settings, as well as a continuous graphical output of all temperature recordings, such that infinite different characteristics of temperature scenarios are theoretically configurable. Together with additional heating element equipment and by using material suitable for field-studies (Table 2), we designed TENTACLE as a mobile, inexpensive device with total material costs of about 5000 EUR for both boxes to work with up to 32 laboratory or field aquatic test systems, i.e. 2500 EUR for one box and 16 test systems. Our goal was to develop a device which offers researchers significant improvements and new possibilities in their experimental designs of aquatic temperature-focused climate change studies, expanded logistic flexibility, and a comprehensible functionality with a reproducible construction. TENTACLE is a low-cost alternative when compared to expensive testing facility upgrades and thus, particularly in academic research with desirable multifunctionality but limited budget, potentially of high interest for researchers who seek for new opportunities in their indoor or outdoor, small- or large-scale aquatic (including fresh- and salt waters) experiments across different geographical locations.

-

•

TENTACLE as a transportable, inexpensive, multifunctional temperature monitoring and controlling device offers in fresh- and salt waters, indoor and outdoor micro- and mesocosms new and environmentally realistic climate change-related experimental designs.

-

•

Arduino microcontroller-based TENTACLE allows for up to 3 different climate change-related temperature manipulations including controlled ambient temperature fluctuations for laboratory applications, elevated temperature fluctuations, and heatwaves.

-

•

GUI for TENTACLE allows for easy adjustments of the heating or ambient mode and the scenario with the included temperature manipulation characteristics being: maximum temperature in-/de-crease of sinusoidal temperature curves, maximum top temperature, start/end time of heating (ambient temperature), temperature increase by X °C (elevated temperature), heatwave target temperature X °C with start and ending date, and selection of data saving directory and time interval.

-

•

TENTACLE has 32 sockets for digital temperature sensors with adjustable data saving interval providing information about (natural) temperature dynamics, changes, and manipulation status in up to 32 aquatic test systems.

-

•

TENTACLE has 32 electricity sockets to connect replaceable heating elements with different electrical power for temperature manipulations in aquatic test systems of different size.

Table 2.

Complete bill of materials list, including the parts for the TENTACLE device, additional equipment for indoor- and outdoor application and previously used heating elements.

| Designator | Component | No. | Cost/EUR | Total cost/EUR | Store | Material type |

|---|---|---|---|---|---|---|

| Inside TENTACLE | ||||||

| Cabinet | Rittal cabinet G0036806 | 2 | 161.00 | 322.00 | technischeunie.nl | Polymer |

| Microcontroller | Controllino MEGA 100–200-00 PLC-control module | 2 | 335.00 | 670.00 | conrad.nl | Semiconductor |

| DIN rail power supply | Mean Well DR-60–12, 12 V, DC 4.5A 54 W | 2 | 27.99 | 55.98 | conrad.nl | Semiconductor |

| Type 2 surge protection | Phoenix contact val-ms 230ST | 2 | 40.93 | 81.86 | conrad.nl | Semiconductor |

| Residual current circuit breaker | Schneider ACTI9 ICV40 1PN B 6A 4,5KA | 2 | 131.20 | 262.40 | technischeunie.nl | Composite |

| Residual current circuit breaker | Schneider DOMAE Vigi 4.5KA B16 30MA | 6 | 92.55 | 555.30 | technischeunie.nl | Composite |

| Fuse terminal | Phoenix Contact ST ST 4-HESI (5x20) | 34 | 4.39 | 149.26 | technischeunie.nl | Polymer/Metal |

| Connection terminal | Wago Topjob S 3-DR. 2.5MM2 BL. | 10 | 0.91 | 9.10 | technischeunie.nl | Polymer/Metal |

| Earth terminal | Wago Topjob S 3-DR. 2.5MM2 GR/GE | 4 | 1.59 | 6.36 | technischeunie.nl | Polymer/Metal |

| Twin terminal | Wago Topjob S 3-DR. 2.5MM2 GR. | 20 | 0.86 | 17.20 | technischeunie.nl | Polymer/Metal |

| Glass fuse | Schurter cartridge TD, 4A, 250 V, 5mmx20mm | 32 | 0.29 | 9.28 | nl.farnell.com | Glass/Metal |

| Solid state relay | Sensata/Crydom 5A, Zero Cross, DIN rail, 280 V, Maximum load | 8 | 110.15 | 881.20 | nl.rs-online.com | Semiconductor |

| General small electric wiring supply | Depending on connected electrical component | – | 50.00 | 50.00 | General electrical supply | Semiconductor |

| Outside TENTACLE | ||||||

| Cabinet door lock | Rittal KS 1484 cabinet lock | 2 | 12.09 | 24.18 | technischeunie.nl | Polymer |

| T2 safety switch | EATON Industries | 2 | 52.52 | 105.04 | technischeunie.nl | Composite |

| On/Off selector switch | EATON Industries M22-WRK/K10 | 2 | 18.07 | 36.14 | technischeunie.nl | Composite |

| SSTP patch cord | Cat6 network cable, patch cable | 2 | 7.99 | 15.98 | amazon.com | Composite |

| RJ45 connector | Amphenol Socapex, female | 2 | 20.78 | 41.56 | nl.rs-online.com | Composite |

| Gigabit Ethernet computer adapter | Startech.com, USB3.0, USB31000S | 1 | 35.00 | 35.00 | centralpoint.nl | Composite |

| Electricity cable | Helukabel, H07RN-F LS0H, 3G1, 100 m | 1 | 134.40 | 134.40 | conrad.nl | Composite |

| Schuko connector | PCE, black/red, 16A/250 V, 3P, IP54, Taurus 2 | 32 | 3.95 | 126.40 | hornbach.de | Composite |

| Panel mount plug and socket | Hirschmann, ST P. M. 3P, 16A, 250 V ac/dc | 32 | 3.61 | 115.52 | nl.rs-online.com | Semiconductor |

| Grey cable mount | Hirschmann, ST IP54 Grey 2P, at 16A, 250 V | 32 | 5.07 | 162.24 | nl.rs-online.com | Semiconductor |

| Digital temperature sensor (10 m) | ControlByWeb 1-Wire sensor (DS18B20) | 32 | 31.99 | 1023.68 | antratek.nl | Metal |

| XLR chassis mount connector | Rean products, male, 3 way, gold plating | 32 | 3.11 | 99.52 | nl.rs-online.com | Semiconductor |

| XLR cable mount connector | Rean products, female, 3 way, gold plating | 32 | 3.98 | 127.36 | nl.rs-online.com | Semiconductor |

| CEE plug | Mennekes AM-TOP 4P, 400 V, 16A – 6 h | 2 | 13.75 | 27.50 | technischeunie.nl | Polymer |

| Green signal lamp front element | Eaton Industries RMQ-Titan L | 1 | 6.19 | 6.19 | technischeunie.nl | Polymer |

| Green signal lamp holder and LED | Eaton Industries RMQ-Titan M22-LED-G | 2 | 9.00 | 18.00 | technischeunie.nl | Semiconductor |

| Additional equipment for outdoor applications | ||||||

| CEE electric cable (50 m) | H07RN-F Kalle Red 400 V, 16A (Mennekes) | 2 | 120.43 | 240.86 | kalledaskabel.de | Polymer |

| Field power socket | 2 sockets, 3.5 kW, IP44, Art. 3,442,597 | 19 | 9.99 | 189.81 | obi.de | Polymer |

| Cable protection boxes | Heitronic 21050, green, IP44 | 19 | 2.93 | 55.67 | conrad.nl | Polymer |

| Power distributer | Brennenstuhl BKV 2/4 G IP44 | 1 | 62.55 | 62.55 | amazon.de | Composite |

| Additional replaceable heating equipment for indoor and outdoor applications (number of heaters depend on no. of test systems) | ||||||

| Small heater | Eheim thermo control precision heater, 150 W | 14 | 15.52 | 217.28 | aquaristic.net | Glass |

| Small heater | Aqua Medic Titanium heater, 300 W | 19 | 45.49 | 864.31 | aquaristic.net | Metal |

| Large heater | Schego Titanium heater, 600 W | 19 | 54.00 | 1026.00 | nature2aqua.de | Metal |

Design files summary

Mechanical components

TENTACLE is designed for outdoor use which is why we have only used weather resistant components. Both boxes are polymer-made with a metal front and a panel with rubber rings for air sealing. Both boxes are resistant to dust and water, thus IP68 rated. For a protective high voltage power supply, we used a CEE-contact stop with corresponding cabling which is IP44 rated for the connector points. Independent of the type of IP rating, we would always recommend to add other types of material protection to the boxes (e.g. a roof or shelter) because of material corrosion or decay when exposed to outdoor changing weather conditions for longer period.

To connect the digital temperature sensors and heating elements, we made our own custom laser cut-out front panel. The 3D part files that we used for our specific box can be found in the online repository. We designed the panel to fit 16 XLR and 16 STAS connectors. Further details and a description of both connector types can also be found in Summary of the material costs. XLR connectors for the sensor cables were used because of the 3 wiring characteristics (ground, 5 V, and data). Apart from this, the connectors are suitable for outdoor use as they are originally designed for microphones at outdoor events. We used STAS connectors because they are protected against dust and water splashes with international approval. The power rating of these connectors is more than sufficient for our application purposes with rubber seals on the panel mount part.

Electrical components

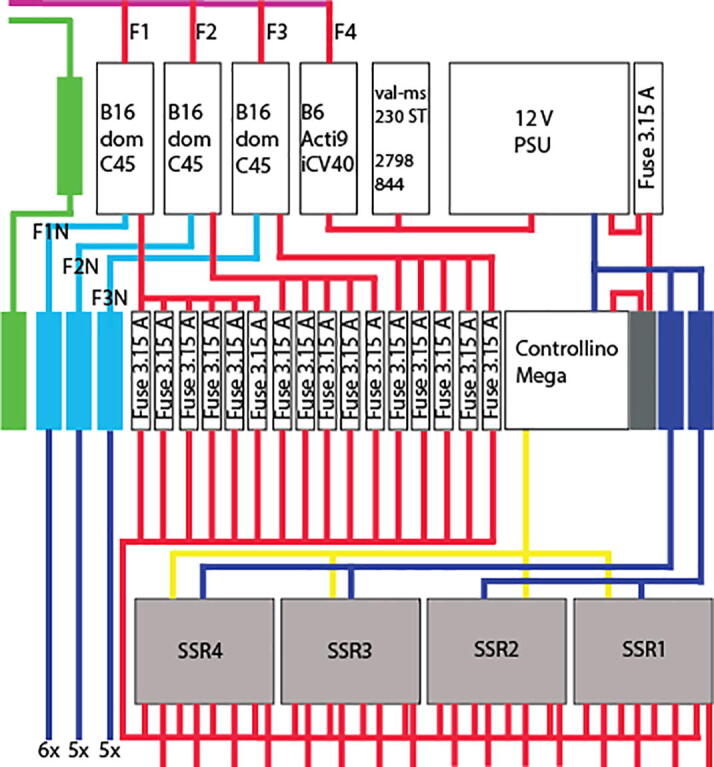

Power distribution is one of the most important aspects during development phase, so we calculated the maximum power demand for small and large experimental designs in case that all heaters were powered at the same time. Such designs would need between 3000 and 18000 W in total, so we electrically designed the box to split power over 4 power leads. Every lead is connected to a separate circuit breaker for extra safety with regards to outdoor application with high voltage.

One box uses 3 of the 4 power leads to power the heater section of the box, so each lead being connected to two times 5 and one time 6 heaters. After every circuit breaker that we placed for the power lead, we also placed fuses for every heater. If 1 of the heaters would malfunction, only 1 heater would switch off and someone can easily identify which heater is faulty due to a burned fuse. The fuses are located in the middle of the box. The heaters are switched on using a Solid State Relay (SSR) controlled by a Controllino Mega. We opted to use SSRs instead of mechanical relays because SSR’s use much less power, produce much less electrical interference, generate less heat and have a longer life span. The only downside is that SSR’s are much more expensive.

The remaining power lead supplies electricity to the Controllino Mega. We opted for this control unit because it is an industrialized Arduino with enough outputs and processing power. At the time of the machinery development phase, our programming knowledge was mostly driven around C/C++ and PLC programming languages which was beneficial for the TENTACLE coding. Since we were using an open source Arduino-like control unit, a lot of the equipment we used had small examples available on the internet on how to read signals and process them using industrialized protocols, such as MODBUS.

We used standard components for the construction of the box based on recommendations and professional electrical designing experience of other colleagues as well. Fig. 3 illustrates TENTACLE’s inside electrical components and cable wiring in a schematic drawing.

Fig. 3.

Schematic drawing of TENTACLE’s inner electrical components and cable wiring. The whole cable wiring consists of: high power bundle of all powering parts (violet), ground wire (green), power and voltage (230 V, 12 V, red), null for the 230 V applied for heating elements (light blue), signal wires coming from the Controllino Mega unit (yellow), and 0 V ground for the 12 V circuit used for the Controllino (dark blue). (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

Arduino software

The software running on the Controllino Mega can be found in the online repository. The program itself can be opened in any C/C++ editor to make adjustments. Additionally, in the online repository we have provided a process flowchart of the code which supports the understanding of the general processes.

The software is designed to work off a configuration given via the computer interface. After a configuration is given, the code will run with the same configurations after an intended reboot or when, for instance, the computer itself has lost power. This is managed by configurations savings to the EEPROM on the controller. We also provide a protocol excel sheet in the online repository where we documented each available MODBUS and EEPROM setting. The sensors are being read over the one-wire protocol and the sensor readings are sent to the computer over a UDP ethernet connection.

Computer interface

The software of the computer interface can be found in the online repository in combination with an installation file. The code of the computer interface is written in C# with an extra library for MODBUS communication. The interface is designed to establish an easy access to all functionalities of TENTACLE. There are tab groups separating all recording from set-up options. All configurations and their operation modes are further described in Operation instructions. Additional feedback boxes facilitate direct communication with TENTACLE.

Design files

All design files described in Table 1 are stored and downloadable in the online repository: https://doi.org/10.17632/xh4h6kn382.2

Table 1.

List of all design files considering electrical design-, laser cut-, Controllino-, and computer software-files for the TENTACLE device.

| Design file name | File type | File descriptions | Location of the file |

|---|---|---|---|

| Electrical design files | |||

| Electrical Layout.png | png | Electrical layout of the electronics inside the box | ./Electronic design/Electrical Layout.png |

| Laser cut files | |||

| Kast connectoren.DXF | DXF | Laser cut drawing of the front panel of the boxes for the connectors | ./Lasercut/Kast connectoren.DXF |

| Controllino files | |||

| Protocol list.xlsx | xlsx | Excel file with all the protocols used for the Controllino | ./Software/Controllino software/Protocol list.xlsx |

| avrtemp.ino | ino | Code for calculating the average temperature of the sensors that are enabled for calculating | ./Software/Controllino software/Code for controllino x/controllinortcv3/avrtemp.ino |

| controllinortcv3.ino | ino | Setup and main loop code for the boxes | ./Software/Controllino software/Code for controllino x/controllinortcv3/controllinortcv3.ino |

| Datalog.ino | ino | Code for writing the sensor data over UDP to pc. This file also has some old code for write to SD card example | ./Software/Controllino software/Code for controllino x/controllinortcv3/Datalog.ino |

| Definement.ino | ino | Defines the output pins to human readable variables used for the code later | ./Software/Controllino software/Code for controllino x/controllinortcv3/Definement.ino |

| Heatercontrol.ino | ino | Code used for the scenarios | ./Software/Controllino software/Code for controllino x/controllinortcv3/Heatercontrol.ino |

| Heatewaveindoor.ino | ino | Code was for early stage indoor testing. Currently not used in this project anymore but can be reprogrammed to do so | ./Software/Controllino software/Code for controllino x/controllinortcv3/Heatewaveindoor.ino |

| Maxhourtempcalculator.ino | ino | Code reads Modbus registers and update the variables used for later | ./Software/Controllino software/Code for controllino x/controllinortcv3/Maxhourtempcalculator.ino |

| maxtemperhour.ino | ino | Code reads Modbus registers and update other registers with the correct maxtemp per hour used in the scenarios | ./Software/Controllino software/Code for controllino x/controllinortcv3/maxtemperhour.ino |

| ModbusStatus.ino | ino | Code read the I/O of the control unit and writes it to the Modbus registers. It also updates the eeprom with newly updated Modbus values | ./Software/Controllino software/Code for controllino x/controllinortcv3/ModbusStatus.ino |

| onewireEdit.ino | ino | Code reads with the onewire protocol all the sensor data and writes it to the correct Modbus address | ./Software/Controllino software/Code for controllino x/controllinortcv3/onewireEdit.ino |

| Realupdate.ino | ino | Code read the sensor data and converts it to readable values and writes it to the correct Modbus registers | ./Software/Controllino software/Code for controllino x/controllinortcv3/Realupdate.ino |

| RTCMod.ino | ino | Code reads the Real Time Clock of the Controllino and writes that time to serial and to the correct modbus registers | ./Software/Controllino software/Code for controllino x/controllinortcv3/RTCMod.ino |

| ScenraioSelect.ino | ino | Code read Modbus registers used for checking if a probe is used for heating or just collecting temperature and writes that to the correct eeprom of the control unit | ./Software/Controllino software/Code for controllino x/controllinortcv3/ScenarioSelect.ino |

| UDP.ino | ino | Code reads the incoming and outgoing data over UDP. It reads the configuration from the interface program and writes sensor data back to the interface | ./Software/Controllino software/Code for controllino x/controllinortcv3/UDP.ino |

| Computer software files | |||

| Visual studio compilation | File are needed to run the program in visual studio | ./Software/Computer interface/CTCS_Controller/ | |

| CTCS_Controller_Serial.sln | sln | ./Software/Computer interface/CTCS_Controller/CTCS_Controller_Serial.sln | |

| Installer compilation | Files are needed to create an installer from visual studio | ./Software/Computer interface/CTCS_installer/ | |

| CTCS_installer.msi | msi | This file is the executable used for installing the interface | ./Software/Computer interface/CTCS_installer/CTCS_installer-SetupFiles/CTCS_installer.msi |

Summary of the material costs

An overview of the costs of the different components of TENTACLE is provided in Table 2.

Building instructions

Physical parts of TENTACLE

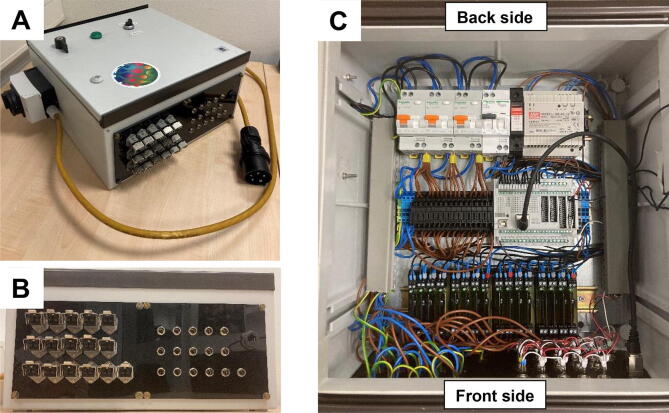

TENTACLE consists of various small parts to be connected with each other to gain full functionality of the device. We got an electrical box from the manufacturer and modified it to our needs for indoor and outdoor experiments. Modifications made are a new front panel in the box (Fig. 4 A,B), so we could plug in our sensors and heating elements without opening the box. The panel was made using laser cutting tools. All laser cutting files (Table 1) can be found in the online repository. For the front panel, we mounted a 6 mm thick acrylic plate and made it water resistant by putting rubber straps between the plate and the box from the inside. By doing so, it’s advisable to use proper cutting equipment and protective measures. Neglecting these precautionary steps before cutting that type of boxes may potentially harm health through the inhalation of thin fibres.

Fig. 4.

The TENTACLE device: external view with closed door and high voltage cable (A), the front panel view (B), and the internal view with all electrical units and cable wiring (C).

Inner, electrical part of TENTACLE

Since TENTACLE uses high power electricity as previously described in Electrical components, it’s highly recommended that only technically qualified personnel build the inner electronics part of the device. In the same section, design and cable wiring for the internal parts of the device are demonstrated. Using the proper wire thickness according to the datasheets of each electrical component is advisable, same as, using rather thicker than thinner wires. Cable wiring in the box is facilitated by first placing electrical components with some additional space by each connector. Once all electrical units are correctly placed in the box, cable wiring can be conducted while the front panel is the last connected part (Fig. 4 C).

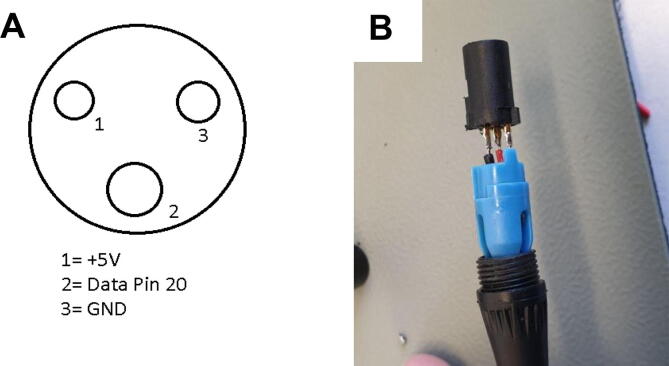

The most time consuming part of device construction is soldering the wires into the limited space. Each sensor connector must be soldered from the inside of the box according to the correct pin out (Fig. 5 A). Everything was soldered on the panel outside of the box and the last wire when inside. The sensor cables are quite small to solder (Fig. 5 B) but an experienced person should be capable of doing so.

Fig. 5.

The correct cable pin out (A) of the sensor cables (B) soldered and installed in TENTACLE.

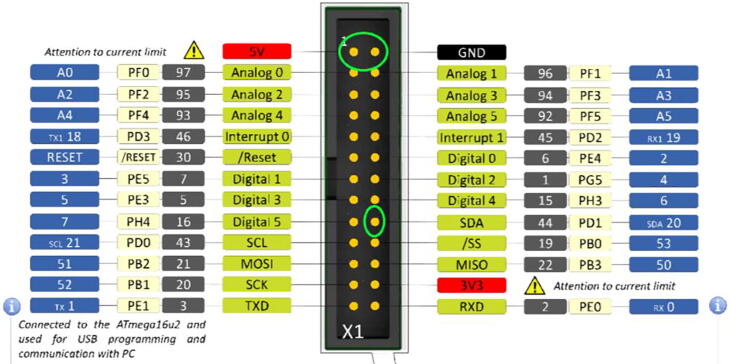

The one-wire uses 5 V as a power source and the Controllino normally uses 12/24 V for it’s in- and output. The great advantage of the Controllino unit is the location of the output pins directly located on the outer top of the control unit. We wired the one-wire sensors directly to the Controllino’s head as graphically shown in Fig. 6. Correct wiring of these cables, indicated by green circles in the figure, is crucial since incorrect cable wiring may lead to electrical failure or even electrical chip damage of the Controllino unit.

Fig. 6.

Controllino’s head with accessible connecting pins on top of the electrical unit. Green circles indicate the correct one-wire cable wiring. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

Software installation

Installing the software is simple and straightforward for the TENTACLE device. The code for the Controllino main control unit and the software used for the computer interface can be found in the online repository. Code upload to the Controllino can be done via the Arduino IDE. The installation of the proper board configuration, to be found on the Controllino website, is required. Additionally, the code for box 1 and 2 is available on the repository. Codes differ only in the local IP-addresses hardcoded in the source code. The installation of the computer interface code runs via an installer file which can be directly downloaded from the online repository. No further actions are needed because the installer file applies all necessary functions for successful TENTACLE communication. It’s noteworthy that the provided interface code only works on Windows operating systems (OS) and is not designed or tested for Linux or any other OS.

Operation instructions

Before using TENTACLE in the experimental test systems, it is advisable to first have a pilot test run with unconnected heating elements, e.g. by crosschecking the visual light output of the solid state relays. This can be done individually for every single slot by choosing any heating scenario.

For the first operational step, make sure that all digital temperature sensors are submerged in the water and connected to the device. Same applies for the heating elements in the test systems which are connected to the Schuko-connector of the electricity cables and finally hooked up to TENTACLE. Previous experiments with the device have shown that simultaneous plugging in of digital temperature sensor and heating element facilitates cable management. Next, make sure that the computer with the installed GUI for TENTACLE has continuous power supply and network connections to both boxes. Open the CTCS_Controller program with the Main configurations on the first opening page, followed by the tabs: Measurement, Probes States & Settings, and Graph. In total, 10 different parameters shown in Table 3 can be set allowing adjustment of: maximum temperature in-/de-crease per hour of sinusoidal temperature curves, maximum top temperature with start and stop time for heating (scenario 0), temperature increase by X °C (scenario 1), heatwave target temperature X °C with start and stop date (scenario 2), selection of data saving directory and time interval, and the selection of probes (up to 32) to be considered in the application and the graphical output. Scenario 0 settings are required when imitation of daily temperature fluctuations are needed, e.g. for indoor experiments without natural diel temperature variation.

Table 3.

GUI with main configurations of TENTACLE including a description of all device settings.

| Settings | Parameter | Description |

|---|---|---|

|

||

| Top panel with 4 tabs | Allows to switch between configurations and monitoring | |

| Maximum temperature in-/de-crease | Sets the maximum increase of temperature per hour | |

| Only for indoor applications: | ||

| Maximum top T | Sets top temperature of a diel | |

| Start time | Sets starting time of heating | |

| Stop time | Sets ending time of keeping top temperature | |

| Temperature increased | Sets elevated temperature | |

| Heatwave (HW) target | Sets HW top temperature | |

| Start date measurement | Sets starting date of the HW | |

| End date measurement | Sets ending date of the HW | |

| Save data to | Sets saving directory of all data | |

| Save data every | Sets saving interval |

Click for the final settings on the Probes States & Settings tab to continue with state and scenario selection of each probe. All possible settings and their corresponding meaning for the temperature scenario are demonstrated in Fig. 7. Default settings of all probes are heating mode and scenario 0. In case of not using all probes and temperature sensors, one can use the temperature sensor additionally for the ambient reference temperature.

Before starting TENTACLE by pressing the Start System button, make sure all settings are corresponding to the experimental design and that the set saving directory is unique. Upon start up, a status message about a stable connection to each individual box is presented and the first temperature reads will be reported instantly in the feedback boxes on the GUI. Reported temperature values can be read from left to right and correspond to the connected temperature sensor slot number. It’s noteworthy that even when a temperature sensor slot is not used, the device will constantly account for the number of connected sensors. The running device can be stopped any time by pressing the Stop System button which is also necessary in case of incorrect entries for the parameter or probes settings. In such a case, it’s useful to create a new data saving directory and to empty the feedback boxes before starting TENTACLE again. Monitored temperatures are continuously updated with the set data saving interval and an overview is presented by clicking the measurement and graph tab. Additionally, we recorded a 8 min long operation instruction video that can be accessed via the online repository.

We distinguish between potential electrical hazards from all electrical parts of TENTACLE as well as mechanical hazards from the additional equipment for laboratory or field application. TENTACLE is operated with a standard 400 V power current cable and plug, such that working with high voltages require adequate cable connection and protection within the device especially when working outdoors with changing weather conditions. We described in the section Hardware description examples of the additional protective measures that we took, apart from the integrated safety features of TENTACLE itself, to prevent any electrical harms. Mechanical hazards can arise from working with large, metal heaters when working with them for longer periods in the field and that is why they should be regularly checked through maintenance. Finally, there’s a risk of burns when replacing the large heating elements in operational mode.

Validation and characterization

Our first indoor study with TENTACLE and aquatic microcosms was conducted in 2019 of which we will use the temperature records for the validation of the system. We were running all three described temperature scenarios in a setup of 30 test systems in total which were placed in water baths. This experimental setup also offered cooling options with a water cooling device to create a temperature decrease in the fluctuations with desired amplitudes. Light conditions were additionally controlled with separately computerized increasing and decreasing light intensity patterns synchronized to the daily temperature fluctuations. We set the temperature recording interval in this experiment to 2 min resulting in 35,280 datapoints for one test system over the experiment.

In a later conducted outdoor mesocosm experiment with 24 test systems, we used the elevated temperature and heatwave scenario with reference to natural daily temperature fluctuations as our ambient regime. In this field experiment, additional outdoor equipment (see Table 2) and heating elements were used as described in Hardware description. The temperature recording interval in this study was set to 3 min in the outdoor study, collecting temperature data of 40,320 datapoints for one test system over the experiment.

There’s at the moment no commercial device on the market which comprises or relates to the described features of TENTACLE. For this reason, comparisons of technical standards with other devices are not possible. Regarding the replaceable temperature sensors and heating elements, all of them were standardized, tested, and certified by the manufacturers. In this case, own calibration of the temperature sensors was not needed and correct wiring for TENTACLE was accomplished by following the manufacturer’s specifications. Additional information like general features, electrical characteristics and performance of the sensors were obtained from the technical data sheets prior purchase. One of the major differences between the used glass heating elements and the titanium versions (Table 2) is that the latter ones do not have an integrated thermostat and thus require a temperature controlling device, such as TENTACLE, to regulate temperature. In contrast, the glass heating elements can heat and maintain a set constant target temperature by default, indicated by a control lamp, and allow for recalibration. For the purpose of generating the different temperature scenarios (Fig. 7) by TENTACLE, these type of heating elements need to be set to highest possible heating temperature so that temperature control is fully guaranteed by TENTACLE.

We address potential uncertainties and the reliability of TENTACLE in the following two subsections Experimental validation and Results and performance of TENTACLE. The suggestions and conclusions made are not based on standard specifications but rather on the outcome of conducted experimental studies and observations during the device applications.

Experimental validation

TENTACLE was continuously running for 7 weeks in the indoor microcosm experiment (Fig. 8) simulating heatwaves for 8 days at the set top target temperature of 26 °C with a subsequent recovery period of 8 days at fluctuating ambient temperatures. Furthermore, fluctuating elevated temperatures of 20.5 to 23.5 °C with a mean of 22 °C were simulated in relation to ambient temperatures of 16.5 to 19.5 °C and a mean of 18 °C (Fig. 1). To maintain these temperature characteristics for the different scenarios, maintaining the cooling water level around the microcosms was crucial. It’s also noteworthy that all test systems were continuously aerated, such that a gentle mixing effect did prevent possible water temperature stratification.

Fig. 8.

An indoor microcosm experiment with the TENTACLE machinery. The different temperature scenarios are described in section Experimental validation and graphically presented in Fig. 1.

Moving from the laboratory to the field application was little effort since only replacement of the heating elements with higher wattage was needed. While temperature manipulations in small indoor systems were rather simply induced with low wattage heating elements, the large outdoor test systems required a great energy input with a maximum application of the functionality of TENTACLE. Hence, prior to the start of an experiment, it is crucial to make estimations of the total required amount of energy needed to crosscheck with the electrical limitations of TENTACLE. In addition, it’s advisable to make an estimation of the expected energy amount needed and associated costs. To ensure an efficient temperature control for a given water volume, we estimated the amount of energy needed by:

| (1) |

where

E = change in thermal energy in joules (J).

m = mass in kilograms (kg).

c = specific heat capacity in joules per kilogram per degrees Celsius (J/kg °C).

ΔT = change in temperature in degrees Celsius (°C).

Wh = 1 W * 3600 sec = 3600 ws = 3600 J

Example: How much thermal energy is needed to increase the water temperature by 0.5 °C of a 1000 L mesocosm test system within maximum 1 h? The specific heat capacity of water is given with 4190 J/kg °C.

2095000 J ÷ 3600 J ≈ 582 Wh

Results and performance of TENTACLE

Fig. 9 presents TENTACLE recordings from a mesocosm outdoor experiment with natural variability in the ambient temperature fluctuations over time. The presented temperature recordings comprise the pre- and after-heatwave time period with continuously elevated temperature fluctuations. Taking natural heating and cooling processes of the mesocosms into account, the adjusted target temperature of the extreme event as well as the temperature delta of the elevated temperature setting versus ambient worked very well. Temperature manipulations ended in this experiment on the 6th of June which is noticeable by unifying temperature records from that day onwards.

Fig. 9.

TENTACLE temperature recordings from an outdoor mesocosm experiment with all three temperature scenarios, including: natural ambient temperature fluctuations (blue), elevated (orange), and heatwave (red) over the last heatwave (7 days) application time period. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

Overall, TENTACLE performed very well in the indoor and outdoor experiment with no observed electronic system failures. All temperature scenarios were working as expected and without functional impairment, although we noted in pre-tests minor, unintended mishaps in temperature control during the building phase due to incorrect cable wiring, which was easily fixed. For this reason, correct and accurate cable wiring during constructing phase of the device is crucial for its full functionality. We additionally noticed a loose contact for a temperature sensor and a defect surge protection in one of the boxes after long-time application of TENTACLE in the field indicating the necessity to consider regular maintenance checks by advised technical staff before further application. Apart from technical aspects, we also noted that the placement of the digital temperature sensors in the water column of a test system needs to be submerged enough to collect representative measurements but not too close to the sediment. As these sensors seem to be very sensitive, wrong placement may lead to faulty and interfering measurements by measuring lower sediment instead of representative water temperatures. We also noticed a lot of unused code in the program itself that has, unfortunately, never been implemented so far, such as code for indoor experiments or logging data to a SD-card in TENTACLE instead of a computer. Finally, it’s worth mentioning that other recorded data of physico-chemical water variables, such as pH, dissolved oxygen, and/or conductivity, can be synced with the temperature data retrospectively. By doing so, common time stamps seem suitable when recording intervals differed among the variables.

The capabilities and limitations of the device are:

-

•

The TENTACLE device is working in indoor and outdoor aquatic micro- and mesocosms.

-

•

All 3 temperature scenarios can be modified and set according to the researchers interests.

-

•

Temperature recordings are working well, but for instance Hobo-loggers may provide backup.

-

•

Electrical limits to control water temperature currently exist with 900 W for 1200–1300 L systems.

-

•

Correct and accurate cable wiring during construction phase is crucial to ensure full functionality.

-

•

Temperature sensors seem to be sensitive such that placement well above sediment is important for representative measurements but also to avoid thermal stratification.

-

•

Regular technical maintenance checks are needed to ensure functionality and security.

Summary

TENTACLE presented here offers multiple features to record and manipulate water temperature to represent future climate-change related scenarios, such as elevated temperature fluctuations and heatwaves as extreme weather events. The technology is independent of any limitations that installed machineries of testing facilities involve and can be used in fresh- and saltwater test systems, indoors and outdoors. Considering temperature manipulations with environmentally realistic temperature fluctuations, the high flexibility as well as the multifunctionality of TENTACLE opens access to improved and novel tools for future climate change-related temperature research questions in a single- or multiple-stressor context.

CRediT authorship contribution statement

Markus Hermann: Conceptualization, Methodology, Investigation, Writing – original draft, Visualization, Supervision. Richard Jansen: Software, Validation, Resources, Data curation, Writing – original draft. Johan van de Glind: Software, Validation, Resources, Data curation. Edwin T.H.M. Peeters: Conceptualization, Methodology, Writing – review & editing. Paul J. Van den Brink: Conceptualization, Methodology, Writing – review & editing, Project administration, Funding acquisition.

Declaration of competing interest

The authors declare to have no known competing financial interests or personal relationships that could have appeared to influence the work communicated in this paper.

Acknowledgments

We acknowledge Frits Gillissen for arranging first contact with Ton van der Zalm and the engineers of Tupola. He was providing all the advice in the early discussions about the design and application of TENTACLE. Frits Gillissen also gave us lessons about electrical limits, and inspirational support and always reminded us of security features during the first development steps. Ton van der Zalm and colleagues always tried their best to translate our scientific ideas to the engineering world. Thanks to Dorine Dekkers who instantly offered organizational support to install new power plugs in the laboratory for our pilot tests and following 1st indoor experiment. Special thanks to the young engineers who accumulated lots of late evening working hours, always supported us from distance (even abroad) with phone calls when help was needed or when technical related questions arose. This work was supported by the ECORISK2050 project (www.ecorisk2050.eu) funded by the European Union's Horizon 2020 research and innovation program under the Marie Skłodowska-Curie grant agreement No [813124].

Biographies

Markus Hermann is an environmental scientist holding a Master degree in Environmental Science from Stockholm University, Sweden, and a Bachelor degree in Geoecology from the Eberhard-Karls University of Tübingen, Germany. Since 2019, Markus is a PhD-candidate of the Chemical Stress Ecology Group, chaired by Paul J. Van den Brink, within the Aquatic Ecology and Water Quality Management Group at Wageningen University and Research, the Netherlands. As an Early Stage Researcher, Markus’ investigations are also part of the Marie Skłodowska-Curie Innovative Training Networks project ECORISK2050 (www.ecorisk2050.eu). Research interests include the effects of chemical stressors (i.e. pesticides) in combination with climate change related stressors (i.e. different temperature scenarios and CO2) on aquatic communities. Particularly how distinct temperature scenarios and/or CO2 affect dynamics and sensitivity of chemically stressed communities, ecosystem recovery potential, chemical fate, and physico-chemical water parameters. To gain a better mechanistic understanding of how aquatic ecosystem are affected by multiple stressors, Markus focuses on experimental research in indoor microcosms and field mesocosms at different ECORISK2050 research sites. In so doing he studies the combined effects in different ecoregions.

Richard Jansen is a young engineer who studied a post-secondary vocational training in Mechatronics and Embedded Systems at ROC A12 (TechNova college) in Ede, the Netherlands. During his study time, Richard worked as an embedded hard- and soft-ware developer together with Johan van de Glind at the Tupola department of Wageningen University and Research. Richard is currently continuing his studies in Artificial Intelligence and Data Science at HU University of Applied Sciences, Utrecht, the Netherlands.

Johan van de Glind is a young engineer currently following HBO-ICT studies at HU University of Applied Sciences, Utrecht, the Netherlands, and in the end of his second year with a special interest in Artificial Intelligence and Data Science. Before, Johan studied Electronics at ROC A12 (TechNova collge) in Ede, the Netherlands, while he also collaborated with Richard Jansen at the Tupola department of Wageningen University and Research, the Netherlands.

Edwin T.H.M. Peeters obtained his PhD degree at Wageningen University, the Netherlands, in 2001. He works as an associate professor at the same university with a special interest in disentangling the effects of multiple stressors.

Paul J. Van den Brink is a personal professor at the Aquatic Ecology and Water Quality Management Group of Wageningen University and a senior scientist at the research institute Wageningen Environmental Research, both belonging to the Wageningen University and Research. At Wageningen University Paul chairs the Chemical Stress Ecology Group. For both affiliations, he is involved in supervising and executing international projects on assessing the ecological effects of contaminants like pesticides, veterinary medicines and personal and home care products as well as those of multiple stressors, including climate change, drought, nutrients and salinization. Other research topics are the development of effect models (e.g. individual based, meta-population models and ecoinformatics, expert base models), traits based ecological risk assessment and ecological risk assessment of chemicals in the tropics.

References

- 1.Masson-Delmotte V., editor. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press; 2021. [Google Scholar]

- 2.Meehl G.A., Tebaldi C. More intense, more frequent, and longer lasting heat waves in the 21st century. Science. 2004;305(5686):994–997. doi: 10.1126/science.1098704. [DOI] [PubMed] [Google Scholar]

- 3.S. E. Perkins, L. V. Alexander, and J. R. Nairn, “Increasing frequency, intensity and duration of observed global heatwaves and warm spells,” Geophysical Research Letters, vol. 39, no. 20, 2012, doi: 10.1029/2012GL053361.

- 4.Woolway R.I., Jennings E., Shatwell T., Golub M., Pierson D.C., Maberly S.C. Lake heatwaves under climate change. Nature. 2021;589(7842):402–407. doi: 10.1038/s41586-020-03119-1. [DOI] [PubMed] [Google Scholar]

- 5.Thomas C.D., et al. Extinction risk from climate change. Nature. 2004;427(6970):145. doi: 10.1038/nature02121. [DOI] [PubMed] [Google Scholar]

- 6.Woodward G., Perkins D.M., Brown L.E. Climate change and freshwater ecosystems: impacts across multiple levels of organization. Philos. Trans. Royal Soc. B: Biol. Sci. 2010;365(1549):2093–2106. doi: 10.1098/rstb.2010.0055. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Salo T., Stamm C., Burdon F.J., Räsänen K., Seppälä O. Resilience to heat waves in the aquatic snail Lymnaea stagnalis: Additive and interactive effects with micropollutants. Freshwater Biol. 2017;62(11):1831–1846. doi: 10.1111/fwb.12999. [DOI] [Google Scholar]

- 8.Arenas‐Sánchez A., López‐Heras I., Nozal L., Vighi M., Rico A. Effects of increased temperature, drought, and an insecticide on freshwater zooplankton communities. Environ. Toxicol. Chem. 2018;p. etc.4304 doi: 10.1002/etc.4304. [DOI] [PubMed] [Google Scholar]

- 9.Van de Perre D., et al. The combined and interactive effects of zinc, temperature, and phosphorus on the structure and functioning of a freshwater community. Environ. Toxicol. Chem. 2018;37(9):2413–2427. doi: 10.1002/etc.4201. [DOI] [PubMed] [Google Scholar]

- 10.Willming M.M., Qin G., Maul J.D. Effects of environmentally realistic daily temperature variation on pesticide toxicity to aquatic invertebrates. Environ. Toxicol. Chem. 2013;32(12):2738–2745. doi: 10.1002/etc.2354. [DOI] [PubMed] [Google Scholar]

- 11.Willming M.M., Maul J.D. Direct and indirect toxicity of the fungicide pyraclostrobin to Hyalella azteca and effects on leaf processing under realistic daily temperature regimes. Environ. Pollut. 2016;211:435–442. doi: 10.1016/j.envpol.2015.11.029. [DOI] [PubMed] [Google Scholar]

- 12.Barbosa M., Inocentes N., Soares A.M.V.M., Oliveira M. Synergy effects of fluoxetine and variability in temperature lead to proportionally greater fitness costs in Daphnia: A multigenerational test. Aquat. Toxicol. 2017;193:268–275. doi: 10.1016/j.aquatox.2017.10.017. [DOI] [PubMed] [Google Scholar]

- 13.Vasseur D.A., et al. Increased temperature variation poses a greater risk to species than climate warming. Proc. Royal Soc. B: Biol. Sci. 2014;281(1779):20132612. doi: 10.1098/rspb.2013.2612. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Sheldon K.S., Dillon M.E. Beyond the mean: biological impacts of cryptic temperature change. Integr. Comp. Biol. 2016;56(1):110–119. doi: 10.1093/icb/icw005. [DOI] [PubMed] [Google Scholar]

- 15.Verheyen J., Stoks R. Current and future daily temperature fluctuations make a pesticide more toxic: Contrasting effects on life history and physiology. Environ. Pollut. 2019;248:209–218. doi: 10.1016/j.envpol.2019.02.022. [DOI] [PubMed] [Google Scholar]

- 16.Pansch C., Hiebenthal C. A new mesocosm system to study the effects of environmental variability on marine species and communities. Limnol. Oceanogr. Methods. 2019;17(2):145–162. doi: 10.1002/lom3.10306. [DOI] [Google Scholar]

- 17.Bellworthy J., Fine M. The Red Sea Simulator: A high-precision climate change mesocosm with automated monitoring for the long-term study of coral reef organisms. Limnol. Oceanogr. Methods. 2018;16(6):367–375. doi: 10.1002/lom3.10250. [DOI] [Google Scholar]

- 18.Duarte G., et al. A novel marine mesocosm facility to study global warming, water quality, and ocean acidification. Ecol. Evol. 2015;5(20):4555–4566. doi: 10.1002/ece3.1670. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Liboriussen L., et al. Global warming: Design of a flow-through shallow lake mesocosm climate experiment. Limnol. Oceanogr. Methods. 2005;3(1):1–9. doi: 10.4319/lom.2005.3.1. [DOI] [Google Scholar]

- 20.Dimitriou P.D., et al. A novel mesocosm setup for benthic-pelagic coupling experiments. Limnol. Oceanogr. Methods. 2017;15(4):349–362. doi: 10.1002/lom3.10163. [DOI] [Google Scholar]

- 21.Wang T., et al. A dynamic temperature difference control recording system in shallow lake mesocosm. MethodsX. 2020;7 doi: 10.1016/j.mex.2020.100930. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Baulch H.M., et al. Climate warming experiments: Design of a mesocosm heating system. Limnol. Oceanogr. Methods. 2003;1(1):10–15. doi: 10.4319/lom.2003.1.10. [DOI] [Google Scholar]

- 23.Urrutia-Cordero P., et al. SITES AquaNet: An open infrastructure for mesocosm experiments with high frequency sensor monitoring across lakes. Limnol. Oceanogr. Methods. 2021;19(6):385–400. doi: 10.1002/lom3.10432. [DOI] [Google Scholar]

- 24.Macaulay S.J., Buchwalter D.B., Matthaei C.D. Water temperature interacts with the insecticide imidacloprid to alter acute lethal and sublethal toxicity to mayfly larvae. New Zealand J. Marine Freshwater Res. 2020;54(1):115–130. doi: 10.1080/00288330.2019.1614961. [DOI] [Google Scholar]

- 25.Leicht K., Seppälä O. Direct and transgenerational effects of an experimental heatwave on early life stages in a freshwater snail. Freshwater Biol. 2019;64(12):2131–2140. doi: 10.1111/fwb.13401. [DOI] [Google Scholar]