Graphical abstract

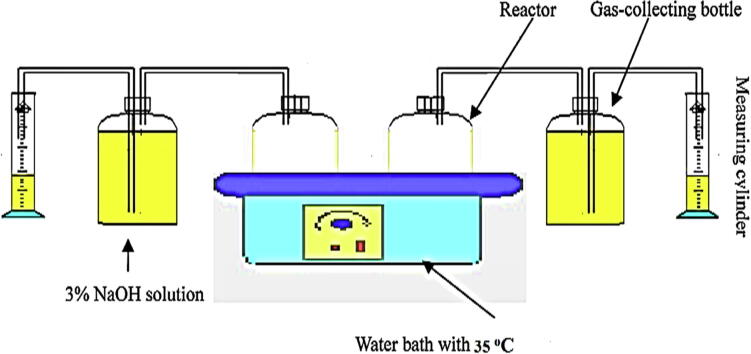

Fig. a - The set-up for biogas production.

Keywords: Waste, Untreated primary sludge, Biomass, Raw Chicken manure, Anaerobic digestion, Biomethane

Abstract

This work aimed to co-digest various wastes to assess the best combination of all mixing ratio, also at choosing the best ratio between untreated primary sludge (UPS) singly from two sources, (South valley University (SUPS) and Abu tesht wastewater station (AUPS) and raw chicken manure (RCM) and comparing the results in either case. The co-digestions of untreated primary sludge from Abu tesht wastewater treatment stations with different levels of raw chicken manure (0:100, 10:90, 30:70, 50:50, 90:10, and 100:0) to obtain the best mixtures. Also, co-digestion of untreated primary sludge from south valley university with different levels of raw chicken manure at the same ratios, to obtain the best mixtures. Batch digestion tests were applied in 2.5 L digester with a working volume of 2.0 L. The samples in triplicates were separately loaded into the digesters locally fabricated and kept for 20 days as a retention period and diluted with the same amount of water. Mesophilic under 35 °C was adopted for untreated primary sludge as well as mixtures with raw chicken manure based on total solids (TS) and volatile solid (VS) proportions. The average biogas yields from AUPS/RCM mixture obtained ranged from 8570 to 5600 ml, by the following descending order, 10: 90 > 90:10 and so on >100:0, and the average biogas yields from SUPS/RCM obtained ranged from 6330 to 5635 ml, in the order of 90: 10 > 10:90 and so on >100:0. The results showed highest biogas yield from AUPS/RCM and SUPS/RCM mixtures with mixing ratio of 10:90 and 90:10, respectively, however, the lowest biogas production detected in separate digestion of AUPS and SUPS. The results indicated that co-digestion between the sludge and raw chicken manure could increase total biogas production volume, enhance sludge treatment process, and produce eco-friendly sludge because of co-digestion process than separate processing of each feedstock.

1. Introduction:

The generation of excess sludge is the main problem faced by wastewater treatment plants (WWTP) in urban areas. Approximately 0.5–2% of treated wastewater becomes necessary to manage sludge at a cost of over 50% of the costs of operation of the WWTP. Anaerobic digestion (AD) of sludge at various temperature conditions is the most widely applied treatment procedure for sludge recovery (de la Rubia et al. 2002, and de la Rubia et al. 2005). Worldwide, the use of renewable energies has become an attractive and alternative energy system due to the rising expense of fossil fuels and the increased pollution caused by their combustion (Sahito, et al. 2014). Biogas production necessitates more arable land, assets and labor than other renewable energy technologies, such as rape methyl ester (RME) manufacturing (Heissenhuber and Berenz, 2005). The anaerobic digestion (digestion without oxygen) of organic matter produces biogas, which is a methane-rich gas. Because the nutritive materials in the feedstock are not lost during the biogas generation, the biproduct of this process is a high-quality fertilizer. Because biogas is methane-rich (55–70%), it can be used for energy or refined to become equivalent to Natural Gas (NG). As a result, several countries have begun to promote the use of alternative energy sources, particularly clean energy sources such as geothermal, wind, small-scale hydropower, solar, biomass, tidal, and wave power (Abd Allah et al., 2021).

Clean energy is less polluting than fossil fuels and has a lower environmental effect as a result. Anaerobic digestion produces biogas, which is a renewable and clean energy source (Esposito, et al. 2012). Many types of organic matters considered as substrates for biogas production as organic municipal waste, manure, sewage sludge and agricultural wastes (Appels et al. 2011). The problem of waste accumulation in the streets and water banks causes pollution and negatively affects health. On the other hand, biomass resources i.e., organic waste, agricultural residues, agricultural and industrial wastes, animal manure, and sewage sludge. The use of these waste resources, especially biomass or the organic components, leads to the achievement of some economic problems in Egypt, such as livestock feed, fertilizers, and fuels, in addition to improving the surrounding environment by reducing air pollution and greenhouse gas emissions, all that can be achieved by concerted efforts of the Waste, Energy, Industry and Agriculture sectors (Nakhla et al. 2013). According to the National Organization for Potable Water and Sanitary Drainage (NOPWSD) and the Holding Company for Water and Wastewater (HCWW), Egypt has 303 WWTP, which process 11.85 106 m3/day of wastewater at a sludge rate of production of 0.48 kg/m3 of treated wastewater, resulting in 5800 tons of sewage sludge produced daily (Ghazy, et al. 2009).

The most common sewage sludge treatment process used in most WWTPs is thickening and dewatering of sewage sludge, followed by storage and then land application. Only at Al Gabel Asfer WWTP, Egypt's largest, anaerobic digestion procedure has been used for sludge stabilization and power generation. Windrow composting is another prominent sewage sludge handling process used in WWTPs such as Cairo's Al Berka WWTP and Alexandria's (9 N) plant (Nakhla, et al. 2013). Recently, there has been a greater focus on reducing surplus sludge because it has become a growing concern for wastewater treatment facilities (WWTPs) due to economic, environmental, and regulatory factors (Mahvi, 2008). Sludge treatment and disposal, for example, can account for up to 60% of total operating costs in municipal wastewater treatment plants (Baghapour et al., 2011, Zhang and Chen, 2020). Biogas has gotten a lot of attention because it has a lot of environmental benefits over fossil fuels (Cheng, J. 2009). Biogas is safe, dependable, inexpensive, and environmentally friendly (Santosh et al., 2004, Turunen et al., 2018). Cheng, (2009) reported that biogas energy can be replicated in a year, whereas fossil fuels take millions of years to regenerate biodegradable wastes from various sources, on the other hand, have a low potential for biogas production due to their low organic matter concentration or biodegradability.

In these instances, anaerobic co-digestion is shown as an effective technology that mixes numerous biodegradable organic substrates capable of increasing biogas generation per kilogram of mixture removal, both at mesophilic and thermophilic settings. (Kim, et al. 2004). The anaerobic process has typically been used to digest surplus sludge in wastewater treatment plants or to treat manure, resulting in biogas that may be utilized to generate energy (Fantozzi and Buratti, 2009). Over the last 10–15 years, researchers have investigated the co-digestion of various organic substrates, and the results showed the synergic impact of both treatments, with the biodegradability of the resulting mix were more than the biodegradability of the separate substrates. It has been demonstrated that anaerobic co-digestion of diverse organic wastes improves biogas generation. The concept of co-digestion has been researched and applied to a variety of substrates, including municipal solid waste, sewage sludge, cow dung, and energy crops (Mata-Alvarez et al., 2011, Facchini et al., 2021). Because of the presence of ammonia, protein, and urea in animal feces, total ammonia nitrogen concentrations are frequently very high (Zeeman, et al. 1985). For anaerobic species, nitrogen is a necessary nutrient (Strik et al., 2006), as a result, the inhibitory effects of ammonia in anaerobic reactors are known to affect primarily the phase of methanogenesis. (Calli, et al. 2005).

Cow, buffalo and poultry farms, are the main suppliers of manure in Egypt. In Egypt's governorates, the amount of manure produced by various animals is assessed to be 11 million tons (El-Hinnawi, 2006). The amount of chicken droppings produced each year is assessed to be in the order of 2.3 million tons (El-Hinnawi, 2006). About 60% of cattle wastes are utilized as fuel by direct burning in low-efficiency burners (lower than 10% efficiency); another 20% is used as organic fertilizer, and the rest is wasted in handling (Nakhla, et al. 2013). The anaerobic co-digestion of two forms of organic wastes, raw chicken manure and raw sewage sludge from wastewater treatment plants, is the subject of research.

Therefore, the objective of this study is to select the operational conditions of anaerobic co-digestion process of untreated primary sludge and chicken manure to enhance the biogas generation, transformation of organic fraction in (UPS) into high quality fertilizer, amelioration of the hygiene via lowering of pathogens, comparing the results obtained from sludge sample of two sources. The batch experiments were created using mesophiles to investigate the anaerobic biodegradability of four different chicken manure and untreated primary sludge combinations.

2. Materials and methods

2.1. Substrates’ collection

Fresh untreated primary sludge (UPS) was collected in sterilized bag from Municipal Wastewater Treatment Plant in Abu tesht and south valley university, Qena, Egypt. The UPS preserved in refrigerator under 4 OC degree until used (Zhang et al. 2011). And raw chicken manure (RCM) was collected from village abu shosha, Abu tesht, Qena, Egypt. All samples were collected in summer season within a period of 7 days to limit the huge differences in substrate features then were analyzed for their chemical constituents.

2.2. Experimental digester and design

The experimental design is represented in Fig. 2. Six digesters were used in a modest lab-scale experiment to explore the feasibility of anaerobic co-digestion of UPS from two sources and RCM. The Laboratory-scale digesters were operated at mesophilic conditions (35 ± 1 °C) with hydraulic retention times of 20 days (Komatsu et al., 2007). Each glass has actual volume was 2.5 L and working volume was 2.0 L. Prior to the biogas volume measurement, all reactors were gently mixed by hand for around 1 min per day. Six different mixing mass ratios of 100:0, 90:10, 50:50, 30:70, 10:90, and 0:100 were tested to obtain the best combination of Abu tesht untreated primary sludge (AUPS) and South valley untreated primary sludge (SUPS) each supplemented individually with raw chicken manure (RCM) as external carbon sources. Separate AUPS or SUPA (100:0) and RCM (0:100) were an aerobically digested as controls.

Fig 2.

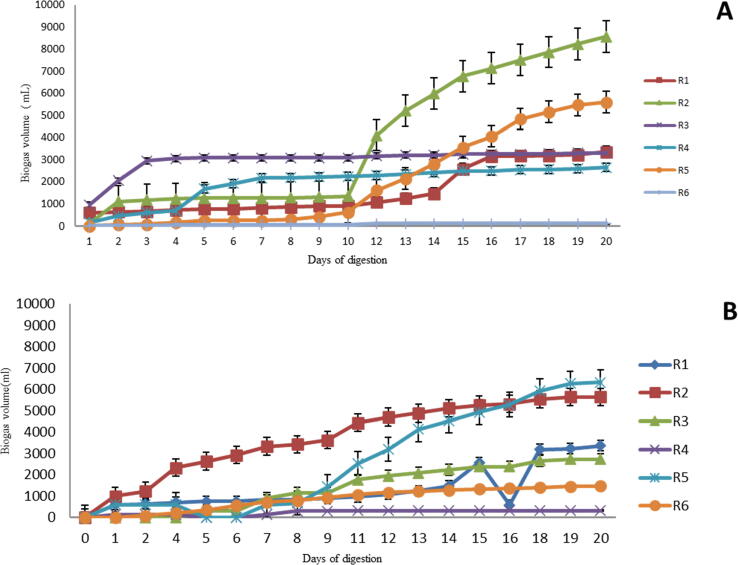

(A) The cumulative biogas production from co-digestion of AUPS/RCM. (B) The cumulative biogas production from co-digestion of SUPS/RCM.

Every treatment was repeated three times with a control to see how different mixed percentages affected biogas output. In the gas collecting bottle, NaOH 3% solution was utilized to remove the generated CO2, NH3, and H2O. The methane created displaced a measurable volume of NaOH solution from the gas-collecting bottle, which was equal to the volume of methane. A measuring cylinder linked to the gas-collecting bottle could so determine the volume of methane produced by each reactor (You et al., 2003, Guo, 2011). When an alkaline solution is used as the displacement liquid for the biogas collected in the measuring cylinder, CO2 is scrubbed from the biogas and only methane is collected. As a result, the solution's displaced volume equals the volume of methane produced. CO2will not be absorbed when employing an acidic solution, hence the amount of displaced gas will be indicative of the total biogas created.

A blank test was carried out in parallel with the assay bottle, using the same amount of anaerobic sludge (South valley sample and Abu tesht wastewater station sample), water, and RCM alone instead of the UPS/RCM mixture ratio. The total biogas produced by each co-digestion ratio is calculated using the difference in gas production between the two digesters and the four mixing ratios. Table 1 summarizes the substrate co-digestion mixing ratio. The volume of created gas was measured in this study using the water displacement method, which assumed that the amount of generated gas was equal to the volume of ejected water in the water collector. Fig. 2 shows a schematic representation of the lab-scale experimental setup.

Table 1.

Treatment description for each reactor.

| Treatment | Description | Mixing ratio(%) |

|---|---|---|

| R1 | (RCM) | 100 |

| R2 | R1: R6 | 10:90 |

| R3 | R1: R6 | 30:70 |

| R4 | R1: R6 | 50:50 |

| R5 | R1: R6 | 90:10 |

| R6 | (AUPS) or (SUPS) | 100 |

2.3. Analytical methods

Moisture, total solids (TS), volatile solids (VS), total nitrogen, total carbon, and the C/N ratio were all measured in untreated primary sludge and raw chicken manure.

TS and moisture content of the samples were estimated by heating at 60 °C for 24 h then at 103 °C for 3 h, then % moisture content was then estimated using the procedure of Chandra, (2009):

| (1) |

| (2) |

where WW is the weight of wet sample, WD is the weight of dry sample

The above oven dried samples applied for the measuring of (TS) were further dried at 550 ± 5 °C temperature for 5 h in a muffle furnace.

The volatile solids (VS) were then determined as follows (Chandra, R. 2009):

| (3) |

where WD is the weight of oven dried sample, WA is the weight of ash left after igniting the sample in muffle furnace.

The %age volatile solid loss was calculated from the following equation:

| (4) |

where VS out and VS in are the %ages of VS at the finish and initial of digestion periods. Biogas samples were collected using a water displacement method (You et al., 2003, Guo, 2011). The volume of alkaline solution displaced from the measure bottle and collected in a graduated cylinder was used to track daily biogas generation (Fig 1, Fig 2). Because the CO2 in the biogas was dissolved in the alkaline solution, it had no impact on the volumetric methane readings (Esposito, et al. 2012). Total plate count, total and fecal coliform were estimated following Saad et al, (2021a).

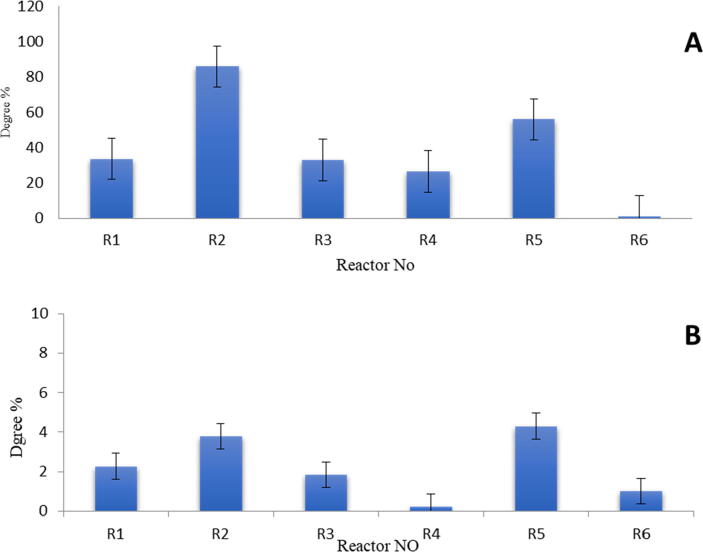

Fig 1.

(A) The biogas production from different mixing ratio of AUPS/RCM after 20 days of anaerobic digestion. Where’s R6 is the control 100% AUPS, (B) The biogas production from different mixing ratio of SUPS/RCM after 20 days of anaerobic digestion. Where’s R6 is the control 100% SUPS.

2.4. Statistical analysis

Data means in triplicate were analyzed by ANOVA at probability level of 5%. The significant differences between means were compared by LSD using SPSS version 19.

3. Results

The features of the substrates are summarized in Table 2. Various species of bacteria participate in the hydrolysis, acid generation, and methane synthesis processes in anaerobic digestion of organic materials. Methanogenesis is regarded to be the most important of these three stages. Microorganisms convert particulate organic matter, such as proteins, polysaccharides, and lipids to soluble form in the 1st stage, hydrolysis. An acetogenic bacteria convert the hydrolysis products to carbon, acetic acid, dioxide and hydrogen. Finally, other types of microbes such as Methanospirilium hungatei, Methanothrix soehngenii and Methanobrevibacter arboriphilus create methane from these acid former end products. (Zehnder, et al. 1980). The current study uses a batch technique to look at the impact of co-digestion between different AUPS or SUPS and RCM combinations on biogas production. The biogas produced is depicted in (Fig. 1A, B) (see Table 3).

Table 2.

Substrates analysis.

| Parameters | (AUPS) | (SUPS) | (RCM) |

|---|---|---|---|

| MC (%) | 23b | 22.036b | 83.11 %a |

| TS (%) | 77b | 77.96b | 90.86 %a |

| VS (%) | 5.4c | 66.683a | 9.14 %b |

| VS/TS (%) | 7b | 85.5a | 0.1c |

| TPC (CFU/ml) | 3 × 105c | 34 × 107b | 67 × 106a |

| TOM % | 5b | – | 86.3a |

| TC % | 2.86b | – | 50.1a |

| TN% | 0.08b | – | 2.36a |

| C/N ratio % | 36a | – | 21b |

The different lowercase letters within raw indicate significant differences.

AUPS: Abu tesht sludge sample TC: total carbon

SUPS: south valley university sludge sample TN: total nitrogen.

RCM: Raw chicken manure C/N ratio: carbon/nitrogen ratio.

TS: total solids. MC: moisture content.

VS: volatile solids. TPC: Total plate count.

TOM: total organic matter.

Table 3.

Aerobic and anaerobic bacteria count on nutrient agar media at 35 °C for 24hr and 48 hr.

| Treatment | AUPS/ RCM aerobic |

AUPS/RCM anaerobic |

SUPS/RCM aerobic |

SUPS/RCM anaerobic |

||||

|---|---|---|---|---|---|---|---|---|

| First | Last | First | Last | First | Last | First | Last | |

| R1 | 26 × 106* | 3 × 105* | 30 × 104* | 2.6 × 106 | 39 × 107* | 19 × 106* | 2 × 105 | 39 × 107* |

| R2 | 120 × 106* | 3 × 105 | 28 × 104* | 50 × 106* | 11 × 107* | 4 × 106* | 3 × 105 | 11 × 107* |

| R3 | 157 × 106* | ≤1 × 105 | 15 × 104* | 11 × 106* | 5 × 107 | 88 × 106* | 19 × 105* | 5 × 107 |

| R4 | 143 × 106* | 4 × 105* | 8 × 104 | 4.5 × 106 | 7 × 107* | 16 × 106* | 3 × 105* | 7 × 107* |

| R5 | 7 × 106 | 4 × 105* | 10 × 104 | 4.7 × 106 | 3 × 107 | 13 × 106* | 1 × 105 | 4 × 107 |

| R6 | 4 × 106 | ≤1 × 105 | 22 × 104* | 4 × 106 | 2 × 107 | 19 × 106* | 16 × 105* | 3 × 107 |

*Indicate significant differences between values at p ≤ 0.05.

For all reactors, the cumulative gas production is shown to grow with time in Fig. 2 A, B. The cumulative biogas yield in R2 digestion mixing ratio was 8570 ml which higher than that of R5 mixing ratio of 5600 ml that higher than R1 mixing ratio of 3365 ml and also higher than R3 mixing ratio of 3305 ml higher than R4 mixing ratio, 2655 ml higher than R6 mixing ratio, this result indicates that the biogas products of anaerobic digestion of Abu tesht sludge sample the 10 /90 of UPS/ RCM higher than the other mixing ratio, also 90/10 higher the other mixing ratio. The results indicate that to enhance biogas production from UPS through the co-digestion with RCM it is important to use 10/90, or 90/10 UPS/RCM mixing ratio. The cumulative biogas yield of R5 digestion mixing ratio was was 6330 ml which higher than that of R2 mixing ratio of 5635 ml that higher than R1 mixing ratio of 3365 ml and also higher than R3 mixing ratio of 2735 ml higher than R6 mixing ratio of 1040 ml higher than R4 mixing ratio, This result indicates that the biogas product of anaerobic digestion of south valley university sludge sample of the 90 /10 UPS/ RCM higher than the other mixing ratio, also 10/90 higher the other mixing ratio. The results indicated that to accelerate biogas yield from UPS through the co-digestion with RCM it is important to use 10/90, or 90/10 UPS/RCM mixing ratio.

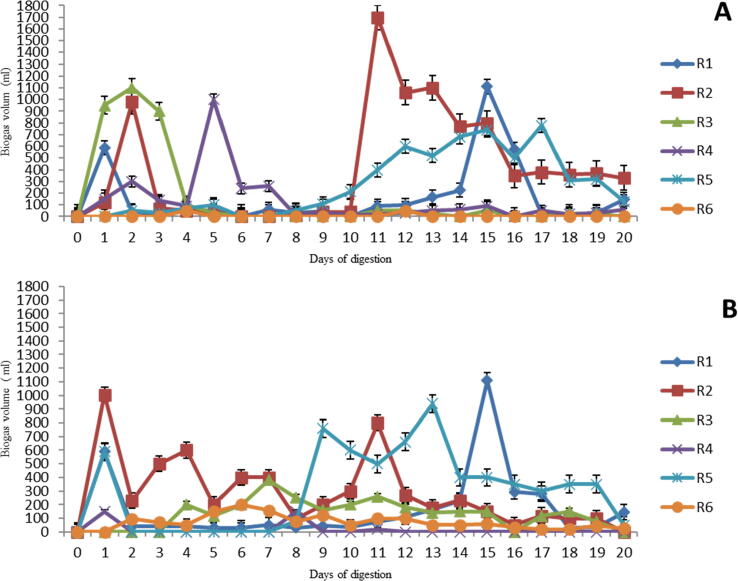

In all treatments the initial biogas, the produced gas increased sharply within the 1st days of digestion and then decreased gradually after wards (Fig. 3 A, B). The biogas production initiated from the 1st day. Daily biogas production rates from UPS/RCM reactors of Abu Tesht sludge sample are also represented in (Fig. 3A). A peak biogas rate of manufacture of 2760 ml /day was observed after the 12th day from UPS/RCM of Abu tesht sludge sample showed in (Fig. 3 A). Additional peaks were observed. The co-digestion mixing ratio used in these trials showed different components with different concentrations and rate of biodegradability. Also, Daily biogas production rates from UPS/RCM reactors of south valley sludge sample are also shown in (Fig. 3B). A peak biogas manufacture rate of 1100 ml /day was noticed after the 4th, 11th, and 15th day from UPS/RCM of south valley sludge sample from UPS/RCM co-digestion mixing ratio of 10/90, 90/10, and 0/100 showed in (Fig. 3B). Additional peaks were observed. The co– digestion mixing ratio used in these trials revealed various components with various level and rate of biodegradability (see Fig. 4).

Fig. 3.

(A) Daily biogas production from different AUPS/RCM co-digestion mixing ratio. (B) Daily biogas production from different SUPS/RCM co-digestion mixing ratio.

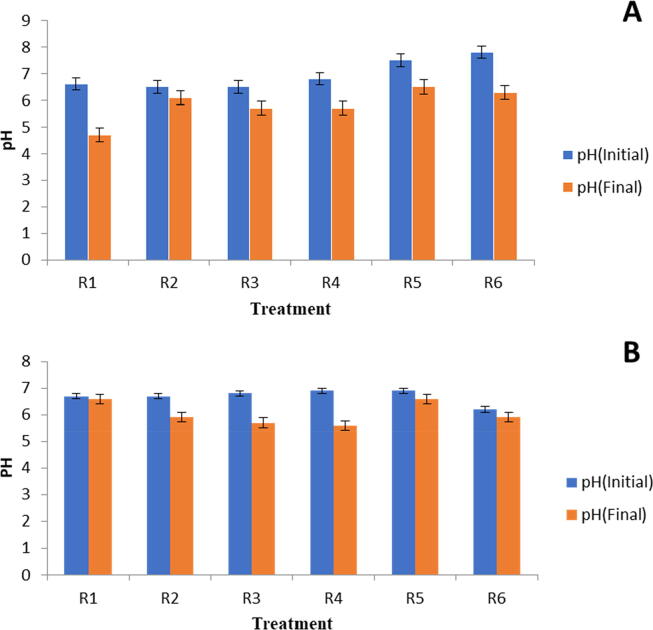

Fig 4.

(A) Initial and final pH of AUPS/RCM samples, (B) Initial and final pH of SUPS/RCM sample.

The degree of sanitization of UPS/RCM waste builds on the digestion type and nature of UPS/RCM substrate, as well as, anaerobic co-digestion of UPS/RCM in a biogas plant considered a serious treatment technique for the lowering of indicators as well as, pathogens. In bio slurry samples, the average load of total coliforms and fecal coliforms was lower than in bio waste samples (Table 4). There was a statistically significant link between anaerobic digestion of biogas plants and a lower in total coliforms (P 0.001) and fecal coliforms (P < 0.001) (P = 0.002) (Table 4).

Table 4.

Total and fecal coliform for all samples on M-endo agar media at 44 °C for 24hr and M-fc agar media at 44 °C for 48 hr.

| Treatment | Abu tesht sludge sample (AUPS/RCM) |

South valley university sludge sample (SUPS/RCM) |

||||||

|---|---|---|---|---|---|---|---|---|

| Initial total coliform CFU/100 ml |

Final total coliform | Initial fecal coliform CFU/100 ml |

Final fecal coliform CFU/100 ml |

Initial total coliform CFU/100 ml |

Final total coliform CFU/100 ml |

Initial fecal coliform CFU/100 ml |

Final fecal coliform CFU/100 ml |

|

| R1 | 185 × 104* | ≤1 | 138 × 104* | ≤1 | 120 × 104* | ≤100 | 45 × 104 | ≤100 |

| R2 | 34 × 104* | 1 | 66 × 102* | 1 | 163 × 104* | ≤100 | 51 × 104* | ≤100 |

| R3 | 22 × 104* | 58* | 9 × 102* | 30* | 176 × 104* | ≤100 | 176 × 104* | 3 × 102* |

| R4 | 210 × 104* | ≤1 | 202 × 102* | ≤1 | 178 × 104 | 200* | 110 × 104* | 8 × 102* |

| R5 | 49 × 104* | 13* | 9 × 102 | 13* | 188 × 104* | 85 × 102* | 63 × 104* | 8 × 102 |

| R6 | 3 × 104* | ≤1 | 2 × 102* | ≤1 | 205 × 104* | 10 × 103* | 200 × 104* | 9 × 102* |

*Indicate significant differences between values at p ≤ 0.05.

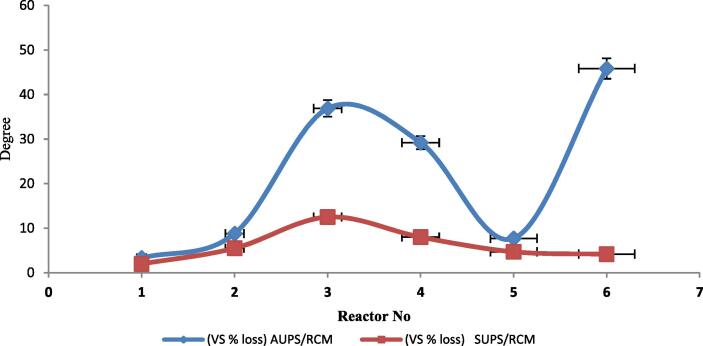

The amount of volatile solid % was reduced from 83% to 75 % and 58% to 53% in case of 10/90 and 90/10% AUPS with RCM where as volatile solid % was reduced from 84.7% to 80 % and 78.7% to 75 % in case of 10/90% and 90/10% SUPS with RCM. It revealed that the reduction in volatile solid % leads to increase in biogas production. Highest reduction in volatile solid % was observed in AUPS samples that directly related to biogas production. This was shown in Fig. 5.

Fig. 5.

Volatile solid loss per co-digestion mixing ratio.

The anaerobic co-digestion of two forms of organic wastes, raw chicken manure and raw sewage sludge from wastewater treatment plants. In this investigation, the output of effect of start pH of digester on biogas yield is summarized in Table 4. The optimum pH 7.0 gave the best biogas products. As found in Table 4, pH is a serious factor for keeping functional anaerobic pH is a serious factor for keeping anaerobic digestion. A typical pH is in the range of 6.5–7.6. The aggregation of volatile fatty acids causes a drop in pH during fermentation, resulting in a reduction in biogas volume (Table 5, Table 6A, Table 6B, Table 7).

Table 5.

Initial and final pH of co-digestion mixing ratio.

| Treatment | AUPS/ RCM |

SUPS/RCM |

||

|---|---|---|---|---|

| pH (Initial) | pH (Final) | pH (Initial) | pH (Final) | |

| R1 | 6.6 | 4.7* | 6.7 | 6.6 |

| R2 | 6.5 | 6.1 | 6.7 | 5.9 |

| R3 | 6.5 | 5.7* | 6.8 | 5.7 |

| R4 | 6.8* | 5.7 | 6.9* | 5.6* |

| R5 | 7.5 | 6.5* | 6.9 | 6.6* |

| R6 | 7.8* | 6.3 | 6.2* | 5.9 |

*Indicate significant differences between values at p ≤ 0.05.

Table 6A.

Total and volatile solids for AUPS/RCM samples.

| AUPS/RCM Treatments (%) | TS (Initial) % | VS(Initial)% | MC (Initial)% | TS (Final) % | VS (Final)% | MC% (Final)% | |

|---|---|---|---|---|---|---|---|

| 0/100 | R1 | 19.6a | 83.66a | 80b | 21.6a | 80.9a | 78c |

| 10/90 | R2 | 16.7b | 83a | 83b | 18.2b | 75.7b | 81.7b |

| 30/70 | R3 | 5.7c | 80ab | 94ab | 18.5b | 50.5 cd | 81.4b |

| 50/50 | R4 | 1.19d | 67.8c | 98.8a | 17bc | 48 cd | 82.9b |

| 90/10 | R5 | 1.05d | 58d | 98a | 2.4c | 53.9c | 97.6a |

| 100/0 | R6 | 0.899e | 55d | 99.1a | 1.2c | 29.8d | 98.9a |

The different lowercase letters within raw indicate significant differences.

The different lowercase letters within column indicate significant differences.

Table 6B.

Total and volatile solids for SUPS/RCM samples.

| SUPS/RCM Treatments (%) | TS (Initial) | VS (Initial) | MC% (Initial) | TS (Final) | VS (Final) | MC% (Final) | |

|---|---|---|---|---|---|---|---|

| 0/100 | R1 | 40a | 85.6a | 59.9c | 21.6a | 83.9a | 78c |

| 10/90 | R2 | 21b | 84.7a | 79b | 18b | 80ab | 81bc |

| 30/70 | R3 | 13.9c | 82.9ab | 86ab | 14b | 72.5bc | 85.9b |

| 50/50 | R4 | 8d | 81.3ab | 92a | 5.3c | 74.8b | 94.6a |

| 90/10 | R5 | 2.9e | 78.7b | 97a | 4.5c | 75b | 95.4a |

| 100/0 | R6 | 0.8f | 72c | 0.99d | 2.9d | 69c | 97a |

The different lowercase letters within column indicate significant differences.

Table 7.

Volatile solid loss per co-digestion mixing ratio.

| Treatment (%) | (VS % loss) AUPS/RCM | (VS % loss) SUPS/RCM | |

|---|---|---|---|

| 0/100 | R1 | 3.3e | 1.985e |

| 10/90 | R2 | 8.8d | 5.5c |

| 30/70 | R3 | 36.88b | 12.5a |

| 50/50 | R4 | 29.2c | 7.995b |

| 90/10 | R5 | 7.7d | 4.7c |

| 100/0 | R6 | 45.82a | 4.16667d |

The different lowercase letters within column indicate significant differences.

4. Discussion

The accumulation of agricultural and industrial wastes adversely in streets and deranges affects the health and environment (Saad et al, 2021b). These wastes are valuable biomass resources i.e., organic waste, agricultural residues, agricultural and industrial wastes, animal manure, and sewage sludge. The use of these waste resources, especially biomass or the organic components, leads to the achievement of some economic problems in Egypt, such as livestock feed, fertilizers, and fuels, in addition to improving the surrounding environment by reducing air pollution and greenhouse gas emissions, all that can be achieved by concerted efforts of the Waste, Energy, Industry and Agriculture sectors (Nakhla et al. 2013).

Anaerobic digestion is a microbial process in which organic waste and biomass are converted into biogas (Magrí et al., 2017). During wastewater treatment, organic matter (sludge) is obtained, which is expensive for WWTP and depends on the efficiency of the plant. Therefore, there are cost-effective alternative methods that aim to reduce digestion time and maximize biogas production (Martínez et al., 2017). Initial treatment of solids (Ruffino et al., 2016; Divyalakshmi et al., 2017). Pyrolysis is an initial treatment to destroy or dissolve solid organic matter and precipitate it easily accessible to anaerobic microorganisms and depends on COD in organic matter, temperature, and pH (Perea-Elvira et al., 2006; Nazari et al., 2017).

Other methods used to dissolve complex organic matter such as ultrasonic cavitation, high-pressure homogenization, ozone, and hydrolysis thermal treatment are the most widely used (Tyagi and Lo, 2011; Chozzi et al. 2014; Fernandez Polanco and Tatsumi, 2016). It leads to an increase in the biodegradation of sludge, which increases the organic load in the digestive system (Pilli et al., 2015). The disadvantage of the method is the increased energy consumption of wastewater treatment plants (Fernandez Polanco and Tatsumi, 2016).

In the case of pyrolysis as an initial treatment for sludge, steam is injected into the reactors during short periods, so this process has times that do not need to use steam. But during short working periods, the demand for steam in the plant increases. Therefore, the solution to the problem is to store steam at a pressure higher than the pressure required for heat treatment; however, this process is expensive, as the steam has a specific volume, therefore, the steam can be stored in the form of saturated water under pressure and when the pressure is reduced, steam is generated, which is transferred to the reactors under optimal conditions from pressure, temperature and time. Thus, energy consumption is reduced.

In co-digestion, biogas production increases by 2.5–4 times compared to digesting sludge in sewage plants (Shen et al., 2015). Many wastewater treatment plants have become energy producers (Nghiem et al. 2017, Shen et al. 2015, Macintosh et al., 2019). The raw materials (sludge from organic matter and waste) are converted into biogas then gas engines produce an excess of 20% energy. CO2 and other gases reduce the biogas quality of its applications. Therefore, the gas must be treated before applications such as transportation fuels or natural gas network injection. Secondary gases are removed by physical or chemical washing and membrane separation. The choice of purification technology depends on the composition and quality of the gas and the available resources. The amount of chicken droppings produced each year is assessed to be in the order of 2.3 million tons (El-Hinnawi, 2006). About 60% of cattle wastes are utilized as fuel by direct burning in low-efficiency burners (lower than 10% efficiency); another 20% is used as organic fertilizer, and the rest is wasted in handling (Nakhla, et al. 2013). The anaerobic co-digestion of two forms of organic wastes, raw chicken manure and raw sewage sludge from wastewater treatment plants. In this investigation, the output of effect of start pH of digester on biogas yield is summarized in Table 4. The optimum pH 7.0 gave the best biogas products. This finding is in concur with (Sambo et al., 1995, Okeh et al., 2014). As found in Table 4 pH is a serious factor for keeping functional anaerobic pH is a serious factor for keeping anaerobic digestion. A typical pH is in the range of 6.5–7.6 (Parkin and Owen, 1986). The aggregation of volatile fatty acids causes a drop in pH during fermentation, resulting in a reduction in biogas volume (see Table 5, Table 6A, Table 6B, Table 7).

5. Conclusion

The usefulness of UPS Co-digestion for biogas production was explored, and the role of anaerobic digestion in batch operations were provided. The reactors using 10/90 % and 90/10 % UPS had the greatest results for UPS biodegradation and methane generation. Some factors, such as substrate type, concentration, pH, temperature, stirring, and bacteria seeding, can influence biogas generation. To boost biogas generation, bacteria were seeded into the setups, and digestion was carried out at a mesophilic temperature. The UPS sludge is anaerobically degradable and produces little biogas, however co-digestion with RCM increased the rate of biogas production.

Funding

This study was supported by the Taif University Researchers Supporting Project (TURSP-2020/105), Taif University, Taif, Saudi Arabia.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

We appreciate and thank Taif University for the financial support for Taif University Researchers Supporting Project (TURSP-2020/105), Taif University, Taif, Saudi Arabia.

Footnotes

Peer review under responsibility of King Saud University.

References

- Abd Allah W.E., Tawfik M.A., Sagade A.A., Gorjian S., Metwally K.A., El-Shal H. Methane production enhancement of a family-scale biogas digester using cattle manure and corn stover under cold climates. Sustainable Energy Technol. Assess. 2021;45:101163. [Google Scholar]

- Appels L., Lauwers J., Degrève J., Helsen L., Lievens B., Willems K., Dewil R. Anaerobic digestion in global bio-energy production: potential and research challenges. Renew. Sust. Energ. Rev. 2011;15(9):4295–4301. [Google Scholar]

- Baghapour M., Jabbari E., Baskaran K. Reducing of excess sludge production in wastewater treatment using combined anaerobic/aerobic submerged biological filters. J. Environ. Health Sci. Eng. 2011;8(3):207–218. [Google Scholar]

- Calli B., Mertoglu B., Inanc B., Yenigun O. Effects of high free ammonia concentrations on the performances of anaerobic bioreactors. Process Biochem. 2005;40(3–4):1285–1292. [Google Scholar]

- Chandra R. Centre for Rural Development and Technology; IIT Delhi: 2009. Studies on production of enriched biogas using jatropha and pongamia deoiled seed cakes and its utilization in I.C. Engines. PhD thesis. [Google Scholar]

- Cheng J. CKC Press; New York: 2009. Biomass to Renewable Energy Process; pp. 151–163. [Google Scholar]

- De la Rubia M.A., Perez M., Romero L.I., Sales D. Anaerobic mesophilic and thermophilic municipal sludge digestion. Chem. Biochem. Eng. Q. 2002;16(3):119–124. [Google Scholar]

- De la Rubia M.A., Romero L.I., Sales D., Perez M. Temperature conversion (mesophilic to thermophilic) of municipal sludge digestion. AIChE J. 2005;51(9):2581–2586. [Google Scholar]

- El-Hinnawi E. IMC/PS-217; Cairo University, Project: 2006. Renewable energy sector in Egypt, bioenergy industry, a study carried out for Industrial Mo- Dernization Program (IMP) by Energy Research Center (ERC) Faculty of Engineering. [Google Scholar]

- Esposito G., Frunzo L., Liotta F., Panico A., Pirozzi F. Bio-methane potential tests to measure the biogas production from the digestion and co-digestion of complex organic substrates. Open Environ. Eng. 2012;5:1–8. [Google Scholar]

- Facchini F., Mummolo G., Vitti M. Scenario analysis for selecting sewage sludge-to-energy/matter recovery processes. Energies. 2021;14(2):276. [Google Scholar]

- Fantozzi F., Buratti C. Biogas production from different substrates in an experimental Continuously Stirred Tank Reactor anaerobic digester. Bioresour. Technol. 2009;100:5783–5789. doi: 10.1016/j.biortech.2009.06.013. [DOI] [PubMed] [Google Scholar]

- Ghazy M., Dockhorn T., Dichtl N. Sewage sludge management in Egypt: current status and perspectives towards a sustainable agricultural use. World acad. Sci. Eng. Technol. 2009;57:492–500. [Google Scholar]

- Guo Y.F. South China Agricultural University; 2011. Anaerobic digestion of kitchen waste under high OLR and acidification of the remedial measures. Master thesis. [Google Scholar]

- Heissenhuber A., Berenz S. Energieproduktion als Managementaufgabe in landwirtschaftlichen Unternehmen organisatorische und betriebswirtschaftliche Herausforderungen. In: Lohmann Informationen, April–Juni. 2005;2(2005):19–22. [Google Scholar]

- Kim H.W., Shin H.S.K., H.s. Anaerobic co-digestion of sewage sludge and food waste using temperature-phased anaerobic digestion process. Water Sci. Technol. 2004;50(9):107–114. [PubMed] [Google Scholar]

- Komatsu T., Kudo K., Inoue Y., Himeno S. Anaerobic codigestion of sewage sludge and rice straw. J. Jpn. Sewage Works Assoc. 2007;531:139–150. [Google Scholar]

- Mahvi A.H. Sequencing batch reactor: A promising technology in wastewater treatment. Iran. J. Environ. Health Sci. Eng. 2008;2(5):79–90. [Google Scholar]

- Mata-Alvarez J., Dosta J., Macé S., Astals S. Codigestion of solid wastes: a review of its uses and perspectives including modeling. Crit. Rev. Biotechnol. 2011;31(2):99–111. doi: 10.3109/07388551.2010.525496. [DOI] [PubMed] [Google Scholar]

- Nakhla D.A., Hassan M.J., El Haggar S. Impact of biomass in Egypt on climate change. Nat. Sci. 2013;5(6):678–684. [Google Scholar]

- Okeh O.C., Onwosi C.O., Odibo F.J.C. Biogas production from rice husks generated from various rice mills in Ebonyi State. Nigeria. Renew. Energy. 2014;62:204–208. [Google Scholar]

- Parkin G., Owen W.F. Fundamentals of anaerobic digestion of wastewater sludges. J. Enviro. Eng. 1986;112(5):867–920. [Google Scholar]

- Saad A.M., El-Saadony M.T., El-Tahan A.M., Sayed S., Moustafa M.A., Taha A.E., Ramadan M.M. Polyphenolic extracts from pomegranate and watermelon wastes as substrate to fabricate sustainable silver nanoparticles with larvicidal effect against Spodoptera littoralis. Saudi J. Biol. Sci. 2021;28(10):5674–5683. doi: 10.1016/j.sjbs.2021.06.011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Saad A.M., Sitohy M.Z., Ahmed A.I., Rabie N.A., Amin S.A., Aboelenin S.M., El-Saadony M.T. Biochemical and functional characterization of kidney bean protein alcalase-hydrolysates and their preservative action on stored chicken meat. Molecules. 2021;26(15):4690. doi: 10.3390/molecules26154690. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sahito A.R., Mahar R.B., Ahmed F. Effect of buffalo dung to the water ratio on production of methane through anaerobic digestion. Mehran University Res. J. Eng. Technol. 2014;33:237–244. [Google Scholar]

- Sambo A.S., Garba B., Danshehu B.G. Effect of some operating parameters on biogas production rate. Renew. Energy. 1995;6(3):343–344. [Google Scholar]

- Santosh, T. Sreekrishman, T.R. Kohli, S., Rana, V., 2004. Enhancement of biogas production from solid substrates using different techniques- a review bioresource technology. Vol. 95, pp. 1-10. [DOI] [PubMed]

- Strik D.P.B.T.B., Domnanovich A.M., Holubar P. A pH-based control of ammonia in biogas during anaerobic digestion of artificial pig manure and maize silage. Process Biochem. 2006;41(6):1235–1238. [Google Scholar]

- Turunen V., Sorvari J., Mikola A. A decision support tool for selecting the optimal sewage sludge treatment. Chemosphere. 2018;193:521–529. doi: 10.1016/j.chemosphere.2017.11.052. [DOI] [PubMed] [Google Scholar]

- Zhang Y., Cañas E.M.Z., Zhu Z., Linville J.L., Chen S., He Q. Robustness of archaeal populations in anaerobic co-digestion of dairy and poultry wastes. Bioresour. Technol. 2011;102(2):779–785. doi: 10.1016/j.biortech.2010.08.104. [DOI] [PubMed] [Google Scholar]

- You J.Y., Xiao B., Yang J.K. A feasibility study on anaerobic digestion of municipal solid waste (in Chinese) Energ. Eng.S. 2003;2:28–30. [Google Scholar]

- Zeeman G., Wiegant W.M., Koster-Treffers M.E., Lettinga G. The influence of the total ammonia concentration on the thermophilic digestion of cow manure. Agric. Was. 1985;1985(14):19–35. [Google Scholar]

- Zehnder A.J.B., Huser B.A., Brock T.D., Wuhrmann K. Characterization of an acetate-decarboxylating, non-hydrogen-oxidizing methane bacterium [Methanobacterium soehngenii] Arch. Microbiol. (Germany, FR). 1980;124(1):1–11. doi: 10.1007/BF00407022. [DOI] [PubMed] [Google Scholar]

- Zhang Z., Chen Y. Effects of microplastics on wastewater and sewage sludge treatment and their removal: a review. Chem. Eng. J. 2020;382 [Google Scholar]