Abstract

This comprehensive review highlights the diverse chemistry and applications of polymer-supported triphenylphosphine (PS-TPP) in organic synthesis since its inception. Specifically, the review describes applications of the preceding reagent in functional group interconversions, heterocycle synthesis, metal complexes and their application in synthesis, and total synthesis of natural products. Many examples are provided from the literature to show the scope and selectivity (regio, stereo, and chemo) in these transformations.

This comprehensive review highlights the diverse chemistry and applications of polymer-supported triphenylphosphine (PS-TPP) in organic synthesis since its inception.

1. Introduction

One of the latest advances in recent years has been the utility of solid-phase synthesis as a strategy to prepare chemical libraries,1 biologically active molecules, and natural products.2,3 Adaptation of solution phase synthetic techniques to use on solid supports offers some key advantages over solution-phase chemistry such as ease of purification, recyclability of the solid matrix, and use of excess reagents to achieve complete reaction conversion. Consequently, polymer-supported reagents have found many applications in synthetic organic chemistry. As such, the use of supported reagents in medicinal chemistry has been nicely showcased by Ley in the multi-step synthesis of drug targets and natural products such as sildenafil (Viagra),4 epimaritidine5 and epibatidine.6 One of the most useful reagents to which many chemical transformations can be credited is polymer-supported triphenylphosphine (diphenyl-polystyrylphosphine or polystyryldiphenylphosphine (1), PS-PPh2), an analogue of the ubiquitous triphenylphosphine (PPh3). The latter is a common reagent used in many chemical transformations where in many cases it gets oxidized to triphenylphosphine oxide (Ph3PO). Removal of Ph3PO from the product requires tedious chromatographic separation and/or crystallization processes which renders PPh3 impractical. As an alternative, polystyrene-supported triphenylphosphine was introduced. This reagent has an advantage over the its soluble counterpart because it can be separated along with any oxidation byproduct by filtration. The reagent can be easily prepared in one step and for convenience is commercially available from several chemical suppliers (100–200 mesh, extent of labeling: ∼3 mmol g−1 triphenylphosphine loading). The immobilized reagent was first reported in 1971 and has been extensively used ever since.7 However, the full synthetic potential of the reagent and variations thereof is still being established and several research groups around the globe are still aggressively pursuing such endeavors as demonstrated by the recent surge of research articles published by various groups on a wide range of transformations mediated by this reagent. The PS-PPh2 reagent has not yet been thoroughly reviewed in the literature except in some instances where it was briefly featured as a part of reviews of much wider scope.8–10 Thus, in this comprehensive review, an attempt to give an overall detailed picture of the synthetic utility of PS-PPh2 has been made by taking many examples from the literature covering almost 50 years. The review focuses on the preparation of PS-PPh2 and its utility in functional group interconversions, transition metal complexes and their reactions, heterocyclic synthesis, and preparation of natural products. Special focus has been dedicated to the impact of the structural framework of the substrate, substitution pattern, and configuration on reaction times and conditions, as well as on the stereo-, chemo, and regiochemical outcome of the reaction. Therefore we have discussed the synthetic schemes and entries in every table for the various transformations in detail. The scope of the review will be limited to PS-PPh2 and its reactions.

2. Preparation of polystyryldiphenylphosphine (1)

Generally, one of the simplest approaches to immobilize a phosphine ligand on a polymer support involves direct reaction of the desired ligand with a functionalised polymer such as bromopolystyrene or Merrifield's resin. Polystyrene resins are commercial available in a variety types, cross-link densities, and particle sizes. The cross-linked diphenyl-polystyrylphosphine (PS-PPh2, 1) can be prepared from bromopolystyrene (2) via a lithium–halogen exchange process by initial lithiation of the polymer support 2 to form lithiated polystyrene (Scheme 1), followed by reaction with chlorodiphenylphosphine (PPh2Cl).7,11–13 There are however drawbacks associated with this approach. Reaction of cross-linked bromopolystyrene with butyllithium often leads to unwanted side-reactions involving the C C bonds of the divinylbenzene crosslinking. Consequently, the product resin becomes contaminated and shows poor swelling properties. More efficient preparation of the polystyryl-lithium species that precludes attack of the divinylbenzene crosslinking moiety involves reaction of cross-linked polystyrene with the 1 : 1 complex of n-butyl-lithium and N,N,N′N′-tetramethylethylenediamine (TMEDA).14 An alternative preparation of PS-PPh2 (1) involves reaction of cross-linked bromopolystyrene (2) with lithium diphenylphosphide (3).7,12,13,15 This method represents the more common route for the attachment of monodentate phosphines to polymer resins. PS-PPh2 is insoluble in all typical organic solvents and is readily available through several chemical vendors as 2% divinylbenzene crosslinked polystyrene beads (100–400 mesh size) with loading ranges from 1.0 mmol P per g to over 3.0 mmol P per g. The reagent can be handled like a typical solid and is amenable to long term storage, although preferably under inert atmosphere to avoid aerial oxidation.

Scheme 1. Synthesis of DVB-crosslinked polystyryldiphenylphosphine 1.

3. Polystyryldiphenylphosphine-mediated functional group interconversions

3.1. Wittig reagents

3.1.1. Carbonyl olefination with p-polystyryldiphenyl-benzyl-phosphonium chloride

The Wittig reaction16 represents on of the most used chemical methods for olefin synthesis involving phosphines in solution. Not surprisingly, the first reported application of PS-TPP involved a Wittig reaction. Castells was the first to report the use of polymer-bound triphenylphosphine in this capacity to synthesize stilbene (40–60% yield) from the reaction of benzaldehyde with p-polystyryldiphenyl-benzyl-phosphonium chloride, prepared by reacting PS-TPP with neat benzyl chloride.7 A concurrent investigation by Heitz and Michels17 on polymer-supported Wittig synthesis of olefins using polystyrene crosslinked with 0.5 and 2.0 wt% of divinylbenzene (DVB) found that higher yields were possible with a 0.5% crosslinked polystyrene support. This was because only about 75% of the pore volume in a swollen polymer crosslinked with 2% DVB was accessible to substrates with molar masses 300–400, according to gel-chromatographic studies. Heitz and Michels18 also investigated steric control of the Wittig reaction on triphenylphosphane resins. They found that the adduct formed from the reaction of the aldehyde with the ylide can be selectively converted either to the trans- or cis-olefin as the major product in the mixture. The formation of the cis-olefin is kinetically controlled and favored in salt-free medium while the trans-olefin is thermodynamically controlled and predominates if the adduct is formed at low temperature (−78 °C) as the lithium salt is generated by adding lithium perchlorate as a Lewis acid. The study was, however, very limited in scope as the diastereoselectivity was poor and only reported for three olefins. Another concurrent study on the preparation and application of polymeric phosphoranes in the Wittig reaction was reported by Mckinley and Rakshys using the standard 2% crosslinked polystyryldiphenyl phosphine.19 Although the carbonyl–olefination reactions proceeded with methylene, ethylene, and benzylidene polymeric ylides using aromatic and aliphatic aldehydes and ketones, the conversion of the carbonyl compound was incomplete and yields were generally low (24–72%). It is noteworthy that these earlier papers reported syntheses of alkenes in fluctuating yields, depending on the polymer used and particular reaction conditions. Thus, further improvements were required for a useful methodology of general applicability.

3.1.2. Polymer-supported phase transfer catalysed Wittig reaction

Phase transfer catalysed reactions20 have been used extensively in organic synthesis, although they have been used to a much lesser extent in polymer chemistry. Thus, chemical reactions that combine the advantages of both experimental techniques are of interest. Hodge et al. described a phase transfer catalysed Wittig reaction between aldehydes 6 and polymer-bound phosphonium salt residues 5, prepared from PS-TPP and various organic halides 4 (Scheme 2).21,22 The reaction proceeds at room temperature and the small molecules are tethered to the polymer with bonds which are stable to both acid and base. The Wittig reaction was carried out in CH2Cl2 with 50% aqueous NaOH and a phase transfer catalyst (tetrabutylammonium iodide (TBAI) or cetyltrimethylammonium bromide (CTAB)). These conditions offered the highest reported olefin 7 yields compared to those reported by earlier work on polymer-supported Wittig reagents.17–19,23,24

Scheme 2. Polymer-supported phase transfer catalysed Wittig reaction. Reagents and conditions: (a) PS-TPP, chlorobenzene; (b) 5 : 6 (1.5 : 1 equiv.), 50% NaOH, TBAI or CTAB (2 mol%), 2–16 h.

As shown in Table 1, high yields of essentially pure alkenes were obtained from arylalkylphosphonium salts and various aldehydes (entries 1–9). However, while the alkylphosphonium salt (entry 10) reacted with a moderate yield with a reactive aldehyde, alkylphosphonium salts did not react with any aldehydes (entry 11). The Wittig reactions were performed with both, crosslinked and linear PS-TPP, although the former was more convenient since the resulting oxidized byproduct could be directly removed by filtration whilst the latter and it oxide were soluble and required precipitation workup. This renders linear polymers generally unsuitable. The isomeric ratios (cis : trans) were not determined for all olefins, although the measured ones were comparable to those obtained under conventional phase transfer catalysed conditions (entry 1; E : Z (100 : 0); entry 3; E : Z (57 : 43); entry 4; E : Z (44 : 56)). A point that merits comment is that the Wittig reaction can take place without any added catalyst, albeit more slowly, producing much lower yields as well. Ketones also failed to react with the phosphonium salts.

Reactions of polymer-bound phosphonium salts 5 derived from PS-TPP (1) and aldehydes 6 under phase-transfer conditions.

| Entry | Halide 4 (R1-X) | Aldehyde 6 | Catalyst | Yield 7 (%) |

|---|---|---|---|---|

| 1 | Benzyl chloride | 9-Formylanthracene | CTAB | 98 |

| 2 | Benzyl chloride | Benzaldehyde | CTAB | 92 |

| 3 | Benzyl chloride | p-Methyl-benzaldehyde | CTAB | 100 |

| 4 | Benzyl chloride | p-Chloro-benzaldehyde | TBAI | 97 |

| 5 | Benzyl chloride | Furan-2-aldehyde | CTAB | 90 |

| 6 | Benzyl chloride | Heptaldehyde | TBAI | 93 |

| 7 | 4-t-Butylbenzyl chloride | Formaldehyde | CTAB | 95 |

| 8 | 2-Bromoethylnaphthalene | β-Naphthaldehyde | CTAB | 65 |

| 9 | 2-Bromoethylnaphthalene | Formaldehyde | CTAB | 67 |

| 10 | Allyl bromide | p-Chloro-benzaldehyde | None | 78 |

| 11 | MeI or n-hexyl bromide | p-Chloro-benzaldehyde | TBAI | 0 |

3.1.3. Wittig reagents bound to crosslinked polystyrenes with variable crosslinking densities

Building on the earlier work describing polymer-supported Wittig reagents, Ford et al. reported a detailed study on the impact of varying the extent of crosslinking of the polystyrene support on yields of Wittig products.13 The polymer-supported reagents with 0.5% and 2% cross-linked polystyrenes that had been used earlier were too gelatinous and unsuitable for large-scale filtration.17 Thus, more highly crosslinked and rigid polystyrene supports were being sought out, although on the expense of lower Wittig yields, since penetration of reagents into all of the functional sites and out of the more highly cross-linked polymer matrices would be expected to be poor especially with large substrates. Ford described the use of Wittig reagents supported on polystyrenes with up to 20% cross-linking and with reactants as bulky as 10-nonadecanone (Table 2, entries 8 and 9) and the 3-keto steroid, cholest-4-en-3-one (Table 2, entries 10 and 11). The Wittig reagents were prepared on 2%, 8%, and 20% DVB crosslinked polystyrene from the reaction of crosslinked PS-TPP and either MeI (8a) or BnBr (8b), to afford the methyl-(9a) and benzylphosphonium (9b) salts, respectively (Scheme 3).

Alkenes from polymer-bound methylphosphonium salts 8a.

| Entry | Copolymer, % crosslinking | Carbonyl compound 10 | Wittig product 11 | Yield (%) |

|---|---|---|---|---|

| 1 | 2 | (CH2)5C O | (CH2)5C CH2 | 99 |

| 2 | 2 | PhCH CHCHO | PhCH CHCH CH2 | 95 |

| 3 | 8 | PhCH CHCHO | PhCH CHCH CH2 | 52 |

| 4 | 20 | PhCH CHCHO | PhCH CHCH CH2 | 83 |

| 5 | 2 | Ph2C O | Ph2C CH2 | 94 |

| 6 | 8 | Ph2C O | Ph2C CH2 | 61 |

| 7 | 20 | Ph2C O | Ph2C CH2 | 74 |

| 8 | 2 | (n-C9H19)C O | (n-C9H19)C CH2 | 96 |

| 9 | 20 | (n-C9H19)C O | (n-C9H19)C CH2 | 62 |

| 10 | 2 | Cholest-4-en-3-one | 3-Methylenecholest-4-ene | 91 |

| 11 | 20 | Cholest-4-en-3-one | 3-Methylenecholest-4-ene | 87 |

Scheme 3. Polymer-supported Wittig reactions. Reagents and conditions: (a) PS-TPP 1 : halide 8 (1 : 2 molar ratio), DMF, 70 °C, 2 d; (b) 9 : sodium methylsulfinylmethylide (1 : 3 molar ratio), THF/DMSO (1 : 1), −10 °C, 6 h, then 10 (1 molar equiv.), RT, 6 h, then reflux 24 h.

As shown in Scheme 3 and Table 2, Wittig reactions of the methylidenephosphoranes, generated from phosphonium salts 9 under basic conditions, were complete after 6 h at room temperature, followed by heating for 24 h at 60 °C. The chemical yields in all cases depended on the polymer as follows: 2% crosslinked polymer produced higher yields than >20% crosslinked polymer >8% crosslinked polymer. A similar trend was observed for olefins generated from polymer-bound benzylphosphonium salts. In this case, E/Z diastereomeric ratios ranged from 72/28 to 43/57. In general, reactions of the phosphoranes 9 with aldehydes and ketones afforded olefins in 73–96% yields with the 2% crosslinked polymer, 52–77% yields with the 8% cross-linked polymer, and 72–87% yields with the 20% cross-linked macroporous polymer. Ford showcased the utility of phosphonium salts on 2% cross-linked polystyrene and on 20% cross-linked macroporous polystyrene in the synthesis of ethyl retinoate.25 The preparation of olefins from polymer-supported phosphonium salts derived from PS-TPP (1) and various carbonyl compounds and elaboration thereafter has also been exploited by Ley for the synthesis of β-hydroxyamines.26

3.1.4. Mono-olefination of symmetrical dialdehydes with polymer-supported Wittig reagents derived from PS-TPP and various halides

Castells and co-workers exploited the pseudo high dilution environment provided by polymer supported phosphonium salts to effect mono-olefination of symmetrical dialdehydes (Scheme 4).27 The olefination reactions were carried out using 1 : 1 molar ratio of polymer supported phosphonium salts 13 and 19 to dialdehydes (isophthalaldehyde (14) and terephthalaldehyde (15)). The phosphonium salts were prepared from PS-TPP 1 and benzyl bromide (12a), benzyl chloride (12b), or methyl bromoacetate (18). The Wittig reaction afforded olefins in variable yields as E/Z geometric isomers (16 and 17), and in the case of phosphonium salt 19 as single diastereomers (20 and 21). The exclusive mono-olefinization was attributed to the formation of a betaine intermediate with one of the two aldehydes which blocks all active sites on the polymer, preventing the second carbonyl group from reacting. Interestingly, mono-olefinization still took place even when excess phosphonium salt to dialdehyde (2 : 1 molar ratio) was employed.

Scheme 4. Mono-olefinization of dialdehydes. Reagents and conditions: (a) PS-TPP : BnBr (or BnCl); (1 : 6.5 (or 1 : 16.3 for BnCl) molar ratio), benzene, reflux, 16 h (with BnBr) or 5 h (with BnCl); (b) 13 : 14: (or 15); (1 : 1 molar ratio), ethylene oxide (10.5 equiv.), benzene, 68 h at RT, then reflux at 45–50 °C for 6 h; (c) PS-TPP : methyl bromoacetate (18); (1 : 3.6 molar ratio), benzene, 7 d; (d) 18 : 14 or 15; (1 : 1 molar ratio), ethylene oxide (14.3 equiv.), benzene.

3.1.5. Preparation of vinyl ethers and thioethers via Wittig reagents

Polystyryldiphenyl-methoxymethyl- (23a), methylthiomethyl-phosphonium (23b), and benzyl-phosphonium chlorides (23c) were prepared by Akelah23 by treating PS-TPP (1) with chloromethylmethylether (22a), chloromethylthioether (22b), and benzyl chloride (22c) respectively (Scheme 5). These reagents were employed for the conversion of carbonyl compounds and formate esters into vinyl-ethers (24a), thioethers (24b), and alky-β-styrylethers (25) in high yields.

Scheme 5. Preparation of vinyl ethers, thioethers, and alky-β-styrylethers. Reagents and conditions: (a) 23a; PS-TPP : MeOCH2Cl : carbonyl (1 : 1.5 : 1), toluene, 50 °C, 48 h; 23b; PS-TPP : MeSeCH2Cl : carbonyl (1 : 1.5 : 1), toluene, 50 °C, 48 h; 23c; PS-TPP : BnCl (1 : 2), toluene, 50 °C, 24 h; (b) 24a : PhLi (1 : 1), ether, RT, 24 h; 24b : PhLi (1 : 1), THF, RT, 24 h; (c) 25: PS-TPP : 23c (1 : 1), NaOMe, MeOH, RT.

3.2. PS-TPP halophosphorane complexes

3.2.1. Polymer-supported dichlorophosphorane

Polymer-supported dichlorophosphoranes (26 and 28) were first prepared in 1974 from PS-TPP (1) and its related benzyl analogue 27 by initial oxidation with peracetic acid to the corresponding polymer-bound phosphine oxides, followed by treatment with carbon oxychloride (phosgene) to provide the desired halophosphorane complexes 26, and 28 (Scheme 6).28

Scheme 6. Preparation of halophosphorane complexes. Reagents and conditions: (a) (i) 40% peracetic acid in acetic acid, CH2Cl2, 25 °C, 3 h; (ii) phosgene (excess), 25 °C, 1 h.

Reagents 26 and 28 were used successfully for the synthesis of acid chlorides from carboxylic acids (Table 3, entries 1–3 and 5–7), a nitrile from a primary amide (entry 4), a chloroalkene from a ketone (entry 10), an imidoyl chloride from an anilide (entry 8), and an alkyl chloride from an alcohol (entry 9). The recovered resin-bound phosphine oxide was rephosgenated back to the halophosphorane reagent for reuse.

Chemical conversions using cross-linked polymeric phosphine dichloridesa.

| Entry | Polymeric phosphine dichloride | Reactant | Product | Yield (%) |

|---|---|---|---|---|

| 1 | 26 | PhCH2CO2H | PhCH2COCl | 100 |

| 2 | 26 | p-CH3C6H4CO2H | p-CH3C6H4COCl | 98 |

| 3 | 26 | HO2CC6H4CO2H (p) | ClOCC6H4COCl (p) | 91 |

| 4 | 26 | PhCH2CONH2 | PhCH2CN | 78 |

| 5 | 28 | HO2CC6H4CO2H (p) | ClOCC6H4COCl (p) | 95 |

| 6 | 28 | HO2CC6H4CO2H (p) | ClOCC6H4COCl (p) | 98 |

| 7 | 28 | HO2CC6H4CO2H (m) | ClOCC6H4COCl (m) | 87 |

| 8 | 28 | PhCH2CONHC6H5 | PhCH2C(Cl) NC6H5 | 93 |

| 9 | 28 | PhCH2OH | PhCH2Cl | 88 |

| 10 | 28 | PhCH2COCH3 | PhCH2C(Cl) CH2 | 75 |

Reagents and conditions: 1 : 1 molar ratios of polymeric phosphine dichloride : reactant, CH2Cl2, RT, 30 min.

3.2.2. Condensation of N-alkoxycarbonyl α-amino acids with primary amines using PS-TPP and CCl4

The combination of PS-TPP and carbon tetrachloride comprises a convenient coupling system for the amidation of N-alkoxycarbonyl α-amino acids and primary amines.29 Such a process is often beset with shortcomings associated with epimerization of the N-terminal residue and purification of the product. However, the preceding method reported by Landi and Brinkman is not afflicted by the aforementioned problems. The reagent system proved effective for N-Boc (t-butoxycarbonyl) and N-Fmoc (9-fluorenylmethoxycarbonyl) amino acids, as well as N-CBz (benzyloxycarbonyl) substrates (Table 4). Typically, the procedure involved refluxing an equimolar mixture of the N-protected amino acid and the amine with 4-methylmorpholine (29) (1.1 equiv. or 2.2 equiv. if the amine was an acid salt) and PS-TPP (2 equiv.) in a binary solvent mixture of CH2Cl2 and CCl4 (2 : 1). Interestingly, although earlier work of Relles28 and Hodge30 described the formation of acid chlorides from the reaction of polymer-supported dichlorotriphenylphosphorane with carboxylic acids, these intermediates were not present or involved in the current condensation. The active electrophile was found to be a resin-bound mixed phosphinic anhydride.

Condensation of N-alkoxycarbonyl α-amino acids and primary amines.

| ||||

|---|---|---|---|---|

| Entry | R1 | R2 | Amine | Yield (%) |

| 1 | CH2CO2Bn | Bn | l-Phenylalanine-OMe·HCl | 96 |

| 2 | CH2C6H4(OBu-t)-4 | CH2C13H9 | l-(−)-α-Methylbenzylamine | 89 |

| 3 | CH2OBn | t-Bu | l-(−)-α-Methylbenzylamine | 99 |

| 4 | CH2CO2Bn | Bn | d-Phenylalanine-OMe·HCl | 100 |

| 5 | Bn | t-Bu | l-(−)-α-Methylbenzylamine | 88 |

| 6 | CH2CO2Bn | t-Bu | l-(−)-α-Methylbenzylamine | 96 |

| 7 | CH2CO2Bu-t | t-Bu | l-Phenylalanine-OMe·HCl | 100 |

| 8 | (CH2)2SMe | t-Bu | l-(−)-α-Methylbenzylamine | 79 |

| 9 | (CH2)4NHCO2CH2C6H4Cl-2 | t-Bu | l-(−)-α-Methylbenzylamine | 78 |

3.2.3. Preparation of dipeptides using PS-TPP and CCl4

Polymer-supported triphenylphosphine and carbon tetrachloride have also been successfully used for the synthesis of dipeptides. Appel described the synthesis of three small peptides from N-protected amino acid and amino acid ester salts using PS-TPP and CCl4. The reaction was heated at 40 °C in acetonitrile as solvent to afford the peptides in 70–76% yields (Table 5).31

Preparation of dipeptides with polymeric triphenylphosphine and CCl4a.

| Entry | N-Protected amino acid | Amino acid ester | Peptide | Yield (%) |

|---|---|---|---|---|

| 1 |

|

|

|

76 |

| 2 |

|

|

|

70 |

| 3 |

|

|

|

70 |

Reagents and conditions: 3 : 1 : 1 : 2 molar ratios of PS-TPP/CCl4 : N-protected amino acid : amino acid ester : Et3N, acetonitrile, 40 °C, 1 d.

3.2.4. Preparation of acid chlorides and alkyl chlorides using PS-TPP and CCl4

The PS-TPP–CCl4 reagent system has also been applied successfully to convert carboxylic acids into acid chlorides,30,32 and thiols32 as well as alcohols15,30,32 into alkyl chlorides (Scheme 7). The reactions do not generate HCl and thus the conditions are essentially neutral.

Scheme 7. Reactions of carboxylic acids, thiols, and alcohols with PS-TPP in CCl4.

Some representative examples of the conversion of carboxylic acids into acid chlorides, and alcohols/thiols into alkyl chlorides are summarized in Table 6. Generally, a carbon tetrachloride solution of the carboxylic acid, alcohol, or thiols in the presence of excess PS-TPP (1.3–2 molar equiv.) was heated at reflux for 1–5 h and the oxidized polymer resin was removed at the end of reaction period by filtration. Carbon tetrachloride was used as a co-reagent and as a solvent. A range of aliphatic and aromatic carboxylic acids, thiols, and alcohols were suitable substrates and gave good yields (50–98%), except for the secondary alcohol, cyclohexanol (entry 13). In this case, some elimination occurred, giving a mixture of chlorocyclohexane and cyclohexene. The acetonide protecting group (entry 12) remained intact, underscoring the advantage of neutral conditions. Interestingly, substrate selectivity based on size was not a factor in determining the reaction rate considering that substrates need to diffuse into the polymer to react. For instance, 5β-cholan-24-ol (entry 14), which represents a relatively large substrate, reacted satisfactorily with the reagent. Mechanistically, the polymer-supported reactions involving the conversion of alcohols into alkyl chlorides seem to follow similar pathways to those observed for the free Ph3P reagent as judged by the quantity of phosphine (2 equiv.) consumed per mole of alkyl chloride and by the quantity of chloroform produced at the end of the reaction. Formation of the polymeric chlorinating species appears to be the slow step, although the PS-TPP reactions have been shown to be faster than those using Ph3P due to a microenvironmental effect.32,33 The suggested mechanism also required that polymer supported phosphine residues react together.33 This is consistent with Sherrington's work in which the conversion of alcohols into alkyl chlorides was retarded or even inhibited when highly crosslinked PS-TPP (>15% crosslink ratio of styrene to DVB) was utilized.34 Although highly crosslinked polymers favour the formation of chloroalkanes because the alcohol penetrates the matrix more easily, the inherent rigidity and lack of backbone mobility hinders the approach and reaction of non-adjacent phosphine residues, and therefore inhibit the preceding transformation. As a result, the aforementioned chlorination reactions are best carried with Ph3P supported on polystyrene of low crosslink ratio (1–2%).35

Conversion of carboxylic acids into acid chlorides and alcohols into alkyl chloridesa.

| Entry | Carboxylic acid/alcohol | Acid chloride/alkyl chloride | Yield (%) |

|---|---|---|---|

| 1 | n-Octanoic | Octanoyl chloride | 63 |

| 2 | Phenoxyacetic | Phenoxyacetyl chloride | 50 |

| 3 | Stearic | Stearoyl chloride | 82 |

| 4 | Cinnamic | Cinnamoyl chloride | 77 |

| 5 | Benzoic | Benzoyl chloride | 90 |

| 6 | α-Furoic | 2-Furanoyl chloride | 82 |

| 7 | β-Naphthoic | 2-Naphthoyl chloride | 84 |

| 8 | n-Octanol | 1-Chlorooctane | 98 |

| 9 | 2-n-Butoxyethanol | 1-(2-Chloroethoxy)butane | 94 |

| 10 | Benzyl alcohol | Benzyl chloride | 88 |

| 11 | Hexadecyl alcohol | 1-Chlorohexadecane | 98 |

| 12 | 4-Hydroxymethyl-2,2-dimethyl-1,3-dioxolane | 4-(Chloromethyl)-2,2-dimethyl-1,3-dioxolane | 78 |

| 13 | Cyclohexanol | Chlorocyclohexane | 40 |

| 14 | 5β-Cholan-24-ol | 24-Chloro-5β-cholane | 78 |

| 15 | Octadecanethiol | 1-Chlorooctadecane | 78 |

| 16 | 3-Phenylpropanethiol | (3-Chloropropyl)benzene | 82 |

| 17 | Phenylmethanethiol | Benzyl chloride | 95 |

Reagents and conditions: 1.3 : 2 molar ratios of PS-TPP : carboxylic acid or alcohol, CCl4, 77 °C, 1–5 h.

3.2.5. Synthesis of amides from carboxylic acids and amines using PS-TPP and CCl4

Hodge et al. also demonstrated that carboxylic acids could be directly converted into amides by treatment with carbon tetrachloride and PS-TPP in the presence of at least 2 molar equivalents of the amine (Table 7).32 The reaction was reminiscent to that reported earlier by Appel and Willms whereby several peptides were prepared using the same reagent.31 Amides were prepared in 1,2-dichloroethane (DCE) containing 10% CCl4 by volume (entries 1, 2 and 5) or in CCl4 under reflux for 3 h to afford the amides in 57–94% yield. The same system was used by Hodge to convert primary carboxamides and oximes into nitriles or imidoyl chlorides in good yields.

Preparation of amides from carboxylic acids and aminesa.

| Entry | Acid | Amine | Amide | Yield (%) |

|---|---|---|---|---|

| 1 |

|

Ph–NH2 |

|

86 |

| 2 |

|

Ph–NH2 |

|

57 |

| 3 |

|

|

|

72 |

| 4 |

|

|

|

83 |

| 5 |

|

Ph–NH2 |

|

94 |

Reagents and conditions: 2.2 : 1 : 2 molar ratios of PS-TPP : carboxylic acid : amine, DCE/10% CCl4 or CCl4, reflux, 3 h.

3.2.6. Polymer-supported triphenylphosphine-carbon tetrabromide and triphenylphosphine dibromide: conversion of alcohols into alkyl bromides

Hodge et al. reported the use of polymer-supported triphenylphosphine dibromide (PS-TPP–Br2) and the combination of polymer-supported triphenylphosphine and carbon tetrabromide (30) (PS-TPP–CBr4) to convert alcohols into alkyl bromides (Table 8).36 The former reagent had been used earlier for the cleavage of ethers,37 and to prepare imidoyl bromides, ketenimines, and carbodiimides.38 The required PS-TPP–Br2 was prepared from PS-TPP and bromine in CHCl3 and was used to convert a range of alcohols to bromides at reflux temperature. However, the use of PS-TPP–CBr4 was more advantageous since HBr is not a byproduct and reactions were faster (5–40 min), cleaner, and did not require heating in the case of primary and some secondary alcohols (Table 8, entries 1–8). Bulky substrates (entries 9–11) required more vigorous conditions but nevertheless still gave good yields of the bromides. Inversion of configuration was observed with trinorbornan-endo-2-ol (entry 10) and (−)-bornan-2-ol (entry 11).

Conversion of alcohols to bromides with PS-TPP and CBr4a.

| |||

|---|---|---|---|

| Entry | Alcohol | Bromide product | Yield (%) |

| 1 | 1-Octanol | 1-Bromooctane | 98 |

| 2 | Benzyl alcohol | Benzyl bromide | 80 |

| 3 | 3-Phenylpropan-1-o1 | (3-Bromopropyl)benzene | 81 |

| 4 | 4-Phenylbutan-1-o1 | (4-Bromobutyl)benzene | 82 |

| 5 | 4,4,4-Triphenylbutan-1-o1 | (4-Bromobutane-1,1,1-triyl)tribenzene | 73 |

| 6 | Undec-10-en-1-o1 | 11-Bromoundec-1-ene | 89 |

| 7 | Cinnamyl alcohol | Cinnamyl bromide | 89 |

| 8 | Octan-2-o1 | 2-Bromooctane | 76 |

| 9 | Adamantanol | 1-Bromoadamantane | 97 |

| 10 | Trinorbornan-endo-2-ol | Trinorbornan-exo-2-yl bromide | 89 |

| 11 | (−)-Bornan-2-ol | Bornan-exo-2-yl bromide | 71 |

Reagents and conditions: 2.2 : 1.1 : 1 molar ratios of PS-TPP : CBr4 : alcohol, CHCl3; entries 1–8 (RT, 5–40 min); entries 9–11 (61 °C, 16 h).

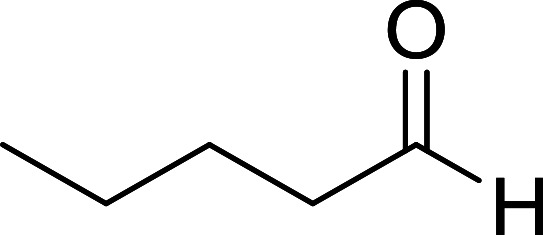

3.2.7. Synthesis of dibromoalkenes by reaction of carbonyl compounds with PS-TPP and CBr4

Aldehydes and ketones react with dibromomethylene ylides 32, generated from the reaction of carbon tetrabromide with Ph3P (Scheme 8, reaction 1), to give 1,1-dibromoalkenes 34 (reaction 2). Additionally, the carbonyl group may react with the accompanying triphenylphosphine dibromide (33) produced in the first step (reaction 1) to produce gem-dibromides 35 (reaction 3). Hodge investigated the synthesis of 1,1-dihaloalkenes by reacting carbonyl compounds with PS-TPP and carbon tetrahalides (CBr4 and CCl4).39 The reactions with carbon tetrachloride required harsh conditions and generally produced inseparable mixtures of dichloroalkene and gem-dichloride. However, the reaction with CBr4 proceeded at 20 °C and in most cases afforded dibromoalkenes (34) in good and consistent yields (87–98%) with minimal formation of gem-dibromides 35 (3–13%). Mechanistically, the olefination reactions using the PS-TPP/CBr4 reagent system proceeds through the polystyryl ylide intermediate shown in Scheme 8.

Scheme 8. Synthesis of dibromoalkenes and gem-dibromides from carbonyl compounds with PS-TPP/CBr4 reagent system.

3.2.8. Conversion of epoxides to halohydrins

Polystyryldiphenylphosphine–halogen complexes (PS-TPP–X2) comprise convenient reagents for the conversion of epoxides to halohydrins under very mild and non-acidic conditions.40 They are semi-crystalline solids which are easy to handle, stable at room temperature, and amenable to storage for weeks. However, they undergo rapid decomposition if they are exposed to moisture giving the corresponding hydrogen halide and phosphine oxide. The halogen complexes were prepared by treating PS-TPP with an equimolar amount of bromine (1 M) or iodine (1 M) solution, or by bubbling gently gaseous chlorine through the suspended polymer resin in CH2Cl2. The halogens got consumed immediately and the formation of the complexes was almost instantaneous. Epoxide-ring opening reactions proceeded in high yields (Table 9) and maintained regio- and stereo-selectivity when compared to the same transformation carried out with Ph3P–X2 complexes.

Conversion of epoxides to halohydrins using PS-TPP–X2 complexesa.

| Entry | Epoxide | Halohydrin | Yield (%) |

|---|---|---|---|

| 1 |

|

|

X = I: 97 |

| X = Br: 95 | |||

| X = Cl: 96 | |||

| 2 |

|

|

X = I: 95 |

| X = Br: 96 | |||

| X = Cl: 98 | |||

| 3 |

|

|

X = I: 95 |

| X = Br: 96 | |||

| X = Cl: 97 | |||

| 4 |

|

|

X = I: 95 |

| X = Cl: 97 | |||

| 5 |

|

|

95 |

Reagents and conditions: 1.2 : 1 molar ratio of PS-TPP–X2 : epoxide, CH2Cl2, RT, 10 min.

3.2.9. Esterification of carboxylic acids using polystyryldiphenylphosphine–halogen complexes (PS-TPP–X2)

Caputo et al. also demonstrated the utility of polystyryldiphenylphosphine–halogen complexes (PS-TPP–X2) in the condensation of carboxylic acids and alcohols to afford esters in high yields and under mild conditions (Table 10).41 The complexes were prepared as before40 and the procedure involved adding the acid to an equimolar amount of the complex, followed by stirring at room temperature for 10–15 min. Subsequent addition of the alcohol and warming up to 40–50 °C gave the desired ester in high yield within 1–3 h. The halogen complexes act both as condensating agents and acid catalysts. The reaction was assumed to involve protonated acyl halides as the key intermediates that react with the added alcohol. The advantage of this protocol include rapid ester formation, directly from the acid, broad range of alcohol and carboxylic acid substrates, and simple workup. The iodine complex (PS-TPP–I2) was most practical, among the three halogen complexes, as the formation of esters with PS-TPP–Cl2 was slow, whereas the use of PS-TPP–Br2 resulted in some bromination of double bonds for unsaturated substrates.

Esterification of carboxylic acids using PS-TPP–I2 complexesa.

| |||

|---|---|---|---|

| Entry | Carboxylic acid | Alcohol | Yield (%) of ester |

| 1 | CH3CO2H | 5α-Cholestan-3β-ol | 96 |

| 2 | CH3CO2H | 5α-Cholestan-3α-ol | 85 |

| 3 | PhCO2H | CH3OH | 90 |

| 4 | PhCO2H | 5α-Cholestan-3β-ol | 85 |

| 5 | CH3(CH2)6CO2H | 5α-Cholestan-3β-ol | 93 |

| 6 | CH3(CH2)14CO2H | CH3OH | 98 |

| 7 | CH3(CH2)14CO2H | 5α-Cholestan-3β-ol | 92 |

| 8 | CH3(CH2)16CO2H | CH3CH2OH | 95 |

| 9 | CH3(CH2)16CO2H | 5α-Cholestan-3β-ol | 94 |

| 10 | Linoleic acid | CH3OH | 87 |

| 11 | Linoleic acid | 5α-Cholestan-3β-ol | 84 |

Reagents and conditions: 1.1 : 1.1 : 1 molar ratio of PS-TPP–I2 : carboxylic acid : alcohol, CH2Cl2, 40–50 °C, 1–3 h.

3.2.10. Microwave assisted conversion of alcohols to alkyl halides with PS-TPP–X2 complexes

Microwave assisted organic synthesis has been implemented as a technology in organic chemistry since the mid-1980's.42 Recently, a microwave assisted procedure for the conversion of allylic, benzylic and aliphatic alcohols to the corresponding alkyl bromides and iodides using polymer-supported triphenylphosphine and iodine or bromine was described by Rokhum et al.43 The iodination and bromination reactions were complete within 7 minutes under microwave irradiation conditions and gave alkyl halides in yields ranging from 76–96% (Table 11). Primary alcohols converted to the corresponding halides at a faster rate than secondary alcohols and preference of secondary over tertiary substitution was observed with unsymmetrical diols (entry 13). In case of symmetrical diols (entry 14), the mono-iodinated products were obtained in very high yields (88–93%). The methodology features high chemo- and regio-selectivity behaviour, short reaction times, product isolation requiring only filtration and solvent removal.

Synthesis of alkyl halides from alcoholsa.

| |||

|---|---|---|---|

| Entry | Alcohol | Product | Yield (%) |

| 1 | Benzyl alcohol | Benzyl iodide | 93 |

| 2 | 4-Methoxy-benzyl alcohol | 4-Methoxy-benzyl iodide | 96 |

| 3 | 3,4-Dimethoxy-benzyl alcohol | 3,4-Dimethoxy-benzyl iodide | 89 |

| 4 | 4-Nitro-benzyl alcohol | 4-Nitro-benzyl iodide | 96 |

| 5 | 3-Chloro-benzyl alcohol | 3-Chloro-benzyl iodide | 95 |

| 6 | 4-Chloro-benzyl alcohol | 4-Chloro-benzyl bromide | 91 |

| 7 | 4-Bromo-benzyl alcohol | 4-Bromo-benzyl bromide | 92 |

| 8 | 3-Phenylpropan-1-ol | (3-Bromopropyl)benzene | 81 |

| 9 | Octan-1-ol | 1-Iodooctane | 92 |

| 10 | 3-Methylbut-2-en-1-ol | 1-Iodo-3-methylbut-2-ene | 87 |

| 11 | Cyclohexanol | Iodocyclohexane | 76 |

| 12 | Diphenylmethanol | (Iodomethylene)dibenzene | 85 |

| 13 |

|

|

79 |

| 14 |

|

|

88–93 |

Reagents and conditions: 1 : 1.2 : 1 molar ratio of alcohol : PS-TPP : X2 (X= I, Br), MW, 120 °C, CH3CN, 3–7 min.

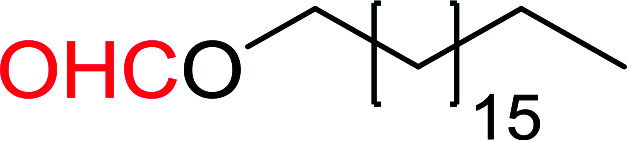

3.2.11. Formylation of primary and secondary alcohols using PS-TPP and iodine

The conversion of alcohols into formic acid esters is a well known protection strategy.44 Unfortunately, many of the methods used to prepared formate esters use drastic conditions and suffer from serious limitations which include heating the alcohol in 85% formic acid or employing uncommon reagents. Palumbo et al. exploited PS-TPP–halogen complexes in the synthesis of formic acid esters from various primary and secondary alcohols (Table 12).45 It is noted that tertiary alcohols under the same conditions failed to give the desired formate esters and instead afforded the alkyl halides. Both iodine and chlorine complexes (PS-TPP–I2 and PS-TPP–Cl2) were suitable, whereas the bromine complex (PS-TPP–Br2) was not tolerated at least with unsaturated alcohols due the co-occurrence of a side reaction involving some bromination of double bonds. The iodine complex was the most convenient considering the ease of handling compared with chlorine.

Conversion of alcohols into formate esters by PS-TPP–I2–dimethylformamide adductsa.

| Entry | Alcohol | Formate ester | Yield (%) |

|---|---|---|---|

| 1 |

|

|

93 |

| 2 |

|

|

90 |

| 3 |

|

|

90 |

| 4 |

|

|

92 |

| 5 |

|

|

78 |

| 6 |

|

|

84 |

| 7 |

|

|

92 |

Reagents and conditions: 2.3 : 2.3 : 2.4 : 1 molar ratios of PS-TPP : I2 : DMF : alcohol, RT, 30 min.

3.2.12. Acetalization of carbonyl compounds with PS-TPP–I2 complex

Cyclic and acyclic acetals, dithioacetals, and oxathioacetals are very common groups used to protect the carbonyl function of aldehydes and ketones.46 One drawback of acetalization, besides using alcoholic media and Brønsted acid catalysts, is the generation of water during the reaction and the need to remove it by physical or chemical means to drive the equilibrium forward. Thus, a strategy to prepare acetals from carbonyl compounds and alcohol, diols, dithiols, or hydroxythiols under anhydrous conditions and devoid of water formation has been described using the combination of PS-TPP and I2.47 In this approach, the carbonyl compound in anhydrous acetonitrile is treated with a pre-formed PS-TPP–I2 complex, followed by the desired protecting reagent. An adduct is formed between the positively charged phosphorus atom and carbonyl oxygen, thus activating the carbonyl carbon center for nucleophilic addition by a molecule of the protecting reagent (Scheme 9). A subsequent non-equilibrium step involves the elimination of PS-TPPO and generation of an oxygen-stabilized carbocation which undergoes further reaction with a second reagent molecule or a tethered nucleophile on the same reagent to afford the final product.

Scheme 9. Mechanism of acetalization of carbonyl compounds using PS-TPP–I2.

The devised procedure for acetalization tolerates aliphatic and aromatic aldehydes and ketones, as shown in Table 13. It is noted that in order to avoid acidic medium for certain substrates, anhydrous Et3N was added in portions throughout the reaction.

Acetalization reactions of ketones and aldehydes catalysed by PS-TPP–I2 complexa.

| ||||

|---|---|---|---|---|

| Entry | R1 | R2 | R3 | Yield (%) |

| 1 | Ph | Me | –O-(CH2)2-O– | 80 |

| 2 | Ph | Me | –S-(CH2)2-S– | 98 |

| 3 | Ph | Me | –S-(CH2)2-O– | 92 |

| 4 | Ph | Ph | –S-(CH2)2-S– | 86 |

| 5 | Ph | Ph | –S-(CH2)2-O- | 88 |

| 6 | Ph | H | –S-(CH2)2-S– | 98 |

| 7 | Ph | H | –S-(CH2)2-O– | 85 |

| 8 | n-C7H15 | H | –O-(CH2)2-O– | 84 |

| 9 | n-C7H15 | H | –S-(CH2)2-S– | 98 |

| 10 | n-C7H15 | H | –S-(CH2)2-O– | 85 |

| 11 | –(CH2)2CH(t-C4H9)(CH2)2 | n-C4H9S– | 80 | |

| 12 | –(CH2)2CH(t-C4H9)(CH2)2 | CH3O– | 92 | |

Reagents and conditions: 1.2 : 1 : 4 molar ratio of PS-TPP–I2 : carbonyl compound : protecting reagent, Et3N (for entries 1, 3, 8 and 12), MeCN, RT, 40 min.

3.2.13. Polymer-supported triphenylphosphine dibromide (PS-TPP–Br2–imiH) and diiodide (PS-TPP–I2–imiH): conversion of alcohols into alkyl iodides

Building on Hodge's earlier work regarding the use of polymer-supported triphenylphosphine dibromide (PS-TPP–Br2) in the conversion of alcohols into alkyl bromides,36 Classon prepared a similar polymer-supported phosphine–halogen complex using iodine in combination with imidazole (PS-TPP–I2–imiH).48 The addition of imidazole enhanced reactivity and neutralized liberated HI, resolving reactivity and yield issues encountered earlier by Hodge et al. in the bromination of alcohols using the related PS-TPP–Br2 complex.36 Other bases such as pyridine or Et3N were examined, although much lower yields were generally obtained. The halogenation reactions were performed in heated toluene which provided a two phase liquid–liquid reaction system and promoted faster reactivity than other solvents because the non-polar character of the solvent appears to destabilize the charged phosphonium halide intermediate and drive decomposition to the uncharged alkyl iodide and phosphine oxide byproduct. The iodinations examined involved the synthesis of iodides from alcohols, using various carbohydrates as substrates. Acid-sensitive groups such as acetals, glycosidic linkages, and triphenylmethyl ethers remained intact under reaction conditions (Scheme 10). However unprotected polyhydroxy sugars were unsuitable as substrates and gave complicated reaction mixtures.

Scheme 10. Conversion of alcohols into alkyl iodides with PS-TPP–I2 complex. Reagents and conditions: 3 : 1.3 : 3 : 1 molar ratios of PS-TPP : I2 : imidazole : alcohol, toluene, 50–120 °C, 3–8 h.

3.2.14. Synthesis of (E)-nitroalkenes from aldehydes and nitroalkanes PS-TPP and I2

Bez et al. described the first solid phase one-pot procedure for the synthesis of (E)-nitroalkenes 38 (ref. 49) by reacting diverse aromatic, aliphatic, and α,β-unsaturated aldehydes (36) with nitroalkanes (37) in the presence of polymer-bound triphenylphosphine, iodine and imidazole (Table 14). Although the same transformation proceeded with similar efficiency using triphenylphosphine instead of its polymer-bound analogue, easy removal of the unwanted polymer-bound triphenylphosphine oxide provided the edge for practical application of the protocol. The reaction generally gave good yields except with less electrophilic aldehydes such as 3,4-dimethoxybenzaldehyde (entry 8) and 3,4-methylenedioxybenzaldehyde (entry 9) which also required longer reaction time (3 h) for complete conversion.

Synthesis of (E)-nitroalkenes from aldehydes and nitroalkanesa.

| ||||

|---|---|---|---|---|

| Entry | Aldehyde | R2 | Nitroalkene product | Yield (%) |

| 1 |

|

H |

|

93 |

| 2 |

|

CH3 |

|

89 |

| 3 |

|

H |

|

84 |

| 4 |

|

H |

|

93 |

| 5 |

|

CH3 |

|

89 |

| 6 |

|

CH3 |

|

89 |

| 7 |

|

H |

|

81 |

| 8 |

|

H |

|

55 |

| 9 |

|

CH3 |

|

58 |

Reagents and conditions: 1 : 1.5 : 1.5 : 1.5 : 2 molar ratios of aldehyde : nitroalkane : PS-TPP : iodine : imidazole, RT, CH2Cl2, 1–3 h.

3.2.15. Preparation of N-protected β-iodoamines from β-amino alcohols using PS-TPP–I2 complex

Enantiomerically pure N-protected β-iodoamines are important synthetic precursors used for the preparation of d- or l-β-amino acids, which themselves represent challenging synthetic targets.50 One approach to the preparation of β-amino acids consists of homologating the requisite α-aminoacid, whereby the α-carboxyl group gets converted into an alkyl halide in preparation for the subsequent homologation step. Longobardo et al. developed a general synthesis of chiral N-protected β-iodoamines 40, possessing either d- or l-configuration, by treating the precursor chiral N-protected β-aminols 39 with PS-TPP–I2 complex.51 The β-aminoalcohols were accessed from N-protected α-aminoacid or commercial β-aminols. As shown in Table 15, the conversion was effective for β-aminols protected with the most frequently used N-protecting groups (Cbz, Boc, Fmoc) without any detectable racemization of the stereocenter. The utility of this methodology was later demonstrated by Longobardo et al. in the synthesis of enantiopure N- and C-protected homo-β-amino acids by direct homologation of α-aminoacid.52 The devised process involved reducing the carboxyl group of N-protected α-amino acids and converting the resulting N-protected β-amino alcohols into the corresponding β-iodoamines with PS-TPP–I2, which represented the key step of the strategy. Subsequent cyanation and acidic hydrolysis of the β-amino cyanides afforded enantiopure homo-β-amino acids.

Synthesis of N-protected β-iodoamines using PS-TPP–I2 complexa.

| |||

|---|---|---|---|

| Entry | PG | R | Yield (%) |

| 1 | Cbz | Me | 89 |

| 2 | Cbz | Bn | 90 |

| 3 | Boc | CH(CH3)3 | 90 |

| 4 | Boc | CH2COOBn | 82 |

| 5 | Boc | Ph | 95 |

| 6 | Fmoc | Me | 92 |

| 7 | Fmoc | Bn | 94 |

| 8 | Fmoc | CH2CH(CH3)3 | 94 |

Reagents and conditions: 2.2 : 2.5 : 1 molar ratios of PS-TPP/I2 : imidazole : alcohol, CH2Cl2, reflux, 1 h.

3.2.16. Peptide synthesis using PS-TPP–I2 complex

The utility of the polystyryl diphenylphosphine–iodine complex (PS-TPP–I2) has also been showcased in peptide synthesis.53 The action of the complex involves converting the free carboxylic acid group of a N-protected α-amino acid into an acyl donor intermediate, followed by nucleophilic substitution by the amino function of a second, C-protected α-amino acid, affording fully protected dipeptides. Using this approach, Longobardo and coworkers were able to couple various N-protected α-amino acid with α-aminoacyl esters, by using PS-TPP–I2, in high yields and without detectable racemization of the reacting substrates (Table 16).53 Neutral reaction conditions were secured by the addition of excess imidazole to neutralize the released hydrogen iodide. Thus, the process was effective for substrates carrying the common N-protecting groups (Fmoc, Boc, Cbz) and tolerated acid sensitive S- and O-protecting groups like the trityl (entry 3), methyl (entries 2 and 3), tert-butyl (entry 4), and benzyl groups (entry 5).

Preparation of dipeptides with polymeric triphenylphosphine and I2a.

| Entry | N-Protected α-AA | O-Protected α-AA | Dipeptide | Yield (%) |

|---|---|---|---|---|

| 1 |

|

|

|

99 |

| 2 |

|

|

|

98 |

| 3 |

|

|

|

95 |

| 4 |

|

|

|

95 |

| 5 |

|

|

|

95 |

Reagents and conditions: 2.2 : 2 : 1 : 1 : 2.5 molar ratios of PS-TPP : I2 : N-protected α-amino acid : O-protected α-amino acid : imidazole, CH2Cl2, RT, 30 min.

3.2.17. Monoesterification of symmetric diols using PS-TPP–I2 complex

The preparation of carboxylic acid esters from di- or polyhydroxylated substrates is a challenging synthetic task and the introduction of reliable strategies towards the selective monoesterification of such alcohols is useful.54 Rokhum and Pathak reported the use of PS-TPP/iodine in coupling reactions between carboxylic acids and alcohols or amines to produce esters and amides, respectively.55 More importantly, the PS-TPP–I2 reagent has been shown to affect the monoesterification of symmetrical diols without resorting to high dilution or slow addition conditions. As shown in Table 17, the monoesterification of 1,6-hexanediol (entries 1–5) and 1,8-hexanediol (entries 6–8) with various carboxylic acids was achieved in high yields (84–92%) in the presence of DMAP and preformed PS-TPP–I2 complex.

Preparation of monoesters from diols using PS-TPP and iodinea.

| ||||

|---|---|---|---|---|

| Entry | Alcohol | Carboxylic acid | Product | Yield (%) |

| 1 | HO(CH2)6OH | Benzoic acid |

|

88 |

| 2 | Propanoic acid |

|

91 | |

| 3 | Pentanoic acid |

|

87 | |

| 4 | 4-Methylbenzoic acid |

|

84 | |

| 5 | 4-Nitrobenzoic acid |

|

92 | |

| 6 | HO(CH2)8OH | 3-Nitrobenzoic acid |

|

84 |

| 7 | Benzoic acid |

|

85 | |

| 8 | Lauric acid |

|

91 | |

Reagents and conditions: 1.5 : 1.5 : 1 : 1 : 3 molar ratios of PS-TPP/I2 : alcohol : carboxylic acid : DMAP, THF/CH2Cl2 (1 : 3 v/v), RT, 18–22 h.

3.2.18. Iodination, bromination, and chlorination of alcohols with PS-TPP/X2 and PS-TPP/NCS imidazole systems

Building on the previous reports describing the use of PS-TPP and iodine for the conversion of α-amino acids and sugars into the corresponding iodides,48,52,56 Kita et al. extended the methodology to the halogenation of alcohols under new conditions.57 The reagent system was prepared by treating a suspension of PS-TPP in CH2Cl2 at room temperature with imidazole and iodine, bromine, or N-chlorosuccinimide (NCS). Subsequent addition of various allylic, benzylic, and primary alcohols gave the halogenated products in very high yields (88–98%) (Table 18). The reactions worked well with ortho, meta, para-, and multisubstituted benzylic alcohols (entries 2–9), as well as allylic (entries 10–12) and simple alcohols (entries 1, 13 and 14). While the iodination and bromination reactions were complete within 2 h in all cases, the chlorination reaction (entry 14) required 24 h for complete conversion. Finally, when the reagent system was tested on secondary alcohols, the reaction was very slow and unpractical for such systems.

Halogenation of alcoholsa.

| |||

|---|---|---|---|

| Entry | Alcohol | Alkyl halide | Yield (%) |

| 1 | Benzyl alcohol | Benzyl iodide | 97 |

| 2 | o-Tolylmethanol | 1-(Iodomethyl)-2-methylbenzene | 95 |

| 3 | (2-Bromophenyl)methanol | 1-Bromo-2-(iodomethyl)benzene | 95 |

| 4 | (2-Methoxyphenyl)methanol | 1-(Iodomethyl)-2-methoxybenzene | 96 |

| 5 | 3-(Hydroxymethyl)benzonitrile | 3-(Iodomethyl)benzonitrile | 98 |

| 6 | (3-Nitrophenyl)methanol | 1-(Iodomethyl)-3-nitrobenzene | 98 |

| 7 | (4-Methoxyphenyl)methanol | 1-(Iodomethyl)-4-methoxybenzene | 92 |

| 8 | (2,4-Dichlorophenyl)methanol | 1-(Iodomethyl)-2,4-dichlorobenzene | 97 |

| 9 | (2,4-Dimethoxyphenyl)methanol | 1-(Iodomethyl)-2,4-dimethoxybenzene | 95 |

| 10 | (E)-3-Phenylprop-2-en-1-ol | (E)-(3-Iodoprop-1-en-1-yl)benzene | 95 |

| 11 | (Z)-3,7-Dimethylocta-2,6-dien-1-ol | (Z)-1-Iodo-3,7-dimethylocta-2,6-diene | 91 |

| 12 | (E)-3,7-Dimethylocta-2,6-dien-1-ol | (E)-1-Iodo-3,7-dimethylocta-2,6-diene | 88 |

| 13 | p-Tolylmethanol | 1-(Bromomethyl)-4-methylbenzene | 96 |

| 14 | p-Tolylmethanol | 1-(Chloromethyl)-4-methylbenzene | 90 |

Reagents and conditions: entries 1–12; 1.3 : 1.3 : 1.3 : 1 molar ratios of PS-TPP : I2 : imidazole : alcohol, CH2Cl2, RT, 15–120 min; entry 13; same conditions except Br2 was used; entry 14; same conditions except NCS was used and the reaction was stirred for 24 h.

3.2.19. Synthesis of glycosyl iodides

A new and stereoselective synthesis of α-d-glycosyl iodides obtained by the replacement of the free anomeric hydroxyl functional group of fully protected sugars using PS-TPP–iodine complex was reported by Caputo and co-workers.56 Thus, the addition of various protected sugars to a mixture of PS-TPP, iodine, and imidazole, at room temperature, resulted in the rapid conversion to the α-glycosyl iodide anomer (Table 19). No traces of the β-anomers were observed in any of the examples, suggesting that the process is thermodynamically controlled.

Preparation of glycosyl iodides from protected sugarsa.

| |||

|---|---|---|---|

| Entry | Carbohydrate | Protection group | Yield (%) |

| 1 | d-Glucopyranose | 2,3,4,6-Tetra-O-acetyl | 97 |

| 2 | d-Glucopyranose | 2,3,4,6-Tetra-O-benzyl | 95 |

| 3 | d-Galactopyranose | 2,3,4,6-Tetra-O-acetyl | 95 |

| 4 | d-Galactopyranose | 2,3,4,6-Tetra-O-benzyl | 92 |

| 5 | d-Mannopyranose | 2,3,4,6-Tetra-O-acetyl | 95 |

| 6 | d-Mannopyranose | 2,3,4,6-Tetra-O-benzyl | 94 |

| 7 | d-Mannofuranose | 2,3,5,6-Di-O-isopropylidene | 98 |

Reagents and conditions: 1.9 : 1.9 : 3.5 : 1 Molar ratios of PS-TPP : I2 : imidazole : sugar.

3.2.20. Esterification of alkylphosphonic acids

Alkylphosphonates have many synthetic and pharmaceutical applications.58 In addition, methyl, ethyl, i-propyl and n-propyl esters of alkyl phosphonic acids are registered chemical warfare agents (CWAs).59 The related O,O′-dialkyl alkylphosphonates (DAPs) are very useful reference chemicals that have been used as markers of nerve agents.60 However, since they are also classified as CWAs, they are not available commercially and access to this class of compounds becomes inevitable during verification analysis. Dubey et al. reported a procedure for the preparation of DAPs by esterification of alkylphosphonic acids using primary alcohols, iodine, imidazole, and PS-TPP (Table 20).61 Pure phosphonate esters were obtained by vacuum distillation in 83–94% yield following removal of PS-TPP oxide and imidazolium iodide by filtration.

Esterification of alkylphosphonic acidsa.

| ||||

|---|---|---|---|---|

| Entry | R1 | R2 | Product | Yield (%) |

| 1 | CH3 | CH3 | O,O′-Dimethyl methylphosphonate | 85 |

| 2 | CH3 | C3H7 | O,O′-Dipropyl methylphosphonate | 90 |

| 3 | CH3 | C5H11 | O,O′-Dipentyl methylphosphonate | 94 |

| 4 | CH3 | C10H21 | O,O′-Didecyl methylphosphonate | 82 |

| 5 | C2H5 | C2H5 | O,O′-Diethyl ethylphosphonate | 90 |

| 6 | C2H5 | C5H11 | O,O′-Dipentyl ethylphosphonate | 92 |

| 7 | C2H5 | C10H21 | O,O′-Didecyl ethylphosphonate | 84 |

| 8 | C3H7 | CH3 | O,O′-Dimethyl propylphosphonate | 87 |

| 9 | C3H7 | C5H11 | O,O′-Dipentyl propylphosphonate | 92 |

| 10 | C3H7 | C10H21 | O,O′-Didecyl propylphosphonate | 83 |

Reagents and conditions: 1 : 3 : 6.6 : 3 : 2.5 molar ratios of alkyl phosphonic acid : iodine : imidazole : PS-TPP : alcohol, 45–50 °C, CH2Cl2, 2 h.

3.2.21. Acetonation of sugars (protection of diols) with triphenylphosphine polymer-bound/iodine complex

The triphenylphosphine polymer-bound/iodine complex is a strong Lewis acid and a dehydrating agent as shown by the many transformations presented thus far.62 Palumbo et al. exploited this feature to prepare O-isopropylidene derivatives of various sugars by condensing the sugar with acetone.63 The isopropylidene function has been widely used in carbohydrate chemistry to protect diols and in certain cases sugar derivatives incorporating such a group have shown antipyretic and anti-inflammatory activities.64 The synthesis of the reagent complex involved adding a solution of iodine to an equimolar amount of polystyryl diphenylphosphine suspension at room temperature under dry N2 atmosphere and dark conditions. Subsequent addition of an acetone solution of the sugar to the suspension then afforded the thermodynamically more stable acetonides within 30 minutes in very high purity and yields (Table 21).

Preparation of O-isopropylidene sugar derivativesa.

| Entry | Sugar | O-Isopropylidene derivatives | Yield (%) |

|---|---|---|---|

| 1 | d-Glucose |

|

95 |

| 2 | d-Ribose |

|

95 |

| 3 | d-Mannose |

|

95 |

| 4 | l-Arabinose |

|

95 |

| 5 | d-Galactose |

|

97 |

Reagents and conditions: 2 : 2 : 1 molar ratios of PS-TPP : I2 : sugar, acetone, RT, 45 min.

3.2.22. Conversion of alcohols to alkyl halides with catalytic amounts of PS-TPP

As shown earlier, Kita et al.57 had already reported a convenient method of iodination of alcohols using PS-TPP/iodine/imidazole reagent system. Rokhum reported a modification of Kita's method, switching imidazole with DMAP.65 However in both approaches the catalyst (imidazole/DMAP) was used in excess and the recovery and reuse of the reagent system was not possible. A major drawback of using equimolar amounts of PS-TPP for the halogenation of alcohols is the formation of polymer-supported triphenylphosphine oxide byproduct as the end of the reaction, which in principle may be recycled using reducing conditions.66,67 However, in order to avoid the inconvenience associated with recovering and recycling the polymer through reduction, Rokhum described a clever approach to the selective halogenation of alcohols using catalytic amounts of polymer-supported triphenylphosphine–methylacrylate complex 41.68 The protocol involves reactions of PS-TPP and methylacrylate in dichloromethane (10 mL) at room temperature for two minutes to generate in situ the triphenylphosphine–methylacrylate complex 42 (40 mol%). Subsequent addition of iodine and polymer supported triphenylphosphine, followed by the alcohol afforded the desired iodide products in 78–93% yields. The procedure was successful with primary aliphatic alcohols, as well as secondary and tertiary ones, although the latter took longer time from complete conversion. Allyl alcohols were also converted into the corresponding iodides without affecting the olefinic bonds. Direct bromination using the reported reaction conditions proceeded as well to afford the desired bromides in high yields (87–91%) (Scheme 11).

Scheme 11. Solid phase conversion of alcohols to iodides using PS-TPP–MA and soluble Ph3P.

3.3. Application of polymer-supported phosphonium salts derived from PS-TPP as traceless linkers for solid phase synthesis of alkenyl, alkyl and heterocyclic products

Solid-phase synthesis of small organic molecule libraries for drug discovery programs has been one of the key driving forces responsible for the rapidly expanding field of combinatorial chemistry.69 Consequently, a large number of polymeric supports have been devised to immobilise compounds via polar functional groups such as alcohols, amides, and carboxylic acids.69 With the growing need to access a diverse range of small molecules, additional linker groups were required to meet the demand. One particular type, termed “traceless” linkers, leave no remnants in the cleaved product of the functionality utilized to tether the substrate to its support. Hughes showcased the utility of polymer-bound phosphonium salts derived from PS-TPP as traceless linkers for the solid-phase synthesis of small molecules.70 Thus, as shown in Scheme 12, the phosphonium salt 44 was prepared from 2-nitrobenzyl bromide (43) and PS-TPP, followed by reduction of the nitro group to generate the polymer-bound aniline 45. Finally, the aniline was acylated with 4-methoxybenzoyl chloride to afford anilide 46. The polymer-supported substrate 46 was elaborated and cleaved, via hydrolysis or an intramolecular Wittig/cyclization reaction in a traceless manner, to afford alkenyl, heteroaryl, and alkyl products (47–49) in 78–82% yield.

Scheme 12. Solid-phase synthesis polymer-supported phosphonium salts derived from PS-TPP. Reagents and conditions: (a) DMF, 70 °C, 48 h; (b) Na2S2O4, EtOH, reflux, 90 min; (c) HBr, MeOH, dioxane; (d) 4-methoxybenzoyl chloride, pyridine, CH2Cl2, 5 h; (e) NaOMe, MeOH, reflux, 4 h, 81%; (f) toluene, DMF, distill; (g) KOtBu, reflux, 45 min, 78% for both steps; (h) methyl 4-formylbenzoate (2 eq.), NaOMe (2 equiv.), MeOH, reflux, 2 h; (i) Girard's Reagent T (3 equiv.), AcOH, 18 h, 5 was produced in 82% overall yield as a 3 : 1 mixture of E/Z isomers.

3.4. Staudinger reaction

3.4.1. Reduction of nucleoside azides to amines

Functionalization of nucleosides by converting the sugar moiety into an aminosugar has been extensively studied.71,72 Reducing an azido function attached to the carbohydrate part represents one of the most convenient means for the preparation of the amine group.72 Building on this early work, Holletz and Cech described the reduction of nucleoside azides to amines under mild conditions and good yields using PS-TPP (Table 22).73 The reaction was executed in two steps using pyridine or dioxane as solvents. In the first step, reaction of PS-TPP with the azido nucleoside afforded an iminophosphorane, which upon subsequent hydrolysis in the second step with water or concentrated ammonia, led to the formation of the amine. While water hydrolysis left the base protecting group intact (entries 1, 2 and 3), ammonia was used in cases where simultaneous hydrolysis and N-deprotection was desired (entries 5 and 6). The reaction workup required only filtration of the suspended PS-TPPO and evaporation of the filtrate in vacuo to afford pure products in nearly quantitative yields (89–100%).

Reduction of azido nucleoside to amines using PS-TPPa.

| |||

|---|---|---|---|

| Entry | Azido nucleoside | Amine product | Yield (%) |

| 1 |

|

|

98 |

| 2 |

|

|

100 |

| 3 |

|

|

100 |

| 4 |

|

|

89 |

| 5 |

|

|

93 |

| 6 |

|

|

94 |

Reagents and conditions: entries 1 and 2; 5 : 1 molar ratio of PS-TPP : azido nucleoside, dioxane, RT, 2 h, then H2O, 2 h; entry 4; molar ratio of PS-TPP : azido nucleoside, pyridine, RT, 3 h, then NH3 (32%), 5 h; entries 3, 5 and 6; 5 : 1 molar ratio of PS-TPP : azido nucleoside, dioxane, RT, 2 h, then NH3 (32%), overnight.

3.4.2. Conversion of sugar azides to sugar isothiocyanates

Isothiocyanates are very useful synthetic intermediates in carbohydrate chemistry,74 and have been utilized in the synthesis of various functional groups as well as heterocyclic rings.75 Azides comprise convenient precursors as means to introduce the isothiocyanate group to sugars via a tandem Staudinger–aza-Wittig reaction of the azide with Ph3P and carbon disulfide.75 Fernández et al. demonstrated the utility of PS-TPP in lieu of Ph3P in the one-step preparation of non-anomeric sugar isothiocyanates from primary and secondary sugar azides (Table 23).76 While primary azidodeoxy sugars afforded the corresponding primary deoxyisothiocyanato in high yields (entries 1–3), secondary azides, especially those with the azide group located at an endocyclic carbon atom, gave much lower yields (entries 5 and 6). Mono- and disaccharides, including pyranose and furanose derivatives, protected with a variety of labile and sensitive O-protecting groups underwent successful functional group interconversion, illustrating the scope of the method. This strategy was not successful with glycosyl azides because of the higher reactivity of the anomeric isothiocyanate. Prior to the work of Fernández et al., a similar reduction reaction of a 3′-azidonucleoside using PS-TPP was reported by Cech and Zehl as a technical improvement to the preparation of isothiocyanato derivatives.77 The proposed mechanism of these reactions involve initial formation of a polymer-supported iminophosphorane intermediate, followed by a cyclization reaction with carbon disulfide to give a four-membered ring, and subsequent cycloreversion of the ring to afford the isothiocyanate.

Synthesis of deoxyisothiocyanato sugars from azidodeoxy sugarsa.

| |||

|---|---|---|---|

| Entry | Azide | Isothiocyanates | Yield (%) |

| 1 |

|

|

95 |

| 2 |

|

|

97 |

| 3 |

|

|

86 |

| 4 |

|

|

73 |

| 5 |

|

|

24 |

| 6 |

|

|

18 |

Reagents and conditions: 1.2 : 1 : 10–25 molar ratios of PS-TPP : azidodeoxy sugars : CS2, dioxane, RT, 16–48 h.

3.4.3. A one-pot aza-Wittig based polymer supported route to primary and secondary amines

Azides have been employed as the nitrogen source for the preparation of primary amines by converting the azide into an iminophosphorane (the Staudinger reaction), followed by hydrolysis.78 This approach, however, can not be used to access secondary amines because imine intermediates are not involved. Hemming and co-workers disclosed a study describing the conversion of azides 50 into α-unsubstituted primary amines 51 or α-branched secondary amines 52via the intermediacy of polymer-supported iminophosphoranes and imines (Table 24).79 Their strategy involved a Staudinger reaction between PS-TPP and various azides (R1-N3), affording polymer-supported iminophosphoranes. Subsequent in situ aza-Wittig reaction of the resulting iminophosphorane with aromatic or alkyl aldehydes (R2CHO) gave imine intermediates, which were either reduced in situ to the corresponding α-unsubstituted primary amines (path a), or functionalized via 1,2-addition of organometallic reagents (R3MgX or R3Li) to afford α-branched secondary amines (path b). The use of trimethylsilyl azides (R1 = TMS, entries 11–13) permitted synthesis of primary amines following in situ N-desilylation, whilst using benzyl azides allowed access to N-benzyl protected amines (entry 1, 6, 9 and 10). On the other hand, the wide range of suitable organometallic reagents allowed the preparation of synthetically useful homoallylic amines (entries 10 and 11). The yields ranged from 52–99% for most substrates except when the hindered pivalaldehyde was used (entry 6).

Synthesis of primary and secondary amines from azides and aldehydes using PS-TPPa.

| ||||

|---|---|---|---|---|

| Entry | R1 | R2 | R3 | Yield (%) |

| 1 | Bn | Ph | H | 99 |

| 2 | Ph | p-F-C6H4 | H | 69 |

| 3 | Ph | n-Pr | H | 71 |

| 4 | Ph | Me | H | 52 |

| 5 | p-MeO-C6H4 | Ph | H | 91 |

| 6 | Bn | t-Bu | H | 17 |

| 7 | Ph | PhCH CH | n-Bu | 96 |

| 8 | Ph | Ph | n-Bu | 99 |

| 9 | Bn | Ph | n-Bu | 83 |

| 10 | Bn | Ph | H2C CHCH2 | 91 |

| 11 | TMS | Ph | H2C CHCH2 | 79 |

| 12 | TMS | p-MeO-C6H4 | n-Bu | 69 |

| 13 | TMS | Ph | Ph | 59 |

Reagents and conditions: (i) 4 : 1 molar ratio of PS-TPP : azide, THF, RT, 2–3 h. (ii) Aldehyde (1.5 molar equivalent), THF, reflux, 3 h; entries 1–6, path a, NaBH3CN or NaBH4 or BH3-THF (1.5 molar equivalent), MeOH, NH4Cl (aq), RT, 1 h; entries 7–13, path b, R3MgX or RLi, NH4Cl (aq), RT, 1 h.

3.4.4. Aza Wittig synthesis of pyrido[1,2-c]pyrimidine heterocycles

Pyrido[1,2-c] pyrimidines comprise a promising class of heterocycles which may potentially provide novel superoxide scavengers and anti-inflammatory agents.80 Molina and co-workers designed a solid-phase synthesis of these fused azaheterocycles via an aza Wittig reaction under mild reaction conditions. Their strategy for the synthesis of pyrido[1,2-c] pyrimidines 55 and 56 is outlined in Scheme 13. Staudinger reaction between PS-TPP (1) and ethyl α-azido-β-(2-pyridyl)acrylate (53) in dry CH2Cl2 at room temperature gave the polymer-bound iminophosphorane 54. Subsequent reaction of 54 with carbon dioxide or carbon disulfide at 90 °C afforded pyrido[1,2-c]pyrimidines 55a and 55b in 83% and 93% yield, respectively. On the other hand, aza Wittig reaction of iminophosphorane 54 with aromatic isocyanates produced the carbodiimides 58 through the intermediacy of species 57. The former (58) underwent regioselective electrocyclization to give the corresponding pyrido[1,2-c]pyrimidines 56 in yields ranging from 82% to 90%.

Scheme 13. Preparation of pyrido[1,2-c]pyrimidines. Reagents and conditions: (i) CH2Cl2, RT; (ii) solid CO2 or CS2, toluene, sealed tube, 90 °C; (iii) Ar-NCO, CH2Cl2, RT.

3.4.5. Synthesis of secondary amines from alkyl azides and alkyl halides

The most popular methods for the synthesis of secondary amines use either reductive aminations or alkylation procedures on primary amines. However, overalkylation leading to the formation of the corresponding tertiary or quaternary ammonium salts is difficult to avoid. Classon et al. described a one-pot, two-step procedure that delivers only secondary amines from the corresponding azides and reactive alkyl halides using polymer-bound, triphenylphosphine-supported synthesis (Table 25).81 The solid-phase method involves a Staudinger reaction between PS-TPP (1) and the azide to afford the corresponding phosphoazide which rapidly eliminates nitrogen to give an iminophosphorane intermediate. Subsequent alkylation with alkyl (entries 1 and 6), allyl (entry 4), or benzyl (entries, 2, 3, 5 and 7) halides produced the corresponding resin-bound disubstituted aminophosphonium salts. Finally, the secondary amines were freed from the solid support by hydrolytic cleavage using methanolic KOH. The yields obtained were good in all examples (78–87%) except when phenylazide was used (21%) (entry 5). The low yield was attributed to its reduction to the corresponding aniline.

Synthesis of secondary aminesa.

| ||||

|---|---|---|---|---|

| Entry | Azide | Alkyl halide | Product | Yield (%) |

| 1 |

|

MeI |

|

81 |

| 2 |

|

|

|

82 |

| 3 |

|

|

|

87 |

| 4 |

|

|

|

78 |

| 5 |

|

|

|

21 |

| 6 |

|

MeI |

|

85 |

| 7 |

|

|

|

82 |

Reagents and conditions: (i) PS-TPP, THF, 5 min. RT.; (ii) azide, THF, 4 h, RT.; (iii) alkyl halide, THF, 16 h, RT; (iv) KOH–MeOH, 4 h, 65 °C; 2 : 1 : 3 : 10 molar ratios of PS-TPP : azide : alkyl halide : KOH–MeOH.

3.4.6. Synthesis of glucopyranosyl amides using PS-TPP

The presence of the glycosyl amide motif in naturally occurring biomolecules like glycoproteins and nucleic acids has inspired interest in the synthesis of compounds containing such structural feature.82 In particular, glycosyl amides have been synthetically targeted because they have been suggested as potential inhibitors of glycosyl hydrolases83 and the binding of fibroblast growth factor (FGF-2) to heparin.84 Norris et al. devised a method for the introduction of the glycosyl amide by way of a Staudinger process in which a glycosyl azide reacts with PS-TPP, followed by reaction of the resulting iminophosphorane with an acid chloride (Scheme 14).85

Scheme 14. Synthetic strategy towards the synthesis of glucopyranosyl amides using PS-TPP. Reagents and conditions: 1.3 : 1 : 2 molar ratios of PS-TPP : azide : acid chloride, CH2Cl2, 40 °C, 6 h.

Norris et al. reacted 2,3,4,6-tetra-O-acetyl-β-d-glucopyranosyl azide with PS-TPP and various acid chlorides (Table 26, entries 1–9) using a parallel synthesizer to prepare a small library of glucopyranosyl amides. The excess acid chloride was removed at the end of the reaction by treatment with polymer-supported tris(2-aminoethyl) amine. Optimum yield was observed with p-nitrobenzoyl chloride, underscoring the preference of the polymer-bound iminophosphorane for highly electrophilic acid chlorides (entry 1). On the other hand, the highly hindered pivaloyl chloride inhibited the reaction between the iminophosphorane intermediate and acid chloride (entry 8).

Synthesis of glucopyranosyl amides from carboxylic acids.

| Entry | Acid chloride | Azide | Glucopyranosyl amide yield (%) |

|---|---|---|---|

| 1 |

|

|

93 |

| 2 |

|

40 | |

| 3 |

|

72 | |

| 4 |

|

55 | |

| 5 |

|

56 | |

| 6 |

|

61 | |

| 7 |

|

61 | |

| 8 |

|

— | |

| 9 |

|

40 |

3.5. The Mitsunobu reaction

3.5.1. Esterification using PS-TPP

The condensation of alcohols with carboxylic acids via triphenylphosphine-azodicarboxylate activation is one of the most reliable and common methods for esterification (the Mitsunobu reaction).86 However, byproducts from the Mitsunobu reaction and excess reagents are non-volatile and soluble in organic solvents necessitating difficult chromatographic separation of the desired product almost always. PS-TPP was first utilized in the Mitsunobu reaction by Amos et al. in 1983 for the preparation of esters from alcohols and carboxylic acids (Table 27).87 The use of PS-TPP conferred convenience in terms of purification of the ester product. The method worked well with aliphatic and aromatic acids and tolerated a variety of functional groups as shown in Table 27. The yield was unaffected in the series of benzoic acids substituted with electron-donating and electron-withdrawing groups (entries 1 and 4–7). As anticipated, secondary alcohols (entries 3, 4 and 11) gave consistently lower yields than primary alcohols (entries 1, 2 and 5–10) and tertiary alcohols were too hindered and remained unreacted. When an optically pure alcohol was used (entry 11), inversion of the chiral center was observed.

Preparation of esters from alcohols and carboxylic acids using PS-TPPa.

| ||||

|---|---|---|---|---|

| Entry | Alcohol | Carboxylic acid | Ester product | Yield (%) |

| 1 | PhCH2OH | PhCO2H | PhCO2Bn | 86 |

| 2 | PhCH2OH |

|

|

86 |

| 3 | C2H5CH(CH3)OH |

|

|

64 |

| 4 | Cyclopentanol |

|

|

75 |

| 5 | 1-Heptanol |

|

|

90 |

| 6 | 1-Heptanol |

|

|

89 |

| 7 | 1-Heptanol |

|

|

84 |

| 8 | PhCH2OH | (CH3)CCO2H | (CH3)CCO2Bn | 99 |

| 9 | EtOH | HO2C(CH2)4CO2H | EtO2C(CH2)4CO2Et | 79 |

| 10 | 1-Heptanol |

|

|

92 |

| 11 |

|

PhCO2H |

|

65 |

Reagents and conditions: 1.8 : 1.4 : 1 : 1 molar ratios of PS-TPP : DEAD : carboxylic acid : alcohol, THF, 25 °C, 4 h.

3.5.2. Synthesis of aryl ethers from phenols and alcohols

Georg and co-workers88 reported the first example of a Mitsunobu reaction86 using PS-TPP in the synthesis of aryl ethers. The group prepared a library of aryl ethers from phenols with electron releasing and electron withdrawing groups and various alcohols (Table 28).88 In a typical experiment, PS-TPP, diethyl azodicarboxylate (DEAD), the alcohol, and the phenol in dichloromethane were stirred at room temperature for 4–12 hours. Filtration of the resin, followed by evaporation of the solvent in vacuo and purification by column chromatography afforded pure aryl ethers in 59–94% yields. It is noted that presence of electron withdrawing substituents at the aromatic ring of the phenol (Cl and CN) accelerated the reaction rate, whereas electron donating substituent (OMe) generally reduced the reaction rate, resulting in a slower reaction progress.

Preparation of aryl ethers from alcohols and phenols using PS-TPPa.

| |||||

|---|---|---|---|---|---|

| Entry | Phenol | Alcohol | Aryl ether | Product | Yield (%) |

| 1 | R1 = CN | R2 = heptyl | R1 = CN | R2 = heptyl | 68 |

| 2 | R1 = CN | R2 = benzyl | R1 = CN | R2 = benzyl | 94 |

| 3 | R1 = CN | R2 = furfuryl | R1 = CN | R2 = furfuryl | 88 |

| 4 | R1 = Cl | R2 = heptyl | R1 = Cl | R2 = heptyl | 65 |

| 5 | R1 = Cl | R2 = benzyl | R1 = Cl | R2 = benzyl | 88 |

| 6 | R1 = Cl | R2 = furfuryl | R1 = Cl | R2 = furfuryl | 84 |

| 7 | R1 = OMe | R2 = heptyl | R1 = OMe | R2 = heptyl | 63 |

| 8 | R1 = OMe | R2 = benzyl | R1 = OMe | R2 = benzyl | 86 |

| 9 | R1 = OMe | R2 = furfuryl | R1 = OMe | R2 = furfuryl | 78 |

Reagents and conditions: 1.5 : 1.5 : 1.5 : 1 molar ratios of PS-TPP : DEAD : alcohol : phenol.

3.5.2.1. Stereochemical inversion of secondary alcohols

Georg et al. found that polymer-supported triphenylphosphine can replace triphenylphosphine in the Mitsunobu reaction to form stereochemically inverted secondary alcohols.89 The procedure addresses the most significant drawback associated with the Mitsunobu reaction which includes removal of excess triphenylphosphine and its oxide by-product. The protocol is very comparable to the standard Mitsunobu reaction in regards to yield, stereochemical inversion, reaction time, and even inversion of sterically hindered secondary alcohols. As shown in Table 29, benzylic, alkyl, and cyclic secondary alcohols underwent successful inversion of configuration, although yields were slightly lower with the former two types of substrates (entries 3 and 5) and much lower for sterically hindered ones (entry 6). It is noted that no racemisation was observed for substrates bearing an acidic proton at the stereocenter (entries 2 and 4). The yields reported were in general comparable to those obtained when the inverted products were prepared using standard homogeneous Mitsunobu conditions, suggesting that the reactivity of PS-TPP is similar to its free form. Many of the inverted esters were hydrolyzed to the corresponding alcohols with LiOH which were isolated in 95–97% yields. Optical rotation analysis of the alcohols showed complete inversion of configuration when compared with the starting material.

Stereochemical inversion of secondary alcoholsa,b.

| |||

|---|---|---|---|

| Entry | Alcohol | Inverted ester | Yieldc (%) |

| 1 |

|

|

98 |

| 2 |

|

|

74 |

| 3 |

|

|

65 |

| 4 |

|

|

76 |

| 5 |

|

|

71 |

| 6 |

|

|

25 |

Reagents and conditions: 1 : 1.2 : 2 : 2 molar ratios of alcohol : R3COOH (R3COOH = 4-nitrobenzoic acid or chloroacetic acid) : DEAD : PS-TPP, THF, RT, 3–12 h.

Reagents and conditions: LiOH, H2O/acetone, RT, 95–97% yield.

The yield shown is for step a.

3.5.3. Synthesis of aryl ethers from aminoalcohols