Abstract

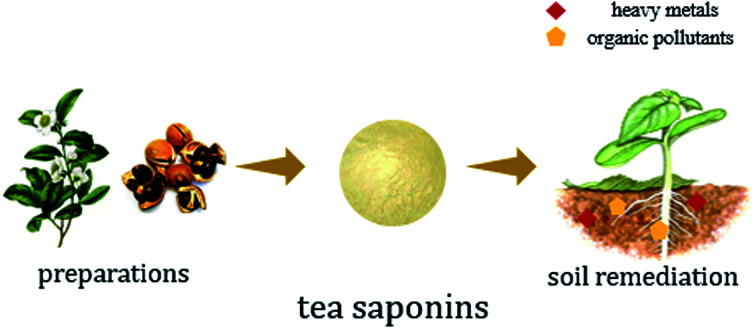

Tea saponins, found in Camellia plants, are natural non-ionic surfactants that offer obvious beneficial effects in soil remediation. Most tea saponins are extracted from the Camellia oleifera seed meal, with the leaves and flowers of Camellia sinensis as potential sources. Water extraction and ultrasound-assisted water extraction combined with acetone precipitation are recommended for the industrial extraction and purification of tea saponins, considering multiple factors. The detailed physical, chemical and biochemical properties of tea saponins need to be clarified, especially whether tea saponins with slightly different structures from distinct sources have different soil remediation properties. Applied in leaching remediation, phytoremediation and microbial remediation, tea saponins desorb heavy metals from contaminated soil as well as enhancing their bioavailability. Tea saponins improve the accumulation of pollutants by hyperaccumulators as well as the degradation of organic pollutants by microorganisms. Currently the mechanisms of tea saponins are not clear, although they are proven to be effective natural surfactants for the remediation of contaminated soils. This review enriches our understanding of tea saponins from various aspects and encourages further studies of industrial extraction and purification, and the field remediation mechanisms of tea saponins, making better use of Camellia plants and contributing to environmental protection.

This review details the industrial extraction and purification processes of tea saponins from Camellia plants and clarifies their mechanisms for soil remediation.

Introduction

Soil, one of humanity’s most valuable resources, is severely polluted by heavy metals and organic pollutants all over the world. In China, for instance, the “Bulletin on the Survey of Soil Pollution in China” issued in 2014 (ref. 1) shows that the total soil over-standard rate in China is 16.1%, of which inorganic pollutants account for 82.8%, followed by organic pollutants. Cadmium (Cd), nickel (Ni), copper (Cu), arsenic (As), mercury (Hg) and lead (Pb) are major inorganic pollutants, and benzene hexachloride (BHC), dichlorodiphenyltrichloroethane (DDT) and polycyclic aromatic hydrocarbons (PAHs) are major organic pollutants. For arable land, the over-standard rate is 19.4% and the main pollutants are Cd, Ni, Cu, As, Hg, Pb, DDT and PAHs. Given the current severe state of soil pollution, it is not only of great urgency but also of significant importance to amend contaminated soil both for environmental protection and agricultural production, which is worth researching.

According to the principle of remediation, soil remediation is simply classified as physical remediation, chemical remediation or bioremediation. Soil remediation technologies have been developed over the past decades. However, complex methods, the long time required for remediation and the expensive investment, along with low remediation efficiencies, still hinder the large-scale application of soil remediation techniques, such as excavation/disposal, soil washing, soil vapour extraction (SVE), stabilization/immobilization, chemical reduction/oxidation, and electrokinetic and thermal desorption.2–4 With its advantages of environmental friendliness, low cost, low energy consumption and no secondary pollution,5–9 bioremediation is an effective method for soil remediation, although its efficiency is affected by the bioavailability of pollutants. This is mostly low due to the low mobility of the forms of pollutants existing in soils, thus reducing the efficiency of bioremediation for contaminated soils.

The use of surfactants like sodium dodecyl sulfate (SDS)10 or chelating agents,11–13 such as natural low molecular weight organic acids (NLMWOAs), ethylene diamine tetraacetic acid (EDTA), ethylene diamine disuccinate (EDDS) and humic substances (HS), can increase the bioavailability of pollutants in contaminated soil. EDTA may form a chemically and microbially stable complex with heavy metals in soil, in turn impacting soil quality and causing groundwater contamination;14 at the same time, there is a lack of detailed research on the persistence of EDTA–metal complexes in soils.15 As a result, surfactants, especially natural surfactants, may be a more suitable choice for increasing the bioavailability of soil contaminants.

Tea saponins, found in the roots, stems, leaves, flowers and seeds of Camellia plants,16–23 are natural non-ionic surfactants. It has been verified24–29 that tea saponins contribute to improving the bioavailability of hyperaccumulators and microorganisms on Cd, Pb, PAHs and polychlorinated biphenyls (PCBs) in contaminated soils. The helpful influences of tea saponins in the leaching remediation of soils have also been investigated and confirmed.30–33

Although the mechanism of tea saponins improving the bioavailability of pollutants in contaminated soils is not yet fully understood, and the application of tea saponins has been investigated with only a few heavy metals and organic pollutants, the results of existing studies suggest that tea saponins deserve in-depth and extensive researches, not just on their sources, structures and properties, but also on their preparation, effects and mechanisms. This will be greatly beneficial to fully utilize the resources of Camellia plants and increase the bioremediation efficiency of contaminated soils.

The purpose of this review is to summarize current researches on tea saponins, from their preparations to applications, with a view to thoroughly explain the potential value of tea saponins in soil remediation.

Preparation of tea saponins

To acquire tea saponin powder with a relatively high purity, the following four steps are usually required: extraction, concentration, purification (crude and refined) and desiccation. Tea saponins are composed of sapogenins (aglycons), saccharides (glycosyl groups) and organic acids,34 and their structures change slightly as their sources change. For example, cinnamic acid34 is present in the structure of tea-leaf saponins but not in that of tea-seed saponins. There are few systematic studies on the structure of tea saponins, and it is not clear whether tea saponins from diverse sources have different physicochemical properties.

Source

Existing researches demonstrate that various organs of plants in the genus Camellia contain tea saponins, as shown in Table 1.

Sources of tea saponins.

| Species | Plant organ | References |

|---|---|---|

| Camellia japonica | Leaf, stem | 16 |

| Camellia reticulata | Seed | 17 |

| Camellia chekiangoleosa Hu | Seed | 18 |

| Camellia sinensis | Root, flower, seed, leaf | 19, 21, 23 and 38 |

| Camellia oleifera | Seed | 22 and 35 |

Camellia oleifera seed meal, a by-product of Camellia oil extraction, is the main source of tea saponins.17,22,35–37 Tea-seed saponins (theasaponins) are also a product of the comprehensive utilization of Camellia oleifera seed resources. The leaves and flowers of Camellia sinensis have the potential to become new sources of tea saponins, namely tea-leaf saponins (foliatheasaponins) and tea-flower saponins, thus expanding the sources of tea saponins and reducing the relative surplus of tea-leaf production in some countries, such as China, by encouraging the use of excess tea leaves and seemingly useless tea flowers.

Extraction

Taking into consideration the dissolution properties of tea-seed saponins34 (crystals of tea-seed saponins are insoluble in ether, chloroform, acetone, benzene and petroleum ether; hardly soluble in cold water, anhydrous ethanol and anhydrous methanol; slightly soluble in warm water, carbon disulfide and ethyl acetate; soluble in aqueous ethanol, aqueous methanol, n-butanol and glacial acetic acid), water extraction and alcohol extraction are the basic extraction methods. On the basis of these two extraction methods, microwaves, ultrasound or light-waves can be applied to increase the yield of tea saponins; aqueous enzymatic extraction, supercritical fluid CO2 extraction and homogenate extraction have also been tried. Table 2 demonstrates that alcohol extraction is the most widely utilized extraction method.

Methods for extracting tea saponins.

| Extraction method | Extracting agent [volume fraction] | Yield (%) | References | |

|---|---|---|---|---|

| Water extraction | Water | 8.04–8.5 | 39 and 40 | |

| Ultrasound-assisted water extraction | 21.32 | 41 | ||

| Alcohol extraction | Methanol | [70%] | 14.45 | 42 |

| Ethanol | [63–100%] | 7.28–28.81 | 18 and 43–47 | |

| [70%] + 0.1% NH4·H2O | 22.41 | 48 | ||

| [75%] + 3% NaOH | 21.35 | 49 | ||

| n-Propyl alcohol | [90%] | 15.31 | 50 | |

| Microwave-assisted alcohol extraction | Ethanol | [50–65%] | 12.16–18.56 | 35, 51 and 52 |

| Ultrasound-assisted alcohol extraction | Ethanol | [70–80%] | 18.54–28.38 | 19 and 53 |

| [75%] + 0.1% NH4·H2O | 19.50 | 54 | ||

| Microwave ultrasound-assisted extraction | Ethanol | [72%] | 13.5 | 55 |

| Microwave light wave-assisted extraction | Ethanol | [80%] | 8.68 | 56 |

| Aqueous enzymatic | Cellulase | 6.8–20.23 | 57–59 | |

| Neutral protease | 6 | 60 | ||

| Supercritical fluid CO2 extraction | Ethanol | [65%] | 15.23 | 61 |

| Homogenate extraction | Ethanol | [78%] | 21.09 | 62 |

In contrast to common extractions, the performance comparison of the extraction methods employs yield (%) instead of extraction ratio (%) because the real contents of the tea saponins are unknown. The difference in yield between tea saponins obtained using the same extraction method reflects the difference between the contents of tea saponins from distinct sources. Because of the different sources used for extraction, e.g. seeds, leaves or flowers of plants, it’s difficult to compare the performances of the extraction methods listed in Table 2. However, alcohol extraction, especially ethanol extraction, appears to give a higher yield, and ultrasound works better than microwave- and light-wave-assisted extraction.

Optimizing the variables in an extraction is helpful to achieve a higher yield within a certain range. Table 3 presents variables that might impact the yield of tea saponins. Previous studies found significant interactions between the extraction temperature and extraction time, as well as between the extraction temperature and the liquid–solid ratio,38 suggesting that response surface methodology (RSM) optimization is necessary for the extraction of tea saponins.

Variables optimized in the extraction of tea saponins.

| Method | Variable | Method | Variable |

|---|---|---|---|

| Common extraction | Particle size | Microwave-assisted extraction | Microwave power |

| Liquid–solid ratio | Microwave treatment time | ||

| Extraction time | Ultrasound-assisted extraction | Ultrasonic power | |

| Extraction temperature | Ultrasonic frequency | ||

| Number of extractions | Ultrasonic treatment time | ||

| Alcohol extraction | Alcohol type | Light-wave-assisted extraction | Light-wave treatment time |

| Alcohol volume fraction | Supercritical fluid CO2 extraction | Pressure | |

| Aqueous enzymatic extraction | Fungus type | Medium | |

| Fungus concentration | CO2 flow rate |

Meanwhile, in one study, the yield of tea saponins obtained by traditional extraction methods, such as Soxhlet extraction, was used as a denominator. Then, the yield of tea saponins obtained by the investigated extraction method was acted as the numerator. Therefore, the extraction rate of the method under investigation was acquired.21 The results of this study showed that ionic liquids, in particular [Ch]Cl salt, were clear alternatives to organic solvents in the extraction of plant metabolites, such as saponins, and represented a novel but effective way to extract saponins from tea leaves.

The dissolution properties of tea-leaf saponins and tea-flower saponins are not well understood, and they are extracted from different sources than tea-seed saponins. Thus, an appropriate method for extracting tea saponins from the leaves and flowers of Camellia sinensis may not be the same as that for extracting tea saponins from the seed meal of Camellia oleifera. This indicates that the extraction of tea-leaf and tea-flower saponins requires a finer selection of methods and optimization.

Purification

The purification of tea saponins is divided into crude purification and refined purification. Usually precipitation73,77 is used for crude purification, with calcium oxide or alum as precipitation agents. Another method53,67 to obtain crude tea saponin powder is centrifugation, drying tea saponin solutions at low temperature or in a vacuum oven after evaporating the extractants. Table 4 shows some refined purification methods for tea saponins.

Methods for the refined purification of tea saponins.

| Refined method | Precipitating agent | Purity (%) | References |

|---|---|---|---|

| Two-phase system extraction | 20% (NH4)2SO4 + 23% n-propyl alcohol (w/w) | 78.12 | 63 |

| Reversed-phase column chromatography | Methanol | 95 | 64 |

| Ethanol | 99.12 | 55 | |

| Macroporous resin | AB-8 | >80–96.13% | 39 and 65–67 |

| XR910X | 94.26 | 68 | |

| D101 | 60.14 | 69 | |

| Molecularly imprinted polymers | Acrylamide–β-cyclodextrin | 89 | 70 |

| Flocculation + ultrafiltration | Chitosan | 85 | 36 |

| Ultrafiltration | 91 | 71 | |

| Precipitation | Acetone | 72.06 to >93 | 50, 72 and 73 |

| Cholesterol | >98.5 | 74 | |

| Ether | 97.9 | 75 | |

| Recrystallization | Ethanol–hydrochloric acid | 81.8 | 76 |

In terms of operability, the cost of the instruments and reagents, and the purity of tea saponins, acetone precipitation is the easiest and most convenient refined purification method. Through the optimization of purification variables, tea saponin powder with a purity of over 90% can be obtained by acetone precipitation; this purity is sufficient for determination of the compositions and structures of tea saponins, as well as their physical, chemical and biochemical properties.

Identification and quantification

Identifying the composition and structure of tea saponins benefits our understanding of the compounds. For the application of tea saponins in soil remediation, it is important to know whether tea saponins from various sources, which have subtly different compositions and structures, have different effects on contaminated soils.

Tea saponins are a type of oleanane pentacyclic triterpene saponin mixtures. Their glycosides are derivatives of β-amyrin with the basic carbon frame of oleanane.78 Tea saponins from different sources have different structures, such as theasaponins A4 (1), A5 (2), A6 (1), A7 (2), B5 (3), C1 (3), E8 (4), E9 (5), G1 (6) and H1 (7), along with E3 (1), E4 (2), E5 (3), E6 (4), and E7 (5) from the seeds of tea plants (Camellia sinensis),78,79 as well as foliatheasaponins I, II, III, IV, and V from the leaves of tea plants (Camellia sinensis).80–82 Arabinose, xylose, galactose and glucuronic acid are the main saccharides. Angelic acid, tiglic acid, acetic acid and cinnamic acid are the major organic acids. Hydroxyl groups on sapogenins form esters with organic acids.

Low pressure, medium pressure, or high performance liquid chromatography (HPLC) and reversed-phase high performance liquid chromatography (RP-HPLC) are the usual methods83–85 used to isolate tea sapogenins, along with a trial of droplet counter current chromatography (DCCC), as seen in Table 5. Mass spectrometry (MS) and nuclear magnetic resonance (NMR)84–86 have significant roles in identifying the structures of tea sapogenins.

Methods for identifying and quantifying tea saponins.

| Identification | Quantification |

|---|---|

| High performance liquid chromatography (HPLC) | Gravimetric method |

| Reversed-phase high performance liquid chromatography (RP-HPLC) | Spectrophotometry |

| Mass spectrometry (MS) | Thin layer chromatography |

| Nuclear magnetic resonance (13C or 1H NMR) | High performance liquid chromatography (HPLC) |

Spectrophotometry is the most commonly utilized method for determining the content of saponins in solutions, particularly the vanillin–sulfuric acid/perchloric acid87,88 method for tea saponins. The principle of the vanillin–sulfuric acid/perchloric acid method is that under acidic conditions, aldolization occurs between the sapogenins obtained by hydrolyzing tea saponins and the aldehyde group in vanillin, then a new color-rendering conjugated system is acquired. Under a certain wavelength of light, the absorbance of this new color-rendering conjugated system is highly linear with the tea saponin content; therefore, the vanillin–sulfuric acid/perchloric acid method is suitable for the quantitative determination of tea saponins. Moreover, the results of the vanillin–sulfuric acid/perchloric acid method were confirmed to be consistent with those of HPLC.87

Physical, chemical and biochemical properties of tea saponins

The physical, chemical and biochemical properties of tea saponins have been determined for tea-seed saponins extracted from Camellia oleifera seed meals. As a kind of saponin, tea saponins are similar to saponins, with antibacterial, anti-inflammatory and anti-oxidation properties and activities such as hemolysis, fish poison, and so on.23,69,89–94 This section focuses on the corresponding physical, chemical and biochemical properties of tea saponins that contribute to the remediation of contaminated soils. It should be noted that no studies have aimed to determine the biodegradability of tea saponins in soils.

Content variation and distribution

As a secondary metabolite, the tea saponin content in Camellia plants changes as the physiological stage of Camellia plants changes. Although there is very little literature on this point, clues can still be acquired from the existing literature.

During the ripening process, the tea-seed saponin content in the seeds of Camellia oleifera increased at first, followed by a decrease, and tended to be stable in the later period of maturity. Its distribution in different parts of the seed was: kernels > fruit shells > seed shells.95 As for the dynamic variation of tea saponins in Camellia oleifera leaves,96 the results showed that with an increase in tree age, the content of tea saponins in Camellia oleifera leaves increased initially and then decreased, reaching a maximum value around the fifth year. The content of tea saponins kept increasing with increasing leaf age; the tea saponin content in the leaves of 30-year-old trees showed significant volatility from January to December, with a high level from August to October, indicating that the old leaves of Camellia oleifera from around August to October were a more appropriate choice for the extraction of tea saponins. These conclusions also benefit the selection of Camellia sinensis leaves for tea saponin extraction: excess old leaves, as well as leaves needing to be pruned in the summer, are nice choices.

Physical and chemical properties

Surface activity

The critical micelle concentration (CMC) of tea saponins is determined by the classic method of surface tension measurement. Researchers97 discovered that the CMC and the surface dilational modulus of tea saponins were 0.63 g L−1 and 36.99 mN m−1, whereas after esterification, tea saponin esters had significantly better surface activity, with values of 0.45 g L−1 and 25.31 mN m−1.

The influence of pH and electrolyte concentration on the CMC of tea saponins was also investigated. It was shown98 that with an increase of the solution pH the CMC increased, while the surface dilational modulus decreased. NaCl had little effect on the CMC but it decreased the surface dilational modulus of tea saponin solutions by breaking the hydrogen bonds between surfactant molecules on the surface, suggesting that tea saponin solutions have a higher surface activity under neutral or weakly acidic conditions.

It was also verified that tea saponin sodium sulfate99 had a higher surface activity compared to tea saponins. The CMC value of tea saponin sodium sulfate was 0.1%, which was lower than the value of 0.15% for tea saponins; the hydrophilic–lipophilic balance (HLB) of tea saponin sodium sulfate was 19.06, which was higher than the value of 16.25 for tea saponins.

Generally speaking, tea saponins perform well as surfactants, with a CMC of 0.5% and HLB of approximately 16,73,100 and it is worth investigating suitable measures, such as esterification, for improving their surface activities without affecting their soil biodegradability.

Foaming ability, foaming stability and emulsifiability

Compared with other surfactants, for example non-ionic decyl glucoside, amphoteric cocoamido propyl hydroxy sulfoBetaine, or anionic ammonium laureth sulfate, the foaming ability of tea saponins is weaker than that of ionic surfactants, but significantly better than that of amphoteric surfactants. The foaming ability of tea saponins is weaker than that of the non-ionic surfactant decyl glucoside, although their foaming stability is obviously higher than that of decyl glucoside and cocoamido propyl hydroxy sulfoBetaine.101

The foaming ability of tea saponins increased as the concentration of the tea saponin solution increased.100 Nevertheless, from a concentration of 0.6%, the foaming tendency of the tea saponin solutions obviously weakened, and their foaming stability tended to become steady after 0.5%; the highest foam layer appeared at around 200 mm and decreased by 28% after 24 hours.

The water separation time decreased successively between tea-leaf saponins and vinyl acetate, toluene, salad oil and cyclohexane.73 The longer the water separation time, the stronger the ability of the tea-leaf saponins to emulsify. Hence, tea-leaf saponins have good emulsifiability with salad oil and toluene and have a strong emulsifiability in vinyl acetate.

Spectral characteristics

The infrared spectroscopy (IR) and ultraviolet spectroscopy (UV) characteristics both reflect the structural differences between tea saponins from distinct sources.

Researchers34 found that the IR spectra of tea-seed saponins and tea-leaf saponins are similar, with merely the absorbance of tea-leaf saponins near 1630 cm−1 higher than that of tea-seed saponins. Meanwhile, there are obvious differences in the absorption intensity near 780 cm−1. In the UV spectra, an absorption peak appears at 215 nm, which is caused by α and β conjugated double bonds in angelic acid; the absorption peak at 280 nm only appears in the UV spectrum of tea-leaf saponins and corresponds to cinnamic acid, the unique organic acid found in tea-leaf saponins.

Biochemical properties

There is a prerequisite to utilizing tea saponins to improve the bioremediation of contaminated soils: tea saponins must have no toxic effects on hyperaccumulators or microorganisms, or at least no toxic effects within a certain concentration range. Up to now, studies in this area have rarely been seen.

Effects on seed growth

The effects of tea saponins on seed growth depend not only on the concentration of tea saponins, but also on the species of plants. For Brassica rapa L. cv Tokyo Green,102 less than 200 mg L−1 of tea saponins had no significant effect on the root lengths of seedlings, with significant inhibition at 200 mg L−1, suggesting that tea saponins were safe for seedlings at concentrations under 200 mg L−1. For Chinese flowering cabbage (Brassica parachinensis), mung bean (Vigna radiata) and maize (Zea mays),103 the seed germination rates (excluding mung bean) and root lengths of these three species were significantly inhibited by tea saponins at experimental concentrations ranging from 0.2% to 8.0%, and the inhibitory effects intensified as the concentrations of tea saponins increased. Germination rates decreased in the order of maize > Chinese flowering cabbage > mung bean, while root lengths decreased in the order of Chinese flowering cabbage > maize > mung bean.

These results indicate that the concentration of tea saponins that is safe for seed growth might be less than 0.1%, and perhaps 0.02%.

Effects on antioxidant system activities in vivo

Similarly to their effects on seed growth, tea saponins have a range of relatively safe concentrations in terms of impacts on the activity of antioxidants in vivo. The activity of superoxide dismutase (SOD) in the leaves of Brassica rapa L. cv Tokyo Green102 was gradually decreased in tea saponin solutions. The activity of peroxidase (POD) decreased with concentrations of tea saponins lower than 20 mg L−1 and then increased relative to the control; the activity of catalase (CAT) was higher than that in the control for tea saponin concentrations from 50 mg L−1 to 100 mg L−1. Although the content of malondialdehyde (MDA) varied in the solutions, tea saponins had no statistically significant influence on the antioxidant enzyme systems and MDA content of Tokyo Green seedlings at concentrations from 5 to 200 mg L−1.

Effects on enzyme activities in soils

Research demonstrated that as the tea saponin concentration increased, the activity of CAT in soils decreased significantly, with polyphenol oxidase (PPO) activity increasing significantly;103 the activities of dehydrogenase and nitrate reductase also increased.24,104

After the addition of tea saponins, the activity of CAT is reduced because the permeability of the microbial cell membranes is impacted (in existing applications of tea saponins for soil remediation, the soil enzymes mainly come from soil microorganisms). PPOs appear differently. Under normal conditions, intracellular PPOs are bound to the cell membrane, with activities kept at low levels. Nonetheless, when exposed to external stress, PPOs increase the resistance of an organism to pathogens, and thus potential PPOs are activated.105 Following this point, it can be concluded that applying tea saponins as natural surfactants in soil remediation increases the bioavailability of pollutants in soils; meanwhile, changing the activities of enzymes found in soils promotes the degradation of pollutants by microorganisms.

Applications in soil remediation

Leaching remediation, phytoremediation and microbial remediation are three aspects of soil remediation in which tea saponins are utilized. The heavy metals Pb, Cd, Zn, Cu, Cr, Mn and Ni, as well as the organic pollutants pyrene, PAHs, PCBs, polybrominated diphenyl ethers (PBDEs), monophenyl tin, diphenyl tin and triphenyl tin, are the major contaminants studied by researchers.

Mechanisms

The use of tea saponins in soil remediation is still at the application stage, in which their feasibility must be investigated and confirmed. Therefore, as the mechanisms have not been explored, there is little literature on the mechanistic effects of tea saponins in soil remediation.

Currently, most scholars classify the effects of tea saponins in soil remediation according to two aspects: (i) tea saponins desorb heavy metal ions from their various forms in soils. The desorption performances are in the order exchangeable > carbonate fraction > Fe–Mn oxides > organic fraction > residual fraction,106 meaning that more heavy metal ions are transferred from bound states to free states and are then absorbed by hyperaccumulators or microorganisms, improving their utilization of heavy metal ions. (ii) Tea saponins significantly enhance the solubility of phenyltin, the permeability of membranes, the expression of proteins, the density of cells and the use of Cl− and PO43−, and reduce the release of intracellular Na+, NH4+, K+ and Mg2+, increasing the biodegradation of phenylation accordingly.29

Future researches on mechanisms should diverge in two directions: (i) how do tea saponins change the forms of heavy metal ions in soils? Are the desorption performances consistent for different heavy metal ions, or complex-contaminated heavy metal ions? (ii) How do tea saponins affect the uptake, translocation and accumulation on heavy metal ions or organic pollutants by hyperaccumulators? How do tea saponins affect the membrane permeability of microorganisms, the expression of proteins, the density of cells, the use of Cl− and PO43−, and the release of intracellular Na+, NH4+, K+ and Mg2+?

Leaching remediation

The performance of tea saponins in leaching remediation is considered acceptable but is weaker than that of chelating agents, such as EDTA plus citric acid,107,108 and the majority of pollutants studied are heavy metals, as seen in Tables 6 and 7.

Applications of tea saponins in leaching remediation for removing heavy metals.

| Heavy metal (form) | Tea saponin concentration | Removal ratio (%) | References | |

|---|---|---|---|---|

| Pb, Cd, Zn, Cua | 7% | 6.74, 42.38, 13.07, 8.75 | 33 | |

| Pb, Cd, Cr, Mn | 20% | 60.5, 72.6, 10.9, 38.8 | 32 | |

| Pb | (Exchangeable) | 6% | 69.8 | 107 |

| (Carbonate fraction) | 54.8 | |||

| (Fe–Mn oxides) | 30.4 | |||

| (Organic fraction) | 40.9 | |||

| (Residual fraction) | 7.1 | |||

| Pb, Zn, Cu | 22% | ∼35, ∼38, ∼28b | 109 | |

| Pb, Cd, Zn, Cu | 7% | 43.71, 96.36, 71.73, 20.56 | 110 | |

| Pb, Cd | 7% | 50.0, 62.6 | 99 | |

| Pb, Zn, Cu | 4% | 9.72, 22.81, 11.32 | 108 | |

| Pb, Ni | 5.0 g L−1 | 83.5, 87.1 | 30 | |

| Cd, Ni | 7.5 g L−1 | 94.1, 89.4 | 31 | |

The order of removal ratios corresponds to the order of heavy metals listed in the first column.

These three removal ratios were obtained from figures and are not accurate.

Applications of tea saponins in leaching remediation for removing organic pollutants.

| Organic pollutants (form) | Tea saponin concentration | Removal ratio (%) | Comments | References | |

|---|---|---|---|---|---|

| PBDEs | 5.0 g L−1 | 94.6 | Two successive soil washing cycles + 5.0 ml L−1 peanut oil | 30 | |

| PCBs | 97.1 | ||||

| PAHs | 95.1 | ||||

| PAHs | (3) | 7.5 g L−1 | 98.2 | Two successive soil washing cycles + 15.0 ml L−1 soybean oil | 31 |

| (4) | 96.4 | ||||

| (5) | 92.3 | ||||

| PAHs | (3) | 2% | 84.3 | +50 mM KNO3 | 104 |

| (4) | 92.3 | ||||

| (5) | 85.6 | ||||

Among the heavy metals investigated, the leaching effects of tea saponins on Cd are the best, followed by Ni, Zn, Pb, Cu and Cr. The differences between heavy metal ions may be attributed to the common forms of these heavy metals that exist in soils; for instance, exchangeable Cd was the dominant species in 15 kinds of soil samples investigated by Deng et al.111 Considering the soil over-standard rate in China,1 Cd, Ni, Cu and Pb deserve further researches; mixtures of tea saponins and chelating agents are worthy of trials since they do not impact the soil biodegradability.

The removal ratios achieved by tea saponins for organic pollutants are higher than those for heavy metals, as detailed in Table 7. Ye et al. thought30,31 that after consecutive washing, residual PAHs and heavy metals mainly existed in forms with extremely low bioaccessibility in soil; thus, after two washing cycles the environmental transfer risk of co-pollutants in the soil appeared limited. Even so, they performed phytoremediation30 or microbial remediation31 after two washing cycles to remove residual heavy metals and PAHs, indicating that a combination of distinct methods for soil remediation has better effects.

Phytoremediation

Studies using tea saponins for phytoremediation are in their infancy; the only heavy metal studied is Cd, and the organic pollutants pyrene and PCBs have been studied, as presented in Table 8. However, tea saponins performed better in phytoremediation when compared with leaching remediation.

Applications of tea saponins in phytoremediation.

| Pollutant | Accumulator | Tea saponin concentration | Increase in ratio (%) | References |

|---|---|---|---|---|

| Cd | Lolium multiflorum | 40 mg L−1 | Above: 8; under: 11a | 24 |

| Cd | Amaranthus caudatus | 3 g kg−1 | 25 | |

| Cd | Saccharum officinarum | 0.3% | Leaf: 30.1; stem: 156.8; root: 96.9 | 26 |

| Pyrene | Lolium multiflorum | 40 mg L−1 | Above: 135; under: 40 | 24 |

| PCBs | Zea mays | 0.1% | PCB 14 : 172b | 26 |

| PCB 18 : 168 | ||||

| PCB 77 : 94 | ||||

| PCB 156 : 140 |

‘Above’ means parts of the plant above the ground and ‘under’ means parts of the plant under the ground.

These data were measured at the root of the plant.

Because the root is the main organ for plants to absorb water and nutrients, after tea saponin treatment the roots of hyperaccumulators will accumulate more heavy metal ions and increase the plants’ bioconcentration of these heavy metals. At the same time, when the concentration of tea saponin solution reaches a certain range, it benefits the transfer of heavy metals in the accumulating plant. Taking the heavy metal Cd and the hyperaccumulator Boehmeria nivea as an example,112 the translocation factor showed an upward trend with an increase in tea saponin concentration. When the concentration of tea saponin solution was 2.5 mmol L−1, the Cd bioconcentration factors of various parts of Boehmeria nivea reached a maximum. When the concentration of tea saponin solution was in the range of 0.1–2.5 mmol L−1, Cd transfer was helped in the Boehmeria nivea plant.

The selection of suitable hyperaccumulators is an important part of phytoremediation, and the effects of tea saponins on increasing the bioconcentration factors of accumulating plants can expand the range of hyperaccumulators. Accumulators could be turned into hyperaccumulators with the assistance of tea saponins; this could help the promotion of phytoremediation in different climates and regional contaminated soils. Applications of tea saponins in the phytoremediation of other heavy metal contaminated soils and soils contaminated with combined heavy metals also deserve to be studied.

Microbial remediation

The targets of microbial remediation associated with tea saponin treatment are organic pollutants such as PCBs, BDE209, monophenyl tin, diphenyl tin and triphenyl tin. The effects of tea saponins on increasing the biodegradation efficiencies of organic pollutants are significant, as shown in Table 9.

Applications of tea saponins in microbial remediation.

| Pollutant | Bacteria | Tea saponin concentration | Biodegradation efficiency | References |

|---|---|---|---|---|

| PCBs | WTSa | 1000 mg L−1 | PCB 77 : 4.3 times | 113 |

| PCB 118 : 4.8 times | ||||

| PCB 138 : 2.8 times | ||||

| YTS | PCB 77 : 7.1 times | |||

| PCB 118 : 9.1 times | ||||

| PCB 138 : 8.9 times | ||||

| BDE209 | Brevibacillus brevis | 1 g L−1 (5 days) | 55% | 28 |

| Triphenyl tin | Bacillus thuringiensis | 60 mg L−1 (7 days) | 1 mg L−1 to 283 μg L−1 | 29 |

| Diphenyl tin | 1 mg L−1 to 270 μg L−1 | |||

| Monophenyl tin | 1 mg L−1 to 235 μg L−1 |

WTS and YTS were separated from soil and temporally named by the authors of ref. 113.

Due to the excellent performances of tea saponins in improving the biodegradation efficiencies of organic pollutants in microbial remediation, the utilization of tea saponins for the microbial remediation of heavy metal contaminated soils and heavy metal–organic pollutant contaminated soils could also be considered.

Conclusion and perspectives

Due to their wide range of sources, relatively simple extraction and purification methods, and significant effects in leaching remediation, phytoremediation and microbial remediation, tea saponins are proven to be effective natural surfactants that are beneficial for soil remediation, and deserve in-depth researches on their preparation procedures and mechanisms.

Industrial extraction and purification

Preparing tea saponins with purities of more than 90% in industry is the first key step in promoting the application of tea saponins in soil remediation.

Comprehensively considering factors such as the yield and purity of tea saponins, the operability of the extraction and purification methods, and environmental friendliness, it is recommended to use water extraction or ultrasound-assisted water extraction combined with acetone precipitation to obtain high-purity tea saponins in industry. Excess tea (Camellia sinensis) leaves in autumn and winter, as well as tea (Camellia sinensis) flowers, are potential sources of tea saponins that merit attention.

Further research on mechanisms

To study the mechanisms of tea saponins in soil remediation, it is first necessary to clarify whether tea saponins from different sources with slightly different structures have different properties, especially the physical, chemical and biochemical properties relevant for soil remediation. Then, mechanistic researches can be divided into several steps: (i) studying the desorption effects and mechanisms of tea saponins on single-contaminated soils, including single heavy metals and single organic pollutants; (ii) studying the desorption effects and mechanisms of tea saponins on complex-contaminated soils, such as complex heavy metal contaminated soils and complex organic pollutant contaminated soils; (iii) studying the desorption effects and mechanisms of tea saponins on heavy metal–organic pollutant contaminated soils.

The adsorption characteristics of heavy metals and organic pollutants on tea saponins and the cell walls of hyperaccumulators, the impacts of tea saponins on heavy metal and organic pollutant accumulation and speciation transformations in hyperaccumulators, and the molecular mechanisms of tea saponins promoting hyperaccumulator growth and alleviating heavy metal stress also need to be compared, clarified and uncovered.

Field remediation

Field remediation is a concrete measure for achieving scientific research results. The effects of tea saponins are truly realized when tea saponins are practically applied for the large-scale field remediation of contaminated soils. Field remediation requires studies on the performance of tea saponins in different kinds of soil, and application conditions like the concentration of tea saponins must be adjusted accordingly to fit the climate and environment of contaminated soils, to make the best use of tea saponins.

Conflicts of interest

There are no conflicts to declare.

Supplementary Material

Biographies

Biography

Xiao-Lan Yu.

PhD candidate Xiao-Lan Yu majored in Biosystems Engineering. Xiao-Lan Yu studies in-depth developments and the comprehensive utilization of tea (Camellia sinensis) resources, the safety of prepared tea and tea infusions, and phytoremediation in soil remediation and related areas. Her doctoral thesis aims to study the use of tea saponins to increase the efficiency of phytoremediation in heavy metal contaminated soils.

Biography

Yong He.

Professor Yong He is the Dean of the College of Biosystems Engineering and Food Science and “Qiushi” Distinguished Professor of Zhejiang University, and was selected as a Thomson Reuters Highly Cited Researcher in 2016 (the only one selected in China in the field of Agricultural Sciences). Professor Yong He works on digital agriculture, the agricultural Internet of things, rural area informatization, agricultural aviation, intelligent agricultural equipment and other fields of scientific research and education. Professor Yong He has published more than 400 papers and SCI includes more than 300 articles, of which 9 were selected as the most cited agricultural science papers in ESI from the past 10 years.

References

- P. R. of C. Ministry of Environmental Protection and P. R. of C. Ministry of Land and Resources, Bulletin on the Survey of Soil Pollution in China, 2014 [Google Scholar]

- Marques A. P. G. C. Rangel A. O. S. S. Castro P. M. L. Crit. Rev. Environ. Sci. Technol. 2009;39:622–654. doi: 10.1080/10643380701798272. [DOI] [Google Scholar]

- Long X. Yang X. Ni W. Chinese J. Appl. Ecol. 2002;13:757–762. [PubMed] [Google Scholar]

- Bolan N. Kunhikrishnan A. Thangarajan R. Kumpiene J. Park J. Makino T. Kirkham M. B. Scheckel K. J. Hazard. Mater. 2014;266:141–166. doi: 10.1016/j.jhazmat.2013.12.018. [DOI] [PubMed] [Google Scholar]

- Dixit R. Wasiullah Malaviya D. Pandiyan K. Singh U. B. Sahu A. Shukla R. Singh B. P. Rai J. P. Sharma P. K. Lade H. Paul D. Sustainability. 2015;7:2189–2212. doi: 10.3390/su7022189. [DOI] [Google Scholar]

- Mosa K. A. Saadoun I. Kumar K. Helmy M. Dhankher O. P. Front. Plant Sci. 2016;7:1–14. doi: 10.3389/fpls.2016.00303. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chaney R. L. Malik M. Li Y. M. Brown S. L. Brewer E. P. Angle J. S. Baker A. J. M. Curr. Opin. Biotechnol. 1997;8:279–284. doi: 10.1016/S0958-1669(97)80004-3. [DOI] [PubMed] [Google Scholar]

- Gaur N. Flora G. Yadav M. Tiwari A. Environ. Sci.: Processes Impacts. 2014;16:180–193. doi: 10.1039/C3EM00491K. [DOI] [PubMed] [Google Scholar]

- Lee J. H. Biotechnol. Bioprocess Eng. 2013;18:431–439. doi: 10.1007/s12257-013-0193-8. [DOI] [Google Scholar]

- Pacwa-Płociniczak M. Płaza G. A. Piotrowska-Seget Z. Cameotra S. S. Int. J. Mol. Sci. 2011;12:633–654. doi: 10.3390/ijms12010633. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Agnello A. C. Huguenot D. Van Hullebusch E. D. Esposito G. Crit. Rev. Environ. Sci. Technol. 2014;44:2531–2576. doi: 10.1080/10643389.2013.829764. [DOI] [Google Scholar]

- Xi M. Bai Z. Zhao Z. Soil Fertil. Sci. 2008:6–11. [Google Scholar]

- Evangelou M. W. H. Ebel M. Schaeffer A. Chemosphere. 2007;68:989–1003. doi: 10.1016/j.chemosphere.2007.01.062. [DOI] [PubMed] [Google Scholar]

- Padmavathiamma P. K. Li L. Y. Water, Air, Soil Pollut. 2007;184:105–126. doi: 10.1007/s11270-007-9401-5. [DOI] [Google Scholar]

- Lombi E. Zhao F. J. Dunham S. J. McGrath S. P. New Phytol. 2000;145:11–20. doi: 10.1046/j.1469-8137.2000.00560.x. [DOI] [Google Scholar]

- Chen S. Xie Q. Ye Z. Ye X. J. Anhui Agri. Sci. 2013;41:2675–2677. [Google Scholar]

- Guo L. Gu D. Li D. Ren X. Ge C. Pu Y. China Oils Fats. 2016;41:74–76. [Google Scholar]

- Zhan Y. Xie Y. J. Anhui Agri. Sci. 2012;40:104–105. [Google Scholar]

- Lu W. Ning J. Fang S. Jiang S. Wei H. Sci. Technol. Food Ind. 2012:296–300. [Google Scholar]

- Ji M. Shu H. Sun Z. Guo F. Wang Y. J. Anhui Agri. Sci. 2009;37:17077–17079. [Google Scholar]

- Ribeiro B. D. Coelho M. A. Z. Rebelo L. P. N. Marrucho I. M. Ind. Eng. Chem. Res. 2013;52:12146–12153. doi: 10.1021/ie400529h. [DOI] [Google Scholar]

- Hu J.-L. Nie S.-P. Huang D.-F. Li C. Xie M.-Y. Int. J. Food Sci. Technol. 2012;47:1676–1687. doi: 10.1111/j.1365-2621.2012.03020.x. [DOI] [Google Scholar]

- Sur P. Chaudhuri T. Vedasiromoni J. R. Gomes A. Ganguly D. K. Phytother. Res. 2001;15:174–176. doi: 10.1002/ptr.696. [DOI] [PubMed] [Google Scholar]

- Liu X. Cao L. Wang Q. Zhang X. Hu X. Environ. Sci. Pollut. Res. 2017;24:18946–18952. doi: 10.1007/s11356-017-9515-2. [DOI] [PubMed] [Google Scholar]

- Cay S. Environ. Monit. Assess. 2016;188:1–8. doi: 10.1007/s10661-016-5334-z. [DOI] [PubMed] [Google Scholar]

- Xia H. Chi X. Yan Z. Cheng W. Bioresour. Technol. 2009;100:4649–4653. doi: 10.1016/j.biortech.2009.04.069. [DOI] [PubMed] [Google Scholar]

- Wang Q. Liu X. Zhang X. Hou Y. Hu X. Liang X. Chen X. Environ. Sci. Pollut. Res. 2016;23:5705–5711. doi: 10.1007/s11356-015-5784-9. [DOI] [PubMed] [Google Scholar]

- Tang S. Bai J. Yin H. Ye J. Peng H. Liu Z. Dang Z. Chemosphere. 2014;114:255–261. doi: 10.1016/j.chemosphere.2014.05.009. [DOI] [PubMed] [Google Scholar]

- Huang J. Ye J. Ma J. Gao J. Chen S. Wu X. Chem. Eng. J. 2014;249:167–173. doi: 10.1016/j.cej.2014.03.110. [DOI] [Google Scholar]

- Ye M. Sun M. Wan J. Fang G. Li H. Hu F. Jiang X. Kengara F. O. J. Chem. Technol. Biotechnol. 2015;90:2027–2035. doi: 10.1002/jctb.4512. [DOI] [Google Scholar]

- Ye M. Sun M. Xie S. Liu K. Feng Y. Zhao Y. Wan J. Hu F. Li H. Zong L. Jiang X. Pedosphere. 2017;27:452–464. doi: 10.1016/S1002-0160(17)60341-2. [DOI] [Google Scholar]

- Wang S. Yu H. Li Z. Wan D. Environ. Sci. Technol. 2016;39:277–282. [Google Scholar]

- Li G. Zhang Z. Jing P. Zhou N. Lin L. Yuan Y. Yu M. Transactions of the CSAE. 2009;25:231–235. [Google Scholar]

- Wan X., Tea Biochemistry, China Agriculture Press, Beijing, 3rd edn, 2011 [Google Scholar]

- He J. Wu Z. Zhang S. Zhou Y. Zhao F. Peng Z. Hu Z. J. Surfactants Deterg. 2014;17:919–928. doi: 10.1007/s11743-013-1523-8. [DOI] [Google Scholar]

- Zhang K. Qian H. Zhang T. Fan L. Food Sci. Technol. 2003:68–70. [Google Scholar]

- Li M. Guo S. Du M. Fei X. Zhong H. China Oils Fats. 2017;42:121–124. [Google Scholar]

- Gong W. Huang Y. Ji A. Peng W. Liu C. Zeng Y. Yang R. Wang X. Sheng J. J. Sci. Food Agric. 2017:1–8. doi: 10.1002/jsfa.8721. [DOI] [PubMed] [Google Scholar]

- Chen X. Xiao D. Huo G. Long H. Liu J. J. Chin. Cereals Oils Assoc. 2017;32:88–95. [Google Scholar]

- Li L. Yu W. Liu G. Liu H. Kuai L. Li L. Chen X. Appl. Chem. Ind. 2016;45:78–81. [Google Scholar]

- Qi X. Zhang S. J. Food Sci. Technol. 2014;32:59–64. [Google Scholar]

- Liu Y. Hu J. Zhou Y. Cereal. Oils Process. 2008:80–83. [Google Scholar]

- Xiong W. Li X. Fu J. Wang H. Zhu R. Han X. Food Res. Dev. 2016;37:28–32. [Google Scholar]

- Liu B. Quan C. Huang X. Chen Y. Zhang Y. China Oils Fats. 2013;38:84–86. [Google Scholar]

- Zhao S. Xue Z. Yang C. Wei M. China Oils Fats. 2010;35:64–67. [Google Scholar]

- Li M. Wang C. J. Chin. Cereals Oils Assoc. 2011;26:38–41. doi: 10.1002/jsfa.4173. [DOI] [PubMed] [Google Scholar]

- Yu J. Chen Y. Chen Y. Meng Y. Sci. Technol. Food Ind. 2007;28:171–172. [Google Scholar]

- Shi G. Wang H. Hua R. Zhou B. Xu J. Deng L. Mod. Chem. Ind. 2011;31:37–40. [Google Scholar]

- Gong Q.-S. Xiao Y. Liang M.-N. Liu Y.-Q. Huang P. Guihaia. 2015;35:120–125. [Google Scholar]

- Yu H. Chen H. Wu B. Ren W. Food Sci. 2013;34:58–62. [Google Scholar]

- Peng Y. Zhou J. Guo H. Cereal. Oils. 2009:27–29. [Google Scholar]

- Gong Z. Liang D. Zhang Z. Xiao W.-J. J. Tea Sci. 2013;33:358–363. [Google Scholar]

- Li J. Li Y. Dang P. Food Sci. 2008;29:154–156. [Google Scholar]

- He Z. Zhang H. Zhang X. Nat. Sci. J. Xiangtan Univ. 2015;37:80–85. [Google Scholar]

- Chen X. Wu D. Chen S. Huang D. Jiangsu Agric. Sci. 2017;45:186–190. [Google Scholar]

- Guo H. Deng Z. Peng Y. Zhang S. Liu W. Sci. Technol. Food Ind. 2008;29:168–170. [Google Scholar]

- Wang X. J. Chin. Cereals Oils Assoc. 2011;26:76–78. [Google Scholar]

- Zhou H. Yang D. Jiangsu Agric. Sci. 2016;44:362–364. [Google Scholar]

- Li X. Li J. Cao W. Wen X. Wu H. Shi Y. China Oils Fats. 2012;37:54–57. [Google Scholar]

- Wang X. J. Chin. Cereals Oils Assoc. 2013;28:40–43. [Google Scholar]

- Lv X. Li Z. Food Ferment. Ind. 2005;31:23–26. [Google Scholar]

- Zhu X. Lin H. Chen X. Xie J. Wang P. Transactions of the CSAE. 2011;27:402–406. [Google Scholar]

- Zhang T. Xiong D. Chen C. Xu G. Chen J. Fine Chem. 2015;32:1009–1013. [Google Scholar]

- Zhang H. Zhang W. Jiang J. Du J. Yang F. China Oils Fats. 2015;40:94–98. [Google Scholar]

- Hou R. Wan X. Huang J. Food Ferment. Ind. 2005;31:130–132. [Google Scholar]

- Sun J. Cai C. Liang R. Yang C. China Surfactant Deterg. Cometics. 2017;47:312–316. [Google Scholar]

- Yang P. Zhou M. Zhou C. Wang Q. Zhang F. Chen J. J. Sep. Sci. 2015;38:656–662. doi: 10.1002/jssc.201401123. [DOI] [PubMed] [Google Scholar]

- Gu J. Yang R. Xie B. Zhang W. Zhao W. Hua X. Food Mach. 2017;33:153–158. [Google Scholar]

- Lin G. J. Chin. Cereals Oils Assoc. 2016;31:76–79. [Google Scholar]

- Guo H. Xiong J. Ma W. Wu M. Yan L. Li K. Liu Y. J. Sep. Sci. 2016;39:4439–4448. doi: 10.1002/jssc.201600834. [DOI] [PubMed] [Google Scholar]

- Li M. Zhao Y. Yang W. Yu B. China Oils Fats. 2008;33:53–56. [Google Scholar]

- Liu J. Gao Y. Food Sci. Technol. 2005:59–61. [Google Scholar]

- Xie Q. Li Y. Chen S. Jiangsu Agric. Sci. 2014;42:206–208. [Google Scholar]

- Yang K. Huang M. Chem. Ind. For. Prod. 2001;21:44–48. [Google Scholar]

- Zhou S. Yang G. Liu C. Food Sci. Technol. 2008:184–188. [Google Scholar]

- Tang H. Sun Q. Zhang Y. Dai L. Wang H. Cheng S. China Oils Fats. 2012;37:69–71. [Google Scholar]

- Liu H. Zhou J. Li H. Guo H. Mod. Food Sci. Technol. 2008;24:571–574. [Google Scholar]

- Yoshikawa M. Morikawa T. Nakamura S. Li N. Li X. Matsuda H. Chem. Pharm. Bull. 2007;55:57–63. doi: 10.1248/cpb.55.57. [DOI] [PubMed] [Google Scholar]

- Yoshikawa M. Morikawa T. Li N. Nagatomo A. Li X. Matsuda H. Chem. Pharm. Bull. 2005;53:1559–1564. doi: 10.1248/cpb.53.1559. [DOI] [PubMed] [Google Scholar]

- Sagesaka Y. M. Uemura T. Watanabe N. Sakata K. Uzawa J. Biosci., Biotechnol., Biochem. 1994;58:2036–2040. doi: 10.1271/bbb.58.2036. [DOI] [PubMed] [Google Scholar]

- Morikawa T. Nakamura S. Kato Y. Muraoka O. Matsuda H. Yoshikawa M. Chem. Pharm. Bull. 2007;55:293–298. doi: 10.1248/cpb.55.293. [DOI] [PubMed] [Google Scholar]

- Morikawa T. Matsuda H. Li N. Li X. Yoshikawa M. Helv. Chim. Acta. 2007;90:2342–2348. doi: 10.1002/hlca.200790240. [DOI] [Google Scholar]

- Zhang H. Zhang W. Hu Z. Qi Y. Gong R. Food Sci. 2013;34:153–156. [Google Scholar]

- Li N. Li X. Feng Z. Yoshikawa M. Chinese J. Med. Chem. 2007;17:306–309. [Google Scholar]

- Li N. Li X. Feng Z. J. Shenyang Pharm. Univ. 2008;25:544–548. [Google Scholar]

- Yin L. ZHang J. Song G. Sierkemdeke A. Guo M. Zhong Y. J. Chin. Cereals Oils Assoc. 2013;28:97–101. [Google Scholar]

- Zhang T. Xiong D. Xu G. Chen C. Chen J. Sci. Technol. Food Ind. 2016;37:53–56. [Google Scholar]

- Hou R. Wan X. Huang J. Food Ferment. Ind. 2005;31:62–65. [Google Scholar]

- Sagesaka Y. M. Uemura T. Suzuki Y. Sugiura T. Yoshida M. Yamaguchi K. Kyuki K. Yakugaku Zasshi. 1996;116:238–243. doi: 10.1248/yakushi1947.116.3_238. [DOI] [PubMed] [Google Scholar]

- Yamauchi Y. Azuma K. Tomita M. Horie H. Kohata K. Jpn. Agric. Res. Q. 2001;35:185–188. doi: 10.6090/jarq.35.185. [DOI] [Google Scholar]

- Sagesaka-Mitane Y. Sugiura T. Miwa Y. Yamaguchi K. Kyuki K. Yakugaku Zasshi. 1996;116:388–395. doi: 10.1248/yakushi1947.116.5_388. [DOI] [PubMed] [Google Scholar]

- Yan X. Wei J. Xu J. Li J. Guo X. Sci. Technol. Food Ind. 2014;35:159–162. [Google Scholar]

- Wang L. Wan X. Hou R. Xu J. Wu H. J. Anhui Agric. Univ. 2013;40:642–648. [Google Scholar]

- Lv X. Qu S. Sun X. Li Z. Food Sci. 2005;26:86–90. [Google Scholar]

- Li H. Fang X. Zhong H. Fei X. Luo F. Cereal. Oils. 2013;26:24–26. [Google Scholar]

- Yan R. Liao Y. Chen Y. Wang G. Yin X. Xu L. J. Henan Agric. Sci. 2015;44:33–36. [Google Scholar]

- Feng J. Chen Y. Liu X. Liu S. Food Chem. 2015;171:272–279. doi: 10.1016/j.foodchem.2014.08.125. [DOI] [PubMed] [Google Scholar]

- Mao L. Qi Y. Sun Z. Zeng Q. Yan F. J. Tianjin Polytech. Univ. 2016;35:32–36. [Google Scholar]

- Yang L. Fu L. Shen J. J. Soil Water Conserv. 2012;26:263–266. [Google Scholar]

- Liu R. Xia C. Zhu Q. J. Tea. 1996;22:10–13. [Google Scholar]

- Wu X. Huang R. Huang C. Wang B. Song H. China Clean. Ind. 2017:38–42. [Google Scholar]

- Dong J. Jing P. Li G. Zhou N. Yuan Y. Yu C. Zhang M. Chinese J. Oil Crop Sci. 2011;33:185–188. [Google Scholar]

- Hou J. Li N. Lv H. Zeng Q. Wu Q. J. Agro-Environ. Sci. 2015;34:660–665. [Google Scholar]

- Sun M. Ye M. Shen F. Xu J. Ye C. Yu L. Hu F. Li H. Jiang X. Kengara F. O. Clean: Soil, Air, Water. 2016;44:667–676. [Google Scholar]

- Kong J. Sun Q. Tu Y. Chen X. Gao Y. Yang X. Chinese Wild Plant Resources. 2011;30:13–17. [Google Scholar]

- Chen Z. Lei G. Su Y. Fang X. Ecol. Environ. Sci. 2015;24:1394–1398. [Google Scholar]

- Chen Z. Lei G. Zhao S. Jiang X. Peng X. Environ. Chem. 2014;33:1314–1320. [Google Scholar]

- Yi L. Wang W. Liu Y. Tao Y. Wen J. J. Saf. Environ. 2014;14:225–228. [Google Scholar]

- Wu L. Lyu H. Su C. Zeng D. Mo X. Chinese J. Environ. Eng. 2014;8:4486–4491. [Google Scholar]

- Zhang Z. Li G. Zhou N. Jing P. Jiao W. Zhang S. J. Soil Water Conserv. 2008;22:67–70. [Google Scholar]

- Deng Z. Zhu X. Guo B. Wang X. Wu J. Zhang J. J. Nanchang Univ. (Eng. Technol.) 2012;34:341–346. [Google Scholar]

- Li B. Li P. Soil Water Conserv. China. 2017:34–37. [Google Scholar]

- Li X. Fang Z. Xia H. J. Tea Sci. 2015;35:91–96. [Google Scholar]