Abstract

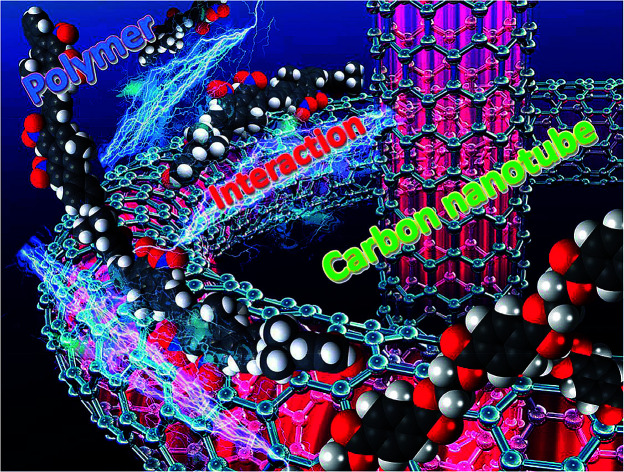

This paper provides an overview of recent advances in research on the interfacial characteristics of carbon nanotube–polymer nanocomposites. The state of knowledge about the chemical functionalization of carbon nanotubes as well as the interaction at the interface between the carbon nanotube and the polymer matrix is presented. The primary focus of this paper is on identifying the fundamental relationship between nanocomposite properties and interfacial characteristics. The progress, remaining challenges, and future directions of research are discussed. The latest developments of both microscopy and scattering techniques are reviewed, and their respective strengths and limitations are briefly discussed. The main methods available for the chemical functionalization of carbon nanotubes are summarized, and particular interest is given to evaluation of their advantages and disadvantages. The critical issues related to the interaction at the interface are discussed, and the important techniques for improving the properties of carbon nanotube–polymer nanocomposites are introduced. Additionally, the mechanism responsible for the interfacial interaction at the molecular level is briefly described. Furthermore, the mechanical, electrical, and thermal properties of the nanocomposites are discussed separately, and their influencing factors are briefly introduced. Finally, the current challenges and opportunities for efficiently translating the remarkable properties of carbon nanotubes to polymer matrices are summarized in the hopes of facilitating the development of this emerging area. Potential topics of oncoming focus are highlighted, and several suggestions concerning future research needs are also presented.

The state of research on the characteristics at the interface in polymer nanocomposites is reviewed. Special emphasis is placed on the recent advances in the fundamental relationship between interfacial characteristics and nanocomposite properties.

1. Introduction

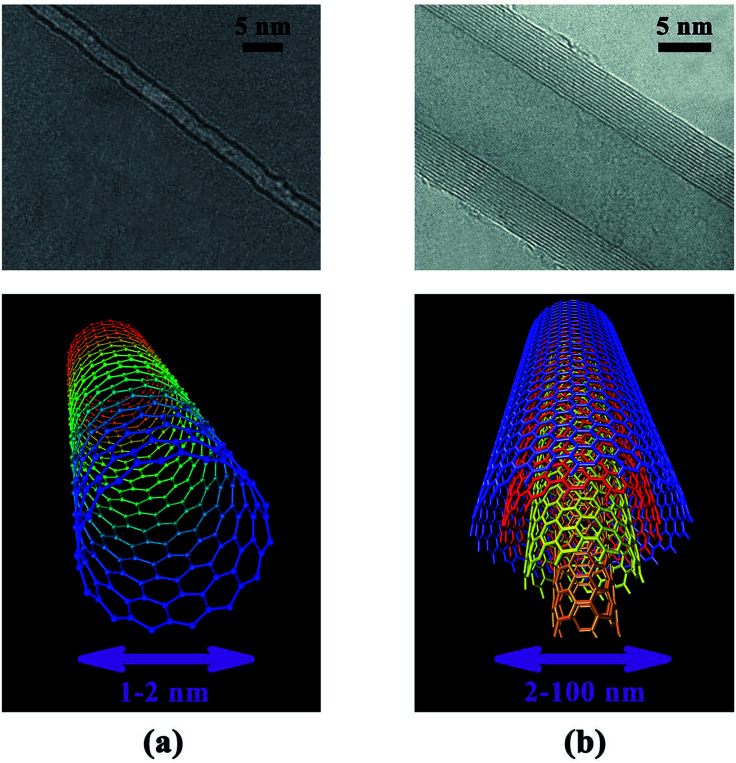

Carbon nanotubes were first observed by Iijima1,2 nearly three decades ago, and since then, they have been the focus of considerable research.3,4 Carbon nanotubes can be categorized as single-walled and multi-walled carbon nanotubes,1,2 and a multi-walled carbon nanotube consists of multiple rolled layers of graphene, as shown in Fig. 1. Carbon nanotubes have generated tremendous scientific and technical interest over the past decade due to their unique properties at the nanoscale. Extraordinary physical and mechanical properties have been reported for this form of carbon with a cylindrical nanostructure.3,4 As a consequence, carbon nanotubes offer unique opportunities for the development of fundamentally new nanomaterials.

Fig. 1. Transmission electron microscopy images and schematic diagrams of carbon nanotubes, showing typical diameters of (a) a single-walled carbon nanotube and (b) a multi-walled carbon nanotube. The microscopy image of the single-walled carbon nanotube is adapted with permission from ref. 5. Copyright 2012, Springer Nature Limited. The microscopy image of the multi-walled carbon nanotube is adapted from the “Endo Laboratory” website.6.

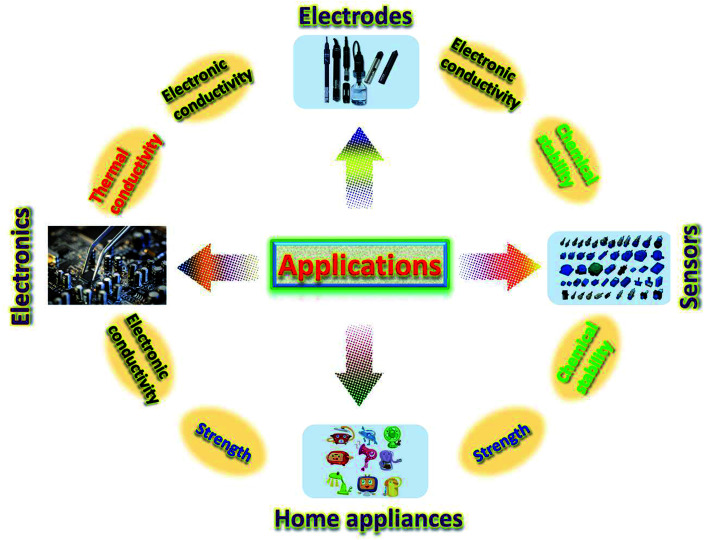

Due to the unique properties of carbon nanotubes, there has been an increasing interest in the development of nanocomposite materials.7–10 In particular, the outstanding mechanical properties are expected to have many advantages to develop the nanocomposite materials reinforced with carbon nanotubes.11,12 As a result, there has been a large focus on the research and development of carbon nanotube-based polymer composite materials.13,14 The first polymer nanocomposite material reinforced with carbon nanotubes was reported by Ajayan et al.15 in 1994. Since the realization of the remarkable properties of carbon nanotubes, various advanced carbon nanotube–polymer composite materials have been prepared by using a variety of fabrication techniques.16,17 A broad range of potential applications can be envisioned for the use of carbon nanotube–polymer composite materials, and some examples of their application are shown in Fig. 2.

Fig. 2. Examples of the potential application of carbon nanotube–polymer composite materials.

There has been considerable research in attempting to utilize carbon nanotubes as reinforcements for polymer composite materials, and significant progress has been made.7–10 However, after nearly three decades of research, the potential of carbon nanotubes as reinforcement in polymer composite materials has not been fully realized.11 To harness the unique attributes of carbon nanotubes exhibited at the nanoscale, it is necessary to resolve the issues related to the basic principle of the nanoscale mechanical reinforcement of polymer matrices with carbon nanotubes,11 as well as the characteristics of the interface between the carbon nanotube and the surrounding polymer matrix.18 To achieve the optimal reinforcement with carbon nanotubes, it is of great importance to understand the relationship between nanocomposite properties and interfacial characteristics.11,13

Great achievements have been made in the field of carbon nanotube–polymer composites during the past few years.11–17 However, poor dispersion and weak interfacial bonding remain obstacles for effectively incorporating carbon nanotubes into polymer matrices. There are still significant challenges encountered while exploring carbon nanotubes as filler materials to be overcome. It is often difficult to achieve a uniform dispersion of carbon nanotubes in the polymer matrix,11 as well as to enable a strong interaction at the interface between the carbon nanotube and the polymer matrix.18 Various attempts have been made to effectively reinforce a polymer matrix with carbon nanotubes.19–22

The issue related to the uniform dispersion of carbon nanotubes is critical to efficient reinforcement in polymer nanocomposite materials.23 Much effort has been devoted to improve the dispersion of carbon nanotubes, such as the use of physical treatment,13 surfactants,21 and chemical functionalization of the surface of carbon nanotubes.22,23 Additionally, strong interfacial bonding is critical to take full advantage of the exceptional properties of carbon nanotubes. Functionalization has been suggested to be an effective approach to acquire high-performance nanocomposite materials because of the ability to significantly improve the dispersion of carbon nanotubes and to greatly enhance the bonding at the interface.23

Much attention has been focused on the characteristics of the interface. To improve the properties of the polymer nanocomposites reinforced with carbon nanotubes, it is necessary to have a better understanding of the characteristics of the interface at the nanometric level.24,25 The interface plays a significant role in the stress transfer between the carbon nanotube and the polymer matrix, and the consequent improvement in nanocomposite properties. The characteristics of the interaction at the interface have been widely studied,24,25 and great achievements have been made in this field, as reviewed by Rahmat and Hubert.18 Unfortunately, it remains unclear how to optimize the interface for mechanical reinforcement. Furthermore, there is still a lack of understanding of the interaction at the interface. To unlock the potential of carbon nanotubes, it is important to fully understand the underlying mechanism responsible for the interfacial interaction at the molecular level to further optimize the interface in polymer nanocomposite materials.26

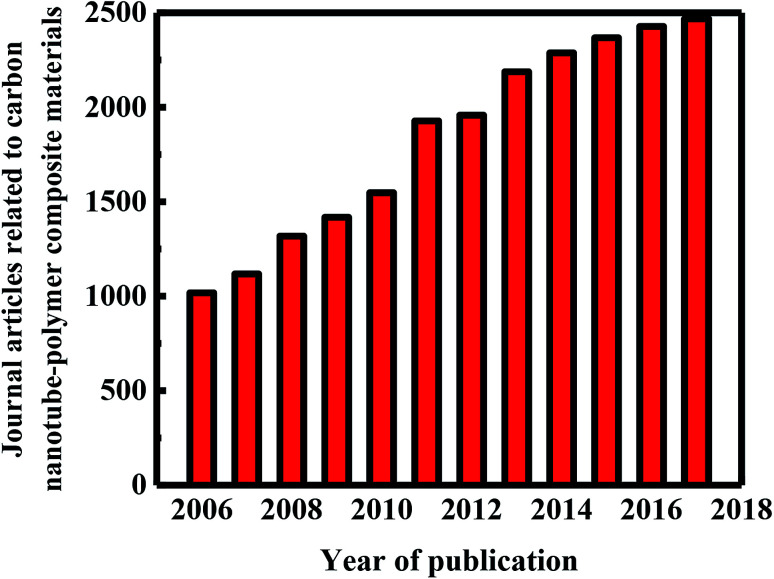

There is a large number of literatures about the topic discussed here, but a limited number of relevant previous review articles13,18,22–34 are available. Fig. 3 shows how the number of English language refereed journal articles in carbon nanotube–polymer composite materials has steadily increased since 2010. In recent years, the number of publications dealing with various aspects of the polymer nanocomposite materials containing carbon nanotubes has increased markedly. As a consequence, an overview article is required, and the objective of this paper is to address this need. Most of the relevant journal articles have been published since 2010, so that is the focus of this review.

Fig. 3. Recent English language refereed journal publications related to carbon nanotube–polymer composite materials. The data are collected from the Engineering Village© web-based information service. The number of publications dealing with various aspects of the polymer composite materials has increased markedly in recent years.

While significant insights have been achieved in this field, there are still many critical issues that need to be addressed to harness the maximum benefits from the remarkable properties of carbon nanotubes. In this paper, the recent advances in the development of carbon nanotube–polymer composites are reviewed, and the progress, remaining challenges, and future directions of research are discussed. Special emphasis is placed on the characteristics of the interaction at the interface.

2. Dispersion and characterization techniques

2.1. Dispersion of carbon nanotubes

The advantages of carbon nanotube–polymer composites include improved stiffness, strength, and fracture toughness. Unfortunately, the expected improvement in the properties of these polymer composites has not been fully realized. Their properties have been found to be critically dependent upon the degree of the dispersion of carbon nanotubes, the interfacial adhesion between the carbon nanotube and the polymer matrix, and the alignment along the principal axis of applied force.18,23 To employ carbon nanotubes as effective reinforcement in polymer composite materials, it is important to achieve uniform dispersion of carbon nanotubes within the polymer matrix. The synthetic methods of the polymer nanocomposite materials have overwhelmingly focused on improving the degree of the dispersion of carbon nanotubes, given the fact that uniform dispersion can significantly improve the properties of these nanocomposite materials.23

Much effort has been devoted to the fabrication of the composite materials. There are a number of effective methods for fabricating polymer nanocomposites with high mechanical or physical properties.23,26 The potential of carbon nanotubes as reinforcements has not been fully realized due partly to the difficulties associated with the dispersion of carbon nanotubes. Considerable progress has been made in the development of the techniques targeting good dispersion.35–38 Hence, the principles and features of these dispersion techniques are briefly summarized here.

Various methods have been proposed to improve the dispersion of carbon nanotubes in a polymer matrix. The most common method used to disperse carbon nanotubes is the ultrasonication technique. High-power ultrasonication is an effective method to disperse carbon nanotubes in a polymer matrix, but is only suitable for dispersing carbon nanotubes in small batches. The characteristics of the various mechanical techniques used for dispersing carbon nanotubes in a polymer matrix are summarized in Table 1, which can serve as a guideline for selecting an appropriate dispersion technique to synthesize carbon nanotube–reinforced polymer composite materials. Nevertheless, the techniques used for dispersing carbon nanotubes in a polymer matrix are not limited to those listed in Table 1. In practical operation, a combination of these techniques are often adopted.39–41 Overall, dispersion of carbon nanotubes in polymer matrices is problematic, and it still remains an active area of research at present.

Comparison of various mechanical techniques used for dispersing carbon nanotubes in a polymer matrix.

| Technique | Factor | |||

|---|---|---|---|---|

| Damage to nanotubes | Suitable polymer matrix | Availability | Governing factors | |

| Ultrasonication | Yes | Soluble polymer, low viscous polymer or oligomer, monomer | Commonly used in lab, easy operation and cleaning after use | Power and mode of sonicator, sonication time |

| Calendering | No | Liquid polymer or oligomer, monomer | Operation training is necessary, hard to clean after use | Rotation speed, distance between adjacent rolls |

| Ball milling | Yes | Powder (polymer or monomer) | Easy operation, need to clean after use | Milling time, rotation speed, size of balls, balls to nanotube ratio |

| Shear mixing | No | Soluble polymer, low viscous polymer or oligomer, monomer | Commonly used in lab, easy operation and cleaning after use | Size and shape of the propeller, mixing speed and time |

| Extrusion | No | Thermoplastics | Large-scale production, operation training is necessary, hard to clean after use | Temperature, configuration and rotation speed of the screw |

2.2. Characterization techniques

To better understand the macroscopic properties of polymer nanocomposite materials, a detailed characterization of several important microstructural features such as the dispersion state and the alignment of carbon nanotubes in polymer matrices is required. The main methods intended to characterize the microstructures of polymer nanocomposite materials can be categorized as microscopy and scattering techniques. Masenelli-Varlot et al.42 have reviewed the recent advances in the microscopy techniques for a better understanding of the mechanical and physical properties of carbon nanotube–reinforced polymer composite materials. Several imaging techniques such as scanning electron microscopy, transmission electron microscopy, near-field microscopies, and focused ion beam microscopy have been introduced, and their principles have also been briefly discussed.42 Microscopy and scattering techniques can provide a quantitative description of the morphology of polymer nanocomposite materials, and they are complementary for structural characterization.43–46

Transmission electron microscopy and scanning electron microscopy techniques can be used to characterize the microstructural features of nanocomposite materials, such as the dispersion state of carbon nanotubes in polymer matrices and the magnitude of the interfacial adhesion between them.47 Other important factors such as the alignment of carbon nanotubes in the polymer matrix, as well as other common analyses involving distribution and quantification of the dimension of carbon nanotubes can also be explored by using these electron microscopy methods. Solá48 have reviewed these electron microscopy techniques, and have also discussed their strengths and limitations, respectively. There is need for improving different aspects of the electron microscopy techniques, particularly the image contrast of carbon nanotubes within the polymer matrix.48

It is critical to determine the size distribution of suspended carbon nanotube objects. Given the variability in dimensions, characterization the size of carbon nanotubes is best accomplished with an imaging method, specifically atomic force microscopy.49–51 Atomic force microscopy has become an important technique in the field of composite materials due to its unique ability to image and characterize structures in liquid, ambient, and vacuum environments.52–54 Recently, light, neutron, and small-angle X-ray scattering techniques have also been used to quantitatively analyze the structure of carbon nanotubes in suspensions. Electron microscopy techniques are in principle more powerful than scattering techniques for elucidating the morphologies of polymer nanocomposite materials.45 Although transmission electron microscopy is typically used to “visually” characterize the dispersion state of carbon nanotubes, it is not an accurate means to determine this important quantity. In contrast, scattering techniques are the most appropriate means to characterize dispersion.46

The dispersion state of carbon nanotube in a polymer matrix should be evaluated over a broad range of scales and can be accomplished by using the following imaging techniques: transmission electron microscopy, scanning electron microscopy, scanning probe microscopy, polarized Raman spectroscopy,55–57 optical microscopy, and confocal microscopy. In recent years, confocal laser scanning microscopy has been successfully applied to evaluate the dispersion state of carbon nanotubes in polymer matrices.58,59 Scattering techniques, such as wide-angle X-ray scattering, small-angle X-ray scattering, and polarized Raman spectroscopy, are very useful for analyzing the alignment of carbon nanotubes in polymer matrices. Standard Raman spectroscopy has been used to monitor deformation of carbon nanotubes in a polymer matrix. Polarized Raman spectroscopy has been widely used to examine the alignment of different carbon nanotube assemblages.60–64 However, these scattering techniques seem difficult to interpret the dispersion state of carbon nanotubes in polymer matrices. This is because the contrast ratio is significantly lower, as well as the presence of rigid rod behavior is not equivalent to the uniform dispersion of carbon nanotubes at all length scales. At a local length scale, ultraviolet-visible-near infrared absorption spectroscopy can be used to determine the dispersion state of single-walled carbon nanotubes in solutions and nanocomposite materials qualitatively.65–69 This is because only individual or small bundles of single-walled carbon nanotubes exhibit sharp absorbance peaks,65 which can be termed as van Hove singularities. In contrast, large bundles, associates with the poor dispersion of carbon nanotubes, exhibit only monotonically decreasing absorbance with increasing wavelength.65,70

All common conventional microscopy techniques have their specific disadvantages about the image of the dispersion of carbon nanotubes within a polymer matrix. Optical microscopy is useful to assess the large-scale agglomerates of carbon nanotubes, but this technique becomes incapable to accurately determine the dispersion state at the sub-micron scale.71,72 Scanning probe microscopy, more specifically atomic force microscopy, and scanning electron microscopy can provide sufficient information about the surface features of polymer nanocomposite materials. However, these imaging techniques in general only yield a characteristic three-dimensional appearance of the surface of carbon nanotubes within a polymer matrix.73,74 While the spatial resolution achieved with transmission electron microscopy can offer sufficient information about the microstructure of carbon nanotubes, there are intrinsic challenges and imaging artifacts that need special attention to properly characterize the bulk characteristics of polymer nanocomposite materials.75,76

3. Functionalization of carbon nanotubes with polymers

Chemical modification or functionalization can effectively improve the dispersion state of carbon nanotubes. Given that mechanical properties of the composite materials depend critically upon the efficiency of load transfer at the interface,18,25 chemical functionalization is an effective approach to increase the strength of the interface. Functionalization of the surface of carbon nanotubes has received a significant amount of attention recently due to its potential applications in many fields. Chemical functionalization provides a convenient way to improve the dispersion state of carbon nanotubes as well as to modify the characteristics of the interface, which in turn may improve the properties of the polymer nanocomposite materials. Therefore, the nature of chemical functionalization may play an important role in determining the properties of the polymer nanocomposite materials reinforced with carbon nanotubes. This modification method will become more prevalent, since significant progress has been made recently in the field of chemical functionalization.

3.1. Functionalization method

The performance of the composite materials depends strongly upon the dispersion state of carbon nanotubes and the interaction at the interface.18,23 It has been realized that the main obstacle in the translation of the remarkable physical and mechanical properties of carbon nanotubes into useful polymer composite materials is the nonreactive nature of the carbon nanotubes, which ultimately results in a weak interfacial interaction with the polymer matrix that leads to inefficient load transfer and phase separation.23 Therefore, much effort has been devoted to develop various approaches to modify properties of the surface of carbon nanotubes.77–79 Functionalized carbon nanotubes have been playing an increasingly important role in the research, development, and application of the composite materials. Considerable advances related to the science and technology of chemical functionalization have been made.4,77,80,81 The principles of modification methods along with the benefits and disadvantages associated with these methods have been reviewed by Ma et al.23

It is necessary to improve the dispersion state of carbon nanotubes and the efficiency of load transfer at the interface in order to achieve optimum performance of the composite materials.13 Unless the interface is carefully designed, interfacial slippage may be appeared due to poor load transfer at the interface.82 Chemical functionalization of carbon nanotubes is of great importance to significantly improve the dispersion state of carbon nanotubes as well as to effectively enhance the load transfer efficiency in the composite materials.13,83 Various methods of the chemical functionalization of carbon nanotubes have been developed.4,84 The grafting of macromolecules onto the surfaces of carbon nanotubes has also been paid much attention during the past few years. It is expected that the addition of a whole polymer chain affects the properties of the carbon nanotubes and their affinity to polymer matrices more greatly than that of low molecular weight functionalities.

To improve the properties of the composite materials, low-cost and industrially feasible approaches to modification of the surface of carbon nanotubes have been much pursued vigorously in recent years. These approaches for the functionalization of carbon nanotubes by polymers can be simply divided into two categories, involving either non-covalent or covalent bonding between the carbon nanotube and the polymer matrix.85–87 Non-covalent functionalization of carbon nanotubes includes non-covalent coating with surfactants, surface wrapping with long polymer chains, and non-covalent adsorption of non-charged polymer chains. Non-covalent modifications utilize π–π interactions and van der Waals forces by adsorption of polymers, biomolecules, polynuclear aromatic compounds, or surfactants. Non-covalent functionalization helps to separate the carbon nanotube aggregates and improve the dispersion state of carbon nanotubes, while the structural integrity of carbon nanotubes is preserved and thus their properties are not disrupted.78

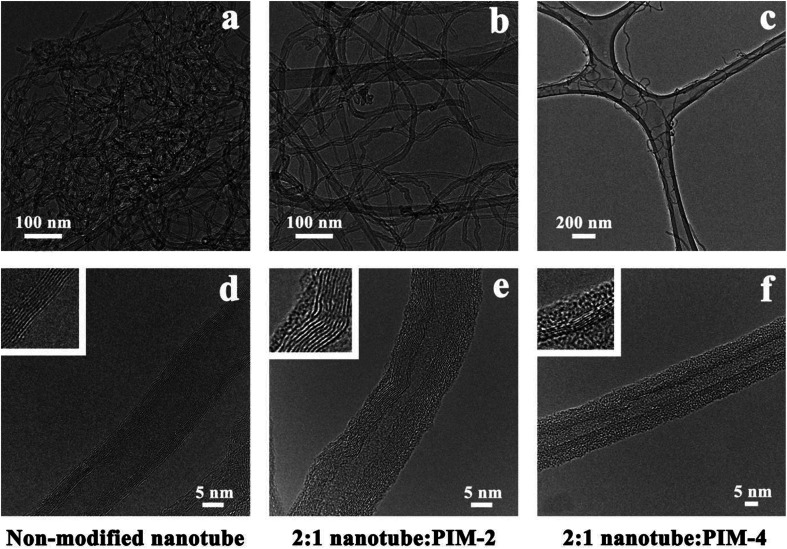

The interaction between carbon nanotubes and polymers, surfactants, or low-molecular-weight molecules has been widely studied.23,39,77–80 Conjugated polymers have been found recently to strongly interact with the surface of carbon nanotubes through π-stacking, in addition to small molecules with extended conjugation. This strong interaction allows the backbone of the conjugated polymers to wrap carbon nanotubes efficiently,78 as shown in Fig. 4. Unfortunately, the agents that can be used for this method are very limited, their dispersion is not very stable, and most importantly, it is difficult to further modify carbon nanotubes with different functionalities.

Fig. 4. Transmission electron microscopy images for (panel (a)) pristine multi-walled carbon nanotubes, (panel (b)) PIM-2-modified multi-walled carbon nanotubes, and (panel (c)) PIM-4-modified multi-walled carbon nanotubes. Panel (d) high-resolution transmission electron microscopy for pristine multi-walled carbon nanotubes; the magnified area in the box shows the smooth surface of the walls of the carbon nanotube. Panel (e) high-resolution transmission electron microscopy for the PIM-2-modified multi-walled carbon nanotubes; the magnified area in the box shows the walls of the carbon nanotube with a thin layer of the coating polymer on the surface. Panel (f) high-resolution transmission electron microscopy for the PIM-4-modified multi-walled carbon nanotubes; similar to panel (e), the magnified area in the box shows the walls of the carbon nanotube with a thin layer of the coating polymer on the surface. The information about the chemical structures of conjugated polyelectrolytes PIM-2 and PIM-4 is described in ref. 78. The figure is adapted with permission from ref. 78. Copyright 2015, American Chemical Society.

The second method of carbon nanotube functionalization is covalent modifications. Covalent modifications attach a functional group onto ends or side wall of carbon nanotubes. Covalent modifications may alter the intrinsic properties of carbon nanotubes, but can greatly improve the solubility and compatibility of carbon nanotubes, which highlights the importance of this functionalization method. There are two overarching methods, “grafting to” and “grafting from”, to prepare the polymer nanocomposites containing carbon nanotubes.88–90

3.2. “Grafting to” method

According to the “grafting to” method, end-functionalized polymer molecules react with complementary functional groups located on the surface of either pristine or pre-functionalized carbon nanotubes to form tethered chains.91–95 The “grafting to” method mainly exploits carbon nanotube bound carboxylic acid groups in esterification or amidation reactions with hydroxyl or amine containing polymer or organic molecules.96–99 Unfortunately, there is limitation in the availability of acid groups generated through oxidation procedure on the surface and tips of carbon nanotubes.27 Furthermore, carbon nanotubes are usually digested in acid over a long period of time in order to introduce a large concentration of acid groups on their surfaces, which can damage the sp2 network severely and may greatly shorten the length of carbon nanotubes.27

The problems associated with wrapping and adsorption have also arisen during covalent grafting of macromolecules onto the surface of carbon nanotubes.100,101 The level of grafting is inversely proportional to the molecular weight of polymer, and grafting high molecular weight polymers is inefficient when the “grafting to” method is used. The “grafting to” method is preferred to attach small molecules on the surface of carbon nanotubes, although it has been widely used.27

3.3. “Grafting from” method

The “grafting from” method utilizes the polymerization initiated from the surface of carbon nanotubes by attached initiating groups.102–107 Appropriate initiator is covalently attached to the surface of carbon nanotubes, depending upon the polymerization mechanism selected for grafting. In recent years, atom transfer radical polymerization, reversible addition-fragmentation chain transfer polymerization, ring-opening metathesis polymerization, and in situ free radical polymerization have been successfully used to synthesize carbon nanotube–reinforced polymer composite materials.27 Grafting high molecular weight polymers could be efficient when the “grafting from” method is used.100,101 Furthermore, a quite high grafting density can be achieved by using this method. In recent years, there has been an increasing interest in the use of living anionic polymerization for the preparation of carbon nanotube–reinforced polymer composite materials. Even at a very low concentration of initiator, high-molecular-weight polymer nanocomposites can be synthesized in a controlled manner by using this polymerization mechanism.108,109

3.4. Mixed mechanism

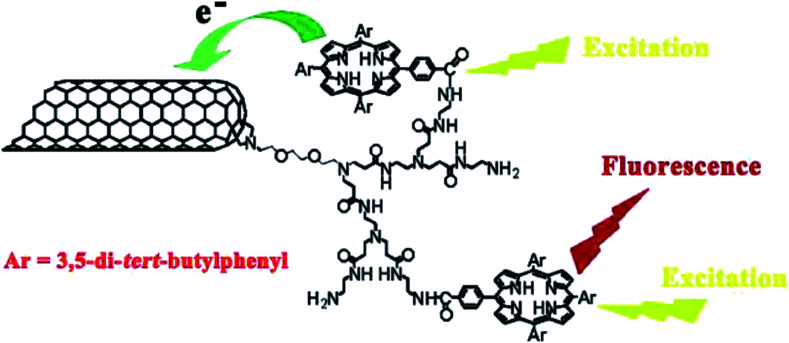

Hyperbranched poly(amidoamine) grafted multi-walled carbon nanotubes have been prepared by using a “grafting from” method.110 Single-walled carbon nanotubes functionalized with polyamidoamine dendrimers have also been prepared,111 as shown in Fig. 5. The synthesized polymer nanocomposite material was a second-generation polyamidoamine dendrimers. Firstly, single-walled carbon nanotubes were functionalized by a 1,3-dipolar cycloaddition reaction, followed by the formation of a pyrrolidine ring functionalized with a N-tert-butoxycarbonyl-protected amine group. Secondly, the amino groups interacted with ethylenediamine and methyl acrylate to synthesize the carbon nanotubes grafted with the first-generation polyamidoamine. The same reaction sequence resulted in the second-generation dendrimer. Thermogravimetric analysis was performed, and the results indicated a loss of weight of approximately 33%.

Fig. 5. Reaction scheme for the synthesis and characterization of a series of single-walled carbon nanotubes functionalized with polyamidoamine dendrimers. The figure is adapted with permission from ref. 111. Copyright 2006, American Chemical Society.

Xu et al.112 reported single-step in situ synthesis of polystyrene-grafted multi-walled carbon nanotubes by cobalt-60 γ-ray irradiation. Chemical functionalization of carbon nanotubes was accomplished through γ-ray irradiation. The functionalized carbon nanotubes were characterized by thermal gravimetric analysis, and the polymer content could be up to 15 wt%, depending on the duration of irradiation. They suggested that chemical functionalization of carbon nanotubes accomplished through γ-ray irradiation involves both “grafting to” and “grafting from” mechanisms.

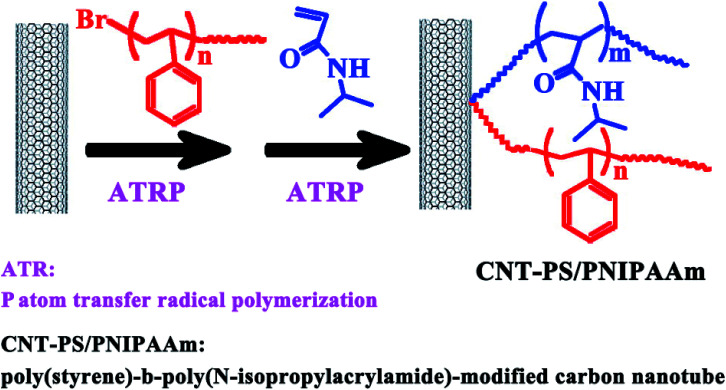

Liu and Chen113 prepared bromine-terminated poly(styrene) by using an atom transfer radical polymerization method, which was then grafted to multi-walled carbon nanotubes. The bromine atom is transferred from poly(styrene) to the surface of carbon nanotubes during the grafting process, and served as the initiator. In a subsequent step, a surface-initiated atom transfer radical polymerization of poly(N-isopropylacrylamide) from the carbon nanotube–poly(styrene) surfaces was carried out. Through the method combining “grafting to” and “grafting from”, the surface of carbon nanotubes were bounded by the a polymer brush consisted of two arms, i.e., poly(styrene) and poly(N-isopropylacrylamide), as shown in Fig. 6.

Fig. 6. Incorporation of amphiphilic v-shaped poly(styrene)-b-poly(N-isopropylacrylamide) polymers onto the surface of multi-walled carbon nanotubes through sequential “grafting-to” and “grafting-from” techniques. The figure is adapted with permission from ref. 113. Copyright 2007, American Chemical Society.

3.5. Endohedral filling

There is an increasing interest in trapping polymer macromolecules into carbon nanotube channels. The first successful experiments on filling carbon nanotubes with polymers were reported by Liu et al.,114 who used supercritical carbon dioxide, an excellent solvent, to encapsulate polystyrene into hollow multi-walled carbon nanotubes with a length of approximately 2–3 μm and an outer diameter of approximately 40–50 nm. In this approach, the initiator of benzoyl peroxide and the monomer of styrene were carried into the cavities of carbon nanotubes by means of supercritical carbon dioxide. Both of the two components remained in the hollow cores of carbon nanotubes after removing the carbon dioxide, followed by polymerizing the monomers. Liu et al.114 prepared a carbon nanotube–polystyrene composite by using this technique. Furthermore, the concentration of fillers in the composite can be controlled by the release rate of supercritical carbon dioxide during the soaking process. On the other hand, preliminary experiments on the synthesis of carbon nanotube–polyacetylene composites have been carried out using a similar procedure.115 Steinmetz et al.116 reported the results of carbon nanotubes filled with the conducting polymer, polypyrrole, and the photo-conducting polymer, poly(N-vinyl carbazole), using supercritical fluid impregnation.

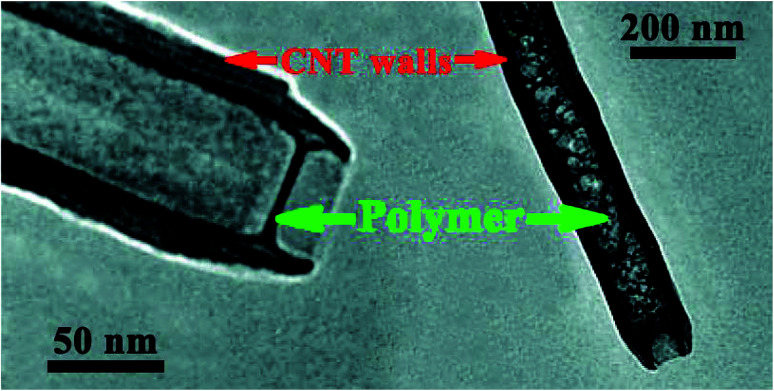

Previous studies have shown that polymer encapsulation in carbon nanotube channels is feasible using a two-step process.114–116 Firstly, supercritical carbon dioxide carries the monomer (initiator) components into the carbon nanotube cavities. Secondly, after the removal of carbon dioxide, the monomers are polymerized at a certain temperature. The supercritical fluid method, in principle, can be used to prepare other polymer nanocomposites containing carbon nanotubes. Consequently, Bazilevsky et al.117 devised a method to selectively intercalate relatively low-molecular-weight polymers into open-end, as-grown, wettable carbon nanotubes at room temperature in open air. Relatively low-molecular-weight polymers, such as poly(caprolactone) and poly(ethylene oxide), were encapsulated in multi-walled carbon nanotubes with diameters of 50–100 nm, as confirmed by transmission electron microscopy shown in Fig. 7. This revealed the morphological characterization of mixtures in nanoconfinements affected by intermolecular forces. This method can be explained by a novel self-sustained diffusion mechanism, as discussed in the literature.117 Larger macromolecules remained outside of the carbon nanotubes, whereas relatively small, flexible polymer molecules were allowed to enter. A theoretical model was also presented to describe the physical transport mechanism believed to be responsible for the selective filling of carbon nanotubes with different polymers.

Fig. 7. Transmission electron micrographs of poly(caprolactone) deposited inside multi-walled carbon nanotubes. They were obtained by dispensing poly(caprolactone) in methylene chloride over open-end, as-grown, wettable carbon nanotubes. The figure is adapted with permission from ref. 117. Copyright 2007, American Chemical Society.

4. Carbon nanotube–polymer interfaces

Mechanical properties of the polymer composites reinforced by carbon nanotubes have been widely studied.118–121 The ultimate goal is to achieve the polymer nanocomposites which are optimally reinforced. Recently, the carbon nanotube–polymer interface have attracted increasing attention.122–125 The interface is of fundamental importance, because it governs the load transfer efficiency and plays an important role in determining the mechanical properties of the polymer nanocomposites.126–131 As a consequence, the properties of these nanocomposites are highly dependent upon the nature of the interface, i.e., control of properties at the interface is critical. The nature of the interface is further complicated because the dimension of carbon nanotubes is of the same order of magnitude as that of polymer chains.

In addition to good dispersion and orientation of the carbon nanotubes, the interface needs to be carefully engineered to achieve a combination of adequate stress transfer at low strains and frictional energy dissipation at higher strains.132–135 Otherwise, poor load transfer at the interface may result in interfacial slippage and reduced performance of the polymer nanocomposites.14 Current efforts are focused on optimization of the interface to provide better interfacial load transfer, which demands a better understanding of the interfacial characteristics.136–139 It has been found that the interfacial characteristics can significantly influence the efficiency of carbon nanotube reinforcements in improving properties of the polymer nanocomposites.140–143

To ensure efficient load transfer, various approaches have been proposed for the optimization of the interface. One effective way to improve the interfacial bonding is chemical functionalization of the surface of carbon nanotubes. The ultimate interface is realized by constructing chemical bonds between the carbon nanotube and the polymer matrix. Chemical functionalization can provide a means for tailoring the interface to achieve optimal performance of the polymer nanocomposite materials. Consequently, the utilization of chemically functionalized carbon nanotubes offers tremendous scope for tailoring the interface and the development of advanced nanocomposite materials.

The efficiency of interfacial stress transfer has been widely studied,18 since the interaction at the interface is essential to understand the factors influencing the mechanical behavior of carbon nanotube–polymer composites. In particular, the stress-transfer mechanism is an important issue to be addressed, using both experiments and analysis.37 Experimental results showed that the strength of carbon nanotube–polymer composites is lower than that predicted by theory.144,145 This phenomenon may be attributed to poor interfacial bonding.11 Therefore, special attention should be paid to the interaction at the interface.

Some interesting results have described progress on addressing the above issue.146 The strength at the interface has been measured using nano-pull-out tests.147–156 These experiments are very difficult to perform and the scatters in the data are significantly high. Interfacial shear strength can be measured from the bulk composite by load transfer experiments, at higher load there is slippage between the carbon nanotube and the polymer matrix. Barber et al.147 have reported the force required to separate individual carbon nanotubes from polymer matrices, measured by reproducible nano-pull-out experiments using atomic force microscopy. Since the radius of gyration of polymers is of the same order of magnitude as the outer diameter of carbon nanotubes, the polymer chains close to the interface behaved differently than the bulk.147 Experimental and theoretical results obtained for the shear strength of the interface are listed in Table 2.

Experimental and theoretical results obtained for the shear strength of the interface between the carbon nanotube and the polymer matrix.

| Observed strength | System | Author | Reference |

|---|---|---|---|

| 47 MPa | Pull-out measurement of multi-walled carbon nanotubes from polyethylene-butene | Barber et al. | 147 |

| 17–88 MPa | Pull-out tests of multi-walled carbon nanotubes from a polyethylene-butene matrix for various diameter nanotubes | Barber et al. | 148 |

| 22–138 MPa | Pull-out measurement of chemically modified multi-walled carbon nanotubes from epoxy matrix | Barber et al. | 149 |

| 170 MPa | Pull-out measurement for a carbon nanofiber–reinforced epoxy composite | Manoharan et al. | 151 |

| Larger than 160 MPa | Collagen wrapped single-walled carbon nanotube in polyvinyl alcohol matrix | Roy et al. | 152 |

| 3.5–14 MPa | Pull-out tests of an individual multi-walled carbon nanotube from poly-ether-ether-ketone | Tsuda et al. | 153 |

| 6.24 ± 3.6 MPa | Pull-out measurement for an individual multi-walled carbon nanotube from an epoxy matrix | Ganesan et al. | 154 |

| 36–51 MPa | Pull-out tests of multi-walled carbon nanotubes from poly(methyl methacrylate) | Xu et al. | 155 |

| 10.3–24.1 MPa | Multi-walled carbon nanotubes and epoxy using shear-lag analysis | Yashiro et al. | 156 |

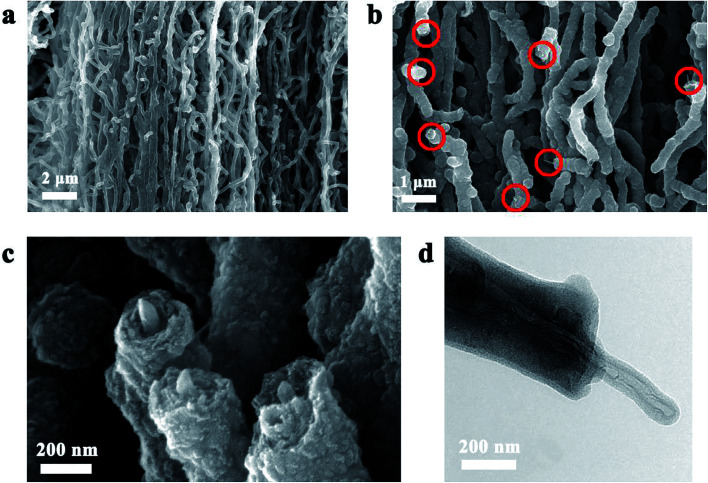

Recent studies have demonstrated that there exists significant interaction at the interface.78,118,123,139,143,157 Dassios and Galiotis139 reported the manufacturing of millimeter-high, vertically aligned multi-walled carbon nanotube–poly(vinyl alcohol) composite mats. Direct evidence of significant interfacial interaction was gave by means of thermogravimetric analysis, as well as scanning electron microscope and transmission electron microscopy images, as shown in Fig. 8. It was found that extensive polymer sheathing occurred homogeneously over the carbon nanotubes in the mats without affecting their alignment, morphology, or physical characteristics. The procedure did not evolve any chemical modification or oxidation of the carbon nanotube surfaces.

Fig. 8. Poly(vinyl alcohol)-coated multi-walled carbon nanotubes in the composite. Panel (a) vertical alignment of multi-walled carbon nanotubes was retained in the composite mat. Panel (b) morphology at low-magnification. Open circles demonstrated carbon nanotube core tips exposed through the surrounding polymer. Panel (c) close-up of tips showing layers of poly(vinyl alcohol) absorbed around the carbon nanotubes. Panel (d) transmission electron microscopy image of poly(vinyl alcohol) absorption around a carbon nanotube. The figure is adapted with permission from ref. 139. Copyright 2012, Elsevier Ltd.

Recent studies have suggested that the chemical nature of the interface may play an important role in determining the mechanical properties of the final composite.79,158 Direct and indirect measurements have been performed for shear strength of the interface, and the results indicated that there exists strong bonding at the interface, which conflicts with other results that poor interfacial bonding and clean pull-out of carbon nanotubes have been reported.144,159 The magnitude of the strength of carbon nanotubes may preclude embedded carbon nanotube tensile failure in large numbers resulting in the dominant failure mode to be carbon nanotube pull-out. In order to obtain the best performance from the nanocomposite materials, it is necessary to achieve an increase in the shear strength of the interface by one order of magnitude or more. It remains unclear how to optimize the interface for mechanical reinforcement at the nanoscale. However, the evidence available suggests that chemical functionalization is an effective approach to increase the strength of the interface.

In addition to experimental measurements, theoretical treatments of carbon nanotube pull-out have attracted significant attention over the past decade.159–165 While experimental science has generated tremendous insights into the nature of the interface, mathematical and computational approaches can complement experimental studies by providing easy manipulation, analysis, and insights at the molecular level.166–171 Due to the inability of conducting experimental measurements at the nanoscale, computational approaches are invaluable in elucidating the mechanism underlying the improvement of the interfacial strength between the carbon nanotube and the polymer matrix. While the first-principles method, based on density-functional theory and pseudopotentials, may provide valuable information about the energetics and structure of polymer nanocomposite systems, this method is limited to smaller molecular systems and shorter times due to its high computational cost. In contrast, molecular dynamics and Monte Carlo simulations can significantly reduce the computational cost, and thus are applicable to larger molecular systems for longer times. As described by Haghighatpanah and Bolton,163 the macroscopic properties of polymer nanocomposites, such as the interfacial shear strength and Young's modulus, can be obtained through molecular dynamics simulations. It can also provide a unique insight into the mechanical performance of these composites at the nanoscale. Frankland and Harik159 modeled a carbon nanotube pulled-out from a polymer matrix to predict the force required.

To further optimize the performance of the interface, it is necessary to understand the mechanism of interfacial adhesion at the molecular level. Liao and Li172 have modeled the characteristics of the interface between carbon nanotubes and a polystyrene matrix by using molecular dynamics simulations and continuum elastic theory. They found that in the absence of atomic bonding of the carbon nanotube surface with the matrix, the interfacial adhesion comes from the interaction between electrostatic and van der Waals forces, deformation induced by these forces, and stress-deformation arising from the mismatch in the coefficients of thermal expansion between the reinforcement and the matrix material. Several other mechanisms have been proposed to describe these interfaces. To understand the factors influencing interfacial adhesion, Lordi and Yao173 investigated the sliding frictional stresses and binding energies between pristine carbon nanotubes and different polymer matrices. They suggested that in comparison with frictional forces and binding energies, a helical conformation of the polymer around the carbon nanotube can significantly improve the strength of the interface. However, further research is still needed to better understand how to optimize the performance of the interface.

5. Strongly coupled carbon nanotube–polymer systems

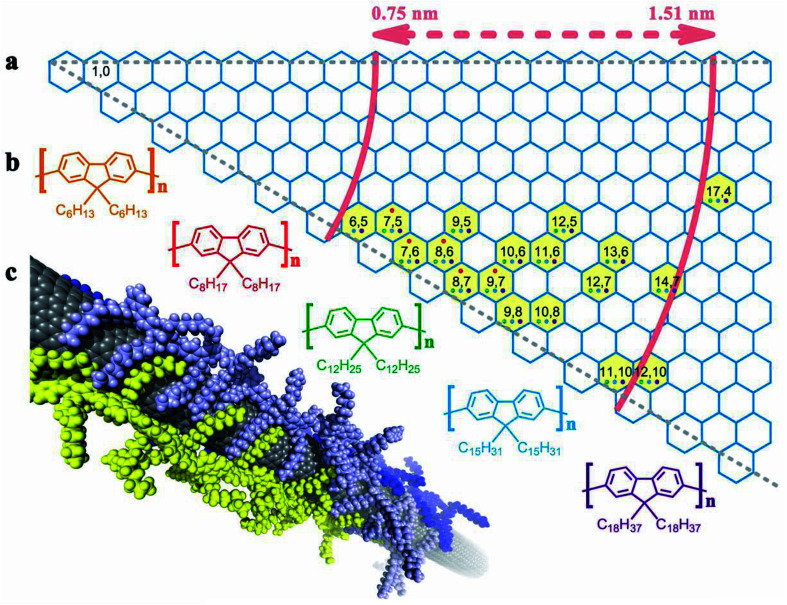

The degree of interfacial adhesion is important in understanding the nature of the interface, since it plays an important role in determining the properties of carbon nanotube–polymer composites.148 To enhance the load transfer efficiency in these nanocomposite materials, strong interfacial bonding is critical.120 Great efforts have been made to improve the efficiency of interfacial stress transfer.11,22 Unfortunately, there is still lack of understanding of the interfacial bonding between the carbon nanotube and the polymer matrix. Efforts to improve the performance of the interface include: wrapping of polymer matrix molecules around the carbon nanotube,174 as illustrated in Fig. 9, and introducing covalent bonding at the interface.175 In particular, a helical conformation of the polymer around the carbon nanotube can form a strong bond at the interface.173

Fig. 9. Panel (a) chirality map of single-walled carbon nanotubes selected by polymer wrapping. In yellow the single-walled carbon nanotubes selected are underlined; the color of the dots inside the hexagons indicates which of the polyfluorene derivatives (color code used for the chemical structures) is able to select the carbon nanotubes. Panel (b) chemical structure of the polyfluorene derivatives used: poly(9,9-di-n-hexylfluorene-2,7-diyl), poly(9,9-di-n-octylfluorene-2,7-diyl), poly(9,9-di-n-dodecylfluorene-2,7-diyl), poly(9,9-di-n-pentadecylfluorene-2,7-diyl), and poly(9,9-di-n-octadecylfluorene-2,7-diyl). Panel (c) structure as obtained by molecular dynamics simulations of three poly(9,9-di-n-dodecylfluorene-2,7-diyl) chains wrapped around a (12,10) carbon nanotube after 10 nanoseconds at constant-pressure in toluene solution. The figure is adapted with permission from ref. 174. Copyright 2013, John Wiley & Sons, Inc.

While the load transfer at the interface is certainly less than ideal, strong interfacial bonding is possible in conducting polymer nanocomposite materials.174,176 From mechanics point of view, available literatures to date also offered evidence of strong carbon nanotube–polymer interactions at the interface. Intrinsically conducting polymers or, more popularly, conducting polymers are a sub-class of conjugated polymers. Conducting polymers are a conjugated π-electron system, extending over a large number of recurring monomer units. The conduction mechanism is related to the motion of charged defects within the conjugated framework, and is highly dependent upon the level of doping.177 Typical examples are polyacetylene,177 polyphenylenevinylene,178 and polyaniline.14,179 Great efforts have been made to optimize the physical properties of conducting polymers.177

Multi-walled carbon nanotubes can serve as a conducting filler in a conjugated luminescent polymer, poly(m-phenylenevinylene-co-2,5-dioctyloxy-p-phenylenevinylene),180–182 and polyaniline.14,179,183 It has been demonstrated that the electronic structure of poly(m-phenylenevinylene-co-2,3-dioctoxy-p-phenylenevinylene)184 and other types of conducting polymers is modified by the presence of carbon nanotubes,185,186 suggesting that there is strong coupling between the conjugated π-electron system and the multi-walled carbon nanotube. In a different poly(2,6-pyridinylenevinylene-co-2,5-dioctyloxy-p-phenylenevinylene)-wrapped system,186 it has been suggested that the protonation of the polymer is promoted by the presence of single-walled carbon nanotubes, and the electrical property of the polymer nanocomposite material is also significantly improved. The polymer nanocomposite material containing carbon nanotubes and conjugated polymers is a strongly associating, tightly bound system. The molecular geometry of the polymer nanocomposite material is single or multi helical wrapping of single-walled carbon nanotubes by the polymer.186 On the other hand, wrapping of polymers around carbon nanotubes may be utilized to synthesize polymer nanocomposite materials, since the physical and mechanical properties of polymers can be greatly improved.187–189

Wrapping of polymers around carbon nanotubes, as well as strong bonding at the interface, was reported for a different type of macromolecules, i.e. biopolymers such as peptides and deoxyribonucleic acid (DNA). The interaction at the interface between carbon nanotubes and a specific type of DNA has been exploited for various applications such as drug delivery, gene therapy, sensing, and nanotechnology.190 They also affected the properties of the final composite,191 especially mechanical properties. Uniform dispersion of carbon nanotubes within a DNA matrix can be achieved,192 and their complexes have been found to enable separation of carbon nanotubes190,193 as well as preparation of composites and fibers194–196 and nanometer-scale electronic (nanoelectronic) devices.197,198 An in-depth review of the science and technology of carbon nanotube–DNA composite materials and related applications is available in the literature.190

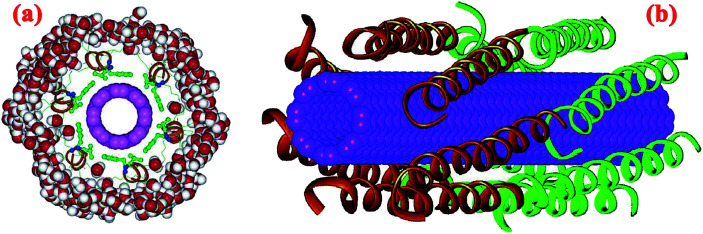

Dieckmann et al.199 described an amphiphilic peptide specifically designed to disperse single-walled carbon nanotubes and to control the assembly of the amphiphilic peptide-coated carbon nanotubes into a macromolecular structure. It was found that single-walled carbon nanotubes can induce the preferential folding of amphiphilic peptide into a specific configuration, and the peptide–peptide interaction between adjacent peptide-wrapped carbon nanotubes can be utilized to control the self-assembly of the fibers. The concept is demonstrated in Fig. 10. Scanning electron microscopy and transmission electron microscopy images were acquired, and Raman spectroscopy was used to examine the structure of the fibers. The results indicated that the amphiphilic peptide-coated carbon nanotubes were aligned along the axis of the fibers.

Fig. 10. Model illustrating potential interactions between a synthetic, hydrophilic polypeptide and an individual single-walled carbon nanotube. Panel (a) cross-section view of a carbon nanotube (pink cylinder) wrapped by six peptide helices (one heptad of each shown). The backbone of each peptide is denoted by an orange ribbon, and the Val and Phe side chains packed against the carbon nanotube surface are rendered in green. The 5 Å thick water shell used in the energy refinement of the model is rendered as creatine phosphokinase spheres (red: oxygen, white: hydrogen, green: carbon, blue: nitrogen). Panel (b) view of peptide-wrapped carbon nanotube illustrating the 12 peptide helices used in the model. The head-to-tail alignment of helices in two adjacent layers (orange and green layers) is maintained throughout the molecular dynamics simulation. The unwinding observed at the C-terminus of each helix was manually introduced at the beginning of the molecular dynamics simulation to mimic the distortion observed in the crystal structure of coil-VaLd. The figure is adapted with permission from ref. 199. Copyright 2003, American Chemical Society.

To improve the degree of the dispersion of carbon nanotubes, wrapping of polymers around carbon nanotubes was also suggested in additional systems.200,201 Wrapping of water-soluble polymers may lead to screening of the hydrophobic interaction at the interface between the carbon nanotubes and water. A variety of linear water-soluble polymers has been examined, and this approach has been found to be robust and general. The thermodynamic driving force for the wrapping of polymers around carbon nanotubes in an aqueous environment has also been identified.200,201

6. Interfacial interaction improvement techniques

While significant insights into the nature of carbon nanotube–polymer interactions at the interface have been achieved, there are still a number of issues that need to be addressed.202,203 The physical and mechanical properties of the nanocomposites reinforced with carbon tubes is strongly influenced by the characteristics of the interface.140–143 To realize their potential as reinforcement for polymers, it is necessary to optimize the interface.18 Unfortunately, there is a lack of understanding of the characteristics of the interaction at the interface. Further investigations into the relationship between composite properties and interfacial optimization are needed to achieve optimal reinforcement of polymer matrices with carbon nanotubes.

While some important factors influencing properties of the polymer nanocomposites have been identified, there exist reports containing contradictory findings with regard to the effect of carbon nanotubes on a particular property.12 The contradictory findings could be partly due to technical reasons, such as differences in processing conditions and material characteristics. On the other hand, the role of several important factors such as the carbon nanotube curvature204,205 needs to be further determined. These factors may be critical to achieving optimal properties of the composites. However, regardless of the effect of carbon nanotube on the properties of the composites, there is still a gap between experimental results and theoretical predictions due to imperfect dispersion and especially poor load transfer at the interface.204,206 In the case of low carbon nanotube loadings, the experimental data are usually far behind the idealized results predicted by a rule-of-mixtures approach. In the case of high carbon nanotube loadings, the degree of improvement in mechanical properties is somewhat limited by relatively high viscosities of the polymer nanocomposites as well as the resulting void defects.22 The characteristics of the interaction at the interface play an important role in determining the properties of the polymer nanocomposites.18 Moreover, the issue of carbon nanotube dispersion is critical to efficient reinforcement, and lies partly in the interfacial interaction characteristics of the composite. Furthermore, the interfacial interaction properties should be tailored for the desired performance, when designing a carbon nanotube–polymer composite. Finally, to better understand the physical and mechanical behavior of the polymer nanocomposites, it is necessary to explore the characteristics of the interaction at the interface. There has been considerable research in attempting to improve the interfacial interaction. The interfacial interaction can be categorized into two types: non-covalent and covalent interaction.18 The recent advances in the interfacial interaction at the nanometric level is briefly discussed here.

6.1. Non-covalent interaction

It is an effective way to improve the load transfer at the interface through strengthening non-covalent bonding between the carbon nanotube and the polymer matrix by introducing specific interactions such as a CH–π interaction and especially a π–π interaction. Non-covalent interactions can be classified into different types such as van der Waals forces or π–π stacking. There have been a variety of techniques developed for enhancing the non-covalent interaction in carbon nanotube–polymer composites, such as bridging, specific interfacial area, wrapping. These techniques are of particular interest, because they enables one to tailor composite properties while still preserving nearly all of the carbon nanotube's intrinsic properties.

The bridging technique can be utilized to allow a polymer chain interacted with two or more reinforcements simultaneously. The bridging phenomenon is determined by the ratio of the average interface-to-interface distance between the nearest reinforcements to the radius of gyration of long polymer chains.207 As a result, the possibility of bridging phenomenon increases by using higher molecular weight polymers or with increasing the carbon nanotube content. An important issue for load transfer is the interfacial area between filler and polymer, as reported by Cadek et al.208 The specific interfacial area is the interfacial area per unit volume of a carbon nanotube–polymer composite, depending on diameter and loading of the reinforcement as well as the polymer to reinforcement density ratio.207 It has been found that there is a linear dependence of tensile modulus on the interfacial area per unit volume in carbon nanotube–polymer composites.208 Furthermore, as the specific interfacial area increases, the properties of polymer nanocomposite materials will become increasingly dominated by the nature of the interface.32

The non-covalent “wrapping” of polymer chains around a carbon nanotube is an interesting phenomenon that affects the properties of the composites. This wrapping behavior can be utilized to solubilize carbon nanotubes, tune the dispersity of carbon nanotubes, drive assembly mechanisms, and alter the functionalization of the carbon nanotubes.209–212 Consequently, the wrapping mechanism not only helps to improve the dispersion efficiency of carbon nanotubes in polymers, but also results in a stronger interfacial interaction. Wrapping is a general phenomenon occurring at the interface between the carbon nanotube and the polymer matrix, although the physicochemical states of such interfacial interactions are still poorly understood. The driving forces for wrapping are likely to be a combination of interactions due to electrostatics and aromaticity hydrophobic forces, and van der Waals forces.

Experimental evidence for polymer wrapping of carbon nanotubes has been reported.174,209,210 However, it is yet to be understood how non-covalent wrapping of polymers around the surface of carbon nanotubes contributes to the physical and mechanical of the composites. This molecular phenomenon is likely to be governed by the flexibility and affinity of the polymer species for the carbon nanotube. The polymer with a semi-flexible or stiff backbone tends to wrap around a carbon nanotube with a more distinct, helical conformation than that with a flexible backbone.213,214 In contrast, the polymer a flexible backbone with bulky and aromatic side groups prefers intrachain coiling rather than wrapping around a carbon nanotube.215Fig. 11 shows examples of flexible and stiff backbone polymers interacting with single-walled carbon nanotubes. The chemical composition of a polymer can influence the wrapping mechanism of its chains around a carbon nanotube. For example, aromatic groups along the backbone of the polymer chain prefer to optimize the π–π stacking interaction at the interface and, consequently, dictate the distinct conformation for adsorption. In addition, the presence of aliphatic side groups can weaken the interaction occurred at the interface. Furthermore, the geometric parameters of carbon nanotubes and polymers can significantly affect the wrapping mechanism.207 When the diameter of carbon nanotubes is much smaller than the radius of gyration of polymers, there exists a strong interaction at the interface, thus improving interfacial load transfer and increasing the elastic moduli of the nanocomposite material. Consequently, nanocomposite materials with small diameter carbon nanotubes and high molecular weight polymers may lead to tight wrapping of polymers around a carbon nanotube.

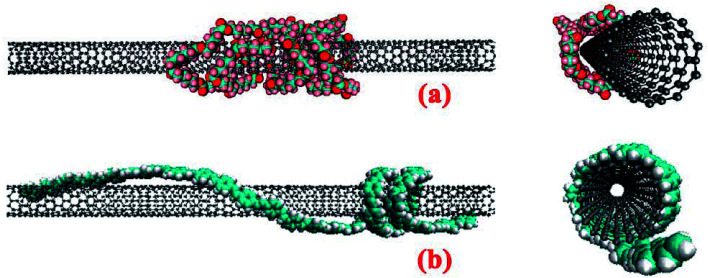

Fig. 11. Molecular dynamics snapshots of polymer chains introduced into a single-walled carbon nanotube. Panel (a) shows flexible backbone poly(caprolactone) interacting with the carbon nanotube at 3200 ps.215 The colors used for the polymer represent the following atoms: carbon is aqua, hydrogen is pink, and oxygen is red. Panel (b) shows stiff backbone poly(para phenylene vinylene) interacting with the carbon nanotube at 2400 ps.213 The colors used for the polymer represent the following atoms: carbon is aqua, and hydrogen is white. The figure is adapted with permission from ref. 213 and 215. Copyright 2010, American Chemical Society.

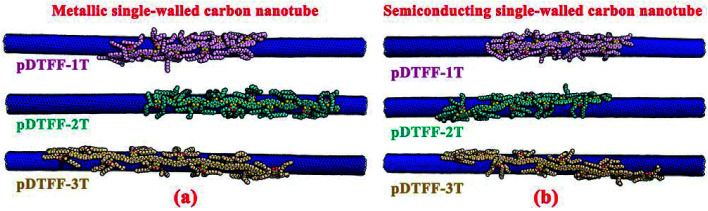

A facile and efficient method was developed by Wang et al.216 to enrich a large quantity of semiconducting single-walled carbon nanotubes through the use of a series of polymers. Molecular dynamics simulations were also performed to understand how to improve the yield and quality of the final composite material. They found that polymer side chains play an important role in determining the selectivity to the final composite. Representative snapshots of the molecular dynamics simulations are shown in Fig. 12. The selectivity toward the desired product slightly increases with increasing the ratio of thiophene to dithiafulvalene units in the polymer backbone. Furthermore, they also fabricated solution-processed thin film transistors with a high on to off ratio.

Fig. 12. Representative snapshots of the molecular dynamics simulations performed for (panel (a)) a metallic single-walled carbon nanotube and (panel (b)) a semiconducting single-walled carbon nanotube with pDTFF-1T, pDTFF-2T, and pDTFF-3T polymers. The pDTFF-mT polymer represents poly(dithiafulvalene-fluorene-co-m-thiophene). The figure is adapted with permission from ref. 216. Copyright 2013, American Chemical Society.

The non-covalent interaction method is closely related to the physical adsorption and wrapping of polymers around a carbon nanotube. This method will be particularly advantageous for taking advantage of the inherent properties of carbon nanotubes, since the structural integrity of carbon nanotubes is preserved and thus their unique properties are not disrupted. Recent studies have demonstrated that polymer crystallization can improve the non-covalent interaction, which shows great promise for preparing high-performance polymer nanocomposite materials.217,218 A facile, highly effective technique is non-covalent grafting of carbon nanotubes with end-functionalized polymers.219,220 There is a strong non-covalent interaction at the interface by using this technique. This technique is expected to have a number of advantages for the synthesis of high-performance polymer nanocomposite materials. For example, physical and mechanical properties of the final composite can be significantly improved by using this technique, and the dispersibility of carbon nanotubes into a polymer matrix can also be highly increased.

6.2. Covalent interaction

The covalent interaction method involves the attachment of chemical bonds to either the ends or sidewalls of carbon nanotubes. In this context, strong interfacial bonding is established during the creation of covalent chemical bonds between the carbon nanotubes and the polymer matrix. This method can effectively enhance the interaction at the interface, and can easily give rise to higher interfacial shear strength, thus improving the mechanical properties of a polymer nanocomposite material.32 Covalent functionalization also provides an effective way to tailor the interface to achieve optimal performance of the composite materials.221,222 The interfacial adhesion can be greatly improved by using the covalent interaction method, and the load transfer efficiency can also be significantly enhanced. This method can be achieved by using the covalent chemical functionalization of the open-ends or sidewalls of carbon nanotubes. Hirsch,77 Meng et al.,80 and Balasubramanian and Burghard81 reviewed the recent advances in the development of reliable techniques for the covalent chemical functionalization of the open-ends or sidewalls of carbon nanotubes. The techniques discussed in these review articles can further expand the application range of carbon nanotubes. In particular, it is possible to chemically tailor the properties of the surface of carbon nanotubes in order to enable the design of polymer nanocomposite materials for engineering applications.

The covalent interaction method is an effective way to increase the strength of the interface between the carbon nanotube and the polymer matrix by introducing specific functional groups to the surface of carbon nanotubes. The functional groups on the surface of carbon nanotubes should be carefully designed in order to improve the compatibility with the polymer matrix.79,223,224In situ polymerization is an effective method to improve the compatibility, and to improve the formation of covalent bonds between the functionalized carbon nanotubes and the polymer matrix.225,226 Covalent chemical functionalization of carbon nanotubes has been successfully applied to reactive polymers. Chemical functionalization of the chains of stable and non-reactive polymers such as commercially-available engineering plastics has also been reported by Chang and Liu227 through an ozone-mediated process. Polymer-functionalized carbon nanotubes were prepared to improve the compatibility with the polymer matrix.227 Ozonization of non-reactive polymer chains, instead of carbon nanotubes, was used. The experiments demonstrated the capability of carbon nanotubes functionalized by a matrix polymer as effective fillers in polymer nanocomposite materials. On the other hand, covalent functionalization of carbon nanotubes can also be accomplished through microwave irradiation224,228,229 and plasma enhanced chemical vapor deposition.230

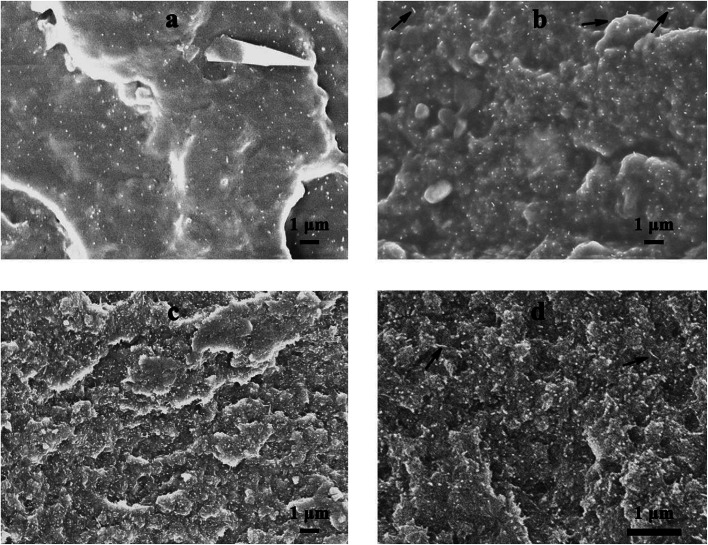

To improve the properties of polymer nanocomposite materials, uniform dispersion of carbon nanotubes within the polymer matrix is a critical issue. Covalent functionalization of carbon nanotubes can improve the dispersion state of carbon nanotubes, and modify the properties at the interface, which eventually leads to the improved performance of polymer nanocomposite materials.231–233 With respect to mechanical properties of the composites, the load transfer efficiency can be significantly enhanced through covalent functionalization, since it is an effective method for tuning the properties at the interface.234 The covalent functionalization of carbon nanotubes leads to a change of carbon hybridization from sp2 to sp3, resulting in a possible partial loss of conjugation, with consequences for electron-acceptor and electron-transport properties. Polarized Raman spectroscopy is a powerful tool used to characterize the degree of the functionalization of carbon nanotubes through an increase in the intensity ratio of D Raman band to G Raman band as well as in the intensity of D′ Raman band.227 The latter is known to be directly influenced by the disorder in carbon nanotubes. Furthermore, thermal gravimetric analysis showed that pristine carbon nanotubes do not show significant weight loss until 850 °C, whereas there is a loss of the mass of functionalized carbon nanotubes prior to this temperature.227 Scanning electron microscope images of the fractured surface of functionalized carbon nanotube–polymer composites give further evidence of strong bonding at the interface.226,232 The representative field emission scanning electron microscope images of the cross-sectional fracture of multi-walled carbon nanotube–nylon 6 composites with the achieved dispersion of carbon nanotubes in the polymer matrix are shown in Fig. 13. Furthermore, transmission electron microscopy images suggested that the outer bundles of multi-walled carbon nanotubes are covered by amorphous polymer layers.224,227 Finally, the covalent interaction between the carbon nanotube and the polymer matrix can significantly affect the properties of polymer nanocomposite materials.235

Fig. 13. Field emission scanning electron microscope images of the cross-sectional fracture of multi-walled carbon nanotube–nylon 6 composites: panel (a) PRC10-II, panel (b) PRC10-I, panel (c) PRCS10 and panel (d) PAC10. For more detailed information about the definitions of these composites, the reader is referred to the relevant literature.226 It was clearly observed from panel (b) that the carbon nanotubes were broken, as indicated by arrow, which is of great importance to research and develop methods for the preparation of multi-walled carbon nanotube–reinforced polymer composites. It is interesting to note that a belt like carbon nanotube was observed which interconnected polymer lumps, as indicated by arrow in panel (d). This typical phenomenon also indicated that there was a strong interfacial adhesion between the carbon nanotube and the polymer matrix, and a sufficient load transfer from the polymer matrix to the carbon nanotubes. The figure is adapted with permission from ref. 226. Copyright 2009, Elsevier B.V.

Covalent functionalization provides a means for tailoring the interface to achieve optimal performance of the composite materials.236–238 Covalent functionalization can greatly improve the dispersion and interfacial bonding of the carbon nanotubes in a polymer matrix, and thus the route to the composite materials with excellent performance can be realized. The dispersion state of carbon nanotubes can be significantly improved and the bonding at the interface can also be substantially enhanced through covalent functionalization, thus providing a potential method to take full advantage of the remarkable physical and mechanical properties of carbon nanotubes. However, an obvious drawback of this method is the disruption of the bonding of the graphene sheet, which may eventually lead to the degradation of the performance of the composite materials. Covalent functionalization may cause a loss of mechanical and physical properties of the composite materials, since most of these properties are extended π-conjugation-dependent. Since each covalent functionalization site scatters electrons, this method has a profound influence on the electrical properties of the composite materials.

The purification process and other preparation steps should be strictly controlled during covalent functionalization to prevent the introduction of a large amount of defects into carbon nanotubes that may result in the deterioration of the performance of the composite materials.226 The creation of covalent chemical bonds at the interface can enhance the interaction between the functionalized carbon nanotubes and the polymer matrix, and higher interfacial shear strength can be achieved.232 Furthermore, the efficiency of interfacial stress transfer can be significantly improved, especially when covalent and non-covalent functionalization are used simultaneously.239

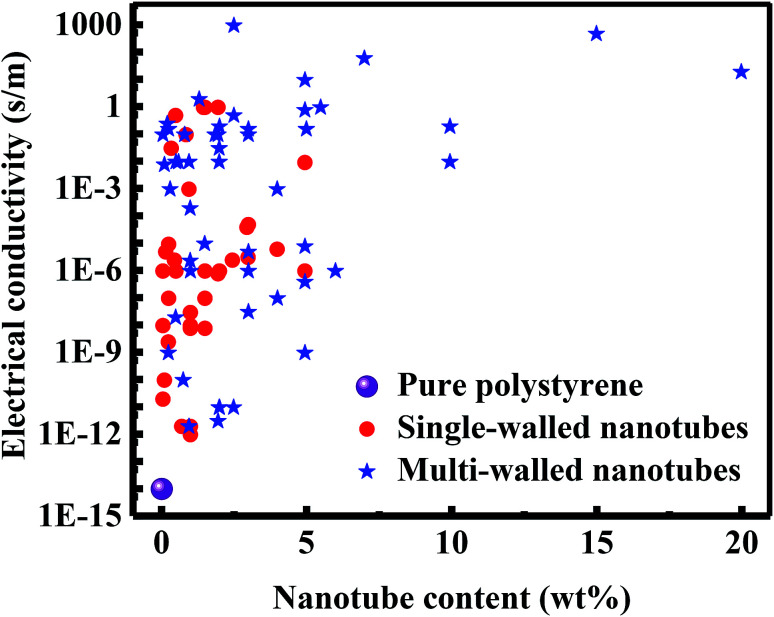

7. Property improvements

The outstanding properties of carbon nanotubes open up new perspectives for carbon nanotube–reinforced composite materials. The remarkable physical and mechanical properties of carbon nanotubes have attracted intensive attention in recent years, with the development of polymer nanocomposite materials for both functional and structural applications.240–246 The physical and mechanical properties of carbon nanotube–polymer composite materials have been extensively studied. From processing and application points of view, the improvement in mechanical properties is of special interest. The significantly improved electrical conductivity of these composite materials with the addition of a very small amount of carbon nanotubes is very important in many practical applications.247–251 Unfortunately, it is difficult to simultaneously achieve the improvement of several properties of polymer nanocomposite materials, since their properties are dependent upon a multitude of factors.22 Nevertheless, it is possible to simultaneously improve the mechanical and electrical properties of polymer nanocomposite materials, which is the focus of this section.

While great achievements have been made in the field of polymer nanocomposite materials, the ability to efficient translate the exceptional properties of carbon nanotubes into the polymer matrix is handicapped by the lack of the precise knowledge of the properties of polymer nanocomposite materials.29,32 Significant improvement in the properties of these nanocomposite materials through the incorporation of carbon nanotubes has been achieved. Consequently, it is highly desirable to summarize some important properties of carbon nanotube–polymer composite materials in comparison with the same properties of polymer matrices. A brief summary of the several important, physical and mechanical properties presented here serves to exemplify such improvement. The brief summary gives a generalization of the recent results of the physical and mechanical properties of carbon nanotube–polymer composite materials, as well as illustrates the improvement of these properties obtained from both experimental measurements and theoretical predictions.

7.1. Influence factors

The properties of these nanocomposite materials depend upon several factors such as type and amount of impurities in the carbon nanotubes, carbon nanotube purification process, synthetic process used to produce carbon nanotubes, carbon nanotube orientation in the polymer matrix, length, diameter, and aspect ratio of the carbon nanotube objects in the composite. These variations in carbon nanotubes account for the apparent inconsistent results reported in the literature. The given information only about the matrix polymer and the concentration of carbon nanotubes is insufficient. While it is impossible to quantify all of the factors listed above, it is very necessary to provide more accurate and complete information in order to reduce discrepancies between the published results obtained for similar composite materials. It has been suggested that the entire research should be carried out by using the same batch of purified carbon nanotubes in order to clarify the factors influencing the properties of carbon nanotube–polymer composite materials.22

It is important to understand the mechanism underlying the interaction at the interface at the molecular level to improve the properties of carbon nanotube–polymer composite materials. The interaction at the interface can significantly influence the dispersion state of carbon nanotubes, but its effect on the performance of polymer nanocomposite materials is potentially quite complex, depending on the target properties.252,253 It is important to note that the optimal microstructure for one physical property of polymer nanocomposite materials might not be the best microstructure of another physical property. In addition, the importance of the relationship between network structure and physical properties has been highlighted by the research group of Uttandaraman Sundararaj,254–256 and the effect of the geometry of fillers has been also clearly clarified.

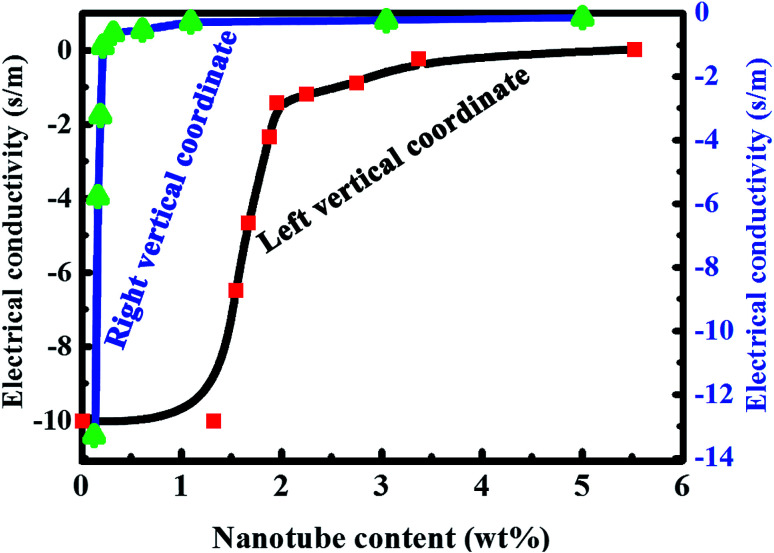

Recently, the importance of the synthesis method of carbon nanotubes has also been highlighted by the research group of Uttandaraman Sundararaj.257–260 The electrical conductivity of polymer nanocomposite materials can be controlled by adjusting the nitrogen doping level of carbon nanotubes.257,259 Polyaniline is a conductive polymer, thus enabling a strong interaction with carbon nanotubes. The presence of polyaniline can enhance the capacity of adsorption of carbon nanotubes on the surface of a polymer matrix as well as the degree of their dispersion, thus improving the properties of final nanocomposite materials.257,259 In addition, the catalyst and temperature used for the synthesis of carbon nanotubes may be significant, because they can significantly affect the physical properties of polymer nanocomposite materials.258,260 Consequently, these operating parameters must be carefully designed to improve the performance of final nanocomposite materials.

On the other hand, there is an increasing interest in the development of the polymer blend nanocomposite materials containing carbon nanotubes in order to further improve the physical properties for practical applications.261,262 The addition of a small amount of carbon nanotubes is an effective way to manipulate the morphological characteristics of immiscible polymer blends, thus improving the properties of final nanocomposite materials.263 Although considerable progress has been made in this field,263 there is still a lack of understanding of the mechanism underlying the carbon nanotube induced morphological changes. To improve the properties of final nanocomposite materials, it is necessary to manipulate the microstructure of immiscible polymer blends. Morphology refinement is probably the most common consequence. This effect can be attributed to various factors such as the interfacial localization of carbon nanotubes. Recently, molecular simulations have been performed by the research group of Uttandaraman Sundararaj264 to gain insight into the interaction at the interface between carbon nanotubes and different polymer chains. They have found that the migration of carbon nanotubes between different phases plays an important role in determining the morphological changes of polymer blend nanocomposite materials.264 This finding is of particular importance, as it holds great promise for improving the properties of final nanocomposite materials.

The physical properties of carbon nanotube–polymer composites arise from the respective characteristics of the two components, and from the microstructures produced while fabricating and processing these nanocomposite materials. Therefore, much more efforts should be made to improve the control of the morphology of these polymer nanocomposite materials by using a combination of creativity and practicality. The development of the robust correlation between physical properties and interfacial characteristics will further advance the design of these polymer nanocomposite materials.

7.2. Mechanical properties

The extraordinary mechanical properties, fiber-like structure, high aspect ratio, and low density of carbon nanotubes provide unique opportunities for the development of polymer nanocomposite materials.22 The outstanding potential of carbon nanotubes as reinforcement for polymers has been realized.265–270 The mechanical properties of polymer composite materials can be significantly improved by using carbon nanotubes as a filler. Carbon nanotubes have been widely utilized as a filler to reinforce both thermoset polymers271–274 and thermoplastic polymers.275–280