Abstract

At present, plastic waste accumulation has been observed as one of the most alarming environmental challenges, affecting all forms of life, economy, and natural ecosystems, worldwide. The overproduction of plastic materials is mainly due to human population explosion as well as extraordinary proliferation in the global economy accompanied by global productivity. Under this threat, the development of benign and green alternative solutions instead of traditional disposal methods such as conversion of plastic waste materials into cherished carbonaceous nanomaterials such as carbon nanotubes (CNTs), carbon quantum dots (CQDs), graphene, activated carbon, and porous carbon is of utmost importance. This critical review thoroughly summarizes the different types of daily used plastics, their types, properties, ways of accumulation and their effect on the environment and human health, treatment of waste materials, conversion of waste materials into carbon-based compounds through different synthetic schemes, and their utilization in energy storage devices particularly in supercapacitors, as well as future perspectives. The main purpose of this review is to help the targeted audience to design their futuristic study in this desired field by providing information about the work done in the past few years.

1. Introduction

In the last couple of decades, a growing concern for researchers is electronic waste, as it is a profligate waste on the planet. According to analysis ∼44.7 million tons of e-waste was engendered in 2016, and it is predicted that it will reach ∼52.2 per million tons in 2021 by following a growth rate of 3–4% per annum. E-waste comprises various constituents containing glass, ceramics, metals, and polymers.1

Polymers further comprise plastics, cellulose, rubbers, and wax macromolecules composed of smaller units called monomers and are broadly categorized into different classes based on their origin as natural, artificial (synthetic), and semisynthetic molecules. Plastics are artificial/synthetic polymers containing a wide range of synthetic/semisynthetic organic malleable molecules which can be turned into solid objects. Since 1907, after the production of the first synthetic plastic in New York, plastics have occupied an important place in the routine life of humans. Almost all facets of routine life involve plastics, such as clothing, transport, telecommunications, footwear, and packaging materials that enable the transport of a broad range of drinks, eatables, and other goods. Moreover, their desirable properties, such as economical nature, low maintenance requirements, lightweight, stability, weathering resistance, transparency, decreased toxicity, good electrical insulation, excellent thermal properties, and design flexibility compared to other solid components, expedite the practical applications of plastics in various commercial, industrial, and agricultural activities. There is further room for novel applications of plastics that will be quite beneficial in the future, such as the development of renewable energy sources, novel medical applications, and reduced energy utilization in transport.2,3 In the last 60 years, due to the large-scale utilization of plastic in different applications, it is ranked as the most widely employed material in the world, with global use surpassing 260 million tons/annum, and it now accounts for about 10% of total generated waste.4,5

According to the latest survey, only in 2019, plastic global production was ≈370 million metric tons, and among these 36.4% are anticipated to be incinerated; a similar fraction (36.4%) is expected to be dumped into landfills or excreted in the environment, and only 27.2% will be consumed in recycling. These forecasts undoubtedly project the plastic wastes’ mismanagement due to improper recycling/reusing of these materials, which consequently leads to soil, freshwater, and ocean contamination worldwide via plastic wastes. Due to their lightweight, durable nature, plastics have become a widespread element of marine litter with succeeding influences on a natural ecosystem and all living organisms.6,7

Currently, preventive strategies to lessen the plastic wastes discharged to the environment (upstream responses) and strategies to diminish their impact after their release into the environment (downstream responses) are considered important tools to tackle the crisis of global plastic waste, and proper waste management comes into the category of upstream responses. Conversely, the plastic wastes’ recycling process has several limitations, one of which results in the product’s economic attractiveness.8−15

2. Types of Plastic

Plastics are macromolecules prepared by the polymerization process and can be molded by applying the appropriate amount of pressure, heat, or some other external force. Polymerization is the process of linking individual units of identical or different molecules (“mers”) through chemical reactions to develop the long-chain structure of macromolecules accompanied by properties quite different from those of starting molecules. Different types of polymers based on their properties and nature are categorized as rubbers or elastomers, plastics, and fibers.16−20

Two main types of plastics are thermoplastics and thermosetting plastics (Figure 1).

-

(i)

Thermoplastics

Thermoplastics are composed of linear chains of molecules held by weak Van der walls forces and, once prepared, can be molded repeatedly into different shapes by applying temperature until they lose their identity, as they are flexible.

Examples: polyethylene, polystyrene, polypropylene, polycarbonate, nylon, etc., where polystyrene, polyethylene, and polypropylene fall into the category of addition polymers while nylon and polycarbonate are types of condensation polymers.

Daily life applications: polystyrene cups, polyethylene buckets, nylon ropes, etc.

-

(ii)

Thermosetting Plastics

Thermosetting plastics are fabricated by the route of irreversible polymerization; once designed or shaped they are unable to be softened again by thermal reactions due to strong attractive forces and a highly cross-linked structure, and material charring occurs on heating.

Examples: urea formaldehyde, phenol formaldehyde, melamine formaldehyde, thermosetting polyester, etc. All of these are types of condensation polymers.

Applications: Formica tabletops, Bakelite electrical switches, and melamine cutlery.20−22

Figure 1.

Commonly used plastics in our daily life. Reproduced with permission from ref (22). Open access article 2017, RSC.

2.1. Types of Thermoplastic Polymers

The ideal properties of thermoplastic polymers, such as corrosion resistance, low density, user-friendly design, and high strength, are responsible for the greater demand for plastics than for aluminum and other metals. The three subtypes of thermoplastics are mentioned below:

-

(i)

Crystalline Thermoplastics

A material with highly ordered molecular chains and translucent properties is called a crystalline thermoplastic. High mechanical impact resistance as compared to other types is the salient feature of these materials.

Examples: high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP).

-

(ii)

Amorphous Thermoplastics

Materials with randomly arranged molecular chains and transparent nature are amorphous thermoplastics.

Examples: poly(methyl methacrylate) (PMMA), polyvinyl chloride (PVC), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polystyrene (PS).

-

(iii)

Semicrystalline Polymers

The properties of semicrystalline materials are a combination of the properties of both the above-mentioned types.

Examples: polyamide imide (PAI) and polybutylene terephthalate (PBT).

The most widely utilized plastics in our routine life are thermoplastics, and among them the most common are PE (polyethylene) 29.6%, PP (polypropylene) 18.9%, PVC (polyvinyl chloride) 10.4%, PUR (polyurethane) 7.4%, PS (polystyrene) 7.1%, and PET (polyethylene terephthalate) 6.9%, respectively.23

3. Physical Properties of Different Types of Plastics

Plastics have characteristic physical characteristics, essential to be considered during the processing of any product. The physical data for numerous commercially available plastics are provided in Table 1.24

Table 1. Commonly Used Plastics and Their Physical Propertiesa.

| Plastic | Thermal properties |

Strength |

Density | ||||

|---|---|---|---|---|---|---|---|

| Chemical name | Tm (°C) | Tg (°C) | Td (°C) | Cte (°C) | Tensile psi | Compressive psi | (g/cm3) |

| LDPE (Low-density polyethylene) | 122 | 1900 | 0 | 0.914–0.940 | |||

| 124 | 4000 | ||||||

| HDPE (High-density polyethylene) | 130 | 79 | 59 | 3200 | 2700 | 0.952–0.965 | |

| 137 | 91 | 110 | 4500 | 3600 | |||

| PP (Polypropylene) | 168 | –20 | 107 | 81 | 4500 | 5500 | 0.900–0.910 |

| 175 | 121 | 100 | 6000 | 8000 | |||

| PS (Polystyrene) | 74 | 68 | 50 | 5200 | 12000 | 1.04–1.05 | |

| 105 | 96 | 83 | 7500 | 13000 | |||

| PVC (Polyvinyl chloride) | 75 | 57 | 50 | 5900 | 8000 | 1.30–1.58 | |

| 105 | 82 | 100 | 7500 | 13000 | |||

| PI (Polyimide) | 310 | 277 | 45 | 10500 | 30000 | 1.36–1.43 | |

| 365 | 360 | 56 | 17100 | 40000 | |||

| PMMA (Poly(methyl methacrylate)( | 85 | 79 | 50 | 7000 | 10500 | 1.17–1.20 | |

| 105 | 107 | 90 | 11000 | 18000 | |||

| PC (Polycarbonate) | 150 | 138 | 68 | 9500 | 12500 | 1.2 | |

Tm, crystalline melting temperature; Td, heat distortion temperature (66 psi load); Cte coefficient of linear thermal expansion; Tg, glass transition temperature (the plastic becomes brittle below this temperature); compressive psi, compressive strength (load necessary to crush a sample of the plastic); tensile psi, tensile strength (load necessary to pull a sample of the plastic apart).

4. Impact of Plastic Accumulation

Plastics are non-biodegradable, mostly composed of hydrogen, carbon, and other elements, such as nitrogen, chlorine, etc., and are the main reason for the municipal waste management problem (Figure 2). According to the latest survey of the United Nations, the annual production of plastic in 2020 is over 400 Mt, and it is expected to be double (800 Mt) in 2035 and to increase to the value to 1600 Mt by 2050. The manufacturing process of plastic leads to the release of an excessive amount of detrimental gaseous substances in the air such as Dioxin, carbon monoxide, hydrogen cyanide, and nitrogen oxides, which have serious/detrimental effects on human health and the environment. Furthermore, 4.5 billion tons of plastic wastes dumped in landfills or excreted in the environment harm the soil’s microbial content. In 2018, it was reported that the intensity of trace gases generated from low-density polyethylene increases with the increase of incubation time.25,26

Figure 2.

Plastic waste and its harmful effects on the environment and human health. Reproduced with permission from ref (80). Copyright 2021 Elsevier.

4.1. Impact of Plastic Accumulation on the Environment and Human Health

According to the 2020 survey, 195 countries were found to be responsible for the production of 400 Mt of plastic waste, and ≈8.8 Mt was observed to be released in the ocean. Plastic wastes are the main source of organic pollutants, heavy metals, chemicals, and pathogens. Furthermore, a toxic compound released after abiotic degradation of waste plastic badly affects the quality of water and soil, and the hydrophobic nature of plastics enhances their accumulation with other contaminants, such as organic pollutants, polyaromatic hydrocarbons (PAHs), and polychlorinated biphenyls (Table 2). There are numerous chemicals added to plastics during the manufacturing process to modify their properties, such as phthalates, bisphenol A, and flame retardants, which harm animal and human health and predominantly affect the endocrine systems. Additionally, the toxic monomers also tend to be cross-linked to create cancer and reproductive issues.27

-

(i)

The major concern of society in the present era is water contamination via plastic wastes as they deteriorate the fishing industry, are detrimental for ocean animals, and devastate the aquatic environment. The studies have revealed that 60–80% of marine debris comprises plastic wastes that are widespread on sea beds and shorelines, in the marine environment, and at the sea surface. Additionally, ingestion of microplastics and their long-lasting accretion affect the food chain, and abiotic degradation through rain, wind, and the sun is responsible for the leaching of chemicals from plastics and leads to consequent ancillary pollution problems within groundwater, surface water, and marine water bodies.28−30

-

(ii)

Regarding soil contamination, settlement of various plastic wastes on the soil surface or their penetration into soil layers from sludge, irrigation via wastewater, fertilizers, biosolids, or landfilling is the main source of soil pollution and could result in declined crop production as well as soil infertility due to release of toxins, and over 500 years is required for complete plastic decomposition. The plastic wastes dumped in landfills not only occupy a huge area of land but also inevitably discharge large quantities of chemicals comprising catalyst remnants, oligomers, and polymerization solvents along with a broad range of plastic additives. These hazardous chemicals influence the quality of the soil and surrounding groundwater.31,32

-

(iii)

The third incineration of plastic wastes releases numerous pollutants into the atmosphere and leads to air pollution, another severe environmental issue. In the process of solid waste management and disposal, plastic solid waste incineration with municipal solid waste (MSW) releases harmful chemicals including metals, aldehydes (-CHO), particulate matters (PMs), methane (CH4), carbon monoxide (CO), nitrogen oxides (NOx), carbon dioxide (CO2), polyaromatic hydrocarbons (PAHs), furan (C4H4O), volatile organic compounds (VOCs), and other solid materials (i.e., residue and ash) which intensify the levels of inorganic salts, heavy metals, and several organic compounds in the environment. The most alarming issue is the discharge of some carcinogenic substances such as PAHs, dioxins, and nitro-PAHs, through incineration of PET, PVC, PE, and PS. Moreover, an excessive amount of tenacious free radicals (highly reactive and unstable) in both the solid residual ash and soot creates adverse health effects particularly to human lungs.33−38

-

(iv)

Plastic disposal significantly affects human health, directly or indirectly via digestion and inhalation, respectively. Specifically, the tenacity of microplastics is responsible for multiple biological responses such as inflammation, apoptosis, genotoxicity, oxidative stress, necrosis, tissue damage, carcinogenesis, and fibrosis in the case of uninterrupted exposure. The leaching of residual monomers and unbound chemicals and the desorption of the associated hydrophobic organic contaminants also result in worsening of human health conditions. Moreover, all plastics generate free radicals by C–H bond dissociation during interaction of reactive oxygen species (ROS) with light and transition metal carcinogenic resin monomers by decomposition of polyvinyl chloride, polystyrene polymer, and epoxy resin. Thus, keeping in mind the plastic mismanagement wastes and the worldwide impact of plastics on human health, wildlife, and the environment, there is an exigent requirement for novel and effective technologies for plastic wastes’ disposal and treatment.39−41

Table 2. Effect of Plastic Accumulation on Human Health and Environmental Health.

| Sr. No | Effect on aquatic life | Effect on soil | Effect on environment | Effect on humans |

|---|---|---|---|---|

| 1 | Deteriorated fishing industry | Decreased crop production | Polluted air | Inflammation |

| 2 | Polluted water bodies | Soil infertility | Release of toxic gases | Tissue damage |

| 3 | Polluted aquatic environment | Contaminated soil and groundwater | High concentration of heavy metals, salts, and organic compounds | Oxidative stress |

| 4 | Change in soil pH | Release of carcinogenic substances and highly reactive free radicals in the air | Carcinogenesis |

5. Types of Waste Plastics and Their Recyclability

Among the different types of commonly used plastics, some are more smoothly recyclable than others. However, the quality of recycling is greatly affected by the contaminants present in the form of dirt, paper, printing inks, additives, metals, foil, pesticides, foreign bodies, and partially oxidized polymers easily noticeable in HDPE and PET bottles collected from pavements. For some commonly consumable plastics, their tendency to be recycled and their accumulated contaminants are stated in Table 3.24

Table 3. Commonly Used Plastics, Their Recyclable Nature, and Their Contaminants.

| Type | Abbreviation | Recyclabilty | Description | Contamination |

|---|---|---|---|---|

| Type 1 | PET | Yes | Polyethylene terephthalate | PVC, green PET, Al, water, glue, oligomers |

| Beverage bottles | ||||

| Type 2 | HDPE | Yes | High-density polyethylene | PP, milk residue, pigments, paper, EPS, cork |

| Milk, detergent, and oil bottles, toys, containers, plastic bags | ||||

| Type 3 | PVC | Yes, but not common | Polyvinyl chloride | PET, PE, paper, Al foil, PP |

| Food wraps, vegetable oil bottles, blister packages or automotive parts, beverage bottles | ||||

| Type 4 | LDPE | Yes | Low-density polyethylene | Paper receipts, printing ink, food scraps |

| Plastic bags, wraps, garment bags | ||||

| Type 5 | PP | Yes | Polypropylene | Pb, Cu, acid, grease, dirt |

| Refrigerated containers, bottle tops, some carpets, food wraps, battery cases | ||||

| Type 6 | PS | Yes, but not common | Through away utensils, meat packing, protective packing | |

| Type 7 | Some | Others | ||

| Layered or mixed plastic |

5.1. Management of Waste Plastic

According to a survey, more than 40% of produced plastic is utilized as single use packaging materials, including food containers, baby bottles, and materials for medical applications. Due to excessive utilization of plastic products, the plastic particles can be easily detected in air, rain, soil, snow, tap/bottled water, salt, tea, beer, and food. In addition, an ongoing pandemic condition due to COVID-19 has made the plastic waste management process more complicated (Figure 3). The transmission fear and global administrative regulations have led to the elevated consumption of personal protective equipment, personal hygiene products, single use bags, and containers and have resulted in the overall increase in plastic waste. Furthermore, national lockdowns, as well as home quarantine orders, have motivated the augmented reliance on online distribution of food and some other essential grocery items, which has persuaded a plausible rise in the generation of plastic packaging waste. Although this paradigm underscores the worth of plastics at the public level, it also underlines our vulnerabilities toward pollution.42,43

Figure 3.

Accumulation of plastic waste through different sources during COVID 19. Reproduced with permission from ref (40). Copyright 2021 Elsevier.

Management of waste plastics is an important process to effectively dispose of plastics or to manufacture new products. Some of the important techniques for the management of waste plastics are given in Figure 4 and Table 4.28

Figure 4.

Conventional and new technologies for waste plastic management.

Table 4. Pros and Cons of Different Solid Waste Management Techniques.

| Sr. No | Solid waste management technique | Advantages | Disadvantages |

|---|---|---|---|

| 1 | Landfilling | (i) Cheap | (i) Production of toxic chemicals |

| (ii) Deal with a large volume of waste | (ii) Occupy large volume | ||

| (iii) Reduced transportation distance | (iii) Leeching of heavy metal to ground, soil pollution | ||

| (iv) Applicable to nonrecyclable waste | (iv) Deforestation | ||

| 2 | Incineration | (i) Reduction of waste volume | (i) Costly |

| (ii) Devastation of combustible toxins | (ii) High energy input | ||

| (iii) Energy recovery | (iii) Cause air pollution | ||

| (iv) Minimum area of land occupied | (iv) Not applicable to all types of materials | ||

| 3 | Pyrolysis | (i) Ideal for waste plastic management | (i) Technology in the evolution process |

| (ii) Reduced greenhouse gas emission | (ii) Relatively cheap | ||

| (iii) Procession of the large variety of feedstock | (iii) Relatively expensive compared to landfilling | ||

| (iv) High energy recovery | (iv) Thermoplastic effectively treated |

5.1.1. Landfilling

The most conventional strategy employed for waste management in most countries is landfilling. The addition of additives such as antioxidants and stabilizers supports the waste plastic polymers discarded in landfills to slow down the plastic biodegradation process for a long time. Thus, landfilling seems not to be an appropriate methodology for waste plastic management, and its utilization should be limited due to (i) the long-term firmness of plastics, (ii) their slow kinetics for biodegradation, (iii) limited available sites for landfilling, (iv) complete utilization of starting materials, and (v) health issues arising due to groundwater contamination by leeching and inclusion of toxic chemicals as well as their tendency to leach from landfill sites to groundwater.29−31

5.1.2. Incineration

Waste plastics’ incineration is responsible for the excessive release of distinct matter along with harmful gases. The partial combustion of polypropylene (PP), polyethylene (PE), and polystyrene (PS) during thermal treatment may cause high concentrations of CO (carbon monoxide) and noxious substances to be discharged as combustion of polyethylene (both LDPE and HDPE) at different temperatures releases volatile organic compounds (VOCs) and semi-VOCs, particularly paraffin, olefins, aldehydes, and short-chain hydrocarbons. Benzene, among VOCs, is a known carcinogen and is released during plastic combustion, while PVC engenders carbon black, dioxins, and aromatic compounds such as chrysene and pyrene. Moreover, hazardous materials’ emissions may comprise color pigments and halides that encompass heavy metals such as copper, chromium, cobalt, lead, selenium, and cadmium. Hence, incineration is also not considered to be a good approach for plastic waste management. Plastics also contain certain additives such as plasticizers, antioxidants, fire retardants, light and thermal stabilizers, pigments, lubricants, and antistatic agents depending on the plastic type, its application, and its service circumstance. Research has revealed that most of these additives tend to mimic, interfere with, or block the hormonal system of the endocrine system and are termed endocrine disordering chemicals (EDCs). Persistent organic pollutants (POPs), also known as “forever chemicals”, is the term used for many of them. Mostly flame retardants, such as polychlorinated biphenyls (PCBs), polybrominated diphenyl ethers (PBDs), hexachlorobenzene, hexabromobiphenyls (HBBs), short-chain chlorinated paraffin (SCCP), hexabromocyclododecane (HBCD), and fluorinated tensides such as perfluorooctanoic acid (PFOA), all are included in this class. These organic compounds show resistance toward environmental degradation via biological, chemical, and photolytic processes.44

5.1.3. Mechanical Recycling

As compared to the incineration and landfilling processes, the better technique for waste management is waste plastics’ recycling.34 Generally, recycled polymers are more economical than new plastic, but actually, the price variation depends on the category of polymer and the polymer quantity in the plastic in the range of 20–100%. The recycling process is divided into four main classes: primary, secondary, tertiary, and quaternary recycling.14,45−47

Mechanical recycling is subdivided into two types: upcycling and downcycling of waste plastic.

5.1.3.1. Downcycling of Plastic Waste

The downcycling technique is employed for plastics inferior in quality and functionality as compared to the original plastic. However, contrary to other materials such as metal and glass, recycled plastics are unable to persistently perform the same function after recycling, as usually plastics lose certain qualities, such as optical clarity, mechanical integrity, and other inherent features, which tends to make them unfit for their preliminary applications. The physical approaches which are part of this process include collection, isolation, washing, cleaning, desiccation, chipping/sizing, filling, dyeing, accumulation, and pelletization, respectively. The deterioration of recycled products and change in the properties owing to the decrease in molecular weight after successive cycles due to chain scissions are the foremost constraints of this process. So, this process is most appropriate for the recycling of thermoplastics such as PET, LDPE, and HDPE because they can be remelted and then turned into novel products. On the contrary, materials such as thermosetting plastics, hybrids, and high-melting-point viscous polymers are not fit for downcycling.48,49

5.1.3.2. Upcycling of Plastic Waste

Upcycling, also termed creative reuse, is the progression of waste plastic materials’ transformation into fresh materials/products of better quality for artistic value/environmental value, for instance, upcycling of plastic bottles into flower pots, garden sprinklers, bird feeders, green parking canopies, Christmas trees, chandeliers, kid’s toys, and much more. Chemical processing is the method of upcycling waste single as well as mixed plastics. The facile and economical nature of the process is the main advantage of this process. However, the limitation of this process is that multiple solid waste plastics cannot be recycled due to the presence of impurities. Moreover, an increased content of waste plastics in the feed mixture leads to the declining quality of the output product. To enhance the efficacy of the process, mandatory steps need to be performed, such as (a) the segregation of wastes based on particular resins and colors, followed by thorough washing and (b) the re-extrusion of plastic in the form of pellets due to good melting properties and mixing with the original resin to get better quality products. Plastic bottles manufactured from a blend of recycled PET and new PET are an example of this process.50−52

5.1.4. Pyrolysis

Pyrolysis is the process of thermal degradation (tertiary recycling) of solid waste plastic at the temperature range 300–900 °C in a nonoxygenated environment to produce gaseous fuel and liquid. Plastics are polymeric substances made up of monomers, and pyrolysis is a process of transformation of used and discarded plastics into valuable products in the form of fuel, monomers, and other beneficial resources. Pyrolysis is a comparatively advantageous technique of waste management as compared to other conventional approaches in the following ways: (a) Most of the waste plastics downcycled during recycling produce articles of the lower process and produce poor quality products as plastic losing its salient features of clarity, flexibility, and strength during multiple cycling is avoided in pyrolysis. (b) The high cost is associated with sorting, blending, and washing before waste plastics’ mechanical recycling is completely excluded in the pyrolysis technique. Additionally, (c) mechanical recycling comprises the melting and remolding of discarded or used plastics into fresh articles. So, only thermoplastic waste articles can be effectively utilized in this technique. On the contrary, in the pyrolysis process, both thermoplastic and thermosetting plastics are utilized as feedstock. Moreover, (d) the pyrolysis technique is highly proficient toward the treatment of novel material composites, particularly in the evolving technology to replace traditional materials with polymeric composites in the of majority applications. In conclusion, depending on the composition of the feedstock, the reaction conditions such as temperature, reacting gas, heating rate, and catalytic process (in the presence of a catalyst) or thermal pyrolysis (in the absence of a catalyst), final product, yield, and composition can be varied.53−55

5.2. Classification of Pyrolysis Based on Heating Rates

The pyrolysis process can be classified into multiple categories depending on the operating conditions, such as pyrolytic temperature, volatile matter residence time, and heating rate. The three primary types of pyrolysis based on heating rate are fast pyrolysis, slow pyrolysis, and flash pyrolysis (Figure 5).56

Figure 5.

Different types of pyrolysis along with controlling factors and obtained products. Reproduced with permission from ref (56). Copyright 2021 Elsevier.

5.2.1. Slow Pyrolysis (Nonisothermal)

Slow pyrolysis is the process of slow heating (heating rate of 10 °C/s) of the precursors in a nonoxygenated environment. Instead of complete combustion, the volatile parts from the organic material are evaporated partly, and a char (product) remains behind and consists of 80% carbon. Carbonization is another term used for slow pyrolysis accompanied by char as the main product as compared to the liquid product in fast pyrolysis.

5.2.2. Fast Pyrolysis (Isothermal)

Fast pyrolysis comprises the rapid heating (heating rate is 100 °C/s) of the feedstock at moderate temperatures (400–600 °C) for a short residence time to get a huge amount of liquid fuel during pyrolysis in a reactor operated isothermally. It is the most conventional technique utilized for plastic waste pyrolysis in research and practical work.

5.2.3. Ultrafast/Flash Pyrolysis

Ultrafast or flash pyrolysis is a tremendously prompt thermal decomposition technique for pyrolysis accompanied by a high heating rate, and the final products are bio-oil and gases. Heating rates range from 100 to 10,000 °C/s along with short-term residence time.

5.3. Other Classifications of Pyrolysis

5.3.1. Thermal Pyrolysis Technique

Thermal pyrolysis or cracking, also called thermochemical treatment (TCT), is the process of depolymerization/cracking of the resources of the plastic through thermal treatment in the range 350–900 °C in the presence of a low oxygen concentration or the absence of oxygen. Because of cleavage of chains and bonds as well as breakage of intramolecular and intermolecular forces, mostly the required elevated temperature is up to 900 °C. The products are obtained in all three states of matter: solid (char), liquid fuel, and gases. The liquid fuel is generally extracted from the condensable segment of the volatile product and is usually a blend of olefins, paraffin, isoparaffins, and aromatic fractions such as naphthalene, while the residual noncondensable fraction is a gas with a high calorific value.33

5.3.2. Microwave-Assisted Pyrolysis Technique

Microwave pyrolysis, termed microwave-assisted pyrolysis, is the pyrolysis technique that comprises microwave dielectric heating. During pyrolysis, the interaction of microwaves with diverse materials occurs in three different ways, (i) transmitted through perfect insulators, (ii) reflected by conductors, or (iii) absorbed and decomposed on the way inside the targeted materials based on their dielectric feature, and the heat is engendered inside dielectric materials as a result of molecules’ agitation by applying alternating electromagnetic fields. In the case of plastic materials, the mechanism of microwave pyrolysis depends on the magnitude of the microwave energy absorbed by the absorbent and the subsequent thermal heat transferred to the plastic by conduction. Moreover, the uniform distribution of heat depends on the physical properties as well as the absorbent volume ratio, and the different powers of the microwaves completely control the different product distributions.

It has been observed that as compared to catalytic and thermal pyrolysis, the main advantage of microwave-induced pyrolysis is to get desired chemicals and fuels with great ease from plastic waste.42 The literature proves the microwave pyrolysis of the majority of single plastic types such as polyethylene (PE), polystyrene (PS), polypropylene (PP), polyvinyl chloride (PVC), and poly(ethylene terephthalate) (PET) in the presence of microwave absorbent.57

Undri et al. in 2014 pyrolyzed PP and HDPE by using carbon and tire as the microwave absorbers. The HDPE complete decomposition was achieved by the interaction of plastic with the microwaves of power 6 kW, and 37 wt % was the yield of liquid product, while in the case of PP, a low-density liquid product was obtained at any reaction condition because inferior and complete degradation of material was achieved after an exposure time of 50 min. In 2012, Hussain et al. pyrolyzed the polystyrene foam waste material by interacting it with radiation of frequency 2450 MHz by using a domestic oven. The high temperature (≈ melting point of aluminum) was attained by interacting the microwaves with the closely positioned aluminum coil. The product obtained consists of liquid fuel (88 wt %), gases (9–10 wt %), along with residual char. The enactment of microwave-assisted pyrolysis of HDPE and toothpaste tubing (aluminum/polymer laminates) was studied in a semibatch apparatus by providing a mixed feedstock during the experiment. The pyrolysis temperature was in the range 500–700 °C, and the uncontaminated aluminum was obtained from the toothpaste tubing along with hydrocarbons. The same products with equal molecular weight distribution were obtained from the pyrolysis of HDPE and toothpaste tubes. The main products (81–93%) were linear hydrocarbons, alkanes, alkenes, and dialkenes; the remaining was a complex blend of cyclic, branched aliphatic, and aromatic compounds.58,59

5.3.3. Catalytic Pyrolysis Technique

Catalytic pyrolysis involves the degradation of the polymeric material through thermal treatment in the presence of a catalyst and the absence of oxygen. The primary function of a catalyst is to obtain the desired product with a specific composition by less consumption of energy and in a lower processing time. The most commonly utilized catalysts for plastic waste product pyrolysis described in the literature consist of alumina, silica, zeolites, clay, fluid catalyst converter, and mobile classification of materials (MCM-41). Higher conversion efficiency is usually attained with zeolitic catalysts as compared to nonzeolitic catalysts owing to their greater acid strength. It was recommended that moderate acidity and large pore size of the silica–alumina catalyst loaded in the upper layer favorably catalyze the conversion of polyethylene into liquid hydrocarbons. Recently, many researchers implemented clay as a catalyst for the pyrolysis of plastic. Catalytic cracking of PE over clay catalysts and its comparison with an ultrastable zeolite were examined by Manos et al., and they stated that at the temperature 600 K, the zeolite was found to be more stable than clay and to completely decompose the polyethylene. The liquid products obtained over clay catalysts were found to be heavier due to the milder acidity of clay.57,60−62

5.3.4. Factors Affecting the Pyrolysis Process and Product of Pyrolysis

The operational factors which typically affect the process to be carried out include pressure, temperature, residence time, type of reactor, nature of the feedstock, and experimental conditions. It is indispensable to ponder the limits of the experiment process and to recognize the controlling factors of the process, such as feedstock and other essential factors that can influence the process as optimized parameters and result in the maximum yields of byproducts in pyrolysis. Thus, by regulating and amending the process parameters (Figure 6), the anticipated end products can effectively be produced.63

Figure 6.

Different parameters affecting the pyrolysis product.

5.3.4.1. Influence of Plastic Types

In pyrolysis, the nature of the feedstock material and its purity influence the product distribution and can limit the process for a requisite time for conversion and to get the desired products.

LPDE and HDPE both are examples of polyethylene plastics but possess different amounts of branching as well as cross-linking, as LDPE, with a high magnitude of branching and cross-linking, restricts the polymer chains’ close packing and leads to a plastic product with low density. Pyrolysis of both these thermoplastics produces an oil/wax or gas product, and the hydrocarbon composition depends on the polymer’s original structure. For example, PE is thermally decomposed by polymeric chain random scission to produce a broad range of hydrocarbon chains that become stable and generate a series of n-alkanes (C1–C60) as well alkenes and alkadienes at lower concentrations. Polypropylene, a type of polyalkene plastic, identically produces a mixture of alkanes, alkadienes, and alkenes. At a low temperature of ∼500 °C, an oil/wax is obtained with a high concentration of an aliphatic product rather than aromatic fragments, while at high temperature, the aromatic content tends to increase rather than the aliphatic part.

Polystyrene (PS), an aromatic polymer, on thermal cracking produces an aromatic nature product with a maximum amount of styrene (∼50–79 wt %) along with a dimer and trimer of styrene accompanied by other aromatic compounds, such as xylene, toluene, and alkylated benzenes.

Polyvinyl chloride (PVC) polymer has a chainlike structure, and the expected product is aliphatic. However, dechlorination and removal of HCl from the polymer chain at ∼300 °C lead to C=C bonds which through cyclization give aromatic compounds. Desorbed HCl is absorbed by additives of the process such as FeOOH or Fe3O4.

Polyethylene terephthalate (PET) comprises aromatic, linear, and oxygenated hydrocarbon groups, which on thermal scission of the polymer during thermal degradation produce benzoic acid and terephthalic acid along with gaseous products such as CO and CO2.64,65

The substantial amounts of hydrochloric acid and benzoic acid produced during the pyrolysis of PVC and PET are corrosive and toxic to the reactors. So, both of these polymers are typically omitted from the pyrolysis process.53

5.3.4.2. Influence of Catalyst

Among the distinctive catalysts for the plastic pyrolysis process, e.g., HZSM-5, FCC, MCM-41, mordenite, zeolites, and amorphous alumina-silica, the acidic zeolites are the most studied catalysts. Zeolite catalysts prove to be efficient catalysts for cracking, aromatization, and isomerization due to their definite physicochemical properties, such as microporous crystalline structure and strong acidity. The catalyzed pyrolysis of plastic products, particularly in the presence of HZSM5, produces more aromatic hydrocarbons than the uncatalyzed pyrolysis process. Furthermore, enhanced cracking of polymers in the presence of a zeolite catalyst typically produces gases while amorphous silica–alumina pyrolysis catalysts are responsible for the production of light olefins, without altering the formation of aromatic compounds. ZSM-5 promotes the development of both branched and aromatics hydrocarbons, along with a substantial amount of gaseous hydrocarbons. Catalytic reforming of plastic over Al-MCM-41 actively plays its role in gasoline production due to the feebler acid properties along with the larger pore size of the catalyst. In the presence of both Y-zeolite and, ZSM-5 catalyst decreased the oil yield dramatically decreases in favor of gas production. As compared to the ZSM-5 catalysts, Y-zeolite favors the production of more and more aromatic compounds due to distinctive physical and chemical catalytic properties, such as surface area, pore size, and surface acidity.66−69

5.3.4.3. Influence of Temperature

Temperature is the major controlling factor of the pyrolysis process irrespective of the nature of the feedstock. The extent of bond scission and, hence, the proportion of oil and gas produced depends mainly on the pyrolysis temperature, where higher temperatures lead to higher levels of bond scission and, hence, more C1–C4 gases. In the process of plastic waste pyrolysis, high temperature results in a greater concentration of gaseous fragments due to enhanced cracking reactions accompanied by decreased oil/wax yield. The yield of propylene and ethylene tends to increase with the increase in temperature. Temperature not only affects the yields but also affects the quality of the product, by altering the kinetic mechanism of the pyrolysis process. The general observation is that high temperature leads to the formation of more oily compounds due to the transformation of large size paraffin/olefins into shorter molecules along with less yield of solid residue.70

The importance of catalysts for product distribution and liquid yield becomes less substantial when the temperature is increased, as the reaction becomes identical to the thermal degradation process. Principally, the catalytic pyrolysis proceeds at a much lower temperature with a higher cracking rate than thermal pyrolysis under identical reaction conditions.71,72 For different plastics, it has been observed that HDPE degradation started above 325 °C followed by complete degradation at temperatures ≥467 °C. Rapid heating also accelerates the degradation process and consequently leads to faster kinetics. On the other hand, in the case of LDPE, the degradation starts at 360 °C. In 2010, Jung et al. reported that the PP degradation at a temperature underneath 400 °C is less than that of PE. However, PS degradation starts at the lowermost temperature among commonly studied plastics, as it starts to degrade around 300 °C, even lower than the preliminary decomposition of PET. So, the conclusion is that induced breakage of carbon chains is mainly controlled by the temperature condition of pyrolysis to a large extent. Furthermore, in the case of low-density polyethylene, the pyrolytic reaction in a fluidized bed at 700 °C with long-term vapor residence time mainly produces an oil/wax (28.6 wt %) with a high concentration of benzene, toluene, xylene, and polycyclic aromatic compounds. In addition, a high temperature of 740 °C and pyrolysis product recycling lead to a higher concentration of aromatic compounds.70,73

5.3.4.4. Influence of Vapor Residence Time

Another factor along with temperature which significantly affects the composition and yield of the process of pyrolysis is the vapor’s residence time in a reactor. A literature survey revealed that the different waste plastics’ flash pyrolyses in micro- and macroscale reactors designate that a short-term vapor residence time produces a high-olefin-content gas. The controlled residence time is a big challenge for reactor designers. Milne, and colleagues invented and utilized a fenestrated centrifugal riser terminator in a conventional fluid bed reactor. This terminator tends to separate solid products from gases in less than 20 min with ≈99.5% separation efficiency. Such quick isolation is critically very important when the main objective is to rapidly quench the reaction and to carry it out at high temperatures with reduced vapor residence time.74 Al-Salem et al. in 2009 thoroughly studied the impact of residence time and temperature on the degradation of PS and LDPE. It was witnessed that secondary reactions proceed at long residence time accompanied by the conversion of oil products into gas and char. In the case of LDPE, 91.1 wt % oil product along with 8.70 wt % gas was obtained at zero residence time at 450 °C while oil production was reduced to 61 wt % along with 28.5 wt % gaseous fractions when the residence time was increased to 120 min. On the other hand, in the case of PS, it was completely degraded to liquid products and a minimum amount of char and gas even at zero vapor residence time.27

5.3.4.5. Effect of a Flow Rate of Nitrogen Gas

Nitrogen, being an inert gas, does not show so much interference in the pyrolysis process carried out inside the reactor, but it augments the transfer of the volatiles’ fraction into the condenser and leads to the gases provision for condensation into liquid fuel. According to the literature, the nitrogen flow rate of 10 mL/s is mostly applied for the majority of the plastic pyrolysis process.75

5.3.4.6. Effect of Polymer to Catalyst Ratio

According to the literature, another important factor significantly affecting the composition and yield of the pyrolysis process is the polymer to catalyst ratio. The survey concludes that the conversion efficiency is not directly proportional to the catalyst amount. The conversion tendency is enhanced up to a certain limit with the increase of the catalyst amount, and after that, no appreciable change is observed with an increase of the catalyst amount. Akpanudoh et al. analyzed the relationship of polymer to catalyst with the polymer degradation process in the presence of highly stable Y-zeolite catalysts. After an initial increase in the conversion process, a decline was observed with the further upsurge in catalyst amount, and the maximum conversion efficiency was obtained with 7% of pure catalyst.76

5.3.4.7. Effect of Pressure

Mostly the pyrolysis processes are carried out at atmospheric pressure, so the impact of pressure needs to be fully understood to fulfill a major research gap of pyrolysis studies. Murata et al. (2004) studied the HDPE pyrolysis process in the pressure range 0.1–0.8 MPa in a continuous stirred tank reactor and observed that with the increase of pressure, the gas production increases from 6 to 13 wt % at 410 °C while at 440 °C the gas production was enhanced from 4 to 6 wt %. The study concludes that at low temperature, the influence of pressure is significant and it tends to diminish with an increase of temperature. It was also described that the gaseous product’s average molecular weight decreases with the upsurge of operating pressure. Moreover, it was further observed that the kinetics of double bond formation reduces at high pressure because of the relationship of C–C bond breaking with the double bond establishment. Thermal degradation of plastic is due to two types of C–C bond scission occurring simultaneously: (a) random chain scission, where facile product formation occurs due to reduction in the molecular weight of the polymer (the rate of this pressure-independent process is proportional to the number of C–C links) and (b) chain-end scission, where reactor content dissipation gives volatile products (pressure-dependent chain-end scission takes place at a liquid/gas interface and produces volatile products).77

5.3.4.8. Type of Reactor

Until now, multiple reactors have been designed for the conversion of a variety of plastic wastes into three types of products, solids, liquids, and gases, as the yields of particular products depend on the reactor design as well as the operating parameters. Several methods are proposed for the categorization of the process and apparatus designs. Currently conical spouted bed, batch, semibatch, fixed bed, rotary kiln, and fluidized bed reactors are available reactors for the pyrolytic reaction.78

6. Conversion of Waste Plastic to Carbon-Based Compounds

Waste plastic can be converted into a variety of products, among which the most valued product is carbon. For carbon-containing value-added products, a rich source of carbon is waste plastic because of its high carbon content.79,80 The transformation of solid waste plastic into carbon-based materials was first reported in 2004, by Parra colleagues. During this study, a series of activated carbons were obtained by PET pyrolysis under an inert atmosphere and then were successively activated with CO2 to prepare materials with high-H2-adsorption tendencies. Since 2004, numerous reported data reveal the production of many other carbon-based materials from plastics, such as carbon microspheres, carbon nanotubes (CNTs), carbon nanofibers (CNFs), 2D graphene-based materials, fullerene graphite, and composite materials.81

The reason for the growing interest in carbon materials is their exclusive properties, such as high surface area, electronic conductivity, porosity, rich and flexible surface chemistry, and stable structure at high temperatures. Consequently, carbon-based materials are increasingly employed in different fields, such as catalysis, biomedical, environmental, energy, analytical, and electronic applications. Moreover, the latest invention of consumer products revealed that at present carbon-based materials are the second most commonly used class of nanomaterials, being exceeded only by metal nanoparticles.82−86

6.1. Synthesis Schemes to Obtain Carbon-Based Materials from Waste Plastic

This category of carbon-based materials consists of activated carbon (AC), graphite, graphene, fullerene, and carbon nanotubes (CNTs). Among them, carbon nanotubes (CNTs) are the material of interest for researchers due to their distinctive characteristics and their potential use in a wide range of applications. CNTs are physically as well as chemically stable materials with extraordinary electrical conductivity along with tensile strength greater than 100 times that of stainless steel. Carbon nanotubes are extensively utilized in composite materials as conductive fillers or to enhance the composite strength, as conductive coatings and paints, in transistors for semiconductors and microelectronics, in energy storage, in biosensors for environmental applications, and in medical devices.87−90

6.1.1. Catalytic Pyrolysis

The main techniques employed for CNTs’ synthesis include arc discharge, laser ablation, and the CVD method (Table 5). However, to fabricate CNTs from solid waste plastic, different approaches are utilized. For example, polyethylene is used as a carbon source to synthesize carbon nanotubes through a two-step pyrolysis process in the presence of nickel plate catalysts retained inside a quartz tube reactor maintained at moderate temperature. Defect-rich CNTs of 10–20 nm in diameter accompanied by carbon nanofibers were obtained through this process. The advantages of this technique are the low temperature and energy requirements with the controlled composition of the product, while the high cost of the catalyst and low yield of the product are the main disadvantages of this approach.91

Table 5. Comparison of Carbon-Based Materials’ Synthesis Approachesa.

| Synthetic approach | Advantages | Disadvantages |

|---|---|---|

| Catalytic pyrolysis | (i) Low temperature and energy requirement | (i) High cost of catalyst |

| (ii) Controlled composition of the product | (ii) Low yield of the product | |

| CVD | (i) High growth rate | (i) Complicated process |

| (ii) Good yield of product | (ii) high-temperature requirement | |

| (iii) Better option for the development of the epitaxial thin film | ||

| Pyrolysis deposition CVD | (i) Simple and facile | (i) Structure destruction during the template etching technique |

| (ii) Reuse of plastic with a lower amount of solvent | ||

| (iii) Ordered porous structure | ||

| Thermal decomposition | (i) Material with controlled pore size, high surface area, and conductivity | (i) High temperature results in large pore volume, low energy density, and conductivity |

| Activation method | (i) One-pot process with low-temperature requirement | (i) Low product purity |

| (ii) Ordered structure with good porosity and high surface area | (ii) Large volume of water required for washing purpose | |

| Template-based method | (i) Highly ordered structure | (i) Structure collapse or disorder |

| (ii) Pore blockage during etching | ||

| Hydrothermal carbonization | (i) Simple approach to get valuable materials with oxygen functionalities | (i) High cost and undeveloped porosity |

| One-pot synthesis | (i) Simple, affordable, and reproducible nature of the process | (i) Polymer amount and the nature of the reactor |

| Thermochemical conversion | (i) Fast conversion rate | (i) High temperature |

| (ii) High surface area | (ii) Uncontrolled morphology | |

| (iii) Environmentally benign product by complete conversion of organic parts into carbon-based materials | ||

| Stepwise cross-linking | (i) Favorable technique for the fabrication of a thermally stable cross-linked structure | (i) Partial deterioration of structure upon heating |

| (ii) Moderate porosity |

Here is a comparison of different techniques utilized for the synthesis of carbonaceous materials such as activated carbon, graphene, and carbon nanotubes.

6.1.2. Batch Pyrolysis–Catalysis

A joint, fixed bed, batch pyrolysis–catalysis reactor system is another option to get CNTs by catalytic pyrolysis of waste polypropylene (PP) in the presence of nickel catalyst at a temperature above 600 °C. Multiwalled carbon nanotubes (MWCNTs) of diameters 10–25 nm along with lengths around 100 μm are easy to prepare by this approach.92

6.1.3. CVD Method

CNTs can also be synthesized by the combination of the pyrolysis process with the chemical vapor deposition method. The overall process of plastic waste conversion into CNTs consists of two consecutive stages. The first stage consists of the conversion of waste plastic into volatile vapors in a nonoxygenated environment at a moderate temperature. In the second stage, these vapors at high pressure (1 MPa) and temperature in the presence of Ni-based catalyst are converted into CNTs through the chemical vapor deposition technique. The positive points of CVD are the high growth rate, good yield of product, and better option for the development of the epitaxial thin film. However, a complicated process with a high-temperature requirement is the negative point of this technique.93

Furthermore, single layer graphene was prepared via mixed plastic waste packaging material enclosing PS and PE. The hydrocarbon-rich gas produced in the furnace at 500 °C is directed toward a CVD system working under atmospheric pressure on a copper foil at 1020 °C in an Ar/H2 atmosphere. The PMMA film-coated monolayer graphene conveyed to a SiO2/Si substrate develops hexagonal-shaped crystals.94

6.1.4. Pyrolysis–Deposition Followed by CVD

Another way to obtain mesoporous carbon is to combine the pyrolysis–deposition approach with the CVD technique. In situ pyrolysis of polystyrene provides waste polystyrene as a rich carbon source in the presence of Fe(NO3)3 catalyst and a hard template of SBA-15. A mixture of Fe-modified SBA-15 and PS was then pyrolyzed in a tube furnace. The small organic gases generated during pyrolysis were absorbed and deposited into Fe-SBA-15 mesochannels by capillary action and then changed to carbon–silica composites. Later on, the etching of Fe and silica produced ordered mesoporic carbons (OMCs) with morphology identical to SBA-15. This method is highly recommended, as it is simple, is facile, uses less solvent, and reuses plastic waste to obtain an ordered structure with high porosity. However, the destruction of a structure during template etching restrains this technique.95

6.1.5. Thermal Decomposition

A facile, reproducible, and economical thermal decomposition approach was used to prepare graphene from PET obtained from waste bottles. In this process, raw PET was torn and screened to get the appropriate size particles in the range 1–3 mm with the help of a traditional sieve shaker. After that, waste PET was transferred to a stainless steel autoclave and then pyrolyzed in a tube furnace at 800 °C for 1 h. The product was then cooled down overnight to obtain graphene. This technique is recommended when the requirement is to obtain material with controlled pore size, high surface area, and high conductivity. However, at high temperature, large pore volume leads to low energy density and conductivity, which restrict its application at high-temperature conditions.96

6.1.6. Activation Methods

Activation is deliberated as a method for turning industrial raw materials into active materials. The process of pyrolysis is commonly utilized to turn industrial waste into carbon-based materials at high temperatures in the absence/less amount of oxygen. The activation method is also employed for the synthesis of carbonaceous materials, and it consists of pyrolysis followed by activation of material. Furthermore, a one-pot process with a low-temperature requirement and an ordered structure with good porosity and high surface area are the salient features of this process, but the drawback of this process is that product purity is low and a large volume of water is required for washing purposes.97

6.1.6.1. Physical Activation Method

Physical activation usually takes place right away from the step of pyrolysis carried out at elevated temperatures of about 1200 °C in the presence of air/steam/carbon dioxide or a mixture of them. The air, CO2, and steam act as activating agents during the above-mentioned process, and the most commonly available activating agent utilized for the conversion process is the steam due to its low cost and no further treatment being required for the elimination of useless products. During the activation process, the steam is generally amalgamated with pyrolysis in one pot, and the oxygen-functionalities-rich surface produced during the reaction enhances the wettability and specific capacitance of the manufactured carbonaceous materials.

The process of physical activation consists of two steps: (a) the first step is the heating of the carbon source in an inert environment by heating between 400 and 900 °C to eliminate bulky volatile materials; (b) the second step is the partial gasification step employing an oxidizing agent in the temperature range 350–1000 °C. The active oxygen groups in the oxidizing agents burn away the side products of the pyrolysis process entrenched in the pores and consequently lead to the opening of clogged pores. Moreover, the microporous structure is obtained when the more reactive areas of the carbon framework are burned away and produce CO and CO2. The magnitude of annealing depends on the activation temperature and used gas.98−100

6.1.6.2. Chemical Activation Method

In the one-pot chemical activation process, an activating agent, such as a strong base (KOH, NaOH), an acid (H3PO4, H2SO4), or a salt (K2CO3, ZnCl2, FeCl3), is implanted into the pores of carbon precursor before pyrolysis and then heated in the temperature range 450–900 °C. It is a laboratory-level process and provides good control of the pore size distribution. On the contrary, the chemical activation processes’ downsides are that plenty of water is needed to flush away the impurities produced during the activation step and polluted water management. The most commonly utilized alkali for the industrial waste materials’ activation is KOH due to its short activation time, low-temperature requirement, high yield, and distinct micropore size distribution, as well as the huge specific surface area of the resultant porous carbon structure with excellent charge storage capacity. The most important controlling factors for the KOH activation process include (i) the mass ratio of carbon precursor/KOH, (ii) the rate of heating (3–10 °C/min), (iii) the activation temperature, and (iv) the activation time (1–4 h). Time is the main factor, as excessive activation leads to large pore volume, which is responsible for decreased conductivity, low energy density, and loss of power capability of the activated carbon. So a magnificently tailored microporous structure and good surface chemistry of prepared porous carbons via the KOH activation process are decisive to fabricate high-performance supercapacitors. Extensive efforts have been made by researchers for the synthesis of tailored microstructured carbon materials for energy storage applications. For example, the conclusions of deep analysis of the study of KOH activation of carbonaceous materials are that (i) the high temperature and greater carbon/KOH ratio lead to activated carbon with large micropores, (ii) the micropore integration and presence of small mesopores in the carbon nanostructured framework intensify the porosity and interconnected porous networks with original textural properties, and (iii) the pore size, carbon structure, and surface functionalities are among the crucial factors which control the performance of a supercapacitor, as normalized capacitance drops with the rise of micropore size. Furthermore, heteroatom incorporation through oxygen-/nitrogen-rich precursors can proliferate the specific capacitance via the pseudocapacitance effect.101−103

Activated carbon can be produced from different types of plastics, and its properties depend on the precursors and synthetic scheme. A good precursor is that which contains high carbon content and low concentration of inorganic matter content, as in the case of PET, which is available in the pure state. The AC is produced from PET by the eminent process of physical and chemical activation. The process consists of two steps: (i) carbonization in the N2 environment and (ii) activation by air, CO2, or steam and then impregnation with H3PO4, ZnCl2, or KOH.104,105

6.1.7. Template-Based Method

Different templates, such as soft templates, hard templates, or the combination of both templates, are utilized for the preparation of an activated carbon-based material. Moreover, zeolites, porous sacrificial structure controlling agents, are also functional materials for the conversion of industrial waste into carbonaceous materials for supercapacitor applications. Desired and highly ordered structures can be obtained by this technique. However, the limitation of this process is the structure collapse or disorder and pore blockage during etching of a template or in the case of a soft template.

6.1.7.1. Hard Template-Based Method

The hard template method, as the name indicates, uses hard particles such as polymer colloids and SiO2 as a sacrificial stencil to develop a macroporous structure. Usually, the voids of colloidal particles in the templates are filled by fluid-like carbon raw materials that pierce into the templates and then turn to a solid. Afterward, in pyrolysis treatment, the solid fillers are converted into a solid carbon framework under an inert environment, and then the sacrificial templates surrounding the air holes left in the initial positions of the solid particles are excluded by the pyrolysis treatment or by chemical etching. A subsequent KOH activation process produces a hierarchically porous carbon structure, and a combination of the heteroatom-rich compound with a precursor develops a heteroatom-doped ordered porous carbon structure.106

6.1.7.2. Soft Template-Based Method

The soft template method is an attractive approach due to its appealing benefits, such as the ability to produce carbon-based materials of different morphologies under less harsh experimental settings. Moreover, the heteroatom-rich compound can also be utilized for the synthesis of the doped ordered porous carbonaceous material for application as a supercapacitor electrode. To prepare the hierarchical porous carbon-based materials accompanied by mesopores and macropores to get good electrochemical performances in supercapacitors, a better option is to mix both the soft and hard template methods. Generally, the triblock copolymer micelles and hard particles are used as mesoporous and macroporous templates, and during the preparation, the cavities of the hard templates are occupied by the soft templates. The macropore-based ordered porous carbon supercapacitor electrode shows excellent performance due to facilitated ion transport and electrolyte access and enhances the loading and dispersal of electroactive materials.

6.1.7.3. Template-Free Method

Till now, extensive work has been done by researchers to get porous activated carbon by coupling carbon precursors with innumerable templates for applications in supercapacitors. However, it is also possible to prepare porous hierarchical activated carbon materials without introducing any templates. The main advantages of template-free methods are their ease, short times, and affordable prices as compared to template-based methods.107

6.1.8. Hydrothermal Carbonization Method

The hydrothermal carbonization approach produces hydro char, a moderately carbonized product, which possesses a high degree of oxygen functionalities and a low degree of condensation. The hydro char accompanied by porosity and tunable surface functionalities is a tempting source of carbon yield. The hydrothermally synthesized hydro char possesses low porosity as well as insufficient specific surface area. Consequently, to improve the physical and chemical properties of as-synthesized materials, activation/carbonization is required. Moreover, the porous carbon materials with highly ordered structures obtained from hydro char possess a large number of heteroatoms. The different carbon-based electrode materials with surface functionalities may foster the capacitive behavior in both aqueous and organic electrolytes while the electrochemically active functional groups augment the carbon electrode wettability and enhance the specific capacitance by fully utilizing accessible ions and surface groups. It is a highly efficient simple approach to obtain valuable materials with oxygen functionalities. However, high costs and undeveloped porosity limit the application of this technique.107−110

6.1.9. One-Pot Synthesis

Among the different processes utilized for the conversion of waste plastics to CNTs, one-pot synthesis of carbon nanotubes starts from solid polymers mixed with catalysts followed by heat treatment to catalytically decompose the plastics through pyrolysis. The liquid or gaseous product obtained by decomposition serves as a carbon source for the development of CNTs on the surface of the catalyst. Polymers such as polypropylene (PP), polyethylene (PE), polystyrene (PS), polyvinyl chloride (PVC), poly(vinyl alcohol) (PVA), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), polycarbosilane (PCS), and phenol-formaldehyde (PF) are extensively studied through this method, and various catalysts are utilized, such as transition metals either in elemental form (iron, nickel, etc.) or in the form of chemical compounds (nickel oxides, ferrous chloride, ferrocene, cobalt acetate, etc.). The main source of heat is either electric furnaces (autoclaves, fixed beds, fluidized beds) or fuel combustion. The simple, affordable, and reproducible nature of the process is its salient feature, but different factors, such as the amount of polymer and the nature of the reactor, also matter.92,111−114

6.1.10. Thermochemical Conversion

The thermochemical transformation of polymer solid wastes into activated carbon with good adsorption tendency as well as energy is an auspicious way of conversion. Polymeric wastes are very significant raw materials to produce economically activated carbon materials. Polymeric waste in the form of polyolefin wax (POW) with average molecular mass 1100 and melting point around 115 °C when heated in the air at 360 °C decomposes to low-molecular-weight products, which slowly evaporate. During the synthesis of activated carbon, 200 g of POW is heated up to 115 °C (melting point) and then 98% H2SO4 is added dropwise with continuous stirring followed by heating up to 160 °C. The obtained solid product after washing and drying at 150 °C is carbonized at 600 °C. The carbonized product of POW was then subjected to the process of water steam activation for 60 min at 800 °C. The obtained solid product with a high surface area due to porosity is termed POW-AC. Faster conversion rate, high surface area, environmentally benign nature, and complete conversion of organic parts into carbon-based materials are the pros of this process, while high temperature and uncontrolled morphology are the cons of this technique.115

6.1.11. Stepwise Cross-linking

A novel strategy of stepwise cross-linking is used to prepare porous nitrogen-doped porous carbon (NPC) through the controlled pyrolysis of polyethylene terephthalate by using a mixture of melamine with the molten salt NaCl/ZnCl2. During the conversion process, a robust cross carbon framework is attained by elimination of weak bonds of the cross-linked structure via NaCl/ZnCl2. The resultant material possesses a large surface area of 1173 m2/g along with rich nitrogen content, without any activation process, and shows a good tendency toward CO2 adsorption and generation of solar-driven steam. This green technique is highly favorable for the fabrication of a thermally stable cross-linked structure. However, partial deterioration of structure upon heating and consequent moderate porosity restricts its application.116

7. Different Applications of Carbon-Based Materials

Figure 7 not only represents the current trends and research track in effective utilization of a wide variety of carbon-based nanomaterials (CNMs) but also specifies the important role of solid waste management in futuristic progress and innovations. The high carbon content of solid waste materials is an attraction seeking factor that encourages the scientific community to transform these waste materials into diverse CNMs such as activated carbon, graphene, CQDs, and CNTs. Furthermore, in the past few years, scientists have paid attention to doping (metal oxides, conducting polymers, organic reagents) and functionalization of these materials to make them more effective. The solid reasons for extensive utilization of CNMs in different areas of science and technology are their excellent properties and surface modifications to get the specific properties, which make them effective in different fields, such as supercapacitor electrode materials, batteries, solar cells, catalyst supports for proton-exchange membrane fuel cells (PEMFC), drug delivery, bioimaging, aerospace, medicinal biology, and the latest weapon technology.117−137

Figure 7.

Multiple applications of solid waste-derived carbon-based materials. Reproduced with permission from ref (137). Copyright the authors 2021 open access.

7.1. Applications of Carbon-Based Materials in Energy Storage Devices

The most promising way of obtaining carbon precursors is plastic wastes, due to their high carbon content, abundance, and low cost. The percentages of carbon content in the different available plastics are as follows: polypropylene (86%), polyethylene (86%), polyvinyl chloride (PVC) and polystyrene (92%), low-density polyethylene (LDPE), and polyacrylonitrile (PANI) (68%) as well as polyethylene terephthalate (≈63%). Among these sources, the cheapest source of high carbon content is polyethylene in plastic bags. Carbon-based materials synthesized from waste plastic by different techniques are efficiently utilized for sensors, biomedical applications, energy conversion processes, and energy storage devices such as supercapacitors and batteries.

It is a well-known fact that carbon-based nanomaterials are the most commonly used electrode materials in electrochemical capacitors, due to their high surface area, diversity of structures, good electrical conductivity, and highly porous textures. Other salient features of nickel cobalt manganese (NCMs) are high thermal and chemical stability, controlled surface chemistry and morphology, and wide operating voltage window. Moreover, on the commercial level, their nontoxic economical nature and easy availability make them a potential candidate for the electrode material in supercapacitors.138

The utilization of waste plastic in Li-ion batteries results in drastically reduced priced Li-ion batteries and enlarges their utilization in a wide variety of buses and electric cars. The reduced battery price makes it feasible to effectively utilize them in large-scale wind and solar power plants. Plastic products such as polyethylene plastic (shopping bags), with a useful life of a few minutes and a non-biodegradable nature, can be effectively employed as the anode material in Li-ion batteries by the pyrolysis of sulfonated plastic. During carbonization, high-temperature treatment results in cross-linked sulfonated PE at a temperature around 500 °C, and then the plastic is decomposed to carbon chips. The finely ground carbon chips are effectively utilized as the anode material in the lithium-ion battery as it is composed of 80% carbon derived from polyethylene.139

7.1.1. Supercapacitors, Their Types, and Different Parameters to Express the Efficiency of the Supercapacitor

Among the innumerable unconventional electric-power-derived devices, such as batteries, supercapacitors (SCs), and fuel cells, which are being utilized in various fields, e.g., hybrid cars, portable electronic devices, and electric mass transit-based vehicles, etc., SCs have caught the attention of researchers due to their exceptional electrochemical performances in terms of high specific power, excellent cyclic stability, and a prompt charge–discharge process.140,141 SCs are a kind of capacitor that are also recognized as ultracapacitors, electrical double layer capacitors (EDLCs), electrochemical capacitors (ECs), or pseudocapacitors. The main components of a SC configuration include the current collector, electrolyte, and electrodes with a huge specific surface area (SSA), responsible for the 1000 times greater capacitance than conventional capacitors.142−145 The energy storage process based on the charge–discharge mechanism is identical in both capacitors and supercapacitors. However, the capacity of charge storage in supercapacitors is in the range 100–1000 F in a device possessing low equivalent series resistance accompanied by good energy and power density. SCs also show more safety, device stability, a low level of heating, and a flexible and lightweight nature The specific energy (energy density) determines how long the energy storage device can be utilized, and the specific power (power density) signifies how rapidly a device can deliver the energy.146−148

Based on the charge storage principle, supercapacitors are divided into three main types, such as (i) EDLCs, that store the charge produced in a non-Faradaic reaction through a double layer, (ii) pseudocapacitors (PCs), that store the charge produced through a Faradaic reaction (redox reaction) at various potentials, and (iii) asymmetric supercapacitors (ASSCs), where the charge storage mechanism depends on both Faradaic as well as non-Faradaic reactions.149,150 The different parameters used to assess the practical applications of supercapacitor include energy density, power density, voltage window, time, impedance, and cell capacitance. The energy density represents the tendency of a material to store energy for a long time, and the power density represents the joint effect of the energy density and device efficacy to deliver the energy from the device, while capacitance is the material’s tendency to collect energy and then store it as an electrical charge on the surface of the conductor at a different potential. The controlling factors for both energy and power density are the electrolyte stability along with the utilization of electroactive material. The major limitation observed in the commercial application of supercapacitors is their inferior energy density value, which can be improved by using (a) the electrode possessing high specific capacitance, (b) electrolytes working in a wide potential range, and (c) an integrated systems optimized structure. Charge–discharge cycle, electrochemical impedance, and cyclic voltammetry are the three different means of electrochemical testing. The different factors affecting the capacitive behavior of supercapacitors comprise the following: (a) the surface area of the electrode directly affects the capacitance of the material; (b) pore structure features, such as the pore size, pore shape, and pore distribution, strongly influence the capacitance of the electrode material by varying the ion and the charge transport process; (c) the electrode conductive nature and the insertion of conducting material with binding properties into the electroactive material effectively elevate its electrochemical response by preventing its volume expansion; (d) an impure electrode or electrolyte results in current leakage followed by self-discharge of the supercapacitor; (e) contrary to organic and aqueous electrolytes, ionic liquids show reluctance toward the redox process; (f) aqueous electrolytes are comparatively more stable than organic and ionic liquids; (g) the capacitor resistance mainly relies on the resistivity of the electrolyte as well as ions of different sizes diffusing toward and out of the electrode; (h) structural defects, such as vacancies, defected surfaces, and basal edges of the electrodes, serve as electroactive sites for ions’ adsorption and consequent enhanced capacitance; (i) as the energy is stored on the electrode surface, a porous nature of the electrode gives outstanding performance; (j) well-defined and preferably crystalline facets intensely enhance the storage tendency of materials.151−157

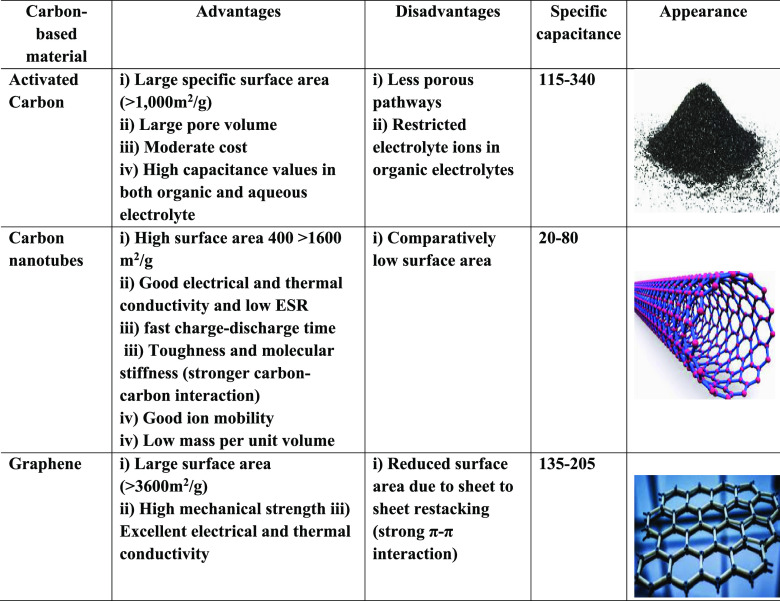

7.2. Carbon-Based Materials Utilized in Supercapacitors and Different Ways to Improve Their Efficiencies

Various materials, such as carbon-based materials, metal oxides, and conducting polymers, are utilized in different types of supercapacitors. However, among these options, carbon-based materials are the best option for energy storage devices such as supercapacitors, as mentioned in Table 6.158

Table 6. Comparison of the Physicochemical Properties of Materials Used in Supercapacitors (Open Access).

| Physiochemical properties | Carbon-based materials | Metal oxides | Conducting polymers |

|---|---|---|---|

| Non-Faradaic capacitance | Very high | medium | Medium |

| Faradaic capacitance | Low | Very high | Very high |

| Conductivity | Very high | Low | Very high |

| Energy density | Low | High | Medium |

| Power density | High | Low | Medium |

| Cost | Low | High | Low |

| Chemical stability | Very high | Low | High |

| Cycle life | Very high | Medium | Medium |

| Easy fabrication process | Medium | Very low | High |