Abstract

Under the condition of heavy oil thermal recovery, the cement sheath is easy to crack in the high temperature environment, resulting in the decrease of cement paste strength, which may further cause sealing failure and oil and gas production safety accidents. In this paper, the influence of graphite on the mechanical properties of cement paste under the simulated thermal recovery of heavy oil was studied, and its mechanism is explored by testing and analyzing the microstructure. The phase composition and microstructure of graphite–cement composites were determined by X-ray diffraction analysis (XRD) and scanning electron microscope (SEM), and the thermogravimetric analyzer (TG/DTG) was used to analyze the heat resistance of the graphite–cement composites. The results show that the addition of graphite significantly improved the strength and deformation resistance of the Class G oil well cement at high temperature (300, 400, and 500 °C) and low temperature (50 °C), and the optimal addition amount is 0.07%. The microscopic analysis shows that the incorporation of graphite promoted the formation of hydration products, and played a role in filling pores and reducing microcracks in cement pastes. At the same time, due to the better thermal conductivity of graphite, it can balance the internal thermal stress of the cement pastes and inhibit the strength decline of cement pastes under high temperature environments. The integrity of cement pastes was guaranteed through the mechanism of “crack deflection” and “crack bridging”. The research results of this paper have presented a certain theoretical basis and new ideas for the development of cementing slurry systems in heavy oil thermal recovery wells.

1. Introduction

With the vigorous exploitation of global oil resources, heavy oil thermal recovery has become a research hotspot in recent years. However, heavy oil has a high viscosity and a high density. In the mining process, the resistance is large, and the conventional mining method does not easily meet the required mining output. At present, the main ideas for increasing the production of heavy oil are to reduce the viscosity of the heavy oil, increase the permeability of the reservoir, and increase the production pressure difference, and one of the most commonly used techniques is to increase the oil recovery.1 The main technologies are thermal recovery technologies such as steam injection thermal recovery and oil formation burning.2 The production process of steam injection thermal recovery is shown in Figure 1. During the production process, the temperature of the cement ring will reach 500 °C or even higher.3 When the cement sheath matrix is subjected to high temperature, because the instantaneous high temperature environment and its heterogeneous porous material, the internal thermal stress will be generated, then it causes significant changes in the microstructure and chemical composition of cement pastes, resulting in the reduction of cement sheath strength and sealing failure. Therefore, improving the deformation resistance of the cement sheath at high temperature and maintaining the mechanical properties and integrity of the cement sheath have become more and more important technical issues in the context of heavy oil thermal recovery.

Figure 1.

Mechanism of steam injection heavy oil thermal recovery.

At present, there are mainly two ways to improve the mechanical properties and integrity of cement pastes at high temperature: One is to optimize the chemical composition of cement and increase the relative content of high-temperature resistant hydration products in cement hydration products. For example, silica,4 crystalline silicon,5 metakaolin,6 rice husk ash,7,8 slag and fly ash9,10 are added into the cement slurry to reduce the calcium silicon ratio in the cement slurry formula to prevent the strength degradation of the cement sheath. However, the incorporation of a single material has little effect and the cost is relatively high. Another is to introduce materials with high strength or high thermal conductivity at high temperature to optimize the internal microstructure of cement paste. For example, whiskers,11 fibers,12,13 latex,14 and rubber particles15 are introduced into the cement slurry to study the mechanical properties and integrity of cement pastes at high temperature. However, these studies were mainly carried out below 300 °C, and the latex and rubber particles showed poor properties at higher temperatures, Also there is a problem that the compatibility with cement paste is not very good. In addition, for the application of fibers and whiskers in cement slurry, there is still a problem of poor dispersion, which will have an adverse impact on the strength of cement paste. Graphene,16 nanographite,17,18 graphene nanosheet,19,20 graphene nanotube,21−23 carbon nanofiber,24,25 graphene oxide,26 and so on have achieved good results in maintaining the integrity and strength of a cement stone structure at high temperature due to their good thermal conductivity. However, because of their high price, it is difficult to realize large-scale application in the cementing industry. Therefore, the appropriate materials are needed to ensure the integrity and mechanical properties of cement stone at high temperature, These materials need to have a relatively low price, and at the same time have good compatibility with the cement pastes, to ensure that the cement sheath meets the structural and performance requirements of the heavy oil thermal recovery conditions, and to ensure the long-term safe production of oil and gas.

Graphite is a common material with a wide range of sources and has the characteristics of high purity and low impurities. In addition, graphite has very good physical and chemical properties. For physical properties, graphite has high thermal conductivity and low thermal expansion coefficient, so that even suffering a large temperature difference, its volume change rate can be ignored. Also with the increase of temperature, the strength of graphite will increase. At the same time, the graphite also has good lubricity and thermal shock resistance,27 In terms of chemical properties, graphite is resistant to corrosion by acids, alkalis, and organic solvents. Therefore, graphite is introduced into cementing slurries to improve their mechanical properties.

The feasibility of application of graphite-cement composite material in heavy oil thermal recovery was explored. During the cementing operation, the cement slurry is pumped in place, and it is allowed to solidify at a relatively low temperature (50 °C) before being subjected to thermal load.28,29 To truly simulate the change of cement sheath under heavy oil thermal recovery conditions, in this paper, the mechanical properties of cement pastes at low temperature (50 °C) and high temperature (300–500 °C) are studied. Scanning electron microscope (SEM), X-ray diffraction analysis (XRD), and thermogravimetric analyzer (TG/DTG) were used to study the hydration products of cement pastes. Through the comprehensive analysis of the test results of the mechanical properties by SEM, XRD, and TG/DTG, the influence law of graphite on the mechanical properties of cement paste under the condition of heavy oil thermal recovery was explored, and its action mechanism was explored by testing and analyzing the microstructure.

2. Experimental Methods

2.1. Materials

The Class G high sulfate-resistant cement used in the experiment was provided by Sichuan Jiahua Special Cement Co., Ltd., and its main chemical composition is shown in Table 1. Quartz sand is provided by Chengdu Bihaikang Environmental Protection Technology Co., Ltd. Its chemical composition is shown in Table 2. The particle sizes of Class G oil well cement and quartz sand are shown in Figure 2. The median particle size of the Class G oil well cement D50 is 10.22 μm, and that of quartz sand D50 is 193.88 μm. The graphite is provided by Qingdao Meiterui Graphite Co., Ltd. its macroscopic morphology is shown in Figure 3. Its micromorphology and EDS scanning are shown in Figure 4, Figure 5, and Table 3. Its particles are uneven in size and show irregular lamellar structure. In addition, the EDS results show that the graphite has high purity and no other impurities.

Table 1. Chemical Composition of Class G Oil Well Cement.

| CaO | SiO2 | Fe2O3 | Al2O3 | SO3 | MgO | K2O | TiO2 | others | |

|---|---|---|---|---|---|---|---|---|---|

| % | 62.07 | 20.49 | 4.07 | 3.61 | 3.47 | 1.86 | 0.68 | 0.26 | 3.24 |

Table 2. Chemical Composition of Quartz Sand.

| SiO2 | Fe2O3 | Al2O3 | MgO | K2O | TiO2 | others | |

|---|---|---|---|---|---|---|---|

| % | 99.35 | 0.02 | 0.18 | 0.01 | 0.21 | 0.19 | 0.04 |

Figure 2.

Particle size distribution of Class G oil well cement and quartz sand.

Figure 3.

Macroscopic morphology of graphite.

Figure 4.

Micromorphology of graphite.

Figure 5.

EDS scan result of graphite.

Table 3. EDS Scan Result of Graphite.

| element | wt/% | atomic/% |

|---|---|---|

| C | 100 | 100 |

| total | 100 | 100 |

The additive used is the fluid loss agent (G33S) produced by Henan Weihui Chemical Co., Ltd., which is an AMPS-amide-carboxylic acid polymer fluid loss agent and an acetone–formaldehyde condensate type dispersant (SXY-2), G33S can adjust the viscosity of the slurry, and SXY-2 can improve the pumpability and mixing of the cement slurry to meet the requirements of cementing construction.

2.2. Experimental Methods

The effect of different graphite additions on the mechanical properties and the microstructure of Class G oil well cement with sand at high and low temperature was studied. According to API RP 10B recommended “Oil Well Cement Materials and Experiment Specifications”,30 the cement slurry was prepared according to Table 4. The prepared slurry was poured into the corresponding mold and maintained in a 50 °C constant temperature water bath. Low temperature mechanical properties were tested after curing 1d, 3d, 7d, and 14d. For the high temperature performance test, the experimental process is shown in Figure 6. The cement pastes that have been cured for 7d in a 50 °C constant temperature water bath should be taken out first. The solvent replacement method was used in which the pastes were soaked in alcohol for 3d31−33 to remove the capillary water and prevent the cement pastes from bursting suddenly due to the evaporation of free water in a high-temperature environment. Subsequently, the dried cement pastes were placed in a high-temperature curing kettle at 300 °C, 400 °C, and 500 °C. The heating rate was controlled to 10 °C/min, and then set at a constant temperature for 7d after reaching the predetermined temperature. Before testing the mechanical properties, the samples were cooled in the furnace for more than 24 h to reach the ambient temperature.

Table 4. Formula of Cement Slurry.

| group | water cement ratio | graphite (%) | cement (%) | fluid loss agent (%) | dispersant (%) | defoamer (%) |

|---|---|---|---|---|---|---|

| C0 | 0.44 | 0 | 100 | 1 | 0.5 | 0.02 |

| C001 | 0.44 | 0.01 | 100 | 1 | 0.5 | 0.02 |

| C003 | 0.44 | 0.03 | 100 | 1 | 0.5 | 0.02 |

| C005 | 0.44 | 0.05 | 100 | 1 | 0.5 | 0.02 |

| C007 | 0.44 | 0.07 | 100 | 1 | 0.5 | 0.02 |

| C009 | 0.44 | 0.09 | 100 | 1 | 0.5 | 0.02 |

Figure 6.

Flowchart of high temperature experiment of cement pastes.

The compressive strength test was carried out in accordance with the GB/T 1939-2012 Chinese National Standard Oil Well Cement Test Method. The prepared slurry is cured in a cube mold (50.8 mm × 50.8 mm × 50.8 mm) to a predetermined age, used the TY-300 pressure tester (Wuxi Jianyi, China) at a loading rate of 71.7 kN/min ± 7.2 kN/min for testing. The average value of five samples in each group was taken as strength data.34

The tensile strength test was carried out according to the Brazilian splitting tensile test method,35 the splitting tensile strength of the columnar (Φ 50.8 mm × 25.4 mm) cement stone was tested using the TY-300 pressure testing machine. Four samples were tested in each group and their average value was taken as the final strength.36

The uniaxial compressive strength of cement paste was tested by an electronic universal material testing machine (WDW-100Dd, Jinan Shijin, China) in accordance with the relevant provisions in the standard for test methods of engineering rock mass (GB/T 50266-99).37

The Dx-2700 X-ray diffractometer produced by Dandong Fangyuan Instrument Co., Ltd. was used to study the effect of graphite on the phase change during cement hydration, the test conditions are as follows: the scanning step size is 0.04°, the time of each step is 1 s, and the diffraction angle range is 10–80°.

ZEISS EVO MA15 scanning electron microscope produced by Carl Zeiss company in Germany was used to observe the section morphology of cement paste samples. The dried cement paste samples were knocked into a small sheet sample. The block sample was then stuck to the sample seat with conductive adhesive, and gold was sprayed on the fresh section of the sample by ion sputtering. The sample was then put it into the scanning electron microscope for observation. The working voltage was 5 kV, and the emission current was 10 μA.

The TGA/SDTA851/e thermal analyzer (Mettle Toledo, Switzerland) was used to test the heat loss of the selected cement pastes. The dried cement pastes were knocked, and then ground with a mortar until there was no particle feeling by hand. Then the sample was put into the instrument for testing. The test parameters were 40–800 °C, the heating rate was 10 °C/min, and the test atmosphere was 60 mL/min nitrogen.

3. Results and Discussion

The mechanical properties, phase composition, and micromorphology of graphite cement paste with different dosages were studied and compared with the blank group. After each group of tests, the relationship between mechanical properties, graphite content, and temperature changes was discussed, and the mechanism was explored by microscopic analysis.

3.1. Compressive Strength

The compressive strength of C0, C001, C003, C005, C007, and C009 cement paste samples cured in 50 °C constant temperature water bath for 1 d, 3 d, 7 d, and 14 d was tested. The experimental results are shown in Figure 7a. It can be seen from the figure that the compressive strength of each group of cement pastes increased with the increase of curing time. However, the addition of graphite did not significantly improve the compressive strength of cement pastes for 1 d and 3 d. After curing for 7 d, it showed an improvement effect on the compressive strength of the cement pastes. After curing for 14 d, the compressive strength of the cement pastes increased first and then decreased with the increase of graphite content, but it was still higher than that of pure cement pastes. At this time, the compressive strength of sample C001 was 23.92 ± 0.39 MPa, the compressive strength of sample C003 was 24.31 ± 0.38 MPa, and the compressive strength of sample C005 was 27.99 ± 0.70 MPa, which increased by 0.70%, 2.36%, and 17.85%, respectively, compared with 23.75 ± 0.080 MPa of pure cement paste C0. When the graphite content was 0.07%, the compressive strength of C007 cement paste reached the maximum of 34.32 ± 0.23 MPa, which is 44.51% higher than that of pure cement paste C0. However, the compressive strength of sample C009 showed a decreasing trend of 27.84 ± 0.48 MPa, which is 17.22% higher than that of pure cement sample C0. This indicates that a graphite content of 0.07% is the most beneficial to the compressive strength of cement pastes.

Figure 7.

The compressive strength of cement pastes with different graphite content at different ages and different temperatures: (a) compressive strength of cement pastes cured at 50 °C with different graphite content at different ages; (b) compressive strength of cement pastes with different graphite content cured at 300, 400, and 500 °C for 7 d.

Compressive strength is the most intuitive method to evaluate the high-temperature resistance of cement-based materials.1Figure 7b shows the compressive strength of C0, C001, C003, C005, C007, and C009 cement samples with different graphite content after curing for 7 d at 300, 400, and 500 °C. It can be seen from the figure that with the same graphite content, the strength of cement pastes decreased with the continuous increase of temperature. This is because cement paste itself is a kind of porous material. Under a high temperature environment, pore pressure produces thermal stress due to an internal thermal mismatch of cement pastes, decomposition of hydration products, and evaporation of pore water,38 which causes cracks and expansion of cement pastes and ultimately causes strength decline.39 When the cement pastes with different graphite content are at the same temperature, it can be found that the compressive strength of cement pastes keeps increasing with the increase of graphite content and reaches the maximum when the content of graphite is 0.07%. Then the compressive strength decreases but is still higher than that of pure cement sample C0. This is because the relatively high graphite content causes more microcracks and pores in the cement pastes, and its better thermal conductivity is conducive to the internal heat balance of the cement pastes to reduce thermal stress and maintain high compressive strength.

3.2. Tensile Strength

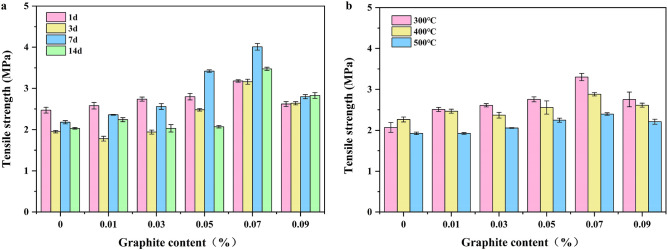

Figure 8 shows the tensile strength of cement pastes cured at 50 and 300–500 °C with different graphite content at different ages. It can be seen from the figure that at the same curing temperature, the tensile strength of the cement samples increased gradually with the increase of graphite content. When the graphite content reaches 0.07% of the weight of cement, the tensile strength of cement paste sample decreased, but it was still higher than that of pure cement paste sample. At the same graphite content, the tensile strength of cement paste decreased with the increase of temperature, this is consistent with the variation rule of compressive strength. Therefore, for the tensile strength, a graphite content of 0.07% is more appropriate. By comparing the tensile strength of the graphite-doped cement sample under temperature curing at 50 °C and 300–500 °C, the tensile strength of cement paste sample decreased less at high temperature. This shows that graphite incorporation has a certain effect on maintaining the integrity of cement.

Figure 8.

Tensile strength of cement pastes with different graphite content at different ages and different temperatures: (a) Tensile strength of cement pastes cured at 50 °C with different graphite content at different ages; (b) tensile strength of cement pastes with different graphite content cured at 300, 400, and 500 °C for 7 d.

3.3. The Curve of Stress and Strain

According to the analysis of compressive strength and tensile strength of cement sample in sections 3.1 and 3.2, it is found that when the graphite content is 0.07%, the cement paste has better mechanical properties at both low temperature and high temperature. The stress at the maximum strain in the uniaxial tensile test can be used to estimate the cracking stress of cement paste.40 Therefore, in this section, uniaxial stress–strain tests were carried out on C0 and C007 cement paste samples cured at 50 and 500 °C, and the experimental results are shown in Figure 9. Figure 9a is the uniaxial stress–strain curve of the cement paste cured at 50 °C, and Figure 9b is the uniaxial stress–strain curve of the cement paste cured at 500 °C. It can be seen from the figure that, no matter at low temperature or high temperature, the graphite-mixed cement paste sample C007 shows the same change trend as the pure cement paste sample C0. For the C007 sample, the stress value at the maximum strain of the cement paste was higher than the stress value of the C0 cement paste sample regardless of whether it was at high temperature or low temperature. Therefore, the sample C007 had a higher cracking stress. The peak stress value and the area enclosed by the stress–strain curve of sample C007 were larger than that of pure cement sample C0. Because the elastic modulus of sample C007 and sample C0 in the low stress area was not much different, and the strain value and stress value of C007 were greater than that of C0, the area of the stress–strain curve was larger. In other words, the deformation resistance of cement paste mixed with graphite is stronger than that of pure cement paste.

Figure 9.

Stress–strain curve of cement paste at low temperature and high temperature: (a) stress–strain curve of C0 and C007 cured at 50 °C; (b) stress–strain curve of C0 and C007 cured at 500 °C.

On the basis of the above mechanical property analysis, it can be seen that the addition of graphite can improve the compressive and tensile strength of Portland cement paste and significantly improve the deformation resistance of cement paste. The performance of cement pastes with graphite content of 0.07% is the most significantly improved, and the decline of cement paste strength can be restrained under high temperature environment.

3.4. XRD Analysis

Figure 10 is the XRD diffraction pattern of C0 and C007 cement paste samples cured for 7 d at different temperatures. It can be seen from the figure that the incorporation of graphite has no effect on the types of cement hydration products. The main hydration products are calcium hydroxide (CH), hydrated calcium silicate (C–S–H), and calcium carbonate (CaCO3). In addition, there are some tricalcium silicate (C3S) and dicalcium silicate (C2S) that have not undergone a hydration reaction. It is worth noting that the peak value of CH diffraction (about 32.02°) of C007 sample cured at 50 °C for 7 d is significantly lower than that of C0, indicating that the addition of graphite inhibits the formation of CH. Compared with the diffraction peak intensity of C–S–H, it can be seen that the strength of cement paste sample C007 mixed with graphite is higher than that of pure cement paste C0, indicating that graphite provides nucleation sites and promotes the formation of C–S–H.

Figure 10.

XRD contrast analysis diagram of cement pastes with different graphite content curing at different temperatures: (a) XRD comparative analysis of C0 and C007 cement paste samples cured at 50 and 300 °C; (b) XRD comparative analysis of C0 and C007 cement paste samples cured at 50 and 400 °C; (c) XRD comparative analysis of C0 and C007 cement paste samples cured at 50 and 500 °C; (d) XRD comparative analysis of C0 and C007 cement paste samples cured at 300, 400, and 500 °C.

According to the XRD patterns of cement paste samples C0 and C007 cured at 300 °C for 7 d in Figure 10a, it can be found that the type of hydration products is the same as that cured at 50 °C. However, the intensity of the CH diffraction peak is higher than that of cement paste cured at 50 °C, and the intensity of the C2S diffraction peak and C–S–H diffraction peak is lower than that of cement paste cured at 50 °C. This may be due to the further hydration reaction of the cement, which also explains the increase in strength of the cement pastes after curing at 300 °C. The decrease of the C–S–H peak intensity is due to the water loss transition of C–S–H caused by the external temperature being higher than its stable temperature. Figure 10b shows that when the curing temperature is 400 °C, the diffraction peak intensity of CH in pure cement paste drops significantly,16 while the diffraction peak intensity of CH in C007 cement paste hardly changes. This is because the addition of graphite improves the heat resistance of cement and delays the phase transformation of CH. Compared with that of the cement paste cured at 50 °C, the diffraction peak types of the cement paste cured at 500 °C changed greatly. Figure 10c shows that the peak of CH disappears and a new diffraction peak appears, indicating that phase transformation had taken place completely. Owing to exposure to air for high-temperature curing, the CH reacted with atmospheric CO2 and transformed into CaCO3.41 Comparing the C007 and C0 cement paste samples cured at 500 °C, the diffraction peak intensity of CaCO3 in C007 cement paste was higher than that of C0 cement paste, indicating that more CH was carbonized, which means that its hydration degree is higher than that of C0 cement paste. It can be seen from Figure 10d that with the increase of temperature, the diffraction peak intensity of each phase in C0 cement paste decreased rapidly, while the diffraction peak intensity of each phase in C007 cement paste decreased slowly, indicating that the addition of graphite can improve the thermal stability of each phase in cement paste and delay its phase transformation time.

Figure 11 shows the XRD patterns of C0 and C007 cement paste samples at 50, 300, 400, and 500 °C. It can be seen from the figure that with the increase of temperature, the diffraction peak intensity of cement hydration product decreased rapidly and a biological phase transformation occurred. The incorporation of graphite into the cement paste can improve the heat resistance of the cement stone and delay the phase transition temperature of the material.

Figure 11.

XRD comparative analysis of cement paste with different graphite content at low and high temperature.

3.5. Microscopic Morphology Observation

In this section, the micromorphology of C007 cement paste cured at 50 and 500 °C was observed, and the differences of cement paste hydration products at 50 and 500 °C were analyzed and discussed.

Figure 12 and Table 5 show the results of EDS point scanning of C007 cement paste samples cured at 50 and 500 °C. It can be seen from the figure that the results of dense phase scanning in cement paste samples at various temperatures mainly include carbon (C), calcium (Ca), aluminum (Al), and silicon (Si). It can be seen from Table 3 that the C atom content of the dense phase in the C007 cement paste sample cured at 50 °C is as high as 98.98%, and it is inferred that the phase is graphite. Observing the C007 cement stone sample cured at 500 °C, it can be seen that the atomic content of C in the dense phase is only 82.40%, and the atomic content of Ca and Si is 12.64% and 4.44%, respectively, which may be due to the hydration products coated on graphite.

Figure 12.

Scanning results of C007 cement paste samples at 50 and 500 °C.

Table 5. Scanning Results of C007 Cement Paste Samples at 50 and 500 °C.

| 50 °C |

500 °C |

|||

|---|---|---|---|---|

| element | Wt/% | atomic/% | Wt/% | atomic/% |

| C | 96.88 | 98.98 | 60.53 | 82.40 |

| Al | 0.06 | 0.03 | 0.86 | 0.52 |

| Si | 0.47 | 0.20 | 7.62 | 4.44 |

| Ca | 2.59 | 0.79 | 30.99 | 12.64 |

| total | 100.00 | 100.00 | 100.00 | 100.00 |

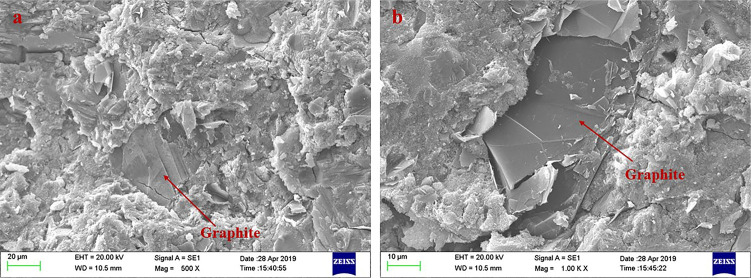

Figure 13 is the micromorphology of C007 cement paste sample cured at 50 °C for 7 d; it can be observed from Figure 13a that the structure of graphite-doped cement paste was dense, there were a large number of hydration products, and the graphite was well combined with the cement paste matrix. When the cement paste was loaded to produce cracks and propagate to the graphite particles, the cracks tore the graphite particles and then stopped propagation. This mechanism maintained the integrity of the cement paste matrix to a certain extent, and the macroperformance is the improvement of compressive strength and tensile strength.

Figure 13.

Micromorphology of cement paste mixed with 0.07% graphite after curing at 50 °C for 7 d: (a) surface morphology of cement paste; (b) interface bonding between cement paste matrix and graphite.

Figure 13b shows that hydration products were closely bound and a small amount of hydration products were attached to graphite particles. When the cement paste is impacted by an external load to produce a crack, the graphite particles can delay the crack propagation by absorbing part of the energy and changing its propagation direction, which ensures the stability of the internal structure of the cement paste to a certain extent.

Figure 14 is the micromorphology of C007 cement paste sample cured at 500 °C for 7 d. It can be seen from Figure 14a that the structure of cement paste after high-temperature curing was relatively loose, and the crystal structure and morphology of hydration products change due to high-temperature dehydration, resulting in a large number of holes in the cement sample. At the same time, because of the huge temperature difference, high thermal stress was generated in the cement paste, resulting in more microcracks and damage to the structural integrity of the cement paste.42,43Figure 14b and Figure 14c show that after high temperature curing, the hydration products gradually transform into granular shape, and irregularly shaped calcium carbonate (CaCO3) can be observed.44 At the same time, the hydration products were more attached to the graphite, and its better thermal conductivity made the relative thermal stress of the cement paste smaller, which also explained why the strength decline of the C007 sample was lower.

Figure 14.

Micromorphology of cement paste mixed with 0.07% graphite after curing at 500 °C for 7 d; (a) morphology and structure of C007 cement paste sample cured at 500 °C for 7 d; (b) interface bonding between C007 cement paste matrix and graphite cured at 500 °C for 7 d; (c) morphology of hydration products of C007 cement paste samples cured at 500 °C for 7 d.

3.6. Thermogravimetric/Differential Thermal Analysis

The samples of C0 and C007 cement paste cured at 50 °C for 1 d and 7 d were analyzed by TG/DTG, and the results are shown in Figure 15. It can be seen from the figure that there are four endothermic peaks for both C0 and C007 samples cured for 1 d and 7 d, that is, there is four times the weight loss. At 50–100 °C, it is mainly the evaporation of free water inside the cement paste. Weight loss in the range of 100–300 °C is related to the dehydration of C–S–H and ettringite (AFt).45 Weight loss at 400–500 °C is mainly caused by dehydration of the CH hydroxyl group.46 CaCO3 is the main decarbonization at 700–800 °C.47 By observing Figure 15a, it can be found that the loss rate of cement paste sample C007 mixed with graphite in each weight loss stage was slightly higher than that of pure cement paste sample C0, which indicates that the addition of graphite slowed down the hydration process in the early stage of cement hydration to a certain extent, which is consistent with the results of compressive strength and XRD test. It is worth noting that the maximum weight loss rate of graphite-doped cement sample C007 lagged behind that of pure cement sample C0 in each weight loss stage, indicating that the addition of graphite improved the high temperature resistance of cement and increased its thermal conductivity. The cement paste samples cured for 7 d demonstrated the same change trend as the cement pastes cured for 1 d, as shown in Figure 15b.

Figure 15.

Thermal analysis curve of cement paste with different graphite content at different ages: (a) thermal analysis curves of C0 and C007 cement paste samples cured at 50 °C for 1 d; (b) thermal analysis curves of C0 and C007 cement paste samples cured at 50 °C for 7d.

3.7. Mechanism Analysis

Under the conditions of heavy oil thermal recovery, the cement sheath will bear high temperature instantly, while the solidified cementing cement sheath has many micropores and is heterogeneous material, which easily produces thermal stress and destroys the integrity of the cement sheath. As shown in Figure 16, when the heat is transferred to the micropores in the process of cement paste matrix transfer, the air in the pores will expand instantaneously, resulting in large thermal stress, causing microcracks in the cement paste matrix and eventually damaging the integrity of the cement sheath, resulting in serious decline in its mechanical properties and even sealing failure. The addition of graphite into cement will fill the micropores in the cement matrix. When the graphite-oil well cement based composite material is in a high temperature environment for an instant, because graphite has higher strength and better thermal conductivity, it can quickly conduct heat through itself without causing heat to stay in the pores to generate large thermal stress. This ensures the integrity of the cement sheath and reduces the generation of microcracks. Combined with the previous microanalysis, it can be seen that graphite, having a higher strength, absorbs and digests the cracking stress of the cement paste matrix, so that the mechanical properties of the cement paste are less degraded and the higher strength of the cement paste is maintained.

Figure 16.

Mechanism diagram of graphite reinforced cement paste at high temperature

4. Conclusion and Prospect

In this paper, the influence of graphite on the mechanical properties of cement paste is studied by simulating the thermal recovery of heavy oil, and its mechanism is explored by testing and analyzing the microstructure.

-

(1)

The addition of graphite improves the strength and deformation resistance of Class G oil well cement, and the optimal dosage is 0.07%. The compressive strength and tensile strength of cement paste cured at 50 °C for 14 d increased by 44.51% and 9.28%, respectively. The compressive strength of cement paste cured at 300, 400, and 500 °C increased by 33.11%, 41.72%, and 48.67%, respectively, and the tensile strength increased by 59.52%, 27.21%, and 14.75%, respectively.

-

(2)

The addition of graphite in Class G oil well cement promoted the formation of hydration products, filled the pores in the cement paste and reduced the effect of microcracks. At the same time, due to its good thermal conductivity, graphite can balance the internal thermal stress of the cement paste and inhibit the strength decline of the cement paste under a high temperature environment.

-

(3)

Graphite has a strengthening effect on Class G oil well cement paste because it can be inserted or embedded into the pores of cement paste to reduce the porosity. In addition, due to the high hardness and good thermal conductivity of graphite, the heat can be quickly transmitted through graphite without causing the heat to stay in the pores to generate large thermal stress, so as to ensure the integrity, reduce the generation of microcracks, and enhance the mechanical properties of the cement paste.

This study found that it is feasible for graphite to enhance the mechanical properties and heat resistance of oil well cement paste. However, for graphite to be applied in heavy oil thermal recovery wells, the properties of graphite-cement based composites at higher temperatures requires further exploration. In addition, the high-temperature in situ test of cement paste is also worth studying, which has theoretical guiding significance for improving the integrity and durability of cement sheath under actual working conditions.

Acknowledgments

The authors appreciate the support of the Sinopec Key Laboratory of cementing and completion Limited Scientific Research Project “Functional derivative graphene oxide preparation and its application in cementing slurry”. The authors would also like to thank the Advanced Cementing Materials Research Center of SWPU for kind assistance with the experiments.

This research was funded by Sinopec Key Laboratory of cementing and completion Limited Scientific Research Project “Functional derivative graphene oxide preparation and its application in cementing slurry” The fund’s participation in this research is as follows: The fund provides support for research ideas, experimental equipment, materials, and funds for the research content of this article. The sponsor participated in the research design, data collection, analysis, interpretation, and the writing and submission of this article for publication.

The authors declare no competing financial interest.

References

- Cheng X.; Dong Q.; Ma Y.; Zhang C.; Gao X.; Yu Y.; Wen Z.; Zhang C.; Guo X. Mechanical and thermal properties of aluminate cement paste with blast furnace slag at high temperatures. Constr. Build. Mater. 2019, 228, 116747. 10.1016/j.conbuildmat.2019.116747. [DOI] [Google Scholar]

- Askarova A.; Turakhanov A.; Markovic S.; Popov E.; Maksakov K.; Usachev G.; Karpov V.; Cheremisin A. Thermal enhanced oil recovery in deep heavy oil carbonates: Experimental and numerical study on a hot water injection performance. J. Pet. Sci. Eng. 2020, 194, 107456. 10.1016/j.petrol.2020.107456. [DOI] [Google Scholar]

- Cheng X.; Dong Q.; Li Z.; Guo X.; Duan W. Influence of potassium titanate whisker on the mechanical properties and microstructure of calcium aluminate cement for in situ combustion. J. Adhes. Sci. Technol. 2018, 32, 343–358. 10.1080/01694243.2017.1355226. [DOI] [Google Scholar]

- Wang C.; Chen X.; Zhou W.; Wang Y.; Xue Y.; Luo F. Working mechanism of nano-SiO2 sol to alleviate the strength decline of oil well cement under high temperature. Nat. Gas Ind. B 2019, 6, 517–523. 10.1016/j.ngib.2019.03.008. [DOI] [Google Scholar]

- Pernites R. B.; Santra A. K. Portland cement solutions for ultra-high temperature wellbore applications. Cem. Concr. Compos. 2016, 72, 89–103. 10.1016/j.cemconcomp.2016.05.018. [DOI] [Google Scholar]

- Mabeyo P. E. Improving oil well cement strengths through the coupling of metakaolin and nanosilica. Upstream Oil Gas Technol. 2021, 7, 100048. 10.1016/j.upstre.2021.100048. [DOI] [Google Scholar]

- Vidal A. V.; Araujo R. G. S.; Freitas J. C. O. Sustainable cement slurry using rice husk ash for high temperature oil well. J. Clean. Prod. 2018, 204, 292–297. 10.1016/j.jclepro.2018.09.058. [DOI] [Google Scholar]

- Santiago R. C.; Costa B. L. S.; Silva F. P. F.; Medeiros R. L. B. A.; Nascimento R. A. B.; Aum P. T. P.; Freitas J. C. O. Sustainable cement blends for oil well steam injection using rice husk ash. J. Pet. Sci. Eng. 2021, 199, 108281. 10.1016/j.petrol.2020.108281. [DOI] [Google Scholar]

- Qu B.; Martín A.; Pastor J. Y.; Palomo A.; Fernández Jiménez A. Microstructural characterisation of hybrid cement after exposure to high temperatures. Constr. Build. Mater. 2020, 262, 1–10. 10.1016/j.conbuildmat.2020.120843. [DOI] [Google Scholar]

- Cui S.; Liu P.; Su J.; Cui E.; Guo C.; Zhu B. Experimental study on mechanical and microstructural properties of cement-based paste for shotcrete use in high-temperature geothermal environment. Constr. Build. Mater. 2018, 174, 603–612. 10.1016/j.conbuildmat.2018.04.106. [DOI] [Google Scholar]

- Li L.; Cao M.; Ming X.; Yin H.; Nan Sun Y. Microstructure of calcium carbonate whisker reinforced cement paste after elevated temperature exposure. Constr. Build. Mater. 2019, 227, 1–9. 10.1016/j.conbuildmat.2019.07.335. [DOI] [Google Scholar]

- Jiang D.; Jiang D.; Lv S.; Cui S.; Sun S.; Song X.; He S.; Zhang J. Effect of flame-retardant rice straw fibers on properties of fiber cement-based composites at high temperatures. J. Build. Eng. 2021, 44, 102923. 10.1016/j.jobe.2021.102923. [DOI] [Google Scholar]

- Wang S.; Wu L.; Jiang G.; Jian L.; Zhang T.; Chen S.; Chen L. A high temperature composite cement for geothermal application. J. Pet. Sci. Eng. 2020, 195, 107909. 10.1016/j.petrol.2020.107909. [DOI] [Google Scholar]

- Ramalho R. V. A.; Alves S. M.; Freitas J.C. de O.; Costa B.L. de S.; Bezerra U. T. Evaluation of mechanical properties of cement slurries containing SBR latex subjected to high temperatures. J. Pet. Sci. Eng. 2019, 178, 787–794. 10.1016/j.petrol.2019.03.076. [DOI] [Google Scholar]

- Sukmak G.; Sukmak P.; Horpibulsuk S.; Yaowarat T.; Kunchariyakun K.; Patarapaiboolchai O.; Arulrajah A. Physical and mechanical properties of natural rubber modified cement paste. Constr. Build. Mater. 2020, 244, 118319. 10.1016/j.conbuildmat.2020.118319. [DOI] [Google Scholar]

- Li G.; Zhang L. W. Microstructure and phase transformation of graphene-cement composites under high temperature. Compos. Part B 2019, 166, 86–94. 10.1016/j.compositesb.2018.11.127. [DOI] [Google Scholar]

- Tabatabaei M.; Dahi Taleghani A.; Alem N. Nanoengineering of cement using graphite platelets to refine inherent microstructural defects. Compos. Part B Eng. 2020, 202, 108277. 10.1016/j.compositesb.2020.108277. [DOI] [Google Scholar]

- Peyvandi A.; Soroushian P. Structural performance of dry-cast concrete nanocomposite pipes. Mater. Struct. Constr. 2015, 48, 461–470. 10.1617/s11527-013-0196-0. [DOI] [Google Scholar]

- Du H.; Gao H. J.; Pang S. D. Improvement in concrete resistance against water and chloride ingress by adding graphene nanoplatelet. Cem. Concr. Res. 2016, 83, 114–123. 10.1016/j.cemconres.2016.02.005. [DOI] [Google Scholar]

- Du H.; Pang S. D. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. 10.1016/j.cemconres.2015.05.007. [DOI] [Google Scholar]

- Li G. Y.; Wang P. M.; Zhao X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. 10.1016/j.cemconcomp.2006.12.011. [DOI] [Google Scholar]

- Konsta-Gdoutos M. S.; Metaxa Z. S.; Shah S. P. Multi-scale mechanical and fracture characteristics and early-age strain capacity of high performance carbon nanotube/cement nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. 10.1016/j.cemconcomp.2009.10.007. [DOI] [Google Scholar]

- Musso S.; Tulliani J. M.; Ferro G.; Tagliaferro A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. 10.1016/j.compscitech.2009.05.002. [DOI] [Google Scholar]

- Peyvandi A.; Sbia L. A.; Soroushian P.; Sobolev K. Effect of the cementitious paste density on the performance efficiency of carbon nanofiber in concrete nanocomposite. Constr. Build. Mater. 2013, 48, 265–269. 10.1016/j.conbuildmat.2013.06.094. [DOI] [Google Scholar]

- Sanchez F.; Ince C. Microstructure and macroscopic properties of hybrid carbon nanofiber/silica fume cement composites. Compos. Sci. Technol. 2009, 69, 1310–1318. 10.1016/j.compscitech.2009.03.006. [DOI] [Google Scholar]

- Li X.; Korayem A. H.; Li C.; Liu Y.; He H.; Sanjayan J. G.; Duan W. H. Incorporation of graphene oxide and silica fume into cement paste: A study of dispersion and compressive strength. Constr. Build. Mater. 2016, 123, 327–335. 10.1016/j.conbuildmat.2016.07.022. [DOI] [Google Scholar]

- Zhao X.; Li W.; Wang Y.; Li H.; Wang J. Bioinspired modified graphite film with superb mechanical and thermoconductive properties. Carbon N. Y. 2021, 181, 40–47. 10.1016/j.carbon.2021.05.019. [DOI] [Google Scholar]

- Garnier A.; Saint-Marc J.; Bois A. P.; Kermanac’H Y. An innovative methodology for designing cement-sheath integrity exposed to steam stimulation. SPE Drill. Complet. 2010, 25, 58–69. 10.2118/117709-PA. [DOI] [Google Scholar]

- Bu Y.; Chang Z.; Du J.; Liu D. Experimental study on the thermal expansion property and mechanical performance of oil well cement with carbonaceous admixtures. RSC Adv. 2017, 7, 29240–29254. 10.1039/C7RA03504G. [DOI] [Google Scholar]

- American Petroleum Institute , API RP 10B-2, Recommended practice for testing well cements; American Petroleum Institute, 2013; pp 124. [Google Scholar]

- Gallé C. Effect of drying on cement-based materials pore structure as identified by mercury intrusion porosimetry: A comparative study between oven-, vacuum-, and freeze-drying. Cem. Concr. Res. 2001, 31, 1467–1477. 10.1016/S0008-8846(01)00594-4. [DOI] [Google Scholar]

- Zhang J.; Scherer G. W. Comparison of methods for arresting hydration of cement. Cem. Concr. Res. 2011, 41, 1024–1036. 10.1016/j.cemconres.2011.06.003. [DOI] [Google Scholar]

- Zhang Z.; Zhu Y.; Zhu H.; Zhang Y.; Provis J. L.; Wang H. Effect of drying procedures on pore structure and phase evolution of alkali-activated cements. Cem. Concr. Compos. 2019, 96, 194–203. 10.1016/j.cemconcomp.2018.12.003. [DOI] [Google Scholar]

- Cai J.; Zhang C.; Zeng L.; Xu H.; Wang J.; Liu K.; Cheng X. Preparation and action mechanism of temperature control materials for low-temperature cement. Constr. Build. Mater. 2021, 312, 125364. 10.1016/j.conbuildmat.2021.125364. [DOI] [Google Scholar]

- Zhang C.; Cai J.; Xu H.; Cheng X.; Guo X. Mechanical properties and mechanism of wollastonite fibers reinforced oil well cement. Constr. Build. Mater. 2020, 260, 120461. 10.1016/j.conbuildmat.2020.120461. [DOI] [Google Scholar]

- Yu Y.; Zhang C.; Gu T.; Xu W.; Zhang J.; Zhang G.; Huang S.; Liu K.; Cheng X. Synthesis and evaluation of a new type of oil-well cement temperature-resistant retarder. Constr. Build. Mater. 2021, 302, 124153. 10.1016/j.conbuildmat.2021.124153. [DOI] [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China . GB/T 50266-2013 Standard for tests method of engineeringrock massas; China Planning Press: Beijing, 2013; pp 6–9. [Google Scholar]

- Fu Y. F.; Wong Y. L.; Poon C. S.; Tang C. A. Numerical tests of thermal cracking induced by temperature gradient in cement-based composites under thermal loads. Cem. Concr. Compos. 2007, 29, 103–116. 10.1016/j.cemconcomp.2006.09.002. [DOI] [Google Scholar]

- Zhang X.; Zhang X.; Li Y.; Hu K.; Mao D.; Luo L.; Du T.; Zhang H.; Liu K. Graphite-reinforced Portland cement composites at alternate ultra-high temperatures. Powder Technol. 2021, 378, 647–658. 10.1016/j.powtec.2020.10.039. [DOI] [Google Scholar]

- Yoshitake I.; Zhang W.; Mimura Y.; Saito T. Uniaxial tensile strength and tensile Young’s modulus of fly-ash concrete at early age. Constr. Build. Mater. 2013, 40, 514–521. 10.1016/j.conbuildmat.2012.11.022. [DOI] [Google Scholar]

- Wang D.; Noguchi T.; Nozaki T.; Higo Y. Investigation of the carbonation performance of cement-based materials under high temperatures. Constr. Build. Mater. 2021, 272, 121634. 10.1016/j.conbuildmat.2020.121634. [DOI] [Google Scholar]

- Shui Z. H.; Zhang R.; Chen W.; Xuan D. X. Effects of mineral admixtures on the thermal expansion properties of hardened cement paste. Constr. Build. Mater. 2010, 24, 1761–1767. 10.1016/j.conbuildmat.2010.02.012. [DOI] [Google Scholar]

- Zeng Q.; Li K.; Fen-Chong T.; Dangla P. Effect of porosity on thermal expansion coefficient of cement pastes and mortars. Constr. Build. Mater. 2012, 28, 468–475. 10.1016/j.conbuildmat.2011.09.010. [DOI] [Google Scholar]

- Lin R.-S.; Wang X.-Y.; Yi-Han Effects of cement types and addition of quartz and limestone on the normal and carbonation curing of cement paste. Constr. Build. Mater. 2021, 305, 124799. 10.1016/j.conbuildmat.2021.124799. [DOI] [Google Scholar]

- Liu K.; Cheng X.; Zhang C.; Gao X.; Zhuang J.; Guo X. Evolution of pore structure of oil well cement slurry in suspension–solid transition stage. Constr. Build. Mater. 2019, 214, 382–398. 10.1016/j.conbuildmat.2019.04.075. [DOI] [Google Scholar]

- Monteagudo S. M.; Moragues A.; Gálvez J. C.; Casati M. J.; Reyes E. The degree of hydration assessment of blended cement pastes by differential thermal and thermogravimetric analysis. Morphological evolution of the solid phases. Thermochim. Acta 2014, 592, 37–51. 10.1016/j.tca.2014.08.008. [DOI] [Google Scholar]

- Zeng Q.; Li K.; Fen-Chong T.; Dangla P. Determination of cement hydration and pozzolanic reaction extents for fly-ash cement pastes. Constr. Build. Mater. 2012, 27, 560–569. 10.1016/j.conbuildmat.2011.07.007. [DOI] [Google Scholar]