Abstract

Relationships between grip forces, normal forces, contact area for cylindrical handles, handle diameter, hand size, and palmar hand area were investigated. Additional analyses were performed retrospectively on data collected in two previous studies in which subjects performed maximum grip exertions on cylinders (diameter 38 to 83 mm) while grip force, normal force and contact area were recorded. Hand length, width, and palmar area were measured. Average total normal force on cylinders was 2.3 times greater than grip force measured using a split cylinder. Normal force increased proportionally as a factor of 1.6 times grip force, regardless of handle diameters examined (R2=71%). The ratio of handle diameter to hand length explained 62%, 57%, and 71% variances in grip force, normal force, and contact area, respectively. Estimated hand area (hand length × width) had a linear relationship with measured hand area (using photographs) (R2=91%), although it was 8% less than the measured.

Keywords: Contact area, hand area, hand size, grip force, normal force

1. Introduction

Most grip strength measurements use a dynamometer in which the fingers press one handle against another one that is supported in the palm. The handles are separated by a mechanical or electrical force transducer that displays the resulting grip strength. The Jamar® is a widely used example (Blackwell et al., 1999; Härkönen et al., 1993; Mathiowetz et al., 1985). Grip strength is also measured using a cylinder split along its long axis, i.e., split cylinder (Ayoub and Lo Presti, 1971; Edgren et al., 2004; Grant et al., 1992; Grant and Habes, 1993; Grant, 1994). This cylindrical dynamometer more closely approximates many of the handles used in activities of work, daily living and leisure than does the Jamar® type device.

Grip may be applied to produce normal surface forces that compress the grip object in the hand. This action occurs when two people shake hands, when someone squeezes a rolled up newspaper so that it can be banded, or when a health care provider squeezes a patient’s forearm using their hand to stop bleeding. More commonly, grip is applied to produce normal forces that in turn produce shear or friction force on the surface of a handle to prevent the object from rotating (torque) or sliding around or along its long axis (thrust). This occurs when someone turns a door knob or a screwdriver or when someone pulls on a railing or swings a baseball bat. Thrust can be computed by integrating shear force acting in the longitudinal direction of the handle (Seo et al., accepted). Torque can be computed by integrating the product of the shear force and the moment arm about the axis of rotation (Seo et al., 2007, 2008). Toward this end, data that describe the relationship between normal force, contact area and hand size are needed for various handle sizes.

The aim of this work was to investigate 1) the relationship between grip forces and normal forces applied to cylindrical handles and hand size, and 2) the relationship between grip contact area, handle diameter, and measured and estimated hand areas.

2. Methods

2.1. Procedures

To achieve the stated aims, additional analyses were performed on data collected in two previous studies (Seo et al., 2006, 2007). In the first study (Seo et al., 2006), grip strength was measured using a Jamar® grip dynamometer and split cylinders for four grip spans and diameters, and for two split cylinder force gauge orientations (see Table 1 for details). Total normal force and contact area during maximum grip exertions were also measured for cylindrical handles using pressure sensors. In the second study (Seo et al., 2007), Jamar® grip strength, split cylinder grip strength, normal force, and contact area were measured again for three different cylinder diameters during maximum grip exertions (see Table 1 for details).

Table 1.

Jamar® grip spans, cylindrical handle diameters, split cylinder force gauge orientations used for study 1 (Seo et al., 2006) and for study 2 (Seo et al., 2007) and their dependent variables

| Study 1 (Seo et al., 2006) |

Study 2 (Seo et al., 2007) |

|

|---|---|---|

| Jamar® grip span (mm) | 35, 49, 63, 77 (circumference = 100, 130, 160, 180) |

49 |

| Split cylinder diameter (mm) | 38, 51, 64, 76 (circumference = 120, 160, 199, 239) |

45, 58, 83 |

| Split cylinder force gauge | Parallel & perpendicular to the forearm | Parallel to the forearm |

| Hand size/area | Hand length & width | Hand length & width, Photo hand area |

| Dependent variables | • Grip strength measured using a Jamar® grip dynamometer and split cylinders • Contact area and total normal force measured using pressure sensors |

|

In addition, the subjects who participated in the second study were recruited again to measure their hand areas using photographs. The dorsum of the hand was flat against a table top which had a sheet of white paper with a rectangular frame (20 cm by 25 cm) drawn in the middle. The frame was large enough to include the entire hand in it. The four fingers were parallel with each other and the thumb was abducted away from the hand, while the palmar side of the hand was photographed against the white background using a digital camera. Later, the photos were converted from colored to black and white photos using Adobe® Photoshop®. The percentage of black (hand) within the rectangular frame was automatically calculated in Adobe® Photoshop®. The hand size was determined by multiplying the area of the rectangular frame times the percentage of black. This ‘photo hand area’ was compared to ‘estimated hand area’ – hand length times width.

For the two previous studies (Seo et al., 2006, 2007), subjects’ hand length and width were measured as described in Garrett (1971). Hand length was measured from the middle fingertip to the 1st wrist crease of a flat hand. Hand width was measured from the 2nd to the 5th metacarpal (Garrett, 1971). Maximum grip exertions were performed with the right hand for 5 seconds in a seated posture, with the elbow flexed at about 90 degree and the forearm semi-pronated. Cylindrical handles were grasped in a power grip posture. Each condition was tested twice, and was presented to subjects in a random order. Two minute breaks were given between consecutive trials.

2.2. Apparatus

Grip strength was measured using a Jamar® dynamometer or using a split cylinder which is composed of two halves of the cylinder connected by a force gauge (Ayoub and Lo Presti, 1971; Edgren et al., 2004; Grant et al., 1992; Grant and Habes, 1993; Grant, 1994). The split cylinder was covered with a pressure sensitive pad (Tekscan Pressure Measurement System) that recorded normal pressure on each sensor (sensor size = 5.08 by 5.08 mm). As described by Seo et al. (2007), total normal force was calculated by summing normal forces (normal pressure × sensor size) on all sensors around the cylinder surface. The contact area between the hand and handle was estimated by multiplying the sensor size times the number of pressure sensors that registered pressure (threshold = 5 kPa). Due to difficulties with wrapping the pressure sensitive pad around a small size cylinder, the pressure sensors were used only for handle diameters greater than or equal to 51 mm.

2.3. Subjects

The first study (Seo et al., 2006) collected data for six subjects (3 males and 3 females, age between 23 and 36 years, mean age of 27.5). The second study (Seo et al., 2007) collected data for twelve subjects (6 females and 6 males, age between 21 and 35 years, mean age of 26.7). Three subjects (1 male and 2 female) were common between the two studies. All participants were free of any upper extremity disorders, and gave written informed consent prior to testing. When the two study subjects were combined, the mean hand length was 19.1 ± 1.4 cm for males and 17.1 ± 0.8 cm for females. The mean hand width was 8.3 ± 0.3 cm for males and 7.5 ± 0.5 cm for females. The hand lengths ranged from 1st percentile to 99th percentile for males, and from 1st percentile to 67th percentile for females, based on the air force population data from Garrett (1971).

3. Results

3.1. Grip force & normal force

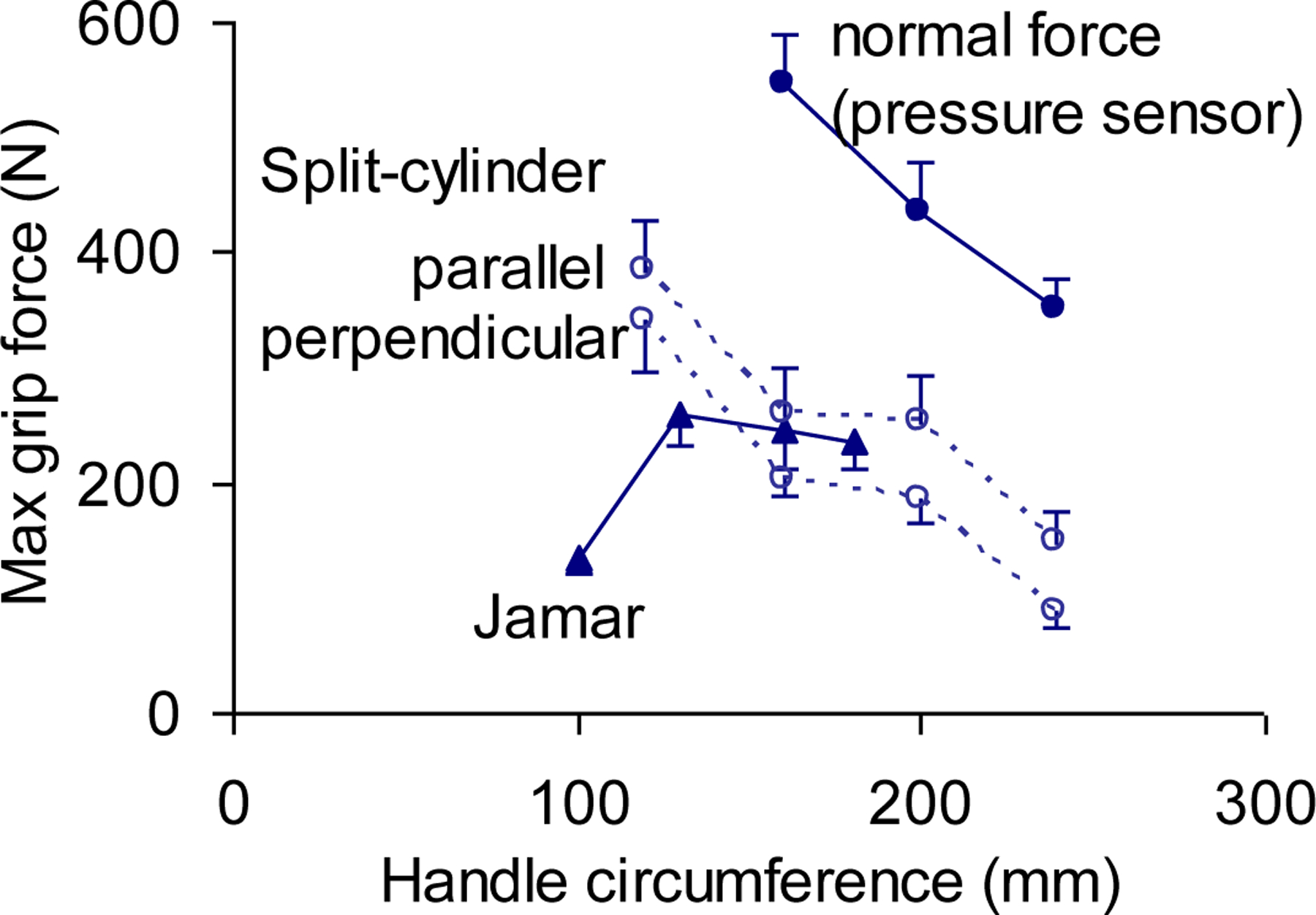

Seo et al. (2006) (Study 1) previously reported grip strengths measured using a Jamar® dynamometer and split cylinders, and normal forces on cylinders during maximum grip exertions. The force data from Seo et al. (2006) are summarized in Figure 1. Seo et al. (2007) (Study 2) previously reported split cylinder grip strengths and total normal forces. In the present work, additional analyses were performed for the data collected in the two studies to show the followings.

Figure 1.

Mean ± SE Jamar® grip strength (▲), split cylinder grip strength with its force gauge parallel to the forearm and perpendicular to the forearm (o), and total normal force measured using pressure sensors (●) for different handle circumferences (Modified from Seo et al., 2006).

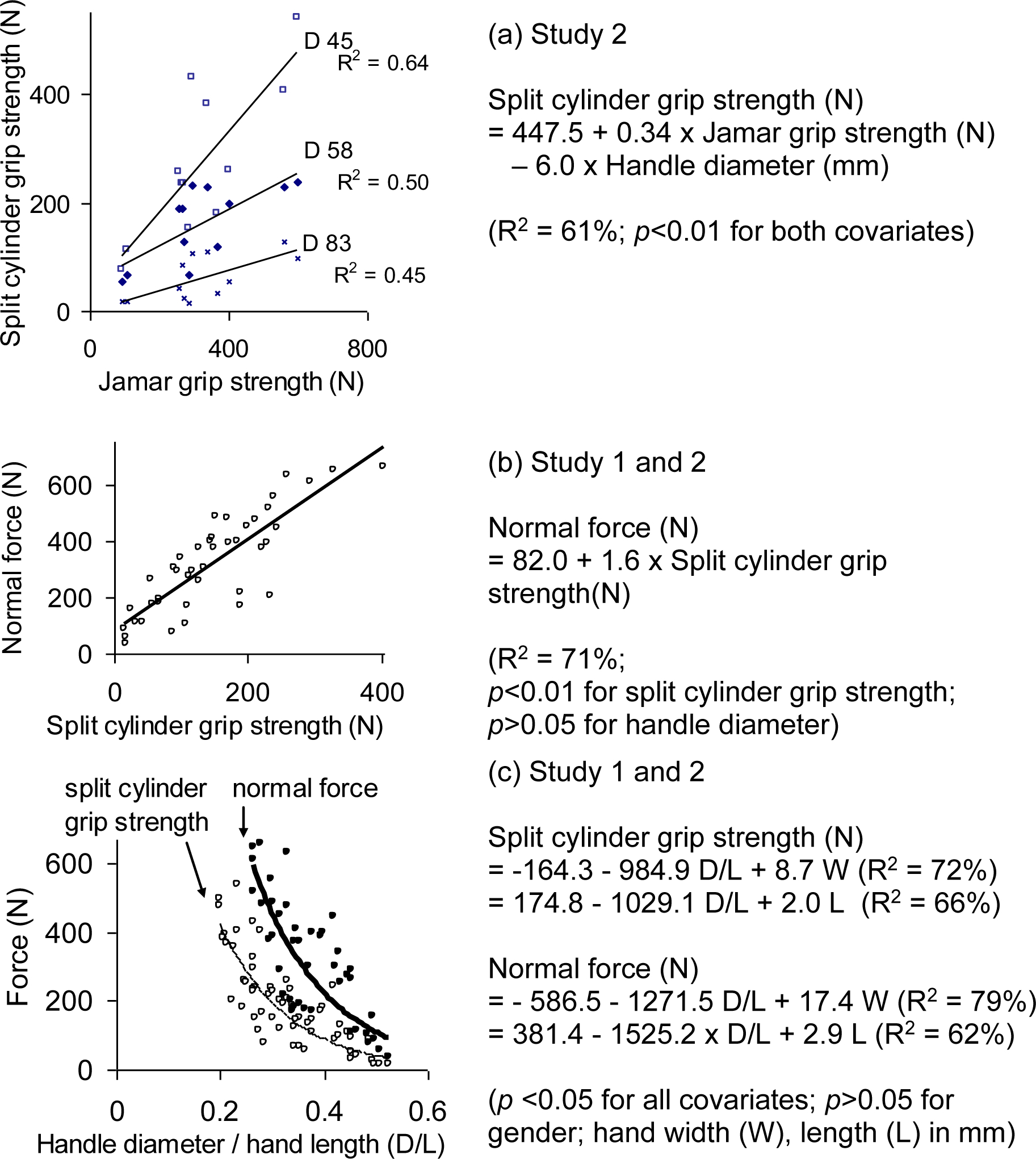

Handle diameter and Jamar® grip strength could explain 61% of variance in grip strength measured using the split cylinder (see Figure 2a). Average total normal force on cylindrical handles was 2.3 times greater than split cylinder grip strength (Figure 1; p<0.01). A linear relationship between normal force and split cylinder grip strength was found in Figure 2b (R2 = 71%). This relationship did not significantly change for different handle diameters (p>0.05). Both split cylinder grip strength and normal force decreased with increasing ratio of handle diameter to hand length (D/L) and hand size (either hand length (L) or width (W)), as shown in Figure 2c (p<0.05). Gender did not have a significant effect on split cylinder grip strength or normal force when D/L and hand size was controlled (p>0.05), although average grip strength and normal force were 46% greater for males than for females (average hand length was 12% greater for males than for females). The D/L alone could explain 62% and 57% variance in split cylinder grip strength and normal force, respectively.

Figure 2.

a: Split cylinder grip strength as a function of Jamar grip strength for handle diameters (D) of 45, 58, and 83 mm (Study 2 (Seo et al., 2007); Jamar setting = 2). b: Normal force as a function of split cylinder grip strength (Study 1 and 2 pooled (Seo et al., 2006, 2007); split cylinder force gauge parallel to the forearm only). c: Split cylinder grip strength and normal force as a function of the ratio of handle diameter to hand length (D/L) (Study 1 and 2 pooled (Seo et al., 2006, 2007); split cylinder force gauge parallel to the forearm only).

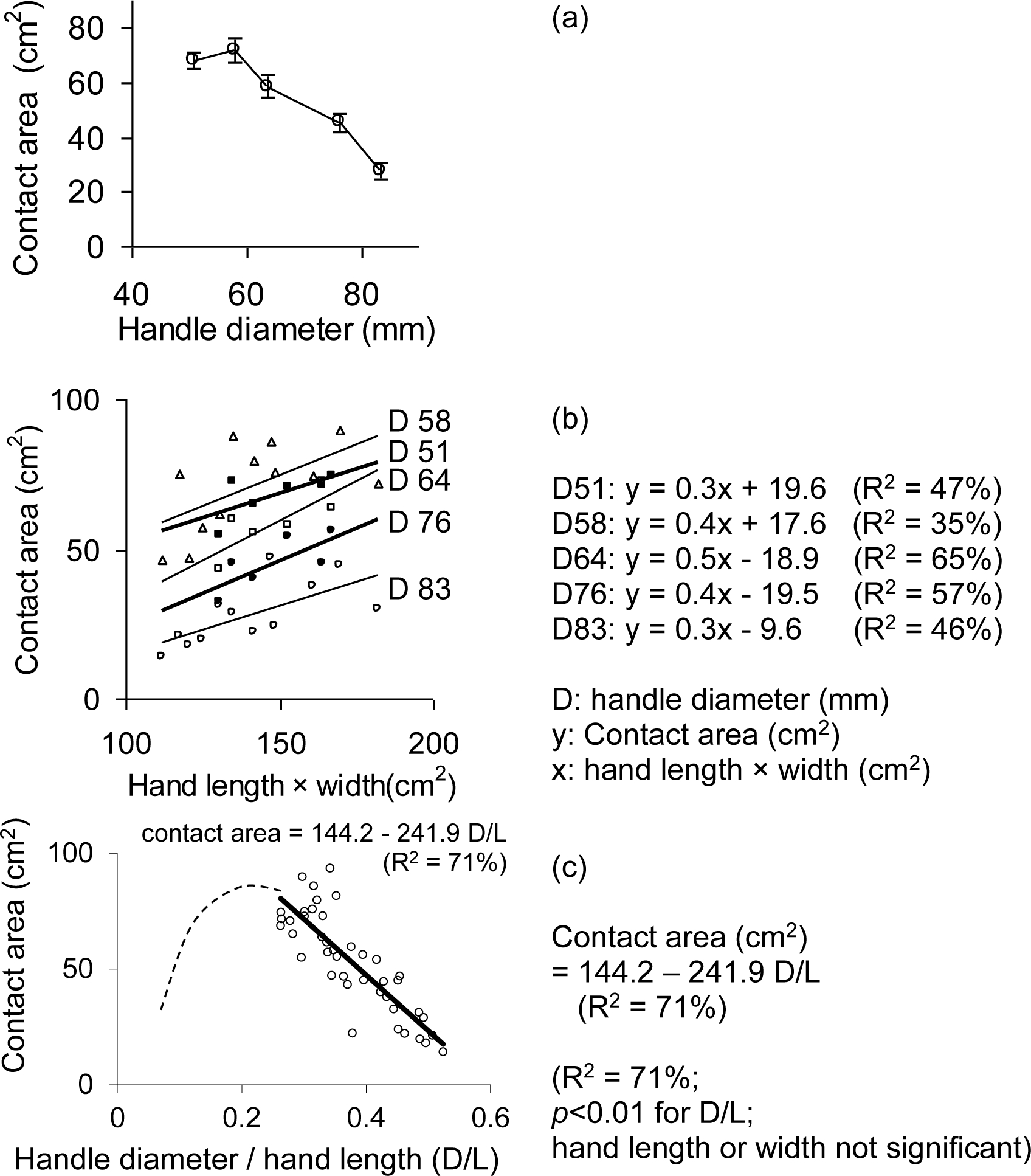

3.2. Contact area & Hand area estimation

Seo et al. (2006) (Study 1) previously reported contact area for four handle diameters. Contact areas measured for three different handle diameters in Study 2 were not reported in Seo et al. (2007). In the present work, the contact area data collected in the two studies were combined. Analyses performed in the present work show that the mean contact area was the greatest for the handle diameters of 51 and 58 mm (Figure 3a). The contact area increased with increasing estimated hand area (Figure 3b). The D/L alone could explain 71% of the variance in contact area (Figure 3c). When D/L was controlled, hand length or width did not significantly affect contact area (p>0.05).

Figure 3.

Contact area (measured using pressure sensors) as a function of handle diameter (a; mean ± SE), as a function of hand area estimated by multiplying hand length and width for each handle diameter (b), and as a function of the ratio of handle diameter to hand length (c). (Study 1 (Seo et al., 2006) and Study 2 pooled).

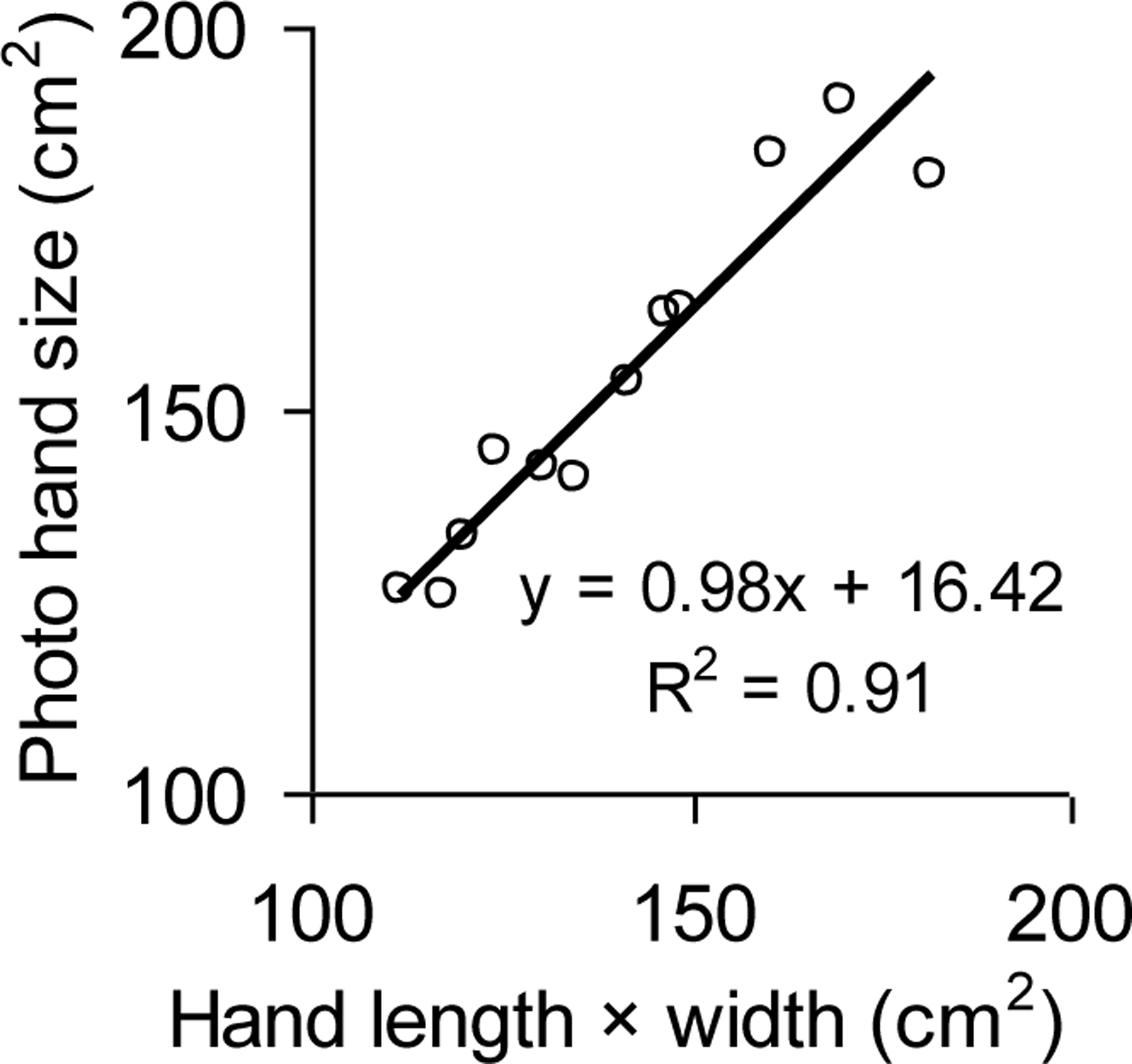

The estimated hand area (hand length times width) was, on average, 8% less than the hand area measured using photographs (p<0.01). A significant linear relationship was found between the photo hand area and estimated hand area, as shown in Figure 4.

Figure 4.

The relationship between hand area measured using photographs and hand area estimated by multiplying hand length and width (Study 2)

4. Discussion

4.1. Aim 1: Split cylinder grip strength vs. normal force

Average split cylinder grip strength was only 46% of average total normal force (Figure 1, Figure 2c). The total normal force is an arithmetic sum of all normal forces on the handle surface, whereas split cylinder grip force measures only force in one direction (aligned to the force gauge). Thus, split cylinder grip force will be equivalent to one half of the sum of cosines of all normal forces on the handle surface to the force gauge axis, if shear force is negligible. The relationship between grip force and normal force presented in Figure 2b may be used to estimate normal force when only a split cylinder is available for handle diameters from 38 to 83 mm.

A major drawback of a split cylinder is that grip force measurement changes with orientations of the split cylinder about its long axis (Figure 1; Edgren et al., 2004; Seo and Armstrong, 2006). Thus, when a split cylinder is used to measure strength capability to use a pivot-action tool, the split cylinder should be oriented the same way as for that tool. Compared to grip force measurement, normal force measurement has following advantages. First, normal force measurement is not affected by device or hand orientation. Second, normal force is proportional to friction force as described by Coulomb (1785). Thus, normal force data can be used to predict friction force which is applied during object manipulation such as lifting (Westling and Johansson, 1984), twisting (Pheasant and O’Neill, 1975; Seo et al., 2007, 2008), or pushing (Seo et al., accepted).

4.2. Aim 1: Grip strength & hand size

Split cylinder grip strength and total normal force increased with increasing hand size (either hand length or width), even when the interaction between handle diameter and hand length (D/L) was controlled (Figure 2c). Split cylinder grip strength or total normal force was not significantly affected by gender, when D/L and hand size were controlled. The contact area did not change significantly with hand size (either length or width) when D/L was controlled (Figure 3c). Thus, the positive correlation between grip strength and hand size is probably not the result of a greater contact area. It may be because people with bigger hands tend to have greater muscular strength (Aghazadeh et al., 1989; Crawford et al., 1997; Yakou et al., 1997).

4.3. Aim 2: contact area vs. handle diameter

Consistent with Pheasant and O’Neill (1975), contact area was the greatest when the handle diameter was 51 or 58 mm, and it decreased as the handle diameter increased from 58 to 83 mm (Figure 3a). As shown in Figure 3c, 71% of the variance in contact area could be explained by the ratio of handle diameter to hand length (D/L). It shows that contact area is primarily determined by the interaction between handle diameter and hand size (Figure 3b, c).

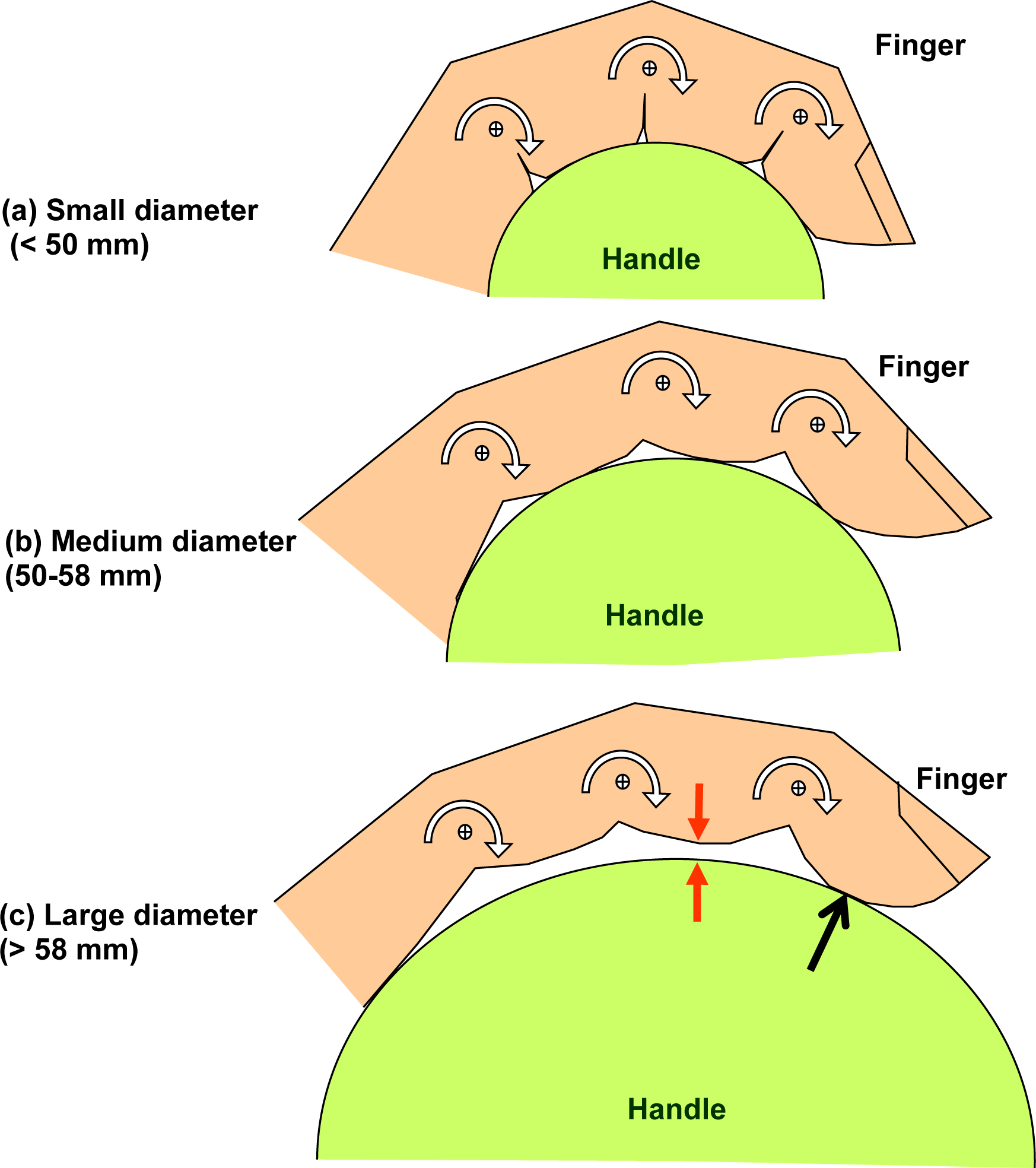

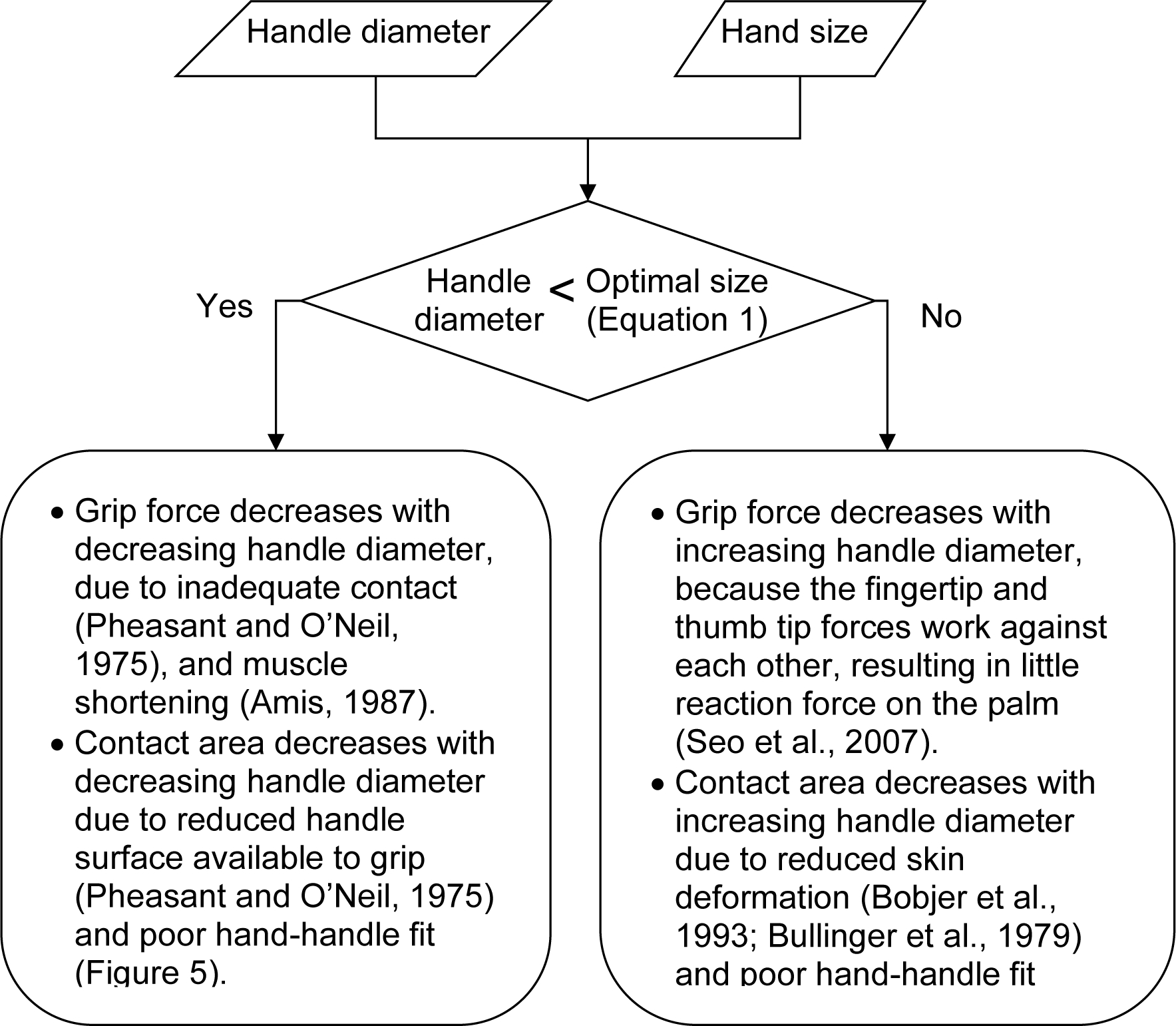

Two explanations may exist for decreasing contact area with increasing handle diameters (for handle diameters greater than 58 mm). First, increase in handle diameter is associated with reduced grip/normal force (Figure 1, Figure 2a), thus less skin deformation on the palmar side of the hand. Reduced grip/normal force and skin deformation can, in turn, result in reduced contact area, as demonstrated by Bobjer et al. (1993) and Bullinger et al. (1979). Second, during gripping, forces are concentrated on the fingertips (Gurram et al., 1993; Seo et al., 2007), which can cause the middle and proximal phalanges to lift off as the distal interphalangeal joint rotates. In fact, force distribution plots showed that, when grasping a large cylindrical object, forces on the palm diminished, resulting in more of a pinch grip (most forces on the fingertips and thumb tip) than a power grip (forces distributed on the whole hand) in Seo et al. (2007). Thus, a handle surface with a large diameter may not fit into the curvature of the fingers, as gripping naturally flexes the fingers, as depicted in Figure 5c (see Figure 6 for summary).

Figure 5.

Hand-handle fit for small (a), medium (b), and large (c) handle diameters. For a small handle diameter, finger flexion results in skin folding and reduced contact with a handle (a). For a large handle diameter, the handle surface may not fit into the curvature of the finger because gripping flexes the fingertip (c).

Figure 6.

Description of the effect of handle diameter and hand size on grip force and contact area, based on previous studies (Amis, 1987; Bobjer et al., 1993; Bullinger et al., 1979; Pheasant and O’Neill, 1975; Seo et al., 2007).

Decrease in contact area for smaller handle diameters was not shown in the two studies (Seo et al., 2006, 2007), since contact areas were measured for handle diameters only from 51 to 83 mm. Other studies showed that the contact area decreases as the handle diameter decreases from 50 to 10 mm (Pheasant and O’Neill, 1975, using photographic paper wrapped around handles touched by the grease hand) or from 38 to 13 mm (Yakou et al., 1997, using ink and paper wrapping around handles). Decrease in contact area for small handle diameters may be due to reduced available handle surface area (Pheasant and O’Neill, 1975; Rohles et al., 1983; Yakou et al., 1997). It may also be because finger flexion causes the skin folded with each other and results in reduced contact with the handle, as illustrated in Figure 5a (see Figure 6 for summary).

Greater contact area can reduce average pressure for a given normal force on the hand (because average pressure is the ratio of normal force to contact area). Thus greater contact area may reduce chances for discomfort or pain from high pressure or pinch (Fransson-Hall and Kilbom, 1993). In addition, greater contact area between skin and an object was shown to be associated with higher friction coefficient (Bullinger et al., 1979; Comaish and Bottoms 1971; Seo, 2007). Thus, greater contact area may be preferred when friction force is applied such as in lifting (Westling and Johansson, 1984), twisting (Pheasant and O’Neill, 1975; Seo et al., 2007), or pushing (Seo et al., under review). Contact area may also be important in control over an object. By spreading the forces and contact points out, the hand can produce a higher moment, and overcome perturbations that may occur during object manipulation.

4.4. Aim 2: Measured hand area vs. estimated hand area

The hand area estimated by multiplying hand length times width was 8% less than that measured using photographs. This is probably because hand width was measured from the 2nd to 5th metacarpal (not including the thumb), which estimates the hand area without the thumb. A linear relationship described in Figure 4 (R2 = 91%) may be used to predict the photo hand area.

4.5. Grip/normal force vs. handle diameter

Several explanations have been suggested for varying maximum grip/normal force with handle diameter. For handle diameters smaller than the ‘optimal diameter’ (diameter that results in the greatest grip force), Pheasant and O’Neill (1975) speculated that grip force is limited by inadequate contact (too little handle surface area available for the hand to work with). In addition, Amis (1987) suggested that grip force may decrease for small handle diameters due to finger flexor muscle shortening (see Figure 6). When the handle diameter increases from the optimal diameter, the fingertips and thumb tip are placed in opposition, and thus, the major active forces from the fingertips and thumb tip becomes working against each other. This results in little reaction force on the palm, thus, reducing total grip/normal force on the hand (Seo et al., 2007; Figure 6).

As for the condition of optimal diameter, Seo et al. (2007) suggested that maximum grip/normal force can be achieved when the fingertips and thumb tip work together against the palm, thus resulting in great reaction force on the palm. From Pheasant and O’Neill (1975)’s data, it can be seen that grip force was highest when the thumb tip was aligned with other four fingertips. Yakou et al. (1997) speculated that the optimum grasping diameter is when the object is in contact with all fingertips and a full area of palm.

Therefore, the greatest grip/normal force is obtained when the centers of the middle fingertip and the thumb tip are aligned parallel to the long axis of a cylindrical handle. Thus, the optimal handle diameter can be predicted by the following equation. The middle fingertip length and thumb tip length were estimated to be 0.108 and 0.158 times of the hand length, respectively (Buchholz et al., 1992).

| (1) |

Using the mean inner grip breadth (diameter of a circle that can be made by touching the thumb tip with the middle fingertip) of 49 mm and the mean hand length of 197 mm reported in Garrett (1971) for air force population, the mean optimal handle diameter can be calculated to be 40 mm. It is almost as same as the optimal handle diameter of 38 mm reported by Ayoub and Lo Presti (1971) and Edgren et al. (2004), considering that the increment in handle diameters tested in their studies is 6 to 13 mm. It also agrees with the data collected in the two previous studies (Seo et al., 2006, 2007).

4.6. Limitation

The two studies (Seo et al., 2006, 2007) examined handle diameters ranging from 38 to 83 mm only. Decreasing grip strength for handle diameters smaller than 38 mm could not be demonstrated in these studies, although that is expected from previous studies (Ayoub and Lo Presti, 1971; Edgren et al., 2004). Contact area was examined for handle diameters from 51 to 83 mm only in these studies, although it can be expected that the contact area will decrease as the handle diameter decreases from 51 mm, based on previous studies (Pheasant and O’Neill, 1975; Yakou et al., 1997). Future studies should include smaller handle diameters for investigation.

Future studies should also examine force distributions and contact areas for different hand postures and object shapes. Studies should be performed to see how contact areas and forces are affected by pathologies such as strokes.

5. Conclusions

Average normal force on cylindrical handles was 2.3 times greater than grip force measured using a split cylinder. Normal force increased proportionally as a factor of 1.6 times grip force, regardless of handle diameters examined in this work (R2 = 71%).

The interaction between handle diameter and hand length (D/L) explained 62%, 57%, and 71% variances in grip force, total normal force, and contact area, respectively.

Estimated hand area (hand length × width) and measured hand area (using photographs) had a significant linear relationship (R2 = 91%). Estimated hand area was 8% less than the measured, probably because the thumb was not included in the estimation.

The quantitative relationships and regression models provided in this paper can be used in design of objects and hand tools to determine optimal handle sizes for maximizing grip strength, total normal force, or contact area. They can also be used as a basis for friction-related studies and applications.

Statement of Relevance.

The quantitative relationships described in this paper can be used in design of objects and hand tools to determine optimal handle sizes for maximizing grip force, total normal force, or contact area.

Contributor Information

Na Jin Seo, Department of Industrial and Operations Engineering, University of Michigan, 1205 Beal Ave. Ann Arbor, MI 48109 USA.

Thomas J. Armstrong, Department of Industrial and Operations Engineering, University of Michigan, 1205 Beal Ave. Ann Arbor, MI 48109 USA

References

- Aghazadeh F, Waikar AM, Lee KS, Backhouse T, Davis P, 1989. Impact of anthropometric variables and sex on grip strength. In: Mital Anil, eds. Advances in Industrial Ergonomics and Safety I. Taylor & Francis, 501–505. [Google Scholar]

- Aldien Y, Welcome D, Rakheja S, Dong R, Boileau P-E, 2005. Contact pressure distribution at hand-handle interface: role of hand forces and handle size. International Journal of Industrial Ergonomics, 35, 267–286. [Google Scholar]

- Amis AA, 1987. Variation of finger forces in maximal isometric grasp tests on a range of cylinder diameters. Journal of Biomedical Engineering, 9, 313–320. [DOI] [PubMed] [Google Scholar]

- Ayoub MM, Lo Presti P, 1971. The Determination of an Optimum Size Cylindrical Handle by Use of Electromyography. Ergonomics, 14 (4) 509–518. [DOI] [PubMed] [Google Scholar]

- Blackwell JR, Kornatz KW, Heath EM, 1999. Effect of grip span on maximal grip force and fatigue of flexor digitorum superficialis. Applied Ergonomics, 30, 401–405. [DOI] [PubMed] [Google Scholar]

- Bobjer O, Johansson S-E, Piguet S, 1993. Friction between hand and handle. Effects of oil and lard on textured and non-textured surfaces; perception of discomfort. Applied Ergonomics, 24, 190–202. [DOI] [PubMed] [Google Scholar]

- Buchholz B, Armstrong TJ, Goldstein SA, 1992. Anthropometric data for describing the kinematics of the human hand. Ergonomics, 35 (3) 261–273. [DOI] [PubMed] [Google Scholar]

- Bullinger HJ, Kern P, Solf JJ, 1979. Reibung Zwischen hand und griff, Forchungs bericht Nr 213. (The effects of materials and surface on the frictional behaviour between hand and handle). Bundesanstalt für Arbeitsschutz und Unfall-forscung, Dortmund, Germany. [Google Scholar]

- Comaish S, Bottoms E, 1971. The skin and friction: deviations from Amonton’s laws, and the effects of hydration and lubrication. British Journal of Dermatology, 84, 37–43. [DOI] [PubMed] [Google Scholar]

- Crawford JO, Wabine E, Nayak L, 2002. The interaction between lid diameter, height and shape on wrist torque exertion in younger and older adults. Ergonomics, 45 (13) 922–933. [DOI] [PubMed] [Google Scholar]

- Edgren CS, Radwin RG, Irwin CB, 2004. Grip force vectors for varying handle diameters and hand sizes. Human Factors, 46 (2) 244–251. [DOI] [PubMed] [Google Scholar]

- Fransson-Hall C, Kilbom A, 1993. Sensitivity of the hand to surface pressure. Applied Ergonomics, 24 (3) 181–189. [DOI] [PubMed] [Google Scholar]

- Garrett JW, 1971. The Adult Human Hand: Some Anthropometric and Biomechanical Considerations. Human Factors, 13 (2) 117–131. [DOI] [PubMed] [Google Scholar]

- Grant KA, Habes DJ, 1993. Effectiveness of a handle flange for reducing manual effort during hand tool use. International Journal of Industrial Ergonomics, 12, 199–207. [Google Scholar]

- Grant KA, Habes DJ, Steward LL, 1992. An analysis of handle designs for reducing manual effort: The influence of grip diameter. International Journal of Industrial Ergonomics, 10, 199–206. [Google Scholar]

- Gurram R, Gouw GJ, Rakheja S, 1993. Grip pressure distribution under static and dynamic loading. Experimental Mechanics, 33 (3) 169–173. [Google Scholar]

- Härkönen R, Piirtomaa M, Alaranta H, 1993. Grip strength and hand position of the dynamometer in 204 Finnish Adults. The Journal of Hand Surgery [Br], 18B (1) 129–132. [DOI] [PubMed] [Google Scholar]

- Mathiowetz V, Kashman N, Volland G, Weber K, Dowe M, Rogers S, 1985. Grip and Pinch Strength: Normative Data for Adults. Arch Phys Med Rehabil, 66: 69–72. [PubMed] [Google Scholar]

- Pheasant S, O’Neill D, 1975. Performance in gripping and turning – a study in hand/handle effectiveness. Applied Ergonomics, 6 (4) 205–208. [DOI] [PubMed] [Google Scholar]

- Rohles FH, Moldrup KL, Laviana JE, 1983. Opening Jars: An Anthropometric Study of the Wrist-Twisting Strength of the Elderly. In Proceedings of the Human Factors Society 27th Annual meeting, 112–116. [Google Scholar]

- Seo NJ, Armstrong TJ, Drinkaus P, 2005. Methods to Measure Static Coefficient of Friction between Hand and Other Materials. The International Society of Biomechanics XXth meeting/American Society of Biomechanics 29th meeting, Cleveland, OH. [Google Scholar]

- Seo NJ, Armstrong TJ, 2006. A preferred orientation of a cylindrical hand dynamometer for measuring grip force. The 28th International Congress on Occupational Health, Milan, Italy. [Google Scholar]

- Seo NJ, Armstrong TJ, Ashton-Miller JA, 2006. Grip Forces Measured with Different Methods. In Proceedings of the 16th World Congress on Ergonomics, International Ergonomics Association, Maastricht, Netherlands. [Google Scholar]

- Seo NJ, Armstrong TJ, Ashton-Miller JA, Chaffin DB, 2007. The effect of torque direction and cylindrical handle diameter on the coupling between the hand and a cylindrical handle. Journal of Biomechanics, 40, 3236–3243. [DOI] [PubMed] [Google Scholar]

- Seo NJ, Armstrong TJ, Chaffin DB, Ashton-Miller JA. The effect of handle friction and inward/outward torque on maximum axial push force. Human Factors, Accepted. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Seo NJ, 2007. Development of a Biomechanical Model of Hand Coupling for Axial Torque and Push Exertions on Cylindrical Handles. PhD Dissertation. University of Michigan, Ann Arbor. [Google Scholar]

- Welcome D, Rakheja S, Dong R, Wu JZ, Schopper AW, 2004. An investigation on the relationship between grip, push, and contact forces applied to a tool handle. International Journal of Industrial Ergonomics, 34, 507–518. [Google Scholar]

- Westling G and Johansson RS, 1984, Factors influencing the force control during precision grip. Experimental Brain Research, 53, 277–284. [DOI] [PubMed] [Google Scholar]

- Yakou T, Yamamoto K, Koyama M, Hyodo K, 1997. Sensory Evaluation of Grip Using Cylindrical Objects. JSME International Journal Series C, 40 (4) 730–735. [Google Scholar]