Abstract

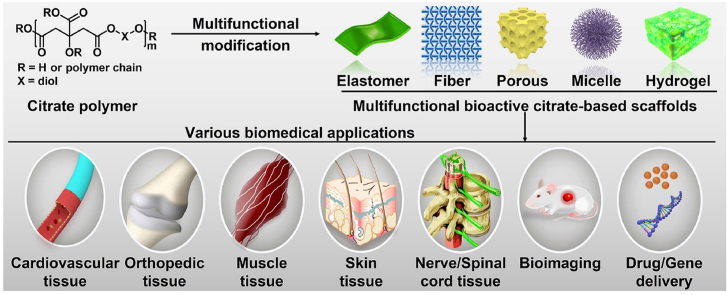

Developing bioactive biomaterials with highly controlled functions is crucial to enhancing their applications in regenerative medicine. Citrate-based polymers are the few bioactive polymer biomaterials used in biomedicine because of their facile synthesis, controllable structure, biocompatibility, biomimetic viscoelastic mechanical behavior, and functional groups available for modification. In recent years, various multifunctional designs and biomedical applications, including cardiovascular, orthopedic, muscle tissue, skin tissue, nerve and spinal cord, bioimaging, and drug or gene delivery based on citrate-based polymers, have been extensively studied, and many of them have good clinical application potential. In this review, we summarize recent progress in the multifunctional design and biomedical applications of citrate-based polymers. We also discuss the further development of multifunctional citrate-based polymers with tailored properties to meet the requirements of various biomedical applications.

Keywords: Bioactive materials, Bioactive polymers, Citrate-based biomaterials, Multifunctional modification, Tissue engineering

Graphical abstract

Highlights

-

•

Multifunctional bioactive citrate-based biomaterials have broad applications in regenerative medicine.

-

•

Recent advances in multifunctional design and biomedical applications of citate-based polymers are summarized.

-

•

Future challenge of citrate-based polymers in various biomedical applications are discussed.

1. Introduction

In recent years, the complexity and diversity of polymers have been regulated by many their molecular, aggregated, and apparent structures, which allow their wide applicability to biomedicine [[1], [2], [3]]. Compared to traditional nondegradable polymers, biodegradable polymers do not require subsequent surgical removal after implantation in vivo, expanding their range of biomedical applications, such as tissue engineering, drug/gene delivery, and bioimaging [4,5]. Polyester biomaterials, a class of synthetic biodegradable polymer materials, have become the most promising biomaterials because of their controllable mechanical properties, good biodegradation, and excellent biocompatibility [[6], [7], [8]].

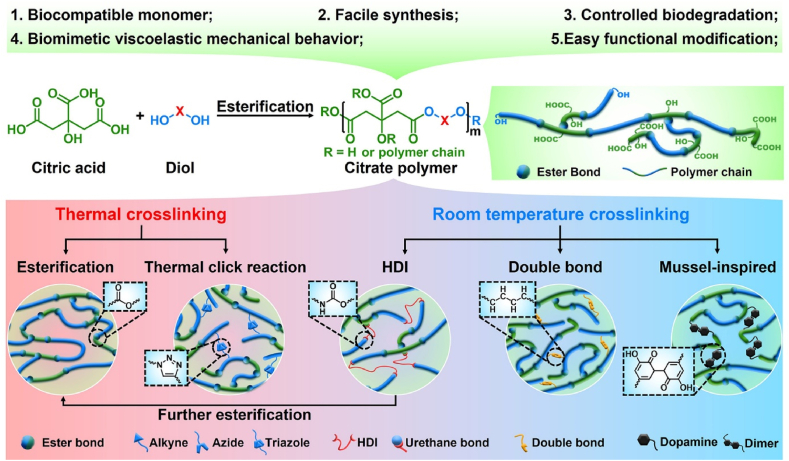

Citric acid, an intermediate of the tricarboxylic acid cycle (TCA cycle), plays an important role in metabolism, calcium chelation, the formation of hydroxyapatite (HA), and regulation of the thickness of the bone apatite structure [9,10]. Moreover, modification of polymers using citric acid produces antioxidant and anti-inflammatory properties, and the residual carboxyl and hydroxyl groups can be further functionally modified [11]. Therefore, citric acid is an ideal starting material for the synthesis of biodegradable polymers. In 2004, Ameer and Yang et al. synthesized a new type of biodegradable citrate-based biomedical elastomer, including poly(hexamethylene citrate) (PHC), poly(octamethylene citrate) (POC), poly(decamethylene citrate) (PDC), and poly(dodecamethylene citrate) (PDDC), using citric acid and diol and utilizing melt polymerization and vacuum thermal crosslinking technology [12]. After continuous studies, the main cross-linking routes of citrate-based polymers include thermal crosslinking (esterification and thermal click reaction) and room temperature crosslinking (HDI crosslinking, double bond crosslinking, and mussel-inspired crosslinking). It is worth noting that polyurethane-doped citrate elastomers require HDI crosslinking at room temperature and further esterification crosslinking at high temperature (Fig. 1) [13,14]. Among the abovementioned citrate-based biomedical elastomers, POC elastomers possess controllable mechanical properties, good biodegradability, and excellent biocompatibility, which is foundational to their biomedical applications [12,15]. Based on work previously published by Ameer and Yang et al., a POC-based biomaterial called “Citregen” as a new type of surgical fixation material, which can not only reconnect damaged tissues but also promote tissue healing after degradation of the citrate. Importantly, the fixation screw “Citrelock” prepared from the synthetic “Citregen” polymer and which has a tissue repair function, has been approved by the Food and Drug Administration (FDA). It is manufactured and sold by Acuitive Technologies, Inc., which further enhances the potential clinical applications of POC-based polymers.

Fig. 1.

Synthesis and properties of citrate prepolymer and citrate elastomers.

The mechanical and degradation properties of POC elastomers can be adjusted by controlling the crosslinking temperature, crosslinking time, degree of vacuum, and molar ratio of the initial monomers during synthesis. For example, an increase in the crosslinking temperature or crosslinking time can increase the crosslinking density of POC to enhance its tensile strength and Young's modulus, reducing the elongation at break and degradation rate. The POC elastomers exhibited a comparable tensile strength (∼6.1 MPa) and Young's modulus (0.96–16.4 MPa) to elastin from bovine ligaments (tensile strength: 2 MPa, Young's modulus: 1.1 MPa) and a comparable maximum elongation (∼265%) with arteries and veins (∼260%) and elastin (∼150%). POC elastomers can be completely degraded in phosphate-buffered saline (PBS) within 6 months and undergo faster degradation due to the action of various enzymes in vivo. In addition, POC elastomers can mediate the nonspecific adsorption of proteins to promote cell adhesion compared with other exogenous adhesion protein coatings, and they do not cause chronic inflammation in vivo. Importantly, POC elastomers can effectively maintain the activity and stability of encased drugs or proteins because of the mild crosslinking temperature and normal pressure during synthesis [12].

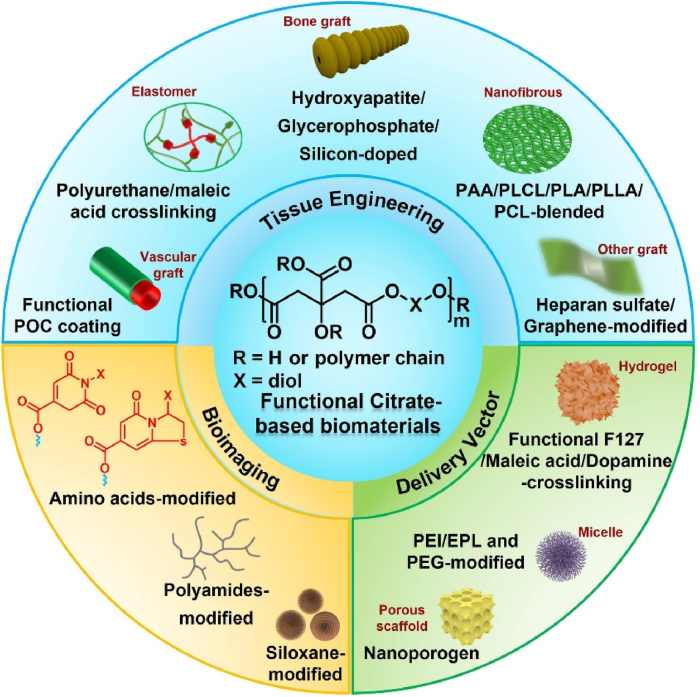

At present, the most commonly used biomedical degradable materials include poly (ε-caprolactone) (PCL), polylactide (PLA), and poly(glycerol sebacate) (PGS) [[16], [17], [18]]. In contrast to PCL and PLA, PGS is a typical elastomeric polymer prepared by a facile polycondensation reaction of glycerol and sebacic acid, which has wide applications in cardiovascular, nerve, cartilage, bone, and corneal tissue engineering through specific chemical modifications [18]. Considering the elastomeric properties and facile synthesis of PGS, POC polymers have been reported using a similar synthesis process, including the use of citric acid and diol. Compared with traditional biodegradable synthetic polymers, POC polymers (Mn = 1085 g/mol) possess many advantages, including simple synthesis, controllable structure, good biocompatibility, biomimetic viscoelastic mechanical behavior, controllable biodegradability, and the capacity for further functional modification, which provide broad application prospects in soft and hard tissue regeneration and nanomedicine design, both in vitro and in vivo [[12], [13], [14]]. However, the conventional POC polymer is water-insoluble and limited with a narrow scope of mechanical properties, bioactivities, and functions, which pose obstacles in using it for application in tissue engineering, bioimaging and drug/gene delivery [12]. To expand their properties and biomedical applications, further functionalization of POC is necessary. In recent years, our group and others have investigated the synthesis and biomedical applications of functionalized POC polymers, which would accelerate the research and clinical applications of citrate-based polymers. In this paper, we mainly discuss the functionalization of citrate-based biomaterials and their biomedical applications (Fig. 2). The properties and benefits of different functional citrate-based polymers used in biomedical applications are summarized to guide further research. Finally, we emphasize the advantages and challenges of multifunctional citrate-based polymers in various biomedical applications.

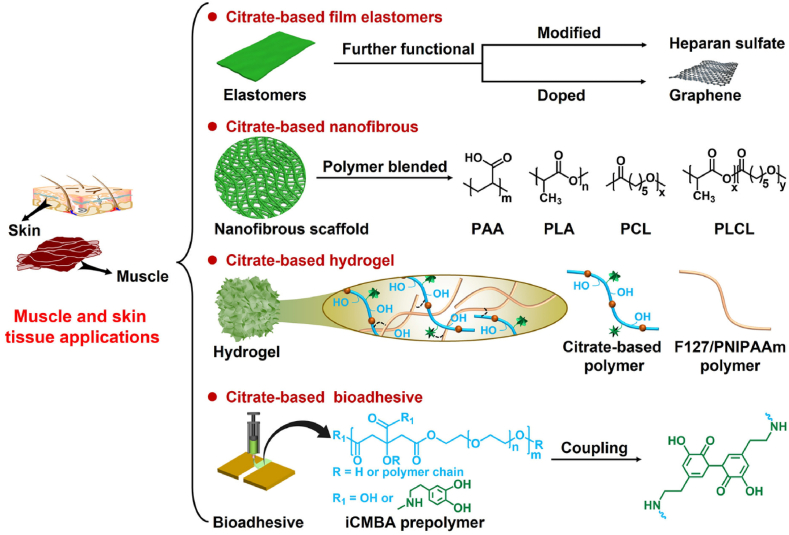

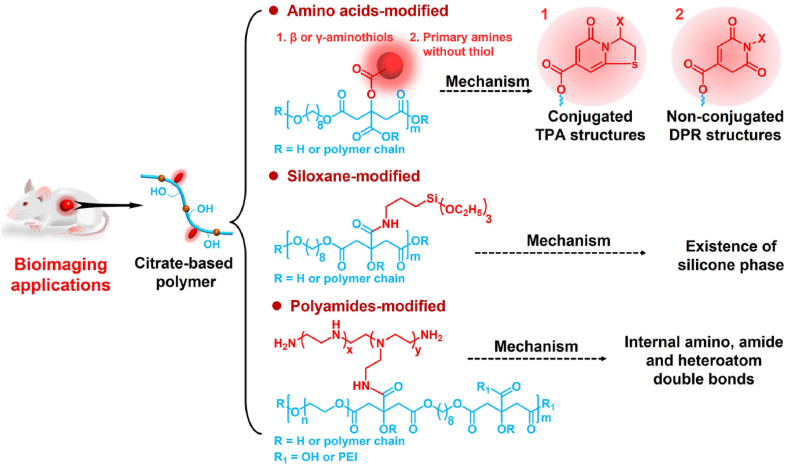

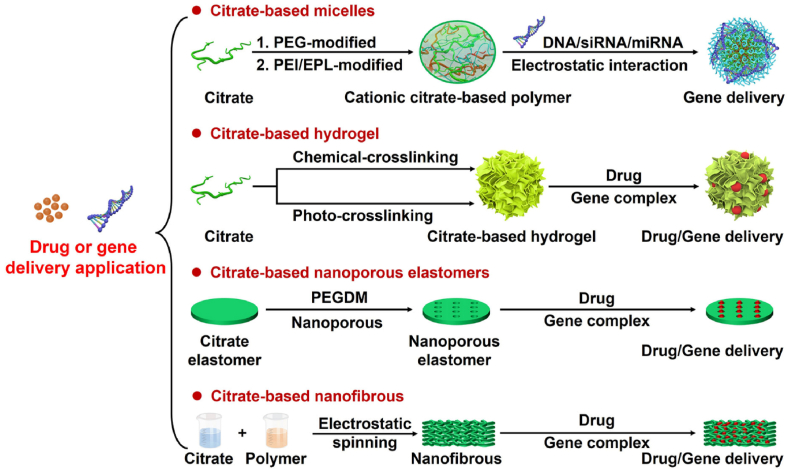

Fig. 2.

Development and biomedical applications of functional citrate-based biomaterials. PAA: poly (acrylic acid); PLCL: poly (l-lactic acid)-co-poly-(3-caprolactone); PLA: polylactide; PLLA: poly (l-lactic acid); PCL: polycaprolactone; F127: Pluronic; PEI: polyethyleneimine; EPL: ε-polylysine; PEG: polyethylene glycol.

2. Functional design for cardiovascular tissue engineering

2.1. Critical factors of biomaterials in cardiovascular tissue engineering

Myocardial tissue has a complex architecture comprising different cells, such as cardiomyocytes; fibroblasts; smooth muscle cells (SMCs); endothelial cells (ECs); and extracellular matrix (ECM), such as fibrin, collagen, and elastin, which together maintain the elastomeric mechanical properties and physiological activities of the heart [19]. ECM plays an important role in cell interconnection, signal transmission, and mechanics [20]. Typical human myocardial tissue has highly elastomeric mechanical properties with an end-diastolic Young's modulus between 0.2 and 0.5 MPa and tensile strength in the range of 3–15 kPa [21]. Previous studies have indicated that various factors, such as mimicking the biochemical environment of the natural myocardium, recruiting and promoting muscle cell division, enhancing tissue vascularization, and controlling the release of repair-related factors, can promote myocardial tissue repair [19,[22], [23], [24]]. Vascular tissue is an expandable and elastic tubular layered structure comprising different cells, proteins, and ECM [19]. The vascular intima is mainly composed of ECs, which are involved in thrombosis prevention, vasomotor regulation, inflammation regulation, and immune regulation [25]. The vascular media mainly comprises SMCs and elastin and plays an important role in vasomotor adjustment, vascular repair, and proliferative diseases [26]. Vascular adventitia mainly comprises fibroblasts, which can strengthen and protect blood vessels and fix them in the surrounding environment [27]. The typical vascular tissue has viscoelastic mechanical properties with a burst pressure up to 3000 mmHg, compliance in the range of 10–20%/100 mmHg, a tensile strength of approximately 4.3 MPa, and a special biological function that prevents platelet adhesion [28]. Previous studies have indicated that various factors can promote vascular tissue repair, such as providing a biochemical environment that mimics natural vascular tissue, inhibiting platelet adhesion, reducing inflammation, promoting endothelialization, and controlling the release of bioactive molecules [19,29,30].

Considering the structure and function of natural cardiovascular tissues, cardiovascular tissue engineering strategies have focused on the development of biomaterial scaffolds to simulate or replace natural cardiovascular tissues, which not only provide the necessary microenvironment for cell proliferation, differentiation, and metabolism but also effectively maintain normal physiological activities. Ideal cardiovascular grafts should possess multifunctional properties, including biomimetic elastomeric mechanical properties, appropriate biodegradation, excellent biocompatibility, inhibition of thrombus and inflammatory reactions, and promotion of endothelialization [[31], [32], [33]]. For example, the biomimetic mechanical properties of vascular grafts can effectively simulate natural blood vessels and maintain the normal physiological activities of blood vessels [31]. Vascular grafts that inhibit thrombi and inflammatory reactions can effectively ensure normal use without thrombus formation and severe inflammatory responses [32]. In addition, endothelialization of vascular grafts can effectively prevent local thrombus formation and restenosis [33].

2.2. Functionalized citrate polymers for cardiovascular tissue engineering

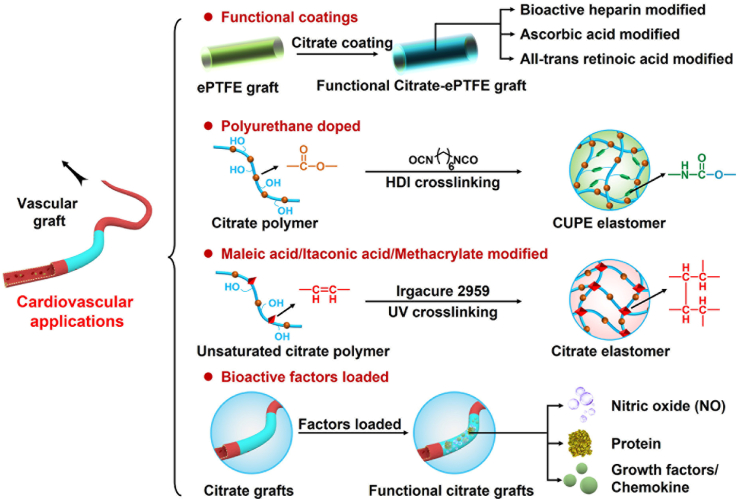

Among the various biodegradable vascular grafts, such as hyaluronan (HA), PCL, and polylactic-co-glycolic acid (PLGA), POC has been extensively studied in vascular tissue engineering owing to its excellent elastomeric mechanical properties, good biodegradability, and biocompatibility (Fig. 3 and Table 1) [[34], [35], [36]]. Motlagh et al. evaluated the hemocompatibility and human aortic endothelial cell (HAEC) compatibility of POC polymers in vitro. POC exhibited good hemocompatibility, including decreased platelet adhesion and clotting, negligible hemolysis, appropriate protein adsorption, and effective support for HAEC attachment and differentiation [37]. Owing to its biomimetic mechanical properties and good hemocompatibility, POC is a good coating biomaterial and vascular implant for cardiovascular tissue engineering applications.

Fig. 3.

Schematic diagram of further functionalized modified citrate-based polymers for vascular applications.

Table 1.

Functionalized citrate-based polymers for cardiovascular tissue engineering.

| Materials | Component | Properties | Tissue engineering | Ref. |

|---|---|---|---|---|

| POC-ePTFE | POC; ePTFE | Hydrophilicity; | Reduce platelets adhesion and macrophage infiltration; Inhibit thrombus; Promote endothelialization | 38,39 |

| Compliance | ||||

| Heparin-POC-ePTFE | POC; ePTFE; Heparin | Anti-thrombogenic; | Inhibit platelets adhesion and thrombus; Supported endothelial cells proliferation and specific phenotype expression | 40 |

| Anti-coagulant | ||||

| POCA- ePTFE | POC; ePTFE; Ascorbic acid | Intrinsic antioxidant | Reduce neointimal hyperplasia | 41 |

| POCR-ePTFE | POC; ePTFE; atRA | Antioxidant; Retinoid-like properties | Reduce macrophage and leukocyte infiltration; Inhibit the intimal formation; Hasten endothelialization | 42,43 |

| POC-PES | POC; PES | Enhanced hemocompatibility | Reduced fibrinogen adsorption and platelet adhesion | 44 |

| CUPE | POC; Polyurethane | Similar tensile strength, tunable burst pressure and suture retention | Inhibit platelets adhesion; Reduce inflammation; Anti-thrombosis | 45–47 |

| POMC | POC; Maleic acid | Controllable mechanical and degradation; Further Modification | Good cytocompatibility; | 48 |

| Reduce inflammation | ||||

| CUPOMC | POC; Maleic acid; Polyurethane | Increased tensile strength; | Support the cell adhesion and proliferation | 49 |

| Great processability | ||||

| POMaC | POC; Maleic anhydride | Increased elongation; Controlled physical structure and properties; Good biocompatibility | Minimally invasive delivery; Soft tissue engineering | 50–52 |

| AP | POMaC; Dopamine | Spatially varying adhesive properties | Biomaterial patches of supporting damaged tissue | 53 |

| PICO | POC; Itaconic acid | Tunable elasticity | Support cardiac tissue organization and viability | 54 |

| POC-PDDC | POC; PDDC | Biphasic tubular mimicked blood vessels; Shorten cells co-culture time | Small-diameter blood vessel scaffold | 55 |

| Porous POC- ECM proteins | POC; ECM proteins | Controlled pore size, porosity and shape | Support cell adhesion | 56 |

| POC-ECM | POC; ECM | Reduce platelet adhesion, Inhibit clotting | Improve thromboresistance and recellularization properties | 57 |

| PITCO | Dimethyl itaconate, Triethyl citrate; 1,8-octanediol | Fast crosslinking time; Semi-permeable; Appropriate elastic properties | Support the cells adhesion and proliferation | 59 |

| mPDDC | PDDC; glycidyl methacrylate | Customizable; Compressible, Self-expanding, Bioabsorbable, Antioxidant | Customize specific 3D-printed vascular scaffold | 60,62 |

| POCDA/PDDCDA | POC/PDDC; NO-donor | Controllable NO release; Compliance | Controlled cytostatic or cytotoxic effects; Inhibit neointimal hyperplasia | 63 |

| MA-POC/MA-PDDC | POC; PDDC; MA; Miscible NO-donor | Strong tensile strength; Radial compressive strength; Sustained release of NO | Local sustained release of NO in the vasculature | 64 |

| MTN | CUPE; GP1b; Anti-CD34 antibodies | Inhibit platelet aggregation; Reduce neointimal hyperplasia | Re-endothelialization in situ | 66 |

| PPCN | Citric acid; PEG; PNIPAAm | Lower critical solution temperature; Intrinsic antioxidant properties | Sustained release of chemokine SDF-1α to support the proliferation of vascular cells | 67 |

| PPC-ET/PEG | Citric acid; PEG; Ethyl thioglycolate | Injectable; Sustained release of citrate and growth factors | Reduce scar formation; | 68 |

| Increase new blood vessel formation |

POC: poly(octamethylene citrate); ePTFE: expanded polytetrafluoroethylene; atRA: all-trans retinoic acid; PES: polyethersulfone; GP1b: glycoprotein 1b; PDDC:poly(dodecamethylene citrate); ECM: extracellular matrix; PEG: polyethylene glycol; PNIPAAm: poly-N-isopropylacrylamide; NO-donor: N,N-Bis(2-hydroxyethyl)ethylenediamine . MA: 2-aminoethyl methacrylate; Miscible NO-donor: diazeniumdiolated N,N-diethyldiethylenetriamine.

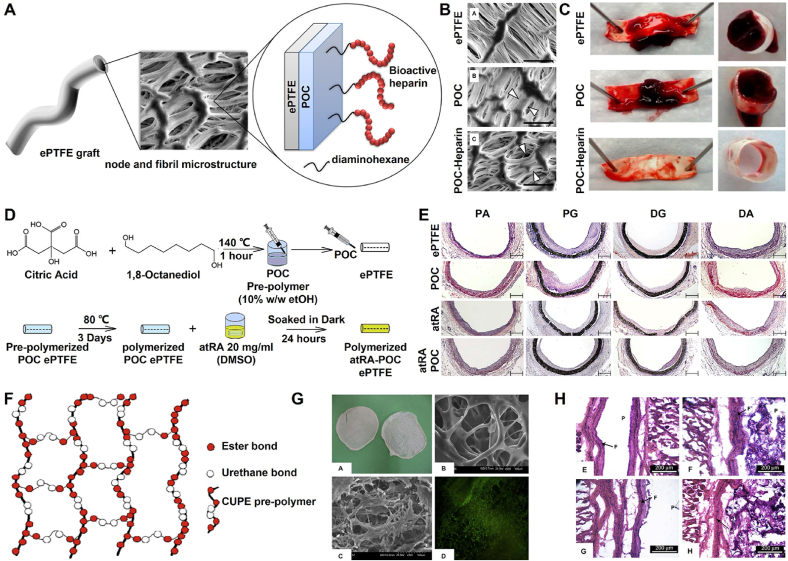

2.2.1. Antithrombus and endothelialization functionalized citrate coating for vascular implants

Yang et al. prepared a POC-ePTFE graft using POC coating to significantly change the surface energy of an expanded polytetrafluoroethylene (ePTFE) graft without changing its compliance. Because POC polymers can reduce the adhesion of platelets and the infiltration of macrophages, the POC-ePTFE graft can not only inhibit thrombi and inflammatory reactions, but also promote the endothelialization of grafts [38]. Kibbe et al. further evaluated the mid-term performance of the POC-ePTFE grafts. After the POC-ePTFE graft was implanted in the porcine carotid artery for 4 weeks, it remained patent without hemodynamically significant stenoses, adverse reactions, or inflammation [39]. Hoshi et al. further developed a bioactive heparin-POC-ePTFE vascular graft by incorporating heparin with antithrombogenic and anticoagulant properties into the POC-ePTFE vascular graft, which not only significantly inhibited whole blood clotting and platelet adhesion, but also supported endothelial cell proliferation and specific phenotype expression (Fig. 4A–C) [40]. Lith et al. prepared ascorbic acid-containing POC-based elastomer (POCA) with intrinsic antioxidant properties, including free-radical scavenging, iron chelation, and lipid peroxidation inhibition, and maintained a high viability of vascular cells. Importantly, POCA-coated ePTFE grafts can reduce neointimal hyperplasia in guinea pig aortic grafts [41]. Subsequently, Lith et al. prepared a biodegradable elastomer (POCR) with antioxidant and retinoid-like properties by incorporating all-trans retinoic acid (atRA) into a POC polymer network. The POCR elastomer also exhibits free radical scavenging, inhibition of lipid peroxidation, and inhibition of vascular smooth muscle cell proliferation and migration [42]. Gregory et al. further fabricated a POCR-coated ePTFE (atRA-POC-ePTFE) vascular graft, which effectively inhibited intimal formation and hastened endothelialization (Fig. 4D and E) [43]. Zailani et al. successfully improved the hemocompatibility of polyethersulfone (PES) membranes through POC blending. POC-PES membranes exhibit reduced fibrinogen adsorption and platelet adhesion; prolonged activated partial thromboplastin time and prothrombin time; decreased TAT, C5a, and C3a activation; and increased Ca2+ absorption [44].

Fig. 4.

Development and cardiovascular applications of functional POC-based biomaterials. (A) Synthesis schematic of the POC-Heparin ePTFE vascular graft; (B, C) SEM micrograph (B) and whole blood clot formation (C) of ePTFE, POC-coated ePTFE and POC-Heparin-coated ePTFE [40]; Copyright 2013, Elsevier. (D) Synthesis schematic of atRA-POC-ePTFE vascular graft; (E) The morphometric analysis for each graft and region, PA: proximal artery, PG: proximal graft, DG: distal graft, DA: distal artery, scale bar = 50 μm [43]; Copyright 2013, Elsevier. (F) Synthesis schematic of CUPE scaffold; (G) The morphology of CUPE scaffold and the state of fibroblast-seeded on CUPE scaffold; (H) Histology of in vivo response to each scaffold after 4-week [45]. Copyright 2008, Elsevier.

2.2.2. Biomimetic mechanics and structure functionalized citrate-based vascular implants

To develop soft, strong and completely elastic POC-based polymers for cardiovascular tissue engineering, Dey et al. reported a polyurethane-doped POC elastomer (CUPE) through 1,6-hexamethylene diisocyanate (HDI) chemical crosslinking and further thermal crosslinking, which possessed a tensile strength of approximately 41.07 MPa and a breaking elongation of approximately 222.66%. The CUPE elastomer exhibited good biocompatibility and effectively inhibited platelet adhesion according to the preliminary hemocompatibility evaluation (Fig. 4F–H) [45]. Subsequently, Dey et al. evaluated the application potential of the CUPE elastomer as a vascular graft. The CUPE vascular graft exhibited tensile strength, tunable burst pressure, and suture retention properties similar to those of native veins and arteries. Compared to poly (l-lactic acid) (PLLA), the CUPE vascular graft released less inflammatory cytokines, good blood compatibility, and antithrombosis [46]. Moreover, Dey et al. prepared a series of CUPE elastomers by varying the diol component, which had a significant difference in physicochemical properties and no influence on long-term biocompatibility in vivo. Therefore, CUPE elastomers may serve as viable vascular grafts for cardiovascular tissue engineering in vivo [47].

In addition to polyurethane-doped POC elastomers, unsaturated polyester-doped POC elastomers, including maleic acid, maleic anhydride, and itaconic acid, have been widely studied in a bid to improve their mechanical properties. Gyawali et al. reported a novel biodegradable POC-based elastomer (POMC) obtained by covalently crosslinking maleic acid for versatile biomedical applications. The POMC elastomer exhibited controllable mechanical, degradation, and swelling properties through a combination of thermal crosslinking and photocrosslinking. Moreover, the residual carboxyl and hydroxyl groups of the POMC elastomer can be further coupled with biomolecules, such as proteins, polypeptides, or antibodies, to promote cell proliferation and adhesion, and they do not cause a strong inflammatory reaction in vivo [48]. Zhang et al. further developed a photocrosslinkable urethane-doped POMC elastomer (CUPOMC) via HDI chemical crosslinking. The CUPOMC elastomer exhibited a drastic increase in tensile strength (∼10.91 MPa) compared to the POMC elastomer (less than 1 MPa) and could support cell adhesion and proliferation. Importantly, CUPOMC prepolymers possess great processability under various conditions because of their compatibility with dual crosslinking methods, including thermocrosslinking and photocrosslinking [49]. In addition, Tran et al. developed a soft biodegradable POC-based elastomeric (POMaC) by replacing maleic acid with maleic anhydride. Compared to the POMC elastomer (elongation of 382%), the POMaC elastomer displayed a higher elongation rate of up to 534%. Moreover, the POMaC elastomer possesses good cytocompatibility and tissue biocompatibility, which supports its potential application as a soft and elastic 3D microchannel scaffold for soft tissue engineering [50]. Montgomery et al. prepared a flexible shape-memory POMaC scaffold polymer with a microfabricated lattice for the design of patches and minimally invasive delivery of functional tissues. The scaffold could effectively return to its original shape after injection without affecting the viability and function of the surrounding cells. The cardiac patch possessed vascularization, macrophage recruitment, and cell survival comparable to those of surgical patches. In addition, minimally invasive delivery to the heart, liver, and aorta has been achieved in pigs [51]. Moreover, Montgomery et al. further fabricated POMaC scaffolds with various shapes by soft lithography and evaluated the effect of the scaffold design on scaffold elasticity, which may offer a promising strategy for precise material design due to its physical structure and properties [52]. Bannerman et al. designed an elastic polymer patch (AP) with spatially varying adhesive properties via the copolymerization of dopamine (DA) and POMaC polymers. The AP patch exhibited negligible cytotoxicity and improved adhesive strength (∼0.44 N/cm−2) to cardiac tissue compared to fibrin glue for the POMaC path (∼0.17 N/cm−2) and elastic modulus (∼43 kPa) comparable to cardiac tissue (relaxed: 10–20 kPa; contracted: 200–500 kPa) [53]. In addition, Huyer et al. synthesized an unsaturated polyester bioelastomer (PICO) using itaconic acid to copolymerize a POC polymer. The PICO bioelastomer exhibited tunable elasticity in the range of 36–1476 kPa and could effectively support cardiac tissue organization and viability [54].

To mimic the intimal and medial layers of blood vessels, Yang et al. fabricated a new degradable biphasic tubular scaffold (POC-PDDC) comprising a connected POC porous phase and PDDC nonporous phase. This biphasic scaffold can shorten the coculture time of SMCs and ECs in vitro to reduce the risk of contamination, and it is expected to be a small-diameter blood vessel scaffold that can reduce the side effects caused by compliance mismatch with host vessels in vivo [55]. In addition, Hidalgo-Bastida et al. prepared a series of porous POC scaffolds with different pore sizes, porosities, and shapes and reported that a decrease in porosity can lead to an increase in the elastic modulus. These porous POC scaffolds can effectively support cell adhesion after coating with three different ECM proteins: fibronectin, laminin, and collagen [56]. Jiang et al. designed POC-based polymer-ECM composites to effectively improve their thromboresistance and recellularization properties. Compared with untreated ECM, the composites can significantly reduce platelet adhesion, inhibit clotting, and support endothelial cell adhesion [57].

2.2.3. 3D printing functionalized citrate-based vascular scaffolds

With the advent of 3D printing processes, customized patient-specific vascular grafts can be manufactured at relatively low cost [58]. Savoji et al. prepared vascular tubes (PITCO) through 3D printing using bioelastomer prepolymers comprising dimethyl itaconate (DMI), triethyl citrate (TEC), and 1,8-octanediol (OD). The tubes possessed a fast crosslinking time (less than 100 s) and had elastic properties (modulus of 11–53 kPa) comparable to those of cardiac tissues. The tubes supported human umbilical vein endothelial cell adhesion and proliferation and were semipermeable, allowing for the exchange of oxygen, nutrients, and metabolic waste in tissue engineering applications. In addition, the endothelialized tubes can support cardiac tissue formation by human pluripotent stem cells (hPSC) [59]. Lith et al. fabricated a photopolymerizable PDDC-based 3D-printed vascular scaffold (mPDDC), including citric acid, 1,12-dodecanediol, and glycidyl methacrylate, using a custom-made microcontinuous liquid interface production system (microCLIP). The vascular scaffold possessed customizable (20 mm length printed for approximately 70 min), compressible, self-expanding, bioabsorbable, antioxidant, and mechanical properties (500 μm thickness) comparable to those of nitinol stents, which strengthened the radial compression of porcine arteries after deployment, suggesting the possibility of preparing customized patient-specific stents in clinical applications [60]. Subsequently, Akar et al. reported mechanically functional 3D-printed bioresorbable citrate-based vascular scaffolds [61]. Ware et al. further presented a methodology that calibrated the high-resolution microcontinuous liquid interface production (μCLIP) process using a dedicated speed working curve method to optimize the high-resolution and high-speed PDDC-based 3D printed bioresorbable vascular scaffold process, including material strength/stiffness, exposure dosage, and fabrication speed. The methodology can not only shorten the fabrication time of the 2 cm-long scaffolds (layer slicing with 5, 10, and 15 μm printed within 26.5, 15.3 and 11.3 min, respectively), but also reduce the thickness (150 μm) required for radial stiffness to a value comparable to those of nitinol stents and the commercial polymer stent ABSORB GT1BVS [62].

2.2.4. Release of bioactive factors from functionalized citrate-based vascular scaffolds

Nitric oxide (NO) delivery is important for vascular applications. Serrano et al. synthesized NO-releasing elastomers (POCDA or PDDCDA) using N,N-bis(2-hydroxyethyl)ethylenediamine and POC or PDDC polymer via a condensation reaction, which can effectively release NO to inhibit the proliferation of angiogenesis intima after covering the blood vessels [63]. Wang et al. synthesized photocrosslinked biodegradable POC-based elastomers (MA-POC) and PDDC-based elastomers (MA-PDDC) functionalized using 2-aminoethyl methacrylate (MA) to sustain NO release. The elastomers exhibited strong tensile strength and radial compressive strength and sustained NO release for at least one week, which provided a new approach for treating thrombosis and vascular restenosis by local sustained NO release into the vasculature [64].

Sharma et al. prepared heparan sulfate-modified POC thin films (heparin-POC) with sustained release of vascular endothelial growth factor (VEGF) to effectively promote vascular regeneration [65]. Su et al. developed a multifunctional targeted nanoscaffold (MTN) comprising a CUPE polymer, glycoprotein 1b (GP1b), and antiCD34 antibodies for in situ reendothelialization. Nanoscaffolds can inhibit platelet aggregation and activation, and promote endothelial progenitor cells for in situ endothelial regeneration. Moreover, the nanoscaffolds can reduce neointimal hyperplasia by 57% and increase endothelial cell regeneration by ∼60% at vascular injury sites over 21 d [66].

Yang et al. synthesized a thermoresponsive biodegradable antioxidant hydrogel (PPCN) comprising citric acid, polyethylene glycol (PEG), and poly-N-isopropylacrylamide) (PNIPAAm) via polycondensation and free radical polymerization. The PPCN hydrogel exhibited a lower critical solution temperature (26 °C) and intrinsic antioxidant properties, including free-radical scavenging, iron chelation, and lipid peroxidation inhibition. The PPCN hydrogel can effectively sustain the release of chemokine SDF-1α to support the proliferation of vascular cells [67]. Yuan et al. reported an injectable citrate-based hydrogel (PPC-ET/PEG) and investigated its performance as an angiogenic biomaterial for improving cardiac repair after myocardial infarction. In a rat myocardial infarction model, this PPC-ET/PEG hydrogel could continuously release citrate and growth factors to significantly reduce scar formation and the infarct area, increase the wall thickness and new blood vessel formation, and improve heart repair after myocardial infarction [68].

3. Bone tissue engineering

3.1. Critical factors of biomaterials in bone tissue engineering

Bone tissue is a natural nanocomposite with a hierarchical structure comprising organic proteins (mainly collagen I), inorganic minerals (mainly calcium phosphate), and multiple cells (osteoblasts, osteoclasts, stem cells, etc.) [69]. The bone ECM is mainly composed of crosslinked collagen fibers, and the bone minerals are calcium phosphate crystals located in and around the collagen fibers [70]. The outer bone tissue is composed of dense cortical bone or dense bone, whereas the interior bone is composed of cancellous or spongy bone. The composition and layered structure of bone tissue provide it with unique mechanical properties and physiological functions [69]. Previous studies have indicated that various factors can promote bone tissue repair, including good mechanical support, nutrient delivery, cell adhesion and proliferation, osteoconductivity (biomineralization deposition), and osteogenesis [69,71,72]. Therefore, bone tissue engineering materials are generally designed based on the physical structure and functional design of the bone tissue, which promotes the growth of new bone tissue and restores its functions. Ideal bone tissue engineering scaffolds should possess multifunctional properties, including biomimetic structural properties, controlled biodegradation, excellent biocompatibility and antibacterial activity, and good osteoconductivity and osteoinductivity [[73], [74], [75], [76]]. For example, the antibacterial activity of scaffolds can effectively prevent related infections after being implanted [75]. The biomineralization ability and osteogenic bioactivity of scaffolds can also provide a suitable environment for bone integration, osteoblastic growth, and osteoblast differentiation, thereby facilitating excellent bone defect repair ability [76].

3.2. Functionalized citrate for bone tissue engineering

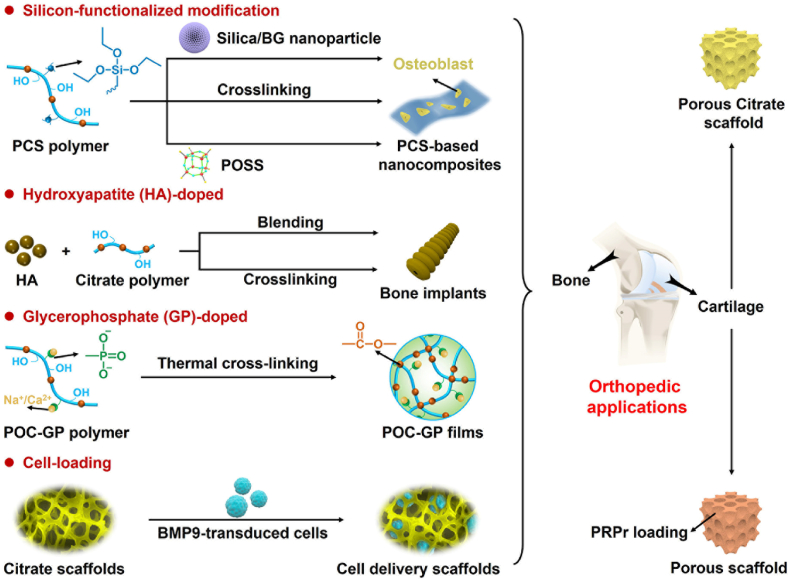

Previous studies have shown that citrate in human bone tissue plays an important role in metabolism, calcium chelation, hydroxyapatite formation, and regulation of bone apatite structure thickness [[77], [78], [79], [80]]. Therefore, citrate polymers have shown promise in bone tissue engineering (Fig. 5 and Table 2).

Fig. 5.

Schematic diagram of further functionalized modified citrate-based polymers for orthopedic applications.

Table 2.

Functionalized citrate-based polymers for bone tissue engineering.

| Materials | Component | Properties | Tissue engineering | Ref. |

|---|---|---|---|---|

| POC/PSC | POC; PSC | Improved mechanical performances | Good bioactivity; Stimulated bone regeneration | 82 |

| IBU-loaded SiO2/β-TCP/POC | POC; Ibuprofen; Silica; β-tricalcium phosphate | Highly interconnected porous network; Sustained IBU release; Antimicrobial property | Infectious bone defects repair | 83 |

| SPOC | POC; AS; GS | Controllable mechanical properties and degradation | Promote cell adhesion and proliferation; Increase ALP activity; mineralization | 84,85 |

| POC-POSS | POC; POSS | Highly tunable elastomeric behavior | Enhanced osteoblasts differentiation | 86 |

| GT/PCS/EPL | Gelatin; PCS; | Biomimetic elastomeric behavior; Controlled spinning diameter and degradation rate | Broad-spectrum antibacterial ability; Enhanced osteogenic bioactivity | 87 |

| ε-polylysine | ||||

| PCS-SN | PCS; Silica | Uniformly distributed; Controlled elastomeric mechanical properties | Good histocompatibility; Promote osteoblasts adhesion and proliferation | 88 |

| PCS-BGN | PCS; BGN | Enhanced mechanical properties | Intrinsical biomineralization activity; Improved osteogenic differentiation | 89 |

| PEC-GS/BG | POC, BG | Improve angiogenesis and osteoblast differentiation | Enhance bone regeneration | 90 |

| PPM | PCS; PCL; miRNA complexes | Control miRNA loading and release | Enhance bone regeneration | 91 |

| POC-HA | POC; HA | Similar mechanical properties; Controlled degradation; Good biocompatibility | Good osteoblasts adhesion and proliferation; Osteogenic differentiation; mineralization | 92–96 |

| Porous POC-HA | POC; HA | Promotion of cell migration and tissue inward growth and diffusion | facilitate graft fixation and tissue integration | 97 |

| Porous POC-HA/PLL | POC; HA; poly(l-lactide) | Appropriate mechanical; Promote the infiltration and ingrowth of tissue | Promote graft fixation and anterior cruciate ligament reconstruction | 98 |

| POC-nHA | POC; smaller HA nanoparticles | Increased mechanical properties; Reduced degradation rate | Promote osteogenesis and craniofacial bone repair | 99 |

| POC-Click-HA | POC-Click; HA | Appropriate porosities; Controllable compressive strength | Promote osseointegration, periosteal remodeling and new bone formation | 101 |

| POC-M-click-HA | POC-Click; HA; MDEA | Rapidly degradable; Higher load and stiffness | Promote spinal fusion | 102 |

| CUPE-HA | CUPE; HA | Higher osteogenesis effect than POC-Click-HA | Calvarial defects repair | 103 |

| CBPBHA | CUPE; POC; HA | Higher compressive strength | Excellent osteoconductivity and osseointegration | 104 |

| CTBCs | POC; HA; Tannic acid; Silver nanoparticles | Improved compression strengths, degradation properties and antibacterial activity | Enhanced cell adhesion, proliferation and biomineralization; promote bone regeneration | 105 |

| iCMBA-HA | Citric acid; PEG; Dopamine; HA | Good injectability and adhesion; Suitable compressive strength and degradation rate | Increase bone mass and recover bone strength | 106 |

| CMWAs | Citric acid; PEG-PPG-PEG diol; Dopamine; Magnesium whitlockite | Excellent adhesion; Enhance the strength of bone-tendon bonding | Promote bone-tendon healing | 107 |

| PEGMC-HA | Citric acid; Maleic anhydride; PEG; HA | Controllable mechanical properties and viscoelastic; Injectable | promote ALP activity and calcium deposition of osteoblasts; osteonecrosis treatment | 108,109 |

| BPLP-PSer/HA | BPLP; Phosphoserine; HA | Promote osteogenic differentiation of MSCs | Promote bone regeneration | 110 |

| POC-HA/CS | POC; HA; Chitosan | Antibacterial activity | Antibacterial biodegradable bone screw | 113 |

| POC-ZnO | POC; Zinc oxide nanoparticles | Good antibacterial properties, Controllable release kinetics profile | Drug release and antiinfection-related tissue engineering | 114 |

| PCGL/GM | Citric acid; Glycerol; Gentamicin | Enhanced antibacterial efficacy | Antiinfection-related tissue engineering | 115 |

| PPCNG/BMP9-transduced cells | PPCN; Gelatin; MSCs/iCALs/iMAD | Thermoresponsive; Good angiogenic and osteogenic differentiation | Promote cranial defects repair | 116–118 |

| PPCNG-GO | PPCN; Gelatin; Graphene oxide | Thermoresponsive; Enhanced osteoinductive ability | Promote bone repair | 119 |

| PPCN–Sr/PPCN-phos/PPCN-cRGD | PPCN; Strontium/Phosphate/Arg-Gly-Asp peptide | Thermoresponsive; Induce osteoinductive and osteogenic differentiation | Bone regenerative engineering | 120 |

| POC-GP-Ca | POC; GP-Ca | Controlled mechanical properties and degradation | promoted osteogenic differentiation and bone regeneration | 121 |

POC: poly(octamethylene citrate); PSC: phytic acid-derived bioactive glass; AS: 3-aminopropyltriethoxysilane; GS: 3-(2,3-glycidoxy) propyltrimethoxysilane; POSS: polyhedral oligomeric silsesquioxanes; PCS: 3-aminopropyltriethoxysilane grafted POC; BGN: silica-based bioactive glasses nanoparticles; BG: bioactive glass; PCL: poly (ε-caprolactone); PPCN: thermoresponsive POC-based polymer comprised of citric acid, polyethylene glycol and poly-N-isopropylacrylamide; BMP9: bone morphogenetic protein-9; MSCs: mesenchymal stem cells; iCALs: murine-derived calvarial mesenchymal progenitor cells; iMAD: immortalized murine adipocyte; GP-Ca: calcium glycerophosphate; HA: hydroxyapatite; POC-Click: azide-alkyne modified POC polymer; MDEA: N-methyldiethanolamine; CUPE: POC-based polymer comprised of POC and polyurethane; PEG: polyethylene glycol; PEG-PPG-PEG diol: poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol); ALP: alkaline phosphatase; BPLP: amino acid-modified POC.

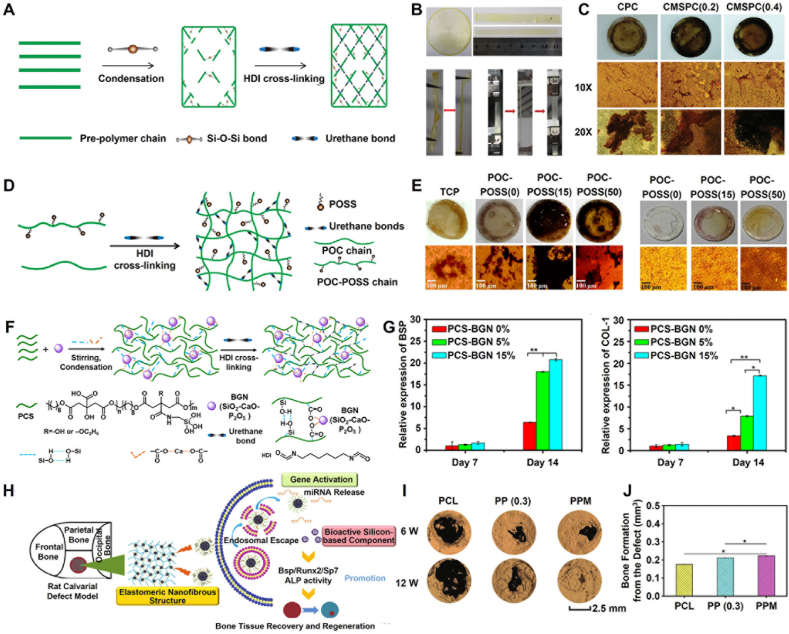

3.2.1. Si-functionalized citrate-based polymers for enhanced mechanics and osteogenesis

The doping of Silicon (Si) could effectively improve the mechanical properties of scaffolds and promote bone formation [81]. Ren et al. developed a series of POC/PSC composites using a POC polymer and phytic acid-derived bioactive glass (PSC). The POC/PSC composite exhibited improved mechanical performance owing to the formation of calcium dicarboxylate bridges, and its compressive strength and modulus were approximately 50 MPa and 1.3 GPa, respectively. In addition, the POC/PSC composite showed good bioactivity and cytocompatibility, integrated well with surrounding tissues, and stimulated bone regeneration in rat femoral condyle defects [82]. Chen et al. fabricated a novel ibuprofen (IBU)-loaded POC-based scaffold (SiO2/β-TCP/POC) using silica, β-tricalcium phosphate, and a POC polymer via a 3D printing technique, which possessed a highly interconnected porous network (macropores: 350–450 mm and mesopores: 3.65 nm) with a high load and sustained release of IBU. In addition, the scaffold exhibited effective antimicrobial properties and could be used in the repair of infectious bone defects [83]. Du et al. reported a series of silica-grafted POC hybrid elastomers (SPOC), including POCAS (POC and 3-aminopropyltriethoxysilane) and POCGS (POC and 3-(2,3-glycidoxy) propyltrimethoxysilane), produced via melt polymerization and vacuum thermal crosslinking technology. SPOC hybrid elastomers possess controllable mechanical and degradation properties and can significantly promote the adhesion and proliferation of myoblasts, fibroblasts, bone marrow mesenchymal stem cells, and osteoblasts. Moreover, the POCAS elastomer exhibits a higher modulus (approximately 22.1 MPa) and elongation (approximately 134%) than the POCGS elastomer [84]. To improve the mechanical properties of POCAS elastomers, Du et al. prepared a multifunctional POC hybrid elastomer (CMSPC) through the chemical crosslinking of HDI instead of thermal crosslinking. Compared to POCAS elastomers, CMSPC elastomers exhibited better mechanical properties, including a modulus (approximately 976 MPa) and elongation (approximately 309%) comparable to that of trabecular bone and tibia tissues. In addition, the CMSPC elastomer significantly promoted the proliferation of osteoblasts, increased alkaline phosphatase activity and biomineralization deposition, and promoted the expression of osteogenic genes and osteogenic differentiation (Fig. 6A–C) [85]. In addition, Du et al. developed a series of polyhedral oligomeric silsesquioxane (POSS)-grafted POC hybrid elastomers (POC-POSS) by applying a thermal polymerization strategy. The POC-POSS elastomers exhibited highly tunable elastomeric behavior in the hydrated state, and they significantly enhanced the differentiation of osteoblasts by upregulating alkaline phosphatase (ALP) activity, calcium deposition, and the expression of osteogenic genes (Fig. 6D and E) [86]. Xi et al. developed a biomimetic antibacterial nanofibrous scaffold (GT-PCS-EPL) using gelatin (GT), POCAS prepolymer (PCS), and ε-polylysine (EPL) via electrospinning and facile thermal crosslinking. The GT-PCS-EPL nanofibrous scaffold exhibited biomimetic elastomeric behavior, controlled spinning diameter and degradation rate, good biocompatibility, broad-spectrum antibacterial ability, and enhanced osteogenic bioactivity capacity, making it a promising nanofibrous scaffold for smart infection-related bone-tissue regeneration applications [87]. Li et al. reported a silica nanoparticle (SN)-reinforced biodegradable PCS hybrid elastomer (PCS-SN) produced through an in situ nanoparticle formation process. The PCS-SN elastomer exhibited evenly distributed SNs with a uniform size and spherical morphology, and controlled elastomeric mechanical properties and biodegradation. In addition, this PCS-SN elastomer with good histocompatibility can effectively promote the adhesion and proliferation of osteoblasts [88]. Li et al. further reported a silica-based bioactive glass nanoparticle (BGN)-based PCS hybrid elastomer (PCS-BGN) with intrinsic biomineralization activity for bone tissue regeneration. The PCS-BGN elastomer showed significantly enhanced mechanical properties, low inflammatory response, and improved osteogenic differentiation (Fig. 6F and G) [89]. In addition, Zhao et al. prepared a hybrid (PEC-GS/BG) using bioactive glass (BG) and citrate (PEC-GS) at the molecular level for bone regeneration. In the rat femoral condyle critical defect model, there was no significant difference in the bone mineral density of defects between the PEC-GS/BG group (509 ± 21 mg/cm3) and the autogenous bone group (517 ± 21 mg/cm3), indicating that the PEC-GS/BG hybrid had angiogenesis and osteoblast differentiation comparable to that of autogenous bones [90]. Yu et al. prepared a bioactive nanofibrous scaffold (PPM) using PCL and PCS polymers via electrospinning to load miRNA complexes to promote bone regeneration. The PPM nanofibrous scaffold effectively controlled miRNA loading and release and promoted the differentiation of osteoblasts and bone regeneration in vivo (Fig. 6H–J) [91].

Fig. 6.

Development and orthopedic applications of silicon-doped POC-based biomaterials. (A) Synthesis schematic of CMSPC elastomers; (B) Mechanical properties of CMSPC hybrid elastomers; (C) Osteogenic differentiation of MC3T3-E1 cells after culture with CMSPC elastomers [85]; Copyright 2015, John Wiley and Sons. (D) Synthesis schematic of POC-POSS elastomers; (E) Calcium deposition mineralization on different elastomers with cells (left) and without cells (right) [86]; Copyright 2016, American Chemical Society. (F) Synthesis schematic of PCS-BGN elastomers; (G) Osteoblastic genes expressions of MC3T3-E1 after culture with PCS−BGN elastomers [89]; Copyright 2018, American Chemical Society. (H) Schematic diagram of PPM nanofibrous scaffold to recover bone tissue defect; (I) Micro-CT images of new bone formation in rat calvarial defect model; (J) Bone formation from the defect in 6 weeks [91]. Copyright 2019, John Wiley and Sons. (For interpretation of the references to colour in this figure legend, the reader is referred to the Web version of this article.)

3.2.2. HA-doped functionalized citrate-based nanocomposites for enhanced osteogenesis

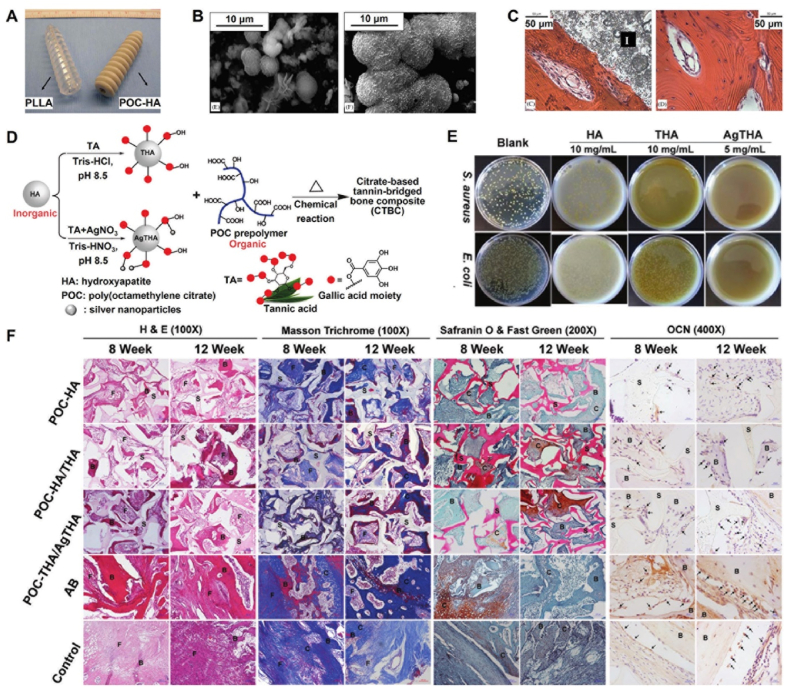

In addition to functional modifications, POC-based nanocomposites have broad applications in bone-tissue engineering. Qiu et al. reported a bioceramic-elastomer composite (POC-HA) with mechanical properties similar to those of natural bone using a POC polymer and hydroxyapatite (HA). Simulating the inorganic content of natural bone, the POC-HA composite containing 65% HA had the slowest degradation rate. The POC-HA composite exhibited good osteoblast adhesion and proliferation, biocompatibility, and mineralizing effects, suggesting that it has potential applications in the fabrication of osteoconductive bone screws (Fig. 7A–C) [92]. Qulub et al. further evaluated the mechanical properties and biocompatibility of POC-HA composites with different HA contents (62%, 65%, 68%, and 71%). The hardness value of the POC-HA composite containing 62% HA was 885.57 MPa, which is close to that of natural bone (150–664 MPa). Moreover, the POC-HA composite exhibited a stable degradation rate of approximately 3.42% for 4 weeks in simulated body fluid, and the total degradation time over 109 weeks (27 months) of the composite fits well into the required fracture bone grafting and healing time (3–21 months) [93]. Subsequently, Chung et al. proved that a POC-HA composite could promote the adhesion, proliferation, and osteogenic differentiation of mesenchymal stem cells (MSCs) [94]. Chung et al. further evaluated the early tissue and long-term responses of POC-HA nanocomposites after implantation into rabbit osteochondral defects. The POC-HA nanocomposites were well integrated with the surrounding bone and cartilage without inflammation after implantation for 6 weeks, and they enhanced osseointegration and bone regeneration after implantation for 26 weeks, indicating that the POC-HA nanocomposites can be used as bone substitutes for osteochondral regeneration [95,96]. Furthermore, Chung et al. prepared a porous POC-HA scaffold using low-pressure foaming to facilitate graft fixation and tissue integration in vivo due to the promotion of cell migration and inward tissue growth and diffusion [97]. Chung et al. prepared a biodegradable tricomponent graft (POC-HA/PLL), including a porous POC-HA scaffold and poly(l-lactide) (PLL) braids, to promote graft fixation and anterior cruciate ligament (ACL) reconstruction. The graft exhibited porous regions and appropriate mechanical properties (maximum load: 256.2 N, modulus: 217.5 MPa) comparable to those of the rabbit ACL (maximum load: 244 N, modulus: 233.7 MPa). Importantly, the graft effectively promoted the recovery of animal weight-bearing function and ACL reconstruction, and its fixation was strengthened by the infiltration and ingrowth of tissue [98]. Remarkably, Levi-Polyachenko et al. prepared an elastic nanocomposite (POC-nHA) using POC and smaller HA nanoparticles (∼200 nm) to improve the elastic modulus and strength of POC-nHA for craniofacial contraction osteogenesis. Compared with POC, the POC/nHA composite exhibited improved mechanical properties with an elastic modulus of 1.21 MPa and a maximum load of 13.17 N and a reduced degradation rate, which is expected to promote osteogenesis and craniofacial bone repair [99]. In contrast to the PLA bioabsorbable screws with reported foreign-body reaction (FBR), including tibia and pretibial cysts, delayed FBR at lateral femoral epicondyle, delayed intra-articular inflammatory reaction, and widening of the osteolytic femoral tunnel [17]. Citrelock based on the POC-HA composite (product: Citregen) has been sold by Acuitive Technologies, Inc. since 2020. Citrate, the main component of Citregen, is a naturally occurring metabolic molecule with antibacterial and anti-inflammatory properties [11,14]. According to previous studies and product introduction, Citregen possesses many advantages, including simple preparation, controllable mechanical properties (bending, compression, and stretching) to adapt to different bone tissues, complete degradation without chronic inflammation to reduce the risk of secondary surgery, and promotion of soft tissue and bone regeneration [[92], [93], [94], [95], [96]]. Therefore, Citregen, an unprecedented innovative bioabsorbable biomaterial, is expected to become the future of bone screws.

Fig. 7.

Development and orthopedic applications of POC-HA complexes. (A) PLLA and POC–HA screws; (B) Mineralization in SBF for POC–HA (65 wt% HA) at 3 days (left) and 15 days (right); (C) H&E stains of decalcified tissue (left) and femur bone (right) after 6 weeks of POC–HA implantation [92]; Copyright 2006, Elsevier. (D) Synthesis schematic of CTBCs; (E) Antibacterial ability of HA, THA, and AgTHA; (F) Histological staining at week 8 and 12 of the decalcified tissue sections containing the implanted materials [105]. Copyright 2020, John Wiley and Sons.

Guo et al. developed a new citrate-based polymer (POC-Click) that can react, through azide-alkyne cycloaddition to enhance the mechanical strength of the material without depleting the carboxyl groups for calcium chelation [100]. Using the POC-click polymer, Guo et al. fabricated a biomimetic POC-click-HA scaffold with a biphasic structure for to repair large segmental bone defects. The biomimetic scaffold exhibited porosities (internal: 70%, external: 5–50%) comparable to cancellous and cortical bones, with a controllable compressive strength (maximum: 37.45 MPa). Importantly, the bionic scaffold could significantly promote osseointegration, periosteal remodeling, and new bone formation in 10 mm-long rabbit segmental radial defects [101]. Tang et al. reported a rapidly degradable citrate-based scaffold (POC-M-click-HA), including N-methyldiethanolamine (MDEA)-modified POC-click and HA, to promote spinal fusion. The scaffold exhibited a higher maximum load (∼880.8 N), stiffness (843.2 N/mm), and spinal fusion rates (80.0%) at 8 weeks postsurgery compared to the PLLA-HA scaffold (maximum load: ∼712.0 N, stiffness: 622.5 N/mm, and spinal fusion rate: 71.1%) [102]. Sun et al. further evaluated the ability of two citrate porous scaffolds (CUPE-HA and POC-Click-HA) to promote calvarial regeneration. Both CUPE-HA and POC-Click-HA scaffolds exhibited satisfactory calvarial defect repair by stimulating proximal bone formation and angiogenesis. Notably, the CUPE-HA scaffold could better promote osteogenesis than the POC-Click-HA scaffold [103].

To improve the strength of POC-HA composites in load-bearing orthopedic applications, Tran et al. prepared a biomimetic citrate-based biodegradable composite (CBPBHA) including CUPE, POC, and HA. The CBPBHA composite exhibited comparable compressive strength (∼116.23 MPa) to that of human cortical bone (100–230 MPa) in contrast to the pure POC-HA composite (∼88.63 MPa), high HA incorporation ability (65 wt%), and excellent osteoconductivity and osseointegration [104]. To improve the mechanical properties and biological activity of the POC-HA composite, Guo et al. prepared a series of tannin-bridged POC-HA composites (CTBCs) using a strong adhesive tannic acid (TA) to bind silver nanoparticles, and then bridged the POC polymer and HA particles through chemical binding. Compared with the POC-HA composite, the CTBCs composite exhibited greatly improved compression strengths and degradation properties, as well as enhanced cell adhesion, proliferation, biomineralization performance, and antibacterial activity. In a lumbar fusion model, the CTBCs composite can promote bone regeneration owing to its good osteoconductivity and osteoinductivity. In addition, the immobilized TA in CTBCs composites retained certain bioconjugation sites, which suggests great potential for further modification and application in bone regeneration (Fig. 7D–F) [105].

Xie et al. prepared a novel injectable citrate-based mussel-inspired bioadhesive bone implant (iCMBA-HA), comprising a dopamine-modified citrate polymer and HA, for comminuted bone fracture therapy. The iCMBA-HA implant exhibited good injectability and adhesion, a suitable compressive strength (∼3.2 MPa) and degradation rate (∼30 d), and good biocompatibility and osteoinductivity, which can effectively increase bone mass and recover bone strength [106]. Yuan et al. further developed a citrate-based adhesive (CMWAs) by compositing magnesium whitlockite and an iCMBA-EPE polymer synthesized using poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol) (PEG-PPG-PEG diol) instead of PEG. The excellent adhesion of CMWAs can enhance the strength of bone-tendon bonding, cartilage formation, and osteogenesis at the bone–tendon interface, which promotes bone–tendon healing [107]. Jiao et al. developed a water-soluble injectable biodegradable composite (PEGMC-HA) using citric acid, maleic anhydride, PEG, and HA and systematically studied its viscoelastic properties. The PEGMC-HA composite possesses controllable mechanical properties and is expected to have potential in bone tissue engineering [108]. Gyawali et al. further proved that the PEGMC-HA composite can effectively promote ALP activity and calcium deposition in osteoblasts in vitro, and it could be injected into porcine femoral head bone defects and can reinforce them for the treatment of osteonecrosis in vivo [109]. Ma et al. reported a citrate-based composite microparticle scaffold (BPLP-PSer/HA) composed of phosphoserine-copolymerized POC (BPLP-PSer) and HA. The BPLP-PSer/HA scaffold could promote osteogenic differentiation of MSCs by providing metabolic energy from metabonegenic regulation, and it significantly promoted bone regeneration in rat femoral condyle and cranial defect models [110].

3.2.3. Antibacterial functionalized citrate-based polymers for antiinfective bone scaffolds

Citric acid can effectively prevent bacterial growth or enhance the antibacterial properties of other antibiotics and thus has potential applications in anti-infection-related tissue engineering [111]. Su et al. evaluated the antibacterial properties of four different biodegradable POC-based polymers against E. coli and S. aureus, including POC, POMC, CUPE, and amino acid-modified POC (BPLP). Compared with the moderate antibacterial properties of POMC, CUPE, and BPLP, the POC polymer exhibited the highest antibacterial properties because of its higher citric acid ratio and faster degradation rate [112]. Considering the antibacterial properties of POC-based polymers, Widiyanti et al. evaluated the antibacterial activity and biocompatibility of a POC-HA composite with 62% HA coated with different amounts of chitosan (1%, 3%, and 5%), and the composite with 3% chitosan coating exhibited the best antibacterial activity [113]. Kompany et al. prepared a novel composite material (POC–ZnO) composed of POC and zinc oxide nanoparticles (ZnO NPs), which exhibited good antibacterial properties and controllable physical characteristics (strength/elasticity), and the release kinetics profiles suggested potential use in controlled drug release and tissue engineering [114]. In addition, Halpern et al. prepared a biodegradable thermoset polymer (PCGL) using citric acid and glycerol by esterification, which exhibited significantly enhanced antibacterial efficacy against S. aureus after loading with gentamicin [115].

3.2.4. Cell/bioactive factors delivery of functionalized citrate-based scaffolds for bone formation

Using the abovementioned thermoresponsive biodegradable antioxidant PPCN polymer, Ye et al. prepared a thermoresponsive scaffold (PPCNG) comprised of PPCN and gelatin for the delivery of bone morphogenetic protein-9 (BMP9)-transduced MSCs to promote local bone formation. Owing to the presence of gelatin, the PPCNG scaffold exhibited enhanced cell adhesion and survival rates and good angiogenic and osteogenic differentiation [116]. Dumanian et al. and Lee et al. further utilized a PPCNG scaffold to deliver BMP9-transduced murine-derived calvarial mesenchymal progenitor cells (iCALs) or BMP9-transduced immortalized murine adipocyte progenitor cells (iMAD), which can promote cranial defect repair by inducing bone formation in vivo [117,118]. Zhao et al. reported that graphene oxide could enhance the osteoinductive ability of PPCNG scaffolds [119].

To effectively eliminate the performance differences in the natural material (gelatin) due to batch-to-batch heterogeneity, Morochnik et al. prepared three different functionalized PPCN-based hydrogels, strontium (PPCN–Sr), phosphate (PPCN-phos), and the cell adhesion peptide Arg-Gly-Asp (RGD) (PPCN-cRGD), for bone regenerative engineering. All hydrogels exhibited thermoresponsive and inductive abilities for osteogenic differentiation of MSCs. Importantly, the PPCN–Sr hydrogel exhibited superior osteoinductive and osteogenic differentiation compared to the PPCN-phos and PPCN-cRGD hydrogels [120]. The above reports suggest that functionalized PPCN-based scaffolds may be promising cell delivery scaffolds for bone tissue engineering.

Moreover, He et al. reported a new class of osteopromotive bioactive biodegradable composites (POC-GP) using a POC polymer and glycerophosphate salts (GP-Ca and βGP-Na) through a one-pot condensation reaction. Compared to the POC-βGP-Na composites, the POC-GP-Ca composite exhibited better cytocompatibility, improved osteogenic differentiation of MSCs in vitro, and promoted bone regeneration in a rabbit femoral condyle defect model [121].

4. Cartilage tissue engineering

4.1. Critical factors of biomaterials in cartilage tissue engineering

Cartilage is a connective tissue that plays important supportive and protective roles in the musculoskeletal system. Cartilage tissue comprises chondrocytes; ECM; and fibers without blood vessels, lymphatic vessels, or nerves [122]. The cartilage ECM mainly consists of collagen (mainly collagen II), glycosaminoglycans (hyaluronic acid, chondroitin sulfate, keratan sulfate, dermatan sulfate, etc.), and glycoproteins [123]. Cartilage tissue generally includes hyaline cartilage, elastic cartilage and fibrocartilage [124]. The articular cartilage is located on the surface of the movable joint, which reduces the friction between adjacent bones and acts as a buffer to maintain the normal movement of the bones. In addition, with the deepening of the articular cartilage layer, the content of chondrocytes gradually decreases, the content of proteoglycans gradually increases, and the collagen fibers change from thin to thick. Meanwhile, the direction of the collagen fibers changes from parallel to the cartilage surface (superficial) to random (middle) to perpendicular to the articular surface (deep) [122]. The unique structure of articular cartilage plays an important role in maintaining tissue moisture, tensile properties, and pressure resistance. Previous studies have indicated that various factors can promote cartilage tissue repair, such as promotion of cell attachment and proliferation, maintenance of chondrocyte morphology and phenotype, induction of cell cartilage differentiation, and synthesis of cartilage ECM [[124], [125], [126], [127]]. Therefore, cartilage tissue engineering materials based on the structure and function of cartilage tissue are generally needed to ensure normal joint movement and promote cartilage regeneration. Ideal cartilage tissue engineering scaffolds should possess multifunctional properties, including suitable pore shape and permeability, excellent mechanical properties, enhanced chondrocyte differentiation, and cartilage tissue formation [[128], [129], [130]]. For example, a suitable pore shape and permeability of scaffolds can effectively enhance cellular colonization and matrix deposition [128]. The excellent mechanical properties of scaffolds can effectively replace defective cartilage and maintain normal joint activity [129]. The chondrogenic activity of scaffolds can also provide a suitable microenvironment for chondrocytes and promote the formation of new cartilage [130].

4.2. Porous citrate-based scaffolds for enhanced chondrocyte differentiation and cartilage formation

For the repair of cartilage damage, compared with conventional tissue-engineered scaffolds including agarose, alginate, polyglycolic acid (PGA), PLLA and PLGA are prone to plastic deformation after cyclic compressive strain due to their limited strength and elasticity [[131], [132], [133]]. Notably, the POC-based polymer scaffolds showed a certain application potential in cartilage tissue engineering, as shown in Fig. 5.

Kang et al. prepared a porous POC scaffold using a salt leaching method for cartilage tissue engineering. The POC scaffold exhibited a recovery ratio higher than 98% after compression compared with the recovery ratios of alginate gel scaffolds (72%), PGA (88%), and PLLA (85%). The POC scaffold can also effectively promote the adhesion, proliferation, and differentiation of chondrocytes and increase the glycosaminoglycan (GAG) and collagen content of chondrocytes cocultured after 28 d in bovine knee cartilage explants, which promotes the formation of cartilage tissue. Therefore, the POC scaffold showed remarkable potential for application as a biodegradation scaffold for cartilage tissue engineering [134]. Jeong et al. examined the influence of pore shape and permeability of two different POC scaffolds, including low-permeability spherical pores and high-permeability cubical pores, on the mechanical properties, matrix production, and mRNA gene expression of chondrocytes. The results showed that low-permeability spherical pores exhibited higher matrix production and mRNA expression than high-permeability cubical pores [135]. Jeong et al. subsequently evaluated the influence of the pore shape and permeability of two different POC scaffolds on cartilage formation of primary chondrocytes in vivo. After 6 weeks, the POC scaffold with low-permeability spherical pores exhibited significantly increased cartilage matrix production, such as sulfated glycosaminoglycan (sGAG), which provided a better microenvironment for chondrogenesis than the high-permeability cubical pores [136]. In addition, Jeong et al. compared the effects on cartilage regeneration for three different scaffolds with the same controlled architecture, including POC, PCL, and PGS. Compared with the PCL and PGS scaffolds, the POC scaffold exhibited the highest sGAG contents and differentiation index and the corresponding DNA and the lowest hypertrophic mRNA expression and matrix degradation after 4 weeks in vitro. Moreover, PCL and PGS scaffolds can promote the proliferation of chondrocytes and the expression of genes related to cartilage formation and promote the expression of genes related to cartilage destruction and ossification, which greatly limit their applications in cartilage repair. Therefore, the POC scaffold is suitable for cartilage repair, and its structure may be critical to clinical cartilage repair [137].

In addition, Rothan et al. reported an elastomeric polycaprolactone triol–citrate (PCLT–CA) porous scaffold loaded with platelet-rich plasma releasates (PRPr) to promote chondrogenic phenotypes and cartilage ECM formation. The PCLT–CA porous scaffold enriched with PRPr showed significantly increased sGAG and collagen II contents, which provided a good microenvironment for cartilage formation [138].

5. Muscle tissue engineering

5.1. Critical factors of biomaterials in muscle tissue engineering

Muscle tissue is a soft tissue that maintains body movements, homeostatic function, and postural support, and it protects internal organs [139]. Muscle tissue is formed by specially differentiated muscle cells combined with connective tissue, capillaries, and nerve fibers [140]. The main characteristic of muscle tissue is its relaxation and contraction behavior [141]. Muscle tissue can be divided into three types: skeletal muscle tissue for force generation and body movements, myocardial tissue for pumping blood to the whole body, and smooth muscle tissue for gastrointestinal peristalsis [142]. Previous studies have indicated that various factors can promote muscle tissue repair, including maintaining the microenvironment for cell adhesion and proliferation, reducing scar tissue formation, as well as promoting myotube formation, and myogenic differentiation [[143], [144], [145]]. Biomaterial-based strategies have exhibited promising applications in muscle tissue repair owing to their bioactivity and biocompatibility. Ideal muscle repair biomaterials should possess multifunctional properties, including controllable mechanical properties, an appropriate degradation rate, a specific 3D structure and porosity, and promotion of myogenic differentiation [[146], [147], [148], [149]]. Controllable mechanical properties can ensure that the biomaterials match the compliance of the native muscle tissue, avoiding fatigue and failure under stress [146]. The degradation rate matching the tissue regeneration rate can effectively provide continued support throughout the repair process and allow for gradual resorption [147]. An appropriate 3D structure and porosity can effectively ensure the infiltration and integration of biomaterials with muscle tissue [148]. Muscle differentiation can effectively promote the formation of new muscle tissue [149].

5.2. Functionalized citrate polymers for muscle tissue engineering

5.2.1. Controllable mechanics functionalized citrate-based polymers for biomimetic milieu

Among various biomaterials, POC-based polymers exhibit application potential in muscle tissue engineering, as shown in Fig. 8 and Table 3 [150,151]. Sharma et al. seeded MSCs onto POC elastomeric thin films (POCfs) to provide a suitable milieu for partial bladder regeneration. The POCfs film exhibited a high uniaxial elastic potential, and its Young's modulus and elongation were 138 kPa and 137%, respectively. The POCfs film can also promote the formation of muscle bundles and the expression of bladder smooth muscle contractile proteins; the muscle/collagen was approximately 1.75 times that of the pure cell control group at 10 weeks, indicating that the POCfs film has great potential for applications in bladder smooth muscle repair [152]. Prabhakaran et al. prepared a biocompatible and elastomeric nanofibrous scaffold (POC/PLCL) using a POC polymer and poly (l-lactic acid)-co-poly-(3-caprolactone) (PLCL) using electrospinning technology for cardiac tissue engineering. The POC/PLCL scaffold possessed controllable mechanical properties and degradation behavior, and its tensile strength and Young's modulus were approximately 1.04 MPa and 0.51 MPa, respectively, when the weight ratio of POC to PLCL was 40:60, which is comparable to that of native cardiac tissue. In addition, the POC/PLCL scaffold can effectively promote the adhesion and proliferation of myoblasts, laying the foundation for its use as a myocardial tissue repair scaffold [153].

Fig. 8.

Schematic diagram of further functionalized modified citrate-based polymers for muscle and skin tissue applications.

Table 3.

Functionalized citrate-based polymers for muscle tissue engineering.

| Materials | Component | Properties | Tissue engineering | Ref. |

|---|---|---|---|---|

| POCfs | POC | High uniaxial elastic potential; MSCs loading and release | Promote muscle bundles formation and proteins expression; Bladder smooth muscle repair | 152 |

| POC/PLCL | POC; PLCL | Controllable mechanical property and degradation; | Promote myoblasts adhesion and proliferation; Myocardial tissue repair | 153 |

| PCEG | POC; Graphene; PEG | Controlled biodegradability; Enhanced elastomeric; Electrochemical conductivity | Promote myogenic differentiation and skeletal muscle regeneration | 154 |

| POCG-PEI600 | POC; PEG; PEI | Biodegradation and Biocompatibility | Enhance myotubes formation; Increase gene expression and protein level; | 155 |

| FPCP | POC; PEG; PEI; F127; PPy@PDA | Injectable; Adhesive; | Increase myogenic genes expression and MHC protein; Promote skeletal muscle regeneration | 156 |

POC: poly(octamethylene citrate); PLCL: poly (l-lactic acid)-co-poly-(3-caprolactone); MSCs: mesenchymal stem cells; VEGF: vascular endothelial growth factor; PEG: polyethylene glycol; PEI: polyethyleneimine; F127: Pluronic F-127; PPy@PDA: polypyrrole@polydopamine; MHC: myosin heavy chain.

5.2.2. Conductive/polyamides functionalized citrate-based polymers for myogenic differentiation

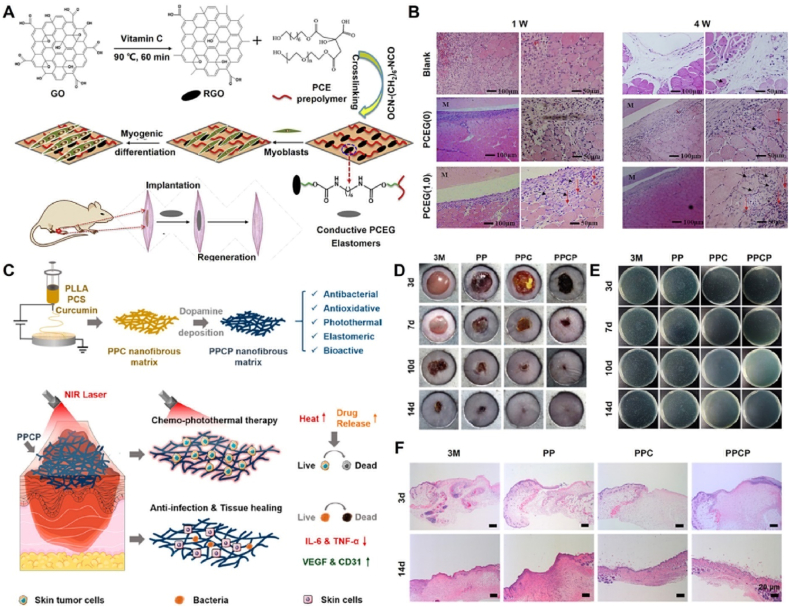

Du et al. first prepared highly elastomeric, conductive, and biodegradable nanocomposites (PCEG) using graphene-doped and PEG-copolymerized POC polymers to promote myogenic differentiation and skeletal muscle regeneration. The PCEG nanocomposites possessed controlled biodegradability, electrochemical conductivity, and significantly enhanced elastomeric behavior. Moreover, PCEG nanocomposites effectively promoted the proliferation and differentiation of myoblasts and significantly enhanced the regeneration of blood vessels and muscle fibers in a rat skeletal muscle lesion model (Fig. 9A and B) [154]. Guo et al. reported a biodegradable and biocompatible cationic citrate polymer (POCG-PEI600), including polyethyleneimine (PEI, 600 Da) and polyethylene glycol (PEG)-modified POC (POCG), for skeletal muscle regeneration. The POCG-PEI600 polymer enhanced myotube formation, gene expression, and protein levels to significantly accelerate myoblast proliferation and differentiation in vitro and in vivo. Significantly, the POCG-PEI600 polymer can effectively facilitate myoblast differentiation of myoblasts (C2C12 cells) by activating the p38 MAPK γ signaling pathway to upregulate p-p38 protein levels, which provides great potential for muscle-related tissue regeneration [155]. Subsequently, Zhou et al. developed an injectable muscle-adhesive hydrogel (FPCP) using the abovementioned POCG-PEI600 polymer, Pluronic F-127 (F127), and polypyrrole@polydopamine (PPy@PDA) to promote skeletal muscle regeneration in vivo. The FPCP hydrogel can increase the expression of myogenic genes and myosin heavy chain (MHC) protein to enhance the proliferation and differentiation of C2C12 cells and myofiber formation and angiogenesis capacity to promote full-thickness skeletal muscle regeneration in vivo [156].

Fig. 9.

Development and muscle and skin tissue applications of functional citrate-based biomaterials. (A) Synthesis schematic of conductive PCEG elastomers; (B) H&E staining of PCEG elastomers after implantation for 1 week and 4 weeks [154]; Copyright 2018, Elsevier. (C) Synthesis schematic of conductive PPCP nanofibrous matrix; (D) Photographs of S. aureus-infected wounds at 3, 7, 10, and 14 days; (E) Colonies derived from infected wound; (F) H&E stained images of wounds [175]. Copyright 2020, American Chemical Society.

6. Skin tissue engineering

6.1. Critical factors of biomaterials in skin tissue engineering

The skin is one of the largest organs in the body and plays important roles in protection, excretion, regulation of body temperature, and external stimulation perception [157]. Skin tissue exhibits softness, smoothness, and good elasticity and comprises an epidermis, dermis, and subcutaneous fat layer. The dermis and subcutaneous fat layer contain blood vessels, lymphatic vessels, nerves, sweat glands, and hair follicles, and there are free nerve endings in the epidermis without blood vessels [158]. However, the skin is often severely damaged by trauma, abrasion, burns, and surgical operations [[159], [160], [161]]. Wound healing can usually be divided into four stages: hemostasis, inflammation, proliferation, and tissue remodeling. The process is affected by various external factors, such as bacterial infection, temperature, pH, and sugar levels [162,163]. Previous studies have indicated that various factors can effectively regulate and accelerate wound healing, such as good hemostasis, removal of pathogenic microorganisms, inhibition of inflammation, regulation of the wound microenvironment, reduction of scar formation, and promoting vascularization. Therefore, wound dressings that can accelerate healing are extremely useful [[164], [165], [166], [167]]. Ideal wound dressings should possess multifunctional properties, including excellent tissue adhesion and porosity, controlled mechanical properties, hemostatic ability, antibacterial activity, anti-inflammatory properties, and sustained bioactive molecule release [[168], [169], [170], [171], [172]]. The tissue adhesion and porosity of the dressing can effectively maintain a local moist environment around the wound and promote good gas transmission [168]. The controlled mechanical properties of the dressing can provide good operability and maintain the stability of the structure [169]. The hemostatic ability of the dressing can effectively control bleeding caused by trauma [170]. Antibacterial and anti-inflammatory properties can effectively prevent microbial infection and regulate the inflammatory microenvironment around wounds [171]. The sustained release of bioactive molecules can effectively promote cell migration and angiogenesis, which accelerate wound healing [172].

6.2. Functionalized citrate polymers for skin tissue engineering

6.2.1. Antibacterial functionalized citrate-based scaffolds for infected wound repair

According to previous reports, citrate-based polymers possess excellent biocompatibility and angiogenesis ability and have potential applications in wound healing, as shown in Fig. 8 and Table 4. Goins et al. developed a novel nanofibrous scaffold (POC/PAA) consisting of a POC polymer and poly (acrylic acid) (PAA) using electrospinning technology for wound healing applications. The POC/PAA scaffolds possessed a structural geometry that mimicked that of the natural dermis, had intrinsic antibacterial activity, and delivered growth factors. Additionally, POC/PAA scaffolds can enhance the adhesion and proliferation of skin fibroblasts, suggesting that they have potential applications in the healing of infected wounds [173]. Xi et al. developed a biomimetic elastomeric polypeptide-based nanofibrous matrix (PCE/PCL) consisting of ε-polylysine (EPL)-modified POC polymer (PCE) and polycaprolactone (PCL) to overcome multidrug-resistant bacteria (MDRB) and enhance full-thickness wound healing. The PCE/PCL matrix exhibited a good tensile elastomeric modulus, which was comparable to that of normal skin tissue; optimized hydrophilicity; and highly efficient broad-spectrum antibacterial activity against E. coli and P. aeruginosa (gram-negative bacteria), S. aureus and E. faecalis (gram-positive bacteria), and MRSA (multidrug-resistant gram-positive bacteria), which can effectively prevent MDRB wound infection and accelerate wound healing by promoting collagen deposition; angiogenesis; related gene expression; and the formation of epidermis, dermis, and hair follicle tissues [174]. Xi et al. prepared a multifunctional nanofibrous dressing (PPCP) consisting of a PCS polymer, PLLA, curcumin, and polydopamine for cutaneous tumor therapy and infection-induced wound healing. The PPCP nanofibrous dressing exhibited good antioxidant, anti-inflammatory, and broad-spectrum antibacterial properties, effectively enhancing chronic wound healing by preventing bacterial infections, reducing proinflammation, promoting angiogenesis, and stimulating collagen deposition (Fig. 9C–F) [175].

Table 4.

Functionalized citrate-based polymers for skin tissue engineering.

| Materials | Component | Properties | Tissue engineering | Ref. |

|---|---|---|---|---|

| POC/PAA | POC; PAA | Mimicked dermis structure; Antibacterial activity; Enhance fibroblasts adhesion and proliferation | Bacterial infection wound healing | 173 |

| PCE/PCL | POC; EPL; PCL | Good tensile elastomeric; Hydrophilicity; Antibacterial ability; Promote collagen deposition and angiogenesis | Bacterial infection wound healing | 174 |

| PPCP | PCS; PLLA; Curcumin; Polydopamine | Antioxidant, Anti-inflammatory; Broad-spectrum antibacterial | Cutaneous tumor therapy and inflection-induced wound healing | 175 |

| POC-C/POC-T/POC-H/POC-M | POC; Quaternary ammonium; Phosphonium | Good antibacterial efficacy; appropriate mechanical properties | Antimicrobial wound dressings | 176 |

| CG-POCG | POC; PEG; chitosan; β-glycerophosphate | Downregulate the pro-inflammatory cytokines; Upregulate angiogenic factors | Accelerate skin wound repair | 177 |

| FEA-PCEI | POC; PEG; PEI; Ibuprofen; F127; EPL; Sodium alginate | Injectable; Antibacterial; Increase anti-inflammatory M2 macrophage; Inhibiting inflammatory factors expression; | Accelerate wound healing and hair follicle neogenesis | 178 |

| FEPCGS | POC; PEG; Siloxane; F127; EPL | Injectable; antibacterial; anti-inflammatory; Promote fibroblasts proliferation and endothelial cells migration | MDRB-infected wound healing | 179 |

| iCMBA | Citric acid; PEG; Dopamin | High adhesion strength; Controllable mechanical properties and degradation properties | Hemostatic adhesive and wound closure | 180,181 |

| iCMBA-EPE/MgO | Citric acid; PEG-PPG-PEG diol; Magnesium oxide | High adhesive strength; Low swelling ratio; Good antibacterial and hemostatic ability | Promote wound closure and potential bone regeneration | 182 |

| AbAf iCs | iCMBA; 10-undecylenic acid | Strong wet tissue adhesion; Long-term antibacterial and antifungal abilities | Bacterial or fungal infections tissue engineering | 183 |

| POC/PLA | POC; PLA | Elastic; Hydrophilic; Sustained release aspirin | Wound dressing | 184 |

| H-HKUST-1 | PPCN; HKUST-1 NPs | Sustained release of copper ions; Antioxidant property; Promotion of collagen deposition and angiogenesis | Accelerate diabetic wound healing | 185 |