Abstract

Our society has undergone a massive technological revolution over the past decade and electronic appliances have now become ubiquitous. The increase in production of electronic products and the growing inherent need to own the latest technology available has led to a significant increase in the amount of E-waste produced each year. India generated 3.2 million tonnes of E-waste in 2020, with metropolitan cities like Mumbai, Delhi and Bangalore leading the list. Proper management and recycling of E-wastes are critical for the sustainability of any modern city today. While industrial and commercial collection of E-wastes has been in the spotlight, solutions for collection of E-wastes from individual households are limited. This article proposes the implementation of a mobile robot that identifies common electronic wastes based on transfer learning and serves as an attachment to existing municipality garbage trucks. The robot moves around, identifies electronic wastes and performs segregation of the identified material via its arm-based lift and storage mechanism. A convolutional neural network–based identification system has been employed for categorising the E-wastes and yields 96% accuracy. This is a first of its kind attempt, especially in India, to collect and segregate E-wastes from homes and individuals. The system will relieve unskilled labour from the hazardous process while providing a 20% decrease in costs over a 5-year period. The application of this article aims to provide a viable mobile solution for E-waste collection from households with minimal human intervention.

Keywords: Solid waste segregation, wastes from electronic and electrical equipment, deep learning, convolutional neural networks, transfer learning, robotics

Introduction

Electronic waste (E-waste) generation has become a primary cause of concern in the digital era due to the sheer volume of its production and the implications it has on our ecosystem. The total quantity of waste electrical and electronic equipment (WEEE) increases at the rate of 2.6 million annually. The global estimation of electronic waste production for 2030 is at 74.8 million tonnes, which is highly concerning and draws attention to the low recycling rate of 17.4%. The definition of electronic wastes encapsulates various forms of electronic products that have lost value and are considered to be frivolous to their owners. From personal gadgets to home appliances, electronic wastes have now found their way into our environment. Most consumer electronic goods contain hazardous metals like lead, cadmium, nickel, mercury, beryllium and zinc. It is therefore essential to separate these wastes from the general solid waste channel. The E-waste domain is also a forum for undertaking business initiatives for precious metal recovery and a means for producing energy via biochemical processes. Hence, the identification, recovery and proper recycling of electronic wastes is an imperative step towards achieving a sustainable future. The increasing illegal export of E-wastes to developing countries to reduce recycling costs is highly concerning from a self-sustainability point of view.

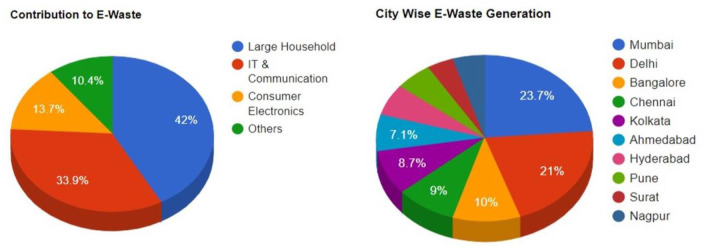

Developing countries like India are severely affected by this disposition of E-waste materials into their countries. While private industries contribute to a significant portion to the total E-waste produced in a country, household appliances combined with consumer electronics constitute close to 55.7% of it in India (Arya and Kumar, 2020). Figure 1 demonstrates the distribution of electronic wastes on the classification of products and the distribution of WEEE among the major cities of India (Joon et al., 2017). Private companies and commercial entities have now started to focus on third-party affiliations to dispose and recycle their electronic wastes. With commercial electronic wastes management attaining the spotlight, the focus towards household and personal electronic goods disposal has taken a backseat. Consumers are not sufficiently educated on how to dispose of electronic goods and this poses a significant problem (Miner et al., 2020). Educating the electronic users is essential for them to assist the waste segregation process, but most consumers do not want to burden themselves with the extra effort of segregating E-wastes, in addition to biodegradable and non-biodegradable segregations. Hence, household E-wastes usually are not processed towards proper methodologies for recycling.

Figure 1.

Contribution of WEEE in terms of type of electronic (left) and city (right) in India.

If consumer E-wastes were to be collected and discarded along with general household wastes, toxic emissions and the environmental pollution caused could damage vital resources in our ecosystem. Policies and regulations surrounding E-wastes are relatively rudimentary compared to other laws governing solid waste management in India (Borthakur and Govind, 2017). Unemployed workers, desperate for work, tread through dump yards in hopes of finding devices with usable parts or metals for scrap. Respiratory problems are reportedly common among those working in these filthy smoke-filled conditions. Automating the separation of collection process of electronics can vastly increase the speed of waste processing and reuse of the component materials while decreasing the harmful effects to the manual workers.

Technological intervention will provide garbage workers with additional tools to facilitate seamless waste management with the E-waste delivered to well-equipped E-waste dedicated recycling centres. Machine learning (ML) applications and robotic automations are viewed as the current forerunners in achieving a smart tomorrow in terms of environmental waste reduction. In this article, we investigate the application of a mobile wheel–based robot as an attachment to garbage trucks with the primary purpose of segregating and collecting electronic wastes during general household trash collection in a city. Our primary focus is towards individual consumers and civilian homes. To facilitate ease of integration with the existing city waste management routes, the robot is an addition to the existing labour system, reducing the manual intervention required.

Related works

The advent of ML techniques for object recognition has intrigued interest for researchers to explore the possibility of applying the same approach towards waste management. Deep learning methods for trash classification have been analysed using the Trashnet dataset to find out the most appropriate modelling approach (Aral et al., 2018) in the past. The Trashnet dataset comprises images of recyclable materials like glass, cardboard, plastic, metal and paper, among other trash items. Data augmentation was carried out to extend the limitations of the dataset size. Testing several different neural network models, DenseNet121 (with fine tuning) was concluded as the best approach for classifying this dataset.

The integration of the Internet of things (IOT) with ML has also gained traction for automating the garbage classification process. Investigations for equipping trash bins with sensors to facilitate automatic image-based waste segregation have been conducted (Pamintuan et al., 2019) and proven efficient in achieving automated separation of biodegradable and non-biodegradable materials. Microcontroller-based convolutional neural network (CNN) smart bins (White et al., 2020) have been developed with the focus of supplementing the waste segregation process in both commercial spaces and households. Smartphones connected to the bins either via Bluetooth or via the Internet provide constant updates to the owner on the status of the bin while maintaining proper management of the wastes. CNNs, for the precise purpose of waste classification in smart bins, have also proven beneficial as additions to the existing smart bin architectures. Praveen Kumar Gupta et al. modelled an IOT and ML integrated waste management system for a city to reduce manual interactions. Deep learning systems for household waste monitoring with real-time feedback of data (Rahman et al., 2020) have been created to offer consumers with instant updates through smartphone apps about the wastes in their homes. Hybrid deep learning methodologies for collecting wastes from public centres use high-resolution cameras and sensors to separate wastes into recyclable and non-recyclable (Chu et al., 2018). Several pretrained networks have also been used to facilitate automation of the waste segregation process through transfer learning (Hana et al., 2017).

Some classification characteristics are distinct for E-waste materials, and utilisation of these features proves beneficial in the garbage partitioning process. Resource recovery and recycling of electronic wastes are drastically improved by including classification of metallic fractions and non-metallic fractions from E-waste materials. Thermal imaging was employed (Gundupalli et al., 2018) to extract feature vectors to be used as the basis for classification. Individual material thermograms were obtained from the E-waste materials. Experimental results conducted on simulated E-wastes confirmed the accuracy and efficiency of their model. Scalable classification of different E-waste materials, upon proper implementation, can benefit recycling plants immensely.

Research work on waste management has also been of great interest in the realm of robotics. Macro-sorting of municipal solid waste materials is a process that requires a huge amount of manual labour. Apart from the tiring nature of work, labourers are also subjected to a toxic and harmful environment that can cause long-term effects on their health. Optimisation of the existing configurations for macro-waste sorting robotic systems was explored and the methodology was applied to sorting mercury free bulbs to provide proof of concept (Pellegrinelli, 2019). The advent of robotics for waste sorting propelled the automated waste management to the next level. Deep neural waste recognition combined with autonomous robots acts a mobile garbage pickup system (Bai et al., 2018). The capacity of robots to navigate efficiently helps achieve the same result as in traditional waste collection. This leads to a decrease in the requirement of physical labour for garbage collection. The primary form of household E-waste disposal has been found to be through the informal sector in countries such as China (Chi et al., 2014). Six different disposal methods were reviewed to identify the most preferred way for consumers to dispose their E-wastes, namely storage, disassembly, discarding, formal sector collection and informal sector collection, with informal collection emerging as the forerunner. While several beneficial governmental schemes have been put in place in China for disposing household electronic wastes through the formal sector, the most prevalent way of disposal remains to be informal due to the high prices offered to the consumers without the requirement of any registration process fulfilments. Other influential factors that motivate consumers to approach the informal way of E-waste disposal (Wang et al., 2017) include revenue obtained by selling of the electronic wastes to peddlers and lack of tax/subsidy support from the local government. Mandating producer responsibility and maintaining a three-way cost responsibility between the consumers, producers and local government (Wagner, 2009) has proved in the past to significantly improve economic costs to the households and the local governments in Maine, USA (Bouvier and Wagner, 2011). The lack of awareness among the population, on the proper disposal techniques of E-waste and the need for formalising the process, was quite evident in multiple countries (Islam et al., 2021).

Inferences

While general waste stream classification is becoming more mainstream, specific emphasis should be placed on proper extraction of E-waste materials due to their toxic nature and high recycle value. Scalable classification of different E-waste materials, upon proper implementation, can benefit recycling plants immensely. While robotic and ML applications have started to contribute to the development of waste management strategies, robotic systems for E-waste isolation, specific to households, can benefit the municipality collection centres significantly in this technological era. This article proposes the Recycle Cube Robot (rCubeBot) as a measure to attain the aforementioned benefits and implement a standardised process of E-waste segregation.

Materials and methods

The proposed rCubeBot system

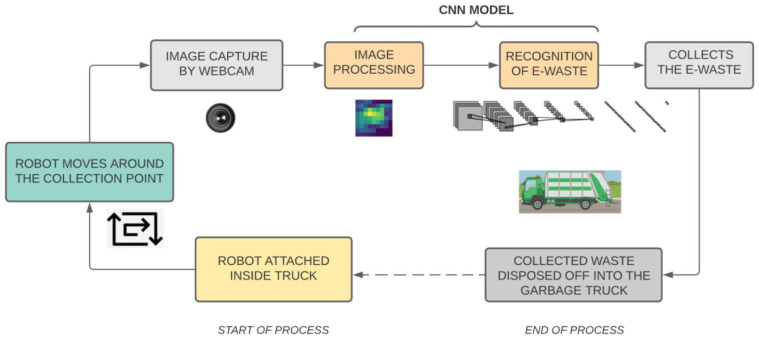

A novel E-Waste robotic system for identification and collection of household electronic wastes has been depicted in Figure 2. The functioning of the system starts at every collection point during a garbage truck’s trip, around a city. At every household collection point, the robot moves around taking individual photographs of the waste materials intended for disposal and identifies the electronic wastes using deep learning. The identified electronic waste is collected and placed within the robot’s storage platform. At the end of collection, the robot moves back into the truck and stores the collected wastes in a secluded space in the truck. Multi-Chamber Waste collection vehicles are now becoming mainstream, replacing traditional refuse vehicles in several parts of the world. In India, the waste collection vehicles are transitioning towards the incorporation of segregated compartment-based container structures to enable waste differentiation during point of collection instead of a final segregation at the recycling centre. While the concentration has been more towards biodegradable and non-biodegradable segregations, the secluded compartment structure required for E-wastes is also very similar to the ones currently in use. At the end of the garbage collection routes, the secluded part can be obtained by the collection centres and sent to the appropriate department for recycling and processing. This will alleviate the requirement of manual labour for segregation and the implied cost of hiring. The main components of the system can be split into two segments. One is the robot itself while the second is a CNN-based identification system, trained and tested on electronic waste images.

Figure 2.

Proposed system process.

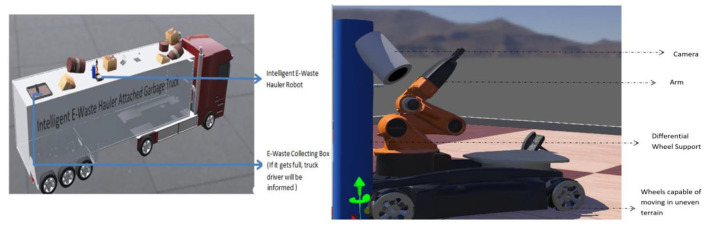

The robotic component of the system

The omnidirectional four-wheeled mobile robot is equipped with an arm and a collection platform. The arm, inspired by Keller und Knappich Augsburg (KUKA)’s youBot (Bischoff et al., 2011), has five degrees of freedom and has a payload capacity of 20 kg. A platform for storing the collected waste is also present. The wheels used are tireless and comprise consecutive rubberised roller attached to the rim, facilitating asymmetric friction for treading on uneven terrain. A Bluetooth-enabled webcam is placed atop the support to attain continuous images of the robot surroundings. The imagery obtained is sent to the deep learning recognition system for identification. If the object is identified as electronic waste, the arm grips the item and places in the collection platform present on the robot. The application programming interfaces (APIs) are robot operating system (ROS) compatible and embedded personal computer (PC) mini Information Technology eXtended (ITX). The operation of this robot is semi-autonomous with the option to switch to manual remote control. Once the wastes identified are on the platform or the payload capacity is reached, the robot dumps the collected items into a separate segment inside the garbage truck meant for E-wastes. Figure 3 illustrates a 3D model of the proposed robot.

Figure 3.

Intelligent E-waste hauler attached truck overview and model of proposed robot.

Integrated recognition system using deep learning

Deep learning systems are becoming more and more popular today due to their accurate results and wide applicability in the field of computer vision. CNNs, which form an integral part of deep learning modelling, are made of manifold components like convolutional layers, pooling layers and fully connected layers. These layers enable the network to analyse spatial hierarchies in the image features with the help of backpropagation. The overall evolution of deep learning models exhibited a significant trend of increase in the depth of the networks. The increase in depth helps obtain better representation of the features by obtaining a better nonlinear approximation of the target function.

Residual neural network (ResNet) (He et al., 2016) is an efficient deep network for performing object recognition tasks and is 8 times more deeper than VGGNet (Simonyan and Zisserman, 2014). Several different variants of ResNet are in existence, operating upon the same conceptual principles but differing in the total number of layers. The ResNet 50 variant implemented in this article comprises 48 convolutional layers with 2 pooling layers. One imperative problem solved by the use of ResNet is vanishing gradient. With the increasing depth of a network, the gradients responsible for calculation of the loss function reduce to zero. This inhibits the learning of the model as the weights are never updated. The ability of gradients to flow back directly from the farther layers to the initial filters has been made possible in ResNets with skip connections. Initial skipping enables faster learning rates due to compression of the network. When the network trains again, expansion of all layers is achieved while the residual network parts explore the feature spaces of the chosen image in detail. A Modified ResNet 50 network (Mod-ResNet50) was trained to recognise the images captured by the rCubeBot. The original pretrained ResNet50 model was modified for transfer learning with the addition of dense and fully connected layers followed by extensive parameter tuning.

Dataset

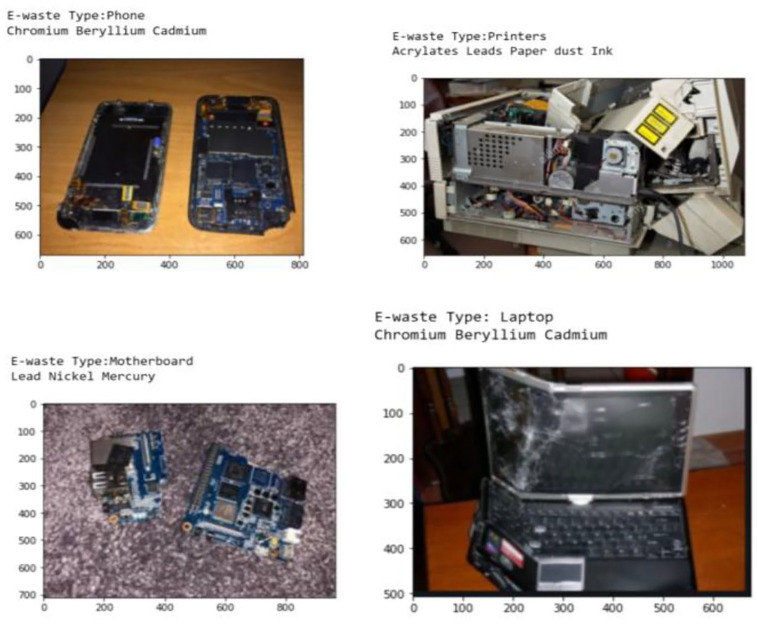

The dataset used consists of 8000 images of most prominent consumer electronic devices with their appearance status ranging from completely functional to critically damaged. The entire dataset is split under 8 different labels (computer keyboards, motherboards, mobile phones, refrigerators, laptops, mouses, radios and televisions) with each label containing 1000 images each of the corresponding device. The dataset was created using a combination of a script-based image scraping from static pages through popular image search engines. The dataset was checked to ensure all the images are relevant to the corresponding label and suitable for classification modelling. All the images were resized to 224 × 224 to ensure their compatibility for training and testing of our E-waste identification model. Figure 1 shows a two-image sample from each category in the dataset.

The 8000 image dataset was split on a 4:1 ratio for training and testing of our modified ResNet50 model. The model was trained and tested on VGG16 network as well to establish a comparative analysis with our model. All images contained an individual electronic waste item (computer keyboards, motherboards, mobile, phones, refrigerators, laptops, mouses, radios and televisions) and are sized to 224 × 224 pixels. A detailed classification report of the performance of the model has been calculated and presented.

Results and analysis

A Webots simulation and python-based implementation of the proposal is presented in this article (Supplemental Material). The main controller of rCubeBot is written in python. The robot will move and capture images using the camera. This controller gets executed as an ‘extern’ controller. We use Pycharm for executing the controller code. If the images are ascertained to be an E-waste with 90% or above accuracy, the secondary controller is initiated. This controller will position the arm for easier lifting. The arm then lifts the object and places it on the surface it has for collection purpose. For controlling the camera as well as differential wheels and robotic arm, multiple concurrent simulation features of Webots are used.

Image classification and categorisation

The image captured by the robot is fed into the trained model for recognition. The model outputs the device label and the possible chemical content based on the nature of the device. The Mod-Resnet50 is implemented for learning and classification purposes. We also implement VGG16, another popular deep learning model, to draw a parallel between the performances of Mod-Resnet50 and VGG 16 for electronic waste segregation. Table 1 presents the classification report of VGG16 upon implementation using our dataset. Table 1 presents the classification of ResNet50, which has been implemented for the robot’s identification system implementation and categorises the given image with higher accuracy.

Table 1.

Comparison of VGG16 classification report and Mod-ResNet50 classification report.

| VGG-16 | Precision | Recall | f1-score | Support | Mod-ResNet50 | Precision | Recall | f1-score | Support |

|---|---|---|---|---|---|---|---|---|---|

| Keyboard | 1 | 1 | 1 | 22 | Keyboard | 0.95 | 1 | 0.98 | 21 |

| Laptops | 0.94 | 0.94 | 0.94 | 17 | Laptops | 1 | 0.94 | 0.97 | 18 |

| Motherboard | 1 | 0.94 | 0.97 | 17 | Motherboard | 1 | 0.89 | 0.94 | 18 |

| Mouse | 1 | 1 | 1 | 32 | Mouse | 1 | 1 | 1 | 32 |

| Phones | 0.89 | 0.94 | 0.92 | 36 | Phones | 0.95 | 0.97 | 0.96 | 37 |

| Radios | 0.71 | 0.91 | 0.8 | 11 | Radios | 0.86 | 0.92 | 0.89 | 13 |

| Refrigerators | 0.96 | 0.96 | 0.96 | 23 | Refrigerators | 1 | 0.96 | 0.98 | 24 |

| TV | 1 | 0.8 | 0.89 | 20 | TV | 0.94 | 1 | 0.97 | 15 |

| Accuracy | 0.94 | 178 | Accuracy | 0.97 | 178 | ||||

| Micro avg | 0.94 | 0.94 | 0.93 | 178 | Micro avg | 0.96 | 0.96 | 0.96 | 178 |

| Weighted avg | 0.95 | 0.94 | 0.94 | 178 | Weighted avg | 0.97 | 0.97 | 0.97 | 178 |

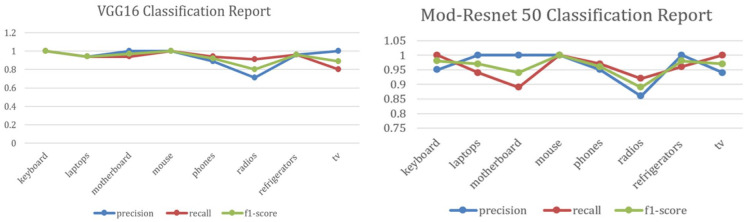

We can conclude that the Mod-ResNet50 outperforms VGG16 in different evaluation metrics such as accuracy, recall and precision. Once the image is categorised under one of the defined labels with an accuracy higher than the threshold accuracy of 90, the robot initiates the process of picking up the item. The arm picks up the item and places it on the platform. If the weight of the object is greater than the payload of the robot, as in the case of refrigerators, the robot identification system can be used by the human garbage collector to locate and separate the electronic waste item. Figure 4 showcases the classification graphs for the implementation of Modified Residual Network 50 (Mod-Resnet 50) and VGG16. Figure 5 demonstrates the recognition system that is implemented for identification in our robot, its output of labels and possible chemical based on the nature of the device identified.

Figure 4.

VGG16 and Mod-ResNet-50 classification graphs.

Figure 5.

Predictions of Mod-ResNet50 mode.

Positioning arm and picking up E-waste logic

Once the image captured is ascertained to be an E-waste, the robot is rotated (moved) with X degree angle where x is the angle difference between the camera position and the arm. After moving/rotating the arm to required degree, the rCubeBot is moved closer in the same position to the E-waste object. First, the robot arm is stretched outwards and then made to reach the object by lowering the angle of the arm. Then the ‘grip’ feature of the arm is used to grip the object and it is moved 100 degrees to place the object on the surface provided on the bot for this purpose. E-wastes collected by the robot are deposited at a secluded part of the garbage collection truck at the end of every household waste collection point. Once the garbage truck completes collection of its designated checkpoints and returns back to the local recycling centre, the secluded part of the garbage can be sent directly for recycling, reuse or extraction of usable components.

Benefits of robotic mobile E-waste hauler

India faces a huge challenge in electronic waste management, with its E-waste generated per capita reaching over 2.4 kg and gaining one of the top three spots in the world, in terms of E-waste volume produced. Each metropolitan city in India garners over 25,000 workers dedicated for the segregation and collection of E-waste material from the solid waste channels. The automation of this separation process can help separate wastes efficiently while protecting labourers from the toxic nature of electronic wastes. The obtained wastes are then inspected to extract valuable elements or components from the remains.

The integration of segregation with the city waste collection process is much more efficient in terms of time and labour. The work accomplished by each of our system en route usually requires 5 hours of salvaging work by 10 labourers after the wastes are delivered at the collection centres. As the segregation takes place at each household collection checkpoint, the aftertime required for classifying is eliminated and the secluded E-waste section can be sent directly for processing. The proposed implementation of this article can relieve manual workers from their hazardous lifestyle while benefitting the government from a financial point for view. The costs of production, operation and maintenance of our proposed robotic system will be close to 80% of the labourer cost required to do the same work on a 5-year period.

Other short-term measures for enhancing the E-waste disposal process includes raising consumer awareness on the process of waste segregation and involving them in the process with well-defined roles and standardisations. Regulatory frameworks for E-waste management and legal frameworks for industries will help maintain records of their E-waste disposal practices. Professional consultations on the end life range of electronic wastes by commercial organisations can help the authorities to arrive at informed conclusions about the disposal. The development of Advanced Recycling Fee and shifting from the extended producer responsibility to producer responsibility organisation initiatives can help propel the efficiency of disposing wastes for industrial entities.

Conclusion

The article proposed a mobile robotic system as an alternative to manual labour for classification and collection of household electronic wastes. The system implemented in this article aims to provide solutions to the rough lifestyles of garbage workers and benefit the government financially. The deployment of these robots will propel the world towards the goal of autonomous waste collection and disposal. The waste identification system used achieves accurate results for electronic wastes and can be implemented as a separate entity at recycling centres. The proposed system combines autonomous robotics and deep learning for electronic waste collection and separation from the general solid waste stream.

Further research directions include increasing the payload of the robot and arm can facilitate the collection of larger appliances like refrigerators and freezers. The addition of more categories of electronic waste items can propel the widespread applicability of the robot in multiple cities.

Supplemental Material

Supplemental material, sj-docx-1-wmr-10.1177_0734242X211052846 for Application of artificial intelligence to enhance collection of E-waste: A potential solution for household WEEE collection and segregation in India by AV Shreyas Madhav, Raghav Rajaraman, S Harini and Cinu C Kiliroor in Waste Management & Research

Footnotes

Declaration of conflicting interests: The author(s) declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Funding: The author(s) received no financial support for the research, authorship and/or publication of this article.

Supplemental material: Supplemental material for this article is available online.

ORCID iD: AV Shreyas Madhav  https://orcid.org/0000-0001-5554-6033

https://orcid.org/0000-0001-5554-6033

References

- Aral RA, Keskin ŞR, Kaya M, et al. (2018) Classification of TrashNet dataset based on deep learning models. In: 2018 IEEE international conference on big data (Big Data), Seattle, WA, 10–13 December, pp.2058–2062. New York: IEEE. [Google Scholar]

- Arya S, Kumar S. (2020) E-waste in India at a glance: Current trends, regulations, challenges and management strategies. Journal of Cleaner Production 271: 122707. [Google Scholar]

- Bai J, Lian S, Liu Z, et al. (2018) Deep learning based robot for automatically picking up garbage on the grass. IEEE Transactions on Consumer Electronics 64: 382–389. [Google Scholar]

- Bischoff R, Huggenberger U, Prassler E. (2011) KUKA youBot – A mobile manipulator for research and education. In: 2011 IEEE international conference on robotics and automation, Shanghai, China, 9–13 May, pp.1–4. New York: IEEE. [Google Scholar]

- Borthakur A, Govind M. (2017) How well are we managing E-waste in India: Evidences from the city of Bangalore. Energy, Ecology and Environment 2: 225–235. [Google Scholar]

- Bouvier R, Wagner T. (2011) The influence of collection facility attributes on household collection rates of electronic waste: The case of televisions and computer monitors. Resources, Conservation and Recycling 55: 1051–1059. [Google Scholar]

- Chi X, Wang MYL, Reuter MA. (2014) E-waste collection channels and household recycling behaviors in Taizhou of China. Journal of Cleaner Production 80: 87–95. [Google Scholar]

- Chu Y, Huang C, Xie X, et al. (2018) Multilayer hybrid deep-learning method for waste classification and recycling. Computational Intelligence and Neuroscience 2018: 5060857. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gundupalli SP, Hait S, Thakur A. (2018) Classification of metallic and non-metallic fractions of e-waste using thermal imaging-based technique. Process Safety and Environmental Protection 118: 32–39. [Google Scholar]

- Hana D, Liu Q, Fan W. (2017) A new image classification method using CNN transfer learning and web data augmentation. Expert Systems with Applications 95: 43–56. [Google Scholar]

- He K, Zhang X, Ren S, et al. (2016) Deep residual learning for image recognition. In: 2016 IEEE conference on computer vision and pattern recognition (CVPR), Las Vegas, NV, 27–30 June, pp.770–778. New York: IEEE. [Google Scholar]

- Islam MT, Dias P, Huda N. (2021) Young consumers’ e-waste awareness, consumption, disposal, and recycling behavior: A case study of university students in Sydney, Australia. Journal of Cleaner Production 282: 124490. [Google Scholar]

- Joon V, Shahrawat R, Kapahi M. (2017) The emerging environmental and public health problem of electronic waste in India. Journal of Health and Pollution 7: 1–7. doi: 10.5696/2156-9614-7.15.1 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Miner K, Rampedi I, Ifegbesan A, et al. (2020) Survey on household awareness and willingness to participate in e-waste management in Jos, Plateau State, Nigeria. Sustainability 12: 1047. [Google Scholar]

- Pamintuan M, Mantiquilla SM, Reyes H, et al. (2019) i-BIN: An intelligent trash bin for automatic waste segregation and monitoring system. In: 2019 IEEE 11th international conference on humanoid, nanotechnology, information technology, communication and control, environment, and management (HNICEM), Laoag, 29 November–1 December, pp.1–5. New York: IEEE. [Google Scholar]

- Pellegrinelli S. (2019) Configuration and reconfiguration of robotic systems for waste macro sorting. International Journal of Advanced Manufacturing Technology 102: 3677–3687. [Google Scholar]

- Rahman MW, Islam R, Hasan A, et al. (2020) Intelligent waste management system using deep learning with IoT. Journal of King Saud University – Computer and Information Sciences. Epub ahead of print 5 September. DOI: 10.1016/j.jksuci.2020.08.016. [DOI] [Google Scholar]

- Simonyan K, Zisserman A. (2014) Very deep convolutional networks for large-scale image recognition. arXiv 1409.1556. [Google Scholar]

- Wagner TP. (2009) Shared responsibility for managing electronic waste: A case study of Maine, USA. Waste Management 29: 3014–3021. [DOI] [PubMed] [Google Scholar]

- Wang W, Tian Y, Zhu Q, et al. (2017) Barriers for household e-waste collection in China: Perspectives from formal collecting enterprises in Liaoning Province. Journal of Cleaner Production 153: 299–308. [Google Scholar]

- White G, Cabrera C, Palade A, et al. (2020) WasteNet: Waste classification at the edge for smart bins. arXiv abs/ 2006.05873. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplemental material, sj-docx-1-wmr-10.1177_0734242X211052846 for Application of artificial intelligence to enhance collection of E-waste: A potential solution for household WEEE collection and segregation in India by AV Shreyas Madhav, Raghav Rajaraman, S Harini and Cinu C Kiliroor in Waste Management & Research