Abstract

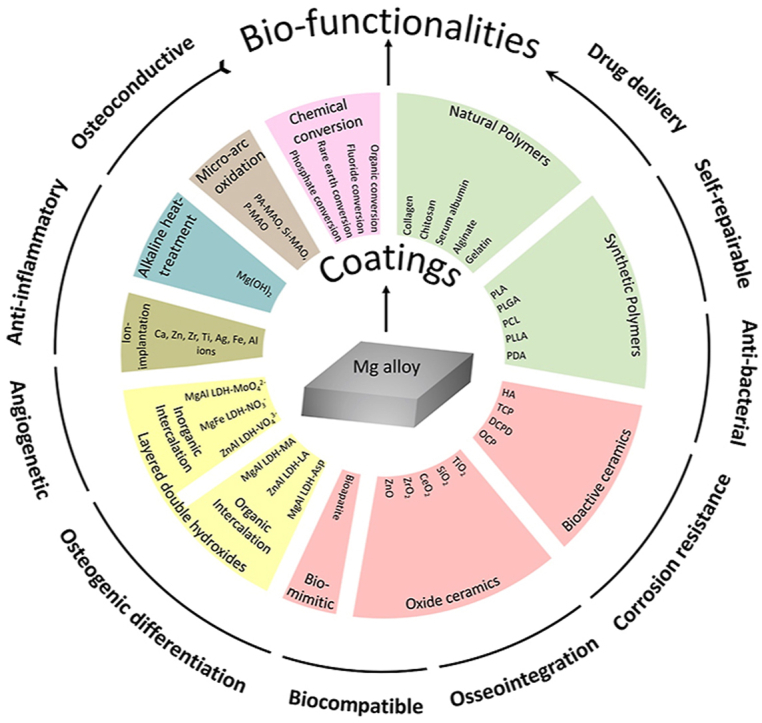

Mg and its alloys evince strong candidature for biodegradable bone implants, cardiovascular stents, and wound closing devices. However, their rapid degradation rate causes premature implant failure, constraining clinical applications. Bio-functional surface coatings have emerged as the most competent strategy to fulfill the diverse clinical requirements, besides yielding effective corrosion resistance. This article reviews the progress of biodegradable and advanced surface coatings on Mg alloys investigated in recent years, aiming to build up a comprehensive knowledge framework of coating techniques, processing parameters, performance measures in terms of corrosion resistance, adhesion strength, and biocompatibility. Recently developed conversion and deposition type surface coatings are thoroughly discussed by reporting their essential therapeutic responses like osteogenesis, angiogenesis, cytocompatibility, hemocompatibility, anti-bacterial, and controlled drug release towards in-vitro and in-vivo study models. The challenges associated with metallic, ceramic and polymeric coatings along with merits and demerits of various coatings have been illustrated. The use of multilayered hybrid coating comprising a unique combination of organic and inorganic components has been emphasized with future perspectives to obtain diverse bio-functionalities in a facile single coating system for orthopedic implant applications.

Keywords: Mg alloys, Corrosion resistance, Bio-functionality, Conversion coating, Multilayered hybrid coating, Coating failures

Graphical abstract

Highlights

-

•

The challenges and current status of coatings are reviewed in light of clinical requirements.

-

•

Multilayered hybrid coatings have been emphasized to obtain diverse bio-functionalities.

-

•

The future developments and research directions on coatings for biodegradable implants are highlighted.

1. Introduction

Magnesium and its alloys are becoming research frontier in the field of biodegradable materials due to their adequate strength, lightweight, and natural biodegradability. For orthopedic implant application, Mg alloys possess similar mechanical characteristics with identical young's modulus (20–45 GPa) comparable to cortical bone (20–27 GPa) [1]. Additionally, Mg alloys mimic the mechanical anisotropic characteristic of cortical bone, which endows superior load-bearing capacity [2]. The combination of such unique properties renders Mg alloys as a promising candidate for orthopedic implant applications. An ideal biodegradable implant is supposed to stimulate the healing response of injured tissue/bone, promote osteointegration, and provide necessary mechanical support at the early stages of implantation [3]. With prolonged immersion in physiological media, implant degradation rate must be synchronized with bone healing rate. During degradation, the supply of released ions must be adequate for the healthy growth metabolism of osteoblast and neovascularization [4]. After providing necessary mechanical fixation upto bone healing time, the implant should be degraded completely and replaced by new bone tissue, eliminating unnecessary follow-up and secondary surgery [5]. However, in the last few decades, researchers have put continuous efforts into synchronizing the degradation rate of Mg-based biodegradable implants. Unfortunately, investigated studies show compromised bio-functionalities during clinical testing, which need to be addressed for full-scale orthopedic implant applications [[6], [7], [8], [9], [10]].

There are multiple outstanding concerns with Mg and its alloys, limiting their application potential for a biodegradable orthopedic implant. The primary issue about Mg-based implants is rapid degradation in a complex physiological environment, which deteriorates mechanical integrity and causes implant failure (within 4–6 weeks), even before the complete healing of natural bone, which usually takes 8–12 weeks [11]. Moreover, if the fracture type is transverse, bones like femur, tibia, and fibula may take longer time (up to 24 weeks) to regain native mechanical strength [12]. Mg alloys are prone to micro-galvanic corrosion due to the highly electronegative electrode potential of −2.37 V, which further accelerates the degradation phenomena in the presence of physiological media [13]. Secondly, Mg suffers from an abnormal phenomenon of negative difference effect (NDE) where corrosion rate and hydrogen evolution increase rapidly with an increase in corrosion potential, which may lead to blockage of blood paths and cause tissue necrosis by H2 accumulation [14]. Thus, wound healing after prosthetic surgery becomes a major challenge. Additionally, the formation of highly alkalized micro-environment at the tissue/implant interface cause cell-apoptosis [15]. Other issues, like difference in in-vivo and in-vitro corrosion resistance, limit the clinical translation of Mg-based implants because the corrosion performance in in-vitro conditions ignores the role of proteins and enzymes present in actual physiological media [16,17]. Nevertheless, it is still debatable to determine whether the proteins assist or hinder the corrosion phenomena of Mg alloys [18]. Another possible reason for such differences may be the presence of dynamic physiological conditions inside human body. However, some studies reported creating semi-dynamic and quasi-static conditions during the in-vitro investigation, but a significant difference exist between the in-vitro and in-vivo degradation response of Mg alloys [[19], [20], [21], [22], [23]].

The degradation rate must be controlled up to the bone healing period to adopt Mg alloys for safe clinical applications. Extensive efforts have been devoted to resolve the degradation issue, mainly dominated by microstructural and surface modification strategies [24]. Micro-alloying considered as a promising method to tailor the degradation rate [25,26] by alloying the Mg with relatively noble elements like Calcium (Ca), Zinc (Zn), Aluminium (Al), Manganese (Mn), Lithium (Li), Scandium (Sc), Strontium (Sr), and rare earth (RE) elements [27]. Some of the Mg alloys such as Mg-Zn-Ca [28], Mg-Ca-La [29], Mg-Sr [30], Mg-Mn-Ca-Zn [31] demonstrated bio-safe degradation rates in the range of 0.2–0.5 mm/year in physiological media due to their tendency to form noble composite oxide layers which act as effective shields against aggressive ions of physiological media [32]. Nowadays, various ceramic reinforcements including β-TCP [33], HA [34], and calcium polyphosphate (CPP) [35] have also been reported to enhance corrosion resistance, bioactivity and mechanical strength of Mg alloys. However, the versatility of their bio-functionalities for clinical qualification is yet to be established. Moreover, alloying of Mg is always challenging due to the low solubility and non-uniform distribution of most alloying elements, resulting in heterogenous and coarse secondary phases [36]. These phases act as potential sites for micro-galvanic cell set-up and thus accelerate the degradation of Mg alloy [37].

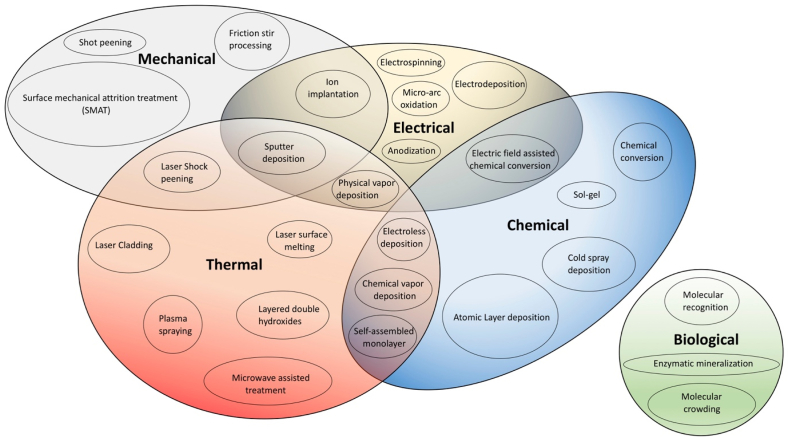

Alternatively, surface modification techniques are more convenient and straightforward approach to control the degradation rate of Mg alloys [38,39]. Surface modification techniques can be categorized based upon the requirement of different energy sources like mechanical, thermal, electrical, biological, and chemical energy, as described in Fig. 1. Coating processes with electric energy as source are widely used for Mg alloys. This category includes Electrodeposition, Micro arc oxidation, Electrospinning, Anodic oxidation, Physical Vapor Deposition, Ion implantation and Chemical Vapor Deposition [40]. These processes can be performed at room temperature or at relatively low temperatures, which is a notable advantage of this category. These coatings are characterized by their highly uniform crystalline structure, improved bonding strength, wear resistance, reproducibility, and facile thickness control [41]. In addition, they can be easily applied to Mg substrates with complex geometries. The surface modification techniques like friction stir processing (FSP), shot peening (SP), and surface mechanical attrition treatment (SMAT) employ mechanical working to physically alter the surface properties of Mg alloys by grain refinement [42,43]. In comparison, thermal surface modification techniques like laser surface melting (LSM) and laser shock peening (LSP) utilize the application of high temperature and pressure to obtain grain refinement [44]. In the case of biodegradable Mg alloys, such surface modifications are extensively reported to enhance the mechanical properties. However, they are not adequate to improve the corrosion resistance of Mg alloys in physiological media [[45], [46], [47]]. Additionally, the unwanted residual stresses generated after thermal or mechanical working affects the corrosion and mechanical properties of Mg alloys [48].

Fig. 1.

Classification of surface modification processes based on various energy sources.

In contrast, surface coatings play an efficient role to act as a physical barrier between the substrate and physiological media to improve the corrosion resistance without disturbing the grain morphology of Mg alloys. However, the surface coating does not improve mechanical properties but plays a vital role in minimizing the mechanical integrity loss of Mg alloys with prolonged immersion in physiological media [49,50]. Surface coatings on Mg alloys are metallic, ceramic, and polymeric. Nowadays, bioactive ceramics, including Ca–P compounds and biodegradable polymers like Polylactic acid (PLA), Poly (lactic-co-glycolic) acid (PLGA), Polydopamine (PDA), and Polycaprolactone (PCL) are gaining interest in orthopedic applications due to superior biocompatibility and biosafe degradability in physiological media.

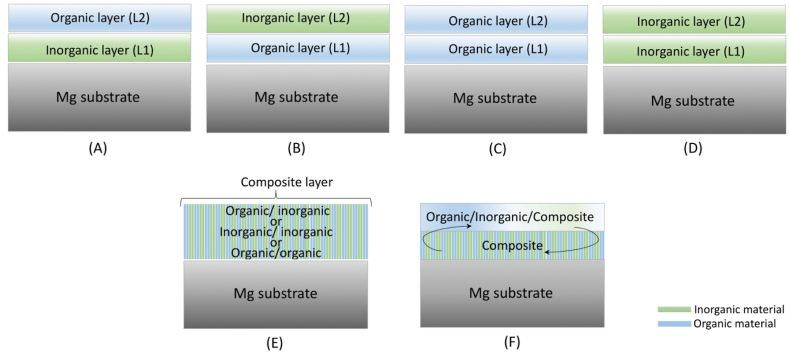

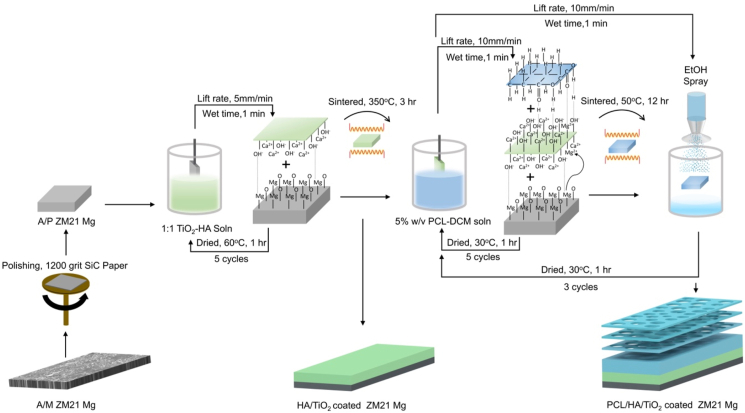

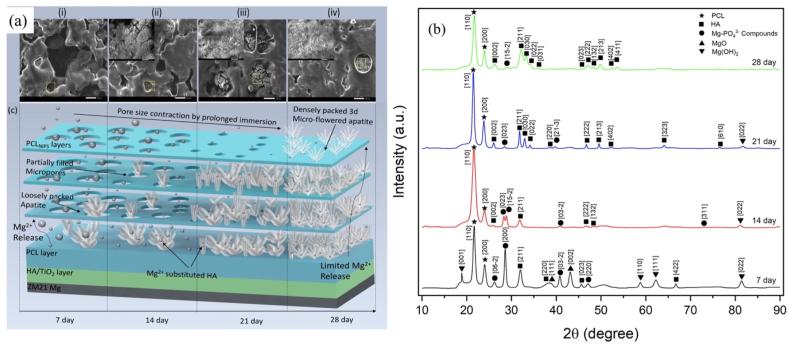

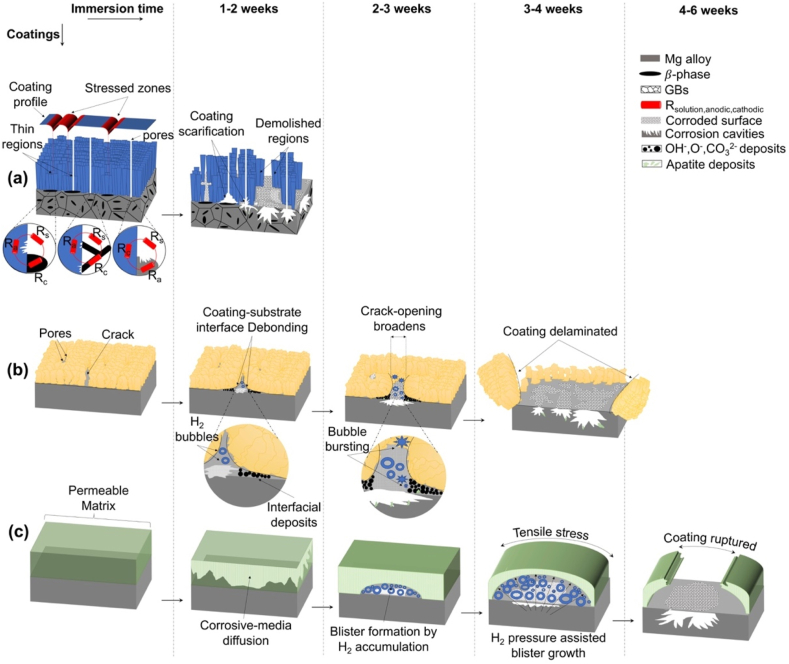

Among numerous surface coating techniques, the selection of appropriate coating architecture is challenging to meet the diverse clinical requirements. In the last few decades, umpteen research has been conducted to explore the various surface coatings on Mg alloys to fulfill clinical bio-functionalities. With a focus on corrosion resistance, adhesion strength, biocompatibility, and other bio-functionalities of surface coatings, this review paper summarizes the progress of various conversion and deposition types of coatings on Mg-based alloys for biodegradable implant application. Hence, the latest developments for a wide range of coating techniques from methodological, structural, and functional perspectives are discussed. A comprehensive analysis between bio-functionalities and simultaneous corrosion performance of the latest coating strategies has been performed to establish the fulfillment of clinical goals.

2. Coatings on Mg alloys: clinical requirements

Generally, Mg-based implants do not have bioactive surfaces, which promote good osseointegration and ward off infection from the implantation site. Accordingly, attention has been focused on developing coating systems that complement essential clinically features [51]. Coatings must be biocompatible and do not trigger any immune or foreign body response to endow such requirements. In any case, the coating must produce an efficient anti-inflammatory response, necessary for the first 3–7 days of implantation [52]. Apart from providing necessary corrosion resistance, Nowadays, specially designed coating serves as a potential stock-house for performing various bio-functionalities to meet the essential clinical requirement. Coatings on Mg implant must be osteoconductive to promote significant osteoblasts' adherence, proliferation, and growth. Additionally, coatings with angiogenesis differentiation are highly recommended for the formation of new blood vessels from pre-existing vessels of host tissue at the early stages of implantation, which accelerates surgical wound-healing and osteoinduction response of implant [53,54].

Coatings must have adequate cohesion and adhesion strength to withstand dynamic stresses associated with locomotive events in the human body. The lack of cohesion or adhesion strength will result in mechanical damage or delamination of coating from the implant surface. Apart from the loading aspect, polymeric coatings are highly prone to damage partially (i.e., scratching, debonding) even during the implant fixation process [55]. Thus, a coating system with self-healing/sealing characteristics is desirable to counter such failures. Finally, coatings must possess anti-microbial properties to deter the risk of surgical site bacterial infections (SSBI), which may lead to surgery failure or death of a patient under severe circumstances [56]. Following traumatic fracture, the inorganic and organic phases of natural bone must rapidly biomineralize. The coating is required to direct the alignment of mineralized phases so that maximum penetration occurs within the bone. Otherwise, randomly aligned mineralized phases can cause a larger space between the bone and implant, which could result in implant loosening. During implant fixation surgery or after implant fixation, dynamic loading conditions within the human body, coatings are prone to damage. Thus, coatings with intelligent self-healing features are essential. The fulfillment of these bio-functionalities by an ideal coating architecture/design will lead the idea of Mg-based biodegradable implant towards the product development phase.

3. Coatings and their current status

Surface coatings on Mg alloys can be obtained by mechanical, thermal, biological, and chemical methods. The surface modifications achieved independently or combined by mechanical or thermal energy are categorized under physical coatings. Surface coatings involving biological methods like biomimetic, bio-inspired, or molecular recognition are called biochemical coatings. Among various surface modification techniques, chemical coatings are the most widespread and investigated technique for the biomedical application of Mg alloys. According to the formation mechanism, the chemical coatings on Mg alloys are generically categorized as conversion and deposition coatings. Conversion coatings are in-situ grown coatings by utilizing the base metal for specific chemical reactions to form a protective layer. In contrast, deposited coatings are produced ex-situ by numerous techniques to be discussed in this review. The detailed classification scheme of conversion and deposited coatings are shown in Fig. 2.

Fig. 2.

Generic classification of coatings for biodegradable Mg alloys.

3.1. Conversion coatings –

Conversion coatings are in-situ fabricated coatings produced by a chemical reaction between the substrate and the coating media. Generally, the surface of metallic substrate undergoes complex reactions in aqueous media by chemical or electrochemical method [57]. Such treatment resulted in oxide/hydroxide formation on the surface of base metallic substrate. The in-situ growth environment provides excellent adhesion strength as compared to deposited coating. Thus, many studies highlighted the application of conversion coatings as an adhesive layer sandwiched between Mg substrate and deposited organic coating [[58], [59], [60]]. The chemical conversion, micro arc oxidation (MAO), layered double hydroxides (LDHs), ion-implantation and alkaline treatment are important conversion coatings on Mg-based alloys for bioimplant applications thoroughly discussed in the present study.

3.1.1. Chemical conversion coatings (CCCs)

CCCs are achieved by the formation of oxide/hydroxide of native or other desirable elements on Mg substrate, which can enhance corrosion resistance, biocompatibility, and osteoconductivity of coated samples. Typically, a chemical conversion process involves a sequence of steps: cleaning in an alkaline environment, etching in an acidic environment, immersion in conversion bath, drying, and water rinsing [61]. In general, a conversion coating works by stimulating the interfacial reactions with the subsequent precipitation/coating formation. The process is triggered by a decrease of the pH and an increase of the Mg2+ concentration at the metal/solution interface [62]. Mg's low standard electrode potential allows protons (H+) and water to be reduced simultaneously upon dissolution. After immersion in aqueous bath solutions, magnesium hydroxide was rapidly formed on the Mg substrate. In neutral (pH 7) or alkaline bath solutions (pH 10) magnesium hydroxide is chemically stable, which results in passivation and inhibits conversion reactions [63]. However, in acidic bath conditions, magnesium hydroxide may be easily attacked by the plentiful protons that are continually supplied to the coating/metal interface by the acidic solution [62]. As a result, localized dissolution occurs on the hydroxide layer, causing the breakdown of passivity and ensuring continued conversion reactions. In an acidic conditions, Mg specimen dissolves aggressively and releases abundant amount of Mg2+ cations. Therefore, in the vicinity of the Mg surface, localized accumulation of OH− ions abruptly increase pH at coating/metal interface (The bulk pH will also rise with prolonged immersion, but that is not relevant during the timescale of coating) [64]. As a result of this local pH increase, a conversion layer over the Mg substrate rapidly forms and precipitates. With prolonged immersion in bath media, the oxide/hydroxide formed on Mg substrate dissolved in a localized manner, facilitating penetration of conversion media. Once bath media reaches the surface of Mg substrate, conversion phenomena again initiated, which facilitates the enrichment of coating density [65]. Hence, the density of deposited coating is increased by prolonged immersion in bath media. Additionally, process parameters like concentration, pH, and temperature of bath media play essential roles in coating quality [66]. Majorly reported chemical conversion coatings on Mg alloys are based on chromates, fluorides, phosphates, and rare earth (RE) elements [67]. Despite excellent corrosion resistance possessed by chromate coatings, its usage has been banned under EU regulations for biosafety purposes [68]. Fluoride conversion coatings have limited bioactivity and poor stability with prolonged immersion in physiological media [69]. Thus, in recent years, various metal-phosphate and rare earth (RE) element based conversion coatings have been extensively researched for effective corrosion resistance and biocompatibility of Mg alloys, as discussed below:

-

•

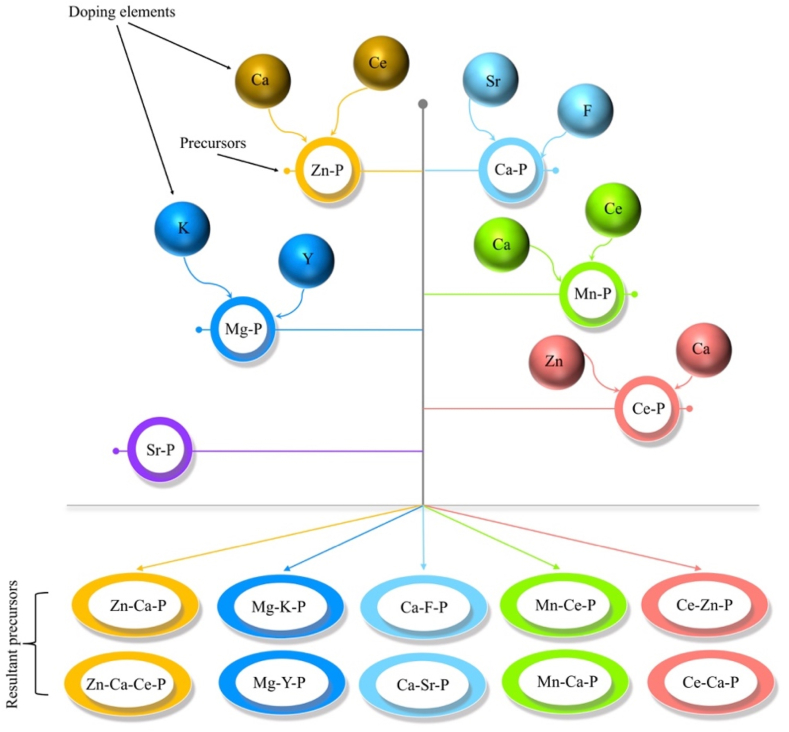

Phosphate conversion coatings (PCCs): Various PCCs containing trace metallic complexes are shown in Fig. 3. Studies reported the doping of additional trace elements to improve the biocompatibility and osteoinduction response of phosphate conversion coatings. Due to the hydroxyapatite (HA) layer formation, Ca–P conversion coatings are of particular interest. HA most closely mimics the mineral phase of natural bone among various Ca–P phases and is highly recognized as an osteoconductive mineral [70]. Additionally, the lowest solubility offers effective corrosion resistance in physiological media. Although HA coatings can be achieved by various techniques like sol-gel and electrochemical deposition, coating's adhesion strength reported for such techniques is relatively low [71,72].

Fig. 3.

Elemental doping and resultant conversion baths used for various phosphate conversion coatings on Mg alloys for orthopedic applications.

However, due to in-situ coating formation, the average adhesion strength of chemical conversion coatings is exceptionally superior up to 19–28 MPa [73]. The osteointegration response of HA coatings is dependent on surface morphology. Nano-plate and nano-sphere like structures greatly enhance the cell attachment compared to whisker or flake-like HA crystal structures [74]. The chemical conversion method can quickly obtain such desired coating morphologies by varying the process parameters like pH, bath temperature, and treatment time, which is difficult to control by other coating techniques [75]. Despite controlled morphology and uniform coating thickness, the fabrication of HA coating free from the fragile surface and spatial defects is still a challenge.

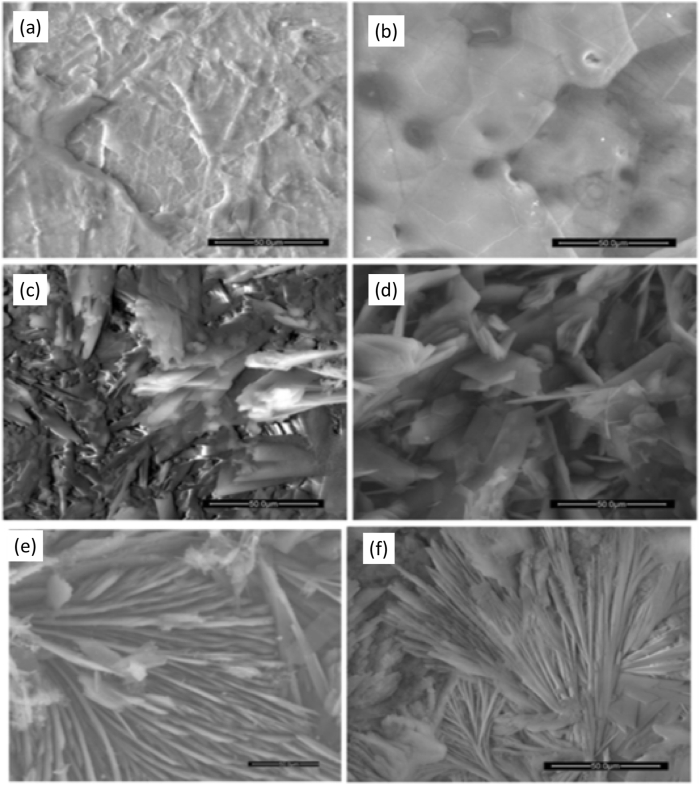

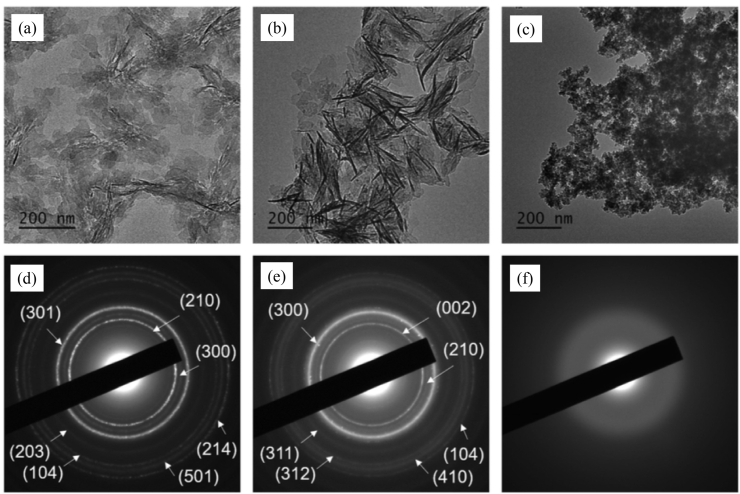

Rahman et al. [73] developed a double-layered Ca–P coating comprised of dicalcium phosphate dihydrate (DCPD) and HA on WE43 and pure Mg alloy. The author reported that after alkaline treatment, DCPD's non-homogeneous flake-like structure got transformed into a uniform plate-like HA structure completely devoid of defects as shown in Fig. 4. The chemically driven HA formation on Mg substrate resulted in significantly high adhesion strength of 28.5 MPa. However, the study lacks a long-term immersion test in physiological media to assess the loss of adhesion strength that may occur during prolonged immersion. Table 1 reports the fabrication parameters, pre/post treatments and performance details of various PCCs achieved on Mg alloys. Maurya et al. [83] deposited bioactive HA coating on Mg–Li alloy by a two-step conversion coating technique to observe in vitro biomineralization response and corrosion resistance. The author reported that the biomineralization tendency of HA-coated substrate became twice when compared to the uncoated sample. However, considerable residual stress value (∼200 MPa) in the coatings result in fatigue cracking and loss in adhesion strength under dynamic loading conditions [84].

Fig. 4.

(a) Surface morphology of WE43 Mg alloy, (b) pure Mg, (c) non-homogenous flake-like structure of DCPD coating on WE43 Mg alloy, (d) non-homogenous flake-like structure of DCPD coating on pure Mg, (e) homogenous plate-like structure of HA coating obtained after alkalization on WE43 Mg alloy, (f) homogenous plate-like structure of HA coating obtained after alkalization on Pure Mg. Reproduced with permission [73]. Copyright 2020, Elsevier.

Table 1.

Various PCCs with subsequent pre/post coating treatment details for biodegradable Mg alloys.

| Coating | Bath Composition | pH | Temp, °C | Duration, mins | Adhesion strength (MPa) | Ecorr (V/SCE) |

Icorr (A/cm2) |

Corrosion rate (mm/year) | Pre/post treatment |

Ref. |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uncoated | Coated | Uncoated | Coated | |||||||||

| Ca–P | 0.7 M calcium nitrate and 1.5 M phosphate acid (85% V/V) | 2.8–3.0 | 40 | 5 | – | −1.43 | −1.35 | 67 × 10−6 | 6 × 10−6 | 0.22 ± 0.03 | – | [76] |

| Mn–P | 0.1–0.5 M H2PO4−, 0.1–0.5 M Mn2+, 0.01–0.05 M NO3−, 0.01–0.05 M EDTA4− | 3.0–4.0 | 60 | 10 | – | −1.65 | −1.62 | 31.5 × 10−6 | 13.2 × 10−6 | – | Pre-treatment of uncoated AZ91-T4 Mg substrate in bath containing EDTA4− and NO3− complexing agents to remove the unwanted Alx(Mn,Fe)y phase | [77] |

| Ca–Mn–Ba–P | 10 ml/L Mn(NO3)2, 10 g/L Ba(NO3)2, 6 g/L Ca(NO3)2·4H2O, and 20 g/L NH4H2PO4 | 3 | 30 | 30 | – | −1.58 | −1.51 | 45.2 × 10−6 | 24.1 × 10−6 | – | – | [78] |

| La–P | (MgNH4PO4)·6H2O, (MgHPO4)·3H2O, 20 g/L La(NO3)3 | 3.75–4.25 | 55 | 20 | – | −1.54 | −1.59 | 40.7 × 10−6 | 7.07 × 10−6 | 0.046 | – | [79] |

| Mn–Ce–P | 0.1 M KMNO4, 0.02 M Ce(NO3)3, 0.02 M K4P2O7 | 1.5 | 25 | 1 | 5B | −1.62 | −1.52 | 15.6 × 10−6 | 2.2 × 10−6 | – | Pre-treatment of LZ91 Mg substrate in alkali environment to achieve thin layer of Mg(OH)2/LiOH and MgO/Li2O | [80] |

| Sr–P | 0.5–1.0 M Sr(NO3)2, 0.03–0.6 M NH4H2PO4 | 1.0–3.8 | 80 | 15 | – | – | – | – | – | – | – | [81] |

| Mg–P | 0.4 m/L Mg(NO3)2, 0.2 m/L H3PO4 | 2.7 | 60 | 20 | 9.4 | −1.51 | −1.54 | 18.8 × 10−6 | 0.20 × 10−6 | – | – | [82] |

| Zn–P | 0.1 m/L Zn(NO3)2, 0.2 m/L H3PO4 | 1.8 | −1.50 | 1.79 × 10−6 | ||||||||

| Zn–Mg–P | 0.4 m/L Mg(NO3)2, 0.1 m/L Zn(NO3)2, 0.2 m/L H3PO4 |

5.6 | −1.43 | 2.57 × 10−6 | ||||||||

| Ca–Mg–P | 0.4 m/L Mg(NO3)2, 0.2 m/L Ca(NO3)2, 0.2 m/L H3PO4 |

5.2 | −1.68 | 0.31 × 10−6 | ||||||||

| Zn–Ca–P | 0.1 m/L Zn(NO3)2, 0.2 m/L Ca(NO3)2, 0.2 m/L H3PO4 |

2.5 | −1.47 | 3.54 × 10−6 | ||||||||

| Zn–Ca–Mg–P | 0.4 m/L Mg(NO3)2, 0.1 m/L Zn(NO3)2, 0.2 m/L Ca(NO3)2, 0.2 m/L H3PO4 |

6.3 | −1.39 | 2.19 × 10−6 | ||||||||

Since Ca–P coatings possess no biocidal response toward bacterial activity, phosphate conversion coatings must be evaluated for osteomyelitis risk. Hu et al. [85] fabricated Ag/HA composite conversion coating on Mg–2Zn–1Mn-0.5Ca alloy. The Ag/Ha coated sample displayed significant zone of inhibition (ZOI) against S. aureus, compared to uncoated samples. By uniform dispersion of Ag particles, the adhesion strength of Ag/HA coatings was enhanced by 3.5 times compared to HA coatings. However, the electrochemical response of composite coating was not attractive due to spatial defects originating from Ag addition. Study has not addressed biocompatibility of Ag/HA composite coating. Ideally, HA (stochiometric Ca/p ratio, 1.67) having lowest solubility index (Ksp 3.7 × 10−58) is considered the most stable form of apatite [86]. However, the leaching of Mg2+ ions occurred via coating defects, causing the substitution of Ca ions in HA. Such a substitution creates structural disorder in HA lattice, which results in high solubility and poor crystallinity with prolonged immersion in physiological media [87]. Being inert to such substitutions, other alternatives like RE-based conversion coatings have gained interest in recent years.

-

•

RE-based conversion coating (REEs): RE elements are well known for their chemical stability and long-term insolubility in physiological media. Rudd et al. [88] firstly introduced RE conversion coatings for Mg alloys for bioimplant application. It was reported that RE conversion coatings provide uniform Mg degradation in aqueous chloride media over large pH fluctuations, usually occurring during Mg corrosion [89]. Generally, famous RE elements applied for conversion coatings on Mg alloys, like cerium (Ce), Yttrium (Y), Lanthanum (La), have no antagonistic effect on living cells at lower concentrations. They play a vital roles in the bio-functioning of the kidney, liver, skeletal muscles, and glands, indeed regulating the immune system by triggering anti-inflammatory reactions [90]. Recently, Han et al. [91] fabricated a Y-based conversion coating on AZ91 D Mg alloy. The coating morphology is composed of dry river-bed type micro-cracks. A post coating treatment by dipping the coated substrate into 30% silica sol sealed the micro-pores. The Ecorr of coated substrate is positively shifted with respective drop in Icorr by 102 folds. A 72-h immersion study conducted in a NaCl environment showed coating stability without any signs of delamination.

Saranya et al. [92] investigated the role of selenium (Se) conversion coating on AZ31 Mg alloy for bio-mineralization and anti-bacterial response. A Bath with 0.2% selenous acid solution was prepared by mixing propanol and water. The substrate was immersed for 3 h to obtain conversion coating. A hydrophobic coating surface with 98.5° ± 1.4 was obtained, which significantly shifted the Ecorr to −0.39 V compared to −1.61 V of uncoated substrate. After seven days of immersion in Earle's solution, a dense apatite growth significantly improved the coating's protective efficiency. However, a higher release of Se ions (29 μg/cm2/day) was observed during initial immersion hours, but with apatite growth, it slowed down to 12 μg/cm2/day, which was below the daily requirement of the human body. The anti-bacterial response of coated sample against P. aeruginosa and S. epidermis was found 52 and 61%, respectively, which is nearly 4–6 times higher than uncoated substrate. Additionally, coated sample exhibits an inhibition zone of 18 mm diameter against S. aureus. The author reported the selenium's capability of producing superoxide radical ions, which destroy the cell metabolism of both gram-positive and gram-negative bacteria. Extending the similar antagonistic properties of RE elements, Kannan et al. [93] reported anti-cancer activity of electrophoretically obtained samarium (Sm) conversion coating on AZ31 Mg alloy. The Sm3+ ions enhanced the affinity of Sm-tetraaza macromolecules towards CXCR4 receptors, which exceptionally boosted the anticancer activity to 87 and 96% after 48 and 72 h, respectively. The biocompatibility of coated samples for mesenchymal stem cell (MSC) line was found 72%, considered to be bio-safe as per ISO standards. Recently, Jian et al. [94] proposed a novel Ce/Mn composite conversion coating for Elektron (EV) 31 Mg alloy with efficient corrosion resistance and self-healing features. Composite bath comprised of 0.1 M KMnO4, 0.02 M Ce(NO3)3 was adjusted at pH 1.5 in room conditions. Thus Mg substrate is treated in the bath for various intervals (i.e., 15, 30, and 60 s). The coating morphology for 30 s treated sample was reported more uniform and compact with a thickness of 680 nm. After seven days of immersion in a 3.5% NaCl environment, the coating shows an adhesion strength of 5B grade. It was observed that the presence of Mn2+ ions facilitates the conversion of Ce(OH)3 (Ksp 1.6 × 10−20) to a highly insoluble Ce(OH)4 compound with a much lower solubility index (Ksp 2.0 × 10−48) [95]. Thus formed stable cerium species deposited at the scratched sites and limited expansion of scratch. In contrast, continued scratch growth was observed for conventionally coated samples by phosphate conversion method due to active corrosion. Nevertheless, Ce compounds are known for suppression of oxidative stress and free radical production, which otherwise, could promote several neurodegenerative diseases, such as Parkinson's disease, trauma, ischemic stroke, Alzheimer's disease (AD), and aging [96]. Recently, Ce based compounds are reported for promoting angiogenesis induction [97] and peroxidase mimicking activity [98] for breast cancer cell detection. However, being a rare-earth element, several studies reported the systemic toxicity and genotoxicity associated with Ce compounds. Pulido et al. [99] investigated that higher surface content of Ce3+ (40–58%) exhibited a toxic effect, due to superoxide dismutase (SOD) mimetic activity and H2O2 production, which is toxic to the cells. However, at lower percentage (between 26% and 36%) it displayed catalase mimetic activity, which broke down H2O2 to molecular oxygen, protecting the cells against oxidative damage. There is still a lack of adequate knowledge regarding the environmental and health risks associated with RE elements. Studies reported that exposure to RE elements might cause neural damage, which declines the locomotor frequency of body bending, head thrashing, and pharyngeal pumping. Under chronic exposure, significant loss of dendrite and soma of neurons induced down-expressions and other behavioural deficits [6,100].

-

•

Fluoride Conversion Coatings (FCCs): Several authors [[101], [102], [103], [104]] reported the development of FCCs on Mg alloys for biomedical implant applications. The coating procedure is typically performed by immersing Mg or Mg alloy substrates in 40%–48% hydrofluoric (HF) acid solution [69,105]. The Mg alloys passivate spontaneously by the formation of Mg(OH)2. In a highly acidic solution like 40–48% HF, the stability of Mg(OH)2 is very poor, and hence it would involve an exchange reaction with HF. Thus, The FCCs are composed a mixture of MgF2 and Mg(OH)2−xFx. However, the spontaneous passivation as well as slow rate of conversion of Mg(OH)2−xFx to MgF2 limit the FCCs thickness [106]. The low-solubility characteristics of FCCs in aqueous physiological solutions possess significant corrosion resistance potential for magnesium alloys. The FCCs often reduces hemolysis to as low as 5%, promotes cell adhesion and proliferation, and does not cause any cytotoxicity. Nevertheless, hydrogen evolution during coating formation leads to the generation of pores in the FCCs, while internal stress promotes cracking of the coated layer. Additionally, the lower thickness, presence of pores and cracks, and a lower F/O ratio determined by the volume fraction of the hydroxyl to fluoride fraction of Mg(OH)2−xFx limit the ability of FCCs to offer long-term corrosion protection in NaCl as well as in physiological solutions. Dziková et al. [107] developed fluoride conversion coating on AZ31 Mg alloy at two coating temperatures, 430 °C, and 450 °C, and three coating times, 0.5, 2, and 8 h in Na(BF4) molten salt. Increased coating temperatures and coating times led to higher coating thicknesses with reduced defects that were uniformly distributed on the coating surface, thereby enhancing corrosion resistance. The defect-producing intermetallic compounds in coatings were stabilized by an increase in temperature and time.

In physiological media, a single FCC is unable to provide meaningful shielding from aggressive ions. Recently, Sathyaraj et al. [108] fabricated a fluoride conversion coating on pure Mg. Following deposition of magnesium phosphate coating in the first stage, magnesium fluoride-magnesium phosphate duplex coating was developed in the second stage. The author reported that the structural homogeneity of the duplex coating was increased with an increase in treatment time from 0.5 to 2.0 h. The positive shift in Ecorr and decrease in Icorr reduced the corrosion rate of duplex coated Mg to 0.023 mm/year, whereas the corrosion rate of MgF2 coated Mg was 0.32 mm/year. The bonding strength of the duplex coating was 13.46 MPa, almost similar to the recommended value of 15 MPa for biomedical applications as per ISO 13779–2 standard. Zhang et al. [109] prepared a stearic acid (SA) modified composite fluoride conversion film (CaF2/MgF2) on AZ31 Mg alloy. The results indicated superhydrophobic response of composite fluoride conversion coating with an average water contact angle of 152°. Therefore offered better corrosion resistance than the fluoride conversion film and fluoride-treated AZ31 alloy. Despite a non-toxic response towards bone marrow mesenchymal stem cells (BMSCs), the coating was not conducive to BMSCs adhesion.

-

•

Organic Conversion Coatings (OCCs): The currently investigated inorganic coatings show excellent adhesion strength, yet there are several issues like poor osteointegration, non-biodegradability, metal contamination that need to be addressed for its clinical usage [110]. Organic conversion coatings based on biodegradable organic polymers are a promising alternative approach. Organic polymers with chelating functional groups can be quickly bonded with the Mg surface [111]. Such chelating groups on the top coating layer provide anchoring sites for deposition of additional coating layers of the same or different composition. Moreover, they act as inherent hosts for inhibitors-loaded nanoreservoirs to impart self-healing characteristics at mechanically damaged coating sites. Most OCCs are carried out using weak organic acids like tannic acid (TA), vanillic acid (VA), stannic acid (SA), gallic acid (GA), and phytic acid (PA) [112]. They form insoluble complexes by chelation with metallic ions released from the substrate at damaged site, which imparts self-healing coating characteristics [113]. Additionally, the OCCs are widely explored for producing super-hydrophobic anion surfaces, which show significant corrosion resistance [114,115]. Saji et al. [112] investigated that the presence of β-phases in Mg alloys affects the reaction kinetics of conversion phenomena by galvanic coupling, resulting in non-uniform coating thickness. Therefore, pre-treatments are primarily required before the deposition of OCCs. Similarly, Post-treatments play an essential role in sealing spatial defects of OCCs. Several attempts have been made to improve the corrosion resistance of organic conversion coatings. The conversion coating is dependent on bath composition, conversion parameters, and pre/post coating treatments, and Table 2 summarizes the fabrication parameters, pre/post treatments, and performance details of various OCCs developed on Mg alloys.

Table 2.

Various OCCs with subsequent pre/post coating treatment details for biodegradable Mg alloys.

| Coating | Bath Composition | pH | Temp, °C | Duration, mins | Adhesion strength (MPa) | Ecorr (V/SCE) |

Icorr (A/cm2) |

Corrosion rate (mm/year) |

Pre/post treatment |

Ref. |

||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uncoated | Coated | Uncoated | Coated | |||||||||

| PA-HA composite | 0.70 wt % PA Soln, 35–50% (wt/wt) HA | 4.5 | 40 | 20 | – | −1.60 | −1.41 | 40.20 × 10−6 | 2.28 × 10−6 | – | – | [116] |

| PA-Ce(III) nanocomposite | 5 mM PA, 20 mM CeCl3 | – | – | 3 | 5B | −1.46 | −1.37 | 3.47 × 10−3 | 4.71 × 10−8 | – | Coated sample treated in ethanol/HDMS (10μl/10 ml) solution for 6 h to obtain superhydrophobicity with contact angle (167.3°). | [117] |

| Vanillic acid | 1.0 mmol/L Vanillic acid soln. | – | 20 | 1440 | – | −1.53 | −1.40 | 56.9 × 10−6 | 0.58 × 10−6 | – | Pre-treatment of uncoated substrate in 1 M NaOH for 24 h. | [110] |

| Vanillic acid | 1.0 mmol/L Vanillic acid soln. | – | 20 | 1440 | – | −1.41 | −1.25 | – | – | – | Pre-treatment of uncoated substrate in NaOH for 1.5 h | [118] |

| PA-Stannic acid multilayer | 2 g/L Ce(NO3)3, 10 ml/L H2O2) (Step-1) |

6 | 40 | 20 | – | −1.42 | −1.28 | 1.81 × 10−4 | 2.12 × 10−7 | – | MAO Pre-treatment in 10 g/L Na2SiO3, 3 g/L NaOH, and 10 ml/L triethanolamine. | [119] |

| 20 g/L Na2SnO3, 4 g/L NaF, 3 g/L NaOH (Step-2) |

12.5 | 60 | 60 | – | ||||||||

| PA/Silane hybrid | PA and γ-APS Soln. with molar ratios (1:1, 1:2, 2:1), mixed with 40 ml EtOH/H2O soln. | 8 | 20 | 30 | – | −1.70 | −1.61 | 49.41 × 10−6 | 3.95 × 10−6 | – | Pre-treatment of uncoated substrate in 3 M NaOH at 80 °C for 24 h | [120] |

| CaP/Collagen | 23.6 g/L Ca(NO3)2·4H2O, 34.2 ml/L H3PO4, 7 mg/ml Col-I Soln prepared in 0.005 acetic acid. |

2.8 | 37 | 10 | – | −1.47 | −1.23 | 27 × 10−6 | 87 × 10−8 | – | Post treatment of Ca–P converted sample by dipping in Col soln. for 15 min. | [121] |

| HA/Tannic acid | 0.05 g Na3PO4, 0.25 g Na2B7O4, 0.04 g C76H52O46, 0.05 g NH4VO3, 0.055 g K2ZrF6, and 0.02 g HNO3 in 50 ml DI H2O (Step-1) |

4 | 37 | 540 | – | −1.46 | −1.30 | 4.89 × 10−6 | 5.64 × 10−8 | – | Pre-treatment of uncoated substrate in 1 M NaOH for 24 h followed by heating at 150 °C for 24 h. | [122] |

| 14 mmol/L Ca(NO3)2, 8.4 mmol/L NaH2PO4, 4 mmol/L NaHCO3 (Step-2) |

– | 37 | 2880 | – | ||||||||

| MgF-Tannic acid | 40% HF (v/v) soln., TA was dissolved in 2 mg/mL Tris–HCl soln to obtain 2 mg/mL final conc. | 10 | 25 | 1440 (HF) | – | – | – | – | 0.24 × 10−6 | – | Pre-treatment of uncoated substrate in 5 M in boiled NaOH for 3 h | [123] |

| 180 (Ta) | ||||||||||||

| Chitosan-Tannic acid | Chitosan (Mw 1.8 × 106) and tannic acid (Mw 1701.2 g/mol) were dissolved (50:50, 50:80) in 0.1 M acetic acid with 2% conc. | – | – | – | σmax (UTS) of coating after 0, 24 and 48 h of immersion in PBS was 3.5, 7.5 and 5.5 MPa | – | – | – | – | – | To analyse tannic acid release profile coated sample immersed in SBF (pH 7.4), SGF (pH 1.2), SIF (pH 6.8) and found suitable for pH around 7. | [124] |

| Chitosan (CHI)/Bioactive glass(BG) | 1.5–6.0 g/L CHI soln. in 1% vol acetic acid, 6 g/L BG | 3.31–3.62 | 75 | 15–120 | – | – | – | – | – | – | – | [125] |

| Gallic acid (GA)- hexamethylenediamine (HD) | GA and HD were mixed (wt % 1:3, 1:1 and 2:1) | – | 37 | 360 | – | −1.59 | −1.61 | 54.0 × 10−5 | 8.0 × 10−7 | – | An in-situ MgO/Mg(OH)2 layer chelated beneath coating layers, obtained from 1:1 and 2:1 bath soln. | [126] |

| Catechol (CA)/polyethyleneimine (PEI) | 2 mg/ml CA, 4 mg/ml PEI | 8.5 | 22 | 720 | 5B | −1.59 | −1.37 | Log (−4.19) | Log (−7.34) | 0.01 | Heparinization treatment was given to coated samples by immersion in 4 mg/ml Heparin dissolved in water-soluble carbodiimide and a mixed solution of 1 mg/ml 1-ethyl-3-(3-(dimethylamino)propyl) carbodiimide hydrochloride (EDC) and 9.8 mg/ml 2- morpholino ethanesulfonic acid (MES). | [127] |

| Epigallocatechin gallate (EGCG)/polyethyleneimine (PEI) multilayer | 1 mg/ml EGCG and 1 mg/ml PEI Soln in Tris-buffer. | 7.4 | 37 | 30 | 5B | −1.33 | −1.25 | Log (−4.46) | Log (−6.65) | 0.05 | – | [128] |

| CaF2- Stearic acid (SA) | Saturated Ca(OH)2 and 0.05 M/L SA ethanol soln. | – | 70 | 240 | 5B | −1.57 | −1.10 | 4.25 × 10−6 | 4.13 × 10−8 | 0.94 | Pre-treatment in 40 wt% HF soln. for 5 days | [109] |

| MnO2 – Stearic acid (SA) | 0.1 M MnSO4, 0.02 M SA in ethanol soln. |

– | 22 | 240 (MnO2) | 5B | −1.61* | −1.32* | *6.84 × 10−7 | 2.70 × 10−8 | – | Pre-treatment in 0.01 M MnSO4 soln. for 1 h. | [129] |

| 300 (SA) | ||||||||||||

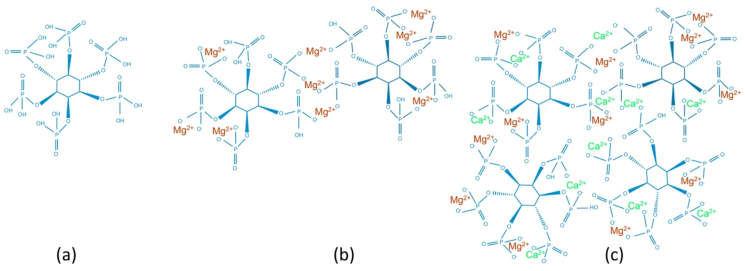

Liu et al. [130] obtained PA/Ca2+ conversion coating on Mg–Sr alloy by layer by layer self-assembly method to deter spatial defects. The introduction of Ca2+ significantly enhanced PA's inter-molecular chelation ability, which resulted in spatial defect-free coating morphology with self-healing characteristics. The PA/Ca2+ coated substrate demonstrated improved electrochemical corrosion resistance compared to uncoated substrate. The PA/Ca2+ coated sample showed an increase in expression for alkaline phosphatase activity (ALP) by 60% compared to the uncoated sample, signifying osteoblast and osteogenic differentiation response of coated substrate. To enhance the corrosion resistance of OCCs, Lin et al. [131] fabricated a noble coating architecture with an organic gallic acid layer sandwich between synthetic PLGA polymer layers on ZK60 Mg substrate for bioresorbable coronary artery stents. The coated sample shows a positive shift in Ecorr to −0.24 VSCE from −1.59 VSCE for bare substrate with a decrease in Icorr nearly 104 times. Apart from highly corrosion resistance behaviour, coated samples show a hemolysis rate of 2.1%, which was less than the clinical bio-safety limit of 5%. Interestingly, GA acts selectively against smooth muscle cells (SMCs) and endothelial cells (ECs). In a 48-h long wound closure study, coated samples show 14% more proliferation towards ECs and inhibit SMCs growth by 4%. Additionally, the uniform release of GA via sandwich PLGA layers enhanced the free radical scavenging by 35% compared to bare substrate in diphenyl-2-picrylhydrazyl (DPPH) media. Thus, anti-oxidative ability eliminates the oxidant stress for vascular tissues and promotes endothelialization. The investigations on OCCs are limited to weak organic acids only. A comprehensive research gap is available to investigate composite/hybrid forms of phenolic molecules like TA, SA, PA, ECGC with synthetic polymers like PCL, PLA, PDA, and PLGA for enhanced corrosion resistance and bio functionalities.

Furthermore, many polyelectrolytes and nanoparticles are known to induce Ca–P conversion coatings on Mg alloy. Cui et al. [132] have developed a novel SnO2-doped Ca–P coating on AZ31 Mg alloy. The embedded SnO2 nanoparticle enhanced the structural integrity and crystallization of the coating. Additionally, they acted as heterogeneous nucleation sites where Mg2+ and Ca2+ combined with PO43− ions [133]. Unfortunately, the porous structure of the coating results in poor bonding strength, not sufficient to be used for clinical applications. Polyelectrolytes have recently attracted attention by inciting Ca–P conversion coatings on Mg alloys as they facilitate heterogeneous nucleation of Ca–P precipitates with uniform coating deposition. Shanaghi et al. [134] reported that the Ca–P layer deposited on PAA-coated AZ91 Mg alloy significantly improves the osseointegration response. Using a special heat treatment, yang et al. [135] developed a defect-free SiO2/PAA coating that acts as a template for mineralizing Ca–P layers on AZ31 Mg alloy. The dense precipitation of Ca–P on SiO2/PAA enhances the corrosion resistance and cytocompatibility response.

3.1.2. Micro arc oxidation (MAO) coatings

MAO, also known as plasma electrolytic oxidation (PEO) or anodic spark deposition (ASD), is an electrochemical technique to grow oxide layers on metallic substrates. MAO produces stable coatings with higher bonding strength and wear resistance, when compared to other anodization techniques like electrophoretic or electrochemical deposition [136]. The set-up consists of an anode (i.e., the substrate), an electrolytic media, and a cathode, usually stainless steel. The coating composition and morphology are dependent on process parameters; applied voltage, bath chemistry, pulse frequency, and reaction time [137]. Typically, MAOed Mg substrates have micro-sized pores [138]. Porous coatings are not recommended for long-term implant applications, because ions can penetrate the pores and damage the Mg substrate with prolonged immersion in physiological media. Thus, alone MAO coatings are not enough for significant shielding of Mg-based implants.

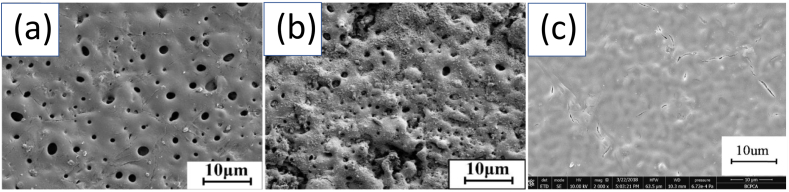

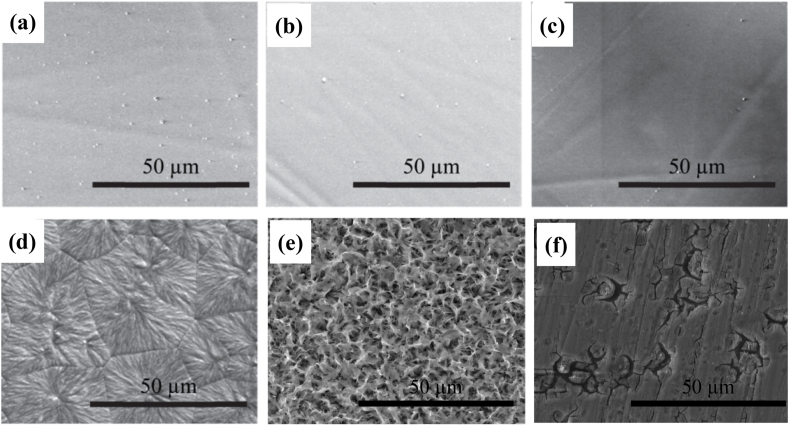

Several studies [[138], [139], [140], [141]] indicated that the addition of trace elements like Ca, P, and Zn to the electrolytic media significantly reduced the pore sizes in MAO coatings. This may be attributed to their deposition at pore openings. Bakhsheshi-rad et al. [112] deposited Zn-HA incorporated MAOed coating on Mg–Ca alloy. The corrosion rate of the Mg–Ca sample (4.5 mm/year) was reduced to 0.2 mm/year, further reduced to 0.02 mm/year by adding TiO2. Additionally, author claimed enhanced anti-bacterial response and cellular adhesion of TiO2-ZnHA MAOed sample towards gram-negative bacteria and MG-63 cell line, respectively. Tang et al. [142] added ZrO2 nanoparticles in an electrolytic solution to produce Zr doped MAO coating on AZ91 Mg alloy. The author claimed that under the high temperature of discharge spark, a stable Mg2ZrO5 compound is formed and deposited in the micro-pores of coating. Compared to MAOed AZ91, the average pore size reduced from 40 mm to 10 mm, which increased corrosion resistance by six orders of magnitude. Wen et al. [143] reinforced the HA matrix with graphene oxide (GO). The GO-HA MAOed coating substantially reduced the pore-density as shown in Fig. 5 (a) and (b), which resulted in a 58-fold drop in Icorr, from 2.12 mA/cm2 for an uncoated sample to 36.43 μA/cm2, respectively. Additionally, GO contains abundant carboxy and carbonyl functional groups, which created strong interfacial bonding via Vander-wall forces with HA molecule and promoted HA attachment resulting in adhesion strength of 40.7 MPa. An alkaline electrolytic solution using Ethylenediaminetetraacetic acid (EDTA) was prepared by Gu et al. [144] After the MAO coating of AZ31 Mg alloy, the sol-gel dip-coating technique deposited the HA layer. The chelating ability of EDTA resulted in strong and uniform HA deposition with effective sealing of spatial defects, as shown in Fig. 5(c). Consequently, The Ecorr from −1.24 V for MAOed AZ31 shifted to −0.309 V for the HA-MAOed AZ31 sample. The HA-MAOed AZ31 sample maintained Ecorr values of −0.59 V after immersion in physiological media for seven days, indicating effective corrosion inhibition.

Fig. 5.

SEM morphologies of (a) MAOed AZ31 (b) HA/GO coated MAOed AZ31 Mg alloy, reproduced with permission [143]. Copyright 2017, Elsevier and (c) EDTA functionalized HA coating on MAOed AZ31 alloy. Reproduced with permission [144]. Copyright 2018, Springer.

To obtain a novel self-sealing approach, Daavari et al. [145] proposed in situ formations of biocompatible and high strength multi-walled carbon nanotubes (MWCNTs) on MAO coating. Besides promoting tissue response and lubricity, MWCNTs have a unique ability to bridge crack-tips caused by high electric discharges, resulting in a smooth and uniform coating surface. The Icorr was significantly decreased by nearly 103 times when compared to the MAOed AZ31 sample. Authors also claimed the introduction of MWCNTs to improve the dry wear performance of MAO coating by reducing the coefficient of friction (μ) by 15% and wear depth by 60% compared to MWCNT free coating.

A polymeric top-coat is widely reported to seal pores, and many studies on polymer-MAO composites/multilayer coatings have also been reported [[146], [147], [148], [149]]. However, the permeable matrix of polymer coating offer pathways for the diffusion of aggressive ions. With prolonged immersion, such ions successfully reached the base Mg substrate. Once corrosion phenomena are initiated, the abundant release of H2 causes blisters formation. The accumulation of H2 under polymeric layer makes them grow and ultimately burst with prolonged immersion [150]. Additionally, polymeric layers are prone to swelling and subsequent delamination in the presence of physiological media [151]. Therefore, recent studies are oriented to address the challenges related to polymeric top-coats for MAO pore sealing. Kannan et al. [152] fabricated an inorganic Ca–P layer sandwiched between the MAOed and PLLA layers on pure Mg substrate using a spin coating technique. The triple-layer barrage positively shifted the Ecorr with significant drop in Icorr from 28.79 μA/cm2 to 0.24 μA/cm2. However, the evaporation of organic residue from the Ca–P layer and chloroform from the PLLA matrix creates spatial defects in the polymeric top layer. Butt et al. [153] cladded a 5–10 μm thick PLA layer on MAOed AZ31 Mg alloy by injection moulding. The author reported that micro-anchoring sites on MAOed surfaces resulted in mechanical locking of the PLA layer. The electrostatic interaction between PLA and MAOed layers resulted in a highly compact two-layered coating with effective sealing. Only 0.14% weight loss was observed after immersion in Hank's solution for 30 days. After immersion, the drop in ultimate tensile strength (UTS) for the PLA-cladded MAO sample was 15% lower than alone MAOed sample. Currently, Polyacrylamide (PAM) hydrogels are gaining interest in enhancing MAO coatings' shielding efficiency. PAM hydrogels have a unique combination of hydrophilic and hydrophobic functional groups that promote in-situ binding in aqueous media and expand the 3D polymeric network for effective covering of underlying substrate. Guo et al. [154] coated Ce-loaded PAM hydrogel on MAOed AZ31 Mg alloy. The Ce2+ ions encapsulated in the polymer matrix oxidized to the more stable Ce4+ ionic state during exposure to physiological media. The packing of Ce4+ ions compacts as the PAM is swallowed by an aqueous solution, which effectively sealed MAO defects. When the coating is mechanically scratched, the release of Ce ions from the PAM matrix forms a compact layer of CeO2 on the scratched area, imbuing it with self-healing properties. Similarly, Zhang et al. [155] deposited a highly stable and biosafe compound Ce-IV between the MAO micro-pores. The pore size of MAOed Mg ranging between (1–5 μm) were entirely closed by the cerium compound, which enhanced the corrosion rate from 10.25 × 10−3 to 4.27 × 10−3 mm/year. Recently, Zhang et al. [156] reported the achievement of self-healing characteristics for pore sealing on MAOed AZ31 alloy by incorporation of bovine serum albumin (BSA) in PBS media. BSA adsorption was caused by electrostatic attraction due to the difference in isoelectric point of BSA (pIBSA 4.7 < pH 7.4) and MAOed AZ31 (pIMAO 12.4 > pH 7.4). During active corrosion of MAOed AZ31 sample in PBS media, the RCH(NH2)COO− group of BSA molecule combined with Mg2+ ions formed an (RCH(NH2)COO)2Mg complex on the surface that effectively sealed the MAO pores and acted. Thus effective shielding against aggressive ions significantly drops the Icorr by 104 times compared to alone MAOed coated sample. Typically, MAO is an anodic coating deposited on secondary phase particles in Mg alloy. Ly et al. [157] observed that coarse size and randomly distributed secondary particles in Mg alloy increase the coating porosity. The author carried out Equal angular channel pressing (ECAP) Mg–Zn–Ca alloy before deposition of MAO layer. The secondary phase particles Ca2Mg6Zn3 were fragmented and uniformly redistributed. The smaller grain size resulted in small-sized micro-arc discharge channels, which resulted in the reduction of avg. pore size from 0.77 μm for MAOed sample to 0.43 μm ECAP/MAOed sample. The corrosion rate of the ECAP/MAOed (0.087 mm/year) sample was nearly ten times lower than the MAOed sample. Xiong et al. [158] pre-treated AZ80 Mg alloy with LSP to obtain grain refinement. The fine-grained surface attributed limited pore channels and reduced average porosity. According to the stress corrosion cracking (SCC) results, AZ80 Mg LSP/MAOed samples fail after 22 h at ultimate tensile stress (UTS) of 267.3 MPa, while the MAOed samples fail after 13 h at 225.5 MPa. The size and distribution of micro-porosities strategically influence the corrosion resistance, adhesion, and biocompatibility response of MAO coatings. More chemically and mechanically driven pre-treatments and post-treatments techniques must be explored deliberately to tailor the micro-porosities in MAO coatings.

Electrophoretic deposition (EPD) is another widely used electrochemical technique for the preparation of bioactive coatings on MAOed Mg alloys. Combining their approaches can significantly reduce degradation rates and improve the biocompatibility, or other desirable properties of Mg alloys. Typically, a thick oxide layer was fabricated using MAO to enhance the corrosion resistance of the underlying Mg substrate; EPD was used to seal the porosity associated with MAO layer and provide desired functionalities. Wu et al. [159] developed MAO and MAO/EPD coatings on AZ31 Mg alloy. MAO coatings exhibit improved corrosion resistance with increasing coating thickness. By increasing the thickness of the EPD coating, the corrosion resistance was marginally enhanced. However, the EPD coating effectively reduces micro porosity and micro cracks in MAO coating, MAO and EPD together yielded corrosion resistance in the range of 108 Ω cm2 in corrosive media. Several studies have reported the fabrication of various Ca–P coatings including HA [[160], [161], [162], [163]] and FHA [164,165] by combination of MAO and EPD techniques. Yu et al. [140] fabricated EPD processed FHAp coating on MAOed AZ31 Mg alloy. Compared to FHAp and MAO alone, FHAp/MAO coating significantly improved cell adhesion, proliferation, and alkaline phosphatase expression. Bakhsheshi-Rad et al. [166] prepared a TiO2 incorporated micro-arc oxidation coating (TMAO) followed by electrophoretically deposited zinc doped HA (ZnHA) coating on Mg-0.7Ca alloy. In comparison to TMAO and ZnHA alone, TMAO/ZnHA coatings demonstrated a greatly enhanced inhibition zone against Escherichia coli (E. coli) without compromising the cell-viability of MG63 osteoblast cells.

3.1.3. Anodic oxidation

The anodic oxidation coating technique uses the principle of classical electrochemical conversion to create a film of varying thickness (5–200 μm) on a substrate. During anodization, Mg (i.e. substrate) serves as an anode and an oxide film is grown on the Mg substrate in presence of aqueous or non-aqueous electrolyte [167]. Being simplest surface modification technique, anodic oxidation coatings are widely reported for efficient corrosion resistance and bioactive response on Mg alloys [[168], [169], [170], [171]]. However, it is difficult to grow protective anodic layers on Mg and Mg alloys due to the unfavorable Pilling-Bedworth ratio (PBR) for MgO [172]. PBR is defined as the ratio of the volume of metal oxide to the volume of the corresponding metal oxidized to produce the oxide. The Oxide layer would not protect a metal surface if PBR is less than unity, because the oxide film formed in that case would be porous or cracked, as usually happened in magnesium's case. Therefore, it is necessary to promote the incorporation of species other than O2− in the electrolytic media to improve the Mg and Mg alloy corrosion resistance through anodic oxide layers. Recently, Zaffora et al. [172] carried out anodic oxidation of AZ31 Mg alloy in K2HPO4 and K3PO4 containing hot glycerol electrolyte to facilitate the formation of Mg3(PO4)2, which exhibits superior PBR and corrosion resistance than MgO layer. Additionally, Mg3(PO4)2 containing oxide layer show better cellular response for MC3T3-E1 cells compared to MgO layer. According to Geng et al. [173] the composition of Mg alloys effects the corrosion resistance offered by oxide layers. Using the same anodization parameters, Mg-1Gd and Mg–1Zn-1Gd yielded MgO, and Mg3(PO4)2 containing oxide layers with more crystalline and defect-free structures, while MgO and Al2O3 containing oxide layers on AZ31 Mg alloy showed higher porosity and larger pores. Consequently, Mg–Gd alloys shows better long-term degradation performance compared to anodized AZ31 Mg alloy. Since, anodic oxidation coatings singularly cannot full fill diverse clinical demands several studies reported their combination with chemical conversion [174,175], electrodeposition [176], LDHs [177], sol-gel [178] coating techniques. These coatings exhibit promising improvement in corrosion resistance and bioactivity of Mg alloys.

3.1.4. Ion implantation-

Ion implantation/Ion beam processing is a technique for introducing highly energetic ions (10–200 KeV) on substrate surface via bombardment. Ion implementation set-up consists of three main components: an ion source, ion accelerator, and target material. This surface coating method modifies the surface tribological characteristics, resulting in improved adhesion between the coating layer and substrate [179]. Two methods can achieve ion implantation: conventional beam-line ion implantation and Plasma Immersion ion Implantation (PIII). The primary advantages like selective surface modification, low temperature, and reproducibility are significant for coating Mg alloys [180,181]. However, amorphization caused during ion implantation causes surface devoid of grain boundaries, resulting in enhanced corrosion [182]. As ion implantation is a non-thermodynamic process, studies have reported the generation of compressive residual stresses and increased surface roughness of the ion-implanted surface. A wide range of ion implantations on biodegradable Mg alloys is reported in the literature, as shown in Table 3. Implantation of Al, Zr, Ce, Sn, Ca, and N ions revealed that the gradient structure of ions in the metal matrix provided a passive oxide layer of the metal substrate and implanted ion [[183], [184], [185]]. The compactness of the composite oxide layer formed at the ion-implanted surface plays a crucial role to enhance the in vitro corrosion resistance. Liu et al. [186] conducted Ag, Fe, and Y ion implantation on Mg -1Ca alloy. The non-uniform aggregation of second phase particles at grain boundaries resulted in an oxide layer with uneven thickness. Additionally, the increase in surface roughness enhanced the corrosion activity for Ag and Fe ion-implanted samples. However, Y ion implantation resulted in a compact Y2O3 layer with minimal MgO presence, decreased the corrosion rate to 0.69 mm/year. Jamesh et al. [187] fabricated Zr ions using the PIII method on ZK60 Mg alloy. Authors reported that Zr exists as Zr4+ ions due to the high energy imparted by PIII (i.e., 182.2 KeV). Zr4+ possesses a very high tendency to form zirconium phosphates instead of calcium phosphates in psychological media, resulting in unstable and soluble apatite [188].

Table 3.

In-vitro corrosion performance of Mg and Mg alloys after implantation of various ions.

| Substrate | Ion implanted | ionic oxide layer (nm) |

Ionic Penetration (nm) | In Vitro corrosion conditions | Icorr uncoated (A/cm2) |

Icorr Coated (A/cm2) |

Corrosion rate (mm/year) |

Ref. |

|---|---|---|---|---|---|---|---|---|

| AZ31 | Al | – | 13 | SBF, 37.5 °C | 2.82 × 10−5 | 3.36 × 10−5 | – | [184] |

| AZ91 | 1.50 × 10−4 | 5.82 × 10−5 | – | |||||

| ZK60 | Zr, O | 23 | 80 | SBF, 37 °C | 4.09 × 10−4 | 1.1 × 10−7 | – | [187] |

| WE43 | Ti, O | 32 | 64 | SBF | 3.27 × 10−4 | 1.44 × 10−5 | – | [191] |

| Mg–1Ca | Ag | 50 | 70 | Hank's solution, 37 °C | – | – | – | [186] |

| Fe | 70 | 110–120 | – | – | ||||

| Y | 95 | 105 | – | 0.69 ± 0.18 | ||||

| Pure Mg | Ce | 26 | 70 | Artificial Hand sweat | 1.06 × 10−4 | 3.99 × 10−5 | – | [183] |

| Ringer's solution | 4.18 × 10−5 | 2.68 × 10−5 | – | |||||

| DMEM | 2.04 × 10−5 | 5.20 × 10−6 | – | |||||

| Mg-Gd-Zn-Zr | Sn | – | 90 | SBF | 1.17 × 10−5 | 5.74 × 10−6 | – | [192] |

| AZ91 | Zr, N | 16 | 80 | NaCl | 4.26 × 10−6 | 1.16 × 10−6 | – | [190] |

| DMEM | 1.08 × 10−5 | 3.92 × 10−7 | – | |||||

| Mg–1Ca | Zn | – | 150 | SBF, 37 °C | 2.48 × 10−4 | 3.21 × 10−4 | – | [193] |

| Pure Mg | Ca | 45 | 30 | SBF, 37.5 °C | 1.61 × 10−4 | 1.00 × 10−4 | – | [182] |

| Zn | 1.40 × 10−4 | – | ||||||

| AZ31 | N | – | 200 | Hank's solution, 37 °C | – | – | – | [194] |

| Pure Mg | Zr | 30 | 60 | SBF | 5.26 × 10−5 | 1.99 × 10−5 | – | [195] |

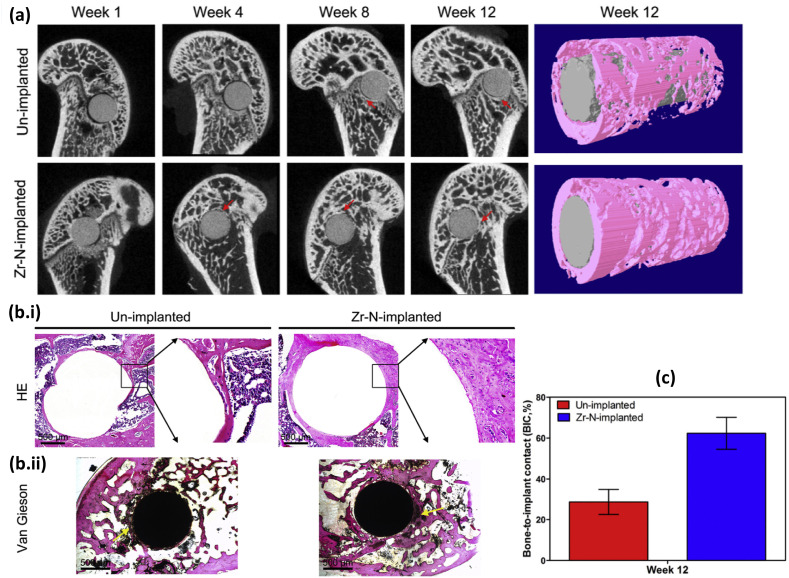

Dual ion implantation has been reported to overcome the limitations associated with single ion implantation. Jamesh et al. [189] investigated the effects of dual ion Zr/N PIII coating on corrosion resistance of WE43 Mg alloy. The formation of ZrN, ZrO2 oxides efficiently passivates the Mg substrate and promotes the mineralization of calcium phosphate instead of Zr–P after immersion in DMEM solution. Similarly, Cheng et al. [190] conducted Zr/N dual ion implantation on AZ91 Mg alloy in female Sprague-Dawley rats. In vitro cytocompatibility test on MG-63 cell line enhanced cell viability and ALP activity. Consequently, in-vivo bone formation improved significantly, as shown in Fig. 6. Despite the anti-inflammatory response, mature and intact bone tissues were found on Zr–N coated AZ91 implant compared to the uncoated implant. The compact oxide layer consisting of metal nitrides/oxides features neutral pH and limited release of Mg ions in the DMEM media. Limited work has been reported for the complex corrosion behaviour of dual ion implemented Mg alloys in physiological media.

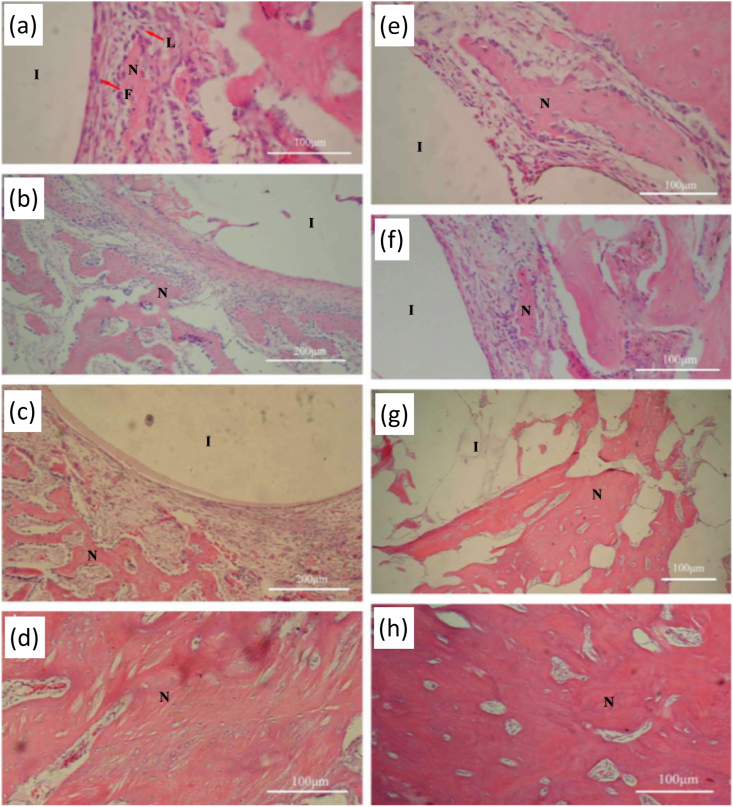

Fig. 6.

(a) Micro-CT 2D characterization of uncoated and Zr–N coated AZ91 Mg alloy after 4, 8, and 12 weeks of implantation at predrilled bone tunnels of lateral femur epicondyles in female Sprague-Dawley rats (The red arrows depict the formation of new bone, the yellow arrows show formation of gas cavities) and 3D reconstruction of bone (pink color) and implant (white color) after 12 weeks of surgery, (b.i) Hematoxylin and eosin (H&E) stained images, (b.ii) Van Gieson's picrofuchsin stained images showing bone formation (yellow arrows) at uncoated and Zr–N coated AZ91 implant, (c) Bone-to-implant contact percentage of uncoated and Zr–N coated AZ91 after 12 weeks of implantation. Reproduced with permission [190]. Copyright 2016, Elsevier.

Recently, Istrate et al. [196] employed a unique atmospheric plasma jet (APS) method in order to deposit ZrO2–Y2O3 and ZrO2–CaO coatings on Mg–Ca and Mg–Ca–Zr substrates. Both coating types show similar Young moduli and a hardness within the range of 0.2–0.4 GPa. For ZrO2–Y2O3 and ZrO2–CaO, the elastic modulus values were measured between 11-27 GPa and 16–31 GPa, respectively. Compared to ZrO2–Y2O3, ZrO2–CaO provides a superior corrosion rate and better adhesion. In the MTT colorimetric tests, moderate cell viability was observed between both coating types, indicating no significant differences in cytocompatibility.

3.1.5. Alkali heat-treatment coatings-

In alkali heat-treatment coatings, Mg alloys are exposed to a supersaturated aqueous solution of NaHCO3, Na2HPO4, and Na2CO3 alkaline compounds in an autoclave maintained at high temperature (i.e. ∼ 500 °C). The pH value of solution decides the density, thickness, and morphology of the coated layer [197]. Usually, alkali heat treatment produces thick coatings consisting of crystalline Mg(OH)2 flakes and a stable hydroxide with good adhesion and corrosion resistance. Tang et al. [198] reported adhesion strength of 60 MPa between Mg(OH)2 layer obtained by alkali heat-treatment. However, numerous spatial defects like pores and cracks limit its tendency as an efficient physical barrier to isolate underlying Mg substrate in corrosive media for longer immersion times. Additionally, chlorine ions in the SBF transform Mg(OH)2 into a highly soluble MgCl2 compound, as shown in Equation (1):

| Mg(OH)2 + Cl− → MgCl2 + OH− | (1) |

The excess of OH− ions increases H2 evolution, which enhances the degradation rate of Mg substrate with prolonged immersion [199]. Therefore, these coatings are not preferable as a top layer. However, as a primer layer, they are well established for better corrosion resistance and the middle layer for strengthening the adhesion between the substrate and the outer layer [200]. In contrast, some studies utilized it as a post-treatment technique to convert amorphous dicalcium phosphate dehydrate (DCPD) coatings to highly crystalline HA coatings, which efficiently shielded the Mg substrate in physiological media [3,141,201,202].

Recently, Pan et al. [203] employed alkali heat-treatment as a pre-treatment on AZ31 B Mg alloy before the deposition of a multilayered self-assembled 3-aminopropyltrimethoxysilane (APTMS), poly (ethylene glycol) (PEG), and fibronectin/heparin complex coating. The significant hydrophilicity exhibited by alkali heat treatment promoted the immobilization of coating layers and resulted in stable multilayered coating architecture. The alkali heating treatment significantly improved the corrosion resistance, resulting in favourable cellular growth conditions. Hence, the cytocompatibility towards endothelial cells was significantly augmented. Additionally, Author reported a notable enhancement in hemocompatibility due to significantly lower hemolysis rate and higher platelet adhesion.

3.1.6. Layered double hydroxide (LDHs) coatings

LDHs coatings possess a unique class of coatings on Mg alloys, which can be achieved by in-situ and ex-situ deposition techniques. LDHs are hydrotalcite-like (HT) compounds composed of noble anionic clays with layered brucite structures [204]. The General formula for LDHs is [M2+1-X M3+X (OH)2]X+ (Am−)x/m. nH2O, here M2+, M3+ symbolizes layer of divalent metallic cations (e.g. Mg2+, Co2+ Zn2+, Mn2+, Cu2+, Ni2+) and trivalent metallic cations (e.g. Al3+, Cr3+, V3+, Fe3+, Mn3+, Y3+) respectively [205]. Am− is the layer of intercalated anions between two subsequent cationic layers. The nature of intercalated anion may be either organic (e.g. Asp, PA, LA) or inorganic (e.g. NO3−, Cl−, PO43−, CO32−). M is the charge of intercalated anion; whereas x represents the molar ratio of M3+/(M3+ + M2+) typically ranging between 0.20 and 0.33 [206]. The LDHs synthesis involved the controlled dissolution of the Mg substrate. Generally, Al-rich Mg alloys like AZ31 are the most favourable and investigated alloy for LDH coatings. The release of Mg2+ and Al3+ ions from the substrate during dissolution provides a necessary supply of cations for the formation of the cationic layer [207]. These cations occupy the octahedral holes in the brucite Mg(OH)2 layer, and interlayer anions intercalate such cationic layers to balance the charge [208]. In the presence of corrosive media, the anions in the double layer structure are replaced by the aggressive anions (such as Cl−), and anion exchangeability is decided by anion exchange equilibrium constants of various LDH anions in the order: CO32− > SO42− > OH− > F− > Cl− > Br− > NO3− > I− [208]. The significant capturing of Cl− ions reduces aggressive ions in corrosive media. Furthermore, the replaced ions from double-layer structures bind with metal ions to form physio-chemically stable precipitates on the coating surface. The corrosion effectiveness of coating depends on the ion-exchange rate of intercalated ions. Thus, the anions equipped with corrosion inhibition, self-healing, self-cleaning, biocompatible, anti-bacteria features provide great potential for a multifunctional approach of LDHs coating on Mg alloy for implant application. It can be seen that the majority of intercalated ions are inorganic and participation of organic anions is minor, although organic compounds are considered more bio-functional than inorganic compounds [209]. One major reason behind such observation is high temperature and pressure conditions. However, ex-situ LDH techniques like co-precipitation (CPT), electrochemical deposition (ED), and Spin coating are suggested as substitutes, but they have limitations of poor adhesion and time consumption [210].

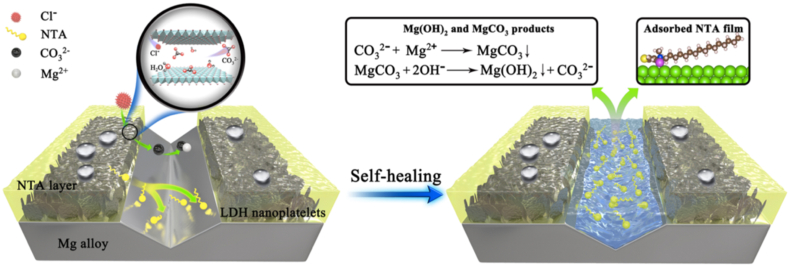

Recently, various inorganic/organic composite and hybrid LDH coatings have been developed to enhance corrosion inhibition, as summarized in Table 4. Cao et al. [208] fabricated Superhydrophobic MgAl-LDH coating by intercalating F− anion. An additional layer of stearate acid was created on MgAl–F-LDH by immersion method. The superhydrophobic behavior (CA = 152.6°) given by stearic acid significantly reduces the adsorption of Cl− ions. The superior ion exchangeability of F− stockpile a large amount of Cl− ions and make a stable MgF2 compound on the coating surface, which further suppress the attacking of aggressive ions. Coating remains intact after 30 days of immersion in a 3.5% NaCl atmosphere with only 3% water uptake compared to 18% shown by alone LDH coating. Recent attempts have been made to achieve self-healing LDH coating by depositing an additional layer of healing agents on LDH coating or introducing healing molecules as an active cation in the double-layered structure. Li et al. [211] proposed a bio-friendly thiophene derivate corrosion inhibitor (CI) for self-healing of Mg–Al-LDH coating by fabricating a noble N-alkyl-N, N-dimethyl-N-(3-thienylmethylene) ammonium bromide (NTA) molecule and deposited on MgAl-LDH by immersion method. Along with a highly positive shift in Ecorr, the stable physiochemical adsorption of NTA provides significant self-healing character on damaged Mg site as systematically shown in Fig. 7. It is worth noting that the biocompatibility of the NTA molecule was not reported. In a unique approach for self-healing, Asl. et al. [212] replaced Al3+ cation in the conventional MgAl–CO32- structure with Ce3+ cation by co-precipitation (CPT) method. On mechanical scratching of the coated substrate, the oxidation of trivalent Ce3+ ion resulted in the formation of tetravalent Ce4+ ion, which formed a highly stable metallic complex with a low solubility index (Ksp, 2 × 10−48), giving super self-healing characteristic. However, due to the size mismatch between Mg2+ and Ce3+ ions, the long-term stability of coating architecture with prolonged immersion in physiological media is yet to be established.

Table 4.

Inorganic and organic intercalated anionic LDH coatings for Mg alloys.

| Substrate | Coating | Coating Method | Thickness (μm) |

Intercalated anion (inorganic) | Ecorr (V/SCE) |

Icorr (A/cm2) |

Corrosion rate (mm/year) |

Additional Bio functionality | Ref. |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uncoated | Coated | Uncoated | Coated | ||||||||||

| AZ31 | ZnAl-LDH | Hydrothermal treatment | 9.49 9.46 10.27 12.71 15.95 |

NO3− Cl− PO43- MoO42- VO43- |

−1.51 −1.51 −1.51 −1.51 −1.51 |

−1.33 −1.20 −1.09 −0.98 −0.88 |

7.48 × 10−5 7.48 × 10−5 7.48 × 10−5 7.48 × 10−5 7.48 × 10−5 |

2.13 × 10−5 7.18 × 10−6 3.68 × 10−6 3.42 × 10−6 3.02 × 10−7 |

– | – | [213] | ||

| AZ31 | MgAl-LDH | Hydrothermal treatment | – | GO | −1.56 | −0.65 | – | – | – | – | [214] | ||

| Mg–Ca | MgFe-LDH | Two-step in-situ growth | – | CO32- | −1.67 | −1.51 | 4.31 × 10−5 | 3.78 × 10−6 | – | [215] | |||

| Mg–3Zn-0.5Zr-0.5Sr | Ag–MgAl-LDH | Hydrothermal treatment | – | – | −1.58 | −1.42 | 2.56 × 10−5 | 2.09 × 10−6 | – | Enhanced Cytocompatibility for MC3T3 cell line. Significant Anti-bacterial response against E.coli and S. aureus. | [216] | ||

| AZ31 | MgFe-LDH/MAO | Hydrothermal treatment | 17 | NO3− | – | – | – | – | – | – | [217] | ||

| AZ31 | MgAl-LDH/PGA | Co-precipitation and hydrothermal treatment | 44 | NO3− | −1.40 | −1.34 | 2.39 × 10−6 | 8.95 × 10−8 | – | Biocompatibility towards NIH-3T3 mouse embryonic fibroblast cells was enhanced | [218] | ||

| AZ31 | MgAl-LDH/PLLA | Steam coating/Dip coating | – | CO32- | −1.46 | −1.29 | 1.18 × 10−5 | 3.69 × 10−8 | – | Cytocompatibility for NIH3T3 cell line was improved significantly. | [219] | ||

| AZ31 | MgAl-LDH/Zn-PDA | Hydrothermal treatment/immersion | 20–50 nm |

NO3− | −1.50 | −1.52 | 1.22 × 10−5 | 1.60 × 10−6 | – | Anti-inflammatory response by polarizing RAW 264.7, Anti-bacteria response against S. aureus and enhanced osteogenic differentiation was shown for MC3T3-E1 cell line. | [220] | ||

| AZ31 | MgAl-LDH/Bg | Hydrothermal treatment/Dip coating | 5 | NO3− F− |

−1.51 −1.51 |

−0.255 −0.324 |

6.65 × 10−5 6.65 × 10−5 |

3.13 × 10−6 1.40 × 10−7 |

– | Self-repair of coating assisted by ion exchange process, the erosion pits were filled by deposition of fluorapatite/MgF2 | [221] | ||

| Intercalated anion (Organic) | |||||||||||||

| AZ31 | ZnAl-LDH MgAl-LDH |

Hydrothermal treatment | 9.49 17.01 |

Asp Asp |

−1.44 −1.44 |

−1.50 −0.8 |

6.98 × 10−5 6.98 × 10−5 |

3.93 × 10−7 2.76 × 10−8 |

– | – | [222] | ||

| AZ31 | ZnAl-LDH | Hydrothermal treatment | 15.65 17.39 |

Asp LA |

−1.51 −1.51 |

−1.50 −1.07 |

7.48 × 10−5 7.48 × 10−5 |

3.93 × 10−7 2.77 × 10−7 |

– | [223] | |||

| AZ31 | MgAl-LDH | In-situ growth | – | 8-HQ | −1.55 | −0.766 | 8.36 × 10−6 | 1.70 × 10−7 | – | – | [224] | ||

| AZ31 | MgAl-LDH | Steam coating | – | MA | −1.45 | −1.29 | 1.29 × 10−5 | 1.04 × 10−5 | – | – | [225] | ||

Fig. 7.

Schematic illustration of self-healing mechanism by NTA adsorption on mechanically damaged MgAl-LDH coating. Reproduced with permission [211]. Copyright 2020, Elsevier.

The latest LDH coatings are still struggling to impart in-situ bio-functional behavior, although they have tremendous encapsulation ability to deliver drugs, corrosion inhibitors, and other biomolecules. However, the unfavorable processing parameters (i.e., high temperature, pressure) and the use of carbonated anions (i.e., CO32−), which suffer from poor ion-exchangeability, limit the ability for in-situ loading and release of bioactive molecules in LDH coatings. To address this issue, Petrova et al. [226] demonstrated the formation of Mg–Al-LDH coating on AZ91 alloy by application of organic chelating agents sodium-diethylenetriamine-pentaacetate (DTPA) and Salicylic acid (SA) at a low temperature of 95 °C. The Mg substrate was treated in a solution maintained at pH value 10 ± 0.1, consisting of chelating agents and AZ91 flakes as a source of Mg and Al ions. DTPA enhances the dissolution of Mg, while SA promotes adsorption and accelerates the growth of LDH coating on the Mg surface. Both chelating agents' synergistic functioning successfully resulted in the formation of LDH coating without the use of high temperature and pressure conditions, which shows its potential to enhance bio-functionalization for clinical applications. However, Al, considered to be neurotoxic, may impede bone calcification and result in osteomalacia when present in excessive levels [210].

Meanwhile, manganese (Mn) happens not to be toxic and activates a variety of enzymes in a physiological environment. Thus, the in-situ synthesis of Mg–Mn hydrotalcite-like films on magnesium alloys appears suitable for clinical applications. Kuang et al. [227] developed Mg–Mn LDHs coatings on pure Mg by an in-situ growth method, which were chemically modified by adsorption of myristic acid (MA). After modification with myristic acid, the solid-liquid contact angle of the Mg–Mn LDHs film (6.8°) was increased to 152.2°, qualifying as a superhydrophobic coating (i.e. Contact angle >150°). The Superhydrophobic coatings exhibited a polarization resistance of approximately 20,000 Ω cm2. This was more than twice as of Mg–Mn LDHs film, and ten times more than pure Mg substrate. However, the drop in contact angle to 60° after 48 h of immersion indicated gradual deterioration of LDH film with prolonged immersion. Recently, Zhang et al. [228] fabricated a black Mg–Mn(Ⅱ)-Mn(Ⅲ) LDH coating on AZ31 Mg alloy to evaluate the biodegradation, osteosarcoma destruction, anti-bacteria, and bone defect regeneration abilities. Due to the unique properties of the constructed black LDH film, including near-infrared optical absorption and reactive oxygen species (ROS) generation in the tumor-specific microenvironment, tumor cells and tissue were significantly eliminated. Furthermore, concomitant bacteria were killed by localized hyperthermia. As a result of the improved corrosion resistance and synergistic bio functions of Mn and Mg ions of the constructed black LDH film, cells were able to adhere, spread and proliferate. This resulted in the promotion of osteogenic differentiation in vitro, and the acceleration of bone regeneration in vivo. Thus, MgMn-LDHs offered an interesting coating architecture for use on orthopedic implants for the treatment of bone tumors and related tissue defects.

3.2. Deposited coatings

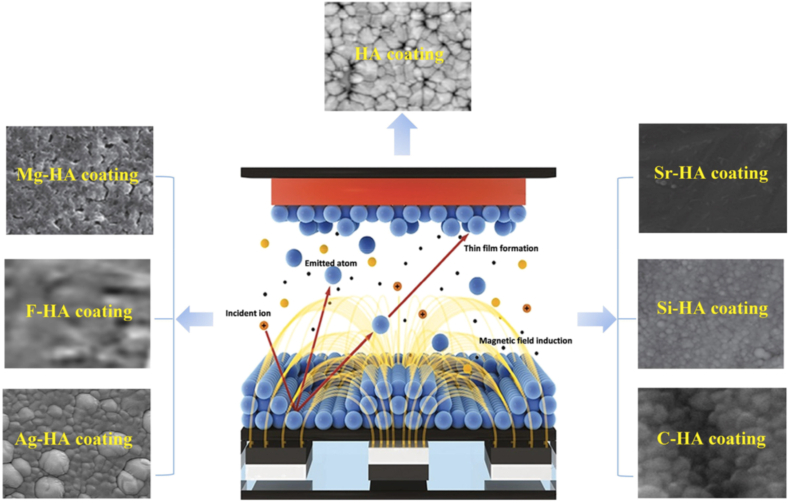

3.2.1. Physical vapor deposition (PVD) –

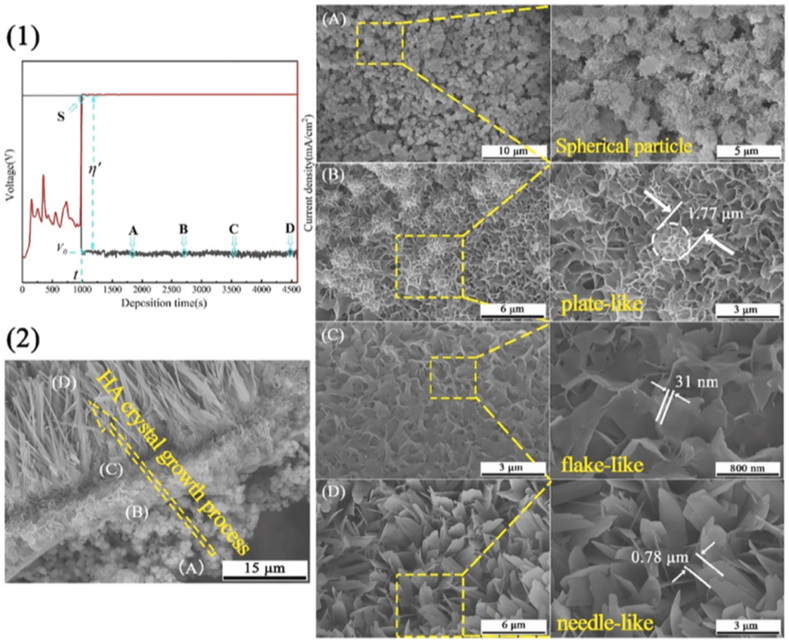

PVD is a standard coating process for Mg and Mg alloys effectively used for four decades for clinical applications. PVD is widely reported for producing high-density coatings with excellent adhesion strength [229,230]. In vacuum conditions, a negatively charged solid target is energized by the bombardment of inert gas atoms. The excited atoms are then transported and condensed at the positively charged Mg substrate. PVD can be achieved by e-beam evaporation and Magnetron sputtering [231]. Magnetron sputtering is preferred over e-beam as it is directional, covers fewer steps, and forms shadow effect [232]. In magnetron sputtering, a magnetic field is configured parallel to the target surface for constraining the electron motion; thus, highly uniform coatings are yielded [233]. The fabrication of Ca–P and various ion substituted Ca–P coatings by PVD magnetron sputtering is widely reported for Mg alloys, as shown in Fig. 8.

Fig. 8.

Schematic illustration of physical vapor deposition via magnetron sputtering for various ion-substituted Ca–P coatings. Reproduced with permission [233]. Copyright 2019, Elsevier.