Abstract

Background

With increasing requirements for medical effects, and huge differences among individuals, traditional surgical instruments are difficult to meet the patients' growing medical demands. 3D printing is increasingly mature, which connects to medical services critically as well. The patient specific surgical guide plate provides the condition for precision medicine in orthopaedics.

Methods

In this paper, a systematic review of the orthopedic guide template is presented, where the history of 3D-printing-guided technology, the process of guides, and basic clinical applications of orthopedic guide templates are described. Finally, the limitations of the template and possible future directions are discussed.

Results

The technology of 3D printing surgical templates is increasingly mature, standard, and intelligent. With the help of guide templates, the surgeon can easily determine the direction and depth of the screw path, and choose the angle and range of osteotomy, increasing the precision, safety, and reliability of the procedure in various types of surgeries. It simplifies the difficult surgical steps and accelerates the growth of young and mid-career physicians. But some problems such as cost, materials, and equipment limit its development.

Conclusions

In different fields of orthopedics, the use of guide templates can significantly improve surgical accuracy, shorten the surgical time, and reduce intraoperative bleeding and radiation. With the development of 3D printing, the guide template will be standardized and simplified from design to production and use. 3D printing guides will be further sublimated in the application of orthopedics and better serve the patients.

The translational potential of this paper

Precision, intelligence, and individuation are the future development direction of orthopedics. It is more and more popular as the price of printers falls and materials are developed. In addition, the technology of meta-universe, digital twin, and artificial intelligence have made revolutionary effects on template guides. We aim to summarize recent developments and applications of 3D printing guide templates for engineers and surgeons to develop more accurate and efficient templates.

Keywords: 3D printing, Guide templates, Orthopedic applications

1. Introduction

With the increasingly close connection between digital technology and orthopedics, we have diagnosed and cured individual patients in patterns of precision, personalization, and digitalization instead of empirical, generalization, and contouring. As a form of digital technology, 3D printing is an effective method to achieve individualization and precision in various orthopedic procedures [[1], [2], [3]].

3D printing, also known as additive manufacturing (AM) or rapid prototyping, is an emerging technology that uses digital model files as the basis for producing objects [3,4]. The technology differs from the traditional methods of modeling, which changes the traditional removal process to an additional process [2,5,6]. It has advantages that are unmatched by traditional processes, such as rapid forming, better repeatability, and individualization to meet unique or special requirements.

In the medical field, it is increasingly used in a wide range of clinical applications, including guide templates, preoperative models, the implant, human tissue, organs, etc [5]. One of the significant applications is the design and fabrication of patient-specific guides to perform drilling and cutting operations. With the evolution of printing materials and advances in medical imaging, the materials that can satisfy 3D printing have evolved from single solid powders such as metals, plastics, and ceramics to mixed liquids, gels, and cells [3]. Radiological diagnosis of computed tomography (CT) and magnetic resonance imaging (MRI) has become less invasive and more informative [4].

The 3D surgical templates are instruments that are used to guide the placement of internal fixations such as screws, assist in bone repositioning, and aid in determining the extent of osteotomy [7]. During cadaver research as well as clinical studies, the template has attracted increasing attention from clinicians because of its position-independent character and the reduction of surgical procedures [[8], [9], [10]]. With the help of guide templates, the surgeon can easily determine the direction and depth of the screw path, choose the angle and range of osteotomy, increasing the precision, safety, and reliability of the procedure [5,7]. It simplifies the difficult surgical steps, shortens the learning curve for physicians, and accelerates the growth of young and mid-career physicians [11]. The reduction of radiations can reduce surgical complications and improve the quality of orthopedic surgery [12,13]. Compared to surgical navigation systems, surgical guides are more convenient and easier to use. In addition, surgical guides can be performed under minimally invasive conditions, reducing the time spent in the operating room, substantial cost savings for the hospital, reduced patient risk [1,2].

Currently, many hospitals have a positive attitude towards the use of 3D printing technology, and it is widely used in orthopedic surgery, but the attendant problems with data acquisition, guide design, manufacturing, and application have increased accordingly [3,14]. The aim of this article is to review the progress and basic application of surgical guides, analyze the limitations. We hope this review would provide useful information for the engineers and surgeons to design and apply more accurate and intelligent guides, especially for those new to this field and who would like to make contributions to this important multidisciplinary biomedical engineering and orthopedic field.

In this article, the history of 3D printing technology is first reviewed before introducing the progress and main applications of the guide templates. Finally, this article discusses the limitations of the guides and, and looks forward to the future, intending to guide clinical.

2. History of 3D printing

Over the past decades, many professors have conducted research into 3D printing. The concept of using 3D medical imaging, specifically CT data, to reconstruct a physical model was first suggested in 1979 [15]. In the mid-1980s, Professor Charles Hull invented and patented the stereolithography apparatus (SLA) for printing 3D models in the USA. Then he founded a company called 3D Systems to focus on the development of 3D printing technology. In 1988, they invented the first printer which is regarded as a pioneer in 3D printing technology [16].

Scott Crump proposed fused deposition modeling (FDM) in the same year and applied it to the first commercial printer in 1991, followed by the founding of Stratas company [2,17]. Carl Dechard invented selective laser sintering (SLS) at the University of Texas in 1986 and was awarded the first SLS patent for printing 3D models in 1989 [17]. In 1992, laminated object manufacturing (LOM) was invented, but it was not widely used due to its inferior performance [18]. 3D printing technology was first patented in 1989, this is also the first time that the term “3D printer” has been used and is licensed for printing plastic, metal, and ceramic parts.

In the medical field, Mankovich reproduced one of the first anatomical models of the skull by SLA based on CT scan data in 1990 [19]. Early on, a company in San Francisco, USA, made all the components of a prosthetic leg for a patient. The concept of computer-aided orthopedic surgical guides was first introduced in the 1990s by German professor Klaus Radermacher to guide implant placement, tumor removal, osteotomy, bone repositioning and to provide accurate placement of implants or prostheses. The use of surgical guides, which allow for the transfer of pre-operative planning to the actual surgical site, can improve the precision, safety, and reliability of surgery, but the limitations of the equipment, materials, and software at the time did not allow for the manufacture of surgical guides to meet the needs of patients.

Since the early 2000s, computer and 3D printing have developed significantly and have been carried out in the medicine, the aerospace industry, the automotive industry, kitchenware, and other manufacturing industries. Surgical guides were first used as a high-precision tool for oral dental implants and have since been used in maxillofacial surgery, abdominal tumor removal, urology, and cardiovascular surgery. The first application in orthopedics was reported to produce guides in the placement of pedicle screws. With the development of technology, it is gradually used in shoulder, hip, knee, ankle, and trauma surgery, greatly improving surgical efficiency [7,20]. Precision, intelligence, and minimal invasiveness are the future direction of orthopedics, and guide templates will play an important role in all aspects of orthopedic surgery.

3. The process of 3D printing

3D printing surgical guides have become a hot spot in the field of medical image computing. Although the steps to generate a digital 3D model vary from different applications, the following are the general steps required to print a 3D model [1,5,7]. We can use imaging equipment to obtain source datasets visualized in two dimensions. With post-processing tools and algorithms, it is possible to produce multiplanar reformations and 3D views of the anatomy.

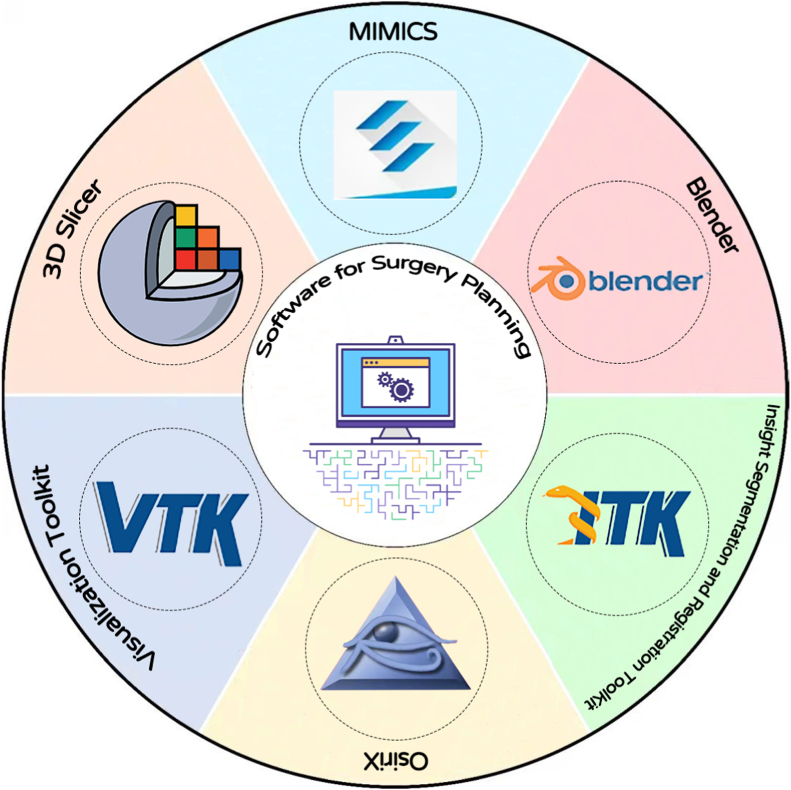

Currently, the medical designed software for surgery planning is mainly divided into three categories [21]. Firstly, the commercially available software, such as the MIMICS system developed by Materialise in Belgium was one of the most widely used and the most comprehensive software [22]. It can perform dedicated anatomical analysis, create accurate virtual 3D models, and plan a surgical procedure virtually [23]. Other software, for example, Analyze, 3D-DOCTOR, SimPlant, and SurgiCase can import image data and export 3D models for 3D analysis, finite element analysis meshing, design, or 3D printing [7].

Then, there are some open-source medical image processing softwares in open source, such as 3DSlicer, OsiriX, and Blender. These open source medical imaging frameworks are freely available to developers. 3DSlicer is the most developed and comprehensive open source image processing tool [2]. It can operate on iOS, Windows, and Linux, which carry out analysis and visualization of diffusion tensor imaging data and automatic image segmentation. However, it has many parameters and is very complicated to use. OsiriX can only operate on iOS system, which carries out medical image processing, 3D visualization, and partial PACS functions [24]. It is very useful but the functions mainly focus on image fusion, image rendering, and image annotation. Blender supports the entirety of the 3D pipeline: modeling, rigging, animation, simulation, rendering, and compositing [25].

Finally, some research organizations have developed Algorithms Toolkit, including Visualization Toolkit (VTK), insight segmentation and registration ToolKit (ITK), and so on [26]. They offer great benefits to researchers, but they have some drawbacks. ITK doesn't provide visualization capabilities and must be used with VTK, which makes it difficult for users to learn from two large and inconsistent development packages [27]. The above software for surgery planning are shown in Fig. 1.

Fig. 1.

The software for surgery planning.

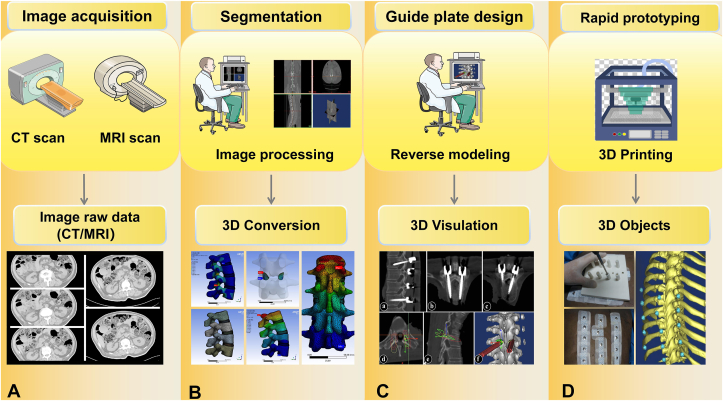

According to the demands of the clinic, we determine the surgical plans, reversely generate surgical guides, and perform 3D printing [4]. The key technologies involved in this method include image acquisition, segmentation/conversion of the medical image, template design, and 3D printing, which are discussed below (Fig. 2).

Fig. 2.

The process of 3D printing (A) The raw data were acquired by using CT or MRI scans of patients (B) Engineers and doctors used Softwares to segment the region of interest area (C) Engineers and doctors completed the 3D reconstruction of the data according to clinical needs (D) According to the data saved in the file, the powders were printed layer by layer to get the final 1:1 recovery of the 3D guide templates.

3.1. Image acquisition

Image acquisition is a very important step in generating a 3D model because the quality of the model depends on the clarity and accuracy of the data [7]. We usually choose CT or MRI data and store the data set in the form of Digital Imaging and Communication in Medicine (DICOM) files [1,28,29]. Although both CT and MRI can be done at ultra-high spatial resolution (400–600 microns) with good quality contrast, CT is widely used in 3D printing because the image post-processing of CT data is relatively simple [2,30]. In addition, several 3D imaging options such as positron emission tomography (PET), single-photon emission computed tomography (SPECT), ultrasound (US), and even images captured on an iPhone are other non-invasive imaging methods that can be used for data collection [1].

3.2. Segmentation/conversion of the medical image

At this stage, either open-source (Osiris® for Macintosh, 3D Slicer® for Windows and Linux, MeVisLab) or licensed (Mimics®, Magics®) can be used to segment the region of interest and complete the 3D reconstruction of the data according to clinical needs. The bone tissue on the image can be segmented manually, but the segmentation is usually not perfect. Part of it is because less bone tissue is selected, and part is because more non-bone tissue is selected. Although automatic segmentation can be done using gray thresholds, the output quality is lower than manual or semi-automatic segmentation. The accurate segmentation of bones requires doctors have good skills and experience in using software segmentation tools [2]. The digital model is still relatively rough and needs further processing. The area to be processed can be converted into a 3D triangular mesh using software, which further processes the mesh data using triangular faces to approximate the shape of the part [31]. Obviously, tiny triangular faces produce smoother surfaces but increase the size of the data. Additional surface refinements can be performed, such as checking and correcting any overlapping surfaces, simplifying image files for more efficient printing.

Nowadays, researchers are focusing on the development of automatic image segmentation algorithms including the region growing method [32], watershed algorithm [33], the deformable biomechanical model method [34], and so on. However, the accuracy of the segmented result may not be sufficient to meet the clinical requirements.

3.3. Guide template design

Afterward, it is processed according to specific clinical needs, surgical approach, and parameters related to the scope of exposure. On this basis, a guiding tube or groove is designed as an intraoperative navigation device. The 3D guides are established to fit, and the obtained guide template data is converted into a printable format. The file should be saved in Stereo Lithography (STL) format [17]. Finally, import the STL file into the 3D printer. Determine the appropriate 3D printing methods and materials based on the clinical requirements, and then build the corresponding physical guides after a certain amount of accumulation based on the collected cross-sectional information. It uses special materials such as metal or plastic powder with laser beams or hot melt nozzles to print the outline of the guide template on the cross-section on a two-dimensional (2D) plane, and then stacks in the z-coordinate layer to form a 3D structure [2]. In addition, in order to simplify the guide design process, some scholars use the C++ programming language (Visual Studio 2013, Microsoft, Redmond, WA) to optimize the operation interface, so that doctors can use the software more easily.

3.4. 3D printing

By reading the data saved in the file, 3D printers manufacture layer by layer to get the final 1:1 recovery of the 3D physical model. The choice of materials is more abundant, such as powder, metal, plastic, etc [2,5]. Table 1 summarizes the 3D Printing technology.

Table 1.

The detailed classification of 3D printing (rapid prototyping or additive manufacturing) technology.

| Types | Description | Materials | Systems for instance | Accuracy | Cost | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| SLA [2,35] | The laser illuminates the bottom of a tank filled with a photo-polymerizing resin. Starting from the bottom layer by layer in the same way to form a 3D model. | Photopolymers | 3D Systems, Rock Hill, SC, USA | +++ | $$ | Large part size, high precision, excellent surface quality, the ability to be waterproof | Moderate strength, photosensitive resin swells or crumples due to changes in physical or chemical conditions |

| FDM [2,17] | The material is heated above its melting temperature. Then extrude and deposit the material layer after layer in the desired shape. | Fused thermoplastic materials or eutectic metals | Stratas Inc., Eden Prairie, MN, USA | ++ | $ | Low cost, good strength, without gases during the printing process | With low speed, the process can lead to high temperatures, which may pose a safety risk |

| SLS [17,18] | The laser selectively scans and melts a layer of material powder at a set speed and energy density. | Small particles of thermoplastic, metal, ceramic, or glass powders | EOS GmbH, Munich, Germany | ++ | $$$ | Large part size, variety of materials, good strength, resistance to water and corrosion, no significant need for support structures | The powdery surface, produces an odor during the melting process |

| LOM [18] | The laser cutting system cuts the contours of the workpiece and hot-melt adhesive coated the workpiece layer by layer to make a three-dimensional workpiece. | Layers of paper or plastic films | Cubic Technologies, Torrance, CA, USA | + | $ | Low cost, large part size | Limited materials |

| SLM [36] | Uses a high power-density laser to melt and fuse metallic powders together; SLM is considered to be a subcategory of SLS. | Metal powders (such as titanium) | Arcam, Molndal, Sweden | ++ | $$ | Variety of materials, relatively low cost | Low speed, rough surfaces, limited materials |

| EBM [36] | The electron beams scan and melt the raw material causing the powders to fuse with each other and solidify. | Metal powders | EOS GmbH | + | $$$ | High forming efficiency, operation in a vacuum environment, avoiding oxidation, and being able to recycle the remaining powder | Less accurate |

SLA = stereo lithography apparatus; FDM = fused deposition modeling; SLS = selective laser sintering; LOM = laminated object manufacturing; SLM = selective laser melting; EBM = electron beam melting.

There are many printing technologies currently in clinical use, SLA [2,35] was the first technology to emerge and be commercialized. It is one of the most intensively researched and widely used 3D printing technologies. Due to its early appearance, the technology is very mature and achieves a high degree of automation to meet the needs of different product models. FDM [2,17] is currently one of the most popular 3D printing technologies. The main clinical applications are preoperative models, intraoperative navigation, and the printing of medical teaching aids. SLS [17] is known as one of the most practical 3D printing technologies due to its low material consumption and high material stability. Because the high temperatures cause the powders to aggregate with each other to form solids, subsequent layers are deposited on the sintered layers until the corresponding 3D model solids are formed. The main clinical applications are the printing of guides, fixation frame, and braces [18].

The EBM and SLM are similar [36]. It's important to note that we need to operate in a vacuum environment. The difference is that the heat source is a laser beam instead of an electron beam. Additionally, Inkjet printing technology, also known as 3D bioprinting technology, is an additive manufacturing technique that can be used for layer-by-layer fabrication of highly complex tissues such as bone and cartilage [2,6,17]. If bioprinting technology can be used to manufacture orthopedic surgical guide templates, it can reduce patient trauma and contribute to the recovery of patient trauma, showing a good application prospect [37].

Even non-professionals can produce impeccable constructions of complex structures with such an easy way in the computer center that has one of these smart printers. There is no need for a specific type of workshop or long-term training for basic access [38]. This encouraged the surgeon to grow up faster through the daily practice of these devices. After all the above work is completed, the surgeon can use the surgical template to perform the operation.

3.5. Printing materials

There are many printing materials that can be used for 3D printing, including photosensitive resin, Polylactic Acid (PLA), Acrylonitrile Butadiene Copolymers (ABS), nylon, and metal [2,39,40]. Since the surgical guides require contact with human tissue directly, it has high requirements on materials [41]. The materials should have no cytotoxicity, no irritation, no skin allergy, and chemical composition in line with the requirements of national and industrial standards [1,42]. According to the physical and chemical properties of the material and various types of surgery, we divide the surgical guides into metal guides and nonmetal guides. Because nonmetal materials are not strong enough, they are often used to make guiding devices, such as round holes to guide Kirschner needles [3]. Metal guides are used to assist the operations of bone-knife and electronic tools in osteotomy or drilling. Because in the process of operation, if the strength is not enough, the surgical guides may create fine chips, and even deformed due to friction heat generation [25].

At present, photosensitive resin is the preferred guide material because of its stable properties and certain strength [43]. ABS and PLA are suitable for some large guides, such as percutaneous spinal guides [44]. The resin can be used for positioning guidance for lower limb osteotomy and deformity correction [45]. Nylon has high precision and high strength, so it is recommended to be used for guide plates with small volume and certain strength requirements like total knee arthroplasty [40,46]. Titanium, medical stainless steel, aluminum alloy, and other metal materials can be processed into guide plates [47]. It can assist the operations of bone-knife and electronic tools in osteotomy or drilling, which increase guide strength and reduce the generation of chips. However, its materials and equipment are expensive, and its costs are high.

4. Basic types and clinical applications of orthopedic 3D printing guide templates

In view of the clinical use of 3D printing orthopedic surgical guides, the guides can be divided into three types: screw placement guides, osteotomy guides, and other series of guides. Osteotomy guides are the main player of 3D printing guides. In orthopedic surgery, 3D printing surgical guides have been used as bone cutting guides and plate positioning guides to help with making corrective osteotomy cuts for malunion cases [23]. It is easier to perform the procedure using the guide because there was no confusion about the bone cutting. The application has resulted in shortened operating time and less intra-operative blood loss [1].

For the radius, a volar Henry approach was assisted by surgical guides, and additional soft tissue release was not required for correction of the deformity [48]. In Bauer's research, all ulnar osteotomies were performed through the subcutaneous approach to the ulna. The drill guides were used first, followed by the osteotomy guides. All cases went according to plan and we encountered no issues in using the guides [49]. To correct the pronated deformity after the first metatarsophalangeal joint arthrodesis accurately, it has been used to guide the bone saw in cutting the metatarsal and proximal phalanx perpendicular to the longitudinal axis [50]. For complicated tibial plateau fracture fixation, the role of the navigational template was to guide the insertion of screws that were locking to the plates. The placement of the locking plate was determined when the location and direction of the screwing were determined [51].

In various types of surgeries, such as the spine, joint, trauma, and bone tumor, the osteotomy guides are used widely. The 3D-printed guides technique makes the preoperative planning more straightforward to execute, without the need for excessive bone cortex removal or multiple fragments, and it increases the chances of success. We will discuss it in different anatomical regions in detail.

Some surgeons often use the freehand technique to select the trajectory of the screw. However, it often leads to postoperative complications, such as vertebral artery and spinal cord injuries, which have a negative impact on the patient's prognosis [52,53]. In order to prevent or minimize the incidence of these complications and determine the optimal trajectory, some operators now use multiple intraoperative X-ray images to guide the orthopedic operation. However, this increases the radiation exposure of both the patient and the surgeon and prolongs the duration of the procedure [54].

Therefore, in order to improve the accuracy and efficiency of the surgery, many doctors have started to investigate 3D printed surgical guides [55]. Adequate stability between the template and the bone is critical in determining whether this technology can be used. Pijpker et al. [56] designed a new 3D printing guide including metal inlays, caudally positioned hooks, and a crosslink support structure that can move more stably with the vertebrae and tested good screw placement accuracy in both the cervical and upper thoracic spine of a cadaver. With regard to the possibility of using the guide template technique for multi-segmental vertebrae, it is still controversial. The reason for this is that large areas of muscle exposure lead to deviations in template placement. In theory, the larger contact area will conduct a better positioning effect. When the surgical exposure site is small, it will block the surgeon's vision, resulting in positioning errors. Therefore, the surgical exposure site must be expanded to ensure that all support points without exception are in contact with the zone of interest [57]. However, excessive dissection of soft tissue may increase the risk of bleeding and infection. Instead, we can choose to use the design of percutaneous guides without the need for surgical exposure site, especially in the parts with thin soft tissues such as ankle joint and iliac crest. Takemoto et al. designed a new template for thoracic pedicle screw placement can reduce the contact area without sacrificing stability [58]. The following will introduce some of their applications in their respective fields. Table 2 shows the main basic research for various types of surgeries and results.

Table 2.

The main basic research of various surgeries.

| Year | Authors | Journal | Case number | Research type | Type of surgery | Results |

|---|---|---|---|---|---|---|

| 2021 | Rho YH et al. [127] | Vet Sci | 8 | dog | A cutting guide and reduction guide for corrective osteotomy | It is useful for novice surgeons to accurately perform corrective osteotomy in dogs without complications. |

| 2021 | Caiti G et al. [137] | Int J Comput Assist Radiol Surg | 5 | cadaver | A cutting and drill guide for fracture of the distal radius | For normal weight arm specimens, navigation of corrective osteotomy via a cast-based guide resulted in transfer errors comparable to those using invasive surgical guides. |

| 2021 | Toni C et al. [9] | Vet Comp Orthop Traumatol | 5 | dog | Lumbar pedicle screws fixation for degenerative lumbosacral stenosis and discospondylitis. | This technique enabled an accurate and safe placement of pedicle screws in the lumbosacral region of dogs with the lumbosacral disease. |

| 2021 | Zhao Y et al. [96] | BMC Musculoskelet Disord | 6 | cadaver | Simultaneously inserting traditional pedicle screws and cortical bone trajectory screws fixation | Using such templates is a safe, feasible, and accurate screw placement method. |

| 2020 | Li Z et al. [44] | J Clin Neurosci | 6 | cadaver | PPSF | It improved the accuracy of PPSF in cadaveric specimens. |

| 2020 | Chen X et al. [86] | Ann Transl Med | 15 | cadaver | Thoracic pedicle screw fixation | The optimal trajectory was obtained through the pedicle central axis, which significantly reduced the risk of cortex breach. |

| 2020 | Easter TG et al. [133] | Vet Surg | 11 | dog | Patient-specific drill guides for HIF | 3D printed guides should be considered as accurate and consistent for placing screws for the treatment of HIF in dogs. |

| 2020 | Liang J et al. [164] | BMC Surg | 17 | cadaver | Acetabular and femoral stem prostheses for THRA | The template of the femoral head can effectively assist surgeons in accurately implanting the femoral head components to the desired position in THRA. |

| 2019 | Pijpker PAJ et al. [56] | Oper Neurosurg | 5 | cadaver | Pedicle and lateral mass screw locus in cervical and upper thoracic vertebrae | The study ultimately resulted in an advanced guide design including caudally positioned hooks, crosslink support structure, and metal inlays. |

| 2019 | Chen XL et al. [66] | PLoS One | 12 | 3D models | Pedicle screw fixation in the upper cervical spine | To implant pedicle screw assisted with the template in the posterior cervical surgery can improve the accuracy of pedicle screw placement and safety of the surgery. |

| 2019 | Fujioka T et al. [82] | Vet Surg | 4 | cadaver | Thoracolumbar pedicle screw fixation | Drill guide templates were useful for accurate intraoperative screw navigation in thoracolumbar fixation in small dogs. |

| 2019 | Wang K et al. [85] | World Neurosurg | 10 | cadaver | Thoracic pedicle screw fixation | Insertion of the CBT screws in the middle-upper thoracic spine with the assistance of the navigation template was safe and convenient. |

| 2019 | Naddeo F et al. [89] | Int J Med Robot | 1 | 3D models | Thoracic pedicle screw fixation | Improvements in terms of precision, duration, and safety were achieved without changing the standard procedure. |

| 2019 | Guo Y et al. [141] | J Hand Surg Am | 12 | cadaver | A drill template for scaphoid fractures | Template to assist screw guidewire placement into an intact scaphoid, mimicking a nondisplaced scaphoid fracture, showed acceptable accuracy in cadaver wrists. |

| 2019 | Wan SX et al. [142] | Curr Med Sci | 10 | cadaver/clinic patients | Mini-invasive percutaneous internal screw fixation for fractured scaphoid | The guide used can assist in accurate placement of the screw, shorten operation time and reduce insertion and X-ray exposure times, reducing the radiation injury and damage to the substance and the blood circulation of carpal bone. |

| 2018 | Zhang G et al. [75] | Orthopade | 12 | cadaver | Cervical pedicle fixation. | This guiding tool may effectively prevent intraoperative drifting and accurately places cervical pedicle screws. |

| 2018 | Peng P et al. [76] | J Orthop Surg Res | 4 | cadaver | CBT screw fixation | Bio-safe drill templates can facilitate cervical anterior transpedicular insertion with good feasibility and accuracy. |

| 2018 | Krämer M et al. [161] | Int J Med Robot | 7 | cadaver | Acetabular cup for total hip arthroplasty | The acetabular cup positioning in total hip arthroplasty procedures can potentially increase the precision of cup placement. |

| 2018 | Wang H et al. [94] | Injury | 15 | bovines | Minimally invasive lumbar pedicle screw placement trajectory | It is promising and could prevent too much radiation exposure intraoperatively. |

| 2018 | Ge DW et al. [95] | Eur Rev Med Pharmacol Sci | 12 | cadaver | Multi-level drill guide template for lumbar pedicle screws | The multi-level drill guide template can be properly applied in pedicle screw placement and promises to be a potential option in clinical application. |

| 2017 | Guo F et al. [65] | PLoS One | 13 | 3D models | Pedicle screw fixation in the upper cervical spine. | The 3D printing navigation template for pedicle screw fixation is easy and safe, with a high success rate in upper cervical spine surgery. |

| 2017 | Yu Z et al. [78] | Eur Spine J | 12 | cadaver | Cervical pedicle placement. | The template combined with the screw tunnel design based on the 3D cutting technique can help facilitate accurate cervical pedicle screw insertion. |

| 2017 | Chen X et al. [144] | Injury | 14 | 3D models | Plates and screws for acetabular fractures | The 3D-printed guiding template helped achieve accurate placement of plates and screws in the pelvis of adult cadavers. |

| 2017 | Sallent A et al. [181] | Bone Joint Res | 5 | cadaver | A cutting guide for pelvic tumor resection | The template improved accuracy in pelvic tumor resections, bringing osteotomy results closer to the parameters set in pre-operative planning, as compared with standard manual techniques. |

| 2017 | Shao ZX et al. [103] | PeerJ | 30 | 3D models | TPTD screw fixation | All TPTD screws were successfully introduced into the 3D-printed model guided by the TPTD screw custom drill guide. |

| 2016 | Chen H et al. [84] | Med Sci Monit | 3 | cadaver | Thoracic pedicle screw fixation | With a high accuracy in placement and convenient operation, it provides a new method for accurate placement of thoracic pedicle screws. |

| 2016 | Zhou Y et al. [157] | Medicine (Baltimore) | 5 | cadaver | The bone-drilling template for Bernese PAO | The application of patient-specific 3D printed bone-drilling and rotation templates in PAO is feasible and may facilitate improved clinical outcomes. |

| 2016 | Huang AB et al. [170] | J Orthop Res | 6 | cadaver | A cutting guide for patellar resurfacing | Customized templates improved the accuracy of patellar resurfacing in terms of obliquity and thickness. |

| 2013 | Hu Y et al. [71] | Eur Spine J | 32 | cadaver | C2 translaminar screws | This technology improves the safety profile of this fixation technique and should be further studied in clinical applications. |

| 2013 | Fu M et al. [11] | PLoS One | 4 | 3D models | ATPS | The drill template is biocompatible, easy-to-apply, and accurate in assisting ATPS insertion. Its clinical applications should be further researched. |

| 2012 | Ma T et al. [83] | Arch Orthop Trauma Surg | 20 | cadaver | Thoracic pedicle screw fixation | We have developed the patient-specific template for thoracic pedicle screw placement with good applicability and high accuracy. |

| 2009 | Ryken TC et al. [73] | J Neurosurg Spine | 4 | cadaver | C3–C7 Pedicle screws | The authors' methods appear to provide an accurate technique and trajectory for pedicle screws placement in the cervical spine. |

| 2009 | Lu S et al. [92] | Int J Med Robot | 12 | cadaver/clinic patients | Lumbar pedicle screws fixation | This method has shown its ability to customize the placement and size of each screw, based on the unique morphology of the lumbar vertebra. |

| 2006 | Hafez MA et al. [166] | Clin Orthop Relat Res | 45 | cadaver/3D models | Cutting blocks for total knee arthroplasty | Patient-specific templates are a practical alternative to conventional instrumentations, but additional clinical validation is required before clinical use. |

| 2001 | Goffin J et al. [53] | Spine | 8 | cadaver/clinic patients | Transarticular C1–C2 fixation | A template with a drill guide might simplify and shorten the surgical act and at the same time enhance the accuracy of C1–C2 transarticular screw positioning. |

PPSF = percutaneous pedicle screw fixation; HIF = humeral intracondylar fissures; THRA = total hip resurfacing arthroplasty; CBT = cortical bone trajectorys; TPTD = transpedicular transdiscal; PAO = periacetabular osteotomy; ATPS = anterior transpedicular screw.

4.1. Spine

Spine surgeons need to deal with a variety of complex spinal problems, including deformity, infection, trauma, and degeneration diseases [59]. In traditional methods of screw fixation, osteotomy, and other operations, the surgeon usually judges whether the screw placement is accurate according to the results of the C-arm or O-arm monitors during the operation or uses computer-aided guidance systems to assist in the placement of the screws [60]. However, due to the varying degrees of proficiency and experience of the surgeon, it is difficult to ensure the accuracy of the operation after the patient's posture changes [61]. The navigation system is expensive, complicated to operate, and has a large amount of radiation exposure. It is difficult to meet the needs of patients and not conducive to universal promotion [12].

As a personalized technology, the patient-specific navigation template can be designed according to the actual situation of the patients [62]. 3D printing screw guides are used to guide precise intraoperative screw placement. The spinal and pelvic region anatomy is complex, adjacent to important blood vessels and nerves. If the screw track trajectory is not ideal, this can lead to a significant reduction in fixation strength and, in severe cases, injury to the vertebral artery, causing significant bleeding problems [61]. The use of pedicle screw guides was first reported in 2005 in a cadaveric study by Berry et al. He tested 3D printing drill templates in cadaveric specimens with varying degrees of success [63]. Subsequently, the professors conducted a large number of experiments for spine pedicle screw placement, vertebral screw placement, cortical bone trajectory (CBT) screw placement, etc [64]. During cadavers and animals study, it improves the surgical team's ability to achieve negative margins.

What is the impact of spinal screw guides on different segments? At present, the main studies and applications of the spine are in vitro simulated screw placement and preliminary clinical applications. We will discuss them in detail separately. Table 3 shows the main clinical application and results of different types of surgery in the spine.

Table 3.

The main clinical application of spinal surgeries.

| Year | Authors | Journal | Case number | Type of surgery | Results |

|---|---|---|---|---|---|

| 2021 | Li Y et al. [67] | Eur Spine J | 60 | Pedicle screw fixation in the upper cervical spine for type II odontoid fractures | 3D printed navigation template leads to greater improvement in the screw safety, efficacy, and accuracy. |

| 2021 | Pijpker PAJ et al. [59] | Spine | 15 | Pedicle and lateral mass screw fixation in the cervical and cervico-thoracic spine | 3D-printed patient-specific drill guides appear to be safe and accurate for pedicle and lateral mass screw insertion in the cervical and upper-thoracic spine. |

| 2021 | Zhao Y et al. [10] | World Neurosurg | 27 | S2AI screw for degenerative scoliosis, revision surgery, spondylolisthesis, and lumbar stenosis | S2AI screw placement assisted by a 3D-printed surgical guide is safe and accurate. |

| 2021 | Liang W et al. [112] | Eur Spine J | 175 | Pedicle screws fixation | 3DP drill guide template was a promising tool for assisting the pedicle screw placement in spinal deformity surgery and deserved further promotion. |

| 2021 | Tu Q et al. [117] | World Neurosurg | 24 | Pedicle screw fixation for hemivertebrectomy and short-segment fixation | 3D-printed individualized templates allow surgery for the correction of congenital scoliosis to enter a new stage of personalized precision surgery. |

| 2021 | Hu PL et al. [120] | J Orthop Surg Res | 36 | PVP for acute painful single segment OVCF | 3D printing template-assisted PVP could minimize fluoroscopy shot operation times and fluoroscopy dosage and is a more precise and feasible operation method. |

| 2021 | He K et al. [100] | Clin Interv Aging | 18 | CBT screws for revision surgery of ASD | Revision surgery for ASD with CBT screws assisted by 3D-printed navigation templates has satisfactory clinical efficacy with the advantages of a short operation time, a small incision, and less blood loss. |

| 2020 | Matsukawa K et al. [102] | Neurosurgical review | 43 | CBT screws for posterior lumbar spinal fusion | A total of 193 screws (97.5%) were placed completely inside the pedicle and there was no incidence of neurovascular injuries. |

| 2020 | Thayaparan GK et al. [80] | J Clin Neurosci | 1 | Cervical pedicle placement for progressive neck pain due to a pathologic fracture of C1. | 3D-printing patient-specific tools and implants that are viable for occipitocervical fixation surgery. |

| 2020 | Zhou W et al. [93] | Arch Orthop Trauma Surg | 31 | Sacroiliac screws placement for sacroiliac complex injury | 3D-printed template technology-assisted surgery for sacroiliac screws placement in sacroiliac complex injury patients possesses advantages such as shortened operation time and reduced X-ray exposure times. |

| 2020 | Zhao Y et al. [104] | BMC Surg | 47 | S2AI screw fixation | The 3D-printed guide technique is superior to the free-hand technique in terms of safety and accuracy. |

| 2020 | Wu C et al. [105] | J Orthop Surg Res | 22 | TSS fixation for sacral fractures | The patient-specific locked navigation template-assisted in TSS placement with less operative time, less intraoperative fluoroscopy, and higher safety of screw placement. |

| 2020 | Wu C et al. [106] | Orthop Surg | 37 | IS fixation for sacral fracture and dislocation | Using the combined template to assist with the insertion of IS screws delivered good accuracy, less fluoroscopy, and shorter operation time, and avoided neurovascular injury as a result of screw malposition. |

| 2020 | Eltes PE et al. [107] | Front Surg | 1 | Pedicle screws fixation | Biomechanical parameters; is more affordable, and the intraoperative X-ray exposure can be reduced. |

| 2020 | Senkoylu A et al. [116] | World Neurosurg | 11 | Pedicle screw fixation for AIS | The use of these low-cost personalized 3D guides is completely safe and effective in both convex and concave sides of the curves. |

| 2020 | Petrone S et al. [101] | J Clin Neurosc | 238 | CBT screws for degenerative lumbosacral disease. | The CBT technique is a safe procedure, especially with accurate preoperative CT scan-based planning. |

| 2019 | Tian Y et al. [13] | Med Sci Monit | 64 | C2 pedicle screws or C2 pars screws fixation in the upper cervical spine. | 3D-printed navigation template technology achieved more accurate C2 pedicle screw placement than C-arm based navigation-assisted. |

| 2019 | Chen PC et al. [108] | Biomed Res Int | 10 | Pedicle screws fixation | 3D printing technology provides an effective alternative for spinal deformity surgery when expensive medical equipment. |

| 2019 | Cecchinato R et al. [109] | Eur Spine J | 29 | Pedicle screw fixation for spinal deformity | 3D-printed pedicle screw guides increase safety in a wide spectrum of deformity conditions. In addition, the total radiation dose is reduced, even considering the need for a low-dose preoperative CT for surgical planning. |

| 2019 | Tu Q et al. [119] | World Neurosurg | 9 | PSOs for severe kyphoscoliosis secondary to AS | 3D-printed templates can guide the performance of planned PSO to provide functional restoration of severe kyphoscoliosis secondary to AS. |

| 2019 | Marengo N et al. [97] | World Neurosurg | 49 | CBT screws for degenerative disease | These devices could also improve placement accuracy and decrease the risk of nerve damage. |

| 2019 | Kim J et al. [98] | World Neurosurg | 1 | CBT screw fixation combined with posterior lumbar interbody fusion | It improved screw placement accuracy while minimizing cortical breach, reduced the operative time, and lower cost compared with intraoperative computed tomography-based neuronavigation. |

| 2018 | Sugawara T et al. [46] | Spine | 103 | Pedicle screw fixation for cervical, thoracic, or cervicothoracic pathologies by the multistep template. | Postoperative CT scans confirmed that 801 screws (98.5%) were accurately placed without cortical violation. There were no injuries to the vessels or nerves. |

| 2018 | Pu X et al. [68] | Clinics | 17 | Pedicle screw fixation in the upper cervical spine for atlantoaxial dislocation and deformity | Atlantoaxial pedicle screw placement assisted by a modified 3D-printed navigation template is worth recommending due to the improved accuracy in screw placement, improved patient safety, and beneficial clinical effects. |

| 2018 | Thayaparan GK et al. [69] | J Clin Neurosci | 3 | Posterior atlantoaxial fixation surgery with C1–C2 transarticular and C1 posterior arch screws. | A safe, accurate, efficient, and relatively inexpensive process to stabilize the atlantoaxial spine using transarticular screws. |

| 2018 | Pijpker PAJ et al. [118] | World Neurosurg | 1 | PSOs for severe congenital kyphoscoliosis in a young girl with skeletal dysplasia | In addition to direct translation of the planned PSO for surgery, the 3D planning also facilitated a detailed preoperative evaluation, greater insight into the case-specific anatomy, and accurate planning of the required correction. |

| 2018 | Li J et al. [43] | J Clin Neurosci | 1 | PVP for fractures of L1 and L3 vertebrae | The perfect fitting between skin and guide template to ensure the puncture stability and accuracy, and increased puncture precision and decreased puncture-related complications, surgical time, and radiation exposure. |

| 2017 | Sugawara T et al. [70] | Spine | 12 | C1LMS-C2PS fixation for atlantoaxial dis-location | The multistep, patient-specific screw guide improves the accuracy of screw insertion and reduces operation time and radiation exposure of posterior C1–C2 fixation surgery. |

| 2017 | Azimifar F et al. [110] | Biomed Eng Online | 12 | Pedicle screws fixation | The proposed template significantly reduced screw misplacements, increased stability, and decreased the sliding and intervention invasiveness. |

| 2017 | Li X et al. [113] | Acta Ortop Bras | 8 | Pedicle screws fixation rigid scoliosis | The placement of pedicle screws shows high accuracy in scoliosis with shorter surgical time, less blood loss, and less radiation exposure. |

| 2017 | Liu K et al. [115] | Eur Spine J | 10 | Pedicle screw fixation for severe and rigid scoliosis (Cobb angle >70° and flexibility <30%) | The incidence of cortex perforation in severe and rigid scoliosis decreased and this technology is, therefore, potentially applicable in clinical practice. |

| 2017 | Zhang Y et al. [121] | Comput Assist Surg | 8 | Intervertebral endoscopy for lumbar disc herniation | This customized navigation board could promote accuracy and diminish the duration of intervertebral disc ablation. |

| 2016 | Deng T et al. [79] | Comput Assist Surg | 10 | Cervical pedicle placement. | This individualized 3D printing screw insertion template was user-friendly, at a moderate cost, and enabled a radiation-free cervical screw insertion. |

| 2016 | Takemoto M et al. [58] | Eur Spine J | 40 | Thoracic pedicle screw fixation for scoliosis and OPLL | This study provides a useful design concept for the development and introduction of patient-specific navigational templates for placing pedicle screws. |

| 2016 | Hu Y et al. [67] | Eur Spine J | 151 | Thoracic pedicle screw fixation for thoracic instrumentation and fusion | The use of template to assist in the placement of mid and upper thoracic pedicle screws may lead to increased accuracy. |

| 2015 | Kaneyama S et al. [55] | Spine | 20 | Midcervical pedicle screws for posterior cervical reconstruction surgery | The templates prevent screwing error along with the change of spinal alignment, guarantee the high accuracy in screw insertion, which allowed surgeons to insert cervical pedicle screws safely. |

| 2015 | Chen H et al. [99] | Med Sci Monit | 43 | Lumbar pedicle screw fixation | 3D printing guide plate can shorten the operation time and reduce the amount of hemorrhage. |

| 2013 | Sugawara T et al. [87] | J Neurosurg Spine | 10 | Thoracic pedicle screw for thoracic or cervicothoracic pathological entities | This simple and economical method can improve the accuracy of pedicle screw insertion and reduce the operating time and radiation exposure of spinal fixation surgery. |

| 2012 | Lu S et al. [111] | Med Biol Eng Comput | 16 | Pedicle screws fixation for scoliosis | The surgical navigation system reduced the perforation rate and insertion angle errors, demonstrating the clear advantage in safe and accurate pedicle screw placement of scoliosis surgery. |

| 2009 | Lu S et al. [72] | Eur Spine J | 9 | C2 laminar screws for basilar invagination | This method has shown its ability to customize the placement and size of each screw, based on the unique morphology of the lumbar vertebra. |

| 2009 | Lu S et al. [74] | Spine | 25 | Transpedicular screw placement for cervical spinal pathology included destabilizing cervical spine injuries, cervical spondylotic myelopathy, and basilar invagination | This method significantly reduces the operation time and radiation exposure for the members of the surgical team. |

S2AI=S2 alar-iliac; PVP = percutaneous vertebroplasty; OVCF = osteoporotic vertebral compression fracture; CBT = cortical bone trajectory; ASD = adjacent segment degeneration; TSS = Transverse sacroiliac screw; IS=Iliosacral screw; AIS = adolescent idiopathic scoliosis; PSOs = pedicle subtraction osteotomies; AS = ankylosing spondylitis; PVP = percutaneous vertebroplasty; C1LMS-C2PS C1 lateral mass screw-C2 pedicle screw; OPLL = ossification of the posterior longitudinal ligament.

4.1.1. Auxiliary screw placement of cervical vertebra

The pedicle screw fixation has become the strongest and most common method of internal fixation in posterior cervical surgery due to its excellent biomechanical properties [8,[65], [66], [67], [68], [69], [70], [71], [72], [73], [74], [75]]. However, it is difficult, inefficient, and risky to place pedicle screws. For the purposes of this study, we usually divide the cervical spine into the atlantoaxial and inferior cervical vertebra (C3–C7).

To solve the issue, Guo et al. [65] designed a navigation template for upper cervical pedicle screw fixation and placed 32 screws on a 3D printing model, with an acceptable rate of 94.60%. Compared to the free-hand screw placement group, the procedure time and frequency of fluoroscopy were reduced, which was beneficial for both the doctor and the patient. Chen et al. [66] modified the conventional 3D printing guide and was more accurate than before. It removed the original guiding channels and replaced them with an inward-moving navigation pole, retaining only the screw holes. In 12 cadavers, 48 screws were placed in cervical specimens, with a good screw placement rate of 97.9%.

In clinical practice, where patients with complex conditions are encountered, the surgical guide also demonstrates a high accuracy rate in screw placement, improving surgical precision and reducing post-operative complications. Compared to the free-hand group, Li et al. [67] have found that the use of templates significantly improves the success rate of pedicle screw placement. 96.7% safety rates were achieved for C1 pedicle screws and even 100% for C2 pedicle screws, showing good promise as an alternative to freehand screw placement in the treatment of odontoid fractures. Pu et al. [68] used a modified 3D printing template with channels on both sides of the guide template as well as a 30 mm long, 3 mm diameter guide pillar. In 17 patients, the modified guide showed a significant improvement in accuracy and safety in atlantoaxial pedicle screw placement, with a success rate of 97.06%.

In addition, some researches have been carried out in other screw placement methods, such as transarticular screw fixation [53], occipitocervical screw [69], C1 lateral mass screw-C2 pedicle screw (C1LMS-C2PS) fixation [70], and C2 translaminar screws (C2TLS) [71,72]. It concluded that a surgical guide could simplify the transarticular screw and C2TLS fixation, improve the accuracy of the screw [71]. In clinical practice, screw misalignment has not been observed. No neural or vascular injuries were observed in each patient [69,72]. Although C1LMS-C2PS fixation has the advantage of reducing the risk of vascular injury and achieving immediate rigid fixation, it is difficult to place screws in this way. Sugawara et al. [70] found template can be precisely fitted and locked to the vertebral template, and screw insertion was successfully completed without cortical invasion of the screw. The mean deviation from the planned trajectory was only 0.70 ± 0.42 mm.

The anatomical variation in the middle and lower cervical spine is large. Without identifiable anatomical landmarks, it is difficult to determine the correct insertion point and angle of insertion, even with fluoroscopic assistance. A number of cadaveric studies were finished to test the influence of guide templates and demonstrated that guides can significantly improve the accuracy of screw placement [11,73]. Through theoretical research, more experience has been gained with the placement of surgical guides, which are also used clinically to assist the surgeon. Lu et al. [74] placed 88 screws through guides in 25 patients with cervical spinal pathology at segments C2–C7. The postoperative placement of screwing guides was proven to be accurate and applicable, reducing the operative time and radiation exposure of the patient. Pijpker et al. [59] found that the point of entry and angular deviation of the 76 screw trajectories were 1.40 ± 0.81 mm and 6.70 ± 3.77°, respectively. A safe level is achieved with no neurovascular injury, facet joint violation, or violation of the pedicle wall.

Whether soft tissue should be considered is still controversial. Through the trial, academics have drawn some lessons on the placement of guides. 1) reduce soft tissue interference with guide placement 2) drill holes of sufficient length, 3) in vitro stimulation to determine trajectory safety 4) guide size not to exceed the spacing of individual vertebrae [13]. However, it has been suggested that attempts can be made to optimize the surface of the guide template by removing soft tissue from the bone surface. Zhang et al. [75] performed a cadaveric study and removed the soft tissue from the bone surface. A total of 158 screws were placed with 98.1% accuracy. On this basis, Peng et al. [76] developed a template for guiding cortical bone trajectory screws. It successfully improved the success rate of screw placement and reduced intraoperative complications. Kaneyama et al. [77] provided the guides for 20 consecutive patients. It was fit directly to the target vertebral template and prevented screw deviation from the expected trajectory even spinal alignment changed during the procedure.

Furthermore, some scholars have also conducted studies on the whole cervical spine [[78], [79], [80]]. They selected the ideal screw access according to a different segment. The navigation templates improved the accuracy and safety for patients with cervical spine fixation. Almost all screws were placed into the vertebral body without cortical invasion. There was no intraoperative vascular or neurological injury.

In summary, 3D printing guides for cervical screw placements are still at the stage of vitro research. Clinical experience exists but there is a lack of randomized controlled long-term observation trials. This may be due to the high requirements of the cervical template for the pedicle entry point, the general instability of the template placement, and the interference of the soft tissues. In addition, a resorbable surgical guide has recently been investigated [81]. The use of bioresorbable guides effectively eliminates the need for template removal after spinal fusion and does not present difficulties in imaging like metal implants. However, the question of whether bioresorbable templates provide sufficient stability for fusion is debatable and is still under investigation and deserves the attention of doctors.

4.1.2. Auxiliary screw placement of thoracic vertebra

The freehand screw placement remains the most dominant for thoracic pedicle screw placement. However, the size of the thoracic vertebra pedicle makes pedicle screw internal fixation difficult and risky. 3D printing templates are now an ideal solution to address these technical challenges [82].

Ma et al. [83] inserted a total of 240 thoracic screws in 20 thoracic cadaveric specimens. The navigational template showed a higher accuracy rate of about 93.4% and a lower incidence of risk than the free-hand method. To effectively assess the effectiveness in the human thoracic spine, Chen et al. [84] applied a surgical guide in the placement of 50 screws in 25 human cadaveric thoracic vertebrae. The high precision of the screw placement and the short operation time deserve promoting clinical trial. In minimally invasive surgery, Li et al. [44] further improved the 3D printing guide. They successfully placed 96 pedicle screws bilaterally in the T6-L1 segment of six adult cadavers, with a 98.6% accuracy rate on CT results. The guide template was not loosened or displaced when operated by a single hand. It shorted the learning curve of the guide template placement and made it worthy of more clinical trials.

Applying guide templates in CBT screws have been attempted in the thoracic spine [58,85]. It was an ideal screw placement for osteoporotic or other diseases that may lead to screw loosening. Further studies in vivo are anticipated. The concept of determining optimal screw trajectory was first proposed by Chen et al. [86]. For each vertebra, there can only be one optimal screw placement trajectory. They designed a 3D printing guide to assist in the placement of 358 thoracic pedicle screws in order to find the optimal trajectory through the central axis of the pedicle. Compared to the design trajectory, 98.6% of the screw entry points were accurate and 98.9% of the screw exit points were accurate.

Physicians have gradually built up confidence in applying guides to complete the surgery, gaining experience in the use of guides for the thoracic spine. Hu et al. [87] placed a total of 582 pedicle screws into the mid and upper thoracic spine in 151 patients. 559 of the 582 screws (96.1%) were located completely within the thoracic pedicle, demonstrating good placement accuracy. Furthermore, Sugawara et al. [88] describe a new fit-and-lock template and multistep screw insertion technique for more accurate screw placement. None of the screws were found to violate the cortex of the pedicles of the vertebra models. For the accurate guidance of the PS insertion, Sugawara et al. [46] produced three templates that could cover the 3D shape of the laminae and developed a unique multistep procedure. Postoperative CT scans confirmed that 801 screws (98.5%) into the cervical and thoracic spine were accurately placed without cortical violation. There were no injuries to the vessels or nerves. Naddeo et al. [89] proposed an innovative design disengaging of 3D printing guides. It accelerated standard surgical procedures, reducing operative time and achieving excellent results in terms of screw positioning accuracy and X-ray exposure time.

4.1.3. Auxiliary screw placement of lumbosacral vertebra

In animal and cadaveric trials, all surgeons gave positive feedback on the 3D printing surgical guide template, such as the ease of handling, the improved accuracy of screw placement, and the significant reduction in radiation exposure [9,[90], [91], [92], [93]]. Furthermore, they tested the feasibility of 3D printing surgical guides for minimally invasive lumbar pedicle screw placement. It demonstrated that the guides can significantly improve the accuracy of screw placement, reduce excessive radiation exposure [94,95]. Zhao et al. [96] simultaneously placed traditional pedicle trajectory (TPT) and CBT screws in cadavers, with 82.5% of the screws located entirely in the cortical bone. It was a safe and accurate method of pedicle screw placement. This template showed a potential option for clinical applications.

The first clinical study of surgical guides for posterior lumbar cortical bone trajectory screws was performed by Marengo et al. [97]. Subsequently, an increasing number of authors have reported the use of guides in lumbar screw placement [[98], [99], [100]]. It offers a similar effect in the cadaveric study. At the follow-up, patients showed a reduction in pain and claudication. Petrone et al. [101] evaluated 238 patients undergoing CBT fusion for degenerative lumbosacral disease. Through comparison, the use of surgical guides reduced operative time, radiation exposure, and complication, providing a higher screw placement success rate of 93.9% than other modalities of screw placement. More clinical studies about the long-term outcomes and accuracy are needed to directly compare the placement of traditional pedicle screws with CBT screws. Matsukawa et al. [102]evaluate the clinical accuracy of long CBT screw placement using a patient-specific template guide. A total of 193 screws (97.5%) were placed completely inside the pedicle and there was no incidence of neurovascular injuries. In recent years, a novel 3D printing guide template-assisted transpedicular transdiscal (TPTD) lumbar screw fixation has been designed and validated on a 3D printing spine model [103].

Sacral fractures are a common clinical disease. In the placement of S2 Alar-Iliac (S2AI) screws, many surgeons used a 3D printing surgical guide [10,104]. Compared to the freehand screw placement group, it showed a higher accuracy rate with the use of a guide template. In the placement of transverse sacroiliac screw (TSS), Wu et al. [105] used a guide to assist placement in 22 patients with sacral fractures. The use of the guides significantly reduced the patient's operative time and radiation exposure [106].

More importantly, Eltes et al. [107] proposed a 3D printing guide based on patient-specific biomechanical characteristics, which is cheaper and reduces intraoperative X-ray exposure. Such a guide could be used in revision spine surgery or in more challenging cases after further clinical validation. However, it is also important to consider that separate design of the navigation template requires software support, a complex guide design process, and a long learning curve to operate the software.

4.1.4. Spinal deformities

Currently, the pedicle screw has been the major surgical method for the correction of spinal deformities. Because the screws can pass through the anterior, middle, and posterior columns of the spine, pedicle screws are used for better correction and stabilization instead of other fixation devices [5]. However, variations in spinal deformities which are complicated with arch root deficiency, rotation and compression of the vertebral body, joint and disc hyperplasia, fusion, and ossification of the attached ligaments, resulted in difficult identification of traditional bony marks and insertion angles [108]. The use of conventional imaging data, such as X-rays, makes it difficult for the surgeon to obtain visual and accurate 3D anatomical information, resulting in a high failure rate of screw placement. In addition, because of the great variability between patients with different spinal deformities, patients often have secondary structural variations in the lung, spinal cord, great vessels, and nerve roots [109].

3D printing guides abandon the previously anatomical positioning of the vertebral body, overcome alterations in spatial vertebral structure, and eliminate the need for expensive equipment [58,108,110,111]. Liang et al. [112] compared 1384 pedicle screws placed by templates with 1392 pedicle screws placed by freehand, the accuracy of templates assisted placement was significantly higher than that of the freehand. The operation time and blood loss were all significantly reduced in the 3D printing template group. Li et al. [113] retrospectively analyzed sixteen patients and found that the position of the pedicle screws was more accurate if using the template. Cecchinato et al. [109] observed that the screw placement accuracy was significantly higher in the guide group at 96.1% than in the freehand group at 82.9%, with a spinal correction rate of 60%, demonstrating the feasibility of replacing the traditional freehand screw placement technique.

Particularly in the correction of severe (Cobb angle >70°) and rigid (flexibility <30%) scoliosis is still pretty high risk [112]. Luo et al. [114] designed a surgical guide for patients with severe scoliosis and used it to assist in the placement of pedicle screws in 15 patients. 244 pedicle screws were placed and the success rate of the assisted placement was 96%, shortening the operative time. Though there were limited clinical reports about the application of multi-level drill guide templates in scoliosis. Liu et al. [115] applied a multi-level template in 48 pedicle screws in severe and rigid scoliosis. 93.8% of the pedicle screws were accurately placed by template, and all screws were implanted one time without adjustment. This study demonstrates that the use of guides significantly reduces the incidence of cortical perforation in severe and rigid scoliosis and that this technique has clinical potential.

Congenital scoliosis is one of the more difficult problems in spinal deformity correction surgery. Drawbacks of these techniques consist of high radiation exposure to the young child, increased operative time, potential blood loss, and high cost. For adolescents who are still in the process of development, Senkoylu et al. [116] designed a 3D pedicle screw guide and achieved positioning accuracy in 92.5% of the screws with a total of 134 screws. Tu et al. [117] used 3D printing guides to assist screw placement in 24 patients with scoliosis, with an overall accuracy rate of 95.56% significantly higher than the 82.76% achieved in the conventional treatment group.

4.1.5. Spinal osteotomy

It is essential to plan and design the extent of the osteotomy accurately before surgery. Due to the complexity of spinal deformities, spinal osteotomy has been widely used in the orthopedic treatment of spinal deformities with good clinical results. But if the osteotomy is too large, the adjacent spinal nerves and blood vessels may be damaged, making it difficult to maintain spinal stability, while if the osteotomy is too small, it will not be effective in improving the appearance of the deformity, achieving adequate decompression and achieving spinal balance. Therefore, 3D printing spinal osteotomy guides based on individual patient design can provide precise guidance for osteotomy procedures, freeing spinal osteotomy from the constraints of experience to the digital stage and simplifying the procedure.

During the design of the guide template, factors such as the sagittal and coronal balance of the spine, the relaxation of the spinal nerves, the cardiopulmonary status, and the compliance of the prevertebral vessels should be taken into account, as well as the degree of muscle pull, so that the appropriate osteotomy area can be determined. Pijpker et al. [118] used 3D printing patient-specific osteotomy templates to guide the pedicle subtraction osteotomies. It is the first report describing this technique for complex spinal osteotomies. The patient was discharged without any neurological deficit after 8 days. Early postoperative radiographs showed good correction of the posterior convexity deformity with a reduction in the posterior convexity angle from 74° to 22° and normalization of the coronal plane. Tu et al. [119] report a new method to perform complicated asymmetric wedge pedicle subtraction osteotomy in patients with severe thoracolumbar kyphoscoliosis secondary to AS. Postoperative X-rays showed a mean correction of 65.9° at the osteotomy site. At the last follow-up, a CT scan showed bone fusion at the osteotomy site without screw loosening in all 9 patients.

4.1.6. Others

In recent years, there have been attempts to use a 3D printing guide applying puncture technology in Percutaneous vertebroplasty (PVP) [43,120] and intervertebral endoscopy surgery [121]. Through preoperative simulation in the software, we could establish optimal skin entry points, needle trajectories, insertion depths, and make the best puncture plan, reducing the operation duration of intervertebral disc ablation. Following the accurate puncture pathway, the incidence of cement leakage could be reduced. Although in theory, the guides are able to achieve accurate screw placement, the problem of accurate matching and the lack of a stable apposition surface due to soft tissue slippage of 3D printing guides remains to be solved. Because of the limitations of printing materials, we need to solve the problem of templates deformation after low-temperature steam disinfection.

4.2. Trauma

Due to the complexity and diversity of fracture types, traumatic surgery has a wide range of treatment options, resulting in widely varying outcomes. Some complex comminuted fractures require solid anatomical knowledge and extensive surgical experience, but even then it is difficult to achieve good alignment and precise fixation, often resulting in unsatisfactory fracture repositioning and misaligned template and screw fixation [122]. In addition, some patients with fracture malunion often suffer from varying degrees of pain or dysfunction, which seriously affects their quality of life [25]. It requires osteotomy surgery to alter the force lines of the limb in order to correct the deformity, ensure joint stability, and relieve pain. The osteotomy methods are divided into angular, rotational, and translational osteotomies. The selection of osteotomy area is based on the principles of facilitating osteotomy fixation, promoting fracture healing, and not interfering with joint function. Over the past decade, orthopedic surgeons have increasingly used 3D printing technology to create intraoperative aids including cutting guides, guidewires, and guides for screws. As shown in Table 4, this allows surgeons to perform complex fracture fixation and discontinuous reconstruction.

Table 4.

The main clinical application of traumatic surgeries.

| Year | Authors | Journal | Case number | Type of surgery | Results |

|---|---|---|---|---|---|

| 2021 | Casari FA et al. [139] | Arch Orthop Trauma Surg | 7 | A drill template for distal intraarticular radius fracture | The template navigated intraarticular radius fracture treatment is feasible, safe, and accurate. |

| 2021 | Duan D et al. [124] | Pain Res Manag | 1 | Opening wedge high tibial osteotomy | Patient-specific plates have the advantages of small trauma, few complications, simple operation, and fast recovery in treating knee osteoarthritis. |

| 2020 | Dong XP et al. [125] | Asian J Surg | 1 | Bone grafting and screws for tibial plateau fracture (Schatzker type V) | 3D printing assisted percutaneous guide plate in the reduction and internal fixation of tibial plateau fracture is safe and effective. |

| 2020 | Sun L et al. [126] | Injury | 54 | Indirect reduction and internal fixation with the minimally invasive percutaneous plate osteosynthesis (MIPPO) | MIPPO assisted by 3D printing navigation templates could practically improve surgical accuracy and eliminate postoperative rotational deformity in patients with distal femoral fractures. |

| 2020 | Zhang YW et al. [129] | Asian J Surg | 1 | A cutting guide for transverse tibial bone transport | The operations of TTBT guided by 3D printing guide plates can effectively protect the relative integrity of bone window and periosteum. |

| 2020 | Hu X et al. [134] | J Orthop Surg Res | 35 | A cutting guide for cubitus varus deformity | Individualized navigation templates simplify procedures, reduce operation time, and improve accuracy. |

| 2019 | Nie W et al. [123] | Injury | 11 | Screw fixation for bicondylar tibial plateau fractures | It provides a comprehensive understanding of fracture features, accurate patient-specific preoperative planning, and intraoperative guidance for real surgeries |

| 2019 | Oka K et al. [135] | J Orthop Sci | 1 | A cutting guide for cubitus varus deformity | The limb's appearance considerably improved and the range of elbow motion reverted to what it had been before surgery. |

| 2019 | Chen K et al. [143] | Biomed Res Int | 28 | “Blunt end” Kirschner wire (KW) insertion for unstable pelvic fractures | The “blunt end” KW technique with a 3D printed external template is a safe and effective method. |

| 2018 | Chen Y et al. [132] | J Bone Joint Surg Am | 131 | Plate and screw fixation for fractures of the proximal end of the humerus | The clinical outcomes in both the virtual surgical and 3D printing groups were better than those in the conventional group. |

| 2017 | Bauer AS et al. [149] | J Pediatr Orthop | 19 | A cutting and drill guide for deformity of the forearm | 3-dimensional computer modeling permits complex and multiple osteotomies to be done safely to achieve deformity correction in children. |

| 2015 | Huang H et al. [51] | Australas Phys Eng Sci Med | 6 | Plate and screw fixation for Schatzker classification V or VI tibial plateau fracture | This technology improves the accuracy and efficiency of personalized internal fixation surgery. |

| 2015 | Omori S et al. [136] | J Shoulder Elbow Surg | 17 | A cutting guide for cubitus varus deformity | The 3D correction of cubitus varus deformity was performed accurately within the allowable error limits. |

Kirschner wire = KW

Traumatic cases are mainly classified as the pelvis, lower limbs requiring weight-bearing, non-weight bearing humerus and ulna, radius, and navicular bone of the hand [23].

4.2.1. Femur and tibia

With regard to the lower limbs, almost all clinical measurements of the femur and tibia show inadequate postoperative correction [25]. In particular, the degree of correction of the tibial plateau osteotomy in the coronal and sagittal planes differs considerably from the preoperative plan. The basic requirement for the treatment of tibial plateau fracture is to restore the force line of the limb and the flatness of the joint surface. To evaluate the accuracy of personalized preoperative planning of plate and screw for the complex tibial plateau fracture surgery, Huang et al. [51] used 3D printing surgical guides to identify 33 screw entries and place six locking compression plates in six patients with tibial plateau fractures. Postoperative X-rays showed no significant differences in parameters such as screw length, entry point, and screw orientation from the preoperative plan, with well-matched plates and good application results. Other surgeons applied templates in patients with bicondylar tibial plateau fractures or wedge high tibial osteotomy [123,124]. The postoperative screw fixation and osteotomy was accurate and no perioperative complications such as infection, deep vein thrombosis (DVT), or neurovascular injury occurred within follow-up.

Minimally invasive surgery can reduce patient trauma, muscle scar formation, and recovery time, but the procedure is more difficult. Dong et al. [125] reported a case of percutaneous guide in minimally invasive internal fixation of a tibial plateau fracture. Postoperative imaging showed precise fracture repositioning, flat articular surface, and satisfactory screw fixation, which can be a clinical option to achieve minimally invasive treatment of tibial plateau fractures. Sun et al. [126] reviewed a total of 54 patients who underwent minimally invasive percutaneous plate osteotomy (MIPPO) of distal femur fractures. The template-guided MIPPO group was found to have greater surgical accuracy, with less variation in femoral length, anatomical lateral distal femoral angle (aLDFA), anatomical posterior distal femoral angle (aPDFA), and anteversion angle, with neater alignment and more significant advantages. In addition, the assistance of the guide can reduce the gap between novice and experienced surgeons [127].

Tibial plateau malunion (TPM) can be restored to the anatomical position of the knee surface using intra-articular corrective osteotomy, but precise restoration is not easy. Hsu et al. [128] used 3D printing surgical guides to provide precise positioning of the osteotomy and improve TMP outcomes, which is a viable alternative to conventional surgery. Zhang et al. [129] designed a guide to assist in transverse tibial bone transport (TTBT) surgery in order to promote the impact of vascular regeneration in treating patients with diabetic feet. The guide effectively protects the relative integrity of the bone window and periosteum.

However, these surgical guide templates also have their limitations. The precise positioning of the surgical guide is achieved by adequate exposure around the bone, blood flow to the periosteum may be compromised. The lack of soft tissue may lead to postoperative wound complications (e.g. infection). Furthermore, the use of a surgical guide is limited to certain anatomical boundaries to remove periosteal soft tissue [130].

4.2.2. Humerus

In humeral disease, the surgical guide is mainly used to assist in the correction of cubitus varus deformity. The key to osteotomy is the determination of the osteotomy region, the osteotomy angle, and the length of the bottom edge. Traditional osteotomy angles are based on radiographic measurements and have unsatisfactory osteotomy accuracy. 3D printing osteotomy guides can be used to greatly improve osteotomy accuracy, reduce postoperative complications and reduce operating room costs [131]. But compared with computer-assisted virtual surgical technology in fractures of the humerus, the templates exist controversial [132].