Abstract

Freshwater and energy are critical components for the growth and progress of societies. The scarcity of freshwater and rapid population growth, especially in remote countries, has led to an urgent need to develop desalination technologies in order to raise its productivity and reduce its energy consumption rates. Membrane distillation is one of the effective methods characterized by its high productivity, but its disadvantage by higher electricity consumption. Also, solar stills are one of the sustainable and economical technologies, but the disadvantage by lower productivity. Accordingly, this manuscript dealt with a comprehensive review and detailed comparison of the most important modifications and innovations that were made to the design of the membrane distillation units, which aim to reduce electricity consumption rates, as well as the design of solar stills, which aims to maximize the productivity and efficiency. This was done by providing a detailed comparison of the most important three axes of modifications and innovations that were addressed by recent previous studies on the design of membrane distillation units and solar stills, and their statement as follows: preheating technology, use of the thermal storage materials, and nanomaterials technology. Finally, based on this review, the authors make some recommendations for future work in the field of solar and membrane desalination.

Keywords: Membrane distillation, Solar stills, Preheating technology, Thermal storage mediums, Nanomaterials, Performance improvement

Introduction

Water is the most valuable and vital natural resource of all species. Fortunately, natural water is the most abundant compound on Earth, covering about 71% of the Earth’s surface (USGS 2019). Despite this, natural freshwater resources around the world are very scarce (Mekonnen and Hoekstra 2016). This is because about 97% of the water on Earth is in the oceans with a salinity range of 3.5–5%. Only 2.5% of the world’s total water resources are fresh; and only 31.4% of them can be accessed to support life on Earth (Powers 2017). Freshwater resources are available either as groundwater in the ground or as surface water in rivers, lakes, etc. In recent years, the stress on the available freshwater resources has been exacerbated as a result of many factors, the most important of which are: population growth, climatic changes, urban expansion, and changing lifestyles and prosperity. About 2.1 billion people during the current time period lack access to safely managed drinking water (UN-Water 2018; Xiao et al. 2021; Altarawneh et al. 2020). It is expected that by 2030, about 700 million people will be displaced worldwide due to the scarcity of fresh water (Wei et al. 2021; Al-Otoom and Al-Khalaileh 2020; Sharon et al. 2020). To overcome the problem of fresh water scarcity, some strategies have been developed that aim to reduce the demand for fresh water by implementing conservation practices or adjusting prices. However, previous strategies to mitigate fresh water demand do little to provide optimal solutions in highly affected regions (Gude 2017; Pourafshar et al. 2020; Siddiqui and Dincer 2018). On the other hand, the use of desalination technologies has enabled us to meet the increasing demand for fresh water by making use of the abundant reserves of brackish water and/or seawater.

Among the available desalination techniques, the solar distillation system is an effective procedure that relies on solar energy to produce fresh water, as it is built using locally available materials and also enjoys preserving depleted energy sources by using renewable resources (solar energy), which is clean and environmentally friendly energy (Manchanda and Kumar 2018; Velmurugan and Srithar 2011). Membrane-based desalination also has some advantages such as modularity, compactness, and sometimes the use of solar energy, thus preserving depleted energy sources by using renewable resources (solar energy), which is clean and environmentally friendly energy compared to multi-effect distillation (MED), thermal vapor compression (TVC), mechanical vapor compression (MVC), multi-stage flash distillation (MSFD), electro dialysis (ED), reverse osmosis (RO), freezing, and humidification and dehumidification (HDH) (Velmurugan and Srithar 2011). Despite the advantages of solar stills, the productivity is lower compared to the traditional desalination system. Membrane distillation (MD) has a lot of advantages such as it is operating with low-grade thermal energy and low pressures and large contact area; however, it also has some disadvantages especially high-power consumption which made it essential to reduce the power consumption and increase the efficiency of MD to make it even more practical. As a result of the high energy consumption of MD, it was found that it urgently needs renewable energy sources, heat storage mediums, and new configurations in membrane modules to reduce the required energy and improve the efficiency of MD (Gonzáleza et al. 2017). Ding et al. (2005) analyzed a solar-powered membrane distillation system; results have shown that the plant capacity in June can reach about 300 kg/day with solar energy. Another effective way of water desalination in remote areas is using solar stills. Solar stills use the radiation from the sun to evaporate water in a basin and then the water vapor condensate and accumulate as pure water. Solar stills productivity is affected by different factors like wind speed, solar rays, ambient temperature, glass-water temperature difference, absorber area, water-free surface area, water inlet temperature, basin water depth, and glass angle. The solar intensity, wind velocity, and ambient temperature cannot be controlled as they are meteorological parameters, whereas the remaining parameters can be controlled to improve productivity (Sivakumar and Sundaram 2013). Therefore, a great effort has been made in recent years to develop solar desalination systems, membrane-based desalination systems, as well as research into sustainable and energy-saving methods for fresh water production.

The rates of total energy consumption of desalination units depend on the design of the plant, the type of desalination method, the salinity of the feed water, and the temperature of the feed water. Thermal methods of water desalination require thermal energy and electrical energy, which makes their energy consumption higher than membrane methods that require only electrical energy to desalinate water. Therefore, the rate of total energy consumption required to desalinate 1 m3 of fresh water varies according to the desalination method used, where the total energy consumption required for MED system ranges between 14.45 and 21.35 kWh/m3, for MFS system between 19.58 and 27.25 kWh/m3, for TVC system 16.3 kWh/m3, for MVC system between 7 and 12 kWh/m3, and for ED system it is between 0.7 and 5.5 kWh/m3 (Maleki et al. 2016; Okampo and Nwulu 2021), while the total energy consumption for the RO system ranges between 2 and 4 kWh to produce one cubic meter of fresh water (Maleki et al. 2016; Okampo and Nwulu 2021).

The present manuscript dealt with two very important axes. The first axis dealt with the comprehensive review and a detailed comparison of the most important modifications and innovations that have been made to the design of membrane distillation units, which aims to reduce energy consumption rates as the following: feed water preheating technology, use of the thermal storage materials, and nanomaterials technology. Also, the second axis dealt with a comprehensive review and detailed comparison of the most important modifications and innovations that were made to the design of solar stills, all of which aim to maximize productivity and efficiency as the following: pre-heating technology, use of the thermal storage materials, and nanomaterials technologies. Finally, based on this review, the authors make some recommendations for future work in the field of solar and membrane desalination.

Membrane distillation

Overview

During the last few years, membrane desalination showed a high capability to produce distilled water. Membrane distillation is a dual technology that combined the advantage of thermal distillation and membrane separation (Anvari et al. 2020). Membrane distillation (MD) is classified according to its operational method into; direct contact membrane distillation (DCMD), sweeping gas membrane distillation (SGMD), air gap membrane distillation (AGMD), and vacuum membrane distillation (VMD) (Anvari et al. 2020). The advantages of membrane distillation over other desalination processes are concentration polarization, high rejection of non-volatile compounds, limited fouling, low operating temperature, and low operating pressure (Anvari et al. 2020). Therefore, membrane distillation technology has gained great attention for processes of desalination and treatment of wastewater (Anvari et al. 2020).

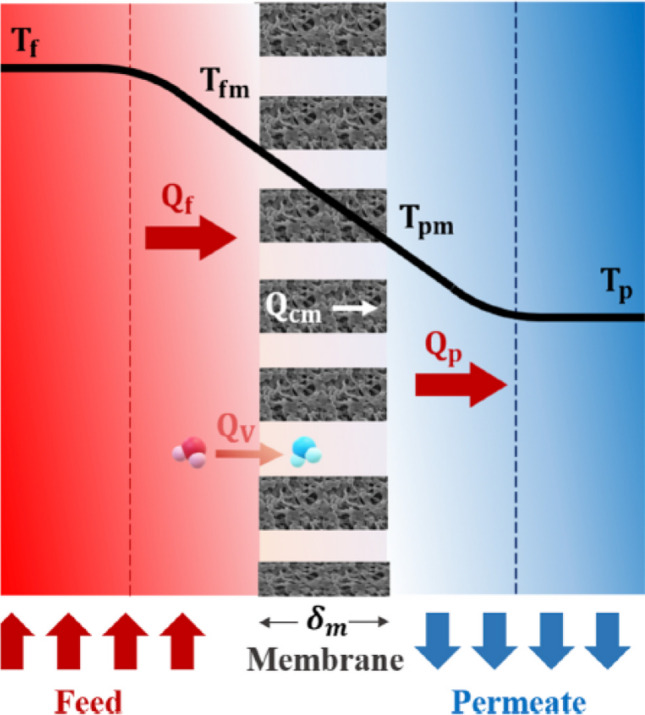

Heat transfer in MD process

The performance of membrane distillation technology depends on the temperature gradient between the feed side and the distillate side, which results in the transfer of heat from the hot side of the membrane to the cold side, and thus the water phase change from a liquid to a vapor state on the surface of the feed side of the membrane. As shown in Fig. 1, the heat transfer through the membrane occurs in three regions: the feed layer Qf, the membrane Qm, and the permeate layer Qp, calculated using Eqs. (1)–(3).

| 1 |

| 2 |

| 3 |

Fig. 1.

Heat transfer mechanisms in direct contact membrane distillation system

where; hf is the coefficient of heat transfer on feed side, hp is a coefficient of heat transfer on permeate side, Tf is a feed temperature, Tfm is a membrane surface temperature in feed side, Tp is a permeate temperature, Tpm is a membrane surface temperature in permeate side, km is a membrane thermal conductivity, δm is the membrane thickness, J is the membrane flux, and ΔHv is the evaporation enthalpy.

The overall heat transfer through the three regions Q is calculated as follows:

| 4 |

| 5 |

Coefficient of overall heat transfer H is calculated as follows:

| 6 |

The membrane surface temperatures on feed and permeate sides Tfm and Tpm are calculated as follows:

| 7 |

| 8 |

Membrane distillation performance enhancement techniques

The most encountered problem in membrane desalination is that it requires high power consumption; a lot of research investigated the performance of membrane desalination with different techniques of improvement to reduce the power consumption and increase the productivity of the membrane distillation. Preheating the inlet water to the membrane is one of the most common methods. Preheating can be done by external heaters like electrical heaters, and it can take place by using solar energy to preheat the water inlet by using solar preheaters, which in turn can reduce the power consumption cost of the electric heater, and it is a renewable and cleaner source of energy (Shafieian and Khiadani 2019). Another very effective way to improve the membrane performance is using thermal storage mediums especially, with solar-driven membranes as the thermal storage medium works as a heat supply for preheating the feed flow when the solar irradiance decreases (Abdelgaied et al. 2020). New configurations of membranes with nanomaterials can also be used to improve membrane performance (Elango et al. 2015).

Feed-water preheating technology

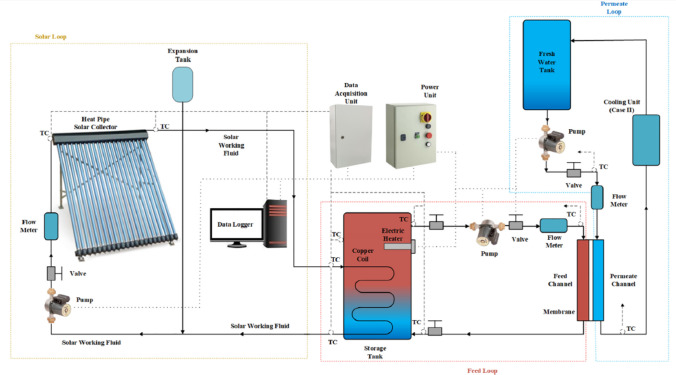

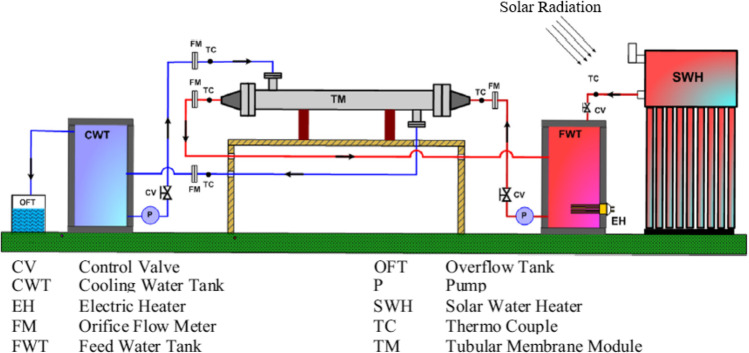

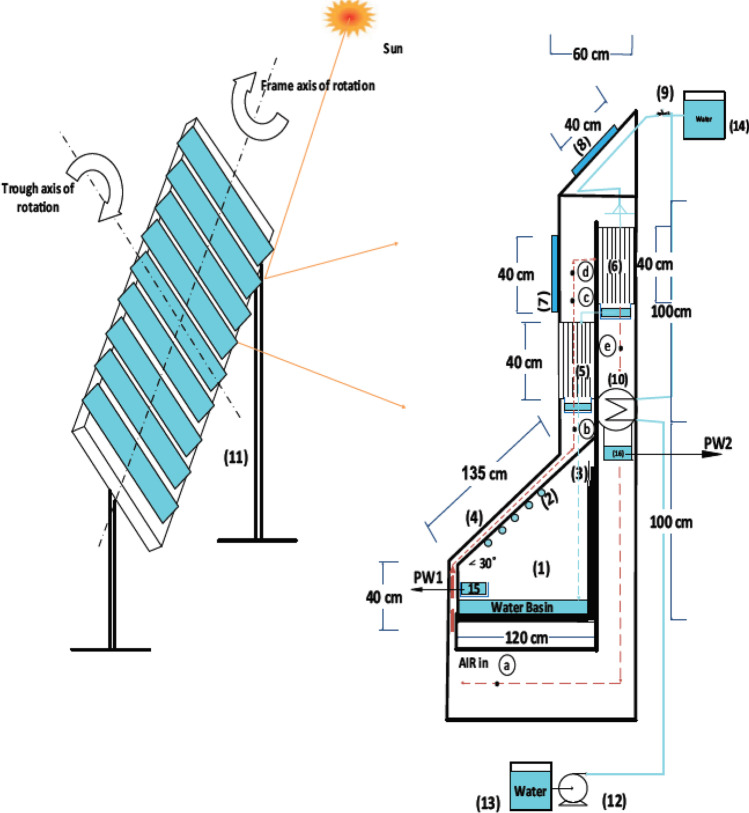

Different researches were done on preheating the feed water before its entering the membrane to increase the vapor pressure difference across the membrane sides which in turn increases the productivity. Shafieian and Khiadani (2019) studied experimentally and theoretically the behavior of the thermal-driven direct tubular contact membrane shown in Fig. 2 by using an electric heater to preheat the feed water before entering the membrane. They found that lower permeate temperature, as well as, higher feed water temperature results in higher freshwater production, and improves the freshwater production of the tubular DCMD unit. The system consists of three main loops including the solar heating loop, membrane feed loop, and membrane permeate loop. Three different operating cases were investigated (summer without cooling unit (Case I), summer with cooling unit (Case II), and winter without cooling unit (Case III)). They found that except for a few minutes in the morning, the solar collector was able to provide all required thermal energy to heat the feed water before entering the membrane unit. By adding permeate water cooling unit in the summer, the maximum production rate will be increased from 2.78 L/m2 h in Case I to 3.81 L/m2 h in Case II, as well as the overall efficiency of the system will be improved from 46.6% in Case I to 61.8% in Case II. Elzahaby et al. (2016) studied a direct contact membrane distillation system assisted by a cooling water tank and solar energy shown in Fig. 3. Effect of salt concentration, feed temperature, feed flow rate, the cooling temperature was investigated. They conducted that the water production rate increases with increasing the feed temperature; however, in this study, to avoid scale formation, the feed temperature is limited to 70 . Recently reported studies examining the effect of feed water preheating systems on the performance of membrane distillation systems are summarized in Table 1.

Fig. 2.

Layout of solar-driven membrane distillation (Shafieian and Khiadani 2019)

Fig. 3.

Schematic of direct contact membrane distillation assisted by solar energy (Elzahaby et al. 2016)

Table 1.

Recent studies on the performance of membrane distillation systems using feed water preheating systems

| Refs | Nature | Improvement-techniques | Results | Remarks |

|---|---|---|---|---|

| Shafieian et al. (2019) | Experimental + Simulation | Feed preheating using electric heater | Permeate water increase by 52 g/m2 min for increasing feed temperature from 30 to 60 °C | It is more efficient to heat the feed water stream to improve water productivity than to use the same amount of energy to cool the permeate stream |

| Shafieian and Khiadani (2019) | Experimental | Feed preheating using evacuated tube solar water collector + Electrical heater |

• Permeate water productivity reached 3.81 L/m2 h with cooling unit • Maximum thermal efficiency of the solar system reached 78% • Exergy efficiency varying between 4 and 5% • Overall system efficiency improved from 46.6 to 61.8% for using the cooling unit in the permeate flow loop • Solar working fluid temperature varying between 37 and 58 °C |

Except 15 min in the morning, the heat pipe solar collector was able to operate the desalination system independently without any additional required thermal energy |

| Elminshawy et al. (2020) | Experimental + Simulation | Electric heater + V-trough solar concentrator PV panels with cooling + Buried water heat exchanger | For feed water of 80 and 144 kg/h, the permeate flux is 0.76 kg/ h, Specific thermal energy consumption is 103 kWh/m3, GOR is 1.36, and produced water cost reached 22.48 $/m3 | The hybrid system has the capacity to produce 19.58 m3 of freshwater per year at a cost of 22.48 $/m3 and to reduce CO2 emissions by 136.82 kg |

| Wang et al. (2019) | Experimental | Solar PV with thermal recovery integrated with MD | Pure water productivity reached 3.25 kg/m2.h for utilizing 5-stage MD integrated with PV | This device can transform an electric power plant from a water consumer to a pure water producer |

| Ding et al. (2005) | Experimental + Simulation | Feed preheating using evacuated tube solar water collector | About 23.5 l/h average water productivity for 0.8 l/min feed flow rate and feed temperature 70 °C | - |

| Elzahaby et al. (2016) | Experimental + Theoretical | Feed preheating using evacuated tube solar water collector + Electrical heater |

• The daily productivity of pure water reaches 40.587 kg/day for 20 L/min feed flow rate and feed temperature 70 °C • Daily efficiency and Gain output ratio reached 60.06% and 0.624 |

- |

| Kabeel et al. (2017a) | Experimental | Feed preheating using evacuated glass tube solar water collector + Evaporative cooler |

• Maximum productivity reached 33.55 L/day • System efficiency reached 49.01% and gain output ratio reached 0.49 • Feed temperature ranged 55–70 °C |

Use of the cooling unit on permeate flow loop improved the system productivity almost 1.25 |

| Soomro and Kimc (2018) | Theoretical | Solar power tower plant to produce the electricity and preheated the seawater before supplied to MD |

• The maximum permeate flux 29.05 kg/ h was achieved at feed temperature 45 °C • The average freshwater produced up to 40,759 L/day • Estimated water cost 0.392 $/m3 |

• Increasing the feed temperature increased the permeate flux • The effect of the feed flow rate is not significant compared to permeate flow rate |

| Siefan et al. (2022) | Experimental | Feed preheating using flat plate solar collector + Solar-powered PV collectors | • Solar powered was a better option for membrane distillation in terms of an environmental footprint | - |

| Sandid et al. (2021) | Experimental and simulation | Feed preheating using flat plate and evacuated tube collectors + electric heater |

• The specific thermal energy consumption ranged from 158.83 to 346.55 kWh/m3 • The hot feed inlet temperature ranged 50–65 °C • The maximum gain output ratio reaches 4.4 • Thermal efficiency reached 72% • Cost of fresh drinking water reached 14.73 $/m3 |

Using solar energy reduces carbon dioxide emissions by 7274.45 kg/year |

| Chang et al. (2022) | Practicality | Feed preheating using evacuated tube solar collector | Permeate flux reached 5.2 kg/m2 h at feed temperature 52 °C | This system is very effective for remote areas and especially for coastal fishery communities |

| Usman et al. (2021) | Economic feasibility | Feed preheating using thermal solar collector and waste heat recovery |

• Increase the membrane permeability for using solar-thermal and waste heat • Reduced the rate of external power required to operate the system from 40 to 60% • Decreased water price from 6.80 $/m3 (the cost of operating the system with the electricity only) to only 1.6 $/m3 |

The contribution of solar heat and waste heat used in the operation of the process leads to a lower cost of water production as well as making the desalination system more competitive, sustainable and economically viable for small and remote applications |

| Gustafson et al. (2018) | Theoretical | Waste heat + Chiller | Permeate water flux reached 22.9 L/m2 h at feed inlet temperature 64 °C and distillate temperature of 30 °C | Membrane productivity depends strongly on waste heat source characteristics |

| Abdelkader et al. (2019) | Experimental | Electrical heater | Permeate flux reached 13 kg/m2 h at a water temperature difference of 30 °C | - |

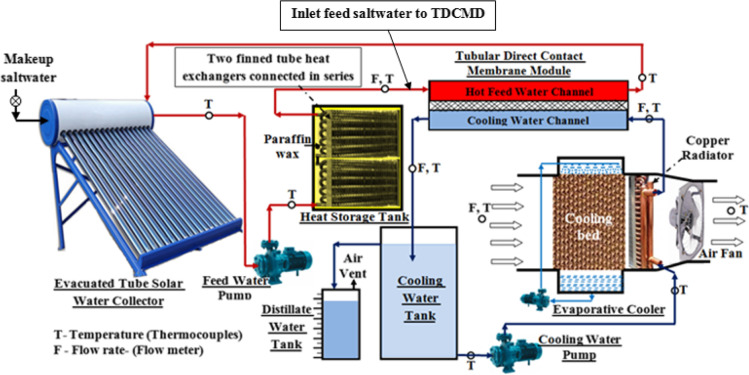

Membrane with thermal storage mediums

Thermal storage mediums are used in membrane desalination systems to store waste heat from any other process. It is often used with solar systems as it stores heat from the sun in daytime and use it as heat source for feed flow of membrane at night. Thermal storage mediums can be sensible like molten salt or latent like paraffin wax. Abdelgaied et al. (2020) built a test rig shown in Fig. 4 to improve a behavior of solar-assisted membrane distillation using the energy storage medium as paraffin wax. They conducted that the freshwater production rate is varying between 3.47 and 4.35 l/h at a feed flow rate of 16 l/min, respectively. Also, the gain output ratio reached 1.123 and 1.25 for 12 and 16 l/min feed flow rate, respectively. Recently reported studies examining the effect of thermal storage mediums on the performance of membrane distillation systems are summarized in Table 2.

Fig. 4.

Test rig of solar-powered membrane distillation with energy storage mediums (Abdelgaied et al. 2020)

Table 2.

Recent studies on the performance of membrane distillation systems using heat storage materials

| Ref | Nature | Improvement-techniques | Results |

|---|---|---|---|

| Abdelgaied et al. (2020) | Experimental | Evacuated tube solar collector + Paraffin wax as energy storage materials (Solid/liquid heat capacity 2.95/2.51 kJ/kg °C) + Evaporative cooling |

• For utilizing the Paraffin wax as energy storage materials, the productivity will be improved by a rate varying between 33.11 and 43.18% compared to cases without storage materials • GOR for a solar TDCMD with EC reached 0.93. While adding the Paraffin wax increases the GOR to 1.25 |

| Chafidz et al. (2014) | Experimental | Evacuated tube solar collector + Thermal storage tank contains hot water + heat pump driven by PV cell | 15.39 L/h average productivity with feed temperature of 69 °C |

| Chang et al. (2012) | Theoretical | Flat plate solar collector + Thermal storage tank contains hot water | 0.12 kg water productivity in 6 h |

| Gustafson et al. (2018) | Experimental + Theoretical | Waste heat + Chiller + Thermal storage tank contains hot water | The higher water flux occurs when the waste heat source is on because it stores a greater quantity of heat at a faster rate |

| Kim et al. (2021) | Theoretical | Feed preheating using flat plate and evacuated tube collectors + Thermal storage tank with phase change materials (Sodium alum (NaAl(SO4)2·12H2O) with heat capacity of 181 kJ/kg) with 28-stage vacuum membrane distillation |

• Gain output ratio of 28-stage system reached 47% • System performance improved with increasing number of stage • The produced fresh water cost reached 0.97 $/m3 |

Nanomaterials in membrane distillation

Nanomaterials can be described as a material that is in one dimension is less than 100 nm. At this size, material properties may change on the chemical and physical sides. Nanomaterials are characterized by a large surface area, more strength, and stability. Carbon-based nanomaterials and nano-zeolite will be discussed as they showed a remarkable improvement in water desalination.

Carbon-based nanomaterials

Carbon-based nanomaterials such as carbon nanotubes and graphene have been widely used for their important features like high surface area, high thermal conductivity, have a low thermal expansion coefficient, and high mechanical strength. These properties, especially the high thermal conductivity, tend to improve the performance of membrane productivity and salt rejection. Bhadra et al. (2013) utilized the carboxylated nanotubes which are more polar to improve the productivity of membrane distillation (MD), a sweep gas membrane with 1 L/min dry air was used and results showed a flux reaching 19.2 kg/ with salt rejection 99%. Recently reported studies examining the effect of carbon-based nanomaterials on the performance of membrane distillation systems are summarized in Table 3.

Table 3.

Recent studies on the performance of membrane distillation systems using carbon-based nanomaterials

| Reference | Material used |

Operating conditions | Results | Remarks |

|---|---|---|---|---|

| Wimalasiri and Zou (2013) |

SW-CNT/graphene nanosheets for CDI electrodes |

25 ml/min feed flow, 780 mg/L NaCl aqueous solution, 25 °C, 2 V voltage | 98% salt removal efficiency | - |

| Baek et al. (2014) | VA CNT + Epoxy |

2–10 bar, 10–30 °C, with 600 rpm stirring speed, and 200 mg/L polyethylene oxide (PEO) |

1100 ± 130 L/h.m2.bar. water flux and the PEO rejection of the VACNT membrane as examined was 78% |

Membrane size Avg pore diameter (nm) 4.8 ± 0.9 Pore density(#/cm2) 6.8*1010 |

| Dumée et al. (2010) |

MD with 50 mg/m2 MW-CNT Matrix |

Deionized water on cold side of MD, 35 g/L NaCl solution on hot side | 99% salt rejection and 12 kg/.h water flux rate | Water flux rate about 40 kg/m2.h at 28 kPa (Hot: 70 °C; Cold: 5 °C) |

| Li et al. (2014) | CNT/PES | 60 Psi | VA-CNTs water transportation was 3 times the CNT/PES membrane and 10 times higher than the pure PES membrane under the same pressure | - |

| Shawky et al. (2011) | Nanocomposite of MW-CNT/polyamide (15 mg MW-CNT/g PA) | NaCl Aqueous solution (4000 ppm) at room temperature, 3.9 MPa |

76 ± 1.1% salt rejection, 28 ± 0.8 L/h.m2.bar. Flux |

- |

| Lee et al. (2015) | CNT | pressure at 1 bar | The water permeability through CNT millimeter thick UF membrane was 30,000 L/m2.h.bar | - |

| Bhadra et al. (2013) | Carboxylated CNTs (MWCNT-COOH/PVDF) | 24 mL/min feed flow rate, 3.4 wt.% NaCl solutions, 1 L/min dry air, 60–90 °C |

19.2 kg/h.m2 Productivity 99% salt rejection |

The flow remained constant as the salt concentration increased, reaching 19.2 kg/h m2 |

| Yan et al. (2012) | (0.4 SW-CNT/PANI) | NaCl solutions with an initial conductivity of 100 μS/cm, 20 ml/min feed flow, 1.2 V |

The salt removal efficiency is 78.4% Regeneration rate of 100% for 0.4 SWCNT/PANI |

|

| Wang et al. (2014) |

CNT/Polypryrrole Electrodes |

100 μS/mm NaCl aqueous solution | Saturated adsorption capacity was 96% and 43.99 mg/g for reactivation rate | - |

| Amini et al. (2013) | 0.1% MW – polyamide/CNT | 10 mM feed NaCl aqueous solution, 2 M NaCl draw solution, 23 °C, 240 kPa | 96.7 L/h m2 water flux nearly 160% higher than TFC membrane | - |

| Park et al. (2014) | VA-CNT | The pure water permeabilities for the VA-CNT membrane 1000 ± 100 L/m2.h.bar | - | |

| Zhao et al. (2014) | 0.1% MW-polyamide/CNT | NaCl Aqueous solution (2000 ppm, 7 pH, 25 °C), 16 bars | 28.05 L/h.m2 water flux and 90% salt rejection | With increase in the amount of MWNTs in the membrane, the water flux increased from 14.86 to 28.05 L/m2.h while the salt rejection decreased slightly |

| Jia et al. (2010) | CNT Forward osmosis | 0.58 M NaCl aqueous solution (feed), 1 atm, and 300 K | 100%-salt rejection for different sized CNTs | Water flux possessed by the CNT membranes tends to increase at first and then decrease with the increase of the CNT diameter in the investigating range |

Nano-zeolite in membrane distillation

Nanosized zeolites are crystalline microporous solids with physicochemical characteristics like those of micron-sized crystals (Mintova et al. 2016). Nano-zeolite is characterized by a large surface area and easy shaping. Using nano-zeolite in desalination showed a promising future in increasing the productivity of membrane distillation. Anis et al. (2019) found that with 0.5% weight of nano-zeolite, the productivity increased by 34.2% with the salt rejection of 99.52%. Recently reported studies examining the effect of Nano-zeolite on the performance of membrane distillation systems are summarized in Table 4.

Table 4.

Recent studies on the performance of membrane distillation systems using nano-zeolite

| Reference | Material used |

Operating conditions | Results |

|---|---|---|---|

| Anis et al. (2019) | Nano-zeolite | 25 bars, 25,000 mg/L NaCl solution |

For 0.5 wt.% nano zeolite: A salt rejection of 99.52% with a flux increase of 34.2% |

| Liu and Chen (2013) | Nano-zeolite | Aqueous NaCl (with initial NaCl concentration of 1 mol/L | 100% rejection of salt, the permeability is about 2 × m/Pa.s |

| Kim et al. (2013) | Nano-zeolite | - | 98.8% Salt rejection and 37.8 L/ m2.h water flux |

Solar stills

Overview

The use of solar distillers is one of the appropriate ways to address the problem of freshwater scarcity, but the main problem of solar distillers is the low rate of daily water production. The intensity of solar radiation has a direct impact on the productivity of solar distillers since the hot and dry climatic conditions characterize most of the remote regions that suffer from water scarcity and have a high solar intensity. The use of solar distillers can help these countries save drinking water. The performance of solar distillers is mostly affected by the rates of water evaporation and condensation on the glass surface, where the increase in the temperature difference between the basin water and the glass cover (condensing surface) helps to increase the water productivity of the solar distillers.

Theoretical analysis of solar stills

Thermal analysis of the solar distillers was found to be dependent on the co-efficient of internal heat transfer and efficiency. The formula of these parameters was discussed below (Baskaran and Saravanane 2021):

The thermal efficiency ηth of the solar distiller depends on the entirety of hourly productivity , latent heat of vaporization hfg, solar intensity I(t), and the projected area A of solar distillers which calculated as follows:

| 9 |

Latent heat of vaporization hfg and entirety of hourly productivity calculated by the following Eqs. (10), (11):

| 10 |

| 11 |

The co-efficient of evaporative heat transfer hew calculated by:

| 12 |

The co-efficient of convective heat transfer hcw calculated by:

| 13 |

The co-efficient of radiative heat transfer hrw calculated by:

| 14 |

where, , is basin water temperature, is glass cover temperature, and and are partial vapor pressures at free water surface and glass cover, respectively.

Solar still performance improvement

Solar stills use the heat from the sun’s irradiance to evaporate the water and then condense it on a glass sheet to produce pure water. The main goal to improve the distillers performance is to increase the amount of heat absorbed by the solar still, this can be achieved by using thermal storage materials with high thermal conductivity to increase the absorbed heat and even store it; also preheating the feed flow to the solar still can improve the performance as it makes the process faster and requiring less sun irradiance; another way is to use the nanofluids due to high thermal conductivity of these materials.

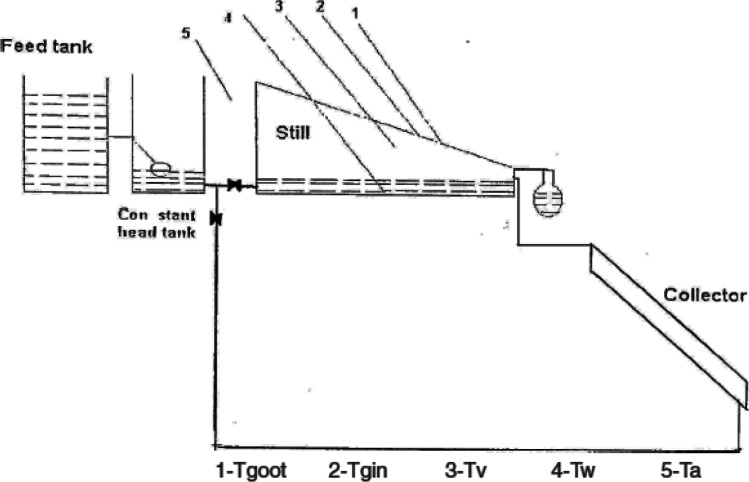

Preheating the feed flow of solar still

Badran and Al-Tahaineh (2005) investigated the effect of using solar heaters on the production of the solar stills, Fig. 5; they found that coupling of a solar collector with distiller improved the production by 36%, as the productivity with solar collector 3510 mL and without the solar heater was 2240 mL. Mahmoud et al. (2018) studied the effect of adding a solar concentrator to increase the heat directed to the solar still integrated with humidification-dehumidification desalination system shown in Fig. 6; results showed that with a concentration ratio of 4 and a Basin water height of 0.01 m, the system yield was about 16.3 kg/. Recently reported studies examining the effect of feed water preheating technologies on the performance of solar distillers are summarized in Table 5.

Fig. 5.

A solar still coupled with solar collector (Badran and Al-Tahaineh 2005)

Fig. 6.

Layout of hybrid humidification-dehumidification/solar still integrated with photovoltaic panels and solar concentrators (Mahmoud et al. 2018)

Table 5.

Recent studies on the performance of solar distillers using feed water preheating technologies

| Ref | Nature | Solar still type | Improvement-techniques | Results | Remarks |

|---|---|---|---|---|---|

| Mahmoud et al. (2018) | Experimental + Theoretical | Single slope | HDH desalination unit + solar photovoltaic/thermal (PV/T) panels combined with solar concentrator |

• The system yield was about 17 kg/m2 at basin water temperature 80 °C • Electrical efficiency of PV/T reached 7.8% and 9.4% for the preheated water and air, respectively |

The yield decreases with increases in the circulating air flow rate and the basin height |

| Sathyamurthy et al. (2015) | Experimental + Theoretical | Semi-circular | Semi-circular trough with baffles | The daily yield is 3 kg/m2 with daily efficiency of 38% | The daily yield improved by 16.66% |

| Kabeel and Abdelgaied (2019) | Experimental | Single slope | Photovoltaic/thermal panels with reflectors + air injection system |

• The daily yield reached 6034 ml/m2 with an improvement of 40.98% • Overall efficiency reached 33.55% • Distillate water cost reached 0.014 $/L |

Using an air injection system reduced the distillate water cost by 28.57% compared to reference distillers |

| Badran and Al-Tahaineh (2005) | Experimental | Single slope | Mirrors + Flat plate collector | The productivity increased by 36% | - |

| El-Sebaii et al. (2011) | Experimental + Theoretical | Single slope | Shallow solar pond as preheating unit | The maximum daily production reached 6.68 kg/m2 and average efficiency reached 47.54% | - |

| Fallahzadeh et al. (2020) | Experimental + Theoretical | Pyramid-shaped | Evacuated tube solar water collector | The daily yield reached 6970 ml/m2 and water cost reached 0.0137 $/L | - |

| Amiri et al. (2021) | Experimental + Theoretical | Single slope |

Parabolic trough collector with tracking systems |

Daily yield reached 8 L/m2 Energy efficiency reached 63% |

- |

| Hassan et al. (2020) | Experimental | Single slope | Parabolic trough solar collector integrated with oil heat exchanger | The daily yield reached 8.77 L/m2; Thermal efficiency 40.3%; Water cost reached 0.01937 $/L | Use of these desalination systems mitigated CO2 compared to other desalination systems depending on fossil fuel |

| Alwan et al. (2020) | Experimental | Single slope | Flat plate solar water collector + rotating hollow drum | Productivity reached 5.5 L/m2 day with an improvement of 292%, and the distillate water cost reached 0.048 $/L | The yield improved by 292% compared to reference distillers |

| Azari et al. (2021) | Experimental | Single slope | V-groove solar air collector as preheating unit | The yield, energy, and exergy efficiencies improved by 170%, 170%, and 257%, respectively compared to reference unit; Water cost reached 0.03$/L | - |

| Sharma et al. (2022) | Experimental + Theoretical | Single slope | Evacuated tubular solar collector | Daily fresh water yield reached 7.1 kg/m2 | |

| Thakur et al. (2021) | Experimental | Single slope | V-type solar concentrator | Daily yield reached 5.47 L/m2, energy efficiency reached 57.4%, and exergy efficiency reached 3.8%; water cost reached 0.0102 $/L | Use of V-shape concentrator as preheating unit and minimum water depth are useful to augment the highest performance |

Solar still with thermal storage mediums

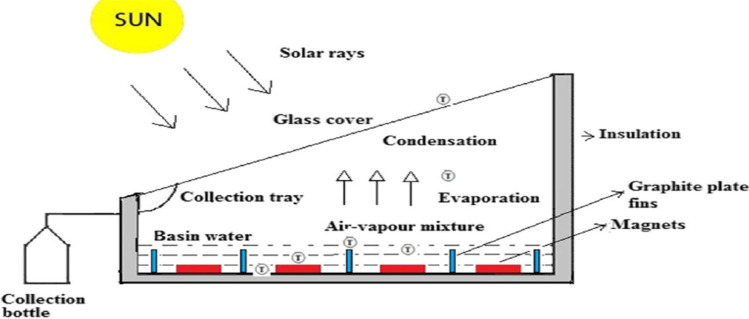

Thermal storage mediums are integrated with solar stills to increase the heat absorbed by the basin of the still and to work as a heat source at night. Dhivagar and Mohanraj (2021) used 16 magnets and 20 graphite plate fins shown in Fig. 7. The results conducted that the yield, energy, and exergy efficiency of graphite plate fins and magnet solar still (GPF-MSS) were increased by 19.6, 21.4, and 18.1%, respectively, compared with conventional solar still. Recently reported studies examining the effect of thermal storage mediums on the performance of solar distillers are summarized in Table 6.

Fig. 7.

Single slope still with magnets and graphite plate fins (Dhivagar and Mohanraj 2021)

Table 6.

Recent studies on the performance of solar distillers using thermal storage mediums

| Ref | Nature | Solar still type | Improvement-techniques | Results |

|---|---|---|---|---|

| Dhivagar and Mohanraj (2021) | Experimental + Theoretical | Single slope | Graphite plate fins as sensible storage materials and magnets |

The average productivity of modified distiller was 23.8% higher than the reference unit The energy efficiency improved by 21.3% compared to reference unit |

| Kabeel et al. (2020a) | Experimental | Pyramid-shaped | Hollow circular fins and paraffin wax as energy storage materials (Solid/liquid heat capacity 2.95/2.51 kJ/kg °C) |

The hollow fins utilization increases the cumulative yield to 5.75 L/m2 with 43% improvement PCM addition increases the daily yield to 8.1 L/m2 with 101.5% improvement |

| Kabeel and Abdelgaied (2017a) | Experimental | Single slope | Cylindrical parabolic concentrator + Paraffin wax as energy storage materials (Solid/liquid heat capacity 2.95/2.51 kJ/kg °C) |

Freshwater daily productivity reached 10.77 L/m2 Distillate cost reached 0.1378 LE/L Daily efficiency reached 46% |

| Kabeel et al. (2021) | Experimental + Theoretical | Tubular |

V-corrugated wick materials |

V-corrugated wick materials improve the yield to 6010 ml/m2, with an improvement of 44.82% The energy efficiency reached 51.4% |

| El-Bialy (2014) | Experimental | Single slope | Floating absorber | The daily productivity improvement ratio was 42.2%, 15.2%, 20.1% and 17.2% when mica, stainless steel, aluminum and copper are used as floating absorbers |

| Sellamia et al. (2017) | Theoretical | Single slope | Heat storage blackened layers of sponge | A 0.5 cm sponge thickness improved a yield by 57.77% |

| Kabeel and Abdelgaied (2017b) | Experimental | Single slope | Coaxial pipes in basin |

The daily yield improved by 97.8% The energy efficiency improved by 90.8% |

| Al-Harahsheh et al. (2022) | Experimental | Single slope | Solar collector as preheating unit + PV panel + Basin tube filled with sodium acetate trihydrate as storage materials (Solid/liquid heat capacity 2.79/3 kJ/kg °C) |

The daily yield reached 9.7 L/m2 and the thermal efficiency reached 54.1% The overall improvement in distillate yield reached 400% compared to reference distiller |

| Maridurai et al. (2021) | Experimental | Single slope | Flat plate solar collector + Paraffin wax as energy storage materials (heat capacity 2.2 kJ/kg °C) | The daily yield improved by 22% compared to reference unit |

| Shehata et al. (2020) | Experimental | Single slope | Ultrasonic waves, reflectors, paraffin wax as energy storage materials (Solid/liquid heat capacity 2.95/2.51 kJ/kg °C), and evacuated solar collector |

Daily yield reached 7.4 L/m2; Distillate cost reached 0.037$/L; Thermal efficiency reached 49%; Distillate yield improved by 44% compared to reference distillers |

| Malik et al. (2021) | Theoretical | Weir-type | Paraffin wax as energy storage materials (solid/liquid heat capacity 2.95/2.51 kJ/kg °C) | Exergy efficiency and annual distilled water improved by 1.47% and 4.35% compared to reference unit |

| Abu-Arabi et al. (2020) | Theoretical | Single slope | Flat plate solar collector + sodium acetate trihydrate as energy storage materials (solid/liquid heat capacity 2.79/3 kJ/kg °C) + glass cover cooling | Daily yield reached 7.4 L/m2 and thermal efficiency reached 49.2% |

| Abdelgaied et al. (2022) | Experimental | Hemispherical | Paraffin wax as energy storage materials (solid/liquid heat capacity 2.17/3.06 kJ/kg °C) and CuO-water–based nanofluid |

Distillate productivity improved by 60.41%, and daily thermal efficiency reached 63.61% Water cost 0.0065 $/L |

Solar still with nanomaterials

Nano Al2O3

Xia et al. (2016) conducted the influences of adding nano Al2O3 and Ti on heat transfer rate; they found that that the thermal conductivity and dynamic viscosity of Al2O3 and Ti nanofluids are both improved with the increase of particle volume fraction. Kabeel et al. (2014) experimented the addition of Al2O3 to a single-sloped solar still with external condenser to improve the condensation of the evaporated water of the still; results have shown a 116% improvement in the productivity of the still. Recently reported studies examining the effect of nano Al2O3 on the performance of solar distillers are summarized in Table 7.

Table 7.

Recent studies on the performance of solar distillers using nano Al2O3

| Ref | Nature | Solar still type | Material used | Results |

|---|---|---|---|---|

| Kabeel et al. (2014) | Experimental | Single slope | Al2O3 |

With the external condenser, the solar still water productivity increased by about 116% Water cost 0.041 $/L |

| Sahota and Tiwari (2016) | Theoretical | Double slope | 0.12% Al2O3 concentration | The enhancement of yield has been found to be 12.2% |

| Chaichan and Kazem (2018) | Experimental | Single slope | Paraffin wax with a nano-Al2O3 | Distillate yield improved by 60.53% |

| Modi et al. (2021) | Experimental | Single-basin dual-slope | 0.1% Al2O3 | Use of Al2O3 improved the yield by 28.53% |

| Kabeel et al. (2017a) | Numerical | Single slope | 0.2% Al2O3 and 0.2% Cu2O | The daily efficiency improved by 73.85% and 84.16% for Al2O3 and Cu2O nanoparticles, respectively |

| Shanmugan et al. (2018) | Experimental + Theoretical | Single slope | Al2O3 | The daily yield was 7.460 kg/m2 in summer and 4.120 kg/m2 in winter |

Nano CuO

Kabeel et al. (2017a) tested experimentally the effect of CuO concentration on the distillate of the solar still; they found that with 10% CuO concentration, the distillate increased by 16%, and by increasing the CuO concentration to 40%, the distillate increased by 40%. Recently reported studies examining the effect of CuO nano material on the performance of solar distillers are summarized in Table 8.

Table 8.

Recent studies on the performance of solar distillers using CuO nanomaterial

| Ref | Nature | Solar still type | Material used | Results |

|---|---|---|---|---|

| Modi et al. (2021) | Experimental | Dual slope | 0.1% CuO concentration | Use of CuO improved the yield by 58.25% |

| Kabeel et al. (2017b) | Experimental | Single slope | 10 to 40% CuO concentration | Utilizing CuO nanoparticles boosted the distillate by 16% and 25% at CuO concentration of 10% and 40%, respectively |

| Gupta et al. (2016) | Experimental | Single slope | 0.12% CuO concentration | Solar still with added nanoparticles produced 3445 ml/m2 per day at water depth of 5 cm |

| El-Gazar et al. (2021) | Experimental + Theoretical | Single slope | Al2O3 + CuO 0.025% for each | Enhancement in the still output yield reached 27.2% in summer and 21.7% in winter compared to reference still |

| Attia et al. (2021) | Experimental | CuO-water–based nanofluid |

Daily yield reached 6.8 L/m2 with an improvement of 76.6% Water cost 0.0066 $/L |

Other nanomaterials

Cuprous oxide (Cu2O), titanium dioxide (TiO2), potassium permanganate (KMnO4), zinc oxide (ZnO), Fe2O3 and SnO2 nanomaterials can also be used to enhance the distiller yield. Elango et al. (2015) compared between using of different nanomaterials on the performance of a single slope solar still, Al2O3, ZnO, Fe2O3 and SnO2 were tested, results showed that the yield improved 29.95, 12.67, and 18.63% for Al2O3, ZnO, and SnO2 nanofluids, respectively. Recently reported studies examining the effect of other nanomaterials on the performance of solar distillers are summarized in Table 9.

Table 9.

Recent studies on the performance of solar distillers using other nanomaterials

| Ref | Nature | Still type | Material used | Results |

|---|---|---|---|---|

| Omara et al. (2015) | Experimental | Single slope | Al2O3 + cuprous oxide | The yield enhanced by 285.10% and 254.88% for using cuprous and Al2O3 nanoparticles, respectively |

| Kabeel et al. (2019a, b) | Numerical | Single slope | 0.02% cuprous oxide | The daily yield improved by 106.86% |

| Shanmugan et al. (2020) | Experimental + Theoretical | Single slope | TiO2 |

In summer: average daily productivity was 7.89 L, and average efficiency of a system was 36.69% In winter: average daily productivity was 5.39 L, and average efficiency of a system was 57.16% |

| Kabeel et al. (2019a) | Experimental | Pyramid solar still | TiO2 black paint coated solar still | The distilled yield improved by 6.1% |

| Nijmeh et al. (2005) | Experimental | Dual slope | KMnO4 | The improvement in energy efficiency reached 26% |

| Elango et al. (2015) | Experimental | Single slope | Al2O3, ZnO, Fe2O3 and SnO2 | The yield improved 29.95, 12.67, and 18.63% for Al2O3, ZnO, and SnO2 nanofluids, respectively |

| Kabeel et al. (2018) | Experimental | Single slope | Graphite nanoparticles | The daily yield reached 7.73 L/m2 |

| Kabeel et al. (2019b) | Experimental | Single slope | Paraffin wax and graphite nanoparticles | The daily yield reached to 7.123, 7.475, 7.937, 8.249, and 8.52 L/m2 for 0.0, 5, 10, 15, and 20% graphite mass concentrations, respectively |

| Kabeel et al. (2020b) | - | Stepped solar still | Graphite and PCM + internal reflectors and evacuated tube collector | The daily distillate productivity varied between 13.6 and 13.62 L/m2 |

| Rufuss et al. (2018) | Experimental | Single slope | PCM + TiO2, CuO, and GO nanoparticles |

Add TiO2, CuO, and GO nanoparticles to PCM improved the yield to 3.92, 4.94, 5.28 and 3.66 L/ per day, respectively Water cost reached 0.026 $/L |

| Nazari et al. (2019) | Experimental + Theoretical | Single slope | Cu2O nanofluid + thermoelectric cooling channel |

Use of 0.08% Cu2O improved the yield and energy efficiency by 82.4% and 81.5%, respectively Water cost reached 0.021 $/L |

| Kabeel et al. (2017c) | Numerical | Single slope | Cu2O + Al2O3 | Use of 0.02% Cu2O and Al2O3 improved the daily yield to 4090 ml/m2 and 2875 ml/m2, respectively |

| Arani et al. (2021) | Experimental | SiO2 nanoparticles | Productivity improved by 55.18%, and water cost reached 0.012 $/L |

Conclusion

In addition to the importance of both membrane desalination plants and solar stills in the field of water desalination, this paper aims to provide a comprehensive review of the most important recent studies aimed at improving performance that was conducted on both membrane desalination plants and solar stills. The improvement axes that were carried out on both the membrane desalination plants and the solar stills were categorized according to three axes that are very effective and have a direct impact on the performance of the membrane desalination plants and the solar stills, which are as follows: feed water preheating technologies, thermal storage materials, and nanoparticles. This survey focuses on showing the impact of the previous improvement axes on pure water productivity, energy efficiency, and the cost of producing pure water. The most important results can be outlined as follows:

• The contribution of solar heat and waste heat used in the operation of the process leads to a lower cost of water production as well as making the desalination system more competitive, sustainable, and economically viable for small and remote applications.

• Permeate pure water through the membrane was increased by 52 g/m2/min for increasing the feed water temperature from 30 to 60 °C.

• Using waste heat and solar thermal energy reduced the cost of pure water produced from the membrane distillation plant from 6.80 $/m3 to 1.6 $/m3 compared to a membrane distillation plant that operated with standalone grid electricity.

• The overall system efficiency of the membrane distillation plant improved from 46.6% to 61.8% for utilizing the pre-cooling unit on the permeate flow loop before entering the membrane unit.

• The pure water productivity of the membrane distillation system will be improved by a rate varying between 33.11 and 43.18% compared to cases without PCM.

• Use of thermal storage materials improved the cumulative yield and the gain output ratio of membrane distillation units by a rate up to 43.2% and 34.4%, respectively.

• With an increase in the amount of MWNTs in the membrane, the water flux increased from 14.86 to 28.05 L/m2.h, while the salt rejection decreased slightly.

• For utilizing 0.5 wt.% nano-zeolite, the salt rejection reached 99.52% and the water flux increased by 34.2%.

• Using the solar collector as a feed water preheating unit is the effective choice that increases the pure water productivity and energy efficiency with rates reaching 40.98% and 57.4%, respectively, and reduces the cost of producing pure water to a rate reached 0.0102 $/L.

• The utilization of nanofluid improved the cumulative productivity of solar stills by a rate up to 116%, and also the use of thermal storage materials (PCM) improved the cumulative productivity of solar stills at a rate of 105.5%.

Recommendation and future scope

In the processes of reducing the electricity consumption rates in membrane distillation units, various modifications were shown in many of the recent studies that were conducted, all of which aim to reduce the electrical power consumption rates, but there is still room for brainstorming. Also in the processes of enhancing the cumulative yield and raising the efficiency of solar stills, various modifications were presented in many of the researches that were conducted, all of which aim to enhance the cumulative yield and raise the efficiency of solar stills, but there is still room for a brainstorm. The following are the most important recommendations that could be useful for further study, correction, and modification of membrane distillation units and solar stills.

• The heat released from the waste outlets in industries and exhaust of the engine is the most effective choice as a feed water preheating unit to improve the performance of membrane distillation units.

• Development of the new combination of the membrane distillation and solar still to achieve the highest performance and lower cost.

• Incorporating high-performance nanomaterials, thermal storage materials, and feed water preheating units in the water treatment process are good choices to achieve the highest performance and lower cost.

• Future studies are also required to be focusing more on the effects of novel combinations of effective modifications in order to determine the best designs of the solar stills that achieve the highest performance and lower cost.

Nomenclature

- ASBS

Active single basin solar still

- CDI

Capacitive deionization

- CNT

Carbon nanotube

- FO

Forward osmosis

- GOR

Gain output ratio

- GPF

Graphite plate fins

- MSS

Magnet solar still

- MW-CNT

Multi-wall Carbon nanotube

- PCM

Phase change material

- PV

Photovoltaic

- SSA

Spectrally selective absorber

- SSP

Shallow solar pond

- SW-CNT

Single wall carbon nanotube

- TDCMD

Tubular direct contact membrane desalination

- VACNT

Vertically aligned carbon nanotube

Author contribution

1. Mohamed Abdelgaied: Conceptualization, Writing—Review & Editing, Supervision.

2. Mohamed Fathi Seleem: Conceptualization, Methodology, Writing - original draft preparation.

3. Mohamed Mahgoub Bassuoni: Conceptualization, Review & Editing, Supervision.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Data availability

Not applicable.

Declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Mohamed Abdelgaied, Email: mohamed_abdelgaied@f-eng.tanta.edu.eg.

Mohamed Fathi Seleem, Email: Mohamed.seleem@f-eng.tanta.edu.eg.

Mohamed Mahgoub Bassuoni, Email: mohamed_mahgoub@f-eng.tanta.edu.eg.

References

- Abdelgaied M, Kabeel AE, Sathyamurthy R. Improving the performance of solar powered membrane distillation systems using the thermal energy storage mediums and the evaporative cooler. Renewable Energy. 2020;157:1046–1052. doi: 10.1016/j.renene.2020.05.123. [DOI] [Google Scholar]

- Abdelgaied M, Attia MEH, Kabeel AE, Zayed ME. Improving the thermo-economic performance of hemispherical solar distiller using copper oxide nanofluids and phase change materials: experimental and theoretical investigation. Sol Energy Mater Sol Cells. 2022;238:111596. doi: 10.1016/j.solmat.2022.111596. [DOI] [Google Scholar]

- Abdelkader S, Gross F, Winter D, Went J, Koschikowski J, Geissen SU. Bousselmi L (2019) Application of direct contact membrane distillation for saline dairy effluent treatment: performance and fouling analysis. Environ Sci Pollut Res. 2019;26:18979–18992. doi: 10.1007/s11356-018-2475-3. [DOI] [PubMed] [Google Scholar]

- Abu-Arabi M, Al-harahsheh M, Ahmad M, Mousa H. Theoretical modeling of a glass-cooled solar still incorporating PCM and coupled to flat plate solar collector. Journal of Energy Storage. 2020;29:101372. doi: 10.1016/j.est.2020.101372. [DOI] [Google Scholar]

- Al-Harahsheh M, Abu-Arabi M, Ahmad M, Mousa H. Self-powered solar desalination using solar still enhanced by external solar collector and phase change material. Appl Therm Eng. 2022;206:118118. doi: 10.1016/j.applthermaleng.2022.118118. [DOI] [Google Scholar]

- Al-Otoom A, Al-Khalaileh AT. Water desalination using solar continuous humidification–dehumidification process using hygroscopic solutions and rotating belt. Sol Energy. 2020;197:38–49. doi: 10.1016/j.solener.2019.12.075. [DOI] [Google Scholar]

- Altarawneh I, Batiha M, Rawadieh S, Alnaief M, Tarawneh M. Solar desalination under concentrated solar flux and reduced pressure conditions. Sol Energy. 2020;206:983–996. doi: 10.1016/j.solener.2020.06.058. [DOI] [Google Scholar]

- Alwan NT, Shcheklein SE, Ali OM. Experimental investigation of modified solar still integrated with solar collector. Case Studies in Thermal Engineering. 2020;19:100614. doi: 10.1016/j.csite.2020.100614. [DOI] [Google Scholar]

- Amini M, Jahanshahi M, Rahimpour A. Synthesis of novel thin film nanocomposite (TFN) forward osmosis membranes using functionalized multi-walled carbon nanotubes. J Membr Sci. 2013;435:233–241. doi: 10.1016/j.memsci.2013.01.041. [DOI] [Google Scholar]

- Amiri H, Aminy M, Lotfi M, Jafarbeglo B. Energy and exergy analysis of a new solar still composed of parabolic trough collector with built-in solar still. Renew Energy. 2021;163:465–479. doi: 10.1016/j.renene.2020.09.007. [DOI] [Google Scholar]

- Anis SF, Hashaikeh R, Hilal N. Flux and salt rejection enhancement of polyvinyl (alcohol) reverse osmosis membranes using nano-zeolite. Desalination. 2019;470:114104. doi: 10.1016/j.desal.2019.114104. [DOI] [Google Scholar]

- Anvari A, Yancheshme AA, Kekre KM, Ronen A. State-of-the-art methods for overcoming temperature polarization in membrane distillation process: a review. J Membr Sci. 2020;616:118413. doi: 10.1016/j.memsci.2020.118413. [DOI] [Google Scholar]

- Arani RP, Sathyamurthy R, Chamkha A, Kabeel AE, Deverajan M, Kamalakannan K, Balasubramanian M, Manokar AM, Essa F, Saravanan A. Effect of fins and silicon dioxide nanoparticle black paint on the absorber plate for augmenting yield from tubular solar still. Environ Sci Pollut Res. 2021;28:35102–35112. doi: 10.1007/s11356-021-13126-y. [DOI] [PubMed] [Google Scholar]

- Attia MEH, Kabeel AE, Abdelgaied M, Abdelaziz GB. A comparative study of hemispherical solar stills with various modifications to obtain modified and inexpensive still models. Environ Sci Pollut Res. 2021;28:55667–55677. doi: 10.1007/s11356-021-14862-x. [DOI] [PubMed] [Google Scholar]

- Azari P, Lavasani AM, Rahbar N, Yazdi ME. Performance enhancement of a solar still using a V-groove solar air collector—experimental study with energy, exergy, enviroeconomic, and exergoeconomic analysis. Environ Sci Pollut Res. 2021;28:65525–65548. doi: 10.1007/s11356-021-15290-7. [DOI] [PubMed] [Google Scholar]

- Badran OO, Al-Tahaineh HA. The effect of coupling a flat-plate collector on the solar still productivity. Desalination. 2005;183:137–142. doi: 10.1016/j.desal.2005.02.046. [DOI] [Google Scholar]

- Baek Y, Kim C, Seo DK, Kim T, Lee JS, Kim YH, Ahn KH, Bae SS, Lee SC, Lim J, Lee K, Yoon J. High performance and antifouling vertically aligned carbon nanotube membrane for water purification. J Membr Sci. 2014;460:171–177. doi: 10.1016/j.memsci.2014.02.042. [DOI] [Google Scholar]

- Baskaran V, Saravanane R. Rendering utility water with solar still and efficiency of solar stills with different geometry — a review, Environmental Nanotechnology. Monitoring & Management. 2021;16:100534. [Google Scholar]

- Bhadra M, Roy S, Mitra S. Enhanced desalination using carboxylated carbon nanotube immobilized membranes. Sep Purif Technol. 2013;120:373–377. doi: 10.1016/j.seppur.2013.10.020. [DOI] [Google Scholar]

- Chafidz A, Al-Zahrani S, Al-Otaibi MN, Hoong CF, Lai TF, Prabu M. Portable and integrated solar-driven desalination system using membrane distillation for arid remote areas in Saudi Arabia. Desalination. 2014;345:36–49. doi: 10.1016/j.desal.2014.04.017. [DOI] [Google Scholar]

- Chaichan MT, Kazem HA. Single slope solar distillator productivity improvement using phase change material and Al2O3 nanoparticle. Sol Energy. 2018;164:370–381. doi: 10.1016/j.solener.2018.02.049. [DOI] [Google Scholar]

- Chang H, Lyu SG, Tsai CM, Chen YH, Cheng TW, Chou YH. Experimental and simulation study of a solar thermal driven membrane distillation desalination process. Desalination. 2012;286:400–411. doi: 10.1016/j.desal.2011.11.057. [DOI] [Google Scholar]

- Chang YS, Ahmad AL, Leo CP, Derek CJC, Ooi BS. Air bubbling assisted solar-driven submerged vacuum membrane distillation for aquaculture seawater desalination. Journal of Environmental Chemical Engineering. 2022;10:107088. doi: 10.1016/j.jece.2021.107088. [DOI] [Google Scholar]

- Dhivagar R, Mohanraj M. Performance improvements of single slope solar still using graphite plate fins and magnets. Environ Sci Pollut Res. 2021;28:20499–20516. doi: 10.1007/s11356-020-11737-5. [DOI] [PubMed] [Google Scholar]

- Ding Z, Liu L, El-Bourawi MS, Runyu M. Analysis of a solar-powered membrane distillation system. Desalination. 2005;172:27–40. doi: 10.1016/j.desal.2004.06.195. [DOI] [Google Scholar]

- Dumée LF, Sears K, Schütz J, Finn N, Huynh C, Hawkins S, Duke M, Gray S. Characterization and evaluation of carbon nanotube Bucky-Paper membranes for direct contact membrane distillation. J Membr Sci. 2010;351:36–43. doi: 10.1016/j.memsci.2010.01.025. [DOI] [Google Scholar]

- Elango T, Kannan A, Murugavel KK. Performance study on single basin single slope solar still with different water nanofluids. Desalination. 2015;360:45–51. doi: 10.1016/j.desal.2015.01.004. [DOI] [Google Scholar]

- El-Bialy E. Performance analysis for passive single slope single basin solar distiller with a floating absorber - an experimental study. Energy. 2014;68:117–124. doi: 10.1016/j.energy.2014.02.095. [DOI] [Google Scholar]

- El-Gazar EF, Zahra WK, Hassan H, Rabia SI. Fractional modeling for enhancing the thermal performance of conventional solar still using hybrid nanofluid: energy and exergy analysis. Desalination. 2021;503:114847. doi: 10.1016/j.desal.2020.114847. [DOI] [Google Scholar]

- Elminshawy NAS, Gadalla MA, Bassyouni M, El-Nahhas K, Elminshawy A, Elhenawy Y. A novel concentrated photovoltaic-driven membrane distillation hybrid system for the simultaneous production of electricity and potable water. Renew Energy. 2020;162:802–817. doi: 10.1016/j.renene.2020.08.041. [DOI] [Google Scholar]

- El-Sebaii AA, Aboul-Enein S, Ramadan MRI, Khallaf AM. Thermal performance of an active single basin solar still (ASBS) coupled to shallow solar pond (SSP) Desalination. 2011;280:183–190. doi: 10.1016/j.desal.2011.07.004. [DOI] [Google Scholar]

- Elzahaby AM, Kabeel AE, Bassuoni MM, Abd-Elbar AR. Direct contact membrane water distillation assisted with solar energy. Energy Convers Manage. 2016;110:397–406. doi: 10.1016/j.enconman.2015.12.046. [DOI] [Google Scholar]

- Fallahzadeh R, Aref L, Gholamiarjenaki N, Nonejad Z, Saghi M. Experimental investigation of the effect of using water and ethanol as working fluid on the performance of pyramid-shaped solar still integrated with heat pipe solar collector. Sol Energy. 2020;207:10–21. doi: 10.1016/j.solener.2020.06.032. [DOI] [Google Scholar]

- Gonzáleza D, Amigo J, Suárez F. Membrane distillation: perspectives for sustainable and improved desalination. Renew Sustain Energy Rev. 2017;80:238–259. doi: 10.1016/j.rser.2017.05.078. [DOI] [Google Scholar]

- Gude VG. Desalination and water reuse to address global water scarcity. Rev Environ Sci Biotechnol. 2017;16(4):591–609. doi: 10.1007/s11157-017-9449-7. [DOI] [Google Scholar]

- Gupta B, Shankar P, Sharma R, Baredar P. Performance enhancement using nano particles in modified passive solar still. Procedia Technol. 2016;25:1209–1216. doi: 10.1016/j.protcy.2016.08.208. [DOI] [Google Scholar]

- Gustafson RD, Hiibel SR, Childress AE. Membrane distillation driven by intermittent and variable-temperature waste heat: system arrangements for water production and heat storage. Desalination. 2018;448:49–59. doi: 10.1016/j.desal.2018.09.017. [DOI] [Google Scholar]

- Hassan H, Yousef MS, Fathy M, Ahmed MS. Assessment of parabolic trough solar collector assisted solar still at various saline water mediums via energy, exergy, exergoeconomic, and enviroeconomic approaches. Renew Energy. 2020;155:604–616. doi: 10.1016/j.renene.2020.03.126. [DOI] [Google Scholar]

- Jia Y, Li H, Wang M, Wu L, Hu Y. Carbon nanotube: possible candidate for forward osmosis. Sep Purif Technol. 2010;75:55–60. doi: 10.1016/j.seppur.2010.07.011. [DOI] [Google Scholar]

- Kabeel AE, Abdelgaied M. Observational study of modified solar still coupled with oil serpentine loop from cylindrical parabolic concentrator and phase changing material under basin. Sol Energy. 2017;144:71–78. doi: 10.1016/j.solener.2017.01.007. [DOI] [Google Scholar]

- Kabeel AE, Abdelgaied M. Performance enhancement of modified solar still using multi-groups of two coaxial pipes in basin. Appl Therm Eng. 2017;118:23–32. doi: 10.1016/j.applthermaleng.2017.02.090. [DOI] [Google Scholar]

- Kabeel AE, Abdelgaied M. Performance enhancement of a photovoltaic panel with reflectors and cooling coupled to a solar still with air injection. J Clean Prod. 2019;224:40–49. doi: 10.1016/j.jclepro.2019.03.199. [DOI] [Google Scholar]

- Kabeel AE, Omara ZM, Essa FA. Enhancement of modified solar still integrated with external condenser using nanofluids: an experimental approach. Energy Convers Manage. 2014;78:493–498. doi: 10.1016/j.enconman.2013.11.013. [DOI] [Google Scholar]

- Kabeel AE, Abdelgaied M, El-Said EMS. Study of a solar-driven membrane distillation system: evaporative cooling effect on performance enhancement. Renew Energy. 2017;106:192–200. doi: 10.1016/j.renene.2017.01.030. [DOI] [Google Scholar]

- Kabeel AE, Omara ZM, Essa FA. Numerical investigation of modified solar still using nanofluids and external condenser. J Taiwan Inst Chem Eng. 2017;75:77–86. doi: 10.1016/j.jtice.2017.01.017. [DOI] [Google Scholar]

- Kabeel AE, Omara ZM, Essa FA, Abdullah AS, Arunkumar T, Sathyamurthy R. Augmentation of a solar still distillate yield via absorber plate coated with black nanoparticles. Alex Eng J. 2017;56:433–438. doi: 10.1016/j.aej.2017.08.014. [DOI] [Google Scholar]

- Kabeel AE, Abdelgaied M, Eisa A. Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials. J Clean Prod. 2018;183:20–25. doi: 10.1016/j.jclepro.2018.02.144. [DOI] [Google Scholar]

- Kabeel AE, Sathyamurthy R, Sharshir SW, Muthumanokar A, Panchal H, Prakash N, Prasad C, Nandakumar S, El Kady MS. Effect of water depth on a novel absorber plate of pyramid solar still coated with TiO2 nano black paint. J Clean Prod. 2019;213:185–191. doi: 10.1016/j.jclepro.2018.12.185. [DOI] [Google Scholar]

- Kabeel AE, Abdelgaied M, Eisa A. Effect of graphite mass concentrations in a mixture of graphite nanoparticles and paraffin wax as hybrid storage materials on performances of solar still. Renewable Energy. 2019;132:119–128. doi: 10.1016/j.renene.2018.07.147. [DOI] [Google Scholar]

- Kabeel AE, El-Maghlany WM, Abdelgaied M, Abdel-Aziz MM. Performance enhancement of pyramid-shaped solar stills using hollow circular fins and phase change materials. Journal of Energy Storage. 2020;31:101610. doi: 10.1016/j.est.2020.101610. [DOI] [Google Scholar]

- Kabeel AE, Dawood MMK, Nabil T, Alonafal BE. Improving the performance of stepped solar still using a graphite and PCM as hybrid store materials with internal reflectors coupled with evacuated tube solar collector. Heat Mass Transf. 2020;56:891–899. doi: 10.1007/s00231-019-02741-8. [DOI] [Google Scholar]

- Kabeel AE, Harby K, Abdelgaied M, Eisa A. Performance improvement of a tubular solar still using V-corrugated absorber with wick materials: numerical and experimental investigations. Sol Energy. 2021;217:187–199. doi: 10.1016/j.solener.2021.02.008. [DOI] [Google Scholar]

- Kim SG, Hyeon DH, Chun JH, Chun BH, Kim SH. Nanocomposite poly (arylene ether sulfone) reverse osmosis membrane containing functional zeolite nanoparticles for seawater desalination. J Membr Sci. 2013;443:10–18. doi: 10.1016/j.memsci.2013.03.065. [DOI] [Google Scholar]

- Kim GS, Cao T, Hwang Y. Thermoeconomic investigation for a multi-stage solar-thermal vacuum membrane distillation system for coastal cities. Desalination. 2021;498:114797. doi: 10.1016/j.desal.2020.114797. [DOI] [Google Scholar]

- Lee B, Baek Y, Lee M, Jeong DH, Lee HH, Yoon J, Kim YH. A carbon nanotube wall membrane for water treatment. Nat Commun. 2015;6:7109. doi: 10.1038/ncomms8109. [DOI] [PubMed] [Google Scholar]

- Li S, Liao G, Liu Z, Pan Y, Wu Q, Weng Y, Zhang X, Yang Z, Tsui OKC. Enhanced water flux in vertically aligned carbon nanotube arrays and polyethersulfone composite membranes. J Mater Chem a. 2014;2:12171–12176. doi: 10.1039/C4TA02119C. [DOI] [Google Scholar]

- Liu Y, Chen X. High permeability and salt rejection reverse osmosis by a zeolite nano-membrane. Phys Chem Chem Phys. 2013;15:6817–6824. doi: 10.1039/c3cp43854f. [DOI] [PubMed] [Google Scholar]

- Mahmoud A, Fath H, Ahmed M. Enhancing the performance of a solar driven hybrid solar still/ humidification-dehumidification desalination system integrated with solar concentrator and photovoltaic panels. Desalination. 2018;430:165–179. doi: 10.1016/j.desal.2017.12.052. [DOI] [Google Scholar]

- Maleki A, Pourfayaz F, Ahmadi MH. Design of a cost-effective wind/ photovoltaic/ hydrogen energy system for supplying a desalination unit by a heuristic approach. Sol Energy. 2016;139:666–675. doi: 10.1016/j.solener.2016.09.028. [DOI] [Google Scholar]

- Malik MZ, Musharavati F, Khanmohammadi S, Khanmohammadi S, Nguyen DD. Solar still desalination system equipped with paraffin as phase change material: exergoeconomic analysis and multi-objective optimization. Environ Sci Pollut Res. 2021;28:220–234. doi: 10.1007/s11356-020-10335-9. [DOI] [PubMed] [Google Scholar]

- Manchanda H, Kumar M. Study of water desalination techniques and a review on active solar distillation methods. Environ Prog Sustain Energy. 2018;37(1):444–464. doi: 10.1002/ep.12657. [DOI] [Google Scholar]

- Maridurai T, Rajkumar S, Arunkumar M, Mohanavel V, Arul K, Madhesh D, Subbiah R (2021) Performance study on phase change material integrated solar still coupled with solar collector, Materials Today: Proceedings, 2021.10.1016/j.matpr.2021.11.539

- Mekonnen MM, Hoekstra AY. Four billion people facing severe water scarcity. Sci Adv. 2016;2(2):e1500323. doi: 10.1126/sciadv.1500323. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mintova S, Grand J, Valtchev V. Nanosized zeolites: Quo Vadis? C r Chimie. 2016;19:183–191. doi: 10.1016/j.crci.2015.11.005. [DOI] [Google Scholar]

- Modi KV, Jani HK, Gamit ID. Impact of orientation and water depth on productivity of single-basin dual-slope solar still with Al2O3 and CuO nanoparticles. J Therm Anal Calorim. 2021;143:899–913. doi: 10.1007/s10973-020-09351-1. [DOI] [Google Scholar]

- Nazari S, Safarzadeh H, Bahiraei M. Experimental and analytical investigations of productivity, energy, and exergy efficiency of a single slope solar still enhanced with thermoelectric channel and nanofluid. Renew Energy. 2019;135:729–744. doi: 10.1016/j.renene.2018.12.059. [DOI] [Google Scholar]

- Nijmeh S, Odeh S, Akash B. Experimental and theoretical study of a single-basin solar still in Jordan. Int Commun Heat Mass Transfer. 2005;32:565–572. doi: 10.1016/j.icheatmasstransfer.2004.06.006. [DOI] [Google Scholar]

- Okampo EJ, Nwulu N. Optimisation of renewable energy powered reverse osmosis desalination systems: a state-of-the-art review. Renew Sust Energ Rev. 2021;140:110712. doi: 10.1016/j.rser.2021.110712. [DOI] [Google Scholar]

- Omara ZM, Kabeel AE, Essa FA. Effect of using nanofluids and providing vacuum on the yield of corrugated wick solar still. Energy Convers Manage. 2015;103:965–972. doi: 10.1016/j.enconman.2015.07.035. [DOI] [Google Scholar]

- Park S, Jung J, Lee S, Baek Y, Yoon J, Kyun D, Hyup Y. Fouling and rejection behavior of carbon nanotube membranes. Desalination. 2014;343:180–186. doi: 10.1016/j.desal.2013.10.005. [DOI] [Google Scholar]

- Pourafshar ST, Jafarinaemi K, Mortezapour H. Development of a photovoltaic-thermal solar humidifier for the humidification-dehumidification desalination system coupled with heat pump. Sol Energy. 2020;205:51–61. doi: 10.1016/j.solener.2020.05.045. [DOI] [Google Scholar]

- Powers M (2017) Water scarcity issues: we’re running out of water. FEW Resources, Org, p. 28.

- Rufuss DDW, Suganthi L, Iniyan S, Davies PA. Effects of nanoparticle-enhanced phase change material (NPCM) on solar still productivity. J Clean Prod. 2018;192:9–29. doi: 10.1016/j.jclepro.2018.04.201. [DOI] [Google Scholar]

- Sahota L, Tiwari GN. Effect of Al2O3 nanoparticles on the performance of passive double slope solar still. Sol Energy. 2016;130:260–272. doi: 10.1016/j.solener.2016.02.018. [DOI] [Google Scholar]

- Sandid AM, Bassyouni M, Nehari D, Elhenawy Y. Experimental and simulation study of multichannel air gap membrane distillation process with two types of solar collectors. Energy Convers Manag. 2021;243:114431. doi: 10.1016/j.enconman.2021.114431. [DOI] [Google Scholar]

- Sathyamurthy R, Nagarajan PK, El-Agouz SA, Jaiganesh V, Khanna PS. Experimental investigation on a semi-circular trough-absorber solar still with baffles for fresh water production. Energy Convers Manage. 2015;97:235–242. doi: 10.1016/j.enconman.2015.03.052. [DOI] [Google Scholar]

- Sellamia MH, Belkisa T, Aliouara ML, Meddoura SD, Bouguettaiab H, Loudiyic K. Improvement of solar still performance by covering absorber with blackened layers of sponge. Groundw Sustain Dev. 2017;5:111–117. doi: 10.1016/j.gsd.2017.05.004. [DOI] [Google Scholar]

- Shafieian A, Khiadani M. A novel solar-driven direct contact membrane-based water desalination system. Energy Convers Manag. 2019;199:112055. doi: 10.1016/j.enconman.2019.112055. [DOI] [Google Scholar]

- Shafieian A, Khiadani M, Nosrati A. Performance analysis of a thermal-driven tubular direct contact membrane distillation system. Appl Therm Eng. 2019;159:113887. doi: 10.1016/j.applthermaleng.2019.113887. [DOI] [Google Scholar]

- Shanmugan S, Palani S, Janarthanan B. Productivity enhancement of solar still by PCM and nanoparticles miscellaneous basin absorbing materials. Desalination. 2018;433:186–198. doi: 10.1016/j.desal.2017.11.045. [DOI] [Google Scholar]

- Shanmugan S, Essa FA, Gorjian S, Kabeel AE, Sathyamurthy R, Manokar AM. Experimental study on single slope single basin solar still using TiO2 nano layer for natural clean water invention. Journal of Energy Storage. 2020;30:101522. doi: 10.1016/j.est.2020.101522. [DOI] [Google Scholar]

- Sharma SK, Mallick A, Singh DB, Tiwari GN. Experimental study of solar energy–based water purifier of single-slope type by incorporating a number of similar evacuated tubular collectors. Environ Sci Pollut Res. 2022;29:6837–6856. doi: 10.1007/s11356-021-16123-3. [DOI] [PubMed] [Google Scholar]

- Sharon H, Reddy KS, Krithika D, Philip L. Viability assessment of solar distillation for desalination in coastal locations of Indian sub-continent – thermodynamic, condensate quality and enviro-economic aspects. Sol Energy. 2020;197:84–98. doi: 10.1016/j.solener.2019.12.080. [DOI] [Google Scholar]

- Shawky HA, Chae SR, Lin S, Wiesner MR. Synthesis and characterization of a carbon nanotube/polymer nanocomposite membrane for water treatment. Desalination. 2011;272:46–50. doi: 10.1016/j.desal.2010.12.051. [DOI] [Google Scholar]

- Shehata AI, Kabeel AE, Dawood MMK, Elharidi AM, Abd-Elsalam A, Ramzy K, Mehanna A. Enhancement of the productivity for single solar still with ultrasonic humidifier combined with evacuated solar collector: an experimental study. Energy Convers Manag. 2020;208:112592. doi: 10.1016/j.enconman.2020.112592. [DOI] [Google Scholar]

- Siddiqui O, Dincer I. Examination of a new solar-based integrated system for desalination, electricity generation and hydrogen production. Sol Energy. 2018;163:224–234. doi: 10.1016/j.solener.2018.01.077. [DOI] [Google Scholar]

- Siefan A, Rachid E, Elashwah N, AlMarzooqi F, Banat F, Merwe RVd. Desalination via solar membrane distillation and conventional membrane distillation: life cycle assessment case study in Jordan. Desalination. 2022;522:115383. doi: 10.1016/j.desal.2021.115383. [DOI] [Google Scholar]

- Sivakumar V, Sundaram EG. Improvement techniques of solar still efficiency: a review. Renew Sustain Energy Rev. 2013;28:246–264. doi: 10.1016/j.rser.2013.07.037. [DOI] [Google Scholar]

- Soomro MI, Kim WS. Performance and economic investigations of solar power tower plant integrated with direct contact membrane distillation system. Energy Convers Manage. 2018;174:626–638. doi: 10.1016/j.enconman.2018.08.056. [DOI] [Google Scholar]

- Thakur AK, Sharshir SW, Ma Z, Thirugnanasambantham A, Christopher SS, Vikram MP, Li S, Wang P, Zhao W, Kabeel AE. Performance amelioration of single basin solar still integrated with V-type concentrator: energy, exergy, and economic analysis. Environ Sci Pollut Res. 2021;28:3406–3420. doi: 10.1007/s11356-020-10625-2. [DOI] [PubMed] [Google Scholar]

- UN-Water, Annual Report 2018, (2018).

- USGS (2019) How much water is there on, in, and above the Earth? Water Sci. URL. https://www.usgs.gov/special-topic/water-science-school/science/how-muchwater-there-arth?qt-science_center_objects=0#qt-science_center_objects. (Accessed 9 February 2020). (WWW document).

- Usman HS, Touati K, Md. Rahaman S, An economic evaluation of renewable energy-powered membrane distillation for desalination of brackish water. Renew Energy. 2021;169:1294–1304. doi: 10.1016/j.renene.2021.01.087. [DOI] [Google Scholar]

- Velmurugan V, Srithar K. Performance analysis of solar stills based on various factors affecting the productivity—a review. Renew Sustain Energy Rev. 2011;15(2):1294–1304. doi: 10.1016/j.rser.2010.10.012. [DOI] [Google Scholar]

- Wang Y, Zhang L, Wu Y, Xu S, Wang J. Polypyrrole/carbon nanotube composites as cathodematerial for performance enhancing of capacitive deionization technology. Desalination. 2014;354:62–67. doi: 10.1016/j.desal.2014.09.021. [DOI] [Google Scholar]

- Wang W, Shi Y, Zhang C, Hong S, Shi L, Chang J, Jin RLY, Ong C, Zhuo S, Wang P. Simultaneous production of fresh water and electricity via multistage solar photovoltaic membrane distillation. Nat Commun. 2019;10:3012. doi: 10.1038/s41467-019-10817-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wei M, Xiang J, Ye H, Zheng H, Wang K, Chen J. Using water-filling and air-releasing to design a natural vacuum solar desalination system. Sol Energy. 2021;220:598–607. doi: 10.1016/j.solener.2021.04.009. [DOI] [Google Scholar]

- Wimalasiri Y, Zou L. Carbon nanotube/graphene composite for enhanced capacitive deionization performance. Carbon N Y. 2013;59:464–471. doi: 10.1016/j.carbon.2013.03.040. [DOI] [Google Scholar]

- Xia GD, Liu R, Wang J, Du M. The characteristics of convective heat transfer in micro channel heat sinks using Al2O3 and TiO2 nanofluid. Int Commun Heat Mass Transfer. 2016;76:256–264. doi: 10.1016/j.icheatmasstransfer.2016.05.034. [DOI] [Google Scholar]

- Xiao J, Zheng H, Jin R, Liang S, Wang G, Ma X. Experimental investigation of a bubbling humidification-dehumidification desalination system directly heated by cylindrical Fresnel lens solar concentrator. Sol Energy. 2021;220:873–881. doi: 10.1016/j.solener.2021.04.006. [DOI] [Google Scholar]

- Yan C, Zou L, Short R. Single-walled carbon nanotubes and polyaniline composites for capacitive deionization. Desalination. 2012;290:125–129. doi: 10.1016/j.desal.2012.01.017. [DOI] [Google Scholar]

- Zhao H, Qiu S, Wu L, Zhang L, Chen H, Gao C. Improving the performance of polyamide reverse osmosis membrane by incorporation of modified multiwalled carbon nanotubes. J Membr Sci. 2014;450:249–256. doi: 10.1016/j.memsci.2013.09.014. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.