Abstract

When metals were added in a pulse mode to methylotrophic-methanogenic biomass, three methane production rate phases were recognized. Increased concentrations of Ni and Co accelerated the initial exponential and final arithmetic increases in the methane production rate and reduced the temporary decrease in the rate. When Ni and Co were added continuously, the temporary decrease phase was eliminated and the exponential production rate increased. We hypothesize that the temporary decrease in the methane production rate and the final arithmetic increase in the methane production rate were due to micronutrient limitations and that the precipitation-dissolution kinetics of metal sulfides may play a key role in the biovailability of these compounds.

Previous research (7, 19, 25, 27) has shown that metal deficiencies can limit the performance of anaerobic digestion systems and that metal supplementation may substantially improve the performance of such systems. In particular, the benefits of nutrient supplements during methanization of industrial wastewaters have been recognized (26, 27).

Methanogenesis from methanol is known to proceed by the following pathways: (i) methanol can be directly converted to methane by methylotrophs, (ii) methanol can be converted with bicarbonate to acetate by acetogens, and the acetate can be metabolized by acetoclastic methanogens, and (iii) methanol can be converted to H2 and CO2, which can be used by hydrogenophilic methanogens and/or acetogens to form methane and acetate, respectively (7). Methanosarcina type bacteria are responsible for direct conversion of methanol to methane, and Ni, Co, and Fe are components of the enzymes that catalyze many of the reactions of this methylotrophic pathway (4, 5, 10, 12, 28). It has been reported that metal supplementation may substantially improve anaerobic treatment of different types of waste streams (8, 9, 20, 27). However, the previously described metal additions that are optimal vary by several orders of magnitude (29). Furthermore, previously published information concerning the relationship between kinetic data and “optimum” metal concentrations is rather unclear. This is illustrated by the fact that for similar batch systems, the metal (Ni or Co) doses can vary from 0 to 40 μM (16, 21–23).

Since methanol-consuming methanogens have specific trace metal requirements and since many industrial waste streams contain methanol as an important contaminant, in the present study we examined the kinetics of methanol consumption by methanogenic biomass in the presence of different Ni and Co concentrations.

Anaerobic granular sludge from a full-scale expanded granular sludge bed, a Biobed EGSB reactor (location, Caldic Europort) developed by Biothane Systems (Delft, The Netherlands), was used. The sludge treated wastewater generated during production of formaldehyde. The waste stream contained primarily methanol and formaldehyde as organic substrates (30). To prevent mass transfer limitations, the granular structure was disrupted with a blender, and the sludge suspension obtained was used as the inoculum. The initial concentration of the inoculum expressed as the amount of volatile suspended solids (VSS) in the reactor, was 1.5 g liter−1. The standard medium used contained the following components: 15 mM NH4Cl, 7 mM KH2PO4, 4 mM MgSO4, 5 mM CaCl2, and 35.74 mM NaHCO3. This medium also contained yeast extract (100 mg/liter) and trace elements, which were present at the following concentrations: H3BO3, 4.03 μM; ZnCl2, 1.84 μM; CuCl2, 1.11 μM; MnCl2, 12.63 μM; (NH4)6Mo7O24, 0.2 μM; AlCl3, 1.86 μM; Na2SeO3, 3.12 μM; and FeCl2, 50 μM. Ni and Co were added as NiCl2 and CoCl2, respectively, at the concentrations indicated below. Methanol was used as the carbon source at an initial concentration of 208 mM (10 g of chemical oxygen demand [COD] per liter). The pH in each reactor during the experimental period was 7 to 7.2. All chemicals were analytical grade, and most chemicals were purchased from Merck (Darmstadt, Germany); yeast extract was purchased from Oxoid Unipath Ltd. (Hampshire, England).

The reactors used were completely stirred plastic vessels. They were filled with 2.5 liters of mineral medium and flushed with a 70% N2–30% CO2 mixture for 20 min, after which Na2S · 8H2O was added to a final concentration of 0.54 mM; finally, Ni and/or Co was added. After a 24-h period, in which we assumed that chemical equilibrium was established, the inoculum and methanol were added. The reactors were operated in batch mode in a temperature-controlled (30 ± 1°C) room. The biogas produced was passed through an Erlenmeyer flask filled with a 20% NaOH solution and then through a tube filled with soda lime pellets with thymol blue indicator. Finally, the gas was passed through a Mariotte flask system containing water for quantification of methane production. The methane produced was monitored continuously by measuring the weight of the displaced water with a pressure sensor (model QB 745; DS-Europe) connected to a programmable data logger system (model CR10; Campbell). The data were recorded every 10 s and were averaged over a 30-min interval. A personal computer programmed to function as a terminal emulator was used to communicate with the data logger. All assays were performed in duplicate.

To assess the main pathway of methanol conversion, methane production by the biomass during degradation of methanol was monitored in 250-ml serum bottles by adding specific inhibitors to 100 ml of the reaction medium in order to block different metabolic routes (6). The inhibitors used were bromoethanesulfonic acid and vancomycin, which were purchased from Sigma Chemical Co. (St. Louis, Mo.) and Janssen (Tilburg, The Netherlands), respectively. The biomass added (previously activated with methanol) contained 0.8 g of VSS liter−1; methanol and inhibitors were added at concentrations of 31 and 50 mM, respectively. The methanol, methane, volatile fatty acids (VFA), and hydrogen in the headspace were measured during the experiment. H2 and CH4 contents were determined as previously described (6). VFA and methanol contents were analyzed by the method of Kortekaas et al. (11), except that for methanol the temperature of the oven was 70°C. A spectrophotometric method (2) was used to routinely analyze preparations for the presence of formaldehyde. VSS contents were determined by standard methods (1). Granule samples were prepared and analyzed by scanning electron microscopy as described previously (29).

The equilibrium concentrations of dissolved and precipitated species were calculated with a chemical equilibrium program written in Turbo Pascal. Phosphate, carbonate, and sulfide species, including metal sulfide complexes, were included. The input concentrations were the concentrations in the standard medium used. The mass balances and reaction equations were solved iteratively by using the Newton-Raphson method. Most of the equilibrium constants were obtained from reference 24; the metal sulfide complex constants were obtained from reference 15.

Scanning electron microscopy observations showed that the predominant bacteria in the sludge were Methanosarcina type bacteria. This was confirmed by assessing the main metabolic route of methanol degradation. The results indicated that methanol was converted via direct methanogenesis and that methane formation through acetate or H2-CO2 did not play an important role.

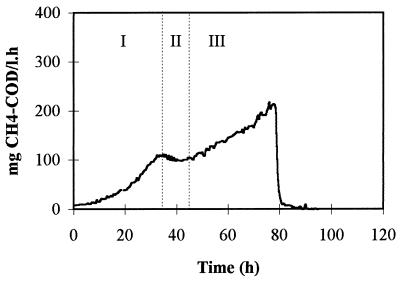

The kinetics of methanogenesis from methanol in the sludge were characterized by the following three phases: (i) an exponentially increasing rate (phase I), (ii) a temporary decrease in the rate (phase II), and (iii) an additional arithmetic increase in the rate (phase III) (Fig. 1). A possible explanation for the decrease in the rate was that the biomass was micronutrient limited. Hence, experiments with different Co and Ni additions were performed.

FIG. 1.

Methane production rate curve for methanol-degrading sludge. The following three phases were distinguished: (i) an exponential methane production rate (phase I), (ii) a decrease in the rate (phase II), and (iii) an additional arithmetic increase in the rate (phase III). Ni and Co were each added at a concentration of 1 μM.

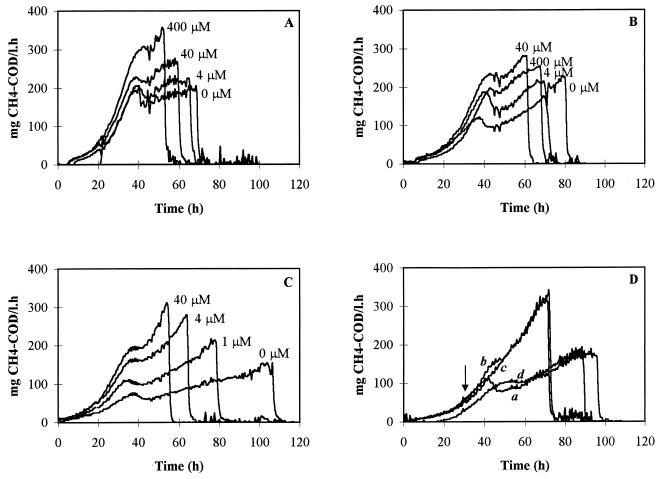

Either Ni or Co was added at a concentrations of 0, 4, 40, and 400 μM, while the other metal was added at a concentration of 40 μM. All of the curves showed that there was a decrease in the methane production rate after approximately 40 h (Fig. 2A and B). However, as the concentration of Co increased, the size of the temporary decrease in the methane production rate decreased and the slope of the arithmetic increase became greater (Fig. 2A). On the other hand, nickel concentrations of 4 and 40 μM increased the methane production rate during phase I (Fig. 2B). Furthermore, it seemed that nickel affected phase I most, whereas cobalt affected phase III most. However, in contrast to the cobalt experiments, addition of 400 μM nickel was inhibitory.

FIG. 2.

Methane production rate curves obtained with methanol. (A) Different initial Co concentrations. In all cases Ni was added at a concentration of 40 μM. (B) Different initial Ni concentrations. In all cases Co was added at a concentration of 40 μM. (C) Different Ni and Co concentrations added simultaneously. (D) Continuous addition of Ni and Co during methanol degradation. Different rates of addition were tested. The arrow indicates when the metals were first added. The rates at which the metals were added were 0 μmol h−1 (line a), 0.05 μmol h−1 (line b), 0.2 μmol h−1 (line c), and 2 μmol h−1 (line d).

Additions containing Ni plus Co were also tested. These micronutrients were simultaneously added at concentrations of 0, 1, 4, and 40 μM each. As in the previous experiments, the metals were added 24 h prior to inoculation. The results (Fig. 2C) clearly demonstrated that metal bioavailability was limited since as the amount of metal increased, the exponential growth during phase I increased, the temporary decrease in phase II was less pronounced, and the arithmetic rate of increase during phase III was faster. However, the observed limitations were not completely eliminated even with metals concentrations as high as 40 μM Ni and 40 μM Co. Therefore, continuous addition of the metals was studied to see whether micronutrient limitations could be overcome.

Co and Ni were added continuously at rates of 0, 0.05, 0.2, and 2 μmol h−1; hence, the concentrations in the reactor after 50 h of addition or an 80-h experimental period (the first doses were added after 30 h) were 0, 1, 4, and 40 μM, respectively. The results of this test are shown in Fig. 2D.

Doses of 0.05 and 0.2 μmol h−1 (1 and 4 μM, respectively) seemed to eliminate limitations, and the previously observed decrease in the methane production rate during phase II was not observed in these experiments. Also, the period of exponential increases in the methane production rate was extended. However, a dose of 2 μmol h−1 (40 μM) appeared to be inhibitory.

Rate curves having the shape shown in Fig. 1 and 2A to C can reflect either (i) limitations due to substrate or nutrient depletion or (ii) production of a toxic compound. The temporary decrease in the methane production rate could not be attributed to substrate limitations since in all cases the methanol concentration at 40 h was more than 3,000 mg of COD liter−1 and the reported apparent substrate affinity coefficient (Ks) for methylotrophic methanogens was 12 mg of COD liter−1 (6). Possible limitations due to the production of formaldehyde, which is a toxic compound and an intermediate (at the oxidation level) during the oxidation of methanol (10), were not detected. Furthermore, the limitations could not be attributed to macronutrient limitations since in separate experiments performed with different amounts of macronutrients the methane production rate was not affected (data not shown).

Spiked addition of metals.

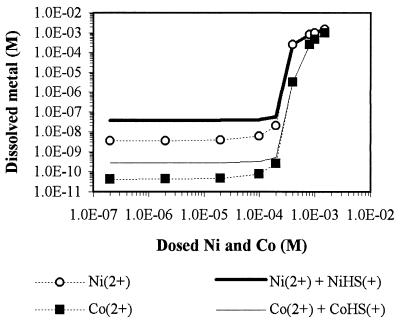

The results of this work clearly show that the biomass was nickel and cobalt limited. Two main theoretical aspects should be considered in order to understand the limitations observed. (i) Assuming that Methanosarcina barkeri Fusaro cells grown on methanol contained 0.135 and 0.06 mg of Ni and Co per g of cells, respectively (18), and that the yield was 0.088 g of cells/g of methanol COD (23), then 2 μM Ni and 0.89 μM Co would be required for conversion of the 10 g of methanol COD liter−1 added in the experiments (Table 1). According to this reasoning, addition of more than 2 μM metal should fulfill the nutrient requirements. However, as the spiked dose experiments showed, this was not the case, and the metals added (>2 μM) seemed to be not available for biomass since limitations were still observed. (ii) If it is assumed that there is chemical equilibrium, then the following trends can be expected: the calculated concentrations of free Ni and Co should increase sharply only when the initial dose of Ni and the initial dose of Co are more than 100 μM, corresponding to the moment that the amount of sulfide added becomes limiting for precipitation reactions (Fig. 3). Although metal sulfide complexes may be important soluble species at pH values greater than 7 (15), at metal concentrations below 100 μM the concentrations of dissolved metals that occur as (i) free metals (M2+), as well as and the concentrations of (ii) free metal plus sulfide complexes (MHS+), should be less than 0.01 and 0.05 μM, respectively (Fig. 3). If dissolution of the precipitated metals were negligible, these concentrations of dissolved metals would not fulfill the nutrient requirements, as indicated in Table 1. Therefore, we concluded that metal shortage must have been compensated for by dissolution of precipitated metal sulfides.

TABLE 1.

Calculated Ni and Co requirements for degradation of 10 g of methanol COD

| Metal | Concn in cells (mg/g of cells) | Yield (μmol of metal/g of cells) | Amt required (μmol/g of COD) | Amt required in phase I (μmol/3 to 6 g of COD)a | Amt required (μmol/10 g of COD) |

|---|---|---|---|---|---|

| Ni | 0.135 | 2.3 | 0.2b | 0.6–1.2 | 2 |

| Co | 0.06 | 1.02 | 0.089b | 0.27–0.5 | 0.89 |

| Ni | 0.1059c | 0.3–0.6 | 1.059 | ||

| Co | 0.084c | 0.25–0.5 | 0.84 |

In general, during phase I approximately 3 to 6 g of COD methanol per g of cells is consumed.

Value calculated by using the cell metal composition reported by Scherer et al. (18) and by assuming that the yield was 4.23 g of cells/mol of methanol (0.088 g of cells/g of COD), as described by Silveira et al. (22).

Experimental value reported by Nishio et al. (17).

FIG. 3.

Calculated equilibrium dissolved metal concentrations with different initial doses of Ni and Co.

Based on these considerations, the general trend in the methane production rate (Fig. 1) can be explained as follows. During the first 30 to 40 h of the process (phase I), readily dissolved precipitates provide the required nutrients, which results in an exponential increase in the methane production rate of the methylotrophic population. However, if the metal uptake rate is higher than the rate of dissolution, then metal-limited conditions for the bacteria prevail. This situation occurred during phase III, when the growth rate increased arithmetically; this increase was determined by the rate of dissolution of metal sulfides. The temporary decrease in the methane production rate (phase II) may have been due to severe metal limitation that was even greater than that in phase III, suggesting that in addition to bacterial growth the specific methane conversion rate is affected by limiting concentrations of Co and/or Ni. It should be noted that different types of precipitates of the same metal can be present in a system (some compounds dissolve faster than others) and that the dissolution rate of a specific metal sulfide may not be constant since it depends on the total surface area.

Continuous addition of metals.

Nutrient limitations can be overcome if the essential metals are added continuously at a proper rate so that their availabilities in solution can fulfill the requirement for biomass activity and growth. The results obtained in the continuous addition experiments clearly show this effect and thus indicate the importance of the dissolution rate kinetics of metal sulfide precipitates in anaerobic digestion processes.

When the metals were added continuously at a rates of 0.05 to 0.2 μmol h−1, the temporary decrease in the methane production rate was eliminated and the period of exponential production was extended (Fig. 2D). These rates of addition corresponded to metal concentrations of 1 to 4 μM and agree well with the calculated metal requirements based on the biomass yield and Ni and Co contents of biomass (Table 1) for Methanosarcina spp. grown on methanol. Other studies have also shown that when essential nutrients are added continuously in fed batch systems, the period of exponential growth of M. barkeri is drastically extended compared to a system in which nutrients are added in one dose (17). Thus, when the amount of substrate is not limiting, metal dissolution might become the rate-limiting step.

Practical implications.

During operation of a continuous reactor, less metal may be required than the amount required in a batch system, because more biological ligands may be produced (3, 13, 14) and because continuous addition of nutrients ensures free metal availability for biomass uptake. In practice, in view of the clear evidence that supplying metal enhances the treatment of several effluents, there is a tendency to add nutrients in excessive amounts. This could lead to inhibitory effects on the biomass and/or to metal accumulation in the sludge. Hence, in order to determine a more rational way to add essential metals, studies to understand the process kinetics of precipitation and dissolution in anaerobic systems in combination with the kinetics of nutrient uptake by the microorganisms are necessary. In this paper we show that a rational supply of metals can be achieved, which in turn may open the possibility of either enhancing or diminishing the production of biomass depending on the treatment and remediation needs.

On-line CH4 monitoring.

With on-line measurements of methane production very detailed kinetic information can be obtained. To our knowledge, there are no previous reports of kinetic data being analyzed by on-line measurement of the CH4 production rate. Furthermore, the informative value of the results can be maximized when rate-time curves are plotted instead of cumulative curves for CH4 production.

Accurate rate data can be obtained only by on-line measurements. The observed decrease and subsequent increase in the rate (Fig. 1, phase II) would have been overlooked with cumulative plots or may have been treated as an analytical error.

Finally, although kinetic data are commonly assessed by assuming that only carbon is limited, discrepancies in previously reported kinetic constants could be due to nutrient limitations in batch experiments, as shown in this study. This suggests that straightforward comparisons of previously published kinetic parameter data are not possible.

Acknowledgments

We thank Merle de Kreuk for help during experimental work and Herman van Leeuwen and Jim Field for valuable discussions.

This work was supported by Biothane Systems International, Delft, The Netherlands.

REFERENCES

- 1.American Public Health Association. Standard methods for examination of water and wastewater. 16th ed. Washington, D.C: American Public Health Association; 1985. [Google Scholar]

- 2.Bailey B W, Rankin J M. New spectrophotometric method for determination of formaldehyde. Anal Chem. 1971;43:782–784. doi: 10.1021/ac60301a050. [DOI] [PubMed] [Google Scholar]

- 3.Becker U, Peiffer S. Heavy-metal ion complexation by particulate matter in the leachate of solid waste: a multi-method approach. J Contam Hydrol. 1997;24:313–344. [Google Scholar]

- 4.Deppemier U, Müller V, Gottschalk G. Pathways of energy conservation in methanogenic archaea. Arch Microbiol. 1996;165:149–163. [Google Scholar]

- 5.Diekert G, Konheiser U, Piechulla K, Thauer R K. Nickel requirement and factor F430 content of methanogenic bacteria. J Bacteriol. 1981;148:459–464. doi: 10.1128/jb.148.2.459-464.1981. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Florencio L, Field A J, Lettinga G. The importance of cobalt for individual trophic groups in an anaerobic methanol-degrading consortium. Appl Environ Microbiol. 1994;60:227–234. doi: 10.1128/aem.60.1.227-234.1994. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Florencio L, Jenicek P, Field A J, Lettinga G. Effect of cobalt on the anaerobic degradation of methanol. J Ferment Bioeng. 1993;75:368–374. [Google Scholar]

- 8.Hoban D J, van den Berg L. Effect of iron on conversion of acetic acid to methane during methanogenic fermentations. J Appl Bacteriol. 1979;47:153–159. doi: 10.1111/j.1365-2672.1979.tb01179.x. [DOI] [PubMed] [Google Scholar]

- 9.Kelly C R, Switzenbaum M S. Anaerobic treatment: temperature and nutrient effects. Agric Wastes. 1984;10:135–154. [Google Scholar]

- 10.Keltjens J T, van der Drift C. Electron transfer reactions in methanogens. FEMS Microbiol Rev. 1986;39:259–303. [Google Scholar]

- 11.Kortekaas S, Vidal G, Yan-Ling H, Lettinga G, Field J A. Anaerobic-aerobic treatment of toxic pulping black liquor with upfront effluent recirculation. J Ferment Bioeng. 1998;86:97–110. [Google Scholar]

- 12.Kräutler B. Chemistry of methylcorrinoids related to their roles in bacterial C1 metabolism. FEMS Microbiol Rev. 1990;87:349–354. doi: 10.1111/j.1574-6968.1990.tb04935.x. [DOI] [PubMed] [Google Scholar]

- 13.Kuo W C, Parkin G F. Characterization of soluble microbial products from anaerobic treatment by molecular weight distribution and nickel-chelating properties. Water Res. 1996;30:915–922. [Google Scholar]

- 14.LaPaglia C, Hartzell P L. Stress-induced production of biofilm in the hyperthermophile Archaeoglobus fulgidus. Appl Environ Microbiol. 1997;63:3158–3163. doi: 10.1128/aem.63.8.3158-3163.1997. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Luther G W, Rickard D T, Theberge S, Olroyd A. Determination of metal (bi)sulfide stability constants of Mn2+, Fe2+, Co2+, Ni2+, Cu2+, and Zn2+ by voltammetric methods. Environ Sci Technol. 1996;30:671–679. [Google Scholar]

- 16.Maestrojuán G M, Boone D R. Characterization of Methanosarcina barkeri MST and 227, Methanosarcina mazei S-6T, and Methanosarcina vacuolata Z-761T. Int J Syst Bacteriol. 1991;41:267–274. [Google Scholar]

- 17.Nishio N, Kakizono T, Silveira R G, Takemoto S, Nagai S. Nutrient control by the gas evolution in methanogenesis of methanol by Methanosarcina barkeri. J Ferment Bioeng. 1992;73:481–485. [Google Scholar]

- 18.Scherer P, Lippert H, Wolff G. Composition of the major elements and trace elements of 10 methanogenic bacteria determined by inductively coupled plasma emission spectrometry. Biol Trace Element Res. 1983;5:149–163. doi: 10.1007/BF02916619. [DOI] [PubMed] [Google Scholar]

- 19.Scherer P, Sahm H. Effect of trace elements and vitamins on the growth of Methanosarcina barkeri. Acta Biotechnol. 1981;1:57–65. [Google Scholar]

- 20.Shen C F, Korsaric N, Blaszczyk R. Properties of anaerobic granular sludge as affected by yeast extract, cobalt and iron supplements. Appl Microbiol Biotechnol. 1993;39:132–137. [Google Scholar]

- 21.Silveira R G, Kakizono T, Takemoto S, Nishio N, Nagai S. Medium optimization by an orthogonal array design for the growth of Methanosarcina barkeri. J Ferment Bioeng. 1991;72:20–25. [Google Scholar]

- 22.Silveira R G, Nishio N, Nagai S. Growth characteristics and corrinoid production of Methanosarcina barkeri on methanol-acetate medium. J Ferment Bioeng. 1991;71:28–34. [Google Scholar]

- 23.Smith M R, Mah R A. Growth and methanogenesis by Methanosarcina strain 227 on acetate and methanol. Appl Environ Microbiol. 1978;36:870–879. doi: 10.1128/aem.36.6.870-879.1978. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Smith R M, Martell A E. Critical stability constants. 4. Inorganic complexes. New York, N.Y: Plenum Press; 1976. [Google Scholar]

- 25.Speece R E, Parkin G F, Gallagher D. Nickel stimulation of anaerobic digestion. Water Res. 1983;17:677–683. [Google Scholar]

- 26.Speece R E, Parkin G F, Bhattacharya S, Takashima M. Proceedings of the European Water Pollution Control Association Conference on Anaerobic Waste Water Treatment 1986. Schiedam, The Netherlands: Industrial Presentations B. V.; 1986. Trace nutrient requirements of anaerobic digestion; pp. 177–188. [Google Scholar]

- 27.Takashima M, Speece R E. Mineral requirements for methane fermentation. Crit Rev Environ Control. 1990;19:465–479. [Google Scholar]

- 28.Thauer R. Biodiversity and unity in biochemistry. Antonie Leeuwenhoek. 1997;71:21–32. doi: 10.1023/a:1000149705588. [DOI] [PubMed] [Google Scholar]

- 29.van Houten R T, Oude-Elferink S J W H, van Hamel S E, Hulshoff Pol L W, Lettinga G. Sulphate reduction by aggregates of sulphate reducing bacteria and homo-acetogenic bacteria in a lab-scale gas-lift reactor. Biores Technol. 1995;54:73–79. [Google Scholar]

- 30.Zoutberg G R, de Been P. The biobed EGSB (expanded granular sludge bed) system covers shortcomings of the upflow anaerobic sludge blanket reactor in the chemical industry. Water Sci Technol. 1997;35:183–188. [Google Scholar]