Abstract

Unheated spores of nonproteolytic Clostridium botulinum were able to lead to growth in sterile deoxygenated turnip, spring green, helda bean, broccoli, or potato juice, although the probability of growth was low and the time to growth was longer than the time to growth in culture media. With all five vegetable juices tested, the probability of growth increased when spores were inoculated into the juice and then heated for 2 min in a water bath at 80°C. The probability of growth was greater in bean or broccoli juice than in culture media following 10 min of heat treatment in these media. Growth was prevented by heat treatment of spores in vegetable juices or culture media at 80°C for 100 min. We show for the first time that adding heat-treated vegetable juice to culture media can increase the number of heat-damaged spores of C. botulinum that can lead to colony formation.

Clostridium botulinum is an anaerobic spore-forming pathogen which can grow and produce a lethal toxin in food. Nonproteolytic C. botulinum is physiologically and phylogenetically distinct from proteolytic C. botulinum (15). Unlike proteolytic strains, which do not grow at temperatures below 10°C, nonproteolytic C. botulinum strains can grow and produce toxin at 3.0°C (14). The importance of this organism has, therefore, increased with the expansion of the chilled-food market. Nonproteolytic C. botulinum is a particular concern in cooked chilled foods with long shelf lives. These products are often pasteurized and then stored at chill temperatures in a vacuum or an anaerobic atmosphere. There is a risk that the combination of heat treatment and refrigerated anaerobic storage, which is designed to prevent growth of non-spore-forming pathogens and spoilage organisms, may allow nonproteolytic C. botulinum to grow with little competition, while an extended shelf life provides additional time for toxin production.

The potential for cooked chilled food to cause botulism depends on the ability of C. botulinum to survive heat treatment in a product and subsequently grow and produce toxin in the resulting product during storage. The ability of C. botulinum to survive heat treatment depends on many factors, including the intrinsic parameters of the heating and recovery media (17). Although thermal destruction of spores of nonproteolytic C. botulinum has been studied in buffer and meat (20), survival in vegetables has not been examined previously. One factor that can greatly increase the measured heat resistance is lysozyme. Heat damages part of the germination system in spores of nonproteolytic C. botulinum, such that the heat-damaged spores remain dormant unless they are incubated in the presence of an enzyme capable of cleaving the peptidoglycan of the spore cortex (20). Many foods of both plant and animal origin have endogenous lysozyme activity (20, 23, 28) and so may increase the recovery of heat-damaged spores. Recently, raw vegetable juice has been shown to increase the measured heat resistance of spores of nonproteolytic C. botulinum (28). In a heat-processed product both spores and food enzymes are heated. It is, therefore, important to determine whether any cortex-degrading enzymes present in raw food survive the heat treatments. The thermal stability of hen egg white lysozyme (HEWL) depends on the composition of the heating medium; HEWL is most stable in an acidic solution, while it is less stable when it is heated in egg white or skim milk (8). When 10 μg of HEWL ml−1 was added to meat medium, sufficient activity remained after heat treatment at 95°C for 15 min to aid growth from heat-damaged spores of nonproteolytic C. botulinum (25). The properties of endogenous lysozymes, some of which may be primarily chitinases, can differ from the properties of HEWL (4, 23). The effect of heat treatment on the ability of lysozymes other than HEWL to induce germination of spores of nonproteolytic C. botulinum has not been described. This is important because, in sealed packages, enzymatic activity must survive heat treatments that damage spores if it is to induce germination of the damaged spores. The importance of this was emphasized by the European Chilled Food Federation Botulinum Working Party, which concluded that more information on the effects of endogenous lysozymes was urgently required (12).

The view has been expressed that vegetables are poor substrates for growth of nonproteolytic C. botulinum (22). Recently, it has been shown that raw broccoli (18) and many cooked vegetables (5) support growth of nonproteolytic C. botulinum and that the time to toxin production in these vegetables at refrigeration temperatures could be similar to the time to toxin production in other food types (6). However, the ability of heat-treated, possibly damaged, spores to grow on vegetables has not been studied previously. Vegetable media used for both heat treatment and subsequent incubation have the additional complication that some properties of vegetables, including endogenous lysozyme activity if it is present, are affected by heat.

The multitude of interacting factors that can influence both spore heat resistance and subsequent germination, growth, and toxin production make it difficult to predict accurately whether spores of nonproteolytic C. botulinum will lead to growth in cooked vegetables. In this study our goal was to measure the ability of spores of nonproteolytic C. botulinum to survive heat treatment in vegetable juices and then lead to growth in the resulting vegetable juices. As thermal sterilization damages endogenous lysozymes, filter sterilization was combined with a novel reduced-pressure boiling method to prepare sterile oxygen-free vegetable juices. Experiments were also performed to generate information concerning individual components of the experimental system. Heat treatments were performed in a standard menstruum, phosphate buffer, as well as in vegetable juices so that we could compare our data with previously published thermal destruction data. Heat-treated spores were enumerated on agar with or without HEWL added in order to determine the proportion of spores in which germination could be induced by lysozyme. The number of heat-damaged spores that led to colony formation on a standard medium or media supplemented with heat-treated vegetable juice was determined to assess the effect of heat treatment on the ability of vegetable juice to increase the number of heat-damaged spores recovered. The ability of spores to survive heat treatment and subsequently lead to growth at 10°C was also tested. While growth studies performed at 30°C allowed us to determine the maximum potential of a medium to support growth of C. botulinum, the potential for growth in refrigerated products is less (29). It is important to keep cooked chilled products at temperatures below 10°C to prevent growth of the heat-resistant proteolytic C. botulinum strains.

MATERIALS AND METHODS

Enumeration of spores heated in deoxygenated media and then incubated in the same media at 30°C.

To determine the number of spores that survived heat treatment in vegetable juice or culture medium and then led to growth in the same medium incubated at 30°C, replicate samples were inoculated with different concentrations of spores, subjected to a heat treatment if required, and then observed to determine whether growth occurred.

(i) Spore preparation.

Nonproteolytic C. botulinum Eklund 17B (NCIB 10642) was used in this study. This type B strain was originally obtained from the National Collection of Industrial Bacteria, Aberdeen, United Kingdom. Spores were produced with a two-phase medium and washed as previously described (24). The washed spores were resuspended in 5 ml of sterile distilled water, enumerated on peptone-yeast extract-glucose-starch (PYGS) agar, and stored at 2°C until they were used.

(ii) Preparation of sterile deoxygenated media by the reduced-pressure boiling method.

The following seven types of deoxygenated media were used in the growth study: turnip (Brassica rapa) juice; spring green (Brassica oleracea) juice; helda bean (Phaseolus vulgaris) juice; broccoli (Brassica oleracea) juice; potato (Solanum tuberosum) juice; PYGS broth (19); and PYGS broth containing 10 μg of HEWL (48,000 U mg−1; Sigma, Poole, United Kingdom) ml−1 (PYGSL broth).

The growth study media were prepared by using a novel reduced-pressure deoxygenation method. Vegetables, purchased from a local retail outlet, were roughly chopped and passed through a juice extractor (Kenwood model JE600). Broth (800 ml) or fresh vegetable juice (800 ml) and resazurin (4 ml; 0.02% [wt/vol]), a redox indicator, were added to a steel jar that had been preheated in a water bath at 58°C. When the temperature of the liquid reached 55°C, the jar was evacuated until the pressure was 20 kPa, and then the jar was filled with an anaerobic gas mixture (10% hydrogen, 90% nitrogen) until the pressure was 121 kPa. This cycle of evacuation followed by gas flushing was repeated four times, and then the jar was continuously evacuated for 15 min. During evacuation the temperature of the liquid remained 55°C. Finally, the jar was flushed with anaerobic gas and evacuated an additional four times, filled with gas, sealed, and placed in a bath containing ice and water. When it was cool, the jar containing the deoxygenated medium was placed in an anaerobic cabinet filled with an atmosphere containing 5% carbon dioxide, 10% hydrogen, and 90% nitrogen. All subsequent manipulations were performed under this atmosphere, either in an anaerobic cabinet or in sealed tubes. The deoxygenated medium was centrifuged (30,100 × g, 45 min, 2°C) to remove the precipitate, and the supernatant was passed through nitrocellulose membrane filters having pore sizes of 0.65, 0.45, and 0.2 μm (Whatman, Maidstone, United Kingdom). Aliquots (5 ml) of the clarified medium were filter sterilized with 0.2-μm-pore-size nitrocellulose filters (Whatman) and placed in sterile 10-ml serum vials (Pierce and Warriner, Chester, United Kingdom); each vial contained a Durham tube. The prepared vials were stored at 2°C until they were used.

(iii) Redox potentials, pH values, and lysozyme activities of deoxygenated media.

The pH values of unheated and heated deoxygenated media were determined in triplicate by using an Orion model 520A pH meter equipped with a Ross sureflow semimicro combination electrode (Orion Research Ltd., East Sussex, United Kingdom). The redox potentials were measured under a continuous flow of anaerobic gas (10% hydrogen, 90% nitrogen) by using a redox probe connected to the same meter, and the standard redox potential was calculated as previously described (11). The lysozyme activities of fresh vegetable juices, deoxygenated juices, and heat-treated juices were determined by measuring the decreases in turbidity of suspensions of Micrococcus lysodeikticus cells as previously described (28), except that up to 400 μl of sample was used.

(iv) Other media.

Serial dilutions of spores were prepared in sterile deoxygenated water. The water was prepared by boiling distilled water containing resazurin (0.0001%, wt/vol) at atmospheric pressure and then letting it cool under an anaerobic atmosphere (10% hydrogen, 90% nitrogen). When the water was cool, cysteine HCl was added to a final concentration of 0.02% (wt/vol), and 9-ml aliquots of the deoxygenated water were dispensed into 15-ml serum vials under a headspace containing the same gas. The sealed vials were heat sterilized at 121°C for 15 min. Sorenson’s phosphate buffer (0.067 M, pH 7.0) was prepared in a similar manner, except that 5-ml aliquots were dispensed into 10-ml serum vials.

(v) Heat treatment.

A 10-fold dilution series of spores of C. botulinum Eklund 17B was prepared in deoxygenated water so that the most concentrated spore suspension contained approximately 107 spores ml−1 and the most dilute spore suspension contained approximately 1 spore ml−1. Aliquots (100 μl) of each spore suspension were inoculated into five replicate vials containing each test medium immediately before each heat treatment. Four treatments were used; vials were not heated or were fully submerged in a water bath at 80°C for 2, 10, or 100 min and then cooled in an ice and water slurry. The temperature of the liquid in eight control vials containing 5 ml of water was measured every 5 s by using thermocouples as previously described (10). When the temperature in all of the vials monitored was less than 10°C, the inoculated vials were transferred to an incubator at 30°C. The lethality of each heat treatment for spores of nonproteolytic C. botulinum was calculated in terms of the equivalent time at the target temperature (80°C) as previously described (10) by using a z value of 6°C (10). Uninoculated vials containing each medium were subjected to each heat treatment and were used for pH, redox, and lysozyme activity measurements.

Heated and unheated vials containing inoculated media were incubated at 30°C for 98 days. These vials were checked for signs of growth (gas formation or turbidity) daily for 1 week, three times a week for the next 8 weeks, and then weekly for the remainder of the incubation period. The number of spores that survived the heat treatment and subsequently led to growth during each observation period was determined from the number of vials in which growth occurred with a five-tube most-probable-number (MPN) procedure (16). The log probability of growth was calculated as follows: log(P) = log(MPN)-log(CFU), where P is the probability of growth from any individual spore in a population, MPN is the MPN of spores leading to growth under the test conditions, and CFU is the number of unheated spores leading to colony formation on PYGS agar.

(vi) ELISA used to confirm growth or toxin production by C. botulinum.

An enzyme-linked immunosorbent assay (ELISA) for C. botulinum toxin (27) modified as described previously (29) was used to determine if growth or toxin production occurred during incubation at 10 or 30°C for 98 days. This assay can detect toxin types A, B, E, and F and is very sensitive, but the trivalent antiserum on which it is based may also recognize inactive toxin, hemagglutinin, or somatic antigens (27). In this experiment the ELISA was used to confirm that growth or toxin production had occurred. Samples from at least five vials inoculated with the fewest spores that led to visible growth and five vials containing the greatest number of spores that did not lead to visible growth were tested for each combination of medium and heat treatment. Samples with an absorbance at 492 nm of >1.5 were considered positive, and samples with an absorbance at 492 nm of <0.2 were considered negative. The seven media tested immediately after inoculation with 106 spores ml−1 were used as negative controls, and media mixed with 1% (vol/vol) PYGS broth in which C. botulinum had grown were used as positive controls.

Growth from spores heated in deoxygenated media and then incubated in the same media at 10°C.

To assess the ability of spores to survive heat treatment and then lead to growth at 10°C in deoxygenated medium, three replicate vials containing each of the seven media were inoculated with 100 μl of spore suspension (approximately 106 spores vial−1) and subjected to one of the four heat treatments described above (28 combinations). The vials were observed to determine whether growth occurred at the same times that the vials in the MPN enumeration study conducted at 30°C were observed, and the presence or absence of growth or toxin production within 98 days at 10°C was confirmed in all vials by using the ELISA.

Thermal destruction of spores heated in buffer.

Four vials containing Sorenson’s phosphate buffer (5 ml) were each inoculated with 100 μl of a spore suspension (approximately 106 spores vial−1), and one vial was subjected to each heat treatment simultaneously with vials containing inoculated media. Decimal serial dilutions of unheated or heat-treated spores were prepared in PYGS broth by using a strictly anaerobic technique, and 100-μl triplicate samples were spread onto PYGS and PYGSL agar plates. The plates were incubated at 30°C under a headspace containing 90% hydrogen and 10% carbon dioxide, and colonies were enumerated after 8 days.

Measured heat resistance of coat-permeabilized spores incubated on agar containing heated vegetable juice.

The ability of pasteurized vegetable juice to increase the measured heat resistance of spores of nonproteolytic C. botulinum was assessed by plating heat-damaged, coat-permeabilized spores onto agar containing unheated or heated vegetable juice. Fresh broccoli juice and flat bean juice were centrifuged (24,000 × g, 30 min, 2°C), and the supernatants were filtered through 0.65-μm-pore-size nitrocellulose membrane filters. Portions (150 ml) of filtered juice or an HEWL solution (10 μg ml−1) were dispensed into glass bottles and then heated in a water bath at 75°C for 10 min and cooled in an ice and water slurry. Unheated and heat-treated vegetable juices and HEWL solutions were centrifuged (24,000 × g, 30 min, 2°C), and the supernatants were passed through nitrocellulose membrane filters having pore sizes of 0.65, 0.45, and 0.2 μm. Aliquots (100 ml) were filter sterilized with 0.2-μm-pore-size nitrocellulose filters and stored frozen at −18°C until they were used. The lysozyme activity of each filtered juice was analyzed by performing the M. lysodeikticus assay as described above. Double-strength PYGS agar (100 ml) was heat sterilized (121°C, 15 min), cooled to 50°C, mixed with an equal volume of filter-sterilized vegetable juice, HEWL solution, or distilled water (warmed to 50°C), and poured into petri dishes. All of the plates were stored in gas jars under a headspace containing 10% hydrogen and 90% carbon dioxide for 48 h before they were used.

Spores were treated with sodium thioglycolate to increase the permeability of the spore coat to lysozyme (20). A 250-μl suspension of washed spores of C. botulinum Eklund 17B was injected into 10 ml of a 1 M sodium thioglycolate solution (pH 10.0) that had been preheated to 45°C. After 10 min, the spores were harvested by centrifugation (10,000 × g, 15 min, 4°C) and washed five times in 0.1 M sodium phosphate buffer (pH 7.0). The washed spores were heated in the same buffer at 90°C for 3 min by using a submerged tube heating method (24). Serial dilutions of treated spores prepared in anaerobic PYGS broth were plated onto each type of medium in triplicate. The inoculated plates were incubated at 30°C in anaerobic jars under a headspace containing 90% hydrogen and 10% carbon dioxide, and colonies were enumerated after 8 days.

RESULTS

Lethality of heat treatments.

Heat treatments in vials submerged in a water bath at 80°C for 2, 10, and 100 min had the same lethality to spores of nonproteolytic C. botulinum as heat treatments at 80°C for 0.1, 5.7, and 100 min, if it was assumed that the z value was 6°C. It was not possible to calculate the effect of heat-up and cool-down on the activity of vegetable enzymes in this system as the relationship between temperature and destruction is not known (i.e., a number equivalent to the z value is not available).

Thermal destruction of spores heated in buffer.

The numbers of spores of C. botulinum Eklund 17B per vial of phosphate buffer that led to colony formation following heat treatment in a water bath at 80°C for 0, 2, 10, and 100 min were 6.9 × 105, 7.2 × 105, <100, and <100, respectively, when incubated on PYGS agar without HEWL and 7.8 × 105, 7.1 × 105, 3.7 × 102, and 4.7 × 102, respectively, when incubated on PYGS agar supplemented with 10 μg of HEWL ml−1. This illustrates that under optimum recovery conditions, spores could survive the heat treatments used in this experiment and subsequently lead to growth.

Redox potentials, pH values, and lysozyme activities of deoxygenated media.

The lysozyme activities of the media before and after reduced-pressure deoxygenation are shown in Table 1. Only PYGSL broth exhibited measurable lysozyme activity after the heat treatment at 55°C used to achieve deoxygenation. This residual activity was reduced during subsequent heat treatment in a water bath at 80°C and was 4.0 and <0.2 μg of HEWL ml−1 after 2 and 10 min of treatment, respectively. The pH values of the deoxygenated media were between 5.5 and 7.0 before heat treatment at 80°C (Table 1), and most of the pH values were the same after heat treatment; the only exception was the pH of spring green juice, which decreased from 5.5 in unheated juice to 5.3 in juice heated in a water bath at 80°C for 100 min. The differences between replicates were less than 0.05 pH unit. The standard redox potentials were between −99 and −155 mV (Table 1). Resazurin was colorless, showing that it was in the reduced form.

TABLE 1.

Lysozyme activities of fresh media and lysozyme activities, pH values, and redox potentials of deoxygenated media

| Medium | Lysozyme activity of fresh medium (equivalent μg of HEWL ml−1) | Deoxygenated medium

|

||

|---|---|---|---|---|

| Lysozyme activity (equivalent μg of HEWL ml−1) | pH | Standard redox potential (mV) | ||

| PYGS broth | <0.2 | <0.2 | 6.9 | −186 |

| PYGSL broth | 9.5 | 8.7 | 7.0 | −198 |

| Helda bean juice | <0.2 | <0.2 | 6.2 | −99 |

| Potato juice | <0.2 | <0.2 | 5.9 | −105 |

| Turnip juice | 23.5 | <0.2 | 5.8 | −155 |

| Spring green juice | 4.9 | <0.2 | 5.5 | −145 |

| Broccoli juice | 0.2 | <0.2 | 6.1 | −112 |

The reduced-pressure boiling method developed to deoxygenate media in this work decreased the redox potentials of the media but also affected their compositions; enzymatic activity decreased, as shown by the reduction in lysozyme activity, and precipitates formed and were discarded. The amount of precipitate depended on the medium. Precipitates were not formed in PYGS or PYGSL broth. Precipitates were formed in all of the vegetable juices, but to different extents; copious precipitate formed in potato juice. The heat treatment used during deoxygenation was not sufficient to destroy all of the enzyme activity or to prevent later precipitation. For example, deoxygenated filtered potato juice was a colorless, transparent liquid but rapidly turned black after exposure to oxygen, suggesting that active oxidases were present (3). Heating deoxygenated potato juice in a water bath at 80°C for 2 min resulted in further precipitate formation and prevented blackening after subsequent exposure to oxygen.

MPN of spores leading to growth after heat treatment in deoxygenated media and incubation in the same media at 30°C.

Unheated spores led to growth in all of the deoxygenated media tested, but the probability of growth was lower in the vegetable juices than in PYGS or PYGSL broth (Table 2). Turnip, potato, and spring green juices were particularly poor at supporting growth; the probability of growth resulting from any one spore in a population was less than 10−6.

TABLE 2.

Effects of heat treatment and subsequent incubation in different media on the log probability of growth from spores of nonproteolytic C. botulinum Eklund 17B incubated at 30°C for up to 98 days

| Medium | Log probability of growth following submergence in a water bath at 80°C fora:

|

|||

|---|---|---|---|---|

| 0 min | 2 min | 10 min | 100 min | |

| PYGS broth | 0.05 | 0.25 | −4.97 | <−6.57 |

| PYGSL broth | −0.35 | >−0.47 | −3.35 | <−6.57 |

| Helda bean juice | −2.64 | −1.75 | −4.21 | <−6.57 |

| Potato juice | −6.57 | −4.72 | <−6.57 | <−6.57 |

| Turnip juice | −6.26 | −6.21 | <−6.57 | <−6.57 |

| Spring green juice | −6.57 | −5.85 | <−6.57 | <−6.57 |

| Broccoli juice | −1.76 | −1.13 | −4.76 | <−6.57 |

Log probability = log (MPN of spores leading to growth in test medium) − log (number of unheated spores able to form colonies on PYGS agar). The lethalities of the treatments in a water bath for 2, 10, and 100 min to spores of nonproteolytic C. botulinum were equivalent to those of heat treatments at 80°C for 0.1, 5.7, and 100 min, respectively, assuming that the z value was 6°C.

In all cases, the probability that a spore would lead to growth in vegetable juice after 2 min of heat treatment in a water bath at 80°C was greater than the probability that a spore would lead to growth in the same juice without heat treatment but was less than the probability that a spore would lead to growth in PYGS or PYGSL (Table 2). The probability that a spore would lead to growth in deoxygenated medium heated for 10 min was less than the probability that a spore would lead to growth in the same medium heated for 2 min. The number of spores that led to growth at 30°C in bean juice, broccoli juice, or PYGSL broth following 10 min of heat treatment in a water bath at 80°C was greater than the number of spores that led to growth in PYGS broth subjected to the same treatment. Spores heated at 80°C for 100 min did not lead to growth in 98 days at 30°C when they were heated and then incubated in the same medium (Table 2).

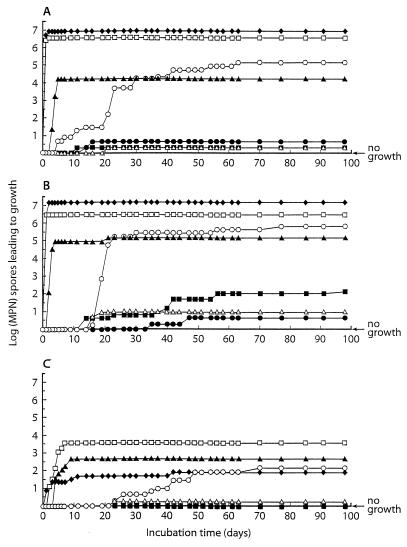

The effect of incubation time on the MPN of spores that led to growth is shown in Fig. 1. The shortest time to growth from spores subjected to each heat treatment was longer in vegetable juice than in PYGS (Table 3), even when the final probability of growth was higher in the vegetable juice. Growth occurred within a relatively short period of time in all replicates of PYGS or PYGSL broth incubated at 30°C; all of the vials containing unheated spores or spores heated for 2 min in a water bath at 80°C were positive for growth between days 1 and 3, and virtually all growth from spores heated for 10 min occurred within 11 days. Only one vial containing PYGS or PYGSL broth became turbid between days 11 and 98. The distribution of times to growth was much wider for spores in vegetable juices. However, growth in an individual vial containing either deoxygenated vegetable juice or PYGS broth seemed to occur very rapidly once it began; one day there was no sign of growth, and the next day the medium was turbid and a large amount of gas had been produced.

FIG. 1.

Effect of medium on the number of spores of nonproteolytic C. botulinum Eklund 17B able to survive heat treatment at 80°C and then lead to growth in the same medium at 30°C. Up to 7 × 105 spores were inoculated into deoxygenated, filter-sterilized PYGS broth (⧫), PYGSL broth (□), helda bean juice (▴), broccoli juice (○), turnip juice (●), potato juice (■), and spring green juice (▵). The inoculated media were not (A) or were heated in a water bath at 80°C for 2 min (B), 10 min (C), or 100 min and then were incubated at 30°C. No growth occurred in media heated for 100 min. The lethalities of the treatments in the water bath for 2, 10, and 100 min to spores of nonproteolytic C. botulinum were equivalent to those of heat treatments at 80°C for 0.1, 5.7, and 100 min, respectively, assuming that the z value was 6°C.

TABLE 3.

Effects of heat treatment and subsequent incubation in media at 10 or 30°C on time to growth resulting from up to 7 × 105 spores of the nonproteolytic strain C. botulinum Eklund 17B

| Incubation temp (°C) | Medium | Minimum time to growth (days) following heat treatment in a water bath at 80°C fora:

|

|||

|---|---|---|---|---|---|

| 0 min | 2 min | 10 min | 100 min | ||

| 10 | PYGS broth | 4+ | 4+ | 9+ | NG− |

| PYGSL broth | 4+ | 4+ | 9+ | NG− | |

| Helda bean juice | NG+ | 61+ | 85+ | NG− | |

| Potato juice | NG− | NG− | NG− | NG− | |

| Turnip juice | NG− | NG− | NG− | NG− | |

| Spring green juice | NG− | NG− | NG− | NG− | |

| Broccoli juice | NG− | NG− | NG− | NG− | |

| 30 | PYGS broth | 1+ | 1+ | 1+ | NG− |

| PYGSL broth | 1+ | 1+ | 2+ | NG− | |

| Helda bean juice | 3+ | 2+ | 4+ | NG− | |

| Potato juice | 11+ | 14+ | NG− | NG− | |

| Turnip juice | 14+ | 35+ | NG− | NG− | |

| Spring green juice | 21− | 14− | 23− | NG− | |

| Broccoli juice | 4+ | 16+ | 23+ | NG− | |

The lethalities of treatments in a water bath for 2, 10, and 100 min to spores of nonproteolytic C. botulinum were equivalent to those of heat treatments at 80°C for 0.1, 5.7, and 100 min, respectively, assuming that the z value was 6°C. NG, no visible growth within 98 days; +, at least one replicate was positive for growth or toxin production on day 98 as determined by the ELISA; −, all replicates were negative for growth or toxin production on day 98 as determined by the ELISA.

Growth resulting from spores heated in deoxygenated media and then incubated in the same media at 10°C.

The ability of 7 × 105 spores to survive heat treatment at 80°C and subsequently lead to growth in the same medium at 10°C is shown in Table 3. Growth occurred in PYGS broth, PYGSL broth, and bean juice but not in turnip, potato, spring green, or broccoli juice.

ELISA detection of growth or toxin production.

The C. botulinum growth determined visually was confirmed by ELISA results for all of the deoxygenated media except bean juice incubated at 10°C and spring green juice incubated at 30°C. The results are summarized in Table 3. Growth or toxin production was detected by the ELISA for all of the inoculated samples of unheated bean juice and bean juice heated for 2 or 10 min in a water bath at 80°C following subsequent incubation at 10°C, although only 2 of the 15 vials were turbid. Growth or toxin production was not detected by the ELISA in any sample of spring green juice, even when growth was observed. When toxic supernatant from a PYGS broth culture was added (1 in 10 [vol/vol]) to unheated deoxygenated spring green juice, the amount of toxin detected by the ELISA decreased with time, and samples were negative after 35 days. The amount of toxin detected in deoxygenated spring green juice that had previously been heated for 2 min in a water bath at 80°C also decreased, but toxin was still detected after 49 days. The measured toxin levels remained stable for 42 days for spring green juice previously heated at 80°C for 10 min and for all of the deoxygenated turnip juice samples. As the toxin was not always stable in spring green juice, the number of spores that led to growth was calculated from the number of vials in which turbidity or gas production was observed.

Measured heat resistance of coat-permeabilized spores incubated on agar containing heated vegetable juice.

The numbers of heated, coat-permeabilized spores able to lead to colony formation on agar supplemented with unheated or heat-treated vegetable juice or HEWL and the measured lysozyme activities of the supplements are shown in Table 4. More heat-damaged spores led to colony formation on PYGS agar supplemented with vegetable juice than on PYGS agar alone. Vegetable juice heated at 75°C for 10 min gave counts similar to those obtained with unheated juice; thus, the heated vegetable juice increased the measured heat resistance of the spores despite the fact that no lysozyme activity was detected by the M. lysodeikticus assay.

TABLE 4.

Numbers of coat-permeabilized, heat-treated spores of nonproteolytic C. botulinum able to lead to colony formation on PYGS agar supplemented with unheated or heat-treated HEWL solution or vegetable juice

| Supplement added to PYGS plating medium | Heat treatment | Lysozyme activity (equivalent μg of HEWL ml−1) | Mean no. of spores that formed colonies ml−1 (95% confidence limits) |

|---|---|---|---|

| Water | None | 4.8 × 103 (±1.1 × 103) | |

| HEWL (10 μg ml−1) | None | 9.5 | 1.6 × 107 (±0.1 × 107) |

| Broccoli juice | None | 5.5 | 1.4 × 106 (±0.2 × 106) |

| Flat bean juice | None | <0.2 | 1.2 × 105 (±0.2 × 105) |

| HEWL (10 μg ml−1) | 75°C, 10 min | 6.0 | 1.5 × 107 (±0.1 × 107) |

| Broccoli juice | 75°C, 10 min | <0.2 | 2.1 × 106 (±0.2 × 106) |

| Flat bean juice | 75°C, 10 min | <0.2 | 7.4 × 104 (±1.2 × 104) |

DISCUSSION

Nonproteolytic C. botulinum Eklund 17B grew in deoxygenated helda bean, broccoli, turnip, potato, and spring green juices at 30°C, although the probability of growth was often lower than the probability of growth in a nutrient culture medium. The time to growth increased as the pH of the medium decreased. However, the times to growth in the vegetable juices were longer than the times to growth expected for culture media at the same pH. Using lag and doubling times obtained from a growth curve at 28°C in PYGS broth at pH 5.4, a pH lower than the pH of any of the vegetable juices, it would be predicted that one spore would lead to turbidity within 2 days (13). The shortest times to growth in bean, broccoli, potato, turnip, and spring green juices were 2, 4, 11, 14, and 14 days, respectively. This illustrates that although pH was an important factor, it was not the only factor that influenced growth from nonproteolytic C. botulinum spores in the vegetable juices. A previous study in which the workers used unheated spores of nonproteolytic C. botulinum and heat-sterilized vegetable purees also showed that toxin production was related to factors in vegetables other than their pH values (5); all of the purees with pH values of 5.72 or more became toxic, none of the purees with pH values of 4.99 or less became toxic, and in purees with pH values between 4.99 and 5.72 toxin production was variable, depending on the vegetable.

All of the media were reduced, and the Eh values were between −99 and −198 mV. The ability to support growth was not directly related to the redox potentials of the deoxygenated vegetable juices; growth was observed first in bean juice, which had the highest redox potential, while spring green and turnip juices had the lowest redox potentials but were the least conducive to growth. Lund and Wyatt (21) showed that under otherwise optimum conditions, the number of spores of nonproteolytic C. botulinum type E required to produce growth in 3 days at Eh values between 0 and 62 mV (adjusted by adding air) was not significantly different from the number of spores required to produce growth at an Eh of −400 or −190 mV, although sodium chloride had a greater inhibitory effect at the higher Eh values.

As the inhibitory effects of the vegetable juices cannot be fully explained by pH or redox potential, other intrinsic factors of the vegetables must be involved. The vegetable juices may contain antimicrobial compounds (7) or may be suboptimal nutritionally. Growth is likely to be affected by a combination of these factors. Whatever the inhibitory factors are, the rapid change from no growth to profuse growth suggests that they affect the lag phase more than they affect the doubling time.

Vegetable juice was less able to support growth from spores at 10°C than at 30°C. In the present study only PYGS broth, PYGSL broth, and bean juice supported growth at 10°C when 7 × 105 spores were used. Growth in deoxygenated bean juice at 10°C was probably slight; although no turbidity or gas was observed in the unheated samples, growth or toxin production was detected by ELISA. Toxin production by nonproteolytic C. botulinum in vegetable media without associated visible growth has been observed previously in cauliflower, broccoli, asparagus, and kale purees incubated at 10°C (6) and in sweet corn, zucchini, sweet potato, cabbage, and leek purees incubated at 30°C (5). This suggests that vegetable-based foods may be toxic without appearing to be spoiled. Toxin production by nonproteolytic C. botulinum before discernible spoilage occurred has been reported for other foods (9, 26). The probability of growth at 10°C in turnip, potato, broccoli, or spring green juice was less than 1 in 106. Vegetables other than bean have been shown to support growth of nonproteolytic C. botulinum at chill temperatures. Toxin was detected within 9 days at 12°C in modified-atmosphere packed raw broccoli inoculated with approximately 106 spores of nonproteolytic C. botulinum type E (18), and 103 spores of strains of nonproteolytic C. botulinum, including strain Eklund 17B, could result in toxin production in cooked potato, mushroom, cauliflower, broccoli, and asparagus purees at temperatures of 10°C or less (6). Carlin and Peck found that the times to toxin production in cooked vegetables inoculated with spores of a mixture of nonproteolytic C. botulinum type B strains were similar to the times reported for other foods (6). However, the vegetables which they used had been sterilized at 121°C for 15 min before inoculation, so they could have had different properties than the mildly heated juice used in the present study.

The heat treatments used could have affected the ability of spores to lead to growth either directly by damaging the spores or indirectly by altering the vegetable juice. Heating spores of nonproteolytic C. botulinum in buffer for 2 min in a water bath at 80°C (equivalent to heating for 0.1 min at 80°C) neither decreased nor increased the number of spores that led to colony formation on PYGS or PYGSL agar. This suggests that the spores were neither damaged nor activated by this heat treatment. In all five vegetable juices tested, the greatest probability of growth at 30°C occurred when the spores and juice had been submerged in a water bath at 80°C for 2 min. As the spores were not heat activated, the increased growth observed was probably related to changes such as thermal destruction of antimicrobial compounds or effects such as precipitate formation in the juice during heating. Vegetables can contain a wide range of antimicrobial agents (7), and it is likely that some of these survived the initial deoxygenating treatment at 55°C. Further heating may have reduced the antimicrobial activity. The peak in the probability of growth after heat treatment at 80°C for 2 min probably reflects a balance between the thermal destruction of spores and the destruction of compounds inhibitory to growth. Subjecting products to heat treatments just sufficient to destroy vegetative bacteria could increase the probability of growth of nonproteolytic C. botulinum not only by removing competition from non-spore-forming organisms but also by increasing the ability of the substrate to support growth. The heat treatment used for long-shelf-life refrigerated products is usually greater than the minimum treatment required to destroy vegetative cells.

When 7 × 105 spores were inoculated into 5 ml of buffer and then heated in a water bath at 80°C for 10 or 100 min, they subsequently led to colony formation on PYGSL agar, but no colonies were formed on PYGS agar. This indicates that some spores survived the heat treatments but were damaged and could not lead to growth unless germination was induced by lysozyme. The ability of lysozymes to aid germination of heat-damaged spores is important only if the enzymatic activity remains following heat treatments that damage spores of nonproteolytic C. botulinum. HEWL was not stable in PYGS broth at 80°C; the HEWL activity decreased from 9.5 μg ml−1 to less than 0.2 μg ml−1 within 10 min under these conditions, and the probability of growth in heated PYGSL broth was lower than the probability of growth from spores heated in buffer and then recovered on plates containing 10 μg of HEWL ml−1. However, more spores led to growth in PYGSL broth than in PYGS broth after the inoculated media were heated for 10 min in a water bath at 80°C. This suggests that spore germination could be induced by a level of HEWL activity lower than the level detectable in the M. lysodeikticus assay. Spores of nonproteolytic C. botulinum are sensitive to between 0.01 and 0.1 μg of HEWL ml−1, and the number of survivors increases with the HEWL concentration up to 1 to 10 μg ml−1 (24). The observed growth patterns are consistent with the hypothesis that low levels of active HEWL (i.e., <0.2 μg ml−1) remain in PYGSL broth after heat treatment at 80°C for 10 min. Spores heated in buffer at 80°C for 100 min led to colony formation when they were subsequently incubated on PYGSL agar plates but did not lead to growth after inoculated PYGSL broth was subjected to the same heat treatment. This suggests that the HEWL concentration in PYGSL broth heated at 80°C for 100 min was less than 0.01 μg ml−1.

Turnip and spring green lysozymes appeared to be more heat sensitive than HEWL when activity was determined by the M. lysodeikticus assay (Table 1); activity was not detected after the heat treatment of 15 min at 55°C used during medium preparation. Such a heat treatment is unlikely to damage spores; the number of spores able to lead to colony formation was not reduced by a heat treatment equivalent to heating at 80°C for 0.1 min. This great difference between the heat treatment required to damage turnip or spring green lysozymes and the heat treatment required to damage spores suggests that these lysozymes would not survive thermal processes severe enough to damage spores and thus would not be present to induce germination of heat-damaged spores. However, supplementing the recovery media with broccoli or flat bean juice that had been heated at 75°C for 10 min increased the number of heat-damaged coat-permeabilized spores able to form colonies. This was despite the fact that these heat-treated juices had no measurable activity in the M. lysodeikticus assay. Either a low level of activity remained (i.e., activity equivalent to 0.01 to 0.2 μg of HEWL ml−1, as discussed above), the vegetables contained enzymes that could cleave peptidoglycan in the spore cortex but not peptidoglycan of M. lysodeikticus, or the vegetables contained some other factor that aided growth from damaged spores. For example, starch is known to improve the recovery of heated spores of C. botulinum (1) and for this reason is included in PYGS medium.

When spores were inoculated into media, heated at 80°C for 10 min, and then incubated at 30°C in the same heated medium, more spores led to growth in bean or broccoli juice than in PYGS broth, despite the fact that the pH and redox potential of the PYGS broth were more favorable for growth than the pH and redox potentials of either of the juices. As heated vegetable juice increased the recovery of heat-damaged spores, the improved growth observed in vegetable juice was probably due to improved recovery of spores. It is also possible that the vegetable juices had a protective effect during heat treatment. The presence of factors that are able to increase the measured heat resistance of spores of nonproteolytic C. botulinum in foods and the ability of these factors to withstand mild heat treatments have important implications in food processing. Thermal destruction studies in which spores are incubated on media that do not contain lytic enzymes could dangerously underestimate the heat process required. Addition of high levels of lytic enzymes to the incubation medium is likely to result in overestimation of the heat process required to prevent growth from spores of nonproteolytic C. botulinum, but it is the safer alternative in situations in which the thermal stability of lytic enzymes, and thus their ability to aid the recovery of heat-damaged spores is not known.

In the United Kingdom it is recommended that in the absence of other controlling factors, long-shelf-life refrigerated products should be heated at 90°C for 10 min or subjected to a process with equivalent lethality (for example, equivalent to heating for 129 min at 80°C) (2). This recommendation was developed by determining the treatment required to reduce the number of spores of nonproteolytic C. botulinum by a factor of 106. Previous work by researchers in our group showed that heating at 90°C for 10 min does not result in a 106-fold reduction in number; spores can remain viable but unable to germinate (20). Under suitable recovery conditions, such as in the presence of vegetable juice or HEWL, the heat-damaged spores can germinate and produce growth. The important question is, do the conditions in the food allow the damaged spores to recover? In the present study, up to 7 × 105 spores did not produce growth at 30°C within 98 days in any of the test media following heat treatment for 100 min at 80°C. Even though more growth occurred in heated vegetable juices than would be predicted on the basis of studies in which standard culture media were used, the thermal processes recommended for production of long-life refrigerated foods gave the desired safety level in these vegetable preparations.

ACKNOWLEDGMENTS

We thank Laurence Naiglin for help in preparing vegetable juice plates and Barbara Lund for helpful comments on the manuscript.

This work was funded by the European Union under contract AIR1-CT92-0125 and by the competitive strategic grant of the BBSRC.

REFERENCES

- 1.Adams D M. Heat injury of bacterial spores. Adv Appl Microbiol. 1978;23:245–261. doi: 10.1016/s0065-2164(08)70072-8. [DOI] [PubMed] [Google Scholar]

- 2.Advisory Committee on the Microbiological Safety of Food. Report on vacuum packaging and associated processes. London, United Kingdom: Her Majesty’s Stationery Office; 1992. [Google Scholar]

- 3.Amiot M J, Fleuriet A, Cheynier V, Nicolas J. Phenolic compounds and oxidative mechanisms in fruit and vegetables. In: Tomás-Baraerán F A, Robins R J, editors. Phytochemistry of fruit and vegetables. Oxford, United Kingdom: Clarendon Press; 1997. pp. 51–85. [Google Scholar]

- 4.Bernier I, Van Leemputten E, Horisberger M, Bush D A, Jollès P. The turnip lysozyme. FEBS Lett. 1971;14:100–104. doi: 10.1016/0014-5793(71)80110-2. [DOI] [PubMed] [Google Scholar]

- 5.Carlin F, Peck M W. Growth and toxin production by non-proteolytic and proteolytic Clostridium botulinum in cooked vegetables. Lett Appl Microbiol. 1995;20:152–156. doi: 10.1111/j.1472-765x.1995.tb00414.x. [DOI] [PubMed] [Google Scholar]

- 6.Carlin F, Peck M W. Growth and toxin production by nonproteolytic Clostridium botulinum in cooked pureed vegetables at refrigeration temperatures. Appl Environ Microbiol. 1996;62:3069–3072. doi: 10.1128/aem.62.8.3069-3072.1996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Conner D E. Naturally occurring compounds. In: Davidson P M, Branen A L, editors. Antimicrobials in foods. New York, N.Y: Marcel Dekker Inc.; 1993. pp. 441–468. [Google Scholar]

- 8.Cunningham F E, Proctor V A, Goetsch S J. Egg-white lysozyme as a food preservative: an overview. World’s Poult Sci J. 1991;47:141–163. [Google Scholar]

- 9.Eklund M W. Significance of Clostridium botulinum in fishery products preserved short of sterilisation. Food Technol. 1982;36:107–112. [Google Scholar]

- 10.Fernández P S, Peck M W. Predictive model describing the effect of prolonged heating at 70 to 80°C and incubation at refrigeration temperatures on growth and toxigenesis by nonproteolytic Clostridium botulinum. J Food Prot. 1997;60:1064–1071. doi: 10.4315/0362-028X-60.9.1064. [DOI] [PubMed] [Google Scholar]

- 11.George S M, Richardson L C C, Pol I E, Peck M W. Effect of oxygen concentration and redox potential on recovery of sub-lethally heat-damaged cells of Escherichia coli O157:H7, Salmonella enteritidis and Listeria monocytogenes. J Appl Microbiol. 1998;84:903–909. doi: 10.1046/j.1365-2672.1998.00424.x. [DOI] [PubMed] [Google Scholar]

- 12.Gould G W. Second European Symposium on Sous Vide Proceedings. Leuven, Belgium: ALMA Sous Vide Competence Centre; 1996. Conclusions of ECFF Botulinum Working Party; pp. 173–180. [Google Scholar]

- 13.Graham, A. F. Personal communication.

- 14.Graham A F, Mason D R, Maxwell F J, Peck M W. Effect of pH and NaCl on growth from spores of non-proteolytic Clostridium botulinum at chill temperature. Lett Appl Microbiol. 1997;24:95–100. doi: 10.1046/j.1472-765x.1997.00348.x. [DOI] [PubMed] [Google Scholar]

- 15.Hatheway C L. Clostridium botulinum and other clostridia that produce botulinum neurotoxin. In: Hauschild A H W, Dodds K L, editors. Clostridium botulinum: ecology and control in foods. New York, N.Y: Marcel Dekker Inc.; 1993. pp. 3–20. [Google Scholar]

- 16.Hurley M A, Roscoe M E. Automated statistical analysis of microbial enumeration by dilution series. J Appl Bacteriol. 1983;55:59–164. [Google Scholar]

- 17.Kim J, Foegeding P M. Principles of control. In: Hauschild A H W, Dodds K L, editors. Clostridium botulinum: ecology and control in foods. New York, N.Y: Marcel Dekker Inc.; 1993. pp. 121–176. [Google Scholar]

- 18.Larson A E, Johnson E A, Barmore C R, Hughes M D. Evaluation of botulism hazard from vegetables in modified atmosphere packaging. J Food Prot. 1997;60:1208–1214. doi: 10.4315/0362-028X-60.10.1208. [DOI] [PubMed] [Google Scholar]

- 19.Lund B M, Graham A F, George S M, Brown D. The combined effect of incubation temperature, pH and sorbic acid on the probability of growth of non-proteolytic type B Clostridium botulinum. J Appl Bacteriol. 1990;69:481–492. doi: 10.1111/j.1365-2672.1990.tb01539.x. [DOI] [PubMed] [Google Scholar]

- 20.Lund B M, Peck M W. Heat resistance and recovery of spores of non-proteolytic Clostridium botulinum in relation to refrigerated, processed foods with an extended shelf-life. J Appl Bacteriol Symp Suppl. 1994;76:115s–128s. doi: 10.1111/j.1365-2672.1994.tb04363.x. [DOI] [PubMed] [Google Scholar]

- 21.Lund B M, Wyatt G M. The effect of redox potential, and its interaction with sodium chloride concentration, on the probability of growth of Clostridium botulinum type E from spore inocula. Food Microbiol. 1984;1:49–65. [Google Scholar]

- 22.Notermans S H W. Control in fruits and vegetables. In: Hauschild A H W, Dodds K L, editors. Clostridium botulinum: ecology and control in foods. New York, N.Y: Marcel Dekker Inc.; 1993. pp. 233–260. [Google Scholar]

- 23.Oishi K, Ishikawa F, Nomoto M. Chitinolytic and lysozymic activities in plants. In: Skyjak-Break G, Anthonsen T, Sandford P, editors. Chitin and chitosan. London, United Kingdom: Elsevier Applied Science; 1989. pp. 185–195. [Google Scholar]

- 24.Peck M W, Fairbairn D A, Lund B M. The effect of recovery medium on the estimated heat-inactivation of spores of non-proteolytic Clostridium botulinum. Lett Appl Microbiol. 1992;15:146–151. doi: 10.1111/j.1472-765X.1992.tb00749.x. [DOI] [PubMed] [Google Scholar]

- 25.Peck M W, Lund B M, Fairbairn D A, Kaspersson A S, Undeland P C. Effect of heat treatment on survival of, and growth from, spores of nonproteolytic Clostridium botulinum at refrigeration temperatures. Appl Environ Microbiol. 1995;61:1780–1785. doi: 10.1128/aem.61.5.1780-1785.1995. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Post L S, Lee D A, Solberg M, Furgang D, Specchio J, Graham C. Development of botulinal toxin and sensory deterioration during storage of vacuum and modified atmosphere packaged fish fillets. J Food Sci. 1985;50:990–996. [Google Scholar]

- 27.Potter M D, Meng J, Kimsey P. An ELISA for the detection of botulinal toxin types A, B and E in inoculated food samples. J Food Prot. 1993;56:856–861. doi: 10.4315/0362-028X-56.10.856. [DOI] [PubMed] [Google Scholar]

- 28.Stringer S C, Peck M W. Vegetable juice aids the recovery of heated spores of non-proteolytic Clostridium botulinum. Lett Appl Microbiol. 1996;23:407–411. [Google Scholar]

- 29.Stringer S C, Fairbairn D A, Peck M W. Combining heat treatment and subsequent incubation temperature to prevent growth from spores of non-proteolytic Clostridium botulinum. J Appl Microbiol. 1997;82:128–136. doi: 10.1111/j.1365-2672.1997.tb03307.x. [DOI] [PubMed] [Google Scholar]