Abstract

Background

Workers are exposed to several risks in academic laboratories due to the presence of potentially hazardous substances. The main objective of this study was to assess the prevalence of accident occurrence and associated risk factors among laboratory workers at the scientific laboratories of the public university in Lebanon and the impact of safety measures training and availability.

Methods

In this observational study, a survey was conducted for one year in scientific laboratories at faculties of the public university.

Results

Among the participants (N = 220), 45.0% have had accidents; the main cause was exposure to chemicals (73.7%) and more specifically by inhalation (45.4%). Females (85.9%) were more exposed to accidents than males. Laboratory workers with a master's degree, a full-time schedule, and more than ten years of experience were significantly more exposed to accidents (p < 0.05). A significant association was found between accident occurrence and training on management of hazardous products (p = 0.044), risks related to workplace (p = 0.030), eyewash and emergency shower (p < 0.001), first aid (p = 0.012), and facial protection availability (p = 0.019). In spite of the lack of safety culture and efficient training on laboratory safety, participants have shown a very good perception regarding safety measures to be applied in case of work accidents.

Conclusion

Based on our findings, the prevalence of accident occurrence is elevated among lab workers at the public university. The impact of regular training on laboratory safety preventive measures is of great importance to ensure the efficiency of occupational health and safety in scientific laboratories.

Keywords: Accident occurrence, Hazardous substances, Public university, Safety measures, Scientific laboratory workers

Abbreviations: OHSA, Occupational and Health Safety Administration; MSDS, Material Safety Data Sheet; PPE, Personal Protective Equipment; PELs, Permissible Exposure Limits; SOP, Standard Operating Procedure; SDS, Safety Data Sheets; SPSS, Statistical Package for Social Sciences; VOC, Volatile Organic Chemicals; OHS, Occupational Health and Safety

1. Introduction

Accident exposures are very common among students, researchers, and lab assistants in scientific laboratories since they are exposed to chemicals and biological hazardous substances [1,2]. The occupational and health safety administration (OHSA) indicated that academic laboratories are 11 times more dangerous than the industrial sector [3]. The duration of exposure to these hazards depends upon the job function and the work tasks [4]. Improper handling of chemicals leads to accidents [5]. They cause serious injuries, health problems, loss of property [3,[6], [7], [8]], and even death [9,10].

Accident-related health problems can be acute or chronic, depending upon the kind and duration of exposure. Acute effects on health can appear rapidly after only one exposure and can lead to rashes, dizziness, coughing, and burns. However, chronic effects on health may take months or years before they are diagnosed and symptoms may include joint pain, neurological disorders, and tumors, and some persons may develop sensitivities to certain types of chemicals [11,12].

These incidents occur by several routes including inhalation, contact with the skin or eyes, ingestion, and injection [13]. For this reason, lab workers must handle hazardous chemicals and manipulate them according to OHSA's regulations. They should be informed about the hazards of chemicals at their workplace and protected from chemical exposures exceeding the permitted levels according to the OHSA permissible exposure limits (PELs) [14]. As for biological hazards, an exposure control plan is also required by OHSA standards for any laboratory worker [15].

Since researchers and lab workers are on the frontline of safety, they must participate in the hazard analysis and mitigation process related to their lab tasks, which support the implementation of corrective and preventive actions. For this purpose, job hazard analysis (JHA) is one component of the larger commitment of a safety and health management system and an excellent systematic approach that can be conducted periodically in academic laboratories. This can reduce workplace accidents and must be complemented by the adoption of appropriate training [16,17].

To avoid these unplanned, unforeseen, or unexpected events having negative impacts on the activities of an individual or organization, it is necessary to adopt adequate safety measures and improve safety culture, practice, and training in scientific laboratories [4,9,14,[18], [19], [20], [21], [22], [23], [24]].

Adherence of institutions to specific legal requirements from OHSA standards involving the provision of appropriate Personal Protective Equipment (PPE) and training on its proper usage will ensure the greatest possible protection of laboratory workers and minimize their exposure to a variety of hazards [25]. Furthermore, the presence of a safety StandardOperatingProcedure (SOP) for each activity involving the use of hazardous materials [9,26] as well as valuable measures provided by the Material Safety Data Sheet (MSDS) to protect lab workers from any potential hazards associated with volatile organic chemicals (VOCs) is recommended [27].

In addition, proper signage and Safety Data Sheets (SDS) for toxic and hazardous materials and availability of other safety laboratory equipment are required for appropriate emergency preparedness and response to any accident scenarios [28]. The exposure of lab workers to accidents and the availability of safety measures were assessed in many countries and in different institutions [6,9]. However, there is no study concerning this issue in Lebanon. The present study aims to evaluate the prevalence of accidents among scientific lab workers at the Lebanese public university, to determine their causes, route of exposure, and impact on workers’ health, to assess the availability of safety measures, safety culture and training, and the perception of lab workers regarding their impacts, and to evaluate the adherence of this institution to the international regulations. Since the Lebanese public university is in perpetual evolution through its involvement in several quality projects to improve its operations and services to ensure a healthy and safe environment, especially in its scientific laboratories, this study will help us suggest corrective actions in relation to severity of accidents to prevent their occurrences and their undesirable impacts on lab workers’ health, property damages, and the environment.

2. Materials and methods

2.1. Study design and population

This work is an observational study based on a survey conducted for one year in the research and practical laboratories of faculties and branches located in the six different governorates of the public university in Lebanon. Two hundred and twenty lab workers participated in the survey, and face-to-face interviews were conducted with 210 participants and only 10 responded to the online survey distributed to lab workers in the public university during the COVID-19 pandemic and lockdown.

2.2. Criteria for participation in this study

The inclusion and exclusion criteria for participating in the study are summarized in Table 1. The candidates of these scientific faculties (researchers, research assistants, master candidates, and Ph.D. candidates) were chosen because they are working in chemical and biological laboratories and are the most exposed to biological and chemical hazards during their activities.

Table 1.

Inclusion and exclusion criteria of the studied population

| Inclusion criteria | Exclusion criteria | |

|---|---|---|

| Scientific faculties of the public university | Pharmacy Public Health Sciences Medicine Of Sciences Doctoral School Of Science And Technology |

Undergraduate students were excluded from the study |

| Laboratories | Research and practical | |

| Sections | Chemical Biological |

|

| Population | Researchers Research assistants Master candidates Ph.D. candidates |

|

| Gender | Male Female |

|

2.3. Data collection and study instrument

The survey was prepared by our team panel based on the existing literature on the prudent practices in the laboratory [29] and guidelines of OHSA regulations [30] (Appendix A).

It was based on a developed questionnaire consisting of 29 main questions organized into four parts. The questions were close-ended. The first part consisted of nine socio-demographic information including different variables (gender, age, years of experience, educational level, type of work schedule, the site and the sections of scientific laboratories, and functions of laboratory workers).

The second part contained eight questions related to the risks associated with workplaces and their impact on participants’ health status (accident occurrence, frequency, type, route, health problems, and related absenteeism from work).

The third part dealt with risk management in these laboratories through 12 questions about the training concerning laboratory safety and the availability of different aspects of safety measures.

The fourth part included 11 safety measures to assess the perception of participants in case of an emergency or accident at work in scientific laboratories of the public university in Lebanon.

Before the distribution of the questionnaire, the first version was piloted and pre-tested with a small representative group of workers to ensure question clarity, format, and sequence, and the information collected through the pilot study was not included in the final analysis. It also showed whether the right responses would be provided by the respondents and clarified ambiguities and uncertainties regarding questions to be asked. Following this pre-survey, some questions were reworded into their final form to encourage respondents to provide accurate, unbiased, and complete information on the final form of the questions which involved grouping and sequencing of some questions to shorten the survey.

Before starting the study, the public university waived the need for oral informed consent of the study protocol. Participants were approached in a way that does not interfere with their duties or normal schedules. Anonymity, privacy, and confidentiality issues were respected throughout the study; each participant was given a code and his or her data were registered only under the code.

2.4. Statistical data analysis

Data were entered and analyzed using Statistical Package for Social Sciences (SPSS) version 23 software. Descriptive analyses were performed as a way of displaying data for a single categorical variable by including frequencies and percentages of each category obtained from the variable's frequency distribution table. Another way to display categorical data for a single variable is using a column graph or bar chart. Data in cross-tabulations were analyzed using the frequencies and percentages of the variables in the sample. Statistical evaluation was conducted through bivariate analyses to study the relationship between two variables: association between the independent factors and the depending variable, which is an accident occurrence during laboratory works.

In all analyses, a p-value of <0.05 was considered significant. The χ2 test was used for comparing categorical variables between groups; when expected values within the cells were <5, the Fisher exact test was used.

3. Results

3.1. Socio-demographic characteristics and affiliation of the studied population

A total of 220 participants were recruited in our study from different sections of scientific laboratories of the public university. Most of the participants (47.7%) were from the faculty of sciences, 25.5% from the doctoral school of science and technology, 16.8% from the faculty of public health, 9.1% from the faculty of pharmacy, and only 0.9% from the faculty of medical sciences. These scientific laboratories were distributed to different branches and in different regions, where the majority of respondents (62.3%) were from Hadath, 18.6% from Tripoli, 5.9% from Nabatieh, 4.5% from Zahle, 6.8% from Al fanar, and 1.8% from Saida. According to the kind of lab, 61.8% belong to research labs and 38.2% to practical labs. As for lab specialty, 55.0% worked in biology labs, 35.9% in chemistry labs, and 9.1% in a biochemistry laboratory.

3.2. Prevalence and description of accident occurrence and the impact on participants’ health in scientific laboratories of public university

Table 2 displays the prevalence and description of accidents faced by scientific laboratory workers. Among 220 participants recruited in our study, 99 participants (45.0%) have had accidents during their lab works. 59.6% have been exposed once, 32.3% between two and four times, only 1.0% between four and six times, and 7.1% more than six times. The major origin of exposure was chemical products (73.7%), 18.2% were scientific equipment, 8.2% were biological agents, and none were by laboratory animals. The route of exposure was predominantly due to inhalation (45.4%), followed by contact with the skin or eyes (40.5%), injury (13.1%), and electrocution (1.0%). Among the accident occurrences, 57.6% of the participants suffered from health problems, and 15.2% were disabled temporarily from work due to these health problems.

Table 2.

Description of accidents and related health problems that occurred among scientific laboratory workers from a public university in Lebanon

| Accident occurrence | Public university (N = 99)(45.0%) | |

|---|---|---|

| Frequency of accident occurrence | 1 time | 59 (59.6) |

| 2–4 times | 32 (32.3) | |

| 4–6 times | 1 (1.0) | |

| >6 times | 7 (7.1) | |

| Type of hazards leading to accident occurrence | Chemicals | 73 (73.7) |

| Equipment | 18 (18.2) | |

| Laboratory animals | 0 (0.0) | |

| Biological agents | 8 (8.1) | |

| Route of accident occurrence | Inhalation | 45 (45.4) |

| Contact with the skin/eye | 40 (40.5) | |

| Injury | 13 (13.1) | |

| Electrocution | 1 (1.0) | |

| Suffering from health problems | Yes | 57 (57.6) |

| No | 42 (42.4) | |

| Health problems leading to absenteeism | Yes | 15 (15.2) |

| No | 84 (84.8) | |

3.3. Correlation of accident occurrence with the characteristics of the studied population

The correlation between accident occurrences and the characteristics of participants during their duties in scientific laboratories is shown in Table 3. Concerning the laboratory workers having had accidents, females (85.9%) were significantly more exposed than males (14.1%) (p = 0.044). Age is not significantly associated with accident exposure (p = 0.364), and 42.3% were aged between 20 and 30 years, 25.3% were between 30 and 40, and 31.3% were more than 40 years old. However, educational level is significantly associated with accident occurrence (p < 0.001), with the majority having a master's degree (60.6%), 28.3% having a bachelor's degree of science, and 11.1% having doctorate. Besides, full-time schedule workers represent the majority exposed to accidents (90.9%) and were significantly associated with accident occurrence as compared to part-timers (9.1%) (p < 0.001). As for years of experience, participants with more than ten years of experience were significantly (p = 0.014) highly exposed to accidents (63.6%) as compared to those with less than 10 years of experience (36.4%). In addition, assistants (67.7%) were also significantly highly exposed to accidents (p < 0.001) as compared with faculty researchers (7.1%), Ph.D. students (4%), master students (17.2%), and volunteers (4%).

Table 3.

Correlation of accident occurrence with the characteristics of the studied population in scientific laboratories of the public university in Lebanon

| Characteristics | Public university (N = 220)) |

p-value | ||

|---|---|---|---|---|

| Non-accident occurrenceN (%) 121 (55.0%) |

Accident occurrenceN (%) 99 (45.0%) |

|||

| Gender | Male | 31 (25.6) | 14 (14.1) | 0.044∗ |

| Female | 90 (74.4) | 85 (85.9) | ||

| Age (years) | Less than 20 | 1(0.8) | 1(1.0) | 0.364 |

| 20–30 | 61 (50.4) | 42 (42.4) | ||

| 30–40 | 33 (27.3) | 25 (25.3) | ||

| >40 | 26 (21.5) | 31 (31.3) | ||

| Educational level | Bachelor degree | 10 (8.3) | 28 (28.3) | <0.001∗ |

| Master | 68 (56.2) | 60 (60.6) | ||

| Doctorate | 43 (35.5) | 11 (11.1) | ||

| Work schedule | Full time | 82 (67.8) | 90 (90.9) | <0.001∗ |

| Part time | 39 (32.2) | 9 (9.1) | ||

| Years of experience | <10 years | 65 (53.7) | 36 (36.4) | 0.014∗ |

| >10 years | 56 (46.3) | 63 (63.6) | ||

| Function | Faculty researcher | 30 (24.8) | 7 (7.1) | <0.001∗ |

| Assistant | 39 (32.2) | 67 (67.7) | ||

| Postdoctoral fellow | 2 (1.7) | 0 (0.0) | ||

| Ph.D. student | 13 (10.7) | 4 (4.0) | ||

| Master student | 34 (28.1) | 17 (17.2) | ||

| Volunteer | 3 (2.5) | 4 (4.0) | ||

p-value detected by the χ2 test for categorical variables showed a significant difference between both the groups.

3.4. Association between accident occurrence and training on safety measures in scientific laboratories of the public university in Lebanon

The correlations between training on safety measures and accident occurrence as the dependent variable are shown in Table 4. A significant association was shown between accident occurrence and training on management of hazardous products according to properties (p = 0.044), risks related to workplace (p = 0.030), eyewash (p < 0.001), emergency shower (p < 0.001), and first aid (p = 0.012). However, no significant association has been shown between accident occurrence and the training on other safety measures including handling contaminated biological products, radioactive products and spills, vapor-emitting activities, safety instructions for carcinogenic materials, the signification of chemical hazard pictograms, chemical hoods, biological safety cabinets, and fire extinguishers (p > 0.05). Besides, no significant association was shown between accident occurrence and the frequency of training on safety measures (p > 0.05). But it should be noticed that 79.8% of those who had accidents did not receive this kind of training and they did not communicate the training information with the OHS service, and rarely with a lab assistant (15.2%) or an instructor (10.1%).

Table 4.

Association between accident occurrence and training on safety measures in scientific laboratories of the public university in Lebanon

| Safety measures training | Public university (N = 220) |

p-value | ||

|---|---|---|---|---|

| Non-accident occurrence n = 121 (55.0) n(%) |

Accident occurrence n = 99 (45.0) n (%) |

|||

| Management of hazardous products according to properties | 31 (25.6) | 14 (14.1) | 0.044∗ | |

| Risks related to workplace | 32 (26.4) | 14 (14.1) | 0.030∗ | |

| Handling a contaminated biological product | 30 (24.8) | 15 (15.2) | 0.093 | |

| Handling a harmful or toxic corrosive product | 28 (23.1) | 15 (15.2) | 0.172 | |

| Handling a radioactive product | 24 (19.8) | 13 (13.1) | 0.208 | |

| Handling a spill | 23 (19.0) | 15 (15.2) | 0.479 | |

| Activities likely to emit vapors | 20 (16.5) | 13 (13.1) | 0.571 | |

| Safety instructions to follow when using carcinogenic materials | 23 (19.0) | 17 (17.2) | 0.861 | |

| Signification of chemical hazard pictograms | 22 (18.2) | 9 (9.1) | 0.078 | |

| Eyewash | 35 (28.9) | 6 (6.1) | <0.001∗ | |

| Emergency shower | 28 (23.1) | 5 (5.1) | <0.001∗ | |

| First aid | 28 (23.1) | 10 (10.1) | 0.012∗ | |

| Chemical hoods | 48 (60.8) | 31 (31.3) | 0.207 | |

| Biological safety cabinets | 24 (19.8) | 13 (13.1) | 0.208 | |

| Fire extinguisher | 29 (24.0) | 13 (13.1) | 0.057 | |

| Frequency of training | Once a year | 28 (23.1) | 15 (15.2) | 0.132 |

| Periodically | 11 (9.1) | 5 (5.1) | ||

| Never | 82 (67.8) | 79 (79.8) | ||

| Communication of training information with | OHS service | 4 (3.3) | 0 (0.0) | 0.129 |

| Laboratory assistant | 16 (13.2) | 15 (15.2) | 0.701 | |

| Laboratory instructor | 18 (14.9) | 10 (10.1) | 0.317 | |

OHS: Occupational Health and Safety.

p-value detected by the χ2 test for categorical variables showed a significant difference between both the groups.

3.5. Correlation between accident occurrence and the availability of safety equipment in scientific laboratories of the public university in Lebanon

The correlations between the availability of safety equipment and the occurrence of accidents as a dependent variable are shown in Table 5. A significant association has been found between facial protection availability and accident occurrence (p = 0.019). However, there were no significant associations between accident occurrence and the presence of other safety equipment including facial, hand, eye skin, and body protection, eyewash, emergency shower, first aid, chemicals hoods, fire extinguishers, biological safety cabinets, fall protection, the plot of hazard pictograms, fire blanket, smoke detectors, hazardous material containers labeling, and MSDS for hazardous materials (p > 0.05). It is remarkable that few participants have MSDS for hazardous materials as well as its accessibility and update MSDS in the public university.

Table 5.

Correlation between accident occurrence and the availability of safety equipment in scientific laboratories of the public university in Lebanon

| Safety equipment availability | Public university (N = 220) |

p-value | ||

|---|---|---|---|---|

| Non-accident occurrence n = 121 (55.0) n (%) |

Accident occurrence n = 99 (45.0) n (%) |

|||

| Facial protection | 62 (51.2) | 67 (67.7) | 0.019∗ | |

| Hand protection (heat-resistant gloves) | 81 (66.9) | 61 (61.6) | 0.479 | |

| Hand protection (latex gloves) | 92 (76.0) | 68 (68.7) | 0.228 | |

| Eye protection | 54 (44.6) | 44 (44.9) | 1.000 | |

| Skin and body protection | 69 (57.0) | 63 (63.6) | 0.336 | |

| Eye wash | 52 (43.0) | 38 (38.4) | 0.582 | |

| Emergency shower | 52 (43.0) | 38 (38.4) | 0.582 | |

| First aid kit | 30 (24.8) | 29 (29.3) | 0.541 | |

| Chemical hoods | 65 (53.7) | 62 (62.6) | 0.217 | |

| Fire extinguisher | 64 (53.8) | 55 (46.2) | 0.786 | |

| Biological safety cabinets | 42 (34.7) | 29 (29.3) | 0.469 | |

| Fall protection equipment | 9 (7.4) | 3 (3.0) | 0.233 | |

| Plot of hazard pictograms | 7 (5.8) | 3 (3.0) | 0.518 | |

| Fire blanket | 7 (5.8) | 6 (6.0) | 1.000 | |

| Smoke detectors | 45 (37.2) | 48 (51.6) | 0.101 | |

| Hazardous materials containers storage in appropriate cabinets | 35 (28.9) | 26 (26.3) | 0.596 | |

| Hazardous materials containers labeling | 34 (28.1) | 24 (24.2) | 0.542 | |

| MSDS for hazardous materials | 12 (9.9) | 9 (9.1) | 1.000 | |

| MSDS | Easy accessibility at all times | 8 (6.6) | 4 (4.0) | 0.544 |

| Up to date in less than 3 years | 2 (1.7) | 3 (3.0) | 0.659 | |

| Are classified in such a way to permit easy identification of the card of a dangerous product | 2 (1.7) | 2 (2.0) | 1.000 | |

MSDS: Material Safety Data Sheet.

p-value detected by the χ2 test for categorical variables showed a significant difference between both the groups.

3.6. Perception of participants regarding safety measures in case of an emergency or accident at work in scientific laboratories of the public university in Lebanon

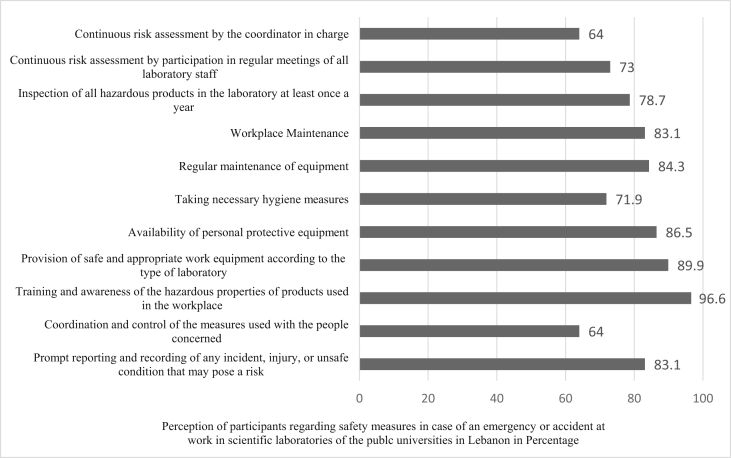

Fig. 1 represents the perception of participants regarding safety measures in case of an emergency or accident during laboratory work. Among participants, 83.1% agreed about the prompt reporting and recording of any incident, an injury that occurred, or any unsafe condition that may pose a risk. The coordination and control of measures used with the responsible persons were highly supported by participants (64%). Training and awareness about the hazardous properties of products used in the workplace were also approved by 96.6%, as well as the provision of safe and appropriate work equipment according to the type of laboratory by 89.9%.

Fig. 1.

Perception of participants regarding safety measures in case of an emergency or accident at work in scientific laboratories of the public university in Lebanon.

The necessity of the PPE availability was also stated by 86.5% and the necessity of taking hygiene measures by 71.9%. In addition, the importance of regular maintenance of equipment was supported by 84.3%, workplace maintenance by 83.1%, and the inspection of all hazardous products in the laboratory at least once a year by 78.7%. Besides, 64% agreed with the benefit of the continuous risk assessment by the coordinator in charge, and 73% encouraged the participation of all laboratory staff in the regular meeting on continuous risk assessment.

4. Discussion

Scientific laboratories are widely seen as a key component of knowledge since most fields of sciences are activity-based explorations into the natural world [31].

Working in such laboratories requires the application of safety measures according to the nature of the laboratory, especially those using various hazardous materials [1,32].

In the present work, we have evaluated, for the first time in Lebanon, the prevalence of accident occurrence and associated factors among workers at the scientific laboratories, as well as the impact of safety measures training and availability. It was achieved through a survey based on the development of a questionnaire.

Our findings revealed that the prevalence of accident occurrence among laboratory workers in scientific laboratories reached 45.0 %. This was aligned with a study evaluating the status of chemical lab safety in Nepal, where 47% of laboratory workers faced accidents due to different hazards in their chemistry teaching labs [33].

Besides, our results showed that 45.0% of laboratory workers recruited in our study were exposed to risks, and chemicals were the most incriminated factors (73.7%). These results were aligned with the report from the AIHA stating that the accident faced by a postdoctoral student was due to the use of some chemicals in which he ignored their risks in advance [34].

The risk of chemical exposure of the laboratory staff of academic and research institutes was increased with the development and diversification of new techniques and materials into the field of science. It was also noticed that the activities inherent to laboratories sometimes involve the use of dangerous substances, such as VOCs. These products presented all categories of risks such as fire, explosion, health, or environmental hazards. Recent studies also mentioned that chronic exposure to chemical compounds in occupational environments was justified enough to monitor the VOCs continuously [12].

The main routes of accidents among participants in order of importance were inhalation (45.4%), contact with the skin or eyes (40.5%), and injury (13.1%). This is in accordance with the literature review stating that the four main important routes for chemicals to become harmful to the body health are inhalation (breathing), contact with the skin or eye, digestive system (ingestion or eating), and injection [35].

In addition, our results showed that 57.6%participants suffered from health problems related to accidents, and 15.2% of them were relieved temporarily from work. Since most of the adverse health effects were caused by chemical solvents as they were widely available in many chemical laboratories, it was recommended to monitor these compounds in occupational environments and necessitated efficient ventilation systems. In addition, all laboratory workers needed to refer to MSDS and prepare a risk assessment datasheet for any chemical before use [36].

Our results showed that female workers (85.9%) were significantly (p = 0.044) more exposed to accidents than males (14.1%). These results were in contrast with a study carried out on occupational injury in America that showed that males reported more work-related injuries (WRI) [37].

In a public university in Malaysia, females were less exposed due to better knowledge, attitude, and practice on WRI (AOR = 2.218, 95% CI = 1.279–3.846) [38]. This discrepancy is maybe due to that females in our study were nearly four times more than males.

Besides, we have found that the educational level of participants increased the risk of accidents among participants having a master's degree (60.6%) as compared to bachelor's degree (28.3%) and Ph.D. students (11.1%). To our knowledge, there was no study dealing with the effects of educational level on accident occurrences among lab workers. An explanation for this variance may be due to the level of knowledge acquisitions and experience of masters' students and their tendency to use safety measures.

In addition, this study revealed that full-time laboratory workers (90.0%) were more exposed to accidents than workers with a part-time schedule. This was potentially due to their long work duration (6–8 hours per day) and higher responsibilities. Our results were aligned with those of a study showing that the risk of accident occurrence being related to the workplace increased significantly with longer duty hours (working at least 12 hours per day was associated with a 37% increased hazard rate and working at least 60 hours per week was associated with a 23% increased hazard rate) [39].

Furthermore, we have noticed that participants with more than 10 years of experience were the most exposed to accidents (52.9 %). The reason could be mishandling or misusing of safety precautions while working with various types of hazardous substances and the negligence with years of experience compared to new users from students. This result was in accordance with a study that hypothesized that younger researchers have correct knowledge of hazardous chemicals and 54.5% of those having more years of experience perceived that they are more exposed to chemical risks compared to the less-experienced workers [40].

Regarding participants' function, research assistants have been recorded to be significantly the most exposed to accidents 67.7% (p < 0.001). This could be explained by the level of awareness and practices of teachers’ assistants due to the lack of continuous training and workshops on laboratory safety measures. A previous study revealed that teaching assistants have sufficient knowledge, particularly on laboratory procedures, techniques, and safety measures [41].

It should be also noted that lab safety knowledge and practices depend on two factors: the first one is having different local educational systems regarding the orientation session and continuous training on safety concepts and the second is the level of implementation of OHSA Laboratory Standards [5].

In terms of laboratory safety training, our results indicated a significant positive association between accident occurrence and the training on the management of hazardous products according to properties (p = 0.044), risk related to workplace (p = 0.030), and the following safety equipment: eyewash and emergency shower (p < 0.001) and first aid (p = 0.012). This is consistent with a previous study, in which 25% of researchers did not follow training regarding specific hazards with which they are exposed [22].

Similarly, a study which conducted an assessment on the safety culture and compliance of Canadian academic laboratories revealed that inadequate training of laboratory staff did not enforce them to protect themselves in case of any incident in their workplace [42].

Moreover, a previous study reported that the students were not aware and familiar with potential hazards and risk warning signs. This requires preparation of safety training programs to support them to get more practices and increase their compressibility about chemical hazard warning signs to avoid their accident exposure in the laboratories [11].

Regarding the availability of safety equipment, our results showed that only facial protection (tool of PPE) was significantly associated with accident occurrence (p = 0.019). The reason might be due to improper use of facial protection equipment such as safety goggles, the negligence to change the facial mask as recommended by OHSA, or inadequate supplies provided by the lab [43].

However, there were no significant associations between accident exposure and the presence of other safety equipment (p > 0.05). Also, a lack of MSDS for hazardous material as well as its accessibility and modification was noticed. Previous studies emphasized the importance of having all safety tools to ensure a safe environment for all staff working in any laboratory and these tools play a crucial role in protecting them and minimizing incidents from any chemical or biological hazards [3,44].

The present observational study was conducted on a small sample group (220 participants) working in research laboratories. Sampling bias was detected by convenient sampling. The limitations of this study were due to the refusal of some individuals to participate in the survey.

Our findings showed that although participants from the public university had a very good perception regarding safety measures to be applied in case of an emergency or accident at work in scientific laboratories, accidents were frequent, and this can be explained by the lack of training on laboratory safety measures. This is in line with a study carried out at a major southern public university in the United States, where a high perception of laboratory workers was reported regarding safety measures (3.72–1.71, on a scale of 1–5) to ensure a safe climate at the workplace [2].

This study has some limitations. Participants reported accidents that occurred during their laboratory works until the time of the initiation of the study and this might differ depending on their status and their length of stay in the laboratory. In addition, the study included only one institution of Lebanon.

Further studies involving a larger number of workers from different research laboratories of universities in Lebanon are needed to confirm our findings. In addition, the assessment approach should be performed in the future for risks associated with workplaces, equipment, and methods in scientific laboratories by applying the risk management tool “Failure Mode and Effects Analysis”, which is a quantitative descriptive and analytical method that provides a rating based on simple scales in terms of potential severity and then in terms of likelihood of occurrence.

Accident occurrence has an important prevalence among laboratory workers at the public university, where the main cause was chemical exposure, especially by inhalation. This study helps to estimate accident occurrence cause and highlights the importance of risk management and safety culture among the university laboratory staff and students, as well as the impact of regular training on laboratory safety preventive measures to ensure the efficiency of occupational health and safety in scientific laboratories. This can be achieved through the implementation of a safety department responsible for the quality control of safety measures and the development of safety orientation sessions for university staff and students in scientific laboratories. The development of a practical guideline for managing risks faced by laboratory workers is of great importance; this would serve as a tool for good practice and improve environmental safety in scientific laboratories in concordance with international occupational and health standards.

Funding

The authors would like to acknowledge the funding support received from the central administration at the Lebanese University,Beirut, Lebanon, that helped in the study design and data collection.

Conflicts of interest

No potential conflicts of interest were disclosed.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.shaw.2022.02.001.

Appendix A. Supplementary data

The following is/are the supplementary data to this article:

References

- 1.Al-Obaidi O., Abdallh M., Al-Dahhan W. Risk assessment in postgraduate laboratories. J Pub Health Catalog. 2018;1(3):1–4. 2 J Pub Health Catalog 2018 Volume 1 Issue, 2018. 3: p. 3. [Google Scholar]

- 2.Steward J.E., Wilson V.L., Wang W.-H. Evaluation of safety climate at a major public university. J Chem Health Saf. 2016;23(4):4–12. [Google Scholar]

- 3.Lestari F., Bowolaksono A., Yuniautami S., Wulandari T.R., Andani S. Evaluation of the implementation of occupational health, safety, and environment management systems in higher education laboratories. J Chem Health Saf. 2019;26(4–5):14–19. doi: 10.1016/j.jchas.2018.12.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Olewski T., Snakard M. Challenges in applying process safety management at university laboratories. J Loss Prevent Proc Indust. 2017;49:209–214. [Google Scholar]

- 5.Walters A.U., Lawrence W., Jalsa N.K. Chemical laboratory safety awareness, attitudes and practices of tertiary students. Saf Sci. 2017;96:161–171. [Google Scholar]

- 6.Adole A. Accident and incident investigation. Saf Manag Syst: Appl Aviat Indust. 2020:125. [Google Scholar]

- 7.Alsubiaee K.M., Alshahrani M.S., Alazmi A.B., Alsadoon R.A. Implementation of safety standards in Saudi Arabian scientific laboratories: an empirical study. J Arthritis. 2017;6(4):1–4. [Google Scholar]

- 8.Cheng S., Zhang J., Wang Y., Zhang D., Teng G., Chang-Chien G.P., et al. Global research trends in health effects of volatile organic compounds during the last 16 years: a bibliometric analysis. Aerosol Air Qual Res. 2019;19(8):1834–1843. [Google Scholar]

- 9.Mulcahy M.B., Boylan C., Sigmann S., Stuart R. Using bowtie methodology to support laboratory hazard identification, risk management, and incident analysis. J Chem Health Saf. 2017;24(3):14–20. [Google Scholar]

- 10.Phifer R. Case study–Incident investigation: laboratory explosion. J Chem Health Saf. 2014;21(5):2–5. [Google Scholar]

- 11.Adane L., Abeje A. Assessment of familiarity and understanding of chemical hazard warning signs among university students majoring chemistry and biology: a case study at Jimma University, Southwestern Ethiopia. World Appl Sci J. 2012;16(2):290–299. [Google Scholar]

- 12.Rastkari N., Khorsand S., Ahmadkhaniha R. Environmental monitoring of occupational exposure to organic solvents in chemical laboratories. J Air Poll Health. 2016;1(4):237–242. [Google Scholar]

- 13.Al-Zyoud W., Qunies A.M., Walters A.U., Jalsa N.K. Perceptions of chemical safety in laboratories. Safety. 2019;5(2):21. [Google Scholar]

- 14.Kaufman J.A. Occupational exposure to hazardous chemicals in laboratories: understanding the OSHA laboratory standard. J Chem Educ. 1992;69(11):911. [Google Scholar]

- 15.Boyce R., Mull J. Complying with the occupational safety and health administration: guidelines for the dental office. Dental Clin North Am. 2008;52(3):653–668. doi: 10.1016/j.cden.2008.03.002. [DOI] [PubMed] [Google Scholar]

- 16.Kjellén U., Albrechtsen E. CRC Press; 2017. Prevention of accidents and unwanted occurrences: theory, methods, and tools in safety management. [Google Scholar]

- 17.Yoon I.K., Seo J.M., Jang N., Oh S.K., Shin D., Yoon E.S. Job hazard analysis: OSHA publication 3071 2002 (Revised) J Chem Eng Jpn. 2012;45(8):976–988. [Google Scholar]

- 18.Foster B.L. Laboratory safety program assessment in academia. Chem Health Saf. 2004;11(5):6–13. [Google Scholar]

- 19.Gomaa A.E., Tapp L.C., Luckhaupt S.E., Vanoli K., Sarmiento R.F., Raudabaugh W.M., et al. Occupational traumatic injuries among workers in health care facilities—United States, 2012–2014. MMWR Morbid Mortal Weekly Rep. 2015;64(15):405. [PMC free article] [PubMed] [Google Scholar]

- 20.Hill R.H., Jr., Finster D.C. Academic leaders create strong safety cultures in colleges and universities. J Chem Health Saf. 2013;20(5):27–34. [Google Scholar]

- 21.Ménard A.D., Trant J.F. A review and critique of academic lab safety research. Nat Chem. 2020:17–25. doi: 10.1038/s41557-019-0375-x. [cited 12 1] [DOI] [PubMed] [Google Scholar]

- 22.Schröder I., Huang D.Y.Q., Ellis O., Gibson J.H., Wayne NL. Laboratory safety attitudes and practices: a comparison of academic, government, and industry researchers. J Chem Health Saf. 2016;23(1):12–23. [Google Scholar]

- 23.Shallcross D.C. Safety education through case study presentations. Educ Chem Eng. 2013;8(1):e12–e30. [Google Scholar]

- 24.Stroud L.M., Stallings C., Korbusieski T.J. Implementation of a science laboratory safety program in North Carolina schools. J Chem Health Saf. 2007;14(3):20–30. [Google Scholar]

- 25.Occupational Safety, Health Administration . US Department of Labor; 2010. Personal protective equipment:(OSHA 3151-12R) [Google Scholar]

- 26.Casadonte D. 2016. Guidelines for chemical laboratory safety in academic institutions. [Google Scholar]

- 27.Occupational Safety, Health Administration . US OSHA; 2011. Laboratory safety guidance. [Google Scholar]

- 28.Sigmann S.B. Playing with fire: chemical safety expertise required. J Chem Educ. 2018;95(10):1736–1746. [Google Scholar]

- 29.Pedrozo M.D.F.M., Philipi A., Jr. Laboratory waste management: evaluation of the disposal procedures routinely adopted by three Brazilian public institutions. Int J Environ Stud. 2005;62(6):687–700. [Google Scholar]

- 30.HAMM . 2021. Hazard awareness & management manual (HAMM). Chapter VI. Hazardous waste directory. 08.0 biohazardous waste.https://extranet.fredhutch.org/en/u/ehs/hamm/chap6/section8.html Available at: [Google Scholar]

- 31.Aladejana F., Aderibigbe O. Science laboratory environment and academic performance. J Sci Educ Technol. 2007;16(6):500–506. [Google Scholar]

- 32.Marendaz J.-L., Suard J.-C., Meyer T. A systematic tool for assessment and classification of hazards in laboratories (ACHiL) Saf Sci. 2013;53:168–176. [Google Scholar]

- 33.Kandel K.P., Neupane B.B., Giri B. Status of chemistry lab safety in Nepal. PloS One. 2017;12(6) doi: 10.1371/journal.pone.0179104. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.AIHA . American Industrial Hygiene Association; 2015. Wrong gloves lead to an acid burn. [Google Scholar]

- 35.Akbarzadeh A., Abasi E., Ghanei M., Hasanzadeh A., Panahi Y. The effects of various chemicals on lung, skin and eye: a review. Toxin Rev. 2016;35(3–4):187–195. [Google Scholar]

- 36.Yousif E., Al-Dahhan W.H., Abd Ali A., Rashad A.A., Akram E. Mind what you put in a furnace: a case study for a laboratory incident. J Environ Sci. 2017;1(1):44–48. [Google Scholar]

- 37.Smith T.D., DeJoy D.M. Occupational injury in America: an analysis of risk factors using data from the General Social Survey (GSS) J Saf Res. 2012;43(1):67–74. doi: 10.1016/j.jsr.2011.12.002. [DOI] [PubMed] [Google Scholar]

- 38.Netto E., Hamedon T.R. Predictors of knowledge, attitude and practices on work related injuries among laboratory staffs in a public university in Malaysia. Int J Public Health Clin Sci. 2017;4(5):139–157. [Google Scholar]

- 39.Dembe A.E., Erickson J.B., Delbos R.G., Banks S.M. The impact of overtime and long work hours on occupational injuries and illnesses: new evidence from the United States. Occupat Environ Med. 2005;62(9):588–597. doi: 10.1136/oem.2004.016667. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Papadopoli R., Nobile C.G.A., Trovato A., Pileggi C., Pavia M. Chemical risk and safety awareness, perception, and practices among research laboratories workers in Italy. J Occupat Med Toxicol. 2020;15(1):1–11. doi: 10.1186/s12995-020-00268-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Ali N.L., Ta G.C., Zakaria S.Z.S., Mokhtar M., Halim S.A. Chemical safety in school laboratories located in urban and rural areas: a case study in cameron highlands, Malaysia. Int J Malay World Civilis. 2018;6:11–16. [Google Scholar]

- 42.McEwen L., Stuart R., Sweet E., Izzo R. Baseline survey of academic chemical safety information practices. J Chem Health Saf. 2018;25(3):6–10. [Google Scholar]

- 43.Ennis R. Routledge; 2019. Osha laboratory standard-implementation guide. [Google Scholar]

- 44.Ayi H.-R., Hon C.-Y. Safety culture and safety compliance in academic laboratories: a Canadian perspective. J Chem Health Saf. 2018;25(6):6–12. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.