Abstract

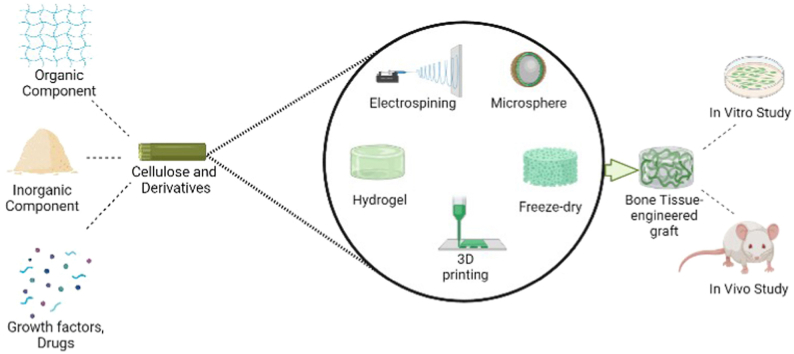

Natural bone constitutes a complex and organized structure of organic and inorganic components with limited ability to regenerate and restore injured tissues, especially in large bone defects. To improve the reconstruction of the damaged bones, tissue engineering has been introduced as a promising alternative approach to the conventional therapeutic methods including surgical interventions using allograft and autograft implants. Bioengineered composite scaffolds consisting of multifunctional biomaterials in combination with the cells and bioactive therapeutic agents have great promise for bone repair and regeneration. Cellulose and its derivatives are renewable and biodegradable natural polymers that have shown promising potential in bone tissue engineering applications. Cellulose-based scaffolds possess numerous advantages attributed to their excellent properties of non-toxicity, biocompatibility, biodegradability, availability through renewable resources, and the low cost of preparation and processing. Furthermore, cellulose and its derivatives have been extensively used for delivering growth factors and antibiotics directly to the site of the impaired bone tissue to promote tissue repair. This review focuses on the various classifications of cellulose-based composite scaffolds utilized in localized bone drug delivery systems and bone regeneration, including cellulose-organic composites, cellulose-inorganic composites, cellulose-organic/inorganic composites. We will also highlight the physicochemical, mechanical, and biological properties of the different cellulose-based scaffolds for bone tissue engineering applications.

Keywords: Cellulose, Cellulose derivatives, Bone tissue engineering, Drug delivery system

Graphical abstract

Highlights

-

•

Cellulose and its derivatives are renewable and biodegradable natural polymers that with great potential for bone tissue engineering.

-

•

Cellulose-based materials can be used various therapeutics directly to the bone to achieve bone regeneration.

-

•

Bioinks made of cellulose-based materials hold great promise to develop patient specific solutions for bone repair using 3D printing.

-

•

Challenges associated with inaccuracies in existing preclinical models, sterilization regulatory barriers still need to be addressed before clinical translation.

Abbreviations

- BC

Bacterial cellulose

- CA

Cellulose acetate

- CMC

Carboxymethyl cellulose

- HPMC

Hydroxyl propyl methyl cellulose

- HEC

Hydroxyethyl cellulose

- EC

Ethyl cellulose

- RC

Regenerated cellulose

- TOCN

Tempo-oxidized cellulose nanofibril

- TOBC

Tempo-oxidized bacterial cellulose

- CNF

Cellulose nanofiber

- CNC

Cellulose nanocrystal

- CNW

Cellulose nanowisker

- SO-CNC

Surface-Oxidized CNCs

- BCN

Bacterial cellulose nanocrystal

- BF

Bamboo fiber

- SO

Spinacae olareacea

- CQ

Cissus quadrangularis

- ApA

3-Aminopropylphosphoric acid

- HMDA

Hexamethylenediamine

- DHT

Dehydrothermal treatment

- PLLA

Poly-l-lactide acid

- PLA

Poly lactic acid

- PHB

poly(3-hydroxybutyrate)

- HAp

Hydroxyapatite

- BG

Bioactive glass

- CS

Chitosan

- PAA

Polyacrylamide

- PVA

Polyvinyl alcohol

- PCL

Polycaprolactone

- PULL

Pullulan

- SA

Sodium alginate

- SF

Silk fibroin

- PU

Polyurethane

- XG

Xanthan gum

- MWCNT

Multiwall carbon nanotube

- BHA

Boron-doped hydroxyapatite

- SPI

Soy protein isolate

- GO

Graphene oxide

- GEL

Gelatin

- COL

Collagen

- HA

Hyaluronic acid

- PVP

Polyvinyl pyrrolidone

- PMMA

Polymethyl methacrylate

- BGP

β-glycerophosphate

- PHEMA

Poly (2hydroxyethyl methacrylate)

- Semi-IPNs

Semi-interpenetrating polymer networks

- hBN

Hexagonal boron nitride

- tBuOH

Tertbutanol

- CAM

Cellulose acetate membrane

- T-CNF

TEMPO-oxidized cellulose nanofibril

- EDC

1-ethyl-3-(3-dimethylaminopropyl) carbodiimide

- NHS

N-hydroxysuccinimide

- STMP

Sodium trimetaphosphate

- NP

Nanoparticle

- GF

Growth factor

- TGF

Transforming growth factor

- FGF

Fibroblast growth factor

- BMP

Bone morphogenetic protein

- rhBMP-2

Recombinant human BMP-2

- p-rhOPN

Plant-derived recombinant human osteopontin

- ALP

Alkaline phosphatase

- RhVEGF

Recombinant human VEGF

- OGP

Osteogenic growth peptide

- PBS

Phosphate buffered saline

- CP

Calcium phosphate

1. Introduction

Bone is a rigid organ that constitutes several vital roles in the body including locomotion, mineral storage, soft tissue protection, and supplying the microenvironment for bone marrow. Even though bone indicates an inherent capacity to regenerate itself from small defects, advanced interventions are required to manage massive bone losses resulting from trauma, accident, surgery, congenital malformation, and tumor resection. These large bone defects lack self-regeneration capability and consequently affect the quality of life of patients [1,2]. Surgical reconstruction that utilizes autogenic and allogenic bone grafts in addition to metal implants has been used as a standard treatment for repairing bone defects. Autogenic bone grafts have been considered the gold standard in surgical operations. Unfortunately, they have several drawbacks, including insufficient donor sites, the need for additional surgery, and increased risk of infection at the implantation site. Allogenic grafts are another class of bone grafts, with insufficient donor sites along with the risk of pathogen transmission and immunological rejection. Inert non-bioactive metal implants have also been used to treat large bone defects. However, challenges associated with the integration of these implants with the surrounding tissue and the mechanical mismatch between the implant and the native bone have hindered their clinical use [3,4]. To mitigate these limitations, therapeutic approaches based on the engineering of tissues that use biomaterials, cells, and bioactive molecules have been emerged to accelerate the over the past few years [5,6].

An ideal bone scaffold must provide a desirable environment for cell attachment, growth, differentiation without inducing any toxic and immunological side effects [[7], [8], [9]]. Additionally, a bone mimicking scaffold with the interconnected porous network, suitable mechanical properties, and appropriate biodegradability is required to construct a functional bone similar to the native structure [10]. A pore size of 300 μm and larger has been recommended to allow acceptable mass transfer and vascularization for guiding cellular behavior in the direction of new bone formation [11]. Additionally, scaffolds should tolerate compressive loads between 5 and 224 MPa [12,13]. Although increasing pore size is desired for cell infiltration and tissue integration, the porosity will negatively affect the mechanical properties. Therefore, scaffolds should be carefully designed to optimize promote tissue remodeling post-implantation without compromising the mechanical properties of the implant. Over the years, various biomaterials from natural and synthetic polymers and ceramics have been examined for bone tissue engineering applications. The development of composite biomaterials that satisfy the needs of bone tissue engineering has been a significant focus of recent research efforts. Composite biomaterials have attracted much attention due to their improved properties compared with pure ceramic and polymer materials. Composite biomaterials are primarily intended to improve the degradation rate, mechanical properties, and bioactivity of scaffolds [14,15]. In addition, numerous studies have been focused on designing hydrogel-based composites that promote the infiltration of cells into the scaffold, increase nutrient transport, deliver bioactive molecules to the implantation site, and improve mechanical integrity at the defect site. Therefore, to achieve the requirements for bone regeneration, biomimetic matrixes were developed to create a suitable microenvironment to encourage osteoblast proliferation and osteogenesis. Also, composites are ideal materials for the controlled and sustained release of drugs and growth factors into the site of defects to enhance therapeutic outcomes. Furthermore, it can reduce the side effects of burst release of drugs [[16], [17], [18]].

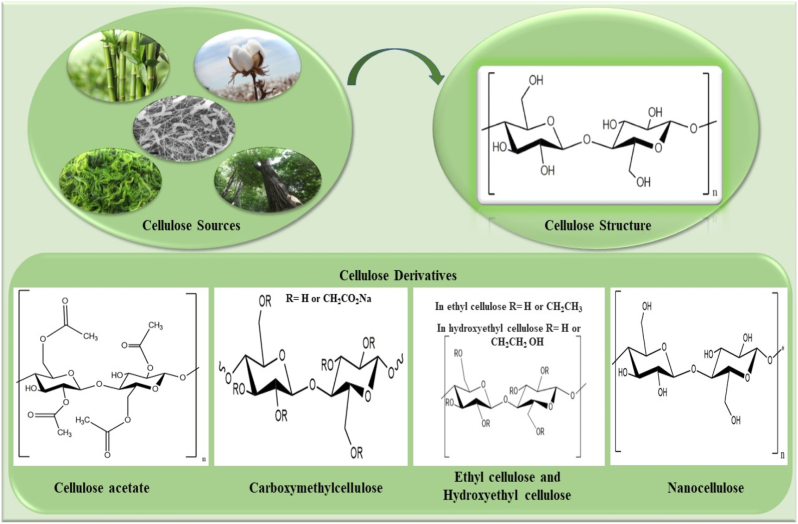

In bone tissue engineering, several types of polymeric materials are used to provide structural support and tissue regeneration. Proteins such as collagen, and gelatin offer a number of advantages, such as high biocompatibility, low toxicity, and enhanced cell responses; however, they fail to provide sufficient mechanical strength and stability in physiological conditions. Polysaccharides such as chitosan, alginate, and starch have a number of advantages, including biodegradability and biocompatibility, but are fragile and typically do not contain cell-binding moieties that promote cell attachment and infiltration. In contrast, synthetic polymers (e.g., PLA, PCL, PHB, and PVA) exhibit strong mechanical properties and tunable mechanical properties and stability in vivo. However, their bioactivity and cell attachment are insufficient for bone tissue engineering [19,20]. Among these polymers, cellulose is a linear polysaccharide abundantly found in natural sources from several plants (cotton, bast plants, wood, and bamboo) to some organisms (bacteria, fungi, algae). Notably, cellulose in the pristine or chemically modified form due to remarkable advantages such as high specific mechanical properties, non-immunogenicity, nontoxicity, source abundance, and low production cost, is one of the most common polysaccharides for fabricating bone substitutes [21,22]. It is worth noting that the origin of cellulose extraction intensely influences these characteristics. This syndiotactic homopolymer comprises d-glucopyranose ring units linked by β-1, 4-glycosidic linkage. High amounts of hydroxyl groups occur on the cellulose chains as a result of plentiful intra- and intermolecular hydrogen bonding in the biopolymer network. Coupled with this, hydrogen bonding gives some unique properties of stability, hydrophilicity, and high available sites for chemical modifications with different functional groups [[23], [24], [25]]. Cellulose esterification and etherification are the most critical modification processes from the application perspective. Cellulose acetate as a cellulose ester and the methylcellulose, ethylcellulose, hydroxyethylcellulose, and carboxymethyl cellulose as cellulose ethers are the well-known appealing cellulose derivatives in biomedicine and pharmaceutics (Fig. 1). Regenerated cellulose is another processed cellulose produced by chemical processing via dissolving cellulose in alkali and carbon disulfide to make a viscose solution [26,27].

Fig. 1.

Chemical formulation of cellulose and its derivatives [27].

Furthermore, crystalline cellulose derivatives, microcrystalline and nanocrystalline cellulose, are explored in different fields of tissue engineering since they exhibit some beneficial features of high surface area, biodegradability, and non-toxicity. Both crystalline derivatives are easily produced through the partial hydrolysis of amorphous regions of pristine cellulose. These crystalline structures vary with diameter from 5 to 20 nm and length of 100 nm to several micrometers for NCC, and diameter of 50 μm with the length of 100–1000 μm for MCC [28,29].

Cellulose and its derivatives have many favorable properties. To improve the material properties, cellulose-based composites were developed by combining two or more compounds, resulting in a suitable matrix with specific properties that cannot be achieved by any of the components individually. Extensive research efforts have been employed to adjust the mechanical properties, biodegradation, bioactivity, and superior biological properties of bone scaffolds by combining cellulose with different organic and inorganic compounds. In addition, cellulose-based composites are capable of loading therapeutic agents to enhance osteoinduction, osteoconduction, and anti-inflammation properties in bone repair [30,31]. Accordingly, cellulose-based composites have a great chance of being an ideal candidate for regenerative medicine and bone tissue engineering applications.

In this review, we will report and discuss the recent developments and applications of cellulose-based composite scaffolds for regenerating damaged bone tissue and delivering biomolecules to the injured bone site.

2. Cellulose-organic composite scaffolds

Polymers of synthetic and natural origin are broadly chosen as extracellular matrix mimicking biomaterial for advancing functional bone scaffolds. Scaffolds composed of natural polymers including proteins and polysaccharides meet inherent bioactivity. Yet, these materials are not recommended for load-bearing bone tissue engineering purposes due to poor mechanical strength. On the other hand, synthetic polymer-based scaffolds, i.e., PLLA, PCL, etc., degrade slowly and tolerate high mechanical forces compared to the natural polymers; however, they do not promote cell adhesion and growth. Accordingly, in recent years, there has been a significant effort made to improve cellulose scaffolds. Pure cellulose is not biodegradable in the human body and has a poor osseointegration that limits its clinical applications in bone tissue engineering. Broadly, it is pointed out that the incorporation of organic phases into a cellulose matrix enhanced the mechanical strength, biomineralization and stimulated osteogenic differentiation. Furthermore, biodegradability of cellulose-based composite are significantly better than those of pure cellulose materials [[32], [33], [34]]. In this section, bone scaffolds composed of organic biomaterials and pristine cellulose, cellulose ester, some cellulose ethers, or crystalline derivatives will be reviewed to understand the role of cellulose in the composite network.

2.1. Bacterial cellulose-organic composites

BC can be produced by microorganisms such as Gluconacetobacter xylinus, Gluconacetobacter, Agrobacterium tumefaciens, Sarcina ventriculi. Compared to plant cellulose, BC has higher crystallinity (above 60%) and chemical purity, containing no impurities of lignin or hemicellulose [35]. This highly crystalline linear biopolymer with thin organized nanofibers (∼20–100 nm) displays a large surface area, high water-holding capacity, and mechanical strength [36]. BC scaffolds were implanted in different bone defects created in the tibia, calvarial bones, and skull in rats and promoted new bone formation without any inflammatory reactions [37]. In polymeric-based bone composites, BC with nanofibrous crystalline structure enhances mechanical strength, while other polymeric parts are commonly added to the network for sharing biological properties. For example, BC-COL nanocomposite was fabricated to support bone repair under enhanced mechanical and biological conditions. Native human bone is the richest source of the connective tissue components comprising type I, type III, and type IV COL. Type I COL fibers as the main organic component (90% of the organic matrix) within the mineralized bone matrix are responsible for supplying tensile strength and expediting bone cell interactions [13]. Similarly, bone composite scaffolds of COL could stimulate bone cell adhesion, growth, and differentiation in an ideal biological environment. For instance, Saska et al. designed a flexible BC nanocomposite scaffold by incorporating type I COL into the polymeric structure [38].. Adding COL reduced the crystallinity, elastic modulus, and tensile strength of the final nanocomposite scaffold relative to the BC scaffold. It is expected that this flexibility facilitates the manipulation of the nanocomposite for surgical procedures. The in vitro examinations verified the osteogenic differentiation and ALP activity of the primary osteogenic cells cultured on this nanocomposite. A nanocomposite scaffold of BC-COL with an interconnected porous structure was also evaluated both in vitro and in vivo [39]. Using the freeze-drying method, ice crystals in BC-COL were transformed into water vapor, resulting in random pore size and interconnected pores, while the residual solvents were removed. This nanocomposite scaffold stimulated osteogenic differentiation of umbilical cord blood-derived MSCs through suitable cell ingrowth and nutrient transport within interconnected pores, and neovascularization was observed after subcutaneous transplantation of the nanocomposite in animal models. In addition, intrinsic water absorption and resistance to contraction of BC increased the water uptake and physical stability of the final scaffold, respectively. Using BC in another polymeric network, i.e., PHB, also enhanced the mechanical strength and biological properties. Good cytocompatibility, cell growth and proliferation were obtained in vitro experiments, and bone matrix production, as well as OSX expression and ALP activity referring biomineralization, was achieved from in vivo examination in critical sized bone defects induced in mice [40].

2.2. Cellulose acetate-organic composites

CA, the acetate ester form of cellulose, is the most abundant natural polysaccharide produced by organic reagents and solvents, and it should be mentioned that its structure is unique in component (occupying about two of third hydroxyl groups of main backbone chains with acetate groups). It is noteworthy that CA is an environmentally friendly material with adjustable biodegradability, wettability, and it is possible to use renewability of this material with the association of admirable processability [41]. Although CA has a lower degree of crystallinity, this material is more favorable due to desirable mechanical strength and electrospinability comparable with other forms of cellulose. Thus, the mentioned properties can prove its versatile application in the bone tissue engineering research [42]. Furthermore, CA can be explored for in vivo studies as a result of having an appropriate molecular weight (30 kDa) because it has been proved that the molecular weight of fewer than 50 kDa can be passed through the kidney [43]. Additionally, CA-based composite scaffolds reveal encouraging up osteoblast attachment, proliferation, migration, and differentiation in vitro due to hydrophilicity and flexibility, and it's bone reconstruction/regeneration in vivo have proved that CA can be explored and applied as a multifunctional platform for simulating bone tissue [44,45].

Considering the interesting findings from CA bone scaffolds, natural polymers involving COL and PULL were combined with CA to obtain progressed functional composite scaffolds for bone repair. Aravamudhan and colleagues achieved an optimized porous structure of CA microsphere matrices via sintering procedure and coated the prepared microspheres with COL type I [46]. For sintering, the CA microspheres were filled into a metal mold containing an adjusted solvent/non-solvent mixture of acetone: cyclohexane and remained until the mixture evaporated. This procedure resulted in the assembling of the microspheres into a unified structure to form a porous scaffold with optimized interconnected pores. After that, COL nanofibers were uniformly deposited on the obtained scaffold via a biomimetic approach to resemble biochemical and biophysical properties of bone matrix. The high coating efficiency of 42% of the COL nanofibers was determined that may be assigned to the hydrophilic nature of CA. This bioactive platform of COL-coated CA microspheres increased the viability and adhesion of human osteoblast cells in comparison with uncoated BC microspheres. This scaffold showed suitable compressive mechanical properties close to the trabecular bone that notably diminished under the wet condition. Regarding outstanding results from COL-coated CA microspheres, the same authors seeded the scaffold with bone marrow stromal cells for more evaluation [47]. Implantation of the cell-seeded composite scaffold into the mouse calvarial critical-sized defect model accelerated the bone healing process and encouraged new bone formation in the region of the bone defect. BMSCs along with the scaffold led to mineral deposition and bone formation by signaling the host cells to enter the defect. Atila et al. developed a cross-linked composite scaffold based on CA-PULL with improved pullulan maintenance using a trisodium trimetaphosphate as a crosslinking agent [42]. PULL is extracted from the fungus Aurobasidium pullulans, and it is a non-toxic, biocompatible polysaccharide with poor mechanical properties [48,49]. Composition with CA and crosslinking the final polymeric network with trisodium trimetaphosphate gave an opportunity to PULL to overcome its mechanical weakness. Finally, this crosslinked CA-PULL scaffold with an equal ratio of the polymers was suitable for bone tissue engineering owing to enhanced mechanical properties, structural integrity during degradation studies, appropriate porosity, uniform fiber morphologies, deposition of apatite-like structures, and cytocompatibility.

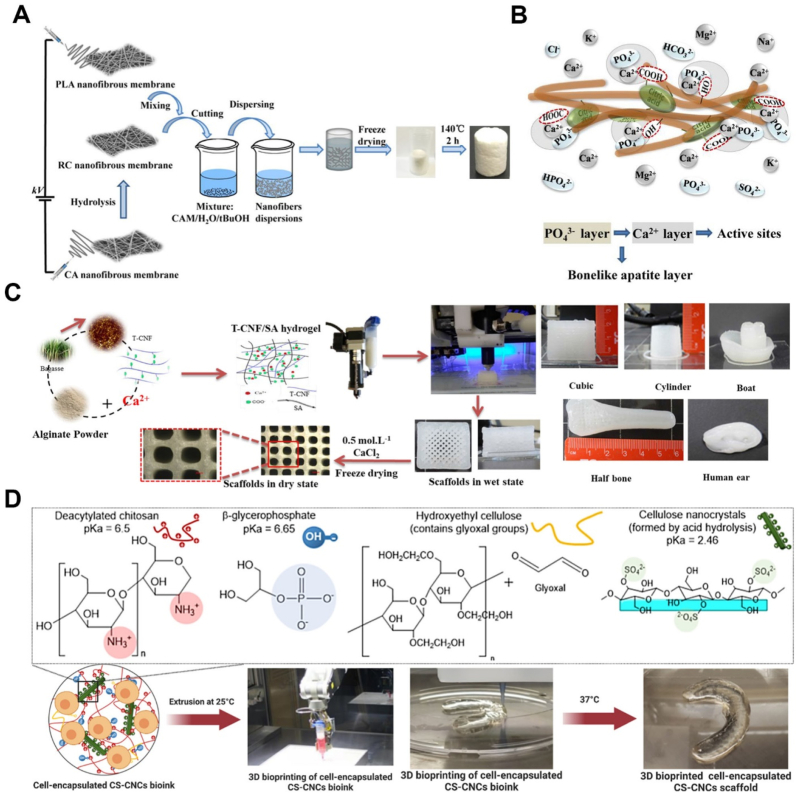

Special attention has been paid to combining CA with synthetic polymers to improve homogenous nanofibers production used for bone tissue engineering. In this regard, electrospun core-shell nanofibers of CA and PVP were developed by homogenous electrospinning without a coaxial needle for biomimetic growth of HAp [50]. PVP and CA owing to low surface energy and high mobility of CA chains were in the shell and core structure, respectively. Prior to mineralization, CA-PVP membranes were treated with deionized water to create the texture of grooves and cavities on the fibers regarding water solubility of PVP which increases the deposition of the mineral crystals. After dipping the treated fibers in SBF solution, mineral crystals with Ca/P ratio of 1.47 nucleated and grew on the surface of the CA-PVP structure. Chen et al. proposed an RC-PLA composite scaffold using a combination of electrospinning and freeze-drying methods for biomineralization and tissue regeneration after bone injuries (Fig. 2 A, B) [51]. Due to the low thickness and restricted shapes of electrospun nanofibers for bone graft, freeze-drying can be used to produce a stable 3D porous scaffold. PLA is a biocompatible polymer that is highlighted by its excellent mechanical properties and biodegradability; however, it has some restrictions of hydrophobicity and a lack of an active site for cell interaction [52]. To address these limitations, RC was generated from electrospun CA nanofibers and then a freeze-dried PLA-RC composite scaffold was prepared. By electrospinning, nanocomposite fibers could be produced that mimic the structure of extracellular matrix, while combining it with freeze drying resulted in a porous structure with appropriate thickness. CA is modified via an alkaline deacetylation process to eliminate the acetate group and produce numerous hydroxyl functional groups for creating esterification crosslinking sites [30]. They reported that the electrospun PLA and RC scaffold were cut, dispersed into the solvent, freeze-dried, and cross-link by citric acid. Water uptake evaluations revealed an increase of around 1300%–3500% that could positively affect cell adhesion and proliferation. Additionally, functional groups of RC-PLA (–COOH, –OH, =C O groups) induced the bio-mineralization process. As a result of the mineral phase deposition, an enhancement in Young's modulus and compressive stress was observed, which could be related to the porosity and confined deformation [51].

Fig. 2.

A. Schematic illustration for PLA/RC scaffold fabrication [51]. B. Calcium and phosphate nucleation by biomimetic method in PLA/RC scaffold [51]. C. 3D printed T-CNF/SA hydrogels in different forms [65]. D. 3D printed cell-encapsulated bio-ink was spontaneously gelled at 37 °C [71].

2.3. Carboxymethyl cellulose-organic composites

CMC is a hydrophilic polysaccharide formed by the chemical modification of cellulose with chloroacetate in an alkali environment. CMC comprises carboxymethyl groups in the C2, C3, or C6 positions of glucose units [53]. Negatively charged water-soluble CMC possesses chelating ability with multivalent cations such as Ca2+. Accordingly, Singh et al. synthesized CMC-SF composite nanofibers for promoting biomineralization in SF bone scaffolds. CMC-SF composite materials were electrospun into nanofibers to create close spatial proximity between bone and scaffold for better osteointegration due to mimic natural extracellular matrix. CMC plays a key role in the uniform nucleation and formation of spherical calcium phosphate crystals on the scaffold through the presence of binding sites on its chains, i.e., COOH and OH functional groups, for calcium cations attachment. As anticipated, CMC increased biomineralization and water uptake in the CMC-SF composite scaffold but demonstrated no significant effect on the mechanical properties. Furthermore, when MSCs has grown on the biomimetic CMC-SF composite substrate, the human MSCs differentiated into the osteogenic lineage [54].

To improve the bioactivity of composite scaffolds based on CMC with high mechanical properties, medicinal plant extracts such as CQ and SO were used in these bone substitutes. For instance, the incorporation of CQ with osteogenic activity into the CMC-CS polymeric network resulted in osteoblast proliferation and mineralization [55]. Moreover, the mechanical strength of the bioactive composite scaffold increased in dry and wet conditions owing to microstructural alterations and reduction of pore size. Also, the incorporation of CQ along with SO as an anti-inflammatory and antioxidant agent with respect, to the CMC-SA scaffold was cytocompatible to the MG-63 Human Osteosarcoma cell line [56].

2.4. Hydroxyethyl cellulose-organic composites

HEC is a water-soluble, non-ionic biopolymer with β-glucose linkage and the capability to bond to various chemical functional groups [57,58]. HEC-based composites have been manufactured by various technologies such as electrospinning and freeze-drying to serve as a bone tissue engineering scaffold. This cellulose ether must be blended with electrospinable biocompatible polymers for the electrospinning procedure due to its non-ionic nature. In this context, Chahal et al. prepared an electrospun nanofibrous composite of HEC-PVA for non-load bearing applications in bone tissue regeneration [59]. The elastic modulus and tensile strength of the nanofibrous composite scaffold increased because of the high tensile strength of HEC. Moreover, the cellular assays proved the cytocompatibility of the HEC composite to human osteosarcoma cells. In another study, Nizan et al. produced a freeze-dried 3D porous nanocomposite scaffold based on HEC-PVA reinforced with CNC [60]. The freeze-drying of HEC-PVA along with CNC nanoparticles provided high porosity and pore interconnectivity with improved nanoparticles stability and prevented nanoparticle aggregation. To reduce the solubility, degradability and increase the physical stability, the prepared nanocomposite was crosslinked by heat treatment at 80 °C. CNC nano-fillers were uniformly distributed within the nanocomposite matrix and created an interconnected pore structure through increasing reaction sites for hydrogen bonding with the polymer chains. The bone cells adhered and proliferated on the HEC-PVP-CNC nanocomposite more efficiently than the HEC-PVP due to its smaller pore size and higher surface roughness.

2.5. Nano- or micro-crystalline cellulose-organic composites

In recent years, CNC and CNF have drawn much attention in bone tissue engineering applications, especially mechanical reinforcement and biomineralization agents. Rod-like particles of CNC are prepared by maintaining crystal regions of cellulose and removing amorphous regions under harsh hydrolysis conditions in acidic media such as sulfuric acid and phosphoric acid. Mechanical techniques are performed for preparing flexible fiber-like CNF composed of both amorphous and crystalline regions with a diameter of less than 100 nm and a length of ≥500 nm [61,62].

CNF has been widely used in bone tissue applications and regenerative medicine, because of its printability, ions deposition, and ability to generate the bone-scaffold interface. In this context, GEL–CNF–based nanocomposite scaffolds were fabricated using CNF, CNF-COOH, or CNF-COOH-ApA [63]. All these nanocomposites demonstrated significantly greater growth and proliferation of MSCs relative to pure GEL scaffold. Furthermore, the addition of ApA moiety to the carboxylated-CNFs in GEL–CNF–COOH-ApA nanocomposite enhanced the HA-like crystals deposition by providing flexible phosphonate groups with high mobility and the capacity of tuning HA patterning through strong ionic bonds with Ca2+ ions. Similarly, a nanocomposite of GEL-TEMPO-oxidized CNF with appropriate mechanical stability and degradation rate obtained a conducive substrate for attachment, spreading, and osteogenic differentiation of hBMSC cells [64]. SA-TEMPO-oxidized CNF hydrogel with improved shape fidelity, mechanical, and biological properties was 3D printed for the bone repair application [65]. CNF enhanced the thixotropic behavior and printability of SA; hence, hydrogel viscosity rapidly recovered before and after applying the shear force. The pure SA hydrogel was soft and simply collapsed, whereas the SA-CNF hydrogel was stable due to balanced viscosity. The printed SA-CNFs hydrogel was cross-linked using calcium chloride solution to achieve a rigid stable scaffold. It was reported that carboxyl functional groups on both SA chains and TEMPO-oxidized CNFs tended to react with calcium cations which resulted in strong binding of the CNFs on the polymer chains and therefore improved mechanical strength. Likewise, it was found that the incorporation of TEMPO-oxidized CNFs improved the stiffness and compressive properties of the hydrogels. Furthermore, biomineralization in the presence of TEMPO-oxidized CNFs and a crosslinking agent resulted in the development of hydroxyapatite with an average crystal size of 25.4 nm, which is similar to natural apatite in native bone tissue (Fig. 2. C). An attempt to design suitable scaffolds for proliferation and osteogenic differentiation involves the use of a TEMPO-oxidized CNF coating via alkaline hydrolysis on PCL scaffold [66]. CNF gave hydrophilic properties and roughness on 3D printed PCL surface to facilitate protein adsorption, actin cytoskeleton formation, alkaline phosphatase activity, mineral formation, and osteogenic differentiation of human bone marrow-derived mesenchymal stem cells.

In bone tissue engineering, it has been shown that the addition of CNC to scaffolds improved matrix mechanical properties, mineralization density, and hydrophilicity [67]. For example, mechanical properties, hydrophilicity, degradability, and cytocompatibility of 3D printed PLLA scaffold was controlled by the addition of CNC fillers into the printer ink [67]. With the 3D printing technology, desired exterior outline could be made from PLLA- CNC to fit the bone defect to mimic the complex patterns of bone defects. A high crystallized strong nanocomposite scaffold was obtained by hydrogen bonding interaction between the hydroxyl group of CNCs and the carboxyl groups of the PLLA matrix. 3% wt.% CNC into the PLLA scaffold increased compressive strength and compressive modulus to 24.0 ± 0.25 MPa and 381 ± 9.54 MPa compared to PLLA scaffold (8.24 ± 0.22 MPa and 84.6 ± 8.95 MPa). By incorporation of CNC fillers into the PLLA scaffold, the water contact angle decreased (from 91.59° to 62.87°) and the weight loss increased (from 9.58 ± 0.25 to 11.65 ± 0.25). In another study, an electrospun PLA-CNC nanocomposite scaffold was fabricated for potential application in the bone tissue engineering [68]. In vivo experiments verified the defect size decreased with improvement in bone regeneration in the vicinity of the nanocomposite scaffold. Electrospun bioactive mats of aligned or random cellulose-CNCs nanofibers were fabricated and functionalized with rhBMP-2 [69]. The evaluation of osteo-differentiation and mineralization capacity for bone repair showed that aligned and functionalized cellulose-CNCs nanofibrous scaffolds increased the proportion of BMSCs and mineralized nodules formation that demonstrated in vitro osteogenic differentiation and ALP activity. Moreover, implanting nanocomposite scaffolds made of cellulose-CNCs-rhBMP-2 with aligned fibers in a rabbit calvarial bone defect promoted oriented collagen deposition on aligned fibers, cortical bone formation, and mineralization in the defective site. Recently, Hong et al. reported a nanocomposite composed of SO-CNCs and PCL with the ability to mineral formation [70]. In this regard, SO-CNCs obtained from sulfuric acid-hydrolyzed CNCs showed improved calcium phosphate mineral formation, and SO-CNC were non-toxic to MC3T3 preosteoblasts at concentrations of up to 3 mg/mL during a 24 h period. Additionally, the incorporation of SO-CNC into nanocomposites as nanofiller and the nucleating agent was shown to enhance the ultimate tensile strength (18.2 ± 0.3 MPa), Young's modulus (492.5 ± 44.1 MPa), hydrophilicity, and calcium-phosphate deposition in presence of carboxyl groups. Maturavongsadit et al. synthesized hydrogels based on CS-CNC along with BGP gelling agent and HEC for bone bioprinting [71]. The volume fraction and hydrogen bonding between CS and CNCs increased the viscosity of the hydrogels when the scaffold contained CNCs and MC3T3-E1 cells (5 million cells/mL). At 37 °C, HEC with glyoxal groups in the polymeric chains can create hydrogel via Schiff-base reaction between CS amine groups and HEC aldehyde groups. ALP activity, collagen synthesis, and high-capacity cell encapsulation of the generated hydrogels make them suitable for bone defect healing. (Fig. 2 D).

Owing to BCN's remarkable merits, this polymer can enhance the porous microstructure, mechanical reinforcement, and biological activity [72]. In contrast, the use of SA for bone tissue engineering is often limited by the lack of cell recognition sites and poor mechanical properties. To address this issue, SA combined with BCN, GEL, and CS have emerged as a way to produce the nanocomposite scaffold with well-defined properties [73]. In this regard, BCN was obtained from sulfuric acid hydrolysis of the pristine bacterial cellulose, and SA-BCN nanocomposite hydrogel alternatively immersed in CS and GEL solutions to obtain layer by layer assembly nanocomposite. Layer-by-layer electrostatic assembly for the surface modification of SA-BCN is effective way to enhance its uniform morphologies and pores due to the high specific surface area and formation of polyelectrolyte complex. CS-GEL layer by layer assembly on the SA-BCN surface improves stability and cytocompatibility owing to the polyelectrolyte complex formation. The produced SA matrix provided uniform morphologies and mechanical reinforcement by entrapping BCN, and the scaffold increased cell attachment due to the reinforcing effect and porous structure, in addition, gelatin as the outer layer improved cell adhesion.

PUs possesses versatile biocompatibility, biodegradability, and physicomechanical properties. which can be regulated by the addition of some polymers such as PAA and HEMA into the PUs matrix. Further, dispersion of CNWs reinforcing materials within the PU matrix significantly promoted mechanical resistance. For example, Shahrousvand et al. investigated the structures and mechanical properties of bimodal foam nanocomposites made of PU and CNW [74]. The combination of PU and CNW seems to have the potential to become an ideal nanocomposite scaffold due to the hydrogen bonding between urethane groups and active hydroxyl groups, which is an appealing choice for hMSC proliferation and osteogenic differentiation. In a similar study, Padash et al. developed PU-PAN-CNW foam matrices that could support proliferation and osteogenic differentiation of human mesenchymal stem cells for potential bone tissue engineering applications [75]. PAN is attractive for biomedical applications due to its high polar nitrile groups for interaction with the biomolecules. They reported an increase in the amount of cell viability (above 90%), osteogenic differentiation, ALP activity, and osteogenic gene expression in presence of nanostructured components that provided a suitable environment of biological properties. Shahrousvand et al. synthesized a Semi-IPNs of PU-PHEMA-CNWs which was seeded with hMSCs [76]. PHEMA is a hydrophilic polymer with suitable mechanical properties. But CNWs play a key role in improving the physical and mechanical properties of the matrix. PU-PHEMA-CNWs fabricated by solvent casting/particulate leaching possessed large and small pores related to salt particles and sugar, respectively. The small pores led to highly interconnected channels that were suitable for cell communication, while the large pores could support cell implantation. The nanocomposite exhibited a higher strength, stiffness, ALP activity, calcium deposition, and osteogenic differentiation was also noticed in presence of PHEMA and CNWs in the PU matrix. In addition to NC, the MCC can be incorporated in polymer matrices to create a suitable matrix for mechanical behavior and biological response improvement. For example, 3D printing has been used to produce composite scaffolds made of PCL and MCC [77]. Moreover, the use of a composite scaffold of PCL-MCC demonstrated that sheep bone marrow cells located significantly on proposed scaffolds, and the presence of MCC caused an increase in cell proliferation and reinforcement effect, likely due to the presence of microtopography and crystallinity normally absent on PCL alone.

It can be assumed from the literature on the cellulose-organic composite scaffolds that cellulosic biomaterials have remarkable effects on physical, mechanical, and biological characteristics. The fabrication method, physical and mechanical properties, and key biological performance of cellulose-organic scaffolds are summarized in Table 1. Hydroxyl functional groups on the cellulose chains act as positions for biomineralization, crosslinking, and intramolecular hydrogen bonding with other organic biomaterials. Therefore, we can have a stable polymeric composite with a tunable porous network and high tolerability for even load-bearing applications. Water holding capacity of the cellulose and some derivatives besides their biomineralization ability can be considered the key cues for directing bone cell behaviors. Taken together, these structural and biological properties can be mainly altered based on types of cellulosic biomaterials and manufacturing methods. Based on the findings, cellulose-based composites are becoming more popular due to their enhanced properties and applicability compared to single-phase materials. Accordingly, there is no one substance that can fulfill all the requirements for tissue regeneration. In order to overcome the disadvantages associated with each kind of material, they have been combined with other materials to use the synergistic advantageous properties. The combination of cellulose with an organic component (COL, SA, PULL, PLA, PHB and etc.) can be used to design successful biomaterials that enhance physical and biological properties. Further, the development of laboratory methods for producing scaffold materials has provided us with a broad range of options for manipulating the physiochemical properties of these materials. These methods such as electrospinning, freeze-drying, 3D printing, solvent casting/particulate leaching and etc. permit the proper processing and use of materials in the laboratory and clinic. In summary, freeze-dried scaffolds led to interconnected porous structures that facilitated the nutrients, oxygen and metabolic wastes exchange to promote the cell and blood vessel ingrowth. On the other hand, fibrous scaffolds made by electrospinning can significantly mimic the structure of the natural extracellular matrix, while, 3D printing provided complex designs for mimicking the shape, size, and dimension of bone defects. Depending on the tissue and its certain characteristics and properties, an appropriate process can be selected to manufacture.

Table 1.

Cellulose- organic composite scaffolds in bone tissue engineering.

| Composite | Fabrication method | Pore size (μm) | Porosity (%) | Mechanical properties | Type of study | Key biological results | Ref |

|---|---|---|---|---|---|---|---|

| BC-PHB | Salt leaching technique | 5–50 | ___ | Tensile Strength (MPa): 15 ± 1.0 Young Modulus (MPa): 1400 ± 101 |

In vitro, In vivo (critical size calvaria defect in mice) | Increased proliferation of 3T3-L1 preadipocytes, in vivo osteoblast differentiation, new bone formation, enhanced ALP activity and OSX expression | [40] |

| CA-PULL | Electrospinning | 20–100 | (41.98 ± 10.56)- (67.64 ± 4.89) | Young's modulus (MPa): (0.43 ± 0.01) to (1.68 ± 0.09) Elastic modulus (MPa): (2.97 ± 0.09) to (5.50 ± 0.79) |

In vitro | Enhanced adhesion, proliferation and differentiation of human osteogenic sarcoma cell line, promoted ALP activity | [42] |

| CA-COL | Oil-in water solvent-evaporation technique | 185.4 ± 8.6 | 33.9 ± 5.2 | Compressive modulus (MPa): 266-(75 ± 33)-22 (Dry scaffold), 130-(53 ± 13)-97 (Wet scaffold) Compressive strength (MPa): 12-(15 ± 2)-23 (Dry scaffold), 7-(15 ± 1)-24 (Wet scaffold) |

In vitro | Increased adhesion and proliferation of human osteoblast cells | [47] |

| PLA-RC | Electrospinning and Freeze-drying | Minor pores: smaller than 20. Major pores: 50 to 150 |

Around 96 | Young's modulus (kPa): 16.5 to 54.9 | In vitro | Increased biomineralization and bone-like apatite formation | [51] |

| Na-CMC-CS- CQ | Freeze-drying | 148–239 | ___ | Compression Moduli (kPa): 654.4 (dry condition), 87.65 (wet condition) |

In vitro | Enhanced adhesion, proliferation, and mineralization of osteoblasts, increased osteogenic activity and ALP activity | [55] |

| HEC-PVA | Electrospinning | (9.55 ± 0.17)- (5.98 ± 0.5) | ___ | Tensile Strength (MPa): 2.63 to 10.54 Elastic modulus (MPa): 188 to 349.25 |

In vitro | Increased attachment and proliferation of human osteosarcoma cells | [59] |

| HEC-PVA-CNC | Freeze-drying | 33.4-∼54.1 | 77 | ___ | In vitro | Increased adhesion and proliferation of human fetal osteoblast cells | [60] |

| TEMPO-oxidized CNF- GEL |

Freeze-drying | 8–150 | 71.4 ± 1.4 | ___ | In vitro | Increased attachment, spreading and osteogenic differentiation of hBMSCs, enhanced RUNX2 and SPP1 expression | [64] |

| CNC-PLLA | Selective laser sintering | 450–600 | ___ | Tensile strength (MPa): 7.93 ± 0.31 Modulus (GPa): 2.33 ± 0.07 |

In vitro | Enhanced adhesion, proliferation and differentiation of MG-63 cells, increased ALP activity | [67] |

| Cellulose-CNCs-BMP-2 | Electrospinning | 272.4 ± 31.64 nm | 77 | ___ | In vitro, In vivo (cranial bone in rabbit) | Increased osteogenic differentiation of BMSCs, enhanced ALP activity and calcium content, induced in vivo collagen assembly direction, cortical bone regeneration | [69] |

| BNC -SA-CS-GEL | Freeze-drying and Layer-by-layer assembly | 30–300 | 77.4 | compressive strengths (MPa): 0.27 | In vitro | Increased attachment, proliferation and differentiation of MC3T3 -E1 cells, enhanced ALP activity | [73] |

| CNW-PU | Solvent casting/particulate leaching | 20–150 | 82 | Tensile strength (kPa): 112 | In vitro | Promoted proliferation, adhesion, and osteogenic differentiation of hMSCs, increased ALP activity and calcium content | [74] |

| CNWs-PU-PHEMA | Solvent casting/particulate leaching | 20–150 | 85 | Tensile elasticity moduli (kPa): 80.5 Tensile strength (kPa): 89.8 |

In vitro | Enhanced osteogenic differentiation of hMSCs and bone mineralization | [76] |

| MCC-PCL | 3D Printing | 450–500 | 57 ± 2 | Compressive modulus (MPa): 7 | In vitro | Increased proliferation of sheep bone marrow cells | [77] |

3. Cellulose-inorganic composite scaffolds

Calcium phosphate-based bioceramics such as HAp are well-known osteoconductive inorganic materials, while bioactive glasses are generally recognized as osteoinductive biomaterials. Tissue-engineered scaffolds of both inorganic biomaterials are being developed for bone regeneration, even though their brittleness and low fracture toughness have remained a big challenge. One strategy being investigated to promote the structural integrity and mechanical properties of the inorganic scaffolds is to compose them with biopolymers. Here, we will review the literature on cellulose-inorganic composites to clarify the influence of the organic part, i.e., cellulose or its derivatives, on the properties of the final structure as a bone scaffold.

3.1. Bacterial cellulose-inorganic composites

Bone tissue engineering consists to reconstruct/regenerate damaged bone tissue, using organic and inorganic substances or a combination of those to simulate its functionality because bone natural tissue contains two major components; an organic matrix (COL) and an inorganic phase (HAp and CP). Among diverse types of synthetic and natural polymers [78], BC can be used to fabricate tissue-engineered scaffolds due to its prominent properties as we discussed in Section 2.1. From material point of view, as a result of non-animal origin, BC is compatible and does not cause any allergic response in comparison with COL. Interestingly, various studies reported that BC and COL fibers are similar in structure [79,80]. In addition, BC has high mechanical strength; 2 GPa tensile strength, and 138 GPa Young's modulus, and these results proved BC can provide mechanical performance close to the natural bone tissue which has been reported that the tensile strength and Young's modulus are approximately 15–20 GPa and 100–160 GPa, respectively. In addition, the textural properties of BC are distinguishable from plant cellulose; it has smaller nano-fibers and higher tensile strength due to the nano-fibril network structure [81]. Thus, the mentioned properties make this a potential bio-membrane for bone tissue regeneration. However, the main drawback of BC in bone tissue engineering is the inability to bond directly to the bone tissue [82]. To overcome these limitations, some studies have been reported based on incorporating HAp into pure BC. For instance, Fang et al. and Hong et al. [83,84], fabricated BC-HAp nanocomposite scaffold via soaking BC membrane into SBF solution in two separated studies. Their results showed that BMSCs adhered and proliferated on BC-HAp composite scaffold better than pure BC, and ALP activity and the expression of osteopontin, osteocalcin, bone sialoprotein was far better than those seeded on pure BC. It had been shown the amount of apatite growth and its crystallinity was associated with soaking time. Moreover, ionic interactions were occurred between negatively charged OH groups of BC and calcium ions of SBF, where calcium ions can bind phosphate ions to create the initial nuclei, then apatite formation was enhanced by uptake of phosphate and calcium ions from the surrounding SBF fluid. Similar results were observed by Sundberg et al. which fabricate interconnected macroporous BC composite scaffold through using paraffin porogen particles, then mineralized with HAp [85]. The results indicated that although HAp incorporation resulted in smaller pore size, it did not have a negative effect on cell/scaffold interaction and ALP activity. Additionally, Tazi et al. showed osteoblast attachment and growth can be promoted on BC-HAp composite scaffold compared with pure BC due to the presence of phosphate and calcium on the surface of the BC-HAp composite scaffold [86]. Another study has been reported based on in vivo evaluations, Saska et al. generated BC nanocomposite membrane via alternative soaking technique. Compared with plant cellulose, it had no allergic reactions, experimentally, and BC membrane enhanced apatite's particles growth substantially which may be related to better textural properties (nanofiber diameters ranged 10–50 nm) and larger surface area [87].

In addition, few studies have shown that pure BC cannot support apatite formation. Thus, different modification methods were employed to enhance physicochemical properties of BC scaffolds such as, the phosphorylation [88], electron beam radiation [89], surface modification [90,91], and alkaline treatment technique [92]. BC membrane suffers from a lack of apatite formation. It should be noted that hydroxyl groups of BCs cannot provide a potential site for nucleation and growth of apatite crystals. For example, Wan et al. fabricated a BC-HAp nanocomposite scaffold with soaking BC fibers into static culture containing CaCl2, then its surface was modified through phosphorylation procedures by phosphoric acid (H3PO4) in dimethyl formamide (DMF) [88]. The results showed that apatite formation improved with phosphorylated BC fibers which revealed durable ionic interaction between the phosphate groups and calcium ions. Another study was reported by Ahn et al. BC-HAp composite scaffold was developed by electron beam irradiation to alter physicochemical properties and enhance HAp adsorption [89]. The results showed that HAp adsorption was associated with incubation time. Moreover, mechanical properties were enhanced due to more HAp content. In addition, the biological properties were improved in comparison with pure BC. In the other study, Zimmermann et al. produced BC bone-like nanocomposite structure via a bioreactor/pump system, then the surface was modified with CMC, which resulted in a higher apatite formation [90]. Similar results were also observed by Wan et al. where the BC membrane was modified by CNT coating [93]. It resulted in a smaller nanofiber diameter because of the evaporation of excess gases at 600–1200 °C during the carbonization procedure, which enhanced carbon content, improved HAp formation as well. In addition, Gao et al. produced BC/polylysine nanocomposite scaffold in order to enhance the apatite formation [91]. Based on the reported results, polylysine (cationic charge, NH+3) and BC (anionic charge, OH−) resulted in the formation of BC-polylysine nanocomposite scaffold, which soaking BC-polylysine into CaCl2 enhanced Ca+2 adsorption onto the membrane due to electrostatic interaction. Thus, the applied method improved apatite formation. Niamsap et al. combined CNCs into BC-HAp nanocomposite scaffold as a dispersant agent for preventing HAp agglomeration [94]. The biological properties revealed no cytotoxicity potential while CNCs combinations resulted in superior physicochemical properties. Another study was designed to modify the biological properties of BC nanocomposite membrane with alkaline treatment technique, which resulted in improving apatite nucleation ability of BC, where Ca+2 activation enhanced ionic interaction between negatively charged hydroxyl groups and calcium ions [92]. The magnetized BC-HAp containing Fe3O4 nanocomposite scaffold was also synthesized by Torgbo et al. and it was revealed that adding magnetite NPs resulted in improving mechanical properties (Compressive strength: 9.87 MPa; Stiffness: 1.85 GPa) with appropriate porosity (81.1%), which is similar to human cancellous/trabecular alternative bone tissue [95]. Moreover, by adding Fe3O4 to the BC-HAp structure, the surface roughness increased and consequently resulted in enhanced osteoblast cells viability and proliferation.

In addition, appropriate pore size, biodegradability, and bioactivity were considered prominent to produce the bone-like structure. In this regard, some studies have been designed to address this issue. It should be noted that one reason for blending BC into HAp is the lack of proper pore size, which is noticeable in the scaffold characterization [83]. Regarding the previous studies, Zimmermann et al. and Grande et al. reported that the cell/scaffold interaction of BC nanocomposite membrane is limited due to the micro-textural properties of [90,96]. However, the structural properties of BC-HAp composite scaffold showed better interaction comparable with pure BC. To develop a well-designed substrate for bone tissue regeneration/reconstruction, oxidized BC-HAp nanocomposite scaffold was prepared by laser patterning technique because the nano-fibrous structure (about 50–200 nm) of pure BC was not suitable for vascularization and cell migration, and it did not show in vitro degradation experimentally. The results revealed osteoblastic cells were attached and proliferated on oxidized BC-HAp nanocomposite scaffold more than pure BC which was related to larger pore size (about 300 μm), and the in vitro degradation was increased up to 25% which made it a better candidate for bone tissue engineering [97]. Different approaches were designed to modify the membrane's porosity, such as in situ with porogens [[98], [99], [100]] or ex vivo with laser treatment [97,101,102]. However, the lack of interconnectivity also needs to be addressed. Another study was reported by Bayir et al. developed a novel BC-HAp composite scaffold by shredded agar technique, which was based on the dispersion of different percentages of agar NPs into Hestrin & Schramm solution homogenously to enhance pore size [81]. The results showed a larger pore size (275 μm) proper for SaOs-2 cell attachment and proliferation, and mineralization was enhanced compared with pure BC. In general, fully BC biodegradation in the body could prove BC application as an ideal biomaterial because its exclusive monomers are glucose which has an influential effect on cell growth. Hu et al. fabricated BC membrane, further incorporating cellulase enzyme to promote the rate of in vitro degradation, which showed 100% biodegradation after 4 weeks into SBF [103]. Moreover, scaffolds for guided bone tissue regeneration (GBTR) need to be bioactive and biocompatible [104], which can be suitable substrates for bone tissue formation and pharmaceutical applications [105]. In this regard, Luz et al. produced an oxidized BC membrane with the incorporation of Sr, which has a similar performance to Ca2+ to immobilized bioactive enzymes for enhancing osteogenesis and improving in vitro degradation [106]. The results showed oxidized BC adsorbed more Sr than pure BC because of enhanced targeted sites, which then enhanced water uptake capacity. The in vitro degradation and bone tissue regeneration also were enhanced substantially both in vitro and in vivo. In addition, Ramani et al. showed that incorporation of GO into BC-HAp structure produced with wet chemical precipitation technique tailored in vitro degradation in comparison with pure BC [79]. The mechanical properties were not reported, while in vitro degradation results mentioned that incorporation of GO into BC-HAp composite scaffold could make a compact network comparable with pure BC. Moreover, the osteogenic activity and cell compatibility could demonstrate a potential membrane for bone tissue regeneration.

Although, the incorporation of inorganic materials like HAp, CP, and BG can induce osteoconduction and osteoinduction, being brittle and mechanically weak have been recognized as the main drawbacks of the inorganic materials [107]. A combination of synthetic biopolymers and crosslinking agents like glutaraldehyde were studied previously to enhance the mechanical strength of these composites [37]. It had been proved that mechanical properties of HAp scaffold increased after the combination of BC to its microstructure [108]. Besides, blended BC-HAp showed far better osteoconductivity and biocompatibility than COL-HA [109]. Furthermore, different techniques were employed to improve the mechanical properties of the BC-HAp composite scaffold [90]. For instance, Gutiérrez-Hernández et al. used MWCNTs-loaded BC-HAp nanocomposite scaffold to reinforce mechanical/biological properties [110]. The results showed MWCNTs functionalized with carboxyl groups resulted in decreasing risk of toxicity due to negatively charged surface, which is more favorable for osteoblastic attachment and proliferation.

The bone-like apatite can be evaluated and created in vitro via SBF, so this technique has been recognized as a prominent approach to estimate the bioactivity of the composite [111]. To improve apatite layer formation, BC gel was placed in SBF solution containing Ca2+ and ions. In another study, BC membrane was soaked into static culture and mineral phase which improved apatite layer formation [112]. Another method, which was based on fabricating BC/nano-HAp composite scaffold is the electrospinning [113]. This technique is a versatile approach because it can make a proper membrane with adjustable fiber diameter, pore size, porosity, tensile strength, using a wide range of natural and synthetic polymers to develop a bone-like structure.

3.2. Plant cellulose-inorganic composites

Cellulose is a main structural component of plant cell walls and can be easily extracted from plant sources especially wood and cotton [[114], [115], [116], [117], [118]]. Additionally, plant-derived cellulose is inexpensive and plentifully available. Plant fibers offer a wide range of properties, especially excellent mechanical strength and flexibility, and provide adjustable biodegradation [115] which can promote HAp properties—such as improving mechanical properties and increasing the rate of in vitro degradation in order to produce a well-defined bone tissue-like construction [[119], [120], [121]]. Although collagen is a natural part of the bone structure that can be a suitable site for HAp nucleation and growth, it suffers from inadequate mechanical strength [115]. The physicochemical and biological effects of plant cellulose have been studied in many research areas [115,122]. Ma et al. used a bamboo source to prepare plant cellulose [115]. First, bamboo fibers (BF) were characterized, where BF properties were observed under different conditions and treatment including alkali-treated (NaOH solution), acid-treated (H2SO4 solution), and dissolved BF into NaOH. Then BF-HAp nanocomposite scaffolds were produced through the precipitation method. The results clearly show that alkali treatment and dissolved BF resulted in reduced apatite formation due to decreased hydrogen bonds compared with pure BF. On the other hand, the acid-treated technique enhanced HAp nucleation and growth. However, all prepared nanocomposite scaffolds revealed suitable mechanical strength, water absorption, bioactivity, and cell compatibility. In another study He et al. prepared cellulose from cotton which was produced into NaOH/urea aqueous solution at −12 °C, then Na2SO4 aqueous solution was used to produced cellulose-HAp nanocomposite scaffold [122]. The prepared porous cellulose-HAp nanocomposite scaffold showed good mechanical properties because of particle reinforcement agent and strong bonding between cellulose and HAp, which resulted in good cell compatibility, where 293T cells spread and proliferated well on the surface due to appropriate pore size.

Despite researchers have tried to address different requirements of bone tissue-like structure with the incorporation of HAp into cellulose scaffold including good textural properties (pore size and porosity), mechanical properties (elastic modulus and compressive strength), sufficient bioactivity (apatite nucleation and growth), and cell compatibility, it is not yet accessible to fabricate the scaffold with similar properties as same as bone tissue with just incorporation of HAp into cellulose. To achieve this goal, Saber-Samandari et al. investigated titanium dioxide (TiO2)-incorporated polyacrylamide-grafted cellulose (from cotton by dissolving into dimethylformamide and lithium chloride)-HAp nanocomposite scaffold via freeze-drying method [114]. The presence of TiO2 resulted in producing an interconnected nanocomposite scaffold with appropriate internal roughness, similar mechanical strength with trabecular bone tissue. In addition, the incorporation of TiO2 decreased water uptake capacity. The cell/scaffold interaction with L929 cells also showed good biological properties.

3.3. Cellulose acetate-inorganic composites

To induce bone formation and HAp mineralization on cellulose derivative, different techniques such as HAp-coating, grafting of adhesive peptides, oxidation, and phosphorylation have been explored [[123], [124], [125]]. Despite HAp can promote bone cell osteogenic differentiation and biomineralization, it suffers excessively from poor mechanical properties and poor dispersion and aggregation in the polymer solution [126,127]. To overcome poor mechanical strength and dispersion, some techniques were purposed, including surface functionalization and co-electrospun nanoparticles [128,129]. For example, Liu et al. produced GO-incorporated CA nanocomposite electrospun scaffold which resulted in decreasing nanofiber diameter (from 595 to 285 nm) due to higher electron charge density, improving substantially mechanical strength (Young's modulus and the tensile stress were 7.2 and 2.7 times more than pure CA), and biomineralization of GO-incorporated CA scaffold was much higher than pure CA because the anionic hydroxyl and carboxyl groups of GO enhanced Ca2+ deposition which resulted from in mineralization, apatite nucleation and growth as well as enhancing the osteogenesis of hMSCs [128].

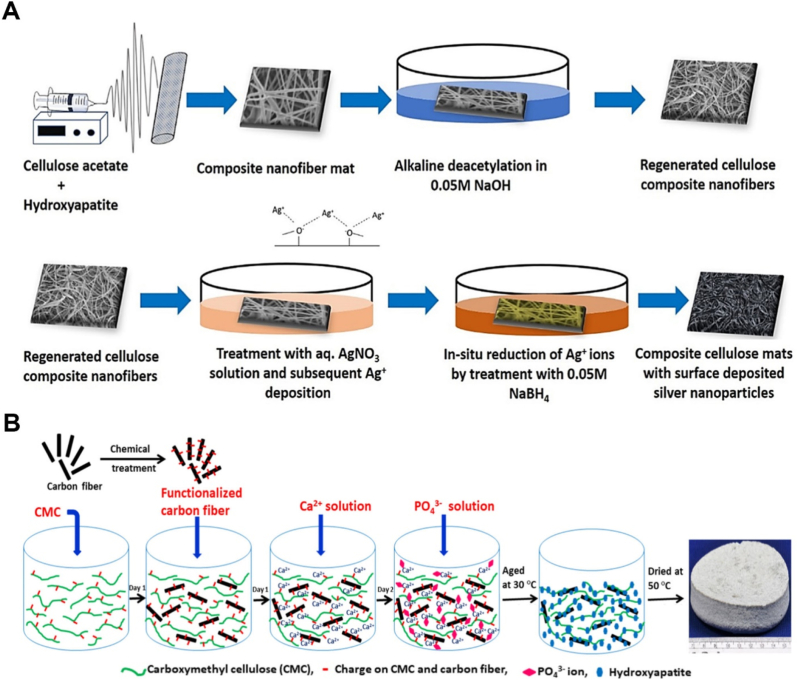

In addition, some studies were accomplished to produce RC using CA [130,131]. The main purpose of these investigations is to use unique properties of pure cellulose such as desirable mechanical strength, higher crystallinity, lower solubility, better hydrophilicity, and slow in vitro degradation which is more favorable in the bone tissue engineering [132]. For example, Sofi et al. developed RC nanocomposite electrospun scaffold via facilely alkaline de-acetylation technique [133]. Next, HAp and Ag NPs were incorporated into the prepared nanofibers via surface coating through electrostatic and van der Waals interactions (Fig. 3 A). The acetone-water solvent was used as a dispersion agent, then NaOH was used to de-acetylate RC nanofibers. The incorporation of HAp and Ag resulted in promoting apatite layer formation and biological properties. In addition, antibacterial activity was enhanced against S. aureus and E. coli.

Fig. 3.

A. Illustration of the fabricating regenerated cellulose fibers containing HAp and Ag NPs [133]. B. Schematic of creation of 3D carbon fiber reinforced CMC-HAp ternary composite [142].

3.4. Carboxymethyl cellulose-inorganic composites

During recent years, CMC has been drawn much attention in bone tissue engineering applications. CMC as a cellulose derivative is spectacular in structure because it is developed as follows: replacing some carboxymethyl groups with hydroxyl groups which results in higher biocompatibility and water solubility, designing for a wide range of biomedical demands [134], such as the cell adhesion properties to fabricate tissue-engineered scaffolds [135]. In addition, some studies have been reported that CMC can induce expression of BMSCs [136] and osteoblast cells [137]. Thus, CMC can be applied for bone tissue regeneration. For example, Qi et al. fabricated CMC-CP composite scaffold via alternative soaking technique into Na2HPO4 and CaCl2 solution, and for evaluation of osteoblast cells behavior and tissue formation, it was assessed both in vitro and in vivo [134]. The prepared scaffold enhanced osteoblast differentiation of hMSCs with higher Sp7 and Osterix expression (osteoblast markers), calcification, and ALP activity as well. Moreover, in vivo evaluations on the mouse calvarial model revealed an improvement in bone tissue regeneration compared to the control group.

Although prepared CMC as an anionic membrane offers biocompatibility and biodegradability, it suffers from a lack of appropriate mechanical strength [137]. CMC can improve apatite formation due to offering carboxyl groups (-COOH) which have been explored by different methods including in situ synthesis [138], co-precipitation [139], one-pot synthesis method [140,141], and wet precipitation [142]. Garai et al. fabricated a CMC-HAp nanocomposite scaffold with different percentages of CMC by using the biomineralization process (calcium nitrate aqueous solution) [143]. The results demonstrated that there was a linear relationship between porosity percentages and mechanical properties, where increasing porosity percentage resulted in higher mechanical characteristics. It should be noted that the mechanical properties (compressive modulus: 157–330 MPa; compressive strength: 1.74–12 MPa) of the CMC-HA nanocomposite scaffold were equal with the cancellous bone. Therefore, it can be concluded that, in addition to chemical compositions, the textural properties can affect directly on the mechanical properties and the cellular behaviors [144]. Another study also proved the importance of using HAp, where they fabricated CMC-HAp nanocomposite scaffold via one-pot technique [140]. The one-pot technique is a novel approach employing gel foam as pore-forming agent, which also the presence of gel enhanced its osteogenic activity. Moreover, another study was carried out by Sarkar et al. designed to enhance mechanical properties of CMC-HAp composite scaffold with the addition of carbon fiber (CF), where its compressive strength, flexural strength, and flexural modulus were increased significantly after a combination of CF into the membrane as same as human bone tissue (Fig. 3B) [142]. Therefore, excellent biocompatibility, biodegradability, and bioactivity make CMC a multifunctional platform for producing a bone tissue-like structure. However, their properties can be developed, and the mechanical properties need to be modified.

3.5. Nanocellulose-inorganic composites

As mentioned in section 2.5, CNCs and CNWs are well-known as promising and strong materials for producing bio-composite scaffolds because of reliable and adjustable properties, such as excellent biocompatibility, renewability, non-immunogenicity, and stiffness [145,146]. In addition, having Young's modulus ∼130 GPa, plus providing highly hydrophilic substrate as a result of a multitude of hydroxyl groups make CNCs and CNWs as potential candidates for bone tissue engineering comparable to COL or SF. Some studies are designed to show the potential of CNCs and CNWs through combining organic and inorganic materials because the inorganic phase improves the physicochemical properties of the organic material [147,148]. For instance, Fragal et al. fabricated a functionalized CNWs nanocomposite scaffold with carboxylic (COO−) or amine (NH2) groups by biomimetic mineralization process (CaCl2 solution) in order to induce targeted sites to increase HAp nucleation and formation, where Ca+2 and PO4−3 ions were bonded to the hydroxyl, carboxyl and amine groups which resulted in promoting hydrogen and anionic interactions [145]. All obtained data proved that this manipulated structure enhanced osteogenesis as well as cell/scaffold interaction, suggesting a prominent scaffold for bone demands. In another study, 45S5 BG was prepared with foam replication method, then coated with CNWs through dip-coating technique to improve its properties [148]. The prepared nanocomposite scaffold resulted in a highly porous and interconnected membrane, and mechanical properties were modified while it did not negatively affect bioactivity and cell compatibility (MG-63 cells) due to favorable pore size and morphological properties, and the wettability was also enhanced. Furthermore, a CNWs-based composite scaffold with specific surface compositions was designed to observe the chemical effect of different inorganic acids (HCl, H3PO4, and H3SO4) in the biomimetic method as well wet chemical precipitation. The results showed preparation of CNWs-based scaffold by biomimetic method resulted in higher HAp nucleation and growth than wet chemical precipitation. Interestingly, CNW(H3SO4)-HAp illustrated better physicochemical and biological properties among other composite scaffolds, i.e., CNW(HCl)-HAp and CNW(H3PO4)-HAp, which exerted unique cell viability and apatite growth. However, CNCs and CNWs are not degradable in the human body, and by just combining CNCs or CNWs with HAp, the composite scaffold would show poor mechanical properties [87,149]. Thus, simulating bone structure through using CNCs or CNWs has not yet completely addressed the requirements.

To fabricate a similar structure to bone tissue, some researches have been focused on combining CNCs or CNWs with other substitutes or using different approaches [[150], [151], [152], [153]]. For instance, Huang et al. designed a process to enhance mechanical properties of CNC [150]. To improve HAp nucleation, the sulfonic groups as an activate agent were replaced with ionic groups (like calcium ions). They fabricated CNC-HAp composite scaffold via freeze-casting method by applying different temperature. The HAp content was controlled with pH (reaching ∼ 47% at pH = 9.0), and the porosity was determined with HAp content and freezing temperature (from 70 to 91% with different percentages and temperature). The high mechanical properties (compression modulus and compression stress were 227.6 kPa and 61.7 kPa, respectively) was achieved due to its oriented structure and textural properties. To promote biodegradability and mechanical properties, CNC-HAp composite scaffold crosslinked with PEG and poly (methyl vinyl ether-alt-maleic acid) via esterification reaction, then freeze-casted for producing porous membrane [151]. The results illustrated that mechanical strength (Compression strength: 41.8 MPa) improved significantly (over 20 times higher than CNC-HAp). In addition, in vitro test of composite scaffolds showed the degradation rate was increased substantially, and the highly porous membrane (∼91%) was compatible as it improved bovine serum albumin protein stabilization and reduced the rate of inactivation.

In conclusion, the composition of cellulose-inorganic demonstrates favorable physical, chemical, mechanical, and biological properties especially for bone tissue regeneration. The fabrication method, physical and mechanical properties of cellulose-inorganic scaffolds and key biological results are shown in Table 2. Herein, the various cellulose-based materials (bacterial cellulose, plant cellulose, cellulose acetate, carboxymethyl cellulose, and nanocellulose) and adding inorganic materials to cellulose in bone tissue engineering are reviewed. In addition, as it is discussed above the differences of properties between cellulose-based composite materials and pure cellulose materials is mentioned to shed light the effect of adding inorganic substances into cellulose materials which demonstrate that the physico-chemical and biological properties showed better properties compared to pure cellulose. These composites exhibited desirable features due to apatite formation, osteogenic activity, osteoconduction and osteoinduction, which are unachievable by pure cellulose materials alone. The capability of cellulose and its derivatives to be modified and easy to be processed has made it a multifunctional platform for further studies towards bone tissue engineering.

Table 2.

Cellulose-inorganic composite scaffolds in bone tissue engineering.

| Composite | Fabrication method | Pore size (μm) | Porosity (%) | Mechanical properties | Type of study | Key biological results | Ref |

|---|---|---|---|---|---|---|---|

| BC-HAp Fe3O4 nanoparticles |

Ultrasonic radiation | _ | 81.1 | Compressive strength (MPa): 9.87 Stiffness (GPa): 1.85 |

In vitro | Enhanced viability and proliferation of osteoblast cells | [95] |

| BC-HAp | Laser patterning technique, then modified using periodate oxidation | 300 | _ | Tensile strength (MPa): 0.16 Elastic modulus (MPa): 1.05 |

In vitro | Induced attachment and proliferation of osteoblast cells | [97] |

| TiO2-cellulose-HAp | Freeze-drying method | 70–130 | 87 | Compressive strength (MPa): 4.1 | In vitro | Increased attachment, viability and proliferation of fibroblast cells | [114] |

| CMC-HAp-Gel | One-pot method | 2.5–900 | 80 | Compressive strength (MPa): 11.8 ± 1.5 Compressive modulus (GPa): 0.243 ± 0.031 |

In vitro | Enhanced osteogenic activity | [140] |

| CMC-HAp-PVA | Biomineralization process | 1–10 | 11–80 | Compressive strength (MPa): 1.74 to 12 Compressive modulus (MPa): 157 to 330 |

In vitro | Improved migration and proliferation of bone marrow-mesenchymal stem cells | [143] |

| CNW-45S5 BG | Foam replication | 200–550 | 93 | Compressive strength (MPa): 0.06 ± 0.01 | In vitro | No negative effect on bioactivity and cytocompatibility of MG-63 cells | [148] |

| CNC-HAp-PEG- PMVEMA | Freeze-casting | _ | 91 | Compression strength (MPa): 41.8 | In vitro | Improved bovine serum albumin protein stabilization and reduced the rate of inactivation | [151] |

4. Cellulose-organic/inorganic composite scaffolds

To prepare a functional scaffold based on cellulose mimicking bone tissue, we need a proper choice of composition of organic and inorganic biomaterials that should be organized in a homogenous integrated network via appropriate fabrication methods. Consequently, in this section, we will report the recent efforts for scientific research on the use of cellulose-organic/inorganic composites in bone regeneration applications.

4.1. Bacterial cellulose-organic/inorganic composites

Numerous investigations have been conducted on multicomponent organic/inorganic BC-GEL/HAp composite scaffolds for bone tissue engineering. In one study, a nanocomposite of enwrapped BC nanofibers into crosslinked GEL network was successfully synthesized and then a homogenous layer of HAp was bio-mineralized on the surface of the BC-GEL composite [154]. MSCs well interacted with this bioactive nanocomposite and recognized it as a suitable substrate for proliferation and growth. In another study, a BC membrane was modified via laser patterning technique in order to introduce parallel-microchannel arrays (approximately 200–300 μm in diameter) into the surface [155]. After that, the prepared BC membrane was coated with GEL and immersed into SBF for HAp deposition. This micro-pattern topography supplied a substrate with large and interconnected pores for attachment and proliferation of chondrogenic rat cells. Recently, a nanocomposite of BC-GEL/BHAp was fabricated and characterized for bone tissue engineering [156]. The mechanical and biological properties of the nanocomposite were significantly improved relative to the neat GEL scaffold. The biological results indicated an increase in attachment, proliferation, differentiation, and migration of Saos-2 cells within nano BHAp-containing composites. Here, boron had a determinative role in the direction of cellular activities. This essential trace element presents at a concentration around 56 ppm in healthy human bone, which stimulates new bone formation helping the variety of the metabolic actions and preventing tissue loss [157].

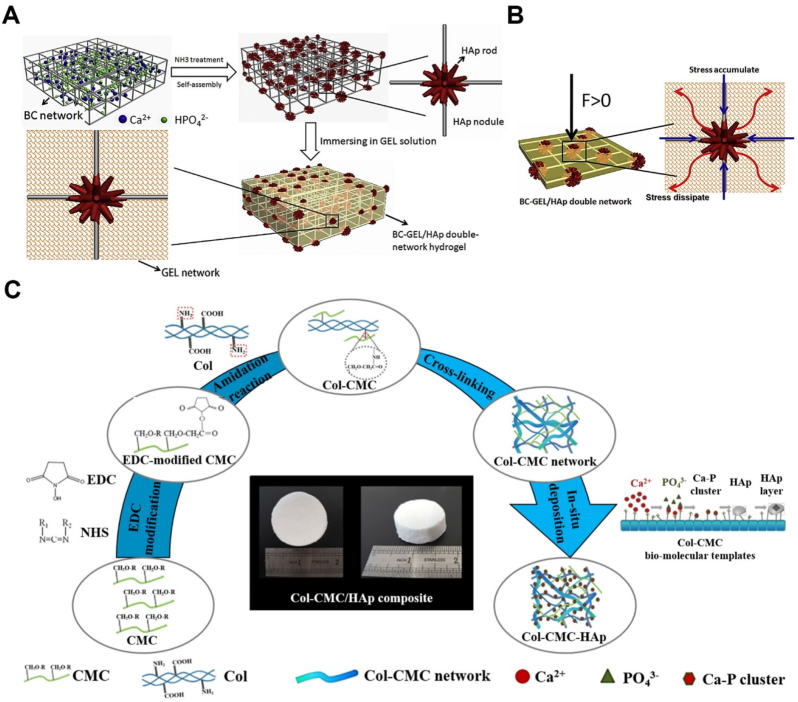

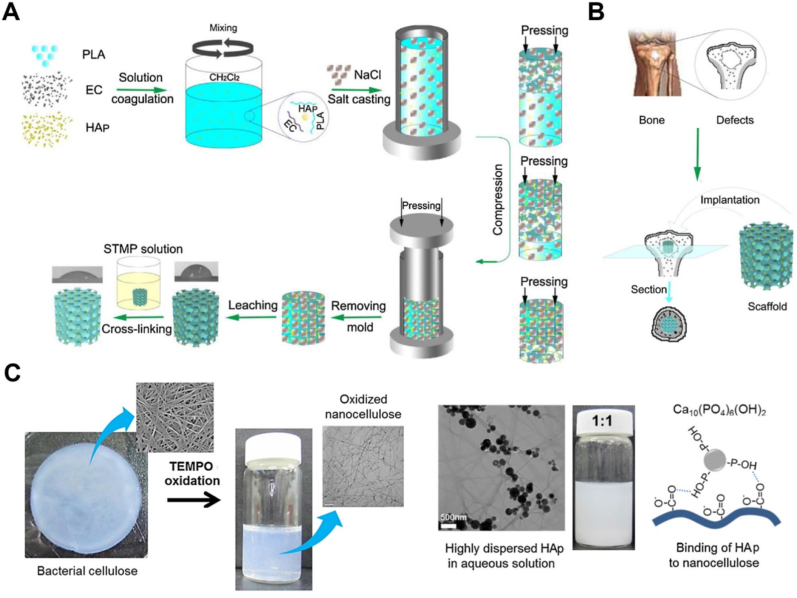

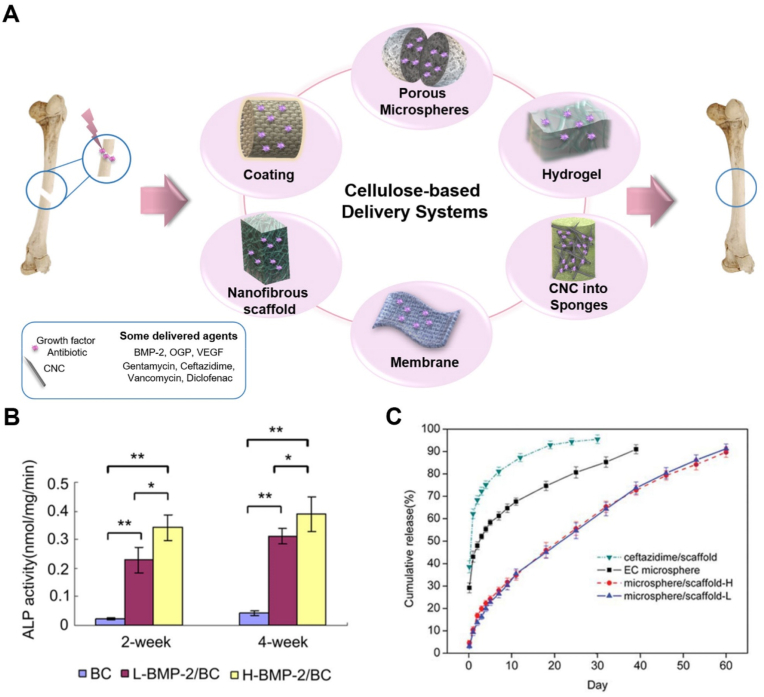

In the above-mentioned reports, the mechanical strength of the composites was not highlighted, instead, those studies mainly focused on the biological properties of the composite construct. Taking augmentation of the mechanical aspects into consideration, a double network scaffold of the BC-GEL containing HAp NPs was constructed. For this purpose, the BC-HAp network was prepared and at the next step, GEL was incorporated into the nanocomposite to modulate the brittleness and stiffness. The final nanocomposite scaffold revealed high compressive strength and tensile strength in comparison with BC-HAp and BC-GEL. The structure of the nanocomposite was mechanically stabilized through the self-assembly of HAp NPs at the nodules of the BC network and the dissipation of the accumulated stress at these sites by GEL molecules. According to the results of biological experiments, rat bone marrow-derived MSCs cultured on the BC-GEL/HAp showed better adhesion and higher proliferation than those cultured on the BC-GEL network (Fig. 4 A, B) [158].

Fig. 4.

A. Schematic of preparation process of the BC-GEL/HAp hydrogel [158]. B. Schematic of stress dissipating of the BC-GEL/HAp composite under external load [158]. C. Schematic of the formation mechanism of Col-CMC/HAp composites [176].