Highlights

-

•

US pretreatment increased the particle size of MCC.

-

•

Surface chemical component was changed by US treatment.

-

•

US treated powders showed lower moisture absorption ability.

-

•

Solubility of MCC was not affected by US.

Keywords: Powder flow, Ultrasound, Moisture sorption, MCC

Abstract

This research investigated the effect of ultrasound (US) pretreatment prior to spray drying on the powder flow and moisture sorption behaviour of micellar casein concentrate (MCC). MCC produced from skim milk microfiltration was sonicated at energy intensity of 0 (control), 47 J/mL (S-2000), 62 J/mL (S-3000) and 76 J/mL (S-4000). The results revealed that US pretreatment significantly increased the average particle size (D50) from 82.46 μm to 100.73 μm and reduced the surface fat content from 19.2% to 13.8%, resulting in decreased basic flow energy, cake energy and cohesion. Besides, the US treated samples showed relatively poor ability to acquire the moisture from the atmosphere than the control. Protein structure analysis showed that α-helix decreased with enhanced US power, while β-sheet and surface hydrophobicity increased, implying hydrophobic groups were exposed and water sorption rate was impeded. As a result, US pretreatment can improve the powder flow and potentially reduce the negative effect of cake formation at high humidity.

1. Introduction

Ultrasound is considered as a nonpolluting and nonionizing form of energy that is generated by mechanical vibrations that produce sequential compression and rarefaction waves in a liquid [1]. Power ultrasound, especially the low frequency ultrasound, is used to change the physical and chemical properties of food by inducing pressure, shear, and temperature difference in the medium and has been applied to dairy research in microorganism inactivation [2], [3], components extraction from cells or tissues [4], [5], enzymatic activity acceleration or inactivation [6], [7] and emulsification improvement [8].

Micellar casein concentrate is a high casein dairy powder with notable nutritional and functional properties for high value commercial applications such as infant and sports nutrition products [9]. In order to extend its potential application, the latest research on the application of US to high-protein powder is mainly focused on the protein modification to improve its solubility [10], foaming properties [11], emulsification [12] and gel properties [13], [14]. However, bulk processing and application of high protein milk powders are often challenging and strongly affected by their poor flow properties. In transporting, handling and processing operations, powder flow properties are very crucial, as changes in flow properties can result in a poor quality or stoppages in processing [15]. In addition, the relative humidity of the environment surrounding a high-protein dairy powder is also a factor that will impact the nature and extent of interparticle interactions occurring in the bulk powder.

With the growing market for high-protein dairy powders, there is a continual need to tailor and control the flow properties of such powders. The methods to improve the flowability of high-protein dairy can be roughly divided into two types: (i) particle size control such as enhancing average particle size [16], narrowing the size distribution [17], [18] and (ii) surface modification such as changing the sphericity or applying surface treatment (enzyme, ozone etc.) to reduce the attractive forces [19], [20]. Mercan, Sert and Akın [15] have been used high-pressure homogenization to produce modified skim milk powder prior to spray drying and found the cake strength and cohesion index was improved compared with the control. Given these changes to the flow properties of the powder particles by high shear treatment, the application of the ultrasound would be a potential choice. To our knowledge, few research has been published on the improvement of MCC powder flowability with ultrasound. The main objective of this research is to evaluate the effect of ultrasound treatment on powder flow and moisture sorption properties of micellar casein concentrates.

2. Material and methods

2.1. Sample preparation

The micellar casein concentrate was obtained according to our previous work by using a 3× stage microfiltration system equipped with a 100 nm pore size ceramic membrane [21]. Then the liquid MCC was immediately transferred to a 10 L metal tank and sonicated using a 20 kHz ultrasonic horn (70 mm diameters, Hongxianglong Biotec, HXL-4000, Beijing, China) at 2000, 3000 and 4000 W for 15 min. During ultrasonication, the temperature of the liquid MCC was controlled below 40 °C through circulating cooling water. The power output (P) and energy density were calculated as follows [22]:

| (1) |

where m is the mass of the sonicated liquid (g); cp the specific heat (J/g K); dT/dt is the slope at the origin of the curve (K/s).

| (2) |

where P represents the power output (W), t is the time (s), v is the volume (mL). According to these calculations, the power output (P) was determined to be 198, 258 and 316 W by calorimetry and the energy density were 47, 62 and 76 J/mL respectively. After ultrasonication, the liquid MCC was subjected to spray-dried (GEA Process Engineering Inc., Dussseldorf, Germany) at 160 °C inlet air temperature and 85 °C outlet air temperature with an atomizing pressure of 0.2 MPa. The spray-dried powder was composed of 80.1% (w/w) protein, 4.5% (w/w) moisture, 1.3% (w/w) fat, 7.6% (w/w) ash, 6.5% (w/w) lactose and stored in containers for further analysis.

2.2. Particle size distribution

The particle size of the MCC powder was determined using a Malvern S3500 (Malvern Instruments, Malvern, UK) image analysis-based particle characterization system. The measurement was made using refractive indices of 1.54 for the particle and the general-purpose model for irregular particles was used to analyse the data [23]. The span of distribution was calculated as: span= (D90-D10)/D50 where the diameters D10, D50 and D90 represent the particle size at 10%, 50% and 90% in a cumulative size distribution respectively.

2.3. Basic flow energy, cake energy and cohesion

FT4 Powder Rheometer (Freeman Technology, Tewkesbury, UK) was used to evaluate the rheological behavior of the powders by measuring the basic flow energy (BFE) before and after cake formation to quantify the resistance. Before powder flow analysis of MCC powders, conditioning cycle procedure was carried out in order to extinguish any user loading difference and to regularize the powder column after lifting. The conditioning cycle consisted of a downward movement of the rotating blade at a tip speed 60 mm/s and path angle of 175° and then an upward movement at a tip speed 60 mm/s and path angle of 175° [24]. After conditioning cycle, the cell is split to remove any powder above a bed height of 80 mm. Then a standard one-test procedure was applied to the bed of powder in the glass vessel (25 mm × 25 mL), whilst applying normal stresses and a helix angle of 5° by rotating the blade (23.5 mm) anti-clockwise with a tip speed of 60 mm/s, thus driving into the powder bed [25]. The torque acting on the blade and vertical force acting on the base was measured and used to calculate the basic flow energy, BFE, which is given as follows and represents the resistance encountered in the movement [26].

| (3) |

where T is the impeller torque, R is the impeller radius, fbase is the force acting on the base, α is the helix angle and h is the impeller penetration depth.

Cake energy (CE): After loaded sample and conducted conditioning cycle, MCC powder was compressed with a compression head (diameter of 48 mm) at a consolidation stress of 3 kPa to stimulate cake formation. Then the compression head was replaced with a blade (23.5 mm) and the experiment was carried out according to the BFE test procedure.The area under the energy cascade curve represents the total CE, which represents the total resistance by powder cake in the movement.

Cohesion: Shear test was determined according to the method of Louati, Bednarek, Martin, Ndiaye and Bonnefoy [27]. Based on the data of normal stress(σ) and shear stress(τ), the mohr–coulomb equation (τ = σ tan(γ) + C) was used for linear regression(γ) to obtain yield trajectory under consolidation stress, and the cohesion C was obtained.

2.4. Dynamic vapor sorption (DVS) and spreading pressure

Moisture sorption and desorption isotherms of MCC powders were obtained with a dynamic vapor sorption analyzer DVS (Surface Measurement Systems, London, UK) equipped with a Cahn microbalance according to the procedure described by Deshwal, Singh, Kumar and Sharma [28]. Spray-dried powders were exposed to the ramping humidity profile from 0% to 98% RH. Then Guggenheim-Anderson de Boer (GAB) equation that was given as follows [29] was used to model water sorption data from 10% to 85% RH and the water content of each sample was plotted as a function of aw.

| (4) |

where aw is the water activity, m (g/100 g non-fat dry solid) is the equilibrium water content, is the monolayer moisture content (g/100 g non-fat dry solid) and K and C are constant. The monolayer moisture content is defined as the water necessary to cover by absorption to hydrophilic and polar groups the entire food surface, including pores and capillaries.

Spreading pressure (π, J/m2), also termed the excess free energy, can be regarded as an expanding pressure exerted by the water film acting against the surface tension of the adsorbent and has been used as the diffusion driving force in porous solids which was used to analyze the sorption phenomena [30]. π is an indicator of the increase in surface tension in the free sorption sites because of the adsorption of molecules [31].

| (5) |

where the Boltzmann constant KB is 1.38 × 10−23 J/K, T is the temperature (K), Am is the surface area of a water molecule (1.06 × 10−19 m2), and C and K are constants in the GAB isotherm model.

2.5. Protein structure analysis and surface hydrophobicity

The changes in the secondary structure of micellar casein concentrate were determined using a Fourier transform infrared (FTIR) spectrum instrument (Model Tensor 27, Bruker Corporation, Bremen, Germany) with an ATR crystal prism accessory according to the method detailed in Ragab, Zhang, Pang, Lu, Nassar, Yang, Obaroakpo and Lv [32]. Peaks corresponding to the second structure were as follows: 1648–1660 cm−1 for α-helix; 1610–1636 cm−1 and 1682–1690 cm−1 for β-sheets; 1661–1681 cm−1 for β-turns; and 1637–1647 cm−1 for random coils.

Hydrophobicity of the MCC solutions was measured according to the procedure described by Yan, Xu, Zhang and Li [33]. MCC powders were first diluted to 4% with a buffer at 7.2, then a series of protein concentrations (0.005–0.25%) (w/v) from each MCC solution was prepared and ANS-Na (sodium-8-anilino-1-naphthalene sulfonate) was added. The relative fluorescence intensity (RFI) of the protein solutions was recorded using a fluorescence spectrometer (F-2500, Hitachi, Ltd., Tokyo, Japan) at excitation and emission wavelengths of 390 nm and 470 nm. A scatter plot of net RFI with protein concentration was applied to calculate the hydrophobicity.

2.6. X-ray photoelectron spectrometer and scanning electron microscopy

Surface atomic chemical elements of C, N, and O of MCC powder were determined using a Thermo ESCALAB 250 X-ray photoelectron spectrometer (Kratos Analytical, Manchester, UK) equipped with a monochromatic Al Kα X-ray (hѵ =1486.6 eV) operated at 150 W. From C, N, and O percentages, the relative amount of fat, lactose, and protein of some dairy powders have been calculated with a matrix formula created from the elemental compositions of the pure milk components [34].

Images of MCC powders were viewed with a SU8010 table-top Scanning Electron Microscope (SEM) (Hitachi High-Technologies Corporation, Tokyo, Japan) with a 10 kV accelerating voltage [24].

2.7. Solubility of spray-dried MCC powder

Powders were added to 150 mL of deionised water in 400 mL beakers to attain 1% (w/v) protein suspensions. The changes in average particle size of the MCC suspensions during magnetic stirring at a constant speed (750 rpm) was determined with a laser light scattering analyser (Malvern Mastersizer 3000, Malvern Instruments Ltd., Worcestershire, UK) with the refractive index of 1.58 at 25 °C [35]. The average particle size of each sample was measured at each 20 min intervals, which took approximately 120 min.

The solubility of the samples was determined according to the method of Anema, Pinder, Hunter and Hemar [36] with slight modifications. Aliquots of stirred MCC solutions were withdrawn and the supernatants were obtained by centrifugation at 2000 g for 10 min at 25 °C. The solubility was calculated according to the following equation:

| (6) |

where W1 and W2 represent the solids in the supernatant and bulk MCC solution respectively.

2.8. Statistical analysis

Analyses were done in triplicate. The data were statistically analyzed with SPSS 18. One-way analysis of variance (ANOVA) with a 95% confidence interval was used to assess the significance of the results obtained. The ANOVA data with P < 0.05 were considered as statistically significant.

3. Results and discussion

3.1. Powder flow behavior

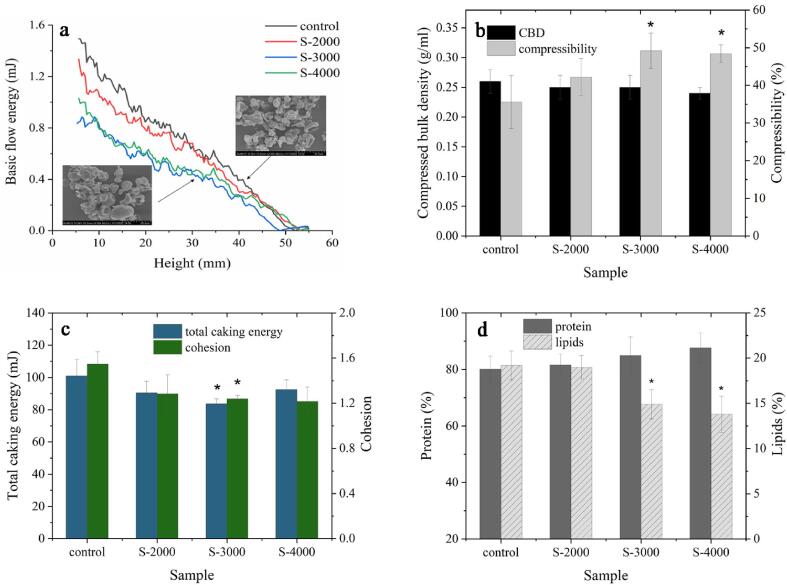

Table 1 shows the particle size distribution of the spray dried MCC powders with or without ultrasound pretreatment. Increasing sonication energy intensity significantly changed the particle size distribution. D50 and D90 increased from initial 82.4 and 110.3 μm to 100.7 and 131.2 μm, while D10 was not significantly affected. The increase in particle size of micellar casein concentrates on ultrasonic treatment is thought to be mainly due to the increased whey protein, casein-casein and casein-whey protein aggregates caused by activation [37], [38]. Owing to the increased particle size, the bulk density of the US treated MCC samples became lower and the space between individual particles increased, reducing the contact area and affect powder flow. Likewise, reducing particle size tends to reduce flowability, because the particle surface area per unit mass increases as particle size decreases, providing a greater surface area for surface cohesive forces to interact and resulting in more cohesive flow [16]. The significantly higher BFE of the control supported this observation (Fig. 1a). In addition to the presence of large aggregates, the temperature of the US-treated samples during spray drying also affect the powder particle size distribution. Previous study have shown that prolonged ultrasonic is often accompanied by the rise of liquid temperature (sometimes over 60 °C), resulting in decreased protein concentrate viscosity prior to spray drying and decreased powder particle size [37].

Table 1.

Particle size values of sonicated micellar casein concentrates powders.

| Sample | D10 (μm) | D50 (μm) | D90 (μm) | Span | BD1 (g/mL) |

|---|---|---|---|---|---|

| Control | 29.44 ± 2.48a | 82.46 ± 3.49a | 110.30 ± 3.45a | 0.98 ± 0.07a | 0.17 |

| S-2000 | 32.16 ± 0.36a | 97.13 ± 4.35a | 114.60 ± 4.11a | 0.89 ± 0.06a | 0.16 |

| S-3000 | 33.16 ± 3.25a | 100.19 ± 10.15ab | 131.21 ± 11.46b | 0.97 ± 0.14a | 0.15 |

| S-4000 | 32.79 ± 1.47a | 100.73 ± 12.80b | 123.46 ± 12.33ab | 0.91 ± 0.10a | 0.15 |

Values are means (n = 4); means in the same column not sharing a common superscript letter are significantly different (P < 0.05).

BD: bulk density after conditioning cycle process.

Fig. 1.

a: Basic flow energy and SEM images of the unsonicated and sonicated micellar casein concentrate samples. b: Compressed bulk density (CBD) and compressibility of the unsonicated and sonicated micellar casein concentrate samples. c: Total cake energy and cohesion of the unsonicated and sonicated micellar casein concentrate samples. d: Protein and lipids(fat) content in the particle surface of the unsonicated and sonicated micellar casein concentrate samples.

During the production, dairy powders were usually conveyed pneumatically through a series of pipes or driven by screw, sometimes over a very long distance within the factory [16]. Cohesive powders, such as MCC, have the ability to build up at compact areas of conveying lines such as elbow bends or form the cake between screw blades caused by mechanical stress. At these points, such cohesive powders will collide with a solid surface and cohesion between particles cause excessive powder build-up, which may cause blockages of powder conveying lines, resulting in process down time [39]. Thus, the decrease in flowability caused by caking phenomenon must be considered. To study the effect of US on caking, a compaction stress of 3 kPa was applied to the powder to stimulate cake formation. Due to the increased particle size and decreased bulk density, US treated MCC powder exhibits greater compressibility under the same compacting stress. As shown in Fig. 1c. The total cake energy for all the samples was between 100.92 and 83.59 mJ, and the highest value was observed in the control. In other words, the total cake energy of MCC powder tends to decrease with the increase of ultrasonic intensity. The cohesion represents the force required to lift the milk powder out of the column with the rotating blade and a lower cohesion indicates decreased cohesiveness between particles, resulting in a decrease in cake strength (Fig. 1c). Except for the average particle size, powder flow was also related to the chemical surface composition. For whole milk powder, their surface is nearly totally covered by free-fat, then the methods involved changing the powder free-fat content such as adding additional fat or protein prior to spray drying will not contribute to additional surface coverage with free-fat [40]. But for milk powder containing less fat content, the situation may be different, and minor changes would heavily affect the surface composition and powder flow. The XPS spectra of O, N and C within the powder samples showed binding energy of 528–536, 396–404 and 282–290 eV respectively. Based on the calculation, the elemental surface composition of the US-treated powder particles was slightly richer in N than the control, implying more protein and less fat content on the surface. During the production of dairy powders by spray drying, fat contained in the atomised droplet will be preferentially located at the powder particle surface during atomisation and subsequent drying, resulting in excess fat at the surface when compared to bulk of the powder [41]. This phenomenon also occurs even in protein-dominated milk powders such as milk protein concentrate (MPC) and milk protein isolate (MPI) [42]. The presence of fat at the surface of powders has a major influence on milk powder cohesiveness, with greater content leads to greater cohesiveness, usually adversely influencing their flowability and rehydration properties. Kim, Chen and Pearce [34] compared the flowability of skim milk powder (SMP) and whole milk powder (WMP) with similar protein content under various particle size and found SMP had lower shear stress. The increase in cohesion was attributed to fat liquefaction resulting in the formation of liquid bridges between the particles. In contrast, the poor flowability of the powders with high surface fat coverage could be drastically improved by removal of fat present on the surface through a brief wash with petroleum ether [43]. As a result, US pretreatment can reduce negative effect of cake formation in MCC powders.

3.2. Moisture absorption

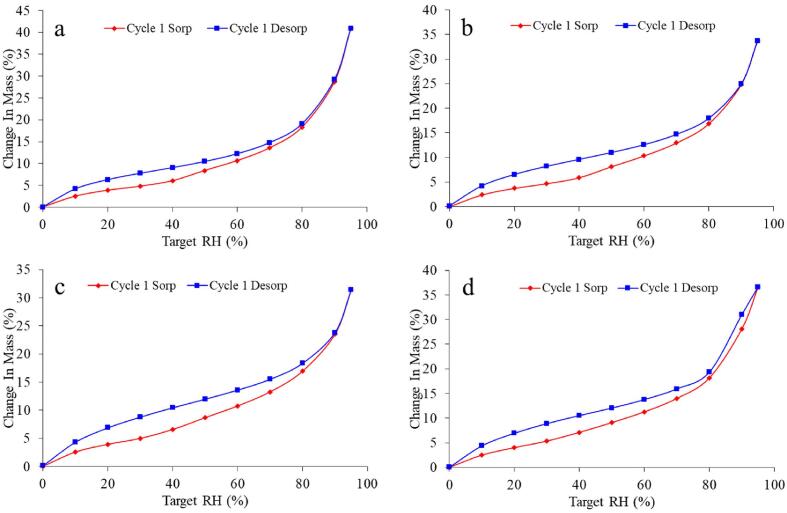

The caking of amorphous food powders with low moisture content is the undesirable transformation of readily free-flowing solids into a consolidated mass that reduces the quality and functionality of the powder, typically when large quantities of powders are stored [44]. In addition to the load or a mechanical force applied to form the cake, the environmental conditions are influential in driving the time consolidation effect, with elevated humidity typically increasing the rate and extent of creep. Like most dairy powders, MCC powders with a subset being deliquescent, have the ability to dissolve in moisture acquired from the atmosphere. Generally, increasing the ambient RH will lead to moisture-absorption and the total mass increase (Fig. 2). At a low RH (below 30% RH), the water uptake rate (slope of the curve) is relatively low. The moisture uptake in this region is probably dominated by surface adsorption. Above 60% RH moisture adsorption increases dramatically, most likely due to bulk absorption dominating the sorption mechanism [45]. The highest water sorption rate and mass changes were observed in the control, while the US treated MCC powders showed lower hygroscopicity and less mass changes. In other words, the US treated samples have relatively poor ability to acquire moisture from the atmosphere, and this is beneficial for powder storage under high humidity conditions. Besides, a sorption hysteresis (which means adsorption potential higher than desorption potential) was observed when RH was below 70% during desorption process, and the US-treated powders have larger lag area than the control, indicating the powders at water adequate conditions was well-hydrated and had a certain moisture holding capacity. Unlike lactose-dominated milk powder, the mass could return to the origin after desorption and no additional water was retained. Due to the glass transition and lactose crystallization, the internal structure of the lactose-dominated powder such as SMP or WMP would be changed during the moisture absorption and desorption process, so that a part of the moisture can still be bound after the desorption is completed [46], [47].

Fig. 2.

Water vapor sorption and desorption isotherm plot at 25 °C of the unsonicated and sonicated micellar casein concentrate samples. a: control, b: S-2000, c: S-3000, d: S-4000. Red line represents the moisture sorption process, blue line represents the moisture desorption process. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)

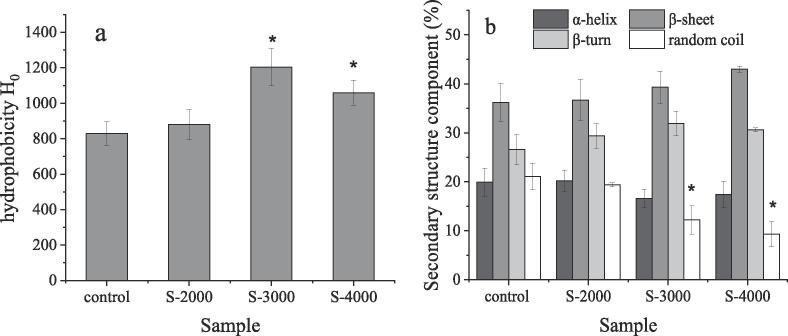

Generally speaking, the smaller the particle size, the lower the hygroscopicity, which is mainly related to the contact area between water molecules and particles and the connection of polar groups of macromolecules. But for protein dominated dairy powder, the water binding ability was mainly depended on protein, irrespective lactose and fat. Therefore, the hydrophobic of the protein was also a factor. Compared with the control, the US treated sample showed higher hydrophobicity, implying parts of hydrophobic portions of protein were appeared which may impede the water absorption. This result was supported by the result of protein secondary structure changes. Fig. 3 shows the changes in the structure of the milk samples, particularly in the amounts of apparent β-sheet and α-helix. In general, a steady increase was observed in β-sheet structure, while a concomitant steady decrease was observed in the α-helix and random coil structure of all samples when compared with the control. The β-sheet structure is connected by intermolecular or intramolecular hydrogen bonds, which helps to maintain hydrophobic amino acids in the internal structure [48], [49]. The increase of β-sheet indicated that the hydrophobicity of the surface increases due to the exposure of hydrophobic sites.

Fig. 3.

Hydrophobicity (a) and secondary structure component (b) changes of the unsonicated and sonicated micellar casein concentrate samples.

3.3. Sorbed water properties

The GAB model was used to model the experimental water content of samples equilibrated at aw of 0.1–0.85 and the parameters are given in Table 2. Monolayer moisture content corresponds to the moisture level above which water bonded to ionic and polar molecules begins to behave as a liquid phase and represents the optimal moisture content for storage stability [50]. Thus, the lower m0 of samples corresponded to their lower water contents. The m0 first decreased from around 5.70 to 5.57 g/100 g with increased US power and then slightly increased. Besides, C represents the strength of binding of water to the primary binding sites [31]. After US treated, C of S-3000 samples was increased, implying water bounded stronger in the monolayer in S-3000 samples than in other samples.

Table 2.

Monolayer values (m0, g/100 g dry solid), constants K and C for the GAB isotherms.

| Samples | m0 | K(×100) | C | R2 |

|---|---|---|---|---|

| Control | 5.70 | 0.89 | 5.97 | 0.912 |

| S-2000 | 5.64 | 0.89 | 5.94 | 0.914 |

| S-3000 | 5.57 | 0.85 | 6.64 | 0.944 |

| S-4000 | 5.62 | 0.88 | 5.82 | 0.891 |

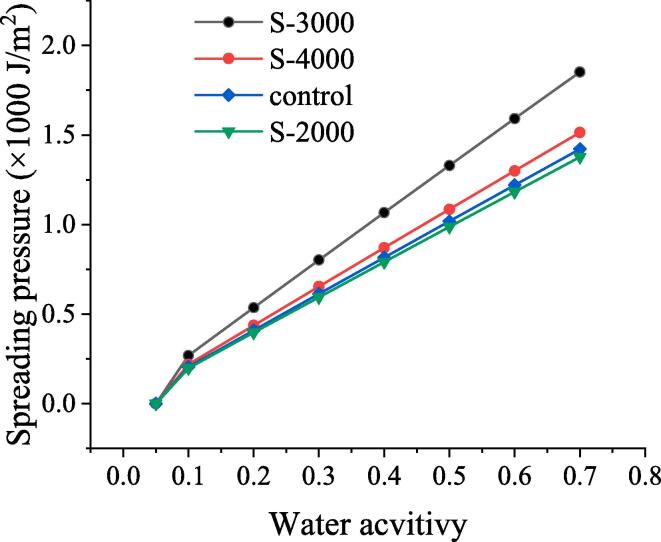

Fig. 4 illustrates the spreading pressure of MCC powder at various aw. US pretreatment increased the spreading pressure of powders at a given aw, and the effects of US increased with increasing aw. These results indicated that the affinity of water molecules to active sites were reduced under US treatment, making it hard to absorb water. Under cavitation effect, the protein structure was changed and more unavailable sorption sites were exposed. This result was in accordance with the hydrophobicity results that US pretreatment enhance the exposure of hydrophobic groups (Fig. 4).

Fig. 4.

Spreading pressure of the unsonicated and sonicated micellar casein concentrate samples.

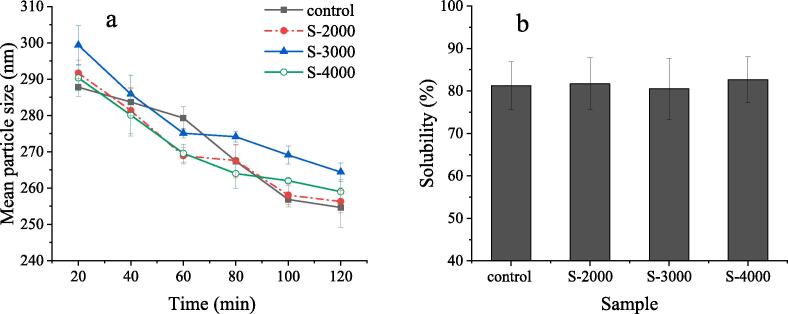

3.4. Solubility

The results in section 3.1 and 3.2 showed that the hydrophobicity and average particle size of US treated MCC were increased compared with the control. Owing to the fact that hydrophobicity and average particle size was related to water contact area and contact angle, the solubility of MCC powder may be affected. Therefore, changes in particle size during rehydration process and the final solubility value needs to be determined. When the dissolved average particle size of MCC without ultrasonication during stirring was closed to the liquid MCC particle size (roughly 240 nm) prior to spray drying, the stir would be stopped and the time was recorded (roughly 2 h). As shown in Fig. 5a, the particle size of all MCC powder samples decreased with prolonged stir time, and the average particle size of US treated MCC was higher than the control, typically within the initial 20 min dissolution process. But with prolonged dissolution time, the difference between the particle size of US treated samples and the control became narrower until no significant difference was observed. This result was also supported by the final solubility that the fresh powder dissolved in water with a similar solubility of 83.2 ± 5.6%. Recent research on the strategies to improve the dairy powder solubility by ultrasonication mainly focus on the rehydration process after spray drying. Consistent results were obtained that the shear force and temperature caused by cavitation could improve the dispersion, resulting in higher broke up rate of agglomerated powder particles such as SMP, MPC and MCP [10], [22], [51]. But the results on dairy powder solubility by ultrasonication prior to spray drying are sometimes confronting and the mechanism is not confirmed. The results of Yanjun, Jianhang, Shuwen, Hongjuan, Jing, Lu, Uluko, Yanling, Wenming, Wupeng and Jiaping [12] showed that solubility of reconstituted milk protein concentrate is increased by ultrasound treatment (20 kHz, 20 min), which is caused by conformational changes in the globular structure of the proteins, exposing the number of charged groups and greater water–protein interactions but some research found US (24 kHz, 600 W) had little effect on the solubility of MPC [23], [52]. The various results might be related to inherent characteristics of the proteins, frequency, time and intensity of sonication treatment. But they all agreed the US provides some protection against storage-induced loss of solubility.

Fig. 5.

Mean particle size changes during rehydration process (a) and final solubility (b) of the unsonicated and sonicated micellar casein concentrate samples.

4. Conclusions

Cohesive high protein milk ingredients, such as micellar casein concentrate (MCC), exhibit poor flowability during transporting, handling and processing, particularly in high humidity condition. The use of high shear techniques, such as ultrasound, can greatly improve the flowability of powders by increasing particle size and changing surface composition. In addition, the US treated powders showed poor hygroscopicity and certain water holding capacity. However, unlike previous research, the solubility of all US treated samples was not significantly affected. This difference may be related to the difference in US energy density, medium type and medium temperature. In the following experiments, the effect of ultrasound on the flowability and moisture sorption properties of dairy ingredients with higher lactose or fat content (such as SMP, WPC etc.) will be investigated, aiming to study the influence of milk components on ultrasonic effect and expand its application.

CRediT authorship contribution statement

Bo Song: Conceptualization, Methodology, Software, Investigation, Formal analysis, Validation, Writing – original draft. Ping Yao: Investigation. Yumeng Zhang: Software. Xiaoyang Pang: Resources. Shuwen Zhang: Data curation, Supervision. Jiaping Lv: Supervision, Project administration, Funding acquisition.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the National Key R&D Program of China (2021YFD2100700, 2021YFD2100703, 2021YFD2100702), Ningxia Key R&D Program (2021BEF02022), Inner Mongolia Science and Technology Program (2021GG0368). We also appreciate the assistance by Mrs. Yanli, and Mrs. Ying Wang, Electorn Microscope Center of National Key Laboratory of Agro-products processing, MARA, Institute of Food Science and Technology, Chinese Academy of Agricultural Sciences, for their technical support during SEM image analysis.

Contributor Information

Shuwen Zhang, Email: zswcaas@hotmail.com.

Jiaping Lv, Email: lvjiapingcaas@126.com.

References

- 1.Al Khawli F., Zhou J., Wang M., Lorenzo J.M., Munekata P.E.S., Ferrer E., Barba F.J. In: Design and Optimization of Innovative Food Processing Techniques Assisted by Ultrasound. Barba F.J., Cravotto G., Chemat F., Rodriguez J.M.L., Munekata P.E.S., editors. Academic Press; 2021. 1 - Mind the gap in the knowledge of the potential food applications of ultrasound based on its mechanism of action; pp. 1–13. [Google Scholar]

- 2.Abrahamsen R.K., Narvhus J.A. Can ultrasound treatment replace conventional high temperature short time pasteurization of milk? A critical review. Int. Dairy J. 2022;131:105375. doi: 10.1016/j.idairyj.2022.105375. [DOI] [Google Scholar]

- 3.Balthazar C.F., Santillo A., Guimarães J.T., Bevilacqua A., Corbo M.R., Caroprese M., Marino R., Esmerino E.A., Silva M.C., Raices R.S.L., Freitas M.Q., Cruz A.G., Albenzio M. Ultrasound processing of fresh and frozen semi-skimmed sheep milk and its effects on microbiological and physical-chemical quality. Ultrason. Sonochem. 2019;51:241–248. doi: 10.1016/j.ultsonch.2018.10.017. [DOI] [PubMed] [Google Scholar]

- 4.D. Bermúdez-Aguirre, G.V. Barbosa-Cánovas, Power Ultrasound to Process Dairy Products, in: H. Feng, G. Barbosa-Canovas, J. Weiss (Eds.) Ultrasound Technologies for Food and Bioprocessing, Springer New York, New York, NY, 2011, pp. 445-465.

- 5.Rodríguez-Gómez R., Zafra-Gómez A., Dorival-García N., Ballesteros O., Navalón A. Determination of benzophenone-UV filters in human milk samples using ultrasound-assisted extraction and clean-up with dispersive sorbents followed by UHPLC–MS/MS analysis. Talanta. 2015;134:657–664. doi: 10.1016/j.talanta.2014.12.004. [DOI] [PubMed] [Google Scholar]

- 6.Scudino H., Silva E.K., Gomes A., Guimarães J.T., Cunha R.L., Sant'Ana A.S., Meireles M.A.A., Cruz A.G. Ultrasound stabilization of raw milk: microbial and enzymatic inactivation, physicochemical properties and kinetic stability. Ultrason. Sonochem. 2020;67:105185. doi: 10.1016/j.ultsonch.2020.105185. [DOI] [PubMed] [Google Scholar]

- 7.Munir M., Nadeem M., Qureshi T.M., Leong T.S.H., Gamlath C.J., Martin G.J.O., Ashokkumar M. Effects of high pressure, microwave and ultrasound processing on proteins and enzyme activity in dairy systems — a review. Innovative Food Sci. Emerg. Technol. 2019;57:102192. doi: 10.1016/j.ifset.2019.102192. [DOI] [Google Scholar]

- 8.Zhou L., Zhang J., Xing L., Zhang W. Applications and effects of ultrasound assisted emulsification in the production of food emulsions: a review. Trends Food Sci. Technol. 2021;110:493–512. doi: 10.1016/j.tifs.2021.02.008. [DOI] [Google Scholar]

- 9.Carter B.G., Cheng N., Kapoor R., Meletharayil G.H., Drake M.A. Invited review: Microfiltration-derived casein and whey proteins from milk. J. Dairy Sci. 2021;104:2465–2479. doi: 10.3168/jds.2020-18811. [DOI] [PubMed] [Google Scholar]

- 10.Wu S., Li G., Xue Y., Ashokkumar M., Zhao H., Liu D., Zhou P., Sun Y., Hemar Y. Solubilisation of micellar casein powders by high-power ultrasound. Ultrason. Sonochem. 2020;67:105131. doi: 10.1016/j.ultsonch.2020.105131. [DOI] [PubMed] [Google Scholar]

- 11.Nazari B., Mohammadifar M.A., Shojaee-Aliabadi S., Feizollahi E., Mirmoghtadaie L. Effect of ultrasound treatments on functional properties and structure of millet protein concentrate. Ultrason. Sonochem. 2018;41:382–388. doi: 10.1016/j.ultsonch.2017.10.002. [DOI] [PubMed] [Google Scholar]

- 12.Yanjun S., Jianhang C., Shuwen Z., Hongjuan L., Jing L., Lu L., Uluko H., Yanling S., Wenming C., Wupeng G., Jiaping L. Effect of power ultrasound pre-treatment on the physical and functional properties of reconstituted milk protein concentrate. J. Food Eng. 2014;124:11–18. doi: 10.1016/j.jfoodeng.2013.09.013. [DOI] [Google Scholar]

- 13.Zhang Y., Zhang S., Song B., Wang X., Zhang W., Li W., Pang X., Zhu H., Lu J., Lv J. Multi-dimensional analysis of rennet-induced micellar casein gels after ultrasound. Int. Dairy J. 2022;126:105293. doi: 10.1016/j.idairyj.2021.105293. [DOI] [Google Scholar]

- 14.Nguyen N.H.A., Anema S.G. Effect of ultrasonication on the properties of skim milk used in the formation of acid gels. Innovative Food Sci. Emerg. Technol. 2010;11:616–622. doi: 10.1016/j.ifset.2010.05.006. [DOI] [Google Scholar]

- 15.Mercan E., Sert D., Akın N. Determination of powder flow properties of skim milk powder produced from high-pressure homogenization treated milk concentrates during storage. LWT. 2018;97:279–288. doi: 10.1016/j.lwt.2018.07.002. [DOI] [Google Scholar]

- 16.Hazlett R., Schmidmeier C., O'Mahony J.A. Approaches for improving the flowability of high-protein dairy powders post spray drying – A review. Powder Technol. 2021;388:26–40. doi: 10.1016/j.powtec.2021.03.021. [DOI] [Google Scholar]

- 17.Stavrou A.G., Hare C., Hassanpour A., Wu C.-Y. Investigation of powder flowability at low stresses: influence of particle size and size distribution. Powder Technol. 2020;364:98–114. doi: 10.1016/j.powtec.2020.01.068. [DOI] [Google Scholar]

- 18.Vlachos N., Chang I.T.H. Investigation of flow properties of metal powders from narrow particle size distribution to polydisperse mixtures through an improved Hall-flowmeter. Powder Technol. 2011;205:71–80. doi: 10.1016/j.powtec.2010.08.067. [DOI] [Google Scholar]

- 19.Sert D., Mercan E. Assessment of powder flow, functional and microbiological characteristics of ozone-treated skim milk powder. Int. Dairy J. 2021;121:105121. doi: 10.1016/j.idairyj.2021.105121. [DOI] [Google Scholar]

- 20.Er B., Sert D., Mercan E. Production of skim milk powder by spray-drying from transglutaminase treated milk concentrates: Effects on physicochemical, powder flow, thermal and microstructural characteristics. Int. Dairy J. 2019;99:104544. doi: 10.1016/j.idairyj.2019.104544. [DOI] [Google Scholar]

- 21.Song B., Zhang Y., Lu J., Pang X., Wei M., Zheng S., Zhang M., Zhang S., Lv J. Effect of different diafiltration process on the protein fractionation of skim milk by cross flow microfiltration. LWT. 2021;152:112330. doi: 10.1016/j.lwt.2021.112330. [DOI] [Google Scholar]

- 22.Chandrapala J., Martin G.J.O., Kentish S.E., Ashokkumar M. Dissolution and reconstitution of casein micelle containing dairy powders by high shear using ultrasonic and physical methods. Ultrason. Sonochem. 2014;21:1658–1665. doi: 10.1016/j.ultsonch.2014.04.006. [DOI] [PubMed] [Google Scholar]

- 23.Augustin M.A., Sanguansri P., Williams R., Andrews H. High shear treatment of concentrates and drying conditions influence the solubility of milk protein concentrate powders. J. Dairy Res. 2012;79:459–468. doi: 10.1017/S0022029912000489. [DOI] [PubMed] [Google Scholar]

- 24.Addo K.A., Bi J., Chen Q., Wu X., Zhou M., Lyu J., Song J. Understanding the caking behavior of amorphous jujube powder by powder rheometer. LWT. 2019;101:483–490. doi: 10.1016/j.lwt.2018.11.059. [DOI] [Google Scholar]

- 25.Hare C., Zafar U., Ghadiri M., Freeman T., Clayton J., Murtagh M.J. Analysis of the dynamics of the FT4 powder rheometer. Powder Technol. 2015;285:123–127. doi: 10.1016/j.powtec.2015.04.039. [DOI] [Google Scholar]

- 26.Forte G., Clark P.J., Yan Z., Stitt E.H., Marigo M. Using a Freeman FT4 rheometer and Electrical Capacitance Tomography to assess powder blending. Powder Technol. 2018;337:25–35. doi: 10.1016/j.powtec.2017.12.020. [DOI] [Google Scholar]

- 27.Louati H., Bednarek X., Martin S., Ndiaye A., Bonnefoy O. Qualitative and quantitative DEM analysis of cohesive granular material behaviour in FT4 shear tester. Chem. Eng. Res. Des. 2019;148:155–163. doi: 10.1016/j.cherd.2019.05.059. [DOI] [Google Scholar]

- 28.Deshwal G.K., Singh A.K., Kumar D., Sharma H. Effect of spray and freeze drying on physico-chemical, functional, moisture sorption and morphological characteristics of camel milk powder. LWT. 2020;134:110117. doi: 10.1016/j.lwt.2020.110117. [DOI] [Google Scholar]

- 29.Vasiljevic T., Toebes A., Huppertz T. Moisture sorption by dairy powders studied by low-field NMR. Int. Dairy J. 2021;119:105062. doi: 10.1016/j.idairyj.2021.105062. [DOI] [Google Scholar]

- 30.C. Simón, L.G. Esteban, P. de Palacios, F.G. Fernández, A. García-Iruela, Thermodynamic properties of the water sorption isotherms of wood of limba (Terminalia superba Engl. & Diels), obeche (Triplochiton scleroxylon K. Schum.), radiata pine (Pinus radiata D. Don) and chestnut (Castanea sativa Mill.), Industrial Crops and Products, 94 (2016) 122-131.doi:https://doi.org/10.1016/j.indcrop.2016.08.008.

- 31.Han J., Fitzpatrick J., Cronin K., Miao S. Effects of different breakage mechanisms on the physical, water sorption, and mechanical characteristics of infant milk formula. J. Food Eng. 2022;321:110939. doi: 10.1016/j.jfoodeng.2022.110939. [DOI] [Google Scholar]

- 32.Ragab E.S., Zhang S., Pang X., Lu J., Nassar K.S., Yang B., Obaroakpo U.J., Lv J. Ultrasound improves the rheological properties and microstructure of rennet-induced gel from goat milk. Int. Dairy J. 2020;104:104642. doi: 10.1016/j.idairyj.2020.104642. [DOI] [Google Scholar]

- 33.Yan S., Xu J., Zhang S., Li Y. Effects of flexibility and surface hydrophobicity on emulsifying properties: ultrasound-treated soybean protein isolate. LWT. 2021;142:110881. doi: 10.1016/j.lwt.2021.110881. [DOI] [Google Scholar]

- 34.Kim E.H.J., Chen X.D., Pearce D. Effect of surface composition on the flowability of industrial spray-dried dairy powders. Colloids Surf., B. 2005;46:182–187. doi: 10.1016/j.colsurfb.2005.11.005. [DOI] [PubMed] [Google Scholar]

- 35.Shanmugam A., Chandrapala J., Ashokkumar M. The effect of ultrasound on the physical and functional properties of skim milk. Innovative Food Sci. Emerg. Technol. 2012;16:251–258. doi: 10.1016/j.ifset.2012.06.005. [DOI] [Google Scholar]

- 36.Anema S.G., Pinder D.N., Hunter R.J., Hemar Y. Effects of storage temperature on the solubility of milk protein concentrate (MPC85) Food Hydrocolloids. 2006;20:386–393. doi: 10.1016/j.foodhyd.2005.03.015. [DOI] [Google Scholar]

- 37.Sert D., Mercan E., Dinkul M., Aydemir S. Processing of skim milk powder made using sonicated milk concentrates: a study of physicochemical, functional, powder flow and microbiological characteristics. Int. Dairy J. 2021;120:105080. doi: 10.1016/j.idairyj.2021.105080. [DOI] [Google Scholar]

- 38.Yang J., Yang M., Qin J., Zeng Q., Wang Y., Han N.a. Effect of ultrasound on the structural characteristics of fresh skim milk. Food Sci. Technol. Int. 2020;26:222–230. doi: 10.1177/1082013219879257. [DOI] [PubMed] [Google Scholar]

- 39.Fitzpatrick J.J., Iqbal T., Delaney C., Twomey T., Keogh M.K. Effect of powder properties and storage conditions on the flowability of milk powders with different fat contents. J. Food Eng. 2004;64:435–444. doi: 10.1016/j.jfoodeng.2003.11.011. [DOI] [Google Scholar]

- 40.Fitzpatrick J.J., Barry K., Cerqueira P.S.M., Iqbal T., O’Neill J., Roos Y.H. Effect of composition and storage conditions on the flowability of dairy powders. Int. Dairy J. 2007;17:383–392. doi: 10.1016/j.idairyj.2006.04.010. [DOI] [Google Scholar]

- 41.Foerster M., Gengenbach T., Woo M.W., Selomulya C. The influence of the chemical surface composition on the drying process of milk droplets. Adv. Powder Technol. 2016;27:2324–2334. doi: 10.1016/j.apt.2016.07.004. [DOI] [Google Scholar]

- 42.Kelly G.M., O'Mahony J.A., Kelly A.L., Huppertz T., Kennedy D., O'Callaghan D.J. Influence of protein concentration on surface composition and physico-chemical properties of spray-dried milk protein concentrate powders. Int. Dairy J. 2015;51:34–40. doi: 10.1016/j.idairyj.2015.07.001. [DOI] [Google Scholar]

- 43.Szulc K., Nazarko J., Ostrowska-Ligęza E., Lenart A. Effect of fat replacement on flow and thermal properties of dairy powders. LWT - Food Science and Technology. 2016;68:653–658. doi: 10.1016/j.lwt.2015.12.060. [DOI] [Google Scholar]

- 44.Aguilera J., del Valle J., Karel M. Caking phenomena in amorphous food powders. Trends Food Sci. Technol. 1995;6:149–155. doi: 10.1016/S0924-2244(00)89023-8. [DOI] [Google Scholar]

- 45.C. Caballero-Cerón, J.A. Guerrero-Beltrán, H. Mújica-Paz, J.A. Torres, J. Welti-Chanes, Moisture Sorption Isotherms of Foods: Experimental Methodology, Mathematical Analysis, and Practical Applications, in: G.F. Gutiérrez-López, L. Alamilla-Beltrán, M. del Pilar Buera, J. Welti-Chanes, E. Parada-Arias, G.V. Barbosa-Cánovas (Eds.) Water Stress in Biological, Chemical, Pharmaceutical and Food Systems, Springer New York, New York, NY, 2015, pp. 187-214.

- 46.Murrieta-Pazos I., Gaiani C., Galet L., Cuq B., Desobry S., Scher J. Comparative study of particle structure evolution during water sorption: skim and whole milk powders. Colloids Surf., B. 2011;87:1–10. doi: 10.1016/j.colsurfb.2011.05.001. [DOI] [PubMed] [Google Scholar]

- 47.Shrestha A.K., Howes T., Adhikari B.P., Bhandari B.R. Water sorption and glass transition properties of spray dried lactose hydrolysed skim milk powder. LWT - Food Science and Technology. 2007;40:1593–1600. doi: 10.1016/j.lwt.2006.11.003. [DOI] [Google Scholar]

- 48.Zhang R., Pang X., Lu J., Liu L., Zhang S., Lv J. Effect of high intensity ultrasound pretreatment on functional and structural properties of micellar casein concentrates. Ultrason. Sonochem. 2018;47:10–16. doi: 10.1016/j.ultsonch.2018.04.011. [DOI] [PubMed] [Google Scholar]

- 49.Chandrapala J., Zisu B., Kentish S., Ashokkumar M. Influence of ultrasound on chemically induced gelation of micellar casein systems. J. Dairy Res. 2013;80:138–143. doi: 10.1017/S0022029912000696. [DOI] [PubMed] [Google Scholar]

- 50.Kaleemullah S., Kailappan R. Monolayer moisture, free energy change and fractionation of bound water of red chillies. J. Stored Prod. Res. 2007;43:104–110. doi: 10.1016/j.jspr.2005.12.001. [DOI] [Google Scholar]

- 51.Chandrapala J., Zisu B., Palmer M., Kentish S.E., Ashokkumar M. Sonication of milk protein solutions prior to spray drying and the subsequent effects on powders during storage. J. Food Eng. 2014;141:122–127. doi: 10.1016/j.jfoodeng.2014.05.017. [DOI] [Google Scholar]

- 52.McSweeney D.J., O'Mahony J.A., McCarthy N.A. Strategies to enhance the rehydration performance of micellar casein-dominant dairy powders. Int. Dairy J. 2021;122:105116. doi: 10.1016/j.idairyj.2021.105116. [DOI] [Google Scholar]