Abstract

Present methods used in three-dimensional (3D) printing, such as selective laser sintering (SLS) and multijet fusion (MJF), have limited applications, especially in relation to the manufacturing of biomedical products. The speed of SLS printing is too low, and high-speed 3D printing technology with MJF uses carbon black particles as a fusing agent, which cannot be removed from the completed 3D printed products. Carbon black and high-energy lasers are not suitable for biomedical applications, especially human implants. A new high-speed 3D method is therefore required. In this study, we used hot oil droplets (175°C) as a new type of fusing agent to melt the biomaterial thermoplastic polyurethane (TPU) powder particles to define the print area. This method replaces lasers and the carbon black fusing agent in high-speed 3D printing technology and is more energy efficient. In addition, this method can be used to not only print on TPU, but also on other flexible materials.

Keywords: Selective oil sintering, Fusing agent, Food oil, Powder bed, Thermoplastic polyurethane

1. Introduction

Thermoplastic polyurethane (TPU) has become a key biomaterial for medical products, because it has good biocompatibility and can be used for human implants[1]. Three-dimensional (3D) printing is a new manufacturing method that can be applied to the manufacturing of customized biomedical products[2], with methods including fused deposition modeling[3], selective laser sintering (SLS)[4], direct light processing[5], and multijet fusion (MJF)[6]. SLS and MJF are types of powder bed fusion (PBF) 3D printing. Fast 3D printing can be defined as a printing process of the form “face (slice) → body”[7]. The printing process used by SLS is of the form “dot→line→surface (slice)→body”; however, the processing speed is limited by this complex procedure. Thus, only MJF constitutes a fast 3D printing method. Fast 3D printing has been recently developed, and fast 3D printing processes such as MJF accelerate the printing process. MJF uses a “2D-to-3D” process, and the printing speed is thus fundamentally higher than that of SLS. High-speed 3D printing technology uses infrared (IR) light as the energy to melt the polymer particles to obtain a 3D pattern[8]. The process is as follows: (i) Depositing a powder layer on a platform; (ii) defining the print area on the powder surface after a fusing agent is deposited; and (iii) finally, irradiating the defined powder surface using an IR lamp[9]. The fusing agent contains carbon black, which is a strong IR absorber. The powder is then sintered by exposing the entire part bed to IR radiation. However, according to reference[10], the carbon black particles are not uniformly deposited on the powder particle surface, which influences the sintering process, and the finished 3D-printed product still contains carbon black particles, which cannot be eliminated. Hewlett Packard’s MJF PBF high-speed 3D printer contains a considerable amount of carbon black particles and hence cannot be used in biomedical products because of its toxicity. In addition, carbon black particles may be inhaled, causing secondary lung injury. Thus, the applications of this technology are limited. Therefore, a high-speed 3D printing method that is environmentally friendly, nontoxic, and can be manufactured in large quantities at a high speed is required. At present, no methods can print TPU, which, as a biomaterial, can be used in biomedical products and is environmentally friendly. The difference between the two types of 3D printing is that the oil droplet can directly define the printing area and heating, while the MJF needs to define the area first and then illuminate and heat it. Therefore, the oil droplet is used as a 3D printing method and only one step is required for the printing speed. SOS’s 3D printing speed must be faster than MJFIn this study; we developed a novel fusing agent (i.e., food oil) that does not require photo absorbers. The oil covers the particle surface uniformly, and the heated oil droplets completely melt the powder. Moreover, when oil is used as the fusing agent, the powder can be directly fused, and the printed area can be accurately defined with heated oil droplets. Moreover, this method can print TPU.

2. Experimental methods

2.1. Materials

TPU (maximum particle size of 100 ) was supplied by BASF. Food oil is canola oil was purchased from a local store and used without any further purification. The boiling point of the food oil was 250°C.

2.2. 3D printing

Figure 1 presents the PBF process of melting TPU particles in a layer-by-layer manner using selective hot oil sintering technology. A commercial powder bed 3D printer (T10 3D printer, Microjet Technology Co Ltd., Taiwan) was used in this work for spreading the TPU micro powder. The hot oil droplets (175°C, droplet size of approximately 2000 μm) were ejected through a glass dropper. Using oil as a fusing agent for high-speed 3D printing technology, all printing processes can be completed in one step. The hot oil can be transformed into small droplets through the multiple glass droppers, and then through a large number of small droplets to define the pre-printed area and shape. The heat source moved along the X and Y axes of the bed to which a thin and uniform powder layer was applied. The base was then lowered based on the thickness of one layer (0.1 – 0.08 mm), and another powder layer was applied and sintered. The powder sintering steps were repeated until a 3D structure was formed. The printed objects are heated on a hot plate set at 220°C for 30 min, cooled at room temperature for 10 min, and then washed with soapy water to remove excess oil for post-processing to complete the final product. The final parts were characterized using scanning electron microscopy (SEM) and a universal tensile machine (UTM).

Figure 1.

Selective oil sintering process.

3. Results and discussion

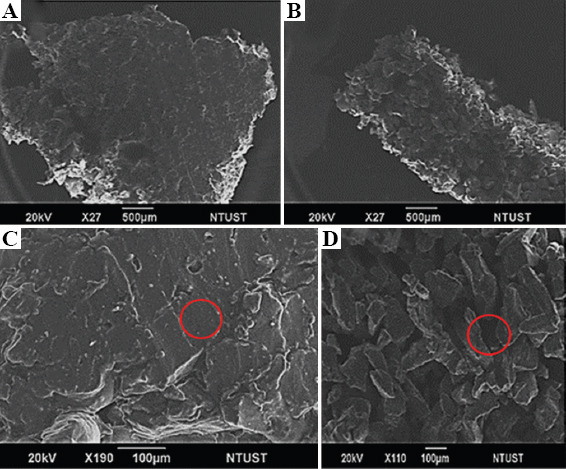

Figure 2 presents the SEM images of the TPU particles fused using two different fusing agents-food oil and carbon black. As illustrated by Figures 2A and C, the energy of the hot oil was sufficient to melt the powder, leaving no porosity (red circle in Figure 2C). When carbon black was used (Figures 2B and D), no melt tracks were formed because carbon black does not cover the particle surfaces uniformly and the heat of the IR absorber is insufficient to melt the powder and solidify it onto the substrate. Moreover, the resulting pore size was approximately 90 in diameter (red circle in Figure 2D).

Figure 2.

Morphology of the thermoplastic polyurethane particles fused using different fusing agents: (A) oil 27×, (B) carbon black 27×, (C) oil 190×, and (D) carbon black 190×.

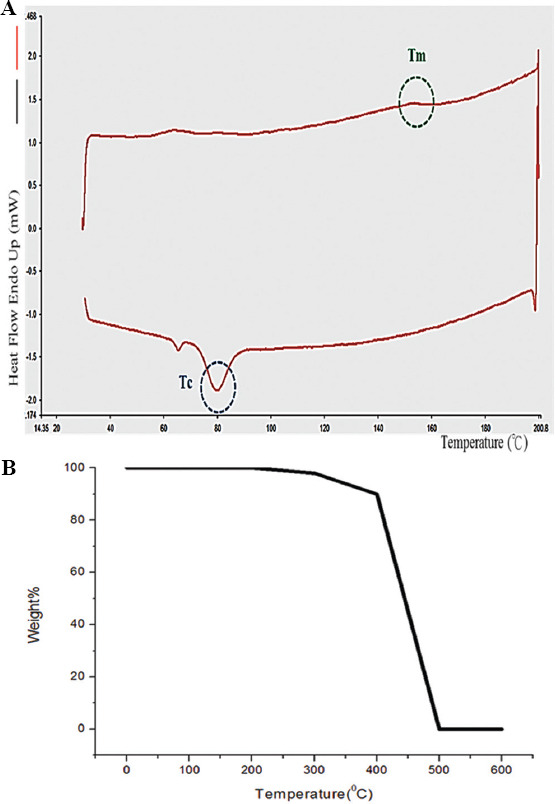

Differential scanning calorimetry (DSC) was used to determine the melting and crystallization temperatures of the TPU particles. A DSC8000 instrument from PerkinElmer was used at a temperature of 20 – 200°C, with a heating rate of 5°C/min. Nitrogen purge gas and 0.5-mg aluminum crucibles were used in the experiments. Figure 3A provides an example of a DSC curve, which indicates that the TPU particles exhibited a melting temperature of approximately 160°C and a crystallization temperature of approximately 80°C.

Figure 3.

(A) Relationship between the peaks in the differential scanning calorimetry curve and particle melting. (B) Thermogravimetric oil curves.

The oil thermal decomposition profiles for the thermogravimetric analysis (TGA; Figure 3B) indicate an oil cracking temperature ranging from 230°C to 500°C, with no residue at 600°C. The decomposition of the food oil involves three steps — decomposition of polyunsaturated fatty acids at 230 – 380°C, decomposition of monounsaturated (MAC) fatty acids at 380 – 480°C, and decomposition of saturated (SAC) fatty acids at 480 – 500ºC. During the decomposition of MAC fatty acids, the carbon double bonds were broken, causing the triglyceride molecules in the vegetable oils to become SAC. This result indicates that food oil samples incubated at 300°C exhibit higher thermal stability. Oil at a temperature above the melting point of the TPU micropowder can be used as the TPU micropowder fusing agent.

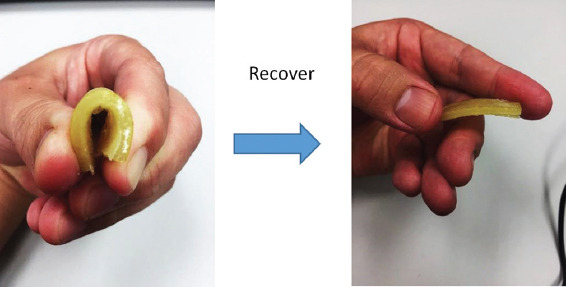

TPU is a flexible and abrasion-resistant thermoplastic used in various manufacturing processes for both consumer and industrial use. The 3D printed samples obtained from TPU regained their original shape after compression (Figure 4). MJF’s printed dimensional accuracies were slightly higher than SOS. This is due to the detailing agent used in the MJF process. The dimensional accuracy of the TPU printed with hot oil on the vertical direction was not as good as TPU printed with carbon black, which might be due to the excessive layer-overlapping during SOS process as a result of oil heat input.

Figure 4.

Compression of the thermoplastic polyurethane sample. The sample regained its original shape after compression.

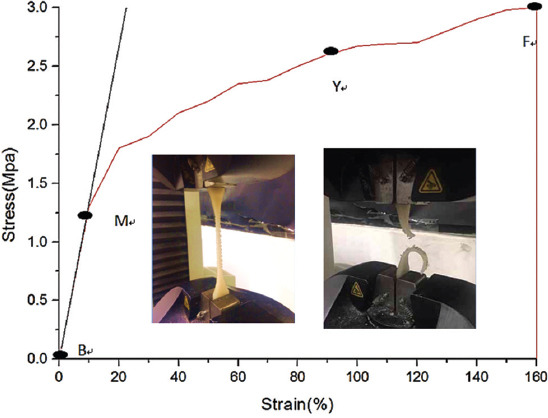

The mechanical properties of the solid TPU were studied with respect to the stress-strain responses (Figure 5). A UTM was used to analyze the mechanical properties of the printed TPU, including its tensile strength and breaking point (Figure 5). The ultimate tensile strength of the pure TPU (without carbon black) reached 2.7 MPa. The break stress is 2.9 MPa. According to the literature[10,11], TPU containing carbon black will change its mechanical properties, but TPU containing carbon black will have better mechanical properties than TPU without carbon black. The stress-strain curves indicated that the pure TPU could be stretched by up to 160%. The full stress-strain curve of the pure TPU contains three regions: (i) An elastic region (0 – 20%), (ii) a plastic region (20 – 150%), and (iii) a break region (160%).

Figure 5.

Stress-strain curves for the pure thermoplastic polyurethane at 20°C.

4. Conclusions

This study developed a new high-speed 3D method using food oil as a new fusing agent material. In addition, we reported the formulation of a fusion ink (food oil) for fabricating 3D structures by combining PBF and inkjet printing. The printed 3D samples exhibit high levels of repeatability and bendability. Thus, this paper describes a novel environmentally friendly fusing agent that can be used for PBF high-speed 3D printing and is suitable for manufacturing biomedical products.

Acknowledgment

This work was financially supported by the “High-Speed 3D Printing Research Center” of National Taiwan University of Science and Technology (NTUST) from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan.

Conflict of interest

The authors have no relevant conflicts of interest to declare.

Author contributions

J.Y.W. guided and supervised the project. J.Y.W. designed and supervised the experiments. J.Y.W., H.C.H. conducted experiments and contributed intellectually to the scientific design of the project. J.Y.W., H.C.H., L.Z.Y. mentored the technical part of the project.

References

- 1.Drupitha MP, Das B, Parameswaran R, et al. Hybrid Electrospun Fibers Based on TPU-PDMS and Spherical Nanohydroxyapatite for Bone Tissue Engineering. Mater Today Commun. 2018;16:264–73. https://doi.org/10.1016/j.mtcomm.2018.06.013. [Google Scholar]

- 2.Bachtiar EO, Erol O, Millrod M, et al. 3D Printing and Characterization of a Soft and Biostable Elastomer with High Flexibility and Strength for Biomedical Applications. J Mech Behav Biomed Mater. 2020;104:103649. doi: 10.1016/j.jmbbm.2020.103649. https://doi.org/10.1016/j.jmbbm.2020.103649. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Lu Q, Song KY, Feng Y, et al. Fabrication of Suspended Uniform Polymer Microfibers by FDM 3D Printing. CIRP J Manufa Sci Technol. 2021;32:179–87. https://doi.org/10.1016/j.cirpj.2020.11.005. [Google Scholar]

- 4.Fina F, Goyanes A, Gaisford S, et al. Selective Laser Sintering (SLS) 3D Printing of Medicines. Int J Pharm. 2017;529:285–93. doi: 10.1016/j.ijpharm.2017.06.082. https://doi.org/10.1016/j.ijpharm.2017.06.082. [DOI] [PubMed] [Google Scholar]

- 5.Guo J, Zeng Y, Li P, et al. Fine Lattice Structural Titanium Dioxide Ceramic Produced by DLP 3D Printing. Ceram Int. 2019;45:23007–12. https://doi.org/10.1016/j.ceramint.2019.07.346. [Google Scholar]

- 6.Srinivas RP, Alomarah A, Masood SH, et al. Mechanical Response of a Compressed Novel 3D Tetrachiral Structure Processed by MJF 3D Printing Process. Mater Today. 2020;46:4776–81. [Google Scholar]

- 7.Xu Z, Wang Y, Wu D, et al. The Process and Performance Comparison of Polyamide 12 Manufactured by Multi Jet Fusion and Selective Laser Sintering. J Manuf Process. 2019;47:419–26. [Google Scholar]

- 8.HP Development Company. L.P. Introduction of HP 3D Printers. 2018. [Last accessed on 2018 Oct 23]. Available form: http://www8.hp.com/uk/en/printers/3dprinters .

- 9.Sillania F, Kleijnena R, Vetterlia M, et al. Selective Laser Sintering and Multi Jet Fusion:Process-Induced Modification of the Raw Materials and Analyses of Parts Performance. Addit Manuf. 2019;27:32–41. https://doi.org/10.1016/j.addma.2019.02.004. [Google Scholar]

- 10.Espera AH, Jr, Valino AD, Palaganas JO, et al. 3D Printing of a Robust Polyamide-12-Carbon Black Composite via Selective Laser Sintering:Thermal and Electrical Conductivity, Macromol. Mater Eng. 2019;304:1800718. https://doi.org/10.1002/mame.201800718. [Google Scholar]

- 11.Tey WS, Cai C, Zhou K. A Comprehensive Investigation on 3D Printing of Polyamide 11 and Thermoplastic Polyurethane via Multi Jet Fusion. Polymers. 2021;13:2139. doi: 10.3390/polym13132139. https://doi.org/10.3390/polym13132139. [DOI] [PMC free article] [PubMed] [Google Scholar]