Abstract

Inclusion of brewer's spent grain flour (BSGF) in food formulations has been reported to have nutritional and health benefits due to the contents like, protein, fibre and phenolic compounds. Bread has been used as common vehicle for functional and nutritive ingredients due to its wide consumption. Several studies attempted to incorporate BSGF flour in baked products. Studies also have reported on the application of maize flour in bread and baked products. However, there is limited information on the possibility of producing bread from composite flour using BSGF with other widely consumed cereals like maize together with wheat flour. The study investigated the optimization of bread recipe made from wheat flour, maize flour and BSGF in order to attain optimal physicochemical and sensory attributes using D-optimal mixture design. A total of 16 runs were formulated using design expert software. The blend proportions of wheat, maize and BSGF had a significant (p < 0.05) influence on bread specific volume, volume and density. Increase in BSGF proportion decreased the specific volume and volume whereas the loaf density increased. The specific volume increased with increase in wheat flour proportion. The combination of high levels of BSGF and maize, however, brought about a slight increase in specific volume compared to combinations of low levels of BSGF and maize flour. The fibre, protein and ash content of bread significantly (p < 0.05) increased with increase in BSGF and maize proportion whereas the effect of maize flour was less pronounced compared to BSGF. The sensory attributes including colour, taste, flavour, texture and overall acceptability were significantly (p < 0.05) reduced with increase in BSGF and maize flour content. Using the optimization criteria where all sensory attributes have to be at least “like slightly” intensity, maximized, specific volume, fiber and protein, that the best results were found between 73 to 87% of wheat, 9–20% maize, and 0–11% BSGF based on graphical optimization. Numerical optimization indicated that best results were using combination of 65% wheat, 20% maize flour, and 15% BSGF with a desirability value of 0.524. According to the results of the study, BSGF can be incorporated up 10% and maize flour up to 20% obtain an acceptable product.

Keywords: BSGF, Bread, Optimization, Mixture design

BSGF, Bread, Optimization, Mixture design.

1. Introduction

Food industry by-products have recently gained attention as functional ingredients because of their nutritional and health benefit and also are cheap sources of valuable ingredients (Ӧztűrk et al., 2002; Mirabella et al., 2014; Lynch et al., 2016; Rachwal et al., 2020). One of such cheap and valuable by-products is brewer's spent grain flour (BSGF). BSGF is a by-product of the brewing process following wort mashing and straining before fermentation. It is the major by-product in the brewing industry accounting for about 85% of all the residue (Mussatto et al., 2006). BSGF is considered to be agricultural waste, with high volumes being generated globally.

BSGF is potentially an important food ingredient particularly in developing countries where poor malnutrition exists (Mussatto et al., 2006). The chemical composition, food manufacturing application and the health benefits of BSGF has been reviewed (Lynch et al., 2016; Mussatto et al., 2006; Rachwal et al., 2020). BSGF is a heterogeneous material consisting of lignocellulosic biomass and is rich in proteins (20–36%), fibre (30–70%), lipids (4.5–8.3) and ash (2.5–3.3%). It contains ca. 12–28% of lignin, 12–25% of cellulose, and 28% of noncellulosic olysaccharides, mainly arabinoxylans (Ӧztűrk et al., 2002; Stojcesak and Ainsworth, 2008; Ktenioudaki et al., 2013a; Waters et al., 2012; Mussatto et al., 2006; Lynch et al., 2016). There is enough evidence that BSGF contains vitamins, minerals, and many amino acids. This by-product is also rich in oligo and polysaccharides and phenolic compounds (Cooray et al., 2017; Lynch et al., 2016; Waters et al., 2012). One major advantage of using BSGF is that it is possible to design products that meet full regulatory requirements since the brewing industry uses material approved for human consumption (Stojceska and Ainsworth, 2008). BSGF has moisture content about 70–80% which together with the high content of polysaccharide and protein make it susceptible to microbial growth and spoilage limiting its utilization. Chemical methods including lactic, acetic, formic and benzoic acids and physical methods like drying, freezing, refrigerated storage, autoclaving and superheated steam has been used to preserve BSGF (Mussatto et al., 2006; Robertson et al., 2010; Lynch et al., 2016).

BSGF has been reported to have health benefits due to the contents like fibre and phenolic compounds. Some of the benefits include accelerated transit time, increased faecal weight and fat excretion (alleviating both constipation and diarrhoea), decreased gallstone incidence in the digestive tract and reduced plasma cholesterol and postprandial serum glucose levels (Waters et al., 2012; Mussatto, 2014; Lynch et al., 2016). The BSGF protein hydrolysates act as a functional ingredient to manage diabetes and hypertension (Connolly et al., 2014). BSGF protein isolate and associated hydrolysate showed a potential in the treatment of inflammatory diseases (McCarthy et al., 2013). The phenolic compounds found in BSGF have been reported to have anti-oxidant, anti-carcinogenic and anti-apoptotic effects (Lynch et al., 2016). Incorporating BSGF into food products will address the increased consumer need for healthier products and also the current global priority for reducing food waste.

BSGF has been used as a functional food ingredient in different types of products which included bread (Waters et al., 2012; Steinmacher et al., 2012; Martins et al., 2018), high fibre enriched bread (Stojceska and Ainsworth, 2008), sour bread (Aprodu et al., 2017; Ktenioudaki et al., 2015; Plessas et al., 2007), breadsticks (Ktenioudaki et al., 2012), baked snacks (Ktenioudaki et al., 2013b), and cookies (Ӧztűrk et al., 2002). Ingredients obtained from BSGF has been used to produce bread and pasta (Martins et al., 2018; Sahin et al., 2021). BSGF has been used to produce extruded snacks (Manyatsi, et al., 2020; Stojceska et al., 2009) and other several baked and cereal-based products (Mussatto et al., 2006; Rachwal et al., 2020).

Due to its wide consumption, bread has been used as common vehicle for functional and nutritive ingredients. In order to reduce cost. Cheaper partial replacers like maize flour have to be used in order to avail bread at an affordable price for low-income segment of the population (Menon et al., 2015). Maize is a staple cereal in many African countries and relatively cheap source of energy. The application of maize for manufacturing bread and other baked products has been reviewed (Ekpa et al., 2019). Maize has been used for making bread and baked products by blending with cereals like wheat and rice (Rai et al., 2012; Nkhabutlane et al., 2014; Manyatsi et al., 2020), rice, sorghum and pearl (Rai et al., 2014), soybeans and soy protein isolates (Oyeyinka et al., 2020; Adeyeye et al., 2017) and tubers (Onyango et al., 2011; Adeyeye et al., 2017) to improve nutritional and functional properties. The quality of maize-based gluten-free bread of different maize genotypes has been reported (Ekpa et al., 2020). The influence of some technologies and non-traditional sour dough on maize dough and on dough functionality and bread quality has been studied (Khuzwayo et al., 2020; Jagelaviciute and Cizeikiene, 2021). Moreover, inclusion of distillers’ spent grain up to 15% has resulted in an acceptable maize-based snack with improved nutritional value (Awoyale et al., 2011).

Despite several researches in the past to incorporate BSGF in baked products, and the contribution maize in bread and baked products there is limited information on the possibility of producing bread from composite flour using BSGF with maize together with wheat flour. The objectives of this research were to study the possibility of producing bread from wheat-maize-BSGF (W:M:BSGF) composite flour, to the study the effect of blending ration on the quality of bread and optimize the proportion of wheat, maize and BSGF flour for an acceptable product using D-optimal mixture design.

2. Materials and methods

2.1. Raw material preparation

Commercial wheat flour (protein 11.8 g/100 g, total fat 2.4 g/100 g, fibre 6 g/100 g) and maize flour (flour protein 6.7 g/100 g, total fat 2.6 g/100 g, fibre 6.6 g/100 g) were sourced from Swaziland Premier milling company. The barley BSGF was sourced from Eswatini Beverages Company (a brewery). The brewer's spent grain was dried in a dehydrator (Excalibur 4926T, Sacramento, USA) immediately after collection, at 78 °C for 20 h. After drying, the grains were ground using a blender (KM-1500 MRC, Holon, Israel) and sifted using a 425 μm test sieve to obtain medium-soft BSGF flour (Ӧztűrk et al., 2002). The flour was then packed and sealed in polyethylene bags and kept in refrigerator until use (Rosell et al., 2001).

2.2. Formulation of composite flour

Design-Expert version 13 (Stat Ease, Inc., Minneapolis, Minnesota) was used to generate a total of 16 runs (formulations). In the formulations BSGF, maize flour (M), and wheat flour (W) were constrained to range from 0 to 30%, 0–20% and 55–100%, respectively based on literature (Stojceska and Ainsworth, 2008; Rai et al., 2012). The wheat flour, the BSGF flour and maize flour were blended according to the generated formulation and composite flours were prepared by thoroughly mixing with a blender (KM-1500 MRC, Holon, Israel). The bread prepared from wheat without BSGF (100% wheat flour) served as a control. Each formulation was made of 400 g flour or composite flour, 5 g salt, 25 g sugar, 10 g yeast and 25 g fat.

2.3. Proximate composition of composite flour and bread

Moisture and ash were determined according to AACC (2000). Total dietary fibre and proteins were determined by AOAC (2000). Soxhlet method was employed to determine fat content.

2.4. Bread baking

The straight dough method where all the ingredients are mixed and kneaded to form the dough was used. The dough samples were allowed to ferment for 45 min followed by kneading again and baked at 180 °C for 30 min (Chauhan et al., 1992). The baked loaves were cooled and packed for further analysis.

2.5. Physical properties of bread

Physical properties were assessed by evaluating the weight, volume, specific volume and density of loaves. Rapeseed displacement method was used for loaf volume (AACC, 2000). Loaf volume to weight ratio was used to determine the specific volume (Eqs. (1) and (2)) (Akara et al., 2009). Electronic weighing scale (E,I,M series N17250, Milton Keynes, UK) was used to measure loaf weight.

| (1) |

| (2) |

2.6. Sensory evaluation

A panel of fifty (50) consumers with age range of 20–45 was selected randomly for sensory evaluation of bread. Informed consent was obtained from panellists indicating their willingness to participate in the study. Firstly, the bread samples were allowed to cool for 40 min at room temperature then sliced into pieces. Panellists were presented with coded bread samples and forms to fill, indicating their level of acceptance. Samples were randomly coded with three-digit random numbers and the panellists were served to test in random order. For each sample, panelists scored their liking or disliking of the attributes using the 9-point Hedonic scale (1-dislike extremely, 9-like extremely). The sensory attributes which were evaluated were taste, colour, flavour, texture and overall acceptance. Those samples which were considered as acceptable were those with all their sensory attributes were greater than or equal to 6.00 (like slightly).

2.7. Experimental design and data analysis

The effect of blending on the physicochemical properties and sensory quality of bread from wheat, maize and BSGF composite flour was studied using D-optimal mixture design. A D-optimal design minimizes the variance of the model regression coefficients (Myers et al., 2016) and allows constraining the mixture components or excluding practically unsound scenarios. The test level of each component in D-optimal design can be selected flexibly and a variable can be tested at as many levels as the researcher wants. A total of 16 runs (4 replicate points, 6 lack of fit points and 6 model points) were generated using Design-Expert Version 13.0 (Stat-Ease, Inc. Minneapolis, Minnesota). The four replicate runs were runs 1, 4, 5 and 6 (Table 1). The experiment was replicated three times. Quadratic (Eq. (3)) and special cubic (Eq. (4)) models shown below (Myers et al., 2016) were fitted to the data and the adequacy of the model was checked based on the values of R2 and adjusted-R2.

| (3) |

| (4) |

where:

Y = the predicted variable

X1,2,3 = the proportions of wheat, maize and BSGF

β′s = the blend coefficients (linear, binary and ternary blend coefficients)

Table 1.

Experimental design points and proportions of wheat, maize and BSG.

| Run | Wheat (%) | Maize (%) | BSG(%) |

|---|---|---|---|

| 1 | 55 | 15 | 30 |

| 2 | 80 | 00 | 20 |

| 3 | 85 | 10 | 5 |

| 4 | 70 | 0 | 30 |

| 5 | 80 | 20 | 0 |

| 6 | 100 | 0 | 0 |

| 7 | 70 | 0 | 30 |

| 8 | 70 | 10 | 20 |

| 9 | 75 | 10 | 15 |

| 10 | 55 | 15 | 30 |

| 11 | 60 | 20 | 20 |

| 12 | 100 | 0 | 0 |

| 13 | 80 | 20 | 0 |

| 14 | 90 | 0 | 10 |

| 15 | 70 | 20 | 10 |

| 16 | 70 | 5 | 25 |

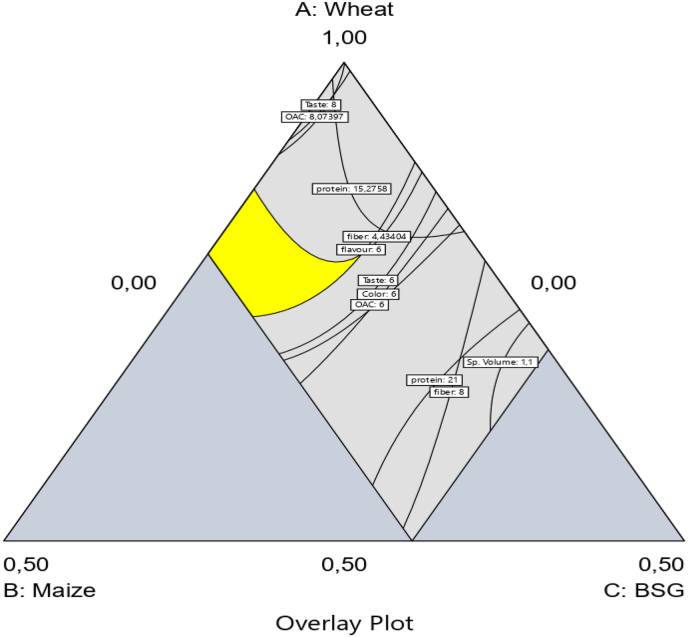

Graphical and numerical optimizations were employed to determine the optimal blending proportions. Optimization criteria was used where all sensory attributes have to be greater or equal to score 6.0 (the “like slightly” intensity), and specific volume, fiber and protein maximized.

An overlay plot was generated for graphical optimization by superimposing the contour plots of the response variables. The optimal region of blends was found based on the optimization criteria. Numerical optimization of the blend proportions was done using the desirability function method. The overall desirability (D) as a function of the desirability value (di) of each response variable is given by Eq. (5) (Montgomery, 2001).

| (5) |

3. Results and discussion

3.1. Physical properties of bread

3.1.1. Weight

The blend proportion significantly (p < 0.05) influenced the loaf weight. The loaf weight ranged from 650 g for the control (100% wheat) to 756 g for samples with 55:15:30% (W:M:BSGF) blend. The relationship between the blend proportion and weight is presented in the response surface (Figure 1a). Increase in the BSGF content resulted in an increase in loaf weight. The magnitude of the coded coefficients indicated that maize appeared to have the least contribution to the loaf weight (Table 2). The relationship between the loaf weight and blend proportion was adequately described by a quartic model with R2 and adjusted-R2 values of 0.961 and 0.940, respectively (Table 2). An increase in loaf weight due to increase in BSGF content has been reported in bread yeast immobilized on BSGF (Plessas et al., 2007). Water absorption has been reported to increase with increase in fibre content due to addition of BSGF (Stojceska and Aintworth, 2008) which significantly contributes to the increase in loaf weight. Loaf weight was observed to increase with increase in maize flour proportion in wheat-maize composite flour bread (Rai et al., 2012). It is worth noting that the negative effect of BSGF can be reduced by increasing maize flour proportion which may also reduce the cost of bread.

Figure 1.

Physical properties (weight, volume, specific volume, density) of bread as a function of blend proportions (A = wheat, B = maize, C= BSG).

Table 2.

Model coefficients and degree of fit for the different bread quality attributes.

| Parameter | Model Coefficients |

Degree of fit |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| β1(W) | β2(M) | β3(BSG) | β12(W×M) | β13(W×BSG) | β23(M×BSG) | β123(W×M×BSG) | R2 | Adj R2 | p-value | |

| Color | 8.19∗ | 4.05∗ | -3.06∗ | 4.28 | 5.86 | 16.59 | -10.36 | 0.949 | 0.910 | <0.0001 |

| flavour | 8.01∗ | -0.2967∗ | -1.59∗ | 8.77 | -0.0675 | 17.75∗ | 0.964 | 0.943 | <0.0001 | |

| texture | 8.07∗ | 4.34∗ | -2.03∗ | 1.40 | 4.66 | 12.35 | 0.923 | 0.880 | <0.0002 | |

| Taste | 8.13∗ | 1.62∗ | -2.25∗ | 6.85 | 3.44 | 14.79 | +1.68 | 0.944 | 0.902 | 0,0001 |

| OAC | 8.08∗ | 0.720∗5 | -4.88∗ | 9.09 | 10.34 | 26.28 | -24.83 | 0.951 | 0.912 | <0.0001 |

| Weight | 655.81∗ | 650.40∗ | 996.68∗ | 69.96 | -498.72∗ | -462.50∗ | 0.961 | 0.940 | <0.0001 | |

| Volume | 849.02 | 931.91 | 928.46 | -488.97 | -420.36 | -85.80 | 0.550 | 0.300 | 0.154 | |

| Sp volume | 1.29∗ | 1.46∗ | 0.8420∗ | -0.8821 | 0.2101 | 0.5335 | 0.653 | 0.480 | 0.036 | |

| Density | 0.7684 | 0.7684 | 0.7684 | 0.7684 | 0.7684 | 0.7684 | 0.652 | 0.478 | 0.036 | |

| Moisture | 37.32∗ | 43.40∗ | 59.01∗ | 0.6667 | -24.42 | -27.75 | 0.999 | 0.994 | 0.054 | |

| Ash | 0.705∗ | 2.10∗ | 10.27∗ | 2.71 | -12.47 | -14.83 | 0.999 | 0.999 | 0.022 | |

| Fat | 0.390∗ | 0.598∗ | 5.91∗ | 2.38 | -9.67 | -7.00 | 0.999 | 0.999 | 0.039 | |

| protein | 14.42∗ | 11.28∗ | 57.79∗ | 29.44∗ | -63.32∗ | -56.67∗ | 0.999 | 0.990 | 0.0039 | |

| Fiber | 1.46∗ | 26.70∗ | 26.04∗ | -19.00∗ | -15.06 | -75.08∗ | 0.999 | 0.990 | 0.007 | |

The coefficients are significant at 0.05.

3.1.2. Bread volume

The results indicated that the blend proportions did not significantly (p > 0.05) affected the bread volume. The bread volume ranged from 725 ml to 897 ml for bread made of 75:10:15% and 55:15:30% (W:M:BSGF), respectively. The changes in loaf volume with blend proportions are presented by the response surface (Figure 1b). Increase in wheat proportion resulted increase in the bread volume. In general increase in the proportion of maize resulted in a decrease in loaf volume. Decrease in volume of bread stick and bread loaves with increase in BSGF content has been reported (Ktenioudaki et al., 2012; Plessas et al., 2007; Rai et al., 2012).

3.1.3. Specific volume and density

The result indicated that specific volume was significantly influenced by the blending ratio. The specific volume ranged from 1.07 to 1.28 ml/g for the 70:5:25 (W:M:BSGF) and the control (100% wheat), respectively. The relationship between the blend proportion and specific volume is presented in the response surface (Figure 1c). The specific volume increased with increase in wheat flour proportion whereas decreased with increase in BSGF proportion. The combination of high levels of BSGF and maize, however, brought about a slight increase on specific volume (Figure 1c). A quadratic model adequately (R2 = 0.653, adjusted-R2 = 0.480 and p < 0.05) (Table 2) described the relationship between the blend proportion and specific volume. Specific volume is an important quality attribute of bread and other baked products. Decrease in specific volume with increase in BSGF content of loaf has been reported in similar studies which was associated with high amount of arabinoxylans (Waters et al., 2012; Stojceska and Ainsworth, 2008; Ktenioudaki et al., 2015; Aprodu et al., 2017). This reduction has been attributed to the significant impact on gluten network development, the disruption of the gluten viscoelastic network and gluten dilution (Waters et al., 2012; Sullivan et al., 2011; Sahin et al., 2021). Earlier studies indicated that maize bread exhibited lower specific volume (1.33 ml/g) compared to bread made from teff (1.6 ml/g), buck wheat (1.69 ml/g) and rice flour (1.8 ml/g) (Hager and Arendt, 2013). A decrease in loaf specific volume with increase in maize flour content has been observed in wheat-maize composite flour bread (Rai et al., 2012). The loaf density was also significantly (p < 0.05) affected by the blend proportion. A minimum (0.780 g/ml) density was found for the 100% wheat loaf whereas a maximum (0.950 g/ml) was observed for loaf made from 70:30% (W:BSGF). The loaf density increased with increase in BSGF proportion. The effect of maize flour was not pronounced compared to the BSGF. Since specific volume and density are related properties, such trend is expected. With high moisture absorption and fibre content in BSGF, increase in the density of samples with high proportion of BSGF is expected. High crumb density has also been reported due to inclusion of BSGF (Aprodu et al., 2017).

3.2. Composition of bread

3.2.1. Moisture content

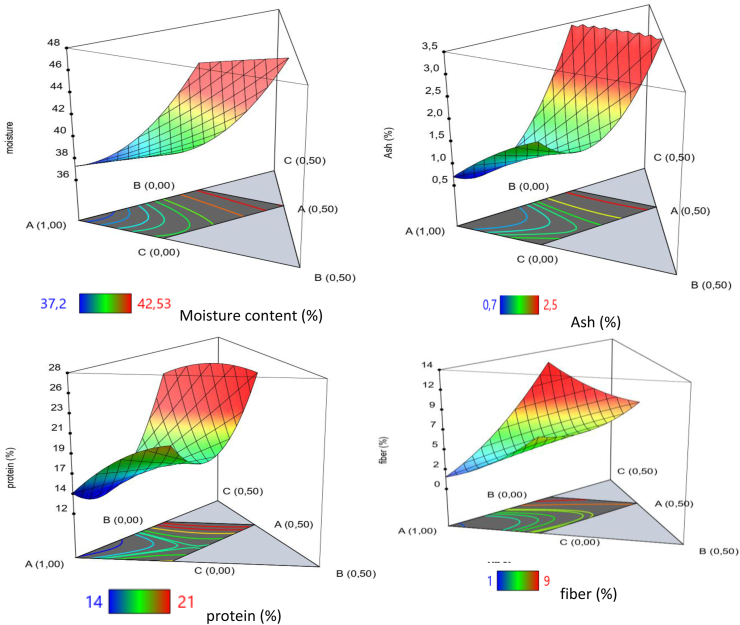

The results indicated that moisture content of bread was not significantly (p > 0.05) influenced by the blend proportion. The maximum and minimum moisture content was 42.5% and 37.2% for bread made of 70:5:25% (W:BSGF) and the control (100% wheat), respectively. The relationship between the blend proportion and specific volume is presented in the response surface (Figure 2a). The moisture content increased with increase in BSGF. There was also slight increase in moisture content with increase in maize content. Increase in moisture content of baked snacks from 3.1 to 7.5% due to increase in BSGF from 0 to 25% has been reported (Ktenioudaki et al., 2013a).

Figure 2.

Composition of bread (moisture content, ash, protein, fiber) as a function of blend proportions (A = wheat, B = maize, C= BSG).

3.2.2. Fibre

The fibre content ranged from 1.44% for the control (100% wheat) to 8.75% for 70:5:25% (W:M:BSGF). The relationship between the blend proportion and fibre content is presented in the response surface (Figure 2b). Increase in the BSGF content brought about a significant (p < 0.05) increase in the fibre content. Increase in maize flour content brought also an increase in the fibre content. A quadratic model well described (R2 = 0.999 and adjusted-R2 = 0.990) the relationship between the blend proportions and the fibre content. The fibre content of maize flour used in this study was slightly higher than the fibre content of the wheat flour, hence the observed increase in fiber content with maize flour. The fibre content in BSGF ranges from 30 to 70% (Ӧztűrk et al., 2002; Mussato et al., 2006; Waters et al., 2012). Thus, is it expected that fibre content in the loaf would increase with increase in the proportion of BSGF. Similar trends were found for baked products where BSGF is incorporated (Ktenioudaki et al., 2015). An increase in fibre content from 6.2 to 20.1% for bread stick (Ktenioudaki et al., 2012), from 2.3 to 11.5% for high fibre enriched bread (Stojceska and Ainsworth, 2008), from 1.98 to 14.09 in cookies (Ӧztűrk et al., 2002) has been reported due to inclusion of BSGF. Addition of 15% BSGF brought about more than double the fibre content in breadsticks (Ktenioudaki et al., 2012). BSGF could be considered as viable high fibre replacement for whole meal bread (Waters et al., 2012).

3.2.3. Protein

Protein content of bread was significantly (p < 0.05) influenced by the blend proportion. The protein content ranged from 14.41% for the control (100% wheat) to 21.47% for 70:5:25% (W:M:BSGF). The relationship between the blend proportion and protein is presented in the response surface (Figure 2c). Increase in the BSGF content resulted in a significant (p < 0.05) increase in the protein content. The contribution of maize flour towards the protein content was the least compared to wheat and BSGF which was evident from the magnitude of the coded coefficient for maize (Table 2). A quadratic model adequately described the relationship between the blend proportions and the protein content. An increase in the concentration of protein is expected due to the fact that the protein in BSGF is high in the order of 13–31% (Ӧztűrk et al., 2002; Lynch et al., 2016; He et al., 2021). An increase in protein content from 14.3 to 18.4% has been reported due to increase in the BSGF content from 0 to 35% in breadsticks (Ktenioudaki et al., 2012). Moreover, BSGF has high levels of quality essential amino acids particularly lysine which is normally at low concentration in cereals (Waters et al., 2012).

3.2.4. Ash

Ash content of bread was significantly (p < 0.05) influenced by the blend proportion. The ash content ranges from 0.69% for the control (100% wheat) to 2.5% for 70:5:25% (W:M:BSGF). The response surface (Figure 2b) presented the relationship between the blend proportion and ash. Increase in the BSGF and maize flour content brought about a significant increase in the ash content. This was evident from the magnitude of the coded coefficients of the maze and BSGF (Table 2). A quadratic model adequately described the relationship between the blend proportions and the ash content. The high ash content of samples with high BSGF content is in line with literature report which indicates that BSGF is a good source of minerals such as calcium, phosphorous, iron, copper, zinc and magnesium (Mussatto et al., 2006; Waters et al., 2012; Ktenioudaki et al., 2015; Lynch et al., 2016). An increase in ash content from 2.6 to 3.4% percent has been reported due to an increase from 0 to 35% BSGF in breadsticks (Ktenioudaki et al., 2012). The available minerals are indicative of the health benefits of BSGF.

3.3. Sensory evaluation results

3.3.1. Colour

The results indicated that the degree of liking for colour score was affected significantly (p < 0.05) by the proportions in the composite flour. The maximum score was 8.16 (like very much) for the 100% wheat and the minimum was 2.77 (dislike moderately) for the sample made from 70:30% (W:BSGF). Bread with 85:10:5% (W:M:BSGF and 90:10% (W:BSGF) had scores of 7.8 and 7.5, respectively with intensity score “like very much”. The colour response as a function of blend proportion is presented in (Figure 3a). The colour score decreased with increase in the BSGF content which was also evident from the negative coefficient of the of the linear blend coefficient (Table 2). Maize flour has a positive influence on the color score as indicated by the positive coefficient for the linear blend term (Table 2). A decrease in crust color score was in wheat-maize flour composite flour bread with increase in maize flour content (Rai et al., 2012). A special cubic model adequately (R2 = 0.949, adjusted-R2 = 0.911 and p < 0.05) (Table 2) described the relationship between blend proportion and sensory colour. The colour of the bread became visually darker as the level of BSGF increased. The highest addition which was 30% of the BSGF was darker as compared to the other levels. Addition of BSGF to other baked products caused undesirable darker colour (Ӧztűrk et al., 2002; Ktenioudaki et al., 2013a; Petrović et al., 2017). Low appearance score which is very much associated with colour was reported for bread containing higher than 15% BSGF (Ktenioudaki et al., 2013b).

Figure 3.

Sensory properties (color, Flavour, Texture, Taste, Overall acceptability) of bread as a function of blend proportions (A = wheat, B = maize, C= BSG).

3.3.2. Flavour

Asignificant (p < 0.05) influence was observed on the flavor score due to blending ratios. The results indicated that the maximum score was 8.05 (like very much) for the control whereas the minimum score was 2.17 (dislike very much for bread made with 70:30% (W:BSGF). The samples with 85:10:5% (W:M:BSGF) and 90:10 (W:BSGF) had score of 6.9 and 6.5 (like moderately), respectively suggesting that inclusion of BSGF and maize flour up to 10% was acceptable by panelists. The flavour response surface as a function of the blend ratio is shown in Figure 3b. Increase in the BSGF and maize flour content had significant negative influence on the flavour. The negative influence of BSGF was more than maize flour which was evident from the negative coded coefficients (Table 2). A quadratic model adequately (R2 = 0.964 and adjusted-R2 = 0.943) described the relationship between blend proportion and sensory flavour (Table 2). BSGF has a characteristic odour due to compounds found in it. Compounds like 3-methyl-butanal (buttery, oily, dark chocolate), and 2,3 butanedione (buttery and cheesy) have been identified odour-active and characterized to confer malty and buttery flavour, respectively which in turn affect the sensory scores negatively (Ktenioudaki et al., 2013b, 2015).

3.3.3. Texture

A significant (p < 0.05) effect was observed on the texture score as a result of blend proportionThe highest score was 7.9 (like very much) for the control whereas the least score was 3.0 (dislike moderately) for bread made with 70:30% (W:BSGF). The samples with up to 10% BSGF resulted in score of 7.0 (like moderately), indicating that inclusion of BSGF up 10% resulted in an acceptable texture. Figure 3c presents the bread texture response as a function of the blend proportions. Increase in the proportion of BSGF resulted in lower texture score and increase in the proportion of wheat resulted an in increase in the texture score. The decrease in the texture score with increase BSGF content could be due to high fibre content in the BSGF rendering a dense product which was also evident in low specific volume. Maize flour has a positive influence on the texture score as indicated by the positive coefficient for the linear blend term (Table 2). A quadratic model well described (R2 = 0.923, adjusted-R2 = 0.881and p < 0.05) the relationship between blend proportion and sensory flavour (Table 2. Earlier studies also indicated that addition of over 10% BSGF affected texture parameters significantly. The limiting effects of BSGF in dough and gluten development could be associated with low texture score for samples with higher BSGF content. Image analysis of samples with 25% BSGF has been reported to exhibit a closed and compact structure (Ktenioudaki et al., 2013b; Aprodu et al., 2017). BSGF has high amount of proteins and fibre which absorb water causing cookie hardening (Petrović et al., 2017).

3.3.4. Taste

The blend proportions significantly (p < 0.05) affected the taste of bread prepared from the composite flour. The maximum score was found to be 8.0 (like very much) for the control sample whereas the minimum score was 2.73 (dislike moderately) for bread made with 70:30% (W:BSGF). Like texture score the samples with up to 10% BSGF resulted in taste score of 7.2 (like moderately), indicating that inclusion of BSGF up 10% resulted in an acceptable taste. Samples with the inclusion of 5% BSGF and 10% maize exhibited a taste score of 7.6 (like very much) which was not statistically different from the control. The response surface for the taste is presented in Figure 3d. Increase in the proportion of BSGF and maize flour content resulted in a decrease in taste score whereas increase in the proportion of wheat resulted in an increased taste score. A special cubic model adequately (R2 = 0.944 and adjusted-R2 = 0.902) described the relationship between blend proportion and taste. A decrease in taste score with increase in maize starch content was reported in wheat flour-rice-maize starch composite bread (Mancebo et al., 2015) and wheat-maize flour composite bread (Rai et al., 2012). The decrease in the taste score with increase BSGF content could be due to high polyphenol content in BSGF which was associated with bitterness taste in baked products (Waters et al., 2012; Herendia-Sandoval et al., 2020).

3.3.5. Overall acceptability (OAC)

The overall acceptability was significantly (p < 0.05) affected by the blend proportion. The maximum score was found to be 7.9 (like very much) for the control sample whereas the minimum score was 2.7 (dislike moderately) for bread made with 70:30% (W:BSGF). The OAC score for the samples with 90:10% (W:BSGF) and 70:20:10% (W:M:BSGF) were 7.8 (like very much) and 7.1 (like moderately), respectively. On the other hand the sample with 75:10:15% (W:M:BSGF) resulted in OAC score of 5.6 (between “nether like nor dislike” and “like slightly”). The result indicated that inclusion of BSGF up to 10% and maize up to 20% resulted in an acceptable product. In general increase in BSGF content decreased OAC as indicated by the magnitude and the negative sign of the model coefficient. The effect of maize flour is not as pronounced as BSGF. The response surface for the OAC is presented in Figure 3e. The relationship between the blend proportions and the OAC was described (R2 = 0.951, adjusted-R2 = 0.914 and p < 0.05) by a special cubic model. BSGF has a characteristic odour due to some odourant compounds like 2-butyl-1-octanol, 3-methyl-butanal, 2-heptane, butanal, benzene and 2,3-butanedione which contribute to the aroma and hence affect negatively the OAC (Ktenioudaki et al., 2013b, Ktenioudaki et al., 2013a). The results indicated that inclusion of BSGF up to 10% resulted in an acceptable product. The findings in this study are in agreement with the previous studies where incorporation BSGF up to 10% resulted in an acceptable bread (Waters et al., 2012) and baked snacks (Ktenioudaki et al., 2013a, Ktenioudaki et al., 2013b) and up to 15%–25% for cookies (Ӧztűrk et al., 2002; Petrović et al., 2017). A decrease in OAC with increase in maize starch content was reported in wheat flour-rice-maize starch composite bread (MAncebo et al., 2015) and wheat-maize flour composite bread (Rai et al., 2012). The results in this study revealed, however, that incorporation of maize in the wheat-maize-BSGF composite flour up to 20% results in acceptable bread. This opens an avenue to diversify the utilization of maize in baked products.

3.4. Correlation of variables

The correlation between the variables is presented in Table 3. All the sensory attributes including colour, flavour, texture, taste and overall acceptability were negatively and significantly (p < 0.01) correlated with the BSGF content whereas wheat flour was positively and significantly (p < 0.01) correlated with the sensory attributes (Table 3). Maize flour, however, did not show a significant association with the sensory attributes. The decrease in overall acceptability with increase in BSGF content could mainly be attributed to decrease in texture and taste scores as shown by the high correlations (r = 0.993) between both attributes and overall acceptability, due to the high fiber content of BSGF. Also the darker colour of bread contributed to the decrease in overall acceptability as demonstrated by a significant negative correlation (r = -0.992) between these attributes as the proportion of BSGF increased (Ӧztűrk et al., 2002; Ktenioudaki et al., 2013b). The loaf weight, moisture content, ash, protein and fiber were negatively (p < 0.05) correlated with wheat flour. Though there was a positive association between maize and moisture, ash, protein and fiber, the association was not significant (p < 0.05) A positive correlation was observed between BSGF and bread density (p < 0.05) and BSGF and loaf weight (p < 0.01). . Such association has been attributed to the disruption of the gluten viscoelastic network (Aprodu et al., 2017). The specific volume was negatively (p < 0.05) correlated with BSGF. This is an expected association since specific volume is the inverse of density. All the proximate compositions including moisture content, ash, fibre and protein were positively (p < 0.01) correlated with the BSGF content due to its high composition in these components.

Table 3.

Correlation coefficients between the different variables.

| Colour | Flavour | Texture | Taste | OAC | Weight | Vol | Sp. vol | Density | Moisture | Ash | Protein | Fiber | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheat | 0.773∗∗ | 0.786∗∗ | .0809∗∗ | 0.806∗∗ | 0.804∗∗ | -0.704∗∗ | -0,110 | 0.513∗ | -0.486 | -.932∗∗ | -0.861∗ | -0.823∗ | -0.917∗∗ |

| Maize | 0.079 | 0.051 | -0.015 | 0.018 | 0.015 | -0.012 | -0.083 | -0.082 | 0.086 | 0.560 | 0.425 | 0.374 | 0.573 |

| BSG | -0.960∗∗ | -0.954∗∗ | -0.935∗∗ | -0.955∗∗ | -0.950∗∗ | 0.816∗∗ | 0.185 | -0.531∗ | 0.498∗ | 0.986∗∗ | 0.986∗∗ | 0.969∗∗ | 0.952∗∗ |

| Colour | 1 | ||||||||||||

| Flavour | 0.984∗∗ | 1 | |||||||||||

| Texture | 0.990∗∗ | 0.981∗∗ | 1 | ||||||||||

| Taste | 0.989∗∗ | 0.985∗∗ | 0.993∗∗ | 1 | |||||||||

| OAC | 0.992∗∗ | 0.980∗∗ | .0993∗∗ | 0.993∗∗ | 1 | ||||||||

| Weight | -0.857∗∗ | -0.820∗∗ | -0.857∗∗ | -0.852∗∗ | -0.865∗∗ | 1 | |||||||

| Vol | -0.132 | -0.070 | -0.059 | -0.117 | -0.124 | 0.353 | 1 | ||||||

| Sp. vol | 0.659∗∗ | 0.679∗∗ | 0.725∗∗ | 0.666∗∗ | 0.670∗∗ | -0.511∗ | 0.621∗ | 1 | |||||

| Density | -0.635∗ | -0.649∗∗ | -0.698∗∗ | -0.637∗ | -0.644∗∗ | 0.519∗ | -0.611∗ | -0.994∗∗ | 1 | ||||

| Moisture | -0.941∗∗ | -0.980∗∗ | -0.941∗∗ | -0.937∗∗ | -0.941∗∗ | 0.922∗∗ | -0.918∗∗ | -0.923∗∗ | 0.915∗∗ | 1 | |||

| Ash | -0.932∗∗ | -0.970∗∗ | -0.927∗∗ | -0.922∗∗ | -0.926∗∗ | 0.956∗∗ | -0.959∗∗ | -0.960∗∗ | 0.956∗∗ | 0.979∗∗ | 1 | ||

| Protein | 0–.900∗ | -0.945∗∗ | -0.893∗ | -0.887∗ | -0.888∗ | 0.950∗∗ | -0.953∗∗ | -0.955∗∗ | 0.950∗∗ | 0.953∗∗ | 0.993∗∗ | 1 | |

| Fibre | -0.811 | -0.885∗ | -0.804 | -0,797∗ | -0.807∗ | 0.867∗ | -0.871∗ | -0.874∗ | 0.868∗ | 0.967∗∗ | 0.972∗∗ | 0.959∗∗ | 1 |

Correlation is significant at the 0.05 level (2-tailed).

Correlation is significant at the 0.01 level (2-tailed).

3.5. Optimization

Optimization was done using graphical and numerical techniques. The optimal blend proportion using graphical optimization was determined by overlaying the contour plots of the sensory and physicochemical attributes. The optimal blend proportion is shown in the shaded region of Figure 4. Bread with maximized protein content from BSGF will address protein malnutrition by providing cheap source of protein. Moreover, consumers will also benefit health wise from high fibre bread using BSGF. The graphical optimization revealed that the best results were found using 73–97% of wheat, 3–20% maize, and 1–11% BSGF. Using the criteria of maximizing all the sensory attributes, protein, fibre, specific volume and minimizing density and weight, the best results using numerical optimization were combination of 65% wheat, 20% maize flour, and 15% BSGF with a desirability value of 0.524. Graphical optimization is preferred when the process variables are few. The researcher has the opportunity to visualize the superimposed plot in order to look at the feasible operating conditions and select the most appropriate region. Though the numerical optimization does not show an overall visual information, it gives specific combination of the level of the independent variables that give the best results.

Figure 4.

An overlay plot showing the optimal region.

4. Conclusion

Increase in BSGF content decreased the specific volume and increased the density significantly (p < 0.05). The fibre, protein and ash content of bread increased with increase in BSGF. The increase in these properties with increase in maize proportion was small compared to due to BSGF. The sensory attributes including colour, taste, flavour, texture and overall acceptability significantly (p < 0.05) reduced with increase in BSGF and maize content. Graphical optimization revealed that the best results were found with proportions 73–87% of wheat, 9–20% maize, and 0–11% BSGF. Numerical optimization indicated that best combination for an acceptable product was 65% wheat, 20% maize flour, and 15% BSGF with a desirability value of 0.524. The results show that BSGF can be incorporated up 10% to obtain an acceptable product using wheat, maize and BSGF composite flour.

Declarations

Author contribution statement

Angel Ginindza: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data.

W. K. Solomon: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

J. S. Shelembe, T. P. Nkambule: Analyzed and interpreted the data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- AACC . tenth ed. The American Association of Cereal Chemist Press; St Paul Minnesota., USA: 2000. Approved Methods of the American Association of Cereal Chemists. [Google Scholar]

- Adeyeye S.A.O., Adebayo-Oyetoro A.O., Omoniyi S.A. Quality and sensory properties of maize flour cookies enriched with soy protein isolate. Cogent Food and Agric. 2017;3:1278827. [Google Scholar]

- Akara E., Ikeda M.T., Ashida K., Tanaka K., Yanaka M., Iida S. Effects of rice flour properties on specific volume of one-loaf bread made from rice flour with wheat gluten. J. Food Sci. Technol. Res. 2009;15(4):439–448. [Google Scholar]

- AOAC . vol. 2. Wilson; Washington: 2000. (Official Methods of Analysis). [Google Scholar]

- Aprodu I., Simion A.B., Banu I. Valorisation of the brewers’ spent grain through sourdough bread making. Int. J. Food Eng. 2017;13 [Google Scholar]

- Awoyale W., Maziya-Dixon B., Sanni L.F., Shittu T.A. Nutritional and sensory properties of a maize-based snack food (kokoro) supplemented with treated Distillers’ spent grain (DSG) Int. J. Food Sci. Technol. 2011;46:1609–1620. [Google Scholar]

- Chauhan G., Zillman P.R., Eskin N. Dough Mixing and Bread making properties of Quinion-wheat flour blends. J. Food Sci. 1992;27:701–705. [Google Scholar]

- Connolly A., Piggott C.O., FitzGerald R.J. In vitro α-glucosidase, angiotensin converting enzyme and dipeptidyl peptidase-IV inhibitory properties of brewers’ spent grain protein hydrolysates. Food Res. Int. 2014;56:100–107. [Google Scholar]

- Cooray S.T., Lee J.J.L., Chen W.N. Evaluation of brewers' spent grain as a novel media for yeast growth. Amb. Express. 2017;7:1–10. doi: 10.1186/s13568-017-0414-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ekpa O., Placios-Rojas, Kruseman G., Fogliano V., Linnemann A.,R. Sub-saharan African maize-based food – processing practices, challenges and opportunities. Food Rev. Int. 2019;35(7):609–639. [Google Scholar]

- Ekpa O., Placios-Rojas N., Rosales A., Renzetti S., Fogliano V., Linnemann A.,R. Genotype selection influences the quality of gluten-free bread from maize. Food Sci. Technol. 2020;125:109214. [Google Scholar]

- Hager A.S., Arendt E.K. Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads on rice, maize, teff and buckwheat. Food Hydrocolloids. 2013;32:195–203. [Google Scholar]

- He Y., Kuhna D.D., O’Keefea S.F., Ogejob J.A., Fraguasa C.F., Wanga H., Huanga H. Protein production from brewer’s spent grain via wet fractionation: process optimization and techno-economic analysis. Food Bioprod. Process. 2021;1(2 6):234–244. [Google Scholar]

- Heredia-Sandoval N.G., Granados-Nevarez M.C., Barca A.M.C., Vásqueza-Lara F., Malunga L.N., Apea-Bah F.B., Beta T., Islas-Rubio A.R. Phenolic acids, antioxidant capacity, and estimated glycemic index of cookies added with brewer’s spent grain. Plant Foods Hum. Nutr. 2020;75:41–47. doi: 10.1007/s11130-019-00783-1. [DOI] [PubMed] [Google Scholar]

- Jagelaviciute J., Cizeikiene D. The influence of non-traditional sourdough made with quinoa, hemp and chia flour on the characteristics of gluten-free maize/rice bread. Food Sci. Technol. 2021;137:110457. [Google Scholar]

- Khuzwayo T.A., Taylor J.R.N., Taylor J. Influence of dough sheeting, flour pre-gelatinization and zein inclusion on maize bread dough functionality. Food Sci. Technol. 2020;121:108993. [Google Scholar]

- Ktenioudaki A., Chaurin V., Reis S.F., Gallagher E. Brewers spent grain as a functional ingredient for breadsticks. Int. J. Food Sci. Technol. 2012;47:1765–1771. [Google Scholar]

- Ktenioudaki A., O’Shea N., Gallagher E. Rheological properties of wheat dough supplemented with functional by-products of food processing: brewers spent grain and apple pomace. J. Food Eng. 2013;116(2):362–368. [Google Scholar]

- Ktenioudaki A., Crofton E., Scannell A.G.M., Hannon J.A., Kilcawley K.N., Gallagher E. Sensory properties and aromatic composition of baked snacks containing brewer’s spent grain. J. Cereal. Sci. 2013;57:384–390. [Google Scholar]

- Ktenioudaki A., Alvarez-Jubete L., Smythc T.J., Kilcawley K., Rai D.K., Gallagher E. Application of bioprocessing techniques (sourdough fermentation and technological aids) for brewer's spent grain breads. Food Res. Int. 2015;73:107–116. [Google Scholar]

- Lynch K.M., Steffen E.J., Arendt E.K. Vol. 122. Institute of Brewing and Distilling; 2016. pp. 553–568. (Brewers’ Spent Grain: a Review with an Emphasison Food and Health). [Google Scholar]

- Mancebo C.M., Merino C., Martinez M.M., Gomez M. Mixture design of rice flour, maize starch and wheat strach for optimization of gluten free bread quality. J. Food. Sci. Technol. 2015;52:6323–6333. doi: 10.1007/s13197-015-1769-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Martins Z.E., Pinho O., Ferreira I.M.P.L.V.O. Impact of new ingredients obtained from brewer’s spent yeast on bread characteristics. J. Food Sci. Technol. 2018;55(5):1966–1971. doi: 10.1007/s13197-018-3107-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Manyatsi N., Solomon W.K., Shelembe J.S. Optimization of blending ratios of wheat-maize-sprouted mungbean (Vigna radiata L.) composite flour bread using D-optimal mixture design. Cogent Food Agric. 2020;6(1) [Google Scholar]

- McCarthy A.L., O'Callaghan Y.C., Connolly A., Piggott C.O., FitzGerald R.J., O'Brien N.M. In vitro antioxidant and anti-inflammatory effects of brewers' spent grain protein rich isolate and its associated hydrolysates. Food Res. Int. 2013;50:205–212. [Google Scholar]

- Menon L., Majumda R.S.D., Ravi U. Development and analysis of composite flour bread. J. Food Sci. Technol. 2015;52(7):4156–4165. doi: 10.1007/s13197-014-1466-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mirabella N., Castellani V., Sala S. Current options for the valorization of food manufacturing waste: a review. J. Clean. Prod. 2014;65:28–41. [Google Scholar]

- Montgomery D.C. fifth ed. John Wiley & Sons; 2001. Design and Analysis of Experiments. [Google Scholar]

- Mussatto S.I. Brewer’s spent grain: a valuable feedstock for industrial applications. J. Sci. Food Agric. 2014;94:1264–1275. doi: 10.1002/jsfa.6486. [DOI] [PubMed] [Google Scholar]

- Mussatto S.I., Dragone G., Roberto I.C. Brewer’s spent grain: generation, characteristics and potential applications. J. Cereal. Sci. 2006;43(1):1–14. [Google Scholar]

- Myers R.H., Montgomery D.C., Anderson-Cook C.M. John Wiley & Sons, Inc; NJ: 2016. Response surface Methodology: Process and product optimization using designed experiments. [Google Scholar]

- Nkhabutlane P., Edu G.R., Kock H.L. Quality characterization of wheat, maize and sorghum steamed breads from Lesotho. J. Sci. Food Agric. 2014;94:2104–2117. doi: 10.1002/jsfa.6531. [DOI] [PubMed] [Google Scholar]

- Onyango G., Mutungi C., Unbehend G., Lindhauer M. Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT- Food Sci. Technol. 2011;44:681–686. [Google Scholar]

- Oyeyinka S.A., Adebayo A.I., Oyeyinka A.T., Akeem A.O., Garuba T., Oladunjoye A.O. Flour functionality, physicochemical and sensory properties of steamed and baked maize meal enriched with defatted soybean. J. Food Process. Preserv. 2020;44 [Google Scholar]

- Ӧztűrk S., Ӧzboy Ӧ., Cacidoğlu İ., Körsel H. Effects of brewers’ spent grain on the quality and dietary fibre content of cookies. Instit. Guild Brewing. 2002;108(1):23–27. [Google Scholar]

- Petrović J.S., Pajin B.S., Tanackov S.D.K., Pejin J.D., Aleksandar Z., Fišteš A.Z., Bojanić N.Ð., Lončarević I.S. Quality properties of cookies supplemented with fresh brewer`s spent grain. Food Feed Res. 2017;44(1):57–63. [Google Scholar]

- Plessas S., Trantallidi M., Bekatorou A., Kanellaki M., Nigam P., Koutinas A.A. Immobilization of kefir and Lactobacillus casei on brewery spent grains for use in sourdough wheat bread making. Food Chem. 2007;105:187–194. [Google Scholar]

- Rachwa K., Waśko, Gustaw K., Polak-Berecka M. Utilization of brewery wastes in food industry. PeerJ. 2020;8:e9427. doi: 10.7717/peerj.9427. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rai S., Kaur A., Singh B., Minhas K.S. Quality characteristics of bread produced from wheat, rice and maize flours. J. Food Sci. Technol. 2012;49(6):786–789. doi: 10.1007/s13197-011-0548-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rai S., Kaur A., Singh B. Quality characteristics of gluten free cookies prepared from different flour combinations. J. Food Sci. Technol. 2014;51(4):785–789. doi: 10.1007/s13197-011-0547-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Robertson J.A., I’Anson K.J.A., Treimo J., Faulds C.B., Brocklehurst T.F., Eijsink V.G., Waldron K.W. Profiling brewers’ spent grain for composition and microbial ecology at the site of production. LWT Food Sci. Technol. 2010;43:890–896. [Google Scholar]

- Rosell C.M., Royas J.A., Benedito D.,B. Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocolloids. 2001;15:75–81. [Google Scholar]

- Sahin A.W., Hardiman K., Atzler J.J., Vogelsang-O’Dwyer M., Valdeperez D., Münch S., Cattaneo G., O’Riordan P., Arendt E.K. Rejuvenated brewer’s spent grain: the impact of two BSGF-derived ingredients on techno-functional and nutritional characteristics of fibre-enriched pasta. Innovat. Food Sci. Emerg. Technol. 2021;68:102633. [Google Scholar]

- Steinmacher N.C., Honna F.A., Gasparetto A.V., Anibal D., Grossmann M.V. Bio-conversion of brewers spent grain by reactive extrusion and their application in bread making. Food Sci. Technol. 2012;46(2):542–547. [Google Scholar]

- Stojceska V., Ainsworth P. The effect of different enzymes on the quality of high-fibre enriched brewer’s spent grain breads. Food Chem. 2008;110:865–872. doi: 10.1016/j.foodchem.2008.02.074. [DOI] [PubMed] [Google Scholar]

- Stojceska V., Ainsworth P., Plunkett A., İbanoğlu Ş. The effect of extrusion cooking using different water feed rates on the quality of ready-to-eat snacks made from food by-products. Food Chem. 2009;114:226–232. [Google Scholar]

- Sullivan P., O’Flaherty J., Brunton N., Arendt E., Gallagher E. The utilization of barly middlings to add value and health benefits to white breads. J. Food Eng. 2011;105:403–502. [Google Scholar]

- Waters D.M., Jacob F., Titze J., Arendt K.E., Zannini E. Fibre, protein and mineral fortification of wheat bread through milled and fermented brewers spent grain enrichment. Eur. Food Res. Technol. 2012;235:767–778. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.