Abstract

Background

The study aimed to assess effect of smokeless tobacco (ST) immersion with thermocycling (TC) on color of Vita Classical shade-guide, surface roughness (Ra) and roughness depth (Rz), and compressive fracture force (CFF) of hybrid polymer-infiltrated-feldspathic ceramic (Vita Enamic), leucite-Feldspathic glass (Vitablocs® Mark II), and zirconia-reinforced lithium silicate (Vita Suprinity) CAD/CAM prosthetic ceramic materials.

Material/Methods

A 48 samples were milled from Vita Enamic, Vita mark II, and Vita Suprinity. VitaPan shade-guide, Ra, and Rz were registered before ST immersion. Then, the same parameters were recorded again after 15 days of ST staining with and without TC. CFFs and fracture modes of samples after 3 months of aging were documented.

Results

A slight change was observed in VitaPan shade-guide. Ra and Rz of Vita Suprinity (VS) recorded the highest values among ceramic groups at 3 time intervals. Increases in Ra and Rz were observed after immersion and staining with TC. ANOVA and Bonferroni post hoc tests were used. Significant differences among and between groups were noticed only before immersion in ST and TC, with P value ≥0.00. The highest mean value and SD of CFFs (MPa and Newton) were recorded in Vita Suprinity, followed by Vita Enamic (VE) and Vita mark II (VMII). Reparable fracture was higher in VMII and VS.

Conclusions

ST staining and TC caused color changes in VitaPan shade-guide and increases in Ra and Rz of tested materials, with highest and lowest values recorded in VS and VE. CFFs were marginally equal to clinically accepted values for VS and equal or slightly higher than the half values for VE and VMII groups.

Keywords: Computer-Aided Design, Compressive Strength, Ceramics

Background

Prosthetic CAD/CAM dental ceramics have become a tremendously significant material in day-to-day prosthesis manufacturing because of their numerous advantages, such as long clinical survival rate, good translucency, durability, biocompatibility, color brightness, and intensity properties as natural non-stained teeth, and excellent long-term esthetic qualities [1,2]. As a consequence of continuing improvements, several materials have been utilized to fabricate ceramic prosthesis; these materials include hybrid polymer-infiltrated feldspathic ceramic-network material (VE), leucite-containing feldspathic glass (Vitablocs® Mark II), and zirconia-reinforced lithium silicate (VS) CAD/CAM prosthetic ceramics [1,3–5]. For a number of years, feldspathic prostheses have been the most widely used restorative material in the esthetic zone due to clinical longevity and the accepted aesthetics of restoration [4,5]. Currently, in modern dental practice, zircon-based ceramic is considered one of the most popular materials to construct ceramic prostheses [6–8], due to its superior mechanical properties and excellent biocompatibility compared with other dental ceramics [9–11].

Globally, tobacco demand has surged in the last several decades. The World Health Organization estimates that the number of smokeless tobacco (ST) users now exceeds 1.3 billion people. In several areas of the world, tobacco has cultural overtones, although its use is a preventable cause of oral cavity, cancerous, and pre-cancerous diseases and can cause death [12]. ST is usually prepared locally [13–15], with a typical snuff-dipping form including species-specific tobacco leaves, such as Nicotiana rustica and Nicotiana glauca [14]. In addition, it is largely manmade, prepared by crushing of the tobacco along with ash, oils, calcium oxide, flavors, and black pepper [15]. ST is widespread in southern regions of Saudi Arabia (Khameis Moushiet, Najran, and Jazan), where it is used orally or nasally [5,14,15]. In these regions of Saudi Arabia, ST use is observed in individuals as young as 13–17 years old [13,14]. Mostly, these products are habitually positioned in the mouth (vestibule) for a duration between 7–15 min [5,13–15]. Alkhatib reported that, similar to cigarette smokers, ST users exhibit brown discoloration of their upper and lower frontal teeth (area of the positioning of ST) [16].

The surface roughness (Ra) and depth roughness (Rz) of prosthetic dental ceramics in the oral environment are directly related to highly polished surfaces, subcritical crack propagation, and chemical inertness of material atoms, thereby enabling them to prevent degradation in the oral cavity during functions [17]. Ra and Rz decrease the biomechanical and esthetic value of prosthetic restorations and growing susceptibility to aging [18]. Plaque retention with surface staining consistently occurs on rough surfaces of dental restorations [19,20] and cause abrasive damage to opposing dentition [21]; however, it can also be weakened by the presence of surface flaws or/and cracks, which can lead to prosthesis and ceramic material failure [7,22].

All CAD/CAM ceramic materials have different microstructures, grain size, and grain distribution. The dissimilarity of microstructures has an important effect on the clinical performance of these materials. A profilometer device, which measures Ra and Rz, is a useful device for quantifying the microstructure and assessment of the surfaces of ceramic specimens [5,20,23]. Thermocycling (TC) is a popular method of artificial accelerated aging of ceramics because it reproduces the oral environment as an extrinsic factor [24–26]. The water aging method includes standardized thermal variations with baths ranging from 5°C to 55°C for several cycles. The TC method can affect the longevity of restoration and simulate the behavior of ceramic materials in the oral environment [20,27,28].

Few studies have investigated the effect of ST on the color of different ceramic materials used for prosthesis construction, since ST can cause color and/or surface changes in restorations [29]. However, the effects of ST on CAD/CAM prosthetic materials have seldom been studied, and the extent of color and surface changes remains unclear. This paper aimed to assess and compare the effect of ST immersion (15 days) with TC on the Vita Classical shade guide color, surface topography (Ra and Rz), compressive fracture forces (CFFs), and fracture mode of hybrid polymer-infiltrated feldspathic ceramic-network material (VE), leucite-containing feldspathic glass (VMII), and zirconia-reinforced lithium silicate (VS) CAD/CAM prosthetic ceramics. The null hypothesis indicates no difference in Vita Classical shade guide color, Ra, and Rz before and after 15 days ST staining. In addition, no difference was hypothesized regarding the values of CFF and fracture mode after 3 months of aging and 15 days of coffee immersion among the CAD/CAM prosthetic materials used in this study.

Material and Methods

Study Design and Sample Calculation

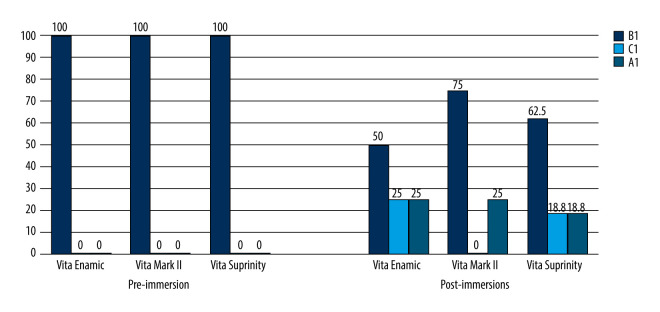

In this study, 3 commonly used and commercially existing CAD/CAM prosthetic ceramic materials were utilized to estimate the effect of ST immersion for 15 days with TC on Vita-pan shade guide color, Ra, Rz, CFFs, and fracture mode of CAD/CAM prosthetic ceramics. The sample size was calculated with Open Epi software (Version 2.3.1, Department of Epidemiology, Rollins School of Public Health, Emory University, Atlanta, USA), with the result revealing the need for a minimum of 48 samples at P=5% with 90% confidence level. The minimum sample size required was used in this study, and the mean differences could not be detected between different ceramic type tested. Figure 1 shows the sequences of steps followed.

Figure 1.

Flowchart showing the study design.

Specimen Construction, Grouping, and Cleaning

The CAD/CAM prosthetic materials were hybrid polymer-infiltrated feldspathic ceramic-network material (VE), leucite-containing feldspathic glass (VMII), and zirconia-reinforced lithium silicate (VS) materials (Vita Zahnfabrik, H. Rauter Bad Säckingen, Germany). A total of 48 (16 for each material) samples of machinable CAD/CAM prosthetic blocks were cut into square slices with a thickness of 1.5±0.2 mm and dimension of 14×12 mm2 with the assistance of a CAD/CAM system (Amann Girrbach, Germany). Then, the samples were polished by 300–800-grit silicon carbide papers to gain an even thickness. Next, the samples were sintered in a dental ceramic furnace (Programat P310; Ivoclar Vivadent AG) for 2 h at 1550°C, in accordance with the manufacturer’s directions. Samples for each group of material (16 samples) were further divided into 3 equal subgroups of 8 based on the type of CAD/CAM prosthetic types. The samples were ultrasonically scrubbed with distilled water to remove any grease residue for 10 min and then dried for 20 s with compressed air prior to immersion [30]. A single operator (S. AlQ) works with the samples, following the directive presented in the leaflet of each CAD/CAM prosthetic ceramic type.

Vita Classical Color Parameter Measurements

The VitaPan classical shade guide (Vita Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säckingen, Germany) assessments were performed by a blind trained operator immediately after the samples came from the laboratory; these assessments were considered as „before.” Ahead of each measurement, the cases were lightly rinsed with distilled water and air-dried. The colors of specimens were assessed with a spectrophotometer (Vita Easyshade® Compact, Vita Zahnfabrik H. Rauter GmbH & Co. KG, Bad Säckingen, Germany) version V against a gray background to mimic the non-existence of light in the oral cavity. This action was done in accordance with the VitaPan shade guide according to ISO/TR 28642: 2016. All specimens were chromatically assessed 3 times, and the median values were determined [31,32].

Arithmetic Surface Roughness and Surfaces Depth Measurements

The surface topographies (Ra and Rz) for the samples were accomplished via a three-dimensional non-contact surface metrology with interferometry (Bruker Contour GTK, Bruker Nano Surfaces Division, Tucson, AZ, USA). The samples were measured by upright scan interferometry using 5× Michelson amplification lens through a field of interpretation of 1.5×1.5 mm2, Gaussian regression filter, a scan speed of 1×, and a threshold of 4. The microscope has a Vision 64 (Bruker) software package that controls the tool locations, statistical evaluation, and graphical output. Measurements of Ra and Rz were conducted twice across the samples at 2 time intervals, at baseline, and after coffee immersions and 3 months of aging [20,23,33,34]. Each sample was scanned 3 times with 0.08 mm length. Then, the average was obtained to calculate the arithmetic Ra and Rz values (in μm) following the ISO 11562 approvals for normalization.

Specimen Immersion in Smokeless Tobacco

All specimens were dipped in and stained with ST (Locally made in Jazan) for 15 days, as stated earlier [4,5]. The ST sample was mixed with water to achieve a certain thickness. Then, the specimens were immersed in ST for 10 min, with a constant weight bearing down on the specimens to ensure that they remained immersed for 10 min (the actual use time for ST) to mimic the intensity generated during dipping of ST. The ST preparations or blouse were replaced twice daily based on real-world use [5,13]. The immersion period was 15 consecutive days, simulating 1 year of drinking coffee [28,33]. Throughout the immersion cycles, the specimens were continuously stirred in the ST mix in an incubator at 37°C (Globolytics Single Phase Bacteriological Incubator, Globolytics Instruments Pvt Ltd., Valasaravakkam, Chennai, Tamil Nadu, India). At the end of each day, the specimens were rinsed under running distilled water and gently dried to remove any ST residue [33,34].

Thermocycling with Aging and Post Immersion Color Measurements

After immersion in ST for 15 days, the samples were removed from the distilled water of the aging machine, and TC process was performed in 5°C water and 55°C water in each tank in accordance with the following sequence and ISO 11405 standards, with a total number of 7500 cycles, followed by rinsing with distilled water and spot drying with tissue paper. VitaPan Classical color parameters measurements were performed following the same protocol regarding position, background, and operator and were recorded as post-immersion readings [2,23,28].

Compressive Fracture Force Test

The values of CFFs were determined with a computer-controlled universal testing machine (Zwick Z010/TN2A, Ulm, Germany) at an across-head speed of 0.5 mm/min by means of a rod with 4 mm diameter as proposed in ISO 6872 and in air at room temperature. The tip of 3-mm-radius hemispherical stainless steel was pointed to the center of each sample after the application of a 0.5 mm thermoplastic resin tape between the force loading tip and the strained CAD/CAM sample surfaces. This tape was used to uniformly distribute the fracture forces for each sample. Along the longitudinal axis, CFFs were applied at the center of each specimen until fracture, and the maximum force load of each sample was recorded automatically (in MPs and Newtons) by a computer connected to the working apparatus [28,35,36]. The CFF tests for all samples were carried out at the King Saud University, Biomaterial Laboratory, College of Dentistry, Riyadh, Saudi Arabia.

Fracture Mode Assessments

The fracture modes were classified based on the following types: 1) reparable fracture, in which the sample was broken in 2 half or 50–50% of the original shape; 2) semi-reparable fracture, in which the samples fracture resulted in 3–4 pieces, and each piece was 20–35% of the original size of the specimen; 3) non-reparable fracture, in which each sample fracture ended or showed 5 or more pieces [28].

Statistical Analysis

The mean±standard deviation (SD) of Ra and Rz of the CAD/CAM prosthetic specimens of Vita Enamic, Vitablocs® Mark II, and Vita Suprinity were documented before and after (Ra and Rz change) immersion in ST with TC and aging for 15 days. The CFFs and fracture modes of the tested materials were applied after aging for 6 months. We used SPSS version 16 (SPSS Inc., Chicago IL, USA) for data analysis. The results with P values less than 0.05 were interpreted as statistically meaningful. We performed ANOVA, followed by Bonferroni post hoc test if there was a significancy between and within the groups.

Results

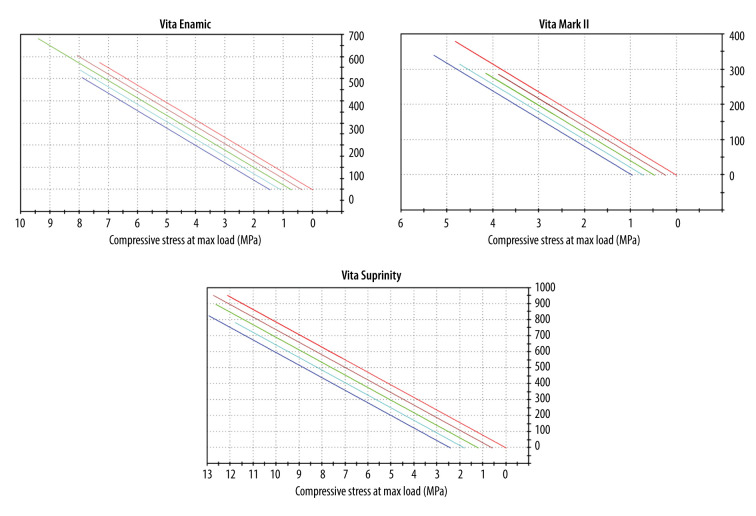

The minimum calculated samples size (48 samples) was used and divided into 3 groups and then into 2 groups according to thermocycling cycles or not. The VitaPan Classic shade guide changes were considered for the tested ceramic types. All samples showed changes in color at baseline (B1) after 15 days of immersion. After the immersion period, Vita Classical shade (B1) remained the same, represented as 75%, 62.5%, and 50% of VMII, VS, and VE materials, separately, whereas the highest change value was 25%, that the transformation to A1 color, for VE and VMII, followed by 18.8% for VS for the same color. However, C1 had recorded values of 25% and 18.8% for VE and VS, individually. No significant differences were detected between and within groups (Figure 2).

Figure 2.

Vita Classic shade color before and after immersion.

Table 1 reveals the Ra and Rz values of VE, VMII, and VS prosthetic CAD/CAM materials before immersion and TC and after immersion with ST and with or without TC for 15 days. Overall, the Ra values of VS were the highest among the ceramic groups at the 3 interval measurements (before immersion and TC, after immersion without TC, and after immersion with TC) with mean (SD) of 0.37 (0.032), 0.19 (0.179), and 0.22 (0.230), respectively. The lowest mean (SD) values were recorded among the VE samples: 0.21 (0.037), 0.15 (0.174), and 0.18 (0.190). In addition, the Rz values were in parallel with the Ra values regarding the type of prosthetic materials and values throughout triplicate measurements (Table 1). The RA and Rz for all prosthetic CAD/CAM groups showed enhanced mean and SD after TC for 15 days (Table 1). The analysis of variance (ANOVA) test showed significant changes among and between groups in terms of the Ra and Rz before immersion in ST and TC, with P value ≥ ≤0.001 (Table 2).

Table 1.

Mean and SD values of Ra and Rz of the used ceramics.

| Parameter | Type of ceramic | Mean and SD |

|---|---|---|

| Ra before immersion and TC | Vita Enamic | 0.21 (0.037) |

| Vita Mark II | 0.33 (0.019) | |

| Vita Suprinity | 0.37 (0.032) | |

| Ra after immersion without TC | Vita Enamic | 0.10 (0.105) |

| Vita Mark II | 0.15 (0.174) | |

| Vita Suprinity | 0.19 (0.179) | |

| Ra after immersion with TC | Vita Enamic | 0.15 (0.151) |

| Vita Mark II | 0.18 (0.190) | |

| Vita Suprinity | 0.22 (0.230) | |

| Rz before immersion & TC | Vita Enamic | 0.25 (0.029) |

| Vita Mark II | 0.36 (0.029) | |

| Vita Suprinity | 0.42 (0.045) | |

| Rz after immersion without TC | Vita Enamic | 0.11 (0.115) |

| Vita Mark II | 0.19 (0.190) | |

| Vita Suprinity | 0.23 (0.236) | |

| Rz after immersion & with TC | Vita Enamic | 0.16 (0.016) |

| Vita Mark II | 0.20 (0.203) | |

| Vita Suprinity | 0.29 (0.029) |

Table 2.

ANOVA test values for Ra and Rz of the used prosthetic materials.

| Parameter | Sum of squares | df | Mean square | F | p-value | |

|---|---|---|---|---|---|---|

| Arithmetical surface roughness (Ra) | ||||||

| Ra before immersion & TC | Between groups | 0.208 | 2 | 0.104 | 112.321 | 0.000 * |

| Within groups | 0.042 | 45 | 0.001 | |||

| Total | 0.250 | 47 | ||||

| Ra after immersion without TC | Between groups | 0.55 | 2 | 0.28 | 1.129 | 0.332 |

| Within groups | 1.102 | 45 | 0.24 | |||

| Total | 1.158 | 47 | ||||

| Ra after immersion & with TC | Between groups | 0.44 | 2 | 0.022 | 0.594 | 0.557 |

| Within groups | 1.677 | 45 | 0.037 | |||

| Total | 1.721 | 47 | ||||

| Roughness depth (Rz) | ||||||

| Rz before immersion & TC | Between groups | 0.241 | 2 | 0.121 | 97.044 | 0.000 * |

| Within groups | 0.056 | 45 | 0.001 | |||

| Total | 0.297 | 47 | ||||

| Rz after immersion without TC | Between groups | 0.117 | 2 | 0.058 | 1.666 | 0.200 |

| Within groups | 1.576 | 45 | 0.035 | |||

| Total | 1.693 | 47 | ||||

| Rz after immersion & with TC | Between groups | 0.126 | 2 | 0.063 | 1.237 | 0.300 |

| Within groups | 2.293 | 45 | 0.51 | |||

| Total | 2.419 | 47 |

Bonferroni post hoc testing among the different prosthetic CAD/CAM materials, Ra, and Rz (before immersion and TC, after immersion without TC, and after immersion with TC) showed a statistically significant difference in Ra before immersion in ST and TC for Vita Enamic, Vita Suprinity, and Vita Mark II, with P value 0.001. In addition, a significant difference with the same P values was recorded for Rz before immersion in ST and TC for the same tested materials (Table 3).

Table 3.

Post hoc (Bonferroni) multi-comparison tests.

| Type of ceramic | Vita Enamic | Vita Mark II | Vita Suprinity | |

|---|---|---|---|---|

| Arithmetic surface roughness | ||||

| Ra before immersion and TC | Vita Enamic | – | 0.000 * | 0.000 * |

| Vita Mark II | 0.000 * | – | 0.001 * | |

| Vita Suprinity | 0.000 * | 0.001 * | – | |

| Ra after immersion without TC | Vita Enamic | Non-significant | ||

| Vita Mark II | ||||

| Vita Suprinity | ||||

| Ra after immersion with TC | Vita Enamic | Non-significant | ||

| Vita Mark II | ||||

| Vita Suprinity | ||||

| Surfaces depth measurements | ||||

| Rz before immersion & TC | Vita Enamic | – | 0.000 * | 0.000 * |

| Vita Mark II | 0.000 * | – | 0.000 * | |

| Vita Suprinity | 0.000 * | 0.000 * | – | |

| Rz after immersion without TC | Vita Enamic | Non-significant | ||

| Vita Mark II | ||||

| Vita Suprinity | ||||

| Rz after immersion & with TC | Vita Enamic | Non-significant | ||

| Vita Mark II | ||||

| Vita Suprinity | ||||

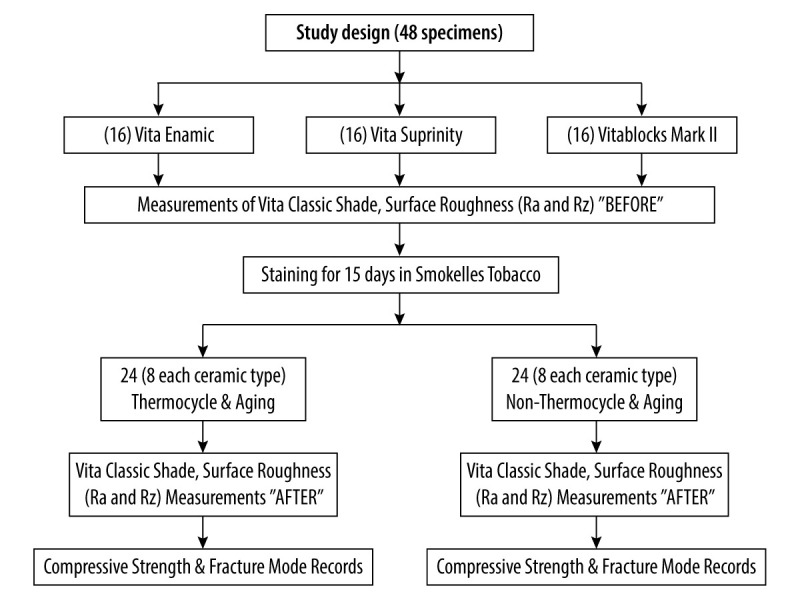

The highest mean value and SD of CFFs (MPa) were observed in Vita Suprinity, followed by Vita Enamic and Vita mark II, with values of 103.59, 60.69, and 36.91, respectively. The same order was recorded for the tested materials with the mean and SD expressed in Newtons: VS > VE, >VM II (Table 4). ANOVA test exhibited significant changes among the tested groups with P value 0.001 for the CFF values (MPa and Newtons). Bonferroni post hoc testing between the different CAD/CAM prosthetic groups and CFF values in MPa and Newtons showed a statistically significant variance between groups, with P value ≥ ≤0.001 (Table 4). Figure 3 presents the values of CFFs in MPa and Newtons in the X- and Y-axis.

Table 4.

Mean and SD values of CFFs by ANOVA followed by Bonferroni test of the ceramics used.

| Parameter | Type of ceramic | Mean and SD | P value |

|---|---|---|---|

| Compressive forces (MPa) | Vita Enamic | 60.69 (2.999)A,B | 0.000 * |

| Vita Mark II | 36.91 (1.429)A,B | ||

| Vita Suprinity | 103.59 (2.875)A,B | ||

| Compressive forces (Newton) | Vita Enamic | 476.66 (49.237)A,B | 0.000 * |

| Vita Mark II | 290.59 (46.234)A,B | ||

| Vita Suprinity | 832.17 (96.477)A,B |

Different superscript letters indicate statistically significant difference withing the respective subgroup (p<0.05) based on ANOVA followed by Bonferroni tests.

Figure 3.

Values of compressive fracture forces in MPa and Newtons.

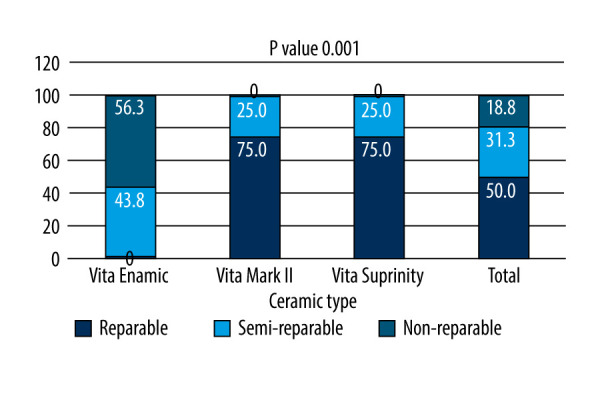

Based on the definitions of fracture types presented in the methodology, reparable fractures were recorded in 75% of VMII and VS, whereas the remaining 25% were semi-reparable. VE contained 56.3% and 43.8% non-reparable and semi-reparable fractures, respectively (Figure 4).

Figure 4.

Percentage of fracture mode.

Discussion

In the present in vitro study, VitaPan Classical shade guide color changes, Ra, and Rz were evaluated using 3 types of CAD/CAM prosthetic materials. VitaPan shade guide color was assessed before and after 15 days of ST immersion and staining with TC, whereas Ra and Rz were evaluated before ST immersion and TC, after ST immersion without TC, and after ST immersion with TC. The null hypothesis ie, the VitaPan shade guide color, Ra, and Rz) showed no difference from previous values, during, and after ST staining and TC and was rejected. Overall, changes occurred in the color of VitaPan Classical shade guide, which agrees with previous studies [31–32]. The Ra and Rz for all tested prosthetic CAD/CAM materials showed increased mean and SD after TC for 15 days, which agrees with the results of Aldosarie et al and Al Moaleem et al [20,27], but differs from the values recorded by Vasiliu et al [23].

In the last several decades, VitaPan Classical shade guides have been used to select tooth color for prostheses. The mismatch or inaccuracy of this process is easily noticed in practice. A device has been developed to overcome the shortcomings using a visual guide. A spectrophotometer is a device that records minute color variations, and its information can be explained in numbers. It has various advantages, such as accuracy, ability to investigate the main components of a series of spectra, and the ability to change information to several color-measuring schemes [5,20,31]. In addition, the device is inexpensive, easy to use, and is frequently used by investigators [37,38]. The Vita Easy Shade color spectrophotometer has better ability compared with other types of spectrophotometers. It can be used during daily clinical dental practice and in laboratories for dental research, with several limitations [39].

With the VitaPan classical shade guide (B1) before the ST immersion and TC for 15 days, B1 (whiter colors) shades remained unchanged in most of the samples in the 3 tested prosthetic CAD/CAM materials. However, 25% of the samples of Vita Enamic and Vita Mark II changed into A1 shades (whiter colors), with no significant differences. In-parallel outcomes were documented by Derafshi et al, who demonstrated significant deviations and changes into darker colors after 24 and 72 h and 7 days of staining in chlorhexidine mouth wash. These variations can be attributed to the type of ceramic substances tested; we tested VE, VMII, and VS, but Derafshi et al tested other ceramic materials, namely, zirconia, and e.max samples, with different components and chemical structures and manufactured by other companies [40]. In addition, with the B1 VitaPan classical shade guide, VE and VS showed 25% and 18.8% changes, respectively, into C1 and C2 (darker color) after 2 weeks of ST staining, which agrees with the results of Adawi et al, who reported similar changes for similar materials after immersion in hot and cold coffee for the same duration of immersion [31]. Similarly, the color of different feldspathic ceramics changed from whiter (B1) into darker tones (C1) after 2 weeks of khat immersion [32]. The highest unchanged color after ST immersion was observed in leucite-containing feldspathic glass (Vitablocs® Mark II) samples, which coincided with the results recorded by Al Moaleem et al, who found that feldspathic ceramic exhibits minimum color change and stability because it has no glass filler, which consistently keeps the surface smooth enough after immersion. Hence, we suggest utilizing feldspathic ceramic contents whenever possible for our ST patients [32]. In a recent study conducted in 2022, color deviations to lighter shades in relation to the VitaPan classical shade guide were recorded and became evident after white and black ST immersion for 2 weeks of Vita Suprinity, Mark II, and Enamic [5].

TC is a prevalent procedure of artificially improved CAD/CAM ceramic aging because it duplicates the oral natural environment as an extrinsic change [23,41]. The water aging technique features identical thermal variations, with bath temperatures reaching from −5 to 55°C for several cycles. This method can affect the durability of CAD/CAM prosthesis and can simulate the performance of ceramic restoration in the oral cavity and environment [23,25,42]. The Ra and Rz for the tested materials were higher after immersion and TC. Similar findings were recorded in CAD/CAM and heat-processed materials tested by Vasiliu et al [23]. A study conducted in 2022 showed that black and white ST affected the Ra of Ceramill Zolid PS, Vita Suprinity, and Vita TriLuxe restorative materials after 2 weeks of immersion [5]. The values of Ra of Vitablocs Mark II, metal ceramic feldspathic materials, zirconia, and natural teeth were higher after khat immersion and TC for 5000 cycles in comparison with values observed before khat staining [27]. Similar findings were recorded by Aldosari et al [20], in which Ra affected all the tested samples (VS, VE, and VMII), and a study by Hajhamid et al on zirconia [7], offering greater values for the polished specimens next to TC. Surface treatments such as type of glazing or polishing had significant impacts on Ra and Rz after TC [23].

Vasiliu et al found that the Ra and Rz of the pressed and milled samples were below 0.2 μm after TC, and this affects the colonization of bacteria. Ra has a direct effect on biofilm development. This procedure leads to periodontal inflammation, but it can also increase the staining of CAD/CAM ceramic restorations. The results of this study showed that several of the tested milled ceramics displayed less change after TC in terms of Ra, whereas the heat-pressed ceramics displayed more significant changes after TC compared with the first one; this finding is explained by the grain size, which almost tripled for the heat-pressed ceramics. In this study, all tested materials showed increases after TC, with the highest Ra and Rz of 0.37 and 0.42 μm, respectively. The Ra or Rz of samples without TC were unaffected [20,23,25,27].

To correlate the outcomes of this spectrophotometric in vitro laboratory study with the in vivo clinical conditions, we created the following scenario: If 1-day storage is equal to 30-days drinking of staining liquids, then the 2-week packing used throughout the current in vitro immersion would correspond to 14 months of an in vivo clinical setting [43]. In another scenario, specimen aging at 3-month intervals for this in vitro soaking period is equal to 10 years of the survival rate of the CAD/CAM prosthetic materials in the oral cavity and environment [44].

The values of CFF and fracture modes before and after ST staining with TC and aging were different for the tested CAD/CAM prosthetic materials. Thus, the second null hypothesis was rejected. In the present study, glazed surfaces had significantly higher compressive fracture values compared with polished ones. This finding agrees with that of Alakkad et al [45], who discovered a relationship between the surface treatments (surface glazing) in increased fracture strength compared with polished surfaces for restorations made by CAD/CAM, with highly significant differences between the two surfaces of the tested samples, such as IPS e.max CAD, Celtra Duo, and IPS Empress CAD. Al Moaleem et al [28] recorded a considerably higher compressive force for feldspathic CAD/CAM materials (Vita Triluxe 396.25) compared with the value recorded in the present study (Mark II 290.59); however, the zirconia group recorded an equal compressive force (777.42 N) in comparison with the 832.17 N obtained for the Vita Suprinity used in the present study. Vita Suprinity CAD/CAM prosthetic materials had the highest fracture strength in comparison with Vita Enamic or Vita Mark II, similar to the findings of Bankoğlu and Sieper et al, who also recorded slightly higher fracture forces among zirconia or nano-ceramic samples [46,47]. Savaş et al reported a higher compressive fracture (in Newtons) for ceramic materials fabricated by CAD/CAM using Lava Ultimate (1525), IPS Empress CAD (1364), and CEREC (1232) after accelerated artificial aging [36]. These force values were higher than those recorded in the current study – 832, 477, and 291 N for Vita Suprinity, Vita Enamic, and Vita Mark II, respectively. These variations can be attributed to the various compositions of CAD/CAM tested materials, although they had a similar fabrication process. In addition, Savaş et al [36] showed no significant difference among the groups according to ANOVA, with P value=0.304, and this outcome differs from results of the present study.

All specimens were CFF-loaded until fracture by a universal testing machine after 15 days of ST immersion. Different fracture modes were recorded. Reparable fractures mainly occurred with Vita Mark II and Suprinity, which is different from the finding of Alahmari et al [35], who recorded mostly catastrophic fractures among tested crowns made of IPS e.max CAD. This finding can be explained by the recording of measurements conducted for the CFF for crowns cemented to natural teeth extraorally, whereas in the present study, we assessed CAD/CAM ceramics in the form of rectangular blocks. Also, similar findings recorded after CAD/CAM composite crowns fracture testes with aging [21]. Savaş et al recorded a smaller percentage of fracture mode (reparable) for zirconia and IPS Empress CAD after accelerated artificial aging [36]. Similar values and percentages, as chipping and bulk fracture, were recorded by Vafaee et al [48] after static load applications: 60% and 40% for Vita Enamic samples and less than 50% and 50% for Lava Ultimate ceramic type (Zircon type). In the present study, semi-reparable and non-reparable fracture modes were mainly observed in Vita Enamic, and lesser results were noted in Vita Suprinity and Vitablocs Mark II (25%) samples. These findings parallel the results of Al Moaleem et al, who examined zirconia and feldspathic ceramics [28]. For further understanding and analysis of fracture mode types, longer storage period and mechanical tests should be carried out.

The present study tested Color, Surface Characteristics, Compressive Fracture, and Fracture Modes of Vita Enamic, Vitablocs Mark II, and Vita Suprinity CAD/CAM materials. In further studies, some unexplored variables could be explored to augment the results of the present study, such as flexural strength [49], hardness [50], and shear strength [51]. A main drawback of the present in vitro study is that it did not precisely simulate the real oral cavity and clinical conditions, which could have resulted in different consequences because of the existence of prosthetic materials, subjects’ saliva, continuous shifting of pH, lack of periodontal ligament chewing cycles, one-directional axial loading, and stress in the oral environment. Long-term clinical investigations are recommended to assess the patterns of Ra, Rz, color changes, fracture forces, and mode of materials currently used in prosthetic dentistry.

Conclusions

The following conclusions were drawn for the current laboratory study. ST staining and TC caused slight VitaPan color changes in Vita Marc II and Vita Suprinity and moderate changes in Vita Enamic samples. Ra and Rz increased in all the tested materials after staining and TC, with the highest values observed in Vita Suprinity samples. CFFs were marginally equal to the clinically accepted amounts for Vita Suprinity (in MPa and Newtons), but they were half the clinically accepted values for Vita Enamic and Mark II. Most of the specimens in Vita Mark II and Vita Suprinity samples showed reparable fractures, whereas non-reparable and semi-reparable fractures were equally recorded in Vita Enamic.

Footnotes

Conflict of interest: None declared

Declaration of Figures’ Authenticity

All figures submitted have been created by the authors, who confirm that the images are original with no duplication and have not been previously published in whole or in part.

Financial support: None declared

Refrences

- 1.Stawarczyk B, Mandl A, Liebermann A. Modern CAD/CAM silicate ceramics, their translucency level and impact of hydrothermal aging on translucency, Martens hardness, biaxial flexural strength and their reliability. J Mech Behav Biomed Mater. 2021;118:104456. doi: 10.1016/j.jmbbm.2021.104456. [DOI] [PubMed] [Google Scholar]

- 2.Wendler M, Stenger A, Ripper J, et al. Mechanical degradation of contemporary CAD/CAM resin composite materials after water aging. Dent Mater. 2021;37(7):1156–67. doi: 10.1016/j.dental.2021.04.002. [DOI] [PubMed] [Google Scholar]

- 3.Aziz A, El-Mowafy O, Paredes S. Clinical outcomes of lithium disilicate glass-ceramic crowns fabricated with CAD/CAM technology: A systematic review. Dent Med Probl. 2020;57(2):197–206. doi: 10.17219/dmp/115522. [DOI] [PubMed] [Google Scholar]

- 4.Aydın N, Karaoğlanoğlu S, Oktay EA, Kılıçarslan MA. Investigating the color changes on resin-based CAD/CAM Blocks. J Esthet Restor Dent. 2020;32:251–56. doi: 10.1111/jerd.12561. [DOI] [PubMed] [Google Scholar]

- 5.Al Moaleem MM, Adawi HA, Alsharif KF, et al. Impact of smokeless tobacco on the color stability of zirconia, zirconia-reinforced lithium silicate and feldspathic CAD/CAM restorative materials: An in vitro study. Coatings. 2022;12:207. [Google Scholar]

- 6.de Araújo-Júnior ENS, Bergamo ETP, Bastos TMC, et al. Ultra-translucent zirconia processing and aging effect on microstructural, optical, and mechanical properties. Dent Mater. 2022;38(4):587–600. doi: 10.1016/j.dental.2022.02.016. [DOI] [PubMed] [Google Scholar]

- 7.Hajhamid B, Alfrisany N, Somogyi-Ganss E. The effect of accelerated aging on crystalline structures and optical properties of different monolithic zirconia: A qualitative systematic review. Dent Mater. 2022;38(4):569–86. doi: 10.1016/j.dental.2022.02.005. [DOI] [PubMed] [Google Scholar]

- 8.Arena A, Prete F, Rambaldi E, et al. Nanostructured zirconia-based ceramics and composites in dentistry: A state-of-the-art review. Nanomaterials. 2019;9:1393. doi: 10.3390/nano9101393. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Ala’a Abu-Obaid AA, Alyabis N, Alzaaqi N. An in vitro evaluation of the effect of polishing on the stainability of different CAD/CAM ceramic materials. Saudi Dent J. 2020;32:135–41. doi: 10.1016/j.sdentj.2019.08.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Haralur SB, Alqahtani RS, Mujayri F. Effect of hydrothermal aging and beverages on color stability of lithium disilicate and zirconia-based ceramics. Medicina (Kauanas) 2019;55:749. doi: 10.3390/medicina55110749. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Raszewski Z. Acrylic resins in the CAD/CAM technology: A systematic literature review. Dent Med Probl. 2020;57(4):449–54. doi: 10.17219/dmp/124697. [DOI] [PubMed] [Google Scholar]

- 12.WHO Study Group on Tobacco Product Regulation. Report on the Scientific Basis of Tobacco Product Regulation. WHO; Geneva, Switzerland: 2015. (WHO Technical Report Series 1001). [Google Scholar]

- 13.Al-Tayar B, Tin-O MM, Sinor MZ, Alakhali MS. Prevalence and association of smokeless tobacco use with the development of periodontal pocket among adult males in Dawan Valley, Yemen: A cross-sectional study. Tob. Induc. Dis. 2015;13:35. doi: 10.1186/s12971-015-0061-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Alsanosy RM. Smokeless tobacco (shammah) in Saudi Arabia: A review of its pattern of use, prevalence, and potential role in oral cancer. Asian Pac J Cancer Prev. 2014;15:6477–83. doi: 10.7314/apjcp.2014.15.16.6477. [DOI] [PubMed] [Google Scholar]

- 15.Bakdash A. Shammah (smokeless tobacco) and public health. Asian Pac J Cancer Prev. 2017;18:1183–90. doi: 10.22034/APJCP.2017.18.5.1183. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Alkhatib MN, Holt RD, Bedi R. Smoking and tooth discolouration: Findings from a national cross-sectional study. BMC Public Health. 2005;5:27. doi: 10.1186/1471-2458-5-27. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Challakh N, Palsa D, Bemmann M, et al. Assessibility of different CAD/CAM ceramics with optical coherence tomography. J Dent. 2021;114:103836. doi: 10.1016/j.jdent.2021.103836. [DOI] [PubMed] [Google Scholar]

- 18.Su Y, Xin M, Chen X, Xing W. Effect of CAD-CAM ceramic materials on the color match of veneer restorations. J Prosthet Dent. 2021;126(2):255e1–e7. doi: 10.1016/j.prosdent.2021.04.029. [DOI] [PubMed] [Google Scholar]

- 19.Kul E, Abdulrahim R, Bayındır F, et al. Evaluation of the color stability of temporary materials produced with CAD/CAM. Dent Med Probl. 2021;58(2):187–91. doi: 10.17219/dmp/126745. [DOI] [PubMed] [Google Scholar]

- 20.Aldosari LI, Alshadidi AA, Porwal A, et al. Surface roughness and color measurements of glazed or polished hybrid, feldspathic, and zirconia CAD/CAM restorative materials after hot and cold coffee immersion. BMC Oral Health. 2021;21:422. doi: 10.1186/s12903-021-01770-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Rosentritt M, Krifka S, Strasser T, Preis V. Fracture force of CAD/CAM resin composite crowns after in vitro aging. Clin Oral Investig. 2020;24(7):2395–401. doi: 10.1007/s00784-019-03099-1. [DOI] [PubMed] [Google Scholar]

- 22.Guilardi LF, Sores P, Werner A, et al. Fatigue performance of distinct CAD/CAM dental ceramics. J Mech Behav Biomed Mater. 2020;103:103540. doi: 10.1016/j.jmbbm.2019.103540. [DOI] [PubMed] [Google Scholar]

- 23.Vasiliu RD, Porojan SD, Birdeanu MI, et al. Effect of thermocycling, surface treatments and microstructure on the optical properties and roughness of CAD-CAM and heat-pressed glass ceramics. Materials. 2020;13:381. doi: 10.3390/ma13020381. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Subaşı MG, Alp G, Johnston WM, Yilmaz B. Effects of fabrication and shading technique on the color and translucency of new generation translucent zirconia after coffee thermocycling. J Prosthet Dent. 2018;120:603–8. doi: 10.1016/j.prosdent.2018.01.018. [DOI] [PubMed] [Google Scholar]

- 25.Malysa A, Wezgowiec J, Grzebieluch W, et al. Effect of thermocycling on the bond strength of self-adhesive resin cements used for luting CAD/CAM ceramics to human dentin. Int J Mol Sci. 2022;23(2):745. doi: 10.3390/ijms23020745. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Dos Santos PH, Catelan A. Albuquerque Guedes, et al. Effect of thermocycling on the roughness of nanofilm, microfilm and micro hybrid composites. Acta Odontol Scand. 2015;73:176–81. doi: 10.3109/00016357.2014.971868. [DOI] [PubMed] [Google Scholar]

- 27.Al Moaleem MM, AlSanosy R, Ahmari NMA, et al. Effects of khat on surface roughness and color of feldspathic and zirconia porcelain materials under simulated oral cavity conditions. Medicina (Kaunas) 2020;56(5):234. doi: 10.3390/medicina56050234. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Al Moaleem MM, Alathwani AA, Alamir AA, et al. Effect of thermocycling and khat extract staining on the optical and mechanical properties of ceramic materials. Medical Science. 2021;25(118):3146–56. [Google Scholar]

- 29.Thompson S, Griffin G, Meyer N, Pelaez LTC. Effect of smokeless tobacco on surface roughness of dental restorations. US Army Med. Dep. J. 2017;2:80–87. [PubMed] [Google Scholar]

- 30.Egilmez F, Ergun G, Cekic-Nagas I, et al. Comparative color and surface parameters of current esthetic restorative CAD/CAM materials. J Adv Prosthodont. 2018;10(1):32–42. doi: 10.4047/jap.2018.10.1.32. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Adawi HA, Al Moaleem MM, Al Ahmari NM, et al. Assessment of color stainability of mailed CAD/CAM ceramic materials after hot and cold coffee immersion at different time intervals. Med Sci Monit. 2021;27:e932745. doi: 10.12659/MSM.932745. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Al Moaleem MM, Homeida HE, Dafalla OM, et al. Evaluation of color changes and surface topography of different feldspathic ceramic materials after khat, catha edulis extract immersion. Biosci Biotechnol Res Commun. 2020;13:160–68. [Google Scholar]

- 33.Al-Angari SS, Eckert GJ, Sabrah AHA. Color stability, roughness and microhardness of enamel, and composites submitted to staining/bleaching cycles. Saudi Dent J. 2021;33(4):215–21. doi: 10.1016/j.sdentj.2020.08.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Al-Angari SS, Meaige S, Almayouf N, et al. The Effects of a coffee beverage and whitening systems on surface roughness and gloss of CAD/CAM lithium disilicate glass-ceramics. J Appl Biomater Funct Mater. 2021;19:22808000211058866. doi: 10.1177/22808000211058866. [DOI] [PubMed] [Google Scholar]

- 35.Alahmari NM, Adawi HA, Moaleem MMA, et al. Effects of the cervical marginal relocation technique on the marginal adaptation of lithium disilicate CAD/CAM ceramic crowns on premolars. J Contemp Dent Pract. 2021;22:900–6. [PubMed] [Google Scholar]

- 36.SAvaş TY, Karaokutan I, Subaşi MG, et al. Evaluation of the fracture strength of different CAD/CAM inlay restorations after accelerated aging. Selcuk Dental Journal. 2019;6:155–62. [Google Scholar]

- 37.Alghazali N, Burnside G, Moallem M, et al. Assessment of perceptibility and acceptability of color difference of denture teeth. J Dent. 2012;40(Suppl 1):e10–17. doi: 10.1016/j.jdent.2012.04.023. [DOI] [PubMed] [Google Scholar]

- 38.AlGhazali N, Burnside G, Smith RW, et al. Performance assessment of Vita Easy Shade spectrophotometer on colour measurement of aesthetic dental materials. Eur J Prosthodont Restor Dent. 2011;19:168–74. [PubMed] [Google Scholar]

- 39.Vichi A, Louca C, Corciolani G, et al. Color related to ceramic and zirconia restorations: A review. Dental Mater. 2011;27:97–108. doi: 10.1016/j.dental.2010.10.018. [DOI] [PubMed] [Google Scholar]

- 40.Derafshi R, Khorshidi H, Kalantari M, Ghaffarlou I. Effect of mouthrinses on color stability of monolithic zirconia and feldspathic ceramic: An in vitro study. BMC Oral Health. 2017;17:129. doi: 10.1186/s12903-017-0419-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Arocha MA, Mayoral JR, Lefever D, et al. Color stability of siloranes versus methacrylate-based composites after immersion in staining solutions. Clin Oral Investig. 2013;17(6):1481–87. doi: 10.1007/s00784-012-0837-7. [DOI] [PubMed] [Google Scholar]

- 42.Al-Qarni FD, Goodacre CJ, Kattadiyil MT, et al. Stainability of acrylic resin materials used in CAD-CAM and conventional complete dentures. J Prosthet Dent. 2020;123(6):880–87. doi: 10.1016/j.prosdent.2019.07.004. [DOI] [PubMed] [Google Scholar]

- 43.Seyidaliyeva A, DiplIng SR, Evagorou Z, et al. Color stability of polymer-infiltrated-ceramics compared with lithium disilicate ceramics and composite. J Esthet Restor Dent. 2020;32:43–50. doi: 10.1111/jerd.12525. [DOI] [PubMed] [Google Scholar]

- 44.Zidan S, Silikas N, Haider J, Yates J. Long-term sorption and solubility of zirconia-impregnated PMMA nanocomposite in water and artificial saliva. Materials. 2020;13:373–43. doi: 10.3390/ma13173732. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Alakkad L, Kostagianni A, Finkelman M, et al. Biaxial flexural strength of various CAD-CAM glass-ceramic materials. Am J Dent. 2021;34:91–96. [PubMed] [Google Scholar]

- 46.Bankoglu Gungor M, Karakoca Nemli S. Fracture resistance of CAD-CAM monolithic ceramic and veneered zirconia molar crowns after aging in a mastication simulator. J Prosthet Dent. 2018;119:473–80. doi: 10.1016/j.prosdent.2017.05.003. [DOI] [PubMed] [Google Scholar]

- 47.Sieper K, Wille S, Kern M. Fracture strength of lithium disilicate crowns compared to polymer-infiltrated ceramic-network and zirconia reinforced lithium silicate crowns. J Mech Behav Biomed Mater. 2017;74:342–48. doi: 10.1016/j.jmbbm.2017.06.025. [DOI] [PubMed] [Google Scholar]

- 48.Vafaee F, Firooz F, Heidari B, et al. A comparative study of flexural strength and fatigue resistance of 2 nanoceramic composite resin CAD/CAM blocks (Lava Ultimate and Vita Enamic) and a lithium disilicate glass ceramic (IPS e. max CAD) Biomedical and Pharmacology Journal. 2017;10:51–58. [Google Scholar]

- 49.Scribante A, Bollardi M, Chiesa M, et al. Evaluation after exposure to acidic drink. Biomed Res Int. 2019;2019:5109481. doi: 10.1155/2019/5109481. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Alamoush RA, Silikas N, Salim NA, et al. Effect of the composition of CAD/CAM composite blocks on mechanical properties. Biomed Res Int. 2018;23:4893143. doi: 10.1155/2018/4893143. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Beltrami R, Colombo M, Cavada A, et al. Influence of enamel exposure to acidic drink on shear bond strength of different fissure sealants. Bioengineering (Basel) 2022;9(1):20. doi: 10.3390/bioengineering9010020. [DOI] [PMC free article] [PubMed] [Google Scholar]