Abstract

Rice noodles have been used as a food model to elucidate the effects of glucono-delta lactone (GDL) dipping coupled with in-pack pasteurization on the physical changes of starch-based gel upon storage. The noodles were subjected to scanning electron microscopy (SEM), X-ray diffractometry (XRD), differential scanning calorimetry (DSC), equilibrium moisture content analysis and starch exudation analysis. Both the SEM and XRD revealed that the treated rice noodles showed an enhanced surface morphology and a lower degree of crystallinity during storage, as compared to the control counterpart. DSC results showed that a lower degree of starch molecule reassociation has taken place in the rice noodles after the GDL dipping and in-pack pasteurization treatment. In addition, the treated rice noodles were observed to contain a relatively higher moisture content and lower starch exudation content during storage.

Keywords: Hurdle technology, Acid-dipping, In-pack pasteurization, Starch retrogradation, Rice noodles

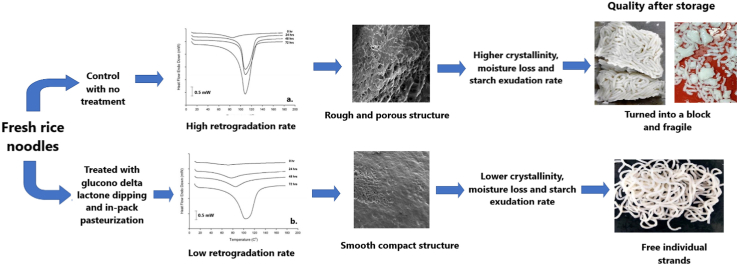

Graphical abstract

Highlights

-

•

Glucono delta lactone (GDL) dipping and in-pack pasteurization delayed starch retrogradation.

-

•

This treatment improved rice noodles surface and core structure.

-

•

Treated rice noodles showed enhanced quality over storage in terms of stickiness and fragility.

1. Introduction

Hurdle technology has been widely used in the food industry to ensure the safety and quality of a food product (Leistner and Gould, 2012). This method of preservation combines different bacteria-inhibiting factors to ensure pathogens in the food products are eliminated or controlled, so that the food product is safe for consumption and has an extended shelf life. By this hurdle technology, different “hurdles” may act synergistically in attacking the cell of pathogens. Therefore, the level of each hurdle would be relatively milder in hurdle technology when compared to when it is being used singly to induce the same inhibiting effect. Among the commonly used hurdles are manipulation of temperature, pH, water activity, redox potential or microstructure, addition of preservative, application of physical preservation techniques such as irradiation, high pressure processing, pulsed electric field, ultrasonication, ozonation, ohmic heating, cold plasma, and many more. The choice of combination relies on the availability of the technology as well as the characteristics of the food product.

To preserve fresh starch-based noodles such as rice noodles for long-term storage, is a great challenge. The shelf life of fresh rice noodles is relatively short (2–3 days) due to its high moisture content (>60%) and high water activity, aw (>0.90) (Rachtanapun and Tangnonthaphat, 2011). This renders the noodles susceptible to microbial attack. Apart from this, the physical deterioration of a fresh rice noodle was a crucial factor as well. Fresh rice noodles tend to become brittle over storage due to a relatively higher rate of starch retrogradation underway during storage, as compared to wheat-based noodles. As a result, the fresh noodle strands become sticky, and consumers will have difficulty freeing the noodle strands from one another after storage. All these reasons explain why the fresh rice noodle market distribution network is limited.

Jianming (1998) investigated the feasibility of preserving fresh noodles by irradiation technology. The results showed that noodles treated with irradiation and stored at room temperature (18–24 °C) could last for 10 days and the acidity of the noodles could be controlled to below pH 6.0. The appearance of the noodles was fresh, and there was no displeasing odour developed after a 10-day storage. Nevertheless, irradiation could be too costly for a noodle industry to adopt and this technology is not readily available in certain countries. Klinmalai et al. (2017) utilized chitosan as a preservative agent on flat rice noodles, as chitosan is known to possess a broad and wide range of antimicrobial activity against bacteria, yeast, and fungi. Results showed that the shelf life of the flat rice noodles was extended by an extra five days without altering their quality. On the other hand, Rachtanapun and Tangnonthaphat (2011) studied the shelf life of flat rice noodles by modifying its packaging conditions and storage temperature. The shelf life was 29 days when the packaged noodles were stored at 4 °C. However, the textural quality of the rice noodles was compromised due to starch molecules retrogradation. This shows that besides the microbial safety issue, the textural quality of the rice noodles could be a stumbling block in warranting a long shelf life. Unfortunately, studies of structural changes and physicochemical properties on fresh rice noodles is scarce in the literature. The aim of this project was to explore the effects of acid dipping (below pH 4.6) and in-pack pasteurization on the physical properties of rice noodles after storage.

In-pack pasteurization is a process where a food product is vacuum packed before being subjected to pasteurization. Glucono-delta-lactone (GDL) was used as an acidulant in the dipping process because GDL would impart a milder acidic tone to the product as compared to the other acidulants (Ramachandran et al., 2006). For high acid or acidified foods (pH ≤ 4.6), it is commonly known that a milder heat treatment is adequate to achieve commercial sterility as compared to those low acid foods (pH > 4.6). Tucker and Featherstone (2011) state that a 6-fold reduction in microbiological load is recommended for high acid food which is lower than the 12-fold reduction recommended for low acid foods. The reasons are: (1) for high acid or acidified foods, the heating process targets at the elimination of spoilage microorganisms and not lethal toxin producers such as Clostridium botulinum or Bacillus cereus, and (2) in high acid or acidified foods, acid is in the foods to guard against the proliferation of surviving microorganisms and germination of spores.

2. Materials and methods

2.1. Materials

Fresh wet rice noodles were purchased from HSB Laksa Marketing Sdn Bhd. The food-grade GDL powder was bought from Euro Chemo-Pharma Sdn. Bhd. (Penang, Malaysia).

2.2. Preparation of GDL solution

GDL solutions were prepared at different concentrations (0%, 0.05%, 0.10%, 0.5%, 1.0% and 1.5% w/v). To prepare 1000 mL of 1.0% GDL solution, an amount of 10.0 g of GDL powder was dissolved in distilled water using a 1000 mL volumetric flask. Then, the pH value of each solution was measured using a pH meter (Mettler Toledo-Model S20 Seven Easy). The determination was triplicated.

2.3. Sample treatment

The fresh wet rice starch noodles were dipped in the GDL solution of different concentrations (0%, 0.05%, 0.10%, 0.5%, 1.0% and 1.5%) for 2 min before being vacuum packed (150 g/pack) and pasteurized at 85 °C for 10 min using a water bath. Samples were stored for 0 h, 24 h, 48 h and 72 h at 4 °C before analysis. Sample treatments were triplicated.

2.4. Scanning electron microscopy (SEM)

The control (dipped in distilled water, 0% GDL) and the treated sample (dipped in 1.5% GDL solution) were subjected to freeze drying, before and after 72 h of chilled storage. The freeze-dried noodle strands were subjected to scanning electron microscopy (SEM Leo Supra 50VP, Carl-Ziess SMT, Oberkochem, Germany). Freeze dried rice noodles were attached to specimen stubs using a two-sided adhesive tape, coated with gold/palladium in a sputter coater. Micrograph of each sample was observed at a magnification power of 200 X under vacuum condition with a 10 kV acceleration voltage. A total of three micrographs at different spot were captured for each sample.

2.5. X-ray diffractometry (XRD)

The freeze-dried samples from Section 2.4 were crushed into powder using a mortar and pestle and sieved through a 250 μm sieve before being subjected to x-ray diffractometry (Diffractometer D5000, SIEMENS, Karlsruhe, Germany) to track changes in the crystallinity of the noodle strands following the method described by Lauro et al. (1999) with modifications. The samples were stored overnight over silica gel at room temperature. Samples were scanned from 5 to 50° (2Ɵ), with Cu Kα-radiation (λ 1.5406 Å) generated at 40 kV and 30 mA.

2.6. Differential scanning calorimetry (DSC)

The powdered and freeze-dried samples from Section 2.5 were subjected to differential scanning calorimetry using a DSC Q200 (TA Instruments, New Castle, DE, US) following the method described in Wu et al. (2010). Approximately 10 mg (db) samples were loaded into a DSC aluminium pan. Deionized water was added to the sample using a micropipette to achieve a water to sample mass ratio of 2:1. Following which, the sample pan was hermetically sealed and left to equilibrate at room temperature for 24 h before analysis. Equilibrated samples were heated from 10 °C to 150 °C at 10 °C/min. The amount of enthalpy recorded was related to the degree of starch molecule association taken place in the noodle strands before and after storage. Onset temperature (To), peak temperature (Tp), conclusion temperature (Tc) and enthalpy of melting (ΔH) were analyzed from the thermogram. The analysis was duplicated for each sample treatment replicate.

2.7. Equilibrium moisture content analysis

The freshly treated rice noodles (dipped in the GDL solution series) in strand form were stored using a moisture dish as described in Low et al. (2020). The samples were exposed to a 0% relative humidity created using phosphorus pentoxide in a desiccator. The weight loss of the noodle strands was recorded at specific interval storage time (0 h, 24 h, 48 h, and 72 h). The analysis was repeated two times for each sample treatment replicate. The equilibrium moisture content of the noodle strands at each specific storage interval was calculated using the following equation:

where,

Weight of moisture dish + lid in g = w1

Weight of moisture dish + lid + sample before drying in g = w2

Weight of moisture dish + lid + sample after drying in g = w3

2.8. Amylose exudation analysis

2.8.1. Preparation of standard curves

Stock solution was prepared by dissolving 0.05 g of potato amylose in 1 mL of 95% ethanol and 9 mL of NaOH in a 100 mL size volumetric flask with the aid of a hot water bath. After dissolution and cooling down, the final volume was topped up with distilled water. Blank and a set of working standard solutions (0.8 ppm, 1.6 ppm, 2.4 ppm, 3.2 ppm and 4.0 ppm) were prepared. Each working standard solution was reacted with iodine before being subjected to spectrophotometry using a UV/visible spectrophotometer (UV-160A, SHIMADZU, Kyoto, Japan) at 620 nm.

2.8.2. Determination of starch content in the sample

The freshly treated samples (dipped in the GDL solution series) were sampled throughout the chilled storage (0 h, 24 h, 48 h and 72 h). Approximately 10 g of the samples were soaked in a 50 mL distilled water and stirred constantly for 20 min to wash out starch exudation from the noodle strands. The samples were filtered using a filter paper. The total amount of starch exudates in the filtrate was determined as amylose following the method described in Khoomtong and Noomhorm (2015). Briefly, 1 ml of the filtrate was transferred to a 50 mL volumetric flask. To each volumetric flask, 1 mL of acetic acid and 2 mL of iodine solution were added. After that, the final volume was made up with distilled water. The absorbance of each sample was measured at 620 nm using a spectrophotometer. The analysis was triplicated for each sample treatment replicates.

2.9. Statistical analysis

All results were expressed as mean ± standard deviation (SD). The Statistical Package Social Science (SPSS) Statistics version 27.0 (IBM Corporation, New York, USA) was used to perform the statistical analysis. t-test and one way analysis variance (ANOVA) followed by Tukey's least significant test were carried out at 5% probability significant level, wherever appropriate.

3. Results and discussion

3.1. pH values of the soaking solutions

The pH values of the GDL solutions prepared at 0.05%, 0.1%, 0.5%, 1.0% and 1.5% (w/v) were 3.24 ± 0.04, 2.96 ± 0.05, 2.62 ± 0.02, 2.43 ± 0.03 and 2.33 ± 0.02, respectively. These pH values are consistent with the established dissociation constant (Ka value) of gluconic acid, which is 1.99 × 10−4- (OECD, 2004) and fell within the common pH range for acid dipping, which is below pH 4.6. The combination treatment of a proper acid dipping below pH 4.6 and an in-pack pasteurization was found to be able to inhibit bacterial growth and toxin formation for food products stored at room temperature (Low et al., 2020). It is worth noting that, different acids offer different sensory characteristics in terms of taste and smell to the product depending on their concentration. However, it was found that GDL is a better acidulant option for food products, since GDL provides the least tartness as compared to other acidulants available (Low et al., 2020; Sumitra et al., 2006).

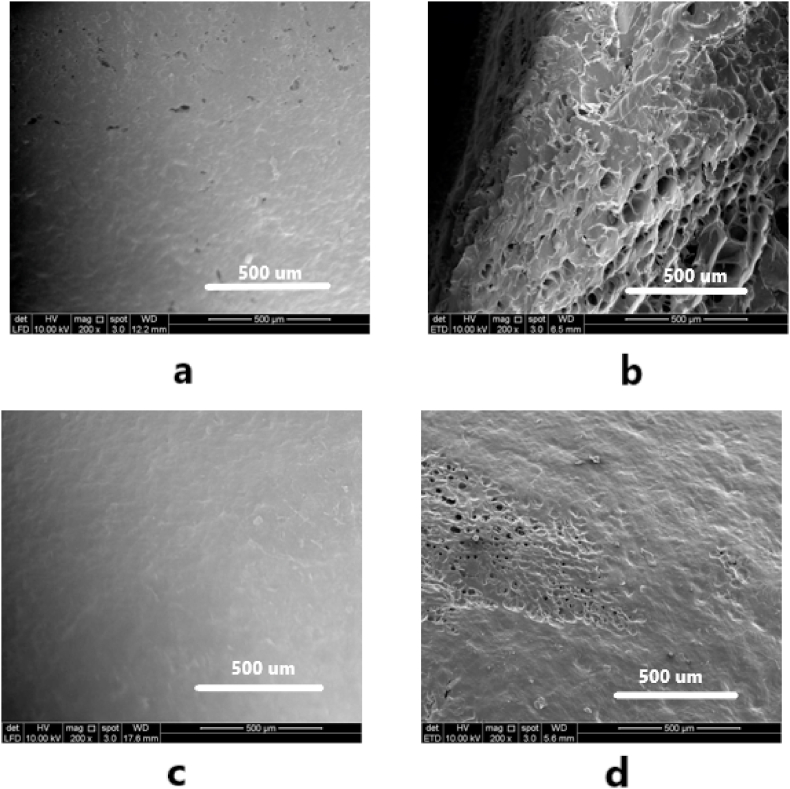

3.2. Scanning electron microscopy

The control sample (dipping in distilled water and no in-pack pasteurization, 0% GDL) together with the sample treated with 1.5% GDL dipping followed by in-pack pasteurization, were sampled at 0 h and 72 h chilled storage for freeze drying and scanning electron microscopy. The scanning electron micrographs of the freeze-dried samples at a magnification power of 200 X are depicted in Fig. 1. As shown in Fig. 1a, the freeze-dried control rice noodle strands showed a surface with no signs of fissures and holes before storage. However, after 72 h of chilled storage, the surface developed into a rough and highly porous structure (Fig. 1b). In comparison, surface of the rice noodle strands treated with 1.5% (w/v) GDL dipping followed by in-pack pasteurization appeared to be smoother before storage (Fig. 1c). The same sample after 72 h chilled storage showed a much more compact texture overall but with signs of fissures and pores (Fig. 1d). These observations indicate that the rice starch noodles without treatment showed a spongelike texture after storage and those with GDL dipping and in-pack pasteurization treatment remained intact and compact with minimal defects after storage. It is believed that the spongelike texture observed could be a result of the extensive starch molecule association taking place over the storage (Utrilla-Coello et al., 2013; Zhang et al., 2014).

Fig. 1.

Scanning electron micrographs of rice starch noodle with and without GDL (1.5% w/v) dipping and in-pack pasteurization treatment, sampled at different storage time. (a) without treatment and sampled at 0 h; (b) without treatment and sampled after 72 h chilled storage; (c) with treatment and sampled at 0 h; and (d) with treatment and sampled after 72 h chilled storage.

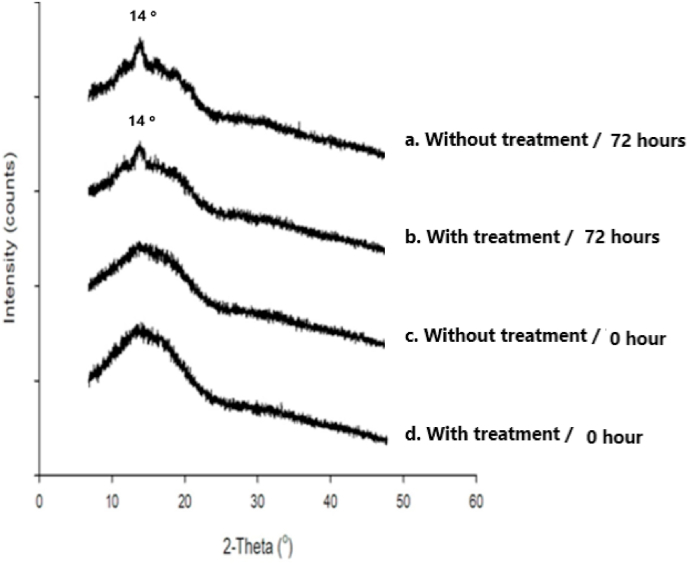

3.3. X-ray diffractometry

Fig. 2 illustrates the X-ray diffraction patterns of the control and the treated rice noodle strands (1.5% w/v GDL coupled with in-pack pasteurization) before and after storage. A clear distinction in terms of peaks pattern was observed. Fig. 2c and d are the X-ray diffraction patterns of the control and the treated samples before storage, respectively. Both diffractograms showed a big hump with no distinctive sign of a peak. This indicates that both samples are amorphous in nature before storage (Zhang et al., 2014).

Fig. 2.

X-ray diffraction pattern of rice starch noodle with and without GDL (1.5% w/v) dipping and in-pack pasteurization treatment, sampled at different storage time. (a) without treatment and sampled after 72 h chilled storage; (b) with treatment and sampled after 72 h chilled storage; (c) without treatment and sampled at 0 h; and (d) with treatment and sampled at 0 h.

However, after storage, there were signs of crystallinity in both samples. This can be proven by the peaks shown in both samples analyzed after 72 h (Fig. 2a and b), which expressed a typical pattern of a retrograded starch. The same diffraction pattern was observed in Wang et al. (2018), Wu et al. (2010), and Zhang et al. (2014), who work on rice starch crystallinity using X-ray diffractometry. A sharp peak was identified in both samples (Fig. 2a and b) at a 2θ angle of 14°. The peak intensity at 2θ angle of 14° for the treated sample seemed to be less intense as compared to the control sample. Once again, this indicates that there was a lower degree of molecule association that has taken place and thus lesser crystallinity showed in the treated sample as compared to the control sample. This observation also reveals that GDL dipping followed by in-pack pasteurization may be able to reduce the retrogradation tendency of the rice starch molecules during storage.

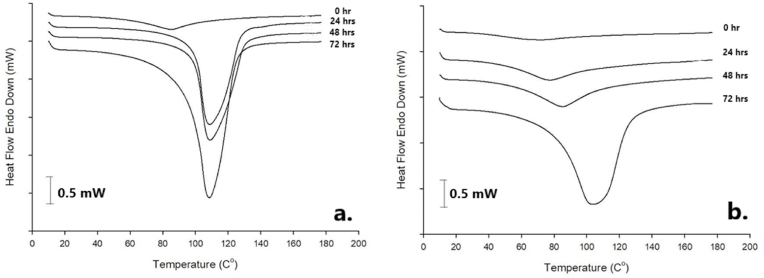

3.4. Differential scanning calorimetry (DSC)

Table 1 tabulates the DSC parameters of the samples analyzed of the control and the treated rice starch noodles samples as a function of storage time. Fig. 3 shows the typical DSC thermograms of the samples studied. In general, the endothermic peak area increased in size over storage for both the control and the treated samples (Fig. 3a and b), and the corresponding enthalpy data in Table 1 are different when compared between the control and the treated samples at each specific storage time. The progressive increase in the size of the endotherms was associated with the starch molecules reassociation during storage (Zhang et al., 2014), that was known as retrogradation. As shown in Table 1, the control rice starch molecules showed a drastic increase in enthalpy change of dissociation within 24 h of storage, which is reflected by the large area of the endothermic peaks shown (Fig. 3a). This indicates that a drastic association of molecules had taken place in the control sample within 24 h of storage. In addition, the narrow temperature range between the onset point (To) and the conclusion point (Tp) of the peak also reveals that the control sample easily associated into crystallites of uniform shapes and sizes (Atichokudomchai et al., 2002; Wang et al., 2020). In comparison, the treated rice noodles showed a smaller size of endothermic peak and have a broader transition temperature range of To-Tc. This indicates that the rate of molecules association of the treated sample was slower relatively, and a drastic association was seen only after 48 h of storage. This observation substantiates the results of the sample surface morphology reported earlier on, where the different degree of starch molecules association has resulted in the surface of the control samples to become rough and highly porous and the treated ones look smoother and more compact after storage. This suggests that rice noodles subjected to GDL dipping and in-pack pasteurization were showing a lower tendency to retrogradation than the control sample during storage.

Table 1.

Differential Scanning Calorimetry parameters of the control and treated samples stored over a period of 72 h.

| Storage time (h) | [GDL] (w/v%) | To (°C) | TP (°C) | Tc (°C) | ΔHr (J/g) |

|---|---|---|---|---|---|

| 0 | 0 | 57.00 | 85.59 | 130.00 | 154.1 |

| 1.5 | 61.30 | 77.61 | 90.51 | 101.3 | |

| 24 | 0 | 99.98 | 108.65 | 137.21 | 704.7 |

| 1.5 | 62.16 | 76.06 | 107.41 | 386.9 | |

| 48 | 0 | 99.63 | 109.11 | 136.58 | 750.2 |

| 1.5 | 63.56 | 85.58 | 113.23 | 550.8 | |

| 72 | 0 | 70.95 | 97.44 | 127.38 | 1086.0 |

| 1.5 | 87.71 | 106.15 | 138.52 | 876.9 |

Note: Mean (n = 6). To, onset temperature; TP, peak temperature; Tc, conclusion temperature; ΔHr, enthalpy of retrogradation. Coefficient variance of all mean values are lower than 10%.

Fig. 3.

Differential scanning calorimetry thermograms of (a) Control rice starch noodles and (b) Rice starch noodles treated by dipping at 1.5% GDL followed by in-pack pasteurization, as a function of storage interval at chilled condition and scanning temperature.

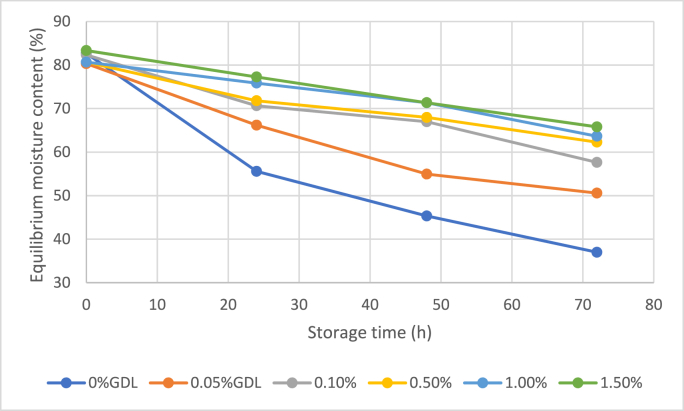

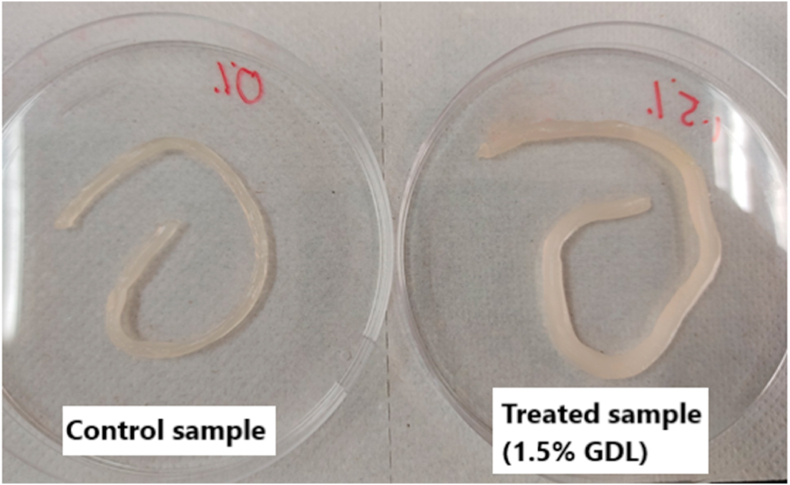

3.5. Equilibrium moisture content analysis

Fig. 4 is presented by plotting the equilibrium moisture content against the storage time for all the samples prepared. The typical coefficient of variance determined was not more than 18%. Results show that the equilibrium moisture content of all the samples prepared was decreased upon storage and the rate of decrement decreased with increase in the GDL concentration (P < 0.05). Fig. 5 shows that control sample was dehydrated while treated sample (1.5% GDL dipping) remained moist after 72 h dehydration. The plausible explanation could be that the GDL treated rice noodles surface has been modified (smoother and more compact as shown in Fig. 1c) to an extent that it reduced moisture loss. On the other hand, it is speculated that the retained water molecules may in turn help to suppress the starch molecule association, causing the formation of imperfect crystallites with various shapes and sizes as illustrated in Fig. 3b. This is in line with Chang et al. (2021) who reviewed that retrogradation of gelatinized starch molecules depends on starch to water ratios, and it was reported that excessive water molecules would interfere with inter-chain hydroxyl groups forming hydrogen bonds and increase the difficulty for the starch molecules to interact that eventually leads to a decreased crystallinity (Chen et al., 2019; Gong et al., 2015; Hsu et al., 2015). On the other hand, Zheng et al. (2020) observed that the lower water exudation would retard starch gel retrogradation during long term storage.

Fig. 4.

The moisture desorption isotherm graph of the rice starch noodles treated by dipping in different concentrations of GDL solutions and in-pack pasteurization. The typical coefficient of variance of the data was <18%, (n = 6).

Fig. 5.

The images of the control sample and the GDL (1.5%) treated sample after desorption by 72 h.

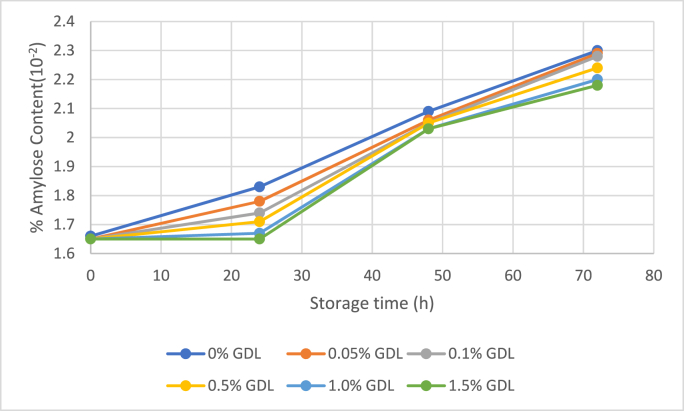

3.6. Starch exudation analysis

Starch exudation data is presented by plotting the amount of starch molecules washed out, calculated as the total apparent amylose content as a function of storage time (Fig. 6). Results show that the amount of starch molecules washed out in the analysis increased progressively with storage time but decreased with progressive increase in the GDL concentration prepared for the dipping treatment (P < 0.05). This means GDL dipping followed by in-pack pasteurization helped to reduce starch exudation of the treated rice noodles during storage. This starch exudation data also explains why the treated rice starch noodles were easily detached from each other into individual strands after storage, while the control samples became sticky and glued into a block during storage. According to Utrilla-Coella et al. (2013) and Chen et al. (2017), when a starch gel undergoes retrogradation, it is normally accompanied by the diffusion of water molecules and starch constituents of low molecular weights. On this note, it is believed that the lower starch exudation rate during storage observed in the treated rice noodle may be attributable to the lower retrogradation rate experienced by the treated rice noodle. This is substantiated by the results in Section 3.3, 3.4.

Fig. 6.

The starch exudation analysis results of the control rice starch noodles and the rice starch noodles dipped in different concentrations of GDL solution before in-pack pasteurization. The typical coefficient of variance of data presented was 13%, (n = 9).

4. Conclusion

The results of scanning electron microscopy, X-ray diffractometry and differential scanning calorimetry have provided substantial evidence to support the claim that the treatment of GDL dipping followed by in-pack pasteurization had caused a significant physicochemical changes to the treated rice noodles. These changes had helped to retain water molecules in the noodle strands and eventually delay starch molecules retrogradation during storage. All these effects have great practical implications, whereby the treated rice noodles would be able to reduce moisture loss when exposed to a drier environment, prevent stickiness and structure fragility formation during storage as well as ward off the noodle strands from turning mushy when it is being soaked in water for a long period.

CRediT authorship contribution statement

Nurul Athirah Shamsudin: Data collection, Formal analysis, Writing – original draft preparation. Yan Kitt Low: Sample preparation. Lai-Hoong Cheng: Study design, method development and manuscript revision.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

This work was supported by Universiti Sains Malaysia under Research University Grant (RUI) [1001/PTEKIND/8014122].

Handling editor: Carl Adams

References

- Atichokudomchai N., Varavinit S., Chinachoti P. Gelatinization transitions of acid-modified tapioca starches by Differential Scanning Calorimetry (DSC) Starch-Starke. 2002;54(7):296–302. [Google Scholar]

- Chang Q., Zheng B., Zhang Y., Zeng H. A comprehensive review of the factors influencing the formation of retrograded starch. Int. J. Biol. Macromol. 2021;186:163–173. doi: 10.1016/j.ijbiomac.2021.07.050. [DOI] [PubMed] [Google Scholar]

- Chen C., Fu W., Chang Q., Zheng B., Zhang Y., Zeng H. Moisture distribution model describes the effect of water content on the structural properties of lotus seed resistant starch. Food Chem. 2019;286:449–458. doi: 10.1016/j.foodchem.2019.01.214. [DOI] [PubMed] [Google Scholar]

- Chen L., Tian Y., Tong Q., Zhang Z., Jin Z. Effect of pullulan on the water distribution microstructure and textural properties of rice starch gels during cold storage. Food Chem. 2017;214:702–709. doi: 10.1016/j.foodchem.2016.07.122. [DOI] [PubMed] [Google Scholar]

- Gong M., Li X., Xiong L., Sun Q. Retrogradation property of starch nanoparticles prepared by pullulanase and recrystallization. Starch-Starke. 2015;68(3–4):230–238. [Google Scholar]

- Hsu R.J.C., Lu S., Chang Y.-H., Chiang W. Effects of added water and retrogradation on starch digestibility of cooked rice flour with different amylose content. J. Cereal. Sci. 2015;61:1–7. [Google Scholar]

- Jianming C. Preservation of fresh noodles by irradiation. Radiat. Phys. Chem. 1998;52:35–38. doi: 10.1016/S0969-806X(98)00069-3. [DOI] [Google Scholar]

- Klinmalai P., Hagiwara T., Sakiyama T., Ratanasumawong S. Chitosan effects on physical properties, texture, and microstructure of flat rice noodles. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2017;76:117–123. doi: 10.1016/j.lwt.2016.10.052. [DOI] [Google Scholar]

- Khoomtong A., Noomhorm A. Development of a simple portable amylose content meter for rapid determination of amylose content in milled rice. Food Bioprocess Technol. 2015;8(9):1938–1946. [Google Scholar]

- Lauro M., Forssell P.M., Suortti M.T., Hulleman S.H.D., Poutanen K.S. α-amylolysis of large barley starch granules. Cereal Chem. 1999;76(6):925–930. [Google Scholar]

- Low Y.K., Esah E.M., Cheng L.H. The impact of glucono-delta lactone (GDL) on rice flour pasting properties and GDL's dipping effects on the quality of rice noodles. J. Food Process. Preserv. 2020;45(3) doi: 10.1111/jfpp.14944. [DOI] [Google Scholar]

- OECD . UNEP Publication; 2004. SIDS Initial Assessment Report on Gluconic Acid and its Derivatives.https://hpvchemicals.oecd.org/UI/handler.axd?id=11548280-9a4f-4550-b0c5-192f53ac9279 Available at. [Google Scholar]

- Rachtanapun P., Tangnonthaphat T. Effects of packaging types and storage temperatures on the shelf life of fresh rice noodles under vacuum conditions. Chiang Mai J. Sci. 2011;38:579–589. [Google Scholar]

- Ramachandran S., Fontanille P., Pandey A., Larroche C. Gluconic acid: properties, applications and microbial production. Food Technol. Biotechnol. 2006;44:185–195. [Google Scholar]

- Sumitra R., Pierre F., Ashok P.A., Christian L. Gluconic acid: properties, applications and microbial production. Food Technol. Biotechnol. 2006;44(2):185–195. [Google Scholar]

- Tucker G.S., Featherstone S. Wiley-Blackwell; Chichester: 2011. Essentials of Thermal Processing. [Google Scholar]

- Utrilla-Coello R.G., Bello-Pérez L.A., Vernon-Carter E.J., Rodriguez E., Alvarez-Ramirez J. Microstructure of retrograded starch: quantification from lacunarity analysis of SEM micrographs. J. Food Eng. 2013;116(4):775–781. [Google Scholar]

- Wang L., Zhang C., Chen Z., Wang X., Wang K., Li Y., Wang R., Luo X., Li Y., Li J. Effect of annealing on the physico-chemical properties of rice starch and the quality of rice noodles. J. Cereal. Sci. 2018;84:125–131. [Google Scholar]

- Wang Y., Hu B., Zhan J., Xu R., Tian Y. Effects of starchy seed crystals on the retrogradation of rice starch. Food Chem. 2020;318:126487. doi: 10.1016/j.foodchem.2020.126487. [DOI] [PubMed] [Google Scholar]

- Wu Y., Chen Z., Li X., Wang Z. Retrogradation properties of high amylose rice flour and rice starch by physical modification. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2010;43(3):492–497. [Google Scholar]

- Zhang Y., Liu W., Liu C., Luo S., Li T., Liu Y., Wu D., Zuo Y. Retrogradation behaviour of high-amylose rice starch prepared by improved extrusion cooking technology. Food Chem. 2014;158:255–261. doi: 10.1016/j.foodchem.2014.02.072. [DOI] [PubMed] [Google Scholar]

- Zheng M., Lin Y., Wu H., Zeng S., Zheng B., Zhang Y., Zeng H. Water migration depicts the effect of hydrocolloids on the structural and textural properties of lotus seed starch. Food Chem. 2020;315:126240. doi: 10.1016/j.foodchem.2020.126240. [DOI] [PubMed] [Google Scholar]