Abstract

The present study aims to investigate the shielding properties of the electromagnetic interference of polymer nanocomposites with different weight percentages of magnetite nanoparticles and cost-effective carbon black nanoparticle (CBN) on different thicknesses. X‐ray diffraction test, Raman spectroscopy, the scanning electron microscopy, and the transmission electron microscope analysis were used for investigating the crystallographic structure, morphology and microstructure of the material. The nanocomposites were successfully prepared using a simple mixing and casting. Their shielding efficiency was measured by a vector network analyzer (VNA) in the frequency range of 8.2 ~ 12.4 GHz. The maximum total shielding efficiency was 36.6 dB at 8.2 GHz for a weight percentage of 15% Fe3O4 composite and 50% CBN (0.7 mm thickness). The results showed that with an increase of nanocomposite thickness, there is a shift of absorption shielding efficiency peak toward a higher frequency. In addition, nanocomposites had the greatest shielding effectiveness in the low-frequency range. It was found that the proper combination of electrical and magnetic losses causes excellent wave absorption. These findings indicated that epoxy resin with a combination of optimal weight percentage of magnetite and carbon black nanoparticle can be used as a suitable shielding in low thickness.

Keywords: Electromagnetic, Shielding properties, Magnetite nanoparticles, Carbon black nanoparticles, Reflective loss

Introduction

Nowadays, given the increasing use of equipment utilizing electromagnetic radiation in their operation, the effects of these waves on the human body or the efficiency of various devices have been investigated [1]. Exposure to electromagnetic fields has been listed as a potential carcinogen for humans by the International Agency for Research on Cancer (IARC) (group 2B) [2]. Various studies on the effect of exposure to electromagnetic fields include the risk of cancer [3], electromagnetic hypersensitivity [4], cognitive effects [5], neurological disease [6], Central Nerve System [7]and reproductive disorders [8]. The control measures to protect workers against electromagnetic fields (radio waves) include following the instructions for working with electromagnetic fields, compliance with permissible exposure limits, reducing exposure time, using technical and engineering methods as well as the appropriate personal protective equipment [9]. Among these, the application of technology and engineering methods, such as using shields is one of the methods to prevent or reduce exposure [10]. Some common types of shields against waves include metals, carbon, ceramics, cement, polymers, hybrids, and composites [11].

Polymer nanocomposites are another class of electromagnetic shields that, in addition to being used to control the exposure of employees, are also used in electrical and electronic equipment and prevent the electromagnetic interference (EMI) [12]. These materials have good conductivity, lower density, and higher corrosion resistance compared with metals [13]. Today, with the advent of nanotechnology, using nanocomposite shields to prevent EMI is a new approach that has recently been considered by researchers [14]. Carbon compounds are one of the best compounds to be used as absorbents due to their good electrical and thermal conductivity [15]. Carbon black nanoparticle (CBN) is an amorphous form of carbon commercially obtained by thermal decomposition or oxidation of hydrocarbons. Carbon black is widely used in the industry as a filler to modify the electrical and optical properties of dispersed materials [16]. Black carbon is used as a conductive filler and reinforcing material for polymer matrices because of its unique properties, which include a wide surface area, good chemical stability, excellent electrical conductivity, and low cost [17]. Ferromagnetic particles with a diameter less than the critical diameter (Dc) exhibit single-zone behavior. The Dc is the maximum diameter of the rod which is quenched to produce 50% martensitic. In single-zone particles, magnetic losses are generally caused by spin rotation, while for larger particles (multi-zone) these losses are mostly due to the movement of the zone walls [18]. Due to the proper attenuation of waves in single-zone ferromagnetic materials, these materials have been widely used in electromagnetic wave absorption applications [19]. Magnetic iron oxide or magnetite (Fe3O4) is one of the ferromagnetic materials with relatively high magnetic properties, which has an excellent ability to absorb electromagnetic waves. Fe3O4 has been investigated as an absorber due to its permittivity and permeability properties, appropriate saturation magnetization and high curie temperature [20].

One of the constant challenges in designing and constructing electromagnetic shields is to achieve a shield with high absorption efficiency in the wide frequency band. The purpose of this research was to investigate the efficiency of electromagnetic interference shielding using cost-effective nanocomposites containing carbon black and iron oxide nanoparticles (as fillers) in the epoxy resin matrix and the frequency range of 8.2 to 12.4 GHz.

Materials and methods

Materials

In this study, an epoxy resin was used as a matrix, and spherical nanoparticles CBN and Fe3O4 were used as a filler (98%, Electrical conductivity: 0.30 Ω.cm, spherical particles of size: 25–50 nm). Epoxy resin (EI-403) is produced by Mokarrar Engineering Material Co. Nanomaterials were supplied from Us Research Nanomaterial.

CBN properties

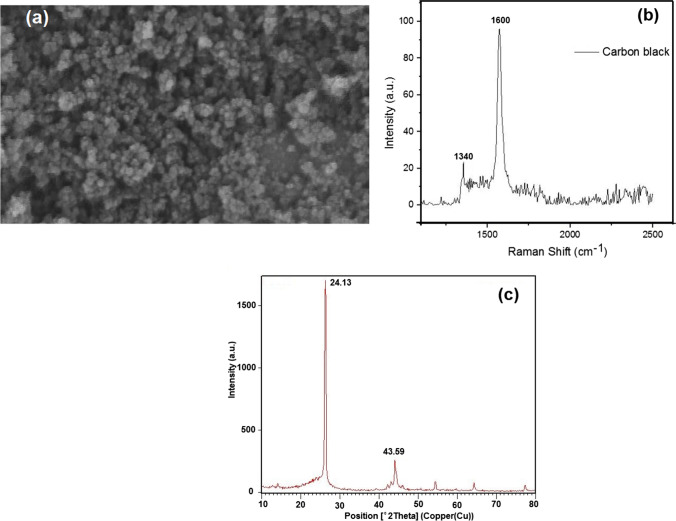

Scanning electron microscope (SEM) (model S-4160 -Hitachi, Japan), Raman spectroscopy (532 nm laser beam, Takram P50C0R10 model, Teksan Co., Iran), and X-ray diffraction (XRD) (Cu Kα λ = 0.154 nm, Ultima IV model, Rigaku Co., Japan) pattern results of CBN are shown in Fig. 1.

Fig. 1.

(a) SEM image, (b) Raman spectroscopy, and (c) XRD results of CBN

Fe3O4 properties

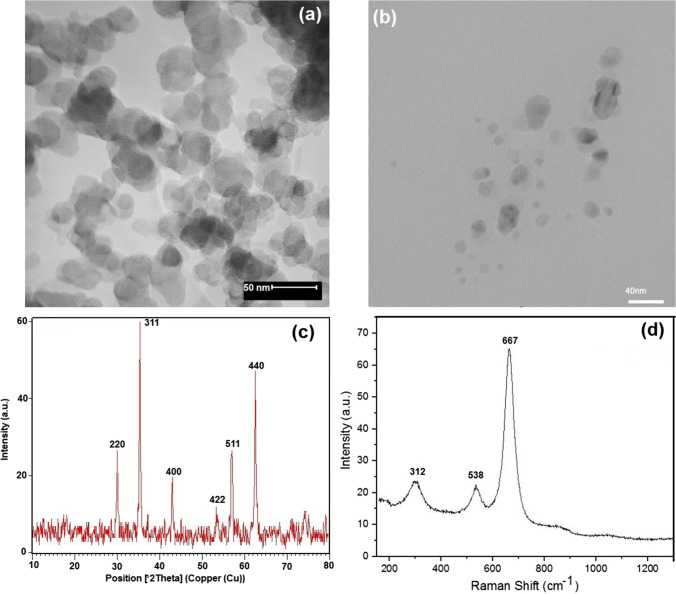

Figure 2 shows SEM image, transmission electron microscope (TEM) image (model Zeiss EM10), Raman spectroscopy, and XRD results of Fe3O4.

Fig. 2.

Microstructure investigation of Fe3O4 (a) SEM image, (b) TEM image, (c) XRD pattern, and (d) Raman spectroscopy

Nanocomposite synthesis

In this study, the desired nanocomposites were prepared using the mixing and casting melt mixing method with different filling percentages in epoxy resin matrix with a thickness of 0.7 mm. The Fe3O4 and Carbon black powders as filler were added to the epoxy resin at different weight percentages (from 15 to 50) and then, they were adequately blended. The nanoparticles weight percentage of the composites is presented in Table 1. Mixing was performed at 60 rpm for 15 min for all the samples. The constituents of nanocomposites in each case were first mixed manually based on the weight percentage and then mixed by the extruder (Brabender Co. produced the 25 DS twin-screw extruder, which has a screw diameter of 25 mm and a length-to-diameter ratio of 40). The speed of movement of the screws was adjusted to 60 rpm. In the end, each mixture was poured into glass casts and cured at 100 C for 2 h [22]. The hole with an outer diameter of 6.9 mm and an inner diameter of 3 mm [23] was used for measuring EM properties of the nanocomposites.

Table 1.

Carbon black and Fe3O4 weight percentages in making nanocomposite samples

| Nanocomposites | FC1 | FC2 | FC3 | FC4 |

|---|---|---|---|---|

| Carbon black Nanoparticles (CBN) | 15% | 15% | 15% | 50% |

| Fe3O4 Nanoparticles | 15% | 30% | 50% | 15% |

To remove the moisture in the nanoparticles, they were placed in a dryer at 90 °C for 2 h [24].

EMI Shielding Efficiency Analysis

The electromagnetic properties of the fabricated nanocomposites were measured by an E8362B vector network analyzer (VNA) (E8362B model, Agilent Co., USA) in the frequency range of 8 to 12.5 GHz (X) based on the transmission/reflection method. To this end, the sample was placed in a coaxial waveguide with the same internal and external diameters as the sample. The values of the microwave permeability and permittivity were extracted based on the Nicholson-Rose-Weir method using scattering indices. The amount of EM wave attenuation of the encountering wave is expressed in decibels by assessing the total shielding efficiency (SET). When the SET value reaches 20 dB, it can reduce 99% of the EM waves [25]. The SET of the fabricated nanocomposites was calculated according to Eqs. (1, 2 and 3) [26–29].

| 1 |

| 2 |

| 3 |

where SER represents shielding efficiency (SE) via reflection, absorption shielding efficiency (SEA) represents SE duo to absorption and SEM represents SE via multiple reflections. is the normalized input impedance at free space and material injector. d is the thickness of composite, and δ is the skin depth, which is shown in Eq. (4) [27, 30]. SEM can be neglected if SEA is more than 10dB.

| 4 |

Reflective loss (RL) is a part of the electromagnetic wave energy reflected towards the source when it comes in contact with the absorber. RL depends on the ratio of the electromagnetic wave impedance to the absorbent impedance and the conductivity and permeability of the shielding material. An RL value equal to 10 dB means that 90% of the emitted wave is absorbed by the absorbent [31]. The transmission line concept, which can be summarized by Eqs. 5 and 6, can be used to determine RL values [32].

| 5 |

| 6 |

where, εr and μr are the complex permittivity and magnetic permeability of the nanocomposite, respectively, f is the frequency, and c is the light speed in open space.

Results and discussion

Microscopy analysis

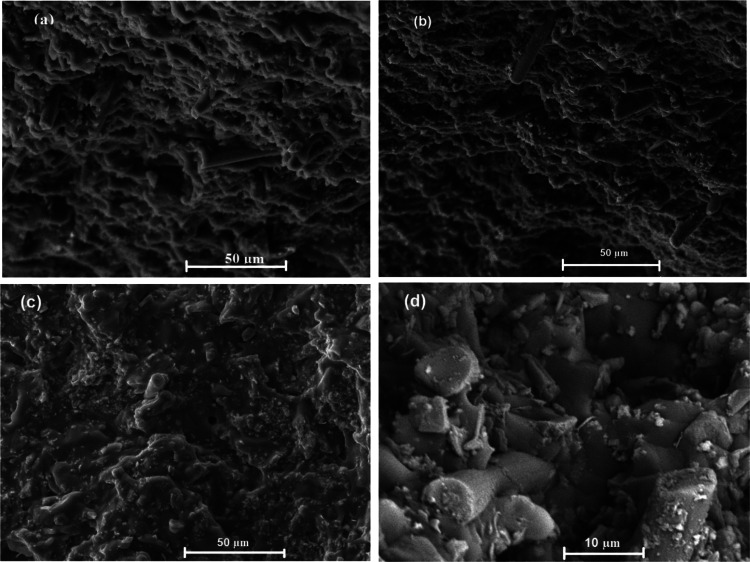

While the high electrical conductivity of Fe3O4 and CBN is one of the main reasons for the high EMI shielding efficiency of the composites fabricated in the study, the distribution of CBN is also significant. The uniform distribution of Fe3O4 and CBN particles in the matrix established a conducting network that provides the optimum EMI shielding possible. In Fig. 3, the obtained SEM micrographs of FC1 to FC4 composites are shown. The images show that in prepared composites, especially for FC1 and FC2 specimens, the mixed nanoparticles form an electron transfer network inside the samples.

Fig. 3.

SEMM images of (a) FC1, (b) FC2, (c) FC3, and (d) FC4 composites

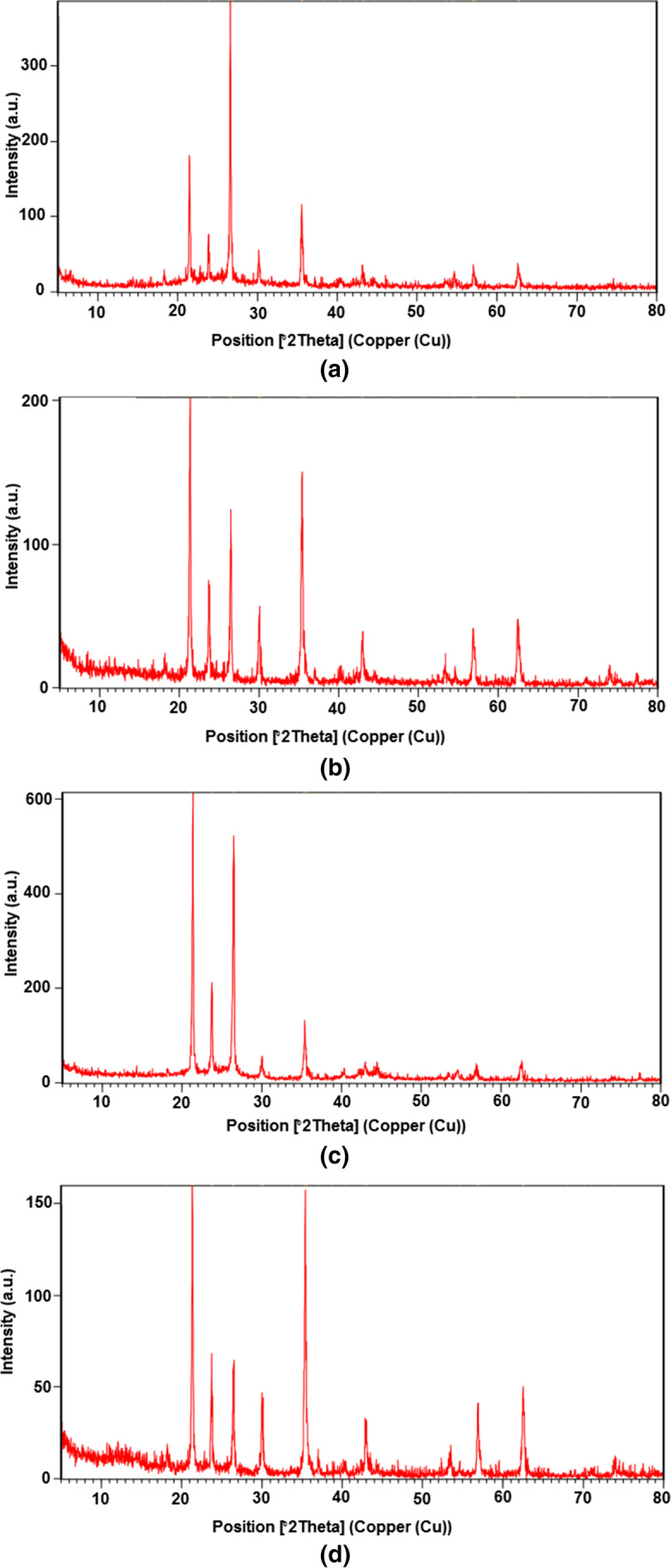

The phase composition, chemical structure, and morphology of the composites were characterized by XRD, as shown in Fig. 4. The XRD result indicated both high crystallinity and purity of the Fe3O4/CBN composites.

Fig. 4.

XRD patterns of (a) FC1, (b) FC2, (c) FC3, and (d) FC4 composites

EMI analysis

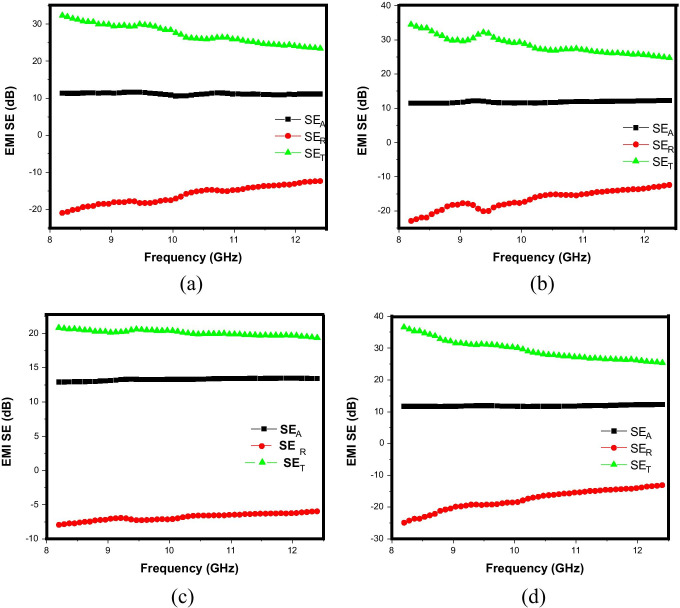

In the study, the EMI shielding effectiveness of different weight percentages of magnetite and CBNs was investigated. In the X-band, the electromagnetic shielding effectiveness of these materials was investigated (8.2–12.4 GHz). All the samples had a thickness of 0.7 mm. The SET, SER, and SEA were determined using the scattering parameters obtained from the VNA. The efficiency of the fabricated samples' SEA, SER, and SET as a function of frequency in a thickness of 0.7 mm is shown in Fig. 5.

Fig. 5.

Comparison of SET, SER, and SEA in samples (a) FC1, (b) FC2, (c) FC3, and (d) FC4 as a function of frequency (8.2–12.4 GHz) (the thickness of all the samples is 0.7 mm)

According to Fig. 5, in all the samples, SET had a higher efficiency at lower frequencies compared with higher frequencies. Moreover, the value of SER at high frequencies was higher than that at low frequencies.

Figure 5, reveals that the mean SEA value for samples FC1, FC2, FC3, and FC4 was 11.21 dB, 11.82 dB, 13.28 dB, and 11.85 dB, respectively. The mean SER value for samples FC1, FC2, FC3, and FC4 was -16.09 dB, -16.63 dB, -6.81 dB, and -17.61 dB, respectively. Moreover, the lowest and highest SET values in the prepared nanocomposites were 20.10 dB in FC3, and 36.6 dB in FC4, respectively. Therefore, as was shown in Fig. 5d, 50% weight percentage of carbon black in FC4 nanocomposite case more shielding effectiveness because of rising dielectric loss caused by electrical conduction in the specimen. On this basis, this composite has mean higher reflection loss compared with other composites, for instance, the composite has reflection loss -24.9 dB at 8.2 GHz, which was able to reduce over 99% of EM waves [33].

The sample FC3 contained a weight percentage of 50% magnetite and 15% carbon black had a higher mean absorption loss with a maximum of 13.47 dB at 11.89 GHz than the other samples. Therefore, adding magnetite nanoparticles rise in magnetic loss and it case more absorption loss. While, the sample FC3 had less reflection in mean-6.81 dB, because of the low weight percentage of carbon black (15%), which leads to lower electrical conductivity and less dielectric loss in the composite.

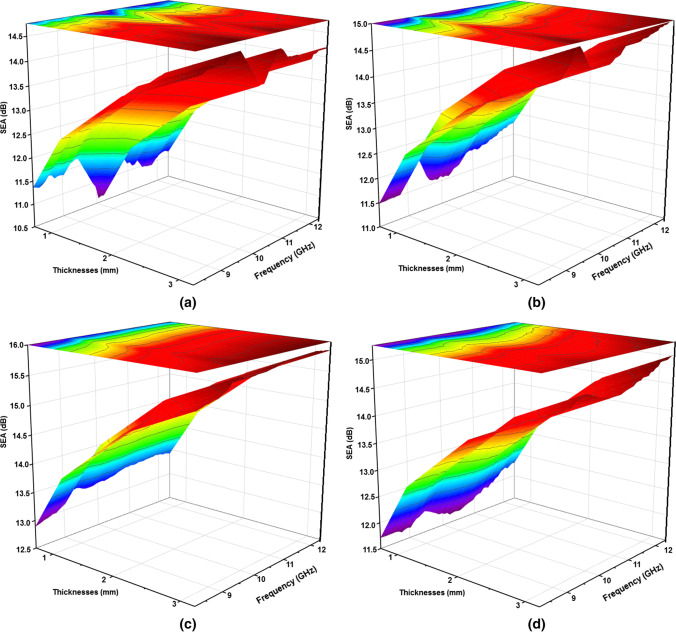

Because of the importance of the absorption efficiency of the prepared shields, the SEA of the nanocomposites was predicted using Eq. (2) in various thickness. The results of the prediction was shown in Fig. 6.

Fig. 6.

SEA as a function of frequency for samples (a) FC1; (b) FC2; (c) FC3; (d) FC4 with different thicknesses

According to Fig. 6, in all four samples, the thickness of 3.2 mm had the highest SEA with an average of 14.84 dB. The results showed that the maximum value of SEA was 15.89 dB in the thickness of 3.2 mm, which appeared at a frequency of 11.89 GHz (sample FC3) and the minimum value of SEA was 10.60 dB in the thickness of 0.7 mm at a frequency of 10.04 GHz (sample FC1). With an increase of nanocomposite thickness, there is a shift of SEA peak toward higher frequency [Fig. 6 (d), 6(f) and 6(h)]. Knowing the SE values will help choose the right sample thickness for shielding.

Table 2 compares the Fe3O4/CBN (FC4) composite material to other commonly used absorbents. Compared with the reduced graphene oxide (rGO)–Fe3O4 (rGO:IO) [34], acrylonitrile-co-butadiene-co styrene(ABS)/ carbon black(CB): carbon nanotubes(CNT) [35], chlorinated polyethylene(CPE)/ carbon black (CB) [36], poly (styrene-b-ethylene-ran-butylene-b-styrene)(SEBS) and carbon additives (SEBS/CB) [37], Ketjen carbon black (K-CB)-ethylene methyl acrylate copolymer (EMA) [38], graphene Nano platelets /Fe3O4/epoxy (G/Fe3O4/epoxy) [39], Fe3O4/graphene foam/poly dimethyl siloxane (Fe3O4/G/PDMS) [40], magnetic reduced graphene oxide (RGO)@Fe3O4 (RGO/Fe3O4) [41], silicone rubber/MWCNTs/Fe3O4 [42], PMMA/Fe3O4@ MWCNTs [43], it can be seen that the sample thickness is thinner for the Fe3O4/CBN composite material.

Table2.

Summary of the last 5 years' EMI SE in sample thickness of different compounds based on Fe3O4 and carbon black

| Composites | Measurement region (GHz) | Thickness (mm) | EMI SE (dB) | Reference |

|---|---|---|---|---|

| reduced graphene oxide–Fe3O4 (rGO:IO) | 8 to 12 | 1 | 14.4–12.6 | [34] |

| acrylonitrile-co-butadiene-co-styrene(ABS)/ carbon black(CB):carbon nanotubes(CNT) | 8 to 12 | 2 | 29.37 | [35] |

| chlorinated polyethylene(CPE)/carbon black (CB) | 8.2–12.4 | 1 | 29 | [36] |

| poly (styrene-b-ethylene-ran-butylene-b-styrene)(SEBS) and carbon additives (SEBS/CB) | 8.2–12.4 | 5 | 17.5 | [37] |

| Ketjen carbon black (K-CB)-ethylene methyl acrylate copolymer (EMA) | 8.2–12.4 | 1 | 18.3 | [38] |

| graphene nanoplatelets /Fe3O4/epoxy(G/Fe3O4/epoxy) | 8–12 | 2 | 17 | [39] |

| Fe3O4/graphene foam/poly dimethylsiloxane (Fe3O4/G/PDMS) | 8.2–12.4 | 1 | 32.4 | [40] |

| magnetic reduced graphene oxide (RGO)@Fe3O4 (RGO/Fe3O4) | 8.2–12.4 | 1 | 13.45 | [41] |

| silicone rubber/MWCNTs/Fe3O4 | 8.2–12.4 | 2 | 27.5 | [42] |

| PMMA/Fe3O4@ MWCNTs | 8.2–12.4 | 2.5 | 13.1 | [43] |

| Fe3O4/CBN (FC4) | 8.2 to 12.4 | 0.7 | 25.4–36.6 | Present study |

The Fe3O4/CBN composite tends to be a promising candidate for high-absorption materials as a result. CBN and Fe3O4 not only cause the dielectric and magnetic loss but also improve the EMI shielding efficiency of the composites by multiple internal reflections. Suitable impedance matching of the composite in the study allow waves to enter the material, and due to several internal reflections in them, the reflected internal radiation energy is subsequently absorbed by the carbon black [44].

In a review of the literature, it was found that similar studies have not been conducted to show the SE of the shielding material with the nanocomposites used in the present study, which was the limitation of this study. Future research could be on optimizing morphology and structure to provide optimal nanocomposites.

Conclusion

In the study, four nanocomposites were prepared by mixing magnetite and carbon black nanoparticles was mixing in epoxy resin, successfully and their shielding EMI efficiency was investigated in the frequency range of 8.2–12.4 GHz. The mixing and casting method has provided a good dispersion of magnetite and CBN in the epoxy resin. The maximum value of SE was 36.62 dB at 8.2 GHz for epoxy resin nanocomposites with a content of a weight percentage of 50% carbon black nanoparticles and 15% magnetite and 0.7 mm in thickness. These magnetite/carbon black nanocomposites based on epoxy resin provide promising opportunities for EMI shielding materials. The Fe3O4/CBN composite not only causes the dielectric and magnetic loss but also improves the EMI SE of the composites by multiple internal reflections. Suitable impedance matching of the composite in the study allows waves to enter the material, and due to several internal reflections in them, the reflected internal radiation energy is subsequently absorbed by the carbon black.

Acknowledgements

Thanks are owed to Baqiyatallah University of Medical Sciences for their technical and financial support with grant number 98000039. The study was approved by the university ethics committee (IR.BMSU.REC.1398.273).

Declarations

Competing Interest

The authors declare that they have no conflicts of interest and no known competing for financial regarding this study.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Moradi M, Naghdi N, Hemmati H, Asadi-Samani M, Bahmani M. Effect of ultra high frequency mobile phone radiation on human health. Electron Physician. 2016;8(5):2452. doi: 10.19082/2542. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Hardell L, Carlberg M. [Comment] Health risks from radiofrequency radiation, including 5G, should be assessed by experts with no conflicts of interest. Oncol Lett. 2020;20(4):1–7. doi: 10.3892/ol.2020.11876. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Morgan LL, Miller AB, Sasco A, Davis DL. Mobile phone radiation causes brain tumors and should be classified as a probable human carcinogen (2A) Int J Oncol. 2015;46(5):1865–1871. doi: 10.3892/ijo.2015.2908. [DOI] [PubMed] [Google Scholar]

- 4.Gruber MJ, Palmquist E, Nordin S. Characteristics of perceived electromagnetic hypersensitivity in the general population. Scand J Psychol. 2018;59(4):422–427. doi: 10.1111/sjop.12449. [DOI] [PubMed] [Google Scholar]

- 5.Son Y, Kim JS, Jeong YJ, Jeong YK, Kwon JH, Choi H-D, et al. Long-term RF exposure on behavior and cerebral glucose metabolism in 5xFAD mice. Neurosci Lett. 2018;666:64–69. doi: 10.1016/j.neulet.2017.12.042. [DOI] [PubMed] [Google Scholar]

- 6.Kim JH, Yu D-H, Huh YH, Lee EH, Kim H-G, Kim HR. Long-term exposure to 835 MHz RF-EMF induces hyperactivity, autophagy and demyelination in the cortical neurons of mice. Sci Rep. 2017;7(1):1–12. doi: 10.1038/srep41129. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Kim JH, Lee J-K, Kim H-G, Kim K-B, Kim HR. Possible effects of radiofrequency electromagnetic field exposure on central nerve system. Biomolecules & therapeutics. 2019;27(3):265. doi: 10.4062/biomolther.2018.152. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Altun G, Deniz ÖG, Yurt KK, Davis D, Kaplan S. Effects of mobile phone exposure on metabolomics in the male and female reproductive systems. Environ Res. 2018;167:700–707. doi: 10.1016/j.envres.2018.02.031. [DOI] [PubMed] [Google Scholar]

- 9.Standard RP. Maximum exposure levels to radiofrequency fields—3 KHz to 300 GHz. Radiation Protection Series. 2002;3.

- 10.Khavanin A. Nonthermal effects of radar exposure on human: A review article. Iranian Journal of Health, Safety and Environment. 2014;1(1):43–52. [Google Scholar]

- 11.Chung D. Materials for electromagnetic interference shielding. Materials Chemistry and Physics. 2020:123587.

- 12.Joshi A, Datar S. Carbon nanostructure composite for electromagnetic interference shielding. Pramana. 2015;84(6):1099–1116. [Google Scholar]

- 13.Kruželák J, Kvasničáková A, Hložeková K, Hudec I. Progress in polymers and polymer composites used as efficient materials for EMI shielding. Nanoscale Advances. 2021;3(1):123–172. doi: 10.1039/d0na00760a. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Ganguly S, Bhawal P, Ravindren R, Das NC. Polymer nanocomposites for electromagnetic interference shielding: a review. J Nanosci Nanotechnol. 2018;18(11):7641–7669. [Google Scholar]

- 15.Arora M, Wahab M, Saini P. Permittivity and electromagnetic interference shielding investigations of activated charcoal loaded acrylic coating compositions. Journal of Polymers. 2014;2014.

- 16.Miqdad H. Effect of Carbon Black Nanoparticles on the Optical Properties of poly (ethylene oxide) Films. Int J Appl Eng Res. 2018;13(6):4333–4341. [Google Scholar]

- 17.Liu H, Wu S, You C, Tian N, Li Y, Chopra N. Recent progress in morphological engineering of carbon materials for electromagnetic interference shielding. Carbon. 2020;172:569–596. [Google Scholar]

- 18.Givord D. Introduction to magnetism and magnetic materials. Magnetism and Synchrotron Radiation: Springer; 2001. pp. 3–23. [Google Scholar]

- 19.Jiles D. Introduction to magnetism and magnetic materials: CRC press; 2015.

- 20.Adebayo LL, Soleimani H, Yahya N, Abbas Z, Wahaab FA, Ayinla RT, et al. Recent advances in the development OF Fe3O4-BASED microwave absorbing materials. Ceram Int. 2020;46(2):1249–1268. [Google Scholar]

- 21.Chen W, Weimin H, Li D, Chen S, Dai Z. A critical review on the development and performance of polymer/graphene nanocomposites. Sci Eng Compos Mater. 2018;25(6):1059–1073. [Google Scholar]

- 22.Ramajo LA, Cristóbal AA, Botta PM, López JP, Reboredo MM, Castro MS. Dielectric and magnetic response of Fe3O4/epoxy composites. Compos A Appl Sci Manuf. 2009;40(4):388–393. [Google Scholar]

- 23.Massango H, Tsutaoka T, Kasagi T. Electromagnetic properties of Fe53Ni47 and Fe53Ni47/Cu granular composite materials in the microwave range. Materials Research Express. 2016;3(9):095801.

- 24.Manafi P, Ghasemi I, Manafi MR, Ehsaninamin P, Asl FH. Non-isothermal crystallization kinetics assessment of poly (lactic acid)/graphene nanocomposites. Iran Polym J. 2017;26(5):377–389. [Google Scholar]

- 25.Arief I, Biswas S, Bose S. Tuning the shape anisotropy and electromagnetic screening ability of ultrahigh magnetic polymer and surfactant-capped FeCo nanorods and nanocubes in soft conducting composites. ACS Appl Mater Interfaces. 2016;8(39):26285–26297. doi: 10.1021/acsami.6b07464. [DOI] [PubMed] [Google Scholar]

- 26.Ghosh S, Ganguly S, Das P, Das TK, Bose M, Singha NK, et al. Fabrication of reduced graphene oxide/silver nanoparticles decorated conductive cotton fabric for high performing electromagnetic interference shielding and antibacterial application. Fibers and Polymers. 2019;20(6):1161–1171. [Google Scholar]

- 27.Jiang D, Murugadoss V, Wang Y, Lin J, Ding T, Wang Z, et al. Electromagnetic interference shielding polymers and nanocomposites-a review. Polym Rev. 2019;59(2):280–337. [Google Scholar]

- 28.Yun T, Kim H, Iqbal A, Cho YS, Lee GS, Kim MK, et al. Electromagnetic shielding of monolayer MXene assemblies. Adv Mater. 2020;32(9):1906769. doi: 10.1002/adma.201906769. [DOI] [PubMed] [Google Scholar]

- 29.Al-Saleh MH, Sundararaj U. Electromagnetic interference shielding mechanisms of CNT/polymer composites. Carbon. 2009;47(7):1738–1746. [Google Scholar]

- 30.Madvari RF, Bidel H, Hosseinabadi S, Pourtaghi G. Effect of Penetration Depth and Thickness on the Performance of Nanocomposite Shield Made in the Frequency Band 8–12.5 GHz. Journal of Military Medicine. 2021;23(5):435–43.

- 31.Huo J, Wang L, Yu H. Polymeric nanocomposites for electromagnetic wave absorption. J Mater Sci. 2009;44(15):3917–3927. [Google Scholar]

- 32.Li C-Q, Xu W, Ding R-C, Shen X, Chen Z, Li M-D, et al. Tunable High-Performance Microwave Absorption and Shielding by Three Constituent Phases Between rGO and Fe3O4@ SiO2 Nanochains. Front Chem. 2019;7:711. doi: 10.3389/fchem.2019.00711. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Sun J, Wang W, Yue Q. Review on microwave-matter interaction fundamentals and efficient microwave-associated heating strategies. Materials. 2016;9(4):231. doi: 10.3390/ma9040231. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Saravanan P, TR SK, Radha R, Balasubramaniam M, Balakumar S. Enhanced shielding effectiveness in nanohybrids of graphene derivatives with Fe 3 O 4 and ε-Fe 3 N in the X-band microwave region. Nanoscale. 2018;10(25):12018–34. [DOI] [PubMed]

- 35.Schmitz DP, Silva TI, Ramoa SD, Barra GM, Pegoretti A, Soares BG. Hybrid composites of ABS with carbonaceous fillers for electromagnetic shielding applications. J Appl Polym Sci. 2018;135(29):46546. [Google Scholar]

- 36.Mondal S, Ganguly S, Rahaman M, Aldalbahi A, Chaki TK, Khastgir D, et al. A strategy to achieve enhanced electromagnetic interference shielding at low concentration with a new generation of conductive carbon black in a chlorinated polyethylene elastomeric matrix. Phys Chem Chem Phys. 2016;18(35):24591–24599. doi: 10.1039/c6cp04274k. [DOI] [PubMed] [Google Scholar]

- 37.Kuester S, Merlini C, Barra GM, Ferreira JC, Jr, Lucas A, de Souza AC, et al. Processing and characterization of conductive composites based on poly (styrene-b-ethylene-ran-butylene-b-styrene)(SEBS) and carbon additives: A comparative study of expanded graphite and carbon black. Compos B Eng. 2016;84:236–247. [Google Scholar]

- 38.Mondal S, Ganguly S, Das P, Khastgir D, Das NC. Low percolation threshold and electromagnetic shielding effectiveness of nano-structured carbon based ethylene methyl acrylate nanocomposites. Compos B Eng. 2017;119:41–56. [Google Scholar]

- 39.Liu H, Liang C, Chen J, Huang Y, Cheng F, Wen F, et al. Novel 3D network porous graphene nanoplatelets/Fe3O4/epoxy nanocomposites with enhanced electromagnetic interference shielding efficiency. Compos Sci Technol. 2019;169:103–109. [Google Scholar]

- 40.Zhu S, Cheng Q, Yu C, Pan X, Zuo X, Liu J, et al. Flexible Fe3O4/graphene foam/poly dimethylsiloxane composite for high-performance electromagnetic interference shielding. Composites Science and Technology. 2020;189:108012.

- 41.Liu Y, Lu M, Wu K, Yao S, Du X, Chen G, et al. Anisotropic thermal conductivity and electromagnetic interference shielding of epoxy nanocomposites based on magnetic driving reduced graphene oxide@ Fe3O4. Compos Sci Technol. 2019;174:1–10. [Google Scholar]

- 42.Yang J, Liao X, Li J, He G, Zhang Y, Tang W, et al. Light-weight and flexible silicone rubber/MWCNTs/Fe3O4 nanocomposite foams for efficient electromagnetic interference shielding and microwave absorption. Composites Science and Technology. 2019;181:107670.

- 43.Zhang H, Zhang G, Li J, Fan X, Jing Z, Li J, et al. Lightweight, multifunctional microcellular PMMA/Fe3O4@ MWCNTs nanocomposite foams with efficient electromagnetic interference shielding. Compos A Appl Sci Manuf. 2017;100:128–138. [Google Scholar]

- 44.Lalan V, Ganesanpotti S. Broadband electromagnetic response and enhanced microwave absorption in carbon black and magnetic fe 3 o 4 nanoparticles reinforced polyvinylidenefluoride composites. J Electron Mater. 2020;49(3):1666–1676. [Google Scholar]