Abstract

The environmental performance of battery electric vehicles (BEVs) is influenced by their battery size and charging electricity source. Therefore, assessing their environmental performance should consider changes in the electricity sector and refurbishment of their batteries. This study conducts a scenario-based Life Cycle Assessment (LCA) of three different scenarios combining four key parameters: future changes in the charging electricity mix, battery efficiency fade, battery refurbishment, and recycling for their collective importance on the life-cycle environmental performance of a BEV. The system boundary covers all the life-cycle stages of the BEV and includes battery refurbishment, except for its second use stage. The refurbished battery was modelled considering refurbished components and a 50% cell conversation rate for the second life of 5 years. The results found a 9.4% reduction in climate impacts when future changes (i.e., increase in the share of renewable energy) in the charging electricity are considered. Recycling reduced the BEV climate impacts by approximately 8.3%, and a reduction smaller than 1% was observed for battery refurbishment. However, the battery efficiency fade increases the BEV energy consumption, which results in a 7.4 to 8.1% rise in use-stage climate impacts. Therefore, it is vital to include battery efficiency fade and changes to the electricity sector when estimating the use-stage impacts of BEVs; without this, LCA results could be unreliable. The sensitivity analysis showed the possibility of a higher reduction in the BEV climate impacts for longer second lifespans (>5 years) and higher cell conversation rates (>50%). BEV and battery production are the most critical stages for all the other impact categories assessed, specifically contributing more than 90% to mineral resource scarcity. However, recycling and battery refurbishment can reduce the burden of the different impact categories considered. Therefore, manufacturers should design BEV battery packs while considering recycling and refurbishment.

Keywords: Environmental impact, Passenger cars, Lithium-ion batteries, Second-life batteries, Repurposing

Graphical abstract

Legend: EoL = End-of-Life, LIB = Li-ion battery.

Highlights

-

•

The environmental impacts of electricity changes and battery end-of-life are assessed.

-

•

Changes in charging electricity reduced the climate change impact by 9.4%.

-

•

Vehicle production is the main driver of climate impacts in the dynamic scenario.

-

•

The impacts of refurbished batteries depend on reusable cells and the second use lifespan.

1. Introduction

The transport sector significantly contributes to the global environmental problems, including climate change (CC), air pollution and toxicity (Colvile et al., 2001; Hooftman et al., 2016; IPCC, 2018). Transport remains one of the most significant sources of greenhouse gas (GHG) emissions. In 2018, direct GHG emissions from transport accounted for approximately 24% of direct energy-related carbon dioxide (CO2) global emissions (IEA, 2020), with passenger road vehicles being the largest contributors accounting for 45% of global transport CO2 emissions (IEA, 2020). In contrast to all other sectors, the GHG emissions from the transport sector in the European Union (EU) increased by 0.9% and 0.8% in 2018 and 2019, respectively (EEA, 2020). Projections on existing mitigation measures estimate a 32% increase in transport emissions by 2030 compared to 1990 levels in the EU (EEA, 2020). Aggressive mitigation measures in the transportation sector are essential to reduce emissions in order to achieve the goals of the European Green Deal of reducing GHG emissions by 55% in 2030 and becoming climate-neutral by 2050 (European Commission, 2019).

Deploying battery electric vehicles (BEVs) is one of the main initiatives to decarbonise and reduce emissions from the transport sector, as they have no tailpipe emissions and can significantly reduce impacts on CC when charged with electricity from renewable energy sources (RESs) (Cox et al., 2018; Koroma et al., 2020). However, the environmental impact of their manufacturing is higher than that of internal combustion engine vehicles (Cox et al., 2018; Koroma et al., 2020) due to battery production, shifting the environmental burden from the use stage to production (Peters et al., 2017). The demand for larger battery sizes to tolerate longer driving ranges has exacerbated the problem. As a result, extending the life of used BEV lithium-ion batteries (LIB) for secondary application (hereafter referred to as ‘refurbished EV batteries’) has been proposed to reduce the environmental impact of battery manufacturing on the BEV life cycle (Casals et al., 2019; Hossain et al., 2019). Additionally, refurbishing EV batteries aligns with the EU's Circular Economy Action Plan to reduce or eliminate waste and pollution and transform products and materials to remain in supply chains for as long as possible (European Commission, 2020).

1.1. Environmental impacts of battery electric vehicles

Life cycle assessment (LCA) is a methodology standardised by ISO, 2006, ISO, 2006 to analyse the environmental impacts of products or systems. LCA has been widely applied to electric vehicles in the scientific literature (Hawkins et al., 2012; Marmiroli et al., 2018; Nordelöf et al., 2014; Peters et al., 2017). However, the existing studies found significantly different results due to their divergence in assumptions. However, most studies conclude that electricity production is the main driver of electric vehicles' climate impact, followed by battery production (Marmiroli et al., 2018; Peters et al., 2017). Furthermore, the importance of battery efficiency and refurbishment has been highlighted (Hossain et al., 2019; Peters et al., 2017). To that end, the following paragraphs examine how these aspects (electricity mix, battery efficiency and refurbishment) have been considered in LCA studies.

The CC impact of a BEV use phase depends on the carbon footprint of the electricity mix used to charge the vehicle (Marmiroli et al., 2018; Nordelöf et al., 2014). However, few studies have considered future changes in the charging electricity mix of BEVs (Cox et al., 2018, Cox et al., 2020; Koroma et al., 2020). Most LCA studies on BEVs have only used an average emission profile of the charging electricity mix for the first year of use throughout the vehicle's lifetime (Marmiroli et al., 2018). As the emission profile of the charging electricity mix will vary throughout the vehicle's lifetime due to expanding RESs (European Commission, 2019), there is a need for LCA studies of BEVs to include these changes throughout the vehicle's lifetime.

Peters et al. (2017) found that the efficiency of traction batteries is critical and can significantly impact the environmental performance of EV batteries and BEVs. Since the traction battery capacity and energy efficiency degrades over time and cycling (Birkl et al., 2017), Eftekhari (2017) and Redondo-Iglesias et al. (2019) found that the decrease in battery energy efficiency can directly influence the lifetime energy consumption of BEVs. Faria et al. (2014) also found that the capacity loss over time for the different BEV driving profiles (represented in terms of C-Rate) directly influenced the BEV energy consumption and the battery ageing mechanism. However, most LCA studies on BEVs have overlooked this aspect, as shown in review studies (Hawkins et al., 2012; Marmiroli et al., 2018; Nordelöf et al., 2014; Peters et al., 2017). In that context, there is a need to assess the environmental performance of a BEV considering the fade in battery capacity and energy efficiency.

From a life cycle perspective, extending the life of used BEV batteries in stationary applications is an initiative to improve the BEV and battery environmental performance (Hossain et al., 2019). After their first use in BEVs, traction batteries still have approximately 60% to 80% of their initial capacity, making them suitable for refurbishment and use in less-demanding applications (Casals et al., 2019). Several LCA studies have suggested environmental benefits when BEV batteries are refurbished (Ahmadi et al., 2017; Bobba et al., 2018; Faria et al., 2014; Richa et al., 2015; Schulz-Mönninghoff et al., 2021). However, different system boundaries are used in the scientific literature – Table 1. Most studies in Table 1, except for Ahmadi et al. (2014b), Casals et al. (2017), and Hill et al. (2020), delimited their system boundaries to the battery life cycle (covering its use in BEVs and secondary applications), excluding the vehicle equipment. The limitation of the system boundary to the battery life cycle does not support the understanding of the environmental performance of a BEV from a life cycle perspective (Schulz et al., 2020). This study aims to broaden the perspective on this issue in context.

Table 1.

System boundaries of LCA studies on refurbished EV batteries. Legend: EoL – end-of-life, M – manufacturing, R – refurbishment, X – included, X* – only energy loss due to battery efficiency and the extra energy needed to carry the battery, X~ – only energy loss due to battery efficiency.

| Author | Vehicle – M | Vehicle use | Vehicle EoL | Battery – M | Battery – R | Battery second use | Battery EoL |

|---|---|---|---|---|---|---|---|

| Cicconi et al. (2012) | X* | X | X | X | |||

| Ahmadi et al. (2014b) | X | X | X | X | X | ||

| Faria et al. (2014) | X | ||||||

| Sathre et al. (2015) | X | ||||||

| Ahmadi et al. (2017) | X | X | X | X | X | ||

| Casals et al. (2017) | X | X | X | X | X | X | |

| Richa et al. (2015) | X* | X | X | X | X | ||

| Bobba et al. (2018) | X | X | X | X | |||

| Cusenza et al. (2019b) | X | X | X | X | |||

| Hill et al. (2020) | X | X | X | X | X | X | |

| Koh et al. (2021) | X | X | X | X | |||

| Schulz-Mönninghoff et al. (2021) | X~ | X | X | X | X |

1.2. Research motivation and novelty

As described, the environmental performance of BEV and refurbished EV batteries are widely studied but often separately, demonstrating a gap in the scientific literature. In addition, the combination of changes in the charging electricity mixes over time, battery efficiency fades, and refurbishment of EV batteries and recycling in the LCA of BEVs have not been investigated for their joint relevance on BEV environmental performance. This study presents an LCA study that integrates these aspects for the first time to assess the environmental performance of a present-day BEV. The following research questions are investigated:

-

1.

What are the environmental impacts of a BEV charged with an average EU electricity mix in 2020?

-

2.

How might these impacts change when the expected yearly increase in RES in the EU electricity mix is considered?

-

3.

To what extent can refurbished EV batteries improve the net environmental performance of BEVs?

2. Materials and methods

A scenario-based LCA was performed based on the ISO 14040 and 14044 standards to assess the LC environmental impacts of a BEV (ISO, 2006, ISO, 2006). A complete vehicle LCA typically consists of two cycles: the equipment life cycle and the well-to-wheels (WTW) life cycle (Nordelöf et al., 2014). The equipment cycle covers all the processes involved in vehicle manufacturing, including material extraction and processing, component manufacturing, vehicle assembly, and end-of-life (EoL). The WTW cycle covers the energy carrier for vehicle propulsion, which is further divided into the well-to-tank (WTT) and tank-to-wheel (TTW) stages. The WTT stage includes all processes from the extraction of primary energy materials to energy conversion, distribution, and storage, while the TTW covers the vehicle operation stage.

The LCA was performed by considering changes in the charging electricity mix over time, battery efficiency fade, vehicle and LIB recycling, and LIB refurbishing. Fig. 1 shows the considered system boundaries and scenarios. The reference scenario included BEV production, the use stage (assuming an average EU electricity mix), and the EoL (vehicle and LIB recycling). In the dynamic scenario, the BEV use stage was assessed considering the projected changes in the EU electricity sector. The refurbished scenario considered the same projected changes in the EU electricity sector existing in the dynamic scenario and BEV refurbishment for a second use in a residential battery storage system.

Fig. 1.

System boundaries and assessed scenarios. Legend: EoL = End-of-Life, LIB = Li-ion battery.

The refurbished scenario assessed the BEV from its cradle to the grave, including its battery's refurbishment and EoL management. The second (stationary) use stage was excluded from the assessment for consistency with the functional unit and the aim of this study. Including the stationary use stage in the refurbished scenario will not reflect the BEV impact but that of the BEV plus stationary usage, which can add discrepancy to the results from the viewpoint of a BEV function. However, extending the life of the used BEV battery implies that the environmental burden of the LIB production and EoL stage could be shared between the BEV and the residential application. Therefore, the product substitution (avoided burden) approach was adopted to address the allocation issue (Majeau-Bettez et al., 2018). This approach extends the system boundary of the assessment to consider an equivalent new LIB (hereafter referred to as “avoided LIB”) in a stationary application by assuming that the refurbished LIB would displace the avoided LIB in practice. As a result, the environmental impacts avoided due to the production and EoL stages of the avoided LIB were then credited as avoided impacts to the BEV total environmental impacts.

The functional unit was defined as driving a European B-segment BEV equipped with a 54.6 kWh LIB for 160,000 km over a lifetime of 12 years (ACEA, 2019a). This functional unit was defined to match the characteristics and performance of Renault Zoe, an exemplary car of this segment (Renault, 2019). This vehicle segment is chosen as the small (A + B) cars representing 40% of total EU car sales from 2009 to 2020 (ACEA, 2021). Vehicle equipment production, battery pack assembly, use phase, and EoL were assumed to occur in Europe. The production of LIB cells was supposed to occur in South Korea. This assumption relies on the fact that a Korean company manufactures the LIB cells of Renault Zoe. In addition, over 88% of the current LIB cell manufacturing capacity is located in Asia (Lebedeva et al., 2016). The production of vehicle equipment and battery packs was assumed to occur in 2019. The BEV use stage was supposed to start in 2020 until its EoL in 2031, with no battery replacement considered. In the refurbished scenario, the LIB cells were refurbished at the EoL of the BEV for residential energy storage, extending its useful life for 5 years. This assumption stems from Casals et al. (2019) findings of 5.9 years for using refurbished EV batteries in buildings for self-consumption services at 60% EoL. However, Casals et al. found that the lifespan of refurbished EV batteries can range from approximately 4.7 to 30 years, depending on the second use. Therefore, a sensitivity analysis was performed on this parameter.

2.1. Life cycle inventory (LCI)

The LCI foreground data were compiled based on secondary sources, including the scientific literature, technical datasheets, reports, and brochures. Ecoinvent database v3.6 (Ecoinvent, 2019; Wernet et al., 2016) was used for the background data. The BEV modelled in this study was defined to characterise a medium-sized car similar to the Renault Zoe, equipped with a 54.6 kWh LIB (Renault, 2019). Further details on each life cycle stage are described in 2.1.1, 2.1.2, 2.1.3, 2.1.4, 2.1.5.

2.1.1. LIB and vehicle production

BEV production was considered for three main units: the vehicle glider, the electric axle drive (e-drive), and the battery system. The key characteristics of the considered BEV are shown in Table S1 of the Supplementary Material (SM) and its mass composition in Table 2. The LCI for glider production was adapted from the Ecoinvent dataset based on the “Golf A4” life cycle inventory from the 2000s (Schweimer and Levin, 2000; Wernet et al., 2016). Thus, the following changes were made to the original dataset from the Ecoinvent database to make the vehicle glider more representative of current passenger cars: the energy for glider assembly was modified to reflect the EU energy mix for the production year (2019), and the production of a 9.3-inch touchscreen tablet for in-vehicle infotainment system was added based on data from Teehan and Kandlikar (2013). The LCI for this change is reported in Table S2 of the SM.

Table 2.

Mass composition of the battery electric vehicle components.

| Unit | Components | Amount | Reference |

|---|---|---|---|

| Glider | Glider (kg) | 1150.1 | Authors' estimatea; Ecoinvent (2019) |

| Electric axle drive | Gearbox (kg) | 23.8 | BRUSA (2019) |

| Electric motor (kg) | 45.5 | Nordelöf et al. (2017); Nordelöf and Tillman (2017) | |

| Inverter (kg) | 10.9 | Nordelöf et al. (2018); Nordelöf (2018) | |

| Converter (kg) | 4.8 | BRUSA (2019); Ecoinvent (2019) | |

| Charger (kg) | 12.0 | BRUSA (2019); Ecoinvent (2019) | |

| PDU (kg) | 3.9 | BRUSA (2019); Ecoinvent (2019) | |

| Li-ion battery system | Battery pack (kg) | 326.0 | NMC 111 cells based on Dai et al. (2018); Winjobi et al. (2020); battery pack components based on Ellingsen et al. (2014) |

Derived from the unladen KLB mass of Renault Zoe (Renault, 2019) by deducting the mass of the battery pack and e-drive.

The electric motor and inverter were modelled based on the scalable life cycle inventory model proposed in Nordelöf et al. (2017) and Nordelöf et al. (2018). The nominal power (100 kW) and the voltage (400 V) of the electric motor and inverter were used as input to the life cycle inventory model to estimate their respective mass and manufacturing data (see Table S3 and Table S4 for inventory data). The converter, power distribution unit, and onboard charger were based on BRUSA (2019), while LCI data and processes for these components were derived from the Ecoinvent database.

Table 3 shows the characteristics of the LIB cells in this study. The LIB cells contained a cathode based on nickel manganese cobalt (NMC) 111 and an anode with graphite as the active material. The NMC battery chemistry was chosen to match the battery pack of Renault Zoe better. In addition, in 2016, the NMC held approximately 26% market share in the overall LIB market (Pillot, 2017), with a projection to reach 63% by 2027 (Fitchsolutions, 2021). Overall, the modelled LIB cells make up 63% of the total mass of the battery pack (Renault, 2019). The production of the LIB cells was modelled based on Dai et al. (2018) and Winjobi et al. (2020). The manufacturing of battery pack components (battery packaging, cooling system, and battery management system) was based on Ellingsen et al. (2014). Finally, the battery pack components were rescaled based on their mass characteristics to represent the LIB capacity of the BEV. Detailed inventory data are provided in Table S5 of the SM.

Table 3.

Characteristics of the LIB cells in this study (Winjobi et al., 2020).

| Characteristics | NMC 111 |

|---|---|

| Cell nominal voltage (V) | 3.7 |

| Nominal capacity (Ah) | 43 |

| Battery cell efficiency (%) | 95 |

| Cell energy density (Wh/kg) | 264.2 |

| Battery pack energy (kWh) | 54.6 |

2.1.2. Vehicle use

The WTT stage of the BEV was modelled from 2020 to 2031 using the average annual mileage electricity consumption and the average electricity profile of each year. For the reference scenario, the average electricity mix for 2020 was used based on the “Stated Policies Scenario” for the EU (IEA, 2019), which assumes the continuity of the current policy measures. Projections for changes in EU electricity generation over time (Table S6 in SM) were used in the dynamic and refurbished scenarios.

The BEV energy consumption was calculated using the driving cycle defined by the Worldwide Harmonised Light Vehicle Test Procedure (WLTP) (ACEA, 2019b). The BEV mass, rolling resistance, and aerodynamic drag were used to calculate the mechanical energy at the wheels required to follow the WLTP cycle. For each time step set of the WLTP driving cycle, the motive force (Fm) and the power at the wheels (Pwheel) were estimated using Eqs. (1), (2), respectively. Additionally, the slope was set to zero through the driving cycle to simplify the calculation. The power supplied by the battery (EPsupply) was calculated using Eq. (3) considering the energy demand for auxiliaries (1740 W based on Miri et al. (2020) – see Table S7 for details) and the efficiency of all the drivetrain components. Additionally, the power from regenerative braking (EPrecover) was recovered using Eq. (4). The average energy supplied by the battery (Eavg) at the tank-to-wheel (TTW) stage was calculated with Eq. (5). Finally, the average energy consumption of the BEV (BEVenergy. cons) was calculated using Eq. (6) as 21.6 kWh/100 km, which considered the estimated yearly average fade in the BEV battery roundtrip efficiency.

| (1) |

where:

Gravitational force (Fg) =m ∗ g ∗ sin (α.)

Rolling resistance force(Froll) = m ∗ g ∗ Cr ∗ cos (α)

Acceleration force (Facc)

Aerodynamic drag force(Fad) = 0.5 ∗ ρ ∗ Cd ∗ AF ∗ v2

Ahmadi et al. (2014a) and Redondo-Iglesias et al. (2019) have shown a strong correlation between the capacity fade and energy efficiency of LIBs. Therefore, the effect of battery degradation was examined by considering the fading of capacity and energy efficiency during the battery first life in a BEV and the second life in a residential as a similar approach has been used in previous studies (Ahmadi et al., 2014a; Richa et al., 2015). It was suggested that the battery pack reaches its first and second EoL at 80% and 65% of its initial capacity, respectively (Ahmadi et al., 2014a; Richa et al., 2015). Following Ahmadi et al. (2014a), a linear degradation in battery efficiency with cycling is considered. The battery was assumed to be cycled on average once every three days. This assumption is based on the average charging frequency of private BEV owners (Koptyug, 2020; Wang et al., 2019) over a 160,000 km lifetime mileage. The roundtrip efficiency of the battery at the start and EoL in a BEV was 90% and 75%, respectively (Gerssen-Gondelach and Faaij, 2012). As a result, the battery efficiency was estimated to degrade linearly with a constant decline of 1.045−4. Thus, the expected increase in the BEV energy consumption (due to battery degradation) was accounted for by considering the battery efficiency fade in the LCA model.

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

where m = vehicle mass (kg), g = gravity (m/s2), Cr= coefficient of rolling resistance, ρ = air density (kg/m3), Cd = aerodynamic drag coefficient, AF = vehicle frontal area (m2), v = vehicle velocity (m/s), α = slope angle, t = time (s), ηm = motor efficiency, ηt = transmission efficiency, ηe = power electronics efficiency, and ηbatt = battery roundtrip efficiency.

The obtained average energy consumption of the BEV (21.6 kWh/100 km) is similar to the real-life consumption data reported for BEVs of a similar weight class (Qi et al., 2018) and Renault Zoe in the Ecoscore database (Ecoscore, 2019). Finally, the use phase assessed impacts due to maintenance, road construction, and nonexhaust emissions (road, brake, and tire wear). These were modelled based on equivalent processes in the Ecoinvent database (Table S8), and their contributions to the environmental life cycle impacts are referred to as “others (use)” in the results section.

2.1.3. End of life

Following the EU directives on the EoL of vehicles and waste batteries (EU, 2000, EU, 2006), vehicles and batteries must be collected and recycled once they reach their EoL. The EoL model developed in this study consists of four different models to match the different scenarios – shown as EoL1, EoL2, EoL3, and EoL4 in Fig. 1. EoL1 and EoL2 are suggested to occur in 2031 when the BEV reaches its EoL. Similarly, EoL3 and EoL4 are proposed to occur in 2036 (when the refurbished LIB reaches its EoL after five years of second life) and 2041 (when the avoided LIB reaches its EoL after ten years), respectively. Table 4 shows the critical aspects of each EoL scenario.

Table 4.

End of Life models adopted in this study. Legend: BMS = battery management systems, BEV = battery electric vehicle, EoL = end of life, LIB = lithium-ion battery.

| Assumptions |

Scenario |

||||

|---|---|---|---|---|---|

| Reference and Dynamic |

Refurbished |

||||

| EoL model | EoL1 | EoL2 | EoL3 | EoL4 | |

| EoL year | 2031 | 2031 | 2036 | 2041 | |

| Life cycle stage | Vehicle & the entire BEV battery | Vehicle & rejected cells and components of the BEV battery | Refurbished LIB | Avoided LIB | |

| Glider | ✓ | ✓ | n/a | n/a | |

| e-drive | ✓ | ✓ | n/a | n/a | |

| LIB pack | LIB cells | ✓ | 50% of BEV LIB cells were recycled & 50% were sent for LIB refurbishment | The remaining 50% of BEV LIB cells that were refurbished were recycled at this stage | 100% of avoided LIB cells were recycled |

| BMS | ✓ | ✓ | ✓ | ✓ | |

| Cooling system | ✓ | ✓ | ✓ | ✓ | |

| Packaging | ✓ | 50% of packaging was recycled & 50% was reused | The 50% packaging that was refurbished was recycled at this stage | ✓ | |

✓ implies included; n/a implies not applicable

The main steps involved in a vehicles' EoL are dismantling, shredding, sorting, treatment of wastes, and recycling of precious materials (Chen et al., 2019). For recycling, the following metals were considered: nickel, cobalt, manganese, aluminium, copper, and steel. All other materials were assumed to be disposed of in a sanitary landfill. The primary material of the BEV glider by mass was steel, while nickel, cobalt, and manganese were in the LIB pack. The dismantling and EoL treatments of both the LIB and the vehicle equipment were modelled based on representative processes in the Ecoinvent database. Likewise, recycling valuable metals from the LIB pack and vehicle equipment (glider and e-drive) was based on Cusenza et al. (2019a) and the Ecoinvent database, respectively. The inventory data per kg of treated component used for the glider, e-drive, battery cells, BMS, packaging, and cooling system are reported in Table S9 of the SM. The recycling rates of the different metals are based on Chancerel and Marwede (2016). The recycling rates were used to account for the avoided impact (by considering primary production processes following the avoided burden approach) due to the recovery of valuable metals.

2.1.4. Li-ion battery refurbishment

LIBs are considered to reach their EoL in automobile applications when a state of health (SoH) of 70%–80% is achieved (Hossain et al., 2019; Podias et al., 2018). Therefore, in this study, 80% for E1 was assumed. Accordingly, the LIB cells were sent to a refurbishment facility and tested to ensure their SoH was sufficient for the second use in stationary applications. In practice, some of the LIB cells used from a BEV battery are unsuitable for reuse (Hossain et al., 2019; Liao et al., 2017; Warner, 2015); thus, 50% of the BEV LIB cells were assumed to be reusable in this study, based on the similar assumption in Richa et al. (2015). However, LCA studies have considered different cell conversion rates (CCRs), i.e., the percentage of LIB cells viable for the second use, ranging from 10 to 100% (Ahmadi et al., 2014b, Ahmadi et al., 2017; Bobba et al., 2018; Richa et al., 2015). As a result, a sensitivity analysis on CCR was performed using the same range to account for its variability.

Damaged modules and broken LIB pack components were also removed and taken to recycling facilities. The broken parts were then replaced during the LIB refurbishment stage. This stage involves battery collection, battery dismantling up to the module/cell level, battery SoH testing, and LIB refurbishment (EcarACCU, 2017). Table 5 shows the data used to model the LIB refurbishment stage. The model for this stage was adapted from Richa et al. (2015), considering transportation and SoH testing impacts. Inventory data for replacing broken components in the refurbished LIB were based on Ellingsen et al. (2014). The reuse of the battery packaging was assumed to be 50%, while 100% of the cooling system and BMS were replaced (Richa et al., 2015).

Table 5.

Inventory of LIB refurbishment at a 50% cell conversion rate.

| Parameter | Amount | Reference |

|---|---|---|

| Battery packaging (kg) | 21 | Adapted from Ellingsen et al. (2014) |

| Battery management system (kg) | 3 | Adapted from Ellingsen et al. (2014) |

| Transport (tkm) | 0.1 | Adapted from Richa et al. (2015) |

| Cooling system (kg) | 3 | Adapted from Ellingsen et al. (2014) |

| Electricity, medium voltage (kWh) | 77.6 | 2 charge/discharge cycle Bobba et al. (2018) |

| Refurbished LIB energy capacity at 80% SoH (kWh) | 21.8 | See Table S10 in the SM |

2.1.5. Manufacture of avoided LIBs

Although Asian and American countries dominate battery production, Europe is making efforts to become a leader in battery technology (Lebedeva et al., 2016). Therefore, it was assumed that by 2031, when the BEV reached its EoL, Europe would have enough LIB manufacturing capacity to meet the local demand. Thus, the equivalent avoided LIB was manufactured and assembled in Europe when the BEV reached its EoL. As a result, the 2031 average electricity mix for the EU was used in the avoided LIB manufacture. The LCI data were based on Winjobi et al. (2020) and Ellingsen et al. (2014) for the LIB cell and battery pack components, respectively. A 10% reduction in energy use to manufacture the avoided LIB was assumed (Van Mierlo et al., 2021). All other aspects of LIB production were assumed unchanged in the future; see Table S11 for inventory data.

2.2. Life cycle impact assessment and sensitivity analysis

The percentage of LIB cells considered viable for refurbishment (CCR) and the refurbished LIB lifespan were examined in a sensitivity analysis (Table 6) to determine the robustness of the results. The LCA calculations were computed using SimaPro software version 9.1 (Pre-sustainability, 2022) and the ecoinvent database version 3.6. The life cycle impact assessment method ReCiPe 2016 (H) v1.04 (Huijbregts et al., 2017) was used. The midpoint environmental impact categories global warming potential (GWP); mineral resource scarcity (MRS); fine particulate matter formation (FPMF); human noncarcinogenic toxicity (HnCT); and human carcinogenic toxicity (HCT) are discussed in detail in Section 3. In addition, the results for other environmental impact categories are reported in the SM (see Tables S12–S14), namely, stratospheric ozone depletion, ionising radiation, ozone formation, acidification, eutrophication, ecotoxicity, land use, fossil resource scarcity, and water consumption.

Table 6.

Parameters for sensitivity analysis.

| Sensitivity parameter | Baseline | Sensitivity scenario |

|---|---|---|

| Cell conversation rate (%) | 50 | 10 to100 |

| Refurbished LIB lifetime (years) | 5 | 1 and 10 |

3. Results and discussion

This section presents comparative results across the three scenarios – Reference, Dynamic, and Refurbished. To estimate the impact of changes in the charging electricity mixes over time, recycling, and LIB refurbishment, the total impact excluding these aspects is shown as the reference scenario without recycling. Thus, the environmental impacts are discussed relative to the reference scenario without recycling.

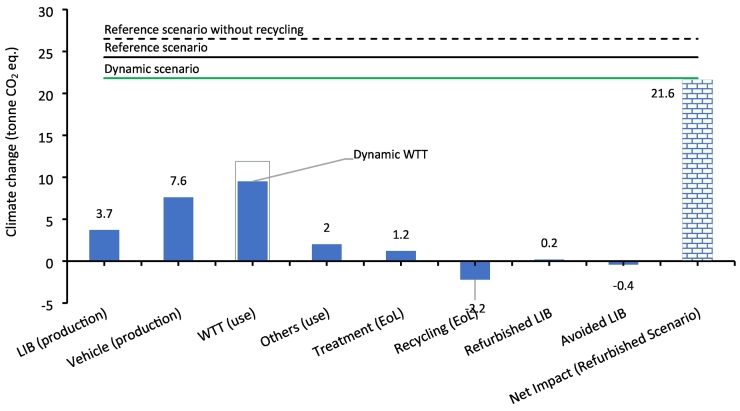

3.1. Climate change

Fig. 2 shows the climate impacts of the BEV with a refurbished battery life cycle. The total lifetime CC impact of the BEV excluding the improvement strategies (reference scenario without recycling in Fig. 2) corresponds to 26.5 tons CO2-eq/vehicle. Recycling the used BEV (including the LIB) contributed to an 8.3% reduction in the BEV climate impact – Reference scenario. When the yearly changes in the charging electricity were considered in the dynamic scenario, the BEV climate impact was reduced by 9.1%. LIB refurbishment contributed to less than a 1% reduction in total climate impacts in the refurbished scenario. Overall, the collective reduction of impacts on CC corresponds to approximately 18.1%, shown as the net impact in Fig. 2.

Fig. 2.

Life cycle climate change impacts of a battery electric vehicle with a refurbished battery. Legend: WTT = Well-to-Tank; Dynamic WTT = changes in electricity production over time; Others (use) = emissions of road, maintenance, and non-exhaust emissions; vehicle (production) represents the production of the glider and e-drive; LIB = Lithium-ion battery; EoL = end-of-life; Treatment (EoL) covers treatment of glider, e-drive, LIB pack & refurbished LIB; Recycling (EoL) covers recycling of glider, e-drive & LIB pack; Avoided LIB covers production, EoL treatment, & recycling of avoided LIB; Net impact = net climate change impacts considering the effects of changes in electricity, vehicle and LIB recycling, and LIB refurbishment.

Vehicle production is the primary driver of impacts to CC, considering its relative increase in the share of the BEV climate impact in the dynamic scenario. The production stage contributed approximately 43% of the BEV climate impacts in the reference scenario without recycling, of which LIB and vehicle production contributed 14% and 28%, respectively. However, its contribution to the BEV net climate impact increases relatively in the dynamic scenario due to the high share of RES in the use stage electricity.

The battery cell was the largest contributor to CC (64.9%) of the LIB pack production stage (Fig. 3 - A). The production of the active cathode material, metals such as aluminium and copper, and the energy demand for producing the battery cell were responsible for most of the LIB pack impacts on CC. In glider manufacturing, conventional and high alloy steels contributed the largest share of glider material by mass and for CC impact (Fig. 3 - B). However, this trend did not occur for all materials used in glider production. For instance, electronic components represented only 0.3% of the glider mass but contributed approximately 17.7% of its climate impact. This is due to the demand for electronic components for in-vehicle infotainment systems, which requires precious metal mining and energy-intensive production.

Fig. 3.

Breakdown of mass and climate changes impacts of the Lithium-ion battery (LIB) production (a) and glider production (b). Legend: BMS – battery management system.

Similarly, the textile share was 3.6% of the glider mass but contributed 7.1% of the glider climate impacts due to its energy-intensive production. These results suggest that CC impact is not always directly proportional to the share of materials by mass. Additionally, the results underline the importance of BEV manufacturing and the role of the embodied GHG emissions of materials used in vehicle production. Therefore, measures to further reduce the environmental impacts of BEV production include using renewable energy at production sites combined with energy-efficient manufacturing processes for materials and improvements along the entire automotive supply chain.

In Table 7, the climate impact on BEV production in this study is compared to the findings of previous LCA studies, considering the relevant assumptions of each study. The comparison found that the CC impact for the BEV production stage in this study is within the range of those reported for BEVs of similar weight and battery capacity. The differences in CC impact reported in the literature are linked to the different assumptions for battery size, energy demand, and the electricity carbon footprint for cell and battery production. The battery chemistry type and the inventory data for battery cell production are also important for explaining the differences.

Table 7.

Comparison of the climate change impacts of BEV production.

| Reference | Climate change (tonne CO2-eq) | Battery size (kWh) | Reference year | Climate change (g CO2-eq/kWh) |

|---|---|---|---|---|

| Bauer et al. (2015) | 10.8 | 50 | 2012 | n/a |

| Cox et al. (2018) | 13.8 | 37.5 | 2017 | ~430 |

| Cox et al. (2020) | 14.8 | 55 | 2017 | ~430 |

| Hill et al. (2020) | 13.9 | 58 | 2020 | Not available |

| Koroma et al. (2020) | 9.7 | 30 | 2016 | 426 |

| This study | 11.3 | 54.6 | 2019 | 359 |

The BEV use stage contributed approximately 45% of the BEV climate impacts in the reference scenario without recycling. However, its contribution was reduced to 36% in the dynamic scenario (see “Reference WTT” and “Dynamic WTT” in Fig. 2). This reduction is attributable to the increasing share of renewable electricity in the dynamic scenario. The dynamic scenario results have shown that including changes in electricity production can reduce CC impacts. Additionally, the use stage can last from 8 to 16 years for passenger cars in the EU (ACEA, 2019a), further demonstrating the need for such modelling efforts, as changes in electricity production will occur during a BEV lifespan. Available LCA studies of present-day BEV have overlooked the effects of changes in electricity production through the BEV lifetime, consequently minimising the environmental advantages of current BEV.

The expected battery roundtrip efficiency degradation contributed to an 8.1% and 7.4% increase in the climate impacts of the BEV use stage for the reference and dynamic scenarios, respectively (Fig. S1 in SM). These results suggest the importance of considering battery efficiency fade in the LCA model of electric vehicles, which is also lacking in existing LCA studies on BEVs. Additionally, it implies that improvements along with key battery performance parameters, such as capacity and efficiency fade, will directly improve BEVs' life cycle climate impacts.

Overall, our results differ from earlier LCA studies showing the BEV use stage as dominant (over 60%) for CC impacts, e.g., Bauer et al. (2015) and Messagie et al. (2014). The difference is linked to the ongoing integration of RES in the present EU electricity mix compared to their publication year - 2014. Additionally, the dynamic scenario accounted for the projected yearly change in the share of RES in the charging electricity mix. These results imply that as the carbon content of the electricity sector is reduced by integrating more RES over time, the CC impact of the BEV use stage will also be reduced, and so its relative share of the BEV total CC impacts. As a result, the CC impacts of the BEV production and EoL stages may become more relevant in the future. Therefore, the automotive industry can consider using renewable energy in their manufacturing sites and select materials with low embodied emissions to reduce the impacts of current BEV production.

3.2. Other impact categories

The production stage contributed over 75% to particulate matter formation (FPMF) emissions (Fig. 4). LIB production accounted for over 45% of the reference scenario without recycling, of which the production of the NMC powder, graphite, and aluminium were the main contributors. FPMF due to road construction and maintenance, vehicle maintenance, and nonexhaust emissions accounted for 8% and that of which are due to electricity production was 9% of the reference scenario without recycling. Changes in the electricity sector showed a 2% reduction due to a reduction in conventional fossil electricity. Additionally, recycling and LIB repurposing showed 17% and 4% reductions in the BEV total FPMF, respectively. These results indicate that recycling and LIB repurposing could improve air quality since waste incineration and landfill are reduced.

Fig. 4.

Fine particulate matter formation (FPMF) of a battery electric vehicle with a refurbished battery life cycle.

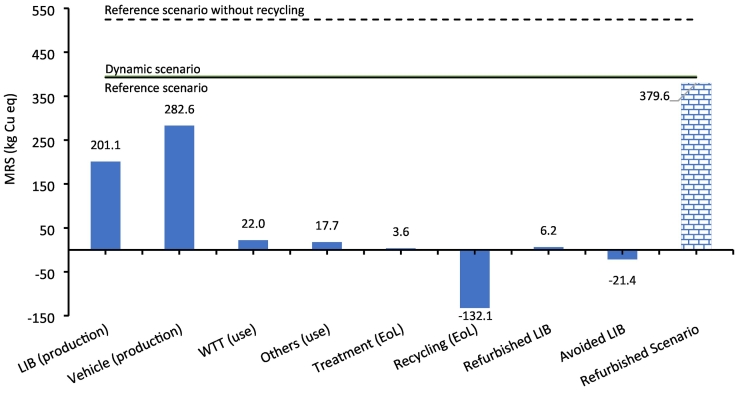

As expected, the BEV production stage contributed the most to mineral depletion, accounting for over 90% of the scarcity potential resulting from the reference scenario without recycling (Fig. 5). Manufacturing the BEV glider and electric drivetrain contributed approximately 54% of this value. This is mainly driven by the increasing vehicle electrification and electronics for in-vehicle infotainment, as shown in Fig. 3. In the dynamic scenario, expected changes in the electricity sector showed less than a 1% increase in this indicator; this is linked to the expected rise in demand for metals in developing and deploying new renewable energy technologies. However, the recycled and refurbished LIBs showed approximately 25% and 3% reductions in MRS potential, respectively. This confirms that recycling and refurbishment are relevant strategies to reduce or delay the use of virgin materials. This reduction in virgin materials reduces the potential for resource depletion and scarcity.

Fig. 5.

Mineral Resource Scarcity (MRS) potential of a battery electric vehicle with a refurbished battery life cycle.

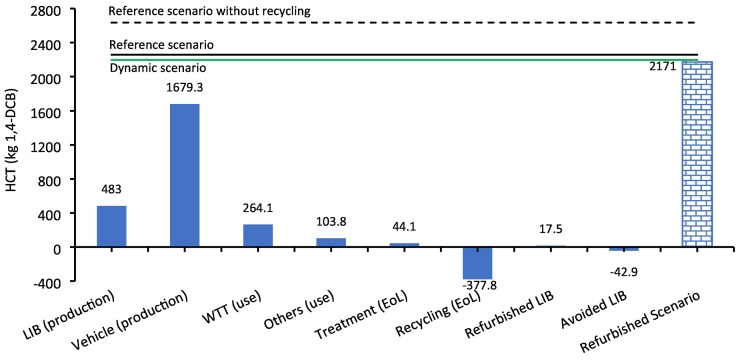

The ReCiPe 2016 impact assessment method differentiates human toxicity into two impact categories, human noncarcinogenic toxicity (HnCT) and human carcinogenic toxicity (HCT) (Fig. 6, Fig. 7). The production stage contributed the most to toxic substances in both HCT (82%) and HnCT (82%) impact categories. The main contributor to HCT was vehicle production, accounting for over 62%, while LIB production accounted for 18%. Similarly, vehicle production contributed over 50%, and LIB production contributed 31% to HnCT. The human toxicity impact categories were mainly driven by metal production due to copper and aluminium in the battery pack and electronic wiring in vehicle production. These impacts were generally linked to mining waste from metal extraction (production stage). The BEV use stage contributed approximately 10% toxicity in HTC and HnCT, driven by waste from digester sludge in bioenergy production. Considering the changes in the electricity sector reduced both HCT and HnCT by approximately 2%. The largest reduction is achieved when recycling is considered. In this case, HCT and HnCT impacts were reduced by 14% and 22%, respectively, while LIB refurbishment showed less than a 2% reduction in both toxicity indicators.

Fig. 6.

Human non-Carcinogenic Toxicity (HnCT) of a battery electric vehicle with a refurbished battery life cycle.

Fig. 7.

Human Carcinogenic Toxicity (HCT) of a battery electric vehicle with a refurbished battery life cycle.

3.3. Influence of recycling, changes in charging electricity, and LIB refurbishment

Overall, recycling at EoL was beneficial across all impact categories and contributed to improvements in the BEV environmental performance from 8% in climate impacts to approximately 25% for MRS impact categories (Table 8). These results show that recycling is critical for those categories where the impact is driven by material and vehicle production. Considering the expected changes in the charging electricity mix through the BEV lifetime is most relevant to mitigate the effects on CC. Reductions in other impact categories are minimal except for MRS, which increased by 0.4% relative to its value in the reference scenario without recycling.

Table 8.

Impact of recycling, changes in charging electricity mix, and lithium-ion battery (LIB) repurposing on the life cycle impacts of a battery electric vehicle. Red cells show increases in the environmental impacts, green cells show reductions greater than or equal to 20%, and yellow cells show reductions between 10% and 20%.

LIB refurbishment resulted in marginal benefits across all impact categories reported in Table 8 under the assumptions that 50% of the LIB cells were viable for refurbishment for 5 years in second life. On the one hand, these results suggest that extending the life of a used BEV battery for second life may not result in effective environmental benefits. For example, an equivalent new LIB (mainly produced from recycled materials) can have better environmental performance, higher charge/discharge efficiency, and a longer lifespan than a refurbished LIB. On the other hand, since many used BEV batteries are expected in the near future and there is uncertainty regarding their current recycling capacity, refurbished EV batteries may provide several advantages in this context. For instance, refurbished LIB can delay the recovery of valued resources from the high quantity of battery waste expected until current recycling facilities are upgraded and become more suitable to manage and effectively recover battery waste.

3.4. Sensitivity analysis

Fig. 8 shows the CC impacts of the refurbished LIB lifespan and the amount of LIB cells viable for refurbishment. These results are compared to the climate impact of the dynamic scenario shown as the green dashed line in Fig. 8. The refurbished scenario resulted in less than a 1% reduction in climate impacts, assuming 50% CCR and a five-year second lifespan. The sensitivity results found further reductions in climate impacts for higher CCR (greater than 50%) and longer second lifespans (greater than five years). The maximum reduction potential for refurbished LIB (approximately 6%) was achieved at 100% CCR for ten years of use in second life. LIB refurbishment benefits are conclusive for the second lifespan of ten years and a CCR greater than 20%. For a 5-year second lifespan, the benefits depend on CCR values greater than 50%, while no benefit was observed for a 1-year second lifespan. These results suggest that the potential for refurbished EV batteries to mitigate the climate impacts of BEVs depends on their second lifespan and the number of LIB cells viable for refurbishment.

Fig. 8.

Sensitivity analysis of climate change impacts of BEV with refurbished LIB under different cell conversion rates and lifespans.

3.5. Opportunities and limitations

This work presents the environmental life cycle impacts of a BEV, considering the implications of battery efficiency fade, refurbished battery life cycle, and changes in RES in the charging electricity mix, which are still lacking in the scientific literature. Furthermore, it presents relevant conclusions to stakeholders, such as the importance of the second lifespan and higher CCR values for refurbished EV batteries. These results can support manufacturers in designing future BEV batteries considering battery refurbishment at the EoL. Likewise, the results can help stakeholders plan and develop sustainable business models for refurbished EV batteries based on their second lifespan and reusable cells for secondary use.

Given the study's prospective nature, the parameters for electricity sector improvements, LIB refurbishment, and avoided LIB were based on secondary data. Therefore, some limitations should be discussed to interpret the results. Access to empirical data is challenging for a growing market such as EVs and refurbished EV batteries. To date, several existing LCA studies on passenger cars have been based on the inventory for glider production of “Golf A4” since the 2000s. Future efforts to provide reliable data on vehicle production are essential, especially for the glider. In addition, changes in the electricity sector have only considered changes in the share of RES in the electricity mix. However, other changes may occur over time, such as changes in the emission factors from energy sources.

Similarly, BEV battery lifetime, battery performance during first and second use, battery refurbishment (collection, testing, refurbishment), and EoL management are essential to increase the robustness of vehicle LCA results. A sensitivity analysis was performed to assess the variability of the refurbished LIB parameters. However, the viability of LIB cells to be considered reusable for refurbishment depends on several factors during the BEV use stage, such as driving patterns, operating temperature, and charging frequency, among other aspects (Martinez-Laserna et al., 2018). Future works should find the opportunity to investigate aspects of refurbished LIB that were out of the scope for this study – such as safety, regulatory framework, and feasible business models.

4. Final remarks

This research is the first to improve the LCA of BEVs by integrating the effects of changes in electricity production over time, battery efficiency fade, refurbished EV batteries, and battery recycling. These improvement strategies were assessed based on three scenarios - reference, dynamic, and refurbished, considering the impact categories GWP, MRS, FPMF, HnCT and HCT. Together, these parameters resulted in a reduction of 18% in the life cycle climate impacts of a present-day BEV.

The study demonstrated that neglecting the impacts of future changes in the EU electricity mix can overstate BEV climate impacts, thus misleading policy-makers. The changes in future electricity production have the most influence, with a 9% reduction in CC in the dynamic scenario. The impacts on CC of the production stage increase relatively as the BEV use stage decreases due to changes in the EU electricity production over time (from 43% in the reference scenario to 47% in the dynamic scenario when compared against the reference scenario without recycling).

The battery efficiency fade increases the BEV energy consumption and increases the use-stage climate impacts by 7.4 to 8.1%. Recycling accounted for a nearly 8% reduction in BEV climate impacts, with reductions of approximately 22% and 25% in the human toxicity and MRS categories, respectively. However, current recycling processes present several challenges and possible improvements, such as better sorting, collection, and recycling mechanisms that could increase the recycling rates of BEV components.

Battery refurbishment generated less than a 1% reduction in BEV climate impacts. However, the lack of primary data adds uncertainty to this result. The sensitivity analysis showed benefits (up to a 6% reduction in the BEV climate impacts); it found that a higher reduction in the BEV climate impacts is possible for longer second lifespans (>5 years) and higher cell conversation rates (>50%). Therefore, despite marginal benefits in the main study, refurbished EV batteries should not be neglected.

This study has shown that BEV is a promising technology for reducing the environmental impacts of the transport sector. However, the lack of access to primary data remains a challenge for LCA practitioners. Therefore, more detailed information and primary data on battery degradation and refurbished EV batteries in specific stationary applications are required for future research. It is equally relevant to further reduce upstream climate impacts at the mining, material processing, and BEV production stages. More importantly, their adoption should go hand in hand with RES integration and better recycling processes for vehicle and EV batteries. Furthermore, the sensitivity analysis results show their potential to support the EU's circular economy transition, demonstrating that refurbished EV batteries can potentially reduce BEV environmental impacts.

CRediT authorship contribution statement

Michael Samsu Koroma: Conceptualisation, Methodology, Data curation, Software, Validation, Formal analysis, Investigation, Writing - original draft, Visualisation. Daniele Costa: Methodology, Validation, Writing - review & editing, Supervision. Giuseppe Cardellini: Writing - review & editing, Supervision. Md Sazzad Hosen: Data curation, Writing - review & editing. Maeva Philippot: Writing - review & editing. Thierry Coosemans: Funding acquisition. Maarten Messagie: Conceptualisation, Methodology, Funding acquisition.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

We acknowledge Flanders Make for their support of the MOBI research group. The research was funded by the EU Horizon 2020 project PANDA - grant agreement number 824256.

Editor: Deyi Hou

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.scitotenv.2022.154859.

Appendix A. Supplementary data

Supplementary material for: Life cycle assessment of battery electric vehicles: implications of future electricity mix and different battery end-of-life management

References

- ACEA . European Automobile Manufacturers Association; 2019. ACEA Report: Vehicles in use - Europe 2019. [Google Scholar]

- ACEA What is WLTP: the Worldwide Harmonised Light Vehicle Test Procedure? | WLTPfacts.eu | An initiative of the European Automobile Manufacturers’ Association. 2019. https://www.acea.auto/ accessed 4.3.20.

- ACEA Fuel types of new cars: battery electric 7.5%, hybrid 19.3%, petrol 41.8% market share in Q2 2021. Eur. Automob. Manuf. Assoc. 2021. https://www.acea.auto/ accessed 10.28.21.

- Ahmadi L., Fowler M., Young S.B., Fraser R.A., Gaffney B., Walker S.B. Energy efficiency of Li-ion battery packs reused in stationary power applications. Sustain. Energy Technol. Assess. 2014;8:9–17. doi: 10.1016/j.seta.2014.06.006. [DOI] [Google Scholar]

- Ahmadi L., Yip A., Fowler M., Young S.B., Fraser R.A. Environmental feasibility of reuse of electric vehicle batteries. Sustain. Energy Technol. Assess. 2014;6:64–74. doi: 10.1016/j.seta.2014.01.006. [DOI] [Google Scholar]

- Ahmadi L., Young S.B., Fowler M., Fraser R.A., Achachlouei M.A. A cascaded life cycle: reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017;22:111–124. doi: 10.1007/s11367-015-0959-7. [DOI] [Google Scholar]

- Bauer C., Hofer J., Althaus H.J., Del Duce A., Simons A. The environmental performance of current and future passenger vehicles: life cycle assessment based on a novel scenario analysis framework. Appl. Energy. 2015;157:871–883. doi: 10.1016/j.apenergy.2015.01.019. [DOI] [Google Scholar]

- Birkl C.R., Roberts M.R., McTurk E., Bruce P.G., Howey D.A. Degradation diagnostics for lithium ion cells. J. Power Sources. 2017;341:373–386. doi: 10.1016/j.jpowsour.2016.12.011. [DOI] [Google Scholar]

- Bobba S., Mathieux F., Ardente F., Blengini G.A., Cusenza M.A., Podias A., Pfrang A. Life cycle assessment of repurposed electric vehicle batteries: an adapted method based on modelling energy flows. J. Energy Storage. 2018;19:213–225. doi: 10.1016/j.est.2018.07.008. [DOI] [Google Scholar]

- BRUSA BRUSA Elektronik AG. 2019. https://www.brusa.biz/en.html accessed 3.19.19.

- Casals L.C., García B.A., Aguesse F., Iturrondobeitia A. Second life of electric vehicle batteries: relation between materials degradation and environmental impact. Int. J. Life Cycle Assess. 2017;22:82–93. doi: 10.1007/s11367-015-0918-3. [DOI] [Google Scholar]

- Casals L.C., Amante García B., Canal C. Second life batteries lifespan: rest of useful life and environmental analysis. J. Environ. Manag. 2019;232:354–363. doi: 10.1016/j.jenvman.2018.11.046. [DOI] [PubMed] [Google Scholar]

- Chancerel P., Marwede M. 2016. Feasibility Study for Setting-up Reference Values to Support the Calculation of Recyclability/Recoverability Rates of Electr(on)ic Products. [DOI] [Google Scholar]

- Chen Y., Ding Z., Liu J., Ma J. Life cycle assessment of end-of-life vehicle recycling in China: a comparative study of environmental burden and benefit. Int. J. Environ. Stud. 2019;76:1019–1040. doi: 10.1080/00207233.2019.1618670. [DOI] [Google Scholar]

- Cicconi P., Landi D., Morbidoni A., Germani M. 2nd IEEE ENERGYCON Conference & Exhibition, 2012/Sustainable Transportation Systems Symposium. Florence, Italy. 2012. Feasibility analysis of second life applications for li-ion cells used in electric powertrain using environmental indicators; pp. 985–990. [DOI] [Google Scholar]

- Colvile R.N., Hutchinson E.J., Mindell J.S., Warren R.F. The transport sector as a source of air pollution. Atmos. Environ. 2001;35:1537–1565. doi: 10.1016/S1352-2310(00)00551-3. [DOI] [Google Scholar]

- Cox B., Mutel C.L., Bauer C., Mendoza Beltran A., Van Vuuren D.P. Uncertain environmental footprint of current and future battery electric vehicles. Environ. Sci. Technol. 2018;52:4989–4995. doi: 10.1021/acs.est.8b00261. [DOI] [PubMed] [Google Scholar]

- Cox B., Bauer C., Mendoza Beltran A., van Vuuren D.P., Mutel C.L. Life cycle environmental and cost comparison of current and future passenger cars under different energy scenarios. Appl. Energy. 2020;269 doi: 10.1016/j.apenergy.2020.115021. [DOI] [Google Scholar]

- Cusenza M.A., Bobba S., Ardente F., Cellura M., Di Persio F. Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles. J. Clean. Prod. 2019;215:634–649. doi: 10.1016/j.jclepro.2019.01.056. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cusenza M.A., Guarino F., Longo S., Mistretta M., Cellura M. Reuse of electric vehicle batteries in buildings: an integrated load match analysis and life cycle assessment approach. Energy Build. 2019;186:339–354. doi: 10.1016/j.enbuild.2019.01.032. [DOI] [Google Scholar]

- Dai Q., Kelly C.J., Dunn J., Benavides T.P. U.S. Department of Energy; Chicago: 2018. Update of bill-of-materials and cathode materials oroduction for Lithium-ion batteries in the GREET model. [Google Scholar]

- EcarACCU The journey of refurbished EV battery cells. https://ecaraccu.nl/refurbished/ 2017 accessed 9.24.21. [Google Scholar]

- Ecoinvent The ecoinvent Database. 2019. https://www.ecoinvent.org/database/database.html accessed 4.10.19.

- Ecoscore Ecoscore: the environmental impact of your car. 2019. https://ecoscore.be/en/info/ecoscore accessed 5.4.19.

- EEA Greenhouse gas emissions from transport in Europe. 2020. https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases-7/assessment accessed 2.22.21.

- Eftekhari A. Energy efficiency: a critically important but neglected factor in battery research. Sustain. Energy Fuels. 2017;1:2053–2060. doi: 10.1039/c7se00350a. [DOI] [Google Scholar]

- Ellingsen L.A.W., Majeau-Bettez G., Singh B., Srivastava A.K., Valøen L.O., Strømman A.H. Life cycle assessment of a Lithium-ion battery vehicle pack. J. Ind. Ecol. 2014;18:113–124. doi: 10.1111/jiec.12072. [DOI] [Google Scholar]

- EU Directive 2000/53/CE of the European Parliament and of the Council of 18 September 2000 on end-of life vehicles. Off. J. Eur. Communities L. 2000;269:34. [Google Scholar]

- EU Directive 2006/66/CE of the European Parliament and of the Council of 6 september 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC. Off. J. Eur. Union L. 2006;266(1) [Google Scholar]

- European Commission . European Commission; Brussels: 2019. The European Green Deal. [Google Scholar]

- European Commission A new circular economy action plan: for a cleaner and more competitive Europe. 2020. https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN

- Faria R., Marques P., Garcia R., Moura P., Freire F., Delgado J., De Almeida A.T. Primary and secondary use of electric mobility batteries from a life cycle perspective. J. Power Sources. 2014;262:169–177. doi: 10.1016/j.jpowsour.2014.03.092. [DOI] [Google Scholar]

- Fitchsolutions EV battery chemistry outlook: high-Nickel NMC & LFP cathode types to gain market share, NM & ASSBs eventual market disruptors. 2021. https://www.fitchsolutions.com/

- Gerssen-Gondelach S.J., Faaij A.P.C. Performance of batteries for electric vehicles on short and longer term. J. Power Sources. 2012;212:111–129. doi: 10.1016/j.jpowsour.2012.03.085. [DOI] [Google Scholar]

- Hawkins T.R., Gausen O.M., Strømman A.H. Environmental impacts of hybrid and electric vehicles – a review. Int. J. Life Cycle Assess. 2012;17:997–1014. doi: 10.1007/s11367-012-0440-9. [DOI] [Google Scholar]

- Hill N., Amaral S., Morgan-Price S., Nokes T., Bates J., Helms H., Fehrenbach H., Biemann K., Abdalla N., Jöhrens J., Cotton E., German L., Harris A., Haye S., Sim C., Bauen A. European Union; Luxembourg: 2020. Determining the environmental impacts of conventional and alternatively fuelled vehicles through LCA. [DOI] [Google Scholar]

- Hooftman N., Oliveira L., Messagie M., Coosemans T., Van Mierlo J. Environmental analysis of petrol, diesel and electric passenger cars in a Belgian urban setting. Energies. 2016;9:1–24. doi: 10.3390/en9020084. [DOI] [Google Scholar]

- Hossain E., Member S., Murtaugh D., Mody J., Mansur H., Faruque R., Sunny S.H. A comprehensive review on second-life batteries: current state, manufacturing considerations, applications, impacts, barriers & potential solutions, business strategies, and policies. IEEE Access. 2019;7:73215–73252. doi: 10.1109/ACCESS.2019.2917859. [DOI] [Google Scholar]

- Huijbregts M.A.J., Steinmann Z.J.N., Elshout P.M.F., Stam G., Verones F., Vieira M., Zijp M., Hollander A., van Zelm R. ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017;22 doi: 10.1007/s11367-016-1246-y. [DOI] [Google Scholar]

- IEA . OECD Publishing; Paris: 2019. World Energy Outlook 2019, World Energy Outlook 2019. [DOI] [Google Scholar]

- IEA . International Energy Agency; Paris: 2020. Tracking transport 2020. [Google Scholar]

- IPCC . Intergovernmental Panel on Climate Change; Geneva, Switzerland: 2018. Global warming of 1.5°c: an ipcc special report on the impacts of global warming of 1.5°c above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change. [Google Scholar]

- ISO . International Organization for Standardization; Geneva: 2006. 140 44 Environmental management - Life Cycle Assessment - requirements and guidelines. [Google Scholar]

- ISO . International Organization for Standardization; Geneva: 2006. 14040 Environmental management - Life Cycle Assessment - principles and framework. [Google Scholar]

- Koh S.C.L., Smith L., Miah J., Astudillo D., Eufrasio R.M., Gladwin D., Brown S., Stone D. Higher 2nd life lithium titanate battery content in hybrid energy storage systems lowers environmental-economic impact and balances eco-efficiency. Renew. Sust. Energ. Rev. 2021;152 doi: 10.1016/j.rser.2021.111704. [DOI] [Google Scholar]

- Koptyug E. Electric cars: charging frequency in Germany 2019 | Statista. 2020. https://www.statista.com/statistics/1180985/electric-cars-charging-frequency-germany/ accessed 9.27.21.

- Koroma M.S., Brown N., Cardellini G., Messagie M. Prospective environmental impacts of passenger cars under different energy and steel production scenarios. Energies. 2020;13:6236. doi: 10.3390/en13236236. [DOI] [Google Scholar]

- Lebedeva N., Persio F.Di, Boon-Brett L. Lithium ion battery value chain and related opportunities for Europe. Brussels. 2016 doi: 10.2760/6060. [DOI] [Google Scholar]

- Liao Q., Mu M., Zhao S., Zhang L., Jiang T., Ye J., Shen X., Zhou G. Performance assessment and classification of retired lithium ion battery from electric vehicles for energy storage. Int. J. Hydrog. Energy. 2017;42:18817–18823. doi: 10.1016/j.ijhydene.2017.06.043. [DOI] [Google Scholar]

- Majeau-Bettez G., Dandres T., Pauliuk S., Wood R., Hertwich E., Samson R., Strømman A.H. Choice of allocations and constructs for attributional or consequential Life Cycle Assessment and input-output analysis. J. Ind. Ecol. 2018;22:656–670. doi: 10.1111/jiec.12604. [DOI] [Google Scholar]

- Marmiroli B., Messagie M., Dotelli G., Van Mierlo J. Electricity generation in LCA of electric vehicles: a review. Appl. Sci. 2018;8:1–35. doi: 10.3390/app8081384. [DOI] [Google Scholar]

- Martinez-Laserna E., Gandiaga I., Sarasketa-Zabala E., Badeda J., Stroe D.I., Swierczynski M., Goikoetxea A. Battery second life: hype, hope or reality? A critical review of the state of the art. Renew. Sust. Energ. Rev. 2018;93:701–718. doi: 10.1016/j.rser.2018.04.035. [DOI] [Google Scholar]

- Messagie M., Boureima F.S., Coosemans T., Macharis C., Mierlo J.Van. A range-based vehicle Life Cycle Assessment incorporating variability in the environmental assessment of different vehicle technologies and fuels. Energies. 2014;7:1467–1482. doi: 10.3390/en7031467. [DOI] [Google Scholar]

- Miri I., Fotouhi A., Ewin N. Electric vehicle energy consumption modelling and estimation – a case study. Int. J. Energy Res. 2020;45:501–520. doi: 10.1002/er.5700. [DOI] [Google Scholar]

- Nordelöf A. A scalable life cycle inventory of an automotive power electronic inverter unit – part II: manufacturing processes. Int. J. Life Cycle Assess. 2018;24:694–711. doi: 10.1007/s11367-018-1491-3. [DOI] [Google Scholar]

- Nordelöf A., Tillman A.M. A scalable life cycle inventory of an electrical automotive traction machine—part II: manufacturing processes. Int. J. Life Cycle Assess. 2017;23:295–313. doi: 10.1007/s11367-017-1309-8. [DOI] [Google Scholar]

- Nordelöf A., Messagie M., Tillman A.M., Ljunggren Söderman M., Van Mierlo J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles – what can we learn from Life Cycle Assessment? Int. J. Life Cycle Assess. 2014;19:1866–1890. doi: 10.1007/s11367-014-0788-0. [DOI] [Google Scholar]

- Nordelöf A., Grunditz E., Tillman A.M., Thiringer T., Alatalo M. A scalable Life Cycle Inventory of an electrical automotive traction machine – Part I: design and composition. Int. J. Life Cycle Assess. 2017;23:55–69. doi: 10.1007/s11367-017-1308-9. [DOI] [Google Scholar]

- Nordelöf A., Alatalo M., Söderman M.L. A scalable Life Cycle Inventory of an automotive power electronic inverter unit – part I: design and composition. Int. J. Life Cycle Assess. 2018;24:78–92. doi: 10.1007/s11367-018-1503-3. [DOI] [Google Scholar]

- Peters J.F., Baumann M., Zimmermann B., Braun J., Weil M. The environmental impact of Li-Ion batteries and the role of key parameters – a review. Renew. Sust. Energ. Rev. 2017;67:419–506. doi: 10.1016/j.rser.2016.08.039. [DOI] [Google Scholar]

- Pillot C. The Rechargeable Battery Market and Main Trends. 2017. pp. 2012–2025. [Google Scholar]

- Podias A., Pfrang A., Di Persio F., Kriston A., Bobba S., Mathieux F., Messagie M., Boon-Brett L. Sustainability assessment of second use applications of automotive batteries: ageing of Li-ion battery cells in automotive and grid-scale applications. World Electr. Veh. J. 2018;9 doi: 10.3390/wevj9020024. [DOI] [Google Scholar]

- Pre-sustainability . Pre-sustainability; 2022. 2022. SimaPro | LCA software for informed change-makers.https://simapro.com/ [Google Scholar]

- Qi Z., Yang J., Jia R., Wang F. Investigating real-world energy consumption of electric vehicles: a case study of Shanghai. Procedia Comput. Sci. 2018;131:367–376. doi: 10.1016/j.procs.2018.04.176. [DOI] [Google Scholar]

- Redondo-Iglesias E., Venet P., Pelissier S. Efficiency degradation model of lithium-ion batteries for electric vehicles. IEEE Trans. Ind. Appl. 2019;55:1932–1940. doi: 10.1109/TIA.2018.2877166. [DOI] [Google Scholar]

- Renault New ZOE - Dimensions & Specifications - Renault UK. 2019. https://www.renault.co.uk/electric-vehicles/zoe/specifications.html accessed 4.3.20.

- Richa K., Babbitt C.W., Nenadic N.G., Gaustad G. Environmental trade-offs across cascading lithium-ion battery life cycles. Int. J. Life Cycle Assess. 2015;22:66–81. doi: 10.1007/s11367-015-0942-3. [DOI] [Google Scholar]

- Sathre R., Scown C.D., Kavvada O., Hendrickson T.P. Energy and climate effects of second-life use of electric vehicle batteries in California through 2050. J. Power Sources. 2015;288:82–91. doi: 10.1016/j.jpowsour.2015.04.097. [DOI] [Google Scholar]

- Schulz M., Bey N., Niero M., Hauschild M. Circular economy considerations in choices of LCA methodology: how to handle EV battery repurposing? Procedia CIRP. 2020;90:182–186. doi: 10.1016/j.procir.2020.01.134. [DOI] [Google Scholar]

- Schulz-Mönninghoff M., Bey N., Nørregaard P.U., Niero M. Integration of energy flow modelling in life cycle assessment of electric vehicle battery repurposing: evaluation of multi-use cases and comparison of circular business models. Resour. Conserv. Recycl. 2021;174 doi: 10.1016/j.resconrec.2021.105773. [DOI] [Google Scholar]

- Schweimer G.W., Levin M. Life Cycle Inventory for the Golf A4. Volkswagen Group; Univeristy of Kassel: 2000. pp. 1–40. [Google Scholar]

- Teehan P., Kandlikar M. Comparing embodied greenhouse gas emissions of modern computing and electronics products. Environ. Sci. Technol. 2013;47:3997–4003. doi: 10.1021/es303012r. [DOI] [PubMed] [Google Scholar]

- Van Mierlo J., Berecibar M., El Baghdadi M., De Cauwer C., Messagie M., Coosemans T., Jacobs V.A., Hegazy O. Beyond the state of the art of electric vehicles: a fact-based paper of the current and prospective electric vehicle technologies. World Electr. Veh. J. 2021;12:20. doi: 10.3390/wevj12010020. [DOI] [Google Scholar]

- Wang H.J., Wang B., Fang C., Li W., Huang H.W. Charging load forecasting of electric vehicle based on charging frequency. IOP Conf. Ser. Earth Environ. Sci. 2019;237 doi: 10.1088/1755-1315/237/6/062008. [DOI] [Google Scholar]

- Warner J. The Handbook of Lithium-Ion Battery Pack Design. Elsevier; Amsterdam, The Netherlands: 2015. Second life and recycling of lithium-ion batteries; pp. 169–176. [Google Scholar]

- Wernet G., Bauer C., Steubing B., Reinhard J., Moreno-Ruiz E., Weidema B., Zah R., Wernet Wernet G. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 2016;21:1218–1230. doi: 10.1007/s11367-016-1087-8. [DOI] [Google Scholar]

- Winjobi O., Dai Q., Kelly J.C. 2020. Update of Bill-of-materials and Cathode Chemistry Addition for Lithium-ion Batteries in GREET 2020. Chicago. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material for: Life cycle assessment of battery electric vehicles: implications of future electricity mix and different battery end-of-life management