Abstract

Part load ratio is often observed in real operations of airport terminal cooling system. This phenomenon is more obvious during the COVID-19 pandemic, as sudden flight restrictions impacting cooling demand are widely adopted in hub airport terminals. This research aims to propose optimal strategies of multi-chiller in airport terminals based on cooling load characteristics modeling, to tackle the aforementioned issues. Numerical experiments based on a real-world Chinese airport terminal are conducted to validate the proposed method. The results show that an average cooling load drop of 30% is observed from scenario of normal flight before COVID-19 to scenario of COVID-19 Period flight, and the average cooling load drop reaches to 44% from scenario of busy flight before COVID-19 to scenario of COVID-19 Period flight. The results also reflect that cooling load presents synchronous trend with passenger flow, but presents asynchronous trend with outdoor temperature. The influence of outdoor temperature on cooling demand delays due to building envelops. It indicates that simple superimposition according to passenger flow change for chiller operation number is reliable, efficient and effective, but is not suitable for outdoor temperature change. The findings are helpful to develop optimal strategies for further real-time control of multi-chiller.

Keywords: COVID-19 pandemic, Airport terminal, Optimal strategy, Energy efficiency, Cooling load characteristics

Nomenclature

- Qdemand

Cooling demand of consumers, W.

- α1

Coefficient of heat transfer through building envelops

- α2

Coefficient of heat transfer from outdoor air

- α3

Coefficient of indoor heat sources

- α4

Coefficient of indoor temperature change index

- α5

Coefficient of indoor comprehensive heat storage

- T

Indoor air temperature, °C

- t

Time.

- T0

Initial temperature of indoor air, °C

- kj

Heat transfer coefficients of the envelop surface j, W/(m2∙K)

- Aj

Heat transfer area of the envelop surface j, m2

- Tout

Outdoor air temperature, °C

- ε

Coefficients of envelop surface thermal performance

- C

Constant parameter of envelop surface thermal performance

- n

Air exchange rate, times/h

- ρ

Air density, kg/m3

- ca

Specific heat, kJ/(kg∙K)

- V

Volume of airport terminal building, m3

- np

Number of occupants

- Qp

Single-person heat production, W.

- Qd

Heat production of equipments, W.

- Qch

Cooling load of chiller, kW

- Qchmax

Maximum rated cooling capacity of chiller, kW

- Tc

Condensing temperature, °C

- Te

Evaporating temperature, °C

- Tref

Reference temperature of thermal comfort, °C

- σ1

Coefficients related to the performance of chiller

- σ2

Coefficients related to the performance of chiller

- Tchs

Temperature of chilled water supply, °C

- Tcos

Temperature of cooling water supply, °C

- mch

Mass flow rate of chilled water, kg/s

- mco

Mass flow rate of cooling water, in kg/s

- ζ1

Coefficients related to the performance of chiller

- ζ2

Coefficients related to the performance of chiller

- ξ1

Coefficients related to the performance of chiller

- ξ2

Coefficients related to the performance of chiller

- μ

Coefficient of thermal discomfort

Acronyms

- SLSQP

Sequential least squares programming algorithm

- PLR

Partial load rate of chiller

1. Introduction

In recent 20 years, the building cooling load in China has been growing at an average annual rate of 13% [1], and the energy consumption of building cooling system has accounted for more than 15% of the national gross energy consumption [2]. In particular, cooling demand for district cooling system (DCS) in hub airport terminals and building complex is huge and developing rapidly [[3], [4], [5]]. There were 229 municipal airports in mainland China in 2017, while this number will increase to be more than 400 by the end of 2035 [6]. DCS in buildings sets up one or more cooling plants to centralize the production of chilled water that is then conveyed to each cooling area [7,8]. Hub airport terminal is a special type of building with large dimension, high ceiling and large area of glazing envelope. Cooling load characteristics of time-space imbalance exist in the DCS of airport terminals. The cooling load can thus be easily fluctuated by influential factor of outdoor temperature. The people flow is another distinctive factor for cooling demand in hub airport terminals. It is difficult to obtain the relationship between cooling demand and cooling supply in DCS real operations, as these factors dynamically change. Because of this reason, part load ratio (PLR) operations of airport terminal cooling system which are often observed in real operations, will greatly influence the coefficient of performance (COP) of chillers. This phenomenon is more obvious during the COVID-19 pandemic, as sudden flight restrictions are widely adopted in hub airport terminals. Therefore, it is necessary to optimize cooling load adaptively on the basis of accurate cooling demand model, to provide reliable, efficient and effective strategical schedules for multi-chiller operations.

For a DCS in hub airport terminals, there is an optimal operation strategy, which keeps operational energy consumption the lowest. However, to obtain this strategy is quite challenging. In order to satisfy cooling load changes for airport terminals, chillers need closely follow the cooling load changes, and make adjustments (e.g., switch on or off) accordingly. The dynamic adjustments of chiller operation will directly lead to constant changes of cooling supply and energy consumption. Therefore, corresponding to dynamic changes of cooling demand, optimal strategies are scheduled to minimize energy consumption on the basis of thermal comfort, and to ensure stable operation at the optimal conditions, based on reliable cooling load characteristics.

Actually, in the designing stage of terminal DCS, great importance have been attached to operational energy efficiency by adopting efficient chillers [9,10]. For example, variable speed drive (VSD) applied to chillers is an effective method to improve the energy performance of single chiller, especially at low part load ratios [11]. A variety of technical schemes are proposed and compared to obtain the most suitable design scheme for the DCS [12]. However, in real operations, it is often observed that the system deviates from the expected energy saving effect proposed in designing. According to an energy consumption survey on 19 Chinese hub airport terminals from 2012 to 2014, the average annual power consumption of per unit area on the terminal building is 177 kWh/(m2·a) [13], while the constraint value is less than 140 kWh/(m2·a) under related Chinese standards [14,15]. The problem mainly lies in that the system operation deviates from the designing conditions, under dynamic changes of both outdoor climate and indoor influential factors (e.g., passenger flow). Thus, how to keep DCS operating in high performance status is a key focus in energy efficiency of hub airport terminals. It is essential that the cooling load characteristics is accurately formulated to satisfy cooling consumers avoiding thermal comfort complaints and to optimize operational energy consumption. Therefore, this research aims to investigate the optimal strategies of terminal cooling system based on accurate modeling of cooling load characteristics, to provide references for the operation control of terminal DCS during COVID-19 pandemic period.

2. Operation control strategies for hub airport terminals

2.1. Overviews of DCS operation control in terminals

A typical DCS in hub airport terminals mainly consists of four parts, i.e., cooling plant, chilled water loop, cooling water loop and ancillary facility. The functions for the four parts are cooling producer, cooling supply, heat rejection and cooling consumers, respectively. The main power consumption components in the four parts are, chiller, chilled water pump (including supply system and return system), cooling water pump and cooling tower, and fan coil. The cooling is produced in the chiller in the form of chilled water. The chilled water is then dispatched by supply pump through networks to the terminal buildings. Water separator and water catchment are set in the chilled water supply system and return system, respectively. The chilled supply water heat exchanges with air in fan coil and the air is supplied into the room/building function. The chilled water after heat exchange returns to chiller by return pump. The heat gain in chiller is dissipated through cooling water pump to cooling tower which heat exchanges with outdoor air.

At present, a prevailing control strategy is that the set values of control variables of cooling system in terminals are all fixed or partially fixed values, e.g., constant supply and return temperature of chilled water and cooling water in variable flow rate system, constant flow rate of chilled water and cooling water in constant flow rate system, constant flow rate of cooling tower, constant supply air temperature in variable air volume (VAV) system [16,17]. The constant settings of system control make the DCS equipments deviate from the optimal operation status in dynamic conditions, and thus increase power consumption. Moreover, optimal control based on dynamic cooling load change is quite challenging, as time lag and system instability often exists [18,19]. In most previous researches, their focus is to study the optimal operation strategy of single energy consumption equipment such as chiller [20] and fan coil [21], while the cooling load characteristics are not fully considered in the problem formulation. In addition, the DCS of airport terminal is mostly driven by multi-chiller in real operation [22]. Energy performance of single-chiller cannot guarantee the comprehensive energy efficiency of multi-chiller system, as the chiller is coupled set with other energy consuming components (e.g., pump, cooling tower). Thus, how to analyze and formulate the system cooling load, and then connect with the optimal method is significant to avoid performance gaps between modeling results and actual operations.

2.2. Control methods in real operation of chillers

The DCS in hub airport terminals are normally set in multi-chiller system, because of limited cooling capacity of single chiller and huge cooling demand of terminal buildings. Multi-chiller system with equal or various cooling capacity can thus provide flexible cooling to match with consumers' demand of terminal buildings. For the multi-chiller system set with equal capacity, the chillers are sequentially switched on/off according to consumers' cooling demand [23]. The optimal strategy of chiller switch-point is generally obtained based on the coefficient of performance of chiller (i.e. COP) at different part load ratio (PLR) [24]. For the multi-chiller system set with different capacity, the optimal strategy is more complex, as the chiller sequencing control is based on matching optimal chiller cooling capacity and the optimal cooling load [25]. Currently, the chiller operation methods in hub airport terminals mainly include three strategies, i.e., optimal cooling load control, optimal sequencing control and optimal COP control [[26], [27], [28]]. In optimal cooling load control, the operation strategy is scheduled based on the cooling load combined with cooling capacity of chillers [29]. The control logic of this strategy is to increase or decrease the operation number of chillers with cooling load changes. The chillers are sequentially switched on/off according to the relationship between hourly cooling load and corresponding cooling capacity of the chillers. In optimal sequencing control, a preliminary operation schedule of chiller sequencing is made based on the estimation of the annual cooling load distribution [30]. In scheduling chiller sequencing, the operation duration of each chiller is relatively uniform on the basis of guaranteeing the indoor temperature of terminal buildings. A daily strategy including regular operation chillers and auxiliary operation chillers is monthly arranged. The regular chillers operate in the set durations, and the auxiliary chillers are switched on when the cooling load is increased to provide enough cooling for buildings [31]. In optimal COP control, the cooling load is adjusted by changing the supply temperature of chilled water and the return temperature of cooling water, under the calculation of maximum COP which is based on the COP-PLR curve of chillers [32]. The optimal control of DCS in airport terminals can be achieved through the adjustments of water temperature settings when the COP of chillers reaches to the maximum value. However, in the water temperature control of chillers, when the supply temperature of chilled water and the return temperature of cooling water are constantly set, the values of COP change with the variations of cooling load. The optimal COP value of chiller which normally does not appear at full-load condition, may flexibly fluctuate in a range (e.g., 70%–80%) of PLR curve [33,34]. The control logic for chiller sequencing/switch on/off control and water temperature control is to reach to the optimal COP value and obtain the optimal operation cost, on the basis of cooling load characteristics and cooling demand satisfaction.

2.3. Cooling load characteristics of terminal buildings

In a typical airport terminal, the cooling load characteristics may vary in demand time and magnitude demand. An accurate and reliable cooling load modeling or descriptive analysis is significant to energy efficiency and to avoid thermal comfort complaints due to overcooling or cooling load deficiency [35]. As the real optimal operations of DCS in terminal buildings are nonlinear and nonconvex problems, the cooling load characteristics are essential to optimization problem formulation. For the cooling load characteristics analysis, there are two major methods, i.e. cooling load modeling/calculation and cooling load baseline description [36,37].

The cooling load modeling/calculation is to describe cooling load distribution by mathematical model, experiential calculation and data driven method [38]. A typical approach of mathematical model is Demand Aggregation Method of Building-scale User (DAMBU) [39], which is based on the Law of Energy Conservation, to calculate the energy changes of building-scale and to obtain the relationship between cooling supply and indoor temperature. Equivalent Thermal Parameters (ETP) [40] is widely used through experiential calculation to describe the cooling load. The environmental parameters (e.g., temperature and humidity) and thermal parameters of building materials (e.g., thermal conductivity, surface heat transfer coefficient, thermal resistance and heat storage coefficient), air leakage and cooling capacity, etc. are equivalent to circuit related parameters (e.g., resistance, capacitance and power supply) in ETP. The mathematical model of cooling load description is not given in the data driven method. Based on the input variables of historical data (e.g., heat source, environmental parameters and occupancy), the nonlinear dynamic model of cooling load under various disturbances is established by mixed integer linear program [41] and deep reinforcement learning [42].

The cooling load baseline description is to set the cooling load of designing status as operation baseline, and to make adjustments in different operation conditions, e.g., different month, and different time of a day. The cooling load adjustments are normally calculated by PLR. The control of cooling load baseline is more adopted in real operation of terminals, as it is more flexible to the operation strategies mentioned above. For instance, the cooling capacity of designing status is chosen according to the baseline of cooling demand in July, the operational PLR in April may be much lower. Implementing chiller sequencing at all times will increase the average PLR from 65% (61.73% of the total operating time in under-load conditions) to 78% with a 15.81% reduction in the energy consumption observed [43]. The variations may exist in different months, daytime and night, different occupancy (flight arrangements), and different function areas. Thus, it is essential to obtain the cooling load characteristics of typical control baselines (e.g., outdoor temperature and passenger flow in airport terminals) for corresponding operation strategies.

2.4. Optimal control formulation

The optimization proposed in this research is comprised of two targets, one is to maximize the operational COP of multi-chiller system and to guarantee indoor thermal comfort in terminals. A three-stage programming including cooling load characteristics description, chiller operational COP/power consumption modeling and problem formulation is employed to formulate the schedule problem of DCS operation in terminal buildings.

Firstly, cooling demand characteristics of terminals are described based on the cooling load distribution modeling, as presented in Eqs. (1), (2), (3), (4), (5), (6).

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

where, Qdemand is the cooling demand of consumers, in W. α1-α5 are coefficients. α1 is the coefficient of heat transfer through building envelops; α2 is the coefficient of heat transfer from outdoor air; α3 is the coefficient of indoor heat sources, including indoor equipment power and occupancy (passenger flow); α4 is the coefficient of indoor temperature change index; α5 is the coefficient of indoor comprehensive heat storage. T is the indoor air temperature, in °C. t is time. T0 is the initial temperature of indoor air, in °C. kj, Aj are the heat transfer coefficients (in W/(m2∙K)) and the heat transfer area (in m2) of the envelop surface j, respectively. Tout is the outdoor air temperature, in °C. ε, C are the coefficients and the constant parameter of envelop surface thermal performance, respectively. n is the air exchange rate, in times/h. ρ is the air density, in kg/m3. ca is the specific heat, in kJ/(kg∙K). V is the volume of airport terminal building, in m3. np, Qp are the number and the single-person heat production (in W) of occupants, respectively. Qd is the heat production (in W) of equipments, respectively.

From the cooling load model above, it shows that most of the influential factors are constant coefficients for an existing airport terminal. The cooling load mainly fluctuates by dynamic influential factors of outdoor temperature and indoor occupancy (passenger flow). Therefore, it is essential to obtain the relationships between these two factors and cooling load for terminal chiller operation.

Secondly, The comprehensive operational coefficient of performance (COP) and the energy consumption of chiller are formulated, as given in Eqs. (7), (8), (9).

| (7) |

| (8) |

| (9) |

where, PLR is the partial load rate of chiller, which is defined as the ratio of cooling load (Qch) to the maximum rated cooling capacity (Qch max) of chiller. Cooling load (Qch) is combined with the cooling demand (Qdemand) and cooling loss during transportation which is assumed to be 10% of cooling demand [44]. Tc and Te are the condensing temperature and evaporating temperature, respectively, which can be calculated as follows in Eqs. (10), (11), (12). σ1 and σ2 are coefficients related to the performance of chiller.

| (10) |

| (11) |

| (12) |

where, Tchs and Tcos are the temperature of chilled water supply and cooling water supply, respectively, in °C. mch and mco are the mass flow rate of chilled water and cooling water, respectively, in kg/s. ζ1, ζ2, ξ1 and ξ2 are coefficients related to the performance of chiller.

Thirdly, the optimization problem of maximizing the operational COP of chillers and minimizing thermal discomfort together with constraints (e.g., thermal balance and equipment limits) are formulated, as presented in Eqs. (13), (14), (15), (16), (17), (18), (19), (20). In the formulation of thermal discomfort, reference temperature of thermal comfort (Tref) is used. Coefficient of thermal discomfort (μ) is adopted to describe the weighting of operational cost for maintaining indoor thermal comfort of terminal cooling system. To solve the problem formulation, the sequential least squares programming algorithm (SLSQP) is employed. SLSQP optimizer using the Han–Powell quasi–Newton method with a Broydon-Fletcher-Goldfarb-Shanno (BFGS) update of the B–matrix and an L1–test function in the step–length algorithm, based on a slightly modified version of Lawson and Hanson's nonlinear least-squares solver, which can accurately and efficiently deal with operation problems with constraints [45]. The model is further validated in a case-study of Chinese hub airport terminal.

Objective

| (13) |

subject to:

Thermal balance

Thermal comfort

-

(2)

Indoor air temperature

| (14) |

Equipment limits

-

(3)

Cooling capacity of chiller

| (15) |

-

(4)

Chilled water supply temperature

| (16) |

-

(5)

Cooling water supply temperature

| (17) |

-

(6)

Mass flow rate of chilled water pump

| (18) |

-

(7)

Mass flow rate of cooling water pump

| (19) |

-

(8)

Coefficient of thermal discomfort

| (20) |

3. Case study

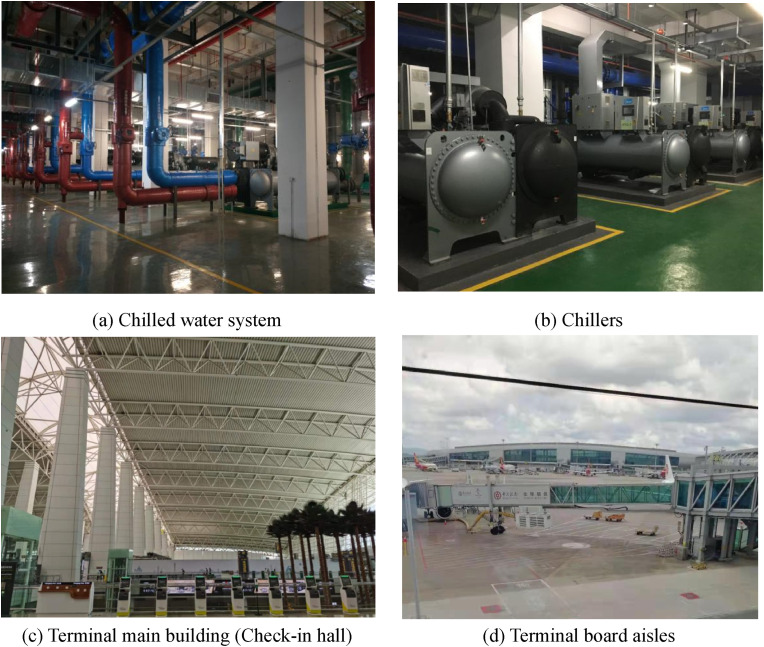

Numerical experiments are conducted to validate the proposed methodology based on a real DCS system of a hub airport terminal in China. The airport terminal is comprised of terminal main building and terminal board aisles (west and east), as presented in Fig. 1 . The annual passenger flow is about 40 million before the COVID-19 pandemic (in 2019) and is about 24 million after the COVID-19 pandemic (in 2020). As a primary-secondary system, the DCS with 24 chillers provides cooling for different the functions of airport terminal, such as check-in hall, departure hall, security area, baggage claim area and office area, etc. The total cooling capacity of the 24 chillers with three kinds of cooling capacity (i.e., 14 × 7034 kW, 6 × 3517 kW, 4 × 1530 kW) is 125698 kW (35740 RT). The detailed information for the terminal DCS is presented in Table 1 and Fig. 2 , respectively.

Fig. 1.

Floor plan of the airport terminal.

Table 1.

Detailed design information for the terminal DCS.

| Area | Cooling capacity of chiller | Chilled water supply/return temperature (°C) | Cooling water supply/return temperature (°C) | Mass flow rate of chilled water (m3/h) | Mass flow rate of cooling water (m3/h) | Power of chiller (kW) | Coefficient of performance (COP) | Design indoor temperature | Cooling load (W/m2) |

|---|---|---|---|---|---|---|---|---|---|

| 480800 m2 of cooling area, 671600 m2 of terminal area | 14 × 7034 kW (2000 RT) | 7/15 | 37/32 | 756 | 1511 | 1256 | ≧5.6 | 25 °C | 261 |

| 6 × 3517 kW (1000 RT) | 7/15 | 37/32 | 378 | 755 | 628 | ≧5.6 | |||

| 4 × 1530 kW (435 RT) | 7/15 | 37/32 | 165 | 329 | 273 | ≧5.4 |

Fig. 2.

Typical pictures of the terminal structures and the cooling systems.

3.1. Variables and parameters

3.1.1. Environmental parameters

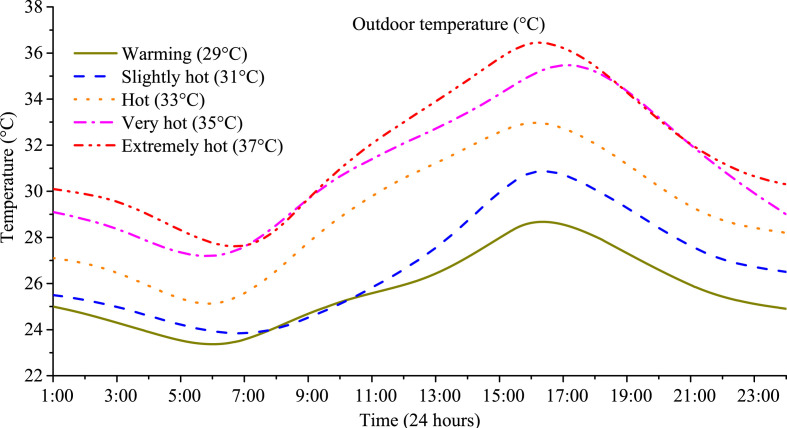

The airport is located in an ocean city of Southeastern China. It is a typical city of hot and humid climate. Based on the local outdoor climate, five typical outdoor temperatures are selected as reference baselines for warming (29 °C), slightly hot (31 °C), hot (33 °C), very hot (35 °C), and extreme hot (37 °C), respectively, as presented in Fig. 3 . Temperature range of 23–27 °C is set as thermal comfort zone and temperature of 25 °C is set as the reference comfortable temperature based on the design parameter.

Fig. 3.

Hourly outdoor temperature in different levels.

3.1.2. Occupancy (passenger flow)

As one of the biggest passenger transportation terminal hub of the world, the annual passenger flow is about 40 millions in 2019, and drops by 40% in 2020 due to the impact of COVID-19 Pandemic. The monthly passenger flow and the daily average passenger flow is presented in Fig. 4 . Based on three typical kinds of daily passenger flow (i.e., 170000 of busy flight before COVID-19 and 120000 of normal flight before COVID-19, 60000 of COVID-19 Period flight), the hourly passenger flow of Normal Distribution is presented in Fig. 5 .

Fig. 4.

Monthly and daily average passenger flow distribution in different months.

Fig. 5.

Hourly passenger flow distribution in different daily maximum conditions.

3.2. Results

The control interval in the optimization solutions is 1 h, based on the cooling load characteristics distributions of terminal buildings and the control strategies in real operations. The initial indoor temperature is set according to outdoor temperature. Based on the analysis above, the control scenarios for passenger flow is set as busy flight before COVID-19, normal flight before COVID-19, and COVID-19 Period flight, respectively. The control scenarios for outdoor temperature which is based on the daily highest temperature is set as warming (29 °C), slightly hot (31 °C), hot (33 °C), very hot (35 °C), and extreme hot (37 °C), respectively. The outdoor temperature conditions are chosen according to the relevant Chinese classification standards (e.g., Grades of surface air temperature assessment (GB/T 35562–2017), Climate index-High temperature (QX/T 595–2021)), based on the local temperature distribution. To further research the balance effect between thermal comfort and energy consumption, thermal discomfort coefficient is adopted in the solutions. The reference temperature of thermal comfort is set as 25 °C. The detail information of the optimization solution is given in Table 2 .

Table 2.

Detail information of the optimization solution.

| Method | Step setting | Convergence status | Convergence time |

|---|---|---|---|

| SLSQP | 1 h | True | One second |

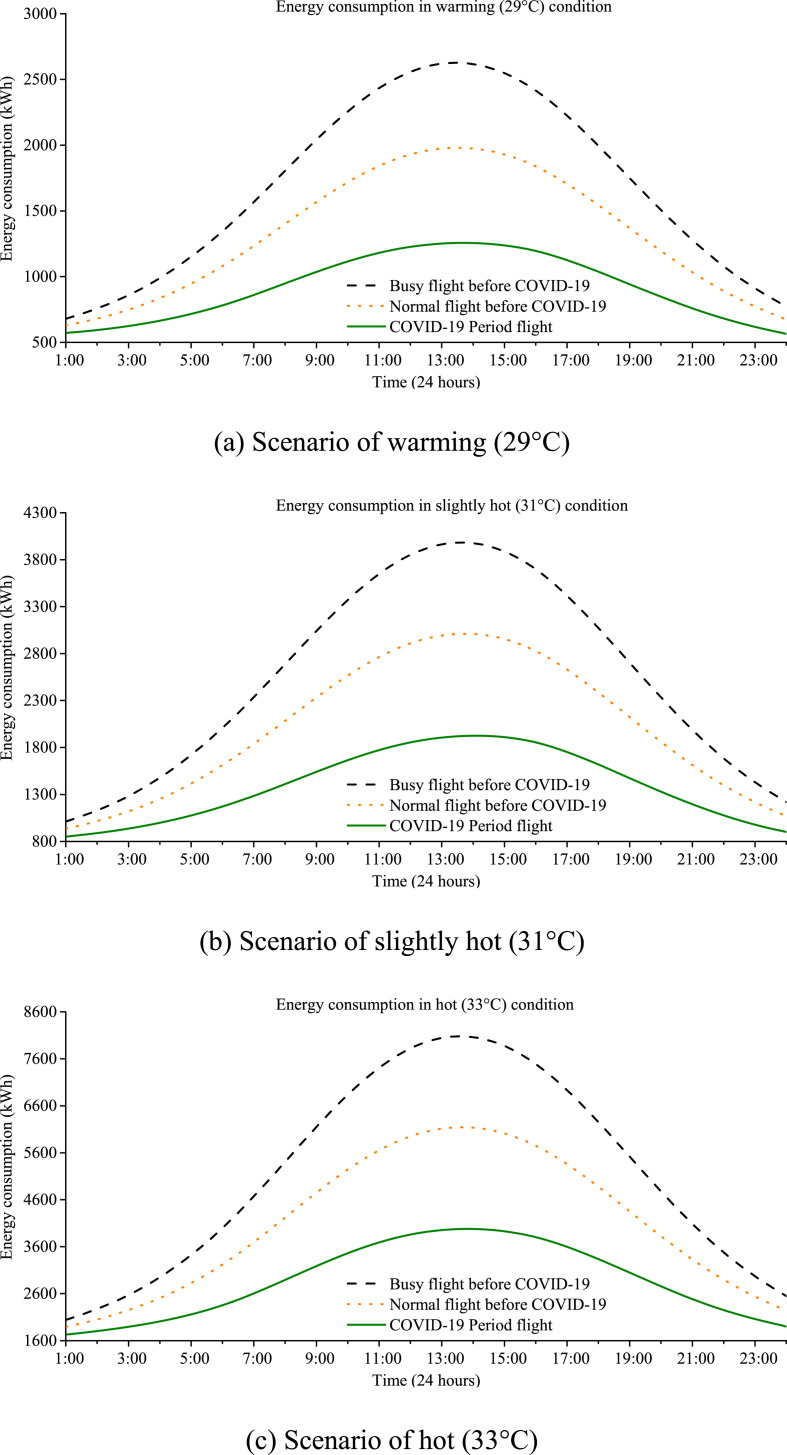

3.2.1. Cooling load characteristics

The cooling load distributions in different scenarios are presented in Fig. 6 , as below. The cooling load is obtained based on the cooling demand model mentioned above, while considering the cooling dissipation in the transportation with a loss coefficient of 1.1. Through the comparisons for scenarios of busy flight before COVID-19, normal flight before COVID-19, and COVID-19 Period flight, similar trends of cooling load characteristics are found in different outdoor temperature conditions. The peak cooling load period for all scenarios falls in the time range of 10:00–17:00, which is the peak period of both passenger flow and outdoor temperature. The daily total cooling load comparisons of different scenarios are presented in Table 3 . The lowest cooling load (144865 kW) appears in the scenario of COVID-19 Period flight-warming (29 °C), while the highest cooling load (1506856 kW) appears in the scenario of busy flight before COVID-19-extreme hot (37 °C). The average cooling load drop from normal flight before COVID-19 to COVID-19 Period flight is 30%, and the average cooling load drop from busy flight before COVID-19 to COVID-19 Period flight reaches to 44%. As aforementioned descriptions of cooling load characteristics, the cooling load is mainly affected by the outdoor temperature and passenger flow (occupancy). Thus, the comparisons indicate that the cooling load characteristics have greatly varied due to the impact of COVID-19 Pandemic in the identical conditions except passenger flow.

Fig. 6.

Cooling load distributions of different scenarios.

Table 3.

Daily total cooling load comparisons of different scenarios (kW).

| scenarios | warming (29 °C) | slightly hot (31 °C) | hot (33 °C) | very hot (35 °C) | extreme hot (37 °C) |

|---|---|---|---|---|---|

| busy flight before COVID-19 | 266904 | 405258 | 822258 | 1292778 | 1506856 |

| normal flight before COVID-19 | 209304 | 318614 | 649877 | 1026484 | 1198287 |

| COVID-19 Period flight | 144865 | 221682 | 457027 | 728570 | 853077 |

| Cooling load drop from busy flight before COVID-19 to COVID-19 Period flight | 46% | 45% | 44% | 44% | 43% |

| Cooling load drop from normal flight before COVID-19 to COVID-19 Period flight | 31% | 30% | 30% | 29% | 29% |

3.2.2. Optimal operation strategies

Based on the cooling load distributions above, the optimal operation strategies of the three kinds of chillers (i.e., 7034 kW, 3517 kW, 1530 kW) for different scenarios are presented as below in Fig. 7 . The initial settings of chiller selection is based on two principles, i.e., 1) the initial cooling capacity of chillers can guarantee the cooling load demand, 2) the chillers with bigger cooling capacity are prior to be selected to reduce the number of small chillers, as the coupled components (e.g., pump, cooling tower) which consume power in the cooling system. For each scenario, it is found that the chiller number difference is much bigger in the peak cooling load period than in other period. As it is described above, the optimization function is comprised of two task, i.e., to maximize the overall operational COP of chillers and to minimize the indoor thermal discomfort. Thus, to obtain the optimal control strategies in peak load period is essential to both minimize the operation cost and to avoid thermal discomfort. Compared with conditions before the COVID-19 Pandemic, it is found that the chiller operation number can be greatly optimized, especially in peak cooling load period. For different scenarios (outdoor temperature), it is found that the chiller number difference is much bigger in higher outdoor temperature conditions. The smallest number of chiller (1 × 7034 kW + 0 × 3517 kW + 0 × 1530 kW) appears in the scenario of COVID-19 Period flight-warming (29 °C), while the biggest number of chiller (12 × 7034 kW + 4 × 3517 kW + 1 × 1530 kW) appears in the scenario of busy flight before COVID-19-extreme hot (37 °C).

Fig. 7.

Optimal operation strategies of the three chillers of different scenarios.

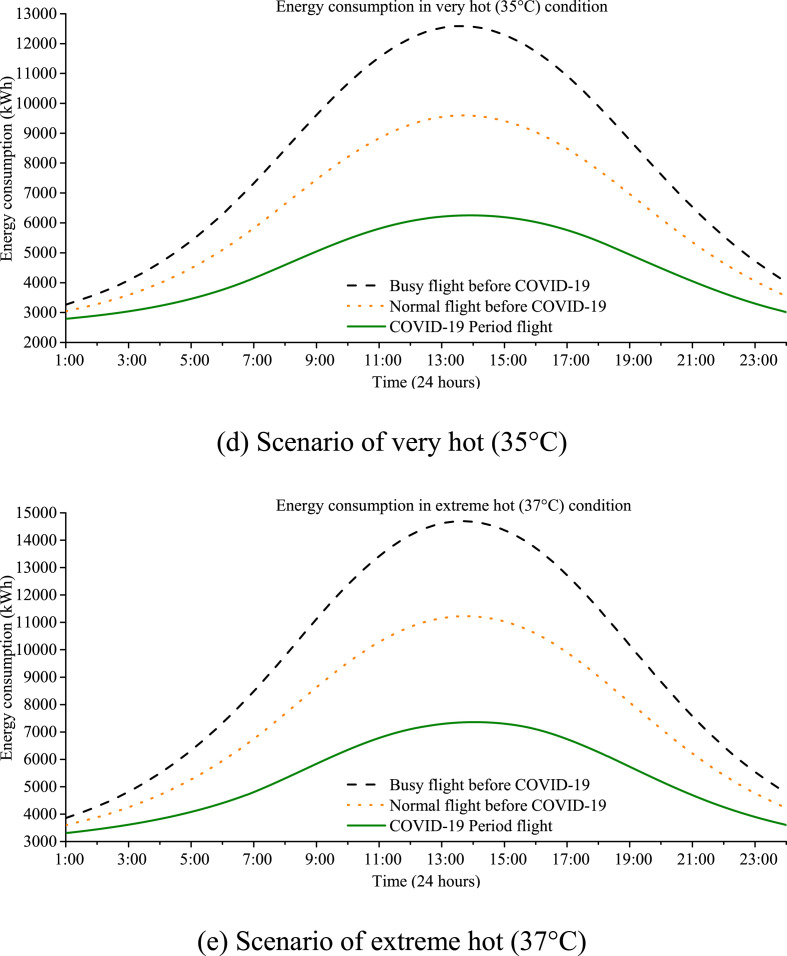

3.2.3. Analysis of energy consumption

By adopting the control strategies above, operational energy consumption of chillers are obtained, as presented in Fig. 8 . When the outdoor temperature rises from warming (29 °C) to extreme hot (37 °C), the daily energy consumption of scenarios of busy flight before COVID-19, normal flight before COVID-19 and COVID-19 Period flight increase by 464%, 471% and 487%, respectively. The lowest energy consumption (21853 kWh) appears in the scenario of COVID-19 Period flight-warming (29 °C), while the highest energy consumption (226594 kWh) appears in the scenario of busy flight before COVID-19-extreme hot (37 °C). The daily energy consumption of chillers of different scenarios is presented in Table 4 . The energy consumption of peak period (i.e., 10:00–17:00) increases faster than that of non-peak period (i.e., 01:00–09:00, 18:00–24:00). The energy consumption of peak period (8 h) accounts for almost half (47%) of the total energy consumption. It indicates that the control strategies in peak period of passenger flow and outdoor temperature is essential to optimize the energy consumption of the cooling system. Due to the impact of COVID-19 pandemic, the passenger flow of airport terminals are restricted. The reduction of passenger flow will result into cooling demand drop. If the control strategies of cooling system remains the same as before the Pandemic, it easily causes operational energy wastes.

Fig. 8.

Operational energy consumption of chillers of different scenarios.

Table 4.

Daily energy consumption of chillers of different scenarios.

| Daily energy consumption (kWh) | warming (29 °C) | slightly hot (31 °C) | hot (33 °C) | very hot (35 °C) | extreme hot (37 °C) |

|---|---|---|---|---|---|

| busy flight before COVID-19 | 40198 | 60995 | 123679 | 194406 | 226594 |

| normal flight before COVID-19 | 31539 | 47971 | 97766 | 154377 | 180202 |

| COVID-19 Period flight | 21853 | 33400 | 68776 | 109595 | 128311 |

3.2.4. Further analysis

Combined with the results of cooling load, optimal control strategies and energy consumption, it can be obtained that there is an obvious decrease from the scenarios of busy flight before COVID-19, normal flight before COVID-19 to COVID-19 Period flight. In addition, cooling load distribution, optimal control strategies of chillers and energy consumption trends regularly follows the change characteristics of outdoor temperature and passenger flow. It indicates that the cooling load characteristics model is correct and accurate. It also reveals that the optimal formulations and solution methods are reliable. The combined methodology is constructive for the control of precise cooling supply under the flight restrictions due to COVID-19 Pandemic. The typical outdoor temperature-passenger flow condition classifications can lay a good basis for the control baselines for multi-chiller optimal operation.

-

(1)

Impact analysis of outdoor temperature. The results show that when the outdoor temperature rises 2 °C (i.e., from 29 °C to 31 °C, 31 °C–33 °C, 33 °C–35 °C, 35 °C–37 °C), the cooling load of scenario of busy flight before COVID-19 increases 138354 kW, 417000 kW, 470520 kW, 214078 kW, respectively. The increase trends show slow growth at the beginning (i.e., 29 °C–31 °C), fast growth in the middle (i.e., 31 °C–33 °C, 33 °C–35 °C), and back to slow growth in the end (i.e., 35 °C–37 °C). The cooling load increase of scenarios of normal flight before COVID-19 and COVID-19 Period flight also conform to this growth trends. Thus, in the optimal schedules of multi-chiller operation in terminal cooling system, simple superimposition for chiller operation number (i.e., switch on/off control) according to outdoor temperature change (increase/decrease) is not suitable, because the influence of outdoor temperature change on cooling demand delays due to the building envelops. If strategies are scheduled with simple superimposition method connecting to typical outdoor temperature, it will inevitably result into mismatch between cooling demand and cooling supply in real operation.

-

(2)

Impact analysis of passenger flow. The passenger flow in hub airport terminals may change greatly in normal period of flights and busy period of flights. Thus, the cooling load will vary accordingly to passenger flow changes. This phenomenon is more obvious under flight restrictions due to the COVID-19 Pandemic. When the passenger flow drops from busy flight before COVID-19 (daily passenger flow about 170000) to normal flight before COVID-19 (daily passenger flow about 120000), normal flight before COVID-19 (daily passenger flow about 120000) to COVID-19 Period flight (daily passenger flow about 60000), the cooling load of scenario of warming (29 °C) decreases 57600 kW and 64439 kW, respectively. The cooling load increase of scenarios of slightly hot (31 °C), hot (33 °C), very hot (35 °C) and extreme hot (37 °C) also conform to this growth trends. It indicates that in the optimal schedules of multi-chiller operation in terminal cooling system, simple superimposition according to passenger flow change (increase/decrease) for chiller operation number (i.e., switch on/off control) is reliable. It is efficient and effective to schedule optimal strategies of chiller operation number with simple superimposition method connecting to passenger flow.

-

(3)

Analysis of overlapping factors of outdoor temperature and passenger flow. The cooling load presents asynchronous increase trend with outdoor temperature and passenger flow. The biggest cooling load appears in the scenario of busy flight before COVID-19-extreme hot (37 °C), where needs the biggest operational number of chillers (12 × 7034 kW + 4 × 3517 kW + 1 × 1530 kW). This biggest operational number of chillers decreases (to 10 × 7034 kW + 3 × 3517 kW + 0 × 1530 kW) during normal flight before COVID-19-extreme hot (37 °C) condition, and decreases (to 7 × 7034 kW + 2 × 3517 kW + 0 × 1530 kW) during COVID-19 Pandemic periods. The hourly energy consumption decreases from 14240 kWh to 10875 kWh and 7113 kWh for normal flight before COVID-19 period and during COVID-19 Pandemic period, respectively. An energy saving of 24% and 35% is obtained by this proposed optimal strategy for the two scenarios, respectively.

Combined the passenger flow characteristics in terminals and the local outdoor temperature distribution, a daily period of cooling demand can be divided into three stages, i.e., first stage from 00:00 to 10:00; 2) second stage from 10:00 to 17:00; 3) third stage from 17:00 to 24:00. In the first stage, the outdoor temperature keeps at a low increase pace, while the passenger flow may greatly increase. The switch on of chiller operation is mainly controlled for the cooling demand variation of passenger flow. In the second stage, both the outdoor temperature and the passenger flow increase to the peak and keep comparatively stable. Thus, the cooling demand of terminal reaches to the peak load period. The optimal strategy for multi-chiller operation maintains during this stage. In the third stage, both the outdoor temperature and the passenger flow gradually decline. However, the two factors perform different influence on cooling demand. The passenger flow change obeys to a decline pace of Normal Distribution. The influence of outdoor temperature decrease on cooling demand delays due to the building envelops. Thus, the cooling load presents asynchronous trend with outdoor temperature change. The switch off of chiller operation is mainly controlled for the cooling demand variation of passenger flow at first, and then for outdoor temperature.

4. Conclusions

This paper comprehensively analyzed the optimal strategies of cooling system in airport terminal buildings, especially focusing on the changes derived from COVID-19 pandemic. The cooling load characteristics model is established. The overall operational COP with thermal comfort is formulated in the objective function. The optimization scenarios considering typical outdoor temperature and passenger flow are structured. Together, they indicate the following:

-

(1)

The influential factors which impact cooling load of terminal cooling system are analyzed, and cooling load characteristics model is obtained. To maximize multi chiller operational COP and to minimize thermal discomfort are combined in the optimization problem formulation.

-

(2)

Based on the cooling load characteristics analysis of airport terminals, it is found that cooling load is mainly affected by outdoor temperature and passenger flow (occupancy). Thus, these two factors are chosen as reference parameters in the optimization scenarios.

-

(3)

The cooling load characteristics perform greatly variations due to the impact of COVID-19 Pandemic. An average cooling load drop of 30% is observed from scenario of normal flight before COVID-19 to scenario of COVID-19 Period flight, and the average cooling load drop reaches to 44% from scenario of busy flight before COVID-19 to scenario of COVID-19 Period flight.

-

(4)

The results show that the cooling load presents synchronous trend with passenger flow variation. However, the cooling load presents asynchronous trend with outdoor temperature change. The influence of outdoor temperature change on cooling demand delays due to the building envelops. Different paces of cooling load variation are observed in outdoor temperature conditions. In the optimal schedules of multi-chiller operation in terminal cooling system, simple superimposition according to passenger flow change for chiller operation number is reliable, efficient and effective. However, simple superimposition for chiller operation number according to outdoor temperature change is not suitable. If strategies are scheduled with simple superimposition method connecting to typical outdoor temperature, it will inevitably result into mismatch between cooling demand and cooling supply in real operation.

The relationships between results of cooling load distribution, optimal chiller control strategies and energy consumption and scenario parameters are clear and reasonable. It reflects that the cooling load characteristics model is accurate and reliable. The strategies can be applied to further real-time control of multi-chiller. The findings also offer more optimal control strategies for emergency use of airport terminals during the COVID-19 pandemic.

Author statement

Biao Yan: Conceptualization, Methodology, Formal analysis, Validation and Writing.

Wansheng Yang: Supervision and Methodology.

Fuquan He: Investigation and Conceptualization.

Kehua Huang: Reviewing and Editing.

Wenhao Zeng: Investigation and Reviewing.

Wenlong Zhang: Reviewing and Conceptualization.

Haiseng Ye: Investigation and Validation.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

This paper was supported by the Guangdong Basic and Applied Basic Research Foundation (Grant No. 2021A1515110449), and the Airport Energy Management System Energy Saving Optimization and Control Model Research Project (No. P-BYGHT-XX1020200367) of Guangdong Airport Baiyun Information Technology Co., Ltd.

References

- 1.International Energy Agency (IEA) and the Tsinghua University Building Energy Research Center (BERC) June 2019. The future of cooling in China. [Google Scholar]

- 2.Building Energy Research Center of Tsinghua University . Building Energy Research Center of Tsinghua University; Beijing: 2020. China building energy use 2020. [Google Scholar]

- 3.Lund Henrik, Alberg Østergaard Poul, Bach Nielsen Tore, Werner Sven, Eric Thorsen Jan, Gudmundsson Oddgeir, Ahmad Arabkoohsar, Vad Mathiesen Brian. Perspectives on fourth and fifth generation district heating. Energy. 2021;227 [Google Scholar]

- 4.Fan Yi, Zhao Xudong, Jing Li, Li Guiqiang, Myers Steve, Cheng Yuanda, Ali Badiei, Yu Min, Golizadeh Akhlaghi Yousef, Shittu Samson, Ma Xiaoli. Economic and environmental analysis of a novel rural house heating and cooling system using a solar-assisted vapour injection heat pump. Appl Energy. 2020;275 [Google Scholar]

- 5.Zhang Wei, Hong Wenpeng, Jin Xu. Research on performance and control strategy of multi-cold source district cooling system. Energy. 2022;239(Part B) [Google Scholar]

- 6.Civil Aviation Administration of China, National Development and Reform Commission . 2016. Ministry of transport of the people's Republic of China, the 13th five-year plan for the development of civil aviation in China. [Google Scholar]

- 7.Wu Wei, Harrison M. Skye. Residential net-zero energy buildings: review and perspective. Renew Sustain Energy Rev. 2021;142 doi: 10.1016/j.rser.2021.110859. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Yuan Jiaqi, Cui Chengliao, Xiao Ziwei, Zhang Chong, Gang Wenjie. Performance analysis of thermal energy storage in distributed energy system under different load profiles. Energy Convers Manag. 2020;208 [Google Scholar]

- 9.Menapace Andrea, Zinck Thellufsen Jakob, Pernigotto Giovanni, Roberti Francesca, Gasparella Andrea, Righetti Maurizio, Baratieri Marco, Lund Henrik. The design of 100 % renewable smart urb an energy systems: the case of Bozen-Bolzano. Energy. 2020;207 [Google Scholar]

- 10.Pourfattah Farzad, Sabzpooshani Majid. On the thermal management of a power electronics system: optimization of the cooling system using genetic algorithm and response surface method. Energy. 2021;232 [Google Scholar]

- 11.Zhang Fan, Guo Heinz-Axel, Liu Zhengxuan, Zhang Guoqiang. A critical review of the research about radiant cooling systems in China. Energy Build. 2021;235 [Google Scholar]

- 12.Lu Fei, Yu Zhenyu, Zou Yu, Yang Xudong. Cooling system energy flexibility of a nearly zero-energy office building using building thermal mass: potential evaluation and parametric analysis. Energy Build. 2021;236 [Google Scholar]

- 13.Zhao Tian. Tsinghua University; 2015. Research terminal environmental quality and energy efficiency measured. [Google Scholar]

- 14.Civil Aviation Administration of China (CAAC) 2016. Guidelines for energy efficiency evaluation on civil airport terminals (MH/T 5112-2016) [Google Scholar]

- 15.Civil Aviation Administration of China (CAAC) 2017. Green terminal standard (MH/T 5033-2017) [Google Scholar]

- 16.Jia Lizhi, Shen Wei, Liu Junjie. A review of optimization approaches for controlling water-cooled central cooling systems. Build Environ. 2021;203 [Google Scholar]

- 17.Xu Yingjie, Shi Qiqi, Chen Ning, Shen Xi, Wang Chunyan, Han Xiaohong. Seasonal energy performance evaluation with new perspective on partial-coupling ejection-compression solar cooling system for modern city buildings. Energy Convers Manag. 2021;233 [Google Scholar]

- 18.Shi Shaofei, Wang Yufei, Wang Youlei, Xiao Feng. A new optimization method for cooling systems considering low-temperature waste heat utilization in a polysilicon industry. Energy. 2022;238(Part A) [Google Scholar]

- 19.Wang Yang, Zhang Shanhong, Chow David, Kuckelkorn Jens M. Evaluation and optimization of district energy network performance: present and future. Renew Sustain Energy Rev. 2021;139 [Google Scholar]

- 20.Cox Sam J., Kim Dongsu, Cho Heejin, Mago Pedro. Real time optimal control of district cooling system with thermal energy storage using neural networks. Appl Energy. 2019;238:466–480. [Google Scholar]

- 21.Yu L., Xie D., Huang C., Jiang T., Zou Y. Energy optimization of HVAC systems in commercial buildings considering indoor air quality management. IEEE Trans Smart Grid. 2019;10(5):5103–5113. [Google Scholar]

- 22.Li Huai, Zhang Shicong, Yu Zhen, Wu Jianlin, Li Bojia. Cooling operation analysis of multienergy systems in a nearly zero energy building. Energy Build. 2021;234 [Google Scholar]

- 23.Zeferina Vasco, Wood F. Ruth, Edwards Rodger, Tian Wei. Sensitivity analysis of cooling demand applied to a large office building. Energy Build. 2021;235 [Google Scholar]

- 24.Zhuang Chaoqun, Wang Shengwei, Shan Kui. A risk-based robust optimal chiller sequencing control strategy for energy-efficient operation considering measurement uncertainties. Appl Energy. 2020;280 [Google Scholar]

- 25.Pieper Henrik, Krupenski Igor, Brix Markussen Wiebke, Ommen Torben, Andres Siirde, Anna Volkova. Method of linear approximation of COP for heat pumps and chillers based on thermodynamic modelling and off-design operation. Energy. 2021;230 [Google Scholar]

- 26.Quirosa Gonzalo, Torres Miguel, Chacartegui Ricardo. Analysis of the integration of photovoltaic excess into a 5th generation district heating and cooling system for network energy storage. Energy. 2022;239(Part C) [Google Scholar]

- 27.Chen Yixing, Yang Chuhao, Pan Xiao, Yan Da. Design and operation optimization of multi-chiller plants based on energy performance simulation. Energy Build. 2020;222 [Google Scholar]

- 28.Ho W.T., Yu F.W. Improved model and optimization for the energy performance of chiller system with diverse component staging. Energy. 2021;217 [Google Scholar]

- 29.Fathollahzadeh Mohammad Hassan, Tabares-Velasco Paulo Cesar. Electric demand minimization of existing district chiller plants with rigid or flexible thermal demand. Appl Energy. 2021;289 [Google Scholar]

- 30.Sadat-Mohammadi Milad, Asadi Somayeh, Habibnezhad Mahmoud, Jebelli Houtan. Robust scheduling of multi-chiller system with chilled-water storage under hourly electricity pricing. Energy Build. 2020;218 [Google Scholar]

- 31.Ho W.T., Yu F.W. Determinants of low energy performance in a multi-chiller system serving an educational premise. Int J Refrig. 2020;114:47–53. [Google Scholar]

- 32.Chen Dengyi, Hu Xiaochun, Meng Dan, Leto Sebastian. Optimal consumption modeling of multi–chiller system using a robust optimization algorithm with considering the measurement, control and threshold uncertainties. J Build Eng. 2020;30 [Google Scholar]

- 33.Seo Byeong Mo, Lee Kwang Ho. Detailed analysis on part load ratio characteristics and cooling energy saving of chiller staging in an office building. Energy Build. 2016;119:309–322. [Google Scholar]

- 34.Catrini P., Panno D., Cardona F., Piacentino A. Characterization of cooling loads in the wine industry and novel seasonal indicator for reliable assessment of energy saving through retrofit of chillers. Appl Energy. 2020;266 [Google Scholar]

- 35.Zabala Laura, Febres Jesus, Sterling Raymond, López Susana, Keane Marcus. Virtual testbed for model predictive control development in district cooling systems. Renew Sustain Energy Rev. 2020;129 [Google Scholar]

- 36.Lin Lin, Liu Xiaohua, Zhang Tao, Liu Xichen, Rong Xiangyang. Cooling load characteristic and uncertainty analysis of a hub airport terminal. Energy Build. 2021;231 [Google Scholar]

- 37.Ding Yan, Su Hao, Liu Kuixing, Wang Qiaochu. Robust commissioning strategy for existing building cooling system based on quantification of load uncertainty. Energy Build. 2020;225 [Google Scholar]

- 38.Ji Ying, Xu Peng, Duan Pengfei, Lu Xing. Estimating hourly cooling load in commercial buildings using a thermal network model and electricity submetering data. Appl Energy. 2016;169:309–323. [Google Scholar]

- 39.Lu S., Gu W., Meng K., Yao S., Liu B., Dong Z.Y. Thermal inertial aggregation model for integrated energy systems. IEEE Trans Power Syst. 2020;35(3):2374–2387. [Google Scholar]

- 40.Jazaeri J., Alpcan T., Gordon R.L. A joint electrical and thermodynamic approach to HVAC load control. IEEE Trans Smart Grid. 2020;11(1):15–25. [Google Scholar]

- 41.Chiam Zhonglin, Easwaran Arvind, Mouquet David, Fazlollahi Samira, Millás Jaume V. A hierarchical framework for holistic optimization of the operations of district cooling systems. Appl Energy. 2019;239:23–40. [Google Scholar]

- 42.Du Yan, Zandi Helia, Olivera Kotevska, Kurte Kuldeep, Munk Jeffery, Amasyali Kadir, Mckee Evan, Li Fangxing. Intelligent multi-zone residential HVAC control strategy based on deep reinforcement learning. Appl Energy. 2021;281 [Google Scholar]

- 43.Yu F.W., Ho W.T. Load allocation improvement for chiller system in an institutional building using logistic regression. Energy Build. 2019;201:10–18. [Google Scholar]

- 44.Zhu Yingxin, Wang Gang, Jiang Yi. Energy consumption analysis of district cooling system. HVAC. 2008;38(1):36–40. [Google Scholar]

- 45.SciPy Tutorial . SciPy Community; 2019. SciPy reference guide (release 1.3.3) [Google Scholar]