Abstract

Active packaging systems come under novel techniques and are creating demands in food packaging aspects. They are specially designed for food products where shelf life is a key driving factor. Their wide range of functionality preserves the color, texture, smell, and taste of the food item retaining their freshness and edibility for longer than any other methods available on market. An active ingredient in packaging systems enables efficient consumable quality which resulted in reduced complaints from consumers. However, techniques must be inexpensive and environment-friendly. The use of biodegradable packaging systems reinforced by exploiting natural compounds forms the latest trend to attract consumer demand in substituting synthetic preservatives in foods that can protect against food spoilage. Natural extracts have gained commercial importance in active packaging nowadays for the delivery of safe and high-quality foods that are being employed in both fresh and processed produce. Development and use of innovative active packaging systems in varied forms are expected to increase in the future for food safety, quality, and stability. The review overviews the beneficial effects of plant acquired components in modulating product quality in packaged form for commercial aspects in the market.

Keywords: Active packaging, Natural ingredients, Biodegradable packaging

Introduction

Packaging of foods comprises advanced technological methods mostly employed for the welfare of societies. Protecting food from harmful effects of oxygen scavengers, water vapor emitters, ultraviolet radiation including contamination from microorganisms and chemical agents forms the main purpose behind food packaging. In the food supply chain, fresh fruit packaging is a vital unit activity beginning from the farm until the product is received by the final consumer. Active food packaging functions by releasing active agents into the food that facilitate improved food quality with stability. This new kind emerged through changing patterns with respect towards customer preferences regarding food products with a longer shelf life (Leistner 2000). The active ingredient within the food packaging system plays an active role in the quality of food and durability either by acting as scavengers or inactivating deleterious compounds through the release of desirable components, having antimicrobial or antioxidant properties. In the preparation of coatings and films, biological materials like proteins, polysaccharides, lipids, or such mixtures are successfully used (Mali et al. 2005; Gottifredi 2007). Even, natural extracts obtained from green plant parts or agricultural wastes forms an ideal candidate by maintaining eco-friendliness and economics. They are also composed of several phenolic compounds and metabolites such as thymol, chitosan, nisin, cinnamon, rosemary, essential oils, clove oils, oregano, thyme, carvacrol, enzymes and many others that can perform as antimicrobial and antioxidant polymers in nature (Priyadarshi and Rhim 2020).

COVID-19 has played a major role in economic development and food systems worldwide having a decisive impact on public health. The packaging industry has faced real importance in times of pandemic and will continue to gain consumer preferences many more in near future. Biopolymers have been considered as a potential environmental-friendly substitute for use as packaging materials compared to the conventional non-biodegradable ones (Ryan et al. 2009). Natural extracts are rich sources of biologically active compounds that could be the potential carrier of antioxidant/antibrowning and antimicrobial agents, therefore incorporation of active agents into biopolymeric packaging material may enable retaining food quality and enhance the shelf life of the packaged product in an environmentally friendly way. The incorporation of natural active agents into bio-films provides benefits such as low antimicrobial concentrations and low diffusion speed compared to synthetic ones (Becerril et al. 2007). There lies the novelty of the current paper that emphasizes on natural extract as highly efficient and on the other hand generally recognized as safe and are environment-friendly. Thus, the aim of this review emphasizes active packaging using biological packaging materials. It focuses on the application of various natural extracts as active ingredients that are feasible in the production of biological packaging material. Additionally, this review also discusses the toxicity and other important latest aspect such as COVID-19 related to active packaging technology.

Biodegradable active packaging coatings/films

Environmental and health concerns encourage the use of biodegradable packaging instead of synthetic packaging. The naturally derived biopolymers such as protein, lipids, and polysaccharides, often serve as the base material for biodegradable packaging. They are recyclable, decompose in a short while, non-toxic, and eco-friendly (Zhang et al. 2021). Plant extracts are an interesting ingredient for biodegradable food packaging because of their natural origin and phytochemical properties, which can be used to obtain active materials to extend shelf life and increase product value (Mir et al. 2018). A food surface can be coated directly with edible/biodegradable materials by spraying, dipping, or panning them (Ahmed et al. 2022). Different biodegradable plastics have different applications in the packaging industry. Due to their flexibility for molding, low cost, good printability, and resistance to a variety of environmental and mechanical factors, synthetic polymer materials are widely used for packaging (Bhargava et al. 2020). The drawbacks of biodegradable plastics such as PLA (brittle nature), PHAs (poor barrier properties), PHB (poor mechanical and thermal properties), PCL (poor hydrophilic properties), starch (poor stabilization and mechanical properties) and cellulose (difficulty in processing) have been improved by making blends of the two biodegradable plastics or with other additives required with respect to particular modification/improvement (Singla et al. 2022). There may be contaminants through the use of recycled plastics, on the other hand, not using them generates a large accumulation of waste, leading to a negative impact on various ecosystems. This is why it is essential to invest in biodegradable polymers that can be used as active bio-based packaging, helping to conserve packaged foods and acting on two key points: increasing the shelf life of food products and taking advantage of residues that would be discarded otherwise (Mir et al. 2018).

Biological packaging system: basic materials for film formulations

For edible films and coatings production, biopolymers viz. polysaccharides, lipids and proteins form the basic materials that are employed mainly (Azeredo 2009; Atarés and Chiralt 2016; Avramescu et al. 2020), due to its biodegradable and compostable characteristics (Kammouna et al. 2013) with regards to slow release of substance where the active contribution of food preservation depends upon packages (Martínez-Abad et al. 2014; Fabra et al. 2016). Sustainable production of films is increasing as they have greater capabilities in use of foods that are produced from enormous compositions achieving reduction in water and gaseous diffusivity that promotes product quality and shelf life (Abugoch et al. 2011). Production in flexible packaged techniques comprises edible coatings and films in food that reduces gaseous interface, respiration, moisture movement along with oxidative reaction rates minimization (Azeredo et al. 2011; Ooi et al. 2012; Maran et al. 2013; Galus and Lenart 2013; Pascall and Lin 2013). Improvement in oxygen barrier, antibacterial and antifungal properties occurs when biological films are reinforced with active ingredients present in natural essential oils and plant additives. Building up nanomaterials in biological packaged medium are studied too for the improvement of packaging characteristics such as increasing food shelf life (Azeredo et al. 2019). Polymeric carbohydrates such as cellulose or lignin and proteins e.g. keratin/gelatin along with wood fibers from lignocellulose comprises higher percentage of cellulose and hemicelluloses. Its film possesses higher firmness, durability, shiny appearance with good transparency (Darni et al. 2017) that is utilized mainly as biobased polymeric material having similar properties. Introducing materials like bioplastics and lignocellulosic fibers, has changed the environment of food packaging profoundly (Berthet et al. 2015). However biopolymeric bioplastics, loses its biodegradability after chemical alteration including polymerization. The sensitive balance of material’s biodegradable packaging should be adequately durable regarding protection (Berthet et al. 2015). Findings are emphasized for the usage of phenolics obtained by fruits and vegetables as active component in packaging material development. There should be control of mass movement with undesirable migrations of components from the package toward the food and vice versa. A special attention should be thus needed to pay in the methods of development for preparing active biodegradable films. Basic materials (polysaccharides, proteins, lipids), plasticizers, additives, and solvents are used as building block for film formulation. Some examples of biological materials used for food packaging is summarized in Table 1.

Table 1.

Biopolymers used in active food packaging systems

| Biopolymer | Application | Source |

|---|---|---|

| Starch |

Biodegradable films prepared by starch/(PVOH) alginate with main oil of copaiba or lemongrass for minimally processed lettuce Combination of consumable yam and maize starch possessing great physical and antibacterial properties by providing nourishment to flavoring packaging materials Characterization of edible films prepared by starch phosphates of of S. burchelli seeds for post harvest conservation of cherry tomatoes Edible film preparation using corn starch, hydroxypropyl methyl cellulose with uncaria gambhir extract and glycerol |

Brandelero et al. (2016) Xiaoyong et al. (2018) Gomes et al. (2016) Santoso et al. (2019) |

| Chitosan |

As a protection of sweet cherry (Prunus avium L.) food grades As a blender in extracts of sweet potato with properties providing pH sensor, antioxidants and moisture barrier Chitosan built materials blended along essential oils of Apricot kernel serving as moisture barriers, antimicrobic & antioxidant agent and shelf-life elongation |

Aider (2010) Yong et al. (2019) Priyadarshi et al. (2018) |

| Protein | Gelatin–chitosan grape seed extracts with or without nisin have been used to coat fresh pork chunks for evaluating the usefulness in maintaining freshness | Xiong et al. (2020) |

Polysaccharides

Polysaccharides besides proteins represent another important pillar for film/coatings due to its property of biodegradability (Avramescu et al. 2020). Starch besides cellulose (CMC, HPC), sodium alginate, inulin, pectin, chitosan, xanthan, etc. forms the major polysaccharides for producing barriers.

Pectin

Ngo et al. (2020) conducted a study by use of pectin with nano chitosan (in varied proportions) where the influence of every component and the ratios among them were studied on the mechanical and barrier characteristics of the film. Yeddes et al. (2020) also reported the preparation of gelatin–chitosan–pectin edible films with rosemary essential oil as an active ingredient.

Starch

Starch being abundant in nature represents the main energy source for animals and humans. There are two linkages of starch: amylose which comprises D-glucose residues in linear α-(1 → 4) linkages and amylopectin forming 6% of α-(1 → 6) linkages as branches of the parental structure. In the presence of plasticizers, elevated temperatures, and mechanical pressing, starch develops thermoplastic traits as it is made of water-insoluble units of varying shape, morphology, and crystalline. Out of many polysaccharides, the importance of starch lies in the availability of cheaper and more diverse forms. Characteristics of starchy films include poor thickness, flexibility, transparency but also weak mechanical characteristics and water vapor permeability limits its use for film production (Sadeghizadeh et al. 2019). There are several advantages to using starch, but the main drawback falls as raw starch is weak, more hygroscopic, with minimum mechanical characteristic. To overcome such limitations, the use of plasticizers is done along with various types of starches.

Chitosan

Chitosan is the deacetylated chitin form comprising properties like degree of acetylation (DA), the composition of nitrogen, molecule structure, that depends on the chitin source (Priyadarshi and Rhim 2020). Soluble form, film production, viscous nature, binding of ions, enzymatic degradation, etc. make chitosan a flexible biopolymer applicable for food packaging (Priyadarshi and Rhim 2020). Films made of chitosan show characteristics such as flexibility, durability, strength, toughness, and high break strength, as well as moderate levels of oxygen and water permeability, which aid in reducing food respiration rates (Priyadarshi et al. 2018). In recent years, chitosan films have been widely used as an active food packaging material. A wide array of fresh and dairy products has been tested experimentally for the effectiveness of chitosan films in preventing contamination and microbial spoilage, thus extending shelf life and improving quality (Grant et al. 2006). Chitosan is applied directly in packaging strips form otherwise as food material coatings. Chitosan films reinforced with nanoparticles exhibit enhanced antimicrobial activity against a variety of food-borne microorganisms, as well as improved mechanical properties due to the reinforcement effect of nanoparticles (Latou et al. 2014; Moller et al. 2004). There is a great deal of literature that describes the incorporation of various additives in chitosan films to impart activity to the neat polymer (Aider 2010). Improved mechanical and barrier properties of chitosan films can be obtained by addition of plasticizer or cross linkers providing enhanced protection to packaged product (Abugoch et al. 2011).

Protein

Protein falls under typical polymers comprising amino acids varying from different sources. It is extracted from animal sources (collagen, gelatin), milk (casein, whey) eggs, and plant sources like corn (zein), soy, wheat (gluten), sorghum, pea, rice bran for packaging purpose. As proteins are abundant possessing better film-forming property hence they are extensively used. The protein-built films show tremendous barrier characteristics considering both gases (i.e. O2 and CO2), and volatile compounds (Bora et al. 2020). Naturally built protein is emerging in nature being effective active agents which is highly abundant and economical. Protein isolates from Phaseolus vulgaris are effectively used along with chitosan showing greater flexibility and low surface free energy that forms higher hydrophobe characteristics, thus making it applicable for packing dehydrated, moisture-sensitive food items (Tang et al. 2013). Denaturation of protein by heat, solvent utilization, and pH provides the film forming criteria. Namratha et al. (2020) developed a film extracted from milk casein (family of phosphoproteins) pectin, alginate glycerol, and probiotic Enterococcus faecium Rp1 that showed antimicrobial and antioxidant characteristics with good physicochemical features for 60 days long.

Lipids

Lipids viz. saturated, monounsaturated, polyunsaturated fatty acids along with waxes and resins come under another major aspect of films and coatings as a primary unit or as plasticizers. Water-resistance properties can be also enhanced through incorporating hydrophobic compounds such as fats, wax, and oils into films (Avramescu et al. 2020).

Active packaging systems

The theory of active food packaging system stands nearly new which is commercially employed for storage, transportation, and distribution of certain food commodities providing technical barriers in packaging fresh horticultural items (Kumar and Thakur 2020). As a promising application in active food packaging, antimicrobials and antioxidants are integrated into films and coatings. The reason lies in inhibiting decay caused by pathogenic bacteria through effective maintenance of concentrations on food surfaces. Active scavengers (absorbers) and active releasers (emitters) come under active packaging methods. Edible film and coatings also include in active packaging system utilized mainly for food preservation and extending shelf life (Bora et al. 2020). The scavenging systems eliminates unwanted components from the surrounding of food i.e. moisture, harmful gases or odor, while emitters enumerate desired components towards packaged food like antimicrobial, antioxidant, flavors, or ethanol. However, the critical product nature may influence food packaging process affecting rates of desorption, absorption or diffusion. The choice of a packaging material also differs depending on the commodities respiratory and transpiratory actions, that needs to be well designed to optimize the shelf life of the product achieved in a shorter time interval (Kumar and Thakur 2020). Plant extracts acquiring complex systems are often employed as active ingredient in food packaging applications. The resulting film developed from natural extract is measured through its contribution towards bioactive and functional characteristics in dual method: -

Separate incorporation of the major bioactive compounds at various concentrations and.

Inclusion of plant extract concentration equivalent to concentration of available bioactive compounds (Silva-Weiss et al. 2013).

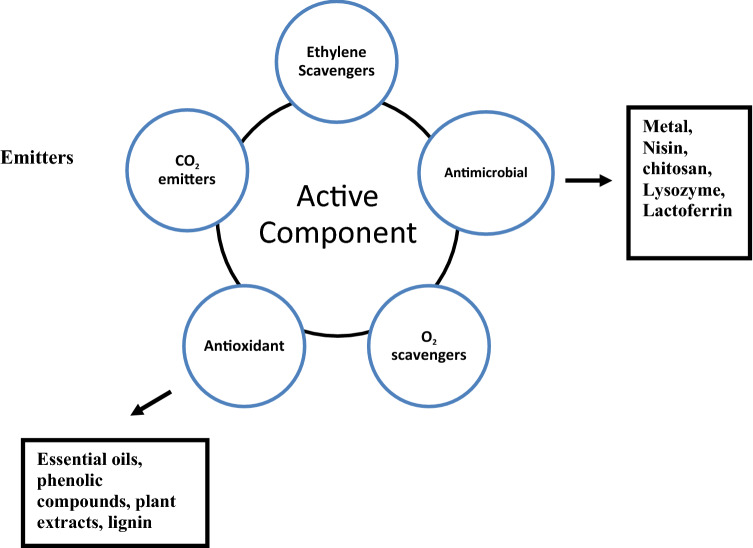

The various types of natural active ingredients used in food packaging is presented in Table 2 and shown in Fig. 1.

Table 2.

Application of active packaging methods

| Type | Process | Active ingredient | Major applications | Sources |

|---|---|---|---|---|

| O2 absorbers | Combination of Iron, metal or acid, catalyst, metallic salts, enzyme-based and nylon | Cucurmin, olive leaf extract | Prepared meat items, Prevent grated cheese and bakery items discoloration | Kumar and Thakur, (2020) |

| CO2 absorbers/ emitters | Reinforcement with Fe2O3 /CaOH, C3Fe2O9 CaO/ NaHCO3 | Cinnameldehyde | Fish and meat items | Anthierens et al. (2011) |

| C2H4 absorbers | KMn04, activated carbon and activated clays | Neem extract | Climacteric Horticulture products | Martín-Belloso et al. (2009) |

| Antioxidant | Corn-zein-laminated, Chitosan film | Thymol, carvacrol, and eugenol, Green tea extract | Flesh & sea foods, seeds, nuts, oils and fried products, Vacuum-packed snacks | Priyadarshi et al. (2018) |

| AM packaging | Film development using organic acids, silver zeolite with spices and herbs | Chitosan matrix, plant essential oils (cinnamon, oregano, lemongrass) | Raw, processed flesh, smoked fish, seafood, dairy items, fresh cut fruits & veggies, Cereals & grains, bakery items, ready-to-eat foods | Ahmad et al. (2020) |

| Moisture absorbents | Incorporation of films using Poly Vinyl Acetate, activated clay, minerals and silica gel | resins, waxes or some insoluble proteins | Tomatoes, Mushroom, strawberries, cereals, grains, seeds, fish, and meat items | Yildirim et al. (2018) |

| Flavor/odor absorbers | Cellulose triacetate, acetylated paper, citric acid, Fe salt/ascorbate and activated carbon/clays | Essential oils | Yildirim et al. (2018) |

Fig. 1.

Active packaging systems (Ahmad et al. 2020)

Properties of active ingredient

Flavors encapsulation or carrier, antimicrobials, antioxidant agents, light absorbent along with food additives.

Maintenance in sufficient gaseous exchange, especially for O2 and CO2 to avoid the loss of aroma, flavor, and nutritional value.

Adequate mechanical resistance for preventing the damage of food surfaces.

Improvement in overall presentation and appearance of the final product by providing color shininess, transparency thus attainment of classical package characteristics with regards to design.

Enhancement of structural properties.

Protection of small pieces of food individually.

Separation of an individual part of the food.

Solubility in the package for preliminary additives or food ingredients.

O2 Absorbers

The presence of oxygen in food packages leads to rapid spoilage of food due to the rapid oxidation of fats and vitamins within food or by promoting the growth of microorganisms such as aerobic bacteria, yeast, and moulds (Dey and Neogi 2019). O2 observers aim to remove oxygen residues available in the food package and act as an active barrier by enhancing barrier properties (Sängerlaub et al. 2013). In food packaging applications, oxygen-scavenging technologies have great potential. The O2-scavenging technologies use mechanisms like iron-based scavenging systems, platinum group metals based scavenging systems, unsaturated hydrocarbon-based scavenging systems, α-tocopherol based scavenging systems, ascorbic acid-based scavenging systems, enzyme-based scavenging systems, micro-organisms based scavenging systems, and other techniques like UV radiation, naturally occurring substances etc. (Dey and Neogi 2019). The potential benefit of O2 absorbers includes discoloration prevention, a decline of molds, reduced rancidity, and browning (Yildirim et al. 2018). Anthierens et al. (2011) proposed a model system for oxygen scavenger polyethylene terephthalate (OS PET) that used Bacillus amyloliquefaciens as an active component. Laohakunjit and Kerdchoecuen (2007) coated 30% sorbitol plasticized rice starch and non-aromatic milled rice containing 25% natural pandan leaf extract (Pandanus amaryllifolius Roxb). The coating process represented a potential perspective to enhance the aroma of rice in addition to reducing the oxidative rancidity while storing grains. In accordance to Wojtunik-Kulesza et al. (2018), citral acts effectively as a radical scavenger due to the presence of conjugated double bond that stabilizes radical obtained, terminating the chain reaction. Lemongrass EOs possesses flavonoids like kaempferol, quercetin, and apigenin in addition to phenolic compounds contributing to the antioxidative potential of their extracts (Syahida, et al. 2020). Khezerlou and Mahdi Jafari (2020) described particular cassava starch films loaded with β-carotene lipid-core nanocapsules that showed better lipid oxidation protection than β-carotene impregnation inside films possessing antioxidant activity. Some commercially available O2 scavenger film are Shelfplus 02, Activ-Film, Amosorb 3000, Cryovac OS film, Darex etc. (Dey and Neogi 2019). In most commercial applications, oxygen-adsorbing components are in form of sachets that are inserted into the package or are adhesively bonded to the inner wall of the package. Although some inconveniences like closure liners containing the oxygen scavenger, dissolution or dispersion of the active substances in the plastic material, or immobilization of enzymes onto the packaging surface affect the process (Lopez et al. 2007). Extensive research needs to be done on developing oxygen scavenging system for effective food preserving application.

Ethylene absorbers

Packaging films were produced commercially centered on the capability of some finely suspended minerals for absorbing ethylene that increased the shelf life. There occur minerals having ethylene adsorbing capacity, but the capacity gets affected after incorporation into plastic films. They help in reducing process of ripening and senescence that enhances quality with prolonged shelf-life. The ethylene scavenger method may include each smaller packet having suitable scavengers for package material or by incorporating ethylene absorbent inside film structure (Gaikwad et al. 2020). Minerals, metals or metal oxides too form good candidates for ethylene elimination (Kumar and Thakur 2020).

Antioxidant

Antioxidants have been incorporated as an active ingredient into plastic films (particularly polyolefins) for polymer stabilization and protection from oxidative degradation, prevention of discoloration, rancidity and food degradation. Most commonly include ascorbic acid, scorbyl palmitate, (BHA), (BHT), citric acid, PG, (TBHQ), tocopherols, (Avramescu et al. 2020). Natural extracts rich in vitamin E often used in the blend as an effective medium. Out of different types of active packaging, those who possess antioxidant activity are significant for the industry, particularly foods. Oxidation is single most major degradation reactions occurring in food are oxidation reducing the conservation (Dantas et al. 2015). Lower molar weight, irradiated chitosan exhibits enhanced antioxidative property in varied meat items. Chitosan along with rosemary extract or tocopherol comprises antioxidative characteristics in frozen stored burgers (Friedman and Juneja 2010). Tapia et al. (2005) and Rojas-Graü et al. (2007) studied application of gel-based coatings and alginate in fresh-cuts viz. apples, papayas along with cysteine, glutathione, ascorbic and citric acids was tested demonstrating that the coatings were strong carriers of antioxidant agents. Most of the antioxidants and anti-browning agents still are hydrophilic which might enhance water vapor transmission rate inducing incorporation of water loss inside films and coatings (Martín-Belloso et al. 2009). Effective antioxidant directing towards delaying oxidation in sunflower oil and fried peanuts has been observed inside Catechin, an active green tea compound with similar characteristics of quercetin (Lopez-de-Dicastillo et al. 2012). With regards, for improving the quality and prolonged shelf life in various eatable products, antioxidant with volatile extracts, EOs, or active components from plants and herbs have been produced. Fresh lyophilized olive leaf extract presented desired properties (in vitro conditions) that were employed for packaging of sliced meat products such as pork (Delgado-Adámez et al. 2016). Color enhancements in addition to lipid oxidation inhibition (lower TBARS) are some of the benefits of antioxidants releasing food packaging systems. However, EOs cannot be consumed due to its strong flavor and for that its use of edible films with bioactive agents to trigger desired functionality is subjected. They improve the film mechanical properties such as optical configuration, tensile strength, as well as being antimicrobial and antioxidant agents. However, the use of smaller quantities of antimicrobic components inside edible films is recommended towards achieving desirable shelf life through their gradual release in products. Some of the active ingredient with antioxidant packaging applications is mentioned below in the Table 3.

Table 3.

Application of antioxidant in food packaging system

| Active ingredient | Packaging material | Food application | References |

|---|---|---|---|

| Citric acid | Cornstarch | Enhancing oxidative stability and preservation of color in Vacuum packed meat products | Júnior et al. (2015) |

| Green tea extract | Chitosan | Oxidative and color stability improvement in pork sausages | Siripatrawan and Noipha (2012) |

| Thymol, carvacrol, eugenol | Corn zein built film | Vacuum packed snacks, Color enhancement and inhibiting decomposition in lipids | Park et al. (2012) |

| Lemongrass Essential oil | Fish gelatin | Extended shelf life | Syahida et al. (2020) |

| Resveratrol | Active linear low-density polyethylene (LLDPE) composites | Binding free radicals declining the process of food oxidation Prolonged shelf-life of red meat | Busolo and Lagaron (2015) |

Antimicrobial (AM)

Biopolymer coating offers great advantage in preventing microbial surface growth on foods by inhibiting the development of certain microorganisms. Natural antimicrobial components are extracted from animal tissues like enzymes; EOs through plants, cinnamon, oregano, rosemary, basil and clove, microbes such as natamycin, nisin, other bacteriocins, organic acids like citric, propionic, and sorbic acid, organic polymers, fungi, and algae including bioactive compounds through vegetables and fruits providing natural bioactive ingredients. Major plant derivatives having antimicrobial effects include aliphatic alcohols, ketones, terpenes, aldehydes, acids, and isoflavonoids. Packaging systems releasing volatile antimicrobials include SO2, ClO2, CO2, ethanol and natural extracts such as EO (Kuorwel et al. 2011). Studies found that polymer like highly deacetylated chitosan can be effectively used as biodegradable, non-toxic, biofunctional, biocompatible that was described by different researchers that comprised high antimicrobial, antifungal activities, antilisterial packaging in food applications (Coma et al. 2002; Aider 2010). It inhibits fungal growth, bacteria and yeasts and effectively acts as suitable matrix for film formation in addition to transport AM additives like acids and salts, EOs, lysozyme and nisin (Sofi et al. 2018). The findings showed that due to its antibacterial activity and bivalent minerals chelating capability, chitosan acquire advantages in contrast to another biomolecule based active film used as packaging component with its special cationic characteristics (Aider 2010).

Antimicrobial food packaging is increasing among the consumers with the increasing demand towards zero preservative ready to eat foods (Jose et al. 2012). AM food packaging eliminates or minimize the microbial growth available inside packaged items or packaging component in varied forms (Appendini and Hotchkiss 2002). Kuorwel et al. (2011) studied various herbs basil, oregano, thyme and their EO being natural AM agents incorporated or coated inside packaged material. Antimicrobials need to be included in the additives as a coating minimum inhibitory concentration (MIC) minimizing the product to be contaminated. The shelf life of foods gets extending through continuous reloading active components at surface of food with minimum degradation of these compounds, such that maintenance of MIC in the food is achieved for desired shelf life. Although change in the organoleptic properties of the packaged food need to be taken into consideration and offers a limiting factor. Antimicrobial films are developed using organic acids and EOs inside biopolymer matrix, that possess the properties to restrict the development of bacteria (Lactobacillus sakei and Serratia liquefaciens) above the exterior of vacuum-packed cured meat items was studied (Aider 2010). Protein incorporation specifically enzymes and bacteriocins in food packaging are also done preventing spoilage produced through food pathogenic microbes. Yildirim et al. (2018) studied lysozyme incorporation in whey protein films (204 mg/g of film) that located inside food, inhibiting Listeria monocytogenes development up to 4.4 log CFU/cm2, thus prolonging the shelf life of smoked salmon. The potential application of antimicrobial food packaging technology can also be developed using microwave treatment in chitosan–starch built film (Dutta et al. 2009). In order to reduce postharvest fungi rotting in grapes caused by Botrytis cinerea, grapefruit seed extract too tend to function synergistically. Some examples of natural extracts and essential oils which are used as antimicrobial agents in food packaging systems are listed in Table 4.

Table 5.

Application of natural extracts as Active Ingredient in Biological Packaging Processes

| Ingredient used | Procedure | Preservation | Sources |

|---|---|---|---|

| Green tea extract, oolong tea extract, black tea extract | Protein film from distilled dried grains with sdoluble | Meat products | Yang et al. (2016) |

| Oregano essential oil and green tea extract | Dark chocolate peanuts, milk chocolate cereals | Lorenzo et al. (2014) | |

| Oregano extract | - | Meat Products | Camo et al. (2008) |

| Oregano, rosemary extracts | Chitosan, pectin | Meat Products, Fresh cut Pears | Xiao et al. (2010) and Souza et al. (2020) |

| Natural extracts from brewery residual waste, rosemary extract | - | Frozen products | Barbosa-Pereira et al. (2014) |

| Barley husk extracts | - | Meat products | Pereira de Abreu et al. (2011) |

| Encapsulated anthocyanins from wine grape pomace | Cassava starch film | Oil products | Stoll et al. (2016) |

| Beet root residue powder | Gelatin capsule residue film | Oil products | Oliveira et al. (2016) |

| WPC | poly-ethylen-glycol (PEG), Glycerol, olive oil cobined with whey protein concentrate (WPC) by emulsification to create films | Improvement of shelf life | Javanmard (2012) |

| Mentha Essential Oil | Chitosan | Papaya | Ekrami, et al. (2019) |

| Orange essential oil | Egg protein | Kashra Cheese | Kavas (2016) |

| Lecithin-encapsulated thyme essential oil | Starch–gellan | Apple, tomato, and persimmon | Sapper et al. (2019) |

| Thymus vulgaris L. essential oil | Pullulan and polymeric nanocapsules containing essential oil | Table grapes (Vitis vinifera L.), Meat | Pina-Barrera et al. (2019), Nieto (2020) |

| Aloe vera gel | starch–chitosan | Edible films | Pinzon et al. (2018) |

| Carvacrol and cinnamaldehyde | Apple, carrot, and hibiscus | Leafy Vegetables | Wu et al. (2016) |

| Lemon EO | Chitosan | Increases antimicrobial activity and prolongs the shelf life of vegetable products, storage-keeping quality strawberries | Perdones et al. (2012) and Sessa et al. (2015) |

| Tea Polyphenols | Chitosan | Enhances sensory quality of Mango (Mangifera indica L.), reduces weight loss and respiration rate and inhibits chlorophyll degradation in fruit peels | Wang et al. (2007) |

| Mango leaf extract | Chitosan | Imparted antioxidant properties to film increasing shelf life of the packed cashew nuts remained preserved for 28 days | Rambabu et al. (2019) |

| Olive, garlic and pepper | Chitosan | Controls PPO activity in Butternut squash (Cucurbita moschata Duch): | Ponce et al. (2008) |

| Murta leaves | Gelatin,CMC | Increases O2 barrier in Apricot | Ihl et al. (2006) |

| Acacia seed | Galactomannan | Enhanced radical-scavenging activity and the phenolic content of the film | Cerqueira et al. (2010) |

Table 4.

Essential oils and extracts from natural sources as antimicrobial agents in Food packaging application

| Active Ingredient | Packaging Application | Food Application | Source |

|---|---|---|---|

| Cinnamon essential oil cinnamaldehyde | Bioploymer like chitosan | Puree | Yildirim et al. (2018) |

| Carvacrol and thymol | Nanocomposites | Strawberry | Zhu et al. (2014) |

| Basil leaf essential oil | Fish-protein isolates/ ZnO nanocomposites | Vegetables | Kuorwel et al. (2011) |

| Extract of Allium spp | Biopolymer Matrix | Ready to eat salads | Dong and Manjeet (2004) |

| Oregano (Lippia graveolens) essential oil | Pectin edible coatings | Tomatoes | Seydim and Sarikus (2006) |

| Lemon EOs | Chitosan | Antimicrobial films in combination with thyme and cinnamon essential oils | Peng and Li (2014) |

| Lime EOs | Gum-based edible coating | Eliminating growth of Colletotrichum gloeosporioides and Rhizopus stolonifer in fresh papaya | Bosquez-Molina et al. (2010) |

| Citrus reticulata var. tangerine EOs | Nanoemulsions based on chitosan nanoparticles | Preservation of seafoods | Rojas-Graü et al. (2007) |

Flavor/Odor absorbers and releasers

Active packaging can also be used to remove unwanted taints or odors from packaged food for absorption of volatile amines from the fish muscle breakdown, as well as aldehydes from the autoxidation caused by lipids. Odor and flavor absorbent is employed to remove undesirable properties that is produced during product deterioration in oxidative and biochemical reactions (Day and Potter 2011). EOs are often stated as GRAS (Generally Recognized as Safe) that are utilized in the form of flavoring agents to various foods like baked items, sweets, ice cream, beverages and chewing gum (Martín-Belloso et al. 2009). Organic acids like citric acid, were also used to scavenge amines and sodium sulphate, other organic sulphates and Tocopherols, have been shown to absorb aldehydes (Day and Potter 2011). Plant extracts have been used from years for improvement of organoleptic properties of food with preservative properties and mechanisms involved in the inhibition of lipid peroxidation (Nieto 2020). Examples of such extracts are provided in Table 5.

Essential oils and extracts from natural sources as active ingredients in food packaging

The application of EOs in active food packaging is currently strongly linked to their incorporation into biodegradable films in conjunction with another biopolymer. Incorporated EOs can enhance antimicrobial and antioxidant activity or reduce water vapor permeability as an additional ingredient directly added to edible films or encapsulated into the edible films. In addition to exhibiting antibacterial and antioxidant properties, EOs are compatible with a variety of foods, enhancing the shelf life and flavor of food products (Carpena et al. 2021). A recent study analyzed the antimicrobial activity of EOs obtained from different sources such as Syzygium aromaticum L., Foeniculum vulgare Miller, Cupressus sempervirens L., Lavandula angustifolia, Thymus vulgaris L., Verbena officinalis L., Pinus sylvestris and Rosmarinus officinalis. Some hydrocarbons and oxygenated monoterpenes commonly present in EOs such as α-pinene, β-pinene and p-cymene, thymol, carvacrol, borneol, linalool, terpineol-4-ol, 1,8-cineole, α-terpinyl acetate and camphor showed effective bactericidal effect (0.2 µg/mL and pH 4.0) against E. coli and L. monocytogenes (Barone et al. 2021). EOs of savory spices and herbs, are of special interest to be used in active food packaging. Some of the most prominent are oregano, thyme, rosemary, cinnamon or basil, along with α-tocopherol or β-carotene (Carpena et al. 2021). Active packaging consists of incorporating and/or immobilizing EOs in a packaging film instead of directly including them in the food, which allows the film to become a dynamic, interactive part of the food preservation process (Almasi et al. 2020). In order to promote a more gradual release of the active compound, encapsulation is most commonly used. The method is divided into two main groups: microcapsules (particles with a diameter of between 3 and 800 µm) and nano-capsules (particles with a diameter of between 10 and 1000 nm or 1 µm) (Barone et al. 2021). Extrusion and casting are two of the most common methods for incorporating active compounds into polymeric materials. As supported by the reports, EOs are considered as adequate active components, which in turn provide added value to the natural extract. EOs into new packaging systems such as biodegradable films could be an alternative option in the food packaging industry. Further studies are needed to evaluate the impact of adding essential oils to new packaging systems on their mechanical, organoleptic, and biological properties, as well as to ensure their safety and lack of side effects for consumers and the environment. A market study is strongly advised before the commercialization of new active packaging materials and the use of EOs so that the acceptance of these new products can be gauged (Carpena et al. 2021).

Safety and toxicity aspect of the active packaging system

Although active packaging can improve the safety and quality of fresh produce, safety concerns and confinements also need to be considered. The concerns should include migration of active materials from packaging material to fresh produce, leakage from sachets to fruits, and accidental ingestion of active materials by humans (Gaikwad et al. 2020). If the active or intelligent ingredient is incorporated into the plastic film, it must follow the toxicity aspect. Each country has its food laws according to the codex commission.

The main toxicity concerns for active materials are:

Food contact approval prior to usage of any type of active ingredient regulating the migration limits (Videira-Quintela et al. 2021).

The active materials shall not alter the composition or organoleptic characteristics of foods, such as masking the presence of spoilage, which might mislead consumers (Actipak 2001).

Migration of active substances needs to be considered carefully along with the breakdown products according to the toxicity for eg. KMNO4. The use of substances released from active packaging shall be governed by the relevant provisions applicable to food (Dainelli et al. 2008).

There is a need for adequate labeling that clearly indicates that the materials are active to avoid confusion to the consumer such as sachet contents (i.e. O2 scavenging sachets) (Davidson and Harrison 2002).

The influence of active packaging on the ecology of microbes and thereafter its effect on food safety must be taken into consideration.

The environmental regulations cover the use, reuse, recycling and identification of the packaging material for ensuring the recycling or recovery of energy from the active packaging components (Dairi et al. 2019).

Careful study should be conducted on the application of antimicrobials and antioxidant packaging on different food-based products with different release levels. In conclusion, it is necessary to consider microorganisms in all aspects while inhibiting them through antimicrobial films and other active packaging techniques (Dainelli et al. 2008).

COVID-19 and active packaging

Packaging for food safety regarding hygienic and sanitary aspects has gained greater attention in recent pandemic times. Food materials are generally packed mainly using different types of packaging materials like stainless steel, cardboard, and plastics that can serve as a survival ground for a longer duration, increasing the chances of disease transmission. For COVID-19, it has been found that SARS CoV-2 can survive in plastic surfaces for a maximum period of three days (Rahman et al. 2020). At a time when the world is experiencing a pandemic of viral infection, the development of packaging with antiviral potential is crucial. Naturally derived products and plant-based compounds such as green tea extract, grapefruit extract, Hibiscus sabdariffa extract, aloe vera, cinnamaldehyde, carvacrol, thymol, zataria, and oregano essential oils were studied and found to be effective antiviral agents with the potential to inhibit the viral spike protein in SARS-CoV-2 (Carpena et al. 2021). Mostly antiviral coatings have been applied in packaging to prevent the spread of human enteric viruses (Chakhalian et al. 2020); however, owing to the emergence of the SARS-CoV-2 pandemic, greater attention should be paid to antiviral active packaging against coronaviruses. Additionally, the herbal extracts of Lycoris radiata, Artemisia annua, Pyrrosia lingua, and Lindera aggregate and its compound lycorine showed antiviral activity against SARS-CoV-1. The essential oils from Laurus nobilis (IC50 of 120 µg ml − 1), Thuja orientalis (IC50 of 130 µg ml − 1), and Juniperus oxycedrus ssp. oxycedrus (IC50 of 270 µg ml − 1) too exhibited activity against SARS-CoV-1 (Loizzo et al. 2008). Thus, studies have shown that there are diverse natural compounds that should be evaluated for the development of viable antiviral packaging providing beneficial activity on the food product. There has been no evidence that foods or food packaging transmit viruses that cause respiratory illnesses. In order to eliminate or reduce the risk of food surfaces and food packaging materials becoming contaminated with the virus, it is imperative that the food industry reinforce personal hygiene measures and provide refresher training on food hygiene principles. Active packaging is also capable of carrying out functions like detecting, recording, tracing when combined with intelligent packaging systems etc. to facilitate decision making to extend shelf life and improve quality of food (Hosseini and Jafari 2019). Some common ones include temperature sensors that demonstrate a false reading by changing color, freshness indicators based on volatile content or hydrogen sulfide content, and gas sensors which alert the user to changes in the interior atmosphere. The latest advances in smart package devices include indicators, data carriers and sensors that provides information about the presence or absence of a substance (Dey and Neogi 2019). Further research on this kind of technology could be employed for detecting a viral substance too in packaging material. Such advanced technologies could contribute significantly to food safety as they can allow the investigators to identify the source of disease and act accordingly within a short period of time.

Conclusion and future prospects

There is no doubt that the use of active and intelligent packaging systems for food has become increasingly popular with innovative applications that deliver enhanced shelf life and greater assurance of food safety. Food packaging technology is continuously evolving keeping in mind to meet the growing challenges from a modern society, including change in the usage of biological materials. Natural extracts having antimicrobial, antioxidant and anti-browning activities, are the best choice for inhibiting the spoilage factors in food products. The increase in market competition to improve food shelf life, while maintaining eco-friendliness and economics, the discovery of biodegradable, biocompatible, non-toxic, and economic biologically active substances are becoming more important at present. Active packaging system contains bioactive ingredients that play an important role in increasing the health-promoting effects of food on consumers through the production of healthier packaged foods. They provide novel biodegradable and eco-friendly alternative to petrochemical-based plastics. The mechanical and barrier properties reported for natural-based biodegradable polymers are poor compared to other packaging materials in food industry which can be improved further by the addition of several other biopolymers in the form of composites/blends. There is wide range of bioactive properties in plant natural sources that remains to be investigated and regulated for application directly on foods and used for the development of active packaging or biopolymer-based edible films for preserving and adding value to foods.

Acknowledgements

The authors would like to acknowledge the support received from UGC-SAP and DST-FIST for carrying out this work.

Authors' contributions

DD: Resources; writing-original draft; visualization. NS: conceptualization; resources; writing-review and editing; visualization; supervision.

Funding

Not applicable.

Availability of data and material

Data and material will be available on request.

Code availability

Not applicable.

Declarations

Conflicts of interest

The authors declare no conflict of interest.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Abugoch LE, Cristián TC, Villamán MC, Yazdani-Pedram M, Diaz-Dosque M. Characterization of quinoa protein- chitosan blend edible films. Food Hydrocoll. 2011;25:879–886. doi: 10.1016/j.foodhyd.2010.08.008. [DOI] [Google Scholar]

- Actipak (2001) Evaluating safety, effectiveness, economic-environmental impact and consumer acceptance of active and intelligent packaging, FAIR project CT-98–4170

- Ahmad QS, Asgher M, Bilal M, Iqbal HMN. Bio-based active food packaging materials: sustainable alternative to conventional petrochemical-based packaging materials. Food Res Int. 2020 doi: 10.1016/j.foodres.2020.109625. [DOI] [PubMed] [Google Scholar]

- Ahmed S, Sameen DE, Lu R, Li R, Dai J, Qin W, Liu Y. Research progress on antimicrobial materials for food packaging. Crit Rev Food Sci Nutri. 2022;62(11):3088–3102. doi: 10.1080/10408398.2020.1863327. [DOI] [PubMed] [Google Scholar]

- Aider M. Chitosan application for active bio-based films production and potential in the food industry: review. LWT Food Sci Technol. 2010;43(6):837–842. doi: 10.1016/j.lwt.2010.01.021. [DOI] [Google Scholar]

- Almasi H, Jahanbakhsh Oskouie M, Saleh A. A review on techniques utilized for design of controlled release food active packaging. Crit Rev Food Sci Nutr. 2020 doi: 10.1080/10408398.2020.1783199. [DOI] [PubMed] [Google Scholar]

- Anthierens T, Ragaert P, Verbrugghe S, Ouchchen A, De Geest BG, Noseda B, Mertens J, Beladjal L, De Cuyper D, Dierickx W, Du Prez F, Devlieghere F. Use of endospore-forming bacteria as an active oxygen scavenger in plastic packaging materials. Innov Food Sci Emerg Technol. 2011;12:594–599. doi: 10.1016/j.ifset.2011.06.008. [DOI] [Google Scholar]

- Appendini P, Hotchkiss JH. Review of antimicrobial food packaging. Innov Food Sci Emerg Technol. 2002;3:113–126. doi: 10.1016/S1466-8564(02)00012-7. [DOI] [Google Scholar]

- Atarés L, Chiralt A. Essential oils as additives in biodegradable films and coatings for active food packaging. Trends in Food Science & Technology. 2016;48:51–62. doi: 10.1016/j.tifs.2015.12.001. [DOI] [Google Scholar]

- Avramescu SM, Butean C, Popa CV, Ortan A, Moraru I, Temocico G. Edible and functionalized films/coatings—performances and perspectives. Coatings. 2020;10:687. doi: 10.3390/coatings10070687. [DOI] [Google Scholar]

- Azeredo HMC. Nanocomposites for food packaging applications. Food Res Int. 2009;42:1240–1253. doi: 10.1016/j.foodres.2009.03.019. [DOI] [Google Scholar]

- Azeredo HMC, Otoni CG, Corrêa DS, Assis OBG, Moura MR, Mattoso LHC. Nanostructured antimicrobials in food packaging: recent advances. Biotechnol J. 2019 doi: 10.1002/biot.201900068. [DOI] [PubMed] [Google Scholar]

- Azeredo HMCD, Mattoso LHC, Mchugh TH (2011) In: B Reddy (Ed.), Nanocomposites in food packaging –a review, advances in diverse industrial applications of nanocomposites. InTech. https://www.intechopen.com/books/advances-in-diverse-industrial-applications-ofnanocomposites/nanocomposites-in-food-packaging-a-review

- Barbosa-Pereira L, Aurrekoetxea GP, Angulo I, Paseiro-Losada P, Cruz JM. Development of new active packaging films coated with natural phenolic compounds to improve the oxidative stability of beef. Meat Sci. 2014;97(2):249–254. doi: 10.1016/j.meatsci.2014.02.006. [DOI] [PubMed] [Google Scholar]

- Barone AS, Matheus JRV, Souza TSP, Moreira RFA, Fai AEC. Green-based active packaging: opportunities beyond COVID-19, food applications, and perspectives in circular economy—a brief review. Compr Rev Food Sci Food Saf. 2021 doi: 10.1111/1541-4337.12812. [DOI] [PubMed] [Google Scholar]

- Becerril R, Gomez-Lus R, Goni P, Lopez P, Nerin C. Combination of analytical and microbiological techniques to study the antimicrobial activity of a new active food packaging containing cinnamon or oregano against E-coli and S-aureus. Anal Bioanal Chem. 2007;388:1003–1011. doi: 10.1007/s00216-007-1332-x. [DOI] [PubMed] [Google Scholar]

- Berthet MA, HeleneA C, Guillard V, Gontard N. Vegetal fiber-based biocomposites: Which stakes for food packaging applications. J Appl Polym Sci. 2015;2016(133):42528. doi: 10.1002/app.42528. [DOI] [Google Scholar]

- Bhargava N, Sharanagat VS, Mor RS, Kumar K. Active and intelligent biodegradable packaging films using food and food waste-derived bioactive compounds: a review. Trends Food Sci Technol. 2020 doi: 10.1016/j.tifs.2020.09.015. [DOI] [Google Scholar]

- Bora H, Kamle M, Mahato DK, Tiwari P, Kumar P. Citrus essential oils (CEOs) and their applications in food: an overview. Plants. 2020;9:357. doi: 10.3390/plants9030357. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bosquez-Molina E, Ronquillo-de JE, Bautista-Baños S, Verde-Calvo JR, Morales-López J. Inhibitory effect of essential oils against Colletotrichum gloeosporioides and Rhizopus stolonifer in stored papaya fruit and their possible application in coatings. Postharvest Biol Technol. 2010;57:132–137. doi: 10.1016/j.postharvbio.2010.03.008. [DOI] [Google Scholar]

- Brandelero RPH, Brandelero EM, Almeida FMD. Biodegradable films of starch/PVOH/alginate in packaging systems for minimally processed lettuce (Lactuca sativa L.) Ciência e Agrotecnologia. 2016;40(5):510–521. doi: 10.1590/1413-70542016405010516. [DOI] [Google Scholar]

- Busolo MA, Lagaron JM. Antioxidant polyethylene films based on a resveratrol containing clay of interest in food packaging applications. Food Packag Shelf Life. 2015;6:30–41. doi: 10.1016/j.fpsl.2015.08.004. [DOI] [Google Scholar]

- Camo J, Antonio Beltran J, Roncales P. Extension of the display life of lamb with an antioxidant active packaging. Meat Sci. 2008;80(4):1086–1091. doi: 10.1016/j.meatsci.2008.04.031. [DOI] [PubMed] [Google Scholar]

- Carpena M, Nuñez-Estevez B, Soria-Lopez A, Garcia-Oliveira P, Prieto MA. Essential oils and their application on active packaging systems: a review. Resources. 2021;10:7. doi: 10.3390/resources10010007. [DOI] [Google Scholar]

- Cerqueira MA, Souza BWS, Martins JT, Teixeira JA, Vicente AA. Seed extracts of Gleditsia triacanthos: functional properties evaluation and incorporation into galactomannan films. Food Res Int. 2010;43(8):2031–2038. doi: 10.1016/j.foodres.2010.06.002. [DOI] [Google Scholar]

- Chakhalian D, Shultz RB, Miles CE, Kohn J. Opportunities for biomaterials to address the challenges of COVID-19. J Biomed Mater Res. 2020;108(10):1974–1990. doi: 10.1002/jbm.a.37059. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Coma V, Martial-Gros A, Garreau S, Copinet A, Salin F, Deschamps A. Edible antimicrobial films based on chitosan matrix. J Food Sci. 2002;67(3):1162–1169. doi: 10.1111/j.1365-2621.2002.tb09470. [DOI] [Google Scholar]

- Dainelli D, Gontard N, Spyropoulos D, Zondervan-vandenBeuken E, Tobback P. Active and intelligent food packaging: legal aspects and safety concerns. Trends Food Sci Technol. 2008;1(19):S103–S112. doi: 10.1016/j.tifs.2008.09.011. [DOI] [Google Scholar]

- Darni Y, Utami H, Septiana R, Fitriana RA. Comparative studies of the edible film based on low pectin methoxyl with glycerol and sorbitol plasticizers. J Bahan Alam Terbarukan. 2017;6(2):158–167. doi: 10.15294/jbat.v6i2.9707. [DOI] [Google Scholar]

- Dairi N, Ferfera-Harrar H, Ramos M, Garrigós MC. Cellulose acetate/AgNPs-organoclay and/or thymol nano-biocomposite films with combined antimicrobial/antioxidant properties for active food packaging use. Int J Biol Macromol. 2019;121:508–523. doi: 10.1016/j.ijbiomac.2018.10.042. [DOI] [PubMed] [Google Scholar]

- Dantas EA, Costa SS, Cruz LS, Bramont WB, Costa AS, Padilha FF, Druzian JI, Machado BAS. Characterization and evaluation of the antioxidant properties of biodegradable films incorporated with tropical fruit pulps. Ciência Rural. 2015;45(1):142–148. doi: 10.1590/0103-8478cr20131458. [DOI] [Google Scholar]

- Davidson PM, Harrison MA. Resistance and adaptation to food antimicrobials, sanitizers, and other process controls. Food Technol. 2002;56(11):69–78. [Google Scholar]

- Day BPF, Potter L (2011) Active packaging. In: Coles R, Kirwan M (eds) Food and beverage packaging technology, Second Edition

- Delgado-Adámez E, Bote V, Parra-Testal MJ, Martín RR. Packag. Technol Sci. 2016;29:649–660. [Google Scholar]

- Dey A, Neogi S. Oxygen scavengers for food packaging applications: a review. Trends Food Sci Technol. 2019 doi: 10.1016/j.tifs.2019.05.013. [DOI] [Google Scholar]

- Dong SC, Manjeet SC. Biopolymer-based antimicrobial packaging: a review. Crit Rev Food Sci Nutr. 2004;44:223–237. doi: 10.1080/10408690490464276. [DOI] [PubMed] [Google Scholar]

- Dutta PK, Tripathi S, Mehrotra GK, Dutta J. Perspectives for chitosan based antimicrobial films in food applications. Food Chem. 2009;114(4):1173–1182. doi: 10.1016/j.foodchem.2008.11.047. [DOI] [Google Scholar]

- Ekrami M, Emam-Djomeh Z, Ghoreishy SA, Najari Z, Shakoury N. Characterization of a high-performance edible film based on Salep mucilage functionalized with pennyroyal (Mentha pulegium) Int J Biol Macromol. 2019;133:529–537. doi: 10.1016/j.ijbiomac.2019.04.136. [DOI] [PubMed] [Google Scholar]

- Fabra MJ, López-Rubio A, Lagaron JM. Use of the electrohydrodynamic process to develop active/bioactive bilayer films for food packaging applications. Food Hydrocol. 2016;55:11–18. doi: 10.1016/j.foodhyd.2015.10.026. [DOI] [Google Scholar]

- Friedman M, Juneja VK. Review of antimicrobial and antioxidative activities of chitosans in food. J Food Prot. 2010;73(9):1737–1761. doi: 10.4315/0362-028x-73.9.1737. [DOI] [PubMed] [Google Scholar]

- Gaikwad KK, Singh S, Negi YS. Ethylene scavengers for active packaging of fresh food producd. Environ Chem Lett. 2020 doi: 10.1007/s10311-019-00938. [DOI] [Google Scholar]

- Galus S, Lenart A. Development and characterization of composite edible films based on sodium alginate and pectin. J Food Eng. 2013;115:459–465. doi: 10.1016/j.jfoodeng.2012.03.006. [DOI] [Google Scholar]

- Gomes MA, Ascheri DPR, de Campos AJ. Characterization of edible films of Swartzia burchelli phosphated starches and development of coatings for post-harvest application to cherry tomatoes. Semina Ciências Agrárias. 2016;37(4):1897–1909. doi: 10.5433/1679-0359.2016v37n4p1897. [DOI] [Google Scholar]

- Grant J, Cho J, Allen C. Self-assembly and physicochemical and rheological properties of a polysaccharide−surfactant system formed from the cationic biopolymer chitosan and nonionic sorbitan esters. Langmuir. 2006;22(9):4327–4335. doi: 10.1021/la060017g. [DOI] [PubMed] [Google Scholar]

- Hosseini H, Jafari SM. Introducing nano/ microencapsulated bioactive ingredients for extending the shelf-life of food products. Adv Coll Interface Sci. 2019 doi: 10.1016/j.cis.2020.102210. [DOI] [PubMed] [Google Scholar]

- Ihl M, Bifani C, Ramirez C, Rubilar M, Motomura Y, Menses C, Infante R, Seguel I. Preliminary study on edible film with a natural plant extract to improve quality of fresh fruit for supply chains. Acta Hortic (ISHS) 2006;712:617–622. doi: 10.17660/ActaHortic.2006.712.75. [DOI] [Google Scholar]

- Javanmard M. Shelf-life of apples coated with whey protein concentrate-gellan gum edible coatings. J Food Biosci Technol. 2012;1(1):55–62. [Google Scholar]

- Jose ML, Maria JO, LoPez-Rubio A (2012) In Ch: Antimicrobial packaging polymers. A general introduction, antimicrobial polymers, First Edition. nstituto de Agroquı ´mica y Tecnologı ´a de Alimentos (IATA), CSIC, Valencia, Spain

- Júnior AV, Fronza N, Foralosso FB, Dezen D, Huber E, dos Santos JHZ, et al. Biodegradable duo-functional active film: antioxidant and antimicrobial actions for the conservation of beef. Food Bioprocess Technol. 2015;8(1):75–87. doi: 10.1007/s11947-014-1376-9. [DOI] [Google Scholar]

- Kammouna M, Haddarc M, Kallelc TK, Dammakc M, Sayari A. Biological properties and biodegradation studies of chitosan biofilms plasticized with PEG and glycerol. Int J Biol Macromol. 2013;62:433–438. doi: 10.1016/j.ijbiomac.2013.09.025. [DOI] [PubMed] [Google Scholar]

- Kavas N, Kavas G. Physical-chemical and antimicrobial properties of egg white protein powder films incorporated with orange essential oil on Kashar Cheese. Food Sci Technol. 2016;36:672–678. doi: 10.1590/1678-457x.12516. [DOI] [Google Scholar]

- Khezerlou A, Mahdi Jafari SM. Nanoencapsulated bioactive components for active food packaging. Handb Food Nanotechnol. 2020 doi: 10.1016/B978-0-12-815866-1.00013-3. [DOI] [Google Scholar]

- Kumar S, Thakur KS. Active packaging technology to retain storage quality of pear cv. “Bartlett” during shelf-life periods under ambient holding after periodic cold storage. Packag Technol Sci. 2020;33:1–16. doi: 10.1002/pts.2501. [DOI] [Google Scholar]

- Kuorwel KK, Cran MJ, Sonneveld K, Miltz J, Bigger SW. Essential oils and their principal constituents as antimicrobial agents for synthetic packaging films. J Food Sci. 2011;76:R164–R177. doi: 10.1111/j.1750-3841.2011.02384.x. [DOI] [PubMed] [Google Scholar]

- Laohakunjit N, Kerdchoecuen O. Aroma enrichment and the change during storage of non-aromatic milled rice coated with extracted natural flavour. Food Chem. 2007;101:339–344. doi: 10.1016/j.foodchem.2005.12.055. [DOI] [Google Scholar]

- Latou E, Mexis SF, Badeka AV, Kontakos S, Kontominas MG. Combined effect of chitosan and modified atmosphere packaging for shelf life extension of chicken breast fillets. LWT Food Sci Technol. 2014;55(1):263–268. doi: 10.1016/j.lwt.2013.09.010. [DOI] [Google Scholar]

- Leistner L. Basic aspects of food preservation by hurdle technology. Int J Food Microbiol. 2000;55:181–186. doi: 10.1016/S0168-1605(00)00161-6. [DOI] [PubMed] [Google Scholar]

- Loizzo MR, Saab AM, Tundis R, Statti GA, Menichini F, Lampronti I, Gambari R, Cinatl J, Doerr HW. Phytochemical analysis and in vitro antiviral activities of the essential oils of seven Lebanon species. Chem Biodivers. 2008;5(3):461–470. doi: 10.1002/cbdv.200890045. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lopez P, Sanchez C, Batlle R, Nerin C. Vapor-phase activities of cinnamon, thyme, and oregano essential oils and key constituents against foodborne microorganisms. J Agric Food Chem. 2007;55:4348–4356. doi: 10.1021/jf063295u. [DOI] [PubMed] [Google Scholar]

- Lopez-de-Dicastillo C, Pezo D, Nerın C, Lopez-Carballo G, Catal ´ a R, ´ Gavara R, Hernandez-Mu ´ noz P. Reducing oxidation of foods ˜ through antioxidant active packaging based on ethyl vinyl alcohol and natural flavonoids. Packag Technol Sci. 2012;25(8):457–466. doi: 10.1002/pts.992. [DOI] [Google Scholar]

- Lorenzo JM, Batlle R, Gomez M. Extension of the shelf-life of foal ´ meat with two antioxidant active packaging systems. LWT-Food Sci Technol. 2014;59(1):181–188. doi: 10.1016/j.lwt.2014.04.061. [DOI] [Google Scholar]

- Maran JP, Sivakumar V, Sridhar R, Immanuel VP. Development of model for mechanical properties of tapioca starch based edible films. Ind Crops Prod. 2013;42:159–168. doi: 10.1016/j.indcrop.2012.05.011. [DOI] [PubMed] [Google Scholar]

- Martín-Belloso O, Alejandra R G, Soliva-Fortuny R (2009) Delivery of flavor and active ingredients using edible films and coatings In: Edible films and coatings for food applications, Ch 10 295. 10.1007/978-0-387-92824-1_10

- Martínez-Abad A, Ocio MJ, Lagaron JM. Morphology, physical properties, silver release, and antimicrobial capacity of ionic silver-loaded poly (L-lactide) films of interest in food-coating applications. J Appl Polym Sci. 2014;131(21):41001. doi: 10.1002/app.41001. [DOI] [Google Scholar]

- Mir SA, Dar BN, Wani AA, Shah MA. Effect of plant extracts on the techno-functional properties of biodegradable packaging films. Trends Food Sci Technol. 2018 doi: 10.1016/j.tifs.2018.08.004. [DOI] [Google Scholar]

- Moller H, Grelier S, Pardon P, Coma V. Antimicrobial and physicochemical properties of chitosan-HPMC-based films. J Agric Food Chem. 2004;52:6585–6591. doi: 10.1021/jf0306690. [DOI] [PubMed] [Google Scholar]

- Namratha S, Sreejit V, Preetha R. Fabrication and evaluation of physicochemical properties of probiotic edible film based on pectin–alginate–casein composite. Int J Food Sci Technol. 2020;55(4):1497–1505. doi: 10.1111/ijfs.14550. [DOI] [Google Scholar]

- Ngo TMP, Nguyen TH, Dang TMQ, Tran TX, Rachtanapun P. Characteristics and antimicrobial properties of active edible films based on pectin and nanochitosan. Int J Mol Sci. 2020;21:2224. doi: 10.3390/ijms21062224. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nieto G. A review on applications and uses of thymus in the food industry. Plants. 2020;9:961. doi: 10.3390/plants9080961. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oliveira A, Iahnke S, Costa TMH, de Oliveira RA, Flores SH. Antioxidant films based on gelatin capsules and minimally processed beet root (Beta vulgaris L. var. Conditiva) residues. J Appl Polym Sci. 2016;133(10):43094. doi: 10.1002/app.43094. [DOI] [Google Scholar]

- Ooi ZX, Ismail H, Bakar AA, Aziz NAA. Properties of the crosslinked plasticized biodegradable poly(vinyl alcohol)/rambutan skin waste flour blends. J Appl Polym Sci. 2012;125:1127–1135. doi: 10.1002/app.34860. [DOI] [Google Scholar]

- Park H-Y, Kim S-J, Kim KM, You Y-S, Kim SY, Han J. Development of antioxidant packaging material by applying corn-zein to LLDPE film in combination with phenolic compounds. J Food Sci. 2012;77(10):E273–E279. doi: 10.1111/j.1750-3841.2012.02906.x. [DOI] [PubMed] [Google Scholar]

- Pascall MA, Lin SJ. The application of edible polymeric films and coatings in the food industry. Food Process Technol. 2013;4:116. [Google Scholar]

- Peng Y, Li Y. Combined effects of two kinds of essential oils on physical, mechanical and structural properties of chitosan films. Food Hydrocoll. 2014;36:287–293. doi: 10.1016/j.foodhyd.2013.10.013. [DOI] [Google Scholar]

- Perdones A, Sánchez-González L, Chiralt A, Vargas M. Effect of chitosan–lemon essential oil coatings on storage-keeping quality of strawberry. Postharvest Biol Technol. 2012;2012(70):32–41. doi: 10.1016/j.postharvbio.2012.04.002. [DOI] [Google Scholar]

- Pereira de Abreu DA, Paseiro Losada P, Maroto J, Cruz JM. Natural antioxidant active packaging film and its effect on lipid damage in frozen blue shark (Prionace glauca) Innov Food Sci Emerg. 2011;12(1):50–55. doi: 10.1016/j.ifset.2010.12.006. [DOI] [Google Scholar]

- Pina-Barrera AM, Alvarez-Roman R, Baez-Gonzalez JG, Amaya-Guerra CA, Rivas-Morales C, Gallardo-Rivera CT, Galindo-Rodriguez SA. Application of a multisystem coating based on polymeric nanocapsules containing essential oil of Thymus vulgaris L. to increase the shelf life of table grapes (Vitis vinifera L.) IEEE Trans Nanobiosci. 2019;18:549–557. doi: 10.1109/TNB.2019.2941931. [DOI] [PubMed] [Google Scholar]

- Pinzon MI, Garcia OR, Villa CC. The influence of Aloe vera gel incorporation on the physicochemical and mechanical properties of banana starch-chitosan edible films. J Sci Food Agric. 2018;98:4042–4049. doi: 10.1002/jsfa.8915. [DOI] [PubMed] [Google Scholar]

- Ponce AG, Roura SI, Del Valle CE, Moreira MR. Antimicrobial and antioxidant activities of edible coating enriched with natural plant extract: in vitro and in vivo studies. Postharvest Biol Technol. 2008;49(2):294–300. doi: 10.1016/j.postharvbio.2008.02.013. [DOI] [Google Scholar]

- Priyadarshi R, Rhim JW. Chitosan-based biodegradable functional films for food packaging applications. Innov Food Sci Emerg Technol. 2020;62(2020):102346. doi: 10.1016/j.ifset.2020.102346. [DOI] [Google Scholar]

- Priyadarshi R, Sauraj K, B., & Negi, Y. S. Chitosan film incorporated with citric acid and glycerol as an active packaging material for extension of green chilli shelf life. Carbohyd Polym. 2018;195:329–338. doi: 10.1016/j.carbpol.2018.04.089. [DOI] [PubMed] [Google Scholar]

- Rahman CF, Sharun K, Jose B, Dhama K. (2020) Covid-19 and food safety: implications and opportunities to improve the food supply chain. J Exp Biol Agric Sci. 2020;8:S34–41. doi: 10.18006/2020.8(Spl-1-SARS-CoV-2).S34.S41. [DOI] [Google Scholar]

- Rambabu K, Bharath G, Banat F, Show PL, Cocoletzi HH. Mango leaf extract incorporated chitosan antioxidant film for active food packaging. Int J Biol Macromol. 2019;126:1234–1243. doi: 10.1016/j.ijbiomac.2018.12.196. [DOI] [PubMed] [Google Scholar]

- Rojas-Graü MA, Olsen C, Avena-Bustillos RJ, Friedman M, Henika PR, Martín-Belloso O, Pan Z, McHugh TH. Effects of plant essential oils and oil compounds on mechanical, barrier and antimicrobial properties of alginate-apple puree edible films. J Food Eng. 2007;81:634–641. doi: 10.1016/j.jfoodeng.2007.01.007. [DOI] [Google Scholar]

- Sadeghizadeh Y, Habibi M, Kamali AA, MahdiBanaei M. Curr Res. Nutr Food Sci J. 2019;7(3):624–637. [Google Scholar]

- Sängerlaub S, Gibis D, Kirchhoff E, Tittjung M, Schmid M, Müller K. Compensation of pinhole defects in food packages by application of iron-based oxygen scavenging multilayer films. Packag Technol Sci. 2013;26(1):17–30. doi: 10.1002/pts.1962. [DOI] [Google Scholar]

- Santoso B, Pratama F, Hamzah B, Pambayun R. The effect of eel's protein extract on the characteristics of edible film from crosslinked modified canna starch. Int Food Res J. 2019;26(1):161–165. [Google Scholar]

- Sapper, M.; Bonet, M.; Chiralt, A. (2019). Wettability of starch-gellan coatings on fruits, as affected by the incorporation of essential oil and/or surfactants. LWT, 116.

- Sessa M, Donsì FG, F, Novel edible coating containing essential oil nanoemulsions to prolong the shelf life of vegetable products. Chem Eng Trans. 2015;43:55–60. [Google Scholar]

- Seydim AC, Sarikus G. Antimicrobial activity of whey protein based edible films incorporated with oregano, rosemary and garlic essential oils. Food Res Int. 2006;39:639–644. doi: 10.1016/j.foodres.2006.01.013. [DOI] [Google Scholar]

- Silva-Weiss A, Ihl M, Sobral PJA, Go´mez-Guille M C, Bifani, V. Natural additives in bioactive edible films and coatings: functionality and applications in foods. Food Eng Rev. 2013;5:200–216. doi: 10.1007/s12393-013-9072-5. [DOI] [Google Scholar]

- Singla M, Prabhakar PK, Sharma A, Meghwal M (2022) Edible and Oral Thin Films: Formulation, Properties, Functions, and Application in Food Packaging and Pharmaceutical Industry. In Edible Food Packaging pp. 411–432

- Siripatrawan U, Noipha S. Active film from chitosan incorporating green tea extract for shelf life extension of pork sausages. Food Hydrocoll. 2012;27(1):102–108. doi: 10.1016/j.foodhyd.2011.08.011. [DOI] [Google Scholar]

- Sofi SA, Singh RJ, Ashraf S, Dar U, Nayik BN, Ahmad G. A comprehensive review on antimicrobial packaging and its use in food packaging. Curr Nutr Food Sci. 2018;14(4):305–312. doi: 10.2174/1573401313666170609095732. [DOI] [Google Scholar]

- Souz VG, Pires JR, Rodrigues C, Coelhoso IM, Fernando AL. Chitosan composites in packaging industry current trends and future challenges. Polymers. 2020;12(2):417. doi: 10.3390/polym12020417. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stoll L, Haas Costa TM, Jablonski A, Hickmann Flores S, de Oliveira RA. Microencapsulation of anthocyanins with different wall materials and its application in active biodegradable films. Food Bioprocess Technol. 2016;9(1):172–181. doi: 10.1007/s11947-015-1610-0. [DOI] [Google Scholar]

- Syahida N, Zuriyati MA, Mohammad RI-F, Zainal ANH. Development and characterisation of gelatine/palm wax/lemongrass essential oil (GPL)-coated paper for active food packaging. Packag Technol Sci. 2020 doi: 10.1002/pts.2512. [DOI] [Google Scholar]

- Tapia MS, Rodríguez FJ, Rojas-Graü MA, Martín-Belloso O (2005) Formulation of alginate and gellan based edible coatings with antioxidants for fresh-cut apple and papaya. IFT Annual Meeting. New Orleans, LA. Paper 36E–43

- Videira-Quintela D, Martin O, Montalvo G. Recent advances in polymer-metallic composites for food packaging applications. Trends Food Sci Technol. 2021;109:230–244. doi: 10.1016/j.tifs.2021.01.020. [DOI] [Google Scholar]

- Wang J, Wang B, Jiang W, Zhao Y. Quality and shelf life of mango (Mangifera Indica L. cv.Tainong') coated by using chitosan and polyphenols. Food Sci Technol Int. 2007;13(4):317–322. doi: 10.1177/1082013207082503. [DOI] [Google Scholar]

- Wojtunik-Kulesza KA, Ciesla ŁM, Waksmundzka-Hajnos M. Approach to determination a structure—antioxidant activity relationship of selected common terpenoids evaluated by ABTS•+ radical cation assay. Nat Prod Commun. 2018;13(3):295–298. [Google Scholar]

- Wu C, Wang L, Hu Y, Chen S, Liu D, Yete X. Edible coating from citrus essential oil-loaded nanoemulsions: Physicochemical characterization and preservation performance. RSC Adv. 2016;6:20892–20900. doi: 10.1039/C6RA00757K. [DOI] [Google Scholar]

- SDNG X, CHENG L, TAN L. Edible iron yam and maize starch convenient food flavoring packaging films with lemon essential oil as plasticization. Food Sci Technol. 2019 doi: 10.1590/fst.13118. [DOI] [Google Scholar]

- Xiao C, Zhu L, Luo W, Song X, Deng Y. Combined action of pure oxygen pretreatment and chitosan coating incorporated with rosemary extracts on the quality of fresh-cut pears. Food Chem. 2010;121:1003–1009. doi: 10.1016/j.foodchem.2010.01.038. [DOI] [Google Scholar]

- Xiong Y, Chen M, Warner RD, Fang Z. Incorporating nisin and grape seed extract in chitosan-gelatine edible coating and its effect on cold storage of fresh pork. Food Control. 2020;110:107018. doi: 10.1016/j.foodcont.2019.107018. [DOI] [Google Scholar]

- Yang H-J, Lee J-H, Won M, Song KB. Antioxidant activities of distiller dried grains with solubles as protein films containing tea extracts and their application in the packaging of pork meat. Food Chem. 2016;196:174–179. doi: 10.1016/j.foodchem.2015.09.020. [DOI] [PubMed] [Google Scholar]

- Yeddes W, Djebali K, Aidi Wannes W, Horchani-Naifer K, Hammami M, Younes I, Saidani Tounsi M. Gelatin-chitosan-pectin films incorporated with rosemary essential oil: optimized formulation using mixture design and response surface methodology. Int J Biol Macromol. 2020;154:92–103. doi: 10.1016/j.ijbiomac.2020.03.092. [DOI] [PubMed] [Google Scholar]

- Yildirim SU, Rocker B, Pettersen MK, Nilsen-Nygaard J, Ayhan Z, Rutkaite RM, Radusin T, Suminska P, Marcos B, Coma V. Active packaging applications for food. Compr Rev Food Sci Food Saf. 2018 doi: 10.1111/1541-4337.12322. [DOI] [PubMed] [Google Scholar]

- Yong H, Wang X, Zhang X, Liu Y, Qin Y, Liu J. Effects of anthocyanin-rich purple and black eggplant extracts on the physical, antioxidant and pH-sensitive properties of chitosan film. Food Hydrocol. 2019;94:93–104. doi: 10.1016/j.foodhyd.2019.03.012. [DOI] [Google Scholar]

- Zhang W, He H, Zhu L, Liu G, Wu L. Food safety in post-COVID-19 pandemic: challenges countermeasures (COVID-19 and food safety: guidance for food businesses: interim guidance) Biosensors. 2021;11:71. doi: 10.3390/bios11030071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhu L, Olsen C, McHugh T, Friedman M, Jaroni D, Ravishankar S. Apple, carrot, and hibiscus edible films containing the plant antimicrobials carvacrol and cinnamaldehyde inactivate Salmonella Newport on organic leafy greens in sealed plastic bags. J Food Sci. 2014;79:M61–M66. doi: 10.1111/1750-3841.12318. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data and material will be available on request.

Code availability

Not applicable.