Abstract

Self-healing materials play an essential role in the field of organic electronics with numerous stunning applications such as novel integrated and wearable devices. With the development of stretchable, printable, and implantable electronics, organic field-effect transistors (OFETs) with a self-healable capability are becoming increasingly important both academically and industrially. However, the related research work is still in the initial stage due to the challenges in developing robust self-healing electronic materials with both electronic and mechanical properties. In this mini-review, we have summarized the recent research progress in self-healing materials used in OFETs from conductor, semiconductor, and insulator materials. Moreover, the relationship between the material design and device performance for self-healing properties is also further discussed. Finally, the primary challenges and outlook in this field are introduced. We believe that the review will shed light on the development of self-healing electronic materials for application in OFETs.

1. Introduction

With the growing demands of renewable energy and the fast development of organic electronics, materials with self-healing ability have attracted increasing interest due to their vast prospects in the fields of electronic skins (E-skins), sensors, supercapacitors, OFETs, solar cells, and so on.1−4 However, it has been a persistent problem that the accumulation of uncontrolled damages by abrasion, breakage, aging, degradation, mechanical damage, or operational fatigue in the process of actual use would lead to an attenuation of the device performance and an increasing shortening of the service life.5 In terms of this issue, with the remarkable ability of human skin to restore itself from wounds as inspiration, novel intelligent self-healing materials (SHMs) that possess the ability to autonomically repair damages inflicted during the operation procedure are becoming increasingly important.6,7 These functional materials with self-healable ability could dramatically increase the durability and prolong the lifetime of the devices. Although very promising progress has been made in soft self-healing fields such as wearable sensors, E-skins, fabrics, and so on, there is still a long way to go for self-healing materials to be used in practical applications or in commercial demands. Self-healing materials should be optimized and improved in three aspects, including fast healing efficiency, biocompatibility, and low cost, which could enhance the performance and lifespan of electronic devices.7

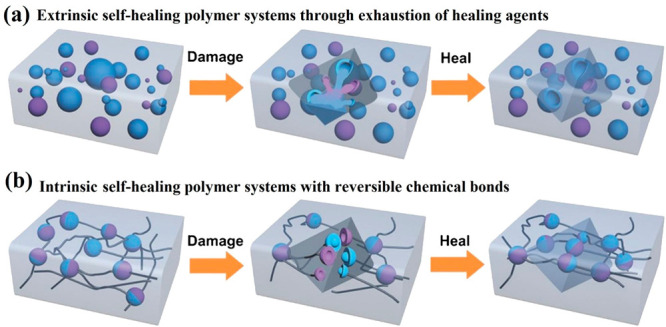

In general, the current SHMs can be broadly divided into two categories based on the trigger requirements and the essential attributes of the self-healing process: nonautonomous healing systems and autonomous healing systems.5 The nonautonomous SHM systems require external stimulation such as temperature, light, heat, pH and so on, while the autonomous healing systems promptly initiate the self-healing behavior when they suffer from damages.8 In addition to the above classifications, the SHMs can also be divided into extrinsic self-healing and intrinsic self-healing depending on whether healing agents are added or not (Figure 1). The extrinsic self-healing strategy is implemented by releasing the healable agents that are encapsulated in the carriers (such as microcapsule and microvascular carriers) to restore the original function in damage locations. In comparison, the intrinsic self-healing procedure depends on the reconstruction of noncovalent supramolecular interactions or dynamic covalent bond networks in SHMs. In other word, the external self-healing ability relies on polymerization or chemical reactions, while the intrinsic self-healing functions usually depend on the chemical cross-linking formed by dynamic covalent bonds or physical cross-linking generated by supramolecular interactions, which could benefit the fulfillment of multiple healing processes at the same location.9,10 However, for comparison, in general device systems, there are neither chemical cross-linking effects nor external polymerization or chemical reactions. The reversible mutual effect cannot occur when a device suffers damage, and thus it cannot exhibit self-healing behavior.

Figure 1.

Schematic illustration of self-healing polymer systems through (a) an extrinsic self-healing mode and (b) an intrinsic self-healing mode. Reproduced with permission from ref (10). Copyright 2017 Wiley-VCH.

Organic field-effect transistors (OFETs) are three-terminal switching electronic devices controlled by the gate voltage, providing adjustable output current within a certain range.11 An OFET is the basic building component in electronic circuits, with the multiple advantages including low cost, readout integration, large-area coverage, and power efficiency, and it possesses wide applications in sensor arrays, active matrix displays, logic circuits, and radio-frequency identification tags.9 Actually, the performance of OFETs has been significantly improved in the last decades, but there are still some difficulties in the areas of long-term stability and large-area uniformity. The key reasons are the interface compatibility problems between organic semiconductors and amorphous polymer insulators (API). In addition, a functional API may expand the application fields for OFETs, such as wearable electronics, high-density memory, and self-healing devices, which makes the investigation of APIs to become more and more important.11 Nevertheless, with the development of flexible, wearable, and self-healing electronics, OFETs face more challenges due to mechanical damages such as cracks and scratches in a long-term use process, which inevitably lead to a lower durability, shorter service life, and worse performance. Consequently, OFETs with self-healing ability have attracted increasing attention, especially in an intrinsic self-healing procedure that can repair the damages without external intervention (with reversible interactions of covalent or noncovalent bonds and/or the molecular movement and rearrangement within polymer networks).8 To date, some important reviews have discussed the self-healing research development of SHMs.3 For example, Bao et al. summarized the developments of functional devices and integrated systems based on self-healing electronic materials from the perspective of soft electronics.4 The Haick group discussed contemporary studies of self-healing soft sensors on material design, device structure, and fabrication methods.12 Latif et al. discussed the potential advantages and challenges of self-healing materials.13 Nevertheless, as far as we know, reviews on the systematic introduction of self-healing OFETs are rare, although it is very important for the development of future flexible organic electronic circuits. Therefore, it is necessary and urgent to summarize the self-healing OFETs. For this purpose, we have summarized the common self-healing strategies and mechanisms for SHMs and described the key breakthroughs and recent progress in SHM OFETs.2,9 Finally, we address several points for further exploration in this flourishing field. We believe that this mini-review could give some guidance and motivate the development of SHM OFETs.

2. Brief Introduction of Intrinsic SHMs

There is a long history of SHMs imitating living organisms to confront deleterious damage and recover the original functionality. Numerous attempts have been made to exploit materials with a self-healing ability. To assess the self-healing ability of a material, three important factors have been proposed: localization (position of the damage), temporality (recovery time), and mobility (dynamic interactions).14 The recovery process can be achieved via the interactions of dynamic bonds or the mutual effects of entanglement and diffusion of polymer chains.15 White et al. further defined healing efficiency (η) as a ratio of changes in material properties as

where f is the property of interest. All of these strategies bring positive help and effective comparison to allow us to evaluate the self-healing ability of materials and/or devices. Despite significant progress in the development of the self-healing field, there are great differences in the methods and characterizations to measure self-healing, which require further research and discussion.16 A specific scheme can be designed and optimized according to the damage of the material.8

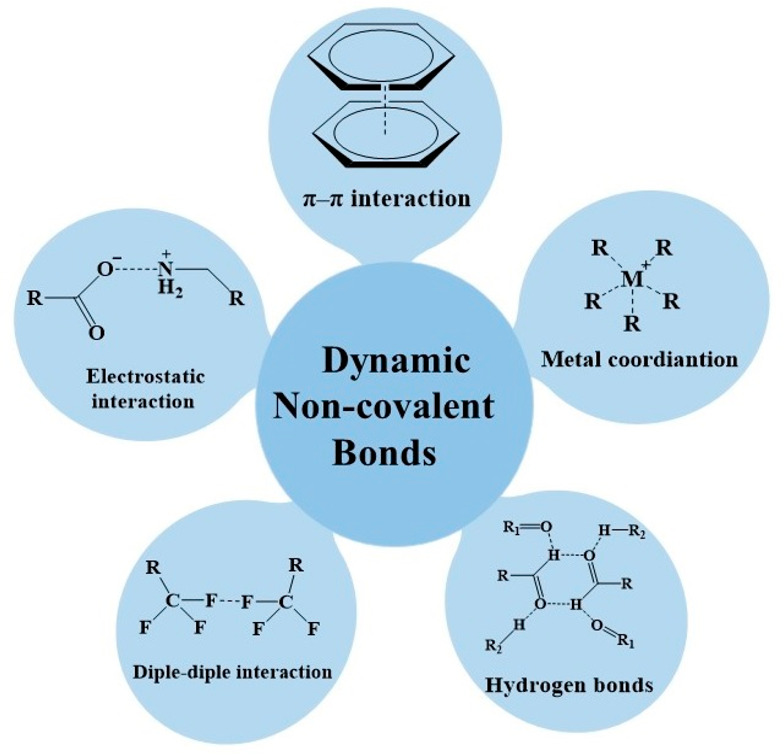

It is noteworthy that the development of reliable and durable intrinsic SHMs cannot occur without a reversible transformation of dynamic bonds, which can avoid complex problems of integration and compatibility of an extrinsic self-healing behavior. As researchers continue to explore, a variety of novel self-healing strategies have been designed: for example, the dynamic covalent bonding interactions (Figure 2) with a self-healing ability, including Diels–Alder reactions, imine bonds, disulfide exchanges, silyl ether linkages, acylhydrazone bonds, diarybibenzofuranone bonds, alkoxyamine bonds, borate ester bonds, diselenide bonds, and hindered urea bonds. These covalent bonds usually have a strong bond energy, so that the material can exhibit a satisfying mechanical property and healing ability.2,8,17 However, most of the SHMs with dynamic covalent bonds need external stimuli (such as light, heat, and pH change) to accelerate the repair rate.18 In comparison, noncovalent bonding interactions with self-healing ability involving host–guest interactions, metal–ligand coordination, hydrogen bonds, π–π stacking interactions, electrostatic interactions, dipole–dipole interactions, and van der Waals forces (Figure 3)14 usually have a lower kinetic stability and a reversible process of dissociation and generation without huge energy consumption. By modification of the types of reversible dynamic bonds and the mobility of chains, the self-healing conditions, efficiency, and the modulus and liquidity of the related polymer can be regulated and optimized.1 As a matter of fact, dynamic behaviors of SHMs on multiple length scales are important for implementing a spontaneous intrinsic healing process. At the macroscopic level, the interfaces of damaged position must be adequately close to each other, thus promoting the dynamic reorganization process. At the molecular level, the obtained polymers must provided plentiful dynamic interactions to exhibit a sufficient dynamics of the polymer chains.15

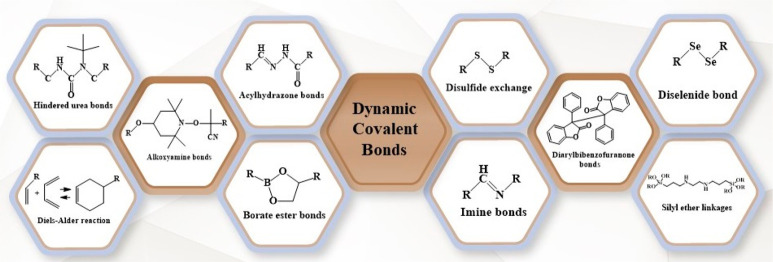

Figure 2.

Chemical structures of various dynamic covalent bonds used in the self-healing process. Reproduced with permission from ref (15). Copyright 2020 American Institute of Physics.

Figure 3.

Chemical structures of various dynamic noncovalent bonds used in self-healing processes. Reproduced with permission from ref (15). Copyright 2020 American Institute of Physics.

In comparison to extrinsic SHMs, intrinsic SHMs can achieve multiple recoveries, avoiding encapsulation and integration of the healing agent in the matrix. Moreover, the intrinsic SHMs are more reliable and durable due to the recombination and reconstruction of intrinsic reversible dynamic bonds.18 Moving forward, various ideas based on intrinsic self-healing behavior have appeared in numerous fields, and we mainly focus on the advances in intrinsic SHMs. In 2008, Leibler et al. first employed the intrinsic self-healing methodology into a supramolecular material, which could be associated together to generate chains and cross-linked networks via reversible dynamic hydrogen bonds.19 When it suffers from mechanical damage, the supramolecular material can be repaired by bridging the fractured surfaces at room temperature, and the recovery process can be accomplished many times. Since then, the intrinsic SHMs have gained extensive attention and gradually became the focus of research. In 2012, Bao et al. demonstrated the first electronic composite material with an ambient, repeatable self-healing property by embedding nanotextured nickel (Ni) microparticles into a supramolecular organic polymer.20 The healing efficiency of the composite material decreased with the surface exposure time due to the hydrogen-bonding reassociation between the cut surfaces. Then, Bao et al. introduced a novel chemical moiety to enhance the dynamic noncovalent cross-linking of the polymer, which could restore its initial morphology and charge mobility upon thermal and solvent annealing treatments when it was damaged by mechanical strain.21 The prepared fully stretchable transistor exhibited satisfying stretchability and healing performance, paving the way for the development of self-healing OFETs.

In recent years, materials with intrinsic self-healing ability are becoming a research hot spot due to their significant role and broad demand in future artificial applications with long durability. There are still some challenges to be solved. For example, SHMs with better self-healing efficiency, rapid healing speed, and stable conductivity are pressingly urgent for the fabrication of devices with a long device life. In addition, the synergistic effect of good conductivity and mechanical performance as well as a simple fabrication process and mild experimental conditions are required to be considered for the design of SHMs. Therefore, we believe that the progress in SHMs will greatly improve the development of flexible electronics.

3. SHMs Applied in OFETs

SHMs have been introduced into OFETs, repairing mechanical damages without external intervention. According to the functions in OFETs, there are mainly three types of SHMs, namely self-healing insulator (dielectric), conductor (electrode), and semiconductor (channel) materials, which are mainly discussed in this section.

3.1. Self-Healing Conductors

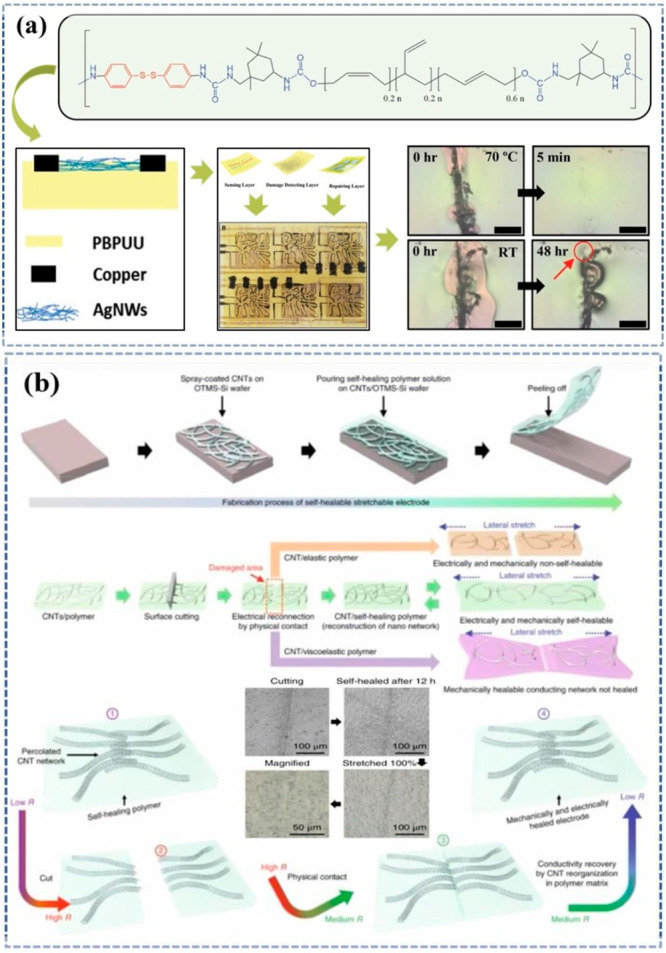

As is well-known, a conducting material can act as the source, drain, and gate electrodes in OFETs. Conducting materials have been investigated extensively in recent years for their indispensability in electronic devices, such as sensors, displays, and energy storage devices. So far, the recovery of conductive pathways for the existing self-healing conductive materials has focused on the physical contact, which could be fulfilled by employing a soft conductive material. The Haick group has designed and synthesized a dynamic soft self-healing polymer material (PBPUU), which exhibited good self-healing ability in complicated underwater conditions (Figure 4a). Furthermore, the capability of eliminating any electrical leakages caused by underwater damage made PBPUU a superior candidate to fabricate electronic devices, which was essential for integrating flexibility and a self-healing ability in electronics. Next, silver nanowires were embedded onto the surface of PBPUU to create self-healing soft electrodes. The PBPUU electrode material showed good stability after repetitive tape tests, and these behaviors were very promising for simultaneously monitoring multiple environmental parameters.22 However, despite some advance in the development of self-healing conductor materials, there are still some difficulties in the application of self-healing active electronic components. Bao et al. presented the self-healing polymer PDMS–MPU0.4–IU0.6 (MPU = 4,4-methylene bis(phenyl urea) and IU = isophorone bisurea), which can form a cross-linked network via strong (MPU) and weak (IU) dynamic bonds incorporated into the PDMS backbone (Figure 4b).23 When the carbon nanotube (CNT) conducting material was embedded into PDMS–MPU0.4–IU0.6, the CNT conductive network was surrounded by a self-healing polymer matrix (PDMS–MPU0.4–IU0.6), the broken CNTs can recover their mechanical and conductive properties following the dynamic reconstruction of the self-healing polymer matrix. To study the self-healing performance of a CNT electrode, the author adopted the method of in situ monitoring to investigate the quantitative damage caused by a razor blade and subsequently compared the effect of different forces (0.5–4 N) and repeated damage (20 times of a 2 N force) on the CNT electrode material at certain time intervals. The results demonstrated that the CNT electrode at the damage region has truly been reconstructed with the self-healing ability. More importantly, the self-healing polymer matrix exhibited general applicability for the conducting network reconstruction, opening possibilities for future robust electronic applications.

Figure 4.

Typical examples of self-healing conductor materials. (a) Chemical structure of PBPUU, PBPUU imbedded with silver nanowires into soft and self-healing electrodes, and the healing speed of the electrode (∼100 μm in width cuts) at different temperatures (70 °C and room temperature). Reproduced with permission from ref (22). Copyright 2020 Wiley-VCH. (b) Fabrication schematic for the self-healing electrode by embedding a CNT conducting network into a self-healing polymer matrix. The electrode could recover its high mechanical and electrical properties when it suffered damage due to the self-recoverability and high toughness of the self-healing polymer matrix (green schematic). Shown in the middle are microscope images of self-healing CNT composite electrodes before and after self-healing (12 h). Reproduced with permission from ref (23). Copyright 2018 Springer Nature.

3.2. Self-Healing Semiconductors

Organic semiconductors play a pivotal role in self-healing OFETs, which can act as the conductive channels and directly determine the device performance. However, semiconductors possessing properties of both self-healing and good charge transport are difficult to achieve because the rigidity of semiconductors attributed to their crystalline structures and conjugated skeletons is contradictory with the high chain mobility of SHMs.12,24,25 With the flourishing prospects in intelligent devices and special requirements under extreme circumstances for SHMs, scientists have devoted massive efforts to exploring new intrinsic SHMs with high performance and high safety and made some advances in the field of self-healing semiconductor materials. For example, the Bao group has invented an intrinsically self-healing film that was prepared by a blend of the semiconductor polymer poly(3,6-di(thiophen-2-yl)diketopyrrolo[3,4-c]pyrrole-1,4-dione-alt-1,2-dithienylethene) with 10 mol % of 2,6-pyridinedicarboxamine (DPP-TVT-PDCA) and the insulating elastomer poly(dimethylsiloxane-alt-2,6-pyridinedicarbozamine) (PDMS-PDCA).26 Both materials contained metal–ligand dynamic bonding sites, and the metal–ligand bonds of cross-linked PDMS-PDCA chains could exchange with DPP-TVT-PDCA chains (Figure 5a). The metal coordination bond could spontaneously reconstruct when it was broken, thus improving the stretchability and self-healing performance of the semiconducting films. To evaluate the self-healing ability, the blended film (200 nm thickness) was cut and left at room temperature. After 24 h, the scar of the cut film autonomously disappeared, and the fabricated OFETs with this semiconductor could bear 500 stretching cycles at 25% strain, without any noticeable degradation in performance. This work is an important breakthrough in the research of self-healing semiconductor materials. Apart from that, another key difficulty in developing self-healing semiconductors for OFETs lies in the high mobility and efficiency in the self-healing process. Oh et al. fabricated a thin-film OFET by employing a stretchable semiconductor material (Figure 5b).21 An intrinsically healable semiconductor material was achieved that was based on DPP repeating units and PDCA units. PDCA units were introduced into the flexible polymer backbone because the dynamic hydrogen bonds can be easily broken to allow energy dissipation when the material is subjected to strain and mechanical stimuli. Due to the spontaneity and self-healing ability, the hydrogen bonds could recover the initial mechanical and electrical properties of the semiconductor polymer. The fabricated OFETs showed a mobility as high as 1.3 cm2 V–1 s–1 and a high on/off current ratio exceeding 1 million. Furthermore, the mobility remained as high as 1.12 cm2 V–1 s–1 at 100% strain (perpendicular to the stress direction). Most important of all, the field-effect mobility can be recovered after a solvent and thermal healing treatment when the material is damaged. OFETs with high mobility and self-healing ability exhibited promising applications in wearable devices. Next, Lee et al. presented self-healing DPP-based polymers with urethane side chains.27 This copolymer featured an accurate alternating donor–acceptor structure and long urethane side chains, providing moderate H-bonding and sufficient solubility (Figure 5c). The dynamic bonds on urethane side chains could facilitate stress dissipation in thin polymer films when they suffered a mechanical deformation. Moreover, the self-healing semiconductors have great potential applications in next-generation stretchable and wearable devices. The limited self-healing ability and low mobility are still a big challenge for the utilization of self-healing semiconductors in OFETs, and the related reports are rare and insufficient. Therefore, it is urgent to develop novel self-healing semiconductors with reasonable mobility and self-healing ability for application in OFETs.

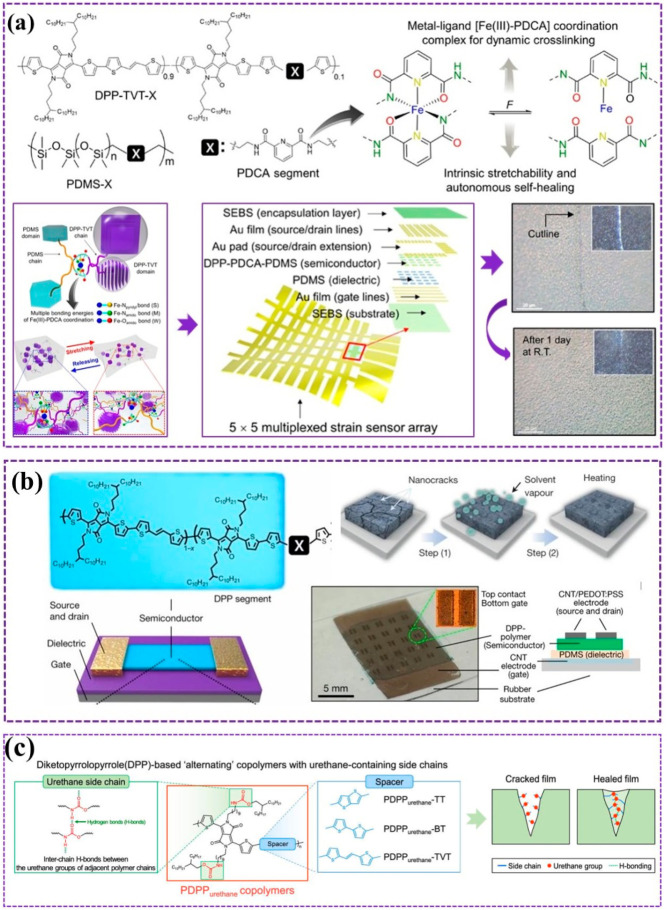

Figure 5.

Typical examples of self-healing semiconductor materials. (a) Chemical structure of DPP-TVT with PDMS and PDCA segments in the polymer backbones as dynamic bonding sites and multiple metal–ligand ([Fe(HPDCA)2]+) interactions, giving a fully stretchable 5 × 5 active-matrix transistor array with self-healing ability. Reproduced with permission from ref (26). Copyright 2019 AAAS. (b) Chemical structure of a semiconductor material, the self-healing behavior of the conjugated polymer films, and a photograph and architecture of a fully stretchable 5 × 5 OFET array fabricated with the semiconductor materials. Reproduced with permission from ref (21). Copyright 2016 Springer Nature. (c) Molecular design for semiconductors containing DPP urethane side chains and spacers (PDPPurethane-TT, -BT, and -TVT), and the corresponding self-healing process of the cracked films by re-formation of hydrogen bonds. Reproduced with permission from ref (27). Copyright 2020 American Chemical Society.

3.3. Self-Healing Insulators

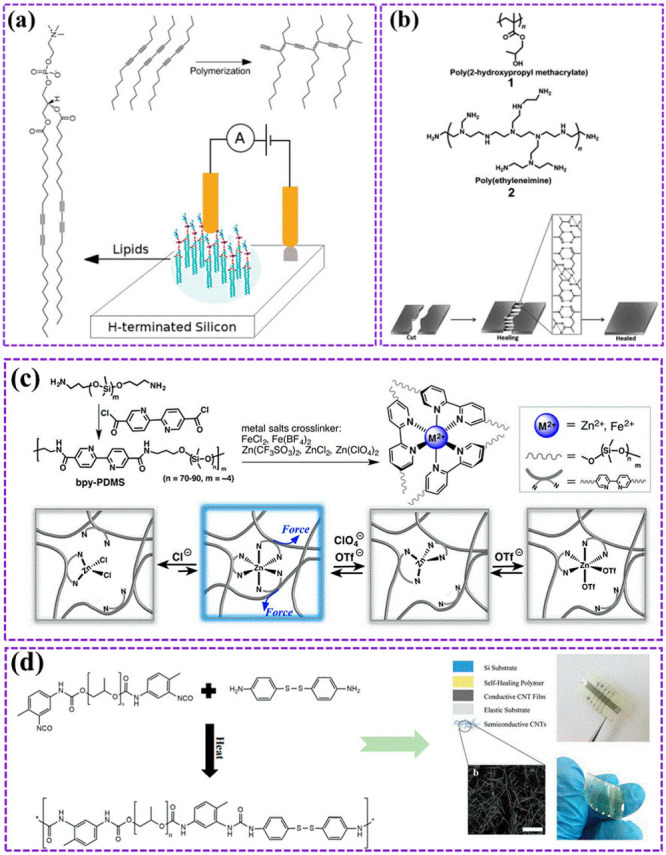

An insulator is usually used as a dielectric layer, a substrate, and an encapsulation layer in OFETs. It is significant and promising to develop insulator materials which simultaneously possess good dielectric properties and an efficient self-healing ability.28 Dumas et al. reported a 1,2-bis(10,12-tricosadiynoyl)-sn-glycero-3-phosphocholine (DCPC) monolayer (2.7 nm) as an alternative to an inorganic oxide dielectric in OFETs (Figure 6a).29 In addition to the good properties in terms of high stability, small current leakage, and low breakdown voltage, the material also exhibited a unique autonomous healing behavior (without any external input) after breakdown. With an increasing number of electrical breakdowns, the recovery time increased from 1 h to several hours, suggesting the aging of the insulator polymer after breakdowns. More interestingly, the insulators (after the 10th dielectric breakdown) restored the initial self-healing time after annealing at 36 °C for 30 min, just as in a reinitialization. Although an ultrathin DCPC monolayer was successfully introduced into OFETs and exhibited self-healing ability at room temperature, it only exhibited the self-healing behavior after electrical breakdown but did not show the recovery behavior after mechanical damage. As the first reported healing and printable insulator material, the blended polymer poly(2-hydroxypropyl methacrylate)/poly(ethylenimine) (PHPMA/PEI) can autonomically repair itself without any added healing agent upon both mechanical and electrical breakdown.28 The introduction of hydroxyl groups (PHPMA) and polymer chains (PEI) distinctly improved the interactions between dynamic hydrogen bonds. Bao and colleagues have demonstrated a self-healing dielectric elastomer based on metal–ligand coordination as cross-linking sites in nonpolar polydimethylsiloxane (PDMS) polymers. 2,2-Bipyridine-5,5-dicarboxylic amide (PDCA) was selected as the ligand unit while Fe2+ and Zn2+ with various counteranions were used as metal salts (Figure 6c). It is notable that the unstable kinetic coordination effect between bipyridine and Zn2+ endowed the dielectric layer with good self-healing ability under ambient conditions. When the metal–ligand (Fe2+,Zn2+-bipyridine) polymer was employed as a dielectric layer, it showed an increased dielectric constant in comparison to pure PDMS and a hysteresis-free transfer characteristic, plausibly because the low ion concentration in PDMS as well as the strong interaction between metal cations and the small Cl– anions could hinder the mobile anions from drifting under the gate bias. This work has given a profound insight into future studies on self-healing flexible and stretchable insulator materials based on the metal–ligand cross-linking effect.30 Now that a self-healing insulator, conductor, and semiconductor have been prepared, a whole OFET made with SHMs is expected. Although it is a great challenge to recover the electrical and mechanical property after certain damage of the whole self-healing device, this work still attracts numerous researchers to solve these problems. For example, Haick et al. reported a representative multifunctional OFET with whole layers having self-healing properties (Figure 6d),6 in which the intrinsic self-healing poly(urea urethane) (PUU) with dynamic hydrogen bonds and disulfide bonds was used as the self-healing insulator. In the process of preparing OFETs, semiconducting carbon nanotubes (CNTs) were applied onto the surface of PUU as the self-healing semiconductor channel, and the conductive CNTs were employed as electrodes by the same method. The polymer PUU could promote the recovery of ultrathin CNT films, thus achieving the desired self-healing function. The obtained OFET exhibited a high hole mobility (10 cm2 V–1 s–1) and a relatively low operating voltage (<8 V), which was applied as a skin tattoo with multifunctional sensing functions, such as temperature and humidity monitoring, indicating promising applications in future diagnosis and physiotherapy. This discovery has raised expectations that self-healing OFETs could increase the sustainability of electronic systems and lead to more intelligent applications. However, unfortunately, further research on the whole OFET devices made by SHMs is rarely discussed, and this needs to be the focus in the future.

Figure 6.

Typical examples of self-healing insulator materials. (a) Lipid layers were elaborated by a direct fusion at the surface, at the bottom is revealed the electrical measurement setup, demonstrating the autonomous self-healing behavior after dielectric breakdown. Reproduced with permission from ref (29). Copyright 2011 American Chemical Society. (b) Chemical structures of 1-PHPMA and 2-PEI and the self-healing process of the PHPMA/PEI polymer blend system, based on the robust hydrogen bonds between the severed surfaces. Reproduced with permission from ref (28). Copyright 2015 Wiley-VCH. (c) Depiction of the synthetic route of cross-linked PDMS and achievement of metal–ligand coordination with Zn2+ and a schematic via Zn2+, the ligand, and the counteranions under the mechanical stress. Reproduced with permission from ref (30). Copyright 2016 American Chemical Society. (d) The synthetic route of the intrinsic self-healing disulfide-containing poly(ureaurethane) (PUU) was based on the two monomers APDS and PPG-TDI, and then the semiconductor CNT network was printed on top of the dielectric layer, fabricating a self-healing transistor array on the PET flexible substrate. Reproduced with permission from ref (6). Copyright 2018 Wiley-VCH.

Recently, the self-healing technology has driven important advances in flexible and wearable electronics, particularly with intrinsic self-healing materials as the key enablers, and this technology has exhibited huge potential applications. For example, Son et al. demonstrated the first autonomous integrated self-healing e-skin system via dynamic reconstruction of a nanostructured conducting network.23 When a broken conductive network was surrounded by a polymer matrix, the broken networks could connect with each other and recover their conducting and mechanical performance by the dynamic reconstruction of the self-healing polymer matrix. In addition, printable and flexible self-healing OFETs also have attracted huge attention for their potential applications in implantable and flexible sensors. Huang et al. developed the versatile self-healing polymer PHPMA/PEI (poly(2-hydroxypropyl methacrylate)/poly(ethylenimine)) and integrated it into OFETs as an insulator material, which exhibited a great potential for low-voltage, highly sensitive, implantable, and operable OFET chemical sensors.28 The integration of a self-healing capability in OFETs will increase the sustainability of electronic systems and lead to more useful and intelligent applications.

4. Conclusions and Outlook

With the rise of novel portable and wearable electronic technology, materials with preferable self-healing ability have broad prospects in OFETs. In this mini-review, we have highlighted the recent advances of SHMs applied in OFETs. In general, the popular patterns are divided into extrinsic and intrinsic self-healing modes for the SHMs. The intrinsic SHMs have become a research hot spot due to their stable and reliable self-healing ability, which could also accomplish multiple recoveries via reversible dynamic covalent or noncovalent bonds. We introduced the recent progress in intrinsic SHMs applied in OFETs from three aspects, including conductor, semiconductor, and insulator materials. Moreover, the existing challenges and perspectives of SHMs in the OFETs have also been discussed. The SHMs could significantly extend the service lifetime, improve the reliability, availability and affordability, and decrease the replacement costs of OFETs. However, the performance of reported self-healable OFETs is not yet comparable to that of their nonhealable counterparts. There are still several key challenges toward the creation of efficient SHMs with satisfying electronic properties.

First, multiscale theoretical simulation and transient analysis techniques are required to elucidate the healing mechanism at the molecular level, which may provide new guidelines to synthesize novel materials, especially tolerable conductors and semiconductors with limited availability. Second, the self-healing process is relatively slow and nonautonomous. Thus, it is highly important to develop an autonomous self-healing system avoiding the use of heat, light exposure, or solvents. Third, the selective triggering of the self-healing process in designated locations is being pursued in integrated electronic systems. In addition to that, the self-healing behavior is usually limited to small-area damages. It is urgent to explore SHMs with the capability of large-area recovery. Fourth, the mechanical properties are mostly sensitive to temperature due to the dynamic noncovalent cross-linked bonds in intrinsic SHMs. Therefore, the thermal stability needs to be improved by constructing thermodynamically stable self-healing systems.

We anticipate that further advances in electronic SHMs will be made to promote the application of self-healing OFETs in wearable electronics and bioelectronics by the deep collaboration of scientists in the fields of chemistry, material science, electronics, theoretical computation, and engineering.

Acknowledgments

We are grateful for the Fundamental Research Funds for the Central Universities (buctrc202103, buctrc202128), the National Natural Science Foundation of China (52103200, 51822308, 21975263, 22171019), the Open Project Program of Wuhan National Laboratory for Optoelectronics (2021WNLOKF005), and the State Key Laboratory of Supramolecular Structure and Materials (SKLSSM2022036).

Biographies

Haoguo Yue is a Ph.D. student in material science and engineering at the Beijing University of Chemical Technology. His research interest is mainly on material design and synthesis, flexible and self-healing organic optoelectronic materials, and electrochromic devices.

Dr. Zongrui Wang is an associate professor at the Beijing University of Chemical Technology (BUCT). She received her Ph.D. degree from the Institute of Chemistry, CAS (ICCAS), in July 2016. From 2016 to 2021, she successively worked as a Research Fellow at Nanyang Technological University, Singapore. In 2021, she joined BUCT as an associate professor. Her present research interest focuses on the molecular assembly of organic optoelectronic materials, flexible electronics, and transistor-based sensors.

Dr. Yonggang Zhen is a professor at the Beijing University of Chemical Technology (BUCT). He received his Ph.D. from the Institute of Chemistry, CAS (ICCAS) in 2010. From 2010 to 2013, he worked as a postdoc researcher at the University of Tokyo. After that, he returned to ICCAS, where he was promoted to Professor in 2018. He moved to BUCT in 2021. His research focuses on the design and synthesis, self-assembly, and crystal engineering of organic optoelectronic materials.

Author Contributions

The manuscript was written by H.Y. All coauthors contributed to preparing a portion of the manuscript. Z.W. and Y.Z. revised and approved all contents and figures of the full manuscript.

The authors declare no competing financial interest.

References

- Gai Y.; Li H.; Li Z. Self-Healing Functional Electronic Devices. Small 2021, 17 (41), 2101383. 10.1002/smll.202101383. [DOI] [PubMed] [Google Scholar]

- Tan Y. J.; Wu J.; Li H.; Tee B. C. K. Self-Healing Electronic Materials for a Smart and Sustainable Future. ACS. Appl. Mater. Interfaces 2018, 10 (18), 15331–15345. 10.1021/acsami.7b19511. [DOI] [PubMed] [Google Scholar]

- Zhang Q.; Liu L.; Pan C.; Li D. Review of recent achievements in self-healing conductive materials and their applications. J. Mater. Sci. 2018, 53 (1), 27–46. 10.1007/s10853-017-1388-8. [DOI] [Google Scholar]

- Kang J.; Tok J. B. H.; Bao Z. Self-healing soft electronics. Nat. Electron. 2019, 2 (4), 144–150. 10.1038/s41928-019-0235-0. [DOI] [Google Scholar]

- Wang S.; Urban M. W. Self-healing polymers. Nat. Rev. Mater. 2020, 5 (8), 562–583. 10.1038/s41578-020-0202-4. [DOI] [Google Scholar]

- Khatib M.; Huynh T. P.; Deng Y.; Horev Y. D.; Saliba W.; Wu W.; Haick H. A Freestanding Stretchable and Multifunctional Transistor with Intrinsic Self-Healing Properties of all Device Components. Small 2019, 15 (2), 1803939. 10.1002/smll.201803939. [DOI] [PubMed] [Google Scholar]

- Huynh T. P.; Sonar P.; Haick H. Advanced Materials for Use in Soft Self-Healing Devices. Adv. Mater. 2017, 29 (19), 1604973. 10.1002/adma.201604973. [DOI] [PubMed] [Google Scholar]

- Zheng N.; Xu Y.; Zhao Q.; Xie T. Dynamic Covalent Polymer Networks: A Molecular Platform for Designing Functions beyond Chemical Recycling and Self-Healing. Chem. Rev. 2021, 121 (3), 1716–1745. 10.1021/acs.chemrev.0c00938. [DOI] [PubMed] [Google Scholar]

- Chang T.; Panhwar F.; Zhao G. Flourishing Self-Healing Surface Materials: Recent Progresses and Challenges. Adv. Mater. Interfaces 2020, 7 (6), 1901959. 10.1002/admi.201901959. [DOI] [Google Scholar]

- Chen D.; Wang D.; Yang Y.; Huang Q.; Zhu S.; Zheng Z. Self-Healing Materials for Next-Generation Energy Harvesting and Storage Devices. Adv. Energy. Mater. 2017, 7 (23), 1700890. 10.1002/aenm.201700890. [DOI] [Google Scholar]

- Jiang Y.; Guo Y.; Liu Y. Engineering of Amorphous Polymeric Insulators for Organic Field-Effect Transistors. Adv. Electron. Mater. 2017, 3 (11), 1700157. 10.1002/aelm.201700157. [DOI] [Google Scholar]

- Khatib M.; Zohar O.; Haick H. Self-Healing Soft Sensors: From Material Design to Implementation. Adv. Mater. 2021, 33 (11), 2004190. 10.1002/adma.202004190. [DOI] [PubMed] [Google Scholar]

- Latif S.; Amin S.; Haroon S. S.; Sajjad I. A. Self-healing materials for electronic applications: an overview. Mater. Res. Express. 2019, 6 (6), 062001. 10.1088/2053-1591/ab0f4c. [DOI] [Google Scholar]

- Utrera-Barrios S.; Verdejo R.; López-Manchado M. A.; Hernández Santana M. Evolution of self-healing elastomers, from extrinsic to combined intrinsic mechanisms: a review. Mater. Horiz. 2020, 7 (11), 2882–2902. 10.1039/D0MH00535E. [DOI] [Google Scholar]

- Xu J.; Ding C.; Chen P.; Tan L.; Chen C.; Fu J. Intrinsic self-healing polymers for advanced lithium-based batteries: Advances and strategies. Appl. Phys. Rev. 2020, 7 (3), 031304. 10.1063/5.0008206. [DOI] [Google Scholar]

- Blaiszik B. J.; Kramer S. L. B.; Olugebefola S. C.; Moore J. S.; Sottos N. R.; White S. R. Self-Healing Polymers and Composites. Annu. Rev. Mater. Res. 2010, 40 (1), 179–211. 10.1146/annurev-matsci-070909-104532. [DOI] [Google Scholar]

- Kosuge T.; Zhu X.; Lau V. M.; Aoki D.; Martinez T. J.; Moore J. S.; Otsuka H. Multicolor Mechanochromism of a Polymer/Silica Composite with Dual Distinct Mechanophores. J. Am. Chem. Soc. 2019, 141 (5), 1898–1902. 10.1021/jacs.8b13310. [DOI] [PubMed] [Google Scholar]

- Jayabalakrishnan D.; Naga Muruga D. B.; Bhaskar K.; Pavan P.; Balaji K.; Rajakumar P. S.; Priya C.; Deepa R. A. B.; Sendilvelan S.; Prabhahar M. Self-Healing materials-A review. Mater. Today: Proc. 2021, 45, 7195–7199. [Google Scholar]

- Cordier P.; Tournilhac F.; Soulie-Ziakovic C.; Leibler L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 2008, 451 (7181), 977–980. 10.1038/nature06669. [DOI] [PubMed] [Google Scholar]

- Tee B. C.; Wang C.; Allen R.; Bao Z. An electrically and mechanically self-healing composite with pressure- and flexion-sensitive properties for electronic skin applications. Nat. Nanotechnol. 2012, 7 (12), 825–832. 10.1038/nnano.2012.192. [DOI] [PubMed] [Google Scholar]

- Oh J. Y.; Rondeau-Gagne S.; Chiu Y. C.; Chortos A.; Lissel F.; Wang G. N.; Schroeder B. C.; Kurosawa T.; Lopez J.; Katsumata T.; Xu J.; Zhu C.; Gu X.; Bae W. G.; Kim Y.; Jin L.; Chung J. W.; Tok J. B.; Bao Z. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature 2016, 539 (7629), 411–415. 10.1038/nature20102. [DOI] [PubMed] [Google Scholar]

- Khatib M.; Zohar O.; Saliba W.; Haick H. A Multifunctional Electronic Skin Empowered with Damage Mapping and Autonomic Acceleration of Self-Healing in Designated Locations. Adv. Mater. 2020, 32 (17), 2000246. 10.1002/adma.202000246. [DOI] [PubMed] [Google Scholar]

- Son D.; Kang J.; Vardoulis O.; Kim Y.; Matsuhisa N.; Oh J. Y.; To J. W.; Mun J.; Katsumata T.; Liu Y.; McGuire A. F.; Krason M.; Molina-Lopez F.; Ham J.; Kraft U.; Lee Y.; Yun Y.; Tok J. B.; Bao Z. An integrated self-healable electronic skin system fabricated via dynamic reconstruction of a nanostructured conducting network. Nat. Nanotechnol. 2018, 13 (11), 1057–1065. 10.1038/s41565-018-0244-6. [DOI] [PubMed] [Google Scholar]

- Bubel S.; Menyo M. S.; Mates T. E.; Waite J. H.; Chabinyc M. L. Schmitt trigger using a self-healing ionic liquid gated transistor. Adv. Mater. 2015, 27 (21), 3331–3335. 10.1002/adma.201500556. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kang E. S. H.; Zhang H.; Donner W.; von Seggern H. Electrical and Structural Origin of Self-Healing Phenomena in Pentacene Thin Films. Adv. Mater. 2017, 29 (15), 1604833. 10.1002/adma.201604833. [DOI] [PubMed] [Google Scholar]

- Oh J. Y.; Son D.; Katsumata T.; Lee Y.; Kim Y.; Lopez J.; Wu H.-C.; Kang J.; Park J.; Gu X.; Mun J.; Wang N. G.-J.; Yin Y.; Cai W.; Yun Y.; Tok J. B.-H.; Bao Z. Stretchable self-healable semiconducting polymer film for active-matrix strain-sensing array. Sci. Adv. 2019, 5 (11), eaav3097. 10.1126/sciadv.aav3097. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee M. Y.; Dharmapurikar S.; Lee S. J.; Cho Y.; Yang C.; Oh J. H. Regular H-Bonding-Containing Polymers with Stretchability up to 100% External Strain for Self-Healable Plastic Transistors. Chem. Mater. 2020, 32 (5), 1914–1924. 10.1021/acs.chemmater.9b04574. [DOI] [Google Scholar]

- Huang W.; Besar K.; Zhang Y.; Yang S.; Wiedman G.; Liu Y.; Guo W.; Song J.; Hemker K.; Hristova K.; Kymissis I. J.; Katz H. E. A High-Capacitance Salt-Free Dielectric for Self-Healable, Printable, and Flexible Organic Field Effect Transistors and Chemical Sensor. Adv. Funct. Mater. 2015, 25 (24), 3745–3755. 10.1002/adfm.201404228. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dumas C.; El Zein R.; Dallaporta H.; Charrier A. M. Autonomic self-healing lipid monolayer: a new class of ultrathin dielectric. Langmuir 2011, 27 (22), 13643–13647. 10.1021/la202333n. [DOI] [PubMed] [Google Scholar]

- Rao Y. L.; Chortos A.; Pfattner R.; Lissel F.; Chiu Y. C.; Feig V.; Xu J.; Kurosawa T.; Gu X.; Wang C.; He M.; Chung J. W.; Bao Z. Stretchable Self-Healing Polymeric Dielectrics Cross-Linked Through Metal-Ligand Coordination. J. Am. Chem. Soc. 2016, 138 (18), 6020–6027. 10.1021/jacs.6b02428. [DOI] [PubMed] [Google Scholar]