Highlights

-

•

We showed that reducing the longitudinal bending stiffness in the forefoot of the Nike Vaporfly 4% has minimal effect on overall running economy

-

•

Biomechanically, the curved carbon-fiber plate in the Nike Vaporfly 4% has the most influence on the metatarsophalangeal joint, with no significant effect on the ankle or knee joints

-

•

The forefoot longitudinal bending stiffness alone likely has minimal effect on performance. Instead, improved performance is likely due to an interaction of the foam, shoe geometry, and other effects of the curved carbon-fiber plate not related to bending stiffness.

Keywords: Biomechanics, Footwear, Mechanical doping, Metabolic rate, Performance

Abstract

Purpose

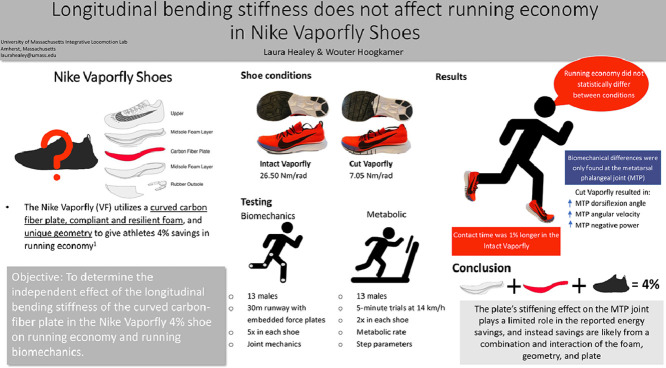

This study aimed to determine the independent effect of the curved carbon-fiber plate in the Nike Vaporfly 4% shoe on running economy and running biomechanics.

Methods

Fifteen healthy male runners completed a metabolic protocol and a biomechanics protocol. In both protocols participants wore 2 different shoes, an intact Nike Vaporfly 4% (VFintact) and a cut Nike Vaporfly 4% (VFcut). The VFcut had 6 medio-lateral cuts through the carbon-fiber plate in the forefoot to reduce the effectiveness of the plate. In the metabolic protocol, participants ran at 14 km/h for 5 min, twice with each shoe, on a force-measuring treadmill while we measured metabolic rate. In the biomechanics protocol, participants ran across a runway with embedded force plates at 14 km/h. We calculated running economy, kinetics, and lower limb joint mechanics.

Results

Running economy did not significantly differ between shoe conditions (on average, 0.55% ± 1.77% (mean ± SD)) worse in the VFcut compared to the VFintact; 95% confidence interval (–1.44% to 0.40%). Biomechanical differences were only found in the metatarsophalangeal (MTP) joint with increased MTP dorsiflexion angle, angular velocity, and negative power in the VFcut. Contact time was 1% longer in the VFintact.

Conclusion

Cutting the carbon-fiber plate and reducing the longitudinal bending stiffness did not have a significant effect on the energy savings in the Nike Vaporfly 4%. This suggests that the plate's stiffening effect on the MTP joint plays a limited role in the reported energy savings, and instead savings are likely from a combination and interaction of the foam, geometry, and plate.

Graphical Abstract

1. Introduction

Performance running shoe technology, such as improved midsole energy return and increased longitudinal bending stiffness (LBS), has recently become a polarizing topic.1, 2, 3, 4, 5, 6, 7 The Nike Vaporfly 4% (VF) shoe utilizes both these technologies to give athletes on average up to 4% savings in running economy compared to popular high-end marathon racing shoes,8, 9, 10, 11 which translates to improved running performance.12, 13, 14, 15 While scientists and bloggers debate whether the foam,8,16 geometry,2 or curved carbon-fiber plate1,17 contributes more to these “super shoes”, the exact mechanisms resulting in 4% metabolic savings are not yet understood.

The use of carbon-fiber plates to improve running economy, while increasingly popular, is not new. In 2006, Roy and Stefanyshyn16 showed small (1%) improvements in running economy with increased LBS. However, since then, reported effects of LBS on running economy have been mixed, with studies finding results ranging from deteriorations,18 to no effect,19, 20, 21 to small effect (∼1%),22 to large improvements (3%−4%)8, 9, 10, 11,23 (for a full review, see Ortega et al.24). Importantly, the largest improvements in running economy have been reported in studies assessing VF shoes,8, 9, 10 suggesting that the geometry and stiffness of the curved VF plate may provide additional savings compared to flat plates previously tested. It is also important to note that the contributions of the foam to these savings are unknown because no studies have addressed the effects of the curved plate and foam independently. Earlier studies have shown that soft and resilient midsole foam using air pockets or thermoplastic polyurethane foam can improve running economy by 1% compared to conventional ethyl-vinyl acetate foam.25,26 The VF studies used state-of-the-art baseline shoes with either ethyl-vinyl acetate foam with air pockets or thermoplastic polyurethane foam (boost); however, the VF midsole foam (polyether block amide) is softer and more resilient.8 In an original analysis of the VFs, Hoogkamer et al.8 hypothesized that energy return from the foam was a key contributor to the metabolic savings. However, because VFs have not been compared without the confounding influence of the carbon-fiber plate, the metabolic savings from the foam remains unknown.

From a biomechanical perspective, increased LBS has been shown to reduce negative work done at the metatarsophalangeal (MTP) joint27, 28, 29 and to alter joint mechanics in the ankle16,19,27,28,30,31 and knee.28 Specifically, in a biomechanical analysis of the VF, Hoogkamer et al.27 found that the curved carbon-fiber plate in the VF prototype resulted in lower work rates at the ankle and reduced dorsiflexion and negative work at the MTP joint compared to control shoes. The researchers therefore concluded that the curved plate provided a clever lever and a stiffening effect that likely contributed to the 4% energy savings. An important limitation of that study is that the tested VF prototype shoes differed in geometry (taller stack height), foam properties (more compliant and resilient), and LBS (stiffer and having a carbon-fiber plate) from the control shoes, once again making the contribution of the plate alone difficult to pinpoint. While the effects of LBS are often evaluated with flat carbon-fiber plates,24 curved plates can be expected to be more effective. Farina et al.32 showed that increased plate curvature can reduce net MTP joint work without increasing ankle plantarflexion moments, and recently Nigg et al.1,17 proposed a theory attributing the majority of VF's energetic benefit to the curved plate's “teeter−totter” effect. However, this theory is as of yet untested.

In the current study, we attempt to determine the isolated effects of the stiffness of the carbon-fiber plate in the VF by cutting the plate and reducing its LBS in the forefoot. Our aim was to determine how LBS independently affects running economy and biomechanics in the VF. We hypothesized (1) that cutting the plates would significantly increase (i.e., worsen) metabolic rate. Based on previous literature reporting ∼1% savings with flat carbon-fiber plates, we expected that reducing LBS by cutting through the curved carbon-fiber plate of the VF would increase metabolic rate during running by about 2%. To accommodate this increased metabolic rate, we hypothesized (2) that decreasing LBS would decrease ankle dorsiflexion angle and plantarflexion moment and (3) that it would increase MTP dorsiflexion angle, plantarflexion moment, and power.

2. Methods

2.1. Participants

A power analysis was performed a priori (G*Power 3.1; Universität Kiel, Kiel, Germany), and it was determined that a sample size of 14 was necessary to achieve an effect size of 0.82. We recruited 17 male participants (aged 24 ± 4 years; weight 67.8 ± 4.3 kg; height 173.3 ± 3.6 cm; mean ± SD) who wore U.S. men's size 9.5 shoes. A total of 13 subjects took part in both the biomechanics and metabolic protocols, while 4 participated in only 1 protocol (2 in each). For the biomechanics protocol, inclusion criteria consisted of running at least 16 km/week. For the metabolic protocol, participants had to additionally be capable of running a 5 km in 19 min or an equivalent performance (10 km in 39 min, marathon in 3 h). For both protocols, participants were excluded if they had a lower extremity injury or surgery in the past 12 months or had any existing orthopedic, cardiovascular, or neuromuscular conditions. All participants gave written consent. The study was approved by the University of Massachusetts Amherst Institutional Review Board (1741 and 1789).

2.2. Shoe conditions

Participants wore 2 pairs of shoes: an intact Nike Vaporfly (VFintact) and a cut Nike Vaporfly (VFcut). In lieu of having 2 identical shoes with and without a carbon-fiber plates, we made 6 medio-lateral cuts through the carbon-fiber plate in the forefoot of new VFs to reduce the plate's effectiveness in bending (Fig. 1). This method should not have affected the geometry and foam properties of the shoes; however, it is possible that the foam was slightly altered in the forefoot due to cutting. Cuts were made just past the depth of the plate using a table saw with an ∼1.5-mm blade. We measured the LBS in extension with a 3-point bending test using a standard material testing machine (Instron ElectroPuls 10000; Instron, Norwood, MA, USA). To perform this test, the shoe was placed on 2 support frames 80 mm apart.22 An Instron tip, aligned with the MTP joint, displaced 5 mm while recording force at 200 Hz. We calculated bending stiffness in N·m/rad based on the force applied to the shoe, displacement of the instron tip, and the distance of the support beams.24 This method was not suitable for measuring the shoe in flexion due to foam deformation. Therefore, we measured the shoe's LBS in flexion using a standard flex tester (Shoe Flexer; Exeter Research Inc., Brentwood, NH, USA), calculating flexion stiffness for the final five of fifty 30-degree flexion cycles.

Fig. 1.

Intact Nike Vaporfly 4% (VFintact) and cut Nike Vaporfly 4% (VFcut) shoe conditions. To create the VFcut, 6 medio-lateral cuts were made through the carbon-fiber plate. Note that the black line is not the exact location of the carbon-fiber plate, but all the cuts were made fully through the plate.

2.3. Experimental set-up and protocol

The study comprised 2 testing protocols: a metabolic protocol and a biomechanics protocol. If subjects completed both protocols on the same day, biomechanics testing was done first.

2.3.1. Metabolic protocol

Participants wore their own shoes for a warm-up of at least 5 min at the test pace of 14 km/h (6:54 min/mile). During the warm-up, participants wore a mouthpiece attached to an expired-gas analysis system to get accustomed to running with it. After the warm-up, participants completed four 5-min trials at 14 km/h on a level, force-measuring treadmill with a rigid deck (Treadmetrix, Park City, UT, USA). Shoe order was randomly assigned, and participants wore each shoe twice in a mirrored order (e.g., VFintact, VFcut, VFcut, VFintact or VFcut, VFintact, VFintact, VFcut). This method reduces bias due to order of conditions and any possible learning or fatigue effects. We used lightweight shoe covers to blind participants to the shoes they were wearing. During each trial we measured horizontal and vertical ground reaction forces (GRF) at 1200 Hz, as well as submaximal rates of oxygen uptake and carbon-dioxide production using an expired-gas analysis system (True One 2400; Parvo Medics, Salt Lake City, UT, USA). After each trial, participants were given a 5-min break while researchers changed their shoes behind a barrier.

We calculated the metabolic rate (i.e., running economy) over the last 2 min of each trial, based on the measured rates of oxygen uptake and carbon-dioxide production using the Peronnet and Massicotte equation.33 Running economy is the energetic cost of running at a specific velocity expressed in W/kg; therefore, lower running economy values will result in an increase in performance.8,12,13 The metabolic rate was averaged between the 2 trials in the same shoe for each participant.

In the last 30 s of each trial, we collected GRF from the treadmill. We opted to use GRF from the treadmill, and not over ground, because treadmill running allowed us to take the average of multiple steps. A custom Python script (Python Software foundation, https://www.python.org/) was used to filter GRF data using a low-pass, second-order Butterworth filter with a cut-off frequency of 20 Hz.34 Contact time was determined using a 25 N vertical GRF threshold to determine toe-offs and touch-downs; these points were then visually inspected to ensure accuracy. We then calculated step frequency, peak vertical GRF, and propelling and braking impulse. Finally, we further visualized these differences in GRF between shoes by plotting the GRF vectors in the sagittal plane relative to the stance phase.

2.3.2. Biomechanics protocol

We placed retro-reflective markers on the participants’ right leg on the greater trochanter, medial, and lateral epicondyles and on the medial and lateral malleoli. The right foot was tracked with markers on the first and fifth metatarsal head and base, the first toe, and a cluster of 3 markers on the heel. To track the thigh and the shank segments, rigid bodies with 4 non-co-linear reflective markers were adhered to the lateral aspects of the thigh and shank.

Participants ran across a 30 m runway embedded with force plates (AMTI Inc., Watertown, MA, USA) at 14 km/h. During the trials, motion capture data (Oqus 3; Qualisys Inc., Gothenburg, Sweden) and GRF data were continuously collected at 200 Hz and 2000 Hz, respectively. We used timing gates to verify that the participant's speed was 14 km/h (with ±4% variance), and we visually made sure that the participants right foot landed directly on a force plate. Participants continued to perform runs until we had collected 5 good trials in each shoe condition.

To process the data, we first visually analyzed, and then gap filled the motion capture data in Qualisys Track Manager (Qualisys Inc., Gothenburg, Sweden). Next, using a custom Python script, GRF and kinematic data were low-pass filtered using a dual-pass Butterworth filter, with the same effective 14 Hz cut-off,27 to prevent artificial fluctuations in joint moments.35,36 For the knee, ankle, and MTP joints, we calculated joint angles, angular velocities, moments, powers, and work during the stance phase using a 3D inverse dynamics model custom built in Python. We assumed the MTP joint moment was 0 until the center of pressure passed the MTP joint center. Finally, we normalized data to 100% of stance phase and averaged the trials in the same shoe condition within each participant.

2.4. Statistics

We used a 2-tailed paired t test to compare metabolic rate, step parameters, and peak biomechanical variables between shoes (R software Version 1.0.44; The R Core Team, Vienna, Austria). Significance was set at α = 0.05, and a Holm-Bonferroni correction was implemented to account for multiple t tests. We also used 1-dimensional spatial parametric mapping in Python to conduct a 2-tailed, paired-sample t test (α = 0.05) for GRF, joint angles, angular velocities, moments, and powers.37 Outputs from spatial parametric mapping are a time series of t values, allowing us to analyze differences across the whole stance phase rather than just peaks or averages.

3. Results

During analysis, 1 participant was removed from the metabolic protocol (n = 14) and 2 participants were removed from the biomechanics protocol (n = 13) due to data quality issues.

3.1. Shoe properties

The VFcut had a bending stiffness of 7.7 N·m/rad, while the VFintact had a bending stiffness of 23.1 N·m/rad in flexion. In extension, the VFcut had a stiffness of 3.1 N·m/rad and the VFintact had a stiffness of 11.1 N·m/rad.

3.2. Energetics and step parameters

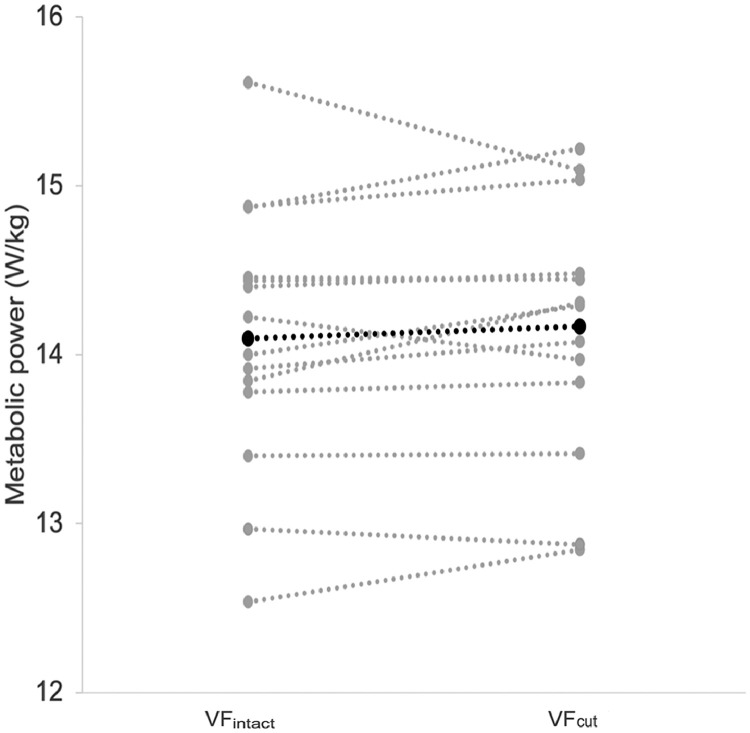

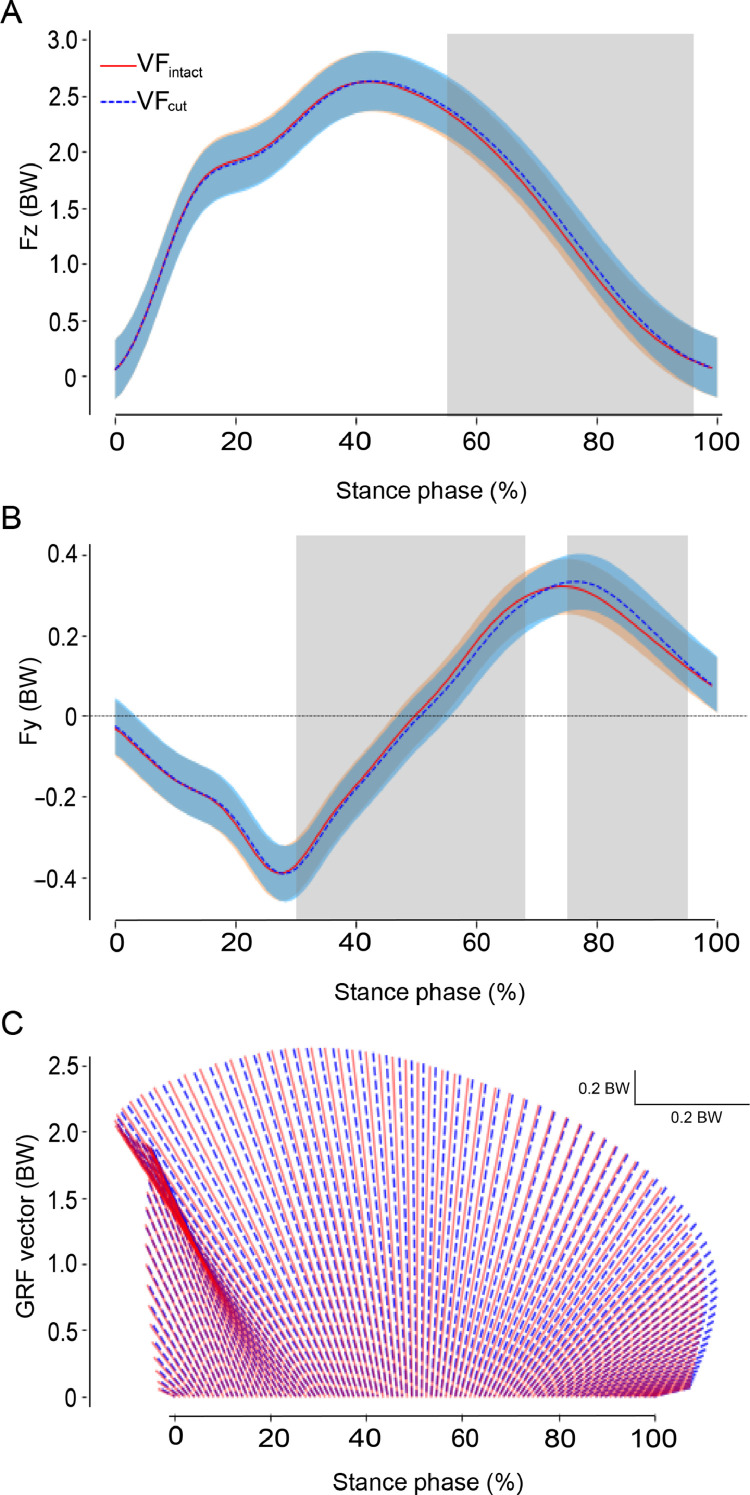

The average metabolic rate was statistically similar (p = 0.306) in the VFcut (14.17 ± 0.74 W/kg) and the VFintact (14.09 ± 0.80 W/kg), with the average change within participants being 0.55% ± 1.77% (95% confidence interval (95%CI): –1.44% to 0.40%; Fig. 2). Individual changes ranged from –3.3% to 3.3% between the VFcut and the VFintact, with 10 of 14 participants having worse running economy in the VFcut condition. Contact time was significantly shorter (p < 0.001) in the VFcut (0.211 ± 0.014 s) compared to the VFintact (0.213 ± 0.014 s), with the average change within participants being –1.19% ± 1.10% (95%CI: –1.77% to –0.61%; Table 1). No significant differences were found for step frequency, braking impulse, propelling impulse, or peak vertical GRF (Table 1). Vertical GRF were significantly higher in the VFcut during 55%−96% of stance phase (p < 0.001). Anterior-posterior GRF were significantly lower in the VFcut compared to the VFintact for 30%−68% and significantly higher in the VFcut compared to the VFintact for 75%−95% of stance phase (both p < 0.001; Fig. 3). Fig. 3C shows GRF vectors across the stance phase. Overall, the patterns look similar, but the GRF vector for the VFintact is directed more forward than for the VFcut for the majority of the stance phase. Note that for around 60%−70% of the stance phase, where the vectors appear to be aligned, the VFintact vector is indeed 1% ahead of the VFcut.

Fig. 2.

Running economy was similar between Vaporfly shoes with intact (VFintact) and cut (VFcut) carbon-fiber plates. The average metabolic rate is shown in black, and individual responses are shown with grey lines. On average, runners had a 0.55% ± 1.77% (mean ± SD) higher metabolic rate in the VFcut than in the VFintact, but this difference was not statistically significant (p = 0.306).

Table 1.

Average metabolic rate and step parameters during treadmill running in Vaporfly shoes with VFintact and VFcut carbon-fiber plates (mean ± SD).

| Variable | VFintact | VFcut | Within-subject change (%) | p |

|---|---|---|---|---|

| Metabolic power (W/kg) | 14.09 ± 0.80 | 14.17 ± 0.74 | 0.55 ± 1.77 | 0.306 |

| Peak vertical GRF (BW) | 2.64 ± 0.20 | 2.64 ± 0.19 | 0.22 ± 0.77 | 0.371 |

| Braking impulse (BW·s) | –0.02 ± 0.00 | –0.02 ± 0.00 | –0.20 ± 1.65 | 0.607 |

| Propulsive impulse (BW·s) | 0.02 ± 0.00 | 0.02 ± 0.00 | –0.22 ± 1.65 | 0.589 |

| Contact time (s) | 0.213 ± 0.014* | 0.211 ± 0.014* | –1.19 ± 1.10* | <0.001 |

| Step frequency (steps/s) | 3.00 ± 0.12 | 3.00 ± 0.12 | 0.02 ± 0.82 | 0.909 |

Note: Average within-subject changes are reported as a percentage difference (VFcut – VFintact)/VFintact × 100%.

Abbreviations: BW = body weight; VFcut = cut Nike Vaporfly 4%; VFintact = intact Nike Vaporfly 4%; W = watt.

p < 0.001, statistical difference between shoe conditions.

Fig. 3.

Ground reaction forces (GRF) during treadmill running in the Vaporfly shoes with intact (VFintact; red) and cut (VFcut; blue) carbon-fiber plates. The shaded bars represent ± 1 standard error. Force traces have been normalized to body weight (BW). (A) Average vertical (Fz) GRF traces, (B) Anterior−posterior (Fy) GRF traces. Grey shaded areas represent where traces are significantly different from each other (p < 0.05) as determined by spatial parametric mapping. (C) GRF vectors during stance phase. Each vector represents 1% of stance phase. Interestingly, around 60%−70% of stance phase, when GRF vectors appear to be the same, the VFcut (blue) is 1% behind the VFintact (red).

3.3. Biomechanics

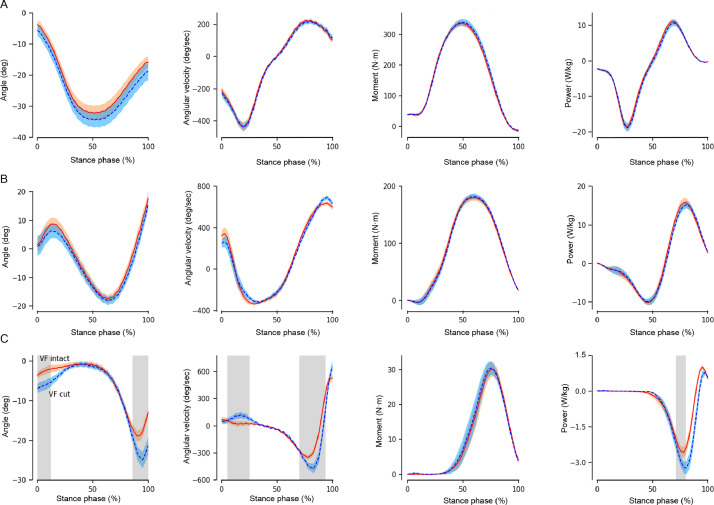

Biomechanical differences were only found in MTP joint mechanics (Fig. 4). MTP joint angles were more dorsiflexed in the VFcut for 0%−12% and 85%−100% of the stance phase (p = 0.013), and peak MTP joint dorsiflexion was significantly higher in the VFcut (p = 0.002; Table 2). This was accompanied by increased MTP joint angular velocity in the VFcut between 11% and 21% and between 77% and 90% of stance phase (p = 0.001). Further, there was significantly more negative MTP joint power in the VFcut compared to the VFintact from 79% to 90% of stance phase (p < 0.001). Negative MTP joint work was significantly higher in the VFcut compared to in the VFintact (p = 0.008), and positive MTP joint work was significantly lower in the VFcut compared to the VFintact (p = 0.023; Table 2).

Fig. 4.

Joint angles, angular velocities, moments, and powers for the (A) knee, (B) ankle, and (C) metatarsal phalangeal (MTP) joints during overground running in the intact Vaporfly (VFintact; solid red line) and cut Vaporfly (VFcut; dashed blue line). Positive values are extension/plantarflexion. Grey regions indicate where the traces are significantly different (p < 0.05) as determined by spatial parametric mapping. Traces are group averages, and shaded regions represent ± 1 SD.

Table 2.

Average knee, ankle, and MTP mechanics during overground running in the VFintact and VFcut (mean ± SD).

| Variable | VFintact | VFcut | Within-subject change (%) | p Value |

|---|---|---|---|---|

| Peak knee flexion (°) | 32.7 ± 10.0 | 34.2 ± 9.5 | 8.8 ± 18.7 | 0.411 |

| Peak knee moment (N·m) | 336.9 ± 32.8 | 336.9 ± 43.9 | 0.8 ± 7.3 | 0.683 |

| Peak ankle dorsiflexion (°) | 17.8 ± 4.9 | 18.2 ± 5.7 | 5.3 ± 26.8 | 0.738 |

| Peak ankle moment (N·m) | 181.9 ± 20.8 | 182.5 ± 17.5 | –0.7 ± 6.3 | 0.876 |

| Peak MTP dorsiflexion (°) | 19.1 ± 5.3* | 25.3 ± 7.8* | 28.7 ± 23.6* | 0.002 |

| Peak MTP moment (N·m) | 31.6± 8.2 | 31.9 ± 8.4 | 6.6 ± 21.7 | 0.875 |

| Positive knee work (J/kg/step) | 0.65 ± 0.32 | 0.55 ± 0.16 | –0.83 ± 22.65 | 0.190 |

| Negative knee work (J/kg/step) | –0.96 ± 0.31 | –0.94 ± 0.25 | –0.37 ± 17.87 | 0.756 |

| Positive ankle work (J/kg/step) | 0.91 ± 0.18 | 0.85 ± 0.14 | –4.81 ± 13.50 | 0.133 |

| Negative ankle work (J/kg/step) | –0.64 ± 0.17 | –0.62 ± 0.19 | –3.84 ± 11.69 | 0.281 |

| Positive MTP work (J/kg/step) | 0.02 ± 0.01* | 0.01 ± 0.01* | –32.07 ± 31.18* | 0.023 |

| Negative MTP work (J/kg/step) | –0.11 ± 0.05* | –0.15 ± 0.06* | 33.06 ± 41.35* | 0.008 |

Note: Average within-subject changes are reported as a percentage difference (VFcut – VFintact)/VFintact × 100%.

Abbreviations: MTP = metatarsophalangeal; VFcut = cut Nike Vaporfly 4%; VFintact = intact Nike Vaporfly 4%.

p < 0.05, statistical difference between shoe conditions.

4. Discussion

This study sought to determine the independent effect of the curved carbon-fiber plate in the VF shoe on running energetics and biomechanics. Our mechanical testing confirmed that the VFcut was dramatically less stiff in flexion (∼66% less stiff) and extension (∼72% less stiff) compared to the VFintact. Interestingly, our results show that reducing the LBS did not substantially change running economy, refuting our first hypothesis. Furthermore, we reject our second hypothesis that reduced LBS would decrease ankle dorsiflexion moment and power. Supporting our third hypothesis, MTP joint dorsiflexion angle and power were significantly larger in the VFcut; however, MTP joint moment was not significantly different between conditions. Our findings are in line with previous research finding small differences in running economy between shoes with and without carbon-fiber plates.16,19,22,23 However, most of these studies used flat plates, and we hypothesized that the curved plate in the VF would result in additional savings and explain ∼2% of the 4% savings reported by Hoogkamer et al.8 and Barnes and Kilding.9 Conversely, there was no detectable difference in running economy between shoe conditions. As such, our findings are in line with the data from the vast majority of studies that evaluated the effects of LBS with flat plates/insoles.18, 19, 20, 21 When directly comparing footwear conditions at the group level, without focusing on individual responders or the individual stiffness condition with the lowest metabolic rate, only the study results of Roy and Stefanyshyn16 and Oh and Park22 showed improvements in running economy (0.8% and 1.1%, respectively). Our results therefore dispute suggestions that LBS from the curved carbon-fiber plate alone is responsible for the majority of the metabolic savings and instead suggest that the savings arise from a combination of the foam, shoe geometry, and other effects of the curved carbon-fiber plate not related to bending stiffness.

These results challenge the recent suggestion that a curved plate alone can provide metabolic savings as high as 6% by acting as a teeter−totter.1,17 The idea behind this suggested teeter−totter effect is that the curved plate would allow the shoe to pivot in mid-stance, and push-off in a way that the force applied at the front of the shoe would create a reaction force at the heel large enough to substantially improve running economy. In this mechanism, the plate needs to provide bending stiffness in extension to enable the pivoting action. However, our current research shows that reducing the bending stiffness in both flexion and extension does not have a substantial effect on running economy. Better understanding the contributions from the highly compliant and resilient foam, as well as the shoe geometry, would further our understanding of how the plate independently contributes to the energy savings.

In general, gross biomechanical measures were similar between shoe conditions; specifically, step frequency, peak vertical GRF, braking impulse, or propelling impulse were not significantly different between conditions. We found a small but significant difference in contact time between the VFcut and VFintact, where contact time in the VFintact was 1% longer than in the VFcut (Table 1). These findings are in line with previous research reporting longer contact times in plated shoes compared to controls. In VF shoes (with an embedded, curved plate), contact time has been found to be 0%−0.6% longer compared to controls.8, 9, 10 Similar findings have also been reported in shoes with flat plates.28,30,38 Previous research has shown that across running speeds, metabolic rate is inversely related to contact time39 in that shorter contact times require faster muscle contractions to produce the force to support body weight. Faster muscle contractions are more energetically costly than slower contractions. Similarly, recent findings from Madden et al.19 and Cigoja et al.40 suggest that stiff shoes may reduce triceps surae muscle contraction velocity and improve overall running economy. While braking and propulsive impulses were similar between shoes, we found significant differences in vertical and anterior−posterior GRF traces (Fig. 3). For the majority of the stance phase, the GRF vector for the VFintact is directed more forward than for the VFcut. When accounting for the differences in contact time, the braking phases are similar, while the propulsive phase is longer for the VFintact than for the VFcut (Supplementary Fig. 1). This longer propulsive phase for the VFintact allows for a lower peak and average propulsive force. Interestingly, the 1% change in contact time and differences in propulsive GRF observed in our study were not enough to significantly affect running economy.

Joint mechanical differences were only found at the MTP joint. Importantly, the MTP joint has been shown to be a relevant location for energy loss during running.41,42 Specifically, when the MTP joint dorsiflexes in stance phase, it absorbs mechanical energy. Our results show that cutting the carbon-fiber plate did indeed result in greater MTP joint dorsiflexion and dorsiflexion angular velocity at touch down and take off (Fig. 4). This is in line with previous studies finding decreased MTP joint dorsiflexion with both flat19,20,29 and curved27 plates compared to controls. Interestingly, we did not find differences in MTP joint moment. However, it is important to note that we calculated the external MTP joint moment, which is a combination of the foot and the shoe. Although we cannot quantify it with our current data, it is likely that the shoe contributed more to the moment in the VFintact than in the VFcut, which would result in a larger contribution from structures in the foot to the MTP joint moment in the VFcut. Furthermore, MTP joint negative power and negative work were significantly lower in the intact shoes (VFintact). While decreasing negative work and energy loss at the MTP joint has been discussed as an important feature of a carbon-fiber shoe,16,31 our study shows that it alone likely has a small effect on overall metabolic energy cost.

We anticipated that cutting the plate would result in lower ankle dorsiflexion velocity and decreased ankle moment. Theoretically, increased LBS can be expected to affect ankle joint mechanics and energetics in several different ways, many of which are related to the opposite effects of potentially increased moment arms with increased LBS30 on joint moment and angular velocity (for a detail review, see Ortega et al.24). Indeed, in our study, small differences occurred in the center of pressure location during the final 10% of the stance phase. Specifically, the center of pressure moves farther away in the VFintact, creating a larger moment arm around the ankle (Supplementary Fig. 2). However, we did not find significant differences in ankle angle, angular velocity, moment, and power. It is worth noting that while it was not statistically different, on average, an individual's positive and negative ankle work was 7.0% and 5.5% greater, respectively, in the VFintact. These findings differ from those of Hoogkamer et al.,27 who reported decreased negative and positive work, as well as differences in peak ankle dorsiflexion and moment in the VF prototypes compared to control shoes. Importantly, the control shoes differed dramatically from the VF in midsole foam and geometry. It is possible that higher positive and negative ankle work might not be metabolically expensive when they result from increased mechanical energy storage and return in the Achilles tendon. Our results are in line with those of Farina et al.,32 who determined that ankle plantarflexion moment was similar between similar shoes with and without a curved plate. Together, these finding suggest that the differences found in the study by Hoogkamer et al.8 are due to differences between shoes other than the LBS of the curved carbon-fiber plate under the forefoot.

We did not find any biomechanical differences at the knee joint between shoe conditions. This is in line with previously reported research.16,19,21,27,43

Ideally, we would have compared identical VF shoes with and without a plate; however, because such shoes are not available, cutting the plate was the next best option. We tried to remove the plate, but this was not possible without irreparable damage to the midsole. Because the plate was still in the shoe, it was likely still interacting with the foam and contributing to medio-lateral bending stiffness. Furthermore, only the forefoot and midfoot sections of the plate were cut. This choice was made because we believe that forefoot and midfoot bending stiffness are most important and because the plate was very close to the insole in the rearfoot. Although we believe that the plate's stiffening effects in the rearfoot likely have little effect, it is possible that the rearfoot part of the plate contributes to the shoe's effectiveness. For example, the plate may spread out the forces under the foot over a larger foam area and/or help stabilize the shoe. Interestingly, the newly released Adidas Adizero Adios Pro (Adidas, Herzogenaurach, Germany) marathon racing shoes have a flat plate in the rearfoot decoupled from a stiff rocker in the forefoot; and while there is no experimental data on how these shoes compare mechanically or energetically to the VF, they perform well in competition. The findings in our study can only apply to the role of the plate in LBS under the forefoot. Future studies should aim to assess identical shoe models with and without an embedded, curved carbon-fiber plate. It is important to note that researchers have been studying this with flat insoles; however, the literature on this subject suggests that curved plates provide a superior advantage.24

We only tested VF shoes on males running at 14 km/h. Previous research has suggested that the effect of LBS on running economy may be speed dependent18 (for a detailed review, see Ortega et al.24). However, because both Hoogkamer et al.8 and Barnes and Kilding9 found that metabolic savings in the VF shoes were consistent across speeds from 14 km/h to 18 km/h, we believe that the speed of 14 km/h used in our study was adequate to test our hypotheses. Our sample size of 14 participants limited our statistical power and therefore may have affected our ability to find significant differences. Lastly, our study sample only included males, some of whom had never run in VFs before. Barnes and Kilding9 found that metabolic savings in the VF shoes were not significantly different between males and females, but differences in sex, body mass, leg length, and shoe size can theoretically affect the relative influence of the plate on running mechanics and energetics, which should be addressed in future research. Although some participants were new to using VFs, we do not believe this influenced our findings because, for example, all participants in the Hoogkamer et al. study8 were unfamiliar with the shoes and still exhibited metabolic savings and biomechanical differences.

When mechanically testing our shoes, we used 2 different methods for quantifying flexion and extension stiffness. Because the plate is embedded within the foam, our 3-point bending test of the VFintact in flexion resulted primarily in displacement due to foam deformation rather than longitudinal bending. Therefore, we decided to use an industry standard flex tester (Shoe Flexer; Exeter Research Inc.) for measuring flexion, and a 3-point bending test for measuring extension. These tests were sufficient for showing that cutting the plate effectively reduced the LBS for flexion and extension; however, care is advised when comparing stiffness values between different testing methods (for a detailed review, see Ortega et al.24). Future work should aim to improve external validity and standardization of footwear LBS assessment so that reported values can be compared across the literature.

As carbon-fiber plates become increasingly popular in running shoe innovation, it is important to understand how they affect running economy and joint mechanics and how this can contribute to improved performance. Future studies should continue to address specific features of shoes by systematically assessing one feature at a time in order to further our understanding of how different features alter running economy and running biomechanics.

5. Conclusion

While multiple studies have assessed the effects of increased LBS and carbon-fiber plates on running economy, our study is the first to directly assess the role of a curved, embedded carbon-fiber plate in 2 identical shoes. We found that reducing LBS, in both flexion and extension, did not significantly alter running economy. Similarly, we found only small biomechanical changes at the MTP joint. Overall, we suggest that the curved carbon-fiber plate alone has minimal impact on the 4% savings in the VF. Instead, the savings likely result from a combination and interaction of the highly compliant and resilient midsole, shoe geometry, and other effects of the curved carbon-fiber plate not related to LBS under the forefoot.

Acknowledgments

We thank the subjects for participating, Sam Zeff for helping with mechanical testing, Sam Carey for helping cut the shoes, and Justin Ortega, Dale Haavind-Berman, Emily Laughlin, Annie Lye, and Adam Lee for help with data collection.

Authors’ contributions

LAH helped with the research design and carried out data collection, data analysis, and drafting of the manuscript; WH conceived the research idea and design, and helped draft the manuscript. Both authors have read and approved the final version of the manuscript, and agree with the order of presentation of the authors.

Competing interests

Wouter Hoogkamer has received research grants from Puma North America and Saucony. This role had no involvement in the study design and writing of the manuscript or the decision to submit it for publication.

Footnotes

Peer review under responsibility of Shanghai University of Sport.

Supplementary materials associated with this article can be found in the online version at doi:10.1016/j.jshs.2021.07.002.

Supplementary materials

References

- 1.Nigg BM, Cigoja S, Nigg SR. Effects of running shoe construction on performance in long distance running. Footwear Sci. 2020;12:133–138. [Google Scholar]

- 2.Burns GT, Tam N. Is it the shoes? A simple proposal for regulating footwear in road running. Br J Sports Med. 2020;54:439–440. doi: 10.1136/bjsports-2018-100480. [DOI] [PubMed] [Google Scholar]

- 3.Frederick EC. No evidence of a performance advantage attributable to midsole thickness. Footwear Sci. 2020;12:1–2. [Google Scholar]

- 4.Dyer B. A pragmatic approach to resolving technological unfairness: The case of Nike's Vaporfly and Alphafly running footwear. Sports Med Open. 2020;6:1–10. doi: 10.1186/s40798-020-00250-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Longman J. Do Nike's new shoes give runners an unfair advantage? Available at: https://www.nytimes.com/2017/03/08/sports/nikes-vivid-shoes-and-the-gray-area-of-performance-enhancement.html?_r=0. [accessed 24.12.2020]

- 6.Muniz-Pardos B, Sutehall S, Angeloudis K, Guppy FM, Bosch A, Pitsiladis Y. Recent improvements in marathon run times are likely technological, not physiological. Sports Med. 2021;51:371–378. doi: 10.1007/s40279-020-01420-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Hoogkamer W. More isn't always better. Footwear Sci. 2020;12:75–77. [Google Scholar]

- 8.Hoogkamer W, Kipp S, Frank JH, Farina EM, Luo G, Kram R. A comparison of the energetic cost of running in marathon racing shoes. Sports Med. 2018;48:1009–1019. doi: 10.1007/s40279-017-0811-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Barnes KR, Kilding AE. A randomized crossover study investigating the running economy of highly-trained male and female distance runners in marathon racing shoes vs. track spikes. Sports Med. 2019;49:331–342. doi: 10.1007/s40279-018-1012-3. [DOI] [PubMed] [Google Scholar]

- 10.Hunter I, McLeod A, Valentine D, Low T, Ward J, Hager R. Running economy, mechanics, and marathon racing shoes. J Sports Sci. 2019;37:2367–2373. doi: 10.1080/02640414.2019.1633837. [DOI] [PubMed] [Google Scholar]

- 11.Hébert-Losier K, Finlayson SJ, Driller MW, Dubois B, Esculier JF, Beaven CM. Metabolic and performance responses of male runners wearing 3 types of footwear: Nike Vaporfly 4%, Saucony Endorphin racing flats, and their own shoes. J Sport Health Sci. 2022;11:275–284. doi: 10.1016/j.jshs.2020.11.012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Kipp S, Kram R, Hoogkamer W. Extrapolating metabolic savings in running: Implications for performance predictions. Front Physiol. 2019;10:79. doi: 10.3389/fphys.2019.00079. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Hoogkamer W, Kipp S, Spiering BA, Kram R. Altered running economy directly translates to altered distance-running performance. Med Sci Sport Exerc. 2016;48:2175–2180. doi: 10.1249/MSS.0000000000001012. [DOI] [PubMed] [Google Scholar]

- 14.Senefeld JW, Haischer MH, Jones AM, et al. Technological advances in elite marathon performance. J Appl Physiol (1985) 2021;130:2002–2008. doi: 10.1152/japplphysiol.00002.2021. [DOI] [PubMed] [Google Scholar]

- 15.Bermon S, Garrandes F, Szabo A, Berkovics I, Adami PE. Effect of advanced shoe technology on the evolution of road race times in male and female elite runners. Front Sports Act Living. 2021;3:653173. doi: 10.3389/fspor.2021.653173. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Roy JPR, Stefanyshyn DJ. Shoe midsole longitudinal bending stiffness and running economy, joint energy, and EMG. Med Sci Sport Exerc. 2006;38:562–569. doi: 10.1249/01.mss.0000193562.22001.e8. [DOI] [PubMed] [Google Scholar]

- 17.Nigg BM, Cigoja S, Nigg SR. Teeter-totter effect: A new mechanism to understand shoe related improvements in long-distance running. Br J Sports Med. 2021;55:462–463. doi: 10.1136/bjsports-2020-102550. [DOI] [PubMed] [Google Scholar]

- 18.Day E, Hahn M. Optimal footwear longitudinal bending stiffness to improve running economy is speed dependent. Footwear Sci. 2020;12:3–13. [Google Scholar]

- 19.Madden R, Sakaguchi M, Tomaras EK, Wannop JW, Stefanyshyn D. Forefoot bending stiffness, running economy and kinematics during overground running. Footwear Sci. 2016;8:91–98. [Google Scholar]

- 20.Flores N, Delattre N, Berton E, Rao G. Does an increase in energy return and/or longitudinal bending stiffness shoe features reduce the energetic cost of running? Eur J Appl Physiol. 2019;119:429–439. doi: 10.1007/s00421-018-4038-1. [DOI] [PubMed] [Google Scholar]

- 21.Beck ON, Golyski PR, Sawicki GS. Adding carbon fiber to shoe soles may not improve running economy: A muscle-level explanation. Sci Rep. 2020;10:17154. doi: 10.1038/s41598-020-74097-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Oh K, Park S. The bending stiffness of shoes is beneficial to running energetics if it does not disturb the natural MTP joint flexion. J Biomech. 2017;53:127–135. doi: 10.1016/j.jbiomech.2017.01.014. [DOI] [PubMed] [Google Scholar]

- 23.McLeod AR, Bruening D, Johnson AW, Ward J, Hunter I. Improving running economy through altered shoe bending stiffness across speeds. Footwear Sci. 2020;12:79–89. [Google Scholar]

- 24.Ortega JA, Healey LA, Swinnen W, Hoogkamer W. Energetics and biomechanics of running footwear with increased longitudinal bending stiffness: A narrative review. Sports Med. 2021;51:873–894. doi: 10.1007/s40279-020-01406-5. [DOI] [PubMed] [Google Scholar]

- 25.Fredrick EC, Clarke TE, Larsen JL, Cooper LB. Paper presented at: International Symposium on Biomechanical Aspects of Sport Shoes and Playing Surface. Calgary, AB. 1983. The effect of shoe cushioning on the oxygen demands of running. [Google Scholar]

- 26.Worobets J, Wannop JW, Tomaras E, Stefanyshyn D. Softer and more resilient running shoe cushioning properties enhance running economy. Footwear Sci. 2014;6:147–153. [Google Scholar]

- 27.Hoogkamer W, Kipp S, Kram R. The biomechanics of competitive male runners in three marathon racing shoes: A randomized crossover study. Sports Med. 2019;49:133–143. doi: 10.1007/s40279-018-1024-z. [DOI] [PubMed] [Google Scholar]

- 28.Cigoja S, Firminger C, Asmussen MJ, Fletcher JR, Edwards B, Nigg B. Effects of midsole bending stiffness on arch deformation of the human foot during running. Footwear Sci. 2019;11(Suppl. 1):S181–S182. [Google Scholar]

- 29.Willwacher S, Kon̈ig M, Potthast W, Brug̈gemann GP. Does specific footwear facilitate energy storage and return at the metatarsophalangeal joint in running? J Appl Biomech. 2013;29:583–592. doi: 10.1123/jab.29.5.583. [DOI] [PubMed] [Google Scholar]

- 30.Willwacher S, König M, Braunstein B, Goldmann JP, Brüggemann GP. The gearing function of running shoe longitudinal bending stiffness. Gait Posture. 2014;40:386–390. doi: 10.1016/j.gaitpost.2014.05.005. [DOI] [PubMed] [Google Scholar]

- 31.Willwacher S, Kurz M, Menne C, Schrödter E, Brüggemann GP. Biomechanical response to altered footwear longitudinal bending stiffness in the early acceleration phase of sprinting. Footwear Sci. 2016;8:99–108. [Google Scholar]

- 32.Farina EM, Haight D, Luo G. Creating footwear for performance running. Footwear Sci. 2019;11(Suppl. 1):S134–S135. [Google Scholar]

- 33.Péronnet F, Massicotte D. Table of nonprotein respiratory quotient: An update. CanJ Sport Sci. 1991;16:23–29. [PubMed] [Google Scholar]

- 34.Kram R, Griffin TM, Donelan JM, Chang YH. Force treadmill for measuring vertical and horizontal ground reaction forces. J Appl Physiol (1985) 1998;85:764–769. doi: 10.1152/jappl.1998.85.2.764. [DOI] [PubMed] [Google Scholar]

- 35.Mai P, Willwacher S. Effects of low-pass filter combinations on lower extremity joint moments in distance running. J Biomech. 2019;95:109311. doi: 10.1016/j.jbiomech.2019.08.005. [DOI] [PubMed] [Google Scholar]

- 36.Bisseling RW, Hof AL. Handling of impact forces in inverse dynamics. J Biomech. 2006;39:2438–2444. doi: 10.1016/j.jbiomech.2005.07.021. [DOI] [PubMed] [Google Scholar]

- 37.Pataky TC. One-dimensional statistical parametric mapping in Python. Comput Methods Biomech Biomed Engin. 2012;15:295–301. doi: 10.1080/10255842.2010.527837. [DOI] [PubMed] [Google Scholar]

- 38.Day EM, Hahn ME. Increased toe-flexor muscle strength does not alter metatarsophalangeal and ankle joint mechanics or running economy. J Sport Sci. 2019;37:2702–2710. doi: 10.1080/02640414.2019.1661562. [DOI] [PubMed] [Google Scholar]

- 39.Kram R, Taylor CR. Energetics of running: A new perspective. Nature. 1990;346:265–267. doi: 10.1038/346265a0. [DOI] [PubMed] [Google Scholar]

- 40.Cigoja S, Asmussen MJ, Firminger CR, Fletcher JR, Edwards WB, Nigg BM. The effects of increased midsole bending stiffness of sport shoes on muscle−tendon unit shortening and shortening velocity: A randomised crossover trial in recreational male runners. Sports Med Open. 2020;6:9. doi: 10.1186/s40798-020-0241-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Sun X, Lam WK, Zhang X, Wang J, Fu W. Systematic review of the role of footwear constructions in running biomechanics: Implications for running-related injury and performance. J Sports Sci Med. 2020;19:20–37. [PMC free article] [PubMed] [Google Scholar]

- 42.Willwacher S, Kon̈ig M, Potthast W, Brüggemann GP. Does specific footwear facilitate energy storage and return at the metatarsophalangeal joint in running? J Appl Biomech. 2013;29:583–592. doi: 10.1123/jab.29.5.583. [DOI] [PubMed] [Google Scholar]

- 43.Cigoja S, Firminger CR, Asmussen MJ, Fletcher JR, Edwards WB, Nigg BM. Does increased midsole bending stiffness of sport shoes redistribute lower limb joint work during running? J Sci Med Sport. 2019;22:1272–1277. doi: 10.1016/j.jsams.2019.06.015. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.