Significance

Small modular reactors (SMRs), proposed as the future of nuclear energy, have purported cost and safety advantages over existing gigawatt-scale light water reactors (LWRs). However, few studies have assessed the implications of SMRs for the back end of the nuclear fuel cycle. The low-, intermediate-, and high-level waste stream characterization presented here reveals that SMRs will produce more voluminous and chemically/physically reactive waste than LWRs, which will impact options for the management and disposal of this waste. Although the analysis focuses on only three of dozens of proposed SMR designs, the intrinsically higher neutron leakage associated with SMRs suggests that most designs are inferior to LWRs with respect to the generation, management, and final disposal of key radionuclides in nuclear waste.

Keywords: nuclear, small modular reactors, energy, waste, nuclear waste

Abstract

Small modular reactors (SMRs; i.e., nuclear reactors that produce <300 MWelec each) have garnered attention because of claims of inherent safety features and reduced cost. However, remarkably few studies have analyzed the management and disposal of their nuclear waste streams. Here, we compare three distinct SMR designs to an 1,100-MWelec pressurized water reactor in terms of the energy-equivalent volume, (radio-)chemistry, decay heat, and fissile isotope composition of (notional) high-, intermediate-, and low-level waste streams. Results reveal that water-, molten salt–, and sodium-cooled SMR designs will increase the volume of nuclear waste in need of management and disposal by factors of 2 to 30. The excess waste volume is attributed to the use of neutron reflectors and/or of chemically reactive fuels and coolants in SMR designs. That said, volume is not the most important evaluation metric; rather, geologic repository performance is driven by the decay heat power and the (radio-)chemistry of spent nuclear fuel, for which SMRs provide no benefit. SMRs will not reduce the generation of geochemically mobile 129I, 99Tc, and 79Se fission products, which are important dose contributors for most repository designs. In addition, SMR spent fuel will contain relatively high concentrations of fissile nuclides, which will demand novel approaches to evaluating criticality during storage and disposal. Since waste stream properties are influenced by neutron leakage, a basic physical process that is enhanced in small reactor cores, SMRs will exacerbate the challenges of nuclear waste management and disposal.

In recent years, the number of vendors promoting small modular reactor (SMR) designs, each having an electric power capacity <300 MWelec, has multiplied dramatically (1, 2). Most recently constructed reactors have electric power capacities >1,000 MWelec and utilize water as a coolant. Approximately 30 of the 70 SMR designs listed in the International Atomic Energy Agency (IAEA) Advanced Reactors Information System are considered “advanced” reactors, which call for seldom-used, nonwater coolants (e.g., helium, liquid metal, or molten salt) (3). Developers promise that these technologies will reduce the financial, safety, security, and waste burdens associated with larger nuclear power plants that operate at the gigawatt scale (3). Here, we make a detailed assessment of the impact of SMRs on the management and disposal of nuclear waste relative to that generated by larger commercial reactors of traditional design.

Nuclear technology developers and advocates often employ simple metrics, such as mass or total radiotoxicity, to suggest that advanced reactors will generate “less” spent nuclear fuel (SNF) or high-level waste (HLW) than a gigawatt-scale pressurized water reactor (PWR), the prevalent type of commercial reactor today. For instance, Wigeland et al. (4) suggest that advanced reactors will reduce the mass and long-lived radioactivity of HLW by 94 and ∼80%, respectively. These bulk metrics, however, offer little insight into the resources that will be required to store, package, and dispose of HLW (5). Rather, the safety and the cost of managing a nuclear waste stream depend on its fissile, radiological, physical, and chemical properties (6). Reactor type, size, and fuel cycle each influence the properties of a nuclear waste stream, which in addition to HLW, can be in the form of low- and intermediate-level waste (LILW) (6–8). Although the costs and time line for SMR deployment are discussed in many reports, the impact that these fuel cycles will have on nuclear waste management and disposal is generally neglected (9–11).

Here, we estimate the amount and characterize the nature of SNF and LILW for three distinct SMR designs. From the specifications given in the NuScale integral pressurized water reactor (iPWR) certification application, we analyze basic principles of reactor physics relevant to estimating the volumes and composition of iPWR waste and then, apply a similar methodology to a back-end analysis of sodium- and molten salt–cooled SMRs. Through this bottom-up framework, we find that, compared with existing PWRs, SMRs will increase the volume and complexity of LILW and SNF. This increase of volume and chemical complexity will be an additional burden on waste storage, packaging, and geologic disposal. Also, SMRs offer no apparent benefit in the development of a safety case for a well-functioning geological repository.

1. SMR Neutronics and Design

A nuclear reactor is designed to sustain criticality, a chain reaction of fission events that generates energy (∼200 MeV per fission event) and extra neutrons that can cause fission in nearby fissile nuclides. The neutron “economy” of a reactor depends on the efficiency of the chain reaction process; the fate of neutrons absorbed by abundant nuclides, such as 238U or 232Th; the fission of newly generated fissile nuclides, such as 239Pu and 233U; and the loss of neutrons across the fuel boundary. These “lost” neutrons can activate structural materials that surround the fuel assemblies. Each of these physical processes generates radioactive waste. Thus, the final composition of the SNF and associated wastes depend on the initial composition of the fuel, the physical design of the fuel, burnup, and the types of structural materials of the reactor.

The probability of neutron leakage is a function of the reactor dimensions and the neutron diffusion length, the latter of which is determined by the neutron scattering properties of the fuel, coolant, moderator, and structural materials in the reactor core (12). The neutron diffusion length will be the same in reactors that use similar fuel cycles and fuel–coolant–moderator combinations; thus, the neutron leakage probability will be larger for an SMR than for a larger reactor of a similar type (SI Appendix, section 1).

For thermal-spectrum reactors, the neutrons undergo elastic scattering with the water or graphite moderator, leading to neutron diffusion lengths that are short relative to the core dimensions. Here, leakage grows quadratically with decreasing core radius and reactor size (SI Appendix, section 1). For instance, a 3,400-MWth PWR will leak <3% of its free neutrons, whereas a 160-MWth iPWR may leak >7% (9). Leakage from fast reactors is also high, at least 4% and up to 25%, depending on the fuel composition and other aspects of core design (13). Overall, both water and nonwater SMRs entail increased neutron leakage as compared with a gigawatt-scale light water reactor (LWR) (SI Appendix, section 1).

Small increases in neutron leakage have a significant effect on core criticality and power output and will lead to reduced SNF burnup (a measure of fuel efficiency expressed in units of energy extracted per mass of heavy metal in the initial fuel; e.g., megawatt-days per kilogram, or MWd/kg) (SI Appendix, section 1) (9, 14) unless compensated for by design changes to the reactor and/or fuel, including

-

•

utilizing a fuel enriched to >5 wt % initial 235U or 239Pu to increase the initial fissile loading and the probability of neutron absorption by a fissile element,

-

•

introducing a neutron reflector to redirect a fraction of leaked neutrons back into the core, and/or

-

•

foregoing a neutron moderator or using graphite rather than water.

Most of the SMR designs listed in the IAEA Aris database incorporate one or all these strategies to improve the core neutron economy (Table 1).

Table 1.

Select SMRs and full-scale reactors to illustrate differences in fuel enrichment, burnup, and reactor materials

| Reactor type | MWth | Enrichment (%) | burnup (MWd/kg) | Vessel lifetime (y) | Moderator (if not water) | Coolant (if not water) | Reflector | Shield | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Boiling water reactors | |||||||||

| BWRX-300 (GE-Hitachi) | 870 | 3.4 | 50 | 60 | 82 | ||||

| ABWRII (GE-Hitachi) | 4,960 | 5.2 | 60 | ||||||

| PWR | |||||||||

| iPWR (NuScale) | 160 | 5 | 34 | 60 | Steel | ||||

| SMART (KAERI) | 330 | 4.8 | 36 | 60 | |||||

| VVER300 (Gidropress) | 850 | 4.8 | 38 | 83 | |||||

| IMR (Mitsubishi) | 1,000 | 4.8 | 46 | 60 | |||||

| AP600 (Westinghouse) | 1,940 | 4 | 55 | 60 | Steel | 84 | |||

| AP1000 (Westinghouse) | 3,400 | 4.8 | 60 | 60 | |||||

| Molten salt reactor (thermal) | |||||||||

| CMSR (Seaborg Technologies) | 250 | 7 | 31 | 12 | NaOH | NaF-KF | NaOH | 85 | |

| IMSR-400 (Terrestrial Energy) | 400 | 3 | 14 | 7 | Graphite | NaF, BeF2, or LiF | Yes | 86 | |

| FUJI (International Thorium MSR Forum) | 450 | 2 | 21 | 30 | Graphite | LiF-BeF2 | Graphite | 87 | |

| ThorCon (Martingale) | 557 | 20 | 256 | 4 | Graphite | NaF-BeF2 | Graphite | 88 | |

| SSR-U/Th (Moltex Energy) | 750 | 5 | 70 | 60 | Graphite | NaF-RbF, ZrF4-NaF-KF | 89 | ||

| Sodium-cooled fast reactor | |||||||||

| Oklo (Oklo Inc.) | 4 | 20 | <10 | 20 | n/a | Sodium | Zirconium + stainless steel | Boron-carbide | 90 |

| 4S-30 (Toshiba) | 30 | 19 | 34 | 60 | n/a | Sodium | Stainless steel | Boron-carbide | 34 |

| 4S-135 (Toshiba) | 135 | 18 | 90 | 60 | n/a | Sodium | Stainless steel | Boron-carbide | 34 |

| PGSFR (KAERI) | 400 | 13–19.5 | 49 | 60 | n/a | Sodium | Lead-oxide (PbO) | Boron-carbide | 91, 92 |

| BN350 (JSC/OKBM) | 750 | 26 | 58 | 20 | n/a | Sodium | Yes | Iron ore | 32 |

| PRISM (GE-Hitachi) | 840 | ∼15 | ∼100 | 60 | n/a | Sodium | Yes | Yes | 74 |

| Traveling wave reactor (TerraPower) | 1,475 | 16 | 150 | 40 | n/a | Sodium | Steel | Boron-carbide | 93 |

| ASTRID (CEA) | 1,500 | 23 | 77 | 60 | n/a | Sodium | Magnesium- oxide | Boron-carbide | 30, 94 |

| BN1200 (JSC/OKBM) | 2,800 | 13 | 112 | 60 | n/a | Sodium | Beryllium | Boron | 95, 96 |

| JSFR (JAEA) | 3,530 | 18–21 | 150 | 60 | n/a | Sodium | Stainless steel | Zirconium- hydride | 97, 98 |

n/a, not applicable.

In this paper, we describe how these changes manifest in water-, sodium-, and molten salt–cooled SMR designs and their impact on the volume, composition, and geologic disposal of SNF/HLW and LILW.

2. Framework for Waste Comparison

The management and disposal of nuclear waste are influenced by the formation and distribution of radionuclides throughout a reactor, which in turn, depend on the geometry, composition, and flow paths of reactor, fuel, moderator, and coolant materials. These specifications were tabulated for 16 SMR designs (Table 1). Of these, the NuScale iPWR, the Toshiba 4S sodium-cooled fast reactor, and the Terrestrial Energy Integral Molten Salt Reactor (IMSR) were selected for in-depth, quantitative and qualitative waste assessments, because reliable reactor and fuel cycle specifications for these designs have been published in (pre-)license and patent application materials. Where proprietary design parameters were redacted from these materials, gaps in the availability of technical data were filled through explicit assumptions, through reference to similar designs analyzed in the scientific literature, or through derivation using known design parameters.

2.1. Metrics.

The quantitative comparison aimed to determine whether advanced reactors will generate less nuclear waste than existing LWRs. SNF and LILW volumes were calculated for each of the three SMR designs, and the results were normalized to the thermal energy generated by the respective reactor or fuel cycle, roughly the reactor power integrated over the reactor lifetime or fuel cycle length (sections 3 and 4). This metric, the energy-equivalent waste volume (in cubic meters per gigawatt thermal-year, or m3/GWth-y), was used to compare SMR and PWR waste volumes relative to their respective energy benefits. Fuel burnup and core geometry specifications were used to estimate the SNF volumes (sections 3.2 and 4), whereas neutron flux and primary coolant loop specifications were used to estimate the volume of reactor material that will become neutron activated or contaminated to result in long- or short-lived decommissioning LILW (sections 3.3, 4.1, and 4.2).

The metrics “volume” and “energy-equivalent volume,” however, do not reflect the radionuclide composition and speciation, much more important parameters for the proper evaluation of the impact on the safety of a geologic repository. Nuclear reactors generate several distinct waste streams, which contain variable concentrations of radionuclides that have a range of half-lives from hours to millions of years and a variety of very different nuclear and chemical properties. Thus, in addition to calculating the SMR waste volumes, we characterize the radiochemical compositions of SNF and LILW streams (sections 3 and 4) and then, discuss their management and disposal as SNF or LILW in a geologic repository (section 4).

2.2. LILW.

Decommissioning LILW that contains low or very low concentrations of short- or long-lived radionuclides (half-lives less than or greater than 30 y, respectively) may qualify for disposal as “short-lived LILW” in a near-surface disposal facility. However, “long-lived LILW” that contains intermediate concentrations of long-lived radionuclides and/or short-lived radionuclides in concentrations high enough to warrant radiation-shielded packaging should be disposed of in a geologic repository that has multiple natural and engineered barriers (6).

In this paper, we classify reactor materials that may become neutron activated via neutron leakage from the active core as long-lived decommissioning LILW (sections 3.3.1 and 4.2), whereas materials that may become contaminated by contact with the primary reactor coolant are classified as short-lived LILW (sections 3.3.2 and 4). Where possible, we refer to neutron flux models or to previous waste characterization studies to justify these SMR LILW classifications. However, in practice, these classifications should be verified through an iterative safety assessment process. This involves sampling and analysis of reactor materials to constrain the source term as well as site-specific radionuclide transport simulations that consider the temporal evolution of a proposed repository, including its natural hydrogeochemistry, as coupled with an engineered barrier system (section 4).

2.3. HLW or SNF.

Similar to LILW, the safe management and disposal of SNF or HLW must take into account metrics beyond mass, volume, or radioactivity. Therefore, we compare the SNF that will be generated by SMRs with that discharged by LWRs in terms of

-

•

the chemistry of the SNF matrix and its radionuclide contents, which influences the environmental mobility of radionuclides and their consequent potential to deliver radiation doses to humans in the biosphere;

-

•

the heat generated by radioactive decay, which can damage the SNF matrix, as well as other components of the barrier system (e.g., the stability of backfill clays used to inhibit radionuclide transport); and

-

•

the concentrations of fissile isotopes in the SNF, which influence its potential to sustain a heat-generating critical chain reaction that can damage the fuel and barrier systems in a geologic repository.

These variables depend on the SNF radiochemical composition (i.e., the radionuclide amount and type, including their chemical properties, half-lives, decay modes, and daughter products), which in turn, depends on the initial fuel composition, its final burnup, and the time elapsed since it was discharged from the reactor. In addition, the in-core neutron energy spectrum affects the types and amounts of radionuclides formed in the fuel and reactor materials, such that the composition of SNF generated by a moderated thermal-spectrum reactor will differ from that generated by a fast reactor. SMR and LWR fuel burnups and compositions are compared in terms of repository design and long-term safety assessments in section 4.

2.4. Waste Chemistry.

Whether a particular nuclear material can be stored or disposed of at a specific facility is, in part, governed by its radiochemical and bulk chemical compositions. LWRs generate decommissioning LILW and SNF in the nominal forms of concrete, steel, zirconium cladding, and UO2. Since these materials do not react rapidly or violently under ambient conditions, they can be stored or disposed of at appropriately designed facilities. On the other hand, non-LWR SMRs employ chemically exotic fuels and coolants (e.g., metallic sodium, metallic uranium, and uranium tetrafluoride) that react rapidly with water and/or atmospheric oxygen. Since experience with handling and disposing of these chemically unstable waste streams is limited, we refer to decommissioning reports from previous experimental reactors to infer the implications that novel SMR materials will have for the direct disposal of their wastes (sections 4). Prior to disposal, exotic spent fuel, coolant, and/or moderator materials will require treatment and conditioning. However, the properties of the by-products and infrastructure associated with these processes are uncertain, so the additional waste streams generated by treatment and conditioning processes are not quantified in this study.

This study also neglects to consider reprocessing, recycling, and dilution because these treatments will not eliminate the need for the storage, transportation, treatment, and disposal of radioactive materials.

3. SMR Waste Streams: Volumes and Characteristics

3.1. Novel SMR Design Features.

Many SMRs adopt an “integral” design, wherein the reactor core and certain auxiliary systems (e.g., steam generators, pressurizers, and/or heat exchangers) are all contained within a reactor vessel (SI Appendix, Figs. S2 and S3). Several SMRs may be colocated at a single power station. For instance, a NuScale iPWR station may host up to 12 160-MWth iPWRs, each submerged in a common reactor pool that shares water with the SNF cooling pool (15, 16).

Primary coolant (e.g., in the form of water, molten salt, or sodium) will be heated at the core and circulated upward through the center of the reactor vessel. At the upper portion of the reactor vessel, the primary coolant is redirected downward to flow over heat exchangers, which warm a secondary coolant that ultimately supports the power train. The primary coolant comes in direct contact with the active core and so, represents an important conduit that, under normal operating conditions, can contaminate the reactor vessel and its contents with radionuclides.

In the case of sodium- and molten salt–cooled SMRs, the primary coolant will be chemically reactive (section 3.4.3), heated to temperatures >500 °C, and highly radioactive (2). Under these extreme conditions, reactor components can have a shorter lifetime than the standard PWR (60 y), and this will increase decommissioning LILW volumes. In addition, nonlight water SMRs will introduce uncommon types of LILW in the form of neutron reflectors and chemically reactive coolant or moderator materials.

The following sections show how the difference between SMR and full-scale reactor core geometries, primary coolant flow paths, and refueling procedures will impact the generation of short- and long-lived decommissioning LILW.

3.2. SNF: burnup, Mass, and Volume.

For PWR and iPWR designs that each employ UO2 fuel enriched to ∼5 wt % 235U, previous investigators report that neutron leakage (section 2) will reduce fuel burnups from ∼55 MWd/kg, as achieved by PWRs, to 26 to 34 MWd/kg for an iPWR (9, 15). Since burn-up details were redacted from the publicly available license application of the NuScale reactor, a burnup of ∼34 MWd/kg is here calculated using the fuel rod dimensions, linear power density, and reactor operating parameters provided for this iPWR (SI Appendix, Table S2) (17). Operating as recommended by NuScale, a 12-module iPWR station (1,900 MWth) would discharge ∼21 MT SNF/y, which is similar to a power station that hosts a single 3,400-MWth PWR (burnup of 57 MWd/kg) (SI Appendix, Table S2). Per energy equivalent, the mass of SNF that will be discharged by an iPWR is 1.7-fold greater than that discharged by a gigawatt-scale PWR (SI Appendix, Table S2).

Like the NuScale iPWR, molten salt– and sodium-cooled SMRs will experience enhanced neutron leakage (section 2 and SI Appendix, section 1). Although these SMR designs may seek to offset the leakage by using neutron reflectors and/or fuel enriched to >5 wt % initial fissile concentration, fuel burnups will be lower than for larger molten salt– and sodium-cooled reactors (Table 1). For instance, the use of 19 wt % initial fissile fuel in a 2-, 30-, or 135-MWth sodium SMR will achieve burnups of <10, 34, or 90 MWd/kg, respectively (Table 1). ThorCon’s 560-MWth molten salt SMR also calls for a fuel enriched to ∼20 wt % fissile isotopes that is claimed to achieve a burnup of 250 MWd/kg. However, 3%-enriched 235U fuel in Terrestrial Energy’s 400-MWth molten salt SMR will achieve a burnup of only 14 MWd/kg (Table 1).

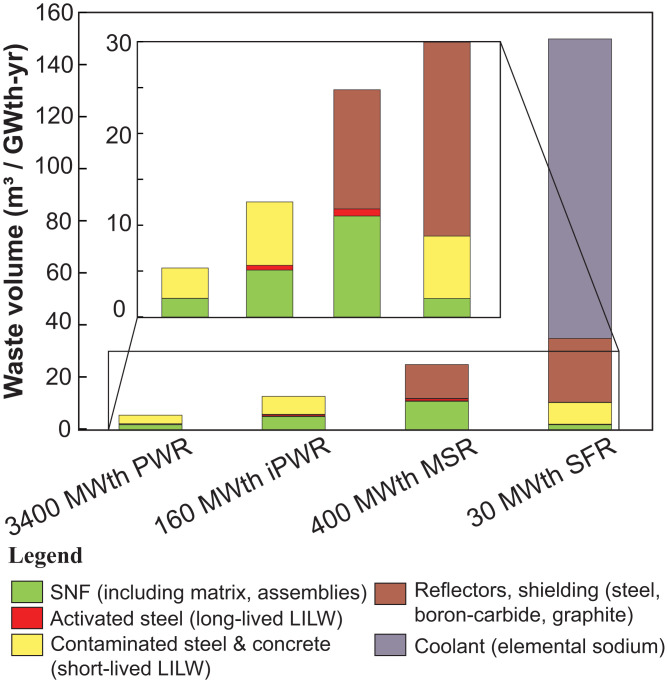

The energy-equivalent mass of SNF generated by these SMRs can be calculated from the inverse of the respective burnup. Whereas a PWR with a burnup of 55 MWd/kg discharges ∼6.5 MT SNF/GWth-y, a nonwater-cooled SMR may discharge 1.5 to >36 MT SNF/GWth-y. These figures, however, solely reflect the mass of uranium, actinides, and fission products in the SNF and neglect contributions from salt or sodium constituents in or around the fuel matrix. Such low-density materials contribute little to mass-based SNF estimates but nevertheless, will contribute to volume-based estimates. For the 160-MWth NuScale, the 400-MWth Terrestrial Energy, and the 30-MWth Toshiba SMR designs, volumetric discharges of 5.1, 11, and 2.0 m3 SNF/GWth-y, respectively, have been calculated as compared with 2.0 m3 SNF/GWth-y for a PWR (Fig. 1 and SI Appendix, section 2). The management and disposal implications for low–burnup SMR fuel are discussed in section 4.

Fig. 1.

Energy-equivalent waste volumes, by waste type, for various SMR designs—including the NuScale iPWR, the Terrestrial Energy IMSR, and the sodium-cooled Toshiba 4S SMRs.

3.3. Long-Lived LILW: Activated Steel from Reactor Vessels and Neutron Reflectors.

In general, long-lived LILW consists of near-core reactor components that have become radioactive or “activated” after absorbing neutrons leaked from the core (18, 19) (section 2). This activated steel contains radioisotopes with half-lives longer than several thousand years (e.g., 59Ni, 14C, 94Nb, 99Tc, 93Zr, 93Mo, and 36Cl) and so, should be disposed of in a geologic repository that will limit and delay the introduction of radionuclides to the surface ecosystem (Table 2) (7, 20, 21).

Table 2.

Activation products and half-lives of core barrel, moderator, neutron reflector, shielding, and coolant materials for various SMR designs

| Material | Activation product (t1/2, y) | Notes | Ref. |

|---|---|---|---|

| Stainless steel | 54Mn (0.85), 55Fe (2.7), 60Co (5.3), 63Ni (1.0e2), 93Mo (4.0e3), 14C (5.7e3), 94Nb (2.0e4), 59Ni (7.6e4), 99Tc (2.1e5), 36Cl (3.0e5) | Depends on the composition of steel | 19, 20 |

| Graphite | 3H (12), 14C (5.7e3), 36Cl (3.0e5) | Plus contamination (corrosion and fission products, actinides) | 99 |

| FLiBe | 18F (2.1e-4), 24Na (1.5e-3), 51Cr (7.7e-2), 59Fe (0.12), 58Co (0.19), 22Na (2.6), 55Fe (2.7), 60Co (5.3), 3H (12), 14C (5.7e3) | Includes FLiBe impurities, neglects contamination by corrosion and fission products, actinides | 100 |

| Sodium | 24Na (1.5e-3), 22Na (2.6) | 24Na, a strong gamma emitter; 134Cs (2.4), 137Cs (30), and 60Co (5.3) in primary coolant also significant | 101 |

| Magnesium-oxide | 24Na (1.5e-3) | Fast reactor reflectors and shielding materials contained within steel cladding (activation products listed in the first row) | 102 |

| Lead-oxide | 210Bi (1.4e-2), 210Po (0.38), 210Pb (22), 205Pb (1.7e7) | 103 | |

| Boron carbide | 3H (12), 14C (5.7e3), 10Be (1.5e6) | 104 | |

| Beryllium | 3H (12), 10Be (1.5e6); due to uranium impurity: 90Sr (29), 134Cs (2.1), 137Cs (30), 244Cm (18), 241Pu (14) | 105 |

FLiBe, a mixture of fluorine, lithium, and beryllium.

3.3.1. Near-core iPWR components.

The degree of activation in near-core reactor steel is directly proportional to the time-integrated flux of neutron exposure or the neutron “fluence” (21). Although a NuScale iPWR generates 95% less heat than a full-scale PWR, the total neutron flux at the periphery of an active iPWR core will be similar to that of the AP1000 (>1014 neutrons/cm2-s) (18, 22).

Activation models that account for the geometry and composition of PWR cores indicate that exposure to a thermal neutron fluence >1021 neutrons/cm2 (i.e., a neutron flux >1012 neutrons/cm2-s for 60 y at 70% capacity factor) will qualify a component as long-lived LILW or Greater-than-Class-C waste, as defined by the US Nuclear Regulatory Commission (SI Appendix, Fig. S1) (19, 21).

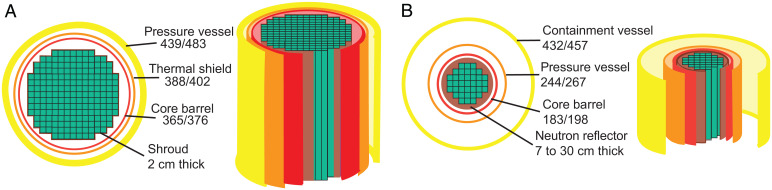

NuScale indicates that the iPWR pressure vessel, located ∼35 cm from the active core, is exposed to a thermal neutron flux of 2.4·1011 neutrons/cm2-s (Fig. 2 and SI Appendix, Fig. S1) (18). This exceeds the thermal flux at the pressure vessel of a PWR (5.3·1010 neutrons/cm2-s) by a factor of 4.5 (23). If the iPWR operates for 60 y at 95% capacity (18), the neutron fluence at the iPWR pressure vessel, ∼4.3·1020 neutrons/cm2, will approach the long-lived LILW activation limit of 1021 neutrons/cm2. Hence, NuScale iPWR components located between the core and the pressure vessel, including the core barrel and the neutron reflector (SI Appendix, Fig. S1), may warrant geologic disposal as long-lived LILW at decommissioning. Whether the NuScale iPWR pressure vessel will also reach long-lived LILW activation levels is uncertain and may vary according to nation-specific regulations.

Fig. 2.

To-scale drawing of (A) 1,000-MWelec PWR and (B) 50-MWelec NuScale iPWR cores showing inner and outer diameters of cylindrical components (in centimeters) and color coded according to anticipated status as short-lived (yellow) or long-lived (light red and maroon) LILW. Orange color indicates uncertainty with respect to short- or long-lived LILW status.

Since the NuScale iPWR components discussed will consist of stainless steel with a composition similar to that of a PWR (i.e., type 304/304L stainless steel) (8, 19), these long-lived LILW estimates are not sensitive to differences in the steel composition and associated neutron absorption cross-sections.

The volume of long-lived LILW that might arise from decommissioning a 160-MWth iPWR was estimated and compared with the corresponding figures for a 3,400-MWth PWR (19) (SI Appendix, Table S3). One iPWR will generate 0.29 or 0.53 m3/GWth-y depending on whether the pressure vessel will be activated to long-lived LILW levels. Compared with a PWR (3.1·10−2 m3/GWth-y), the NuScale iPWR would increase the energy-equivalent volume of long-lived decommissioning LILW waste in need of geologic disposal by a factor of 9 to 17 (SI Appendix, Table S3).

3.3.2. Corroded vessels from molten salt reactors.

Molten salt reactor vessel lifetimes will be limited by the corrosive, high-temperature, and radioactive in-core environment (23, 24). In particular, the chromium content of 316-type stainless steel that constitutes a PWR pressure vessel is susceptible to corrosion in halide salts (25). Nevertheless, some developers, such as ThorCon, plan to adopt this stainless steel rather than to qualify a more corrosion-resistant material for the reactor vessel (25).

Terrestrial Energy may construct their 400-MWth IMSR vessel from Hastelloy N, a nickel-based alloy that has not been code certified for commercial nuclear applications by the American Society of Mechanical Engineers (26, 27). Since this nickel-based alloy suffers from helium embrittlement (27), Terrestrial Energy envisions a 7-y lifetime for their reactor vessel (28). Molten salt reactor vessels will become contaminated by salt-insoluble fission products (28) and will also become neutron-activated through exposure to a thermal neutron flux greater than 1012 neutrons/cm2-s (29). Thus, it is unlikely that a commercially viable decontamination process will enable the recycling of their alloy constituents. Terrestrial Energy’s 400-MWth SMR might generate as much as 1.0 m3/GWth-y of steel or nickel alloy in need of management and disposal as long-lived LILW (Fig. 1, Table 1, and SI Appendix, Fig. S3 and section 2).

3.3.3. Damaged reflectors and shielding from fast-spectrum SMRs.

Since fast-spectrum SMRs—cooled by gas or by molten sodium, lead, or salt—forego a neutron moderator, these designs employ neutron reflectors and shielding to mitigate damage to the reactor vessel caused by fast neutron bombardment (Table 1) (30, 31). Although neutron absorption cross-sections are, in general, lower for fast than for thermal neutrons, fast neutron fluxes in sodium-cooled SMRs will exceed 1015 n/cm2-s (32). Thus, the need to manage and dispose of activated reflector and shielding subassemblies as long-lived LILW can be anticipated. For example, after operating for 20 y, the 750-MWth BN-350 sodium-cooled fast reactor (Kazakhstan: 1973 to 1993) generated ∼13 m3 of activated steel that contained long-lived 59Ni and 94Nb radionuclides in concentrations sufficient to warrant geologic disposal of its reflectors and shielding as long-lived LILW (33).

Common reflector and shielding materials include steel and boron carbide, respectively, but beryllium, magnesium, lead, and other materials have also been considered (31). Although some of these materials form few long-lived activation products, they will be clad by steel cladding that does form long-lived activation products and will be lifetime limited by fast neutron damage (Table 2) (32, 34). Given the 30-y core lifetime and dimensions stated by Toshiba, a 30-MWth sodium-cooled SMR will generate up to 25 m3/GWth-y of activated reflector and shielding assemblies that may be classified as long-lived LILW (Table 1 and SI Appendix, Fig. S3 and section 2; see Fig. 1).

3.4. Short-Lived LILW.

3.4.1. Contaminated iPWR components.

Short-lived LILW is primarily generated by surface contamination of structural materials that have been in contact with the reactor coolant, which carries radioisotopes sourced by ruptured fuel rods and activated corrosion products (35). Inventory reports indicate that a 3,400-MWth PWR in Sweden will generate ∼600 m3 (3.3 m3/GWth-y) of short-lived decommissioning LILW in the form of contaminated steel and activated concrete (SI Appendix, Table S3) (36, 37).

Short-lived LILW from a NuScale iPWR will be dominated by steel from the pressure and containment vessels (Fig. 2) that will become contaminated by radionuclides carried by water in the primary coolant and the reactor pool. Ultimately, the iPWR pressure and containment vessels will generate 17 and 43 m3 of short-lived decommissioning LILW, respectively, equivalent to 6.9 m3/GWth-y (SI Appendix, Table S3). This neglects the iPWR internal components (e.g., the steam generators) and contributions from structural materials in the reactor–SNF pool and so, represents a lower-limit estimate. Therefore, per energy equivalent, a 160-MWth iPWR will generate at least a twofold larger volume of short-lived decommissioning LILW than a 3,400-MWth PWR.

3.4.2. Graphite moderators from molten salt reactors.

Thermal-spectrum molten salt reactor designs tend to employ graphite as both a neutron moderator and reflector (Table 2). This graphite may occupy 60 to 80% of the core volume, the remainder of which will be occupied by a liquid fuel–coolant salt that flows through hollow tubes in the graphite matrix, carrying with it dissolved fuel isotopes and fission products (38). Graphite in the Oak Ridge Molten Salt Reactor Experiment (MSRE) acquired surface contamination by Mo, Te, Ru, and Nb fission products, whereas tritium, Cs, and Sr radioisotopes (generated via decay of Xe and Kr fission products) diffused into the porous structure of the graphite (39, 40). Whether and where this graphite has been disposed of are unclear, although the management and disposal of graphite moderators recovered from Magnox and Reaktor Bolsjoj Mosjnosti Kanalnyj (RBMK) reactors have been complicated by the presence of both short- and long-lived isotopes—including tritium, 14C, corrosion/activation products, fission products, and actinides (Table 2) (41).

Since graphite tends to expand and crack during prolonged irradiation, its lifetime in an SMR will be limited (42). Depending on the magnitude of its neutron flux exposure, graphite lifetimes for the molten salt SMR designs pursued today will range from 2.5 to 30 y (39) (Table 1). Given a stated lifetime of 7 y, the 400-MWth IMSR (Terrestrial Energy) will discharge ∼13 m3/GWth-y of radioactive graphite that will require geologic disposal (Fig. 1, Table 1, and SI Appendix, section 2).

3.4.3. Liquid metal and salt coolants.

When an LWR is decommissioned, many of the radionuclides in its cooling water (section 3.3.1) can be removed by filters and ion exchange resins (43). However, storage, decontamination, and disposal of radioactive sodium- and molten salt–based coolants will need to account for their chemical complexity and tendency to generate explosive or corrosive by-products upon contact with air or moisture.

At the experimental sodium-cooled fast reactors operated during the late twentieth century, decommissioning was complicated by the large volumes of metallic sodium coolant that became contaminated by a 22Na activation product and by Cs isotopes leached from ruptured fuel elements (34). This pyrophoric sodium was deactivated through a pilot-scale water-based process that was performed under an inert atmosphere to prevent the explosion of a hydrogen by-product. Ultimately, the sodium coolant generated several hundred cubic meters of low-level radioactive waste (34). The 30-MWth Toshiba 4S reactor might generate 115 m3/GWth-y of contaminated pyrophoric sodium coolant in need of treatment, conditioning, and disposal (Fig. 1, Table 1, and SI Appendix, section 2).

Similar decommissioning challenges can be anticipated for molten salt reactors that utilize a liquid fluoride–based fuel–coolant salt into which the fissile isotopes are directly dissolved (Table 1). This fluoride salt readily reacts with water to form corrosive hydrofluoric acid and becomes highly radioactive as fission and activation products accumulate over the course of operation. After the 8-MWth MSRE was shut down in 1969, volatile UF6 complexes formed via radiolytic decomposition of the solidified fuel salt that was stored on-site at Oak Ridge National Laboratory. This presented a criticality risk that prompted the removal of fissile material from the solidified salt mass (44), but the continued presence of highly radioactive salt-soluble fission products has stymied further decommissioning. A report that the authors recovered through the Freedom of Information Act indicates that the US Department of Energy, rather than decommissioning and off-site disposal of the salt and reactor components, may entomb this legacy waste on-site (SI Appendix, section 3).

4. Management and Disposal of SMR Waste

The excess volume of SMR wastes will bear chemical and physical differences from PWR waste that will impact their management and final disposal. Although SMR developers tend to describe their waste production in terms of HLW or SNF mass and total radiotoxicity, repository design and postclosure safety analysis depend more on the solubility, environmental mobility, and sorption properties of specific radionuclides and the decay power or heat generation rate of the packaged wastes as well as the recriticality potential of the fissile materials that they contain (45). These parameters correlate to the waste stream radiochemistry and bulk chemical composition, which in turn, depend on the initial fuel composition and enrichment, discharge burnup, and in-core neutron energy spectrum, which are different for SMRs than for PWRs.

4.1. SNF Management and Disposal.

4.1.1. Fuel composition and durability.

PWRs utilize ∼5 wt %–enriched 235U fuel bound in a durable (under reducing conditions) UO2 matrix contained within zirconium-clad fuel rods and supported by steel assembly structures. Over the course of irradiation, uranium atoms fission into a bimodal distribution of lighter fission products and transmute into heavier transuranic elements, such as plutonium. LWR fuel irradiated to a burnup of ∼50 MWd/kg contains ∼4 wt % fission products and ∼1 wt % plutonium, although these concentrations increase with the fuel burnup. In addition, the fuel cladding and assembly structural materials contain activation products formed through neutron absorption reactions.

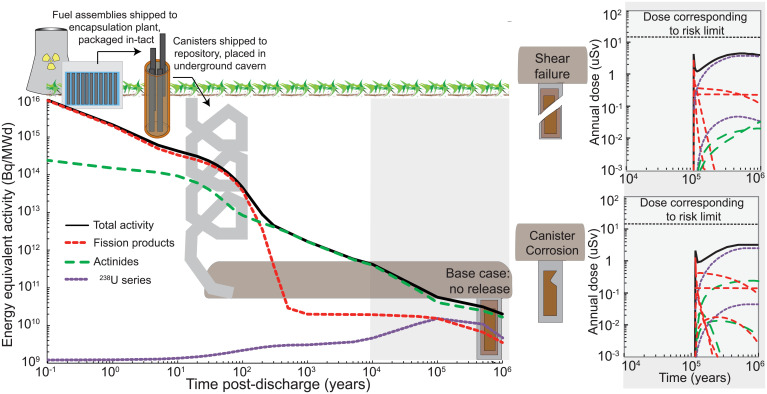

The fission products dominate the radioactivity, dose risk, and decay heat generation of newly discharged SNF, which is initially stored in actively cooled water pools to inhibit the physiochemical degradation of the fuel and cladding, otherwise driven by heat and radiation (Fig. 3). Although ∼95% of this radioactivity decays within a few decades, the fission product fraction consists of a host of isotopes that show significant variation in half-life and chemistry and therefore, are relevant to repository design (section 4.1.3) and to long-term dose risk (section 4.1.2) in addition to SNF storage and handling. Repository performance models indicate that long-lived geochemically mobile fission products, although a small fraction of the long-term SNF radioactivity, can deliver a significant portion of the far-field dose under several repository failure scenarios (Fig. 3 and section 4.1.2) (46, 47).

Fig. 3.

Temporal evolution of radioactivity in LWR fuel by contribution from fission products, actinides, and daughters in the uranium series (Left) as compared with calculated future doses under the two different scenarios of repository failure after 10,000 y (Right). Adapted from refs. 46 and 47.

The transuranic isotopes contain the bulk of the long-term SNF radioactivity (Fig. 3) but form a relatively small number of actinide elements, many of which are chemically bound in the UO2+X fuel matrix (48, 49). Therefore, the long-term chemical behavior of SNF in a geologic repository will be roughly analogous to that of crystalline UO2 (50). The solubility of uranium with respect to crystalline UO2 in pure pH-neutral water is very low, <10−9 M, although this increases to ∼10−7 M in the presence of dissolved oxygen (50–52).

Non-LWR SMRs will generate a similar array of radioisotopes for disposal but will employ fuels with markedly different bulk chemistries. Lacking fuel cladding, the liquid fuel envisioned for molten salt reactors will release gaseous fission products—including isotopes of Xe that decay to high-activity or long-lived isotopes of Cs—to an off-gas system, forming an HLW stream (8, 53). Noble metal fission products, on the other hand, will precipitate throughout the reactor structures (section 3.3.2). Nevertheless, the molten fuel salt will retain the salt-soluble fission products and actinides that, eventually, will solidify into a mass of nominal UF4. In pure water, crystalline UF4 readily hydrates to a UF4·2.5H2O phase that, compared with uranium-oxide, is orders of magnitude more soluble (10−4 M) (54). In water that contains dissolved oxygen, the reaction of crystalline UF4 produces corrosive, hydrofluoric acid (55). This unfavorable chemistry formed the basis of a US Department of Energy (DOE) decision to convert depleted uranium, stored as UF6, to a more stable uranium-oxide rather than dispose of the material as crystalline UF4 (56).

Sodium-cooled SMR designs employ a solid fuel, although for many of the designs listed in Table 1, this is envisioned to consist of stainless steel–clad uranium metal and elemental sodium, both of which classify as pyrophoric. Citing the failure of this type of fuel to meet the waste acceptance criteria for a geologic repository, the US DOE has decided to convert the SNF discharged by previous experimental sodium reactors to a more stable chemical form (8).

Due to their high chemical reactivities, these SMR fuels will need to be processed into a waste form that is suitable for geologic disposal, an objective that the US DOE has suggested might be met using pyroprocessing technology (8). SNF reprocessing facilities generate additional long- and short-lived technological, structural, process, and decommissioning wastes (57). Furthermore, before disposal in a geologic repository, the separated radionuclide streams should be solidified in a durable matrix, such as a radiation-resistant ceramic waste form (58). Although limited data are available to quantify the waste consequences associated with reprocessing and conditioning facilities, the following sections describe the implications for disposal of actinide- and fission product–containing SMR fuel.

4.1.2. Ingestion radiotoxicity vs. repository far-field dose.

Reactor developers sometimes compare the waste burden of different reactors and fuel cycles against the total “ingestion radiotoxicity” of their SNF or HLW. This metric, calculated in Sievert units, reflects the theoretical dose consequence of ingesting a particle of SNF or HLW, including all radionuclides present in the waste at a particular point in time (59). In the first ∼100 y postirradiation, the total radiotoxicity of LWR fuel is dominated by short-lived fission products, whereas 239Pu and 240Pu dominate the long-term SNF radiotoxicity (between 1,000 and 100,000 y postdischarge) (SI Appendix, section 2) (47).

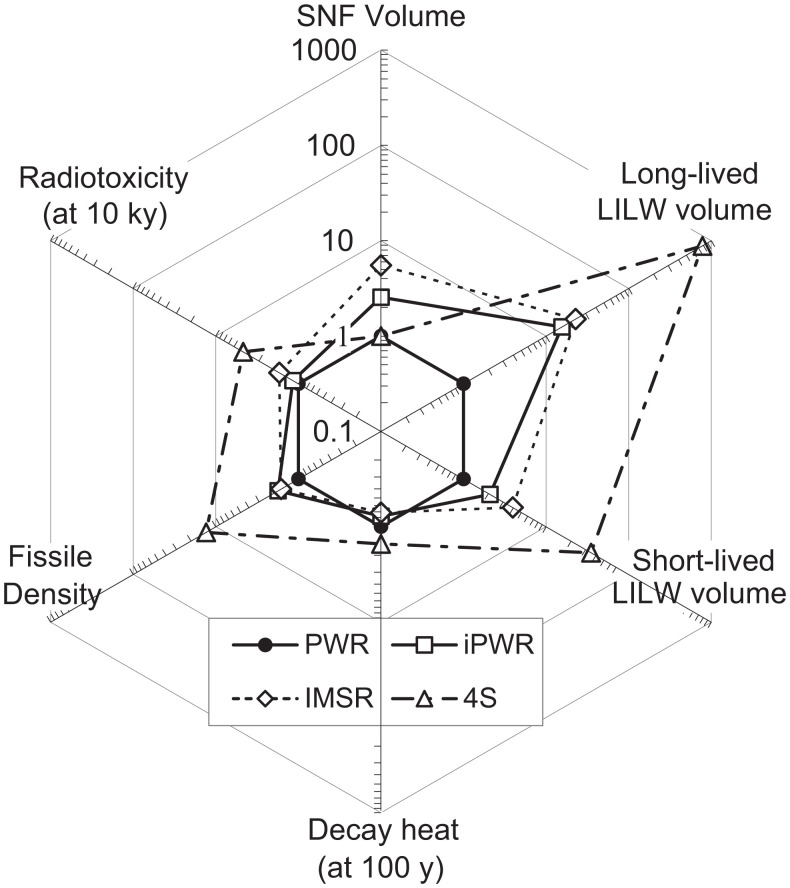

Since the fraction of fission products in SNF is linearly proportional to the fuel burnup, the energy-equivalent fission product radiotoxicity is similar for low– and high–burnup SNF. However, low–burnup SNF contains a higher energy-equivalent concentration of 239Pu and 240Pu, so the radiotoxicity of iPWR SNF (burnup of 33 MWd/kg) is ∼50% higher than that of a PWR (burnup of 50 MWd/kg) at 10,000 y postdischarge (Fig. 4 and SI Appendix, section 2). A similar inverse relation between long-term actinide radiotoxicity and reactor size/burnup will prevail among small non-LWR SMRs, including thermal-spectrum molten salt reactors and sodium fast reactors (60). Fast reactors breed more plutonium than do thermal-spectrum reactors, so the SNF discharged by fast-spectrum SMRs will have a higher energy-equivalent long-term radiotoxicity than thermal-spectrum reactors (SI Appendix, section 2) (61). Overall, SMRs will lead to an increase in long-term SNF ingestion radiotoxicity (Fig. 4).

Fig. 4.

“Radar” chart comparing waste calculation results for various SMRs normalized against respective results for a 3,400-MWth PWR displayed on a logarithmic axis. “SNF Volume” reflects the entire volume of the active core as divided by the total thermal energy produced during one fuel cycle. For the IMSR, the fluoride-based fuel–coolant salt factors into this volume. Short-lived LILW for the IMSR and 4S reactors includes the graphite moderator and sodium coolant, whereas activated reflectors and shielding materials from the 4S reactor are categorized as long-lived LILW. Decay heat and radiotoxicity are shown at 100 and 10,000 y, respectively, similar to the timing of peak buffer temperature and canister failure under an accelerated corrosion scenario for a repository in crystalline rock. Categorizations and calculations are further explained in section 4 and SI Appendix, section 3.

This metric, however, provides little insight into future doses from a geologic repository, where various geochemical processes, complemented by multiple engineered barriers, can limit radionuclide transport from the repository to the surface ecosystem (47). Since many of the actinides are chemically incorporated into the insoluble UO2+x fuel matrix, future releases of the most long-lived and radiotoxic SNF constituents will be low if disposed of in a repository sited in a favorable hydrogeochemical environment. Low-redox conditions are essential to the inhibition of SNF dissolution, as are pH, salinity, and bicarbonate concentrations (49, 50). Hydrology, including hydraulic head, fracture frequency, and matrix permeability, is important to limiting radionuclide advection rates and temporal variations in geochemistry. Hydrogeochemical conditions are highly site specific but in general, are most favorable at depths of a few hundred meters below Earth’s surface. If in the future, groundwater chemistry changes to a composition that destabilizes UO2+X, then many radionuclides will partition onto mineral surfaces through coprecipitation, adsorption, and ion exchange processes. This will further limit far-field radionuclide advection and consequent biological exposures (48, 49, 61).

Accounting for the geochemical mobility of the various radionuclides in SNF, repository evolution models typically attribute most of the dose consequence of a failed SNF canister to long-lived and geochemically mobile fission and activation products, namely 59Ni, 129I, 79Se, 36Cl, and 14C (Fig. 3) (48, 62). In general, these travel as negatively charged chemical species that do not adsorb onto mineral surfaces that are positively charged, a process that would otherwise slow their transport. In addition, the 226Ra progeny of 238U in the SNF may present a far-field exposure risk for repositories constructed in low-redox, fractured crystalline bedrock environments, although exposures will be lower than those associated with natural 226Ra in these environments (48).

Since the energy-equivalent activities of fission and activation products are similar for low– and high–burnup SNF, SMR fuel may not significantly increase the future exposure risks unless the SNF packaging (section 4.1.4) and site selection plans neglect the differences in actinide contents. For instance, the performance assessment for a proposed repository sited in a seismically active and geochemically oxidizing environment (Yucca Mountain, NV) did attribute much of the long-term dose to 239Pu, 242Pu, and 237Np (63). At the Yucca Mountain site, UO2+x and its actinide constituents are relatively soluble, so the dose consequence of SMR fuel disposal would be higher than that of LWR fuel due to relatively high 239Pu and 240Pu contents in low–burnup fuel.

4.1.3. SNF/HLW thermal load and repository size.

After SNF is discharged from a reactor, decaying radionuclides in the fuel emit alpha, beta, and gamma radiation that is absorbed into nearby materials and converted to heat. To preserve the thermal hydraulic, mechanical, and chemical integrity of the repository system, the capacity and spacing of SNF disposal canisters will be configured to dissipate decay heat. Most repositories are designed to maintain temperatures less than 100 °C in the engineered barrier system. Yucca Mountain, however, was designed as a “hot” repository, wherein the temperature of groundwater would exceed the boiling point for a few hundred years postclosure. Consequently, repository dimensions—along with the associated packaging and excavation costs—are, in part, governed by decay heat rather than by waste volume (64, 65).

The duration of interim storage is factored into repository dimension calculations because the SNF decay power decreases over time. The predominant source of decay heat evolves from the fission products 137Cs and 90Sr and their 137mBa and 90Y daughters at 10 to 100 y postdischarge to 241Am and 238Pu at 100 to 1,000 y postdischarge (46). In a repository that will accept SNF/HLW aged 20 to 60 y, near-field temperatures will peak at ∼10 y postclosure. Therefore, fission product decay heat imposes a significant constraint on repository dimensions (46, 66).

In a thermal-spectrum reactor, the energy-equivalent concentration of 238Pu increases with fuel burnup. Thus, for up to 100 y postdischarge, the energy-equivalent decay power is ∼30% higher for 50-MWd/kg burnup than for 33-MWd/kg SNF burnup (Fig. 4 and SI Appendix, section 2). The thermal character of low–burnup SNF implies that, despite the increased volumes associated with SMRs, their impact on the dimensions of an SNF repository may be small.

Models indicate that at 100 y postdischarge, the thermal output of SNF generated by a plutonium-fueled fast SMR (similar to the Toshiba 4S design) will be ∼50% higher than the energy-equivalent PWR fuel (Fig. 4 and SI Appendix, section 2). Thermal data for uranium-fueled fast SMRs are scarce, although large sodium-cooled fast reactors (Table 1) are said to fission minor actinides, like 241Am and 238Pu, more efficiently than thermal-spectrum LWRs and molten salt reactors (61). However, the persistence of short- and long-lived fission products in these fuel cycles will limit their theoretical benefit for repository dimensions. HLW streams that predominately consist of fission products, typically conditioned into borosilicate glass, may require a repository up to 50% as large as a repository for LWR SNF (58). Since repository excavation and backfill account for only ∼10% of the cost of a decommissioning and SNF disposal program (66), a fuel cycle that seeks to reprocess Pu will not significantly reduce nuclear waste management and disposal costs.

4.1.4. Fissile isotopes and recriticality.

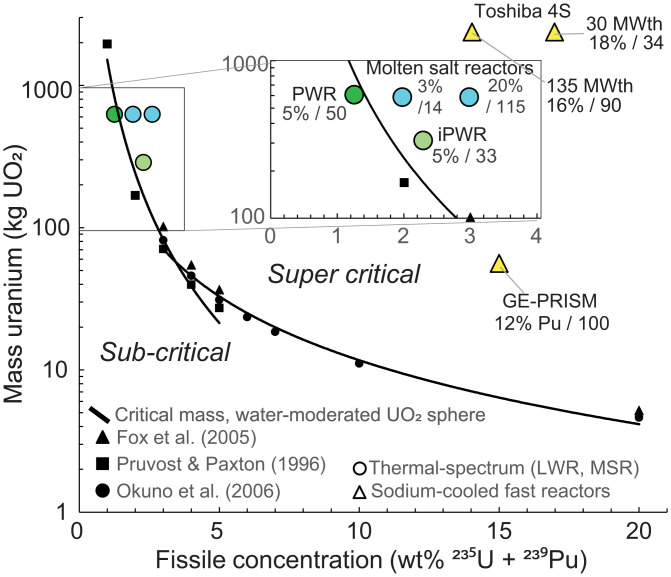

As a primary safety objective, SNF should be stored and disposed of in a subcritical configuration to inhibit its ability to sustain a fission chain reaction. Since the critical mass of water-moderated UO2 decreases exponentially if its fissile isotope concentration increases from 1 to 5% (figure 8 in ref. 67), the mass of SNF that can be loaded into a disposal package is limited by the concentration of fissile 235U, 239Pu, and 241Pu in the SNF. In LWR SNF, the net concentration of these isotopes correlates positively to initial fuel enrichment and negatively to final burnup. Calculations performed to assess long-term criticality safety for several geologic repository designs indicate that fresh 5 wt % 235U–enriched PWR fuel should be irradiated to a burnup >39 MWd/kg to maintain subcritical conditions in canisters loaded with four or more PWR assemblies (68–70).

Since iPWRs will irradiate 5 wt % 235U–enriched fuel to a burnup of <34 MWd/kg, iPWR SNF will not meet the criticality safety standards for existing repository designs (71–75) (Fig. 5 and SI Appendix, section 2). Likewise, sodium-cooled SMR designs, which call for irradiation of fresh fuel with ≫10 wt % 235U or 239Pu to burnups ranging from 10 to 100 MWd/kg, will generate SNF with high fissile isotope concentrations (Fig. 5, Table 1, and SI Appendix, section 2). Quoted fuel enrichments and burnups for molten salt SMR designs are more variable, and published depletion models that estimate the fissile isotope composition of the SNF are scarce. Therefore, we assumed that the isotopic evolutions of fuel in an LWR and a molten salt reactor are similar because both reactors operate under the thermal neutron spectrum. Under this assumption, SNF generated by the Terrestrial Energy IMSR-400, which calls for 3 wt % 235U–enriched fuel irradiated to a burnup of 14 MWd/kg, will contain 2.1 wt % 235U + 239Pu. Like that generated by the NuScale iPWR (2.3 wt %) and the Toshiba 4S SMR (17 wt %), this contains fissile isotopes in higher concentrations than the SNF generated by a PWR (1.3 wt %) (Fig. 4 and SI Appendix, section 2). The case is likely similar for many of the SMR designs listed in Table 1, considering the quoted fuel enrichments and burnups.

Fig. 5.

Concentration of fissile isotopes in SNF (“Fissile concentration”) vs. mass of fuel in each assembly (“Mass uranium”) for various reactors plotted alongside a criticality curve generated from the data of refs. 67, 72, and 73 to illustrate the sensitivity of SNF canister loading to the fissile isotope composition of the SNF. Inset shows enlargement of clustered points, labelled according to reactor-type and the associated initial fuel enrichment and burnup. Derivation of fissile concentration is explained in SI Appendix, section 2 or obtained from refs. 74 and 75. The molten salt SMR designs studied here contain several to tens of metric tons of uranium or thorium fuel that is not bound within structural assemblies and so, are here assigned an assembly mass similar to a PWR. "GE-PRISM" refers to the Power Reactor Innovative Small Module design by GE Hitachi Nuclear Energy.

In general, for a given SNF composition, each canister should contain a subcritical mass of SNF. However, critical masses are very small for materials containing more than a few weight percent fissile isotopes. Whereas a critical mass of PWR SNF is >1,000 kg, critical masses for iPWR and sodium-cooled SMR SNF are only ∼200 and <10 kg, respectively (Fig. 5). Recriticality boundaries and management processes are rarely assessed for unconventional SNF types with elevated fissile isotope concentrations. However, Hicks and Baldwin (71) indicate that SNF from the UK Prototype Fast Reactor would pose a recriticality risk even if disposal canister capacities were limited to a single SNF assembly (burnup of 190 MWd/kg, initial/final 239Pu concentrations of 30/15 wt %). Therefore, novel approaches to canister design and loading will need to be developed for the SMR designs analyzed here and listed in Table 1.

Canisters designed to accommodate the existing PWR SNF inventory have a capacity of four or more assemblies per canister, whereas canisters for iPWR and sodium-cooled SMR SNF might accommodate only one assembly or a fractional assembly, respectively.

Molten salt reactor SNF packaging will likewise deviate from the existing concepts. Vendors typically suggest that the spent liquid fuel salt remains inside the reactor vessels while it solidifies. However, the recriticality incident that almost occurred at the shutdown MSRE as a result of formation and migration of volatile actinide–fluoride complexes (section 3.4.3) (45) illustrates the need to process the actinides in this salt mass, including the fissile 235U, 239Pu, and/or 233U, into a more stable ceramic waste form. Although the DOE eventually accomplished this through a pilot-scale fluoride volatility treatment, no methods to segment and package the remainder of the fission product–containing MSRE salt mass have been developed, as illustrated by the DOE preference to entomb the MSRE on-site at Oak Ridge National Laboratory (section 3.4.3 and SI Appendix, section 3).

The need for SNF segmentation and/or a larger number of disposal canisters and associated packaging operations support the notion that the back end of SMR fuel cycles, as discussed in section 3, entails increased handling of radiologic and fissile material. These packaging challenges will be compounded by the relatively large, energy-equivalent volumes of SMR SNF (sections 1 and 3.2) and will introduce costs and radiation exposure risks to the nuclear fuel cycle.

4.2. LILW Management and Disposal.

SMRs will generate larger, energy-equivalent volumes of LILW than a PWR (Fig. 1 and sections 3.3 and 3.4). Some of this waste may be suited for disposal in a near-surface, short-lived LILW repository (<30-m deep) (7). However, neutron-activated, long-lived LILW is more complicated to manage because radiation exposures must be mitigated on both operational and geologic timescales.

Due in part to the need to limit worker exposures to the radiation emanating from activated LWR components, especially that emitted by the 60Co (t1/2 = 5.3 y) activation product of steel (76), decommissioning represents ∼20% of LWR waste management and disposal costs (67). Since SMRs will generate >10-fold more neutron-activated steel than the energy-equivalent LWR and will introduce the need to chemically treat radioactive sodium and molten salt coolants, they may significantly increase the costs and exposure risks associated with nuclear decommissioning.

After 60Co has decayed, activities of long-lived 59Ni, 63Ni, 14C, 94Nb, and 93Mo will remain sufficiently high to warrant the geologic disposal of activated LWR components (Table 2) (77). Nickel isotopes are soluble under acidic conditions (78), so cementitious barrier materials are employed in LILW repositories to impose alkaline conditions (79) that limit nickel dissolution in the repository groundwater (80). More mobile than nickel, models suggest that 14C and 93Mo will be the dominant contributors to future doses from a repository for activated decommissioning waste (81). Activated SMR and LWR steel will bear similar radiochemical compositions, so 14C and 93Mo may dominate future doses from SMR waste repositories, although such doses, like the energy-equivalent radionuclide inventory, may be higher for SMR wastes. Since few studies focused on constraining the radionuclide inventories of irradiated graphite, molten salt, and sodium are available, the future dose consequence for these waste streams remains unclear.

5. Conclusions

This analysis of three distinct SMR designs shows that, relative to a gigawatt-scale PWR, these reactors will increase the energy-equivalent volumes of SNF, long-lived LILW, and short-lived LILW by factors of up to 5.5, 30, and 35, respectively. These findings stand in contrast to the waste reduction benefits that advocates have claimed for advanced nuclear technologies. More importantly, SMR waste streams will bear significant (radio-)chemical differences from those of existing reactors. Molten salt– and sodium-cooled SMRs will use highly corrosive and pyrophoric fuels and coolants that, following irradiation, will become highly radioactive. Relatively high concentrations of 239Pu and 235U in low–burnup SMR SNF will render recriticality a significant risk for these chemically unstable waste streams.

SMR waste streams that are susceptible to exothermic chemical reactions or nuclear criticality when in contact with water or other repository materials are unsuitable for direct geologic disposal. Hence, the large volumes of reactive SMR waste will need to be treated, conditioned, and appropriately packaged prior to geological disposal. These processes will introduce significant costs—and likely, radiation exposure and fissile material proliferation pathways—to the back end of the nuclear fuel cycle and entail no apparent benefit for long-term safety.

Although we have analyzed only three of the dozens of proposed SMR designs, these findings are driven by the basic physical reality that, relative to a larger reactor with a similar design and fuel cycle, neutron leakage will be enhanced in the SMR core. Therefore, most SMR designs entail a significant net disadvantage for nuclear waste disposal activities. Given that SMRs are incompatible with existing nuclear waste disposal technologies and concepts, future studies should address whether safe interim storage of reactive SMR waste streams is credible in the context of a continued delay in the development of a geologic repository in the United States.

Supplementary Material

Acknowledgments

We acknowledge Julien de Troullioud de Lanversin for his review of section 1 and SI Appendix, section 1. This research was supported by the John D. and Catherine T. MacArthur Foundation through fellowships (to L.M.K.) at George Washington University and at the Center for International Security and Cooperation, Stanford University.

Footnotes

The authors declare no competing interest.

This article is a PNAS Direct Submission. E.J.S. is a guest editor invited by the Editorial Board.

This article contains supporting information online at https://www.pnas.org/lookup/suppl/doi:10.1073/pnas.2111833119/-/DCSupplemental.

Data Availability

All study data are included in the article and/or SI Appendix.

Change History

June 8, 2022: The corresponding author’s contact email address has been updated.

References

- 1.Ingersoll D. T., Deliberately small reactors and the second nuclear era. Prog. Nucl. Energy 51, 589–603 (2009). [Google Scholar]

- 2.International Atomic Energy Agency, “Advances in small modular reactor technology developments: A supplement to IAEA advanced reactors information system (ARIS), 2020 Edition” (2020) (Rep. 2020 Edition, International Atomic Energy Agency.

- 3.Allen T., Fitzpatrick R., Milko J., Keeping Up with the Advanced Nuclear Industry. Third Way (2018). https://www.thirdway.org/graphic/keeping-up-with-the-advanced-nuclear-industry. Accessed 10 October 2019.

- 4.Wigeland R., et al. , “Nuclear Fuel Cycle Evaluation and Screening—Final Report: Appendix C, Evaluation Criteria and Metrics” (Rep. INL/EXT-14-31465 FCRD-FCO-2014-000106, Idaho National Laboratory, 2014).

- 5.Nuclear Energy Agency, “Advanced Nuclear Fuel Cycles and Radioactive Waste Management. No. NEA—5990. Organisation for Economic Co-operation and Development” (2006). https://www.oecd-nea.org/jcms/pl_14008/advanced-nuclear-fuel-cycles-and-radioactive-waste-management?details=true. Accessed 26 September 2020.

- 6.International Atomic Energy Agency, Classification of Radioactive Waste. IAEA Safety Standards Series No. GSG-1. International Atomic Energy Agency (2009). https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1419_web.pdf. Accessed 6 July 2020.

- 7.Krall L., Macfarlane A., Burning waste or playing with fire? Waste management considerations for non-traditional reactors. Bull. At. Sci. 74, 326–334 (2018). [Google Scholar]

- 8.Brown N. R., Worrall A., Todosow M., Impact of thermal spectrum small modular reactors on performance of once-through nuclear fuel cycles with low-enriched uranium. Ann. Nucl. Energy 101, 166–173 (2017). [Google Scholar]

- 9.Kuznetsov V., Barkatullah N., “Approaches to assess competitiveness of small and medium sized reactors. International Conference on Opportunities and Challenges for Water Cooled Reactors in the 21st Century, Book of Extended Synopses. Rep. NP-T-3.7”, International Atomic Energy Agency (2009) https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1619_web.pdf).

- 10.Locatelli G., Bingham C., Mancini M., Small modular reactors: A comprehensive overview of their economics and strategic aspects. Prog. Nucl. Energy 73, 75–85 (2014). [Google Scholar]

- 11.Lokhov A., et al. , Small modular reactors: Nuclear energy market potential for near-term deployment. No. NEA—7213. Organisation for Economic Co-Operation and Development (2016). https://www.oecd-nea.org/jcms/pl_14924/small-modular-reactors-nuclear-energy-market-potential-for-near-term-deployment?details=true. Accessed 5 April 2021.

- 12.Glasstone S., Sesonske A., Nuclear Reactor Engineering (Chapman & Hall, ed. 4, 1994), vol. 1. [Google Scholar]

- 13.Qvist S. A., “Safety and core design of large liquid-metal cooled fast breeder reactors,” PhD dissertation, University of California, Berkeley, CA (2013).

- 14.Glaser A., Hopkins L. B., Ramana M. V., Resource requirements and proliferation risks associated with small modular reactors. Nucl. Technol. 184, 121–129 (2013). [Google Scholar]

- 15.Ingersoll D. T., Houghton Z. J., Bromm R., Desportes C., NuScale small modular reactor for co-generation of electricity and water. Desalination 340, 84–93 (2014). [Google Scholar]

- 16.NuScale Power LLC, Ch. 5: Reactor coolant system and connecting systems. NuScale Standard Plant Design Certification Application, Revision 5. US Nuclear Regulatory Commission (2020). https://www.nrc.gov/docs/ML2022/ML20224A493.pdf. Accessed 5 April 2021.

- 17.NuScale Power LLC, Ch. 4: Reactor. NuScale Standard Plant Design Certification Application, Revision 5. US Nuclear Regulatory Commission (2020). https://www.nrc.gov/docs/ML2022/ML20224A492.pdf. Accessed 5 April 2021.

- 18.Mancini A., Tuite P., Tuite K., Woodberry S., “Greater-Than-Class-C Low-Level Radioactive Waste Characterization. Appendix A-3: Basis for Greater-Than-Class-C Low-Level Radioactive Wastes Light Water Reactor Projections” (Rep. DOE/LLW-114A-3, Idaho National Engineering Laboratory, 1994).

- 19.Herschend B., Long-lived intermediate level waste from Swedish nuclear power plants: Reference inventory. SKB R-13-17. Svensk Kärnbränslehantering AB (2013). https://skb.se/publication/2699385/R-13-17.pdf. Accessed 4 October 2019.

- 20.Love E. F., Pauley K. A., Reid B. D., Use of MCNP for characterization of reactor vessel internals waste from decommissioned nuclear reactors. INEL-95/0419. Idaho Technologies Company (1995). https://www.iaea.org/inis/collection/NCLCollectionStore/_Public/27/031/27031964.pdf. Accessed 4 October 2019.

- 21.US Code of Federal Regulations, Title 10, part 61.55 [10 C.F.R. 61.55] (1982). https://www.nrc.gov/reading-rm/doc-collections/cfr/part061/part061-0055.html. Accessed 4 October 2019.

- 22.W. Nuclear, Reactor. AP1000 Design Control Document, Revision 19 (US Nuclear Regulatory Commission, 2011), chap. 4 (2011). https://www.nrc.gov/docs/ML1117/ML11171A445.pdf. Accessed 2 August 2017.

- 23.Allen T., Busby J., Meyer M., Petti D., Materials challenges for nuclear systems. Mater. Today 13, 14–23 (2010). [Google Scholar]

- 24.Zheng G., Sridharan K., Corrosion of structural alloys in high-temperature molten fluoride salts for applications in molten salt reactors. JOM 70, 1535–1541 (2018). [Google Scholar]

- 25.Martingale, Status Report—ThorCon. International Atomic Energy Agency (2016). https://aris.iaea.org/PDF/ARISThorCon9.pdf. Accessed 10 October 2019.

- 26.Wright R. N., Sham T.-L., Status of Metallic Structural Materials for Molten Salt Reactors. Idaho National Laboratory (2018). https://www.osti.gov/biblio/1467482-status-metallic-structural-materials-molten-salt-reactors. Accessed 11 February 2021.

- 27.Energy T., Status Report—IMSR-400. International Atomic Energy Agency (2016). https://aris.iaea.org/PDF/IMSR400.pdf. Accessed 10 October 2019.

- 28.Kedl R. J., “Migration of a class of fission products (noble metals) in the Molten-Salt Reactor Experiment” (Rep. ORNL-TM-3884, Oak Ridge National Laboratory, 1972).

- 29.Carter J. P., Borrelli R. A., Integral molten salt reactor neutron physics study using Monte Carlo N-particle code. Nucl. Eng. Des. 365, 110718 (2020). [Google Scholar]

- 30.Blanchet D., Fontaine B., “Reflector and protections in a sodium-cooled fast reactor: Modelling and optimization” in 13th International Conference on Radiation Shielding (ICRS-13) & 19th Topical Meeting of the Radiation Protection and Shielding Division of the American Nuclear Society (RPSD-2016), F. Malvagi et al., Eds. (EDP Sciences – Web of Conferences, Paris, France, 2017), vol. 153, pp. 474–480.

- 31.Beck T., et al. , Conceptual design of ASTRID radial shielding sub-assemblies. Nucl. Eng. Des. 330, 129–137 (2018). [Google Scholar]

- 32.Waltar A. E., Todd D. R., Tsvetkov P. V., Eds., Fast Spectrum Reactors (Springer Science & Business Media, 2011). [Google Scholar]

- 33.International Atomic Energy Agency, “Characterization and Management of Radioactive Sodium and Other Reactor Components as Input Data for the Decommissioning of Liquid Metal-cooled Fast Reactors” (Rep. TWR-FR/110, International Atomic Energy Agency, 2002).

- 34.Toshiba Corporation, 4S Design Description. Submitted to US Nuclear Regulatory Commission May 20, 2008. US Nuclear Regulatory Commission (2008). https://www.nrc.gov/docs/ML0814/ML081440765.pdf. Accessed 14 July 2020.

- 35.Kärnbränslehantering S., Low and intermediate level waste in SFR: Reference Inventory. No. SKB R-15-15. Svensk Kärnbränslehantering AB (2002). https://www.skb.com/publication/2480178/R-15-15.pdf. Accessed 10 July 2020.

- 36.Hansson T., Norberg T., Knutsson A., Fors P., Sandebert C., “Ringhals Site Study 2013-An assessment of the decommissioning cost for the Ringhals site” (Rep. SKB R-13-05, Svensk Kärnbränslehantering AB, 2013).

- 37.Anunti Å., Larsson H., Edelborg M., “Decommissioning study of Forsmark NPP” (Rep. SKB R-13-03, Svensk Kärnbränslehantering AB, 2013).

- 38.Zou C. Y., et al. , Optimization of temperature coefficient and breeding ratio for a graphite-moderated molten salt reactor. Nucl. Eng. Des. 281, 114–120 (2015). [Google Scholar]

- 39.Compere E. L., Kirslis S. S., Bohlmann E. G., Blankenship F. F., Grimes W. R., Fission Product Behavior in the Molten Salt Reactor Experiment. ORNL-4865. Oak Ridge National Laboratory (1975). https://inis.iaea.org/collection/NCLCollectionStore/_Public/07/249/7249304.pdf?r=1. Accessed 10 July 2020.

- 40.Forsberg C. W., et al. , Tritium control and capture in salt-cooled fission and fusion reactors: Status, challenges, and path forward. Nucl. Technol. 197, 119–139 (2017). [Google Scholar]

- 41.International Atomic Energy Agency, Nuclear Graphite Waste Management. International Atomic Energy Agency (2001). https://inis.iaea.org/collection/NCLCollectionStore/_Public/32/039/32039321.pdf. Accessed 10 July 2020.

- 42.Scott D., Eatherly W. P., Graphite and xenon behavior and their influence on molten-salt reactor design. Nucl. Appl. Technol. 8, 179–189 (1970). [Google Scholar]

- 43.US Nuclear Regulatory Commission, Radioactive Waste Management Self Study. Chapter 4: Liquid Radioactive Wastes. Document Number ML12151A430. US Nuclear Regulatory Commission (2012). https://www.nrc.gov/docs/ML1215/ML12151A430.html. Accessed 10 July 2020.

- 44.Sautman M. T., Molten Salt Reactor Experiment: Potential Safety Issues. Received by G.W. Cunningham Technical Director, 14 February 1995. Defense Nuclear Facilities Safety Board (1995). https://www.dnfsb.gov/sites/default/files/document/9439/sir_1995414_5145_35.pdf. Accessed 6 December 2021.

- 45.Grahn P., Moren L., Wiborgh M., “Spent nuclear fuel for disposal in the KBS-3 repository” (Rep. SKB TR-10-13, Svensk Kärnbränslehantering AB, 2010).

- 46.Hedin A., “Spent nuclear fuel-how dangerous is it? A report from the project 'Description of risk'” (Rep. SKB TR-97-13, Svensk Kärnbränslehantering AB, 1997).

- 47.Svensk Kärnbränslehantering AB, “Long-Term Safety for the Final Repository for Spent Nuclear Fuel at Forsmark. Main Report of the SR-Site Project” (Rep. SKB TR-11-01, Svensk Kärnbränslehantering AB, 2011).

- 48.Bruno J., Ewing R. C., Spent nuclear fuel. Elements 2, 343–349 (2006). [Google Scholar]

- 49.Ewing R. C., Long-term storage of spent nuclear fuel. Nat. Mater. 14, 252–257 (2015). [DOI] [PubMed] [Google Scholar]

- 50.Thoenen T., Hummel W., Berner U., Curti E., “The PSI/Nagra Chemical Thermodynamic Database 12/07, freely available for the PHREEQC format” (Rep. PSI 14-04, Paul Scherrer Institute, 2014).

- 51.Gorman-Lewis D., Burns P., Fein J. B., Review of uranyl mineral solubility measurements. J. Chem. Thermodyn. 40, 335–352 (2008). [Google Scholar]

- 52.Grenthe I., et al. , Chemical Thermodynamics of Uranium: Chemical Thermodynamics, Vol. 1. Updated from 1992, 2004 versions. Nuclear Energy Agency OECD (2020). https://www.oecd-nea.org/jcms/pl_13704. Accessed 11 Feburary 2021.

- 53.Houtzeel A., Dyer F. F., A study of fission products in the Molten-Salt Reactor Experiment by Gamma. Spectrometry. ORNL-TM-3151. Oak Ridge National Laboratory (1972). https://www.osti.gov/biblio/4659054. Accessed 11 February 2021.

- 54.Grenthe I., et al. , Chemical Thermodynamics of Uranium (Elsevier, 1992), vol. 1. [Google Scholar]

- 55.Kozak M. W., Feeney T. A., Leigh C. D., Stockman H. W., Performance assessment of the proposed disposal of depleted uranium as Class A Low-level Waste. Sandia National Laboratories (1992). https://www.nrc.gov/docs/ML1018/ML101890179.pdf. Accessed 11 February 2021.

- 56.US Department of Energy, “Programmatic Environmental Impact Statement for Alternative Strategies for the Long-Term Management and Use of Depleted Uranium Hexafluoride” (Rep. DOE/EIS-029, US Department of Energy, 1999).

- 57.Schneider M., Marignac Y., Spent nuclear fuel reprocessing in France. International Panel on Fissile Materials (2008). https://fissilematerials.org/library/rr04.pdf. Accessed 27 July 2020.

- 58.Lumpkin G. R., Ceramic waste forms for actinides. Elements 2, 365–372 (2006). [Google Scholar]

- 59.Stauff N. E., Kim T. K., Taiwo T. A., Variations in nuclear waste management performance of various fuel-cycle options. J. Nucl. Sci. Technol. 52, 1058–1073 (2015). [Google Scholar]

- 60.Kim T. K., Taiwo T. A., “Fuel cycle analysis of once-through nuclear systems” (Rep. ANL-FCRD-308, Argonne National Laboratory, 2010).

- 61.ANDRA, “Argile: Evaluation of the feasibility of a geological repository in an argillaceous formation” (Dossier 2005, ANDRA, 2005).

- 62.Grambow B., Mobile fission and activation products in nuclear waste disposal. J. Contam. Hydrol. 102, 180–186 (2008). [DOI] [PubMed] [Google Scholar]

- 63.Rechard R. P., Results from past performance assessments for the Yucca Mountain disposal system for spent nuclear fuel and high-level radioactive waste. Reliab. Eng. Syst. Saf. 122, 207–222 (2014). [Google Scholar]

- 64.Wigeland R. A., Bauer T. H., Fanning T. H., Morris E. E., Separations and transmutation criteria to improve utilization of a geologic repository. Nucl. Technol. 154, 95–106 (2006). [Google Scholar]

- 65.Hökmark H., Lönnqvist M., Kristensson O., Sundberg J., Hellström G., “Strategy for thermal dimensioning of the final repository for spent nuclear fuel” (Rep. SKB R-09-04, Svensk Kärnbränslehantering AB, 2009).

- 66.Svensk Kärnbränslehantering A. B., Plan 2016: Costs from and including 2018 for the radioactive residual products from nuclear power—basis for fees and guarantees for the period 2018–2020. No. TR-17-02. Svensk Kärnbränslehantering AB (2017). https://www.skb.se/publikation/2487964/TR-17-02.pdf. Accessed 27 July 2020.

- 67.Paxton H. C., Pruvost N. L., Critical dimensions of systems containing 235U, 239Pu, and 233U. No. LA-10860-MS. Los Alamos National Laboratory (1987). https://inis.iaea.org/collection/NCLCollectionStore/_Public/19/013/19013587.pdf. Accessed 27 July 2020.

- 68.Scaglione J. M., Wagner J. C., “Burnup credit approach used in the yucca mountain license application” in Proceedings of the International Workshop on Advances in Applications of Burnup Credit for Spent Fuel Storage, Transport, Reprocessing, and Disposition (Nuclear Safety Council of Spain, Córdoba, Spain 2009), pp. 27–30. [Google Scholar]

- 69.Agrenius L., Criticality safety calculations of disposal canisters. No. 1193244. Svensk Kärnbränslehantering AB (2010). https://www.mkg.se/uploads/Arende_SSM2011_37/SSM201137_011_bilaga2_Criticality_safety_calculations_of_disposal_canisters_2.pdf. Accessed 27 July 2020.

- 70.Vasiliev A., et al. , Preliminary assessment of criticality safety constraints for Swiss spent nuclear fuel loading in disposal canisters. Materials (Basel) 12, 494–524 (2019). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 71.Hicks T., Baldwin T., “Review of Burn-Up Credit Applications in Criticality Safety Assessments for Spent Fuel Management and Disposal” (Rep. GSL-1649-4-V3.1, Radioactive Waste Management Limited, 2018).

- 72.Fox P. B., Petrie L. M., Hopper C. M., “Minimum Critical Values Study” (Rep. ORNL/TM-2003/211, Oak Ridge National Laboratory, 2005).

- 73.Okuno H., Yoshiyama H., Miyoshi Y., Calculation of criticality conditions data for single unit homogeneous uranium materials in six chemical forms. J. Nucl. Sci. Technol. 43, 1406–1413 (2006). [Google Scholar]

- 74.Triplett B. S., Loewen E. P., Dooies B. J., Prism: A competitive small modular sodium-cooled reactor. Nucl. Technol. 178, 186–200 (2012). [Google Scholar]

- 75.Ahmad A., McClamrock E. B., Glaser A., Neutronics calculations for denatured molten salt reactors: Assessing resource requirements and proliferation-risk attributes. Ann. Nucl. Energy 75, 261–267 (2015). [Google Scholar]

- 76.Larsson H., Anunti Å., Edelborg M., Decommissioning Study of Oskarshamn NPP. No. R-13-04. Svensk Kärnbränslehantering AB (2013). https://www.skb.com/publication/2625263/R-13-04.pdf. Accessed 4 October 2019.

- 77.International Atomic Energy Agency, Radiological Characterization of Shut Down Nuclear Reactors for Decommissioning Purposes. Technical Report Series No. 389. International Atomic Energy Agency (1998). https://www-pub.iaea.org/MTCD/publications/PDF/TRS389_scr.pdf. Accessed 2 February 2021.

- 78.Huang L. F., et al. , Improved electrochemical phase diagrams from theory and experiment: The Ni–water system and its complex compounds. J. Phys. Chem. 121, 9782–9789 (2017). [Google Scholar]

- 79.Duro L., et al. , Contribution of the results of the CEBAMA project to decrease uncertainties in the Safety Case and Performance Assessment of radioactive waste repositories. Appl. Geochem. 112, 104479 (2020). [Google Scholar]

- 80.Felipe-Sotelo M., et al. , The solubility of nickel and its migration through the cementitious backfill of a geological disposal facility for nuclear waste. J. Hazard. Mater. 314, 211–219 (2016). [DOI] [PubMed] [Google Scholar]

- 81.Crawford J., Screening of radionuclides for radionuclide and dose calculations—report for the safety evaluation SE-SFL. No. P-16-09. Svensk Kärnbränslehantering AB (2018). https://www.skb.com/publication/2492378/P-16-09.pdf. Accessed 4 October 2019.

- 82.Hitachi G. E., Status Report–BWRX-300. International Atomic Energy Agency (2019). https://aris.iaea.org/PDF/BWRX-300_2020.pdf. Accessed 14 July 2020.

- 83.Gidropress, Status Report 84. VVER-300 (V-478). International Atomic Energy Agency (2011). https://aris.iaea.org/PDF/VVER-300(V-478).pdf. Accessed 14 July 2020.

- 84.Westinghouse, Status Report 75–Advanced Passive pressurized water reactor (AP-600). International Atomic Energy Agency (2011). https://aris.iaea.org/PDF/AP-600.pdf. Accessed 14 July 2020.