Abstract

Coaches spend long hours training gymnasts of all ages aided by polyurethane foam used in loose blocks, mats, and other padded equipment. Polyurethane foam can contain flame retardant additives such as polybrominated diphenyl ethers (PBDEs), to delay the spread of fires. However, flame retardants have been associated with endocrine disruption and carcinogenicity. The National Institute for Occupational Safety and Health (NIOSH) evaluated employee exposure to flame retardants in four gymnastics studios utilized by recreational and competitive gymnasts. We evaluated flame retardant exposure at the gymnastics studios before, during, and after the replacement of foam blocks used in safety pits with foam blocks certified not to contain several flame retardants, including PBDEs. We collected hand wipes on coaches to measure levels of flame retardants on skin before and after their work shift. We measured flame retardant levels in the dust on window glass in the gymnastics areas and office areas, and in the old and new foam blocks used throughout the gymnastics studios. We found statistically higher levels of 9 out of 13 flame retardants on employees’ hands after work than before, and this difference was reduced after the foam replacement. Windows in the gymnastics areas had higher levels of 3 of the 13 flame retardants than windows outside the gymnastics areas, suggesting that dust and vapor containing flame retardants became airborne. Mats and other padded equipment contained levels of bromine consistent with the amount of brominated flame retardants in foam samples analyzed in the laboratory. New blocks did not contain PBDEs, but did contain the flame retardants 2-ethylhexyl 2,3,4,5-tetrabromobenzoate and 2-ethylhexyl 2,3,4,5-tetrabromophthalate. We conclude that replacing the pit foam blocks eliminated a source of PBDEs, but not 2-ethylhexyl 2,3,4,5-tetrabromobenzoate and 2-ethylhexyl 2,3,4,5-tetrabromophthalate. We recommend ways to further minimize employee exposure to flame retardants at work and acknowledge the challenges consumers have identifying chemical contents of new products.

Keywords: flame retardants, foam, gymnastics, organophosphate flame retardants, hand wipes, polybrominated flame retardants

INTRODUCTION

Flame retardants including polybrominated diphenyl ether (PBDEs) are added to materials to delay the production of flames and spread of fire. PBDEs include the pentabromodiphenyl ether (PentaBDE) formulation, which was added to polyurethane foam from the 1970’s until being phased out by United States manufacturers in 2004 due to environmental and human health concerns, after being banned in the European Union along with octaBDE [EPA 2014; European Union 2004]. In May 2009, it was added to the Persistent Organic Pollutants (POPs) list of the Stockholm Convention, restricting its usage globally [United Nations 2009]. These restrictions led to the introduction of replacement compounds including additional brominated flame retardants like 2-ethylhexyl 2,3,4,5-tetrabromobenzoate (EH-TBB), bis(2-ethylhexyl) 2,3,4,5-tetrabromophthalate (BEH-TEBP) and organophosphate flame retardants like tris(1,3-dichloro-2-propyl) phosphate (TDCPP), and triphenylphosphate (TPHP).

The toxicities of these replacements have not been well characterized [Allen et al. 2013]. Evidence suggests some are endocrine disruptors (which are chemicals that interfere with hormone systems) and carcinogens [Dishaw et al. 2014; Johnson et al. 2013; Meeker and Stapleton 2010; Meeker et al. 2013; Patisaul et al. 2013; van der Veen and de Boer 2012]. TPHP, BEH-TEBP, EH-TBB, and isopropylated triphenyl phosphate isomers are components of the flame retardant Firemaster 550, which appears to be the second most common flame retardant mixture currently applied to foams, after TDCPP [Hoffman et al. 2014]. Tris(2-chloroethyl) phosphate (TCEP) and tris(1-chloro-2-propyl) phosphate (TCIPP) are also used in some polyurethane foam. Some organophosphate flame retardants have been associated with decreased fertility, reduced sperm motility, altered reproductive and thyroid hormones, and cancer in humans [Carignan et al. 2017; Dishaw et al. 2014; Meeker and Stapleton 2010; Meeker et al. 2013; Preston et al. 2017; van der Veen and de Boer 2012]. We use flame retardant abbreviations described by Bergman et al [2012].

In general, exposure to flame retardants in indoor environments like homes, schools, and offices is thought to be mainly from ingestion of dust, primarily during the transfer of the flame retardants from hands to mouth, with dermal exposure as the next most important route [Abdallah et al. 2015]. However, a recent study estimated that inhalation exposure exceeded intake from ingestion of some chlorinated organophosphate flame retardants [Schreder et al. 2016]. Experimental data using human skin equivalent tissue demonstrates that the fraction of applied PBDEs crossing the skin culture into the receptor fluid increased as the number of bromine atoms decreased [Abdallah et al. 2015]. Animal studies show that TDCPP easily crosses the skin and gastrointestinal tract [Nomeir et al. 1981], and recent studies of human ex vivo skin 28% of applied TCEP, and 13% of TDCPP crossed the dermal barrier [Abdallah et al. 2016]. This value is an estimate, keeping in mind that flux of material across skin is loading-dependent as discussed by Kissel, and varies with the amount applied [2011]. Overall, there is a paucity of information regarding the relative significance of the different exposure routes and the pharmacokinetics of flame retardants.

Most relevant to gymnastics studios, blood levels of PentaBDE flame retardants in collegiate gymnasts were found to be higher than those in the general population [Carignan et al. 2013]. Carignan et al. found some classes of flame retardants at levels 2–3 times higher in hand wipes from gymnasts after practice than before. Surface and pit foam dust contained flame retardants. The concentrations of some flame retardants were 5–6 times higher in the air near the foam pit than on the opposite side of the gymnastics area [2013]. This is important because, in 2014, there were approximately 4.62 million gymnasts aged six years and older in the United States [Statistica 2016]. In another study of gymnastics studios, La Guardia and Hale [2015] performed air sampling for flame retardants on one coach at each of four gymnastics studios while working and while at home. Surface dust samples were also collected at each gymnastics studio and home. Concentrations of some flame retardants were significantly higher in air and surface dust samples from the gymnastics studios than from homes [La Guardia and Hale 2015]. La Guardia and Hale [2015] also found that all foam blocks tested contained multiple flame retardants, excepting the newest foam block which contained EH-TBB and BEH-TEBP.

There has been debate about whether flame retardants should be taken out of many products due to questions about efficacy in fire spread prevention and the possibility of health effects [Clean Water Action 2016]. Several states in the United States have moved to limit the use of flame retardants in products, especially in home furnishings and children’s products [Safer States 2016; Clean Water Action 2016]. However, no limitations have been suggested for gymnastics products.

The National Institute for Occupational Safety and Health (NIOSH) performed a health hazard evaluation at the same four gymnastics studios studied by La Guardia et al. [2015] at the request of the owner, who was concerned about exposures to flame retardants. He decided to replace all the foam blocks in the pits at each of the gymnastics studios (Figures 1 and 2). The objectives of this study were to: 1) assess employees’ skin exposure to flame retardants in the workplace during routine operations, 2) assess employees’ skin exposure to flame retardants in the workplace during pit foam block replacement and intensive cleaning, 3) determine if there was potential for airborne exposure to flame retardants in the gymnastics studios, and 4) determine if replacement foam and intensive cleaning at the gymnastics studios reduced exposure to flame retardants in the workplace.

Figure 1.

Employees cleaning the in-ground pit at one gymnastic studio. Foam dust is visible among the foam blocks

Figure 2.

In-ground pit containing replacement foam blocks at one gymnastic studio

The four gymnastics studios employed 130 coaches that worked on the gymnastics floor and about 20 employees that worked in offices away from the gymnastics floor. Coaches spent some time in the office areas and were responsible for cleaning the entire facility. Approximately 4,800 gymnasts trained at these gymnastics studios every year (ages 6 years and older). Two of the gymnastics studios also offered preschool programs (ages 3 to 5 years old) that included time in the gymnastics areas.

The gymnastics studios were located inside large warehouses and each had at least one in-ground pit filled with foam blocks, about 5 feet deep, and areas with mats and other padded equipment containing polyurethane foam. Mats and padded equipment were covered, by a combination of plastic or mesh. Temperature control was achieved by the use of exhaust fans, forced air heaters, and opening and closing of garage-style doors. One of the gymnastics studios had an office area with a residential-style heating and air conditioning system. The gymnastics areas were separated from non-gymnastics areas with walls and doors.

The gymnastics studios’ owner replaced the pit foam blocks in all the gymnastics area pits with CertiPUR-US® foam, certified not to contain several flame retardants including PBDEs, tris(1,3-dichloro-2-propyl) phosphate (TDCPP), and tris(2-chloroethyl) phosphate (TCEP) (http://certipur.us/about-certipur-us/). First, the old foam blocks were removed (Figure 1), and the interiors of the pits were vacuumed several times using vacuums equipped with high efficiency particulate air (HEPA) filters. Walls, windows, floors, and equipment were then washed with soap and water. Disposable N95 respirators and nitrile gloves were available to employees, but not required. Certi-PUR-US foam blocks were placed in the pits to a depth of about 2 feet (Figure 2). Above that, catamaran netting was installed in the pits to create a trampoline with 3 more feet of foam blocks atop it. The netting allows the use of less foam (3 feet of foam instead of 5 feet as before) and was expected to prevent foam at the bottom of the pit from being compacted and damaged, releasing foam dust.

METHODS

Study Design

To assess employees’ skin exposure to flame retardants in the workplace during routine operations (objective 1) we visited the four gymnastics studios before (June 2014) and after (April 2015) the replacement of the foam blocks in pits and intensive cleaning of the gymnastics studios during several months during Fall 2014 and Winter 2015. We observed work practices and collected preshift and postshift hand wipes on coaches at two of the gymnastics studios. We collected hand wipe samples from 20 coaches before and 18 coaches after foam replacement and cleaning of the gymnastics studios; 12 coaches participated in hand wipe sampling both before and after foam replacement and cleaning. We tested the foam blocks and mats using an energy-dispersive x-ray fluorescence (XRF) device to determine the presence of bromine, and to better understand potential sources of flame retardants exposure in the gymnastics studios. We also analyzed foam blocks for flame retardant content.

To assess employees’ skin exposure to flame retardants in the workplace during pit foam block replacement and intensive cleaning (objective 2), we observed the removal of the foam blocks from and the subsequent cleaning of the pits at one gymnastic studio in October 2014. We took hand wipe samples for flame retardants from three employees before and after they removed the foam blocks and cleaned the pit.

To determine if there was potential for airborne exposure to flame retardants in the gymnastic studios (objective 3), we sampled the indoor surface of glass windows in the gymnastics areas and administrative areas before and after the intervention. Finally, to determine if replacement foam and intensive cleaning at the gymnastics studios reduced exposure to flame retardants in the workplace (objective 4), we compared the data from the window and hand wipes before and after the intervention. Detailed methods are described in the NIOSH report [NIOSH 2017].

Sampling Methods

Hand Wipe Sample Collection

Employees were told to perform their usual duties and to wash their hands as they would typically do during their shift. However, employees were asked to not wash their hands between the time they finished work and the time that post-shift wipe samples were taken. We also asked employees at the end of the shift about (1) how many times they washed their hands with soap and water and (2) how many times they used alcohol hand sanitizer during the shift.

Two 7.6 square centimeter (cm2) sterile gauze pads were soaked in 3 mL of 99% isopropyl alcohol within an amber glass vial. The first gauze pad was used by the employee to wipe both palms from wrist to fingertips and was then returned to the vial and analyzed together as described by Carignan et al. [2013]; the second gauze pad was used to wipe the back of both hands as returned to the vial. Study staff demonstrated hand wipe method to participants and supervised participants while they wiped their own hands. The wipes were combined for analyses into one sample. Field and media blank samples were collected each day. Samples and blanks were stored and shipped on ice before analysis.

Window Wipe Sample Collection

Before foam block replacement, two surface wipe samples were taken from one plate glass window at each gymnastics studio: one inside the gymnastics area and one inside the office area at all four gymnastics studios. This was done twice, once before and once after the replacement of the foam blocks and cleaning of the gymnastics studios. We asked information about last day of window washing and frequency, however staff at the studios did not have that information.

Sampling was similar to that described by Butt et al. [2004], who had determined spatial distributions of deposited flame retardants by sampling dust from windows. Four 7.6 cm2 sterile gauze pads were presoaked with approximately 12 mL of 99% isopropyl alcohol in a 20 mL amber glass vial. Four 1×1 ft2 templates were placed on each window, with a total area of 4 ft2. The interior of each template was wiped horizontally, vertically, and diagonally with one piece of gauze. The gauze was folded in half between complete passes. The wipes from each of the four templates were combined and analyzed as one sample. We collected field and media blanks for quality assurance. Samples and blanks were stored and shipped on ice before analysis.

Foam Block Sample Collection

New replacement foam blocks (n=4) and old foam blocks (n=8) from each of the gymnastics studio were taken for flame retardant analysis. All foam blocks were removed from the pits at the gymnastic studio, except one new foam block was collected after being shipped from the manufacturer before being installed in the pit. Whole foam blocks were taken randomly from the pit. Bulk foam sampling and storage for laboratory analysis was performed as described by Carignan et al. [2013].

Sample Chemical Analysis

Hand Wipe, Window Wipe, and Foam Block Sample Flame Retardant Analysis

The hand wipes, window wipes, and foam blocks were analyzed by the Virginia Institute of Marine Sciences for a panel of 22 flame retardant including the components of PentaBDE (i.e., BDE-28, BDE-47, BDE-66, BDE-85, BDE-100, BDE-99, BDE-154, BDE-153) and other flame retardants currently or historically used in polyurethane foam (i.e., EH-TBB, BEH-TEBP, TCEP, TCIPP, TDCPP). Additional analyses were also conducted on these samples and can be found in the NIOSH report [NIOSH 2017], but were not included in this manuscript. Flame retardants of interest were extracted from each sample using methylene chloride, then purified, and analyzed by atmospheric pressure photoionization tandem mass spectrometry (APPI/MS/MS, Q-Trap3200 MS, AB Sciex, Framingham, MA, USA). A detection limit (dl) 10-times greater than background noise was established at 1.00 ng for all target analytes detected in the wipe samples, 100 ng for the bulk samples and represents the lowest point on each five point calibration curve (r2 >0.985) used for flame retardant quantitation detected in the wipe and bulk samples, respectively. All analytes detected below dl were reported as non-detect (nd) or <1.00 ng wipe−1 and <1.00 μg g−1 bulk samples. (See La Guardia et al. [2013; 2015] for additional sample processing and quantitation procedures.) Further experimental analytical information can be found in the Supplemental Information for this article. For quality control, three unused gauze wipes were each spiked with 100 ng of each of the 22 flame retardants in the panel to determine recovery rates [NIOSH 2016]. The range of mean percent spiked recoveries was 57% to 110%; the mean of the mean percent recoveries for each flame retardant was 84%. The range of coefficients of variation was 4 to 73; the mean coefficient of variation was 11.3 [NIOSH 2016]. Field and media wipe blanks did not show background contamination and hand wipe samples were not corrected.

Foam Equipment Bulk Sample Analysis for Bromine

We looked for bromine in foam blocks, foam equipment, and polyurethane-covered mats at all four gymnastic studios using an energy-dispersive x-ray spectroscopy device (Bruker [S1 Turbo]), as described by Carignan et al. [2013] and Allen et al. [2008]. We held the device to direct x-rays (generated by an x-ray tube) at the sample. We operated the device in the low density plastic mode, which has a detection limit of 1 mg/kg. Each measurement lasted for 30 seconds.

Statistical Analysis

SAS version 9.3 was used for the analysis. For sample results that were reported as “not detected” we used the laboratory reporting limit (1 ng per sample for hand wipes and 10 ng per 4 ft2 for window wipes) divided by the square root of 2 as the estimate [Hornung and Reed 1990]. Hand wipes for all employees at the end of the shift were compared to those before the shift using a paired t-test or a paired sign test, depending on the distribution of the postshift to preshift differences.

The Spearman correlation coefficient was used to determine the correlation between the total number of hours spent at work, the number of times employees washed their hands, the number of times employees used alcohol-based hand sanitizer and the difference between total postshift and preshift flame retardant concentrations on the hands. We calculated the Pearson correlation coefficient for the relationship between bromine content of 8 foam blocks as found using the XRF instrument and via laboratory analyses. We used α ≤ 0.05 as the benchmark for statistical significance. Due to the small sample size, we did not use statistical testing to compare window levels of flame retardants.

RESULTS

Hand Wipe Levels during Routine Gymnastic Studio Operations

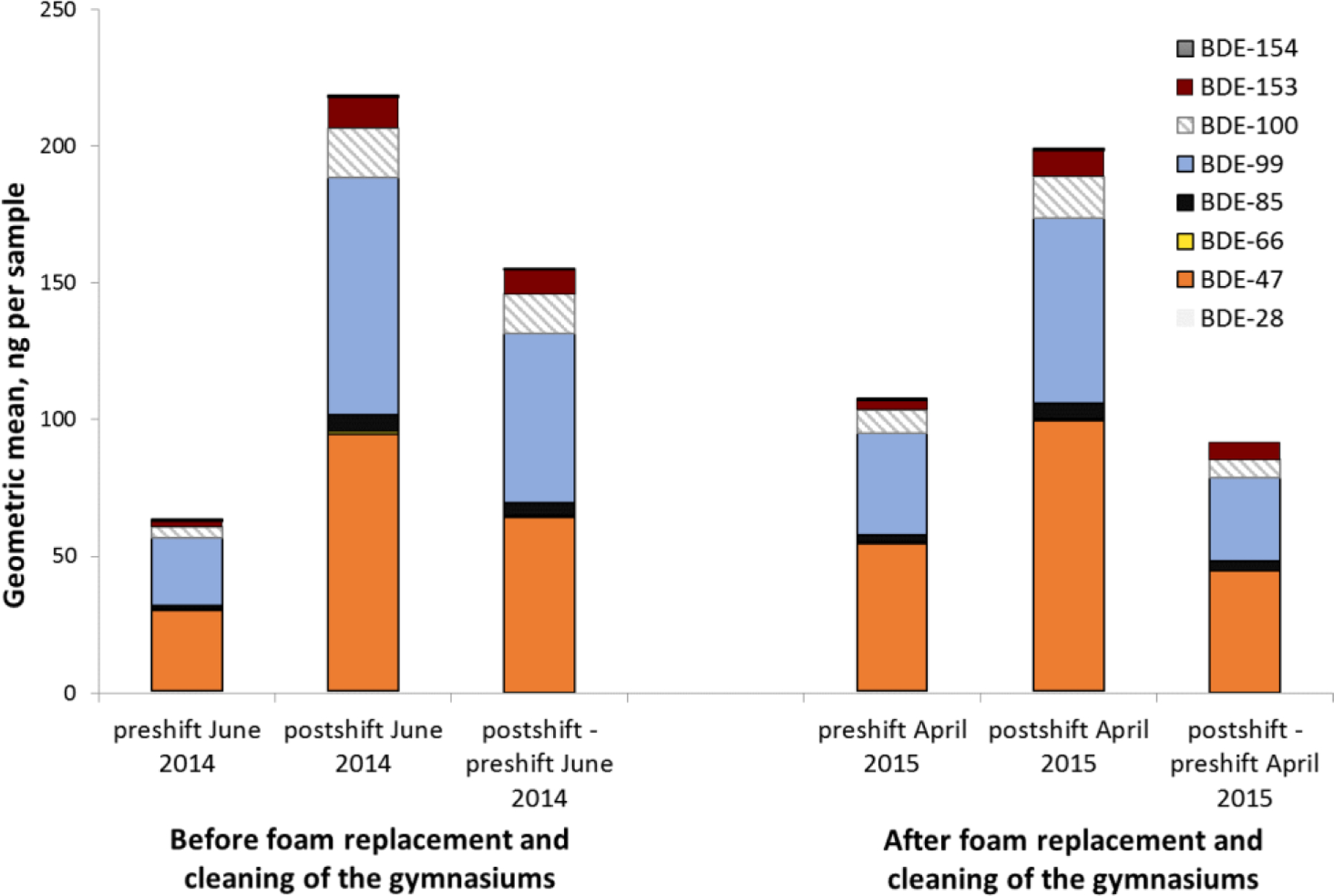

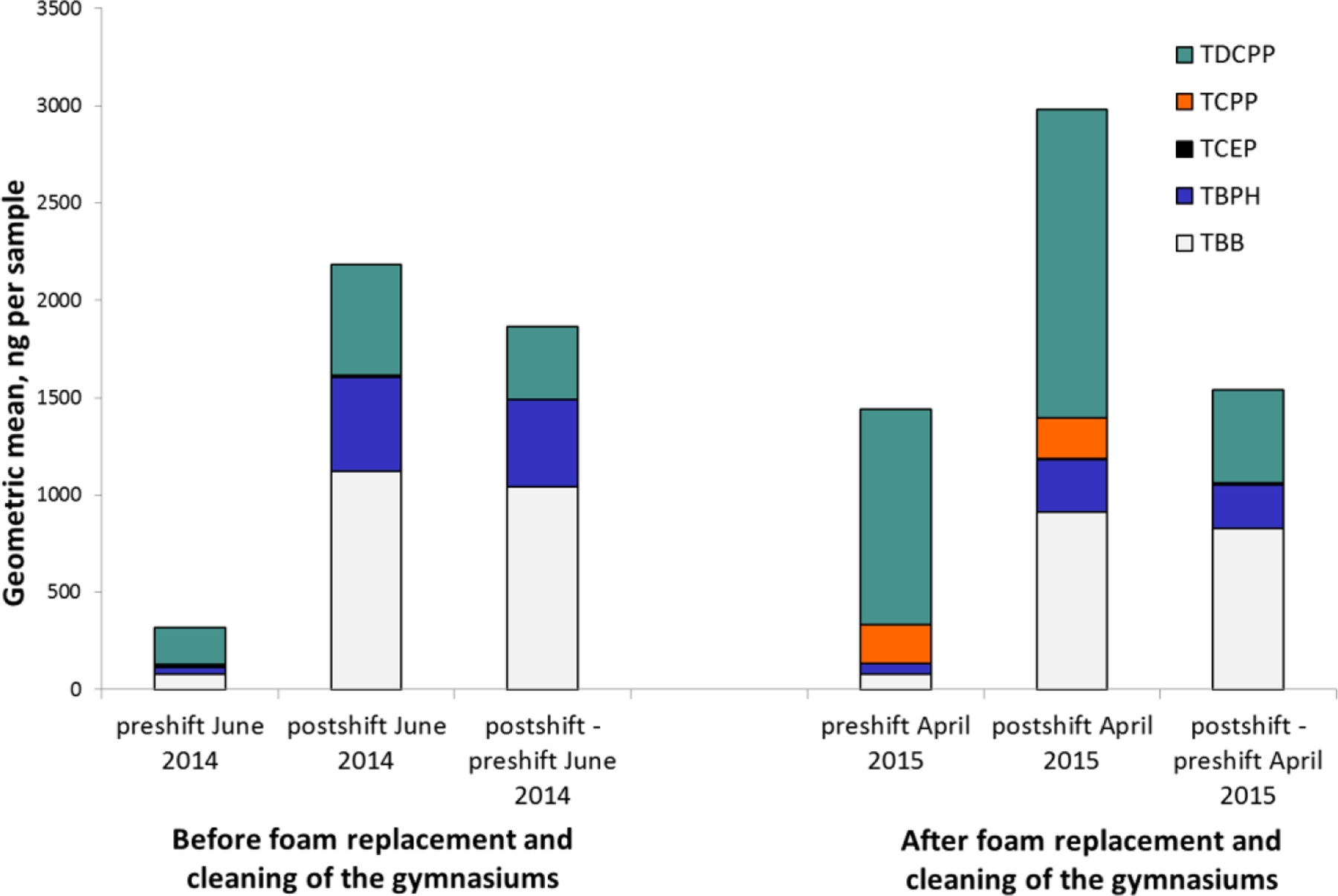

The flame retardants levels on employees’ hands at the beginning and end of their shifts in June 2014 and April 2015 are summarized in Table 1 and Figures 3 and 4. Geometric mean preshift levels on hand wipes were higher during the April 2015 site visit than the geometric mean preshift levels during the June 2014 site visit for nine of the 13 flame retardants. The most abundant flame retardants postshift on both site visits were BEH-TEBP, EH-TBB, and TDCPP. The same flame retardants were measured at significantly higher levels postshift than preshift before and after foam replacement (Table 1). BDE-47, BDE-66, BDE-85, BDE-99, BDE-100, and BDE-153 (all components of PentaBDE, which was used in foam manufactured before 2004 [LaGuardia et al 2016]) were present at significantly higher levels postshift than preshift before foam block replacement and cleaning of the gymnastics studios, although at geometric mean levels much lower than BEH-TEBP, EH-TBB, and TDCPP. After foam block replacement and cleaning of the gymnastics studios, only BDE-153 had significantly higher postshift handwipe levels than preshift levels.

Table 1.

Preshift and postshift geometric mean levels and ranges of flame retardants on employees’ hands (in ng) before and after foam replacement and gymnastics studio cleaning

| Preshift June 2014ƚ (n = 20) GM (range) | Postshift June 2014ƚ (n = 20) GM (range) | P-value | Preshift April 2015ƚ (n = 18) GM (range) | Postshift April 2015ƚ (n = 18) GM (range) | P-value | |

|---|---|---|---|---|---|---|

| PentaBDE | ||||||

| BDE-28 | ND | ND | - | ND | ND | - |

| BDE-47 | 28.8 (7.8–210) | 93.0 (34–280)* | 0.001 | 52.3 (12–680) | 95.8 (7.0–730) | 0.08 |

| BDE-66 | ND | 1.12 (ND–6.4)* | 0.030 | ND | ND | - |

| BDE-85 | 1.31 (ND–7.0) | 6.12 (1.9–16)* | <0.001 | 2.29 (ND–16) | 5.56 (ND–70) | 0.077 |

| BDE-99 | 24.0 (ND–160) | 85.8 (27–280)* | 0.002 | 36.2 (ND–160) | 65.9 (7.80–590) | 0.091 |

| BDE-100 | 3.92 (ND–34) | 18.3 (8.6–43)* | <0.001 | 8.61 (ND–29) | 14.7 (ND–140) | 0.052 |

| BDE-153 | 2.06 (ND–21) | 11.0 (2.4–30)* | <0.001 | 3.15 (ND–34) | 9.07 (ND–110)* | 0.013 |

| BDE-154 | ND | 0.843 (ND–24) | 0.330 | ND | ND | - |

| Other FRS used in polyurethane foam | ||||||

| EH-TBB | 76.2 (15–230) | 1,100 (57.2–5,000)* | <0.001 | 79.2 (13–840) | 885 (31–6,400)* | 0.002 |

| BEH-TEBP | 38.6 (9.50–110) | 478 (39–2,200)* | <0.001 | 50.3 (16–230) | 267 (14–1,500)* | <0.001 |

| TCEP | 1.48 (ND–130) | 0.859 (ND–35) | 0.107 | ND | ND | - |

| TCIPP | 8.54 (ND–820) | 8.63 (ND–520) | 0.742 | 196 (ND–880) | 210 (110–540) | 0.112 |

| TDCPP | 187 (ND–1,400) | 556 (60–4,600)* | 0.0408 | 1,090 (150–4,200) | 1580 (330–3,000)* | 0.0311 |

GM = geometric mean

ND = not detected, result was below the laboratory reporting limit of 1 ng/sample.

Indicates a statistically significant difference (P < 0.05) between postshift and preshift levels of flame retardants during the same visit

June 2014 visit was before the foam block replacement and gymnastics studio cleaning. Our April 2015 visit was after the foam block replacement and gymnastics studio cleaning.

Figure 3.

Preshift and postshift geometric mean levels and ranges of polybrominated diphenyl ethers on employees’ hands (in ng) before and after foam blocks were replaced

Figure 4.

Preshift and postshift geometric mean levels and ranges of other flame retardants used in polyurethane foam on employees’ hands (in ng) before and after foam blocks were replaced

The employees we sampled averaged 4 hours on the gymnastics floor (range: 1–8.5) and 1.9 hours (range: 0–7.5) off the gymnastics floor. During their time off the gymnastics floor, some employees worked in the office, took breaks and lunches, or traveled between the two gymnastics studios. Of the flame retardants used in polyurethane foam, there were statistically significant correlations between hours on the gym floor and change in levels of TCEP (r = 0.52; P < 0.02) on the June 2014 visit and BDE-47 (r = 0.54; P = 0.02) on the April 2015 visit.

Employees reported washing their hands with soap and water an average of twice while at work on both site visits (first visit range: 0–7; second visit range: 0–6). We did not find a significant relationship between change in levels of total flame retardants on the hands and number of times an employee washed his or her hands on the first site visit (r = 0.095; P = 0.69) nor the second site visit (r = 0.431; P = 0.074). Employees reported using alcohol–based hand sanitizer at work an average of once on the first site visit and less than once on the second site visit (first visit range: 0–9; second visit range: 0–5). We did not find a significant relationship between change in levels of total flame retardants on the hands and number of times an employee used alcohol–based hand sanitizer at work on the first site visit (r = 0.018; P = 0.94) nor the second site visit (r = 0.034; P = 0.8933).

Dermal Exposures during Foam Replacement and Pit Cleaning

Table 2 presents data for two of the three employees who participated in hand wipe sampling during pit cleaning and foam replacement activities; the samples for the other employee were not analyzed due to possible contamination of the third participant’s samples during transport. Employee 1 was in the foam pit for 60 minutes and employee 2 for 70 minutes. During this time they handled foam, did not wash their hands, and did not wear gloves. Wipe sample results showed levels of EH-TBB, BEH-TEBP, and TDCPP were higher on employees’ hands after cleaning than before cleaning the foam pit. PBDE levels on hands were similar before and after cleaning the foam pit.

Table 2.

Flame retardants on hand wipe samples before and after removing old foam blocks from and cleaning two in-ground foam pits, October 2014 (ng/sample)

| Flame retardants | Employee 1 before cleaning | Employee 1 after cleaning | Employee 2 before cleaning | Employee 2 after cleaning |

|---|---|---|---|---|

| PentaBDE | ||||

| BDE-28 | ND | ND | ND | ND |

| BDE-47 | 68 | 97 | ND | 28 |

| BDE-66 | ND | ND | ND | ND |

| BDE-85 | ND | 5.3 | ND | ND |

| BDE-99 | 150 | 140 | ND | 40 |

| BDE-100 | 27 | 24 | ND | 18 |

| BDE-153 | 12 | 19 | ND | ND |

| BDE-154 | 28 | 6.3 | ND | ND |

|

Other FRs used in polyurethane foam | ||||

| EH-TBB | 150 | 6,200 | 380 | 3,300 |

| BEH-TEBP | 5.9 | 1,800 | 24 | 930 |

| TCEP | ND | ND | ND | ND |

| TCIPP | ND | 500 | 450 | 510 |

| TDCPP | 890 | 13,000 | 720 | 9,800 |

ND = not detected; result was below the laboratory reporting limit of 1 ng/sample.

Flame Retardants in Gymnastics Studio on Windows

The most abundant flame retardants present on windows in the gymnastics area before foam replacement were BEH-TEBP and EH-TBB (components of Firemaster 550, which is a common flame retardant used in polyurethane foam [Hoffman et al. 2014]) and TDCPP (also common flame retardant in polyurethane foam [Hoffman et al. 2015]) [Table 3]. However, we were not able to determine with clarity when windows tested were last cleaned as each gymnastics studio had different window washing schedules, which were not documented.

Table 3.

Median levels (and ranges) of flame retardants on window wipe samples in ng per 4 square foot (ft2) in four gymnastics studio before and after foam replacement and gymnastics studio cleaning

| Office window June 2014* (n = 4) | Gymnastics area window June 2014* (n = 4) | Office window April 2015* (n = 4) | Gymnastics area window April 2015 (n = 4) | |

|---|---|---|---|---|

| PentaBDE | ||||

| BDE-28 | ND | ND | ND | ND |

| BDE-47 | 74.6 (30–110) | 445 (47–3,100) | 21.1 (ND–700) | 20.7 (8.6–84) |

| BDE-66 | ND | 12.6 (ND–160) | ND | ND |

| BDE-85 | ND | ND | ND (ND–9.3) | ND (ND–8.8) |

| BDE-99 | ND (ND–150) | 537 (ND–8,500) | 16.7 (14–100) | 21.2 (11–86) |

| BDE-100 | ND | 164 (ND–1,300) | 3.65 (ND–5.8) | 2.04 (ND–6.3) |

| BDE-153 | ND | 97.7 (ND–1,400) | ND | ND |

| BDE-154 | ND | ND (ND–130) | ND | ND |

| Other FRs used in polyurethane foam | ||||

| EH-TBB | 162 (110–1,100) | 2330 (220–31,000) | 22.6 (18–220) | 119 (17–220) |

| BEH-TEBP | 79.8 (43–520) | 1660 (130–14,000) | 9.85 (5.3–43) | 47.3 (8.8–92) |

| TCEP | ND (ND–1,000) | 343 (ND–1100) | ND | ND |

| TCIPP | 439 (ND–1,700) | 635 (ND–3,700) | ND (ND–140) | ND (ND–230) |

| TDCPP | 518 (230–1,300) | 9370 (2,400–81,000) | 150 (120–540) | 495 (180–1100) |

ND = not detected; result was below the laboratory reporting limit of 10 ng per 4 ft2

June 2014 visit was before the foam block replacement and gymnastic studio cleaning. Our April 2015 visit was after the foam block replacement and gymnastic studio cleaning.

The most abundant flame retardants we measured on windows in the gymnastics area after foam block replacement were EH-TBB and TDCPP. EH-TBB, BEH-TEBP, and TDCPP levels were reduced more on the gymnastics area windows than on the office windows from the June 2014 to the April 2015 site visit (8.8% more for EH-TBB, 9.5% for BEH-TEBP, and 24% for TDCPP). Gymnastics area window levels of flame retardants were not similar across the four gymnastics studio sites. During the first visit, the highest concentration of each EH-TBB and BEH-TEBP on the gymnastics area windows was more than 100 times the lowest concentration and the highest TDCPP concentration was more than 30 times the lowest concentration.

Bromine and Flame Retardants in Equipment and Foam Blocks

Table 4 summarizes the bromine content of equipment at the gymnastics studios, as measured using an XRF instrument. The pit foam blocks and floor mat foam had greater mean percentage bromine content than other material in the gymnastic studios (Table 1).

Table 4.

Bromine content in equipment in two gymnastics studios measured using a direct reading XRF instrument

| Bromine content (percent by weight) | |||

|---|---|---|---|

| Material | Mean | Minimum | Maximum |

| Equipment covers (n=30) | 0.21 | ND | 2.3 |

| Floor mat foam (n=27) | 1.1 | 0.0001 | 2.9 |

| Pommel horse pad foam* (n=3) | 0.0024 | 0.0024 | 0.0024 |

| Pit foam blocks (n=12) | 1.8 | 0.0001 | 4.1 |

| Carpet (n=2) | – | 0.02* | 0.13* |

| Hard foam equipment and ring foam (n=4) | 0.34 | 0.0029 | 1.3 |

ND=not detected at or above the limit of detection of 0.0001% by weight

Only at one gymnastic studio

The bromine content in old (non-white appearance) and new replacement (white appearance) foam pit blocks determined by chemical analysis in the laboratory correlated well (r = 0.85) with the bromine content measured using the XRF instrument in the field (Table 5). For three of the old foam block samples, the total flame retardant mass was higher than the mass of brominated flame retardants due to the presence of chlorinated flame retardants (i.e., TCEP, TCIPP, TDCPP) in these samples. Supplemental Table S1 displays the individual flame retardant concentration in each block analyzed. Newer blocks contained lower levels of flame retardants by weight than the older blocks but there was variability across blocks. Flame retardant content in older foam block samples, determined by laboratory analysis, varied from 1.4% to 6% by weight for all flame retardants measured, and from 0.0012% to 4% for bromine-containing flame retardants. The predominant flame retardants in the old foam were EH-TBB, BEH-TEBP, and TDCPP. Seven of the eight old blocks contained PBDEs.

Table 5.

Average bromine and flame retardant content (percent by weight) in pit foam blocks determined by XRF and by laboratory analysis

| Sample ID | Foam color | Bromine content by XRF Average (standard deviation) | Bromine-containing flame retardants by laboratory analysis | All measured flame retardants by laboratory analysis |

|---|---|---|---|---|

| 1 | White*,† | 0.002 (0.0003) | ND | ND |

| 2 | White* | 1.6 (0.05) | 2.9 | 2.9 |

| 3 | White* | 1.6 (0.06) | 3.3 | 3.3 |

| 4 | White* | 0.001 (0.0003) | 0.0012 | 0.0012 |

| 5 | Light blue | 0.001 (0.0004) | 0.0036 | 3.5 |

| 6 | Dark blue | 0.029 (0.001) | 0.023 | 2.1 |

| 7 | Dark blue | 1.2 (0.07) | 1.9 | 1.9 |

| 8 | Turquoise | 3.3 (0.04) | 4.1 | 4.1 |

| 9 | Pale yellow | 4.1 (0.04) | 2.3 | 2.4 |

| 10 | Dark blue | 1.3 (0.01) | 1.4 | 1.4 |

| 11 | Light blue | 0.002 (0.0003) | 0.0034 | 6.0 |

| 12 | Turquoise | 2.0 (0.02) | 2.6 | 2.6 |

ND = not detected at or above the minimum detectable concentration of 1 µg/g of foam or 0.0001% bromine by weight

White foam was new replacement foam.

This block was unused.

The flame retardant content in the new foam blocks ranged from “not detected” to 3.3% for all measured flame retardants and for bromine-containing flame retardants by laboratory analysis. None of the four replacement blocks contained PBDEs by laboratory analysis. The new foam blocks did not contain chlorinated flame retardants, with the exception of one block that contained an amount of TDCPP that was likely incidental contamination rather than an intentional ingredient (2.2 μg/g). Two of the four had measurable bromine content by XRF and three of the four had bromine-containing flame retardants by our laboratory analysis. This was due the presence of EH-TBB and BEH-TEBP in these blocks, flame retardants not included in the certification. In the three blocks with measurable levels of EH-TBB and BEH-TEBP flame retardants, the levels varied widely with EH-TBB ranging from 7.49 to 27,400 μg/g foam and BEH-TEBP ranging from 4.53 to 6,330 μg/g foam. No other flame retardants were detected in the new blocks.

DISCUSSION

We found statistically significant across-shift increases in levels of six of eight PentaBDE components before the foam was replaced, but only saw statistically significant across-shift increases of one of eight after the foam was replaced (Table 1 and Figure 3). This implies that employees’ exposure to PentaBDE was reduced after the old foam had been replaced with new foam that did not contain PentaBDEs. However, the geometric mean levels of postshift PentaBDEs levels in handwipes were much lower than those of EH-TBB, BEH-TEBP, and TDCPP even before the foam replacement, indicating that PentaBDEs contributed less to total flame retardant exposure. This is not surprising given that both the old and new foam contributed to the levels of EH-TBB and BEH-TEBP.

Among all coaches tested, hand wipes showed that work at a gymnastics studio was a source of occupational exposure to flame retardants. The composition of the contamination was consistent with the composition of the old foam blocks. We found large and significant increases in levels of EH-TBB and BEH-TEBP on employees’ hands across their workshifts, both before the foam block replacement and after (Table 1 and Figure 4). This was not surprising given the new foam sometimes contained both BEH-TEBP and EH-TBB. These findings are similar to those of Carignan et al. [2013], who noted that median PentaBDE, EH-TBB, and BEH-TEBP levels in hand wipes were 2–3 times higher from gymnasts after practice than before. Hand wipes also showed that two employees’ skin contamination of EH-TBB, BEH-TEBP, and TDCPP increased from before to after removing old pit foam and cleaning the pits.

We also found significant increases in levels of TDCPP on employees’ hands across their work shift, both before the foam block replacement and after (Table 1 and Figure 4). This is important as the levels of the skin may also suggest potential for ingestion if contaminated hands touched mouth or food items. Of note, the increase in TDCPP during the shift appears to be greater after foam replacement than before. This is hard to explain since the new blocks were certified to contain not detectable TDCPP (although our analyses documented a minute amount of TDCPP in one block that is likely contamination during manufacture or at the gymnastic studio when in use rather than intentional addition). Although not confirmed, other foam-containing equipment such as mats and pommel horses, may have also contributed to the TDCPP on employees’ hands, if foam flame retardant composition was similar to the loose old pit foam.

We hypothesized that increased frequency of handwashing would be negatively correlated with change in flame retardant levels on the hands over the shift. However, there was no statistically significant correlation between levels of flame retardants and handwashing, nor with the use of alcohol-based hand sanitizer. One reason for this finding may be because the total number of hours at work was significantly positively associated with the number of times employees washed their hands (P < 0.01), length of shift may have counteracted the protective effect of handwashing. Other reasons include the possibility that aspects of washing other than frequency, i.e., vigor and duration, may be important or we may not have had enough people throughout the frequency range to see a correlation. Other studies have shown a negative association between frequency of handwashing and levels of some flame retardants on hands [Abdallah et al. 2016; Stapleton et al. 2014; Watkins et al. 2011].

Our surface wipe samples from windows indicate that flame retardants likely were released from foam-containing products, became airborne, and then impacted or partitioned on surfaces (e.g., windows). Since the median levels on windows were higher on gymnastics area windows than office windows during the first visit for some flame retardants, activities and foam equipment in the gymnastics studios may have contributed to more airborne and surface flame retardants in those areas. The most abundant flame retardants we measured on gymnastics area windows before and after foam replacement were TDCPP, EH-TBB, and BEH-TEBP. These same flame retardants were found in the old foam we tested, which is also consistent with findings from La Guardia and Hale [2015].

This study has several limitations. The interpretation of the hand wipe sampling results as dermal (and possibly ingestion) exposure is challenging. The hand wipe sampling procedure removes an unknown and variable amount of flame retardants present on the hand. The amount removed from the hand may vary depending on the wiping technique consistency from visit to visit, even though the same instructions were provided to all participants. Furthermore, the amount of flame retardants that can be recovered from the wipes in the laboratory is not well known.

Despite these limitations, hand wipes have been used to measure personal exposure to flame retardants in several studies. Levels of PBDE flame retardants on hands significantly correlated with serum PBDE levels [Stapleton et al. 2012; Watkins et al., 2011;] and were a better predictor of serum PBDE levels than house dust [Stapleton et al. 2012]. In other studies, levels of some alternative flame retardants on hand wipes were significantly correlated with house dust concentrations [Hoffman et al. 2014; Stapleton et al. 2014]. In addition, hand wipe levels of TDCPP, EH-TBB, and TPP were significantly correlated with their urinary metabolites [Hoffman et al. 2014; 2015]. More relevant to our evaluation, EH-TBB and BEH-TEBP on hand wipes of 11 collegiate gymnasts were significantly increased after a practice than before, with median levels of EH-TBB of 61 ng/sample and of BEH-TEBP of 30 ng/sample after practice [Carignan et al. 2013]. The hand wipes were self-administered with the same directions given to participants in both evaluations. We also found significant increases of EH-TBB and BEH-TEBP across the shift, with geometric mean levels of EH-TBB postshift of 1100 ng/sample on the first visit and 885 ng/sample on the second visit, and of BEH-TEBP postshift of 478 ng/sample on the first visit and 267 ng/sample on the second visit on gymnastics coaches’ hands.

Confidence in window dust data conclusions may be tempered by not being able to obtain information about how often windows were cleaned and the date of the last cleaning. We were also not able to control the number of days since window cleaning and standardize that across the site visits. We visited the gymnastics studios all at the same time before and after the replacement of the foam allowing several weeks after the changes were in place to make sure work conditions had stabilized.

With these limitations in mind, flame retardants measured in window wipes were consistent with the La Guardia et al [2015] findings of significantly higher mean inhalable concentrations of EH-TBB and TDCPP in air in the gymnastics studios than in coaches’ homes [La Guardia and Hale 2015]. Median concentrations of most flame retardants on gymnastics area windows in both locations were lower after the studios were thoroughly cleaned during pit block replacement. The absolute reductions were greatest for EH-TBB and TDCPP, which suggest that airborne concentrations were reduced after the replacement of the foam blocks. The levels of TDCPP remained high relative to other flame retardants in window dust after foam replacement, which suggests that (1) residual foam dust from older blocks may have persisted, (2) other foam equipment (that contain TDCPP) may have contributed to airborne dust, or (3) a combination of these sources may have been contributing to the presence of TDCPP.

Although coaches may not have frequent, full body contact with pit and exposed foam like gymnasts have, they usually spend more hours than gymnasts at a gymnastics studio. They also perform cleaning activities in the gymnastics studio on a regular basis. The results of this study could be used to support the development of future studies that include the use of biological samples to document levels of flame retardants in the coaches before and after this type of interventions. The results of this evaluation can provide an example of what gymnastics studio owners and managers can expect when trying to reduce exposures to flame retardants for coaches and gymnasts, a group that typically includes children.

Conclusions

Scientists who research flame retardant exposure and toxicology have not reached a consensus on what levels of exposure to flame retardants are safe or harmful to health. We documented that gymnastics coaches can be occupationally exposed to flame retardants by airborne and skin exposure. The main flame retardants we measured on windows and hands were EH-TBB, BEH-TEBP, and TDCPP. Although it may not be possible to eliminate all flame retardant exposure given their ubiquity, the gymnastics studio foam replacement intervention documented here seemed to have been effective at reducing exposures to PBDEs and TDCPP, but at the same time contributing to continuing exposure to EH-TBB and BEH-TEBP. This study also highlights the challenges employers face when assessing new products for their flame retardant content, despite programs that certify products as being free from certain classes of, but not all, flame retardants.

We provided recommendations to the gymnastics studio management to reduce exposures further, as described in detail in the NIOSH report [NIOSH 2017]. Recommendations included researching and limiting the flame retardant content of any replacement foam, improving housekeeping, and using additional personal protective equipment use during cleaning tasks. Gymnastics studios seeking to replace their foam products should obtain and review foam safety data sheet information prior to purchase or contact the manufacturer even if the foam has been certified to be flame retardant free in some manner.

Supplementary Material

HIGHLIGHTS.

Gymnastics coaches can be exposed to flame retardants in air and on skin at work.

The main flame retardants we found on windows and hands were EH-TBB, BEH-TEBP, and TDCPP.

Replacing foam blocks in the in-ground pits eliminated a source of PBDEs and TDCPP, however continued exposures to EH-TBB and BEH-TEBP.

Foam equipment should be replaced as soon as the foam begins to deteriorate.

Acknowledgments

Thanks to Chen Wang for spectroscopy analytical support to Rosa Key-Schwartz and Paula Fey-O’Connor for chemical analysis quality control, and to Donnie Booher and Kevin Moore for logistics during field visits. The authors are also grateful to Thomas Webster and Courtney Carignan for technical review of the research protocols. We are also grateful to NIOSH staff, journal reviewers, and Madeleine Scammell and Marc Weisskopf for review of the manuscript. Thank you for the thoughtful comments provided by the journal reviewers. Thanks to the gymnastics studios’ administrative personnel and coaches for volunteering in this study. Diana Ceballos is a JPB Environmental Health Fellow. The JPB Foundation supports the JPB Environmental Health Fellowship Program, which is managed by the Harvard Chan School of Public Health. This paper is Contribution No. 3719 of the Virginia Institute of Marine Science, College of William & Mary.

Footnotes

Publisher's Disclaimer: Disclaimer

Publisher's Disclaimer: The findings and conclusions in this report are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention.

REFERENCES

- Abdallah MA, Pawar G, Harrad S [2015]. Effect of bromine substitution on human dermal absorption of polybrominated diphenyl ethers. Environ Sci Technol 49(18):10976–10983, 10.1021/acs.est.5b03904. [DOI] [PubMed] [Google Scholar]

- Abdallah MA, Pawar G, Harrad S [2016]. Human dermal absorption of chlorinated organophosphate flame retardants; implications for human exposure. Toxicol Appl Pharmacol 291:28–37, 10.1016/j.taap.2015.12.004. [DOI] [PubMed] [Google Scholar]

- Allen J, McClean M, Stapleton H, Webster T [2008]. Linking PBDEs in house dust to consumer products using X-ray fluorescence. Environ Sci Technol 42(11):4222–4228, 10.1021/es702964a. [DOI] [PubMed] [Google Scholar]

- Allen JG, Stapleton HM, Vallarino J, McNeely E, McClean MD, Harrad SJ, Rauert CB, Spengler JD [2013]. Exposure to flame retardant chemicals on commercial airplanes. Env Health 12:17, 10.1186/1476-069X-12-17. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bergman Å, Ryden A, Law RJ, de Boer J, Covaci A, Alaee M, Birnbaum L, Petreas M, Rose M, Sakai S, Van den Eede N, van der Veen I [2012]. A novel abbreviation standard for organobromine, organochlorine and organophosphorus flame retardants and some characteristics of the chemicals. Environment International 49(0): 57–82. 10.1016/j.envint.2012.08.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Butt CM, Diamond ML, Truong J, Ikonomou MG, ter Schure AH [2004]. Spatial distribution of polybrominated diphenyl ethers in Southern Ontario as measured in indoor and outdoor window organic films. Environ Sci Technol 38(3):724–731. 10.1021/es034670r [DOI] [PubMed] [Google Scholar]

- Carignan CC, Heiger-Bernays W, McClean MD, Roberts SC, Stapleton HM, Sjödin A, Webster TF [2013]. Flame retardant exposure among collegiate United States gymnasts. Environ Sci Technol 47(23):13848–13856, 10.1021/es4037868. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Carignan CC, Mínguez-Alarcón L, Butt CM, Williams PL, Meeker JD, Stapleton HM, Toth TL, Ford JB, Hauser R [2017]. Urinary organophosphate flame retardant metabolites and pregnancy outcomes among women undergoing in vitro fertilization. Environ Health Persp 125(8). 10.1289/EHP1021. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Clean Water Action [2016]. Massachusetts Senate passes bill to protect children, families, firefighters from toxic flame retardants, http://www.cleanwateraction.org/releases/massachusetts-senate-passes-bill-protect-children-families-firefighters-toxic-flame.

- Dishaw LV, Macaulay LJ, Roberts SC, Stapleton HM [2014]. Exposures, mechanisms, and impacts of endocrine-active flame retardants. Curr Opin Pharmacol 19:125–133, 10.1016/j.coph.2014.09.018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- EPA [2014]. Technical fact sheet – polybrominated diphenyl ethers (PBDEs) and polybrominated biphenyls (PBBs). EPA 505-F-14–006.

- European Union [2004]. Directive 2003/11/EC of the European Parliament and of the Council of 6 February 2003 amending for the 24th time Council Directive 76/769/EEC relating to restrictions on the marketing and use of certain dangerous substances and preparations (pentabromodiphenyl ether, octabromodiphenyl ether). http://eur-lex.europa.eu/eli/dir/2003/11/oj.

- Hoffman K, Fang M, Horman B, Patisaul HB, Garantziotis S, Birnbaum LS, Stapleton HM [2014]. Urinary tetrabromobenzoic acid (TBBA) as a biomarker of exposure to the flame retardant mixture Firemaster® 550. Environ Health Perspect 122(9):963–969, 10.1289/ehp.1308028. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hoffman K, Garantziotis S, Birnbaum LS, Stapleton HM [2015]. Monitoring indoor exposure to organophosphate flame retardants: hand wipes and house dust. Environ Health Perspect 123(2):160–165, 10.1289/ehp.1408669. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hornung RW, Reed LD [1990]. Estimation of average concentration in the presence of nondetectable values. App Occ Env Hyg 5(1):46–51, 10.1080/1047322X.1990.10389587. [DOI] [Google Scholar]

- Johnson PI, Stapleton HM, Mukherjee B, Hauser R, Meeker JD [2013]. Associations between brominated flame retardants in house dust and hormone levels in men. Sci Total Environ 445–446:177–184, 10.1016/j.scitotenv.2012.12.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kissel JC [2011]. The mismeasure of dermal absorption. J Expo Sci Environ Epidemiol 21(3):302–9, 10.1038/jes.2010.22. [DOI] [PubMed] [Google Scholar]

- La Guardia MJ, Hale RC, Newman B [2013]. Brominated flame-retardants in Sub-Saharan Africa: burdens in inland and coastal sediments in the eThekwini metropolitan municipality, South Africa. Environ. Sci. Technol 47(17): 9643–50, 10.1021/es4020212. [DOI] [PubMed] [Google Scholar]

- La Guardia MJ, Hale RC [2015]. Halogenated flame-retardant concentrations in settled dust, respirable and inhalable particulates and polyurethane foam at gymnastic training facilities and residences. Environ Int 79:106–114, 10.1016/j.envint.2015.02.014. [DOI] [PubMed] [Google Scholar]

- Meeker JD, Cooper EM, Stapleton HM, Hauser R [2013]. Exploratory analysis of urinary metabolites of phosphorus-containing flame retardants in relation to markers of male reproductive health. Endocr Disruptors (Austin) 1(1):e26306, 10.4161/endo.26306. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Meeker JD, Stapleton HM [2010]. House dust concentrations of organophosphate flame retardants in relation to hormone levels and semen quality parameters. Environ Health Perspect 118(3):318–23, 10.1289/ehp.0901332. [DOI] [PMC free article] [PubMed] [Google Scholar]

- NIOSH [2016]. Analytical method recovery of flame retardants from spiked gauze wipe media. Draft. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. [Google Scholar]

- NIOSH [2017]. Health hazard evaluation report: occupational exposure to flame retardants at four gymnastics studios. By Broadwater K, Ceballos D, Page E, Croteau G, Mueller C. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, NIOSH HHE Report No. 2014–0131-3268. [Google Scholar]

- Nomeir AA, Kato S, Matthews HB [1981]. The metabolism and disposition of tris(1,3-dichloro-2-propyl)phosphate (Fyrol FR-2) in the rat. Toxicol Appl Pharmacol 57(3):401–413. [DOI] [PubMed] [Google Scholar]

- Patisaul HB, Roberts SC, Mabrey N, McCaffrey KA, Gear RB, Braun J, Belcher SM, Stapleton HM [2013]. Accumulation and endocrine disrupting effects of the flame retardant mixture Firemaster® 550 in rats: an exploratory assessment. J Biochem Mol Tox 27(2):124–36, 10.1002/jbt.21439. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Preston EV, McClean MD, Claus Henn B, Stapleton HM, Braverman LE, Pearce EN, Makey CM, Webster TF [2017]. Associations Between Urinary Diphenyl Phosphate and Thyroid Function. Environ Intern. 101:158–164 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schreder ED, Uding N, La Guardia MJ [2016]. Inhalation a significant exposure route for chlorinated organophosphate flame retardants. Chemosphere 150:499–504, 10.1016/j.chemosphere.2015.11.084. [DOI] [PubMed] [Google Scholar]

- Stapleton HM, Eagle S, Sjodin A, Webster TF [2012]. Serum PBDEs in a North Carolina Toddler cohort: Associations with handwipes, house dust, and socioeconomic variables. Env Health Perspe 120(7):1049–1054, 10.1289/ehp.1104802 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stapleton HM, Misenheimer J, Hoffman K, Webster TF [2014]. Flame retardant associations between children’s handwipes and house dust. Chemosphere 116:54–60, 10.1016/j.chemosphere.2013.12.100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Statistica [2016]. Number of participants in gymnastics in the United States from 2006 to 2015, https://www.statista.com/statistics/191908/participants-in-gymnastics-in-the-us-since-2006/

- United Nations [2009]. Stockholm Convention on Persistent Organic Pollutants adoption of amendments A, B and C. http://chm.pops.int/Portals/0/download.aspx?d=UNEP-POPS-TREATY-NOTIF-CN524-2009.En.pdf

- van der Veen I, de Boer J [2012]. Phosphorus flame retardants: properties, production, environmental occurrence, toxicity and analysis. Chemosphere 88(10):1119–1153, 10.1016/j.chemosphere.2012.03.067. [DOI] [PubMed] [Google Scholar]

- Watkins DJ, McClean MD, Fraser AJ, Weinberg J, Stapleton HM, Sjödin A, Webster TF [2011]. Exposure to PBDEs in the office environment: evaluating the relationships between dust, handwipes, and serum. Environ Health Perspect 19(9):1247–1252, 10.1289/ehp.1003271 [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.