Abstract

Supply chain risk management is considered a topic of increasing interest worldwide and its focus has evolved over time. The recent coronavirus pandemic (known as COVID-19) has forced business to handle a new global crisis and rapidly adapt to unexpected challenges. In an attempt to help companies counteract the pandemic risk, as well as to fuel the scientific discussion about this topic, this paper proposes a systematic literature review on risk management and disruptions in the supply chain focusing on quantitative models and paying a particular attention to highlighting the potentials of the studies reviewed for being applied to counteract pandemic emergencies. An appropriate query was made on Scopus and returned, after a manual screening, a useful set of 99 papers that proposed models for supply chain risk management. The relevant aspects of pandemics risk management have been first identified and mapped; then, the studies reviewed have been analysed with the aim of evaluating their suitability of being applied to sanitary crises. In carrying out this review of the literature, the study moves from previous, more general, reviews about risk management and updates them, starting from the lines of research that have been covered in recent years and evaluating their consistency with future research directions emerging also as a consequence of the pandemic crisis. Gaps and limitations of the existing models are identified and future research directions for pandemics risk management are suggested.

Keywords: Systematic literature review, Risk management, Pandemics, Models, Supply chain

1. Introduction

In complex systems such as supply chains, where integrated flows of materials and information take place beyond the boundaries of individual companies, a substantial degree of inherent uncertainty cannot be avoided (see, e.g., Prater, 2005). Besides, that uncertainty may increase significantly when unexpected disruptions occur. Evidence of this is given by the recent (and still ongoing) crisis due to the coronavirus pandemic (known as COVID-19) which is expected to create an economic depression even more severe than the 2008 financial crisis (Jenny, 2020). This is already true today for certain economic sectors such as travel and tourism, food and agriculture, retail, healthcare systems and academic institutions (Shrestha et al., 2020).

More formally, when discussing risk, it is fundamental to distinguish between the so-called ripple effect and bullwhip effect (Dolgui, Ivanov, & Sokolov, 2018). While the latter deals with the operational and recurrent risks in a supply chain (e.g., demand fluctuation), the ripple effect deals with low-frequency/high-impact disruptions or exceptional risks, such as the risk of a pandemic outbreak. Dolgui et al. (2018) have also highlighted that the ripple effect impacts on the structural dynamics of the supply chain which, consequently, may require middle- and long-term recovery with high coordination efforts and investments.

It is therefore self-evident that modelling approaches for dealing with the risk of disruptions in supply chains are considered a topic of increasing relevance worldwide. In this respect, it is of certain interest to analyse how previous literature reviews about supply chain risk management (SCRM) and disruptions have evolved their arguments in the last years by shifting their focus from the definition and measurement of risk to the identification of the possible strategies which may allow supply chains to adapt themselves, restore acceptable levels of performance, handle uncertainty and, consequently, deal with the aforementioned ripple effect.

Going back over 10 years ago, Khan and Burnes (2007) have analysed the definition of risk by debating about its origin and evolution over time. Then, the authors describe the relationship between risk and uncertainty by adopting the following viewpoint: whilst uncertainty may not be measurable, it is nonetheless a key driver of risk which, instead, is both measurable and manageable. Lastly, the authors have emphasised the need for SCRM models, capable to incorporate risk management tools and techniques from other areas of research (e.g., from the financial area).

This difference between risk and uncertainty has been discussed also by Tang and Musa (2011). In this case, the authors propose a definition of risk based on two key elements: (i) it is related to events with small probability but that may occur abruptly; and (ii) it is associated with negative consequences. They also classify the main supply chain risks as follows: (i) the material flow risk, which originates into the stages of source, make and deliver; (ii) the financial flow risk, which involves improper investments and the inability to settle payments; (iii) the information flow risk, which is related to issues such as information accuracy and security. Once again, the suggested research guidelines include an integration of knowledge from multiple research domains.

Subsequently, the literature review by Durach, Wieland, and Machuca (2015) has narrowed down the perspective by focussing on the concept of supply chain robustness, which the authors define as the ability of a supply chain to resist or avoid change. In the same year, other reviews (by Fahimnia, Tang, Davarzani, & Sarkis, 2015, and Heckmann, Comes, & Nickel, 2015) have broadened the debate about the taxonomies and perspectives within the context of SCRM, thus stressing the lack of clear definitions in the literature. Specifically, the interesting work by Heckmann et al. (2015) has provided a comprehensive definition of supply chain risk as follows: “supply chain risk is the potential loss for a supply chain in terms of its target values of efficiency and effectiveness evoked by uncertain developments of supply chain characteristics whose changes were caused by the occurrence of triggering-events”. Those triggering-events can be referred to as different synonyms such as disturbances, disasters, hazards, crises and, often used in the literature, disruptions. In general, the more susceptible to risk, the more vulnerable a supply chain is. The same authors have also provided a clear definition of supply chain resilience, that is the “supply chain’s ability to return to its original or move to a new, more desirable state after being disturbed”. In other words, according to the authors, a resilient supply chain may also improve its performance (reaching a “more desirable state”) after the occurrence of undesired triggering-events.

A more acute focus on recovery considerations can be found in Ivanov, Dolgui, Sokolov, and Ivanova (2017). The authors have discussed two approaches that can be adopted to protect supply chains against disruptions, namely the proactive approach, which aims at creating certain protections without recovery considerations, and the reactive approach, which aims at adjusting the processes and structures of a supply chain after disruptions have occurred. In their proposed research agenda, the authors highlight the need for integrating operability objectives and new performance indicators (e.g., supply chain resilience) and investigating the dynamic behaviour of the supply chain. A focus on the dynamic risk behaviour of a supply chain can also be found in the review by Bugert and Lasch (2018), where the following formal definition of a supply chain disruption model is presented: such a model “represents a supply chain and all relevant potential triggering events which can potentially impede the supply chain from achieving its operational goals and/or jeopardize the existence of one or more supply chain entities and includes all necessary static and dynamic features to describe potential losses for all supply chain partners in terms of the supply chain’s target values in order to support the coordinated approach amongst supply chain entities to reduce supply chain vulnerability and to increase the supply chain’s predicted ability to return to a stable state after experiencing disruptions in the real system”.

More recently, Hosseini, Ivanov, and Dolgui (2019) have proposed an interesting review of quantitative methods for supply chain resilience analysis based on three lines of defence. The first line of defence is called absorptive capacity and acts prior to a disruption occurring. The second line of defence is the adaptive capacity and refers to the capability of the supply chain to overcome disruptions by implementing nonstandard operating practices without any recovery activities. The third line of defence is the restorative capacity, reflecting the ability of a system to be restored quickly and efficiently when the other lines of defence fail. Based on these lines of defence, the authors propose a new definition of supply chain resilience as follows: the “capability to utilize the absorptive capacity of supply chain entities to repulse and withstand the impacts of perturbations, to minimize the consequences of disruptions and their propagation by utilizing adaptive capacity and to recover performance level to normal operations in a cost-efficient manner using restorative capacity when absorptive and adaptive capacities are not sufficient.” Finally, the authors recommend future research directions on both the methodology side, with particular reference to multi-objective stochastic models, and the subject side, with particular reference to the need of including environmental and social objectives in the SCRM, as well as the opportunity of achieving resilience through Industry 4.0 and digital technology tools. The relationship between Big Data, Industry 4.0 and SCRM, along with the need for a more holistic vision has also been highlighted by Fagundes, Teles, de Melo, and Freires (2020), who have presented one of the most recent reviews on decision-making models and support systems for supply chain risk.

For the sake of this overview, it can also be noted that recent reviews have been conducted about some specific aspects of risk management in supply chains. Those reviews can be categorised as follows: (i) reviews on specific decision problems/risk categories; (ii) reviews on specific industrial sectors; (iii) reviews on specific modelling approaches and techniques. As regards the first group of reviews, Hamdi, Ghorbel, Masmoudi, and Dupont (2018) have dealt with the supplier selection problem under SCRM. Rebs, Brandenburg, Seuring, and Stohler (2018) have evaluated the stakeholder’s influence on sustainable supply chain management by taking into account economic, environmental and social risks. Colicchia, Creazza, Noè, and Strozzi (2019) consider the exposure of supply chains to the so-called “information risks”, such as intentional or non-intentional leakage of information and attacks by hackers. Examples of studies belonging to the second category of reviews are those by Behzadi, O’Sullivan, Olsen, and Zhang (2018), who have dealt with agricultural supply chains, and by Al-Haidous and Al-Ansari (2020), who have focused on liquefied natural gas supply chains. As regard the last category, the number of reviews on specific modelling approaches and techniques is quite limited. Some examples are the works of Snyder et al. (2016), who have reviewed the Operations Research/Management Science (OR/MS) literature on supply chain disruptions, and Rebs, Brandenburg, and Seuring (2019) who have discussed the recent developments in System Dynamics modelling for supply chain management.

The literature reviews discussed above are summarized in Table 1 , where some relevant pieces of information are also shown, namely: the article citation; the indication whether the article focuses on a specific industrial sector or not; the type of reviewed models (quantitative, qualitative or both); the search database used by the authors; the review timespan; the number of works reviewed; the review methodology (LR = Literature Review; SLR = Systematic Literature Review; BNA = Bibliometric/citation Network Analysis); and the suggested research directions. These latter have been divided into four main issues that have emerged as relevant from this analysis: (i) the evaluation of Industry 4.0/digital tools, (ii) the inclusion of environmental/social risks, (iii) the need for multi-criteria (and multi-disciplinary) approaches, (iv) the need for empirical applications and model validation techniques.

Table 1.

Summary of the previous reviews on risk management.

| Article citation | Reviewed models | Search database | Author Keywords | Methodology | Specific industrial sector | Timespan of the review | Number of studies reviewed | Suggested future research directions |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Industry 4.0/digital tools | Environmental/social risks | Multi-criteria approaches | Empirical applications | ||||||||

| Fagundes et al. (2020) | Quantitative | Scopus | Bibliometrics; Multicriteria decision; Risk model; Stochastic and computational model | SLR, BNA | 2001–2018 | 350 | X | X | X | X | |

| Al-Haidous and Al-Ansari (2020) | Quantitative | Multiple scientific databases | Closed loop; Forward loop; LNG; Optimisation; Resilience | SLR | Oil and gas | 2000–2019 | 44 | X | X | ||

| Hosseini et al. (2019) | Quantitative | Google Scholar and Scopus | Capacity resilience; Digital supply chain; Disruption risk; Resilience supplier; Resilient supply chain; Review; Ripple effect; Supply chain resilience; Supply disruptions | SLR; BNA | 2002–2017 | 168 | X | X | X | ||

| Rebs et al. (2019) | Quantitative | Web of Science | Conceptual framework; Literature review; Risk management; Stakeholder influences; Sustainable supply chain management; System dynamics | SLR; BNA | 1998–2017 | 102 | X | X | |||

| Colicchia et al. (2019) | Quantitative/Qualitative | Scopus | Resilience; Risk management; Supply chain disruptions; Supply chain vulnerability; Supply-chain management; Systematic literature review | SLR; BNA | 1998–2017 | 309 | X | X | |||

| Behzadi et al. (2018) | Quantitative | Scopus | Agribusiness supply chain; Resilient; Risk management; Robust | SLR | Agriculture | 1993–2017 | 42 | X | X | ||

| Rebs et al. (2018) | Quantitative/Qualitative | Web of Science | Conceptual frameworks; Empirical studies; Formal models; Literature review; Risk management; Stakeholder influences; Sustainable supply chain management | SLR; BNA | 1994–2014 | 90 | X | X | |||

| Hamdi et al. (2018) | Quantitative/Qualitative | Multiple scientific databases | Hybrid approach; Optimization of a supply portfolio; Qualitative approaches; Quantitative approaches; Simulation approach; SCRM | SLR | 2003–2014 | 124 | X | ||||

| Dolgui et al. (2018) | Quantitative | Not specified | supply chain design; supply chain dynamics; supply chain engineering; supply chain resilience; SCRMt | LR | 2005–2017 | Not specified | X | X | X | X | |

| Bugert and Lasch (2018) | Quantitative | Multiple scientific databases | Modeling; Risk analysis; Risk management; Simulation; Supply chain disruption; SCRM | SLR | 2001–2018 | 57 | X | X | |||

| Ivanov et al. (2017) | Quantitative | Not specified | supply chain design; supply chain dynamics; supply chain engineering; supply chain resilience; SCRM | LR | 2001–2017 | Not specified | X | ||||

| Snyder et al. (2016) | Quantitative | Not specified | Not specified | LR | 1979–2015 | 180 | X | ||||

| Heckmann et al. (2015) | Quantitative/Qualitative | Not specified | Complexity; Resilience; Risk definition; Supply chain management; Uncertainty; Vulnerability | LR | 1987–2014 | Not specified | X | ||||

| Fahimnia et al. (2015) | Quantitative | Scopus | Bibliometrics and network analysis; Quantitative Model; Review; Supply Chain Risk; Uncertainty | SLR; BNA | 1978–2013 | 1108 | X | X | |||

| Durach et al. (2015) | Quantitative/Qualitative | Multiple scientific databases | Antecedents; Dimensions; Supply chain robustness; Systematic literature review | SLR | 2002–2013 | 94 | X | ||||

| Tang et al. (2011) | Quantitative/Qualitative | Web of Science | Citation/co-citation analysis; Risk management; Supply chain | SLR; BNA | 1995–2009 | 138 | X | ||||

| Khan and Burnes (2007) | Quantitative/Qualitative | Not specified | Risk analysis; Risk management; Supply chain management | LR | 1921–2005 | Not specified | X | X | |||

LR = Literature Review; SLR = Systematic Literature Review; BNA = Bibliometric/citation Network Analysis.

Moving from previously published reviews, this paper proposes an updated analysis of the literature on risk management and disruptions in the supply chain, with a particular focus on quantitative models and on the management of a specific risk, such as that of pandemic emergencies. The chosen research methodology is therefore the systematic literature review. The aim of this paper is twofold. First, this study looks at the lines of the research on risk management that have been covered in recent years and evaluates their consistency with the future research directions suggested in literature. Second, this paper has a key distinguishing feature compared to previously published reviews in that it evaluates risk management studies trying to highlight their suitability for being applied to the timely issue of pandemic emergencies. Pandemic crises are a very recent topic, and as such, it is hard to believe that specific models or tools are already available for counteracting this emergency. In light of this consideration, this review makes an attempt to identify the models published in the past literature that, although not focusing exactly on pandemic emergencies, can nonetheless be applied to these situations. The research question of this study therefore refers to the applicability of these models to pandemic emergencies. To answer this question, a comprehensive set of detailed pieces of information are recorded for each study reviewed and a detailed classification scheme is proposed. In reviewing the studies, some specific classification fields will be adopted to expressly evaluate the usability of the available models for managing pandemic emergencies.

The remainder of the paper is organised as follows. After this introduction, Section 2 details the methodological approach followed to create the sample of papers included in the review, together with the classification scheme proposed for the analysis of these papers. Section 3 details the results of the review, which consist in some descriptive statistics followed by a detailed analysis of the studies reviewed, ending with a discussion of their possible usability for pandemic emergencies. Section 4 discusses the implications and limitations of this study and outlines future research directions.

2. Methodology

2.1. Sample construction

A systematic literature review (Tranfield, Denyer, & Smart, 2003) is a two-step approach: the first step is the definition of the inclusion criteria, which should enable the correct selection of pertinent and relevant studies to be reviewed; the second step is the definition of the strategy for locating and selecting the studies (Alderson, Green, & Higgins, 2004). Compared to a traditional review, this approach is more structured and, most importantly, replicable.

As far as the first step is concerned, in this paper we have only included studies:

-

1.

written in English and published in peer-reviewed international journals;

-

2.

expressly focused on proposing technical approaches to risk management in the supply chain.

Looking at the second step, studies were found by carrying out a computerized search using the Scopus database (https://www.scopus.com/), which is one of the largest available databases of scientific publications and is expected to cover almost the whole amount of papers relating to the subject under investigation.

To comply with inclusion criterion #2, an appropriate set of terms relating to supply chain, risk, risk management, disruptions and quantitative models was preliminarily identified. In particular, three groups of keywords were combined for making the search:

-

•

Group 1 included the terms “supply chain” and “logistics”;

-

•

Group 2 included the terms “risk management”, “disruption” and “pandemic”;

-

•

Group 3 consist of the term “quantitative”, which, in line with a previous study (Bugert & Lasch, 2018), was used to expressively focus on technical approaches and models.

A single query was made in September 2020 in the Scopus database by combining the terms of the same group with the OR operator and the different groups with the AND operator. These terms were searcher for in the article title, abstract or keywords of the paper, to ensure that the study focused on the chosen theme; the resulting structure of the query was: TITLE-ABS-KEY (“supply chain” OR “logistics”) AND TITLE-ABS-KEY (“risk management” OR “disruption” OR “pandemic”) AND TITLE-ABS-KEY (“quantitative”).

Moreover, in line with inclusion criterion #1, the query was limited to journal papers type “article” (excluding other forms of publication), whose language is “English”. Review studies were not retained at this stage, as they are unlikely to detail models for risk management, resulting in the impossibility to classify them following the scheme proposed in Section 2.2. Nonetheless, these studies were examined as well, and the most relevant ones were used for delineating the available literature reviews about risk management in the supply chain (cf. Section 1). As far as the timespan is concerned, it was set from 2002 to 2020. Year 2021 was excluded for obvious reasons, as at the time of the query, only a small number of papers relating to 2021 was available on Scopus; hence, the results would not have been representative. Year 2002 was instead the year of the SARS pandemic, which is acknowledged as the first pandemic emergency of the 21st century (Cherry & Krogstad, 2004). The selected timespan is thus expected to capture studies dealing with pandemic emergencies, in line with the scope of this review.

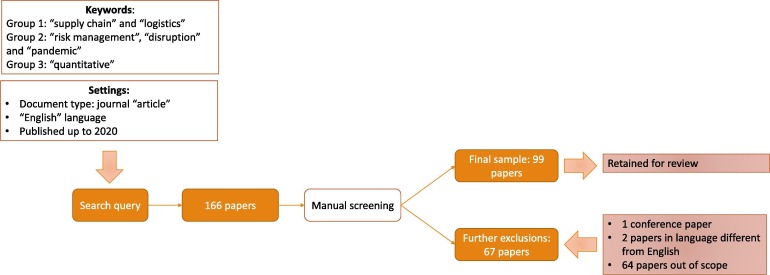

With these settings, the query returned a total of 166 papers, that were retrieved and screened by reading the full document, to ensure that they comply with the inclusion criteria. After reading, some papers were excluded from the original sample because of the following reasons:

-

•

Despite the query settings, one paper was actually published on conference proceedings, probably because of a wrong classification on Scopus, and two papers were not written in English;

-

•

64 papers were excluded because they were out of scope for the present review. Examples of these papers are studies whose central topic was different from risk management in the supply chain, or that do not expressively focus on disruptions or that targeted research fields very different from the supply chain context (e.g., the medical, biological or chemical areas). Similarly, purely conceptual papers, which although discussing the topic of risk, lack the presentation of any risk model, were excluded from the analysis as well.

The screening described above led, overall, to the exclusion of 67 papers, resulting in a final sample of 99 papers. A scheme detailing the various steps followed to identify the sample of papers is shown in Fig. 1 .

Fig. 1.

Steps for the sample creation.

2.2. Papers classification

The 99 papers belonging to the final sample were all research papers, i.e. papers in which the authors describe the results of their own scientific activities. By analysing their specific contents, these papers were further classified into 2 macro-categories, depending on the type of research presented, as follows:

quantitative papers (48): these papers propose, develop or test quantitative models for risk management in the supply chain. According with definitions available in literature (e.g., Bondavalli, Favilla, & Bodini, 2009), by quantitative model we mean a theoretical and formal description of a system or process translated into the language of mathematics;

quali-quantitative papers (51): papers that did not provide a fully quantitative approach were labelled as “quali-quantitative papers”. In these studies, the problem faced is described in a more abstract form, focusing on causality but not providing mathematical equations (Yan, Zhou, Wen, & Chai, 2013). Nonetheless, because of the usage of “quantitative” as a search keyword, these papers own some quantitative aspects, but the authors applied mainly transdisciplinary or mixed research methods, including both quantitative approaches and qualitative ones (Bell, 2007).

2.2.1. Classification fields

For all the papers, an articulated set of data was collected by analysing the full documents. The full list of the key data collected is proposed in Table 2 , together with a description of the relevant classification options. Some data, of descriptive nature, are common across the two categories of papers; at the same time, however, because of the intrinsic difference between quali-quantitative and quantitative papers, additional data are specific to the two categories; the same holds true for the analyses made on the documents. The list of common data includes:

-

1.

Paper’s metadata, i.e. title, authors, journal, year of publication, volume, number and pages;

-

2.

Country, i.e. the nationality of the study. To determine it, we checked expressively the location in which the authors carried out the study or the application of their model as described in the full paper. This logic was preferred compared to more traditional approaches (e.g. determining the nationality of the study looking at the affiliation of the first author – see e.g. Gao, Xu, Ruan, & Lu, 2017), because of two reasons. First, it simultaneously allows for checking the existence of an application for the proposed model, which is relevant for establishing if the model has been tested in a real case. Second, in some cases the studies have been found to span across more countries; this aspect could not be captured if looking at the nationality of a single author only;

-

3.

Main topic, which reflects the paper macro-theme. Relating classification options were derived from the detailed read of the sample of papers;

-

4.

Industry context, i.e. the industry field in which the research has been carried out;

-

5.

Reference to Industry 4.0, sustainability or sanitary emergency management. As far as the former aspects are concerned, recent studies have shown that Industry 4.0 technologies have potential to enhance risk management (e.g., Ivanov & Dolgui, 2020). Similarly, sustainability, besides being a widely debated issue in literature, has been found to have relationships with risk management in supply chains (e.g., Hallikas, Lintukangas, & Kähkönen, 2020). The reference to the management of sanitary emergencies was added with the primary aim to identify models that could be applied to crisis situations such as those involved by the COVID-19 pandemics, although not explicitly referring to this recent sanitary emergency. These classification fields were simply filled with Y/N, to keep track of possible relationships of the paper to the three areas mentioned. The considerations proposed in Table 2 formed the basis for the classification of the papers according to these areas;

-

6.

Disruption type – level 1. This field details the macro-categorization of supply chain disruptions dealt with in the paper as proposed by Christopher and Peck (2004) or a combination of them;

-

7.

Disruption type – level 2. For disruptions classified as external to the company, internal to the supply chain network or external to the network, a second-level classification is provided, in line with Christopher and Peck, 2004, World Economic Forum, 2021 respectively;

-

8.

Approach type. Models were labelled as reactive or proactive depending on their capability of eliminating disruptions before they have a chance to appear or of responding to events after they have happened (Ivanov et al., 2017);

-

9.

Model type. This field is used to detail the specific type of model developed in the study. Classification options different depending on the category of paper, i.e., quali-quantitative vs. quantitative, as described in Table 2.

Table 2.

Classification scheme for quali-quantitative and quantitative papers.

| Paper type |

Classification field | Classification options | |

|---|---|---|---|

| Quantitative | Quali-quantitative | ||

| X | X | Main topic |

|

| X | X | Country |

|

| X | X | Reference to Industry 4.0 |

|

| X | X | Reference to sustainability |

|

| X | X | Reference to pandemics risk management |

|

| X | X | Disruption type – level 1 |

|

| X | X | Disruption type – level 2 | For disruption type “external to the company but internal to the supply chain network”:

|

| X | X | Approach type |

|

| X | X | Model validation |

|

| X | Model type – quantitative |

|

|

| X | Model type - quali-quantitative |

|

|

| X | Model goal |

|

|

For quantitative papers, the following specific data were also collected:

-

1.

Model goal, i.e., the goal(s) of the objective function or in general of the approach/model developed in the study;

-

2.

Model validation, which is a Y/N field indicating whether the approach used by the authors has also been validated, so that it can be regarded as an accurate representation of the system under study. The validation options proposed by Kleijnen (1995) were taken as a guideline for identifying the possible ways in which a model could have been validated by the authors.

As a general rule, papers were classified using just one option per classification field, assigning them to the category that best reflects the contents of the document; the model goal(s) represent an exception in this regard, as more than one objective could actually be included in the model and all objectives were taken into account in the classification.

2.2.2. Relevant aspects for pandemics risk management

The classification fields highlighted in bold in Table 2 have been introduced to expressively judge the suitability of the risk management models to be used in the case of pandemic emergencies, in line with the scope of the paper. These fields are:

-

(1)

Reference to pandemics risk management → Y: it is self-evident that if a paper has been judged positively as far as this point, the model proposed has potentials to be applied to pandemics, although not necessarily targeting this specific context;

-

(2)

Disruption type – level 1 → External to the network: pandemic emergencies are disruptions that fall into this classification option, although external disruptions include various types of disturbances. Because of the similarities of these disruptions, it is possible that a model developed for external disruptions could also be adapted to the case of pandemic emergencies;

-

(3)

Approach type → Reactive: it is hard to think that the occurrence of pandemics can be prevented, meaning that proactive models, intended to avoid or minimise the occurrence of risks, are probably not suitable to be applied to these situations. Rather, it is expected that models that can be adapted to the case of pandemic situations will fall into the “reactive” category;

-

(4)

Main topic → resilience or Model goal → resilience: the models that have assessed the resilience of a system, either in general terms or as a goal in an optimization model, are likely to fit the case of pandemic emergencies. Indeed, sanitary emergencies cannot be forecasted or avoided, and therefore, building a resilient system is probably the most effective way to counteract them.

3. Results

3.1. Descriptive statistics

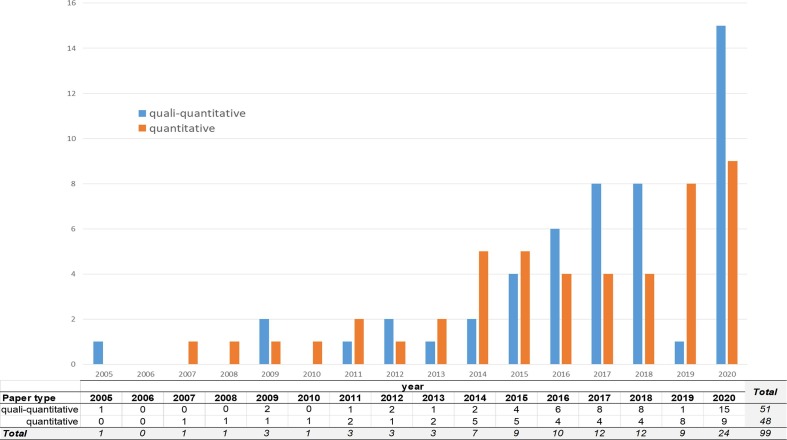

The trend in time of the sample of papers reviewed is shown in Fig. 2 . As this figure shows, the timespan of the useful publications retrieved ranges from 2005 to 2020. In the first years, however, the number of papers published yearly about risk management in the supply chain was quite limited, which is also in line with the fact that the pioneer studies in the field (e.g., Christopher & Peck, 2004) appeared at the beginning of 2000. A significant increase in the number of papers per year is instead observed starting from 2014 and, since then, the number of publications has always increased in time. The highest number of papers was registered in 2020, which is the possible consequence of the significant impact the COVID-19 pandemics had on supply chains in all their processes (Shokrani, Loukaides, Elias, & Lunt, 2020).

Fig. 2.

Trends of the number of papers in time.

As far as the publication outlet is concerned, the papers reviewed were published in 62 different journals; this denotes that the research field is quite dispersed across different publication outlets and is in line with the fact that risk and resilience are multi-facets and trans-disciplinary topics. Risk, for example, can encompass financial, business or technical aspects, and similarly, resilience is a multi-facet property which includes a number of aspects relating to both internal supply chain processes and external environment (Ivanov & Schönberger, 2019). The variety of aspects involves a wide range of possible journals in which topics relating to risk management can be published. Table 3 lists the 16 journals that published at least two papers belonging to our sample, to provide an idea of the top-journals in the field of risk management. Overall, these journals published 53 out of 99 papers in the sample (53.6%). Interestingly, ten of these journals are indexed in technical subject categories of Scopus, such as either Mathematics or Engineering; this is consonant with the intended aim of this review, which focuses on technical approaches to risk management.

Table 3.

Top-journals.

|

Paper type |

|||

|---|---|---|---|

| Journal | quali-quantitative | quantitative | Total |

| International Journal of Production Research | 1 | 6 | 7 |

| Supply Chain Management | 4 | 3 | 7 |

| International Journal of Production Economics | 1 | 5 | 6 |

| Journal of Cleaner Production | 4 | 1 | 5 |

| Industrial Management and Data Systems | 3 | 1 | 4 |

| International Journal of Management Science and Engineering Management | 2 | 1 | 3 |

| International Journal of Supply Chain Management | 3 | 3 | |

| Reliability Engineering and System Safety | 2 | 2 | |

| Annals of Operations Research | 2 | 2 | |

| International Journal of Physical Distribution and Logistics Management | 2 | 2 | |

| European Journal of Operational Research | 2 | 2 | |

| Journal of Industrial Engineering and Management | 1 | 1 | 2 |

| International Journal of Logistics Management | 1 | 1 | 2 |

| Soft Computing | 2 | 2 | |

| International Journal of Operations and Production Management | 2 | 2 | |

| Transportation Research Part E: Logistics and Transportation Review | 2 | 2 | |

3.2. Common classification fields

3.2.1. Main topics

The papers reviewed cover the main topics proposed in Table 4 . In line with the keywords used in the Scopus query, most of the papers (both quantitative and quali-quantitative) focus on risk as the main theme of analysis (55 papers, 56.6% of the studies reviewed). The second most relevant macro-theme is resilience, which is dealt with in 34 papers (34.3% of the sample); it is interesting to note that approximately two thirds of these papers are quantitative, while one third is quali-quantitative. For risk instead, the majority of the papers is of quali-quantitative nature. The last two macro-themes found, i.e., agility and economics, are dealt with in a significantly lower number of papers (7 and 3 respectively). Looking at quali-quantitative studies, papers relating to agility encompass questionnaire surveys (Gunessee, Subramanian, & Ning, 2018), empirical works (L'Hermitte, Tatham, Brooks, & Bowles, 2016) and structural equation models (Ahmed & Rashdi, 2020); quantitative approaches, instead, include analytic models (Xu & Nozick, 2009) and metaheuristic/heuristic models (Chen & Zhang, 2010). Papers focusing the economic aspect of risk deal typically with the post-disruption economic recovery of systems, either caused by a natural disaster (Zeng, Guan, Steenge, Xia, & Mendoza-Tinoco, 2019) or by the recent COVID-19 emergency (Lutfi et al., 2020, Min et al., 2020).

Table 4.

Paper type vs. macro-themes.

|

Paper type |

|||

|---|---|---|---|

| Main topic | quantitative | quali-quantitative | Total |

| Agility | 4 | 3 | 7 |

| Economics | 1 | 2 | 3 |

| Resilience | 21 | 13 | 34 |

| Risk | 22 | 33 | 55 |

| Total | 48 | 51 | 99 |

3.2.2. Disruption type

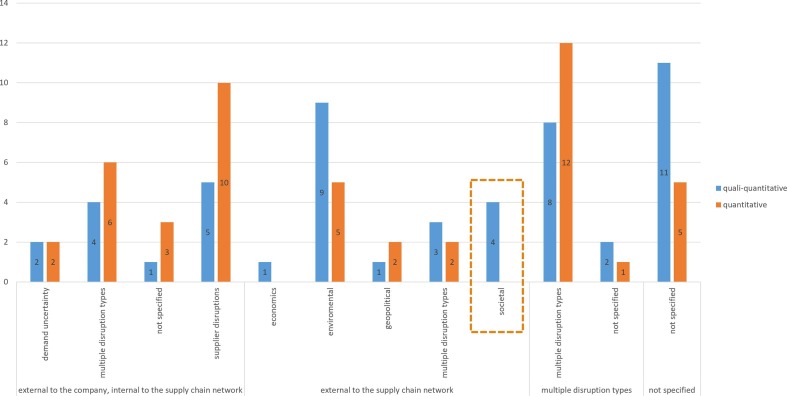

As far as the disruption types-level 1 (Table 5 ), 16 papers provided a generic reference to the theme of disruption management but did not expressively indicate the specific disruption taken into account in the study, which prevents the possibility to make a punctual classification. The remaining papers have mainly evaluated disruptions which are external to the company, either internal to the network (33 papers, 32.3% of the sample) or external to the network (27 papers, 27.3% of the sample). A quite relevant number of papers (23) has taken into account multiple disruption types. It is also interesting to note that no papers have dealt with disruptions internal to the company; this is a reasonable consequence of search terms used in the query and denotes that in general the sample of papers correctly focuses on risk in the whole supply chain.

Table 5.

Paper type vs. disruption types – level 1.

|

Paper type |

|||

|---|---|---|---|

| Disruption type | Quantitative | quali-quantitative | Total |

| external to the company, internal to the supply chain network | 21 | 12 | 33 |

| external to the supply chain network | 9 | 18 | 27 |

| multiple disruption types | 13 | 10 | 23 |

| not specified | 5 | 11 | 16 |

| Total | 48 | 51 | 99 |

Fig. 3 shows the second disruption level, thus detailing the previous classification. Looking at disruptions external to the company, both quali-quantitative and quantitative papers mainly focus on supplier disruptions (41% and 47% respectively), followed by multiple disruption types (33% and 28% respectively). Looking instead at the second classification level, many authors have extended the analysis to more than one disruption: 15 quali-quantitative papers and 20 quantitative papers present multi-disruption models. Focusing on disruption external to the network, many works deal with environmental disasters (50% and 55% respectively), while other categories have received less attention. It is interesting to underline that among quali-qualitative papers, 4 studies fall into the “societal” risk category, which according to World Economic Forum (2021) includes expressly infectious diseases. Instead, no quantitative papers directly focus on societal risks.

Fig. 3.

Paper type vs. disruption types – levels 1 and 2.

3.2.3. Approach type

The approach used by the authors when dealing with risk can be either proactive, reactive or mixed proactive/reactive (Ivanov et al., 2017). For 19 papers reviewed, the exact approach could not be determined (Table 6 ); this is in particular the case for quali-quantitative studies proposing either questionnaire surveys or structural equations models, whose main goal falls outside the development of specific approaches to counteract risk in the supply chain. The remaining papers are almost equally shared among reactive and proactive approaches to risk management (39 vs. 37 papers respectively). Ivanov et al. (2017) have stressed the ever-increasing importance of proactive approaches as resulting from their analysis of the recent literature, for managing the ripple effect of disruptions and effectively designing a resilient system. According to this finding, in our sample the papers dealing with proactive approaches were in fact all written in the last years (from 2012 to 2020).

Table 6.

Paper type vs. approach type.

|

Paper type |

|||

|---|---|---|---|

| Approach type | quantitative | quali-quantitative | Total |

| not specified | 3 | 16 | 19 |

| post-disruption model (reactive) | 28 | 11 | 39 |

| pre/post-disruption model (mixed) | 3 | 1 | 4 |

| pre-disruption model (proactive) | 14 | 23 | 37 |

| Total | 48 | 51 | 99 |

What is most important to observe is that reactive models are mainly quantitative in nature (28 papers out of 39), while proactive models are mainly quali-quantitative (23 papers out of 37). A possible justification for this result is that proactive models, being more recent than reactive ones, have less observations and/or data available, which limits the possibility of modelling the scenario in analytic terms, as instead required in quantitative models.

Further considerations can be drawn from the combination of the approach type and the macro-theme of the study (Table 7 ). As expected, most of the models focus on resilience and risk as the main topics compared to the remaining macro-themes. Moreover, it is interesting to highlight a possible relationship between the approach type (proactive vs. reactive) and the macro-theme (resilience vs. risk); indeed, reactive models have been mainly proposed when dealing with resilience (18 vs. 15 studies), while proactive models have mainly focused on risk (23 vs. 12 studies). A possible explanation for this outcome is that a proactive model is intended to avoid or minimise the occurrence of risks, which justifies the focus on this specific macro-theme, together with the fact that, when successfully counteracting the occurrence of risks, the whole system will need to be less resilient.

Table 7.

Approach type vs. macro-theme.

|

Macro-theme |

|||||

|---|---|---|---|---|---|

| Approach type | agility | economics | resilience | risk | Total |

| not specified | 2 | 3 | 14 | 19 | |

| post-disruption model (reactive) | 5 | 1 | 18 | 15 | 39 |

| pre/post-disruption model (mixed) | 1 | 3 | 4 | ||

| pre-disruption model (proactive) | 2 | 12 | 23 | 37 | |

| Total | 7 | 3 | 34 | 55 | 99 |

3.2.4. Country

For the sake of this paper, “country” denotes the geographical area in which the case study (if any) was conducted. In Table 8 the papers describing at least one real-world application (66 papers out of 99) were grouped into the “single country” application category if they targeted a single State/Nation, or into the “cross-country” application category if the study spans across more than one State/Nation. The remaining papers did not present a real-world case study; they were therefore grouped into two sets, i.e. works which proposed an application in the form of a numerical example, but without a geographic location, and papers that did not provide any kind of application.

Table 8.

Paper type vs. country.

| Country | Quantitative | Quali-quantitative | Total |

|---|---|---|---|

| Single country | 34 | 18 | 52 |

| Cross-country | 6 | 8 | 14 |

| No application | 8 | 8 | 16 |

| Numerical example | 3 | 14 | 17 |

| Total | 51 | 48 | 99 |

By correlating this classification with the original distinction between quantitative and quali-quantitative works, it can be observed that the majority of quali-quantitative papers explicitly refer to real national or international supply chains (18 and 8 papers out of 48, 54.2%). On the other hand, a quite relevant number of quantitative papers did not provide any application or just presented theoretical numerical examples to validate the proposed model (11 studies out of 48, ≈23%). This is probably due to the fact that compared to quali-quantitative approaches, quantitative models need a greater effort for assessing, analysing and interpreting the main assumptions and input data, before being applicable to real-world problems. On the contrary, quali-quantitative studies are mainly focused on empirical data and real case studies (surveys, interviews or questionnaires), typically carried out in one specific country.

Surprisingly, a limited number of papers (14 papers out of 99, including both quantitative and quali-quantitative studies) proposes case studies on international supply chains, resulting in a “cross-country” application. This result emphasizes the critical (and not trivial) role of international collaborations, standards and assessments, along with the need for encouraging applied research in this field. Indeed, the potential worldwide impact of today’s supply chain disruptions, though originated in regional territories, has become more and more evident throughout the evolution of the Covid-19 pandemic crisis.

If limiting the analysis to the 52 papers with a single country application, the geographical distribution of the resulting countries is shown in Fig. 4 . As this figure shows, the most prolific country appears to be China which slightly exceeds the number of case studies produced in Europe (11 case studies) and in the US (7 case studies). In general, a remarkable attention to supply chain disruptions is evident in areas affected by environmental disruptive events: the Eastern Hemisphere with earthquake, flood or tsunami, and the United states affected by tornados and hurricanes.

Fig. 4.

Geographical distribution of the studies with a single country application.

3.3. Analysis of quali-quantitative papers

3.3.1. Model type

Quali-quantitative papers generally have carried out a risk or resilience assessment using typical qualitative approaches; examples of these approaches are empirical studies supported by statistical analyses, structural equation models (SMEs) or multi-criteria decision making (MCDM) models (Table 9 ).

Table 9.

Classification of the quali-quantitative papers as a function of the model type.

| Model type – quali-quantitative | Number of papers |

|---|---|

| Empirical | 18 |

| Multi-criteria decision making (MCDM) | 13 |

| Structural equation modelling (SME) | 12 |

| Fuzzy | 4 |

| Probabilistic | 4 |

| Total | 51 |

The less frequently used approaches are probabilistic models and fuzzy models. The former models include 4 out of 51 studies (7.8% of the sample) and encompass studies based on Bayesian theory used for addressing risk (Abolghasemi, Khodakarami, & Tehranifard, 2015) or resilience management (Yodo & Wang, 2016) by studying relationships among different variables or nodes of the network. Fuzzy models (4 out of 51 studies, 7.8%) instead, have been mainly used for risk identification and assessment; some of them have also included aspects related to Industry 4.0 technologies, with the final aim of ranking risk factors (Dai & Liu, 2020), or of ranking products based on their associated risk (Aqlan, 2016). Again, among fuzzy studies, Niknejad and Petrovic (2016) have tested the propagation of risk in networks using a dynamic fuzzy approach.

Many papers (13 out of 51 studies, 25.4% of the sample) have proposed MCDM approaches for selecting suppliers in a disruptive environment. In such cases, the typical outcome returned by the model is a final suppliers’ ranking, which can be obtained on the basis of their risk profile (Khemiri, Elbedoui-Maktouf, Grabot, & Zouari, 2017), of risk and sustainability (Zimmer, Fröhling, Breun, & Schultmann, 2017), of the resilience profile (Haldar et al., 2012, Paul, 2015), or of the resilience and green aspects (Rajesh & Ravi, 2015). Other MCDM studies have instead applied multi-criteria analysis for risk evaluation and disruption classification, either by using single techniques (e.g., AHP - Ganguly & Guin, 2013) or combining different techniques, such as AHP and TOPSIS (Rathore, Thakkar, & Jha, 2017), or fuzzy ANP and DEMATEL (Ngan et al., 2020).

Two further wide groups of papers include studies that make use of empirical data coupled with statistical analyses to design the model (Kumar et al., 2018) (18 out of 51 papers, 35.3% of the sample), or coupled with SEM (12 out of 51 papers, 23.5%), which has been implemented for studying risk, resilience but also agility and sustainability. In particular, Zineb, Brahim, and Houdaifa (2017) have examined the interrelationships between supply chain resilience and flexibility with redundancy and collaboration. Some authors have dealt with modelling supply disruption risk using SME, studying risk perception (Oliveira & Handfield, 2017) or risk propagation (Zhang, Chen, & Fang, 2018). The remaining empirical studies include post-disruption analysis on real disruptive events (Hittle & Leonard, 2011) or investigation on SCRM practices (Trkman, De Oliveira, & McCormack, 2016). Such papers mainly consist in surveys involving various respondents (Wang, Jie, & Abareshi, 2017), or in interviews with a limited sample of respondents (Durach, Glasen, & Straube, 2017), or in multiple case studies (Kahiluoto, Mäkinen, & Kaseva, 2020).

3.3.2. Relevance to industry 4.0 and sustainability

As far as the disruption type is concerned, quali-quantitative papers can be classified considering various levels of detail; Table 10 shows the disruption type-level 1 combined with the relevance to some emerging topics of risk management.

Table 10.

Disruption types vs. relevance to other topics for quali-quantitative papers.

|

Relevance to other topics |

|||

|---|---|---|---|

| Disruption type | Sustainability | Industry 4.0 | Total |

| external to the company, internal to the supply chain network | 4 | 1 | 5 |

| external to the supply chain network | 3 | 4 | 7 |

| multiple disruption types | 2 | 5 | 7 |

| not specified | 1 | 2 | 3 |

| Total | 10 | 12 | 22 |

A number of authors have analysed disruptions that arise internally to the supply chain but that are external to the company, including green considerations. In particular, these authors have faced the issues of supplier disruptions (Mohammed, 2020) or demand uncertainty (Hernandez and Haddud, 2018, Sato et al., 2020). Multiple SC disruptions have been considered by Hallikas et al. (2020) to study the relationship between purchasing sustainable practice and SCRM. Other authors have discussed the impact of natural disaster and the effect of different moderating factors (Ali & Gölgeci, 2020).

Among the papers that discuss Industry 4.0 and the general concept of risk, Saleem (2020) tested the potential of Industry 4.0 and the moderating role of automated inventory management systems. Setyawati (2018) has studied the structural relationship between supply chain and risk management, considering the positive role of information technology (IT) in decreasing risk and enhancing the effectiveness of supply chain management. Moreover, some articles focused on multiple disruption types including IT aspects (Jüttner, 2005), while Ekwall (2009) focused on criminal actions and proposed a risk assessment model considering the issue of IT security.

3.4. Analysis of quantitative papers

3.4.1. Model type

The classification of the 48 quantitative papers according to the model type is shown in Table 11 .

Table 11.

Classification of the quantitative papers as a function of the model type.

| Model type – quantitative | Number of papers |

|---|---|

| analytic/mathematical or optimization | 25 |

| simulation model/DOE | 11 |

| multi-objective model | 7 |

| meta-heuristic or heuristic model | 5 |

| Total | 48 |

As can be seen from the table, most of the studies (25 papers out of 48, 52%) have proposed analytic/mathematical models, followed by simulation models (11 papers, 22.9%).

Mathematical models have mainly dealt with risk/resilience management, targeting different topics and goals. A mixed-integer optimization model has been developed by Häntsch and Huchzermeier (2016) with the aim of minimizing the exposure of firms to a general risk. Resilience has been faced in terms of mitigation plans, such as actions for managing supply chain disruptions (Behzadi, O'Sullivan, Olsen, Scrimgeour, & Zhang, 2017), models for quantifying the impact of mitigation strategies on disruptive events (Yuan et al., 2020), or proactive policies to mitigate the risk once occurred (Sherwin, Medal, MacKenzie, & Brown, 2020). Other models have evaluated the system resilience (Xu, Wang, & Zhao, 2014) or predicted the point of collapse beyond which the network is unable to reach an acceptable level of performance (Xu, Radhakrishnan, Kamarthi, & Jin, 2019).

Simulation models have been developed to analyse different risk scenarios and investigate the impact of disruptive events on supply chains (Berle, Norstad, & Asbjørnslett, 2013), testing also specific actions to reduce and mitigate the effect, with a focus on risk (Panova & Hilletofth, 2018), resilience (Schmitt & Singh, 2012), or flexibility (Hong, 2015).

Multi-objective models and metaheuristic/heuristic models are less common in the sample of papers retrieved. Among them, Hosnavi, Nekooie, Khalili, and Tavakoli (2019) have proposed a model with the twofold purpose of optimizing both risk and resilience, while Paul, Sarker, Essam, and Lee (2019) have modelled a heuristic procedure to identify a proper recovery plan in line with the disruption type.

3.4.2. Model goal

Correlating the model type with the objective(s) set by the authors in the model itself (Table 12 ) is useful to identify the approaches which best fit the specific goal of the analysis. In this respect, Table 12 shows that in general, the minimum cost objective (taken singularly or in combination with other objectives) is pursued by a large part of the studies; this is in line with the fact that building a supply chain which is robust against disruptions is typically expensive (Florin & Linkov, 2016) and makes cost minimization a primary goal of risk management models. For this purpose, Achurra-Gonzalez et al. (2019) have proposed a cost-based mathematical model, which could be used as a decision support tool by the shipping industry to find a suitable routing solution in disruptive scenarios. A system dynamic model has been developed by Bueno-Solano and Cedillo-Campos (2014) to simulate the impact of terroristic acts on the supply chain cost; a reactive mitigation approach has instead been presented by Paul, Sarker, and Essam (2018), who also developed a heuristic algorithm for building a cost-based recovery plan after single or multiple disruptions. Finally, Zhao and You (2019) have designed a bi-objective model to simultaneously maximise the system resilience and minimize the supply chain cost.

Table 12.

Model type vs. objective(s).

|

Objective |

||||||

|---|---|---|---|---|---|---|

| Model type | Minimum cost | Maximum profit | Minimum time | Maximum efficiency | Maximum resilience | Minimum risk |

| analytic or mathematical | 10 | 3 | 3 | 3 | 2 | 4 |

| meta-heuristic or heuristic | 4 | 1 | ||||

| multi-objective model | 5 | 2 | 3 | 4 | ||

| simulation model/DOE | 4 | 2 | 4 | 2 | 1 | |

| Total | 23 | 6 | 9 | 5 | 6 | 8 |

Interestingly, despite the keywords set in the query, maximizing resilience has been found among the goals of the models in a limited number of cases only. Probably, the underlying complexity of risk or resilience mechanisms, in terms of relationships between decision variables, constraints and assumptions, makes it difficult to clearly model them (Singhal, Agarwal, & Mittal, 2011). This is also confirmed by the lack of analytic studies that include maximum resilience among the objectives of the optimization. As far as the analytic models for risk minimization are concerned, they are limited in number as well, in line with the previous finding. These studies approach the minimization of risk in various ways. Adami, Verschoore, and Sellitto (2020) have provided a model for identifying the most appropriate redundant strategy to reduce the risk profile of a real supply chain, while Kim, Moon, and Shin (2016) have focused on modelling vulnerability as a measure of supply chain risk and its propagation. The study by Sardar and Lee (2015) instead, has evaluated a very specific topic, i.e., the impact of border crossing bottlenecks on supply chain disruptions.

The second top objective is minimum time: the recovery time is, in fact, an important parameter that certifies the capability of a supply chain to restore its initial condition after disturbances. Munoz and Dunbar (2015) have studied the transient response to disruptions of supply chains, by modelling different resilience dimensions related to time: the recovery time to restore an acceptable performance level, the length of the recovery curve, the severity of the impact along the time, the performance loss from the time of the initial performance reduction, and a time-dependant factor that measures the speed and shape of the transient response. The rationale behind the relevance of these parameters is that if minimizing the recovery time, the service provided to the final customer will be marginally affected by disturbances (Annarelli, Battistella, & Nonino, 2020). Similar considerations hold true for the supply chain lead time. When reconfiguring its structure after a disruption, a supply chain could, for instance, resorting to alternative suppliers, which implies additional lead time; under these circumstances, minimizing the additional lead time (and the total lead time of the system) is a typical objective (Bottani, Murino, Schiavo, & Akkerman, 2019). This consideration is also supported by the fact that most of the studies focusing on time or cost objectives have proposed post-disruption (reactive) models, meaning that the goal of the approach is to restore the normal condition of the system after the occurrence of a disturbance (Table 13 ). Among these studies, Liberatore and Scaparra (2011) compared different potential protection plans, with the aim of finding the most robust solution for minimizing the impact of disruptive events. Pitty, Li, Adhitya, Srinivasan, and Karimi (2008) have tested various policies and responses to disruptions, by evaluating the effect of different decisions on the overall system’s economy. Vugrin, Warren, and Ehlen (2011) have assessed the resilience cost of a particular recovery strategy, taking into account the necessary additional market and transportation costs. Rahman, Rifat, Azeem, and Ali (2018) have combined a proactive approach, to predict in advance the potential system’s change, with a reactive mitigation plan, for managing the system during the disruption. Looking at the proactive models, Mari, Memon, Ramzan, Qureshi, and Iqbal (2019) have developed a supplier selection approach with the aim of simultaneously minimizing cost and lead time, while also maximizing the resilience score, so as to make the system ready to face disruptive situations. Other authors have proposed proactive supplier selection models, combining cost and risk considerations (Fang et al., 2016, Yoon et al., 2018).

Table 13.

Approach type vs. objective(s).

|

Objective |

||||||

|---|---|---|---|---|---|---|

| Model type | Minimum cost | Maximum profit | Minimum time | Maximum efficiency | Maximum resilience | Minimum risk |

| pre-disruption model (proactive) | 6 | 2 | 1 | 2 | 2 | 6 |

| post-disruption model (reactive) | 14 | 3 | 4 | 7 | 3 | 1 |

| pre/post-disruption model (mixed) | 2 | 1 | ||||

| not specified | 1 | 1 | 1 | |||

| Total | 23 | 6 | 9 | 5 | 6 | 8 |

3.4.3. Relevance to Industry 4.0 and sustainability

As far as the emerging Industry 4.0 and sustainability topics are concerned, Table 14 shows the correlations between these topics and the type of disruption evaluated by the authors; from this table it is easy to see that most of the quantitative studies focus on disruptions external to the company, but internal to the supply chain.

Table 14.

Disruption types vs. relevance to other topics for quantitative papers.

|

Relevance to other topics |

|||

|---|---|---|---|

| Disruption type | Sustainability | Industry 4.0 | Total |

| external to the company, internal to the supply chain network | 3 | 2 | 5 |

| external to the supply chain network | – | ||

| multiple disruption types | 2 | 2 | |

| not specified | 2 | 1 | 3 |

| Total | 5 | 5 | 10 |

Several papers have targeted topics related to Industry 4.0. Examples of these topics include Internet of Things (Yan, Wang, & Shi, 2017) or information sharing mechanisms (Li, Lin, Wang, & Yan, 2007), which are suggested as potential tools for reducing risks in supply chains. Taking a different perspective, Ghadge, Dani, Chester, and Kalawsky (2013) have instead evaluated Industry 4.0 as a potential source of risk, as it could involve IT failures and problems associated with hardware/software communication.

Other papers have dealt with sustainability, mainly in terms of green aspects. Among these studies Kaur and Singh, 2019, Li et al., 2020 have proposed sustainable procurement models aimed at minimizing the total cost of a system, including carbon emission costs. Voldrich, Wieser, and Zufferey (2020) have presented a multi-objective model for monitoring cost, time, and risk, with the ultimate aim of optimizing the environmental aspects of the system, such as waste reduction in food supply chains. Finally, Kim et al. (2016) have expanded the concept of risk including all the factors that could have a negative impact on the sustainability of a supply chain.

3.5. Application potentials for pandemic disruptions

According to the aim of this paper, this section presents the models that have been considered relevant for a possible application to pandemic risk management. In line with the description previously proposed in Section 2.2.2, the reasons that have led authors to consider these models as suitable for application to pandemic disruptions can be resumed in the following key categories:

-

1.

Reference to pandemics risk management: the paper addresses expressly the topic of pandemic or sanitary emergency.

-

2.

Disruption type “external to the network”: the paper focuses on risks generated by external and exceptional factors, difficult to predict and prevent.

-

3.

Approach type “reactive”: the paper proposes post-disruption analyses or reactive mitigation plans to reduce the impact of the disruptions after they have happened;

-

4.

Resilience: the paper assesses the resilience of a system or aims at optimising resilience as one of the model goals. Increasing resilience is a suitable strategy to be adopted against pandemics, as these disturbances cannot be forecasted or avoided; hence, being ready to these external disruptions, building a resilient system, is an effective way to counteract them.

Moreover, an additional aspect that can be related to pandemic emergencies and that has emerged after an analysis of the papers’ contents is as follows:

-

5.

Disruption propagation: the paper evaluates the disruption propagation and its behaviour in time. Propagation is a typical characteristic of pandemic diseases.

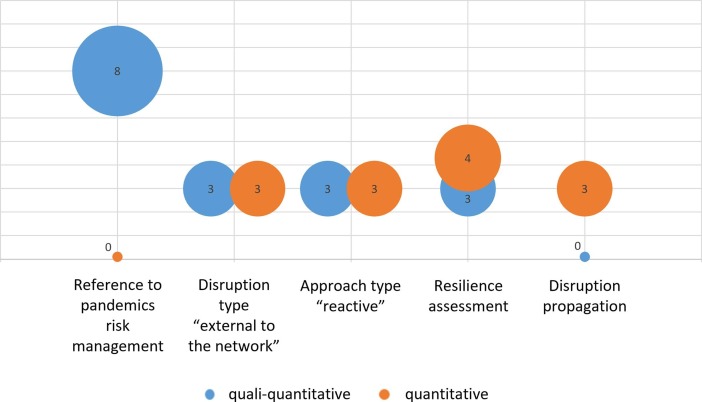

On the basis of the characteristics listed above and on the analyses made in the previous sections, thirteen quantitative papers and seventeen quali-quantitative papers were found to be related to the pandemic risk management. Fig. 5 shows the 30 papers that described models suitable to be applied for pandemic risk management, highlighting their classification into the five categories listed above.

Fig. 5.

Application of models to pandemic disruptions.

Among the quali-quantitative works, four papers have expressly addressed the topic of pandemic crises and their management, and additional four papers have dealt with the sanitary sector and focused on different types of disruption proposing models that could be suitable for implementation even for facing a sanitary emergency. In particular, Kumar (2012) has presented a multiple case study for discussing how different businesses have managed and controlled the avian-flu epidemic. Other studies have expressly debated the COVID-19 pandemic. To be more precise, Min et al. (2020) have discussed the impact of COVID-19 on the food supply chain, while Lutfi et al. (2020) have investigated the effect of social distancing policy on its spread. Belhadi et al. (2020) have provided some results about the destructive effect of pandemic crises on supply chain performance; they have also presented statistics on short/long term response strategies. Among the studies related to the sanitary emergencies but not expressively focused on pandemics, Rodgers and Singham (2019) have evaluated the relationships between nodes of a clinical supply network and assessed the impact of disruptions along the SC; they have finally determined the vulnerable points of the network. Getele, Li, and Arrive (2019) investigated the effect of social ties, institutional support and inter-agency collaboration in mitigating service supply chain risk in the healthcare sector. A model to help companies face service emergencies has been proposed by Merz, Hiete, and Bertsch (2009), focusing on critical infrastructure. Badurdeen et al. (2014) have attempted to identify multiple potential risks, including epidemics and diseases, and to assess propagation and interdependencies between them. No quantitative papers have directly targeted this first category.

The remaining papers do not specifically deal with sanitary emergencies; however, they have found to be somehow related to this topic. As far as the second category is concerned, papers have focused on external factors, and specifically on natural disruptions; these latter own some characteristics which make them similar to pandemic emergencies. In fact, in line with pandemic emergencies, exogenous and exceptional factors are almost impossible to predict in their occurrence and they are also difficult to mitigate. On the basis of these considerations, three quantitative models targeting natural disruptions have been identified as adaptable to the management of sanitary crises. Xu and Nozick (2009) have formulated an optimization model for identifying the optimal supplier selection plan in a disruptive environment, testing various scenarios with different natural disruptions (earthquake, hurricane and fire); a scenario including pandemic could be added to the analysis. Yang and Xu (2015) have investigated the optimal recovery solution to adopt after a natural disruptive event affecting the system upstream and downstream. Geng, Ji, Fan, and Shaikh (2017) proposed a multi-objective optimisation model to limit the impact of exceptional events on the maritime transportation, and different emergency scenarios have been evaluated. In addition, three quali-quantitative papers have assessed natural disruptions, such as catastrophic disruptions (Er Kara & Oktay Fırat, 2018), natural disasters (Ma & Wong, 2018), or natural environment risks (Jiang, Xiong, & Cao, 2017). Once again, these kinds of risks have some traits in common with pandemic emergencies, in that they are all due to external factors and somehow unpredictable; these considerations form the basis for judging the models in the corresponding papers proposed as suitable for a potential application in case of pandemic emergencies.

Otherwise, studies dealt with more general disruptions, which nonetheless present similarities with pandemic emergencies. This is particularly the case for post-disruption analyses and reactive models (category 3), in which the authors have evaluated how an extreme event (which could be easily replaced by a pandemic crisis) has affected a system and proposed possible response strategies to risk and adaptation actions. Among quantitative papers, Paul, Sarker, and Essam (2017) developed a heuristic procedure able to generate a reactive mitigation plan and adapt real-time decisions after the occurrence of a disruption that cannot be predicted. Other studies have presented mitigation plans grounded on Industry 4.0, which could be useful also when managing a pandemic emergency. For example, Micheli, Mogre, and Perego (2014) have discussed, the adoption of IT systems to share data among companies and suppliers, as mitigation measure to reduce both the severity after the occurrence of a disruption and the probability of congestions in the suppliers’ production process. Ivanov, Sokolov, and Dolgui (2014) have added some considerations related to the importance of real-time monitoring, with the purpose of increasing visibility along the supply chain and developing quick recovery strategies in collaboration with all supply chain partners. Among quali-quantitative papers, Baharmand, Comes, and Lauras (2017) have identified and classified the main logistics services needed to mitigate the effect of an unexpected disruption; the impact of using such services has been evaluated as well. Jaroszweski, Hooper, Baker, Chapman, and Quinn (2015) have analysed adaptation actions useful to face severe disruptions that could affect the transport system. In addition, Khayat Basiri, Movahedi Sobhani, and Sadjadi (2020) proposed a risk mitigation model, which suggests drivers for measuring and managing pandemic, e.g., the interruption due to the disruption and the duration of the mitigation strategy.

Other papers have paid attention to the resilience assessment (category 4), focusing on a crucial aspect of emergency management, i.e., the recovery time needed to react to a disruption. Focusing on quantitative papers, Raj et al. (2014) have measured resilience by quantifying the system response time, while Melnyk, Zobel, Macdonald, and Griffis (2014) have modelled the transient response of the system. Ahmadian, Lim, Cho, and Bora (2020) have presented a model to test and improve the recovery capability during a disruptive event. Finally, a combined evaluation of resilience and sustainability has been proposed by Chatterjee and Layton (2020); these authors balanced redundancy and efficiency for optimizing the network configuration under normal conditions and unexpected events. Three quali-quantitative studies have evaluated resilience too, by presenting either general parameters to assess the level of readiness to disruptions (Sureeyatanapas, Waleekhajornlert, Arunyanart, & Niyamosoth, 2020), or by evaluating the supply chain readiness with the aim of improving the preparation and reducing the decisional uncertainty in responding to the disruption (Chowdhury & Quaddus, 2016), or by proposing a resilient supplier selection model in a disaster scenario to reduce the vulnerability of a supply chain system (Haldar, Ray, Banerjee, & Ghosh, 2014). In these models, the same evaluation could be easily carried out including (or adding) pandemic emergencies as the disruption type.

Finally, a number of quantitative papers have explored the issue of disruption propagation (category 5), which is, once again, a typical characteristic of pandemic emergencies. Therefore, the model proposed by Bogataj, Aver, and Bogataj (2016) appears suitable for application since the authors have studied the ripple effect of disruptions and their long-term impacts on a global supply chain. Li and Zobel (2020) have quantified both short-term and long-term behaviours of a system subject to disruptions and its ability to recover the original state; Li et al., 2020 have analysed the forward/backward disruption propagation and its effects on the network. No quali-quantitative papers have directly targeted this category.

4. Discussion, implications and conclusions

This paper has presented a systematic review of the recent literature on risk management and disruptions in the supply chain, with a particular focus on models which are (i) inherently quantitative in nature and (ii) suitable to be applied in the case of a pandemic emergency. The rationale for taking this perspective of analysis, which is quite distant from the existing reviews on SCRM, is twofold. First, the significant and unexpected impact that the COVID-19 emergency has had in recent years on the supply chain has highlighted the need for accurate risk assessment and management approaches. At the same time, however, because of the relative newness of this specific risk, it is hard to believe that models for counteracting the COVID-19 emergency in real supply chains have already been proposed; therefore, the second motivation of this study is to evaluate the SCRM models already available in literature for judging their potential usage in the case of pandemic emergencies.

With this aim in mind, a total of 99 relevant papers, covering the time span between 2005 and 2020 have been reviewed and classified into “quantitative papers”, if a formal mathematical description of the process/system is presented, or “quali-quantitative papers”, if no mathematical/analytic formulae were provided. The two groups of papers have a similar numerousness (51 quali-quantitative papers vs. 48 quantitative papers), suggesting that risk in the supply chain has been studied in literature using various approaches, with a good balance between technical tools and less technical ones. As regards the model type, the empirical analysis is the most popular approach among quali-quantitative works, while the majority of quantitative papers propose exact analytical/mathematical models or simulation models for risk analysis.

An interesting outcome of the review is that the trend of publications in time has always increased, with a peak observed in 2020, which is the reasonable consequence of the impact of the COVID-19 pandemics on the SCRM literature. At the time of writing, very limited results were available for 2021, but it is reasonable to expect that this area of research will experience a significant increase in the next years. This is due, first, to the long-term effects of the COVID-19 crisis which, in turn, is expected to exacerbate the impact of other types of global risks in the supply chain (through a “domino” effect), and therefore will certainly fuel additional research in this field. As a second aspect, studies appearing in 2021 could also be the result of the non-negligible time required for reaching the publication stage in peer-reviewed scientific journals, for which the review and publication process may take months or even years.

From a detailed evaluation of the aforementioned 99 papers and by comparing quantitative and quali-quantitative works, the following key considerations can be drawn.

-

•

The most relevant macro-theme addressed is the general topic of “risk”, treated in the majority of quali-quantitative papers. The second most popular topic is “resilience” which, contrarily to the first macro-theme, is principally dealt with in quantitative papers. This is probably due to the fact that “resilience” is a more defined and circumscribed concept than “risk”, which, on the contrary, is more difficult to model in a quantitative way.

-

•

As opposite to quali-quantitative studies, quantitative papers are more focused on disruptions which are “external to the company but internal to the network”. A possible explanation for this outcome is that this kind of disruptions involves simpler dynamics with respect to those which are instead fully “external to the supply chain network” (and which inherently involve a plethora of complex phenomena). Nonetheless, disruptions “external to the supply chain network” have attracted considerable research interest and form the main focus of most of quali-quantitative papers. Among the disruptions taken into consideration, environmental disruptions (such as natural disasters) are the most investigated ones, while a limited number of studies only (4 papers out of 99) focuses on societal disruptions, which also include pandemic emergencies.

-

•

Quantitative papers are more focused on reactive models than on proactive ones. In the authors’ opinion, this outcome should be taken together with the recent proliferation of proactive methods. Indeed, the development of quantitative models generally needs a deeper understanding of the involved phenomena and dynamics, along with (in most cases) the availability of reliable data. This suggests that quantitative proactive approaches can be developed only if an accurate modelling of the system is available, which means that the targeted risk (or a similar one) has been observed several times in its real occurrence, so that its logics can be accurately modelled to allow the disruption event to be forecasted. This could not always be the case for all supply chain disruptions, and in particular is not the case for disruptions which have (likely) occurred a very limited number of times throughout history, such as pandemic emergencies. On the contrary, reactive models, whose logic is to act after a disruption has occurred to restore the system’s functioning, could more easily be based on quantitative approaches, which do not focus on describing the occurrence of the disruption but rather on modelling the system’s recovery.

-

•

It is interesting to note that a noteworthy number of papers describe at least one real-world application. The majority of these works are quali-quantitative papers, while quantitative papers have more frequently been validated through numerical examples. Surprisingly, a limited number of papers only propose case studies targeting international supply chains (labelled as “cross-country” applications), at the same time stressing the need for improving international collaboration, standards and assessments. In general, a remarkable attention to supply chain disruptions is evident in geographic areas inherently affected by environmental disruptive events, such as the Eastern Hemisphere and the US.

-

•

An increasing, though minor so far, interest towards emerging topics such as Industry 4.0 and sustainability can be observed in the most recent papers (both quantitative and quali-quantitative). It can be noted that works dealing with sustainability are mainly focused on green aspects, leaving the remaining dimensions of sustainability (especially the social one) aside.

-

•