Highlights

ZnxCuy alloy shell was in-situ formed on self-supported three-dimensional nanoporous Zn anode by anionic surfactant-assisted surface alloying of Zn and Cu.

The self-supported nanoporous ZnxCuy/Zn anodes exhibit high-rate capability, outstanding reversibility and stability during Zn stripping/plating because of zincophilic ZnxCuy to guide uniform Zn deposition and facilitate Zn stripping.

Aqueous Zn-ion batteries assembled with nanoporous ZnxCuy/Zn anode and KzMnO2 cathode achieve specific energy of as high as ~430 Wh kg‒1 and retain ~86% after long-term cycles for >700 h.

Supplementary Information

The online version contains supplementary material available at 10.1007/s40820-022-00867-9.

Keywords: Nanoporous metal, Zinc-based alloy anode, Aqueous zinc-ion batteries, Surface alloying

Abstract

Metallic zinc (Zn) is one of the most attractive multivalent-metal anode materials in post-lithium batteries because of its high abundance, low cost and high theoretical capacity. However, it usually suffers from large voltage polarization, low Coulombic efficiency and high propensity for dendritic failure during Zn stripping/plating, hindering the practical application in aqueous rechargeable zinc-metal batteries (AR-ZMBs). Here we demonstrate that anionic surfactant-assisted in situ surface alloying of Cu and Zn remarkably improves Zn reversibility of 3D nanoporous Zn electrodes for potential use as high-performance AR-ZMB anode materials. As a result of the zincophilic ZnxCuy alloy shell guiding uniform Zn deposition with a zero nucleation overpotential and facilitating Zn stripping via the ZnxCuy/Zn galvanic couples, the self-supported nanoporous ZnxCuy/Zn electrodes exhibit superior dendrite-free Zn stripping/plating behaviors in ambient aqueous electrolyte, with ultralow polarizations under current densities up to 50 mA cm‒2, exceptional stability for 1900 h and high Zn utilization. This enables AR-ZMB full cells constructed with nanoporous ZnxCuy/Zn anode and KzMnO2 cathode to achieve specific energy of as high as ~ 430 Wh kg‒1 with ~ 99.8% Coulombic efficiency, and retain ~ 86% after long-term cycles for > 700 h.

Supplementary Information

The online version contains supplementary material available at 10.1007/s40820-022-00867-9.

Introduction

Highly safe and reliable cost-effective rechargeable batteries hold great promise in many emerging large-scale energy storage applications such as electric vehicles and stationary storage of intermittently available renewable energy sources (e.g., solar and wind) [1, 2]. Lithium-ion batteries as one of the most successful energy-storage devices dominate the present commercial electronics [3], but they are far from meeting future needs of grid-level energy storage due to unsustainability issues, such as high-cost and scarcity of lithium resources, and safety concerns caused by highly toxic and flammable organic electrolytes [1, 3–6]. This dilemma has raised urgent demands for developing alternative battery technologies [3–6], especially safe and low-cost aqueous rechargeable batteries based on non-lithium charge carries [7–10]. Among various attractive aqueous battery candidates [11–14], aqueous rechargeable zinc-metal batteries (AR-ZMBs) are of considerable interest because multivalent zinc metal (Zn) features high volumetric and gravimetric capacities (5854 mAh cm‒3 and 820 mAh g‒1), low Zn/Zn2+ redox potential (‒0.76 V versus standard hydrogen electrode, SHE), high Earth abundance and low cost [4, 9, 15–18]. Despite some high-performance cathode materials, such as manganese oxides [19–23], vanadium oxides [24–28] and quinone analogs [29, 30], have been explored to effectively accommodate Zn2+ via intercalation or conversion reactions, most AR-ZMBs still exhibit unsatisfactory rechargeability, hindering their practical implementation as power sources for transportation or reliable solutions for grid integration of renewable energy [4]. This is primarily caused by poor reversibility of metallic Zn anode because of its unique metallurgic characteristics and undesirable side reactions (e.g., hydrogen evolution, corrosion and by-product formation), which usually lead to large voltage polarization, dendrite formation and low coulombic efficiency (CE), during the Zn stripping/plating in ambient aqueous electrolytes [16–18, 31–33]. With an aim at improving the reversibility of Zn stripping/plating, many strategies have been proposed to tackle these irreversibility issues [34], and initial strides have been made in electrolyte modulation with additives to regulate solvation/desolvation process of Zn2+ [35–40] and/or electrical field distribution of Zn protuberances [41–43], crystallographic plane manipulation to guide epitaxial electrodeposition of Zn [44–46], and interface engineering of artificial solid electrolyte interphase (SEI) to inhibit side reactions [47–55]. Nevertheless, these bulk Zn metal-based anodes still undergo large voltage polarizations particularly at high current densities and thus inevitably trigger side reactions and dendrite formation during the long-term Zn stripping/plating, which result in significant compromise in rate capabilities and cycling stability of AR-ZMBs. Nanostructuring of Zn metals is one of facile strategies to depress the Zn dendrite growth and reduce the voltage polarization by making use of high specific surface area to lower local current density and improve mass transport of Zn2+ at electrode/electrolyte interface [56, 57]. However, nanostructured Zn metals usually are of highly chemical activity and undergo severe side reactions because of high-density low-coordination surface atoms [58, 59]. In this regard, it is highly desirable to explore novel Zn-based alloy anodes with highly compatible and stable electrode/electrolyte interfaces for high-performance AR-ZMBs.

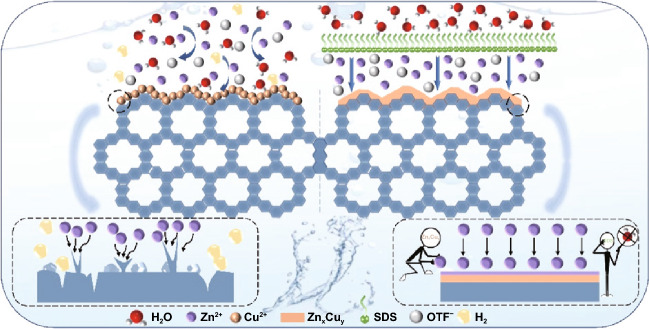

In this work, we report self-supported three-dimensional and bicontinuous nanoporous ZnxCuy/Zn hybrid electrodes, of which the ZnxCuy alloy shell is in situ formed on nanoporous Zn skeleton by anionic surfactant-assisted surface alloying of Zn and incorporated Cu, as highly reversible and dendrite-free metal anodes of AR-ZMBs. Herein, the anionic surfactant is specifically sodium dodecyl sulfate (SDS) consisting of a hydrophobic hydrocarbon tail and a hydrophilic polar headgroup. In zinc trifluoromethanesulfonate (Zn(OTF)2) aqueous electrolyte, these SDS molecules graft on the constituent Cu nanoparticle-decorated nanoporous Zn (Cu/Zn) and exclude free water molecules from electrode/electrolyte interface, enabling the formation of ZnxCuy alloy shell on nanoporous Zn skeleton during Zn stripping/plating processes. As a consequence of the zincophilic ZnxCuy alloy shell guiding uniform Zn deposition with a nucleation overpotential of as low as zero millivolt and the heterostructured ZnxCuy/Zn galvanic couples to facilitate Zn stripping, the nanoporous ZnxCuy/Zn electrodes exhibit ultralow polarizations under current densities up to 50 mA cm‒2 and exceptional stability for 1900 h during Zn stripping/plating in ambient aqueous electrolyte. These outstanding electrochemical properties enlist AR-ZMB full cells assembled with nanoporous ZnxCuy/Zn anode and KzMnO2 cathode to achieve specific energy of ~ 430 Wh kg‒1 (based on the loading mass of KzMnO2 in the cathode) with the CE of as high as ~ 99.8% and retain ~ 86% after long-term cycling for more than 700 h.

Experimental Section

Materials Preparation

Preparation of Nanoporous Zn-Based Anodes

Precursor alloy of Zn50Al50 (at%) was firstly produced by induction melting of high-purity Zn (99.994%) and Al (99.996%) in high-purity alumina crucible and then pouring in iron casting mold with a cooling rate of ~ 10 K s−1 [16]. After cutting into sheets, the Zn50Al50 sheets are chemically dealloyed to prepare nanoporous Zn, in which the less-noble Al component was selectively dissolved in N2-purged KOH solution (1 M) [60, 61]. When rinsed in pure water and ethanol for several times, these nanoporous Zn sheets were immersed in CuCl2 solution (5 mM) for 15 s to obtain nanoporous Cu/Zn hybrid electrodes via a galvanic replacement reaction. The as-prepared nanoporous Cu/Zn sheets were further washed in pure water to remove residual chemical in nanopore channels and directly used as electrodes in symmetric cells. During the electrochemical Zn stripping/plating, there took place surface alloying of Zn and Cu to form ZnxCuy/Zn core/shell structure with a three-dimensional nanoporous architecture.

Preparation of KzMnO2 Cathode

The KzMnO2 nanobelts were prepared by a modified hydrothermal method. Typically, the mixture of KMnO4 (40 mM) and NH4Cl (40 mM) in a Teflon-lined steel autoclave was heated at 150 °C for 24 h in an oil bath and magnetically stirred at a speed of 250 rpm. The KzMnO2-based cathode was prepared by mixing the as-prepared KzMnO2 nanobelts with super-P acetylene black conducting agent and poly(vinylidene difluoride) binder with a weight ratio of 70: 20: 10 in N-methyl-2-pyrrolidone (NMP), and then pasted on titanium foil with the loading mass of 1.0 mg cm−2.

Physicochemical Characterizations

The microstructural and chemical features of nanoporous Zn, Cu/Zn and ZnxCuy/Zn sheets were characterized by a field-emission scanning electron microscope equipped with an X-ray energy-dispersive spectroscopy (SEM–EDS, JEOL, JSM-7900F, 15 kV) and a field-emission transition electron microscope (TEM, JEOL, JEM-2100F, 200 kV). X-ray diffraction (XRD) measurements of all specimens were taken on a D/max2500pc diffractometer with a Cu Kα radiation. Raman spectra were measured on a micro-Raman spectrometer (Renishaw) with a 532-nm-wavelength laser at the power of 0.5 mW. X-ray photoelectron spectroscopy (XPS) analysis was conducted on a Thermo ECSALAB 250 with an Al anode. Charging effects were compensated by shifting binding energies based on the adventitious C 1 s peak (284.8 eV). Ion concentrations in electrolytes were analyzed by inductively coupled plasma optical emission spectrometer (ICP-OES, Thermo electron).

Electrochemical Measurements

Coin-type symmetrical cells were assembled with two identical nanoporous Cu/Zn and Zn sheets, as well as bulk Zn sheets with diameter of 1.2 cm and thickness of 100 µm, separated by a glass fiber membrane (GFM), in 1 M Zn(OTF)2 aqueous solution with or without 1 mM SDS. Electrochemical Zn stripping/plating behaviors of nanoporous Cu/Zn and Zn, and bulk Zn electrodes were measured at various current densities from 0.5 to 50 mA cm−2. Electrochemical impedance spectroscopy (EIS) measurements of as-assembled symmetric cells were taken over the frequency ranging from 100 kHz to 10 mHz with an amplitude of 10 mV at room temperature. The cycling durability tests were performed at current densities of 0.5 and 50 mA cm−2. The nucleation overpotentials of electrodes were investigated in a three-electrode cell in which nanoporous Cu/Zn, Zn or bulk Zn foils were employed as the working and counter electrodes, zinc wire as the reference electrode. Within 1 M Zn(OTF)2 with/without 1 mM SDS, chronopotentiometry measurements were taken at 0.5 mA cm−2. The Tafel curves were tested in the three-electrode configuration with zinc foil as the counter electrode, zinc wire as the reference electrode, and bulk Zn, nanoporous Zn, nanoporous Cu/Zn and nanoporous ZnxCuy/Zn as the working electrodes, respectively, within Zn(OTF)2 aqueous electrolyte. Coin-type full zinc-ion cells were further assembled with the nanoporous Cu/Zn and Zn, bulk Zn as the anode and the titanium foil supported KzMnO2 as the cathode, the GFM as the separator, the 1 M Zn(OTF)2 solution containing with 1 mM SDS and 0.1 M Mn(OTF)2 as the aqueous electrolyte. The rate capability and cycling performance of full cells were carried out on a battery test system.

Theoretical Calculation and Simulation

The density-functional theory (DFT) calculations were performed by using the Dmol3 code. The exchange–correlation potential was based on the functional of Perdew–Burke–Ernzerhof (PBE) of generalized gradient approximation (GGA). The DFT Semicore Pseudopotential (DSPP) method was employed to describe the electron–core interactions. For the basis sets, the double numerical plus polarization (DNP) was used with the real-space global orbital cutoff radius of 4.4 Å. The k-point grid was set at 4 × 4 × 1 for integrating the Brillouin zones. The structures of Zn(002), Cu(111) and ZnxCuy(110) planes were constructed with five layers, and the bottom two layers of the atoms were fixed. The convergence criterions of the energy, maximum force, and maximum displacement were 1 × 10–5 Ha, 0.002 Ha Å−1, and 0.005 Å, respectively.

Results and Discussion

Characterizations of Nanoporous Hybrid Electrodes

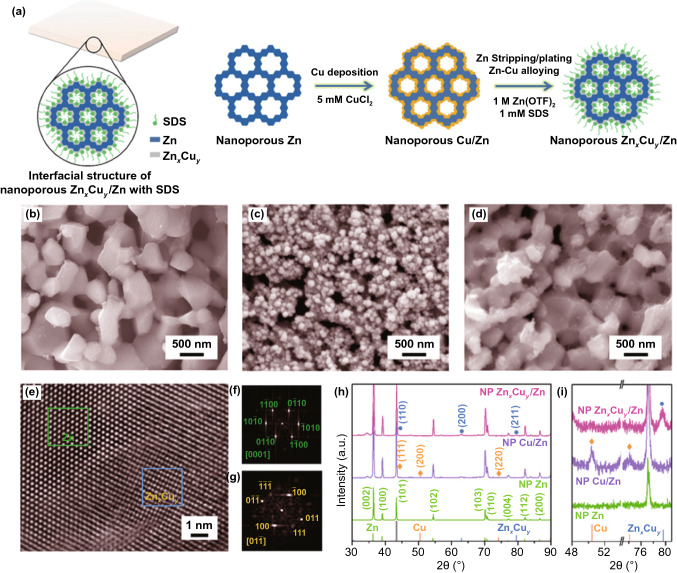

The self-supported nanoporous ZnxCuy/Zn electrodes are prepared by a facile procedure schematically illustrated in Fig. 1a, in which Cu nanoparticles are uniformly incorporated onto nanoporous Zn via a galvanic replacement reaction and then transformed to ZnxCuy alloy shell through surfactant-assisted in situ surface alloying of Cu and Zn during the Zn stripping/plating in Zn(OTF)2 aqueous electrolyte with SDS additive. Therein, nanoporous Zn precursor sheets are firstly fabricated by chemically dealloying Zn50Al50 alloy composed of intercross-linked hexagonal closest packed (hcp) Zn and face-centered cubic (fcc) Al phases (Fig. S1), wherein the less-noble Al one is selectively etched in a N2-purged KOH solution (Fig. S2) [60, 61]. Owing to the immiscibility of Al in Zn [16], selective dissolution of Al phase gives rise to interconnective pure Zn skeleton, different from traditional nanoporous metals prepared by chemically dealloying homogeneous solid-solution alloys, in which there generally remain residual less-noble elements due to parting limit effect [62, 63]. Figure 1b shows a typical SEM image of as-dealloyed nanoporous Zn, displaying a three-dimensional nanoporous architecture consisting of interpenetrative channels and interconnective Zn ligaments with characteristic length of ~ 200 nm. Because of the lowest surface energy of (002) plane [44–46], the nanoporous Zn thermodynamically prefers to expose more (002) planes. This is attested by its XRD patterns (Fig. S3a), in which the characteristic diffraction peak of (002) plane exhibits a relatively high intensity compared with the bulk Zn foil (Fig. S3a). When immersed in CuCl2 solution, Cu nanoparticles with diameter of ~ 50 nm are uniformly incorporated onto nanoporous Zn sheets by a galvanic replacement reaction, as displayed in the representative SEM image of as-prepared nanoporous Cu/Zn (Fig. 1c). With the assistance of SDS molecules that graft on the Cu/Zn surface and exclude free water molecules at electrode/electrolyte interface by making use of their hydrophilic polar headgroups and hydrophobic hydrocarbon tails (Fig. S4), there takes place in situ surface alloying of Cu and Zn to form ZnxCuy alloy shell on nanoporous Zn during the initial electrochemical cycles of Zn stripping/plating in Zn(OTF)2 aqueous electrolyte with SDS additive [64, 65]. Figure 1d shows a typical SEM image of nanoporous ZnxCuy/Zn electrode after the Zn stripping/plating at 0.5 mA cm‒2 for 10 cycles, where the ligament surface of ZnxCuy/Zn becomes much smoother than the rough surface of as-prepared nanoporous Cu/Zn (Fig. 1c). XPS analysis demonstrates the presence of Zn and Cu with an atomic ratio of 60/40 in the ZnxCuy alloy surface, in addition to the elements in the adsorbed SDS (Fig. S5). Scanning transmission electron microscopy energy-dispersive X-ray spectroscopy (STEM-EDS) elemental mapping illustrates that Cu atoms uniformly distribute along the Zn ligament (Fig. S6). Figure 1e shows a high-resolution TEM (HRTEM) image of ZnxCuy/Zn interfacial region, revealing the seamless integration of ZnxCuy alloy shell on Zn core. Viewed along their < 011 > and < 0001 > zone axis, there observe two regions with distinct crystallographic structures corresponding to the cubic ZnxCuy and the hcp Zn, respectively, which are identified by their characteristic fast Fourier transform (FFT) patterns of the selected areas in Fig. 1e-g. XRD characterization of nanoporous ZnxCuy/Zn electrode further verifies the hybrid structure, with two sets of diffraction patterns: the weak diffraction peaks at 2θ = 43.5°, 63.0° and 79.6° corresponding to the (110), (200) and (211) planes of cubic ZnxCuy in space group Pm−3 m(221) (JCPDS No. 02-1231), and the ones else assigned to hcp Zn (JCPDS No. 65-3358) (Fig. 1h), different from the initial nanoporous Cu/Zn with characteristic diffraction peaks of fcc Cu (JCPDS No. 85-1326) (Fig. 1g).

Fig. 1.

Schematic and microstructural properties of nanoporous Zn-based electrodes. a Schematic illustration for nanoporous shell/core ZnxCuy/Zn sheets that are fabricated by surface alloying of Cu and Zn of Cu-decorated nanoporous Zn during sodium dodecyl sulfate (SDS)-assisted electrochemical Zn stripping/plating cycling. b SEM image of nanoporous Zn electrode that is prepared by chemically dealloying Zn50Al50 alloy sheets in KOH solution. c SEM image of nanoporous Cu/Zn hybrid electrode, in which Cu nanoparticles with diameter of ~ 50 nm are deposited on surface of nanoporous Zn skeleton via a galvanic replacement reaction. d SEM image of surface-alloyed nanoporous ZnxCuy/Zn electrode after SDS-assisted Zn stripping/plating in Zn(OTF)2 for 10 cycles. e HRTEM image of ZnxCuy/Zn interface of nanoporous ZnxCuy/Zn electrode. f, g FFT patterns of HCP Zn (f) and cubic ZnxCuy (g) phases corresponding to green and blue squares in e. h Typical XRD patterns of nanoporous Zn, Cu/Zn and ZnxCuy/Zn electrodes. The line patterns show reference cards 65-3358 and 85-1326, 02-1231 for monometallic Zn and Cu, ZnxCuy alloy according to JCPDS, respectively. i A magnification of XRD patterns of nanoporous Zn, Cu/Zn and ZnxCuy/Zn electrodes at the characteristic diffraction peak regions of monometallic Cu and ZnxCuy alloy

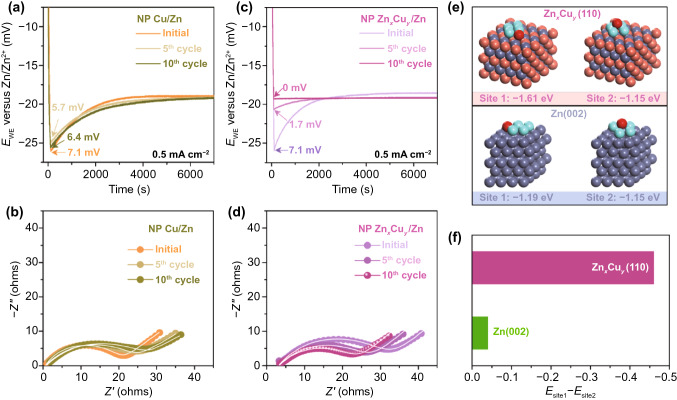

The SDS-assisted in situ surface alloying of Cu and Zn is also demonstrated by XRD characterizations of nanoporous ZnxCuy/Zn. As shown in Fig. S7a, a representative diffraction peak of cubic ZnxCuy appears at 2θ = 79.6° and gradually increases in intensity, along with the attenuation of Cu diffraction peaks (2θ = 50.4° and 74.1°), during the Zn stripping/plating. Owing to the SDS molecules that essentially inhibit side reactions at the electrode/electrolyte interface, metallic Zn prefers to nucleate and then deposit on Cu nanoparticles for electrochemically driven surface alloying. As demonstrated in high-resolution Zn 2p and Cu 2p XPS spectra with invariable chemical states (Fig. S8), there do not additionally produce by-products, such as general zinc oxides [9, 15–18, 31, 32]. While in the Zn(OTF)2 aqueous electrolyte without SDS additive, the nanoporous Cu/Zn still keeps the initial morphology (Fig. S9) and XRD patterns with characteristic diffraction peaks of individual fcc Cu and hcp Zn phases after the Zn stripping/plating for 10 cycles (Fig. S7b), implying that the Cu does not take part in the surface alloying with Zn. This is probably due to the by-product of zinc oxides that are generated little by little to inhibit Zn atom migration in the Zn stripping/plating processes [9, 15–18, 31, 32]. As attested by high-resolution Zn 2p XPS spectra (Fig. S10), the nanoporous Cu/Zn electrode has the oxidized state of surface Zn atoms to remarkably increase compared with its initial surface Zn. When the constituent Cu nanoparticles serve as the nucleation sites, the nanoporous Cu/Zn electrode exhibits the almost same galvanostatic electrodeposition behavior of metallic Zn as the initial one (Fig. 2a), with a nucleation overpotential of ~ 6.4 mV, the difference between the sharp tip voltage (−25.5 mV versus Zn/Zn2+) and the later stable mass-transfer-controlled overpotential (−19.1 mV) [66, 67]. Because of the lower binding energy of Cu(111) surface (Fig. S11), this value is much lower than bulk Zn foil (41.5 mV) and nanoporous Zn (17.6 mV) (Fig. S12), which are primarily composed of (101) and (002) crystal planes, respectively (Fig. S3). In sharp contrast, the nanoporous ZnxCuy/Zn electrode has the Zn nucleation overpotential to gradually decrease to 0 mV (Fig. 2c) and substantially facilitates the nucleation and deposition of metallic Zn because of the lowest binding energy of ZnxCuy(110) (Fig. S11). The enhanced kinetics of Zn nucleation and deposition is further demonstrated by EIS analysis of nanoporous ZnxCuy/Zn electrode (Fig. 2d). In the Nyquist plot, their EIS spectra display single semicircles in high- and middle-frequency range and inclined lines at low frequencies during the Zn stripping/plating processes. Herein, the intersection point on the real axis at the high frequency represents the intrinsic resistance of both electrolyte and electrode (RI); the diameter of semicircle in the middle frequencies corresponds to the parallel connection of charge transfer resistance (RCT) of Zn nucleation/deposition and the constant phase element (CPE); and the slope of the inclined line at low frequencies is the Warburg resistance (Zw). Based on the equivalent circuit with these descriptors (Fig. S13a), the EIS spectra of nanoporous ZnxCuy/Zn electrodes are analyzed using the complex nonlinear least squares fitting method. As shown in Fig. S13b, the nanoporous ZnxCuy/Zn electrode has its RCT to decrease to ~ 19.8 Ω from the initial value of nanoporous Cu/Zn with SDS (~ 29.7 Ω), different from nanoporous Cu/Zn without SDS additive, of which the RCT increases due to the gradual formation of zinc oxides (Figs. 2b and S13c). Furthermore, the Zn atoms thermodynamically prefer to deposit evenly and parallel to the ZnxCuy alloy surface, effectively inhibiting the formation of Zn dendrites. As illustrated by DFT calculations (Fig. 2e), the ZnxCuy(110) surface could afford a special deposition location at the side site (site 1) of early stage with an adsorption energy of as low as ~ −1.61 eV, ~ 0.46 eV lower than the adsorption energy (~ −1.15 eV) at the top site (site 2) (Fig. 2f). This implies a more favorable horizontal growth of Zn on ZnxCuy alloy surface relative to the monometallic Zn(002) plane that features a smooth equipotential surface and compact structure with the energy difference of ~ 0.04 eV for Zn deposition locations at site 1 and site 2 (Fig. 2e) [44–46]. Owing to the ZnxCuy alloy shell that can alleviate the Zn corrosion, the nanoporous ZnxCuy/Zn electrode exhibits a more positive corrosion potential (− 10 mV) and a smaller corrosion current density (3 μA cm−2) than nanoporous Cu/Zn (− 18 mV, 7 μA cm−2), nanoporous Zn (− 36 mV, 9 μA cm−2) electrodes (Fig. S14).

Fig. 2.

Effect of surface Zn-Cu alloying on Zn deposition. a Voltage–time profiles and b EIS spectra of galvanostatic Zn deposition on nanoporous Cu/Zn electrode at 0.5 mA cm‒2 after Zn stripping/plating for 0, 5 and 10 cycles without the assistance of SDS, where there does not take place alloying of Zn and Cu. c Voltage–time profiles and d EIS spectra of galvanostatic Zn deposition on nanoporous ZnxCuy/Zn electrode after SDS-assisted Zn stripping/plating at 0.5 mA cm‒2 for 0, 5 and 10 cycles, which enables the formation of ZnxCuy alloy shell via an in situ surface alloying of Zn and Cu. The current density of galvanostatic Zn deposition: 0.5 mA cm‒2. e Zn deposition at side site (site 1) and top site (site 2) on the Zn(002) and ZnxCuy(110) surfaces with different binding energies. f Comparison of energy difference between site 1 and site 2 at which Zn is deposited on the Zn(002) and ZnxCuy(110) surfaces

Electrochemical Properties of Nanoporous Zn-based Electrodes

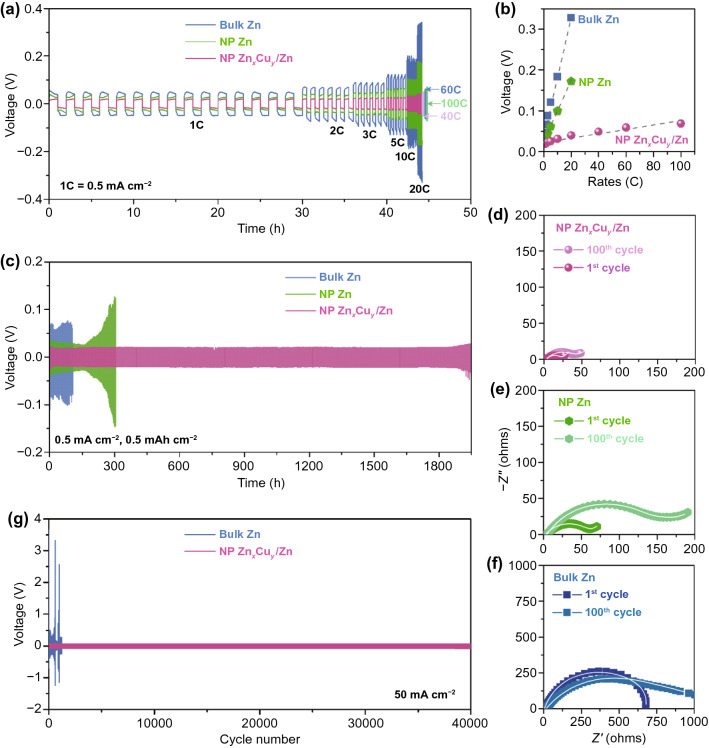

To investigate the Zn stripping/plating behaviors of nanoporous ZnxCuy/Zn electrode, electrochemical measurements are carried out on its symmetric cell in 1 M Zn(OTF)2 aqueous electrolyte with SDS additive. Figure 3a shows the voltage profiles of symmetric nanoporous ZnxCuy/Zn cell during the Zn stripping/plating processes at various rates from 1 to 100C, comparing with those of symmetric ones based on monometallic nanoporous Zn and bulk Zn electrodes in 1 M Zn(OTF)2 aqueous electrolyte without SDS additive, respectively. Here 1C represents a one-hour stripping and plating at the current density of 0.5 mA cm‒2. Evidently, the symmetric nanoporous ZnxCuy/Zn cell exhibits relatively flat and symmetric voltage plateaus with an absolute overpotential of ~ 19 mV at 1C rate, ~ 17 and ~ 28 mV lower than those of the symmetric nanoporous Zn (~ 36 mV) and bulk Zn (~ 47 mV) ones. This observation implies the synergistic effects of chemical and structural features in nanoporous ZnxCuy/Zn electrode, i.e., the highly zincophilic ZnxCuy alloy shell and the large electroactive surface area [68, 69], which facilitate the Zn stripping and plating with a low voltage polarization. As the rate increases to 5C, 10C and 20C, the nanoporous ZnxCuy/Zn cell displays steadily increasing voltage hysteresis of ~ 7, ~ 13 and ~ 21 mV, much lower than the symmetric ones based on nanoporous Zn (~ 26, ~ 73 and ~ 146 mV) and bulk Zn (~ 73, ~ 135 and ~ 280 mV). Even the current density further increases to 50 mA cm‒2 (100C), the nanoporous ZnxCuy/Zn cell still has an overpotential of as low as ~ 69 mV, comparable to the nanoporous Zn cell at 2.5 mA cm‒2 (~ 62 mV) (Fig. 3b). In view that both nanoporous ZnxCuy/Zn and Zn electrodes have almost the same nanoporous architecture, the superior rate capability of nanoporous ZnxCuy/Zn electrode highlights the significant role of ZnxCuy alloy shell in substantially boosting kinetics of Zn nucleation and deposition. This expectation is further attested by their distinct EIS spectra (Fig. S15a), where the symmetric nanoporous ZnxCuy/Zn cell has the lowest RCT value (Fig. S15b).

Fig. 3.

Electrochemical performance of symmetric cells. a Voltage profiles of nanoporous ZnxCuy/Zn symmetric cell at various rates from 1 to 100C (1C = 0.5 mA cm‒2) in 1 M Zn(OTF)2 with 1 mM SDS, comparing with those of symmetric batteries of bulk Zn and nanoporous Zn electrodes in 1 M Zn(OTF)2. b Overpotentials of Zn stripping/plating for symmetric cells based on nanoporous ZnxCuy/Zn and nanoporous Zn, bulk Zn in 1 M Zn(OTF)2 with/without 1 mM SDS as a function of rate. c Long-term cycling stability of Zn stripping/plating for symmetric cells based on nanoporous ZnxCuy/Zn and nanoporous Zn, bulk Zn in 1 M Zn(OTF)2 with/without 1 mM SDS.EIS spectra of d nanoporous ZnxCuy/Zn, e nanoporous Zn and f bulk Zn symmetric cells before and after 100 cycles of stripping/plating in 1 M Zn(OTF)2 with/without 1 mM SDS. g Long-term Zn stripping/plating stability of symmetric cells based on nanoporous ZnxCuy/Zn and bulk Zn electrodes in 1 M Zn(OTF)2 with/without 1 mM SDS at 50 mA cm‒2, respectively

Figure 3c compares the long-term Zn stripping/plating cycling stabilities of nanoporous ZnxCuy/Zn and monometallic nanoporous Zn and bulk Zn electrodes in their symmetric cells, which are performed at the rate of 1C with a constant areal capacity of 0.5 mAh cm‒2. As a consequence of lowering the current density by increasing the electroactive surface area, nanoporous Zn effectively alleviates the voltage polarization of Zn stripping/plating [68, 69]. This enlists the symmetric nanoporous Zn cell to retain stable voltage profile until for 155 h, outperforming symmetric bulk Zn cell that as usual displays violent fluctuation and high overpotential in a short lifetime. When extending the cycling time, there take place severe side reactions of Zn oxidation on nanoporous Zn electrode, which dramatically increases the voltage polarization and then leads to an abrupt failure. Owing to the presence of ZnxCuy alloy shell that effectively guides the reversible and dendrite-free Zn stripping/plating, the symmetric nanoporous ZnxCuy/Zn cell maintains extremely stable voltage profiles at 0.5 mA cm‒2 for more than 1,900 h, outperforming the monometallic nanoporous Zn. The excellent stability of nanoporous ZnxCuy/Zn is further confirmed by the negligible change of EIS spectra before and after the Zn stripping/plating for 100 cycles (Fig. 3d). Therein, the RI and RCT values only increase by ~ 1 Ω and ~ 12 Ω, much smaller than those of monometallic nanoporous Zn (~ 2 Ω, ~ 91 Ω) and bulk Zn (~ 12 Ω, ~ 236 Ω) with severe side reactions of Zn oxidations (Fig. S16). As revealed by Raman spectrum of nanoporous ZnxCuy/Zn after the long-term cycling measurement of Zn stripping/plating (Fig. S17a), there do not display additional Raman bands, in addition to the characteristic ones of ZnO at ~ 381, ~ 437, ~ 580 and ~ 1100 cm‒1 with the almost constant intensities [70]. These observations are different from the observations in nanoporous Zn and bulk Zn electrodes (Fig. S17b-c), where there appear neoformative Raman bands at 252, 305 and 837 cm‒1 corresponding to Znx(OTF)y(OH)2x−y·nH2O [71], in addition to more intensive Raman bands of ZnO at ~ 381, ~ 437, ~ 580 and ~ 1100 cm‒1. The superior stability of nanoporous ZnxCuy/Zn electrode is further illustrated by the almost same nanoporous structure after 500 cycles (1000 h) as the initial one (Fig. S18a). This observation is in sharp contrast with monometallic nanoporous Zn (Fig. S18b) and bulk Zn electrodes (Fig. S18c), which undergoes severe dendrites growth and cracks when only performing for 150 cycles (300 h) and 50 cycles (100 h), respectively. Even at the rate of as high as 100C (50 mA cm‒2) (Fig. 3g), the nanoporous ZnxCuy/Zn does not display evident voltage fluctuation for more than 40,000 cycles of Zn stripping/plating along with the energy efficiency of ~ 99.9% (Fig. S19).

Electrochemical Performance of AR-ZMB Full Cells

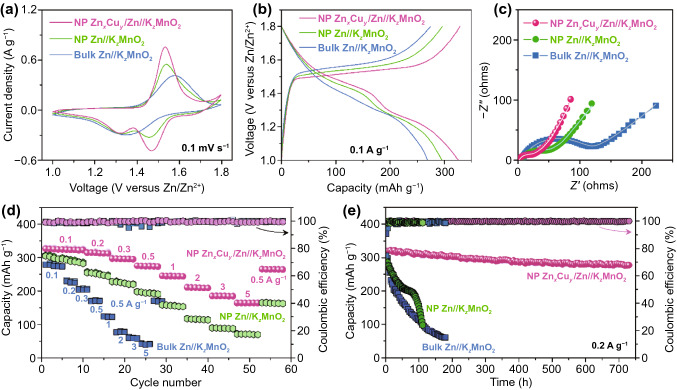

Full AR-ZMB cells are assembled with nanoporous ZnxCuy/Zn electrode as the anode and K+-preintercalated α-MnO2 (KzMnO2) nanobelts as the cathode, a mixture solution of 1 M Zn(OTF)2, 0.1 M Mn(OTF)2 and 1 mM SDS as the aqueous electrolyte (nanoporous ZnxCuy/Zn//KzMnO2). Therein, the KzMnO2 nanobelts are prepared by a modified hydrothermal method (Fig. S20) and then mixed with super-P acetylene black conducting agent and poly(vinylidene difluoride) binder on titanium foil [16, 72]. Figure 4a shows a representative cyclic voltammetry (CV) curve of full AR-ZMB device of nanoporous ZnxCuy/Zn//KzMnO2 at a scan rate of 0.1 mV s‒1, displaying primary redox peaks at 1.55 and 1.47 V that correspond to the intercalation/deintercalation of Zn2+ [16, 19–22]. Although the nanoporous ZnxCuy/Zn//KzMnO2 AR-ZMB has the same KzMnO2-based cathode material as the nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2 ones, it exhibits superior voltammetric behaviors, with a higher current density and a smaller redox peak voltage difference, at various scan rates from 0.1 to 5 mV s‒1 (Fig. S21). These observations imply the significant role of nanoporous ZnxCuy/Zn hybrid anode in improving rate capability of AR-ZMBs by virtue of the synergic effect of ZnxCuy alloy shell and nanoporous architecture on Zn stripping/plating kinetics. Figure S22a-c shows the voltage profiles for the galvanostatic charge and discharge of nanoporous ZnxCuy/Zn//KzMnO2, nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2 AR-ZMBs at various specific currents from 0.1 to 5 A g‒1, displaying obvious voltage plateaus that are consistent with the corresponding redox peaks in their corresponding CV curves (Fig. S21a-c). Here the applied specific current and the achieved capacity are calculated by the loading mass of KzMnO2 in the cathode. Evidently, the use of nanoporous ZnxCuy/Zn anode not only increases the charge/discharge capacities but also improves the energy efficiency of AR-ZMB by lowering the voltage polarization. As shown in Fig. 4b, the discharge capacity of nanoporous ZnxCuy/Zn//KzMnO2 AR-ZMB can reach ~ 325 mAh g‒1 at the specific current of 0.1 A g‒1, higher than those of nanoporous Zn//KzMnO2 (~ 295 mAh g‒1) and bulk Zn//KzMnO2 ones (~ 268 mAh g‒1). Even as the specific current increases to 5 A g‒1, the nanoporous ZnxCuy/Zn//KzMnO2 AR-ZMB still achieves the charge/discharge capacities of ~ 165/ ~ 164 mAh g‒1, with a Coulombic efficiency of as high as ~ 99.2% (Fig. 4d), ~ 2.3- and ~ 3.8-fold higher than the values of nanoporous Zn//KzMnO2 (~ 71/ ~ 71 mAh g‒1) and bulk Zn//KzMnO2 ones (~ 42/ ~ 40 mAh g‒1). The superior rate capability of nanoporous ZnxCuy/Zn//KzMnO2 AR-ZMB is also demonstrated by the EIS spectrum in the Nyquist plot (Fig. 4c), where the RCT value is only ~ 14 Ω, much lower than those of nanoporous Zn//KzMnO2 (~ 38 Ω) and bulk Zn//KzMnO2 (~ 103 Ω) ones, respectively (Fig. S23). When increasing Zn utilization in nanoporous ZnxCuy/Zn electrode to ~ 37.6%, the overall energy density of nanoporous ZnxCuy/Zn//KzMnO2 full cell can reach ~ 204 Wh kg−1 (Fig. S24). The self-discharge performance of nanoporous ZnxCuy/Zn//KzMnO2 cell is shown in Fig. S25. The voltage of the cell evidently drops to 1.531 V in ~ 15 h, which is due to the pseudocapacitive discharge behavior. While in the subsequent ~ 485 h, the nanoporous ZnxCuy/Zn//KzMnO2 cell exhibits a very low self-discharge rate (0.18 mV h−1) because of ultralow insertion kinetics of Zn2+ [16]. Owing to the highly zincophilic ZnxCuy alloy shell guiding the reversible and dendrite-free Zn stripping/plating, the nanoporous ZnxCuy/Zn//KzMnO2 AR-ZMB also exhibits exceptional long-term stability during the galvanostatic charge/discharge cycling measurements. As shown in Fig. 4e, it achieves initial charge/discharge capacities of ~ 320/~ 319 mAh g‒1 (i.e., specific energy of ~ 430 Wh kg‒1) at 0.2 A g‒1 and still retains ~ 86% (~ 278/~ 278 mAh g‒1) after more than 700 h, along with the Coulombic efficiency of as high as ~ 99.8%. Even at the specific current of as high as 1 A g‒1, the capacity retention of nanoporous ZnxCuy/Zn//KzMnO2 AR-ZMB can reach ~ 84% after 800 cycles. However, the nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2 devices undergo fast capacity degradation in 100 h probably due to the poor reversibility of monometallic Zn (Figs. 4e and S26).

Fig. 4.

Electrochemical performance of full Zn-ion cells. a Representative CV curves of full cells of nanoporous ZnxCuy/Zn//KzMnO2, nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2. Scan rate: 0.1 mV s‒1. b Representative charge/discharge voltage profiles of nanoporous ZnxCuy/Zn//KzMnO2, nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2 full cells at the specific current of 0.1 A g‒1 (based on the loading mass of electroactive KzMnO2 at the cathode). c EIS spectra of nanoporous ZnxCuy/Zn//KzMnO2, nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2 full cells. d Comparisons of rate performance and coulombic efficiency for nanoporous ZnxCuy/Zn//KzMnO2, nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2 full cells, where are performed at various specific currents from 0.1 to 5 A g‒1. e Capacity retentions and coulombic efficiencies of nanoporous ZnxCuy/Zn//KzMnO2, nanoporous Zn//KzMnO2 and bulk Zn//KzMnO2 full cells in a long-term charge/discharge cycling measurements at the specific current of 0.2 A g‒1

Conclusions

In summary, we have developed three-dimensional and bicontinuous nanoporous ZnxCuy/Zn hybrid electrodes for the use as highly reversible and dendrite-free Zn anode in aqueous rechargeable zinc-metal batteries. By making use of amphiphilic properties of SDS, there form a hydrophilic SDS/Cu/Zn interface to substantially inhibit side reactions and thus facilitate in situ surface alloying of Cu and Zn during Zn stripping/plating. Owing to the nanoporous architecture to reduce the current density per electrochemical surface area and the ZnxCuy alloy shell to guide uniform and horizontal Zn deposition with a zero millivolt nucleation overpotential and facilitate Zn stripping via the formation of ZnxCuy/Zn galvanic couples, the symmetric nanoporous ZnxCuy/Zn cell exhibits highly reversible and dendrite-free Zn stripping/plating behaviors in 1 M Zn(OTF)2 aqueous electrolyte, with ultralow polarizations and stable voltage profile under various current densities up to 50 mA cm‒2. It maintains stable Zn stripping/plating for as long as 1900 h at 0.5 mA cm‒2 and for 40,000 cycles at 50 mA cm‒2, respectively, outperforming the symmetric cells based on monometallic nanoporous Zn and bulk Zn. These outstanding electrochemical properties enlist AR-ZMB full cells with nanoporous ZnxCuy/Zn anode and KzMnO2 cathode to achieve specific energy of ~ 430 Wh kg‒1 (based on the loading mass of KzMnO2 in the cathode) with the Coulombic efficiency of as high as ~ 99.8% and the retention of ~ 86% for more than 700 h.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51871107, 52130101), Chang Jiang Scholar Program of China (Q2016064), the Program for JLU Science and Technology Innovative Research Team (JLUSTIRT, 2017TD-09), the Natural Science Foundation of Jilin Province (20200201019JC), the Fundamental Research Funds for the Central Universities, and the Program for Innovative Research Team (in Science and Technology) in University of Jilin Province.

Funding

Open access funding provided by Shanghai Jiao Tong University.

Footnotes

Huan Meng, Qing Ran and Tian-Yi Dai have contributed equally to this work.

Contributor Information

Xing-You Lang, Email: xylang@jlu.edu.cn.

Qing Jiang, Email: jiangq@jlu.edu.cn.

References

- 1.Dunn B, Kamath H, Tarascon JM. Electrical energy storage for the grid: a battery of choices. Science. 2011;334(6058):928–935. doi: 10.1126/science.1212741. [DOI] [PubMed] [Google Scholar]

- 2.Cano ZP, Banham D, Ye S, Hintennach A, Lu J, et al. Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy. 2018;3(4):279–289. doi: 10.1038/s41560-018-0108-1. [DOI] [Google Scholar]

- 3.Sun Y, Liu N, Cui Y. Promises and challenges of nanomaterials for lithium-based rechargeable batteries. Nat. Energy. 2016;1:16071. doi: 10.1038/nenergy.2016.71. [DOI] [Google Scholar]

- 4.Tian Y, Zeng G, Rutt A, Shi T, Kim H, et al. Promises and challenges of next-generation “beyond Li-ion” batteries for electric vehicles and grid decarbonization. Chem. Rev. 2021;121(3):1623–1669. doi: 10.1021/acs.chemrev.0c00767. [DOI] [PubMed] [Google Scholar]

- 5.Hwang JY, Myung ST, Sun YK. Sodium-ion batteries: present and future. Chem. Soc. Rev. 2017;46(12):3529–3614. doi: 10.1039/C6CS00776G. [DOI] [PubMed] [Google Scholar]

- 6.Zhang W, Liu Y. Z, Guo, Approaching high-performance potassium-ion batteries via advanced design strategies and engineering. Sci. Adv. 2019;5(5):eaav7412. doi: 10.1126/sciadv.aav7412. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Kim H, Hong J, Park KY, Kim H, Kim SW, et al. Aqueous rechargeable Li and Na ion batteries. Chem. Rev. 2014;114(23):11788–11827. doi: 10.1021/cr500232y. [DOI] [PubMed] [Google Scholar]

- 8.Liang G, Mo F, Ji X, Zhi C. Non-metallic charge carriers for aqueous batteries. Nat. Rev. Mater. 2021;6(2):109–123. doi: 10.1038/s41578-020-00241-4. [DOI] [Google Scholar]

- 9.Liu Y, Lu X, Lai F, Liu T, Shearing PR, et al. Rechargeable aqueous Zn-based energy storage devices. Joule. 2021;5(11):2845–2903. doi: 10.1016/j.joule.2021.10.011. [DOI] [Google Scholar]

- 10.Sui Y, Ji X. Anticatalytic strategies to suppress water electrolysis in aqueous batteries. Chem. Rev. 2021;121(11):6654–6695. doi: 10.1021/acs.chemrev.1c00191. [DOI] [PubMed] [Google Scholar]

- 11.Yang J, Yin B, Sun Y, Pan H, Sun W, et al. Zinc anode for mild aqueous zinc-ion batteries: challenges, strategies, and perspectives. Nano-Micro Lett. 2022;14:42. doi: 10.1007/s40820-021-00782-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Dong H, Tutusaus O, Liang Y, Zhang Y, Lebens-Higgins Z, et al. High-power Mg batteries enabled by heterogeneous enolization redox chemistry and weakly coordinating electrolytes. Nat. Energy. 2020;5(12):1043–1050. doi: 10.1038/s41560-020-00734-0. [DOI] [Google Scholar]

- 13.Wu C, Gu S, Zhang Q, Bai Y, Li M, et al. Electrochemically activated spinel manganese oxide for rechargeable aqueous aluminum battery. Nat. Commun. 2019;10:73. doi: 10.1038/s41467-018-07980-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Li B, Zhang X, Wang T, He Z, Lu B, et al. Interfacial engineering strategy for high-performance Zn metal anodes. Nano-Micro Lett. 2022;14:6. doi: 10.1007/s40820-021-00764-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Ran Q, Shi H, Meng H, Zeng SP, Wan WB, et al. Aluminum-copper alloy anode materials for high-energy aqueous aluminum batteries. Nat. Commun. 2022;13:576. doi: 10.1038/s41467-022-28238-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Wang SB, Ran Q, Yao RQ, Shi H, Wen Z, et al. Lamella-nanostructured eutectic zinc–aluminum alloys as reversible and dendrite-free anodes for aqueous rechargeable batteries. Nat. Commun. 2020;11:1634. doi: 10.1038/s41467-020-15478-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Jia X, Liu C, Neale ZG, Yang J, Cao G. Active materials for aqueous zinc ion batteries: synthesis, crystal structure, morphology, and electrochemistry. Chem. Rev. 2020;120(15):7795–7866. doi: 10.1021/acs.chemrev.9b00628. [DOI] [PubMed] [Google Scholar]

- 18.Zhang N, Chen X, Yu M, Niu Z, Cheng F, et al. Materials chemistry for rechargeable zinc-ion batteries. Chem. Soc. Rev. 2020;49(13):4203–4219. doi: 10.1039/c9cs00349e. [DOI] [PubMed] [Google Scholar]

- 19.Pan H, Shao Y, Yan P, Cheng Y, Han KS, et al. Reversible aqueous zinc/manganese oxide energy storage from conversion reactions. Nat. Energy. 2016;1:16039. doi: 10.1038/nenergy.2016.39. [DOI] [Google Scholar]

- 20.Huang J, Wang Z, Hou M, Dong X, Liu Y, et al. Polyaniline-intercalated manganese dioxide nanolayers as a high-performance cathode material for an aqueous zinc-ion battery. Nat. Commun. 2018;9:2906. doi: 10.1038/s41467-018-04949-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Tang X, Zhou D, Zhang B, Wang S, Li P, et al. A universal strategy towards high–energy aqueous multivalent–ion batteries. Nat. Commun. 2021;12:2857. doi: 10.1038/s41467-021-23209-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Feng D, Gao TN, Zhang L, Guo B, Song S, et al. Boosting high-rate zinc-storage performance by the rational design of Mn2O3 nanoporous architecture cathode. Nano-Micro Lett. 2020;12:14. doi: 10.1007/s40820-019-0351-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Zhai XZ, Qu J, Hao SM, Jing YQ, Chang W, et al. Layered birnessite cathode with a displacement/intercalation mechanism for high-performance aqueous zinc-ion batteries. Nano-Micro Lett. 2020;12:56. doi: 10.1007/s40820-020-0397-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Kundu D, Adams B, Duffort V, Vajargah SH, Nazar LF. A high-capacity and long-life aqueous rechargeable zinc battery using a metal oxide intercalation cathode. Nat. Energy. 2016;1:16119. doi: 10.1038/nenergy.2016.119. [DOI] [Google Scholar]

- 25.Zhang Y, Wan F, Huang S, Wang S, Niu Z, et al. A chemically self-charging aqueous zinc-ion battery. Nat. Commun. 2020;11:2199. doi: 10.1038/s41467-020-16039-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Yang Y, Tang Y, Fang G, Shan L, Guo J, et al. Li+ intercalated V2O5·nH2O with enlarged layer spacing and fast ion diffusion as an aqueous zinc-ion battery cathode. Energy Environ. Sci. 2018;11(11):3157–3162. doi: 10.1039/c8ee01651h. [DOI] [Google Scholar]

- 27.Wang SB, Ran Q, Wan WB, Shi H, Zeng SP, et al. Ultrahigh-energy and -power aqueous rechargeable zinc-ion microbatteries based on highly cation-compatible vanadium oxides. J. Mater. Sci. Technol. 2022;120:159–166. doi: 10.1016/j.jmst.2022.01.007. [DOI] [Google Scholar]

- 28.Li Q, Rui X, Chen D, Feng Y, Xiao N, et al. A high-capacity ammonium vanadate cathode for zinc-ion battery. Nano-Micro Lett. 2020;12:67. doi: 10.1007/s40820-020-0401-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Liang Y, Jing Y, Gheytani S, Lee KY, Liu P, et al. Universal quinone electrodes for long cycle life aqueous rechargeable batteries. Nat. Mater. 2017;16(8):841–848. doi: 10.1038/nmat4919. [DOI] [PubMed] [Google Scholar]

- 30.Zhao Q, Huang W, Luo Z, Liu L, Lu Y, et al. High-capacity aqueous zinc batteries using sustainable quinone electrodes. Sci. Adv. 2018;4(3):eaao1761. doi: 10.1126/sciadv.aao1761. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Fang G, Zhou J, Pan A, Liang S. Recent advances in aqueous zinc-ion batteries. ACS Energy Lett. 2018;3(10):2480–2501. doi: 10.1021/acsenergylett.8b01426. [DOI] [Google Scholar]

- 32.Lu W, Zhang C, Zhang H, Li X. Anode for zinc-based batteries: challenges, strategies, and prospects. ACS Energy Lett. 2021;6(8):2765–2785. doi: 10.1021/acsenergylett.1c00939. [DOI] [Google Scholar]

- 33.Ma L, Schroeder MA, Borodin O, Pollard TP, Ding MS, et al. Realizing high zinc reversibility in rechargeable batteries. Nat. Energy. 2020;5(10):743–749. doi: 10.1038/s41560-020-0674-x. [DOI] [Google Scholar]

- 34.Yi Z, Chen G, Hou F, Wang L, Liang J. Strategies for the stabilization of Zn metal anodes for Zn-ion batteries. Adv. Energy Mater. 2021;11(1):2003065. doi: 10.1002/aenm.202003065. [DOI] [Google Scholar]

- 35.Wang F, Borodin O, Gao T, Fan X, Sun W, et al. Highly reversible zinc metal anode for aqueous batteries. Nat. Mater. 2018;17(6):543–549. doi: 10.1038/s41563-018-0063-z. [DOI] [PubMed] [Google Scholar]

- 36.Yan M, Dong N, Zhao X, Sun Y, Pan H. Tailoring the stability and kinetics of Zn anodes through trace organic polymer additives in dilute aqueous electrolyte. ACS Energy Lett. 2021;6(9):3236–3243. doi: 10.1021/acsenergylett.1c01418. [DOI] [Google Scholar]

- 37.Liu C, Xie X, Lu B, Zhou J, Liang S. Electrolyte strategies toward better zinc-ion batteries. ACS Energy Lett. 2021;6(3):1015–1033. doi: 10.1021/acsenergylett.0c02684. [DOI] [Google Scholar]

- 38.Zhu Y, Yin J, Zheng X, Emwas AH, Lei Y, et al. Concentrated dual-cation electrolyte strategy for aqueous zinc-ion batteries. Energy Environ. Sci. 2021;14(8):4463. doi: 10.1039/d1ee01472b. [DOI] [Google Scholar]

- 39.Zhang B, Qin L, Fang Y, Chai Y, Xie X, et al. Tuning Zn2+ coordination tunnel by hierarchical gel electrolyte for dendrite-free zinc anode. Sci. Bull. 2022 doi: 10.1016/j.scib.2022.01.027. [DOI] [PubMed] [Google Scholar]

- 40.Li L, Liu S, Ba D, Liu W, Gui Q, et al. Electrolyte concentration regulation boosting zinc storage stability of high-capacity K0.486V2O5 cathode for bendable quasi-solid-state zinc ion batteries. Nano-Micro Lett. 2021;13:34. doi: 10.1007/s40820-020-00554-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Sun P, Ma L, Zhou W, Qiu M, Wang Z, et al. Simultaneous regulation on solvation shell and electrode interface for dendrite-free Zn ion batteries achieved by a low-cost glucose additive. Angew. Chem. Int. Ed. 2021;60(33):18247–18255. doi: 10.1002/anie.202105756. [DOI] [PubMed] [Google Scholar]

- 42.Bayaguud A, Luo X, Fu Y, Zhu C. Cationic surfactant-type electrolyte additive enables three-dimensional dendrite-free zinc anode for stable zinc-ion batteries. ACS Energy Lett. 2020;5(9):3012–3020. doi: 10.1021/acsenergylett.0c01792. [DOI] [Google Scholar]

- 43.Wang Z, Dong L, Huang W, Jia H, Zhao Q, et al. Simultaneously regulating uniform Zn2+ flux and electron conduction by MOF/rGO interlayers for high-performance Zn anodes. Nano-Micro Lett. 2021;13:73. doi: 10.1007/s40820-021-00594-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Zheng J, Zhao Q, Tang T, Yin J, Quilty CD, et al. Reversible epitaxial electrodeposition of metals in battery anodes. Science. 2019;366(6465):645–648. doi: 10.1126/science.aax6873. [DOI] [PubMed] [Google Scholar]

- 45.Zheng J, Deng Y, Yin J, Tang T, Garcia-Mendez R, et al. Textured electrodes: manipulating built-in crystallographic heterogeneity of metal electrodes via severe plastic deformation. Adv. Mater. 2021;34(1):2106867. doi: 10.1002/adma.202106867. [DOI] [PubMed] [Google Scholar]

- 46.Zhou M, Guo S, Li J, Luo X, Liu Z, et al. Surface-preferred crystal plane for a stable and reversible zinc anode. Adv. Mater. 2021;33(21):2100187. doi: 10.1002/adma.202100187. [DOI] [PubMed] [Google Scholar]

- 47.Kang L, Cui M, Jiang F, Gao Y, Luo H, et al. Nanoporous CaCO3 coatings enabled uniform Zn stripping/plating for long-life zinc rechargeable aqueous batteries. Adv. Energy Mater. 2018;8(25):1801090. doi: 10.1002/aenm.201801090. [DOI] [Google Scholar]

- 48.Zhang N, Huang S, Yuan Z, Zhu J, Zhao Z, et al. Direct self-assembly of MXene on Zn anodes for dendrite-free aqueous zinc-ion batteries. Angew. Chem. Int. Ed. 2021;60(6):2861–2865. doi: 10.1002/anie.202012322. [DOI] [PubMed] [Google Scholar]

- 49.Wu K, Yi J, Liu X, Sun Y, Cui J, et al. Regulating Zn deposition via an artificial solid–electrolyte interface with aligned dipoles for long life Zn anode. Nano-Micro Lett. 2021;13:79. doi: 10.1007/s40820-021-00599-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Yang X, Li C, Sun Z, Yang S, Shi Z, et al. Interfacial manipulation via in situ grown ZnSe cultivator toward highly reversible Zn metal anodes. Adv. Mater. 2021;33(52):2105951. doi: 10.1002/adma.202105951. [DOI] [PubMed] [Google Scholar]

- 51.Hao J, Li B, Li X, Zeng X, Zhang S, et al. An in-depth study of Zn metal surface chemistry for advanced aqueous Zn-ion batteries. Adv. Mater. 2020;32(34):2003021. doi: 10.1002/adma.202003021. [DOI] [PubMed] [Google Scholar]

- 52.Wang X, Meng J, Lin X, Yang Y, Zhou S, et al. Stable zinc metal anodes with textured crystal faces and functional zinc compound coatings. Adv. Funct. Mater. 2021;31(48):2106114. doi: 10.1002/adfm.202106114. [DOI] [Google Scholar]

- 53.Guo Z, Fan L, Zhao C, Chen A, Liu N, et al. A dynamic and self-adapting interface coating for stable Zn-metal anodes. Adv. Mater. 2021;34(2):2105133. doi: 10.1002/adma.202105133. [DOI] [PubMed] [Google Scholar]

- 54.Jiao Y, Li F, Jin X, Lei Q, Li L, et al. Engineering polymer glue towards 90% zinc utilization for 1000 hours to make high-performance Zn-ion batteries. Adv. Funct. Mater. 2021;31(49):2107652. doi: 10.1002/adfm.202107652. [DOI] [Google Scholar]

- 55.Xie S, Li Y, Li X, Zhou Y, Dang Z, et al. Stable zinc anodes enabled by zincophilic Cu nanowire networks. Nano-Micro Lett. 2022;14:39. doi: 10.1007/s40820-021-00783-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Zhao H, Lei Y. 3D nanostructures for the next generation of high-performance nanodevices for electrochemical energy conversion and storage. Adv. Energy Mater. 2020;10(28):2001460. doi: 10.1002/aenm.202001460. [DOI] [Google Scholar]

- 57.Guo W, Cong Z, Guo Z, Chang C, Liang X, et al. Dendrite-free Zn anode with dual channel 3D porous frameworks for rechargeable Zn batteries. Energy Storage Mater. 2020;30:104–112. doi: 10.1016/j.ensm.2020.04.038. [DOI] [Google Scholar]

- 58.Li C, Xie X, Liu H, Wang P, Deng C, et al. Integrated ‘all-in-one’ strategy to stabilize zinc anodes for high-performance zinc-ion batteries. Natl. Sci. Rev. 2022;9(3):nwab177. doi: 10.1093/nsr/nwab177. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.An Y, Tian Y, Xiong S, Feng J, Qian Y. Scalable and controllable synthesis of interface engineered nanoporous host for dendrite-free and high rate zinc metal batteries. ACS Nano. 2021;15(7):11828–11842. doi: 10.1021/acsnano.1c02928. [DOI] [PubMed] [Google Scholar]

- 60.H. Shi, Y.T. Zhou, R.Q. Yao, W.B. Wang, Q.H. Zhang et al., Intermetallic Cu5Zr clusters anchored on hierarchical nanoporous copper as efficient catalysts for hydrogen evolution reaction. Research 2020, 2987234 (2020). 10.34133/2020/2987234 [DOI] [PMC free article] [PubMed]

- 61.Shi H, Zhou YT, Yao RQ, Wang WB, Ge X, et al. Spontaneously separated intermetallic Co3Mo from nanoporous copper as versatile electrocatalysts for highly efficient water splitting. Nat. Commun. 2020;11:2940. doi: 10.1038/s41467-020-16769-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Oppenheim IC, Trevor DJ, Chidsey CED, Trevor PL, Sieradzki K. In situ scanning tunneling microscopy of corrosion of silver-gold alloys. Science. 1991;254(5032):687–689. doi: 10.1126/science.254.5032.687. [DOI] [PubMed] [Google Scholar]

- 63.Erlebacher J, Aziz MJ, Karma A, Dimitrov N, Sieradzki K. Evolution of nanoporosity in dealloying. Nature. 2001;410(6827):450–453. doi: 10.1038/35068529. [DOI] [PubMed] [Google Scholar]

- 64.Lang XY, Fu HY, Hou C, Han GF, Yang P, et al. Nanoporous gold supported cobalt oxide microelectrodes as high-performance electrochemical biosensors. Nat. Commun. 2013;4:2169. doi: 10.1038/ncomms3169. [DOI] [PubMed] [Google Scholar]

- 65.Jia F, Yu C, Ai Z, Zhang L. Fabrication of nanoporous gold film electrodes with ultrahigh surface area and electrochemical activity. Chem. Mater. 2007;19(15):3648–3653. doi: 10.1021/cm070425l. [DOI] [Google Scholar]

- 66.Yan K, Lu Z, Lee HW, Xiong F, Hsu PC, et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy. 2016;1:16010. doi: 10.1038/nenergy.2016.10. [DOI] [Google Scholar]

- 67.Zhang R, Chen XR, Chen X, Cheng XB, Zhang XQ, et al. Lithiophilic sites in doped graphene guide uniform lithium nucleation for dendrite-free lithium metal anodes. Angew. Chem. Int. Ed. 2017;56(27):7764–7768. doi: 10.1002/anie.201702099. [DOI] [PubMed] [Google Scholar]

- 68.Parker JF, Chervin CN, Nelson ES, Rolison DR, Long JW. Wiring zinc in three dimensions re-writes battery performance—dendrite-free cycling. Energy Environ. Sci. 2014;7(3):1117–1124. doi: 10.1039/c3ee43754j. [DOI] [Google Scholar]

- 69.Parker JF, Chervin CN, Pala IR, Machler M, Burz MF, et al. Rechargeable nickel–3D zinc batteries: an energy-dense, safer alternative to lithium-ion. Science. 2017;356(6336):414–417. doi: 10.1126/science.aak9991. [DOI] [PubMed] [Google Scholar]

- 70.Zhang R, Yin PG, Wang N, Guo L. Photoluminescence and Raman scattering of ZnO nanorods. Solid State Sci. 2009;11(4):865–869. doi: 10.1016/j.solidstatesciences.2008.10.016. [DOI] [Google Scholar]

- 71.Liu C, Xu W, Mei C, Li M, Chen W, et al. A chemically self-charging flexible solid-state zinc-ion battery based on VO2 cathode and polyacrylamide–chitin nanofiber hydrogel electrolyte. Adv. Energy Mater. 2021;11(25):2003902. doi: 10.1002/aenm.202003902. [DOI] [Google Scholar]

- 72.Lv Z, Luo Y, Tang Y, Wei J, Zhu Z, et al. Editable supercapacitors with customizable stretchability based on mechanically strengthened ultralong MnO2 nanowire composite. Adv. Mater. 2018;30(2):1704531. doi: 10.1002/adma.201704531. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.