Abstract

Clostridium botulinum produces a characteristic botulinum neurotoxin which can cause an often fatal neuroparalytic condition known as botulism. Although food-borne botulism is rare, critical screening by food companies is necessary to ensure that food products are safe. At present, the food industry assesses the risks of botulinum neurotoxin production by challenge testing to check any new food products and to check the efficacy of new storage regimes. Challenge testing involves artificial introduction of defined strains of microorganisms into food, and microbial growth and possible toxin production are then monitored. Botulinum toxin is normally analyzed by using the mouse bioassay. However, the mouse bioassay is expensive, slow, and politically sensitive because of animal rights issues. In this paper we describe adaptation of a new assay, competitive reverse transcription-PCR (RT-PCR), to monitor botulinum neurotoxin production. This method accurately measures the level of toxin-encoding mRNA in C. botulinum cells. Measurement of mRNA should provide a good indication of gene expression as mRNA is turned over rapidly in bacterial cells. In addition, the method is rapid, specific, and sensitive. The competitive RT-PCR method was developed to examine C. botulinum E VH toxin gene expression and was used to investigate the level of toxin production by C. botulinum E VH when the organism was grown in two different types of broth. The results which we obtained with the competitive RT-PCR method demonstrated that this method is more rapid and more sensitive than the mouse bioassay.

Clostridium botulinum produces a characteristic botulinum neurotoxin (BoNT) which causes a neuroparalytic condition known as botulism (9). Botulism has been classified into the following four categories: food borne, infant, wound, and unknown (5, 8). The classical food-borne botulism is primarily due to ingestion of preformed toxin in foods. The ingested neurotoxin can survive exposure to the gastric juices, enter the blood stream through the intestine, and cause flaccid muscle paralysis after it blocks acetylcholine release at neuromuscular junctions (18, 21). The BoNTs are categorized on the basis of their serological specificities into seven different types (types A through G) and are some of the most potent toxins known to exist in nature. The lethal dose for mice is 0.3 ng/kg, while the lethal dose for humans is thought to be 0.2 to 2.0 μg/kg (14). The organism is ubiquitous in soils and is commonly detected in raw materials used to prepare food products. Nonetheless, outbreaks of food-borne botulism are rare due to the rigorous application of appropriate processing techniques. Some of the techniques used (e.g., canning) may result in complete sterilization of the food, while others keep the food under conditions that do not allow toxin production. In addition to monitoring the efficacy of the procedures used, it is also essential that food manufacturers verify that production of botulinal toxin in food products can be prevented from time of production to consumption. At present, the food industry assesses the risks of BoNT production by challenge testing and validation. Production of toxin in challenge tests is usually analyzed by the in vivo mouse bioassay, which is the most widely accepted and sensitive assay for detection of BoNT. Although this bioassay can be used to distinguish all toxin types, it has a number of disadvantages. To fully determine the toxin serotype, neutralization tests with specific antisera must be carried out in parallel. The mouse test is also slow, expensive, and politically sensitive because of animal rights issues. BoNT could be detected better and, consequently, the safety of products could be assessed better by a rapid, sensitive, and specific in vitro assay. A number of in vitro assays have been developed; these included enzyme-linked immunosorbent assays, radioimmunoassays, and PCR probe identification assays. At this time, none of these is sensitive enough to replace the mouse bioassay (1, 8, 15, 16, 23, 25).

In this paper we describe adaptation of a new assay, competitive reverse transcription-PCR (RT/PCR), for monitoring BoNT production as a function of mRNA levels. Competitive RT-PCR is a quantitative version of the RT-PCR method in which a known number of copies of an exogenously synthesized control RNA are introduced together with a test RNA sample into a reaction mixture. The basis of the competitive RT-PCR technique is coamplification of a nucleic acid of interest and the control cDNA. This is possible if the target and control have almost the same DNA sequence and, in particular, have identical primer binding sites. Both targets compete for the common primers and reagents in the same reaction tube. Quantification is then accomplished by comparing the PCR signal of the specific template with the PCR signals obtained with known concentrations of the competitor. The amplified control and the target derived from the cDNA of interest can be distinguished by size by constructing standards having the same sequence as the specific target but containing a deletion or an insertion (6, 22).

We describe a competitive RT-PCR method that was designed to quantify toxin production by C. botulinum E VH dolman when it was grown in two different types of broth.

MATERIALS AND METHODS

Bacterial strain and growth conditions.

C. botulinum E VH dolman was used in this study and was chosen because the toxin gene has been sequenced (3). This strain was maintained in cooked meat medium at room temperature. Cultures that were used for RNA extraction were routinely grown in brain heart infusion (BHI) broth (Oxoid) and type E broth (40.0 g of NZ Amine [casein enzyme hydrolysate], 5.0 g of yeast extract, 1.0 g of l-cysteine-HCl monohydrate, 10.0 g of d-glucose [anhydrous], 1 liter of distilled water; pH adjusted to 7.2 with NaOH). Flasks containing 180 ml of broth were each inoculated with 20 ml of an overnight culture and incubated at 33°C in an anaerobic workstation (Don Whitley, Shipley, United Kingdom). The atmosphere inside the cabinet contained nitrogen, carbon dioxide, and hydrogen (80:10:10). Cultures were monitored by monitoring the absorbance at 660 nm, by preparing serial dilutions and then determining viable counts on BHI agar spread plates, and by direct counting with an improved Neubauer counting chamber.

Extraction of total RNA from C. botulinum E VH.

A modified RNA extraction method in which we used triisopropylnaphthalene sulfonic acid (sodium salt) (TNS) buffer (10) was used to extract total RNA from C. botulinum E VH at different stages of growth. The extraction buffer contained 1% TNS, 6% p-4-aminosalicylic acid (sodium salt), 200 mM Tris-HCl, 25 mM EDTA, and 250 mM NaCl (pH 7.8). The cells from a 200-ml culture were harvested by centrifugation (15,000 × g, 10 min, 4°C), resuspended in 1 ml of TNS buffer, and frozen in liquid nitrogen in 1.5-ml microcentrifuge tubes. The cells were left to thaw on ice and transferred to centrifuge tubes. Three volumes of TNS buffer was added to each sample, and the samples were gently mixed. The samples were centrifuged at 7,500 × g for 10 min at 4°C. Each supernatant was collected, and 1 volume of phenol followed by 0.5 volume of chloroform was added. The samples were gently mixed for 30 s and then centrifuged (1,400 × g, 15 min, room temperature). The upper aqueous phase of each sample was removed and placed in a Corex tube, and the RNA was precipitated with 2 volumes of ice-cold ethanol overnight at −20°C. The RNA was pelleted by centrifugation (17,000 × g, 20 min, 4°C), and the remaining alcohol was allowed to evaporate. The pellet was resuspended in 100 μl of sterile Milli-Q water. Total RNA concentrations were determined with a Gene Quant RNA/DNA calculator (Pharmacia). The concentration was determined by measuring the absorbance at 260 nm and using the following relationship: 1 optical density unit = 40 mg of RNA ml−1. Both viable and total cell counts were determined for each RNA preparation.

Removal of genomic DNA from extracted RNA by using RNase-free DNase I.

Contaminating DNA was removed from total RNA by using 10 U of RNase-free DNase I (Boehringer Mannheim) in a 10-μl reaction mixture containing approximately 6 μg of total RNA per μl and 6.25 mM MgCl2. The reaction mixture was incubated for 30 min at 37°C, and the DNase I was inactivated by adding 1 μl of 20 mM EDTA to the mixture and incubating it for 1 min at 37°C and then for 10 min at 65°C.

Developing the construct used to produce control RNA.

The construct used to produce control DNA was designed to be shorter than the target RNA by creating a small, 19-bp deletion in a 250-bp PCR product. The PCR was performed with a 100-μl reaction mixture containing 20 ng of C. botulinum E VH genomic DNA per μl, 40 pmol of each primer (primer S1 forward [5′AGCAAATAGAAAATGAAC3′] and primer S1 reverse [5′GGAATACTATTATTTAGGGTA3′]; (Gibco BRL) per μl, each deoxynucleoside triphosphate (dATP, dGTP, dCTP, and dTTP; Pharmacia) at a concentration of 0.2 mM, 20 mM Tris-HCl (pH 8.4), 50 mM KCl, 1.5 mM MgCl2, and 2.5 U of Taq DNA polymerase (Gibco BRL). The PCR mixture was overlaid with 1 drop of mineral oil before amplification with a Biometra Trio-Thermoblock apparatus. Each PCR cycle consisted of denaturation for 1 min at 94°C, annealing for 30 s at 40°C, and extension for 30 s at 72°C; 31 such cycles were followed by a final extension cycle consisting of 72°C for 10 min. A 600-ng portion of the 250-bp PCR product was digested with restriction enzyme VspI (Gibco BRL) as recommended by the manufacturer. The restriction digest was incubated overnight at 37°C, and then 0.5 M EDTA was added to a final concentration of 10 mM to inactivate the restriction enzyme. The restriction digest of the 250-bp PCR product from C. botulinum E VH was analyzed on a 1.5% agarose gel, which produced three fragments (137, 94, and 19 bp). The two largest fragments were separated from the 19-bp fragment by cutting them from the gel with a scalpel under short-wavelength UV light. The DNA was recovered from the agarose gel slice by using GenElute agarose spin columns (Supelco). The agarose gel slice containing DNA was placed in a washed GenElute column and centrifuged (10 min, 12,000 × g). DNA from the 94-bp fragment and DNA from the 137-bp fragment were collected in a 1.5-ml microcentrifuge tube. The 94- and 137-bp fragments were ligated to produce a 231-bp construct in a 10-μl (final volume) reaction mixture containing 1 U of T4 DNA ligase and 2.5× ligation buffer (Boehringer Mannheim). The ligation mixture was incubated overnight at 14°C, and then the ligase was inactivated (65°C, 10 min). The products were washed by passing the preparation through a Microcon 30 Microconcentrator sterile filter (Amicon) and using sterile water to remove the buffer. The ligated products were resuspended in 10 μl of sterile water.

Construction of the control RNA construct with the T7 promoter for in vitro production of RNA.

A T7 promoter was attached to the 231-bp construct by using a pCR-Script Amp SK(+) cloning kit as recommended by the manufacturer (Stratagene). The resulting plasmid-containing colonies were screened by performing a PCR with a T7 primer (5′GTAATACGACTCACTATAGGGC3′) and the S1 reverse primer to determine if the 231-bp fragment was inserted downstream of the T7 promoter. The PCR conditions and cycles were the same as those used to amplify the 250-bp PCR product. Agarose gel electrophoresis was used to screen for the presence of inserts, and successful recombinants were purified by using large-scale plasmid preparations. Prior to in vitro transcription, the plasmid template was linearized with a restriction enzyme that cleaved downstream of the RNA polymerase promoter and the insert in the multiple cloning site. The plasmid was cut with 20 U of HaeII (Gibco BRL) as recommended by the manufacturer. The restriction digest was incubated (3 h, 37°C) and then inactivated at 65°C for 10 min. Following restriction digestion of the DNA with HaeII, the DNA was purified by adding 50 μg of proteinase K per μl to the restriction buffer (30 min, 37°C), followed by two phenol-chloroform (1:1, vol/vol) extractions and ethanol precipitation prior to the transcription reaction. The digested DNA was resuspended in diethyl pyrocarbonate-treated water (Sigma) to a final concentration of 1 mg ml−1.

Production of control RNA by using an in vitro transcription reaction.

A transcription reaction was performed with a 25-μl reaction mixture containing 1 μg of restricted, proteinase K-treated DNA template, 40 mM Tris-HCl (pH 8.0), 8 mM MgCl2, 2 mM spermidine, 50 mM NaCl, each deoxynucleoside triphosphate (ATP, GTP, CTP, and UTP) at a concentration of 0.4 mM, and 10 U of T7 RNA polymerase (Stratagene). The reaction mixture was incubated for 30 min at 37°C. The DNA template was removed after the transcription reaction by incubating the mixture with 10 U of RNase-free DNase I for 1 h at 37°C. The DNase I was inactivated by adding 1 μl of 20 mM EDTA and incubating the preparation for 1 min at 37°C and then for 10 min at 65°C.

Competitive RT-PCR.

mRNA from C. botulinum E VH grown to the mid-log phase (3 h) and the early stationary phase (5 h) in BHI broth and type E broth were quantified by using the competitive RT-PCR. RT was carried out in a 20-μl reaction mixture containing approximately 2 μg of target RNA and a known amount of control RNA. To quantify C. botulinum mRNA, the control RNA was introduced by using a 1:2 dilution series (4.6 × 10−10 to 9.2 × 10−13 g). Each RT reaction mixture contained (final concentrations) 50 mM Tris-HCl (pH 8.3), 75 mM KCl, 3 mM MgCl2 (Gibco BRL), a deoxynucleoside triphosphate mixture (Gibco BRL) containing each deoxynucleoside triphosphate at a concentration of 1 mM, 100 pmol of S1 reverse primer per μl, 0.5 U of RNase Out (Gibco BRL), 2 μl target of RNA, 1 μl of control RNA, and 20 U of Superscript reverse transcriptase (Gibco BRL). The reaction mixture was incubated at 37°C for 1 h, and then the reverse transcriptase was inactivated (95°C, 5 min). A 5-μl portion of the resulting cDNA was amplified by PCR by using a 100-μl mixture which contained 100 pmol of S1 forward primer per μl, 100 pmol of S1 reverse primer per μl, each deoxynucleoside triphosphate (dATP, dGTP, dCTP, and dTTP; Pharmacia) at a concentration of 0.2 mM, 20 mM Tris-HCl (pH 8.4), 50 mM KCl, 1.5 mM MgCl2, and 2.5 U of Taq DNA polymerase (Gibco BRL). Each PCR cycle consisted of denaturation for 1 min at 94°C, annealing for 30 s at 40°C, and extension for 30 s at 72°C; 31 such cycles were followed by a final extension cycle consisting of 72°C for 10 min. The competitive products were analyzed on a 1.5% Metaphore agarose gel (Flowgen). Duplicate samples were examined, and in the control no reverse transcriptase was added to ensure that only mRNA, not the genomic DNA, was amplified. The densities of the competitively amplified 250- and 231-bp bands at each dilution were measured by using the image analysis software Phoretix 1 D, version 3.0 (Phoretix International Ltd).

Mouse bioassay.

Expression of the C. botulinum E VH toxin gene was detected by the mouse bioassay in the early stationary phase when the organism was grown in BHI broth and type E broth. Extraction and the assay for botulinal toxin were performed as described by Malizo et al. (13). Cells from 200-ml broth cultures were concentrated by centrifugation at 7,500 × g for 30 min at 4°C. The supernatant was decanted and stored at 4°C for further use. The pelleted cells were resuspended in 10 ml of ultrapure water, and lysozyme was added at a concentration of 1 mg ml−1. The cells were incubated on ice for 15 min and then transferred to 37°C and incubated at this temperature for 15 min. The cell debris was collected by centrifugation at 6,000 × g for 20 min at 4°C, the supernatant containing 10 ml of cell lysate was decanted into a sterile universal bottle, and the cell debris was discarded. The 200 ml of cell-free supernatant that was collected previously was added to the 10 ml of cell lysate to make up the toxin sample. By using a Sartorious ultrafiltration cell with a 100-kDa cutoff membrane, four 50-ml portions of each sample were concentrated to a volume of 10 ml. Each 10-ml portion was centrifuged (1,400 × g) by using an Amicon syringe filter (10-kDa cutoff), and the preparation was concentrated to a volume of 1 ml. A portion of each sample was treated with trypsin; 100 μl of extract was added to 350 μl of trypsin buffer (0.1 M sodium phosphate, pH 6.0), and 25 μl of trypsin (100 mg ml−1) was then added. The mixture was incubated at 37°C for 30 min, and the reaction was stopped with 25 μl of soybean trypsin inhibitor (10 mg ml−1; Sigma). Portions (200 μl) of each extract were injected intraperitoneally into duplicate mice and the mice were observed for the onset of classical botulism symptoms, such as lethargy, collapsed rib cages, and paralysis. Neutralization experiments were performed to verify that the toxin was neutralized by its antitoxin (type E antitoxin; reference no. BS0613; Centers for Disease Control and Prevention).

RESULTS

Target RNA extraction from C. botulinum E VH.

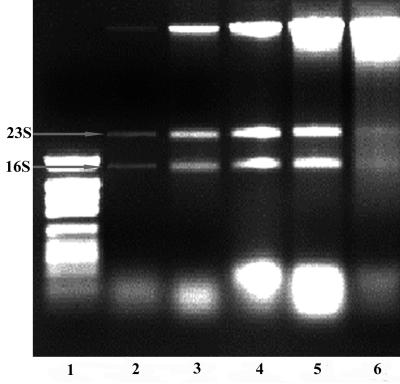

Isolation of RNA requires an effective means of cell disruption, a procedure for separating the nucleic acid from the protein, and a method for purifying the RNA from contaminating genomic DNA. To avoid degradation or denaturation, the RNA must be protected throughout the process from liberated nucleases, strong mechanical forces, high temperatures, and extremes of pH and ionic strength. The RNA extraction method used here was a modification of the method devised by Parish and Kirby, and it involved an extraction buffer containing two detergents (TNS and p-aminosalicylic acid) which effectively extracts RNA and rapidly inactivates nucleases. The secondary structure of the RNA was maintained by the relatively high ionic strength of the extraction buffer and was rendered less liable to degradation by residual nucleases. Several methods of extracting total RNA from C. botulinum E VH were tested; these included performing the TNS extraction procedure at various temperatures (0 to 50°C) and homogenization with glass beads. The most reproducible results were obtained when cells were rapidly lysed with TNS buffer at 0°C (data not shown). The quality of total cellular RNA extracted from BHI broth-grown cells was monitored by agarose gel electrophoresis (Fig. 1), which resulted in sharp, undegraded 3-kb (23S RNA) and 1.5-kb (16S RNA) bands. Unlike commercial kits, the extraction system used here could be used to extract RNA from cells in the stationary phase, and good band formation was observed with extracts obtained during the stationary phase (12 h of growth).

FIG. 1.

Extraction of total RNA from C. botulinum E VH at different growth phases in BHI broth. Lane 1, 100-bp molecular weight marker; lane 2, RNA extracted at the early mid-log phase (3 h); lane 3, RNA extracted at the mid-log phase (5 h); lane 4, RNA extracted at the early stationary phase (7 h); lane 5, RNA extracted at the stationary phase (12 h); lane 6, RNA extracted at the late stationary phase (24 h).

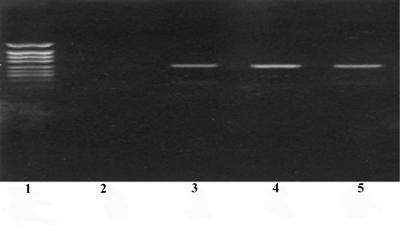

Detection of C. botulinum E VH toxin gene expression by RT-PCR following DNase I treatment.

A total cellular RNA extract was used in an RT-PCR assay to detect C. botulinum E VH toxin-specific mRNA (Fig. 2). An analysis of the gel showed that RT-PCR amplified a 250-bp fragment from C. botulinum E VH target mRNA, as expected. The controls on this gel (Fig. 2, lanes 2, 4, and 5) demonstrated that it was the mRNA, not any contaminating genomic DNA that was coextracted with the total cellular RNA, which was amplified. Lane 3 shows that the 250-bp product was amplified by RT-PCR following treatment with 10 U of DNase I, as the control system in lane 2 did not give false-positive results; therefore, the DNase I removed all trace amounts of contaminating DNA. These results can be compared to the false-positive results shown in lane 4, in which there was no DNase I treatment and a 250-bp band is clearly visible.

FIG. 2.

Detection of C. botulinum E VH toxin gene expression by RT-PCR following DNase I treatment. Lane 1, molecular weight marker (PUC 19 DNA cut with MspI); lane 2, RNA treated with 10 U of DNase I, followed by PCR; lane 3, RNA treated with 10 U of DNase I, followed by RT-PCR; lane 4, RNA not treated with DNase I, followed by PCR; lane 5, RNA not treated with DNase I, followed by RT-PCR.

Production of a 231-bp fragment from control RNA and confirmation by RT-PCR.

The in vitro transcription reaction was performed by using the enzyme T7 polymerase, which is highly specific for the T7 promoter. After in vitro transcription, the remaining DNA template had to be hydrolyzed with 10 U of DNase I to prevent false-positive results. The purified copy RNA was amplified by RT-PCR to produce a 231-bp product. The original primer pair that was designed to produce the 231-bp construct was used in this RT-PCR. The results (data not shown) demonstrated that the copy RNA was amplified to produce a 231-bp product only when both T7 polymerase and reverse transcriptase were present.

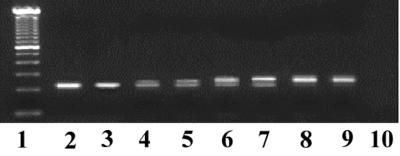

Quantification of C. botulinum E VH toxin gene expression.

With the competitive RT-PCR method, the control RNA and target RNA are made so that the primer binding sites are identical and the sequences are almost identical. Consequently, the kinetics of amplification are likely to be almost indistinguishable as both the target and the control compete for the primers and reagents in the same reaction. In the competitive RT-PCR analysis of C. botulinum E VH, a dilution series of the control RNA was used, and the point at which the concentrations of the control and target amplicons were equal was the point at which the initial control and target template concentrations were equivalent in the reaction mixture. For C. botulinum E VH, the amplified control RNA was 19 bp smaller than the amplified target RNA; this difference distinguished the two amplicons in which we were interested.

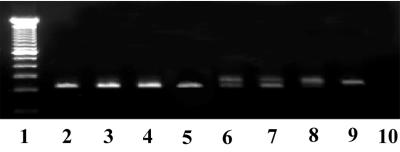

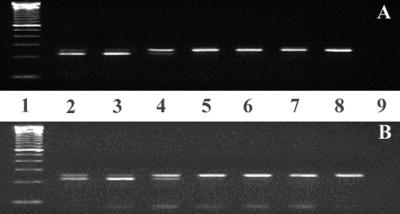

Type E broth is known to stimulate high-titer toxin production, as determined by the mouse bioassay. Using this information, we used the competitive RT-PCR method to investigate expression of the C. botulinum E VH toxin gene when the organism was grown in type E broth and BHI broth. In an initial experiment, we found that at the stationary phase, the target RNA from a type E broth culture corresponded to the control RNA at a dilution of 1:2,500 (Fig. 3). However, the target RNA from a BHI broth culture corresponded to the control RNA at a dilution of 1:250,000 (Fig. 4). These findings show that there was a 100-fold difference in the amounts of toxin produced in the two broth preparations when the competitive RT-PCR was used. The competitive RT-PCR results were compared to the results of the mouse bioassay used to detect C. botulinum E VH toxin production in the two types of broth at the stationary phase. Using the mouse bioassay, we found that type E broth-produced toxin killed the mice only down to a toxin dilution of 1:100, while the BHI broth-produced toxin killed the mice only down to a toxin dilution of 1:1 (Table 1). The mouse bioassay, therefore, revealed that there was a 100-fold difference in the amount of toxin produced between the two types of broth, which correlated with the 100-fold difference detected with the competitive RT-PCR system. Thus, there was a close correlation between the toxin-specific mRNA levels detected by the competitive RT-PCR method and the actual toxin levels detected by the mouse bioassay.

FIG. 3.

Quantification of C. botulinum E VH toxin gene expression in type E broth by competitive RT-PCR. Lane 1, 100-bp molecular weight marker; lane 2, 1:500 dilution of control RNA; lane 3, 1:750 dilution of control RNA; lane 4, 1:1,000 dilution of control RNA; lane 5, 1:2,500 dilution of control RNA; lane 6, 1:5,000 dilution of control RNA; lane 7, 1:7,500 dilution of control RNA; lane 8, 1:10,000 dilution of control RNA; lane 9, 1:50,000 dilution of control RNA; lane 10, PCR control containing no DNA.

FIG. 4.

Quantification of C. botulinum E VH toxin gene expression in BHI broth by competitive RT-PCR. Lane 1, 100-bp molecular weight marker; lane 2, 1:10,000 dilution of control RNA; lane 3, 1:25,000 dilution of control RNA; lane 4, 1:50,000 dilution of control RNA; lane 5, 1:75,000 dilution of control RNA; lane 6, 1:100,000 dilution of control RNA; lane 7, 1:250,000 dilution of control RNA; lane 8, 1:500,000 dilution of control RNA; lane 9, 1:750,000 dilution of control RNA; lane 10, PCR control containing no DNA.

TABLE 1.

Quantification of C. botulinum E VH toxin gene expression in BHI broth cultures and type E broth cultures, as determined by the mouse bioassay

| Culture | No. of mice that survived/no. of mice tested

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Neat | 1:1 Dilution | 1:2 Dilution | 1:5 Dilution | 1:10 Dilution | 1:20 Dilution | 1:50 Dilution | 1:100 Dilution | 1:500 Dilution | 1:1,000 Dilution | Control | |

| BHI broth | 0/2 | 0/2 | 2/2 | 2/2 | 2/2 | 2/2 | 2/2 | 2/2 | 2/2 | 2/2 | 2/2 |

| Type E broth | 0/2 | 0/2 | 0/2 | 0/2 | 0/2 | 0/2 | 0/2 | 0/2 | 2/2 | 2/2 | 2/2 |

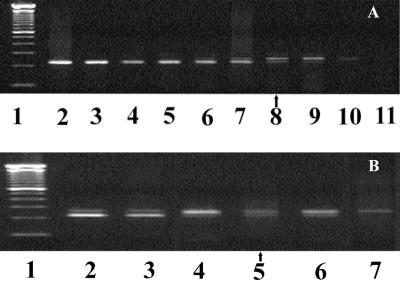

The competitive RT-PCR method was also used to compare toxin gene expression in mid-log-phase and stationary-phase cultures grown in both BHI broth and type E broth. We found that at the mid-log and stationary phases, the target RNA from the type E broth culture corresponded to the control RNA at dilutions of 1:500,000 and 1:5,000, respectively (Fig. 5). Thus, there was 100-times more mRNA present at the stationary phase than at the mid-log phase. However, the target RNA from the BHI broth culture corresponded to the control RNA at a dilution of 1:100,000 for both the mid-log and stationary phases (Fig. 6). Therefore, no difference in mRNA levels as a function of growth phase was apparent for this medium.

FIG. 5.

(A) Quantification of C. botulinum E VH toxin gene expression in type E broth at the mid-log phase by competitive RT-PCR. Lane 1, 100-bp molecular weight marker; lane 2, 1:1,000 dilution of control RNA; lane 3, 1:5,000 dilution of control RNA; lane 4, 1:10,000 dilution of control RNA; lane 5, 1:50,000 dilution of control RNA; lane 6, 1:75,000 dilution of control RNA; lane 7, 1:100,000 dilution of control RNA; lane 8, 1:500,000 dilution of control RNA; lane 9, 1:750,000 dilution of control RNA; lane 10, 1:1,000,000 dilution of control RNA; lane 11, PCR control containing no DNA. (B) Quantification of C. botulinum E VH toxin gene expression in type E broth at the stationary phase by competitive RT-PCR. Lane 1, 100-bp molecular weight marker; lane 2, 1:250 dilution of control RNA; lane 3, 1:500 dilution of control RNA; lane 4, 1:2,500 dilution of control RNA; lane 5, 1:5,000 dilution of control RNA; lane 6, 1:7,500 dilution of control RNA; lane 7, 1:10,000 dilution of control RNA.

FIG. 6.

Quantification of C. botulinum E VH toxin gene expression in BHI broth at the mid-log phase (A) and stationary phase (B) by competitive RT-PCR. Lane 1, 100-bp molecular weight marker; lane 2, 1:50,000 dilution of control RNA; lane 3, 1:75,000 dilution of control RNA; lane 4, 1:100,000 dilution of control RNA; lane 5, 1:250,000 dilution of control RNA; lane 6, 1:500,000 dilution of control RNA; lane 7, 1:750,000 dilution of control RNA; lane 8, 1:1,000,000 dilution of control RNA; lane 9, PCR control containing no DNA.

DISCUSSION

Isolating high-quality RNA is one of the most challenging tasks in modern microbiology. In this paper we describe a modified Parish-Kirby method for extracting intact total RNA from C. botulinum by using a TNS extraction buffer. This powerful detergent-based buffer allows a wide range of growth conditions to be investigated compared to kits that are restricted to mid-log-phase cells. In only a few reports have workers described recovery of mRNA from microbial cells in a form that can be used for molecular analyses, such as cDNA synthesis and RT-PCR analyses (2, 11, 12, 17, 19, 20). The main problem with quantification of bacterial RNA by competitive RT-PCR is the presence of contaminating genomic DNA which is coextracted with the RNA. In eukaryotic systems, RT-PCR primers spanning one or more introns can be designed to prevent amplification of DNA in the time allowed for primer extension. Bacterial systems rely on the use of DNase I treatment for removing contaminating DNA and avoiding false-positive results. The complete removal of contaminating genomic DNA from C. botulinum E VH described here was shown to require 10 U of DNase I, an amount which is three times less than the amount used in previous prokaryotic studies that used 30 U of DNase I to remove DNA (17, 20). Furthermore, heat inactivation of 10 U of DNase I in the presence of EDTA was found to be more reliable than using traditional phenol-chloroform extraction procedures, which were found to reduce the RNA yield by up to 60%.

The development of a competitive RT-PCR technique depends on efficient methods for generating control RNA in vitro. The internal control used in this project was less difficult to produce than the internal controls used in some eukaryotic competitive RT-PCR systems (7, 24). Production of the control RNA involved deleting 19 bp from the sequence of interest before insertion into the vector. Removal of the 19-bp fragment was facilitated by excising the two larger restriction digest fragments from the gel, collecting the DNA from the gel slices with spin columns, and religating, which resulted in a construct that was 19 bp smaller than the target. This technique has been used successfully with Salmonella typhimurium in our labs. In this technique it is also important to note the end point for determining the point at which the amount of amplified target mRNA matches the amount of the diluted control RNA. Observation by eye can be subjective; therefore, the end points were all determined by using densitometry and the image analysis software Phoretix 1 D, version 3.0.

C. botulinum E VH target RNA was successfully quantified by using the competitive RT-PCR technique described here. This assay has proven to be more sensitive and more rapid than the mouse bioassay. When the competitive RT-PCR method was compared with the mouse bioassay, both assays revealed that at the stationary phase, C. botulinum E VH grown in type E broth produced 100 times more BoNT than C. botulinum E VH grown in BHI broth produced. This good correlation indicates that the competitive RT-PCR technique could be used as a more efficient method for detecting C. botulinum toxin gene expression than the mouse bioassay.

When the different growth stages were examined, the competitive RT-PCR assay showed that at the stationary-phase the type E broth culture produced 100 times more BoNT mRNA than the mid-log-phase type E broth culture produced. In the BHI broth culture, there was no difference in toxin gene expression between the two different growth stages. These results showed that a type E broth culture produces higher mRNA levels at the stationary phase than a BHI broth culture produces, indicating that the culture medium affects toxin production. Our results also showed that we could use competitive RT-PCR to focus on the effects of different growth phases in order to investigate what signals might affect toxin production. To date, there is limited data available concerning the kinetics of growth and production of botulinum toxin when factors such as temperature and storage are considered (4). Such factors and conditions need to be fully investigated and examined to ensure that new and existing food products are safe.

The purpose of this project was to develop a competitive RT-PCR method for detection of toxigenic C. botulinum. To do this, the procedure was carried out under optimal conditions for isolating RNA from the bacteria. This method could be used to detect C. botulinum in food samples after the minimum sensitivity is determined. Initial testing of food samples should involve extraction of RNA from homogenized foods that have been spiked with dilutions of C. botulinum cultures. Aranda et al. (1) have shown that PCR can be used to detect C. botulinum types A, B, E, and F in foods, and based on their results obtained with PCR, it is probable that competitive RT-PCR could be used as a sensitive and rapid technique for routine analysis of C. botulinum toxin gene expression.

In conclusion, the competitive RT-PCR method could be a significant development for quantification of C. botulinum toxin gene expression, especially in the food industry, and could help determine the factors that influence botulinum toxin production in foods. The good correlation between the results of the two methods compared in this study illustrates the effectiveness of competitive RT-PCR for investigating C. botulinum toxin gene expression and suggests that this method could be used to investigate prokaryotic gene expression and transcriptional control in general. Little is known about the effects of certain factors at the transcriptional level in bacteria, and it is possible that competitive RT-PCR could be used to provide data concerning what may switch on and off the transcription mechanism.

ACKNOWLEDGMENTS

This work was supported by grants from the Department of Education for Northern Ireland and Campden and Chorleywood Food Research Association.

REFERENCES

- 1.Aranada E, Rodriguez M M, Cordoba J J. Detection of Clostridium botulinum types A, B, E and F in foods by PCR and DNA probe. Lett Appl Microbiol. 1997;25:186–190. doi: 10.1046/j.1472-765x.1997.00204.x. [DOI] [PubMed] [Google Scholar]

- 2.Bej A K, We-yao N, Morgan S, Jones D D, Mahbubani M H. Detection of viable Vibrio cholerae by reverse transcriptase polymerase chain reaction. Mol Biotechnol. 1996;5:1–10. doi: 10.1007/BF02762407. [DOI] [PubMed] [Google Scholar]

- 3.Campbell K D, Collins M D, East A K. Gene probes for identification of the botulinal neurotoxin gene and specific identification of neurotoxin types B, E, and F. J Clin Microbiol. 1993;31:2255–2262. doi: 10.1128/jcm.31.9.2255-2262.1993. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Carlin F, Peck M W. Growth of and toxin production by nonproteolytic Clostridium botulinum in cooked pureed vegetables at refrigeration temperatures. Appl Environ Microbiol. 1996;62:3069–3072. doi: 10.1128/aem.62.8.3069-3072.1996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Collins M D, East A K. Phylogeny and taxonomy of the food-borne pathogen Clostridium botulinum and its neurotoxins. J Appl Microbiol. 1998;84:5–17. doi: 10.1046/j.1365-2672.1997.00313.x. [DOI] [PubMed] [Google Scholar]

- 6.Foley K P, Leonard M W, Engel J D. Quantitation of RNA using the polymerase chain reaction. Trends Genet. 1993;9:380–384. doi: 10.1016/0168-9525(93)90137-7. [DOI] [PubMed] [Google Scholar]

- 7.Gebhardt A, Peters A, Gerding D, Niendorf A. Rapid quantitation of RNA species in ethidium-bromide stained gels of competitive reverse transcription-polymerase chain reaction products. J Lipid Res. 1994;35:976–981. [PubMed] [Google Scholar]

- 8.Harris L, Griffiths M W. The detection of food-borne pathogens by the polymerase chain reaction. Food Res Int. 1992;25:457–469. [Google Scholar]

- 9.Hatheway C L. Clostridium botulinum and other clostridia that produce botulinum toxin. In: Hauschild A H W, Dodds K L, editors. Clostridium botulinum: ecology and control in foods. New York, N.Y: Marcel Dekker, Inc.; 1992. pp. 3–20. [Google Scholar]

- 10.Haylock R, Broda P. Preparation and characterization of mRNA from ligninolytic fungi. Methods Enzymol. 1988;161:221–227. [Google Scholar]

- 11.Jou N T, Yoshimori R B, Mason G R, Louie J S, Liebling M R. Single-tube, nested, reverse transcriptase-polymerase chain reaction for detection of viable Mycobacterium tuberculosis. J Clin Microbiol. 1997;35:1161–1165. doi: 10.1128/jcm.35.5.1161-1165.1997. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Klein P G, Juneja V K. Sensitive detection of viable Listeria monocytogenes by reverse transcription-polymerase chain reaction. Appl Environ Microbiol. 1997;63:4441–4448. doi: 10.1128/aem.63.11.4441-4448.1997. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Malizo C, Harrod J, Kaufman K M, Johnson E A. Arginine promotes toxin formation in cheddar cheese by Clostridium botulinum. J Food Prot. 1993;56:769–772. doi: 10.4315/0362-028X-56.9.769. [DOI] [PubMed] [Google Scholar]

- 14.Middlebrook J L. Cell surface receptors for protein toxins. In: Simpson L L, editor. Botulinum neurotoxin and tetanus toxin. San Diego, Calif: Academic Press; 1989. pp. 95–119. [Google Scholar]

- 15.Notermans S, Hagenaars A M, Kozaki S. The enzyme linked immunosorbent assay (ELISA) for the detection and determination of Clostridium botulinum toxins A, B and E. Methods Enzymol. 1982;84:223–238. doi: 10.1016/0076-6879(82)84020-2. [DOI] [PubMed] [Google Scholar]

- 16.Potter M D, Meng J, Kimsey P. An ELISA for detection of botulinal toxin types A, B and E in inoculated food samples. J Food Prot. 1993;56:856–861. doi: 10.4315/0362-028X-56.10.856. [DOI] [PubMed] [Google Scholar]

- 17.Sails A D, Bolton F J, Fox A J, Wareing D R A, Greenway D L A. A reverse transcriptase polymerase chain reaction assay for the detection of thermophilic Campylobacter spp. Mol Cell Probes. 1998;12:1–6. doi: 10.1006/mcpr.1998.0184. [DOI] [PubMed] [Google Scholar]

- 18.Sakaguchi G. Clostridium botulinum toxins. Pharmacol Ther. 1983;19:165–194. doi: 10.1016/0163-7258(82)90061-4. [DOI] [PubMed] [Google Scholar]

- 19.Selvaratnan S, Schoedel B A, McFarland B L, Kulpa C F. Application of reverse transcription-polymerase chain reaction for monitoring expression of catabolic dMPN gene in a phenol-degrading sequence batch reactor. Appl Environ Microbiol. 1995;61:3981–3985. doi: 10.1128/aem.61.11.3981-3985.1995. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Sheridan G E C, Masters C I, Shallcross J A, Mackey B M. Detection of mRNA by reverse transcription-polymerase chain reaction as an indicator of viability in Escherichia coli cells. Appl Environ Microbiol. 1998;64:1313–1318. doi: 10.1128/aem.64.4.1313-1318.1998. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Simpson L L. Kinetic studies on the interaction between botulinum toxin type A and the cholinergic neuromuscular junction. J Pharmacol Exp Ther. 1980;212:16–21. [PubMed] [Google Scholar]

- 22.Souaze F, Ntodou-Thome A, Tran C Y, Rostene W, Forgez P. Quantitative RT-PCR: limits and accuracy. BioTechniques. 1996;21:280–285. doi: 10.2144/96212rr01. [DOI] [PubMed] [Google Scholar]

- 23.Szabo E A, Pemberton J M, Gibson A M, Eyles M J, Desmarchelier P M. PCR for detection of Clostridium botulinum types A, B and E in food, soil and infant faeces. J Appl Bacteriol. 1994;76:539–545. doi: 10.1111/j.1365-2672.1994.tb01650.x. [DOI] [PubMed] [Google Scholar]

- 24.Tsai S, Wiltbank M C. Quantification of mRNA using competitive RT-PCR with standard curve methodology. BioTechniques. 1996;21:862–866. doi: 10.2144/96215st04. [DOI] [PubMed] [Google Scholar]

- 25.Wictome M, Shone C C. Botulinum neurotoxins, mode of action and detection. J Appl Microbiol Symp Suppl. 1998;84:875–975. doi: 10.1046/j.1365-2672.1998.0840s187s.x. [DOI] [PubMed] [Google Scholar]

- 26.Willems A, East A K, Lawson P A, Collins M D. Sequence of the gene coding for the neurotoxin of Clostridium botulinum type A associated with infant botulism: comparison with other clostridial neurotoxins. Res Microbiol. 1993;144:547–556. doi: 10.1016/0923-2508(93)90004-l. [DOI] [PubMed] [Google Scholar]