Abstract

Recent statistics reveal that the number of individuals with upper or lower extremity dysfunctions has increased alarmingly. It is estimated that approximately 3.3 million Americans use a wheelchair, with an expected 2 million new wheelchair users every year. To assist powered wheelchair users with limited upper limb function, we have been exploring assistive robots that can be mounted on a wheelchair to perform essential activities of daily living (ADL), such as picking/placing an object from out of reach, feeding, etc. In this research, a 6DoF robot, xArm-6 was used as an assistive robot to provide ADL assistance. Experiments were conducted with xArm6 Robot to investigate the motion trajectories and workspace covering essential ADLs. In kinematic analysis, modified Denavit-Hartenberg parameters are used to identify the Robot’s motion path and workspace. On the other hand, the iterative Newton-Euler method was used for dynamic analysis to estimate the joint torques corresponding to each ADL. Experimental results show that xArm-6 can be used for some selected ADLs tasks but not for all essential ADLs.

Keywords: Assistive Robot, Activities of Daily Living (ADL), Kinematics, Workspace, xArm 6 robot

1. Introduction

Over the last decades, the number of Individuals with upper/lower extremity dysfunctions has increased alarmingly. This number is expected to rise as the population ages. Approximately 1.7% of the US population are currently living with central nervous system disorders resulting in difficulty or inability to move the Upper/Lower Extremity (ULE) (Reeve Foundation, 2020). Functional impairments of the ULE are common in the elderly and are often secondary to conditions such as strokes, spinal cord injury, amyotrophic lateral sclerosis, Cerebral Vascular Accidents, trauma, and occupational injuries. Many of these individuals permanently use a wheelchair for their mobility and activities of daily living (ADL). Globally, around 131 million such individuals use a wheelchair (Reeve Foundation, 2020), including about 6.7 million powered wheelchair users. It is estimated that approximately 500,000 Americans use a powered wheelchair. This number has doubled in the last decade (Salminen et al., 2009). At an annual rate of 5.9% a year (on average), the number of wheelchair users has grown (Hu, 2009; Rahman, 2018; Zondervan et al., 2013) and still is rocketing high. More than 90% of wheelchair users report activity limitations, and only 14.7% can complete all the ADL (Mackay and Mensah, 2004). Our customer discovery (Reinhard et al., 2019) revealed that individuals with ULE dysfunctions urgently need self-care and mobility assistance as they cannot perform most ADLs independently. We conducted 220+ interviews (Rahman, 2018) with elderly individuals living at the assisted living centers, individuals with ULE dysfunctions, educators/researchers working on rehab/assistive robotics, stroke survivors, occupational therapists, recreational therapists, physiotherapists, clinicians, caregivers, family members, wheelchair and assistive device manufacturing companies and distributors, assistive technology professionals, and insurance providers to explore customer (target population) pains/needs, market opportunity and trends, and a minimum viable solution to address customer needs. Table-1 summarizes some essential ADLs derived from our customer discovery.

Table 1.

List of Some Essential ADLs based on Customer Discovery (Rahman, 2018)

| No. | Essential ADLs |

|---|---|

| 1 | Picking/ Placing objects from Ground |

| 2 | Picking/ Placing objects from Table |

| 3 | Picking/ Placing objects from Upper Shelf |

| 4 | Holding Medicine |

| 5 | Holding Pen, Maneuvering on paper or surfaces |

| 6 | Opening/closing a drawer/oven |

| 7 | Take food from a plate on a Table to Mouth |

| 8 | Removing hanger from the closet |

| 9 | Holding the phone near the ear or put in speaker mode |

| 10 | Holding objects (up to 10 lbs) |

| 11 | Opening/ closing lid of a jar |

To assist powered wheelchair users in performing the ADLs listed in Table 1, we have been exploring assistive robots that can be mounted on a wheelchair to perform essential ADLs, such as picking/placing an object from out of reach, feeding, etc. It is ideal for a wheelchair-mounted robot to have (a) a small footprint and compact shape, allowing the wheelchair and Robot to pass a door/corridor freely, (b) an extensive reach to cover the ADLs listed in Table 1 but also can be folded when not in use; (c) a high payload capacity to lift the essential ADLs objects; (d) a versatile gripper or auto gripper changing capability so that the Robot can pick/grab wide arrays of essential ADLs objects; (e) light in weight to reduce the mass moment of inertia of overall systems and consumes less energy, and (f) a long battery life so that wheelchair users can uninterruptedly use the system for at least 3–4 hours. Though existing commercially available robots are not designed to be used with a wheelchair as an assistive robot but Kinova Jaco Arm (Kinova Inc., 2021), Ufactory;’s xArm Robot (Ufactory, 2020), meets some of the above criteria. In this research, UFactory’s xArm-6 was used as an assistive robot and mounted on a powered wheelchair (Permobil, M3 Corpus, see Figure 1) to carry out the ADL tasks listed in Table 1. The overall research objective is to investigate xArm-6’s capability to carry out the listed ADLs in Table-1. The xArm-6 is a 6 degrees freedom robot with extended reach and high payload capacity. Experimental results show that xArm-6 can be used for some selected ADLs tasks.

Figure 1.

Joystick (finger-operated) control of a Robot (UFactory). The subject uses the finger joystick to control the Robot (named xArm6) for picking a shoe from the floor.

The rest of the paper is organized as follows. Section 1.1 states the objective of the proposed research. A brief overview of the xArm-6 Robot is presented in Section-2. Section 3 describes the xArm’s kinematics, dynamics, and control architecture. Experimental results are shown in Section-4, and finally, the paper ends with a conclusion in Section-5.

1.1. Objectives

The objectives of this research are to (a) evaluate the xArm-6 Robot’s capability to carry out the essential ADLs listed in Table-1, (b) identify the ADLs specific motion trajectories and workspace for xArm Robot; (c) estimate the overall (combined) ADLs workspace that xArm Robot can effectively serve, and (d) estimate the ADL specific joint torque/energy consumption of the xArm-6 Robot.

2. Over view of theXArm-6 Robot

The xArm-6 Robot, as shown in Figure 1 is a 6 DOF serial robot developed by UFactory. This Robot joint includes high-performance harmonic reducers and brushless motors. The Robot has high payload capacity and good repeatability. Aside from those characteristics, the Modbus RTU protocol and RS-485 communication are implemented in the xArm-6. Thus, the xArm-6 can work using a position, speed, or force control. Likewise, these control modes serve for programmable gripping parameters. The key technical specification of the xArm-6 Robot is summarized below:

High payload capacity (5 Kg), due to the harmonic reducers and brushless motors.

Maximum reach 700 mm.

Repeatability of ±0.1 mm

Integrated joint brakes make the xArm-6 Robot suitable for collaborative applications

Sensitive collision/over-load protection system

However, xArm-6 has some limitations like:

Relatively heavyweight (˜12Kg), due to the size of the motors.

A bulky shape that limits easy maneuvering the wheelchair, especially when passing through the door when mounted on a wheelchair.

The Robot cannot be folded back to the side of a wheelchair due it’s design features (kinematic constraints)

3. xArm 6 Robot’s Kinematics and Dynamics

In kinematic analysis, the Denavit-Hartenberg (DH) parameters are used to identify the xArm configuration of links and joints (Rahman, 2011). On the other hand, the iterative Newton-Euler method was used for dynamic analysis to estimate the joint torques corresponding to each ADL.

3.1. Forward Kinematics:

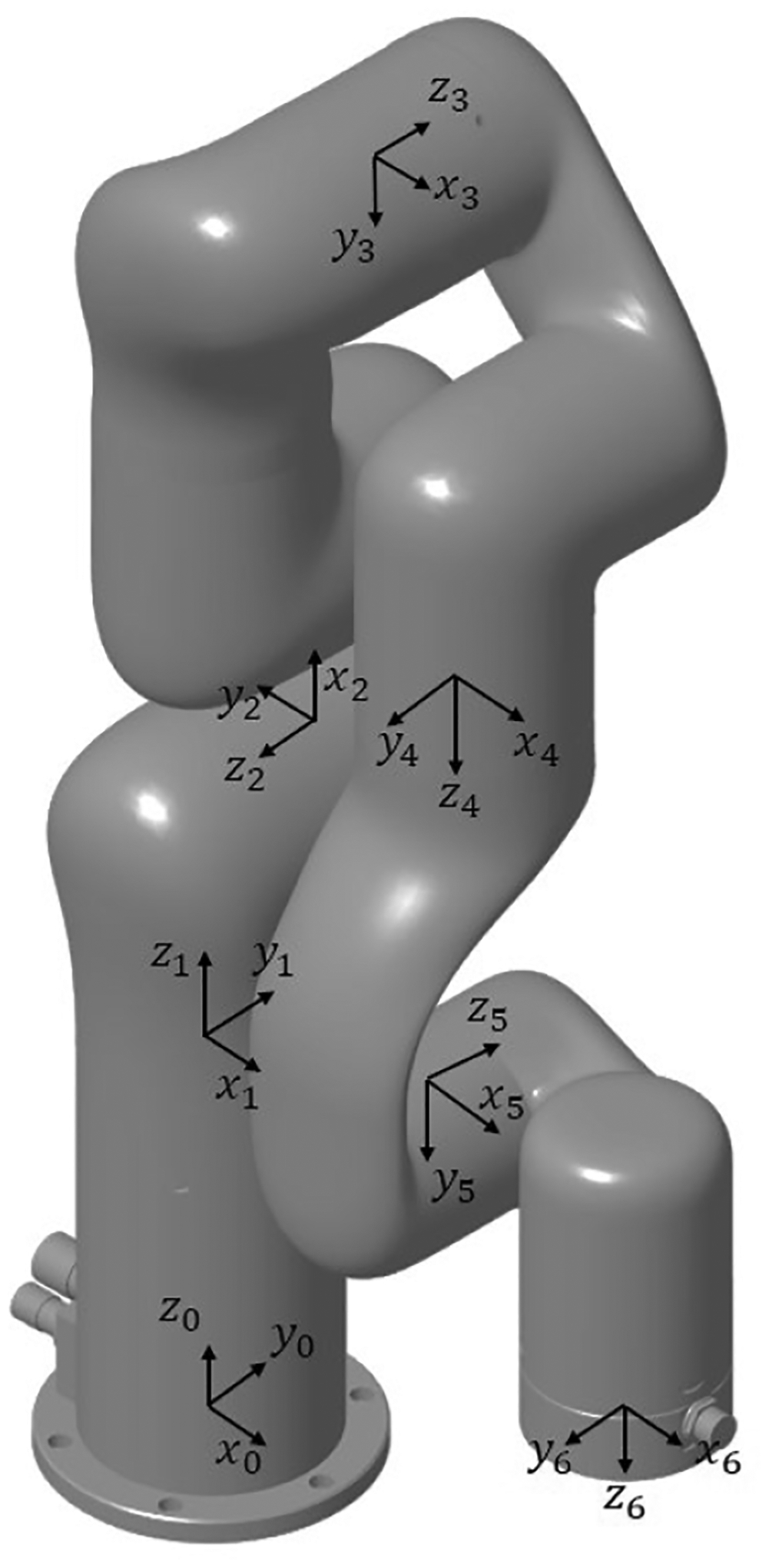

The forward kinematics is the calculation of the end-effector position, given the joint angles. The link frame assignment (according to DH convention) of the xArm-6 Robot is presented in Fig.2, where axes z represents the axis of rotation of each joint. To obtain the forward kinematics, the DH parameters corresponding to the link-frame assignment (see Fig.2) are presented in Table 2. Table-3 summarizes Robot’s link parameters.

Figure 2.

Coordinate frame placement using the Denavit Hartenberg (DH) parameters.

Table 2.

Denavit-Hartenberg parameters of xArm-6 robot

| i | ai | αi | di | θi |

|---|---|---|---|---|

| 1 | 0 | 0 | L 1 | θ 1 |

| 2 | 0 | −π/2 | 0 | θ2+0θ2 |

| 3 | L 2 | 0 | 0 | θ3+0θ3 |

| 4 | L 3 | −π | L 4 | θ 4 |

| 5 | 0 | π/2 | 0 | θ 5 |

| 6 | L 5 | −π/2 | L 6 | θ 6 |

Table 3.

Dimensional parameters of xArm-6 Robots

| L 1 | L 2 | L 3 | L 4 | L 5 | L 6 | 0 θ 2 | 0 θ 3 |

|---|---|---|---|---|---|---|---|

| 267 mm | 289.49 mm | 77.5 mm | 342.5 mm | 76 mm | 97 mm | −1.3849 rad | 1.3849 rad |

The general form homogeneous transformation matrix (HTM) that relates two successive coordinates frames is presented by the equation (1).

| (1) |

Where, is the rotation matrix that represents the frame {i} relative to frame {i − 1} and can be articulated as follows:

| (2) |

and is the vector that locates the origin of the frame {i} relative to frame {i−1} and can be expressed as the following:

| (3) |

Where, αi-1 is the link twist, ai-1 corresponds to link length, di stands for link offset, and θi is the joint angle of the xArm6 Robot. Then, the position of i-coordinate frame relative to the global coordinate frame (frame 0) is given by the successive multiplication of HTMs, as follows:

| (4) |

Finally, the forward kinematics of the xArm-6 Robot is obtained by computing the HTM as follows:

| (5) |

3.2. Dynamics of the xArm-6’s Robot:

The dynamic equation of the xARm6 Robot derived from the Newton-Euler formulation can be written in the following form:

| (6) |

where M(θ) is the 6×6 mass matrix of the manipulator, is an 6×1 vector of centrifugal and Coriolis terms, and G(θ) is an 6×1 vector of gravity terms.

The mass/inertia parameters of the xArm-6 robot are summarized in Table-4. Joint torques of the xArm-6 were derived using equation 6 and mass/inertia parameters outlined in Table-4.

Table 4.

Inertial parameters for each link of xArm-6 Robot

| Link i | Mass (Kg) | Center of Mass (mm) |

|---|---|---|

| Link 1 | 2.177 | [0.15, 27.24, −13.57] |

| Link 2 | 2.011 | [36.7, −220.9, 33.56] |

| Link 3 | 1.725 | [69.77, 113.5, 11.6] |

| Link 4 | 1.211 | [−0.2, 20.0, 26.0] |

| Link 5 | 1.206 | [63.87, 29.3, 3.5] |

| Link 6 | 0.17 | [0, −6.77, −10.98] |

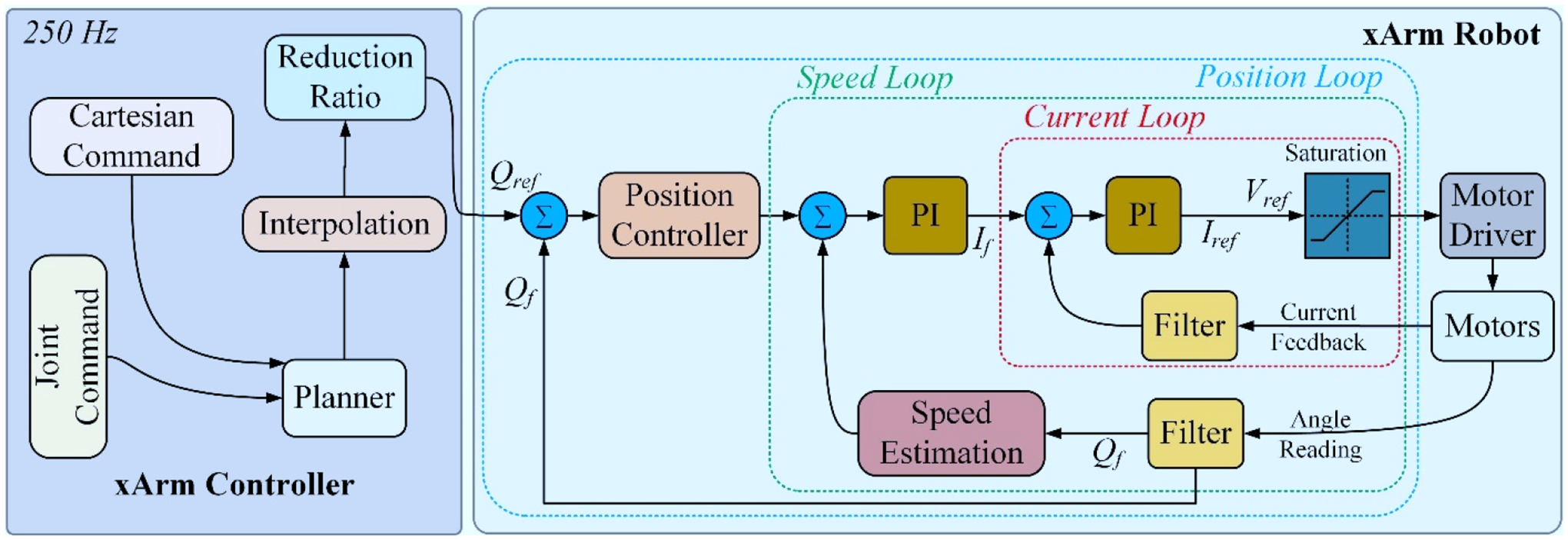

3.3. xArm-6’s Control Architecture:

Figure 3 shows the control architecture for the xArm-6 Robot (Sunny, 2021). The outputs of the xArm controller are the joints’ torque commands and the cartesian commands. The controller updates the torque commands every 4 ms and is executed in xArm controller. For the motor drivers, the torque commands are converted to motor currents and finally to reference voltage as voltage value is the drive command. The proportional-integral (PI) controller is added to realize the real-time control of the system. It also ensures that the proper control torque commands are sent to the joints and the reference voltage commands for the drivers. It also minimizes the differences between desired and measured currents.

Figure 3.

Control architecture of the system.

4. Experiments and Results

Experiments were conducted to investigate xArm-6’s capability to carry out the listed ADLs in Table-1 and task-specific workspace. The desired motion to execute an ADL was taught to the xArm in the teaching mode. Note that the xARm-6 can be maneuvered manually to reach any ADL task location within its workspace in teaching mode. During the experiments, it is observed that xARm-6 is not suitable to accomplish ADLs such as holding medicine, opening/closing lid of a jar, take food from plate on a table to mouth, holding the phone near the ear or putting in speaker mode, holding objects of around 10 lbs due its kinematic constraints (link length and joint configuration), and two-finger grippers. However, xArm-6 Robot, can well execute the following ADLs:

| (i) Picking/placing objects from an upper shelf; | (ii) Removing hanger from the closet. |

| (iii) Picking/ placing objects from the ground; | (iv) Picking/ placing objects from the table. |

| (v) Drawing on a board with a pen, and | (vi) Opening/closing an oven/refrigerator |

Figure 4 shows the motion trajectories of the xArm-6 Robot for the ADLs identified above. The corresponding joint torques are presented in Figure-5. From the results, we can observe that workspace/reach needed to cover the ADLs are:

Figure 4.

Trajectory (motion path) of the xArm’s end-effector position for different ADLs. Where ‘start’ represents the xArm’s end-effector initial position.

Figure 5.

xArm-6’ joint torques corresponding to the ADLs motion shown in Fig. 4.

| • Picking/placing objects from an upper shelf: | X: | 39.72 cm | Y: | 27.64 cm | Z: | 70.25 cm |

| • Removing hanger from the closet | X: | 60.10 cm | Y: | 43.97 cm | Z: | 71.75 cm |

| • Picking/ placing objects from the ground | X: | 55.85 cm | Y: | 0.04 cm | Z: | 51.28 cm |

| • Picking/ placing objects from a table. | X: | 46.68 cm | Y: | 40.92 cm | Z: | 62.05 cm |

| • Drawing on a board with a pen, | X: | 47.88 cm | Y: | 28.21 cm | Z: | 83.93 cm |

| • Opening/closing an oven/refrigerator | X: | 45.75 cm | Y: | 36.39 cm | Z: | 87.63 cm |

From the torque plots in Fig-5, it is found that the maximum joint torque observed in Joint 2, which is is 24.35 Nm in the case of picking/placing objects from the ground. To estimate the overall workspace, all ADLs motions are plotted together in Fig. 6. The result shows that the maximum reach required to cover the above-listed ADLs is X: 60.10cm Y: 43.96cm, Z: 86.63 cm.

Figure 6.

Lateral view of the trajectories(motion path) of the xArm’s end-effector position for different ADLs with the power wheelchair as reference

These results are the important findings to develop a wheelchair-mounted assistive robot. The results obtained in this research will help to identify the Robot kinematic parameters required to perform/cover the above-listed ADLs.

5. Conclusion

As it is necessary to design effective, low-cost, and reasonable solutions which can improve the quality of life of powered wheelchair users, in this paper, a 6DoF robot, xArm-6 is presented to assist in activities of daily living to individuals with upper extremity dysfunctions. The kinematic and dynamic model of xArm was developed using modified Denavit-Hartenberg conventions and Newton -Euler method, respectively. A linear Proportional-Integral (PI) control approach to identify the Robot’s motion path and workspace. Essential ADls are listed based on the customer discovery for the experiments investigating the motion trajectories and workspace covering those ADLs and evaluate the capability of xArm. Experimental results show that the xArm-6 is able to perform the ADLs but not able to do all. The findings of this experiment will help to develop a wheelchair-mounted assistive rotob and identify the robut kinematic parameters required to perform the listed essential activities of daily living.

Figure 7.

Top view of the trajectories(motion path) of the xArm’s end-effector position for different ADLs with the power wheelchair as reference

Acknowledgment

The contents of this study were supported under a grant from the National Institute on Disability, Independent Living, and Rehabilitation Research (NIDILRR grant number 90DPGE0018-01-00). NIDILRR is a Center within the Administration for Community Living (ACL), Department of Health and Human Services (HHS). The contents of this Journal do not necessarily represent the policy of NIDILRR, ACL, or HHS, and you should not assume endorsement by the Federal Government.

Biographies

Elias Jose Munoz Montenegro is a M.S. student at the BioRobotics Lab, University of Wisconsin-Milwaukee. He obtained bachelor’s degrees in mechanical engineering at Universidad del Norte, Cololmbia (2015–2019). More than 5 years he has been researching mechatronics/robotics with emphasis on the analysis and simulation of serial and parallel Robot.

Md Samiul Haque Sunny was born in Netrokona, Bangladesh in 1994. He received the B.S. degree in Electrical and Electronic Engineering from the Khulna University of Engineering and Technology in 2017. He is a Ph.D. student at the BioRobotics Lab, University of Wisconsin-Milwaukee, with a background in Artificial Intelligence, digital signal and image processing, data mining, robotics, biological signal processing, human-machine interface design, and power system stability. He is currently working on developing an eye-gaze controlled user interface deployable to Hololnes-2’s mixed-reality platform to enable a collaborative work environment for individuals with limited upper limb movement, EEG signal for better BCI application, and structures of CNN for upgrading its performance in image recognition.

Ivan Rulik is a Research Assistant and a Master of Science student in Mechanical Engineering at University of Wisconsin-Milwaukee. Got his bachelor’s in science in Electrical Engineering from Universidad de los Andes, Colombia, in 2020, while he participated in IEEE student branch and microelectronics research group. He is currently working in the BioRobotics lab in assistive robotics, mobile robotics, and communications protocols both for IoT for microcontrollers and EtherCAT Field Bus for robotic arms. He brings expertise in programming using C++, Python, Matlab, Labview and designing in CAD with Inventor, AutoCAD and Solidworks. His research interests include assistive robotics, medicine, rehabilitation devices and data analysis using artificial intelligence and machine learning

Javier D. Sanjuan De Caro is a Ph.D. student at the BioRobotics Lab, University of Wisconsin-Milwaukee. He obtained his masters and bachelor’s degrees in mechanical engineering at Universidad del Norte, Cololmbia (2012–2016). His research interest includes dynamics, control, and parallel robots. In Mechanisms and Machine Theory Journal, IEEE Latin America, and other scientific publications, he has served as invited reviewer. Besides, he is one of the founders of the Vertical Integrated Projects (VIP) student association in Universidad del Norte, Colombia. Further info on his homepage: https://www.researchgate.net/profile/JavierSanjuan5

Mohammad Habibur Rahman is an Associate Professor with the Mechanical and Biomedical Engineering Department, University of Wisconsin-Milwaukee, WI, USA. As Director of the BioRobotics Lab at the University of Wisconsin-Milwaukee, he brings the resources and expertise of an interdisciplinary RD team. For more than 15 years he has been researching mechatronics/robotics with emphasis on the design, development and control of wearable robots, collaborative robots, and mobile robots. He received a BSc Engineering (Mechanical)degree from Khulna University of Engineering Technology, Bangladesh in 2001, a Master of Engineering (bio-robotics) degree from Saga University, Japan in 2005 and a PhD in Engineering (bio-robotics) from École de technology sup érieure (ETS), University édu Qu ebec, Canada in 2012. He worked as a postdoctoral research fellow in the School of Physical and Occupational Therapy, McGill University (2012–2014). His research interests are in bio-robotics, exoskeleton robot, intelligent system and control, mobile robotics, nonlinear control, control using biological signals such as electromyogram signals. Dr. Rahman has served as a Guest Editor/Associate Editors and on the editorial board of several journals, including Frontiers in Robotics and AI: Biomedical Robotics.

References

- Hu XL, Tong KY, Song R, Zheng XJ, Lui KH, Leung WWF, … & Au-Yeung SSY (2009). Quantitative evaluation of motor functional recovery process in chronic stroke patients during robot-assisted wrist training. Journal of Electromyography and Kinesiology, 19(4), 639–650. [DOI] [PubMed] [Google Scholar]

- Kinova Inc., (2021). Kinova jaco assistive robotic arm. https://www.kinovarobotics.com/en/assistive-technologies/column-a1/kinova-assistive-robotic-arm

- Mackay J and Mensah G (2004). Atlas of Heart Disease and Stroke. World Health Organization, Brighton, UK. [Google Scholar]

- Rahman MH, Kittel-Ouimet T, Saad M, Kenné JP, & Archambault PS (2011). Dynamic modeling and evaluation of a robotic exoskeleton for upper-limb rehabilitation. International Journal of Information Acquisition, 8(01), 83–102. [Google Scholar]

- Rahman M (2018). NSF: I-Corps: Award#1848912, Customer Discovery: Wheelchair Mounted Robotic Assistive Arm (R2A).

- Reeve Foundation (Jan 08, 2020), Stats about paralysis, available: https://www.christopherreeve.org/living-with-paralysis/stats-about-paralysis

- Reinhard S et al. (2019). Valuing the Invaluable 2019 Update: Charting a Path Forward, available: https://www.aarp.org/ppi/info-2015/valuing-the-invaluable-2015-update.html?cmp=RDRCT-VALUN_JUN23_015e

- Salminen AL, Brandt Å, Samuelsson K, Töytäri O, & Malmivaara A (2009). Mobility devices to promote activity and participation: a systematic review. Journal of rehabilitation medicine, 41(9), 697–706 [DOI] [PubMed] [Google Scholar]

- Sunny MSH, Zarif MII, Rulik I, Sanjuan J, Rahman MH, Ahamed SI, … & Brahmi B Eye-Gaze Control of a Wheelchair Mounted 6DOF Assistive Robot for Activities of Daily Living, Journal of NeuroEngineering and Rehabilitation, 2021 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ufactory (2020), xArm 6, available: https://www.ufactory.cc/products/xarm-6-2020

- Zondervan DK, Smith B, & Reinkensmeyer DJ (2013, June). Lever-actuated resonance assistance (LARA): A wheelchair-based method for upper extremity therapy and overground ambulation for people with severe arm impairment. In 2013 IEEE 13th International Conference on Rehabilitation Robotics (ICORR) (pp. 1–6). IEEE. [DOI] [PubMed] [Google Scholar]