Abstract

The formulation of a vegan salad dressing supplemented with chickpea flour (VC-SD) was optimized by D-optimal mixture design, evaluating the effect of chickpea flour, water and oil on the textural properties of the product. The linear models showed the best fitting and predictive ability, as highlighted by high R2adj and Q2. The Cox-effects of the textural parameters were significant for water and chickpea flour contents, but not for oil. Sensory evaluation indicated that all the VC-SD were characterized by the predominance of pungent/acid odor notes, whereas sourness was the most perceived fundamental taste, together with a sensation of a grainy texture in mouth due to flour particles. Overall, the product can be consumed by vegans and vegetarians because produced without animal-derived ingredients, and is in synergy with the healthful characteristics of Mediterranean diet, in which pulses and extra-virgin olive oil play beneficial roles.

Supplementary Information

The online version contains supplementary material available at 10.1007/s13197-021-05288-x.

Keywords: Plant-based, Emulsion, Back extrusion, Pea protein, D-Optimal mixture design

Introduction

Salad dressings are a category of emulsified semisolid foods prepared from several ingredients such as vegetable oil, acidifying agents (i.e. lemon juice, vinegar), polysaccharides and egg yolk or egg yolk-based ingredient (FDA 2019). Moreover, according to the Food and Drug Administration, salad dressing contains at least 30 g 100 g−1 of fat and 4 g 100 g−1 of liquid egg yolk (FDA 2019). The consumption of salad dressings has increased over time, leading to concerns regarding the nutritional characteristics, due to the presence of high fat content together with cholesterol. The nutritional guidelines, indeed, encourage a diet low in fat and cholesterol in order to reduce the risks of cardiovascular diseases and other illnesses related to diet (Yusuf et al. 2016).

Several strategies have been already applied with the specific aim to reduce the fat content of salad dressings and to substitute the egg yolk with other ingredients, reducing therefore the cholesterol content and improving the nutritional characteristics. Egg yolk is traditionally used as emulsifier; however, a rising number of consumers require egg alternatives allergenic free and suitable for vegan or other dietary patterns (Campbell 2019). Egg yolk can be substituted by several emulsifiers such as pulse proteins (Gumus et al. 2017) or hazelnut milk (Mohammad Alizade Samani and Goli 2019). Moreover, to obtain a functional salad dressing also the inclusion of dietary fiber has been proposed: Tseng and Zhao (2013) suggested the use of grape pomace, which also shows antioxidant activity, whereas orange pulp fiber was used to reduce the fat content and improve the textural properties (Chatsisvili et al. 2012).

In the perspective of improving the nutritional characteristics of salad dressing, the incorporation of pulses flour in the formulation should be also considered. The attention given to pulses increased in the recent years due to several factors including: (i) their valuable role in sustainable agricultural practices and in low-input farming systems (Stagnari et al. 2017); (ii) the beneficial effects on health associated with pulses consumption (Centrone et al. 2020); (iii) the physicochemical and functional properties of pulses flour (Summo et al. 2019a) which make it suitable as a versatile ingredient in several food categories, such as ready-to-eat purées (Summo et al. 2019b), bakery products (Pasqualone et al. 2019), pasta (Teterycz et al. 2020), and traditional street foods (De Angelis et al. 2020). Among pulses, chickpea is the second most produced grain legume worldwide after beans, with an increasing production trend (FAO 2019). Chickpea flour is characterized by a healthy fatty acid profile, not too abundant and rich in PUFAs, accompanied by the presence of several bioactive compounds and by interesting physicochemical and functional properties, such as the high water and oil absorption capacity (Summo et al. 2019a), exploitable in dispersed systems. Despite the use of pulses flour as ingredient for salad dressing preparation was already proposed (Ma et al. 2013, 2016a, b), no studies were carried out with the aim to produce a vegan and reduced-fat salad dressing. The amount of pulses flour used as ingredient should be comprehensively optimized by the approach of experimental design, owing to its significant effect on the physicochemical properties of the final product.

In this framework, the aim of this research was to optimize the formulation of a vegan salad dressing with reduced-fat content, supplemented with chickpea flour (VC-SD). The D-optimal design for mixture was set up for modelling and optimizing the effect of chickpea flour and of the other ingredients on the textural properties of the salad dressing.

Materials and methods

Materials

Kabuli chickpea flour was kindly provided by Andriani spa (Gravina in Puglia, Italy). Extra virgin olive oil (De Santis, Bitonto, Italy), lemon juice (I campagnoli, Bologna, Italy), sugar (NotaDolce, Cesena, Italy), sea salt (Sale Nostrum, Margherita di Savoia, Italy), vinegar (Monari Federzoni, Solara, Italy) and citric acid (Graziano, Rossano, Italy) were purchased by local retailers. Lactic acid, potassium sorbate, guar and xanthan gums were purchased by Special Ingredients (Garlenda, Italy). Pea protein concentrate was purchased by Caremoli spa (Nova Milanese, Italy). A commercial salad dressing (Develey Italia srl, Lana d’Adige, Italy) was purchased by local supermarket and was used as control in the evaluation of the textural properties.

Salad dressing formulation, experimental domain and D-optimal design settings

The ingredients for the VC-SD formulation were chosen according to Ma et al. (2016b) with some modifications. To formulate a vegan and reduced-fat salad dressing the egg yolk was replaced by a pea protein concentrate, which shows a similar emulsifying capacity (Gumus et al. 2017). Moreover, canola oil (Ma et al. 2016b used it in the range 30–50 g 100 g−1) was replaced with a lower quantity of extra virgin olive oil and the content of chickpea flour was increased. The experimental trials were carried out using a mixture design approach. Before, preliminary trials were carried out using different amounts of each ingredient, with the aim to find proper combinations in terms of physical stability (visually evaluated after 2 days of storage at 4 °C) and consistency (evaluated comparing the behavior of the dressing with that of a commercial one, by letting them flow down from a spoon). The preliminary trials, involving the comparison of the textural behavior of the experimental dressing with respect to the commercial control, allowed to define the experimental domain in which was possible to work. The mixture design was then planned to understand the influence of the ingredients and identify their optimum combinations in a rational way (Squeo et al. 2021). Based on the results of the preliminary trials, the experimental domain was defined according to the following constrains for the components, expressed as g 100 g−1 of salad dressing: oil (8 ≤ x1 ≤ 13); water (55 ≤ x2 ≤ 60); chickpea flour (15 ≤ x3 ≤ 20). The sum of the components was equal to 86 g 100 g−1, whereas the remaining 14 g 100 g−1 were constituted by the other ingredients, kept constant. Once defined the experimental domain, the experimental points, among all the possible candidate points, were chosen by means of a D-optimality criterion (Cafaggi et al. 2003), according to the special cubic model: Y = β1x1 + β2x2 + β3x3 + β12x1x2 + β13x1x3 + β23x2x3 + β123x1x2x3, where Y, x and β are the response variables, the components under study, and the model coefficients, respectively. The total number of experiments according to the experimental design was 13 (T1–T13), divided as follows: seven experimental points were selected to model the responses, to which three replicates and three additional experiments were added in order to estimate the pure error and the lack-of-fit, respectively (Lundstedt et al. 1998). The experimental plan is reported in Table 1. The simplest linear regression models were computed according to the following equation: Y = β1x1 + β2x2 + β3x3.

Table 1.

Formulation of the experiments according to the D-Optimal mixture design (expressed as 86 g 100 g−1)

| Trial | Oil | Water | Chickpea Flour | Other ingredientsa | |

|---|---|---|---|---|---|

| T1 | Replicate | 10.7 | 57.65 | 17.65 | 14 |

| T2 | Replicate | 9.5 | 60 | 16.5 | 14 |

| T3 | Model | 9.5 | 56.5 | 20 | 14 |

| T4 | Lack of Fit | 13 | 55 | 18 | 14 |

| T5 | Model | 12 | 55 | 19 | 14 |

| T6 | Model | 10.7 | 57.65 | 17.65 | 14 |

| T7 | Model | 13 | 56.5 | 16.5 | 14 |

| T8 | Replicate | 12 | 59 | 15 | 14 |

| T9 | Model | 9.5 | 60 | 16.5 | 14 |

| T10 | Model | 8 | 59 | 19 | 14 |

| T11 | Lack of Fit | 11 | 55 | 20 | 14 |

| T12 | Lack of Fit | 8 | 60 | 18 | 14 |

| T13 | Model | 12 | 59 | 15 | 14 |

The sum of the three variables accounts for 86 g 100 g−1, whereas the other 14 g 100 g−1 is constituted by other ingredients

aOther ingredients (g 100 g−1): Lemon juice—5.5; Sugar—3.35; Vinegar—2.0; Pea protein—1.0; Salt—1.0; Lactic acid—0.65; Xantan gum—0.28; Guar gum—0.12; Citric acid—0.1

Salad dressing preparation

The salad dressing preparation was divided in three steps: first, 20 g of water, sugar, potassium sorbate, lactic acid, pea protein concentrates guar and xanthan gum were homogenized by using an Ultra-Turrax (model T-25, IKA-Werke GmbH & Co. KG, Staufen, Germany) at 13,500 rpm for 2.5 min. Separately, the remaining water, lemon juice, salt and citric acid were mixed with chickpea flour and homogenized by Ultra-Turrax at 13,500 rpm for 2.5 min. The two phases were mixed together by Ultra-Turrax at 13,500 rpm for 2.5 min. Finally, extra virgin olive oil was added and homogenized by Ultra-Turrax at 13,500 rpm for 2.5 min. The samples were immediately analyzed.

Back extrusion and pH

The back extrusion of the VC-SD was carried out by a Z1.0 TN texture analyzer (Zwick Roell, Ulm, Germany) equipped with a compression disk of 40 mm diameter and a standard back extrusion container of 50 mm diameter, filled with 75 mL of sample. The analysis consisted in a double compression cycle at 1 mm/s until 30% of compression was achieved (Ronda et al. 2017). The commercial salad dressing was used as control. Analyses were performed in quadruplicate. The following indices were calculated, according to Ronda et al. (2017): the “Firmness” (N), i.e. the maximum force recorded during the first compression; the “Cohesiveness” (N), i.e. the maximum negative force recorded during between the two cycles of compression, so that the more negative the value the more cohesive is the dressing; the “Consistency” (mJ), which is defined as the area under the curve recorded during the first compression; the “Viscosity index” (mJ), which is the negative area of the graph, drawn on probe return, derived from the sample remaining on the surface of the disk, synonym of its resistance to flow off.

The determination of pH was carried out by pHmeter (model HI2002, Hanna Instrument, Villafranca, Italy) and was repeated three times at 20 °C.

Sensory analysis

The sensory panelists (4 males; 4 females; age range 29–53) were selected on the basis of their experience in the sensory evaluation of emulsified foods. Training sessions were preliminary carried out in order: (i) to identify the list of the descriptors which best fitted the sensorial characteristics of the salad dressing, starting from those reported in Wendin and Hall (2001); (ii) to define the intensity range of each descriptor and set the scale anchors of each descriptor; (iii) to prove reliability, consistency, and discriminating ability of panelists when testing the salad dressing (Pasqualone et al. 2019). A total of 10 descriptors of appearance, texture, odor and taste were identified. For the sensory evaluation 5 g of VC-SD were served in randomized order, in plastic cups identified with an alphanumeric code. The sensorial descriptors, together with their scale anchors, are reported in Table S1. Each descriptor was evaluated on an unstructured 9 cm scale. The analysis was repeated three times in three different days.

Nutritional composition and energy value

The nutritional composition of salad dressings was calculated according to the ratios of each ingredient and to the information provided by each company in the nutritional labels of the ingredients. The energy value (kCal g−1) of each product was calculated by using the Atwater’s coefficients as reported in Summo et al. (2018).

Statistical analysis

The experimental results were modelled according to the special cubic and linear models and the regression coefficients, together with their significance (p ≤ 0.05), were obtained per each response variable by means of Chemometric Agile Tool (CAT) R-based chemometric software (Leardi et al. 2019). Adjusted coefficient of determination (R2adj), coefficient of determination in cross-validation (Q2), root mean square error in cross-validation (RMSECV) and standard deviation of the residuals, were used to evaluate the models. The Cox-effect of the components (Smith 2005) and the response surface plots were obtained by means of Design-Expert 11 software (Stat-Ease Inc., Minneapolis, USA). The data were subjected to one-way analysis of variance (ANOVA) followed by the Tukey's test to determine the significant differences at α = 0.05, using Minitab 17 software (Minitab Inc., State College, PA, USA). To compare the textural properties to the control the Dunnett’s multiple comparisons test was carried out at α = 0.05.

Results and discussion

Regression models

Table 2 reports the models calculated for each response together with their significance. From an initial evaluation of the special cubic model, clearly appears that only the linear terms were significant. The significance of the sole linear coefficient indicated that no significant interaction existed among the components, i.e. no synergic effect of the combination of two- or three-components in the considered experimental domain was observed (Leardi 2009). Considering that the responses were influenced independently only by the amount of the single ingredients along the defined domain, the responses were modelled according to the linear model.

Table 2.

Regression coefficients of the model (x1: oil; x2: water; x3: chickpea flour) for all the responses measured on the salad dressing produced by the D-Optimal mixture design

| x1 | x2 | x3 | x1x2 | x1x3 | x2x3 | x1x2x3 | R2adj | Q2 | RMSECV | Residuals SD | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Special cubic model | |||||||||||

| Firmness | 0.21 | 0.47 | 0.06 | 0.53 | 0.81 | 0.49 | − 0.25 | 0.70 | 0.38 | 0.07 | 0.05 |

| Cohesiveness | − 0.14 | − 0.27 | − 0.07 | − 0.26 | − 0.28 | − 0.17 | 0.19 | 0.80 | 0.46 | 0.03 | 0.02 |

| Consistency | 2.32 | 3.95 | 0.88 | 5.06 | 6.50 | 5.02 | − 5.35 | 0.60 | 0.28 | 0.59 | 0.44 |

| Viscosity Index | 1.18 | 2.03 | 0.25 | 2.42 | 2.36 | 2.07 | − 2.98 | 0.74 | 0.45 | 0.32 | 0.22 |

| Linear model | |||||||||||

| Firmness | 0.40 | 0.55 | 0.23 | 0.71 | 0.66 | 0.05 | 0.04 | ||||

| Cohesiveness | − 0.22 | − 0.31 | − 0.12 | 0.83 | 0.78 | 0.02 | 0.02 | ||||

| Consistency | 3.83 | 4.93 | 2.33 | 0.67 | 0.60 | 0.44 | 0.40 | ||||

| Viscosity Index | 1.78 | 2.52 | 0.75 | 0.81 | 0.75 | 0.22 | 0.19 | ||||

In bold the significant coefficients (p ≤ 0.05)

R2adj Adjusted coefficient of determination, Q2 coefficient of determination in cross-validation, RMSECV root mean square error in cross-validation, Residual SD standard deviation of the residuals

The linear models had better fitting and predictive ability respect to the special cubic one, as proven by the generally higher values of R2adj and Q2. In particular, the models for the back extrusion parameters (firmness, cohesiveness, consistency and viscosity index) had a Q2 always higher than 0.5, which is considered an acceptable value, and even closer to 0.8, which is considered an excellent value (Lundstedt et al. 1998). The RMSECV is an important parameter representing the predictive error during the cross-validation. The error was generally lower in the linear than the special cubic model and was very similar to the calculated standard deviation (SD) of the residuals. Considering that the residual SD is an estimator of the experimental variance, the agreement of RMSECV with the residual SD indicates the validity of the model, whose error in cross-validation had the same magnitude of the observed variability (Cafaggi et al. 2003).

Textural indices and pH

The textural indices of the 13 experiments and the commercial control are reported in Table 3. The VC-SD having different formulation were characterized by high variability in the textural parameters with significant differences among them, being the trials derived from an experimental design planned to widely cover the experimental domain. The textural characteristics of the commercial dressing were within the range of the 13 experiments. Moreover, the Dunnett’s test carried out between the VC-SD and the commercial control assessed that T13 was statistically similar to the control for firmness, cohesiveness, consistency and viscosity index. T8, T9, T10 and T12 showed no significant differences in consistency between them and the control, while T2, T7, T10 and T12 were statistically similar to the control for the viscosity index. All these experiments showed a high content of water (59–60 g 100 g−1) and a chickpea flour content ranging from 15 to 19 g 100 g−1. Overall, the textural parameters found in our experiments were similar to those of other salad dressing formulations reported in literature (Ma et al. 2016a; Perrechil et al. 2010).

Table 3.

Mean value, standard deviation and results of statistical analysis one-way ANOVA of the textural parameters evaluated by back extrusion of the experiments carried out according to the D-optimal mixture design

| Trial | Firmness (N) | Cohesiveness (N) | Consistency (mJ) | Viscosity index (mJ) |

|---|---|---|---|---|

| T1 | 0.48 ± 0.00a | − 0.25 ± 0.01e | 4.42 ± 0.28ab | 1.95 ± 0.16bc |

| T2 | 0.38 ± 0.03bc | − 0.19 ± 0.01c | 3.69 ± 0.50bcd | 1.49 ± 0.20de* |

| T3 | 0.49 ± 0.00a | − 0.28 ± 0.01 g | 4.51 ± 0.28a | 2.31 ± 0.16a |

| T4 | 0.47 ± 0.00a | − 0.26 ± 0.01ef | 4.23 ± 0.34abc | 2.05 ± 0.13ab |

| T5 | 0.49 ± 0.00a | − 0.27 ± 0.01f | 4.30 ± 0.34ab | 2.09 ± 0.13ab |

| T6 | 0.40 ± 0.01b | − 0.22 ± 0.00d | 3.69 ± 0.32bcd | 1.68 ± 0.12cd |

| T7 | 0.37 ± 0.03cd | − 0.20 ± 0.01c | 3.55 ± 0.43cd | 1.56 ± 0.13de* |

| T8 | 0.25 ± 0.00f | − 0.14 ± 0.00a | 2.37 ± 0.07f* | 0.88 ± 0.07g |

| T9 | 0.28 ± 0.01f | − 0.15 ± 0.00a | 2.68 ± 0.14ef* | 1.07 ± 0.06fg |

| T10 | 0.34 ± 0.00de | − 0.19 ± 0.00c | 3.42 ± 0.16d* | 1.57 ± 0.07de* |

| T11 | 0.48 ± 0.01a | − 0.27 ± 0.00f | 4.44 ± 0.30a | 2.19 ± 0.11ab |

| T12 | 0.35 ± 0.01 cd | − 0.19 ± 0.00c | 3.34 ± 0.20de* | 1.47 ± 0.09de* |

| T13 | 0.31 ± 0.01e* | − 0.17 ± 0.00b* | 3.13 ± 0.20de* | 1.36 ± 0.09ef* |

| Control | 0.31 ± 0.00* | − 0.18 ± 0.00* | 2.93 ± 0.16* | 1.36 ± 0.09* |

Dunnett’s test was carried out vs the control

Different lowercase letters in the same column mean statistical differences at p ≤ 0.05. The asterisk highlights no significant differences vs the control at p ≤ 0.05

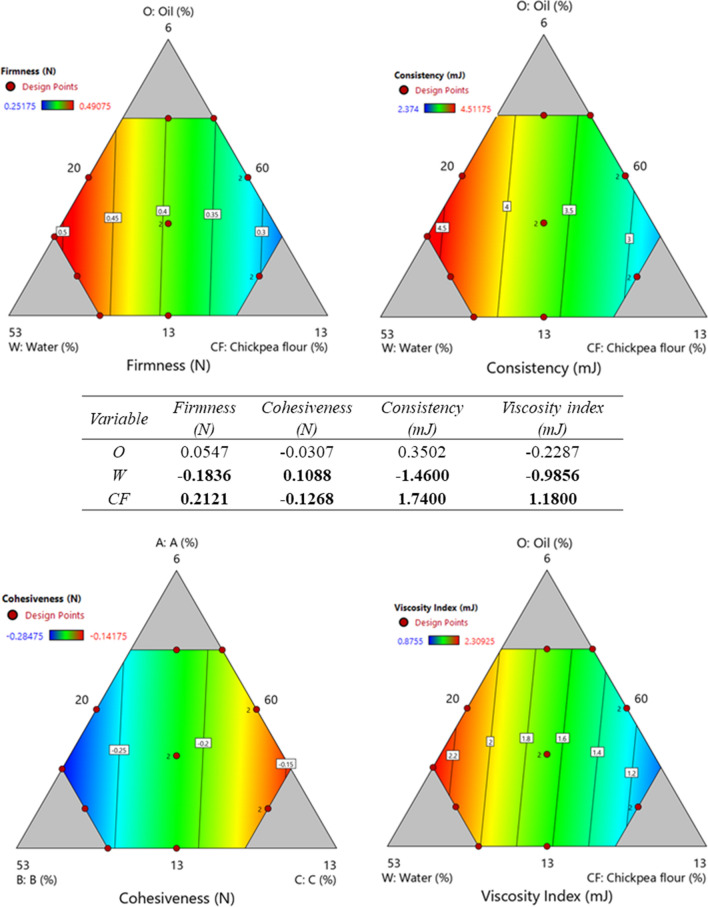

All the linear coefficients were significant (Table 2). Anyway, it should be carefully considered that in mixture designs, the coefficient of a component does not correspond to its real physical effect, so that the “effect” of each component should be evaluated (Leardi et al. 2019; Squeo et al. 2021). More in detail, the Cox-effect of a component is represented by the difference in the response due to the ith component along the direction in which the pairwise ratios of the remaining components will remain constant (Smith 2005). The effect of the components, together with the observation of the contour plots for each response, represents the only way to understand the meaning of mixture models (Leardi 2009; Squeo et al. 2021). Per each component, the Cox-effects on the textural features of salad dressing are shown in Fig. 1. It could be observed that both water (W) and chickpea flour (CF) had a significant effect for all the indices. Thus, as the water content increased, a reduction in firmness, consistency, and viscosity index was always evident, whereas the cohesiveness increased, leading to a less adhesive and sticky product. On the contrary, an opposite behavior was observed by increasing the concentration of chickpea flour. This trend can be easily noted from the contour plots also shown in Fig. 1, where the red areas on the left correspond to the highest values of the back extrusion parameters. Pulses flour has a thickening activity due to the presence of starch. Therefore, the increase of chickpea flour content led to an increase in firmness and viscosity.

Fig. 1.

Contour plots of the textural parameters of the vegan chickpea-based salad dressings (VC-SD) evaluated by back extrusion, together with Cox-effect calculated for oil (O), water (W) and chickpea flour (CF). (In bold significant effects at p ≤ 0.05)

The texture of a dispersed system is the result of several interactions and the formation of complexes between starch, carbohydrates, proteins and lipids (Bortnowska et al. 2014). Moreover, starch composition can significantly influence the textural characteristics of the emulsion. Indeed, as reported by Bortnowska et al. (2014), a higher concentration of amylose promotes the formation of complexes with lipids, resulting in a higher viscosity. Pulses generally have a high amylose content, which is influenced by the species (Huang et al. 2007). This aspect should be considered if different species of pulses are used for the preparation of the salad dressing. Indeed, flours of different types and species could have a different impact on the textural properties. Furthermore, pulses proteins are characterized by emulsifying activity (Du et al. 2014), therefore they can replace proteins of animal origin such as egg yolk or milk-derived proteins (Burger and Zhang 2019). Finally, the oil content showed a smaller influence on the textural parameters than water and chickpea flour, as highlighted by both Cox-effects and contour plots (Fig. 1). Previous studies reported that oil content caused an increase of firmness and viscosity in salad dressings (Ma et al. 2013). However, the small influence on the texture found in our experiments could be explained by the lower oil concentration used. Indeed, Ma et al. (2013), reported that the influence of oil content was less pronounced at the lowest concentration used in their study on dehulled yellow pea-based salad dressing.

VC-SD showed modest but significant differences of pH among the trials, varying from 3.84 to 3.98 (data not shown). All the formulations were characterized by pH values below 4.0, which is one of the factors that may help to keep the product safe. Indeed, the growth of foodborne pathogens such as Salmonella, Escherichia coli, Clostridium botulinum is inhibited at pH lower than 4 (Smittle 2000). The achievement of this pH was obtained by the combination of acidic ingredients, in particular vinegar and lemon juice. Acetic acid, contained in vinegar, is widely used in salad dressings and mayonnaise due to its inhibiting activity against pathogenic microorganisms, higher than citric acid and lactic acid (Smittle 2000). On the whole, the pH values of VC-SD were in the range observed in commercial salad dressings (Perrechil et al. 2010).

Sensory analysis

On the basis of the textural parameters shown in Table 3, four of the thirteen trials were selected, identifying them among those which showed textural characteristics comparable to the commercial salad dressing, according to the Dunnett’s test. In particular, T7, T10, T12 and T13 were chosen. These VC-SD were characterized by a high variability of the ingredients ratio (Table 1). The results of the sensory analysis are shown in Table 4. No significant differences of color were perceived. Consistency was significantly lower in T13, due to lower cohesiveness and firmness compared to the other trials. Moreover, T13 was characterized by a low chickpea flour content and high water and oil contents, which could have led to the lowest consistency. All the VC-SD were characterized by the predominance of pungent/acid odor notes, mainly associated with vinegar, with a score near 4.5 in T10 and T7, which was significantly lower than the score of T12 and T13. By contrast, the odor note associated with lemon was little perceived, with no significant differences among all the trials. No significant differences of taste were found among the VC-SD for all the descriptors evaluated. On the whole, sour was the most perceived fundamental taste, with a score near 5, while the typical flavor of chickpea was minimally perceived, with the same intensity in all the VC-SD, irrespective of the amount of flour. Furthermore, the dressings were also characterized by a grainy texture due to the presence of flour particles. More in depth, T7 was less grainy than T12, without significant differences with the other two trials.

Table 4.

Mean value, standard deviation and results of statistical analysis one-way ANOVA of the sensory evaluation of the selected salad dressing

| Attributes | T13 | T12 | T10 | T7 | |

|---|---|---|---|---|---|

| Appearance and texture | Color | 5.27 ± 0.42a | 5.65 ± 0.07a | 5.97 ± 0.68a | 5.52 ± 0.67a |

| Consistency | 4.03 ± 0.76b | 5.64 ± 0.27a | 5.51 ± 0.43a | 5.81 ± 0.38a | |

| Greasiness | 1.70 ± 0.29a | 1.59 ± 0.04a | 1.21 ± 0.28a | 1.20 ± 0.33a | |

| Graininess | 5.21 ± 0.39ab | 5.66 ± 0.02a | 4.57 ± 0.79ab | 4.27 ± 0.26b | |

| Odor | Acidic/pungent | 5.07 ± 0.03a | 5.05 ± 0.06a | 4.54 ± 0.23b | 4.49 ± 0.10b |

| Lemon | 1.73 ± 0.83a | 1.61 ± 0.02a | 2.45 ± 0.95a | 2.67 ± 1.18a | |

| Taste and flavor | Sourness | 5.22 ± 0.96a | 5.70 ± 0.70a | 4.86 ± 0.42a | 4.83 ± 0.16a |

| Sweetness | 1.95 ± 0.99a | 2.44 ± 1.01a | 1.81 ± 0.79a | 1.97 ± 1.02a | |

| Saltiness | 2.90 ± 0.34a | 2.81 ± 0.19a | 2.40 ± 0.07a | 2.12 ± 0.63a | |

| Chickpea | 3.56 ± 0.72a | 3.79 ± 0.36a | 3.88 ± 0.23a | 3.75 ± 0.14a | |

| Overall acceptability | 5.41 ± 0.24ab | 4.95 ± 0.16b | 5.45 ± 0.14a | 5.10 ± 0.16ab |

Different lowercase letters in the same row mean statistical differences at p ≤ 0.05

By analyzing the correlation between the parameters, no significant correlation was found between the graininess and the flour content of the formulations (data not shown). The overall acceptability was scored near 5 out of 9. However, it should be considered that salad dressings are always consumed in combination with other foods, thus the observed scores could be sufficient for food applications. However, the T12 was the least appreciated dressing, probably due to the highest graininess perceived in this sample. A previous study carried out on legume-based salad dressing reported that the overall acceptability decreases with higher content in legume flour (Ma et al. 2016b). In our study the sensorial characteristics were not influenced by the flour content, but it is possible that the whole ratio of ingredients contributes to the overall acceptability of the products (Table 4).

Nutritional characterization

The nutritional composition of the VC-SD and of the commercial control is reported in Table 5. The incorporation of chickpea flour allowed to obtain a product with an improved protein content, approximately double the commercial dressing. Of particular relevance was the lipid content, which ranged between 8.5 g 100 g−1 in T10 and T12, and 13.4 g 100 g−1 in T7. Therefore, the lipid content was considerably lower than the commercial dressing and this had a relevant effect on the energy values of the products, that could be potentially labelled as “energy reduced” and “reduced fat” according to the current European Regulations (European Commission Regulation 1924/2006). Furthermore, T10 and T12 can be also labelled as “source of protein” according to the same regulation, since at least the 12% of the energy value is provided by protein. Therefore, the nutritional composition of VC-SD was consistently healthier than the commercial dressing, leading to an effective improvement of the product without damaging the textural properties. Overall, since it does not contain animal-derived ingredients, the dressing can be consumed by vegans and vegetarians, nevertheless it is in synergy with the healthful characteristics of Mediterranean diet, in which pulses and extra-virgin olive oil play beneficial roles (Derossi et al. 2020).

Table 5.

Nutritional composition of the chickpea-based salad dressing (calculated values) and of the commercial control expressed as g 100 g−1 of fresh product and energy value expressed as kCal 100 g−1 of fresh product

| T7 | T10 | T12 | T13 | Control | |

|---|---|---|---|---|---|

| Protein | 4.60 | 5.16 | 4.94 | 4.26 | 2.20 |

| Lipids | 13.45 | 8.52 | 8.50 | 12.41 | 34.40 |

| Total Carbohydrates | 13.59 | 15.07 | 14.48 | 12.71 | 7.60 |

| Ashes | 1.49 | 1.56 | 1.53 | 1.45 | 2.40 |

| Fibers | 0.33 | 0.38 | 0.36 | 0.30 | / |

| Energy value | 194.5 | 158.4 | 154.8 | 180.2 | 351.0 |

Conclusion

The D-optimal mixture design allowed to optimize the formulation of vegan salad dressing supplemented with chickpea flour (VC-SD), evaluating the effect of chickpea flour on the physicochemical characteristics of the final product. The linear models showed better fitting and predictive ability respect to the special cubic one, as highlighted by the higher R2adj and Q2. Analyzing the Cox-effects for the textural parameters, we found a significant effect of water and chickpea flour contents. All the formulation showed a pH lower than 4.0, which potentially contributes to the product safety. The sensory analysis indicated that all the VC-SD were characterized by the predominance of pungent/acid odor notes, whereas sourness was the most perceived fundamental taste, together with a perception of a grainy texture given by the flour. Under a nutritional point of view, VC-SD showed an improved protein content, about double that of a commercial dressing, together with a relevant reduction of the lipid content. Overall, the product can be consumed by vegans and vegetarians since it does not contain animal-derived ingredients, nevertheless it was in accordance with the Mediterranean diet, characterized by the presence of pulses and extra-virgin olive oil.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

This research has been performed within the projects: (1) "LEgume GEnetic REsources as a tool for the development of innovative and sustainable food TEchnological system" supported under the “Thought for Food” Initiative by Agropolis Fondation (through the “Investissements d’avenir” programme with reference number ANR-10-LABX-0001-01”), Fondazione Cariplo, and Daniel & Nina Carasso Foundation. The publication was made with co-financing of the European Union—PON Research and Innovation 2014-2020. The authors would thank Dr. Gabriele Fioschi for his support in the preliminary trials and the analytical determinations.

Author contribution

DDA and GS carried out the experiments, analyzed the data and wrote the original draft; AP and CS supervised the work and were responsible of funding acquisition; DDA, GS, AP, and CS conceived the experiments, revised and approved the manuscript.

Availability of data material

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Bortnowska G, Balejko J, Tokarczyk G, Romanowska-Osuch A, Krzemińska N. Effects of pregelatinized waxy maize starch on the physicochemical properties and stability of model low-fat oil-in-water food emulsions. Food Hydrocoll. 2014;36:229–237. doi: 10.1016/j.foodhyd.2013.09.012. [DOI] [Google Scholar]

- Burger TG, Zhang Y. Recent progress in the utilization of pea protein as an emulsifier for food applications. Trends Food Sci Technol. 2019;86:25–33. doi: 10.1016/j.tifs.2019.02.007. [DOI] [Google Scholar]

- Cafaggi S, Leardi R, Parodi B, Caviglioli G, Bignardi G. An example of application of a mixture design with constraints to a pharmaceutical formulation. Chemom Intell Lab Syst. 2003;65:139–147. doi: 10.1016/S0169-7439(02)00045-X. [DOI] [Google Scholar]

- Campbell B (2019) Current emulsifier trends in dressings and sauces. In: Food emulsifiers and their applications. Springer, Cham, pp 285–298

- Centrone M, Gena P, Ranieri M, Di Mise A, D’Agostino M, Mastrodonato M, Venneri M, De Angelis D, Pavan S, Pasqualone A, Summo C, Fanelli V, Valenti G, Calamita G, Tamma G. In vitro and in vivo nutraceutical characterization of two chickpea accessions: differential effects on hepatic lipid over-accumulation. Antioxidants. 2020;9:268. doi: 10.3390/antiox9030268. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chatsisvili NT, Amvrosiadis I, Kiosseoglou V. Physicochemical properties of a dressing-type o/w emulsion as influenced by orange pulp fiber incorporation. LWT-Food Sci Technol. 2012;46:335–340. doi: 10.1016/j.lwt.2011.08.019. [DOI] [Google Scholar]

- De Angelis D, Madodé YE, Briffaz A, Hounhouigan DJ, Pasqualone A, Summo C. Comparing the quality of two traditional fried street foods from the raw material to the end product: the Beninese cowpea-based ata and the Italian wheat-based popizza. Legume Sci. 2020;2:e35. doi: 10.1002/leg3.35. [DOI] [Google Scholar]

- Derossi A, Husain A, Caporizzi R, Severini C. Manufacturing personalized food for people uniqueness. An overview from traditional to emerging technologies. Crit Rev Food Sci Nutr. 2020;60:1141–1159. doi: 10.1080/10408398.2018.1559796. [DOI] [PubMed] [Google Scholar]

- Du SK, Jiang H, Yu X, Jane JL. Physicochemical and functional properties of whole legume flour. LWT-Food Sci Technol. 2014;55:308–313. doi: 10.1016/j.lwt.2013.06.001. [DOI] [Google Scholar]

- European Commission (2006) Regulation (Ec) No 1924/2006 of the European parliament and of the council of 20 December 2006. Off J Eur Union 404:9–25

- Food and Agriculture Organization of the United Nations (2019) Data of crops production. http://www.fao.org/faostat/en/#data/QC. Accessed September 2021

- Food and Drug Administration (FDA)-Department of Health and Human Services (2019) Code of Federal Regulations. 21CFR169.150.

- Gumus CE, Decker EA, McClements DJ. Formation and stability of ω-3 oil emulsion-based delivery systems using plant proteins as emulsifiers: lentil, pea, and faba bean proteins. Food Biophys. 2017;12:186–197. doi: 10.1007/s11483-017-9475-6. [DOI] [Google Scholar]

- Huang J, Schol HA, van Soest JJ, Jin Z, Sulmann E, Voragen AG. Physicochemical properties and amylopectin chain profiles of cowpea, chickpea and yellow pea starches. Food Chem. 2007;101:1338–1345. doi: 10.1016/j.foodchem.2006.03.039. [DOI] [Google Scholar]

- Leardi R. Experimental design in chemistry: a tutorial. Anal Chim Acta. 2009;652:161–172. doi: 10.1016/j.aca.2009.06.015. [DOI] [PubMed] [Google Scholar]

- Leardi R, Melzi C, Polotti G (2019) CAT (Chemometric Agile Tool), freely downloadable at http://gruppochemiometria.it/index.php/software

- Lundstedt T, Seifert E, Abramo L, Thelin B, Nyström Å, Pettersen J, Bergman R. Experimental design and optimization. Chemome Intell Lab Syst. 1998;42:3–40. doi: 10.1016/S0169-7439(98)00065-3. [DOI] [Google Scholar]

- Ma Z, Boye JI, Fortin J, Simpson BK, Prasher SO. Rheological, physical stability, microstructural and sensory properties of salad dressings supplemented with raw and thermally treated lentil flours. J Food Eng. 2013;116:862–872. doi: 10.1016/j.jfoodeng.2013.01.024. [DOI] [Google Scholar]

- Ma Z, Boye JI, Simpson BK. Preparation of salad dressing emulsions using lentil, chickpea and pea protein isolates: a response surface methodology study. J Food Qual. 2016;39:274–291. doi: 10.1111/jfq.12190. [DOI] [Google Scholar]

- Ma Z, Boye JI, Swallow K, Malcolmson L, Simpson BK. Techno-functional characterization of salad dressing emulsions supplemented with pea, lentil and chickpea flours. J Sci Food Agric. 2016;96:837–847. doi: 10.1002/jsfa.7156. [DOI] [PubMed] [Google Scholar]

- Mohammad Alizade Samani E, Goli M. Optimization of mayonnaise formula using hazelnut meal milk as egg yolk substitute at various levels of Xanthan-Guar Gum and response surface methodology. Iran J Nutr Sci Food Technol. 2019;14:75–86. [Google Scholar]

- Pasqualone A, De Angelis D, Squeo G, Difonzo G, Caponio F, Summo C. The effect of the addition of Apulian black chickpea flour on the nutritional and qualitative properties of durum wheat-based bakery products. Foods. 2019;8:504. doi: 10.3390/foods8100504. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Perrechil FDA, Santana RDC, Fasolin LH, Silva CASD, Cunha RLD. Rheological and structural evaluations of commercial Italian salad dressings. Food Sci Technol. 2010;30:477–482. doi: 10.1590/S0101-20612010000200027. [DOI] [Google Scholar]

- Ronda F, Pérez-Quirce S, Villanueva M (2017) Rheological properties of gluten-free bread doughs: relationship with bread quality. In: Advances in food rheology and its applications. Woodhead Publishing, pp 297–334

- Smith WF (2005) Experimental design for formulation. Society for Industrial and Applied Mathematics. SIAM

- Smittle RB. Microbiological safety of mayonnaise, salad dressings, and sauces produced in the United States: a review. J Food Prot. 2000;63:1144–1153. doi: 10.4315/0362-028X-63.8.1144. [DOI] [PubMed] [Google Scholar]

- Squeo G, De Angelis D, Leardi R, Summo C, Caponio F. Background, applications and issues of the experimental designs for mixture in the food sector. Foods. 2021;10(5):1128. doi: 10.3390/foods10051128. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Stagnari F, Maggio A, Galieni A, Pisante M. Multiple benefits of legumes for agriculture sustainability: an overview. Chem Biol Technol Agric. 2017;4:2. doi: 10.1186/s40538-016-0085-1. [DOI] [Google Scholar]

- Summo C, Palasciano M, Angelis De, Paradiso VM, Caponio F, Pasqualone A. Evaluation of the chemical and nutritional characteristics of almonds (Prunus dulcis (Mill). DA Webb) as influenced by harvest time and cultivar. J Sci Food Agric. 2018;98:5647–5655. doi: 10.1002/jsfa.9110. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Summo C, De Angelis D, Ricciardi L, Caponio F, Lotti C, Pavan S, Pasqualone A. Nutritional, physico-chemical and functional characterization of a global chickpea collection. J Food Comp Anal. 2019;84:103306. doi: 10.1016/j.jfca.2019.103306. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Summo C, De Angelis D, Rochette I, Mouquet-Rivier C, Pasqualone A. Influence of the preparation process on the chemical composition and nutritional value of canned purée of Kabuli and Apulian black chickpeas. Heliyon. 2019;5:01361. doi: 10.1016/j.heliyon.2019.e01361. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Teterycz D, Sobota A, Zarzycki P, Latoch A. Legume flour as a natural colouring component in pasta production. J Food Sci Technol. 2020;57:301–309. doi: 10.1007/s13197-019-04061-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tseng A, Zhao Y. Wine grape pomace as antioxidant dietary fibre for enhancing nutritional value and improving storability of yogurt and salad dressing. Food Chem. 2013;138:356–365. doi: 10.1016/j.foodchem.2012.09.148. [DOI] [PubMed] [Google Scholar]

- Wendin K, Hall G. Influences of fat, thickener and emulsifier contents on salad dressing: static and dynamic sensory and rheological analyses. LWT-Food Sci Technol. 2001;34:222–233. doi: 10.1006/fstl.2001.0757. [DOI] [Google Scholar]

- Yusuf S, Bosch J, Dagenais G, Zhu J, Xavier D, Liu L, Pais P, López-Jaramillo P, Leiter LA, Dans A, Avezum A. Cholesterol lowering in intermediate-risk persons without cardiovascular disease. N Engl J Med. 2016;374:2021–2031. doi: 10.1056/NEJMoa1600176. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.